Patents

Literature

508 results about "Micro injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microinjection Microinjection is a technique of delivering foreign DNA into a living cell (a cell, egg, oocyte, embryos of animals) through a glass micropipette. One end of a glass micropipette is heated until the glass becomes somewhat liquified.

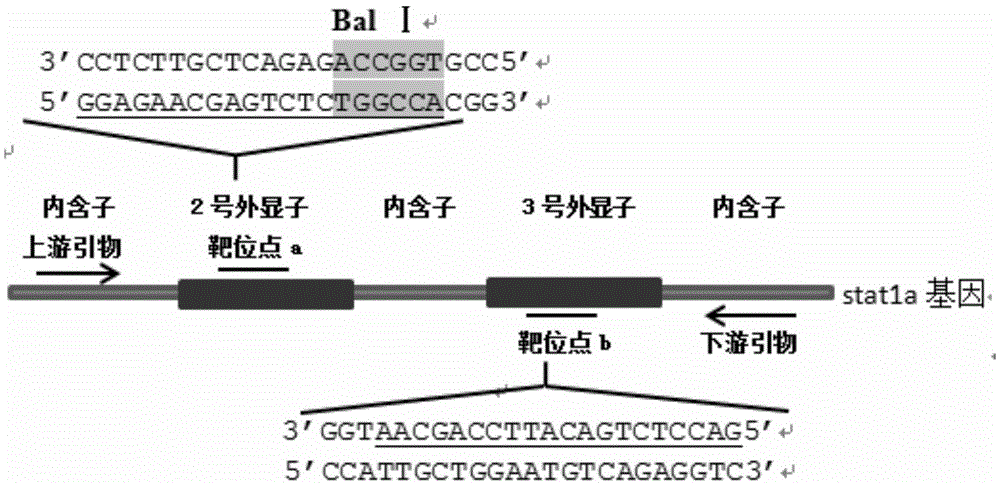

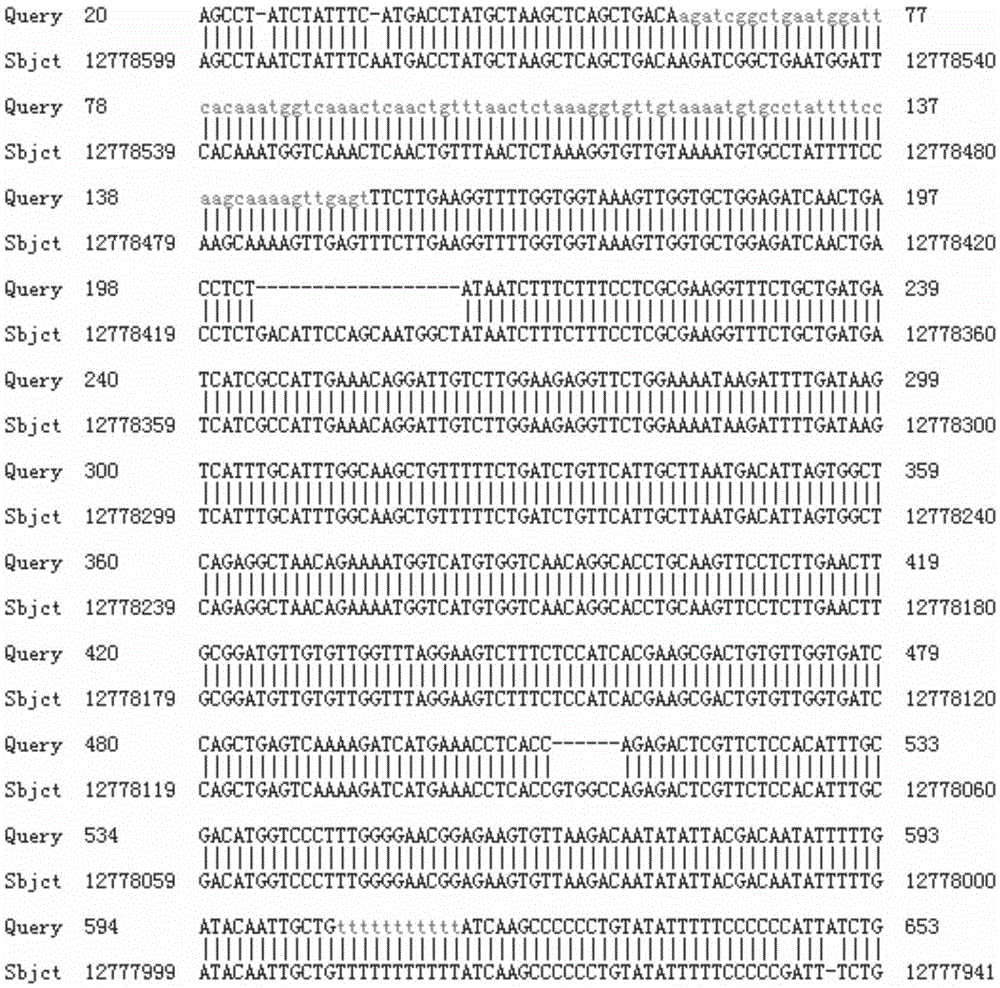

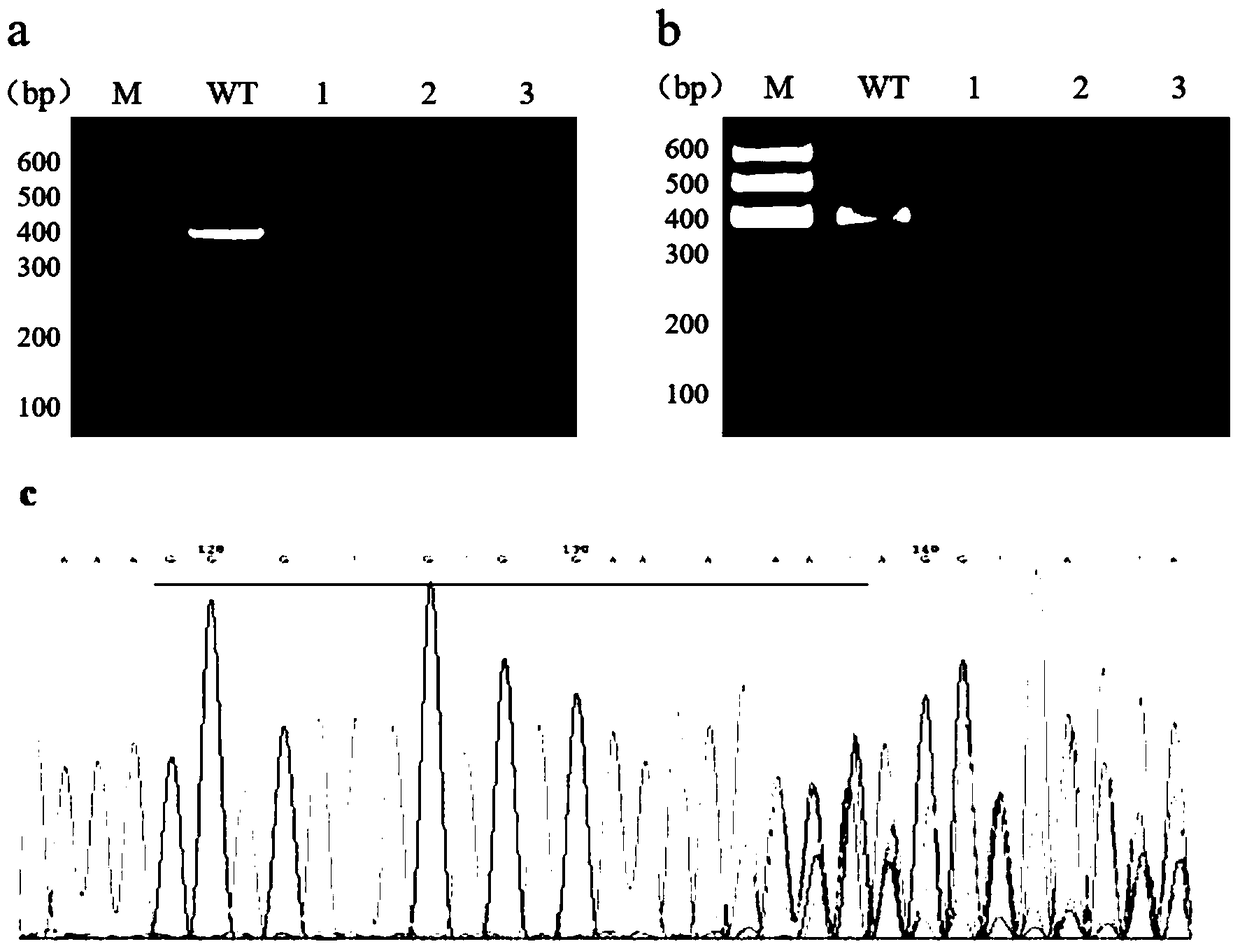

Method for breeding stat1a (signal transducer and activator of transcription 1) gene-deleted zebra fish through gene knockout

InactiveCN105647969AInefficient shooting techniqueLow costMicrobiological testing/measurementPeptidesFish embryoEmbryo

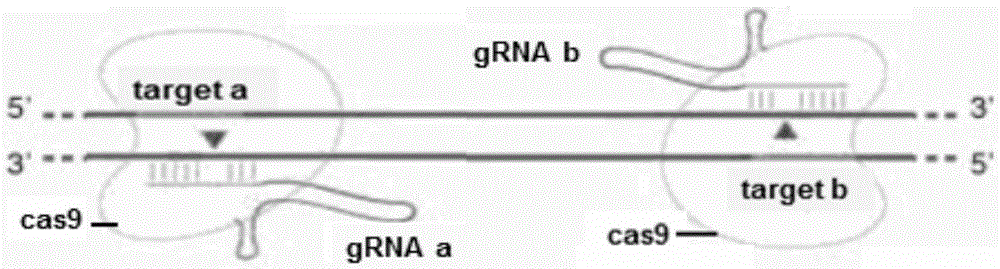

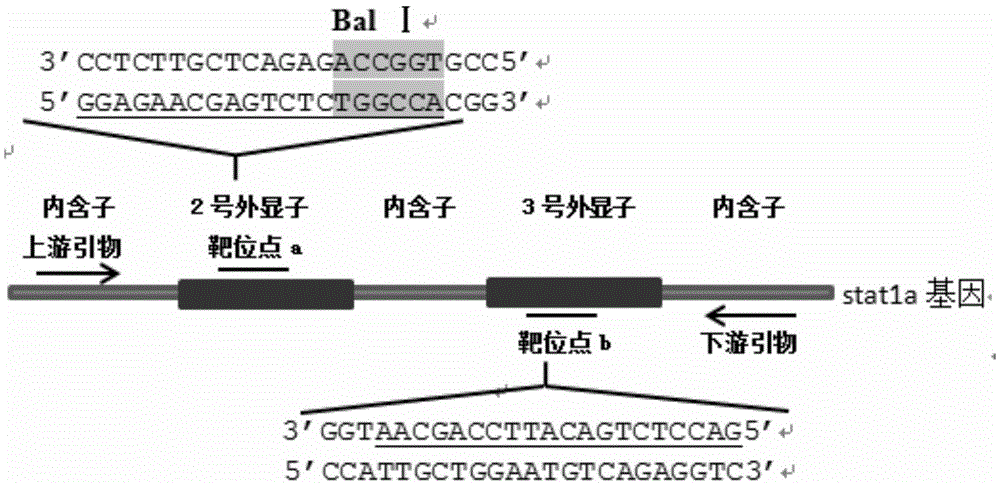

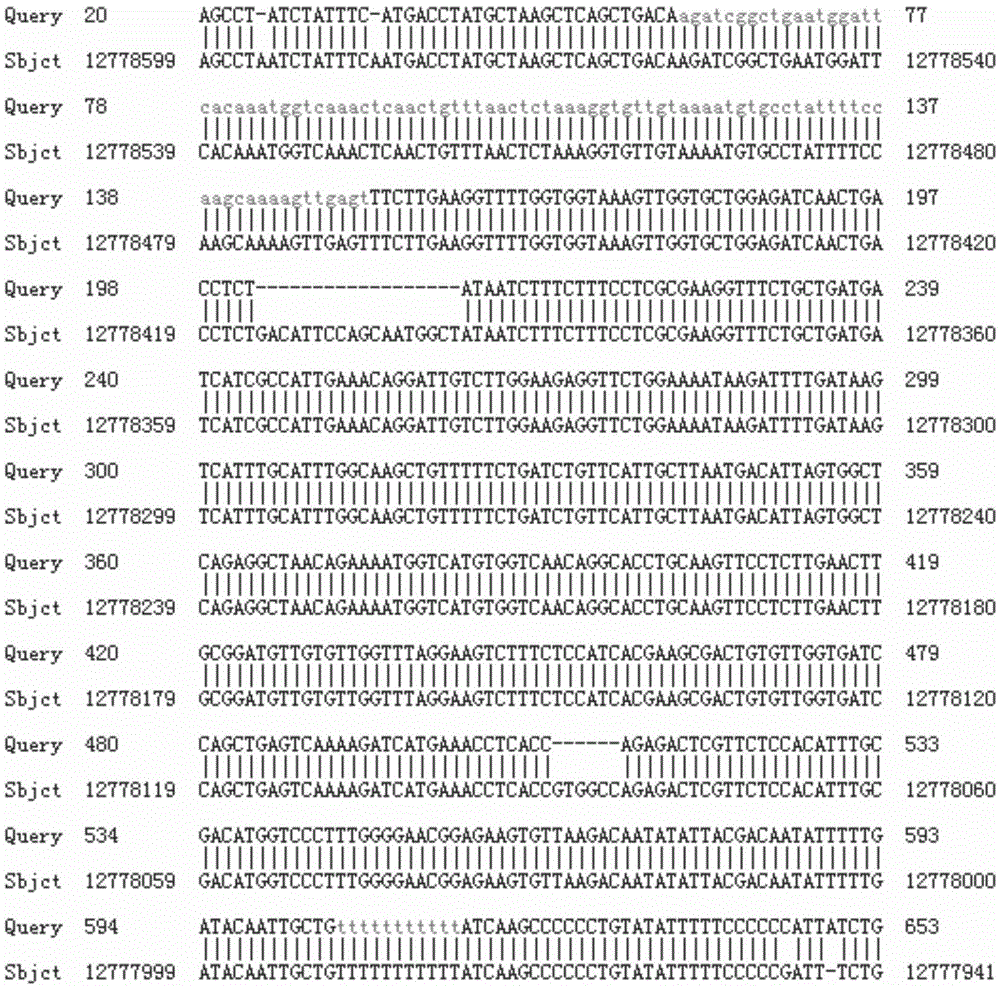

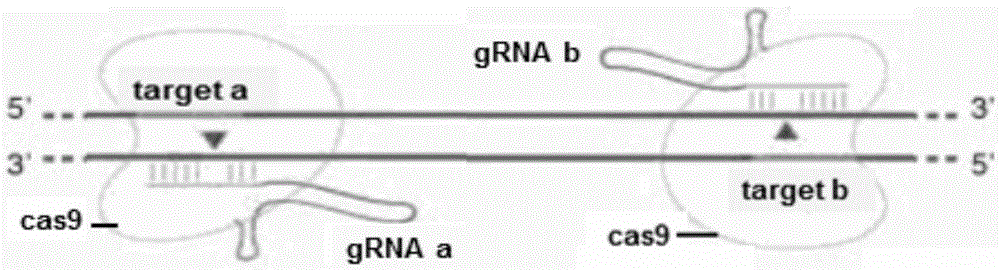

A method for breeding stat1a (signal transducer and activator of transcription 1) gene-deleted zebra fish through gene knockout comprises steps as follows: design of a CRISPR / Cas9 gene knockout target site: a gRNA expression carrier is established and gRNA is synthesized in vitro; micro-injection of a zebra fish embryo; detection of effectiveness of the target site with a T7E1 method through Sanger sequencing; tail cutting identification according to the identification steps after two months of injection; TA cloning of a target sequence; Sanger sequencing of plasmids; obtaining of heritable F1 generation of a zebra fish mutant; obtaining of F2 generation homozygote of the zebra fish mutant, F3 generation pure line inheritance of the gene-deleted zebra fish with the above method, and obtaining of a new zebra fish strain.

Owner:HUNAN NORMAL UNIVERSITY

Statla gene deletion type zebra fish

InactiveCN105594664AInefficient shooting techniqueLow costMicrobiological testing/measurementPeptidesFish embryoEmbryo

The invention provides statla gene deletion type zebra fish. After an experiment design region is knocked out, the sequence is represented as SEQ ID No.1; an experiment comprises the following steps: designing a CRISPR / Cas9 gene knockout target point: constructing a gRNA expression vector and synthesizing gRNA in vitro; carrying out micro-injection of zebra fish embryos; detecting the effectiveness of the target point by a T7E1 method and Sanger sequencing; two months after injection, carrying out tail shearing and identification and carrying out identification steps above; carrying out TA cloning of a target sequence; carrying out Sanger sequencing of plasmids; obtaining an F1 generation of descendible zebra fish mutants; obtaining F2 generation homozygotes of the zebra fish mutants; and carrying out F3 generation homozygous heredity of the gene deletion type zebra fish according to the method above to obtain a new zebra fish line.

