Patents

Literature

47results about How to "High electrical breakdown strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

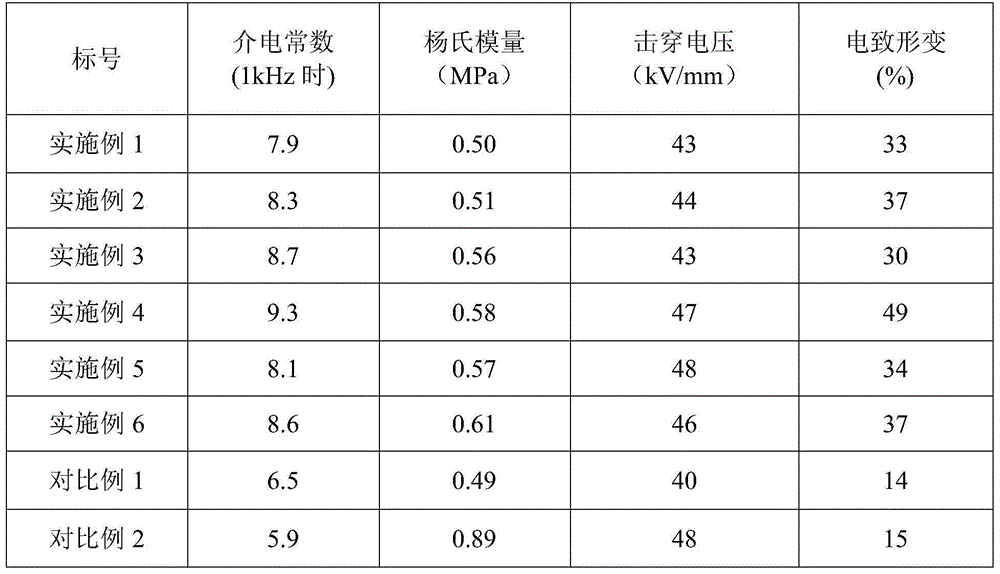

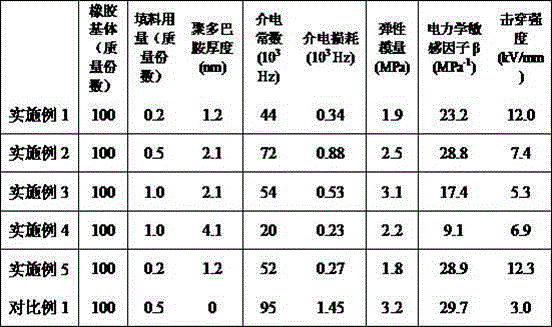

Fluorinated silicone rubber dielectric elastomer composite material and preparation method thereof

InactiveCN104830072ASolve the problem of adding fillers to reduce material stabilityHigh dielectric constantCross-linkElectricity

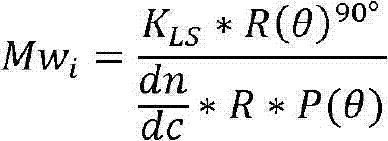

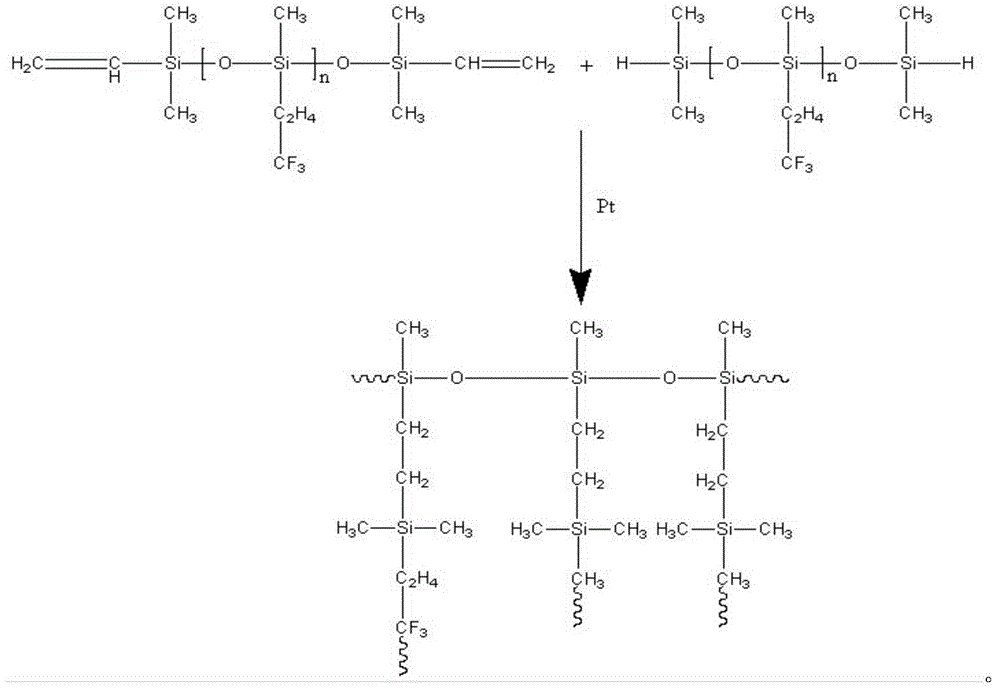

The invention relates to a fluorinated silicone rubber dielectric elastomer composite material and a preparation method thereof. The cross-linking density is changed, the amount of a high-dielectric semiconductor filler is regulated and controlled, and thus the composite material with good dispersion is obtained. The obtained composite material can obtain high dielectric constant with relatively low filling of the semiconductor filler, at the same time, the elastic modulus has no obvious improvement, the electric breakdown strength remains unchanged, and eventually relatively large electrodeformation is produced.

Owner:BEIJING UNIV OF CHEM TECH

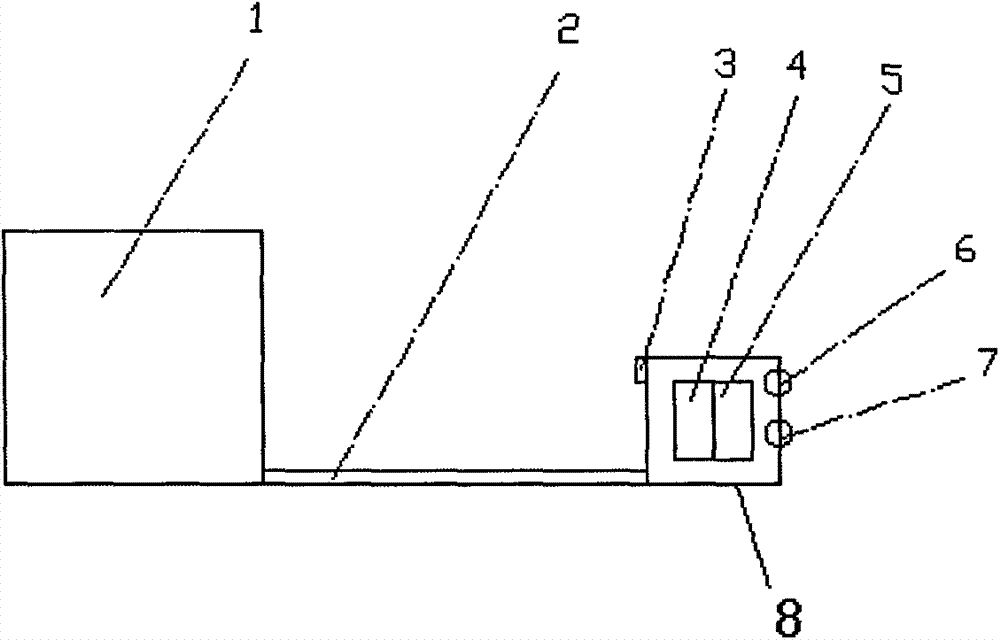

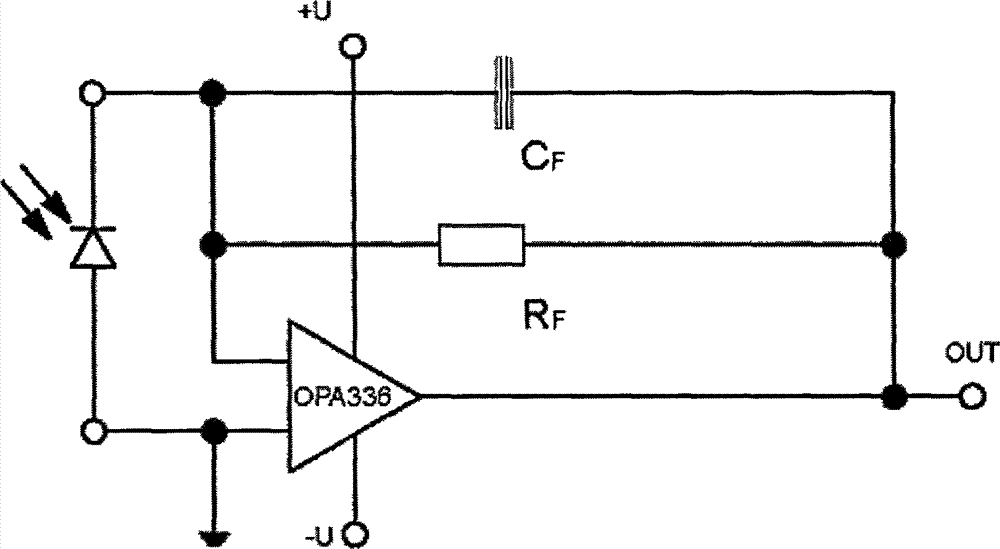

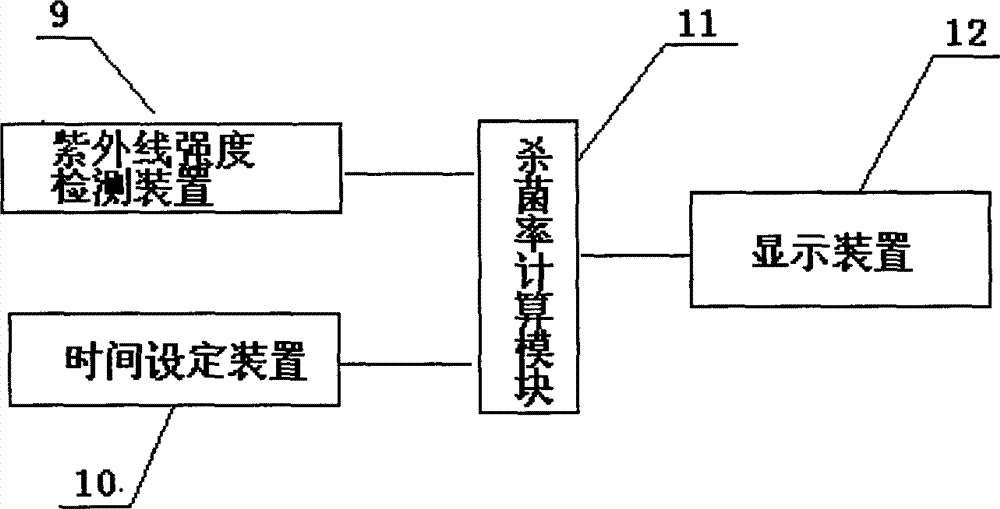

Method and device for detecting ultraviolet (UV) sterilization effect

ActiveCN104707158AGuaranteed killGuaranteed validityLavatory sanitoryDisinfectionUv disinfectionStaphylococcus aureus

The invention discloses a method and device for detecting ultraviolet (UV) sterilization effect. The method comprises the following steps: (1) determining the relationship among the UV radiation strength, UV radiation time, and sterilization rate; (2) detecting the UV radiation strength; (3) obtaining the sterilization rate according to the UV radiation strength and a given radiation time. The device comprises a UV strength detection device, a time setting device, and a sterilization rate calculation module. The method and device can guarantee the effectiveness of a UV sterilization facility on killing bacteria (especially staphylococcus aureus), the sterilization process, which cannot be observed by naked eyes, can be evaluated and controlled, moreover, the UV sterilization facility can be stopped after the staphylococcus aureus is completely killed, the energy waste is avoided, and the practicality of the UV sterilization facility is improved.

Owner:罗旭

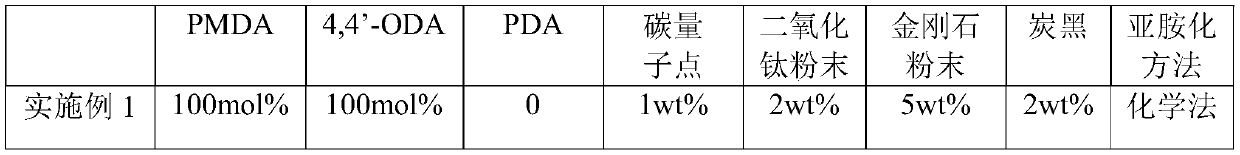

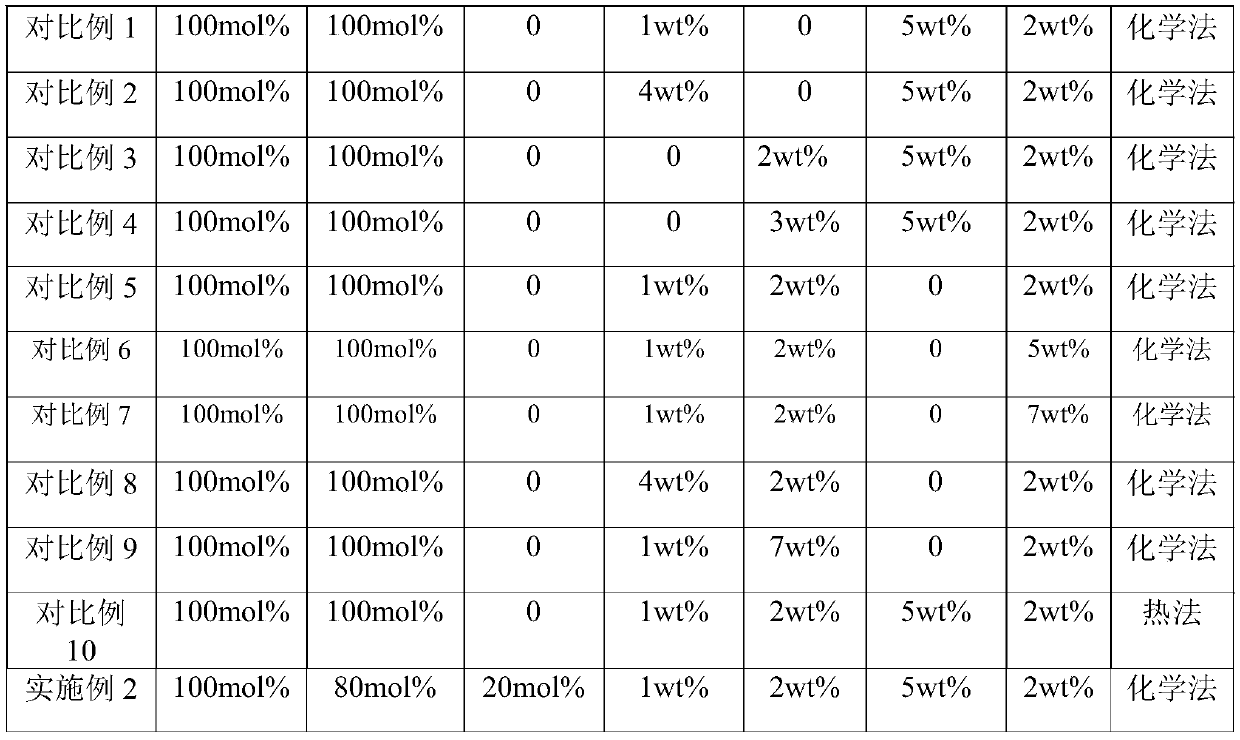

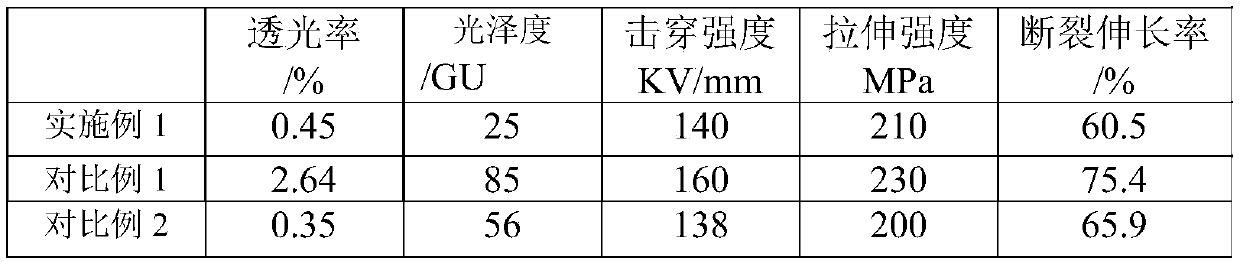

Black matte polyimide film and preparation method thereof

ActiveCN111205646AReduce light transmittanceReduce dosagePhotovoltaic energy generationPolymer scienceTitanium oxide

The invention discloses a black matte polyimide film. Carbon quantum dots, titanium dioxide powder, diamond powder and carbon black are uniformly distributed in the polyimide film. The preparation method of the black matte polyimide film comprises the following steps: adding carbon quantum dots, titanium dioxide powder, diamond powder and carbon black into an organic solvent, adding a dispersing agent, grinding to obtain black slurry; adding diamine and aromatic dianhydride into the black slurry, stirring, stopping stirring after the viscosity of the reaction system reaches 1500-4000 Pa.s, carrying out a vacuum defoaming treatment, forming a film, and heating to carry out imidization to obtain the black matte polyimide film. The black polyimide film has light transmittance of less than orequal to 0.45%, glossiness of less than or equal to 25GU, electric field breakdown strength of more than or equal to 140kV / mm, tensile strength of more than or equal to 210MPa and elongation at breakof more than or equal to 60.5% in a visible light range, and has a good shading effect, electrical insulation property and mechanical property.

Owner:株洲时代华鑫新材料技术有限公司

Polytetrafluoroethylene nanoparticle-filled composite tortuous porous membrane material and preparation method and application thereof

ActiveCN105161659AIncrease capacitySmall surface pore sizeCell component detailsSecondary cells servicing/maintenancePorosityMicrosphere

The invention discloses a polytetrafluoroethylene nanoparticle (PTFE-NP)-filled composite tortuous porous membrane material. With polyimide (PI) nanofiber nonwoven fabric as a base material, holes of the base materials are filled with polytetrafluoroethylene nanoparticles (PTFE-NPs); the PTFE-NPs are 100-300nm in diameter and account for 30%-60% of total weight of the composite tortuous porous membrane material; and the PI nanofiber nonwoven fabric is electrospinning PI nanofiber nonwoven fabric of which the thickness is 9-38 microns, the porosity is 60%-80% and the fiber diameters are less than 0.5 micron. The nano composite tortuous porous membrane material disclosed by the invention has the advantages of high temperature resistance, heat shrinkage resistance, high voltage impact resistance, high current impact resistance and mechanical impact resistance, and is suitable for manufacturing various high-capacity and high-power lithium batteries or super capacitors as a safe battery diaphragm and a safe super capacitor diaphragm. The invention further provides a preparation method of the nano composite tortuous porous membrane material and an application of the composite tortuous porous membrane material as a battery diaphragm.

