Patents

Literature

34results about How to "Small surface pore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

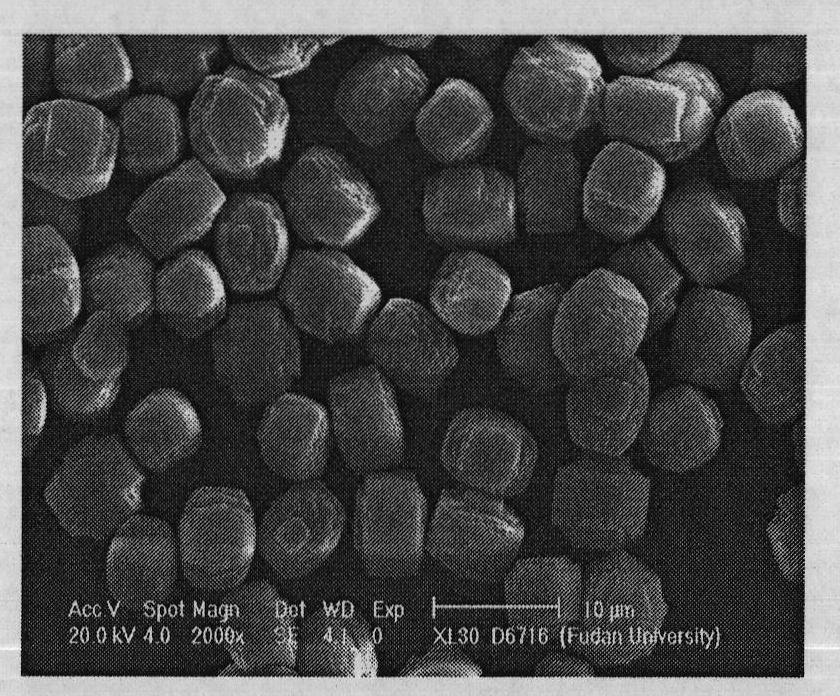

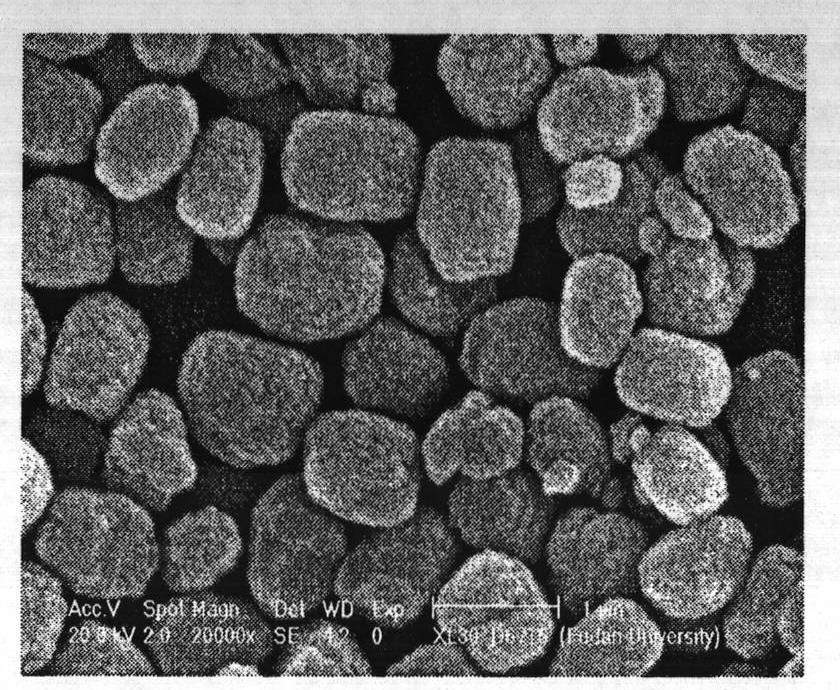

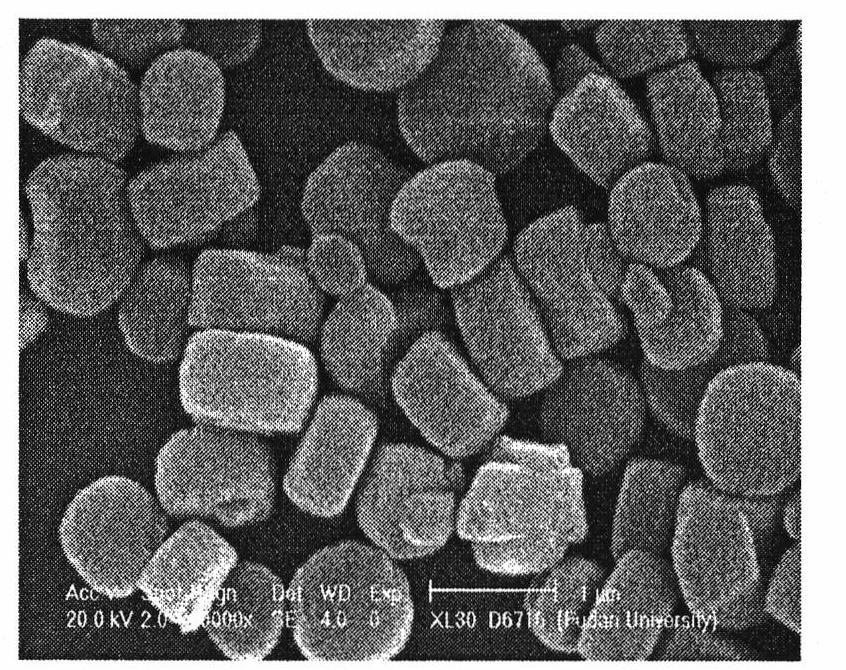

Method for adjusting surface hole diameter of ZSM-5 molecular sieve by surface dealuminizing and compensating silicon

InactiveCN101857243ASmall surface pore sizeMaintain skeleton structurePentasil aluminosilicate zeolitePore diameterFluosilicates

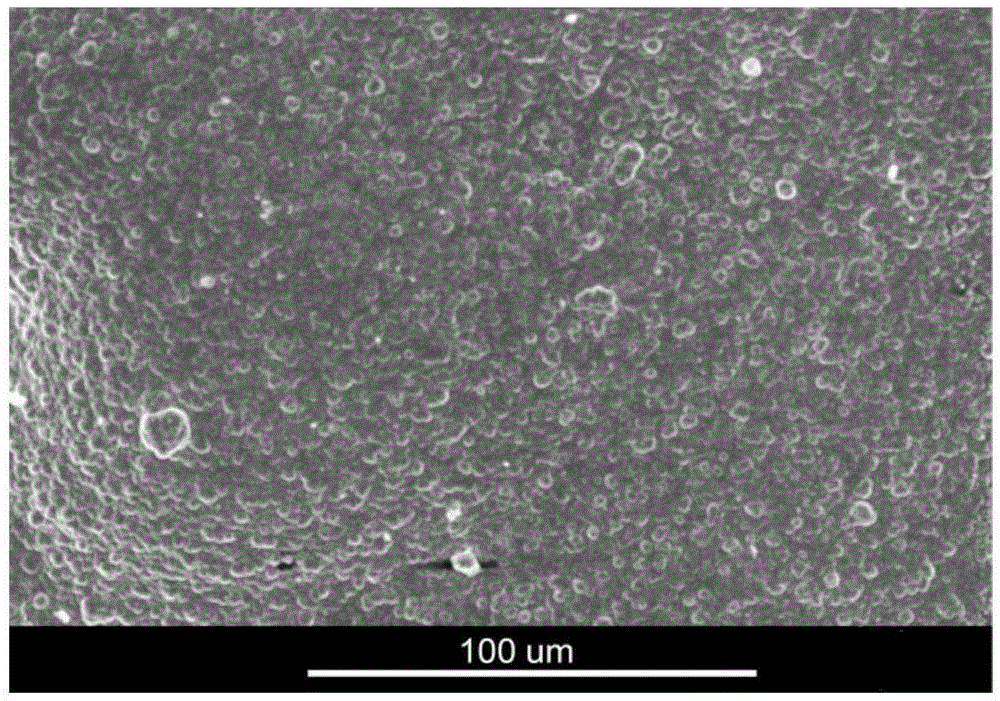

The invention belongs to the technical field of zeolite molecular sieves, in particular to a method for adjusting a surface hole diameter of a ZSM-5 molecular sieve by surface dealuminizing and compensating silicon. The invention accurately controls the surface hole diameter of the molecular sieve by using the treating measure of dealuminizing and compensating silicon on the ZSM-5 zeolite molecular sieve with ammonium fluosilicate solution. An ultrathin layer enriched with silicon is formed on the surface of the ZSM-5 zeolite molecular sieve treated by the method so that the hole caliber on the surface of the molecular sieve is shrunk. The ZSM-5 zeolite molecular sieves with different hole caliber shrinkage level can be selectively obtained by changing different treating conditions. The SM-5 zeolite molecular sieves modified by the method can be used for absorbing a mixture of three isomerides of P-, M-and O-Xylene.