Owner:HUNAN NORMAL UNIVERSITY

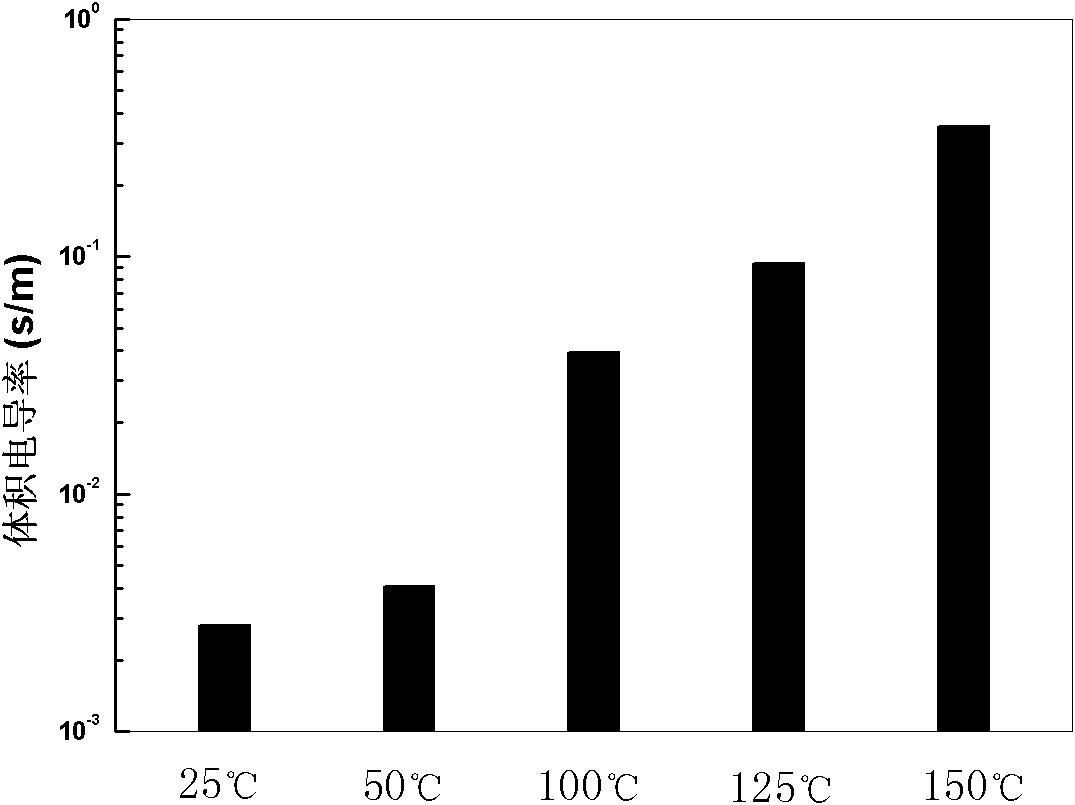

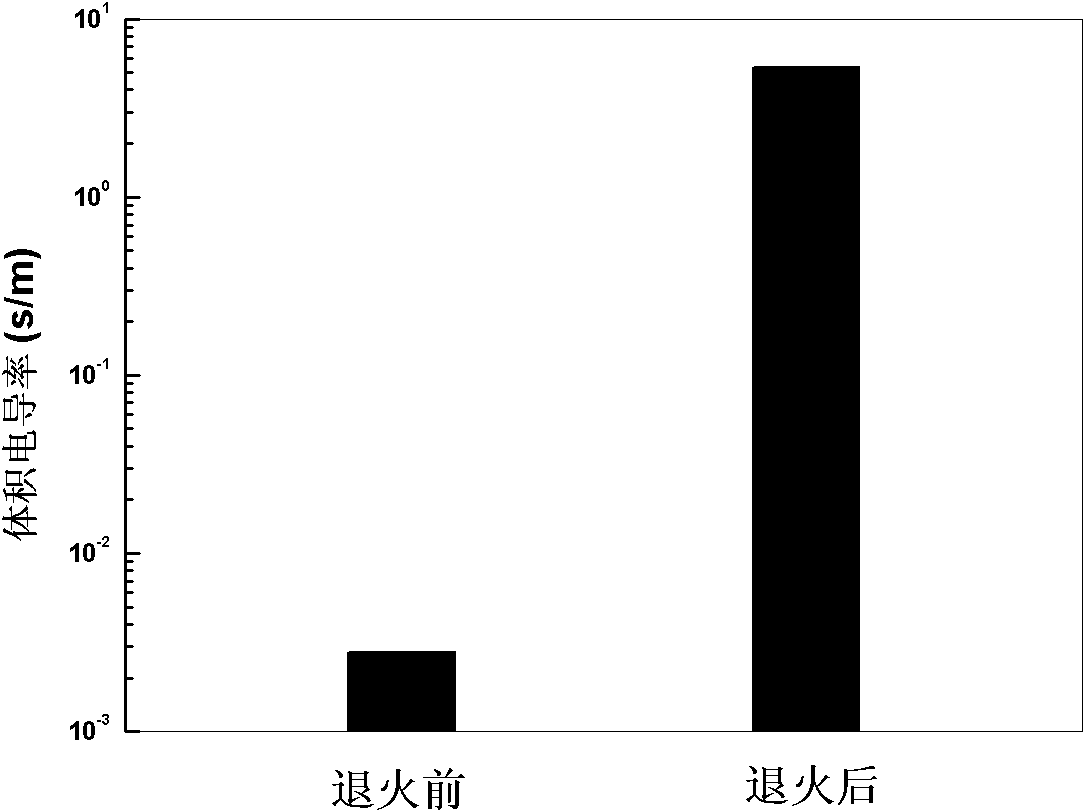

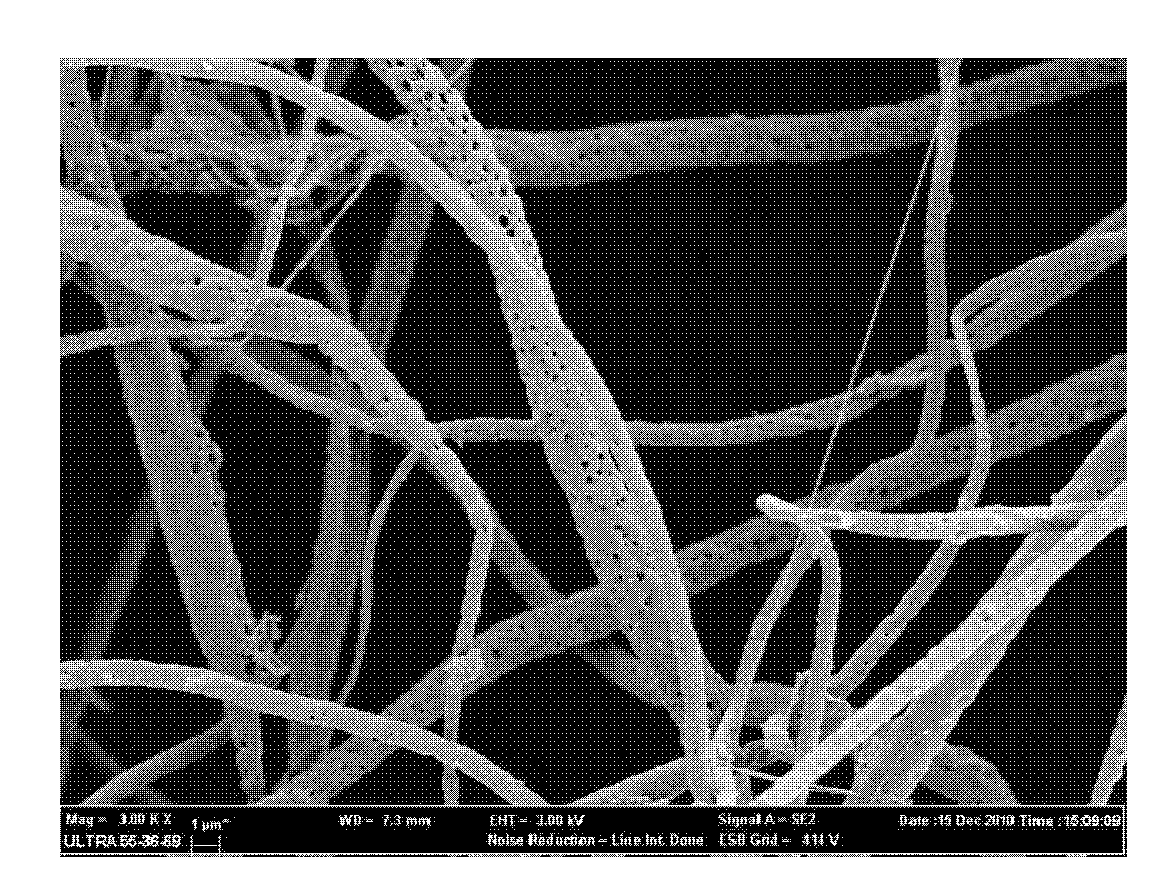

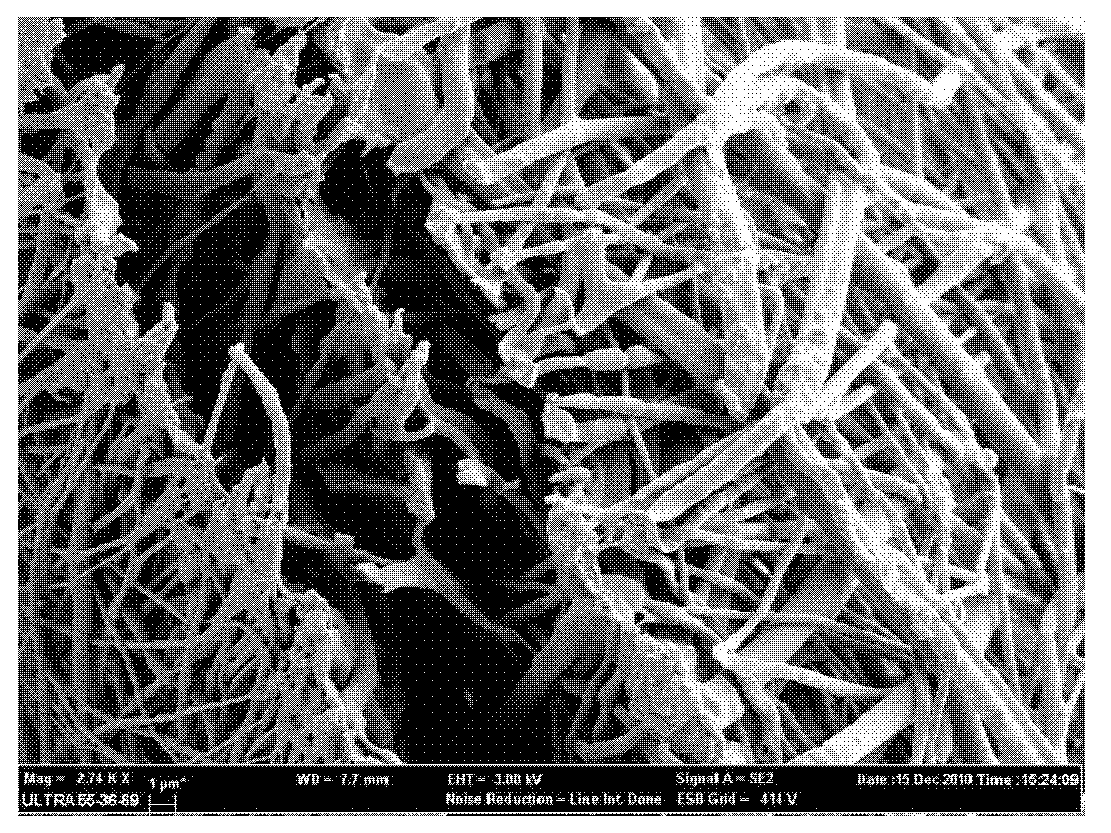

High-conductivity polymer carbon nanotube composite material and micro-processing method thereof

InactiveCN102115558AImprove dispersion stabilityImprove conductivityLiquid crystal compositionsSurgeryCooking & bakingBiomedical sensors

The invention discloses a high-conductivity polymer carbon nanotube composite material and a micro-processing method thereof. The invention is characterized in that the method comprises the following steps: adding 50-99.95 parts of polymer grain or powder, 0.05-20 parts of carbon nanotube, 0-15 parts of antioxidant and 0-15 parts of dispersant into a micro-extruder, a double-screw extruder or a double-screw extruder / micro-extruder combined facility, extruding at a screw rotation speed of 20-500rpm at a polymer melting or softening temperature of Tm+10 DEG C-Tm+80 DEG C for 1-3 times to obtainuniformly dispersed composite material grains, and carrying out micro extrusion, micro injection or micro compaction on the grains to prepare a high-conductivity micro product; or carrying out isothermal or non-isothermal heat treatment on the product in a baking oven with a temperature of Tm-80 DEG C-Tm+20 DEG C for 5 seconds to 1.5 hours; or carrying out after-treatment on the sample in microwaves, infrared rays or plasma. The high-conductivity polymer carbon nanotube composite material disclosed by the invention is used for preparing micro biomedical devices in minimally invasive operations, and used in the field of micro biomedical sensors, micro electronics, micro electro-mechanics or micro-robots.

Owner:SICHUAN UNIV

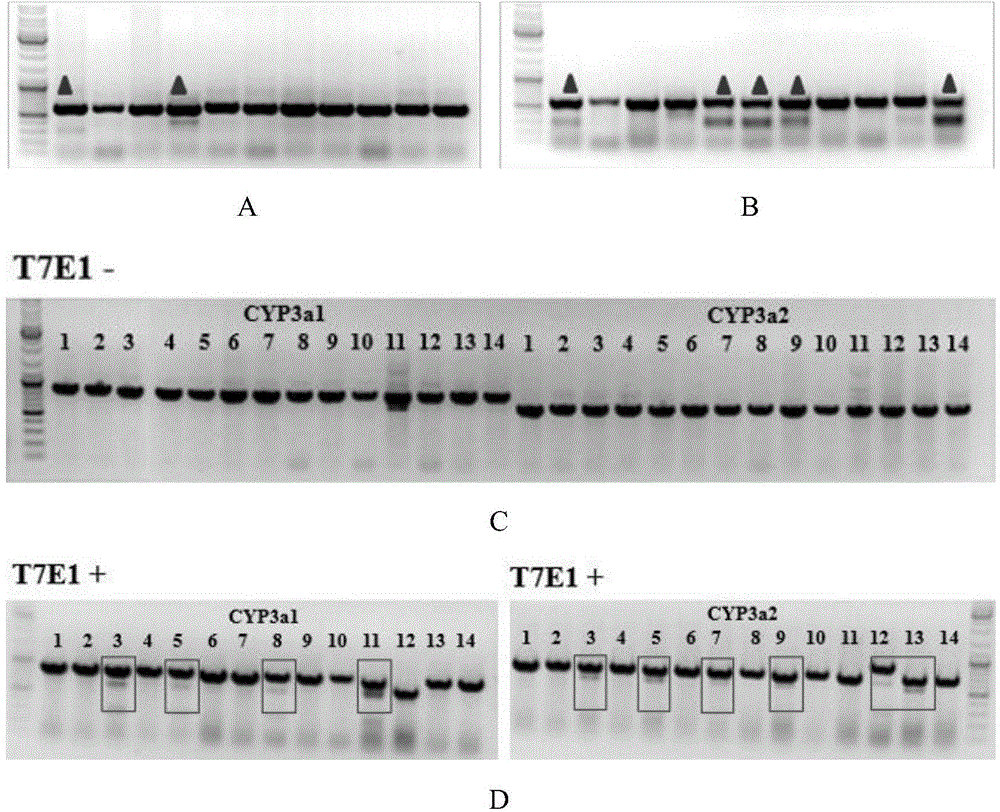

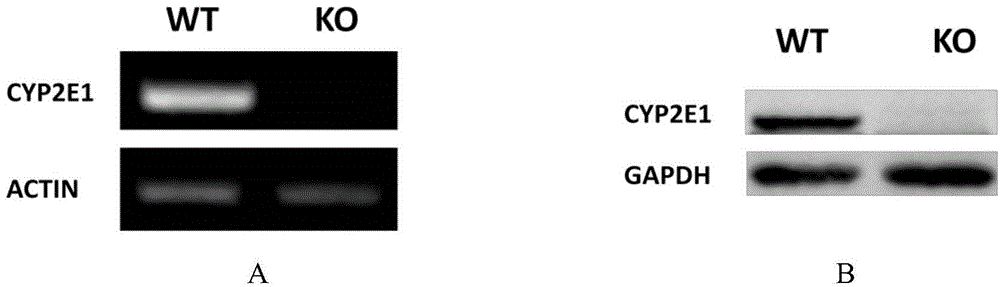

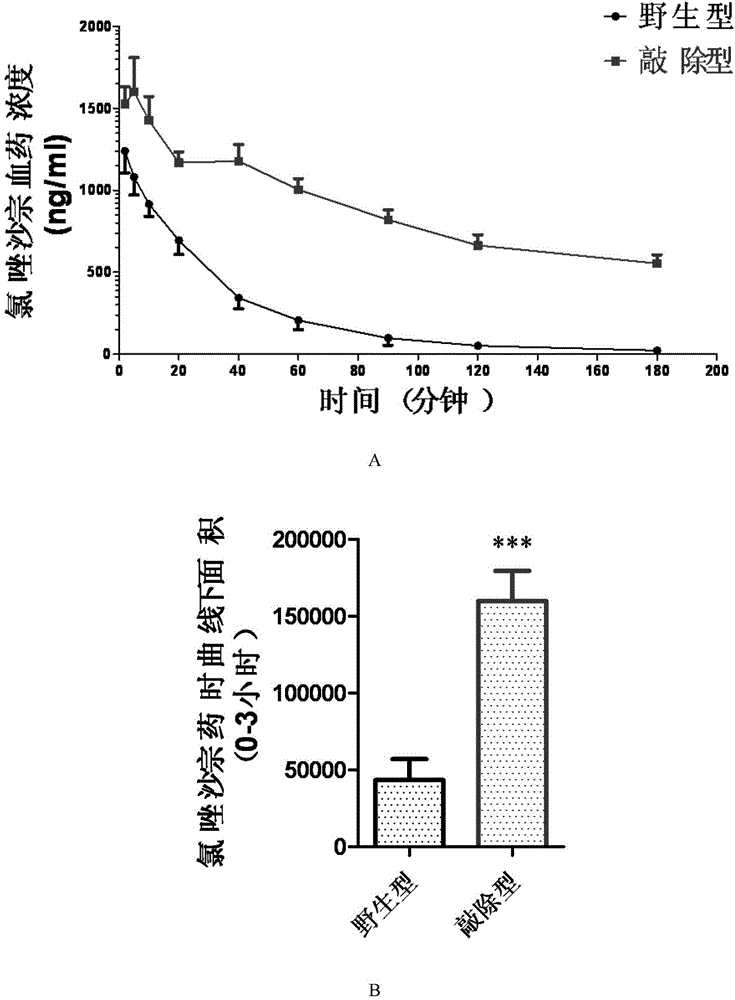

Cultivation method of Cyp gene knocked-out rats, and preparation method of liver microsome of the rats

ActiveCN106148416ADiverse in vitro modelsImprove transfer abilityMicroinjection basedFermentationHepaticaMicro injection

The invention provides a cultivation method of Cyp gene knocked-out rats, and a preparation method of liver microsome of the rats. The Cyp gene knock-out herein includes Cyp single gene knock-out and Cyp multiple gene knock-out. In the method, firstly a Cyp gene knocked-out rat is constructed by means of a CRISPR / Cas system, which includes selection of a knocked-out target site, in-vitro synthesis and transcription of sg RNA and Cas9m RNA, preparation of a pseudopregnant female rat, in-vitro micro-injection and transplanting of a single-cell embryo, and cultivation of the rat, and finally, a homozygote Cyp gene knocked-out rat can be cultured. Furthermore, the liver of the Cyp gene knocked-out rat is extracted and is subjected to homogenization and differential centrifugation to prepare the liver microsome of the rat in Cyp gene deletion. The invention also provides an application of the Cyp gene knocked-out rats and the liver microsome thereof in study on drug metabolism.