Owner:JIANGXI NORMAL UNIV

Epoxy resin encapsulating material and preparation thereof

InactiveCN101440195AHigh electrical breakdown strengthOther chemical processesDielectric lossElectric breakdown

The invention discloses an epoxy resin encapsulating material, which is characterized by comprising 40 to 60 weight portions of EP828 epoxy resin or E51 epoxy resin, 80 to 130 weight portions of platy alpha Al2O3 ceramic powder, 5 to 10 weight portions of coupling agent - gamma-(2,3-epoxy propoxide) propyl trimethoxy silane, 8 to 12 weight portions of curing agent 590 and 0.1 to 1.5 weight portions of plasticizer - di-n-octyl phthalandione. The invention also discloses a method for preparing the epoxy resin encapsulating material, which comprises: firstly, dissolving the coupling agent into ethanol, adding the platy alpha Al2O3 ceramic powder into a mixture under the condition of stirring, and preparing alumina powder; and secondly, adding the plasticizer into the epoxy resin, uniformly mixing the plasticizer and the epoxy resin, adding the alumina powder into a mixture, performing mixing and degasification, adding the curing agent into the mixture, and performing vacuum defoamation and curing to obtain the epoxy resin encapsulating material. By adoption of the platy alpha Al2O3 ceramic powder as filler, the dielectric loss tangent value of the obtained material is reduced from 0.11 in the prior art to 0.02, and the electric breakdown strength is improved from 10kV.m<-1> in the prior art to 84-102kV.m<-1>.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

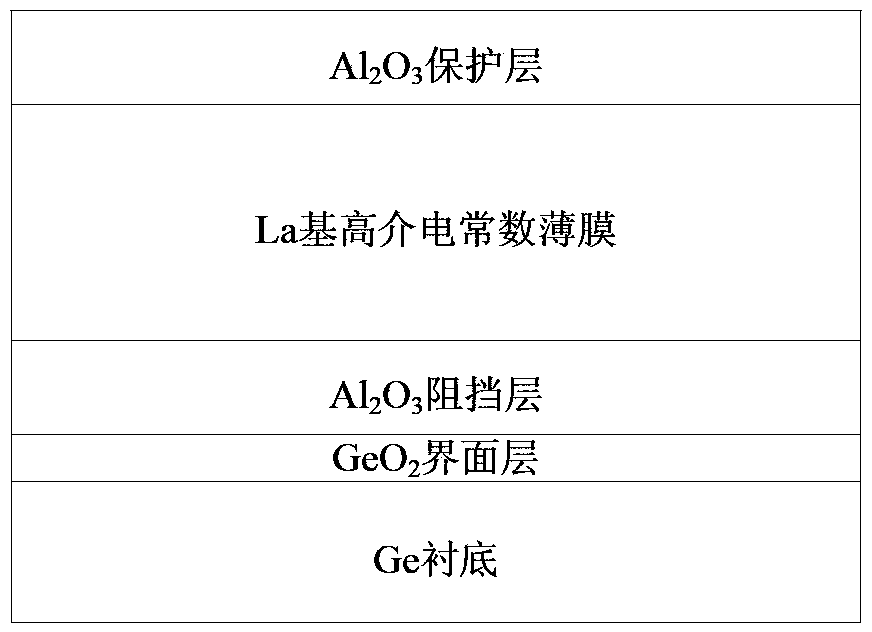

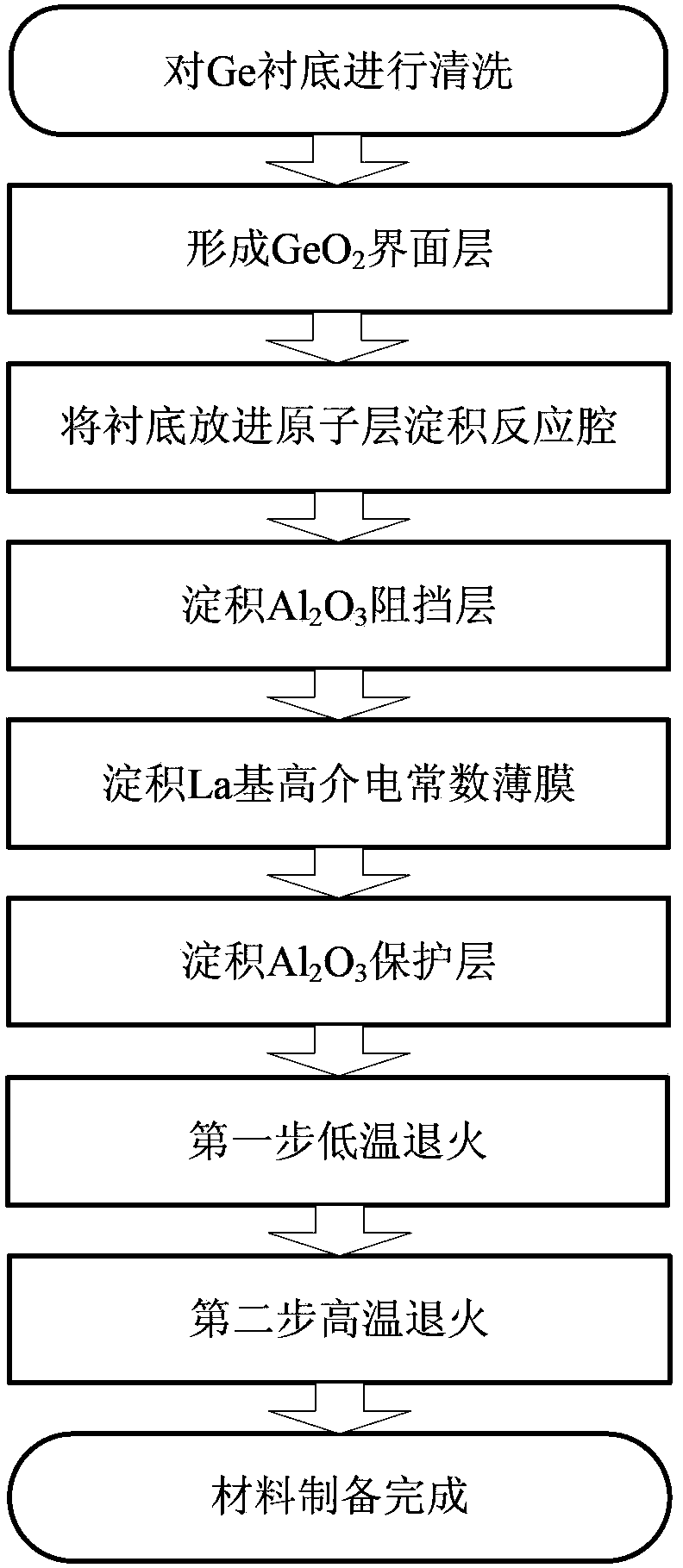

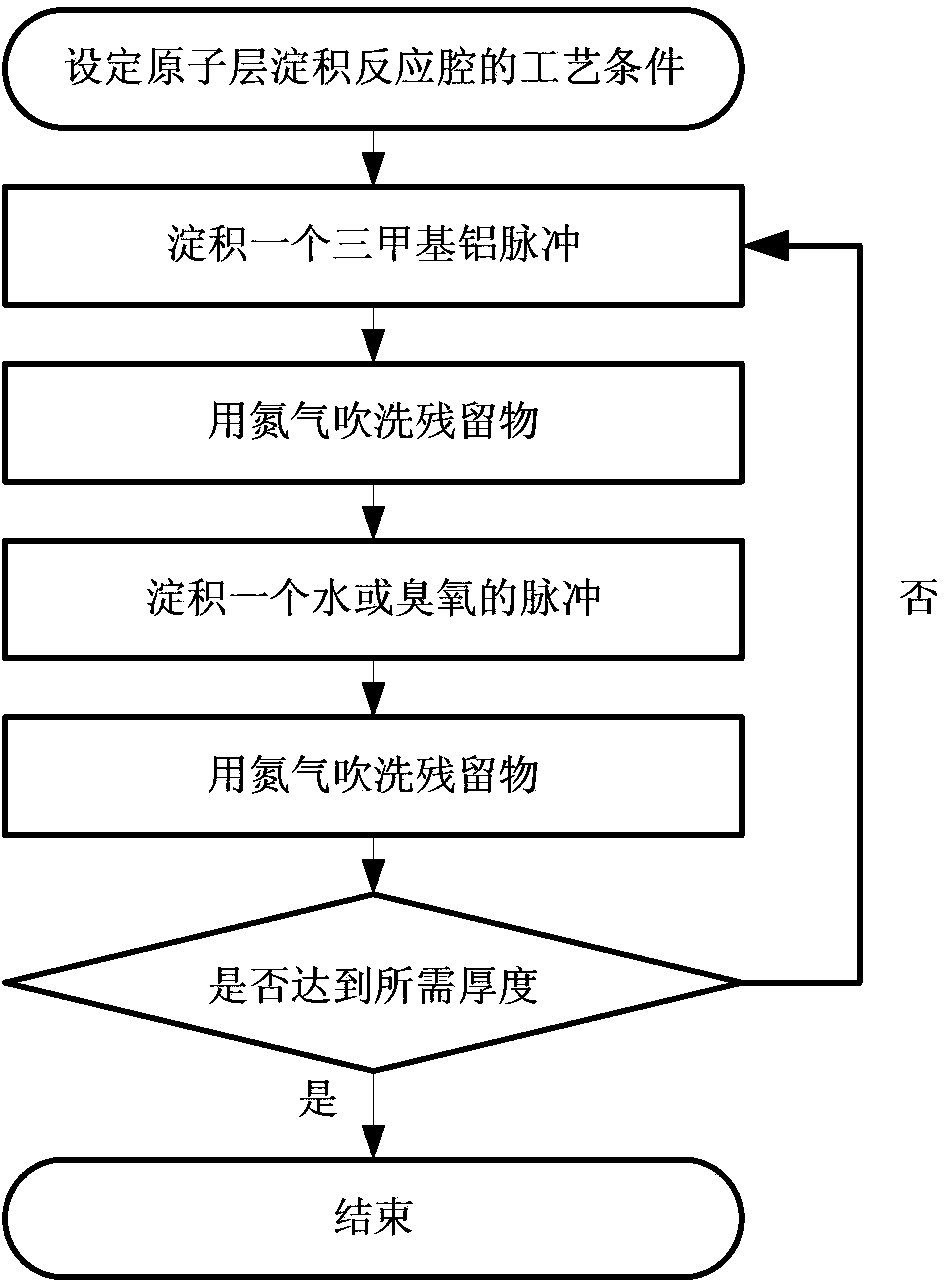

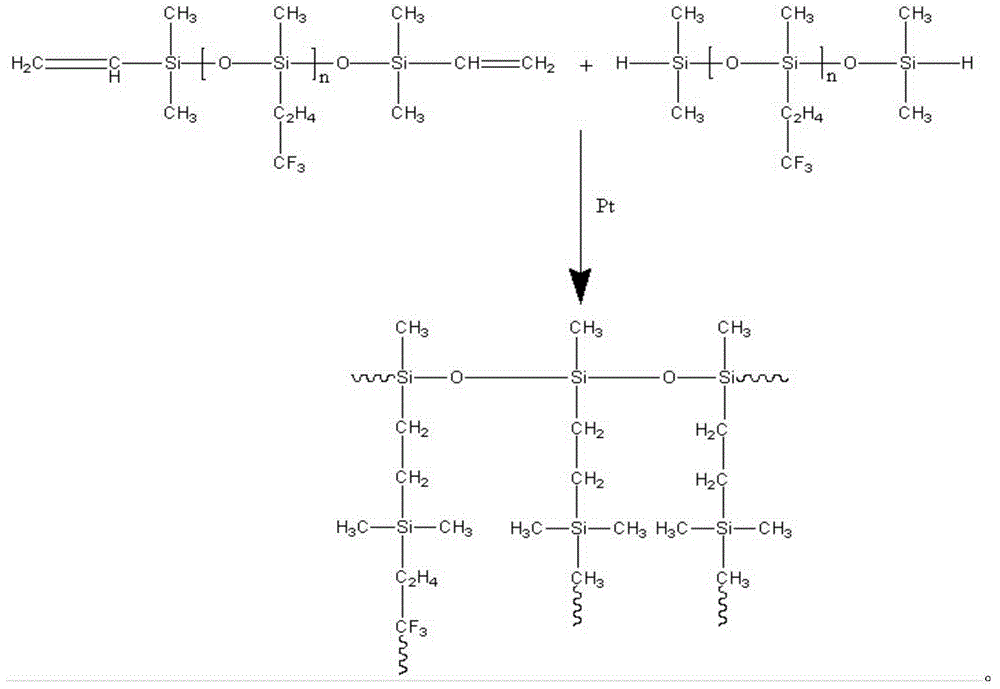

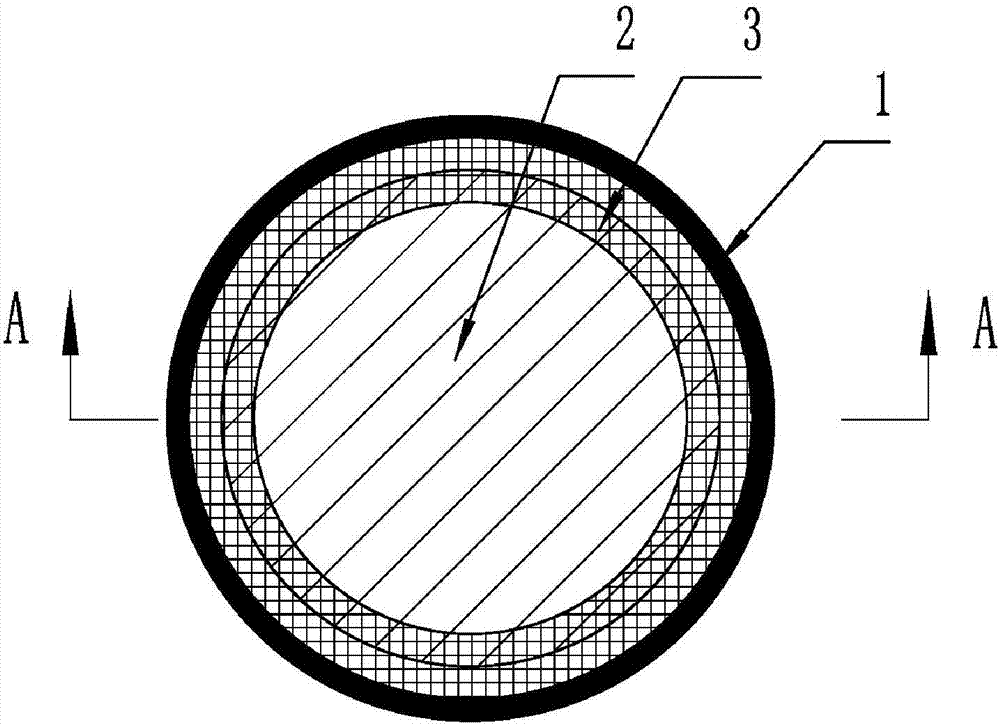

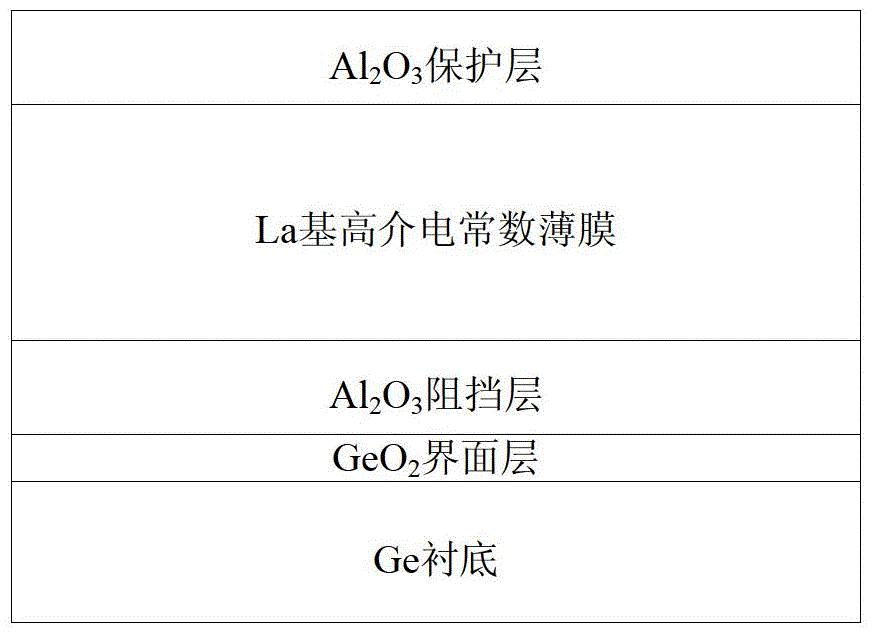

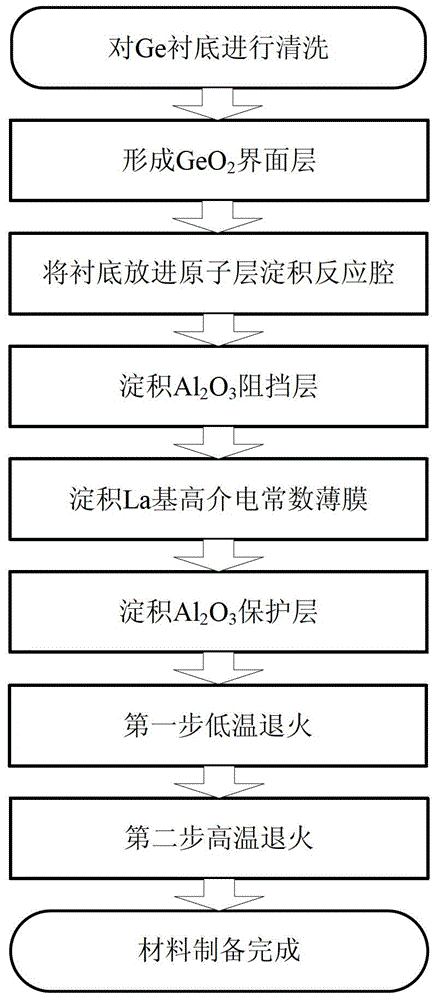

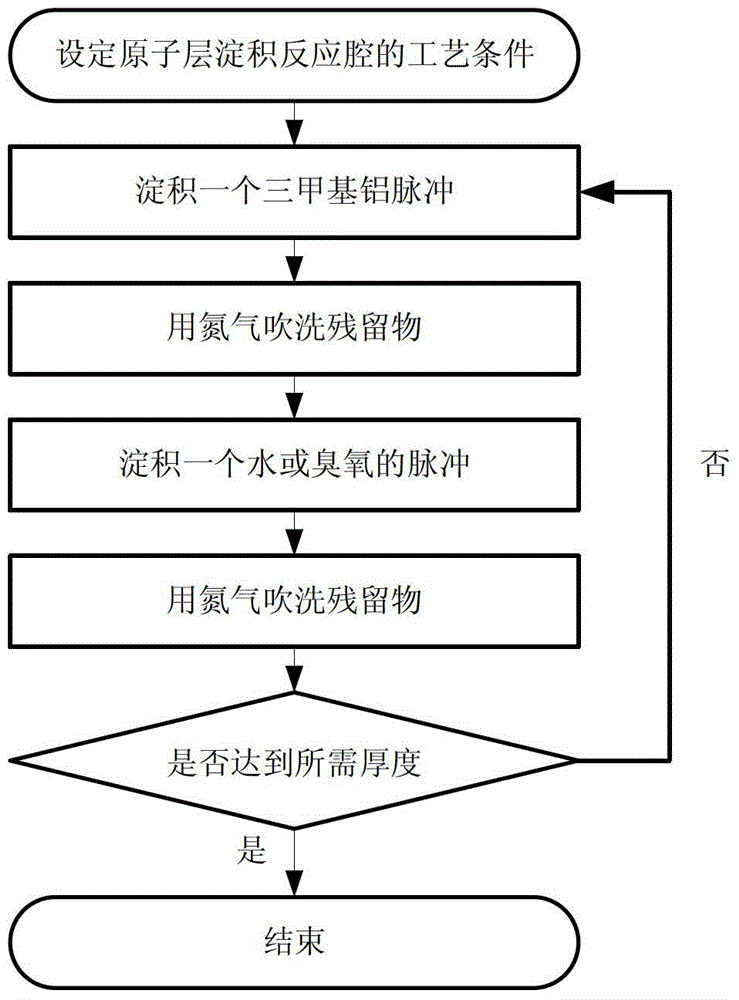

Preparation method for germanium substrate and La-based high-dielectric constant gate dielectric material