Owner:FUDAN UNIV

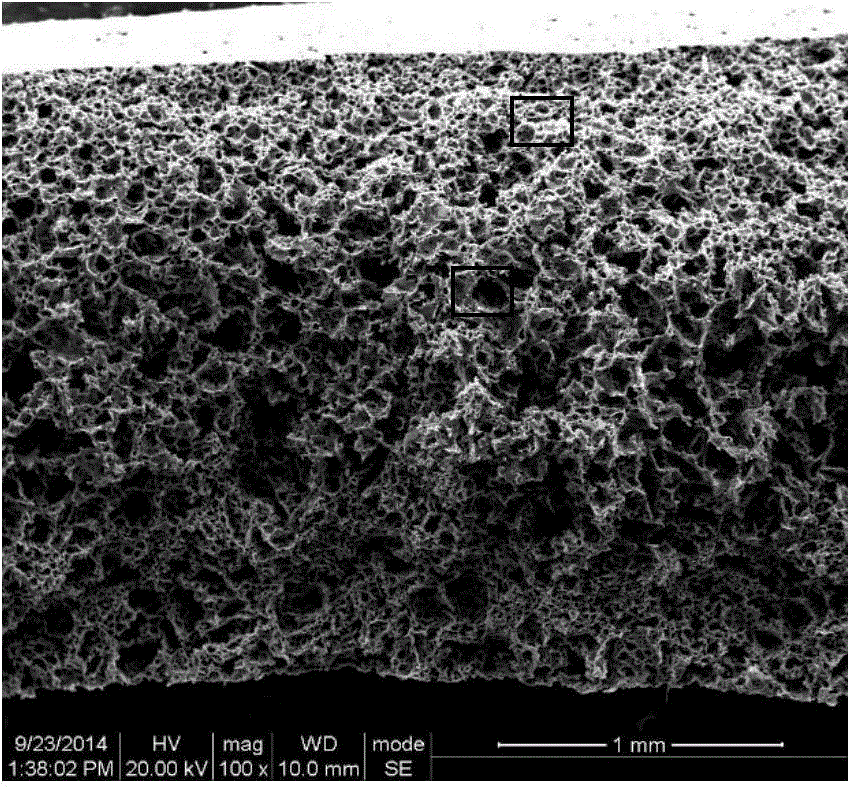

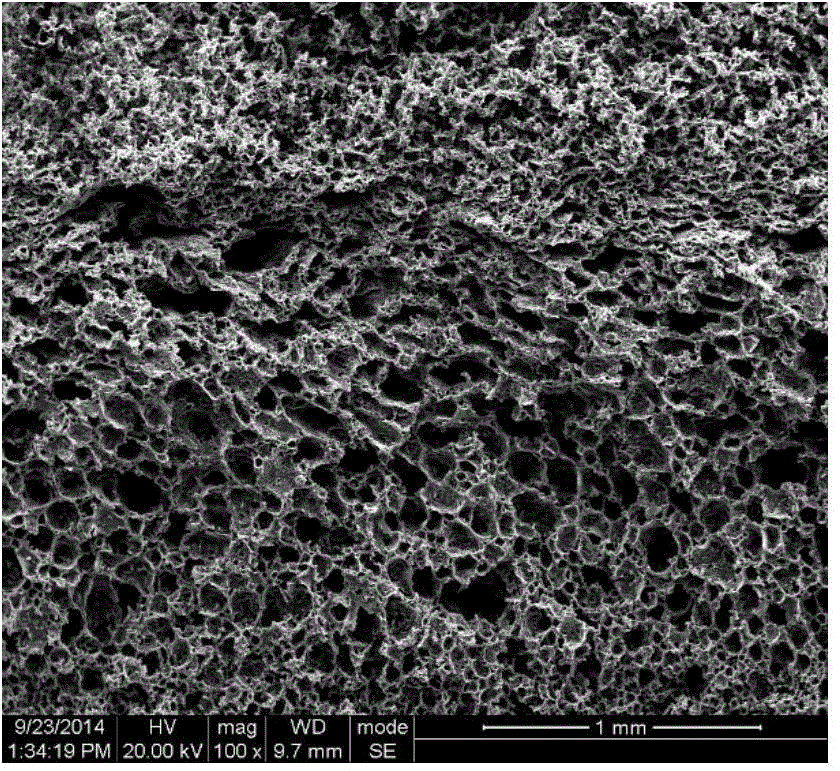

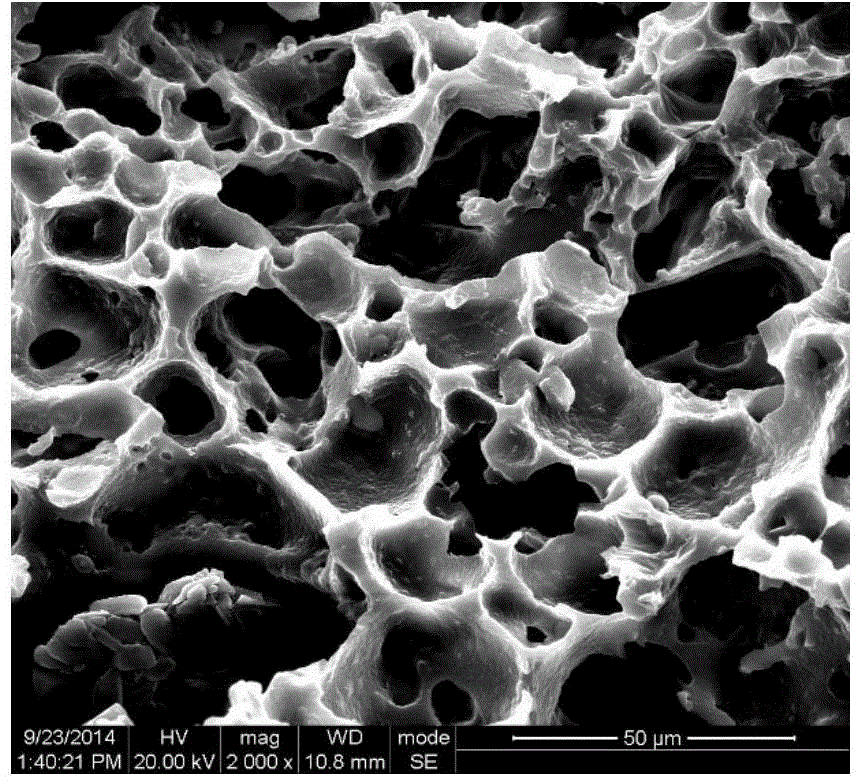

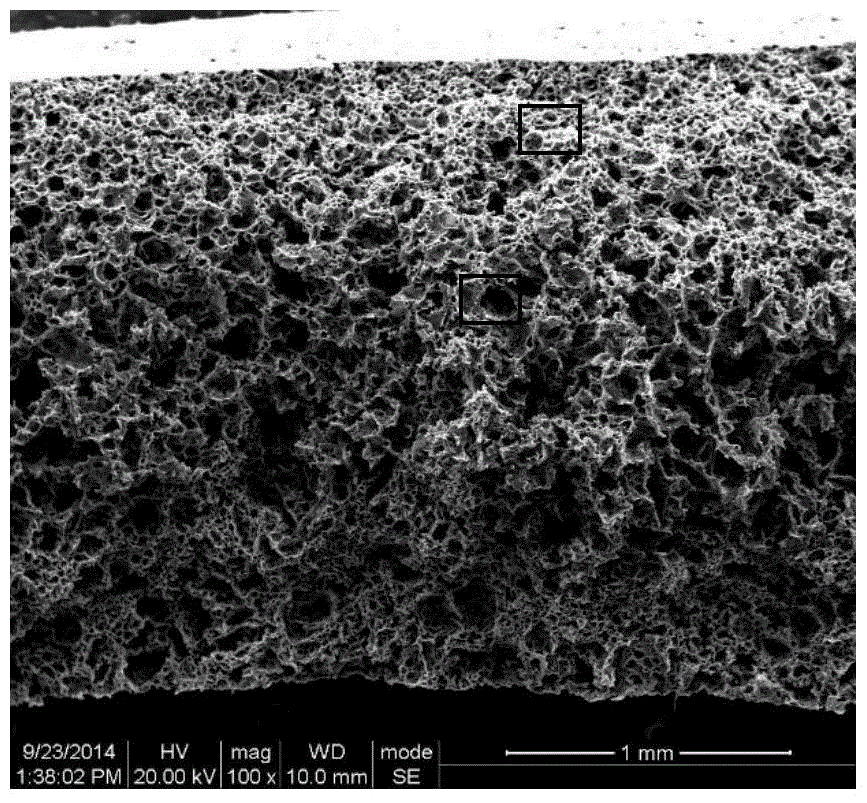

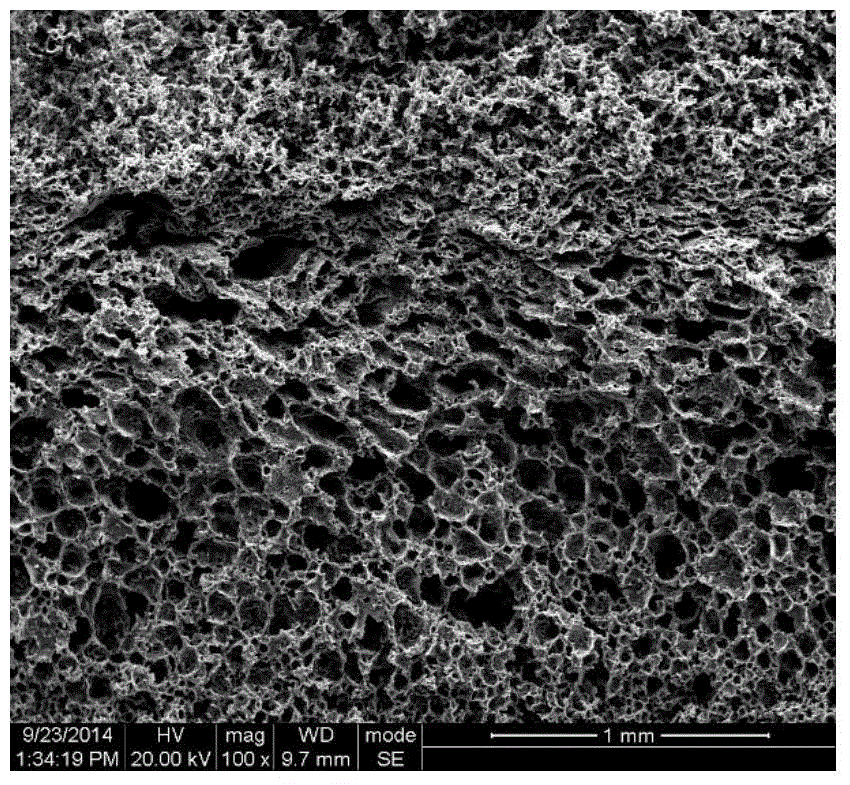

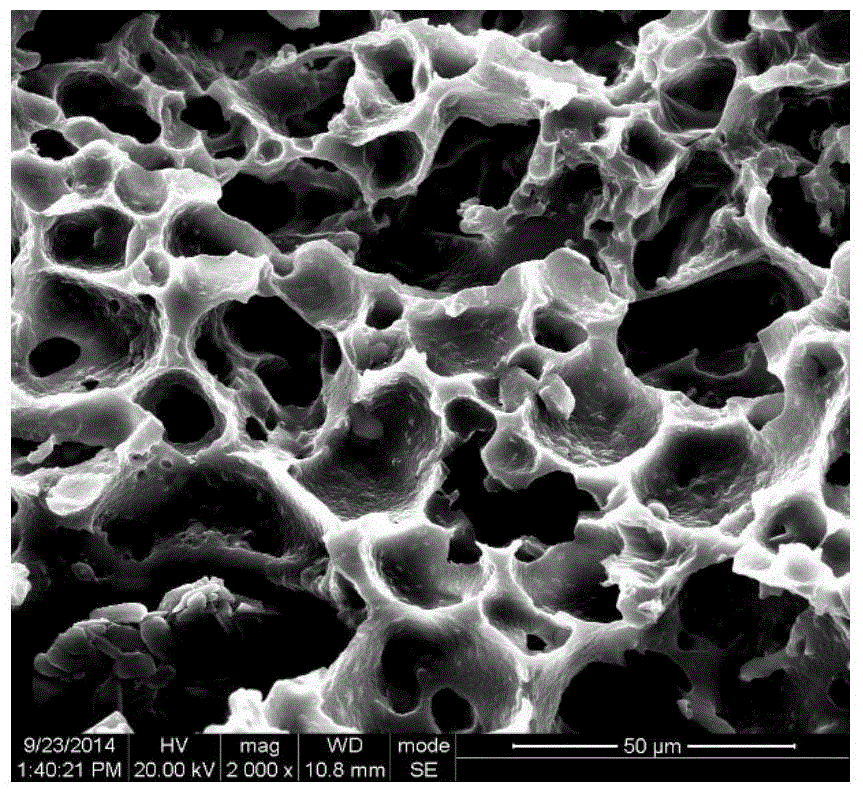

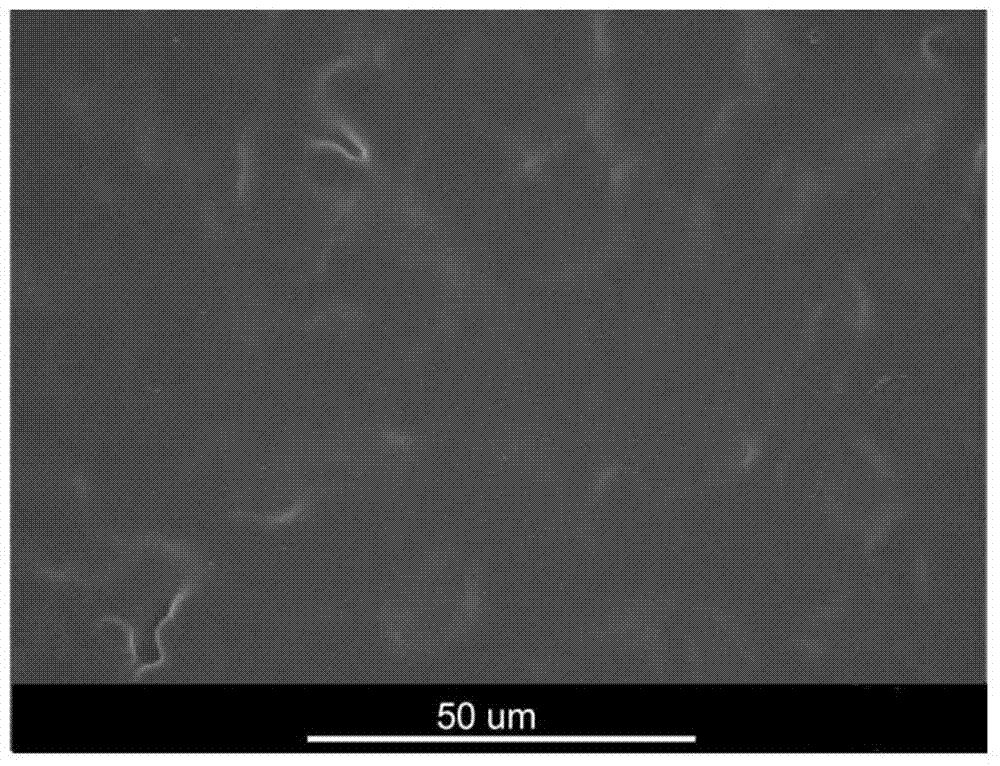

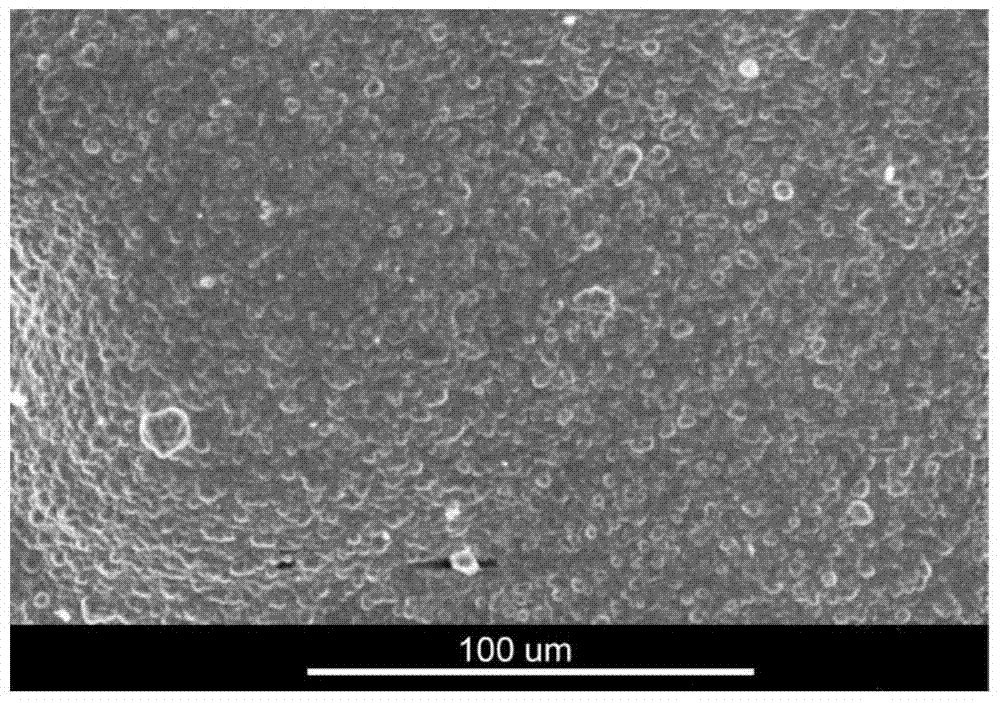

Porous polyurethane film used for artificial skin and having gradient porous structure and preparation method of porous polyurethane