Owner:EAST CHINA NORMAL UNIV

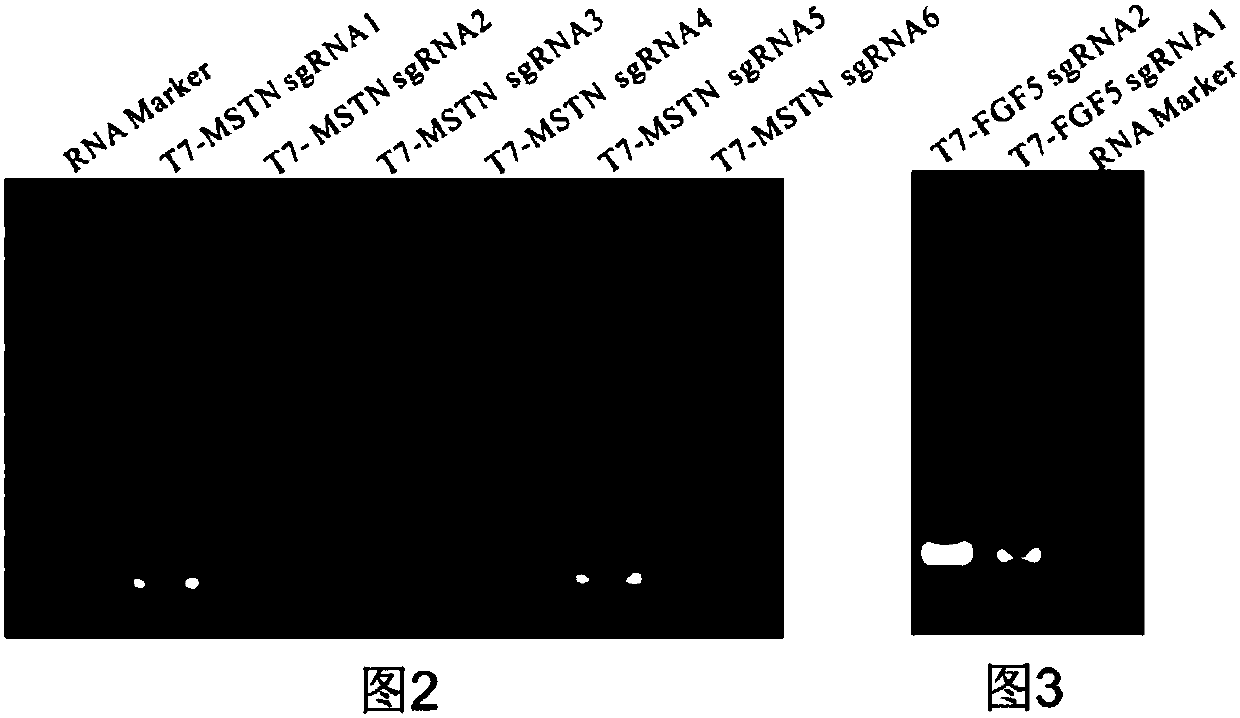

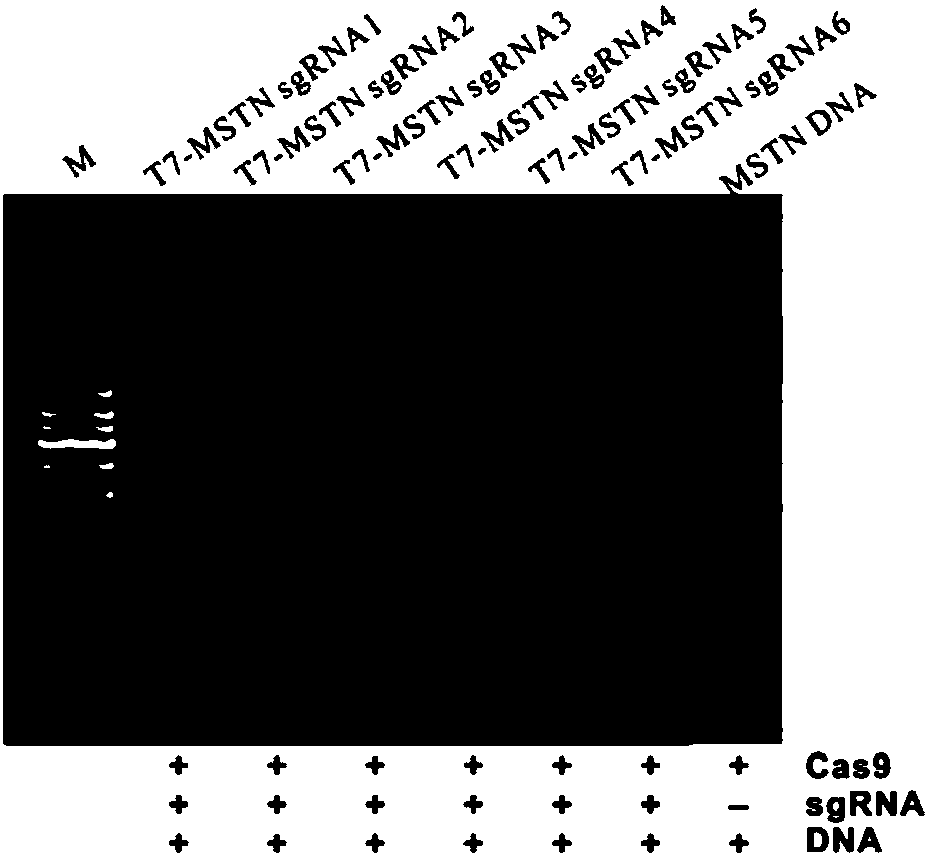

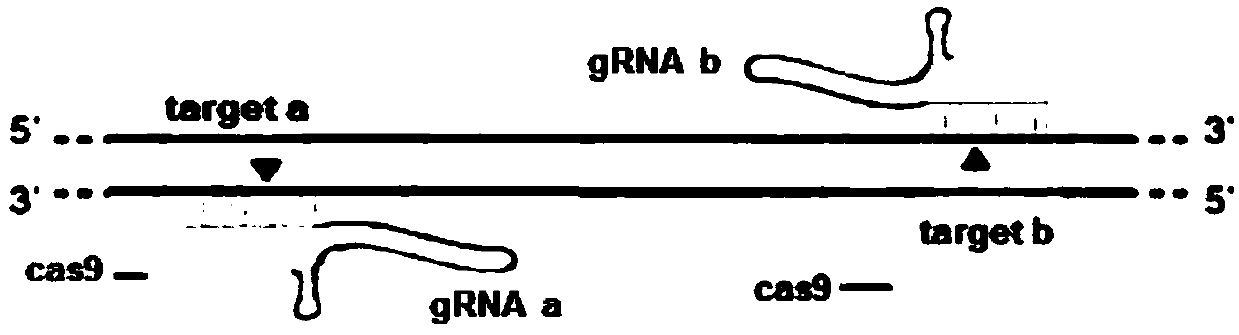

Method for acquiring gene editing sheep by RNA-mediated specific double-gene knockout and special sgRNA for method

ActiveCN105132427AStrong specificityPrecise targeted modificationArtificial cell constructsVertebrate cellsAnimal scienceGenome editing

The invention discloses a method for acquiring gene editing sheep by RNA-mediated specific double-gene knockout and special sgRNA for the method. The sgRNA combination consists of sgRNAMSTN-1 and sgRNAFGF5-1, wherein sgRNAMSTN-1 is sgRNA which can realize specific targeted modification of sheep MSTN gene and is RNA shown in the second to 21st nucleotides in a sequence 6 or RNA with the second to 21st nucleotides of the sequence 6; sgRNAFGF5-1 is sgRNA which can realize specific targeted modification of sheep FGF5 gene and is RNA shown in the second to the 21st nucleotides in a sequence 8 or RNA with the second to 21st nucleotides of the sequence 8. According to the method for acquiring gene editing sheep by RNA-mediated specific double-gene knockout and special sgRNA for the method, the CRISPR / Cas9 genome editing technology and the micro-injection technology are combined, so that the sheep targeting efficiency is higher and more accurate, sheep double-gene knockout is realized for the first time in the generation, improvement on sheep meat production and wool production is greatly promoted, and a larger space and a more effective technical tool are provided for breeding of new sheep varieties.

Owner:新疆畜牧科学院生物技术研究所

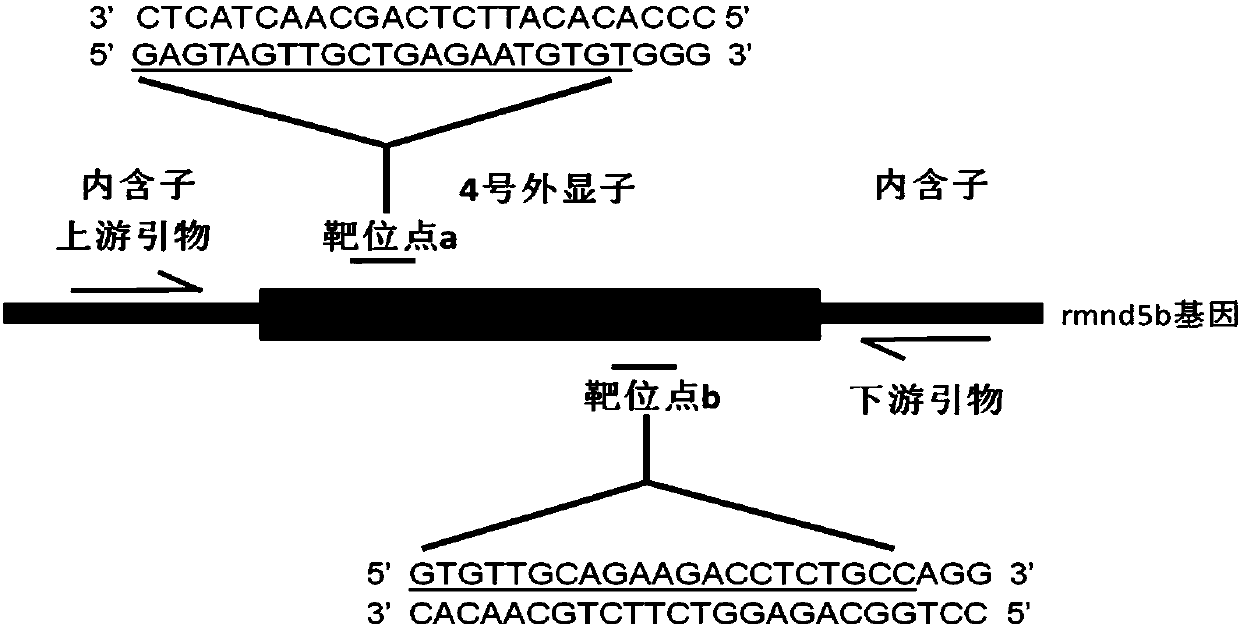

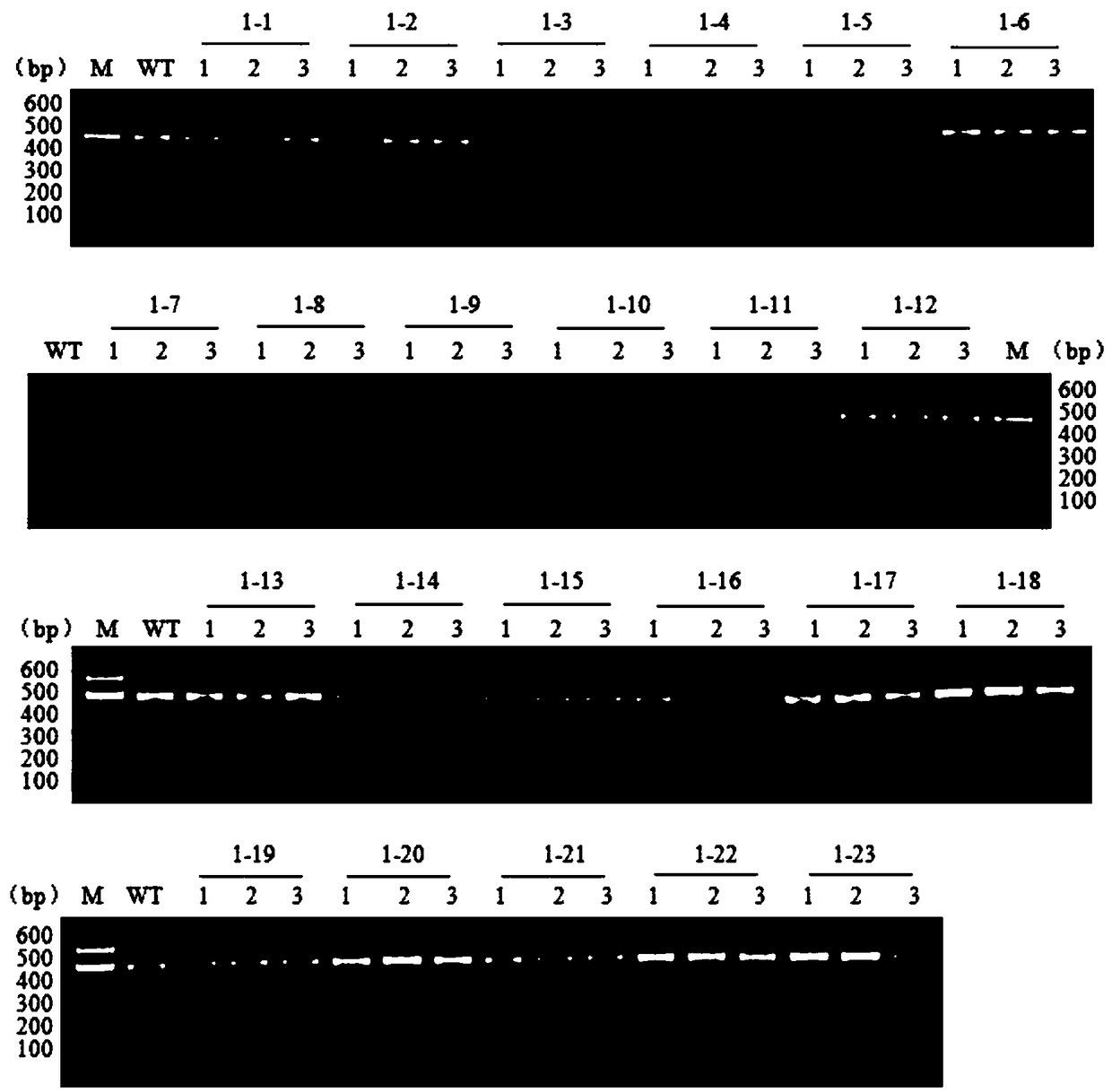

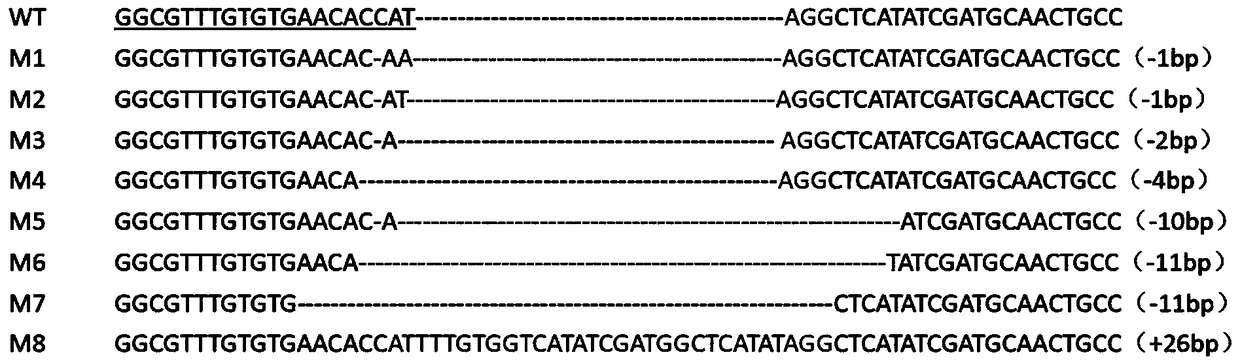

Method for breeding rmnd5b (required for meiotic nuclear division 5homolog B) gene deletion type zebra fish through gene knockout

InactiveCN108018316AEasy to makeLow miss rateHydrolasesStable introduction of DNAMeiotic nuclear divisionEmbryo

The invention discloses a method for breeding rmnd5b (required for meiotic nuclear division 5homolog B) gene deletion type zebra fish through gene knockout and belongs to the field of gene knockout. According to the method, construction of a gRNA expression vector and gRNA in-vitro synthesis are performed through design of a CRISPR / Cas9 (clustered regularly interspaced short palindromic repeats / CRISPR-associated 9) gene knockout target site, micro-injection is performed on an embryo of the zebra fish, the effectiveness of the target site is detected, tail cutting identification is performed, TA cloning is performed on a target sequence, plasmids are subjected to Sanger sequencing, an F1 generation of heritable zebra fish mutants is obtained, the same mutant female fish and male fish are picked from mutants of the F1 generation, hybridization is performed, an F2 generation of the zebra fish mutants is obtained, F2 generation homozygote is picked from the F2 generation of the zebra fishmutants, F3 generation pure-line inheritance is performed, and an rmnd5b gene deletion type zebra fish strain is obtained. The method is lower in off-target rate and has good medical research value inresearch of the correlation between rmnd5b gene deletion and development of other organs.

Owner:HUNAN NORMAL UNIVERSITY

Application of micro injection molding technique for preparing tungsten-base alloy product and micro injection molding method of tungsten-base alloy powder

The invention discloses an application of micro injection molding technique for preparing a tungsten-base alloy product, which can prepare a micro tungsten-base alloy part with a mass less than 0.5g and a relative density greater than 96 percent. The invention also discloses a micro injection molding method of tungsten-base alloy powder, comprising steps of mixing, milling mixing, pelletizing, injection molding, green-ware degreasing, sintering and the like. The adhesive consists of wax, polyethylene, surface modifier and the like, wherein the modifier consists of stearic acid and organic naphthaline by a certain proportion, and the viscosity of the adhesive is dramatically reduced at a high shearing rate, thereby being favorable for filling. The invention adopts two degreasing steps of solvent degreasing and heat degreasing, wherein the first step of solvent degreasing can degrease wax of low melting point and partial surface modifier, and the second step of heat degreasing mainly degreases polymer of high melting point. The high-temperature insulation can remove the adhesive, sinter the degreased green body, improve the intensity of the green body and ensure conformality of the green bodies.