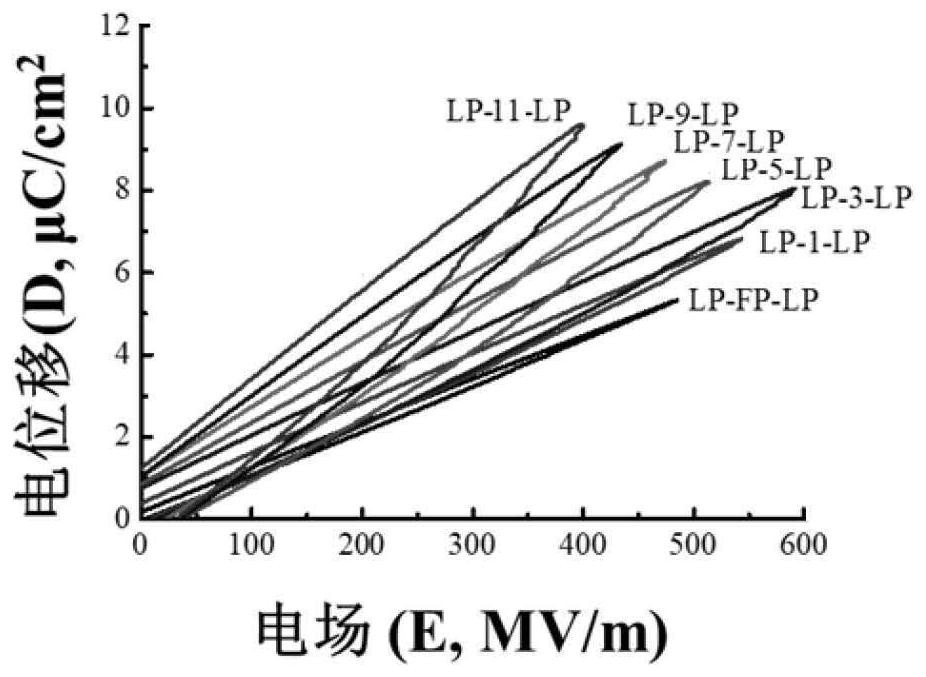

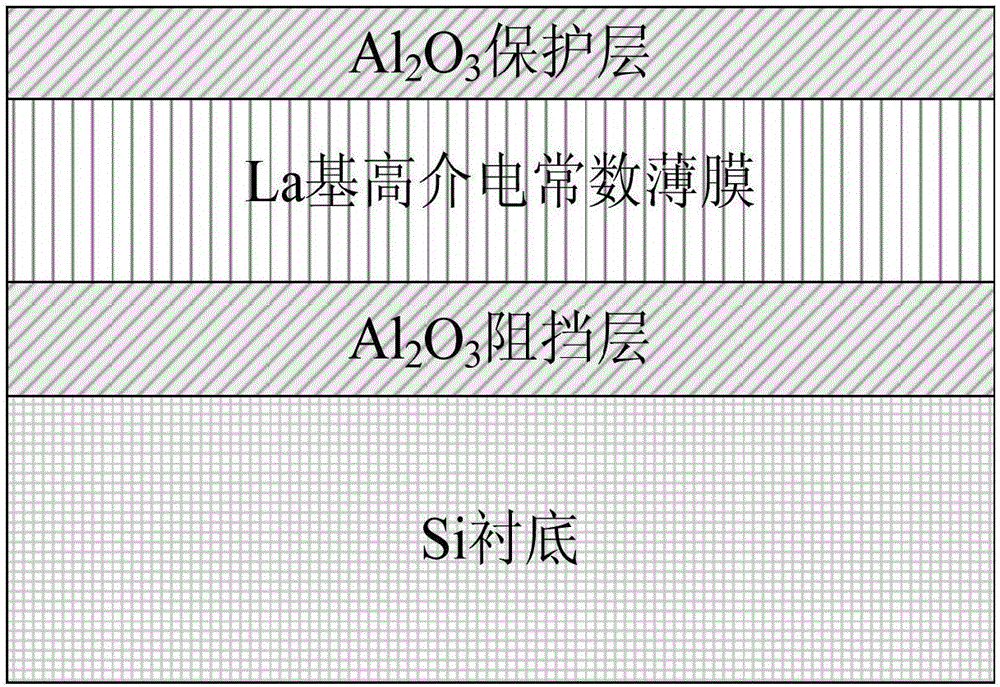

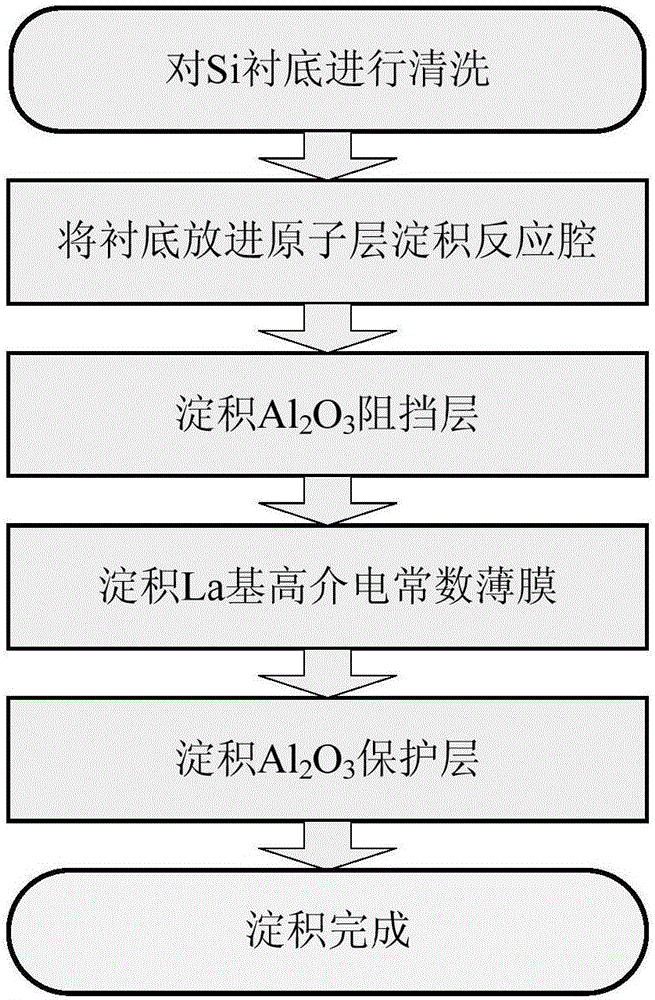

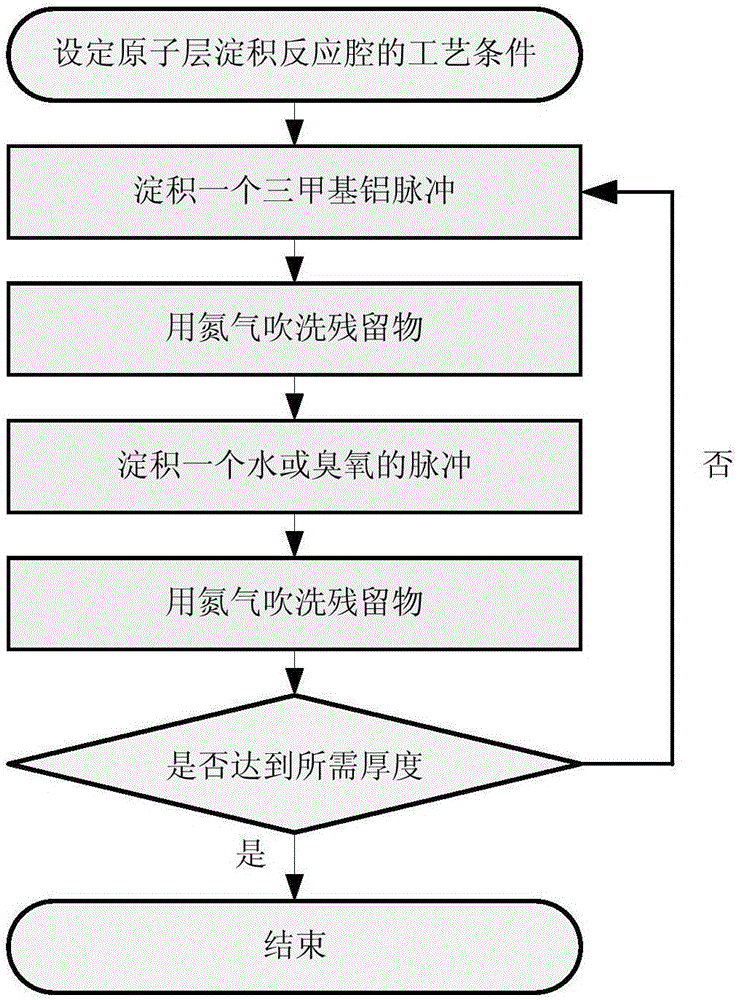

ActiveCN103367409AInhibition of adsorptionPrevent volatilizationSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricGate dielectric

The invention discloses a preparation method for a germanium substrate and La-based high-dielectric constant gate dielectric material. The problems of low dielectric constant and poor thermal stability and thin film compactness of the conventional material are mainly solved. The gate dielectric material comprises an interface layer (1), a barrier layer (2), an La-based high-dielectric constant thin film (3) and a protective layer (4) from bottom to top, wherein the interface layer (1) is made from 0.5 to 1nm thick GeO2; the barrier layer (2) is made from 0.5 to 2nm thick Al2O3; the La-based high-dielectric constant thin film (3) is made from 1 to 10nm thick La2O3 or LaAlO3 or HfLaOx; and the protective layer (4) is made from 1 to 2nm thick Al2O3. The whole material is prepared by an atomic layer deposition method, and is subjected to low-temperature and high-temperature annealing treatment after being prepared. The germanium substrate and La-based high-dielectric constant gate dielectric material has the advantages of high dielectric constant, high thin film compactness, high step coverage, high thermal stability and low surface roughness, and can be used for manufacturing a gate dielectric film of a metal oxide semiconductor field effect transistor.

Owner:XIDIAN UNIV

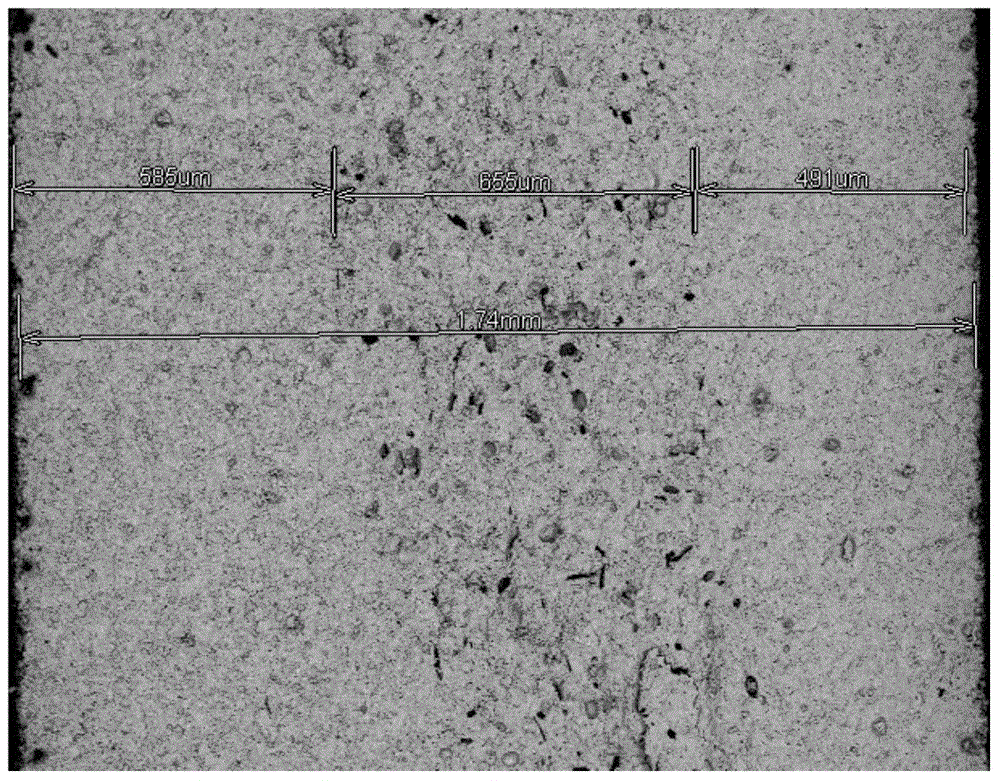

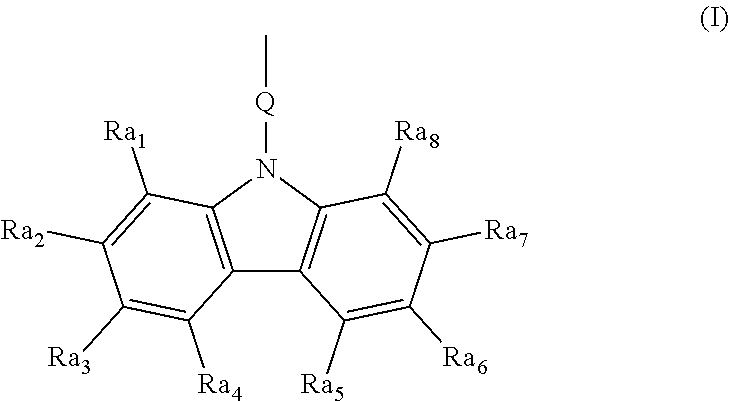

A kind of graphene-based dielectric elastomer composite material and preparation method thereof

The invention relates to a graphene-based dielectric elastomer composite material and a preparing method thereof. The composite material comprises an elastomer matrix, graphene oxide dielectric padding and a crosslinking system, wherein the graphene oxide dielectric padding is oxidation graphene with the surface wrapped by a poly-dopamine organic layer and is scattered in the elastomer matrix in a nanometer horizontal layer mode, and an isolation network structure that an oxidized graphene slice layer which is wrapped by the poly-dopamine organic layer wraps latex particles. According to the preparing method, the dopamine bionic ornament oxidization graphene is adopted, the dielectric loss is obviously reduced, the electric breakdown strength is improved, the organic layer thickness of the poly-dopamine can be regulated through the parameters of the modification process of the dopamine, the dielectric constant, the dielectric loss and the electric breakdown strength of the composite material can be adjusted according to the demands, and the graphene-based dielectric elastomer composite material meeting the safety requirement in the biology medical field can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