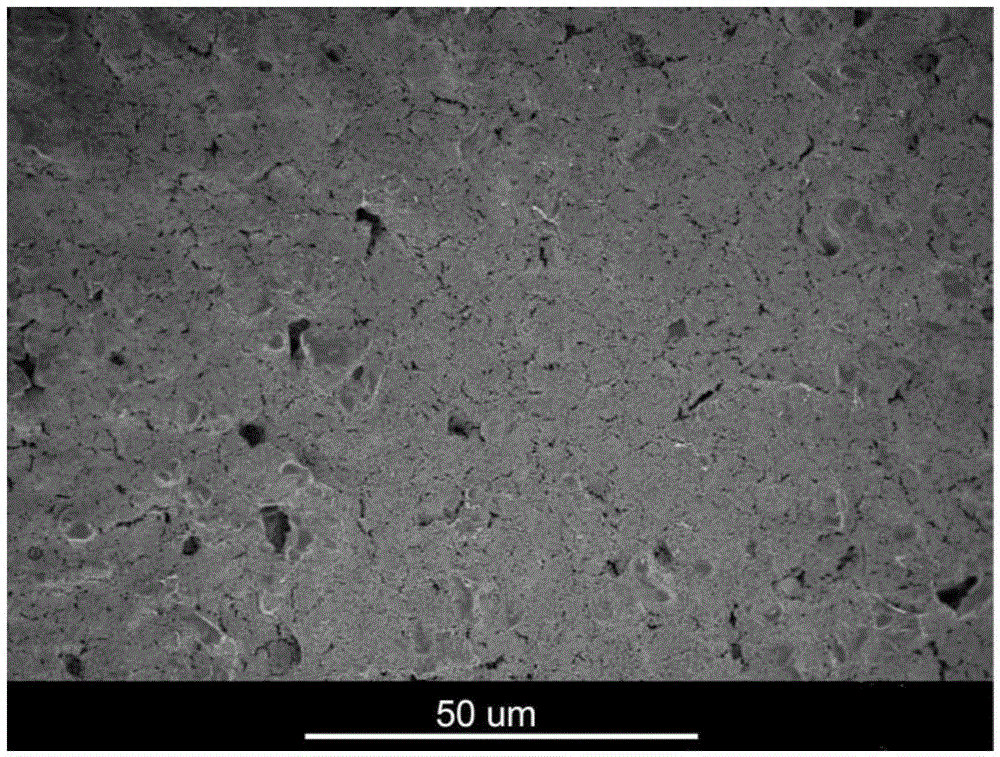

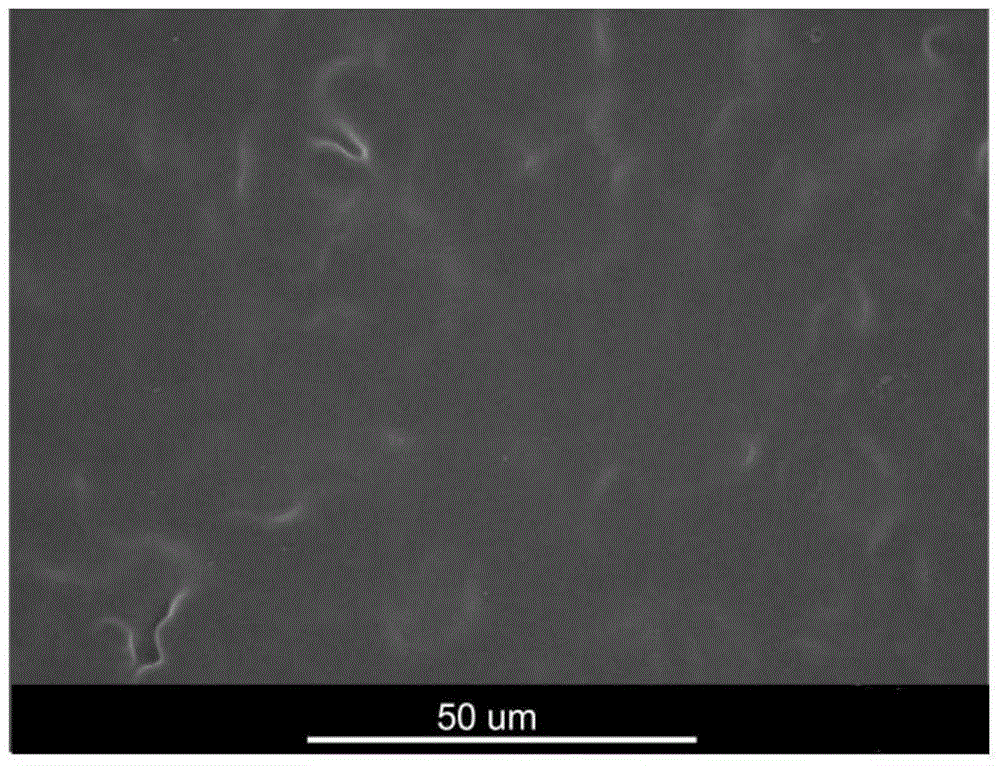

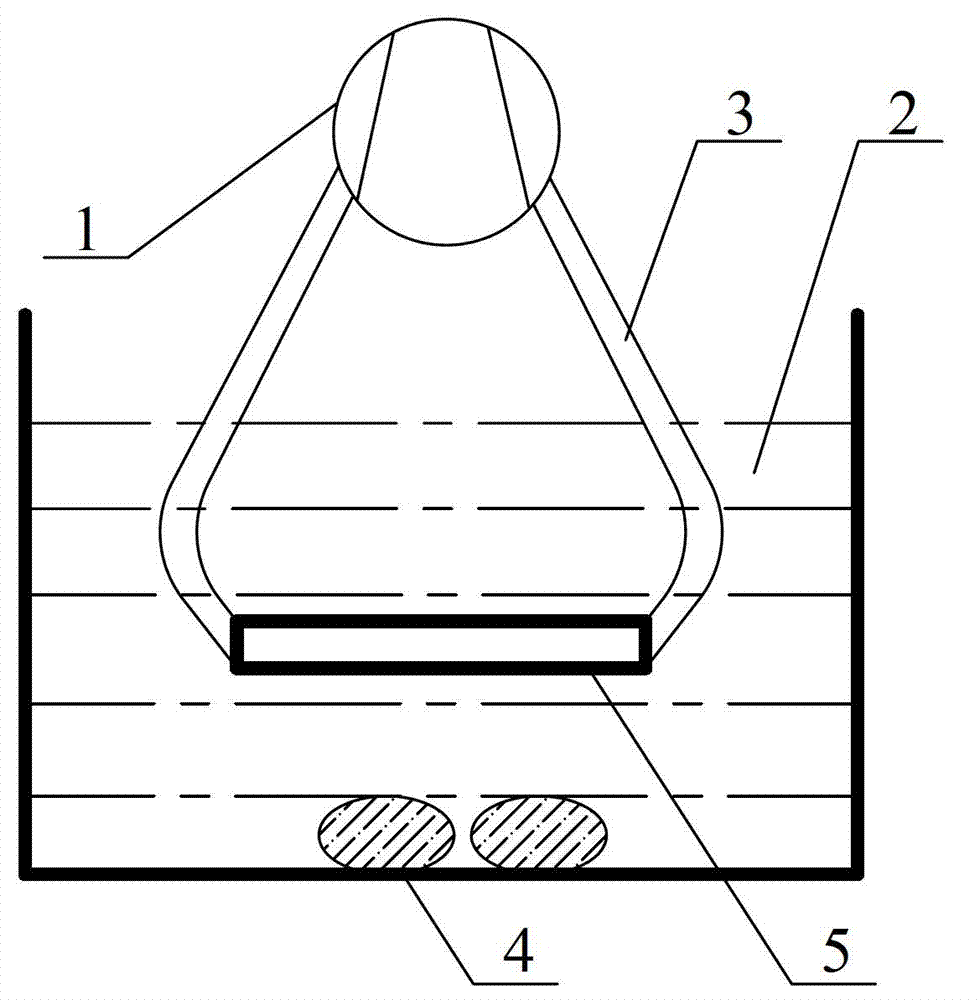

The invention discloses a preparation method of a porous polyurethane film with a gradient porous structure. The preparation method is characterized by comprising the following steps: adding polyurethane into a solvent for dissolving, adding a pore-foaming agent, and mechanically stirring for a period of time to obtain suspension; defoaming the suspension in vacuum, carrying out film casting on a mold, carrying out curing film formation in absolute ethyl alcohol coagulation bath, soaking the film in deionized water to dissolve the pore-foaming agent and completely remove the pore-foaming agent; taking out the film, drying the film in a blast oven to obtain the porous polyurethane film with the gradient porous structure, the upper and lower surfaces of the porous polyurethane film are trim and not curled, and the hand feeling is good. The film can be used as artificial skin and has the advantages of good water and air permeability, high water absorption, excellent mechanical properties, good biological affinity, etc.

Owner:SICHUAN UNIV

Alumina particle-filled composite multi-arc hole membrane material and preparation method and application thereof

ActiveCN105098125AHigh electrical breakdown strengthImprove heat resistanceHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicro nanoShock resistance

The invention discloses an alumina particle-filled composite multi-arc hole membrane material. With polyimide (PI) nanofiber nonwoven fabric as a base material, holes of the base material are filled with micro-nano Al2O3 particles; the diameters of the micro-nano Al2O3 particles are 50-800nm; and the micro-nano Al2O3 particles account for 20%-50% of total weight of the composite multi-arc hole membrane material. According to the micro-nano composite multi-arc hole membrane material, the porosity is 30%-60%; the surface mean pore size is 50-800nm; and the thicknesses are 10-40 microns. The micro-nano composite multi-arc hole membrane material disclosed by the invention has high-temperature resistance, heat shrinkage resistance, high-voltage and high-current shock resistance and mechanical impact resistance, and is suitable for manufacturing various high-capacity and high-power lithium batteries or super-capacitors as a safety battery diaphragm and a safety super-capacitor diaphragm. The invention further provides a preparation method of the nano composite multi-arc hole membrane material, and an application of the nano composite multi-arc hole membrane material as the battery diaphragm.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