Owner:厦门博兴纳新材料科技有限公司

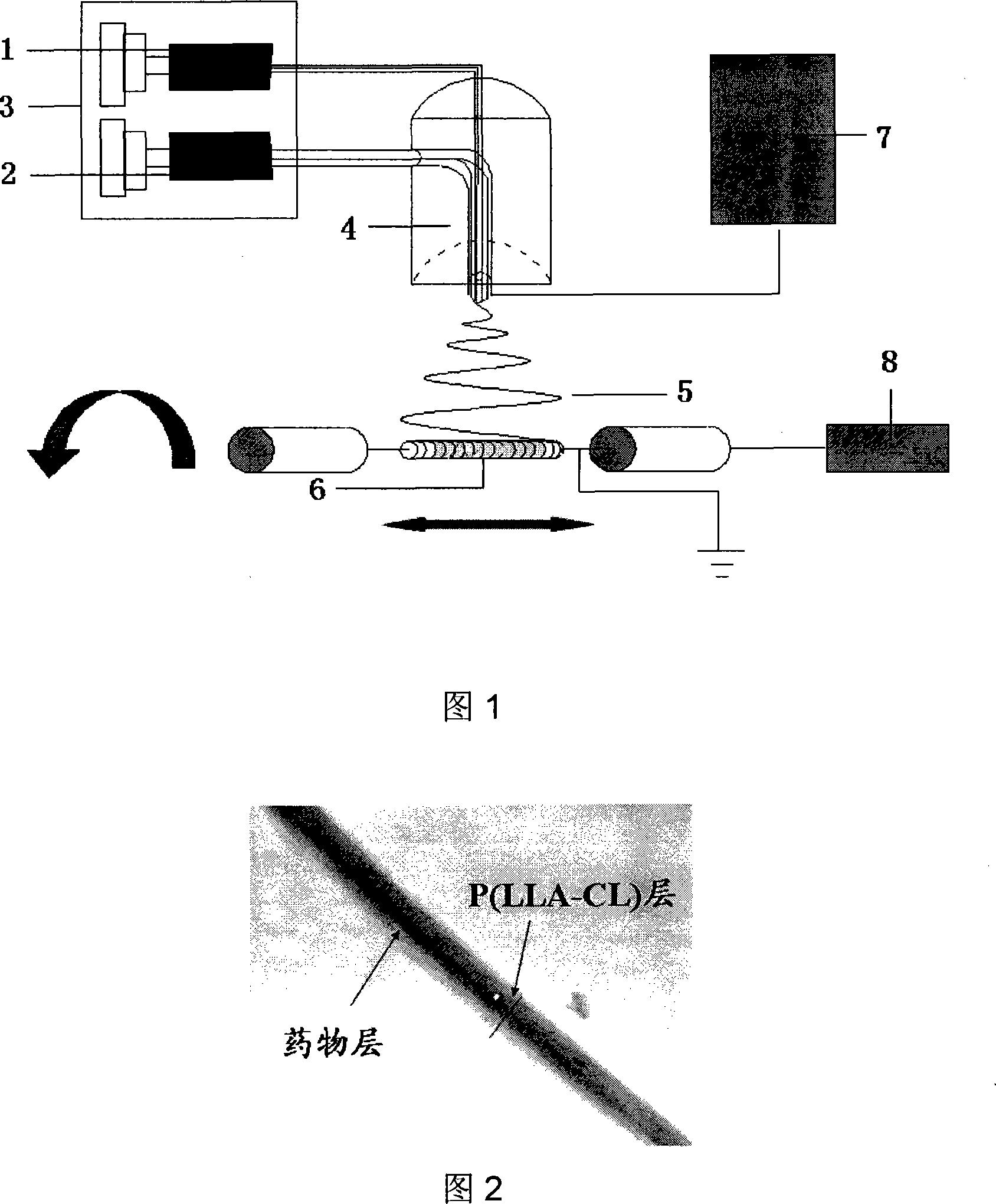

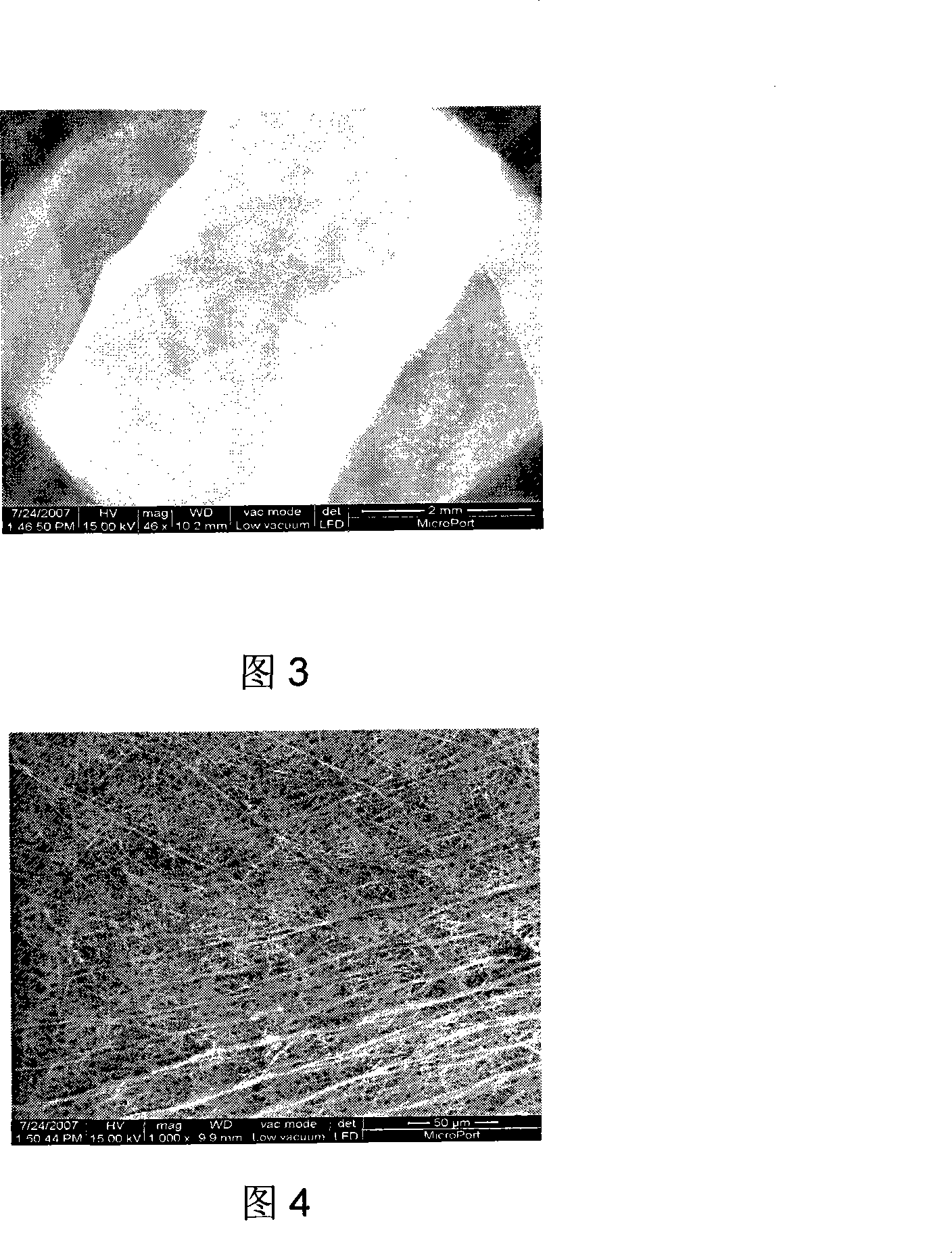

Preparation method of shell core fibre tectorial membrana endovascular stent

The invention relates to a preparation method of a shell core fiber covered endovascular stent graft. The steps are as follows: firstly, a polymer is dissolved in adaptive dissolvent to obtain solution with a certain concentration; secondly, medicine or an artificial polymer and medicine, and a bio-active element are dissolved in the adaptive dissolvent to obtain solution or suspension liquid; thirdly, the solution of the polymer and the medicine or the solution or suspension liquid of the medicine or bio-active element are respectively filled in two injectors, the speed of a micro injection pump, the voltage of an electrostatic generator and the distance of a receiving device are adjusted, fiber is obtained through the static spinning preparation, and the fiber is received as a tube shape or film shape structure; fourthly, the endovascular stent graft is fixed on a revolution axle, through the revolution of the endovascular stent graft, the static spinning fiber are directly received as fibrous membrane covered on the endovascular stent graft. The invention can effectively prevent smooth muscle cells from hyperplasia in the stent graft or from narrowing in the stent graft caused by the other functions, and the shell core fiber for the medicine loading can slowly release the medicine to attain the purpose of curing.

Owner:DONGHUA UNIV

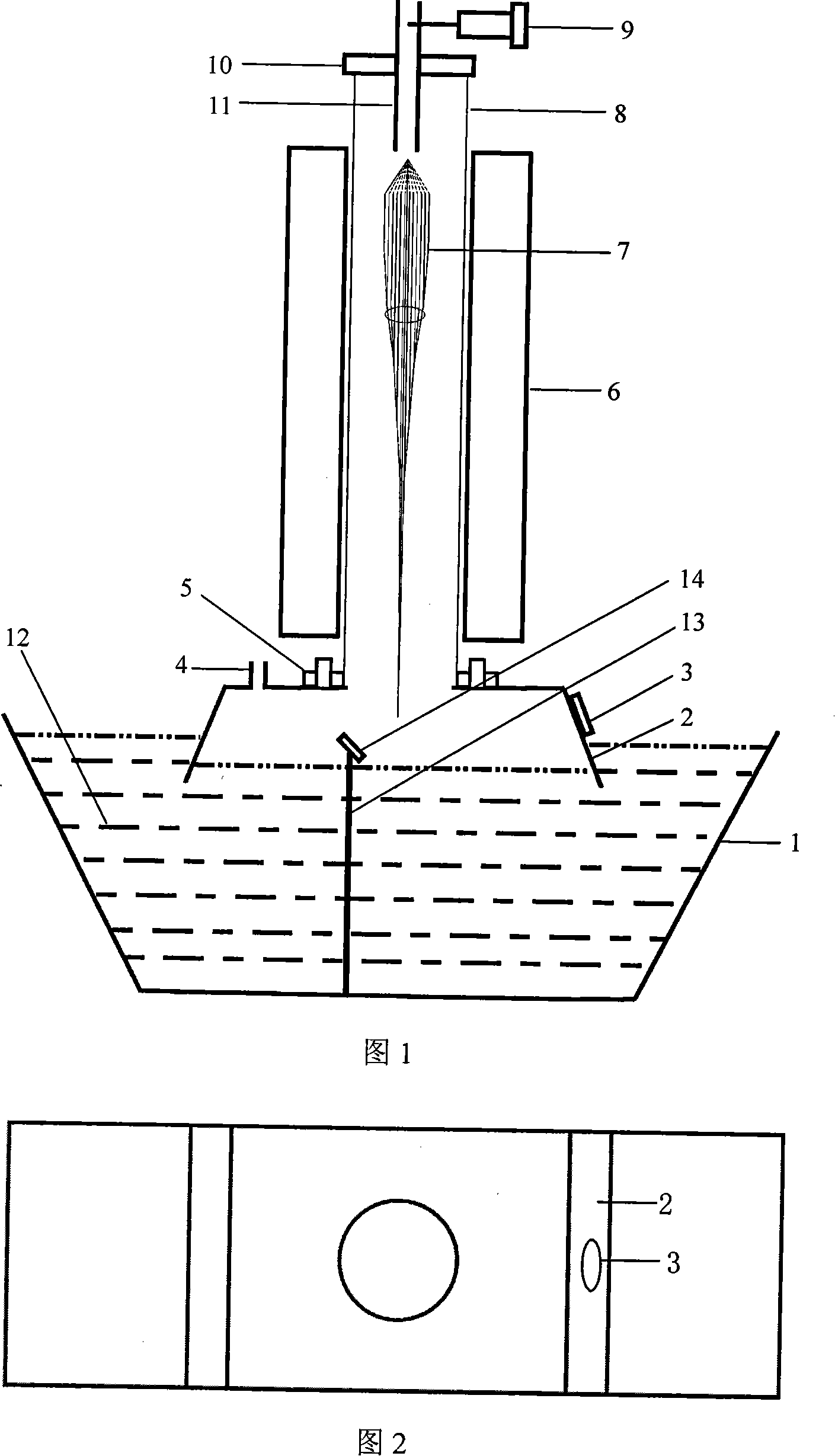

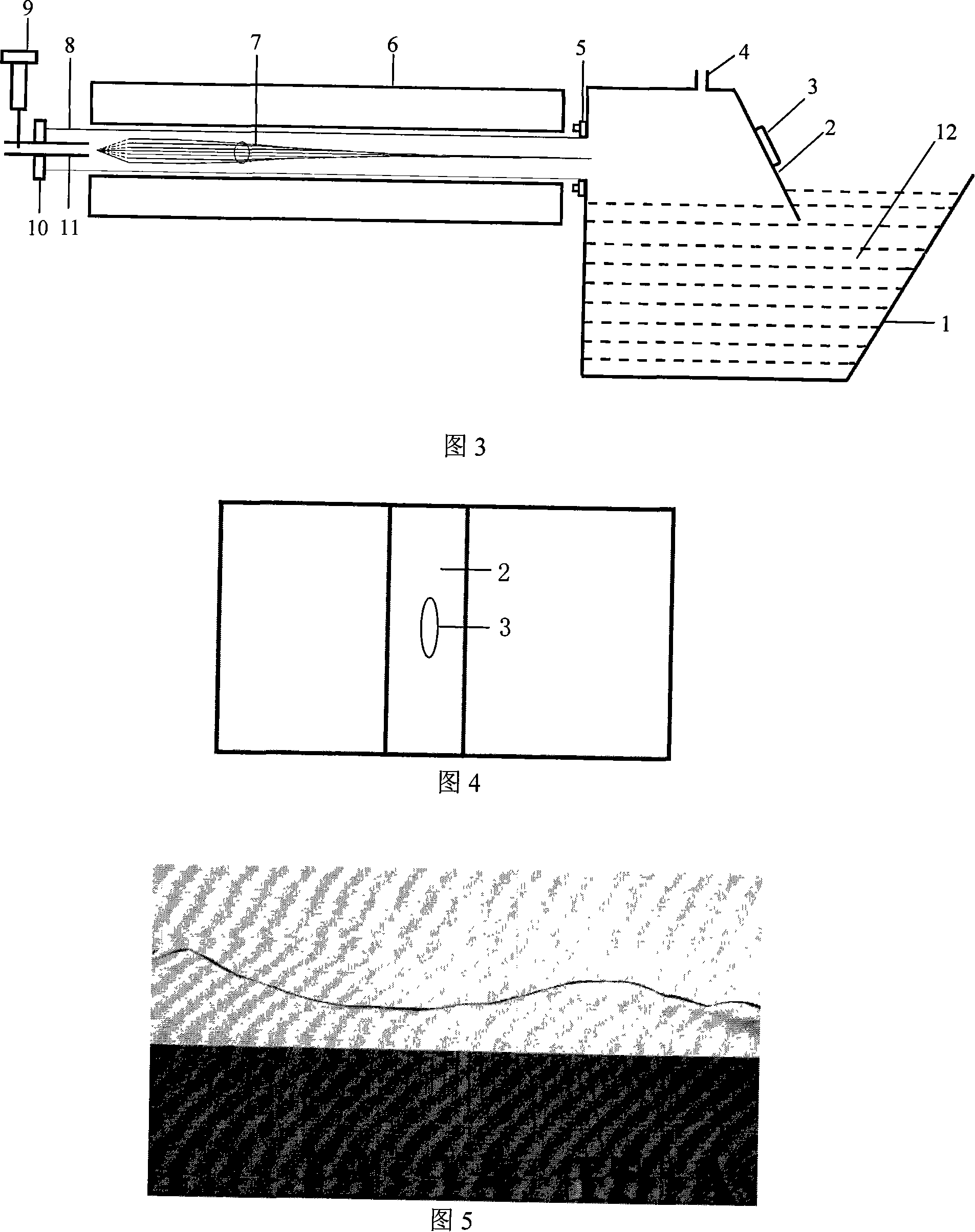

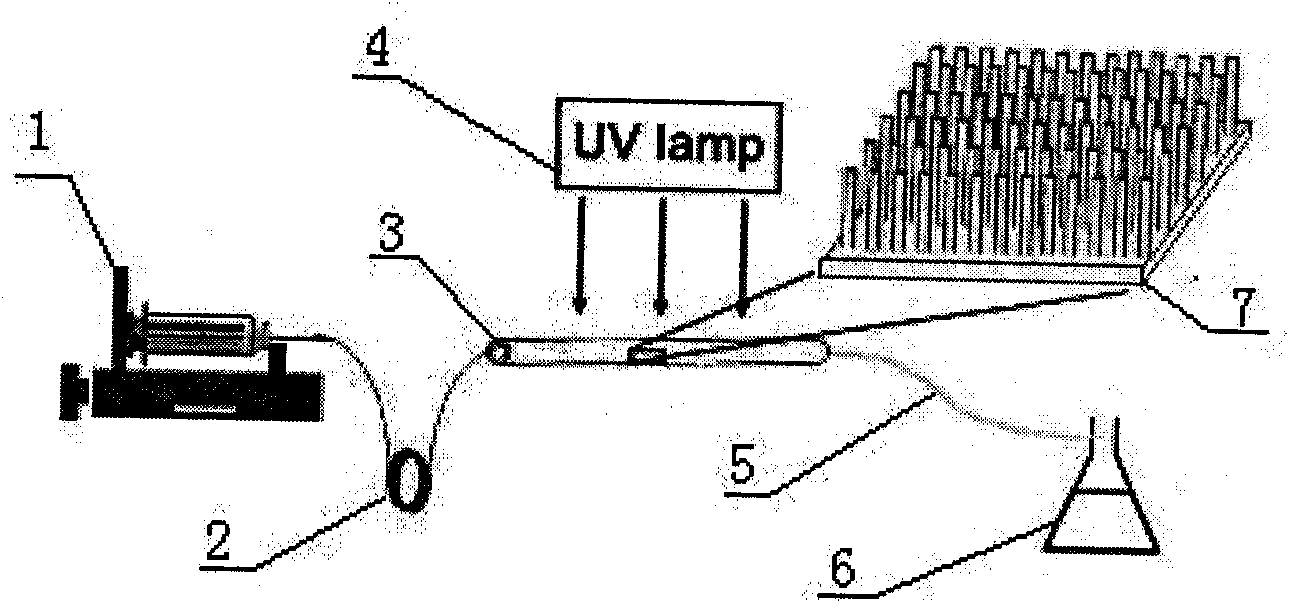

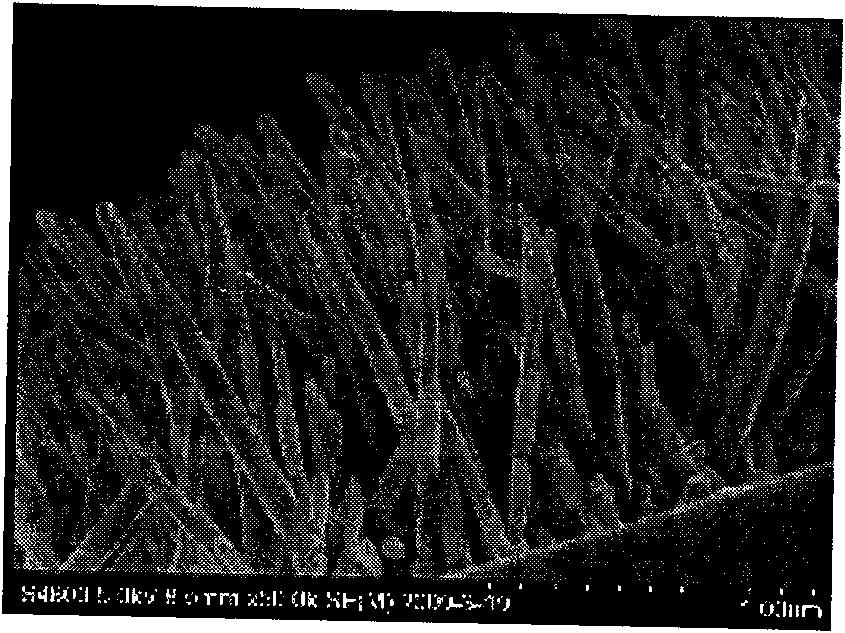

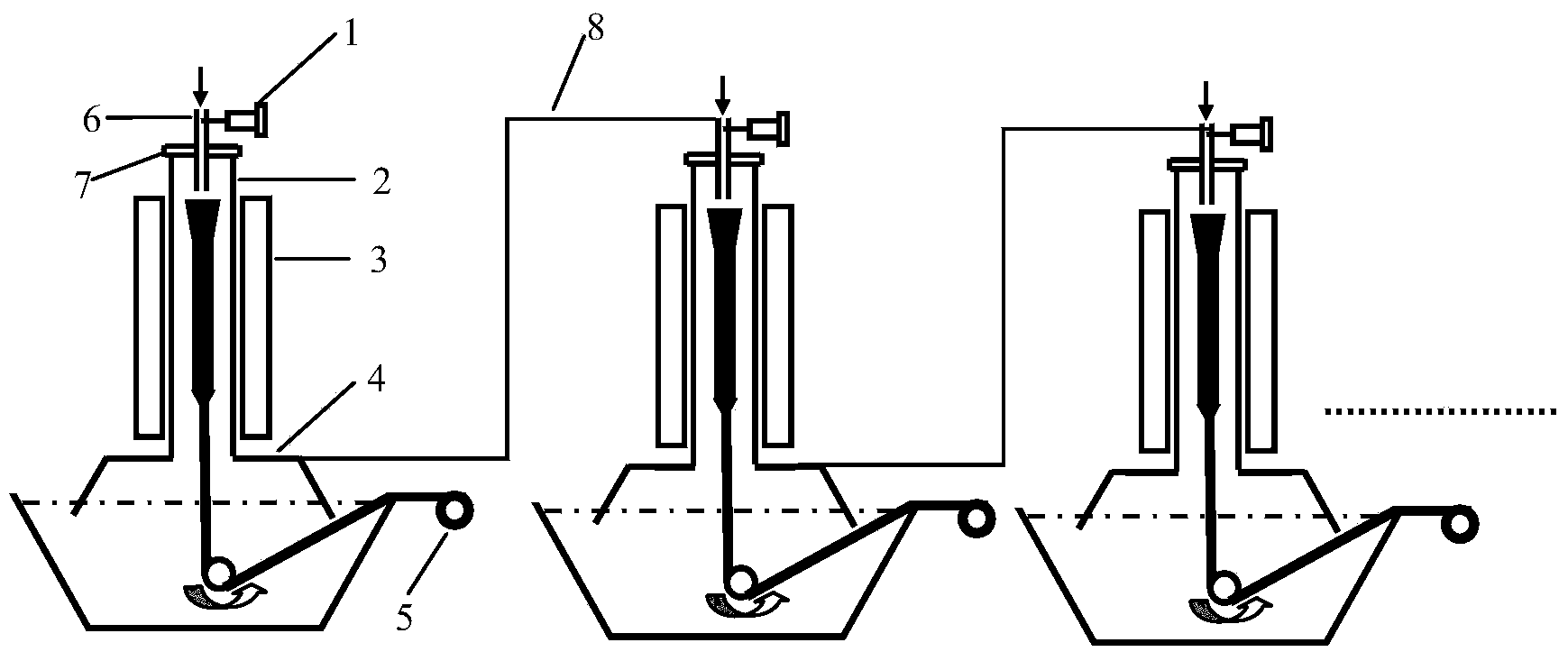

Apparatus and method for producing continuous carbon nano-tube fibre by liquid sealed vapor-phase flow catalytic reaction

InactiveCN101153413ASuitable for large-scale industrial productionHigh purityFibre chemical featuresFiberLiquid medium

The invention discloses a device and method for preparing continuous carbon nanotube fiber through liquid seal gas phase flow catalytic reaction, wherein, the device is used in completing the following steps: a liquid tank is connected with the quartz tube arranged inside a tube furnace through a flange; the aqueous solution which contain H2O, 10 percent of HCl and 10 percent of PVA is adopted as seal liquid; the mixed solution of ethanol, ferrocene, thiophene and water is injected into 500 ml / minH2 to 1,000 ml / minH2 carrier gas flow through a micro-injection pump and is channeled into the quartz tube through a jet nozzle; reaction is completed under 900 DEG C to 1,200 DEG C high-temperature conditions and tubular continuous carbon nanotube fiber is generated at a reaction zone; finally, the generated carbon nanotube fiber is treated through the seal liquid medium or is directly operated at the reaction zone. The invention realizes direct operation of carbon nanotube fiber at the reaction zone and treatment for the generated fiber so as to obtain continuous carbon nanotube fiber with high purity and high strength; moreover, with moderate reaction conditions, the invention is suitable for large scale production of the carbon nanotube fiber and has wide application range.