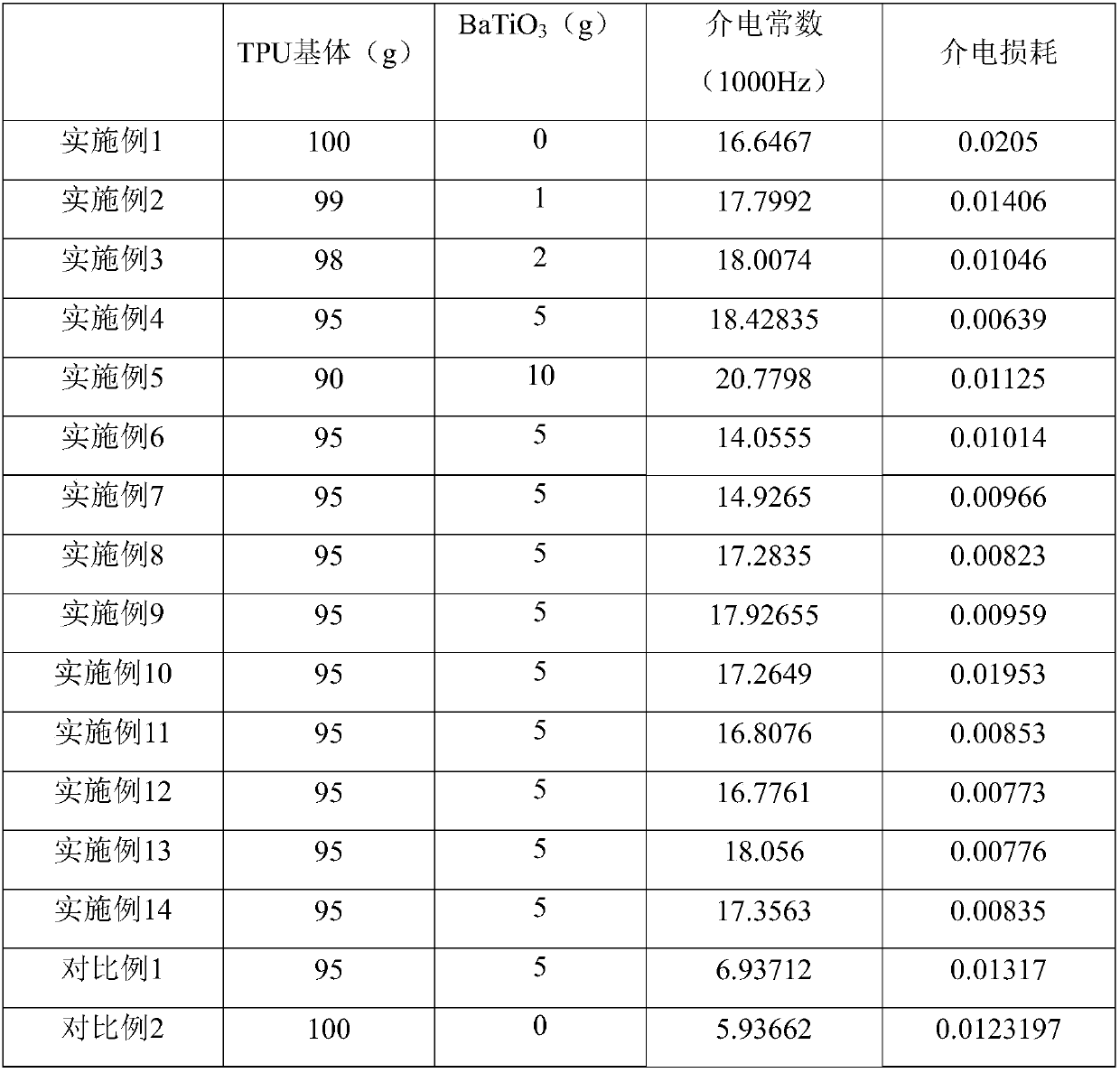

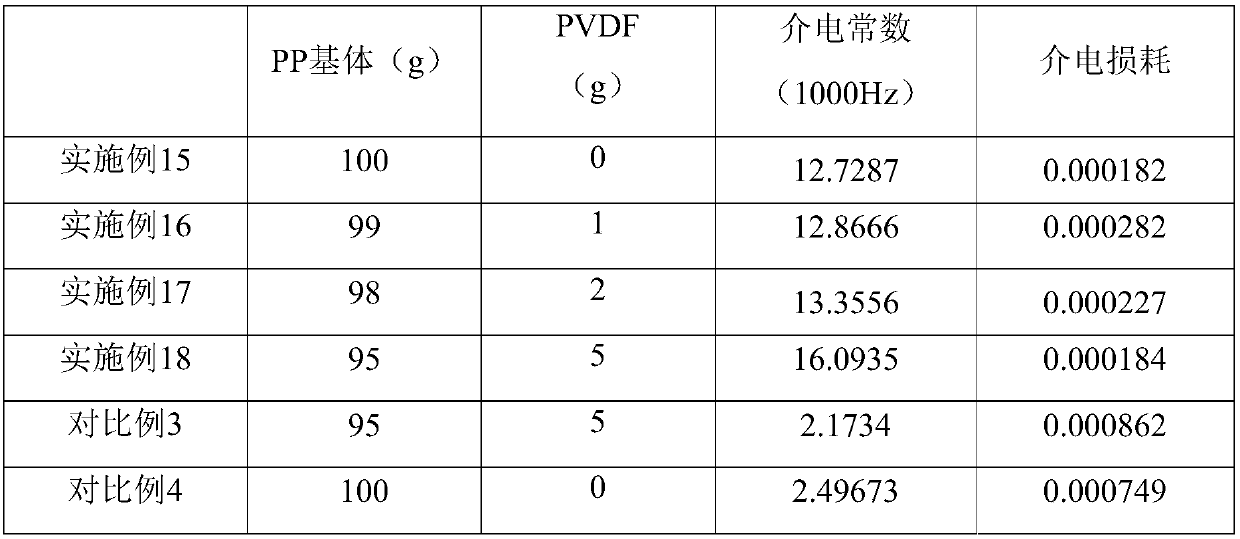

Method for improving dielectric properties of polymer matrix composites

The invention belongs to the field of high dielectric polymer materials, and particularly relates to a method for improving the dielectric properties of polymer matrix composites. The method for improving the dielectric properties of the polymer matrix composites includes preparing the polymer matrix composites by microinjection molding of polymer / dielectric filler blends. The method is simple andeasy to operate, and the obtained composites have high dielectric constants and low dielectric loss.

Owner:SICHUAN UNIV

Composite multi-curved-pore membrane material filled by silicon dioxide particles, and preparation method and application therefor

The invention discloses a micro-nano composite multi-curved-pore membrane material. The polyimide (PI) nanofiber non-woven fabric is taken as the base material; the pores of the base material are filled by silicon dioxide particles; the diameter of the micro-nano silicon dioxide particles is 50-800 nm, accounting for 20-50% of the total weight of the micro-nano composite multi-curved-pore membrane material; and the PI nanofiber non-woven fabric is 9-38 um in thickness, and 60-80% in the porosity. The micro-nano composite multi-curved-pore membrane material prepared by the invention is high temperature resistant, thermal shrinkage resistant, high voltage resistant, high current impact resistant, and mechanical collision resistant, and suitable for being used as safe battery membranes and safe supercapacitor membranes for manufacturing various high-capacity and high-power lithium ion batteries or supercapacitors. The invention also provides a preparation method for the micro-nano composite multi-curved-pore membrane material, and application of the membrane material in being used as the battery membranes.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Zirconium oxide particles filled composite multi-curved-porous membrane material, and preparation method and application therefor

ActiveCN105226219ASmall surface pore sizeHigh electrical breakdown strengthCell component detailsWoven fabricThermal shrinkage

The invention discloses a nanocomposite multi-curved-porous membrane material. The nanocomposite multi-curved-porous membrane material takes polyimide (PI) nanofiber non-woven fabric as a base material, and nanometer zirconium dioxide (ZrO2) particles are filled in pores of the base material; the diameter of the nanometer ZrO2 particles is 50-100 nm, and the weight of the nanometer ZrO2 particles is 30-50% of the total weight of the nanocomposite multi-curved-porous membrane material; the thickness of the PI nanofiber non-woven fabric is 9-38 um, and the porosity is 60-80%. The nanocomposite multi-curved-porous membrane material has high-temperature resistance, thermal shrinkage resistance, high voltage and high current impact resistance, and mechanical collision resistance, so that the nanocomposite multi-curved-porous membrane material is suitable for being used as safety battery membranes and safety supercapacitor members for manufacturing various high-capacity and high-power lithium batteries or supercapacitors. The invention further provides a preparation method for the nanocomposite multi-curved-porous membrane material, and an application of the nanocomposite multi-curved-porous membrane material in being used as the battery membranes.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

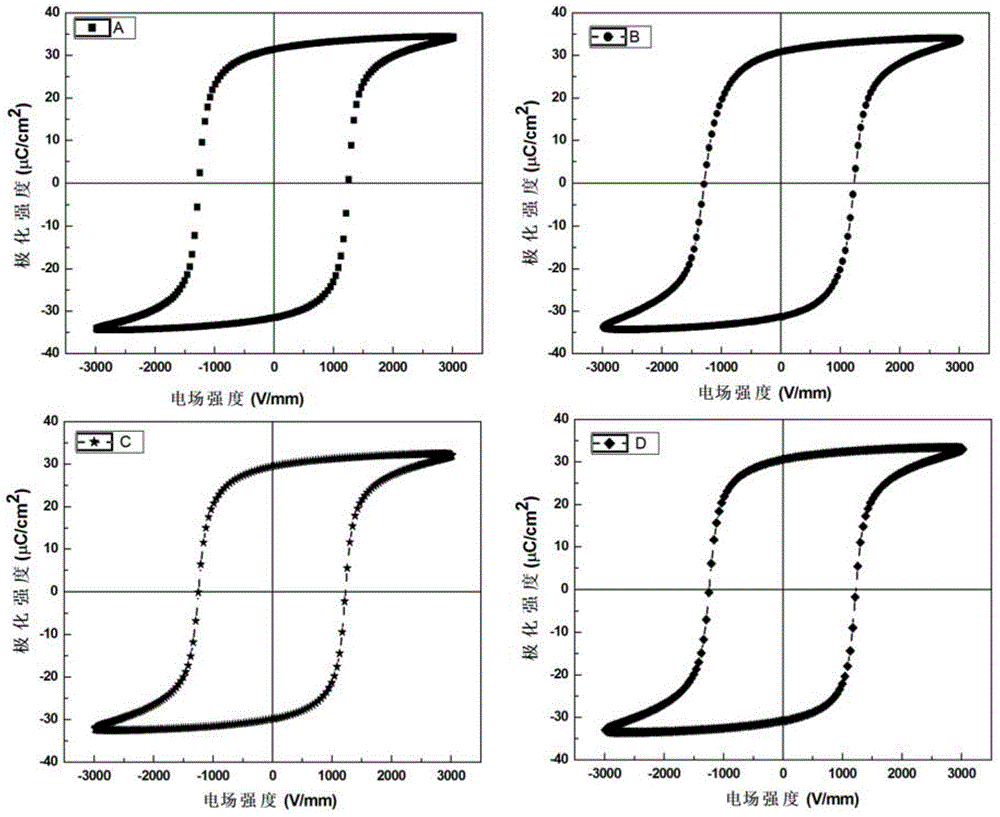

Three-layer structure lead zirconate titanate ferroelectric ceramic material and preparation method thereof

ActiveCN103553601AHigh electrical breakdown strengthReduce lossLead zirconate titanateSilver electrode

The invention discloses a three-layer structure lead zirconate titanate ferroelectric ceramic material and a preparation method thereof. The three-layer structure lead zirconate titanate ferroelectric ceramic material is of a sandwich structure, wherein a core layer of the material is a porous lead zirconate titanate ceramic layer, and the porosity of the core layer is 5-30%; the upper surface and lower surface of the material are compact lead zirconate titanate ceramic layers. The preparation method comprises the following steps: (a) respectively preparing porous lead zirconate titanate ceramic powder and compact lead zirconate titanate ceramic powder; (b) adding the porous lead zirconate titanate ceramic powder to the middle layer of a mold divided into three layers of space by using membranes, adding the compact lead zirconate titanate ceramic powder to the upper surface and lower surface of the mold, removing the membranes, briquetting and demolding; (c) removing plastic, sintering, machining and carrying out silver electrode firing, thus obtaining the ceramic material. The ceramic material provided by the invention has the advantages of high electric breakdown strength, low loss property of compact ceramics and the shock resistance of porous ceramics, so that the reliability and safety of the ferroelectric ceramic material in a pulse power supply are optimized.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

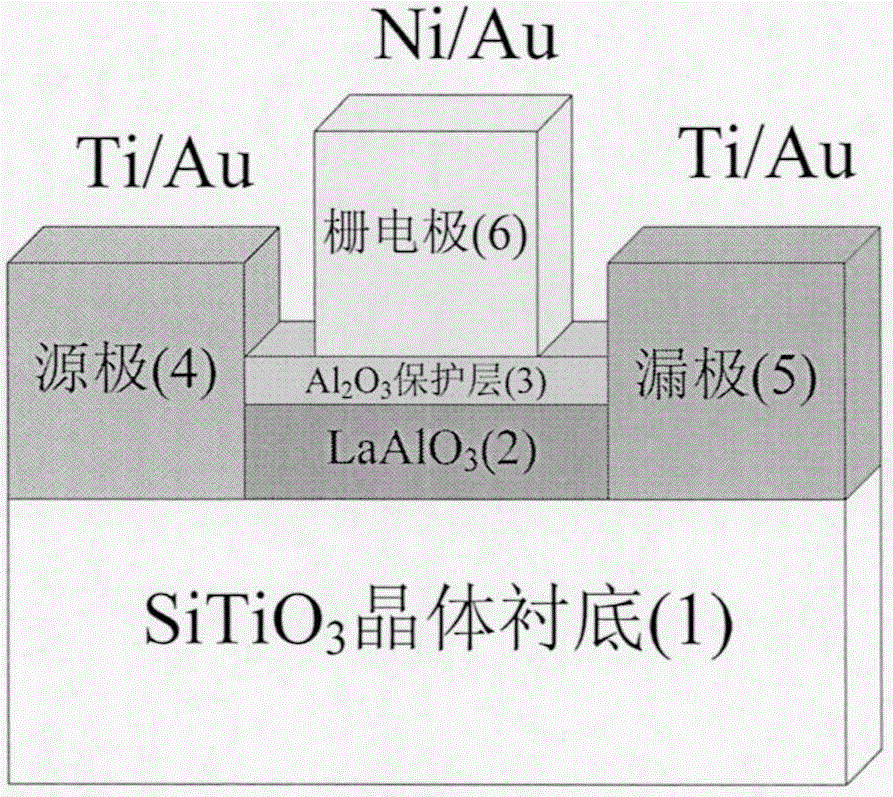

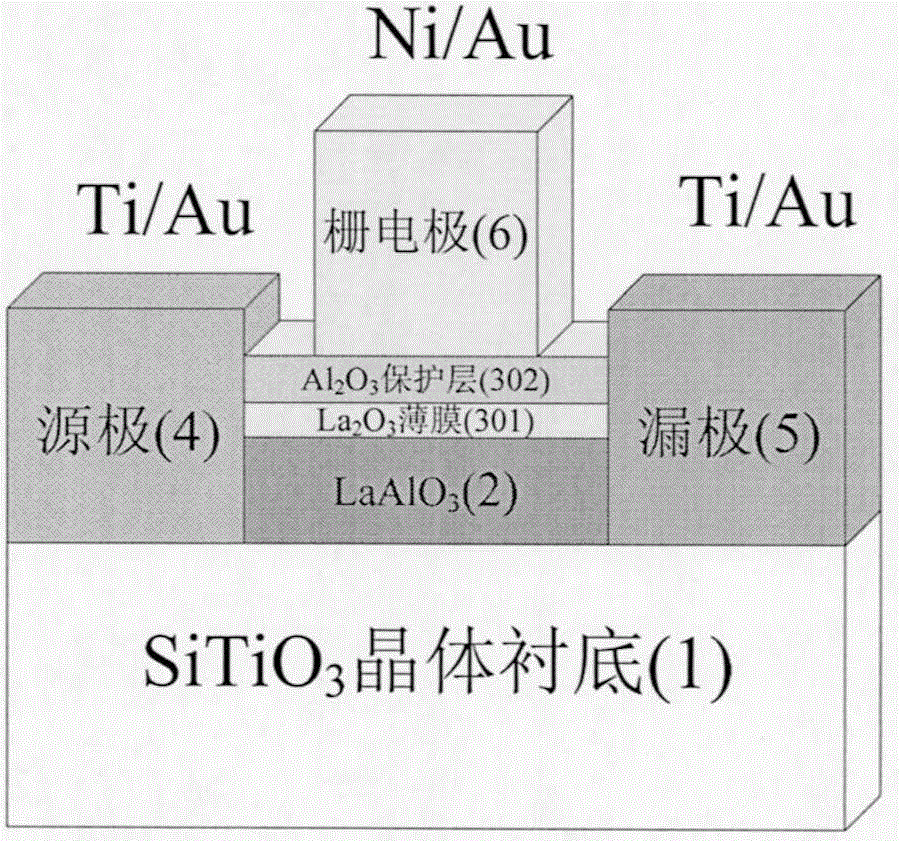

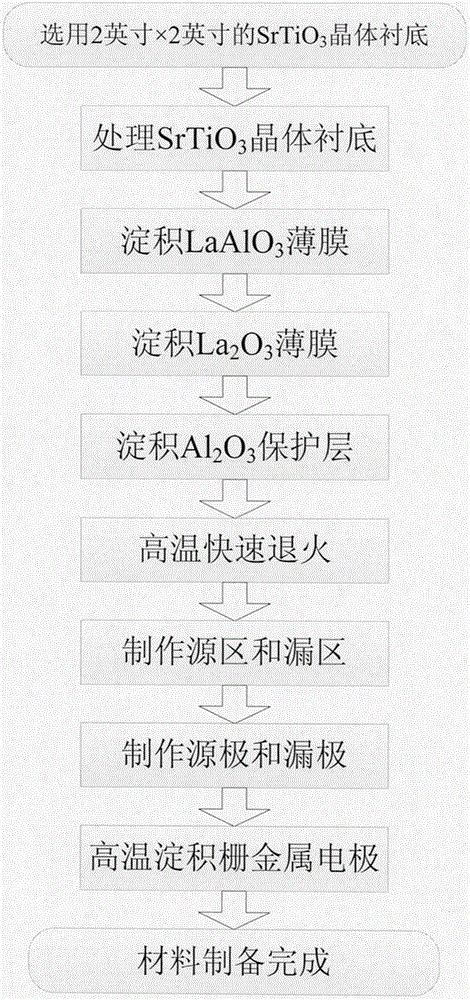

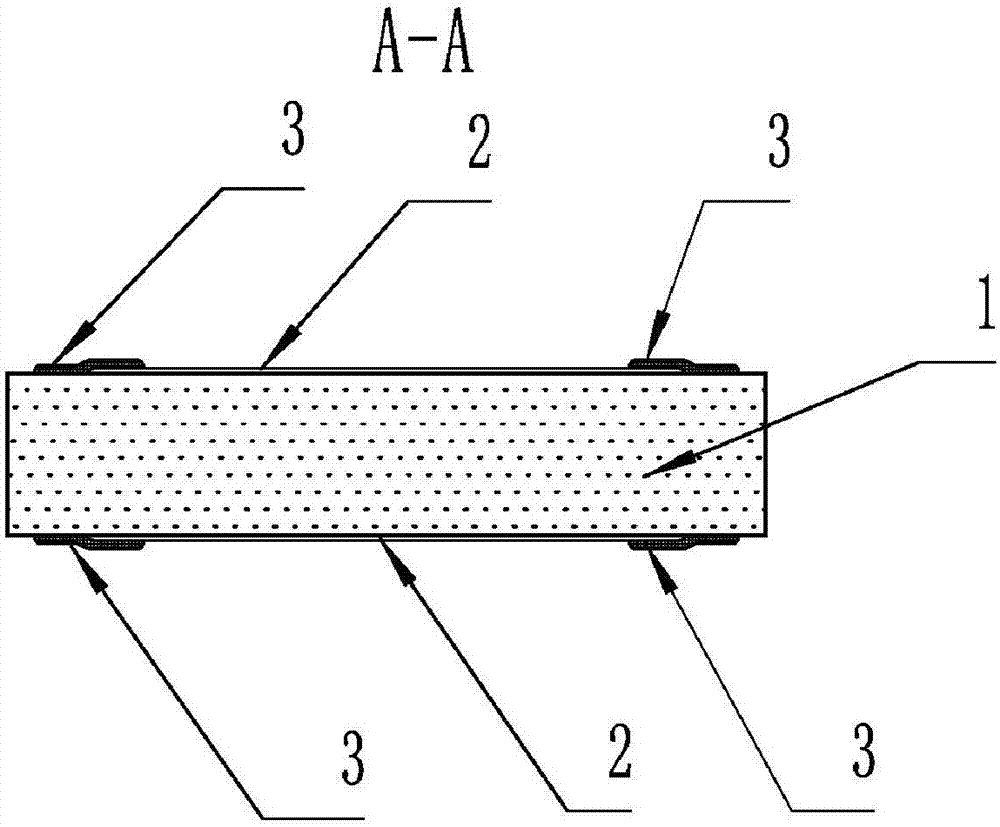

LaAlO3/SrTiO3 heterojunction field effect transistor based on La-based gate and manufacturing method

InactiveCN105470306AWide band gapHigh electrical breakdown strengthSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceGate stack

The invention discloses a LaAlO3 / SrTiO3 heterojunction field effect transistor based on a La-based gate and a manufacturing method, and mainly solves the problem in the prior art that gate capacitance has a poor control capability over device channel charges. The LaAlO3 / SrTiO3 heterojunction field effect transistor comprises a SrTiO3 crystal substrate (1) and a LaAlO3 film (2) from bottom to top, and the LaAlO3 film (2) is provided with a source electrode (4), a drain electrode (5) and a gate electrode (6). A gate medium material layer (3) is arranged between the LaAlO3 film (2) and the gate electrode (6) and forms the gate capacitance of the transistor. The gate medium material layer (3) is of a gate stacking structure formed by a La2O3 film (301) and an Al2O3 protection layer (302). According to the invention, the gate medium material is stable in performance and high in dielectric constant, the thermal stability is good, the gate capacitance control capability is high, gate electrode breakdown voltage is high, and the LaAlO3 / SrTiO3 heterojunction field effect transistor based on the La-based gate can be used for manufacturing a high-performance heterojunction field effect transistor device.