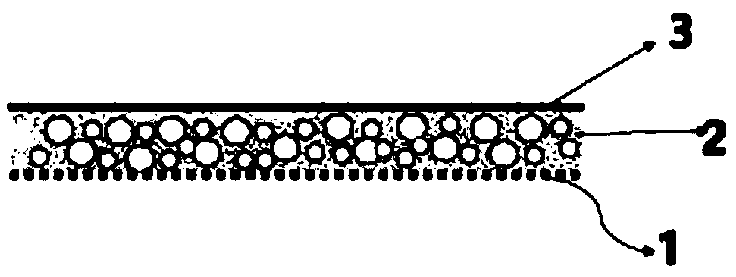

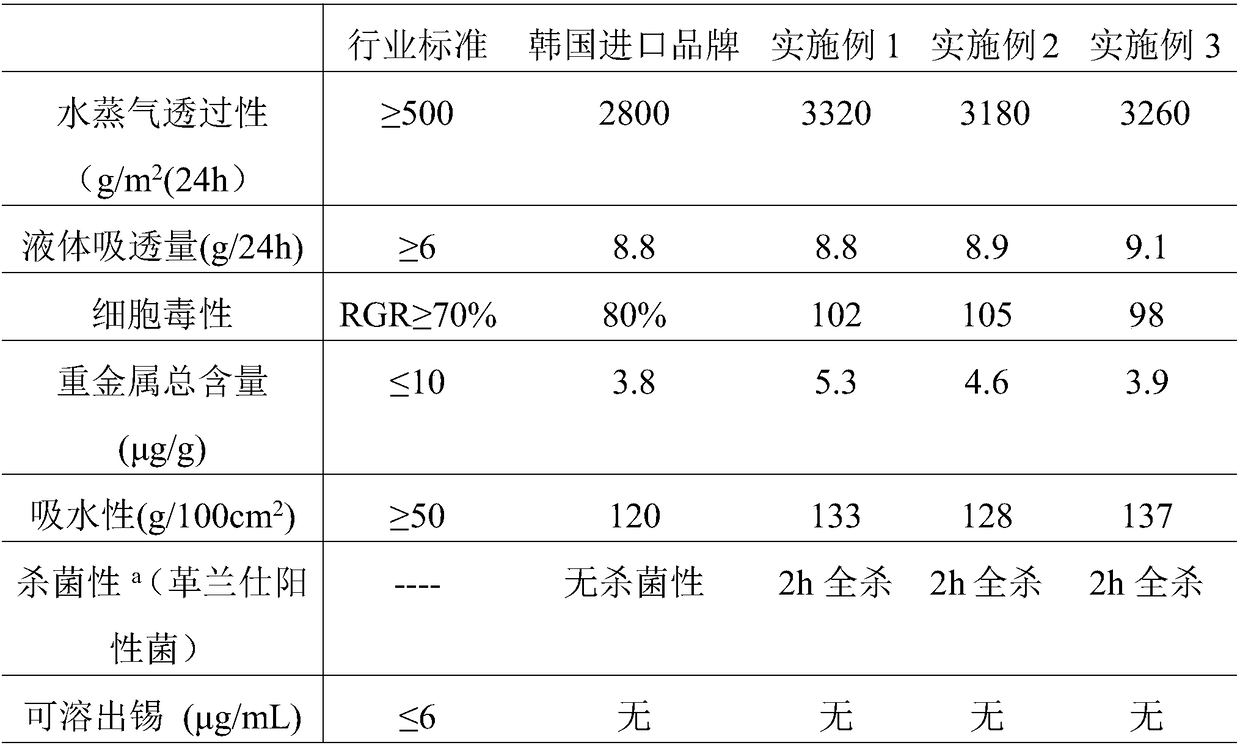

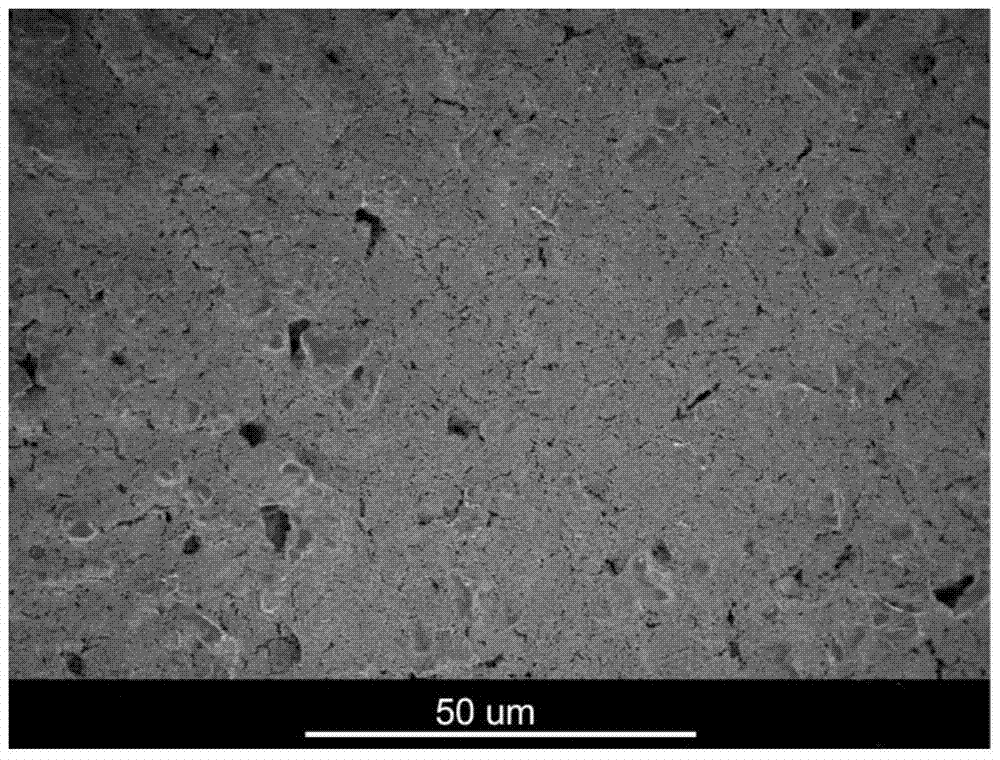

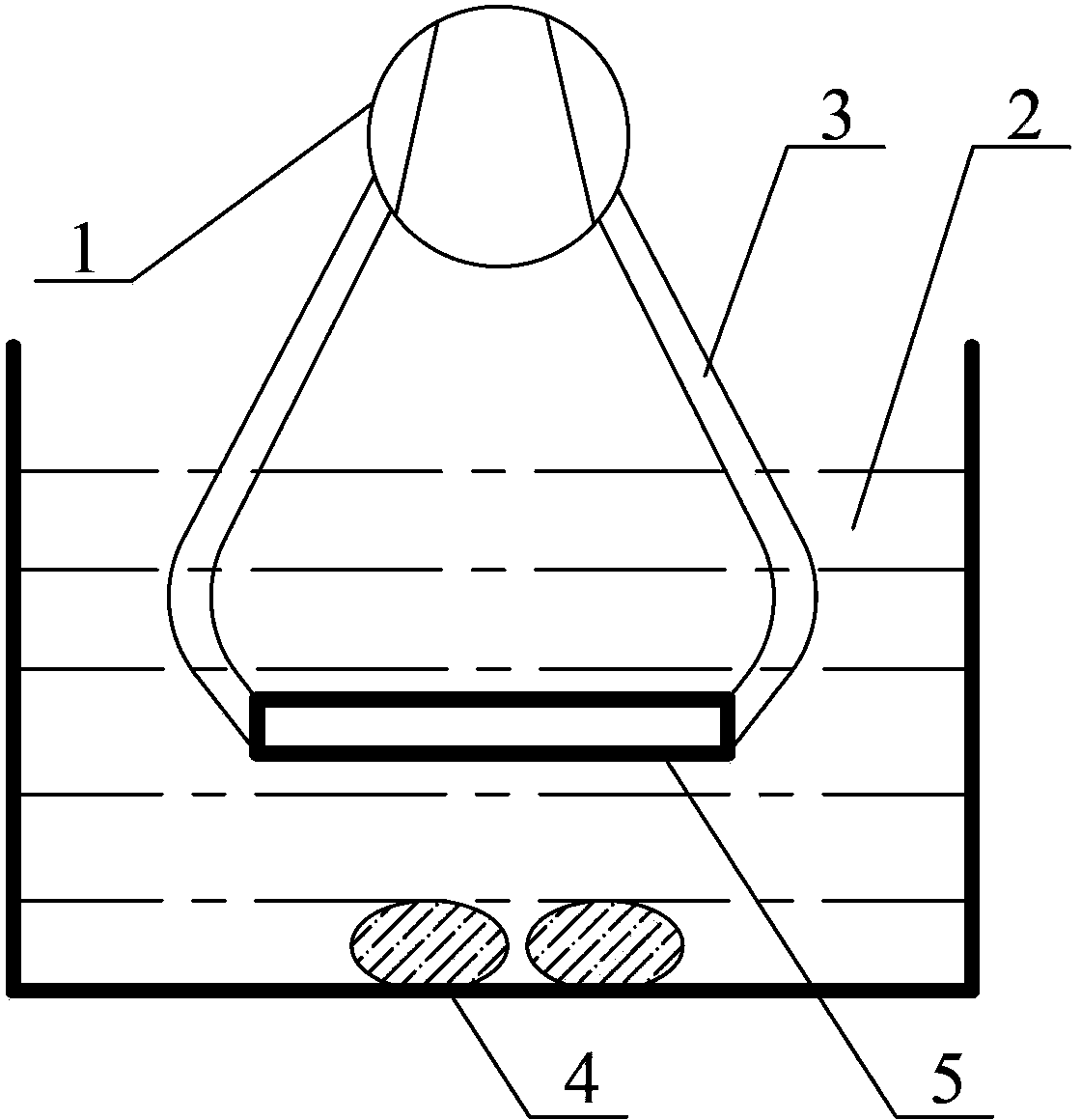

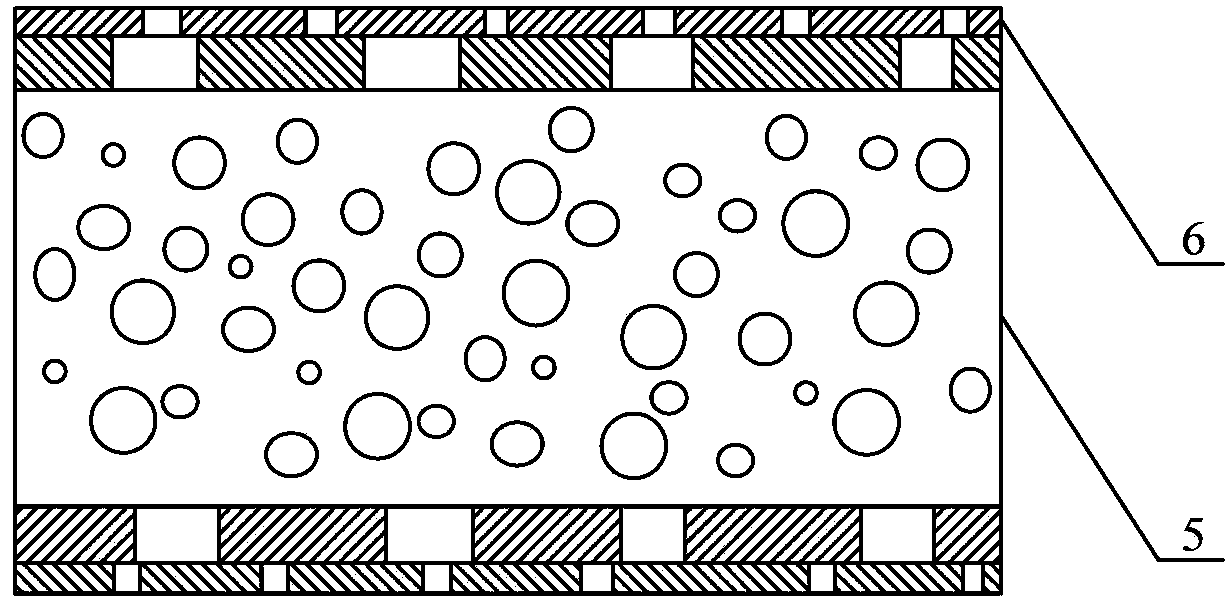

Functional composite dressing with drug sustained release and self-antibacterial effects and preparation method thereof

InactiveCN108939128AReduce frequencyReduce chance of re-injuryNon-adhesive dressingsAdhesive dressingsFunctional compositeBiomedical engineering

The invention disclose a functional composite dressing with drug sustained release and self-antimicrobial effects and a preparation method thereof, belongs to the technical field of medical devices, and solves the technical problems that the existing polyurethane foam dressing has low tendency to breed bacteria, cannot be used for a long time, and has low tendency to adhere with granulation. The functional composite dressing is composed of a wound contact layer, a foam absorbing layer and an external protective layer arranged orderly from inside to outside, wherein the wound contact layer is acomposite material of a slow release medicine and degradable polylactic acid, and the surface of the wound contact layer contains permeation micropores; the foam absorbing layer is an aqueous polyurethane foam material, and the foam absorbing layer has an open cell unit. The external protective layer is thermoplastic polyurethane with a dense surface. The dressing has excellent antimicrobial effect, has low tendency to adhere to a wound, is low in frequency of dressing change, increases the comfort of patients while reducing the degree of skin scars, and is especially suitable for the treatment of wounds caused by device trauma, burns, bacterial fester and ulceration and other reasons.