Owner:TIANJIN UNIV

Preparation method of zebrafish notch2 gene mutant

ActiveCN108707628AGenetic stabilityFacilitate in-depth researchHydrolasesStable introduction of DNAPUC19Embryo

The invention discloses a preparation method of a zebrafish notch2 gene mutant. The preparation method includes: determining positions of knock-out target spots of the notch2 gene; utilizing pUC19-gRNA scaffold plasmid as a template, and performing PCR (polymerase chain reaction) amplification with primers T7-notch2-sfd and tracr rev; subjecting a PCR product to purification and in-vitro transcription to obtain gRNA (guide ribose nucleic acid); introducing the gRNA and Cas9 protein into a cell-stage embryo of zebrafish through micro-injection, and screening to obtain the notch2 gene mutant stable in inheritance. The preparation method has the advantages that by the aid of the CRISPR / Cas9 (clustered regularly interspersed short palindromic repeats, CRISPR / CRISPR-associated genes, cas gene)technology, and by means of selecting a specific section of targeting domain, the notch2 gene in the zebrafish is knocked out, other genes are protected from being 'injured accidentally', the zebrafish without the Notch2 gene is formed, experimental materials are provided for in-depth study on follow-up gene functions, and great significance is achieved on study of Notch signal channels.

Owner:SHANGHAI OCEAN UNIV

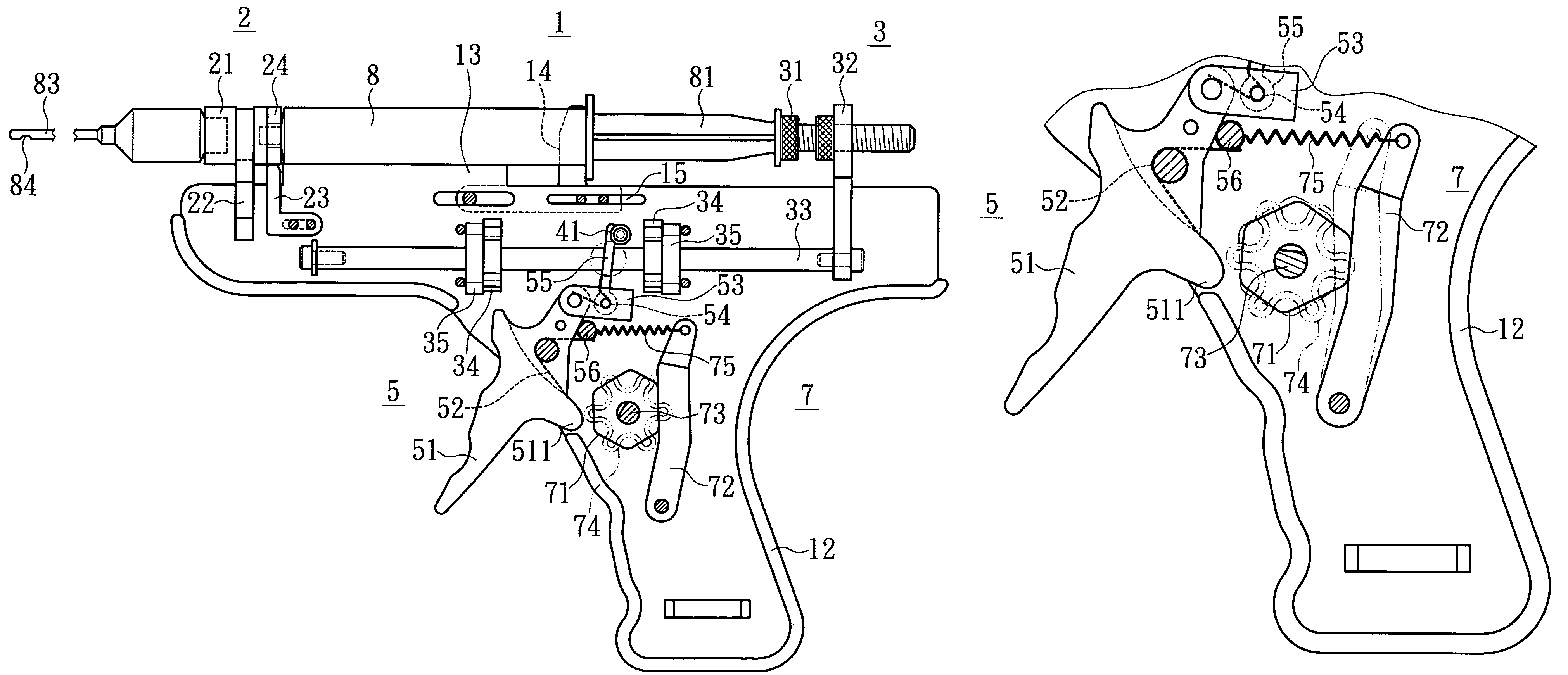

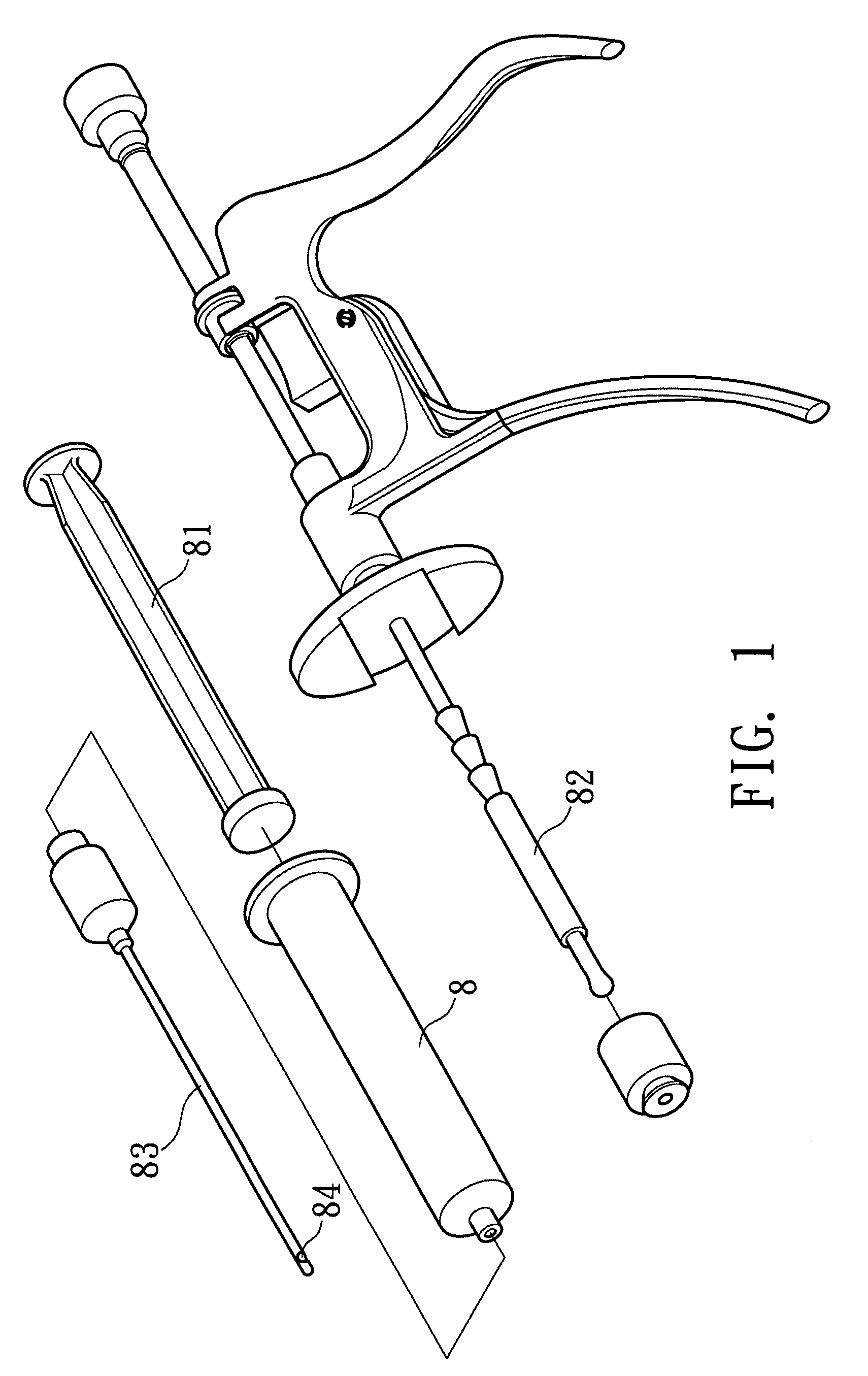

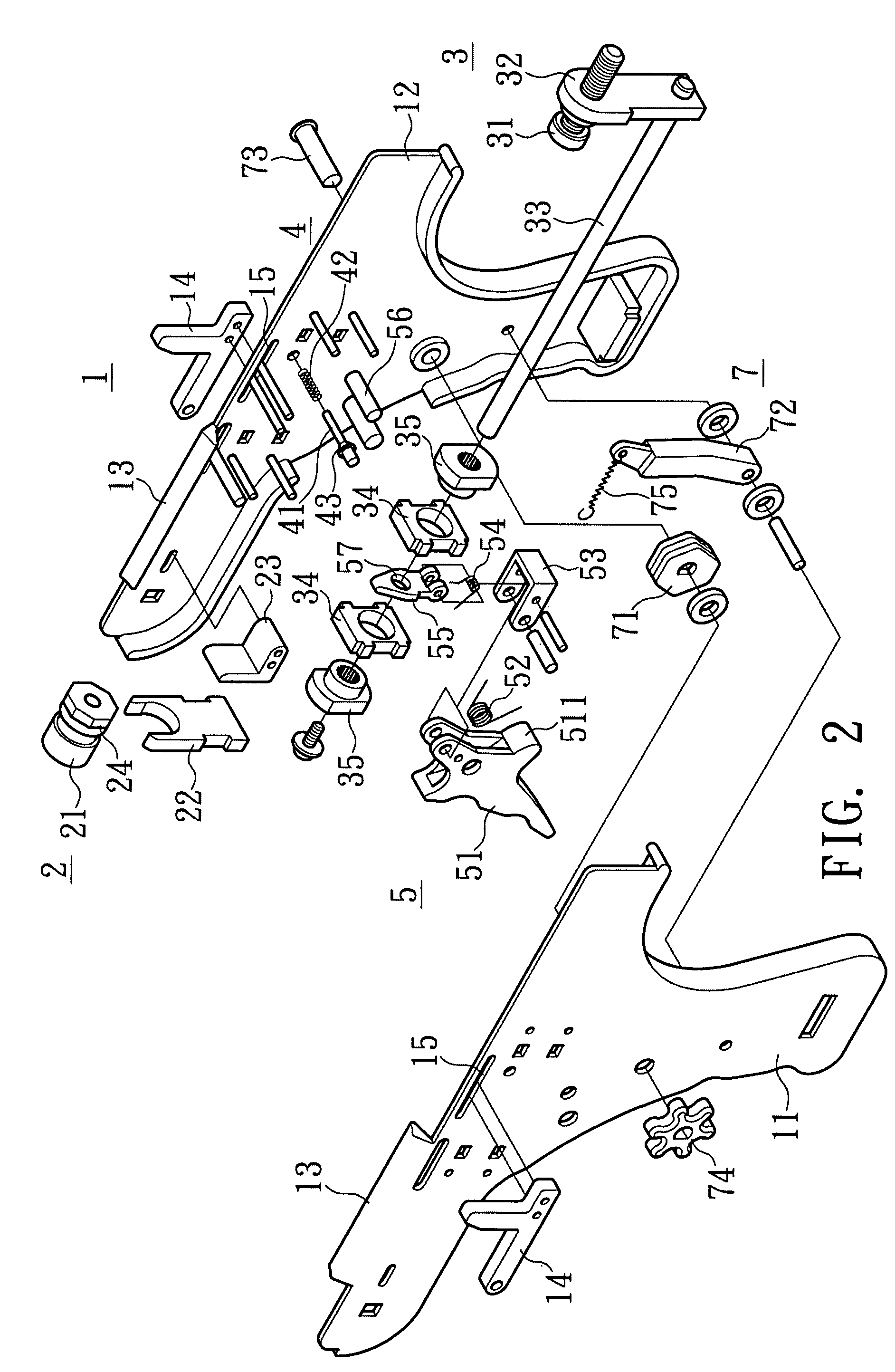

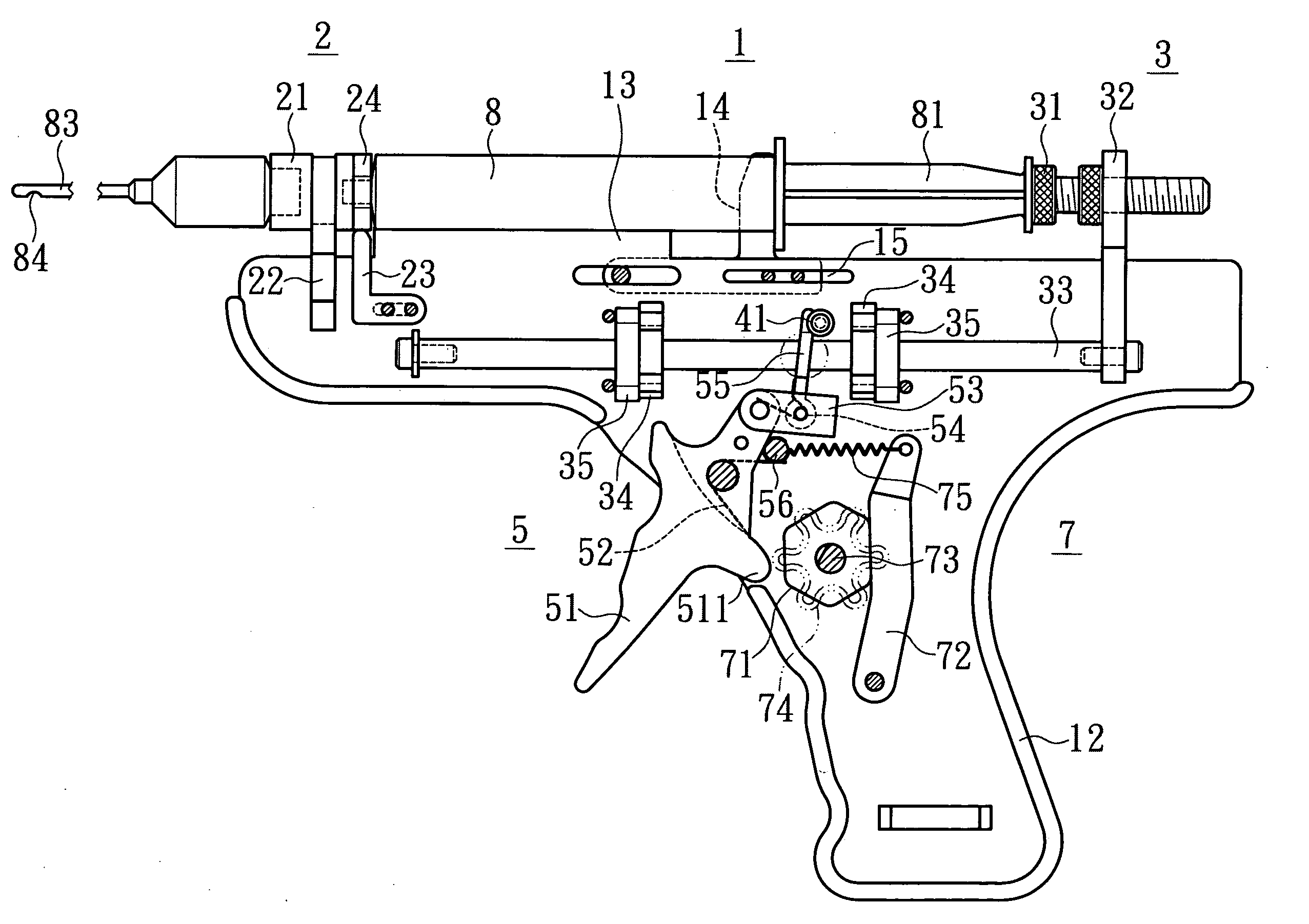

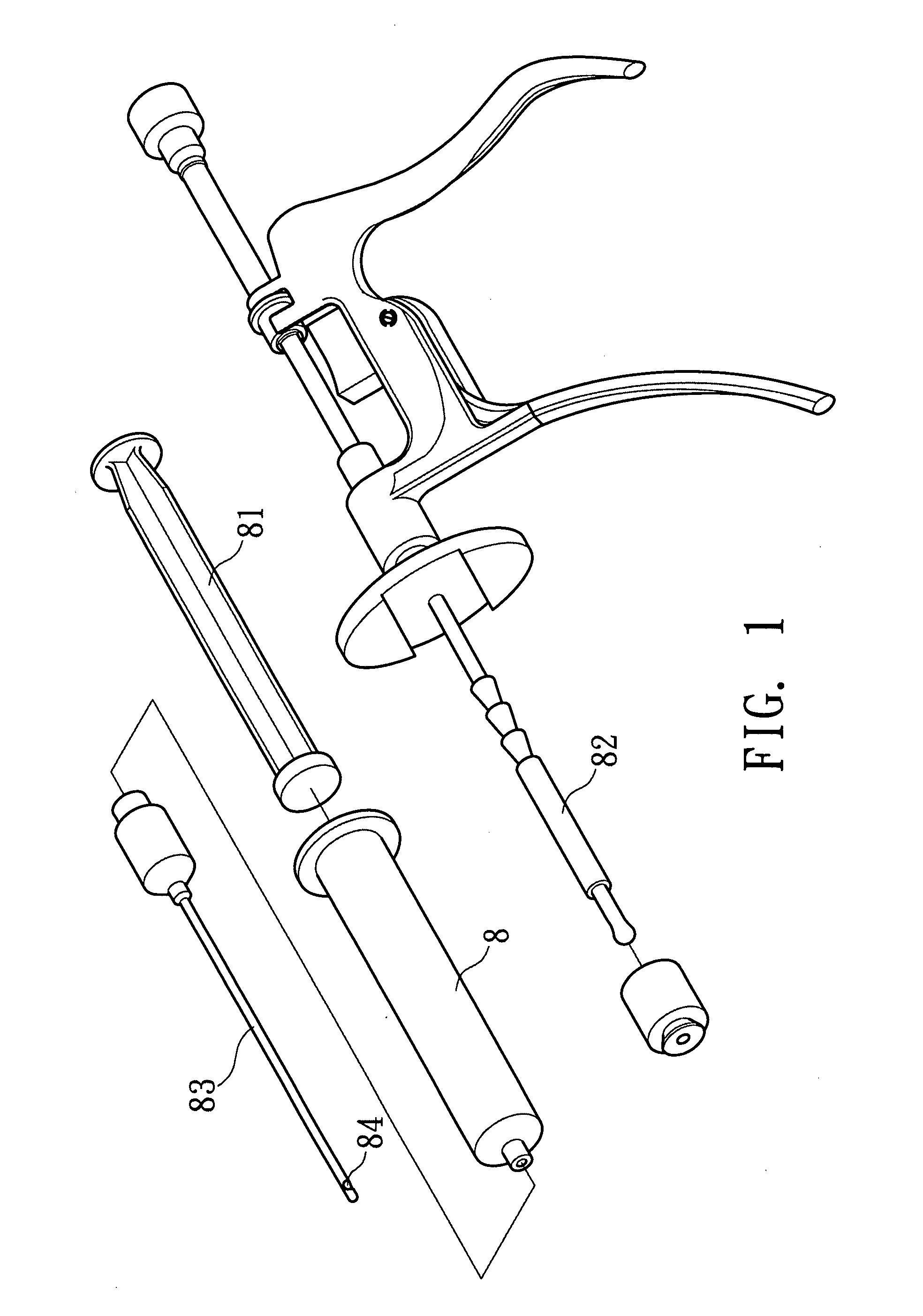

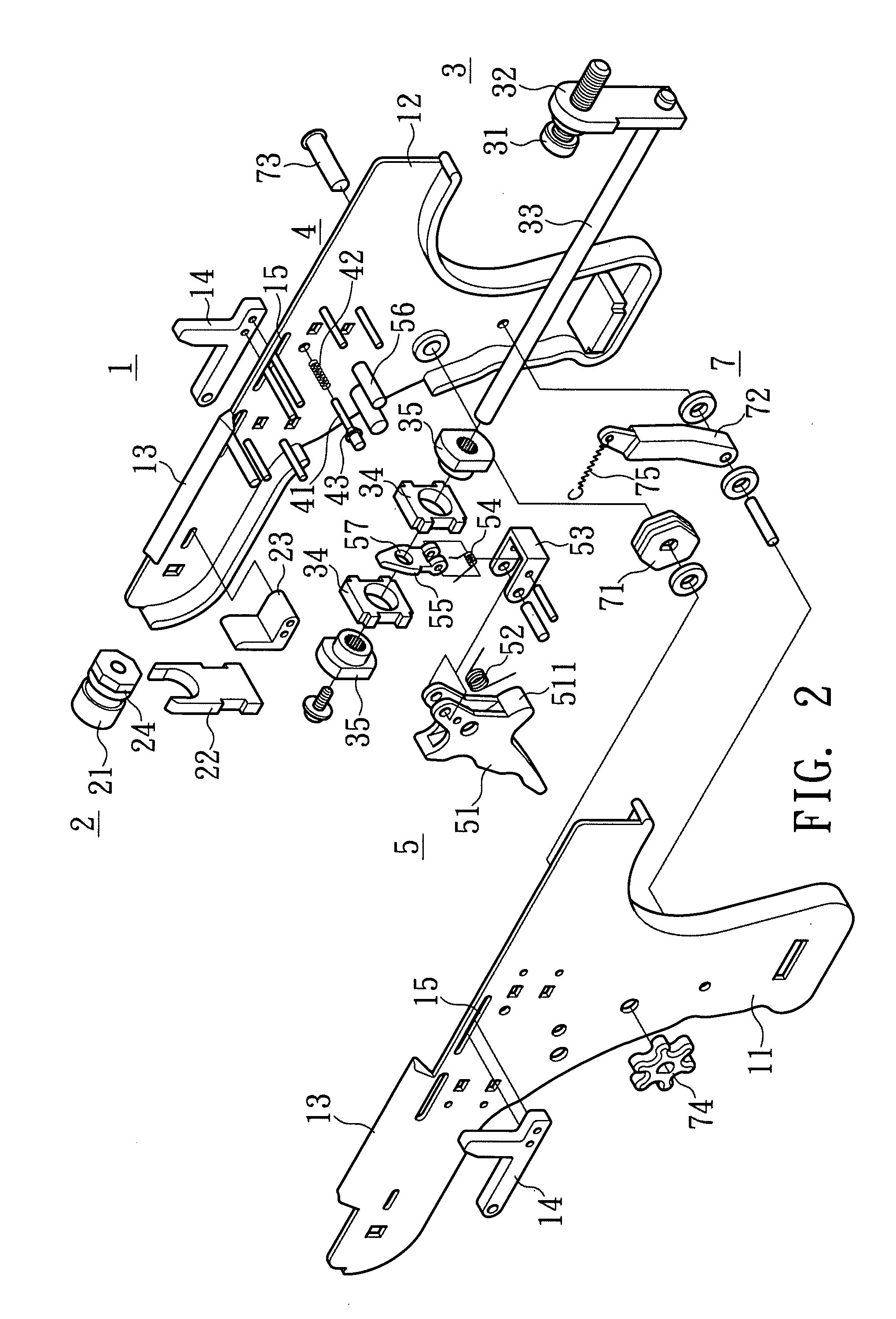

Volume adjustable, micro-injection device

ActiveUS7632251B2Easy to operateImprove accuracyAmpoule syringesMovable measuring chambersInjection volumeAir exposure