Owner:XIDIAN UNIV

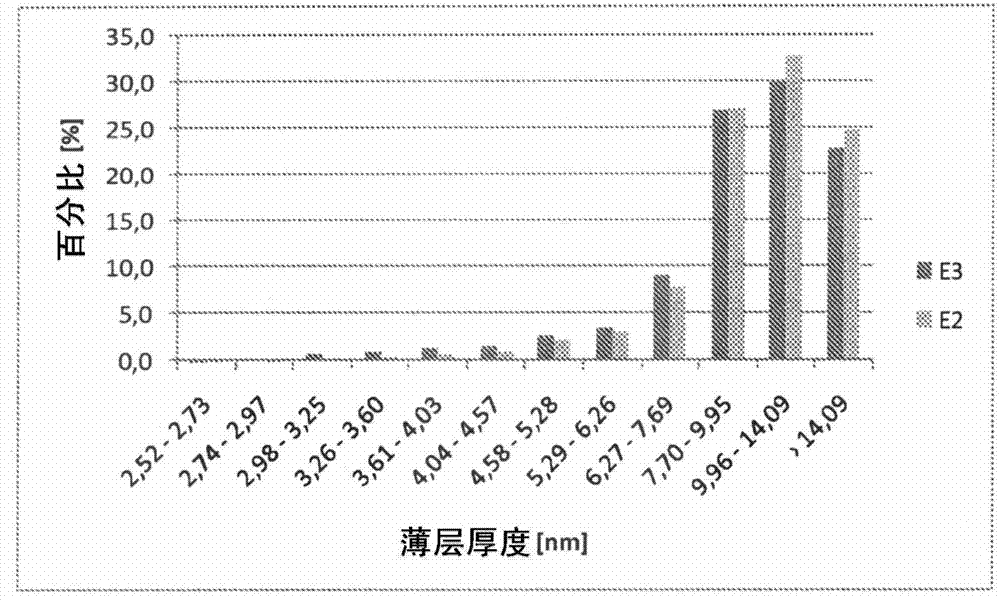

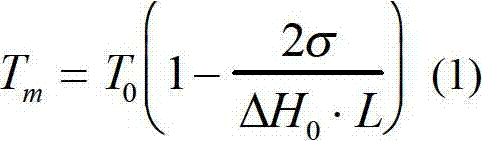

Bopp with homogeneous film morphology

ActiveCN102712716AHigh beta parameterHigh electrical breakdown strengthPlastic/resin/waxes insulatorsSynthetic resin layered productsPolypropyleneMetallurgy

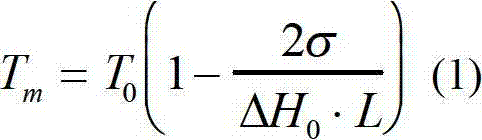

Polypropylene having a melting temperature (Tm) of at least 151.0 DEG C. a xylene cold soluble fraction (XCS) of not more than 1.5 wt.%. and 18.0 to 50.0 wt.% of a crystalline fraction melting at or above 160 DEG C, wherein said fraction is determined by the stepwise isothermal segregation technique (SIST).

Owner:BOREALIS AG

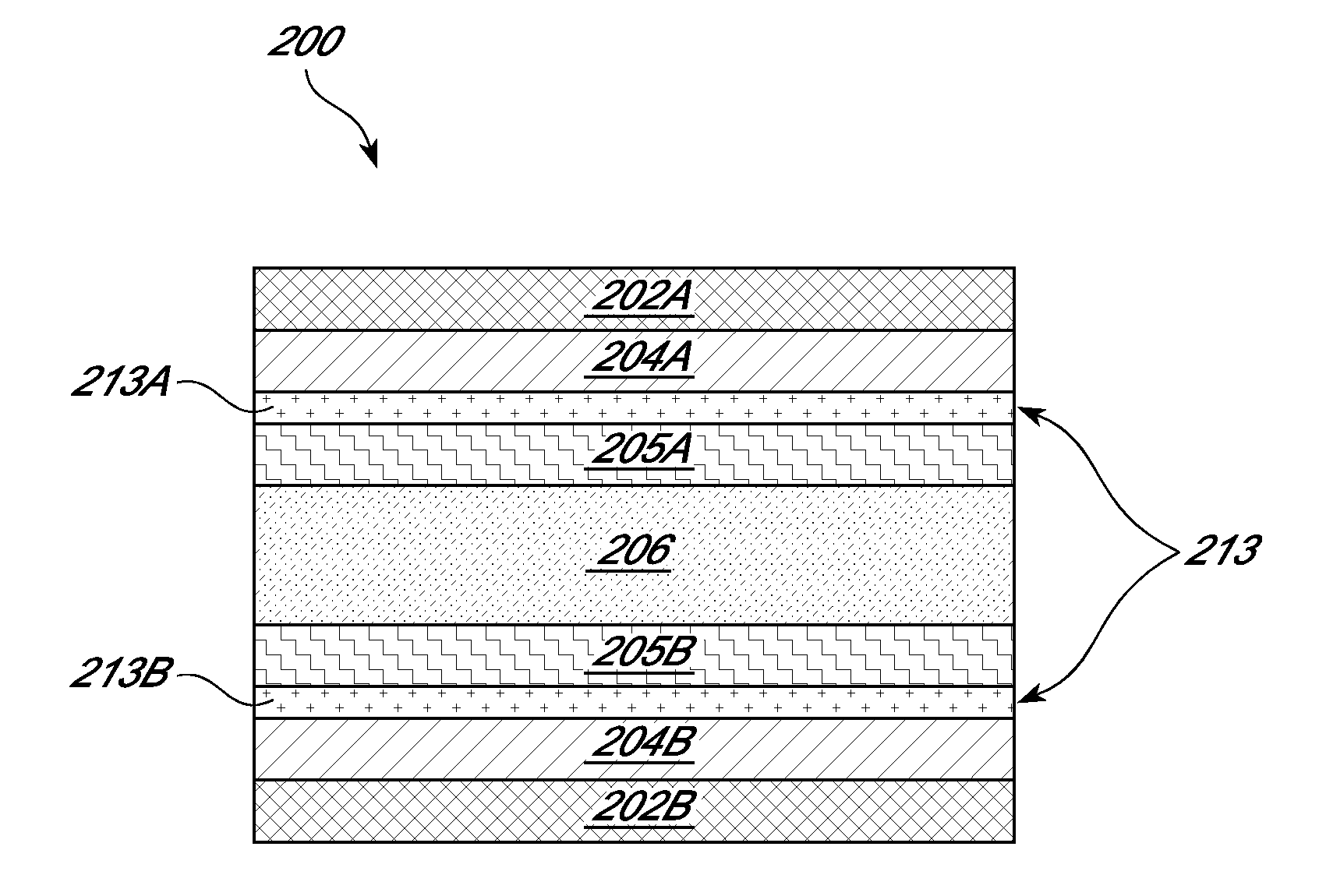

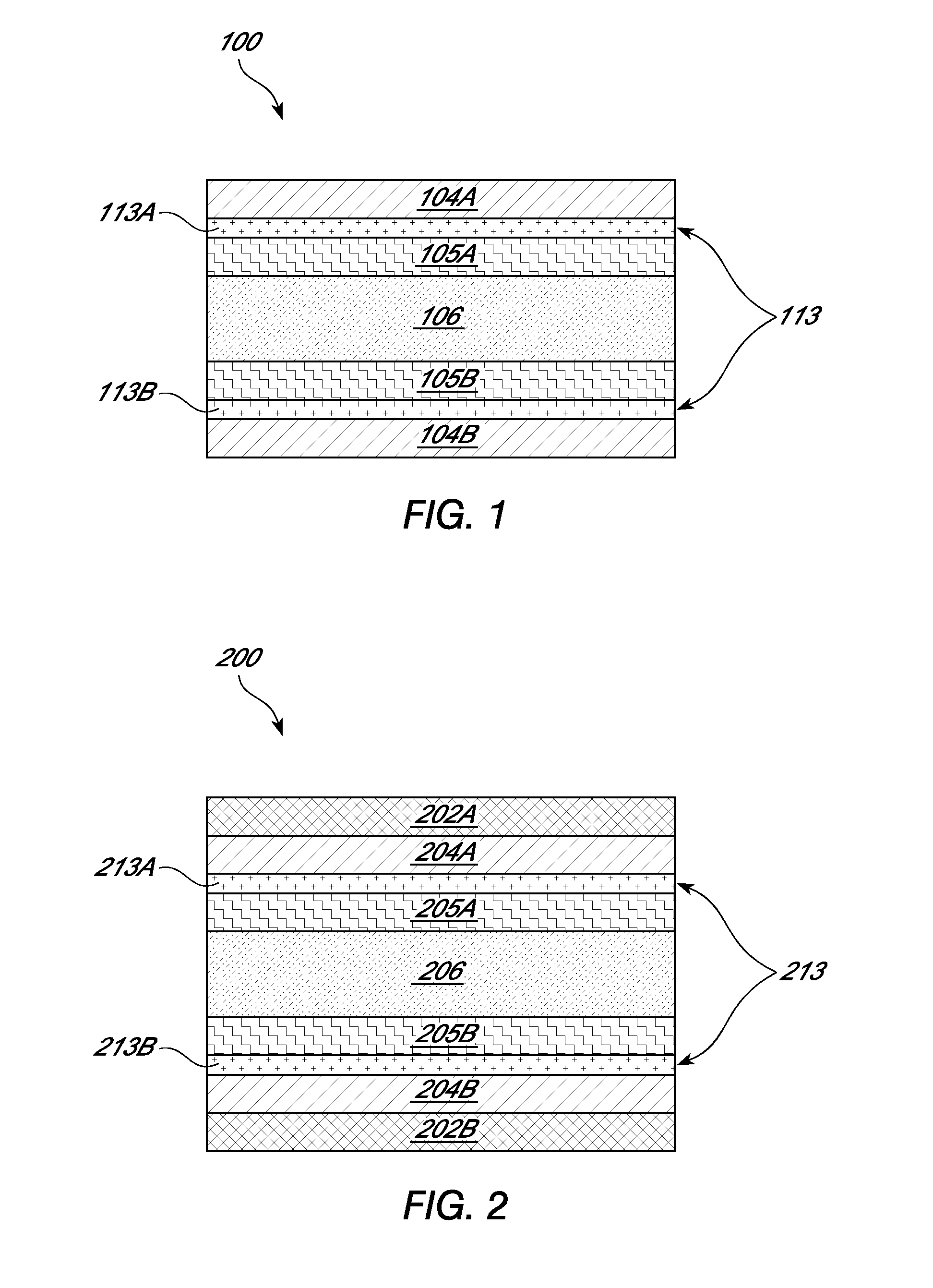

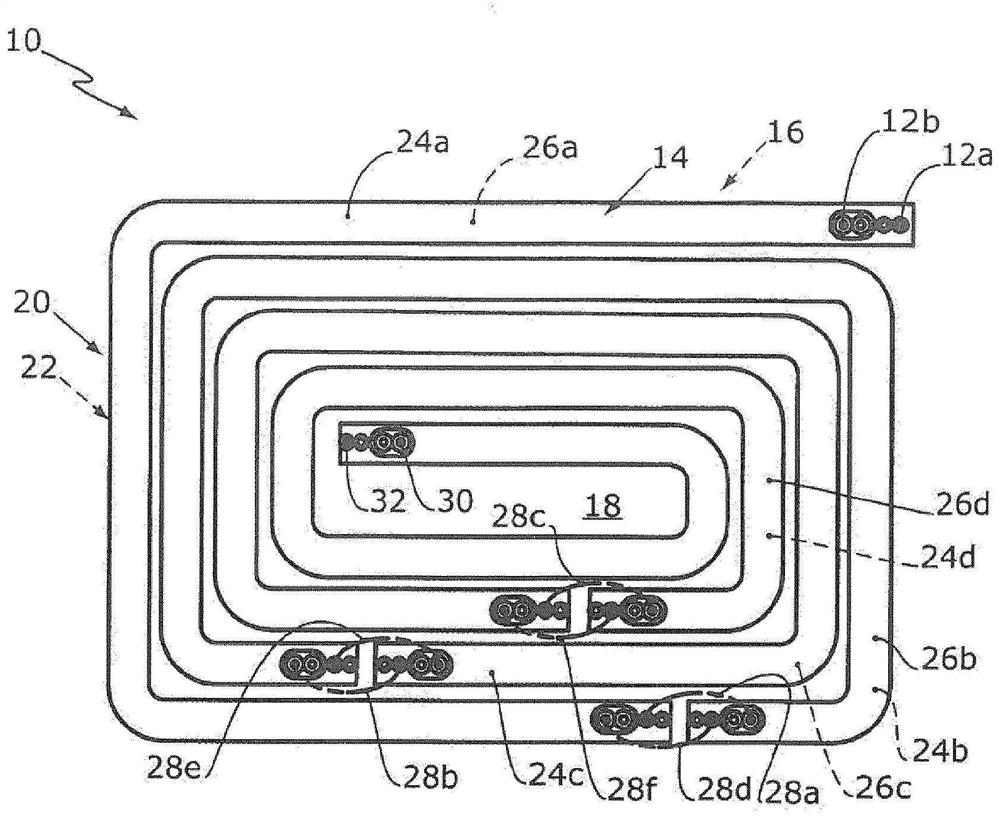

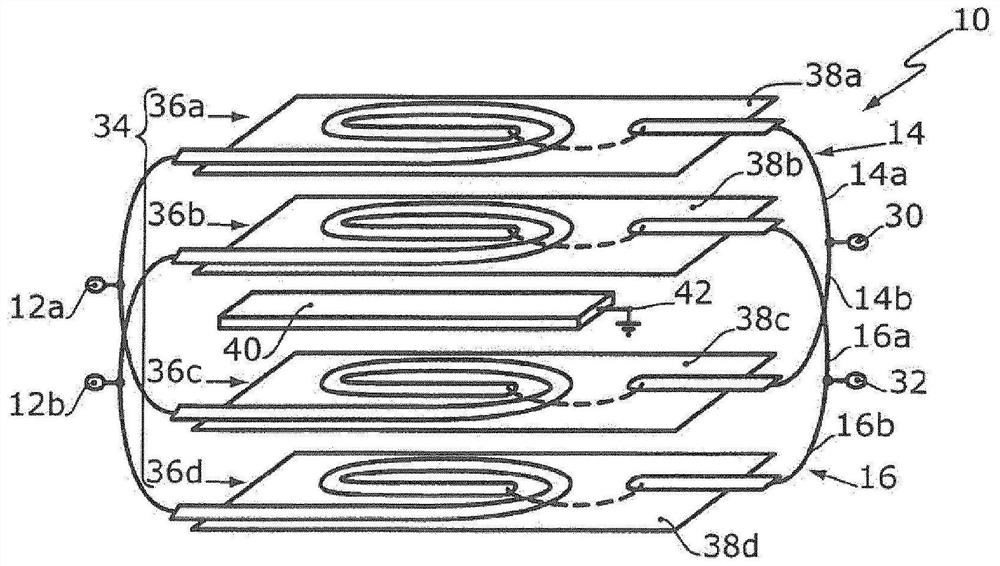

Photorefractive devices having sol-gel buffer layers and methods of manufacturing

InactiveUS20130321897A1High electrical breakdown strengthFast rise and decay timeFilm/foil adhesivesNon-linear opticsGratingElectric breakdown

A photorefractive device (100) and methods of its manufacture are disclosed. The photorefractive device (100) comprises one or more transparent electrode layers (104), one or more sol-gel buffer layers (113), one or more polymer buffer layers (105), and a photorefractive layer (106). The one or more sol-gel buffer layer (113) is interposed between the one or more polymer buffer layer (105) and the one or more transparent electrode layer (104). When a bias voltage is applied to the device (100), the device (100) exhibits improvement in electric breakdown strength compared to a similar device without the one or more dielectric sol-gel buffer layers (113). The device (100) can operate at high bias levels with quick rising and decay times and shows higher grating performance under single nanosecond pulse recording conditions.