Owner:吉林康众新材料科技有限公司

Preparation method of high-flux antifouling composite filter membrane

InactiveCN108579466AGood anti-fouling effectGood high permeabilitySemi-permeable membranesMembranesChemistryPolyelectrolyte

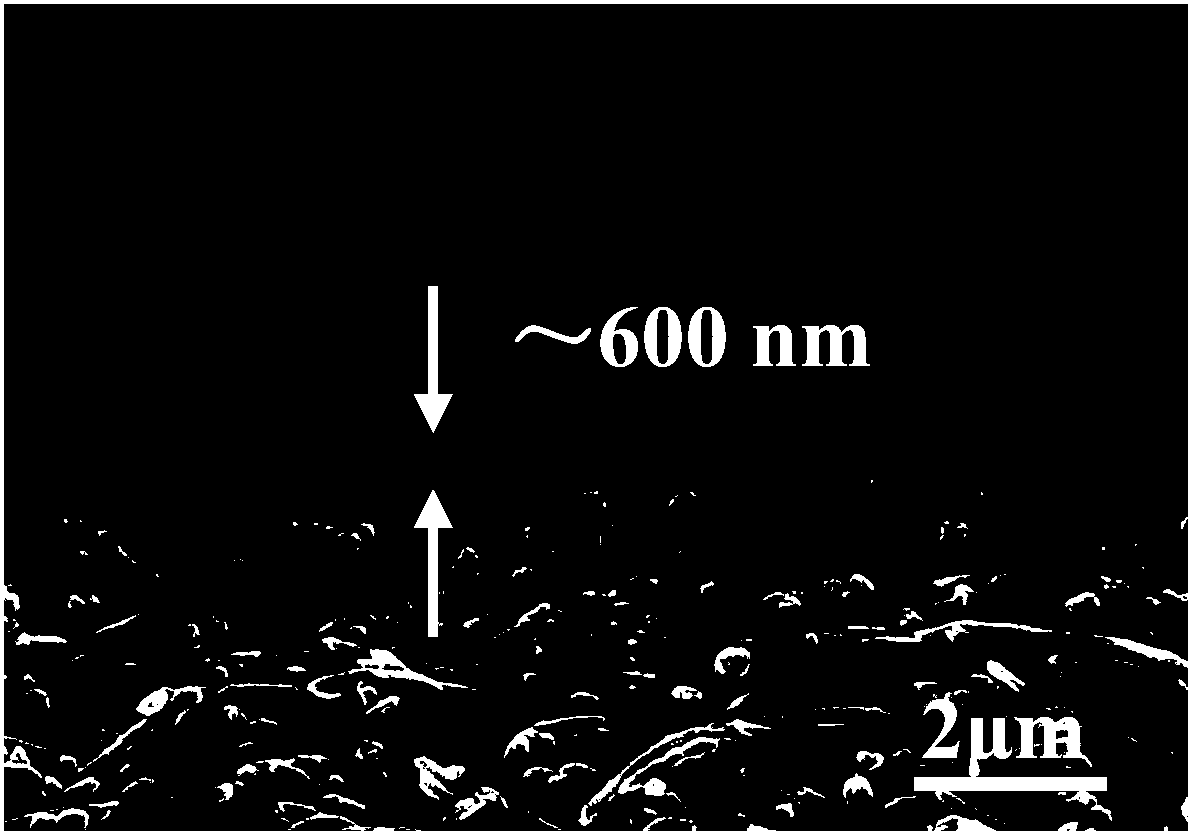

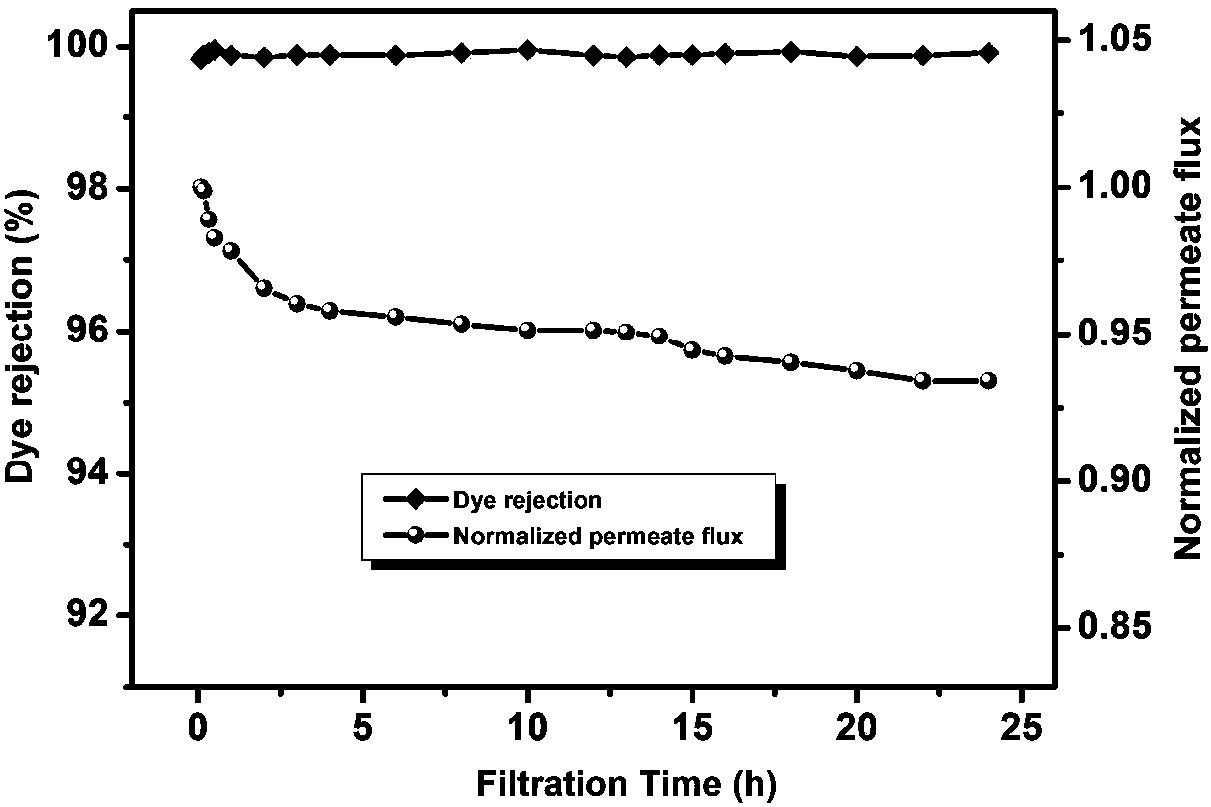

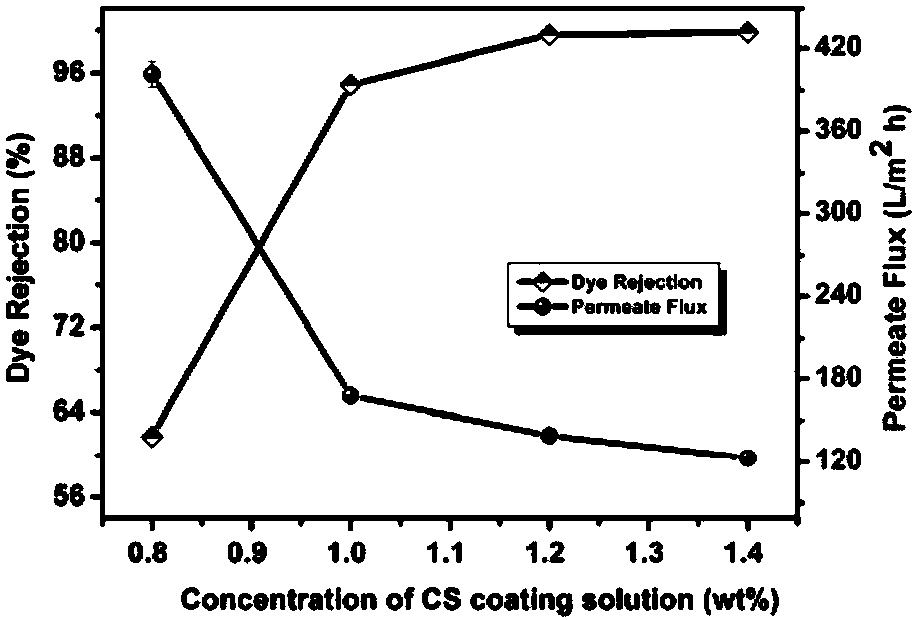

The invention discloses a preparation method of a high-flux antifouling composite filter membrane. The preparation method comprises the steps: dissolving a polymer material into a solvent to prepare an electrospinning solution; then, carrying out electrospinning to obtain nanofibers; next, carrying out cold pressing to obtain a nanofiber-based membrane; dissolving a polyelectrolyte into a solventto prepare a coating solution; then, coating the nanofiber-based membrane with the coating solution, and carrying out standing and drying in the shade at room temperature to obtain a nanofiber-based composite membrane with the surface being provided with a complete cortical layer; and then, soaking the nanofiber-based composite membrane into a dye with charges being opposite to those on the surface cortical layer to obtain the high-flux antifouling composite filter membrane. According to the preparation method, a "pollution layer" of the dye is used as a constituent part of a functional barrier layer of the composite membrane, so that the prepared composite filter membrane simultaneously has a good antifouling effect and high permeability, and the preparation method is simple and easy, environment-friendly, capable of realizing fine regulation of the pore diameter on the surface of the functional barrier layer of the composite membrane and suitable for large-scale production.

Owner:XUZHOU NORMAL UNIVERSITY

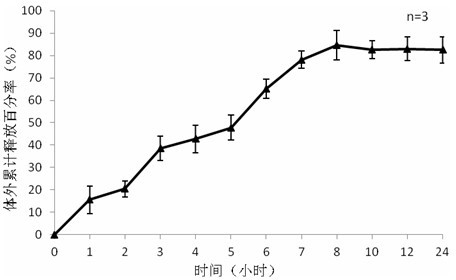

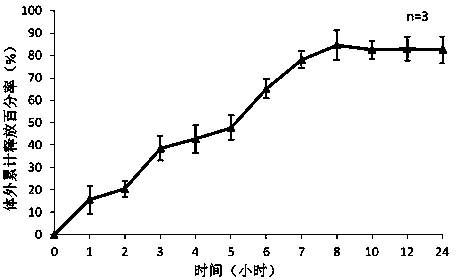

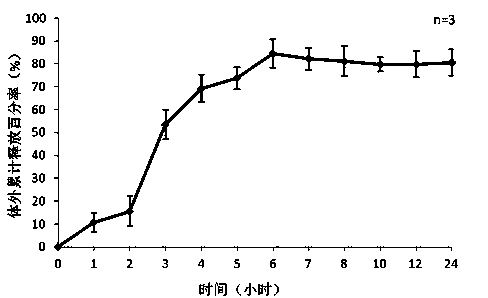

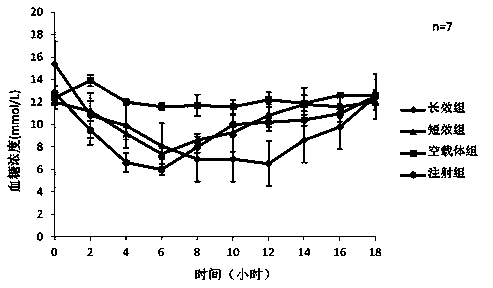

Oral slow release preparation, entrapment material and preparation method

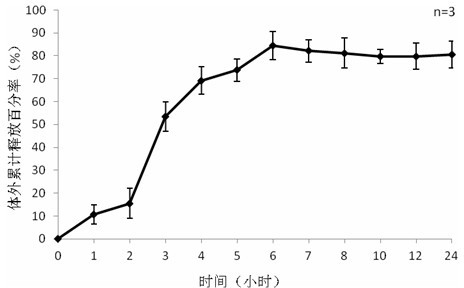

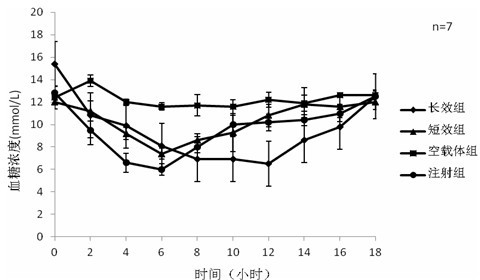

InactiveCN102657871AProlong the action timeLong-lasting hypoglycemic effectPeptide/protein ingredientsMetabolism disorderSodium hyaluronateExenatide

The invention discloses an oral slow release preparation, an entrapment material and a preparation method. A sodium alginate-sodium hyaluronate mixture is taken as an entrapment material; and a prepared protein polypeptide medicament oral slow release preparation consists of the following components in percentage by mass: 0.5-10 percent of medicament and 90-99.5 percent of sodium alginate-sodium hyaluronate mixture. According to the oral slow release preparation, the conventional administration way of a protein polypeptide medicament is changed, the acting time of the protein polypeptide medicament is prolonged, the normal blood sugar level is maintained successfully for 12 hours when exenatide oral microspheres are taken as an example, the administration compliance of a diabetes patient is improved remarkably, and the treatment effect is enhanced.