Owner:DERMATO PLASTICA BEAUTY DPB

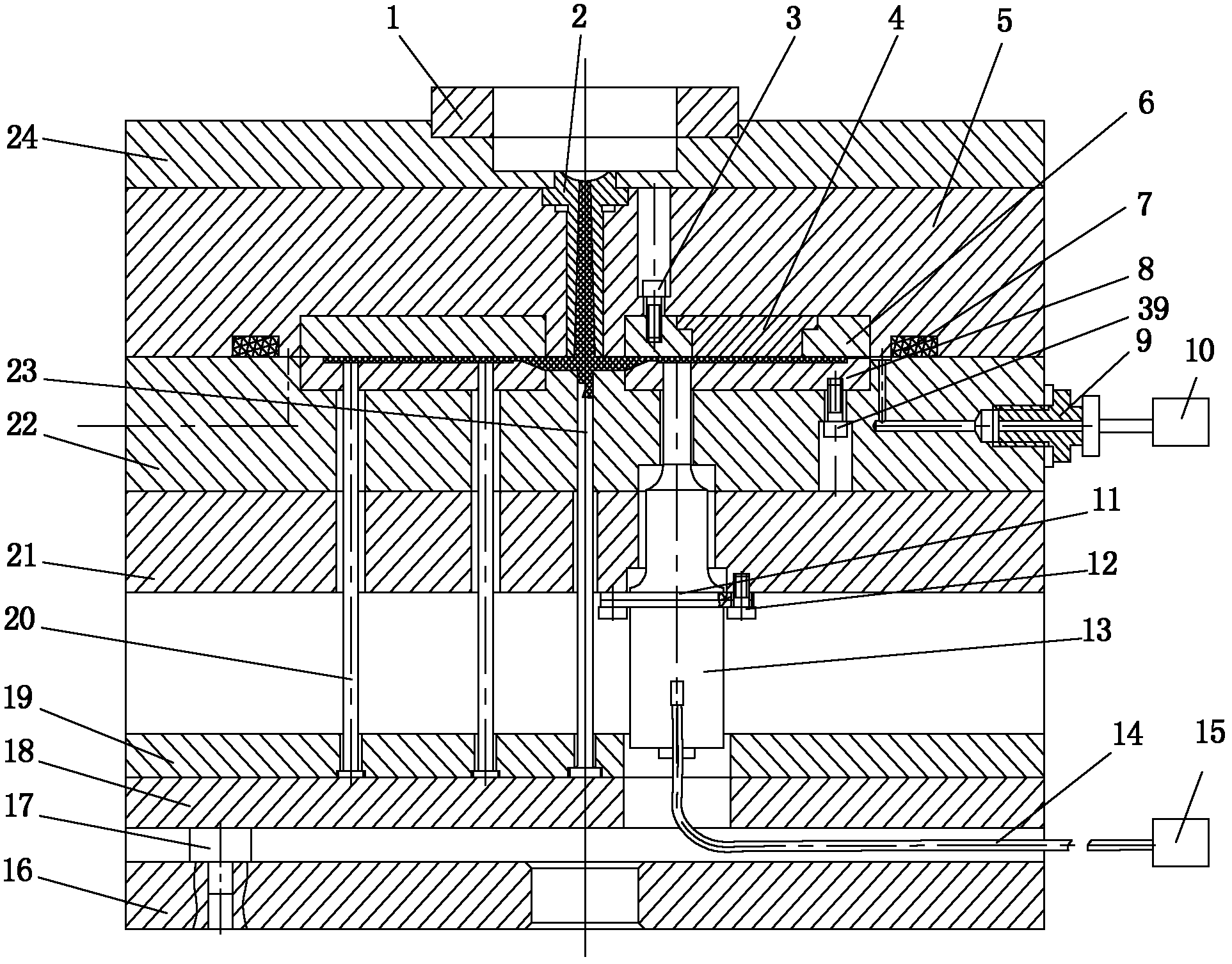

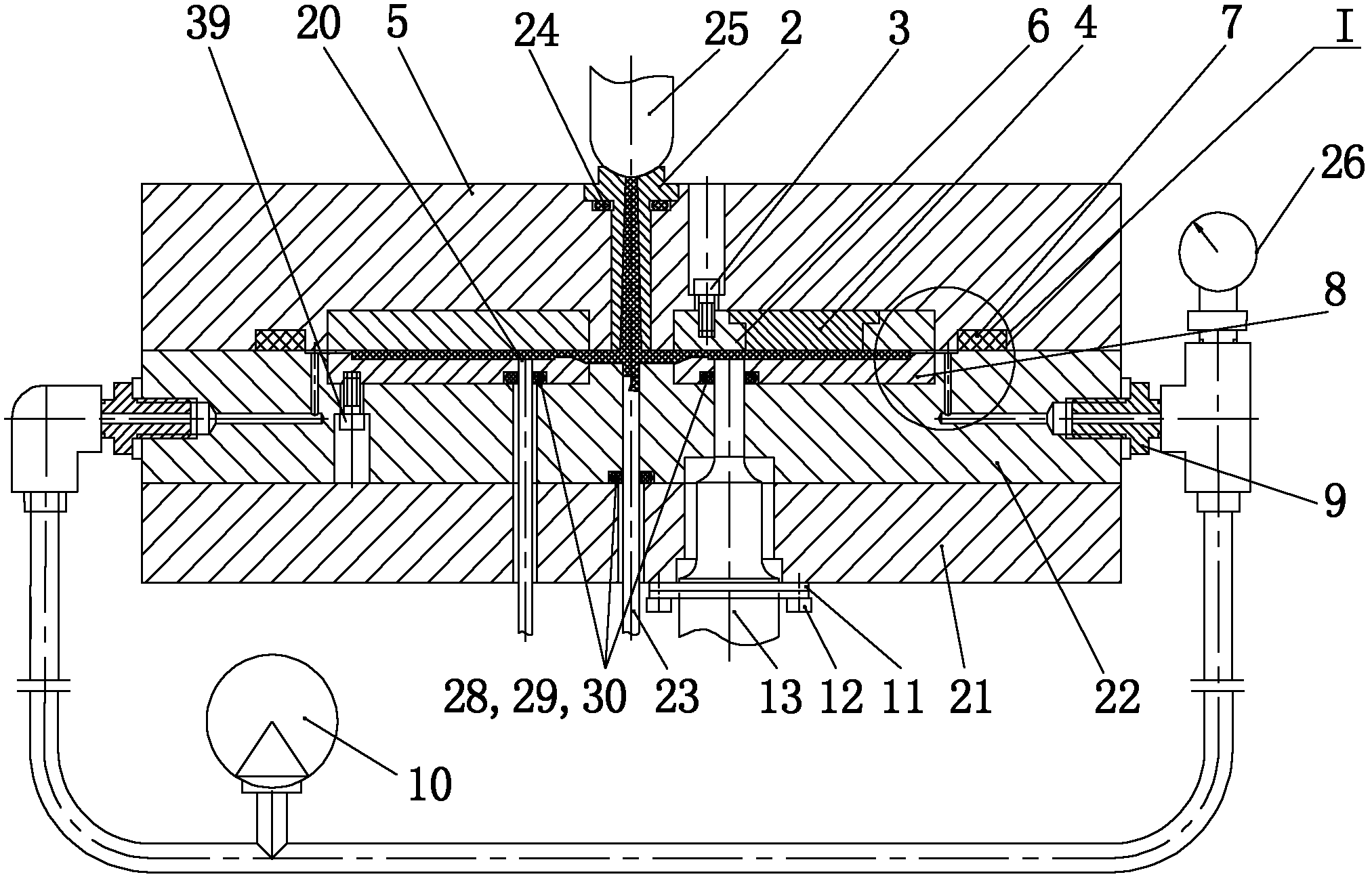

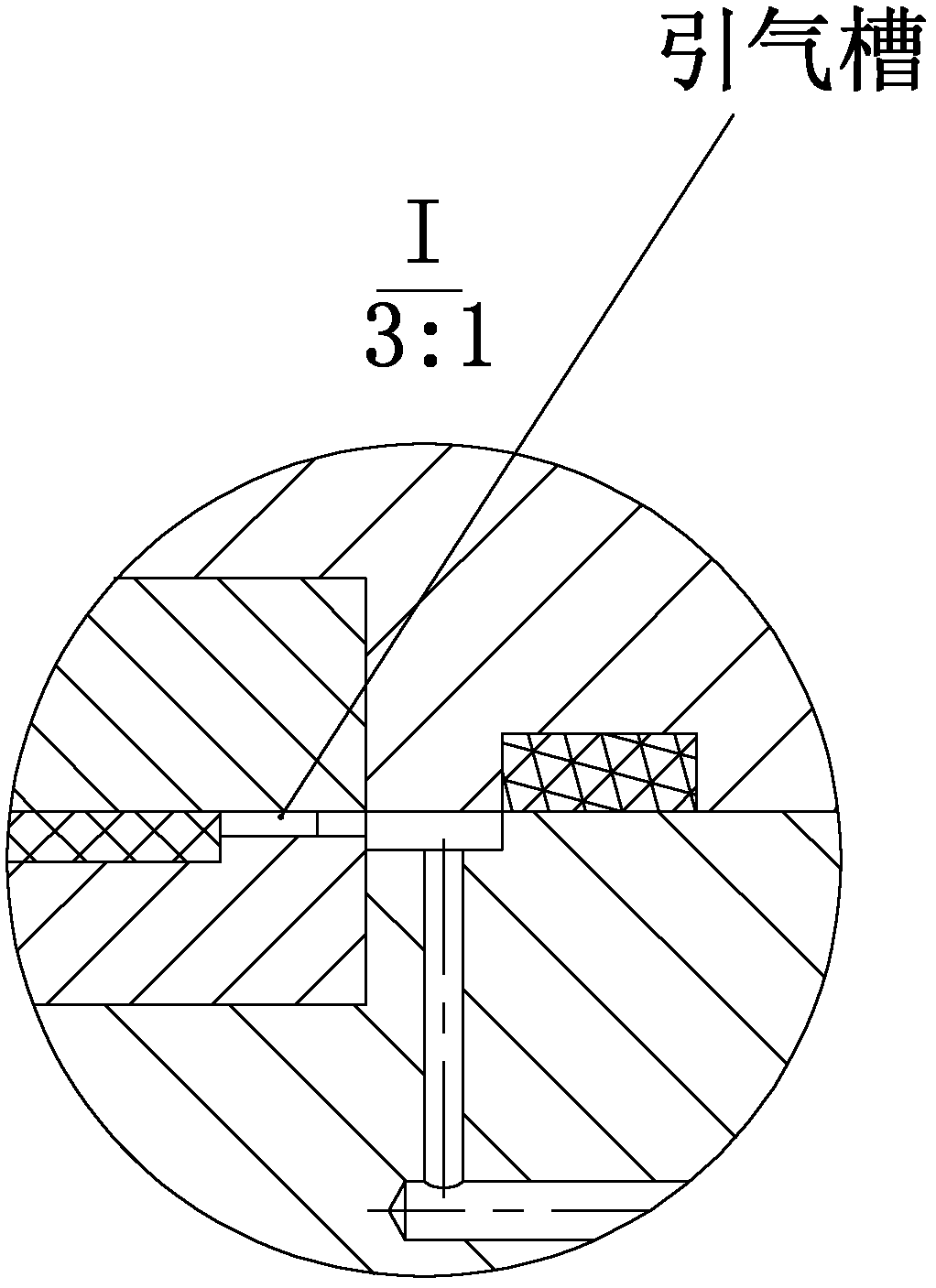

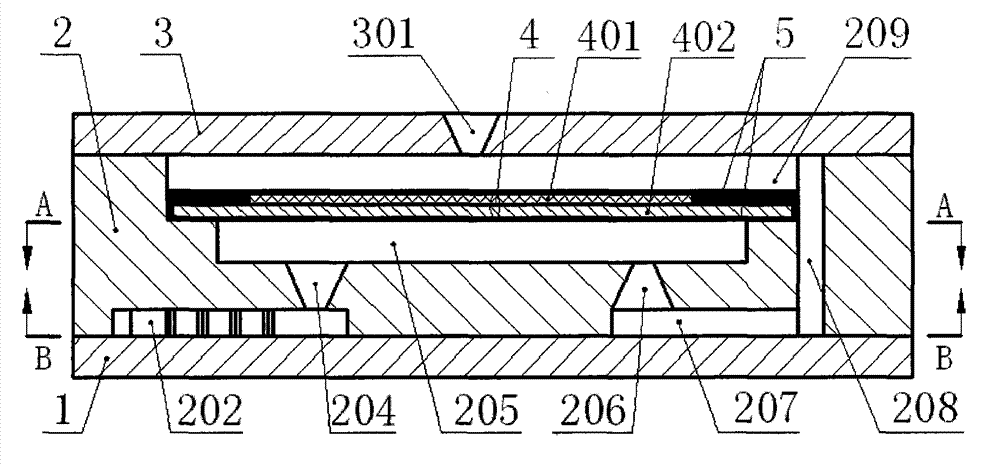

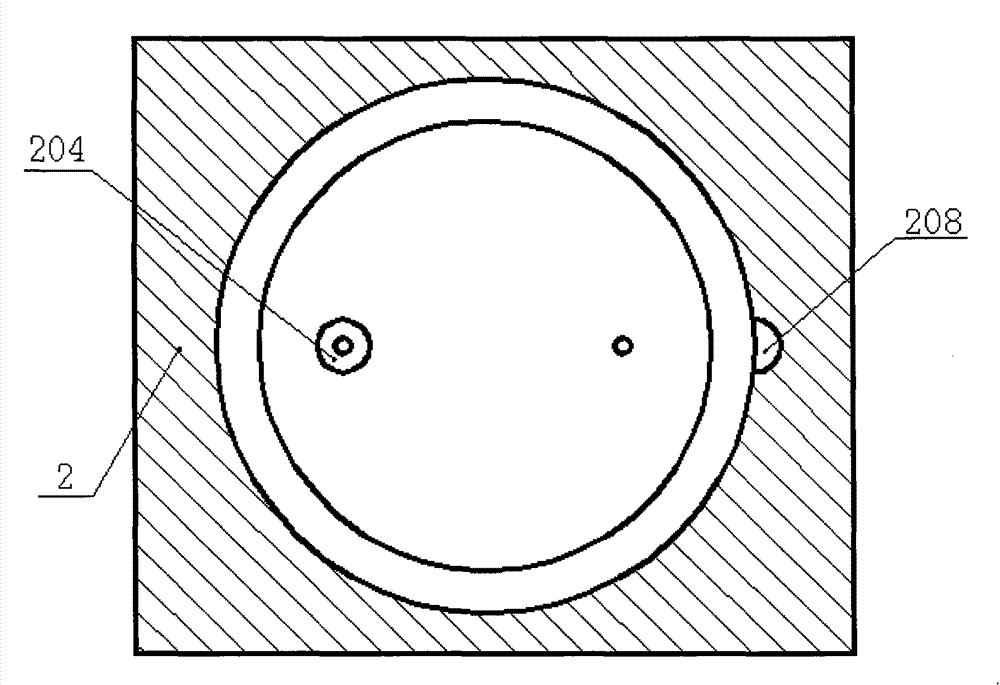

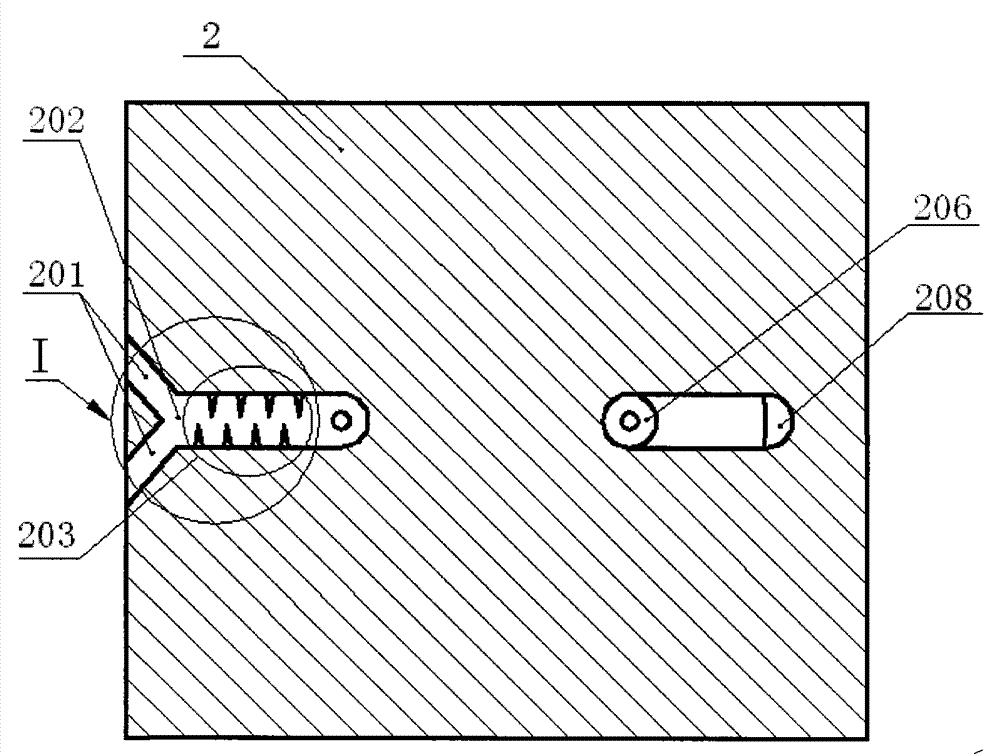

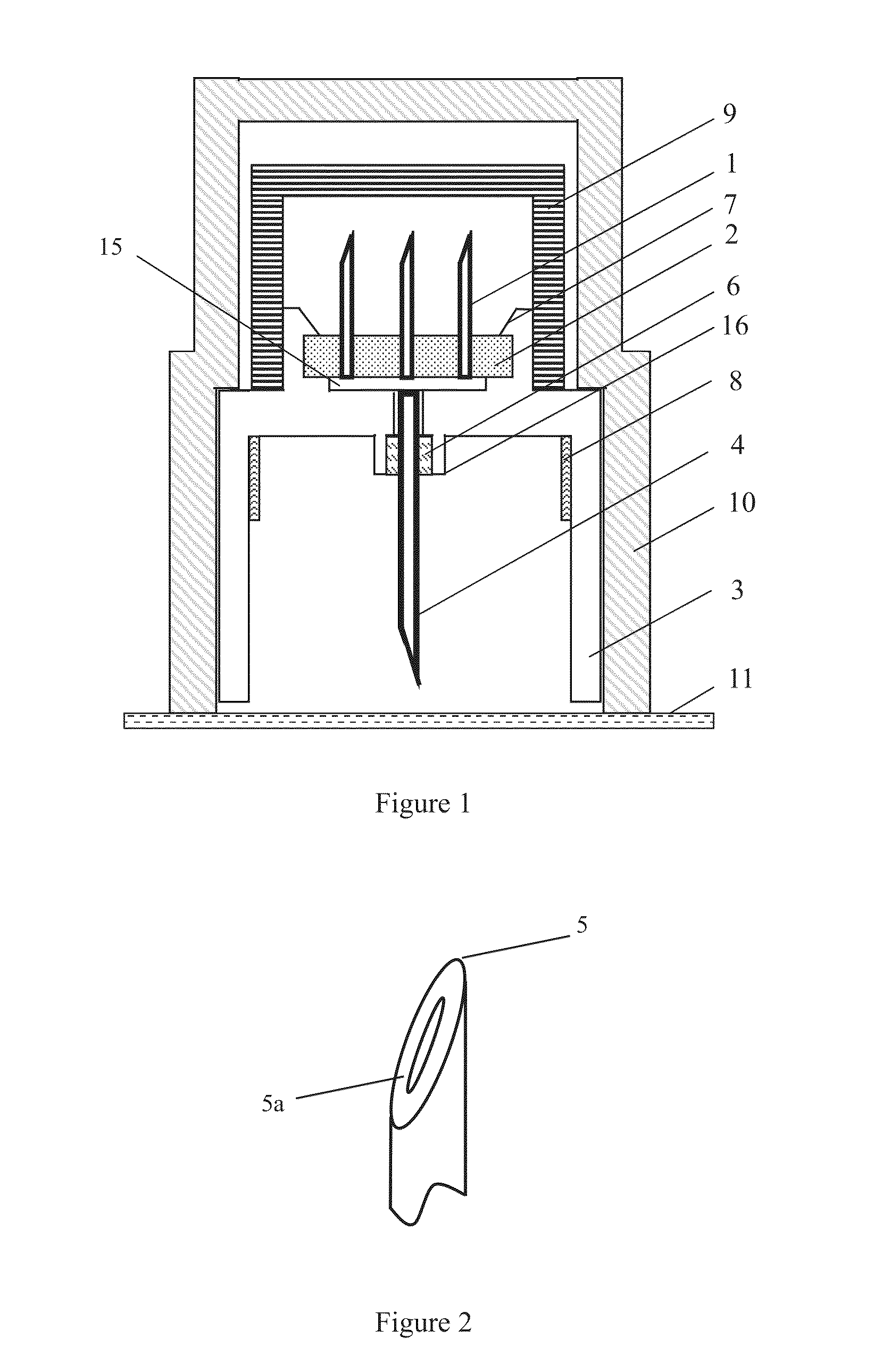

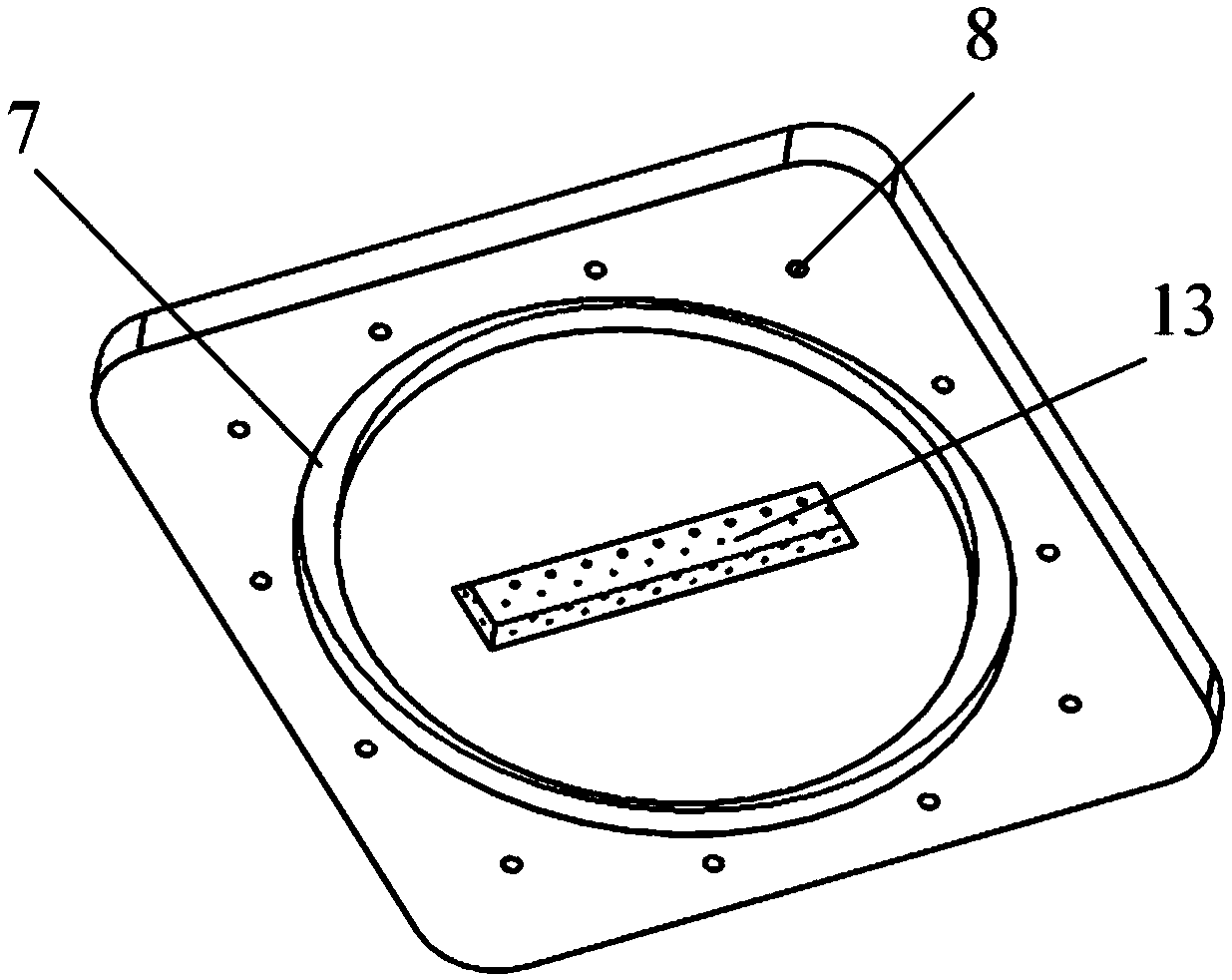

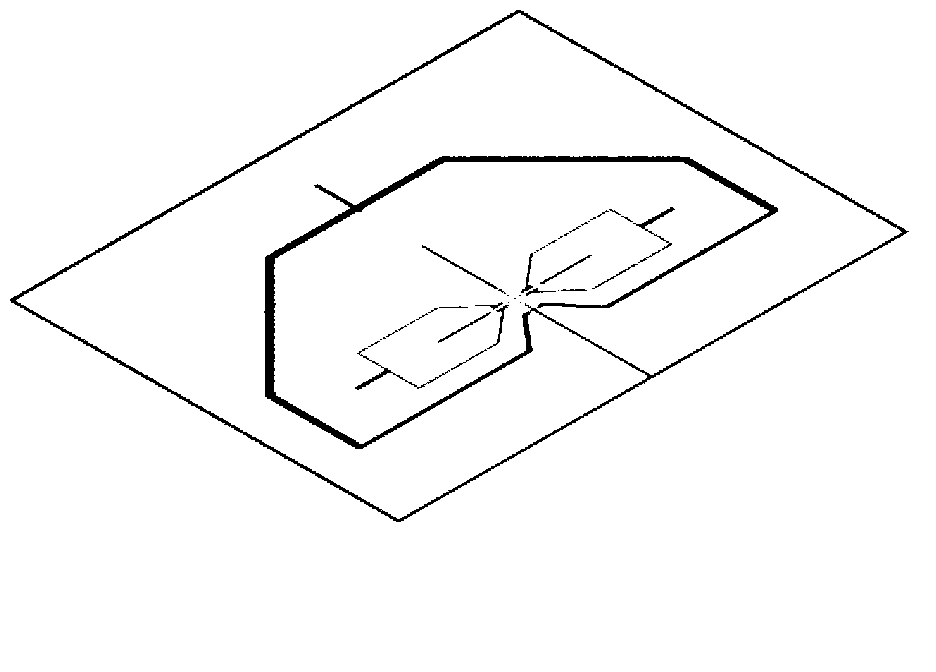

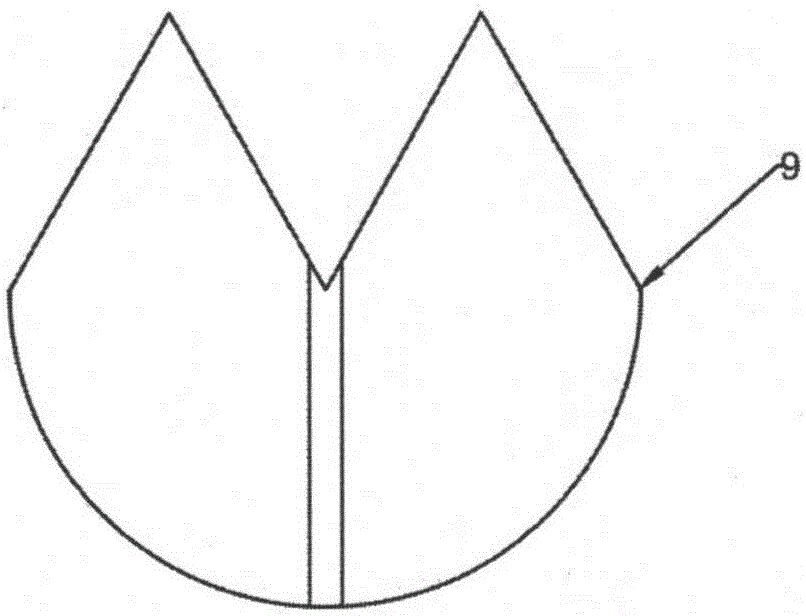

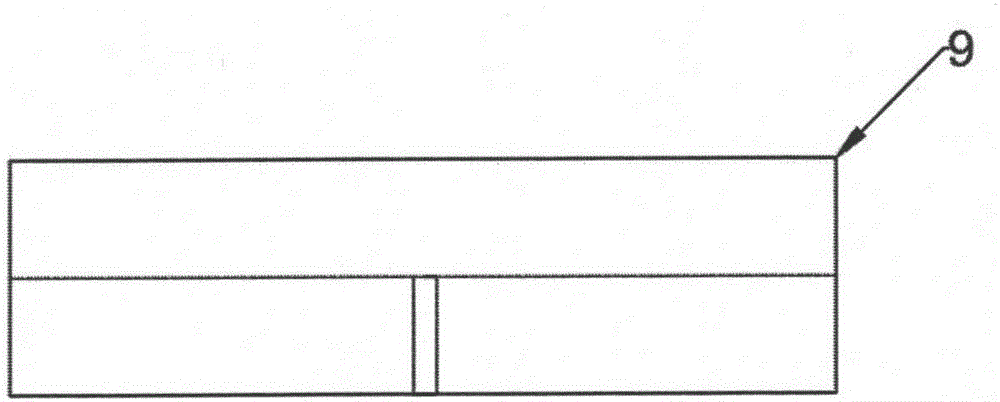

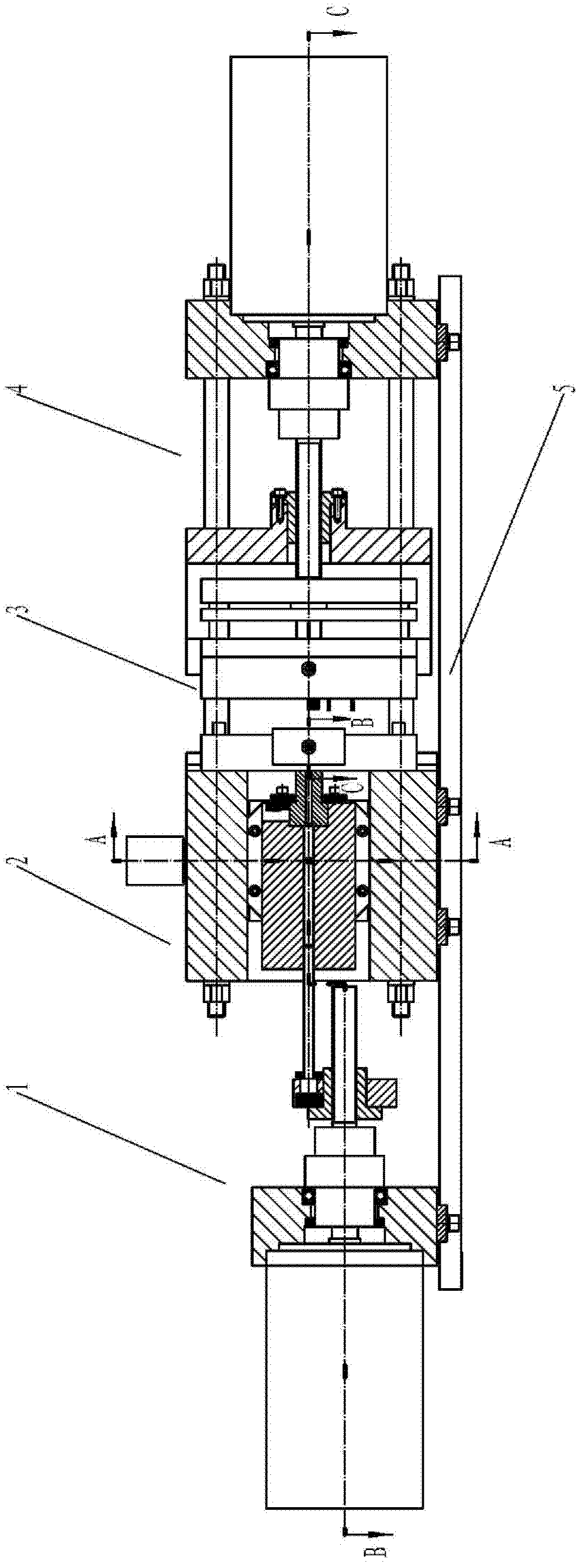

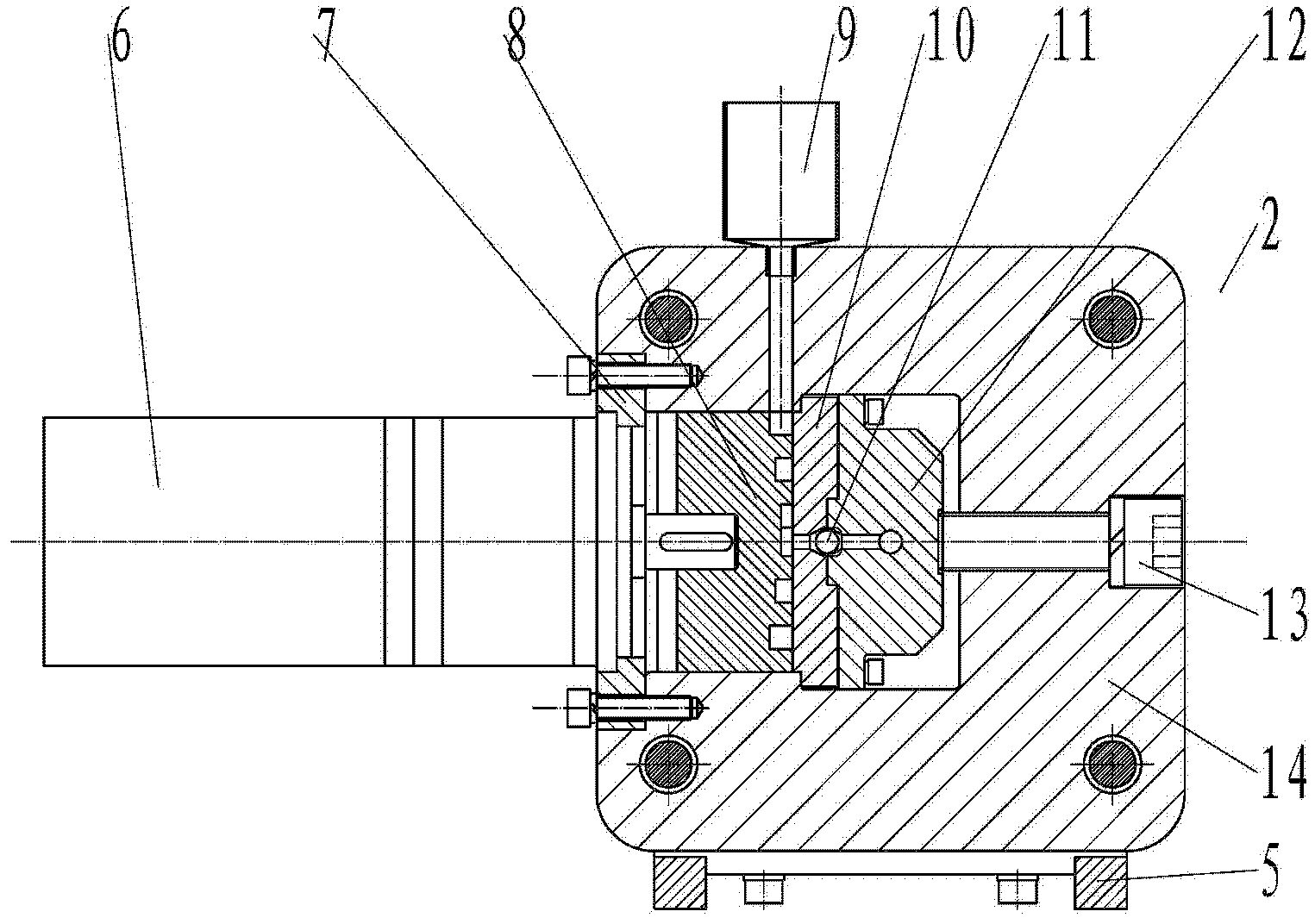

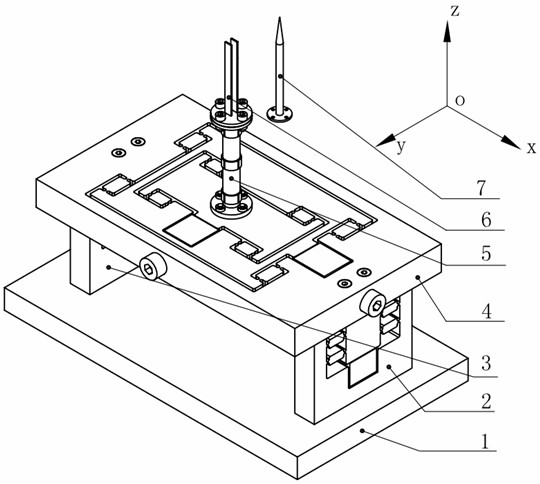

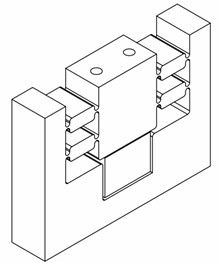

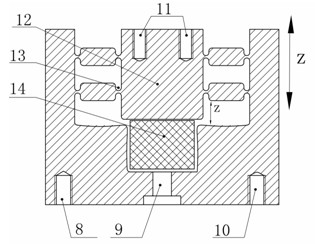

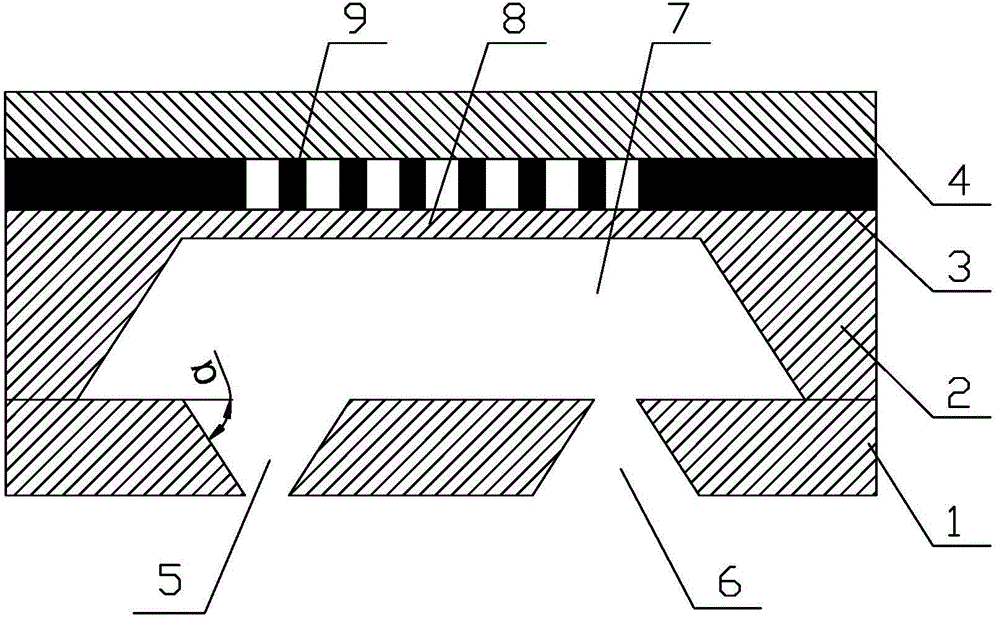

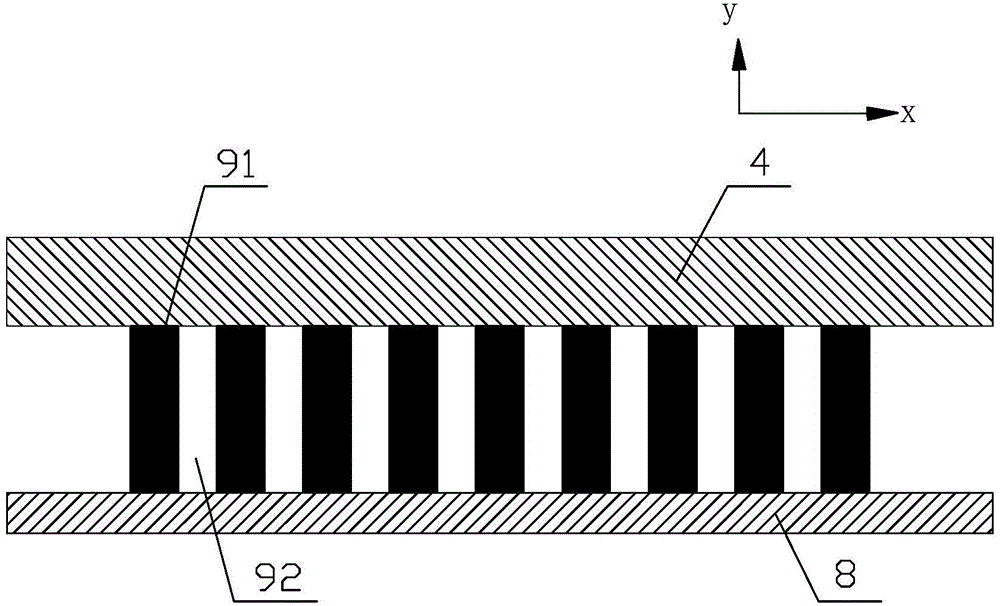

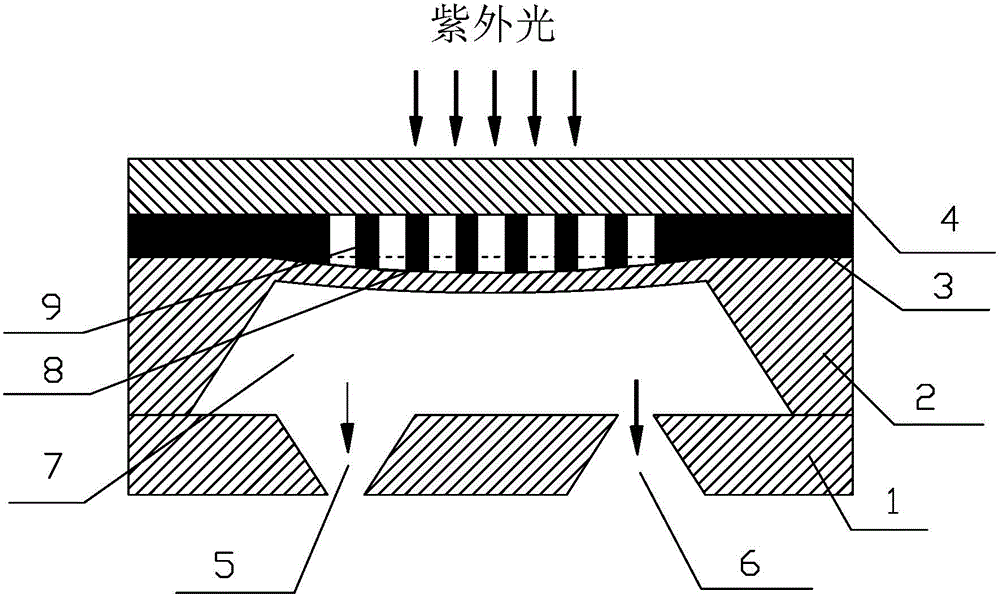

Ultrasonic vibration and vacuumizing integrated micro injection mold and molding method

The invention relates to an ultrasonic vibration and vacuumizing integrated micro injection mold and a molding method and belongs to the technical field of micro injection molding. An embedded structure with a replaceable molding micro-structure insert is adopted by the mold; a part of an end face of an ultrasonic vibrator for processing a molding chamber is capable of directly applying ultrasonic vibration to flux; at the moment of injection molding, a real-time signal in an injection molding machine is utilized to control the starting and stopping of an ultrasonic vibration system and a vacuumizing system; the adopted supersonic vibration frequency is 23-27KHz and the input power is 35-350W; and vacuum degree of the vacuumizing system is -1MPa. According to the molding method provided by the invention, the ultrasonic vibration and vacuum-exhausting are effectively integrated