Owner:NITTO DENKO CORP

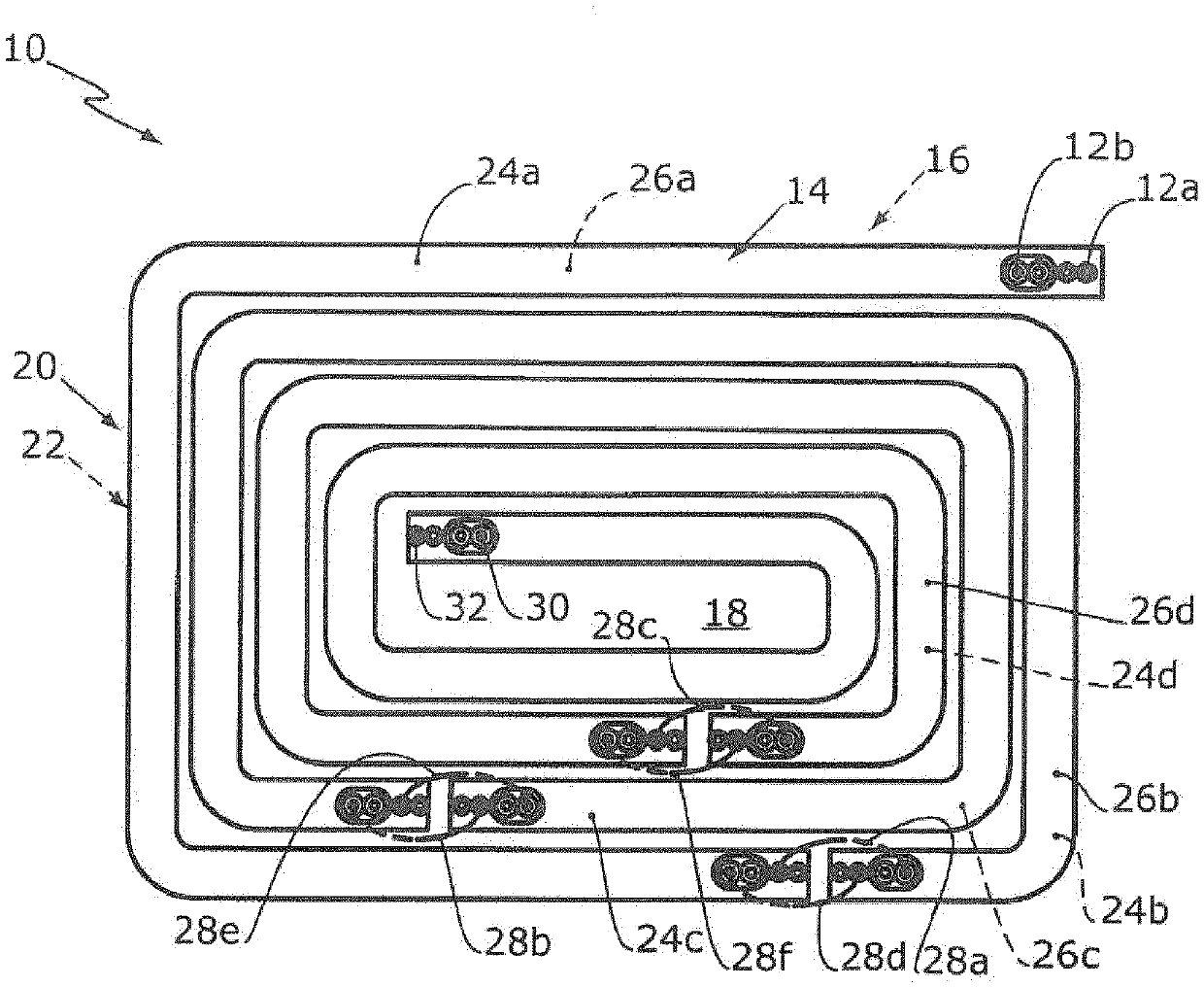

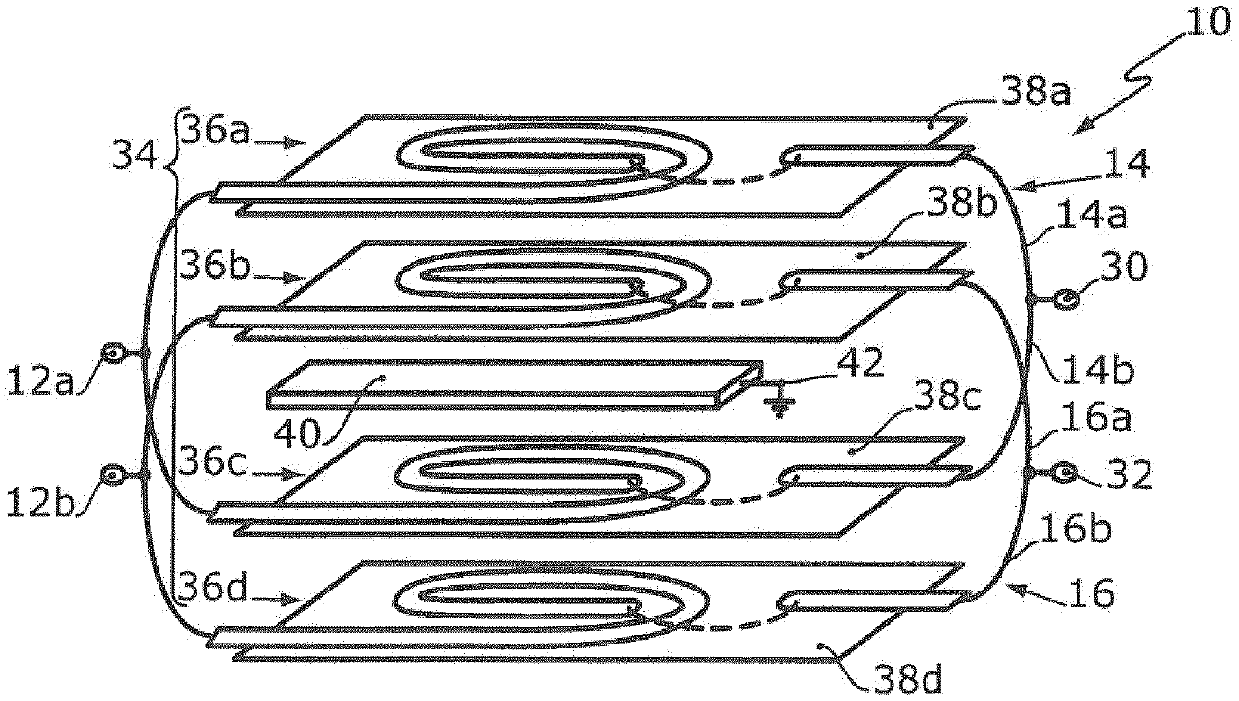

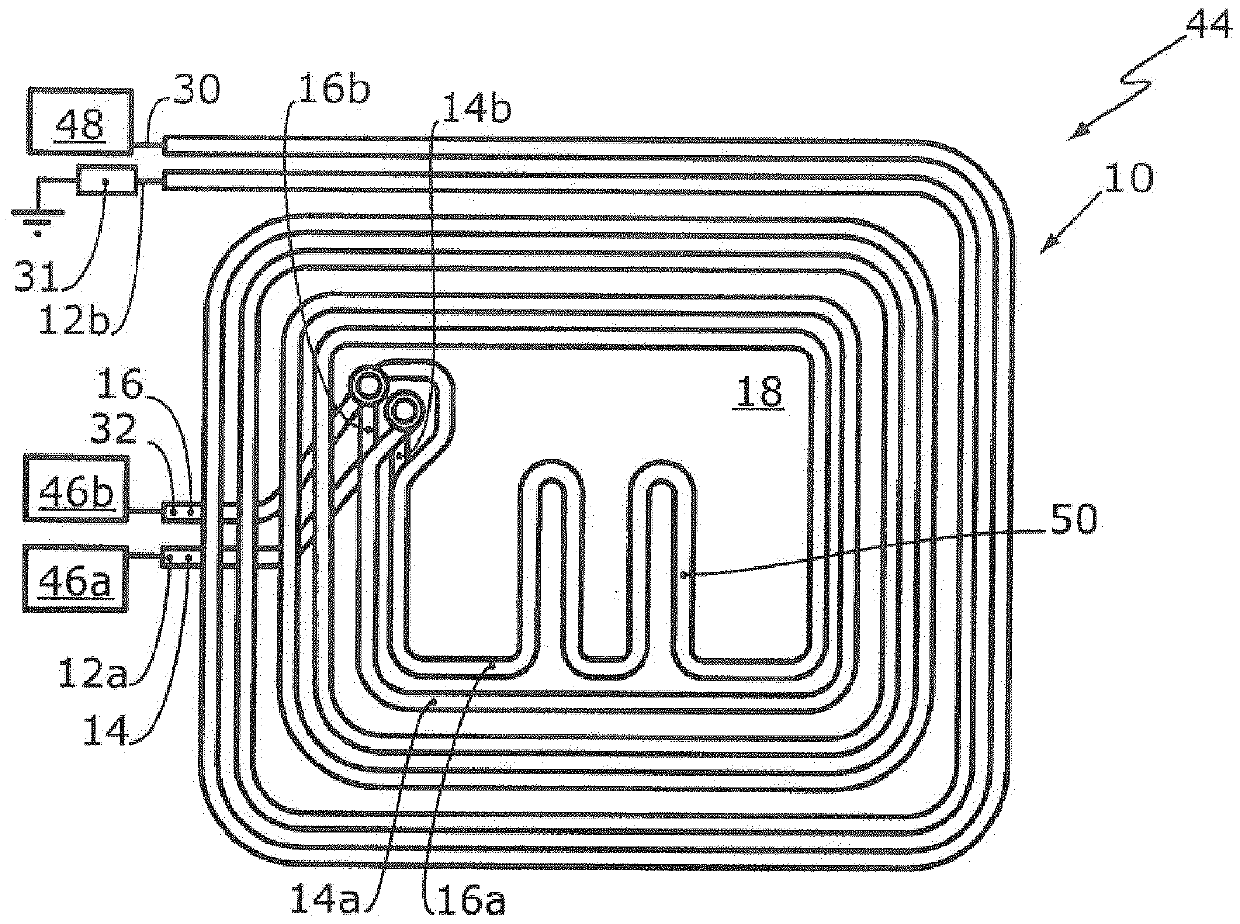

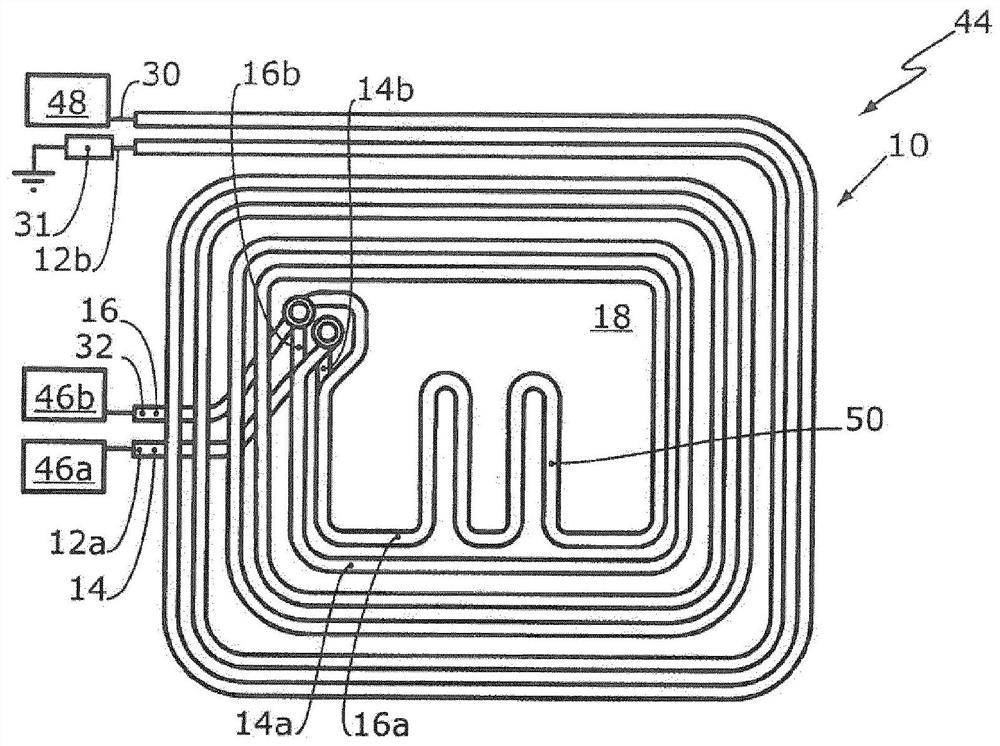

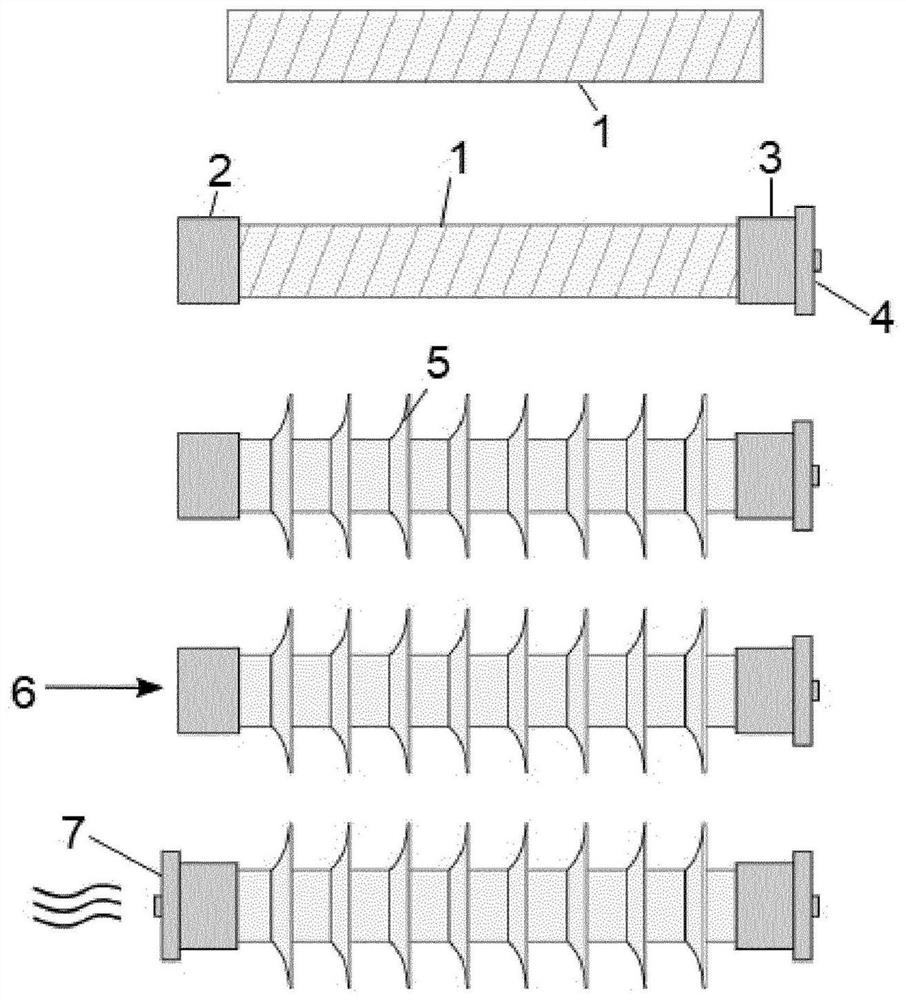

Power combiner having a symmetrically arranged cooling body and power combiner arrangement

ActiveCN107735901AEffect of power characteristicsReduce manufacturing costCoupling devicesElectrical conductorPower combiner

The invention relates to a power combiner (10) comprising a cooling body (40). The power combiner (10) hast at least one first electrical conductor (14) and one second electrical conductor (16). The first electrical conductor (14) and the second electrical conductor (16) are generally mostly arranged equidistant from the cooling body (40). In addition, the first electrical conductor (14) and the second electrical conductor (16) can be arranged alternatingly near or at a distance from the cooling body (40). Alternatively or in addition, the cooling body (40) can be arranged between the first electrical conductor (14) and the second electrical conductor (16). Alternatively or in addition, the first electrical conductor (14) and the second electrical conductor (16) can be divided mostly intoparallel conductor parts (14a, 14b, 16a, 16b), wherein the conductor parts (14a, 14b, 16a, 16b) are distanced from the cooling body (40) in such a way that the first electrical conductor (14) and thesecond electrical conductor (16) are generally mostly at equal distance from the cooling body (40).

Owner:HUETTINGER ELECTRONICS GMBH & CO KG

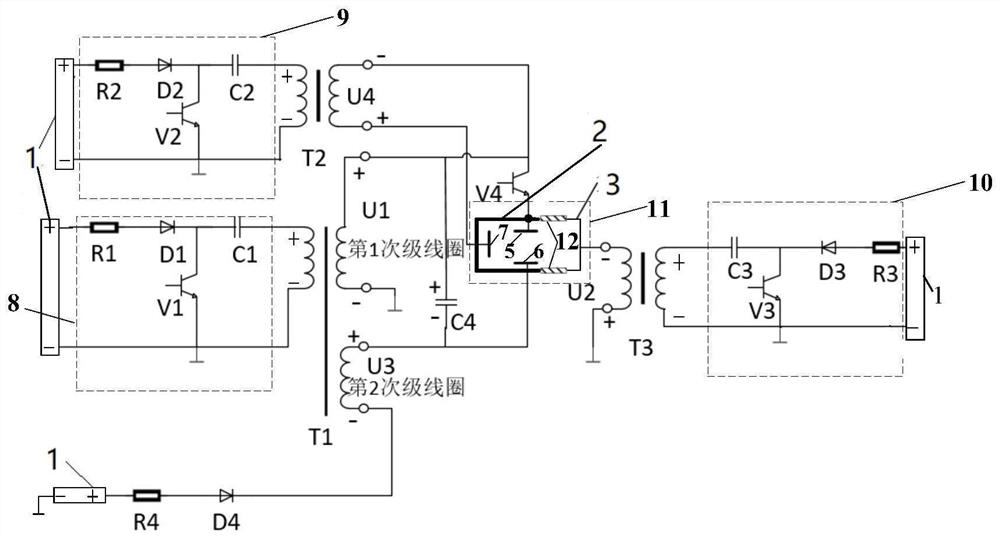

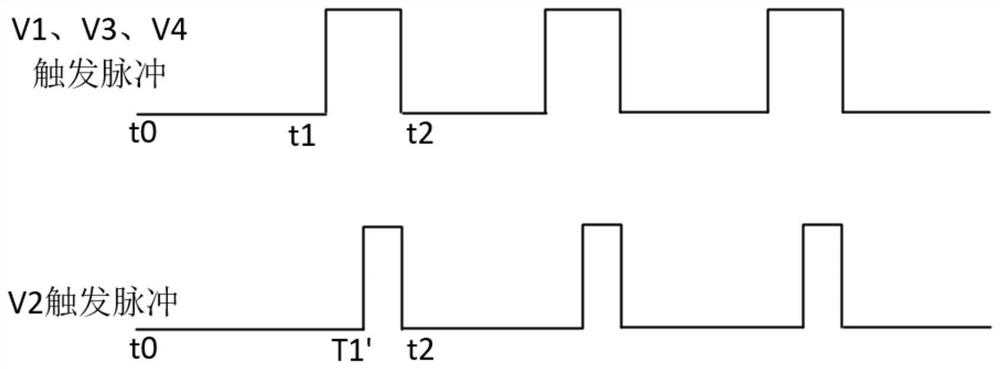

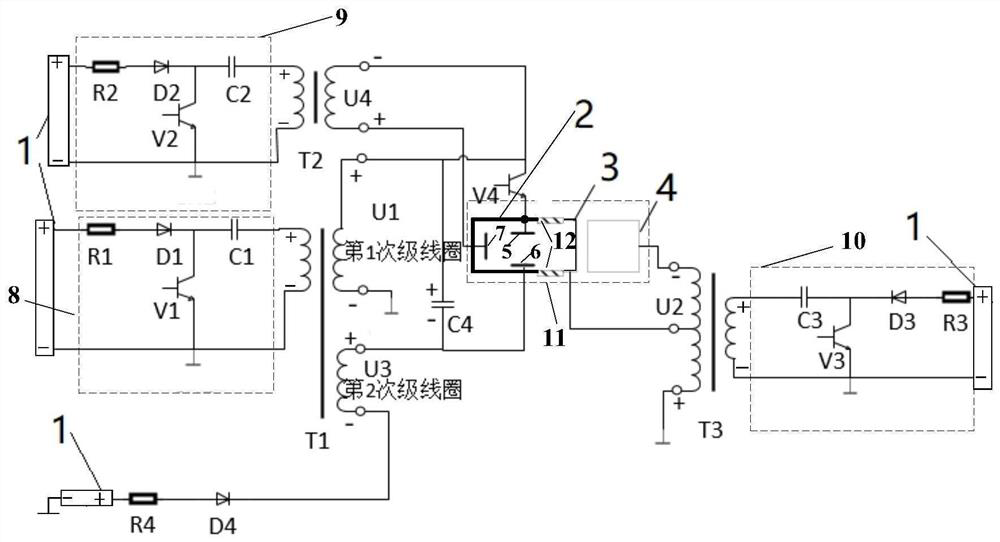

Pulse power supply system and neutron generator

ActiveCN113285627ACompact structureMeet job requirementsDirect voltage acceleratorsPulse generation by energy-accumulating elementCapacitanceEngineering

The invention relates to a pulse power supply system and a neutron generator. Several paths of pulse voltages with different pulse widths and amplitudes can be provided for the neutron generator through four paths of pulse voltages, namely positive acceleration high voltage, negative acceleration high voltage, anode voltage and trigger voltage, so as to meet the working requirements of a vacuum arc ion source neutron generator. The positive acceleration high voltage is generated through the first secondary coil of a first pulse transformer T1, the trigger voltage is generated through a second pulse transformer T2, the anode voltage is generated through the second secondary coil of a first pulse transformer T1 and a main discharge capacitor C4, and the negative acceleration high voltage is generated through a third pulse transformer T3. The second secondary coil of the first pulse transformer T1 and the second pulse transformer T2 serve as a boosting transformer to boost a pulse power supply and also serve as an isolation transformer to solve the problem of suspension voltage, the insulation distance is effectively reduced by adopting a positive and negative acceleration pole structure, and three pulses form a loop to share one charging power supply, so the power supply system is very compact in structure.