Owner:CHINA PHARM UNIV

Method for making palladium film on surface of macro-porous carrier

ActiveCN105233701AGood hydrogen permeabilityImprove surface roughnessSemi-permeable membranesHydrogen separationChemical platingComposite film

A method for making a palladium film on the surface of a macro-porous carrier comprises the following steps: covering the surface of a porous carrier with an organic modification layer through an immersion coating technology, pre-coating the surface of a polyvinyl alcohol modification layer with a layer of palladium crystal seeds by using a sensitization-activation technology, making a palladium film on the surface of the organic modification layer through a chemical plating technology, and carrying out high-temperature thermal treatment under the protection of inert atmosphere to remove the organic modification layer in the palladium composite film in order to obtain the palladium film with good hydrogen permeability. The porous carrier is modified with an organic material, so the surface roughness of the carrier is effectively improved, and the surface aperture of the carrier is reduced; and simple thermal treatment is carried out after chemical plating of the palladium film to remove the organic modification layer, so resistance of the modification layer to hydrogen transfer is avoided. The method has the advantages of simplicity, agility, easy operation and strong practicality.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Polytetrafluoroethylene nanoparticle-filled composite tortuous porous membrane material and preparation method and application thereof

ActiveCN105161659AIncrease capacitySmall surface pore sizeCell component detailsSecondary cells servicing/maintenancePorosityMicrosphere

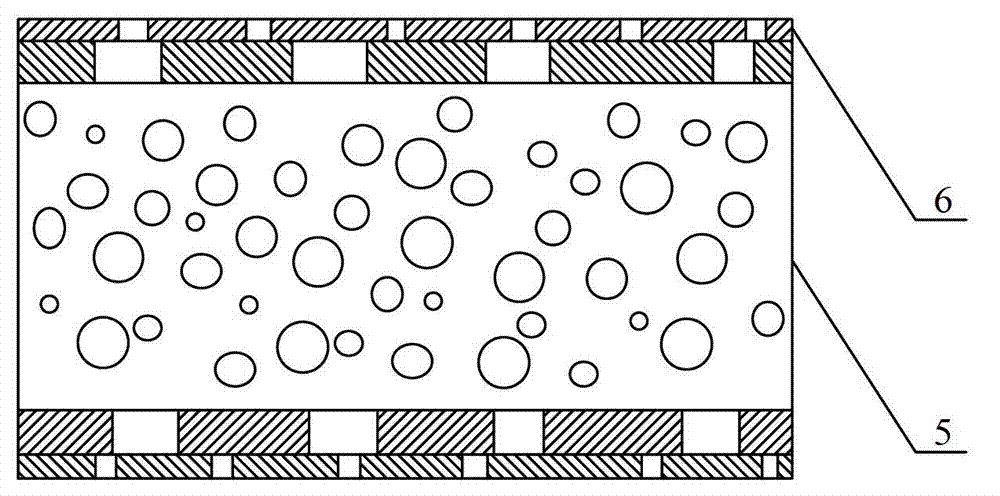

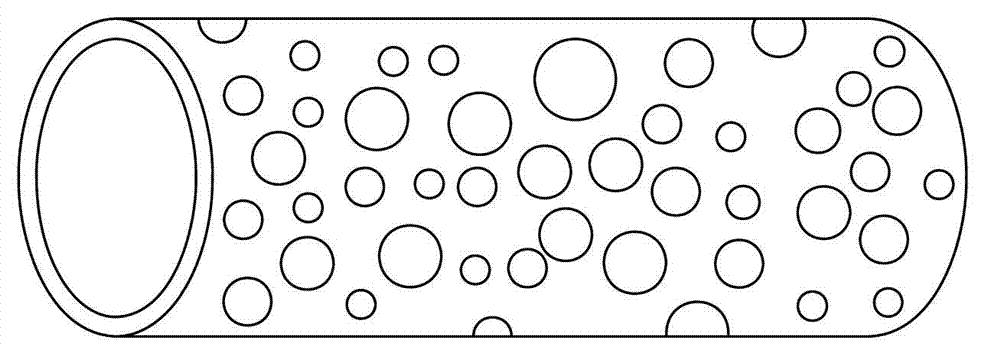

The invention discloses a polytetrafluoroethylene nanoparticle (PTFE-NP)-filled composite tortuous porous membrane material. With polyimide (PI) nanofiber nonwoven fabric as a base material, holes of the base materials are filled with polytetrafluoroethylene nanoparticles (PTFE-NPs); the PTFE-NPs are 100-300nm in diameter and account for 30%-60% of total weight of the composite tortuous porous membrane material; and the PI nanofiber nonwoven fabric is electrospinning PI nanofiber nonwoven fabric of which the thickness is 9-38 microns, the porosity is 60%-80% and the fiber diameters are less than 0.5 micron. The nano composite tortuous porous membrane material disclosed by the invention has the advantages of high temperature resistance, heat shrinkage resistance, high voltage impact resistance, high current impact resistance and mechanical impact resistance, and is suitable for manufacturing various high-capacity and high-power lithium batteries or super capacitors as a safe battery diaphragm and a safe super capacitor diaphragm. The invention further provides a preparation method of the nano composite tortuous porous membrane material and an application of the composite tortuous porous membrane material as a battery diaphragm.

Owner:JIANGXI NORMAL UNIV

Palladium composite membrane taking multihole FeAlCr as substrate and preparation method thereof

ActiveCN101983757AImprove hydrogen corrosion resistanceExtended service lifeSemi-permeable membranesTransition layerHeat treated

The invention discloses a palladium composite membrane taking multihole FeAlCr as substrate and a preparation method thereof. The palladium composite membrane is composed of a multihole FeAlCr substrate tube, a home position oxidation layer, a ceramic transition layer and palladium alloy membrane. The preparation process thereof includes the following steps: firstly, a multihole FeAlCr substrate tube is prepared; secondly, home position oxidation is adopted to form a dense home position oxidation layer on the surface of the multihole FeAlCr substrate tube; thirdly, a ceramic transition layer is coated; fourthly, palladium alloy is coated on the surface of the multihole FeAlCr substrate tube provided with the ceramic transition layer, and heat treatment is carried out, so as to form palladium alloy membrane, thus obtaining the palladium composite membrane. The preparation process of the invention is simple, and design is reasonable. The palladium composite membrane which takes multihole FeAlCr as substrate and is prepared by adopting the invention has high hydrogen permeability, strong hydrogen corrosion resistance and long service life, can be effectively applied to purification and separation of hydrogen and is especially applied to purification and separation of hydrogen isotope.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Composite multi-curved-pore membrane material filled by silicon dioxide particles, and preparation method and application therefor

The invention discloses a micro-nano composite multi-curved-pore membrane material. The polyimide (PI) nanofiber non-woven fabric is taken as the base material; the pores of the base material are filled by silicon dioxide particles; the diameter of the micro-nano silicon dioxide particles is 50-800 nm, accounting for 20-50% of the total weight of the micro-nano composite multi-curved-pore membrane material; and the PI nanofiber non-woven fabric is 9-38 um in thickness, and 60-80% in the porosity. The micro-nano composite multi-curved-pore membrane material prepared by the invention is high temperature resistant, thermal shrinkage resistant, high voltage resistant, high current impact resistant, and mechanical collision resistant, and suitable for being used as safe battery membranes and safe supercapacitor membranes for manufacturing various high-capacity and high-power lithium ion batteries or supercapacitors. The invention also provides a preparation method for the micro-nano composite multi-curved-pore membrane material, and application of the membrane material in being used as the battery membranes.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Zirconium oxide particles filled composite multi-curved-porous membrane material, and preparation method and application therefor

ActiveCN105226219ASmall surface pore sizeHigh electrical breakdown strengthCell component detailsWoven fabricThermal shrinkage

The invention discloses a nanocomposite multi-curved-porous membrane material. The nanocomposite multi-curved-porous membrane material takes polyimide (PI) nanofiber non-woven fabric as a base material, and nanometer zirconium dioxide (ZrO2) particles are filled in pores of the base material; the diameter of the nanometer ZrO2 particles is 50-100 nm, and the weight of the nanometer ZrO2 particles is 30-50% of the total weight of the nanocomposite multi-curved-porous membrane material; the thickness of the PI nanofiber non-woven fabric is 9-38 um, and the porosity is 60-80%. The nanocomposite multi-curved-porous membrane material has high-temperature resistance, thermal shrinkage resistance, high voltage and high current impact resistance, and mechanical collision resistance, so that the nanocomposite multi-curved-porous membrane material is suitable for being used as safety battery membranes and safety supercapacitor members for manufacturing various high-capacity and high-power lithium batteries or supercapacitors. The invention further provides a preparation method for the nanocomposite multi-curved-porous membrane material, and an application of the nanocomposite multi-curved-porous membrane material in being used as the battery membranes.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

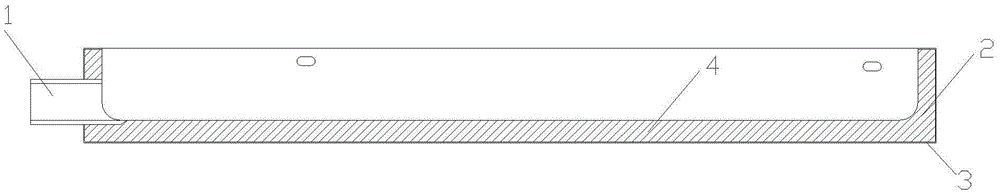

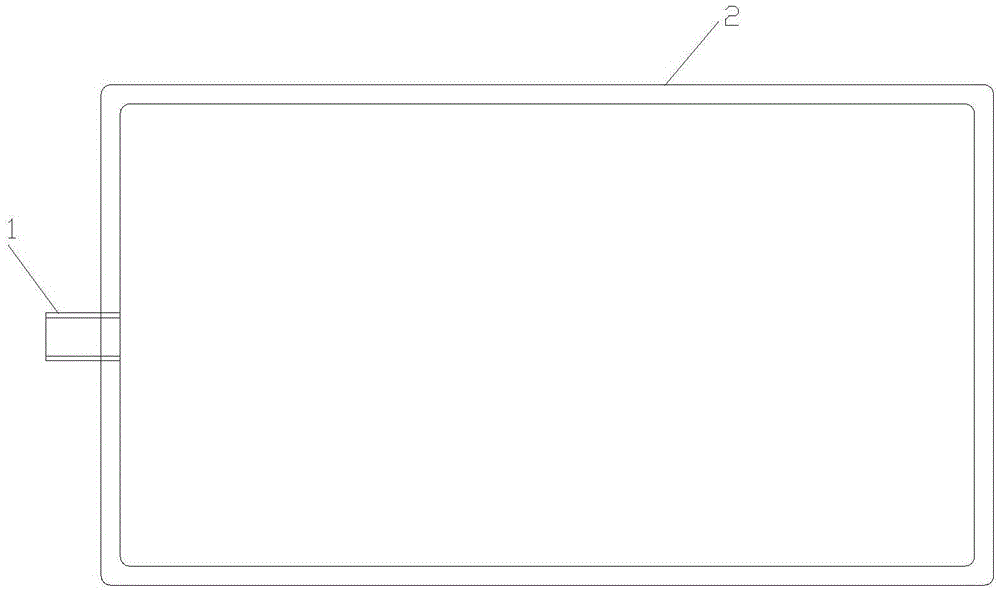

Water pond and production process thereof

InactiveCN105627547ANot easy to penetrateImprove surface strengthCondensate preventionLighting and heating apparatusInsulation layerEngineering

The invention discloses a water pond. The water pond comprises a pond body; pond body includes a plastic uptake liner, a side wall connected with the liner, and a drainage nozzle connected with the side wall; and a polyurethane foaming insulation layer is arranged on the outer side of the pond body. The invention further provides a production process of the water pond. Compared with the prior art, the insulation liner, obtained through plastic uptake, of the water pond is on the inner side of the pond body, and the outer surface of the pond body is the polyurethane foaming insulation layer, so that the pond body is not easy to be scratched, the insulation effect is good, and the strength is high; and the drainage nozzle is tightly connected with the side wall through polyurethane foaming, so that the drainage difficulty caused by welding deformation cannot be generated.

Owner:NANJING YEEU AIR CONDITIONING FITTING CO LTD

PI-AlN-PTFE ternary nano-composite multi-curve pore membrane material and preparing method and application thereof

ActiveCN105047847AImprove temperature resistanceHigh hardnessNon-aqueous electrolyte accumulatorsElectrolytic capacitorsPorosityFiber

The invention discloses a nano-composite multi-curve pore membrane material, polyimide (PI) nano-fiber non-woven fabric serves as the base material, and base material pores are filled with composite nano-particles. The nano-composite multi-curve pore membrane material is characterized in that the nano-particles are formed by mixing polytetrafluoroethylene nanoparticle (PTFE-NP) and aluminium nitride nanoparticle (AlN-NP) at the weight ratio of (7-12) / (8-13). The nano-composite multi-curve pore membrane material is resistant to high temperature, high in hardness, proper in porosity, proper in surface density, good in ion transmission performance and good in mechanical performance, when the nano-composite multi-curve pore membrane material is used in lithium-ion batteries, the problem of a battery micro short circuit due to the excessively-high porosity of a pure polyimide nano-fiber membrane can be solved, and the serious problem of thermal runaway caused by the mechanical collision of the power lithium-ion batteries can be solved.

Owner:JIANGXI NORMAL UNIV

Material for filter pressing of superfine slurry and manufacturing method of material

InactiveCN103239939ASimple preparation processLow costFiltration separationAdhesive cementFirming agent

The invention relates to a material for filter pressing of superfine slurry and a manufacturing method of the material. The material is composed of a basic material layer with a pore diameter and a superfine pore filtering layer arranged at the upper part of the basic material layer, and the material is characterized in that an adhesive cement curing layer is used as the superfine pore filtering layer; superfine pore diameters are distributed on the adhesive cement curing layer; and the adhesive cement curing layer is formed by mixing a resin material, an inert grain, a volatilizable solvent and a curing agent, and drying and curing. The manufacturing method disclosed by the invention is simple in process and low in cost; and the material for the filter pressing of the superfine slurry has the advantages of guaranteeing the superfine pore diameters and reducing filter pressing resistance.