and are applied to the injection molding process of a micro molding piece; the technical conditions, such as limit injection molding pressure and temperature, adopted in the traditional micro injection molding, are avoided; the demand on capacity of the injection molding machine is reduced; energy source and cost are saved; the integrated automatic control for the injection molding machine, the ultrasonic vibration system and the vacuumizing system is realized; and the degree of automation and production efficiency of the micro injection molding process are increased.

Owner:DALIAN UNIV OF TECH

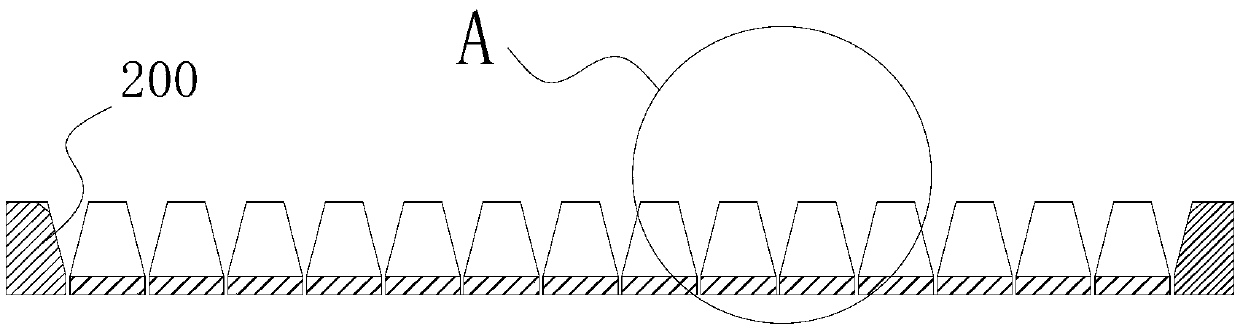

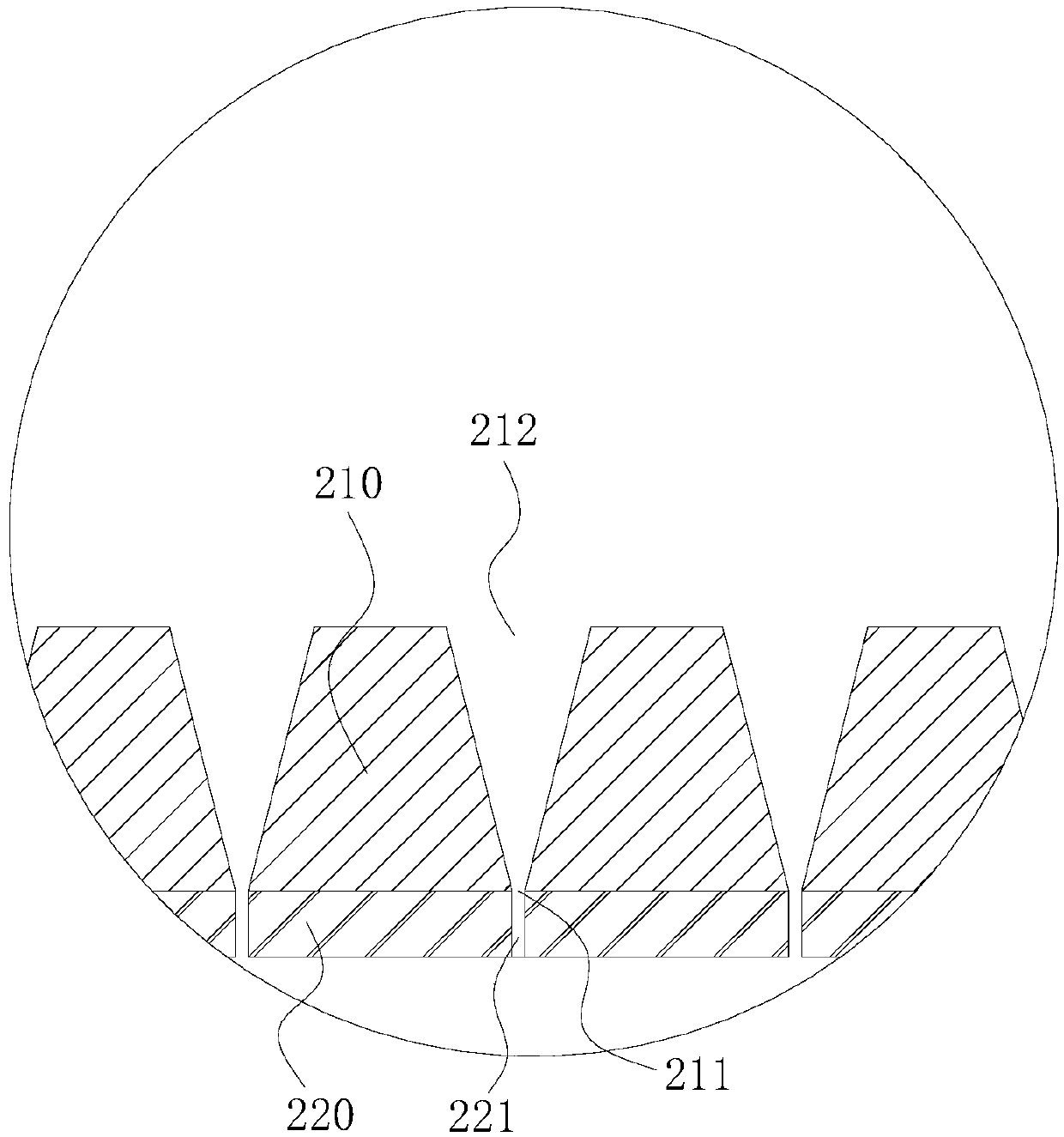

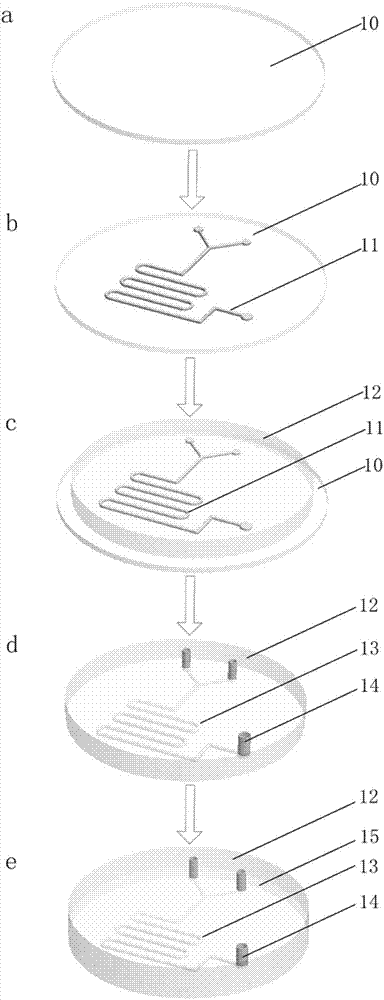

Micro needle chip and preparation method thereof

ActiveCN105498082ARapid perfusionEasy to prepareMicroneedlesMedical devicesCentrifugationProduct gas

The invention relates to a micro needle chip and a preparation method thereof. The preparation method of the micro needle chip comprises steps: flow injection liquids are injected into a female die, the female die is provided with a plurality of cavities which are adapted to the shapes of needle bodies of micro needle chips to form a cavity array, a plurality of injection inlets are arranged on a side surface of the female die, a plurality of exhaust ports are arranged on the other one surface of the female die to form an exhaust surface, a breathable film is covered on the exhaust surface of the female die, gas penetrates the breathable film and liquid is retained in the cavities when injecting, and the flow injection liquids are demolded after being solidified to form the micro needle chip. Because the exhaust ports and the breathable film are matched, the liquid can be hold back and the gas is discharged at