Owner:中科石金(安徽)中子技术有限公司

PI-AlN-PTFE ternary nano-composite multi-curve pore membrane material and preparing method and application thereof

ActiveCN105047847AImprove temperature resistanceHigh hardnessNon-aqueous electrolyte accumulatorsElectrolytic capacitorsPorosityFiber

The invention discloses a nano-composite multi-curve pore membrane material, polyimide (PI) nano-fiber non-woven fabric serves as the base material, and base material pores are filled with composite nano-particles. The nano-composite multi-curve pore membrane material is characterized in that the nano-particles are formed by mixing polytetrafluoroethylene nanoparticle (PTFE-NP) and aluminium nitride nanoparticle (AlN-NP) at the weight ratio of (7-12) / (8-13). The nano-composite multi-curve pore membrane material is resistant to high temperature, high in hardness, proper in porosity, proper in surface density, good in ion transmission performance and good in mechanical performance, when the nano-composite multi-curve pore membrane material is used in lithium-ion batteries, the problem of a battery micro short circuit due to the excessively-high porosity of a pure polyimide nano-fiber membrane can be solved, and the serious problem of thermal runaway caused by the mechanical collision of the power lithium-ion batteries can be solved.

Owner:JIANGXI NORMAL UNIV

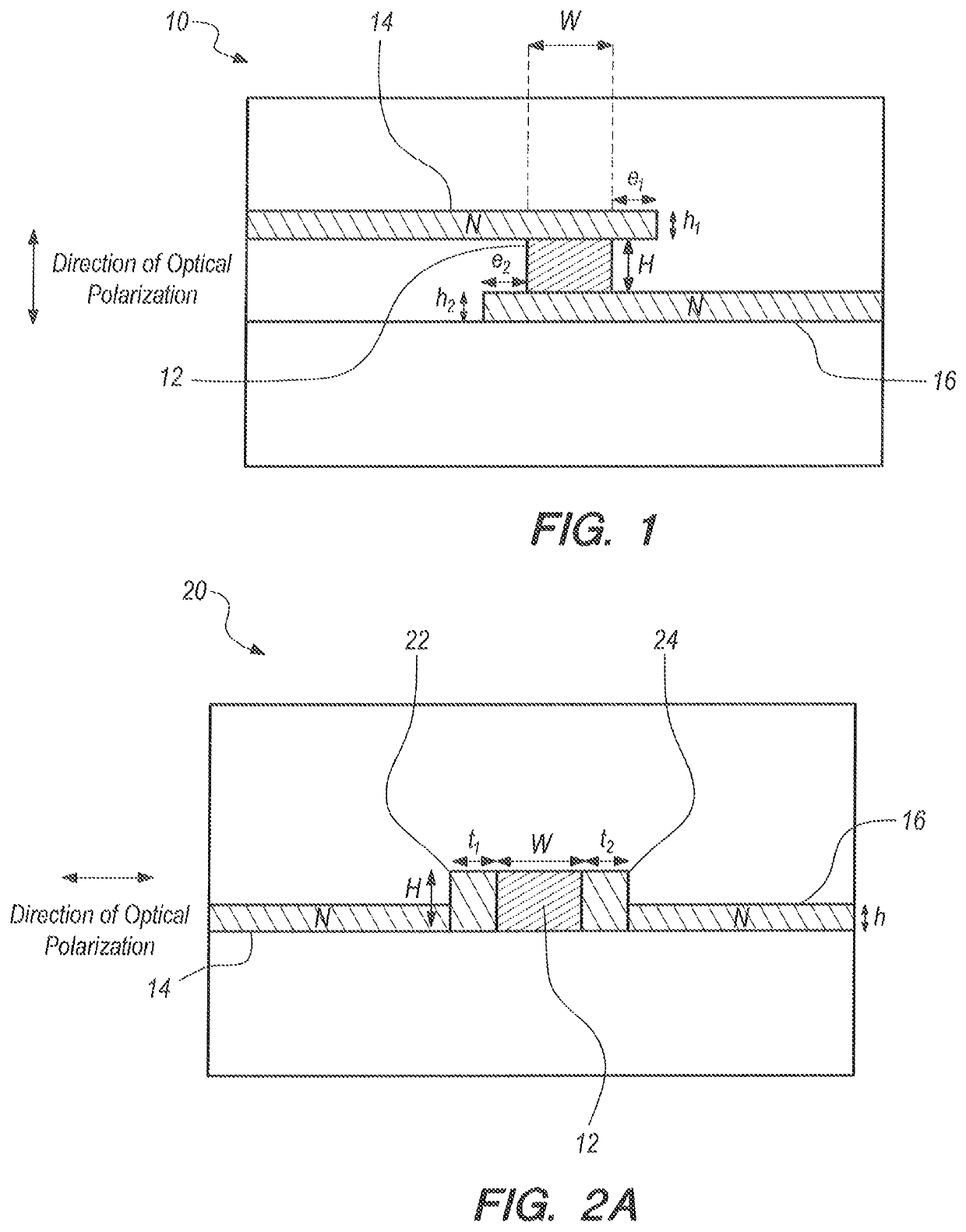

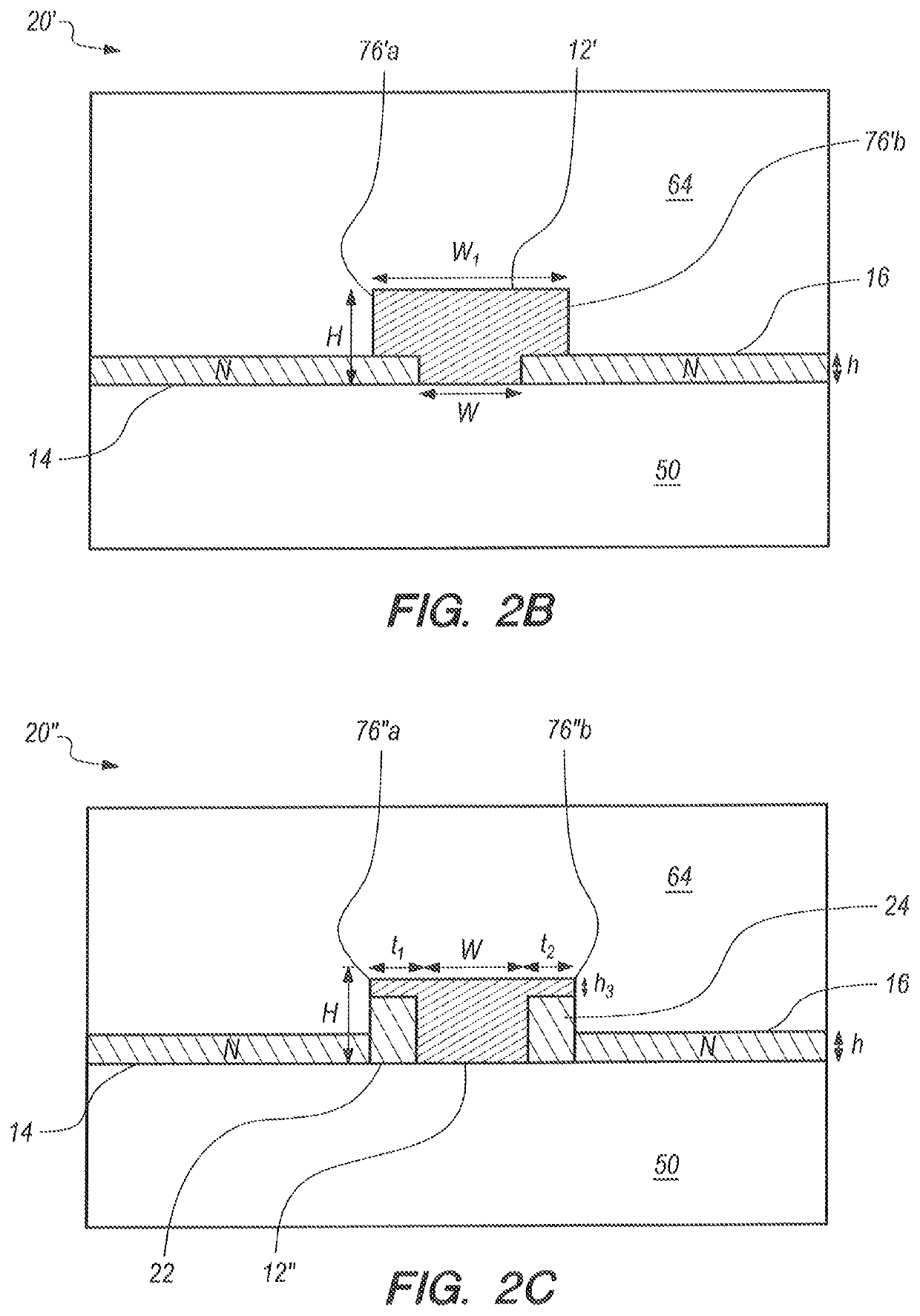

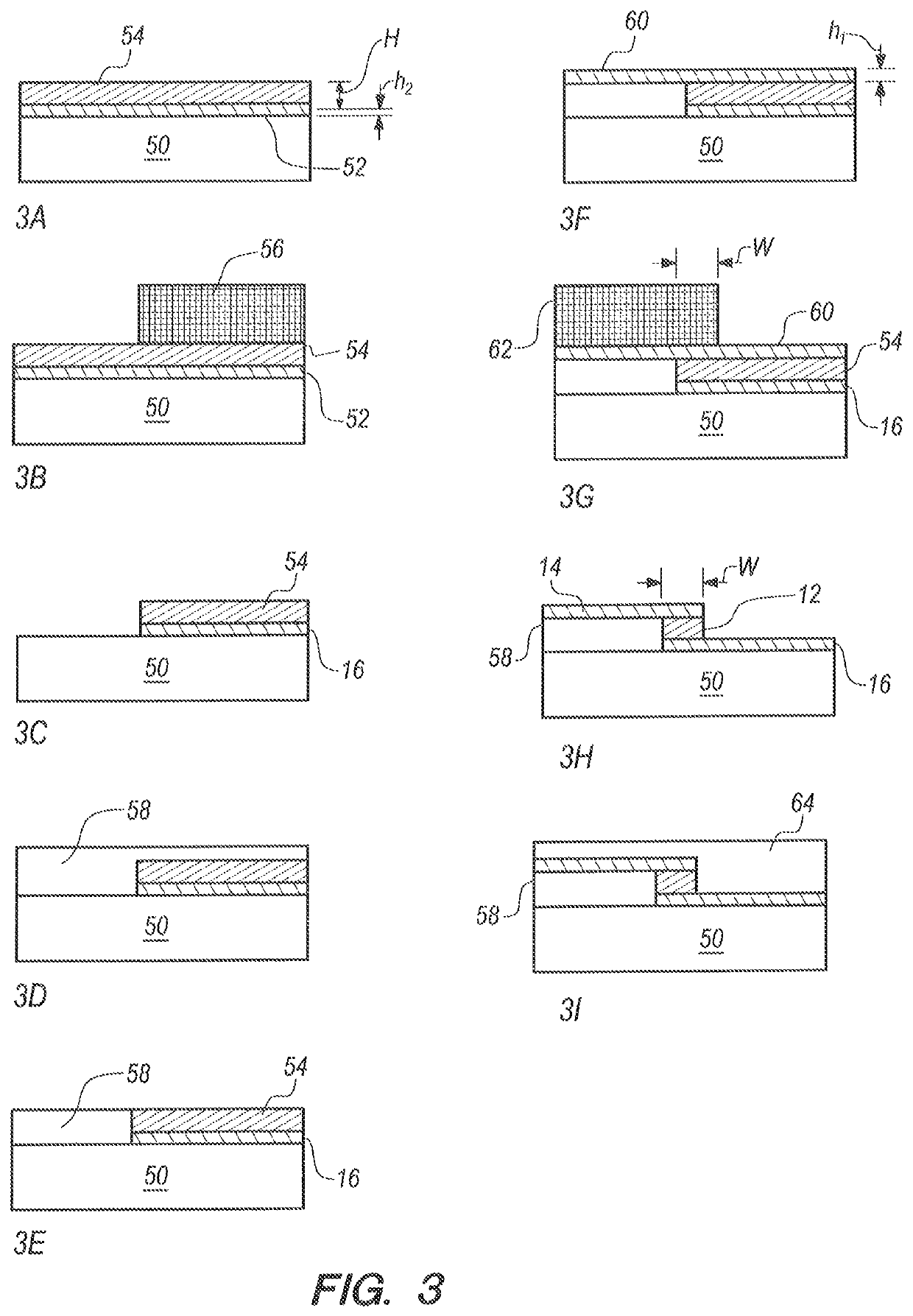

Dielectric electro-optic phase shifter

ActiveUS10895764B1Low V<sub>πIncreased operating bandwidthNon-linear opticsOptical light guidesDielectricRefractive index

An EO phase shifter for modulating an electrical signal onto an optical wave is manufactured using CMOS process tools whereby a waveguide core made of EO material has intimate contacts with its electrodes. Specifically, the waveguide core is made of a Silicon-Rich Silicon Nitride (SRN) material which has a high linear refractive index n and a high third order nonlinear susceptibility. The electrodes are made of P or N doped silicon. Also, polarization of the optical wave is oriented normal to interfaces between the waveguide core and the electrodes. With this combination, the EO phase shifter exhibits high optical confinement, low propagation loss, and a high electro-optic overlap integral for modulation.

Owner:COMS IP HLDG LLC

Bopp-film

ActiveCN102712717AHigh electrical breakdown strengthImprove temperature resistancePlastic/resin/waxes insulatorsSynthetic resin layered productsPolypropyleneChemistry

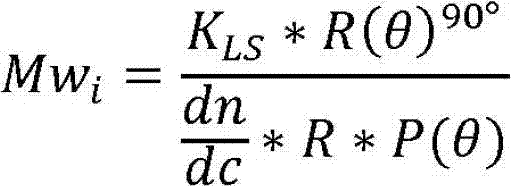

Polypropylene having a melting temperature (Tm) of at least 151.0 DEG C, a melt flow rate MFR2 (230 DEG C) of more than 2.0 g / 10min, a xylene cold soluble fraction (XCS) of not more than 1.5 wt.-%, 13C-spectroscopy, and a number average molecular weight (Mn) of not more than 110 kg / mol.

Owner:BOREALIS AG

Cold-contraction type electric fluorosilicone sleeve and application thereof

ActiveCN105153710AExcellent dielectric propertiesHigh electrical breakdown strengthCable junctionsElectric power transmissionVulcanization

The invention discloses a cold-contraction type electric fluorosilicone sleeve and application thereof. The sleeve is prepared through enabling a -Si-CH=CH2 group in organic polyfluorosilicone and a -Si-H group in organic hydrogen-containing polyfluorosilicone to be subjected to hydrogen-silicon addition reaction in the presence of a noble metal catalyst, and then, carrying out continuous extrusion and vulcanization. According to the cold-contraction type electric fluorosilicone sleeve and the application thereof, the sleeve can be mounted without heating, is low in permanent deformation and can fully meet requirements as long as the inside diameter of a cable accessory is smaller than the outside diameter of a cable insulation by 2mm, and the vulcanization for the product is safe and non-toxic and is free of generation of waste gases, waste water and waste residues; and after vulcanization, the product has excellent expanding tear resistance, insulating performance, tracking resistance, acid / base resistance and ultraviolet resistance, is applicable to the terminal connection of various cables in cable lines and forms an electric power transmission network together with the cables so as to guarantee the connection of cable terminals.

Owner:广东中蓝硅氟新材料有限公司

Composite porous membrane material filled with alumina particles and its preparation method and application

ActiveCN105098125BSmall surface pore sizeReduce porosityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicro nanoFiber

The invention discloses a micro-nano composite multi-curvature membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with micro-nano Al2O3 particles; the micro-nano Al2O3 The particles have a diameter between 50-800nm and account for 20-50% of the total weight of the micro-nano composite multi-curved pore membrane material; the micro-nano composite multi-curved pore membrane material has a porosity between 30-60% , the average surface pore diameter is between 50-800nm, and the thickness is between 10-40μm. The micro-nano composite multi-curved hole membrane material provided by the invention is resistant to high temperature, thermal shrinkage, high voltage and high current impact, and mechanical impact resistance, and is suitable for use as a safety battery separator and a safety supercapacitor separator to manufacture various high-capacity and High power lithium battery or supercapacitor. The invention also provides a preparation method of the nanocomposite multi-curvature membrane material and its application as a battery separator.