Owner:河北东同光电科技有限公司

High-strength antibacterial polyethylene film and preparation method thereof

ActiveCN113209840AHigh strengthImprove antibacterial propertiesSemi-permeable membranesMembranesPropionatePropanoic acid

The invention discloses a high-strength antibacterial polyethylene film and a preparation method thereof. The polyethylene film is a film formed by taking a polyethylene microporous film as a substrate and an ethylene-vinyl alcohol copolymer film as a surface layer and chemically bonding the polyethylene microporous film and the ethylene-vinyl alcohol copolymer film through polyvinyl alcohol. The high-strength antibacterial polyethylene film has the beneficial effects that a pomegranate extracting solution is added, so that the bonding strength and the antibacterial property are improved; an ethylene-vinyl alcohol copolymer film is prepared as a surface layer by using a water-induced reversed-phase method, and the precipitation of PVP is accelerated and the formation of pores is accelerated by using the synergistic effect between polyhexamethylene guanidine propionate and PVP, so that the time cost is reduced; acid groups in the polyhexamethylene guanidine propionate are utilized, so that the polyhexamethylene guanidine propionate / metal nanoparticles spontaneously move towards the surface of the film to form a hydration layer, and the film is antibacterial and antifouling; and the chelating property of the polyhexamethylene guanidine propionate on the metal nanoparticles is utilized, the polyhexamethylene guanidine propionate is attached to the surfaces of the metal nanoparticles, agglomeration of the metal nanoparticles is inhibited, and the uniform dispersity is improved.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

Composite porous membrane material filled with alumina particles and its preparation method and application

ActiveCN105098125BSmall surface pore sizeReduce porosityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicro nanoFiber

The invention discloses a micro-nano composite multi-curvature membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with micro-nano Al2O3 particles; the micro-nano Al2O3 The particles have a diameter between 50-800nm and account for 20-50% of the total weight of the micro-nano composite multi-curved pore membrane material; the micro-nano composite multi-curved pore membrane material has a porosity between 30-60% , the average surface pore diameter is between 50-800nm, and the thickness is between 10-40μm. The micro-nano composite multi-curved hole membrane material provided by the invention is resistant to high temperature, thermal shrinkage, high voltage and high current impact, and mechanical impact resistance, and is suitable for use as a safety battery separator and a safety supercapacitor separator to manufacture various high-capacity and High power lithium battery or supercapacitor. The invention also provides a preparation method of the nanocomposite multi-curvature membrane material and its application as a battery separator.

Owner:JIANGXI ADVANCED NANOFIBER S&T CO LTD

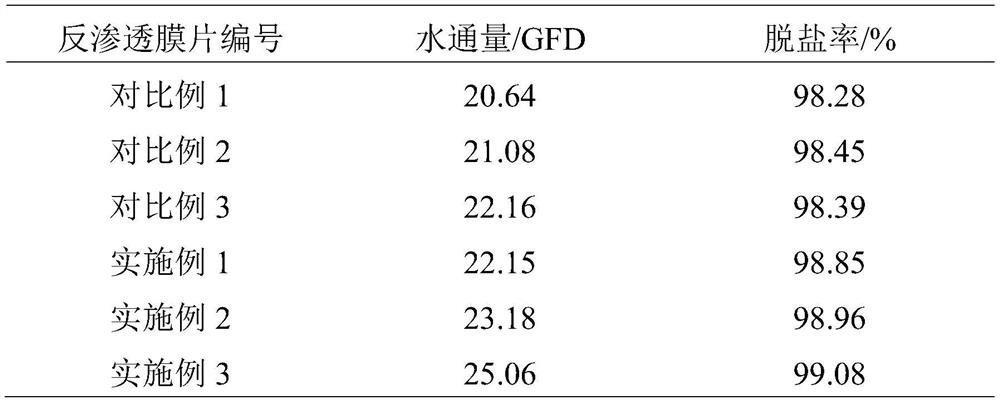

Reverse osmosis membrane with PE microporous membrane as base material and preparation method of reverse osmosis membrane

The invention discloses a reverse osmosis membrane with a PE microporous membrane as a base material and a preparation method of the reverse osmosis membrane. The reverse osmosis membrane comprises the PE microporous membrane, a polysulfone layer coating the PE microporous membrane and a polyamide layer coating the polysulfone layer, the pore diameter of the PE microporous membrane is 0.01-10 microns, the porosity is 70-95%, and the thickness is 20-120 microns. The PE microporous membrane is small in aperture and excellent in homogeneity, the surface of the PE microporous membrane is coated with the polysulfone layer, and due to the fact that organic solvents such as DMF, DMAc, NMP or DMSO are adopted during polysulfone coating, the PE microporous membrane is easily dissolved in the solvents, the PE microporous membrane can be subjected to permeation etching, and the aperture of the surface of the polysulfone layer becomes small and is more uniform. The pore diameter of the polysulfone layer is more uniform, so that the defects of the polyamide layer in the polymerization process are reduced, the polyamide layer is more uniform, and the performance is more excellent. The prepared reverse osmosis membrane has excellent water flux and rejection rate.

Owner:宁波日新恒力科技有限公司

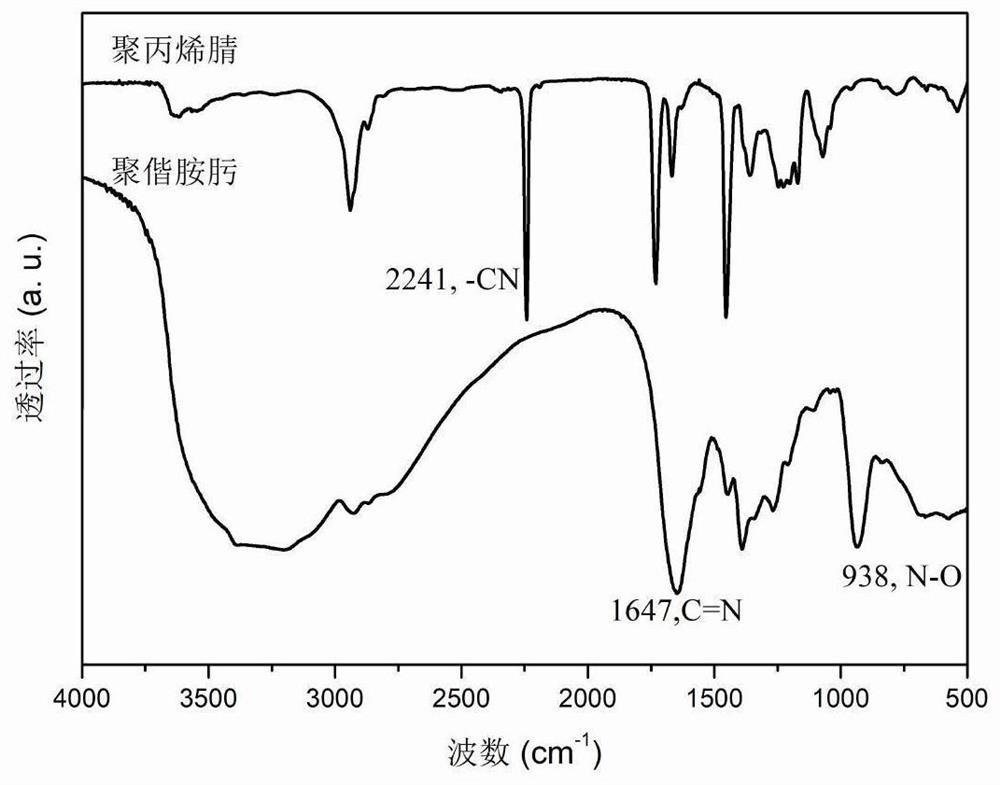

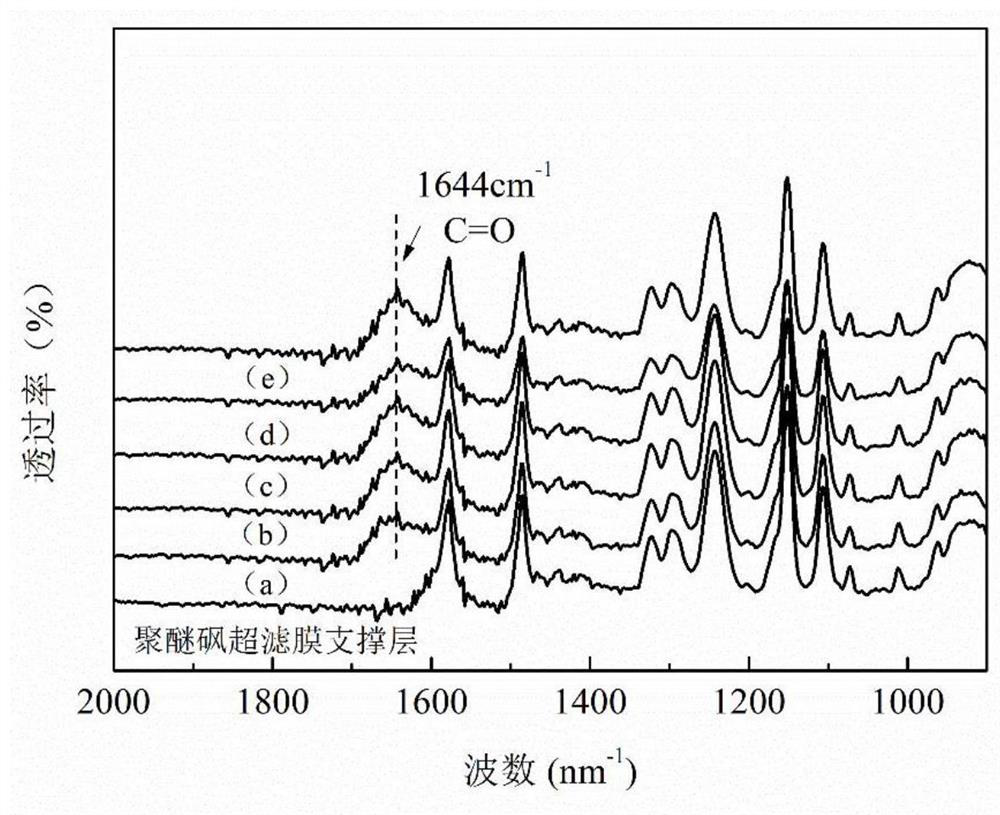

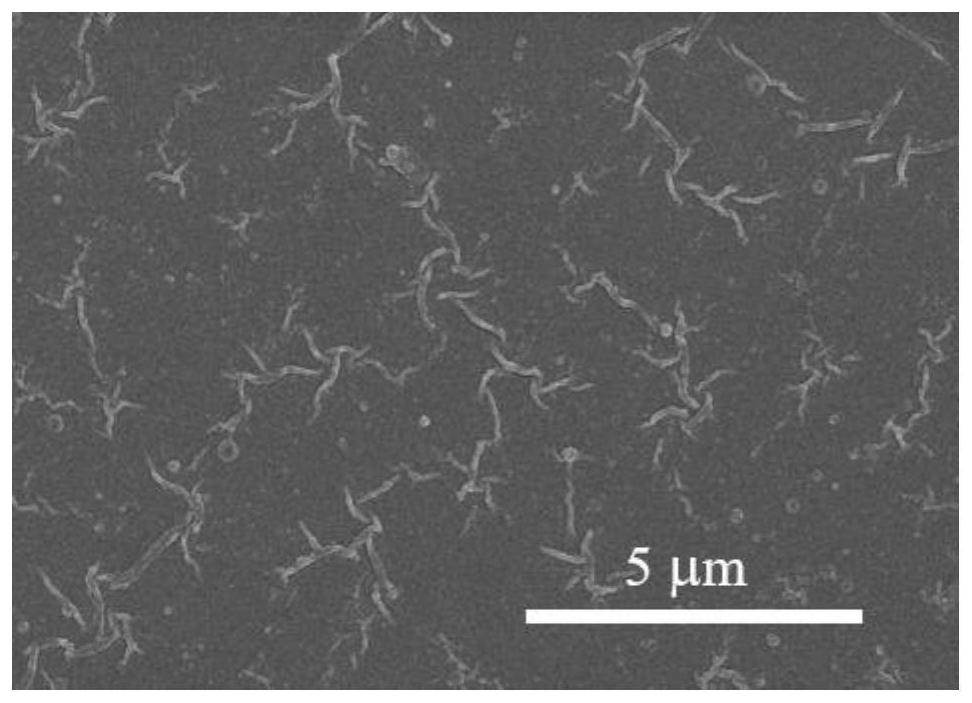

Preparation method of nanofiltration membrane based on polyamidoxime as boundary layer

ActiveCN113413776AHigh electronegativityImprove hydrophilicityWater/sewage treatment bu osmosis/dialysisReverse osmosisElectronegativityOil phase

The invention provides a preparation method of a nanofiltration membrane based on polyamidoxime as a boundary layer, and belongs to the field of nanofiltration membrane preparation. According to the invention, the polyamidoxime rich in amidoxime groups is used as an organic boundary layer, so that the hydrophilicity of the surface of a supporting layer can be obviously enhanced, the uniform spreading of a water solution of a water-phase monomer piperazine on the boundary layer is facilitated, a compact and thin PA layer with small surface aperture is prepared, and the polyamidoxime can generate hydrogen-bond interaction and Lewis acid-base interaction with piperazine, the diffusion of piperazine to an oil phase solution is effectively inhibited, the instability of interfacial polymerization is caused, a wrinkled PA layer with relatively strong electronegativity on the surface is formed, the effective permeation area is further remarkably increased, the permeation transmission channels of the finally obtained nanofiltration membrane are increased and the transmission resistance is reduced due to the reduction of the thickness of the PA layer and the increase of the effective permeation area of the PA layer, and the permeation flus is greatly improved. Meanwhile, the surface of the PA layer has relatively strong electronegativity and relatively small surface aperture, so that the solute rejection rate is increased.

