Method for improving dielectric properties of polymer matrix composites

A technology of composite materials and dielectric properties, which is applied in the field of high dielectric polymer materials, can solve the problems of ceramic materials processing difficulties, failure to meet advanced electronic and electrical technology, and vulnerability, and achieve low cost, low dielectric loss, and electric resistance. The effect of high breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

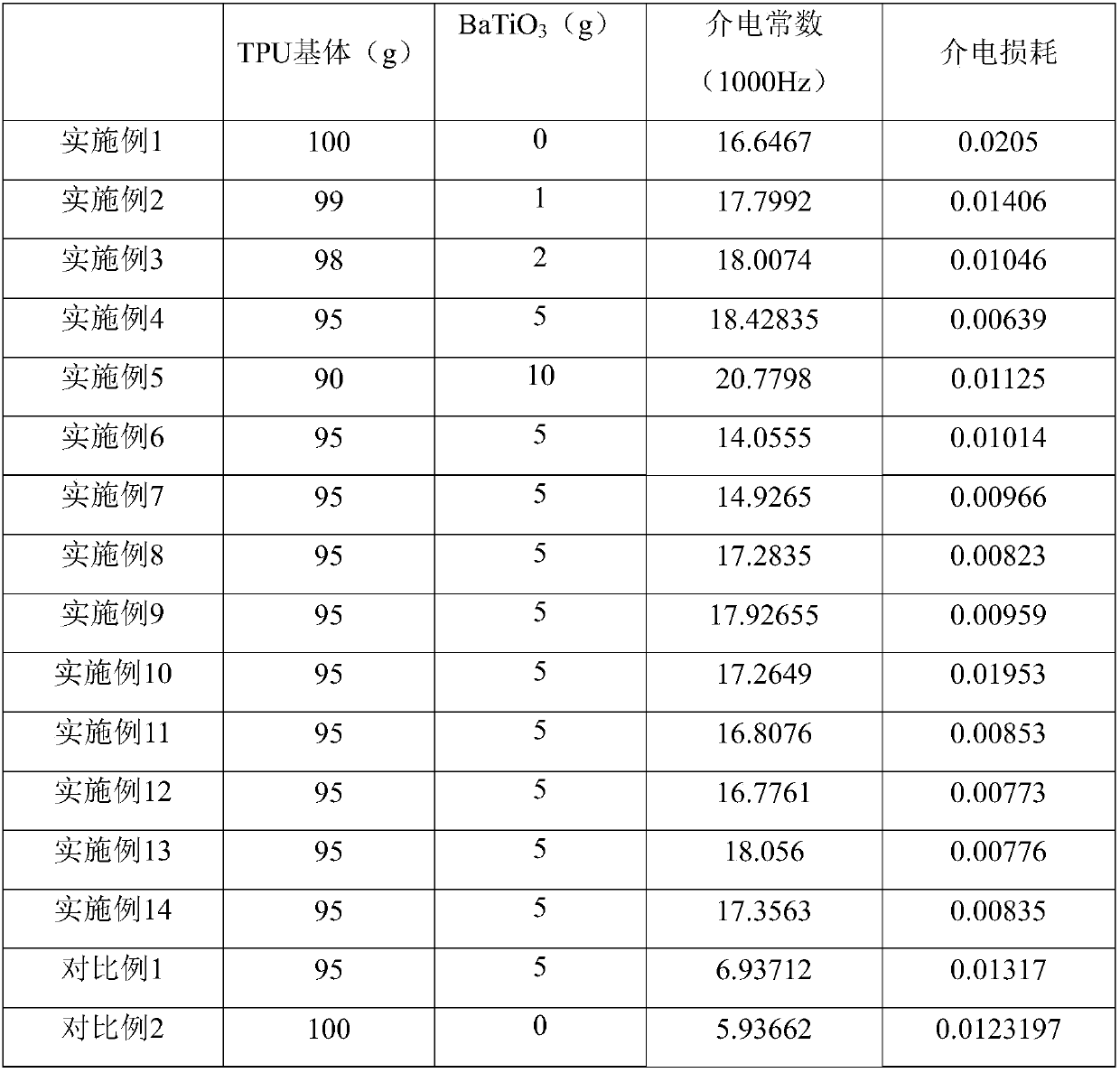

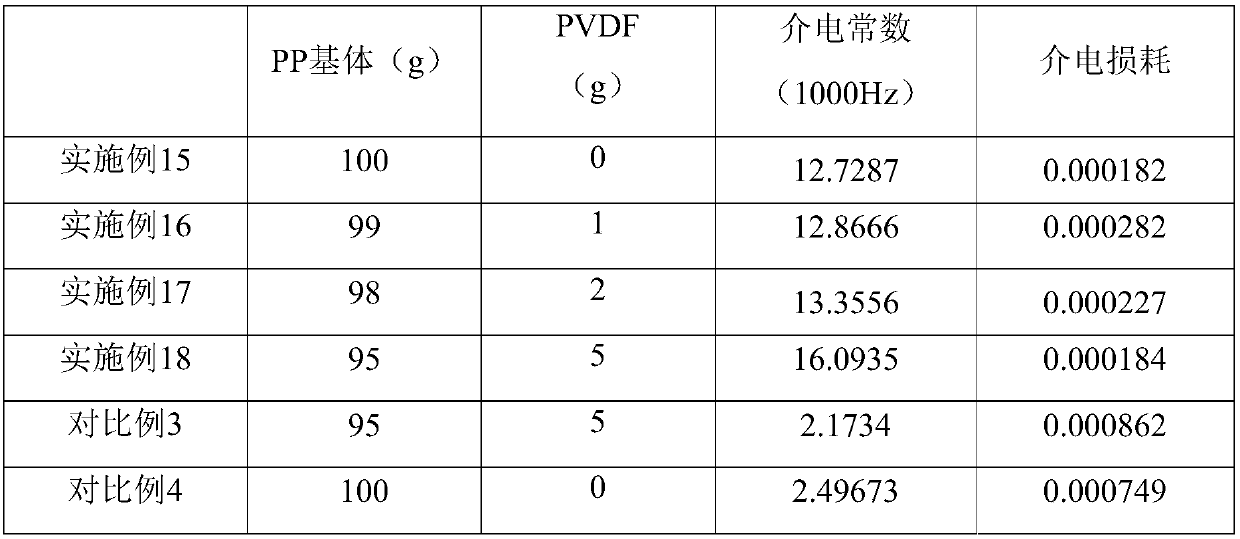

Examples

Embodiment 1

[0042] The thermoplastic polyurethane elastomer used in the examples and comparative examples of the present invention is BASF Elastollan 1180A polyether polyurethane elastomer.

[0043] The concrete preparation steps of preparation method are as follows:

[0044] (1) Add 100g of polyurethane into the torque rheometer for melting and blending, and finally cut it into small pieces as small as soybean grains while hot to obtain blend pellets. The temperature of each section of the torque rheometer is 180°C, and the speed is 60r / min, blending for 10min.

[0045] (2) The pellet obtained in (1) is carried out micro-injection molding by a micro-injection molding machine (Micropower 5, Battenfeld Co., Austria) to obtain a size of 0.3 × 3 × 15mm 3 The micro-injection molding products; the processing temperature of the micro-injection molding is set to 180 / 175 / 175 / 170°C from the inlet to the die respectively; the injection rate is 300mm / s, and the mold temperature is 120°C.

[0046] ...

Embodiment 2

[0048] Preparation method: the specific preparation steps are as follows:

[0049] (1) Use polyurethane elastomer as the matrix and barium titanate as the filler to prepare a composite material with high dielectric constant: 99g TPU and 1g BaTiO 3 Mix manually for 5 minutes, after mixing evenly, add to the torque rheometer to melt and blend, and finally cut into small pieces as small as soybean grains while hot to obtain blend pellets. The temperature of each section of the torque rheometer is 180°C. The rotation speed is 60r / min, and the blending time is 10min.

[0050] (2) The pellet obtained in (1) is carried out micro-injection molding by a micro-injection molding machine (Micropower 5, Battenfeld Co., Austria) to obtain a size of 0.3 × 3 × 15mm 3 micro injection molded products. The processing temperature of micro-injection molding is set to 180 / 175 / 175 / 170°C from the feed port to the die; the injection rate is 300mm / s, and the mold temperature is 120°C.

[0051] Deter...

Embodiment 3

[0053] Preparation method: the specific preparation steps are as follows:

[0054] (1) Use polyurethane elastomer as the matrix and barium titanate as the filler to prepare a composite material with high dielectric constant: 98g TPU and 2g BaTiO 3 Mix manually for 5 minutes, after mixing evenly, add to the torque rheometer to melt and blend, and finally cut into small pieces as small as soybean grains while hot to obtain blend pellets. The temperature of each section of the torque rheometer is 180°C. The rotation speed is 60r / min, and the blending time is 10min.

[0055] (2) The pellet obtained in (1) is carried out micro-injection molding by a micro-injection molding machine (Micropower 5, Battenfeld Co., Austria) to obtain a size of 0.3 × 3 × 15mm 3 The micro-injection molding products; the processing temperature of the micro-injection molding is set to 180 / 175 / 175 / 170°C from the inlet to the die respectively; the injection rate is 300mm / s, and the mold temperature is 120°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com