Owner:JIANGXI ADVANCED NANOFIBER S&T CO LTD

High-energy-tolerance ZnO piezoresistor sheet and preparation method therefor

PendingCN107146667AHigh electrical breakdown strengthTightly boundVaristor coresResistive material coatingHigh energyVoltage

The invention provides a high-energy-tolerance ZnO piezoresistor sheet and a preparation method therefor. A ZnO voltage-sensitive ceramic sheet is manufactured firstly; then silver electrode slurry is printed on the two surfaces of the ZnO voltage-sensitive ceramic sheet, and is sintered to form a silver electrode to obtain a ZnO voltage-sensitive silver sheet with silver electrodes on the two surfaces; finally, an annular insulating and covering material is prepared on the edges of the silver electrodes on the two surfaces of the ZnO voltage-sensitive silver sheet to prepare the ZnO piezoresistor sheet covered with the annular insulating material; and the annular insulating material covers the edges of the silver electrodes for a range of 0.5mm or above inside and outside. No matter whether the prepared ZnO piezoresistor sheet is packaged by adopting an organic material or not or whether the prepared ZnO piezoresistor sheet suffers from a pulse current or not, flashover or arc-over does not occur on the edge and side surface, so that high reliability is achieved.

Owner:SOUTH CHINA UNIV OF TECH

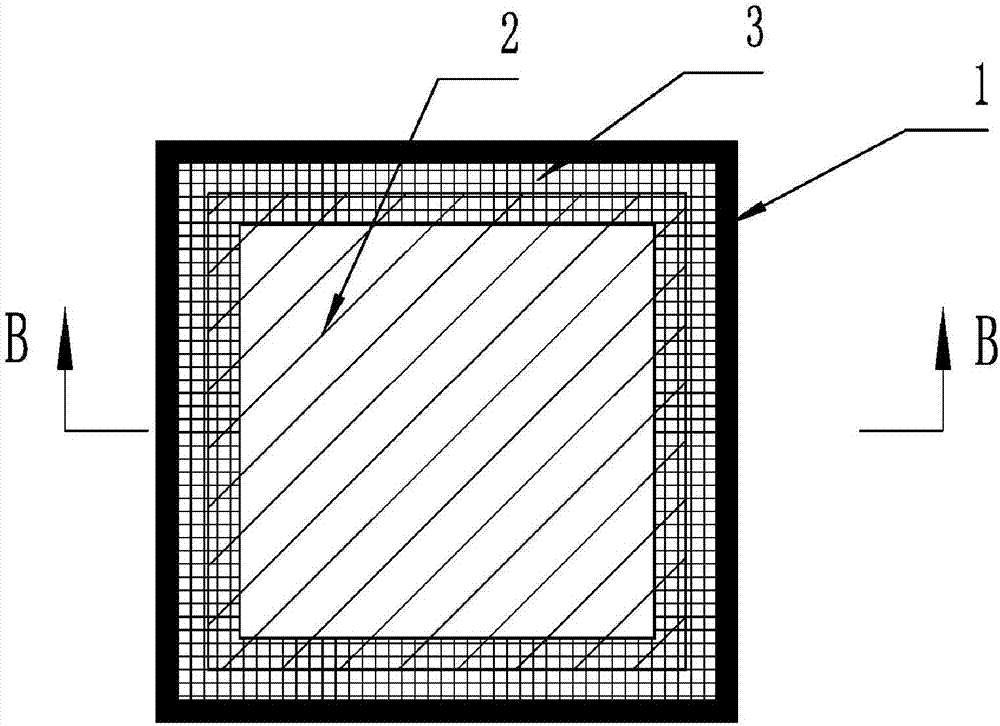

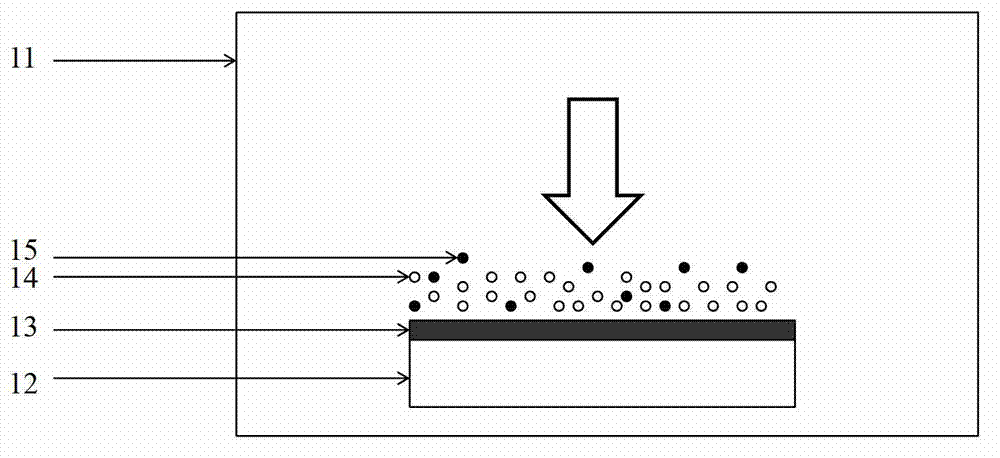

Insulating layer of flexible film transistor and preparation method thereof

InactiveCN102891255AImprove insulation performanceHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingElectric breakdownElectron

The invention discloses an insulating layer of a flexible film transistor and a preparation method of the insulating layer. The insulating layer of the flexible film transistor is a film of hydrocarbon-based polymer formed on a substrate. The preparation method of the insulating layer adopts hydrogen and acetylene gas as raw materials. Under the conditions of room temperature and vacuum, the film of hydrocarbon-based polymer is deposited on the substrate in a plasma enhanced chemical vapor deposition (PECVD) system so as to finish the preparation of the insulating layer of the flexible film transistor. The insulating layer disclosed by the invention has the advantages of good insulating performance and higher electric breakdown strength. Under the condition of room temperature, the preparation method enables the insulating layer to be well compatible with the flexible substrate. The insulating layer can be processed by adopting the PECVD process. The preparation method disclosed by the invention can be used for preparing the flexible film transistor, so as to further promote the development of flexible electron.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of la-based high dielectric constant gate dielectric material based on germanium substrate

ActiveCN103367409BInhibition of adsorptionPrevent volatilizationSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricGate dielectric

The invention discloses a preparation method for a germanium substrate and La-based high-dielectric constant gate dielectric material. The problems of low dielectric constant and poor thermal stability and thin film compactness of the conventional material are mainly solved. The gate dielectric material comprises an interface layer (1), a barrier layer (2), an La-based high-dielectric constant thin film (3) and a protective layer (4) from bottom to top, wherein the interface layer (1) is made from 0.5 to 1nm thick GeO2; the barrier layer (2) is made from 0.5 to 2nm thick Al2O3; the La-based high-dielectric constant thin film (3) is made from 1 to 10nm thick La2O3 or LaAlO3 or HfLaOx; and the protective layer (4) is made from 1 to 2nm thick Al2O3. The whole material is prepared by an atomic layer deposition method, and is subjected to low-temperature and high-temperature annealing treatment after being prepared. The germanium substrate and La-based high-dielectric constant gate dielectric material has the advantages of high dielectric constant, high thin film compactness, high step coverage, high thermal stability and low surface roughness, and can be used for manufacturing a gate dielectric film of a metal oxide semiconductor field effect transistor.

Owner:XIDIAN UNIV

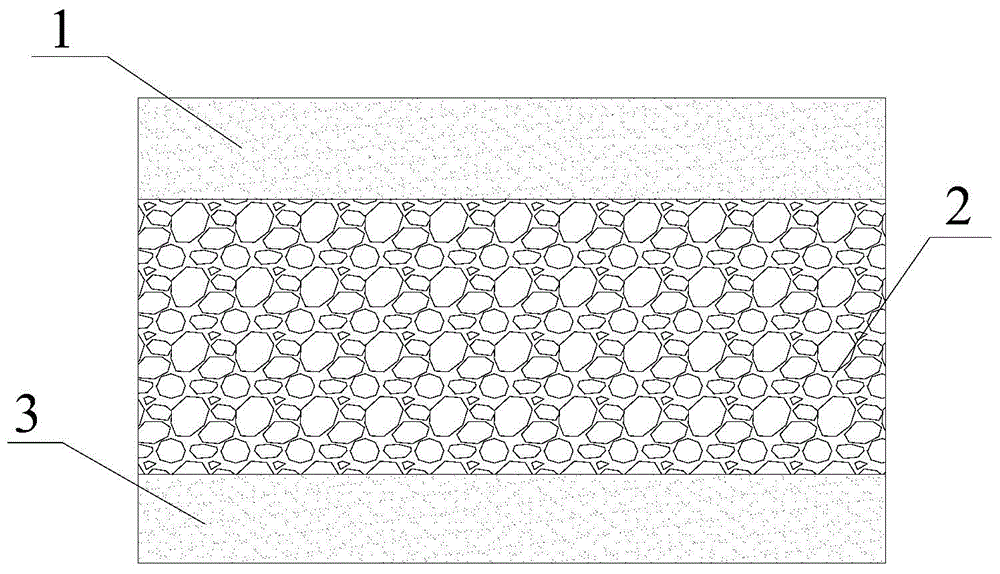

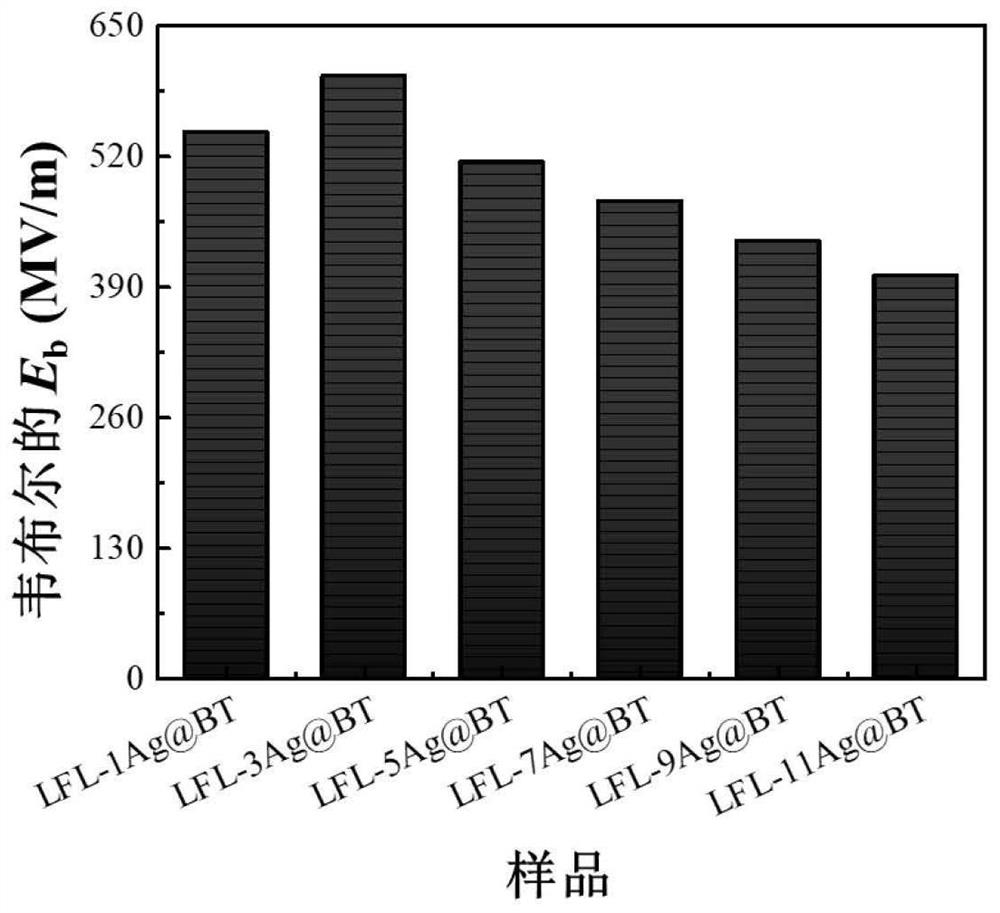

A kind of high energy storage density dielectric composite multilayer film and its preparation method

ActiveCN110862683BHigh breakdown strengthImprove discharge efficiencyCoatingsElectrical field strengthHigh energy

The invention belongs to the field of film materials, and discloses a dielectric composite multilayer film with high energy storage density and a preparation method thereof. The composite multilayer film comprises a top layer, a middle layer and a bottom layer, wherein the top layer and the bottom layer are both made of PEI; the middle layer is made of PVDF, the middle layer is filled with Ag-coated nano BaTiO3 particles, the maximum energy storage performance of the composite multilayer film reaches 20.6-21.3 J / cm<3> under the electric field intensity of 500-650 MV / m, and the maximum energy storage efficiency reaches 80-82%. Meanwhile, the invention also discloses a preparation method of the composite multilayer film. According to the invention, the energy storage density, the energy storage efficiency, the breakdown field intensity and the temperature stability of the dielectric material are effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Composite porous membrane material filled with polytetrafluoroethylene microspheres and its preparation method and application

ActiveCN105161659BSmall surface pore sizeReduce porosityCell component detailsSecondary cells servicing/maintenanceMicrosphereTemperature resistance

The invention discloses a PTFE-NP filled composite multi-curvature membrane material, which uses polyimide (PI) nanofiber non-woven fabric as the base material, and the pores of the base material are filled with polytetrafluoroethylene nano-microspheres ( PTFE-NP); the diameter of the PTFE-NP is between 100-300nm, accounting for 30-60% of the total weight of the nanocomposite multi-curved membrane material; the PI nanofiber non-woven fabric has a thickness of 9 Electrospun PI nanofiber nonwovens between -38μm, porosity between 60-80%, and fiber diameter below 0.5μm. The nanocomposite multi-curvature membrane material provided by the invention is resistant to high temperature, heat shrinkage, high voltage and high current impact, and mechanical impact resistance, and is suitable for use as a safety battery separator and a safety supercapacitor separator to manufacture various high-capacity and high-voltage Power lithium battery or supercapacitor. The invention also provides a preparation method of the nanocomposite multi-curvature membrane material and its application as a battery separator.

Owner:JIANGXI NORMAL UNIV

SOI substrate-based La-based high-dielectric constant gate dielectric structure and manufacturing method thereof

InactiveCN106505098AHigh dielectric constantLow oxygen diffusion coefficientMaterial nanotechnologySemiconductor/solid-state device manufacturingDielectricGate dielectric

The invention discloses an SOI substrate-based high-dielectric constant gate dielectric material, and aims at mainly solving the problems of a low dielectric constant, poor heat stability and thin film compactness and the like of an existing gate dielectric material. The gate dielectric material comprises an SOI substrate (1), a barrier layer (2), an La-based high-dielectric constant thin film (3) and a protective layer (4) from bottom to top, wherein Al2O3 of which the thickness is 0.5-4nm is adopted by the barrier layer (2); La2O3 or LaAlO3 or HfLaOx of which the thickness is 1-10nm is adopted by the La-based high-dielectric constant thin film (3); and Al2O3 of which the thickness is 1-4nm is adopted by the protective layer (4). The whole gate dielectric is prepared by adopting an atomic layer deposition method and the technology is compatible with an existing CMOS technology. The SOI substrate-based high-dielectric constant gate dielectric material has the advantages of a high dielectric constant, good thin film compactness and step coverage, good heat stability and small surface roughness, and can be used for manufacturing of a metal oxide semiconductor field effect transistor.

Owner:XIDIAN UNIV

pi‑aln‑ptfe ternary nanocomposite porous membrane material and its preparation method and application

ActiveCN105047847BImprove temperature resistanceHigh hardnessNon-aqueous electrolyte accumulatorsElectrolytic capacitorsFiberElectrical battery

The invention discloses a nanocomposite multi-porous membrane material, which uses polyimide (PI) nanofiber non-woven fabric as a base material, and the pores of the base material are filled with composite nanoparticles; it is characterized in that: the composite The nanoparticles are composed of polytetrafluoroethylene nanospheres (PTFE-NP) and aluminum nitride nanoparticles (AlN-NP) mixed in a weight ratio of (7-12) / (8-13). The nanocomposite multi-porous membrane material provided by the invention has high temperature resistance, high hardness, moderate porosity, moderate areal density, good ion transport and excellent mechanical properties. The imide nanofiber diaphragm causes the problem of micro-short circuit of the battery due to high porosity; it can solve the serious problem of thermal runaway caused by mechanical collision of power lithium-ion batteries.

Owner:JIANGXI NORMAL UNIV

Power combiner with symmetrically arranged cooling bodies and power combiner arrangement

ActiveCN107735901BReduce manufacturing costHigh electrical breakdown strengthCoupling devicesPower combinerElectrical conductor

The invention relates to a power combiner (10) with a cooling body (40). The power combiner (10) has at least one first electrical conductor (14) and a second electrical conductor (16). The first electrical conductor ( 14 ) and the second electrical conductor ( 16 ) are generally spaced apart from the heat sink ( 40 ) as equidistantly as possible. To this end, the first electrical conductor (14) and the second electrical conductor (16) are alternately arranged close to or remote from the heat sink (40). Alternatively or additionally, the cooling body (40) can be arranged between the first electrical conductor (14) and the second electrical conductor (16). Alternatively or additionally, the first electrical conductor (14) and the second electrical conductor (16) are divided as far as possible into parallel conductor segments (14a, 14b, 16a, 16b), wherein the conductor segments (14a, 14b, 16a, 16b) are spaced apart from the cooling body (40) in such a way that the first electrical conductor (14) and the second electrical conductor (16) are generally as close as possible to the cooling body (40) equally spaced.

Owner:TRUMPF HUETTINGER GMBH CO KG

Dry composite foams as electrically insulating materials

PendingCN114521200ALow densityHigh electrical breakdown strengthPlastic/resin/waxes insulatorsInsulating bodiesChemistryPolymer chemistry

The present invention relates to an insulation device comprising an insulator having a chamber and an electrically insulating material in the chamber wherein the electrically insulating material comprises a dry composite foam. The invention also relates to a method of using the dry composite foam as an electrically insulating material and for manufacturing an electrically insulating device, comprising (a) providing an insulator having a chamber, (b1) either provides a mixture of at least polymer-based thermally expandable microhollow spheres in an expanded state and polymer-based thermally expandable microhollow spheres in an unexpanded state, (b2) either provides a mixture of at least two types of polymer-based thermally expandable microhollow spheres in an unexpanded state, the at least two types of thermally expandable microhollow spheres have different temperature ranges of expansion, and (c) foaming the mixture consisting of the thermally expandable microhollow spheres by heat treatment at a temperature in the range between 50 DEG C and 200 DEG C to form a dry composite foam as an electrically insulating material, the cavity of the insulating body is either filled with a mixture of thermally expandable micro-hollow spheres and foamed there, or the cavity of the insulating body is filled with the dry composite foam obtained by first foaming the mixture of thermally expandable micro-hollow spheres and the cavity of the insulating body is filled with the mixture of thermally expandable micro-hollow spheres.

Owner:MASCHFAB REINHAUSEN GEBR SCHEUBECK GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com