Functional composite dressing with drug sustained release and self-antibacterial effects and preparation method thereof

A slow-release, drug-based technology, applied in dressings, viscous dressings, non-adhesive dressings, etc., can solve problems such as not being able to be used for a long time, easy to breed bacteria, and easy to stick to granulation, so as to reduce the frequency, reduce the chance of re-injury, reduce The effect of wound scars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

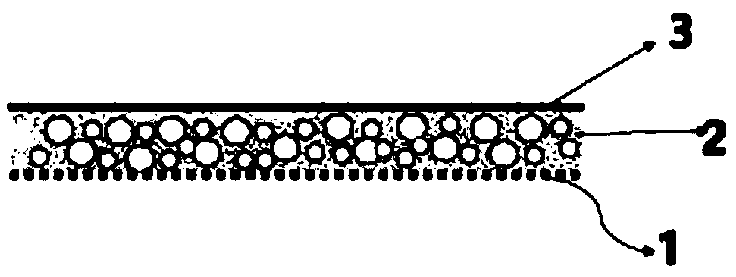

[0046] The preparation method of the above-mentioned functional composite dressing with drug sustained release and self-antibacterial effect, the steps are as follows:

[0047] Step 1, preparing the wound contact layer 1 by the immersion phase precipitation transformation method;

[0048] Add 100 parts by weight of polylactic acid granules, 10-30 parts by weight of polyethylene glycol, and 2-12 parts by weight of sustained-release drugs into a container containing N-methylpyrrolidone, mix and stir to dissolve completely, and prepare A uniform solution with a solid content of 20% to 60%, after defoaming, is evenly coated on the release paper by a coating machine, and then the release paper coated with the mixture layer is soaked in ethanol solution for 5 to 30 minutes, and then put Dry the solvent in an oven at 70-100°C, take it out and peel off the release paper to obtain transparent micropores with a thickness of 10-150 μm and a uniform distribution of pore diameters of 5-50 ...

Embodiment 1

[0056] Step 1. Preparation of wound contact layer by immersion phase precipitation transformation method

[0057] 800g of Add 80g of polyethylene glycol 200, 8g of anesthetic and 8g of blood coagulant into the container containing 5LN-methylpyrrolidone one by one, mix and stir to dissolve completely, and after defoaming, apply it evenly on the release paper by a coating machine , and then soak the release paper coated with the mixture layer in ethanol solution for 10 minutes, put it in an oven at 80°C to dry the solvent, take it out and peel off the release paper to obtain a thickness of 40 μm, a surface pore size of 30 μm, and a pore density of 600 pieces / cm 2 wound contact layer;

[0058] Step 2. Preparation of the external protective layer

[0059] 700g of Add it into a container containing 2L of acetone, stir and dissolve evenly, after defoaming, apply it evenly on the release paper with a coating machine, put it in a 40°C oven to dry the solvent, take it out and pee...

Embodiment 2

[0065] Step 1. Preparation of wound contact layer by immersion phase precipitation transformation method

[0066] 1000g of Add 100g of polyethylene glycol 200, 10g of analgesic and 10g of anti-inflammatory drug into the container containing 5LN-methylpyrrolidone one by one, mix and stir to dissolve completely, and after defoaming, apply it evenly on the release form with a coating machine On the paper, soak the release paper coated with the mixture layer in ethanol solution for 10 minutes, put it in an oven at 80°C to dry the solvent, take it out and peel off the release paper to obtain a thickness of 56 μm and a surface pore size of 40 μm. Hole density is 800 / cm 2 wound contact layer;

[0067] Step 2. Preparation of the external protective layer

[0068] 1000g of Add it into a container containing 2L of acetone, stir and dissolve evenly, after defoaming, apply it evenly on the release paper with a coating machine, put it in a 40°C oven to dry the solvent, take it out an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com