Modified composition for thermal-contraction-resistant seal rings and preparation method of modified composition for thermal-contraction-resistant seal rings

A heat-shrinkable sealing and composition technology, which is used in textiles, papermaking, fiber processing, etc., can solve the problem that the heat-shrinkage resistance of seals is difficult to meet production requirements, and achieves improved heat-shrinkage resistance. The process is simple and the raw materials are easy to use. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

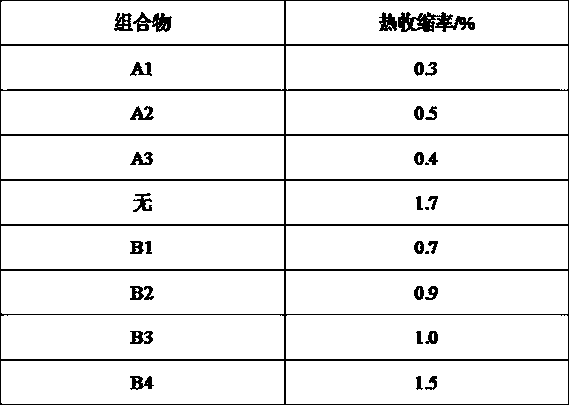

Examples

preparation example Construction

[0013] The invention provides a method for preparing a modified composition for heat-shrinkage sealing rings, the preparation method comprising:

[0014] 1) Contact reaction of polyamide fiber, cyclodextrin, silane coupling agent and water, and then filter and dry the filter cake to obtain modified polyamide fiber;

[0015] 2) Perform solvothermal reaction of modified polyamide fiber, cobalt salt, alkali, urea and ethanol, then filter to take filter cake, and finally calcinate in the presence of protective gas to obtain composite polyamide fiber;

[0016] 3) Mixing composite polyamide fibers, shell powder, attapulgite, barium sulfate whiskers, and rare earth oxides to prepare a modified composition for heat-shrinkage sealing rings.

[0017] In step 1) of the present invention, the amount of each material can be selected within a wide range, but in order to make the modified composition further improve the heat shrink resistance of the sealing ring, preferably, in step 1), poly...

Embodiment 1

[0031] 1) The polyamide fiber, cyclodextrin, silane coupling agent (vinyl triethoxysilane) and water are subjected to a contact reaction in a weight ratio of 30:13:8:180 (the reaction temperature is 70°C, and the reaction time is 4h), then filter the filter cake and dry it (drying temperature is 110°C, drying time is 5h) to obtain modified polyamide fiber;

[0032] 2) Solvothermal reaction of the modified polyamide fiber, cobalt salt (cobalt nitrate hexahydrate), alkali (sodium hydroxide), urea and ethanol in a weight ratio of 50:12:40:18:200 (reaction temperature 130°C, the reaction time is 12h), then filter to take the filter cake, and finally calcine in the presence of protective gas (helium) (from 18°C at 4.8°C / min to 290°C and hold for 340min, then at 1.8°C / min cooling to 230°C and holding for 1.8h, and finally cooling to 20°C naturally) to make composite polyamide fibers;

[0033] 3) Mix composite polyamide fiber, shell powder, attapulgite, barium sulfate whisker, an...

Embodiment 2

[0035] 1) Contact reaction of polyamide fiber, cyclodextrin, silane coupling agent (vinyltrimethoxysilane) and water in a weight ratio of 30:10:5:150 (reaction temperature is 65°C, reaction time is 3h ), and then filtered to take the filter cake and dry it (drying temperature is 100°C, drying time is 6h) to obtain modified polyamide fiber;

[0036] 2) Solvothermal reaction of the modified polyamide fiber, cobalt salt (cobalt chloride hexahydrate), alkali (potassium hydroxide), urea and ethanol in a weight ratio of 50:10:30:15:150 (reaction The temperature is 120°C, the reaction time is 16h), then the filter cake is taken by filtration, and finally calcined in the presence of protective gas (nitrogen) (from 15°C at 4.5°C / min to 280°C and kept for 30min, then at 1.5°C / min cooling to 220°C and holding for 1.5h, and finally cooling to 15°C naturally) to make composite polyamide fibers;

[0037] 3) Mix composite polyamide fibers, shell powder, attapulgite, barium sulfate whiskers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com