Owner:EAST CHINA UNIV OF TECH

A kind of porous polyurethane film with gradient pore structure for artificial skin and its preparation method

Owner:SICHUAN UNIV

A method for preparing palladium membrane on the surface of macroporous carrier

ActiveCN105233701BGood hydrogen permeabilityImprove surface roughnessSemi-permeable membranesHydrogen separationActivation methodPolyvinyl alcohol

A method for preparing a palladium film on the surface of a macroporous carrier, using a dip coating method to cover a layer of organic modification layer on the surface of the porous carrier, and then using a sensitization-activation method to pre-coat a layer of palladium seed crystals on the surface of the polyvinyl alcohol modification layer , and then prepare a layer of palladium film on the surface of the organic modification layer by electroless plating, and finally remove the organic modification layer in the palladium composite film through high temperature heat treatment under the protection of an inert atmosphere, and obtain a palladium film with good hydrogen permeability. The use of organic materials to modify the porous carrier can not only effectively improve the surface roughness of the carrier and reduce the surface pore size, but also the organic modification layer can be removed by simple heat treatment after the electroless palladium plating film, which avoids the effect of the modification layer on hydrogen transmission. generated resistance. The method is simple, flexible, easy to operate and highly practical.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Composite porous membrane material filled with polytetrafluoroethylene microspheres and its preparation method and application

ActiveCN105161659BSmall surface pore sizeReduce porosityCell component detailsSecondary cells servicing/maintenanceMicrosphereTemperature resistance

The invention discloses a PTFE-NP filled composite multi-curvature membrane material, which uses polyimide (PI) nanofiber non-woven fabric as the base material, and the pores of the base material are filled with polytetrafluoroethylene nano-microspheres ( PTFE-NP); the diameter of the PTFE-NP is between 100-300nm, accounting for 30-60% of the total weight of the nanocomposite multi-curved membrane material; the PI nanofiber non-woven fabric has a thickness of 9 Electrospun PI nanofiber nonwovens between -38μm, porosity between 60-80%, and fiber diameter below 0.5μm. The nanocomposite multi-curvature membrane material provided by the invention is resistant to high temperature, heat shrinkage, high voltage and high current impact, and mechanical impact resistance, and is suitable for use as a safety battery separator and a safety supercapacitor separator to manufacture various high-capacity and high-voltage Power lithium battery or supercapacitor. The invention also provides a preparation method of the nanocomposite multi-curvature membrane material and its application as a battery separator.

Owner:JIANGXI NORMAL UNIV

Palladium composite membrane taking multihole FeAlCr as substrate and preparation method thereof

ActiveCN101983757BImprove hydrogen corrosion resistanceExtended service lifeSemi-permeable membranesTransition layerHeat treated

The invention discloses a palladium composite membrane taking multihole FeAlCr as substrate and a preparation method thereof. The palladium composite membrane is composed of a multihole FeAlCr substrate tube, a home position oxidation layer, a ceramic transition layer and palladium alloy membrane. The preparation process thereof includes the following steps: firstly, a multihole FeAlCr substrate tube is prepared; secondly, home position oxidation is adopted to form a dense home position oxidation layer on the surface of the multihole FeAlCr substrate tube; thirdly, a ceramic transition layer is coated; fourthly, palladium alloy is coated on the surface of the multihole FeAlCr substrate tube provided with the ceramic transition layer, and heat treatment is carried out, so as to form palladium alloy membrane, thus obtaining the palladium composite membrane. The preparation process of the invention is simple, and design is reasonable. The palladium composite membrane which takes multihole FeAlCr as substrate and is prepared by adopting the invention has high hydrogen permeability, strong hydrogen corrosion resistance and long service life, can be effectively applied to purification and separation of hydrogen and is especially applied to purification and separation of hydrogen isotope.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of multi-hole metal tube surface zirconia intermediate layer

ActiveCN102755839BSimple preparation processReasonable designSemi-permeable membranesComposite filmSurface oxidation

The invention discloses a preparation method of a multi-hole metal tube surface zirconia intermediate layer. The preparation method comprises the following steps of mixing zirconium powder and water or absolute ethyl alcohol, evenly stirring to prepare powder suspension; enabling two ends of a multi-hole metal tube to be connected with a circulation water type vacuum pump through flexible tubes, then immersing the multi-hole metal tube in the powder suspension, opening the circulation water type vacuum pump to suck under negative pressure, holding the zirconium powder in the powder suspension on the surface of the multi-hole metal tube, forming a layer of zirconium film, and finally airing at room temperature; igniting one end of the zirconium film until combustion reaction spreads to the other end of the zirconium film to obtain the multi-hole metal tube surface zirconia intermediate layer. The preparation method does not need large scale equipment and is simple in process, simple and convenient to control, energy-saving and environment-friendly, and the multi-hole metal tube surface zirconia intermediate layer prepared by the preparation method can effectively reduce surface hole diameter of the multi-hole metal tube, improve bond strength of a zirconia film and the multi-hole metal tube and prolong service life of palladium composite film.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

pi‑aln‑ptfe ternary nanocomposite porous membrane material and its preparation method and application

ActiveCN105047847BImprove temperature resistanceHigh hardnessNon-aqueous electrolyte accumulatorsElectrolytic capacitorsFiberElectrical battery

The invention discloses a nanocomposite multi-porous membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with composite nanoparticles; it is characterized in that: the composite The nanoparticles are composed of polytetrafluoroethylene nanospheres (PTFE-NP) and aluminum nitride nanoparticles (AlN-NP) mixed in a weight ratio of (7-12) / (8-13). The nanocomposite multi-porous membrane material provided by the invention has high temperature resistance, high hardness, moderate porosity, moderate areal density, good ion transport and excellent mechanical properties. The imide nanofiber diaphragm causes the problem of micro-short circuit of the battery due to high porosity; it can solve the serious problem of thermal runaway caused by mechanical collision of power lithium-ion batteries.

Owner:JIANGXI NORMAL UNIV

Oral slow release preparation, entrapment material and preparation method

InactiveCN102657871BChange the routine of drug administrationProlong the action timePeptide/protein ingredientsMetabolism disorderMicrosphereTherapeutic effect

The invention discloses an oral slow release preparation, an entrapment material and a preparation method. A sodium alginate-sodium hyaluronate mixture is taken as an entrapment material; and a prepared protein polypeptide medicament oral slow release preparation consists of the following components in percentage by mass: 0.5-10 percent of medicament and 90-99.5 percent of sodium alginate-sodium hyaluronate mixture. According to the oral slow release preparation, the conventional administration way of a protein polypeptide medicament is changed, the acting time of the protein polypeptide medicament is prolonged, the normal blood sugar level is maintained successfully for 12 hours when exenatide oral microspheres are taken as an example, the administration compliance of a diabetes patient is improved remarkably, and the treatment effect is enhanced.

Owner:CHINA PHARM UNIV

Carbon dioxide adsorption material and preparation method thereof

PendingCN114713188AImprove adsorption capacityThe number of micropores on the surface increasesProductsGas treatmentCarbon nanotubeHeteroatom

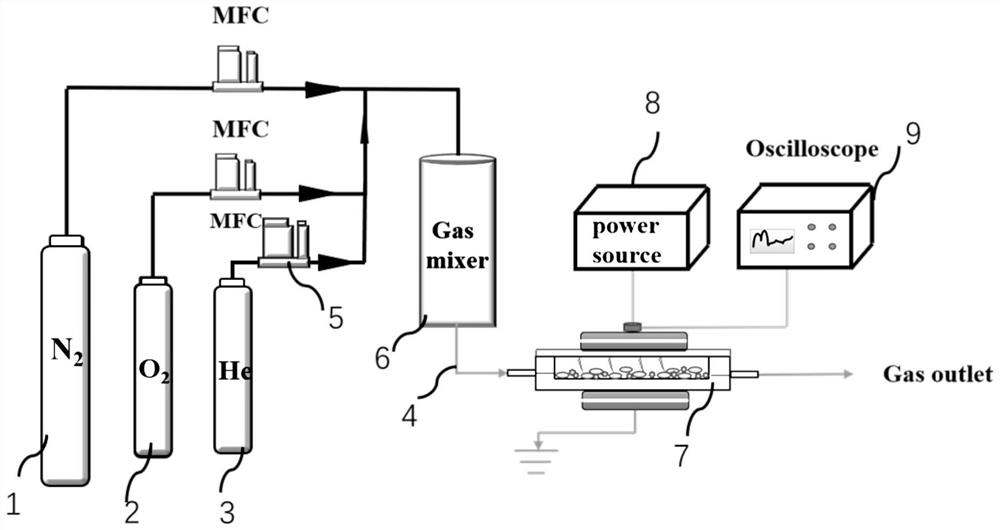

The invention discloses a carbon dioxide adsorption material and a preparation method thereof. The chemical property of the surface of the carbon material is easily influenced by heteroatoms, a nitrogen-containing functional group can show a special hydrogen-bond interaction, and the interaction between carbon dioxide and the functional group is increased by hydroxyl through the hydrogen-bond interaction and electrostatic potential, so that the adsorption of carbon dioxide is facilitated. The carbon dioxide adsorption provided by the invention is obtained by activating the carbon nanotubes in an acidic system and carrying out plasma modification. The carbon nanotube material is subjected to plasma modification, the number of surface micropores of the obtained carbon dioxide adsorption material is increased, the surface aperture is reduced, and the carbon dioxide adsorption capacity of the carbon dioxide adsorption material is remarkably improved. In addition, through plasma modification, the number of nitrogen-containing functional groups of the carbon nanotube material is increased, the electron density of the carbon surface is increased, the surface polarity is increased, and therefore the carbon dioxide adsorption amount is increased.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of multi-hole metal tube surface zirconia intermediate layer

ActiveCN102755839ASimple preparation processReasonable designSemi-permeable membranesComposite filmVacuum pump

The invention discloses a preparation method of a multi-hole metal tube surface zirconia intermediate layer. The preparation method comprises the following steps of mixing zirconium powder and water or absolute ethyl alcohol, evenly stirring to prepare powder suspension; enabling two ends of a multi-hole metal tube to be connected with a circulation water type vacuum pump through flexible tubes, then immersing the multi-hole metal tube in the powder suspension, opening the circulation water type vacuum pump to suck under negative pressure, holding the zirconium powder in the powder suspension on the surface of the multi-hole metal tube, forming a layer of zirconium film, and finally airing at room temperature; igniting one end of the zirconium film until combustion reaction spreads to the other end of the zirconium film to obtain the multi-hole metal tube surface zirconia intermediate layer. The preparation method does not need large scale equipment and is simple in process, simple and convenient to control, energy-saving and environment-friendly, and the multi-hole metal tube surface zirconia intermediate layer prepared by the preparation method can effectively reduce surface hole diameter of the multi-hole metal tube, improve bond strength of a zirconia film and the multi-hole metal tube and prolong service life of palladium composite film.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Composite porous membrane material filled with boron nitride particles and its preparation method and application

ActiveCN105206783BSmall surface pore sizeReduce porosityCell component detailsBoron nitrideNonwoven fabric

Owner:JIANGXI NORMAL UNIV

A kind of ultra-fine slurry filter press material and its preparation method

InactiveCN103239939BSimple preparation processLow costFiltration separationAdhesive cementFiltration

The invention relates to a material for filter pressing of superfine slurry and a manufacturing method of the material. The material is composed of a basic material layer with a pore diameter and a superfine pore filtering layer arranged at the upper part of the basic material layer, and the material is characterized in that an adhesive cement curing layer is used as the superfine pore filtering layer; superfine pore diameters are distributed on the adhesive cement curing layer; and the adhesive cement curing layer is formed by mixing a resin material, an inert grain, a volatilizable solvent and a curing agent, and drying and curing. The manufacturing method disclosed by the invention is simple in process and low in cost; and the material for the filter pressing of the superfine slurry has the advantages of guaranteeing the superfine pore diameters and reducing filter pressing resistance.

Owner:河北东同光电科技有限公司

A kind of high-strength antibacterial polyethylene film and preparation method thereof

ActiveCN113209840BHigh strengthImprove antibacterial propertiesSemi-permeable membranesMembranesHydration reactionPropanoic acid

The invention discloses a high-strength antibacterial polyethylene film and a preparation method thereof. The polyethylene film is a film formed by chemically bonding the polyethylene microporous film and the ethylene-vinyl alcohol copolymerized film with the polyethylene microporous film as the base and the ethylene-vinyl alcohol copolymerized film as the surface layer. Beneficial effects: Add pomegranate extract to increase bond strength and antibacterial properties; use water-induced reverse phase method to prepare ethylene-vinyl alcohol copolymer film as the surface layer, and utilize the synergistic effect between polyhexamethylene guanidine propionate and PVP, Accelerate the precipitation of PVP, accelerate the formation of pores, and reduce time costs; use the acidic groups in polyhexamethyleneguanidine propionate to make polyhexamethyleneguanidine propionate / metal nanoparticles move spontaneously to the membrane surface to form a hydration layer , Antibacterial and antifouling; use polyhexamethylene guanidine propionate to chelate metal nanoparticles, attach to the surface of metal nanoparticles, inhibit the agglomeration of metal nanoparticles, and increase uniform dispersion.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com