the same time, the micro injection effect is excellent. The preparation method of the micro needle chip does not need processes such as centrifugation which are difficult to achieve in industrial manufacture and the like in technological process, also does not need to use technological means such as high pressure or high temperature with high industrialization cost and the like, has the advantages of simple and convenient operation and low cost, and is suitable for industrialization promotion and use.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

Volume adjustable, micro-injection device

ActiveUS20080269671A1Easy to operateImprove accuracyAmpoule syringesMovable measuring chambersAir exposureInjection volume

The present invention relates to a volume-adjustable micro-injection device. The device includes a base structure having a syringe positioning structure and a grip, in which the syringe positioning structure can flexibly accommodate injection syringes with different volumes; a holding structure capable of flexibly adjusting an injection angle of syringe content for easier operation; a qualitative controller capable of accurately controlling injection volume; a pressure pushing structure to hold and push a plunger; an injection controller interlinked with the qualitative controller and the pressure pushing structure; and an eject structure facilitating simple operation and easy replacement of injection syringes. In contrast to conventional structures, the present invention provides advantages that control injection volume more accurately, address better injection angle control, allow for the syringe contents to be free from air exposure, require no special syringes, and allow for single-handed replacement of the injection syringe.

Owner:DERMATO PLASTICA BEAUTY DPB

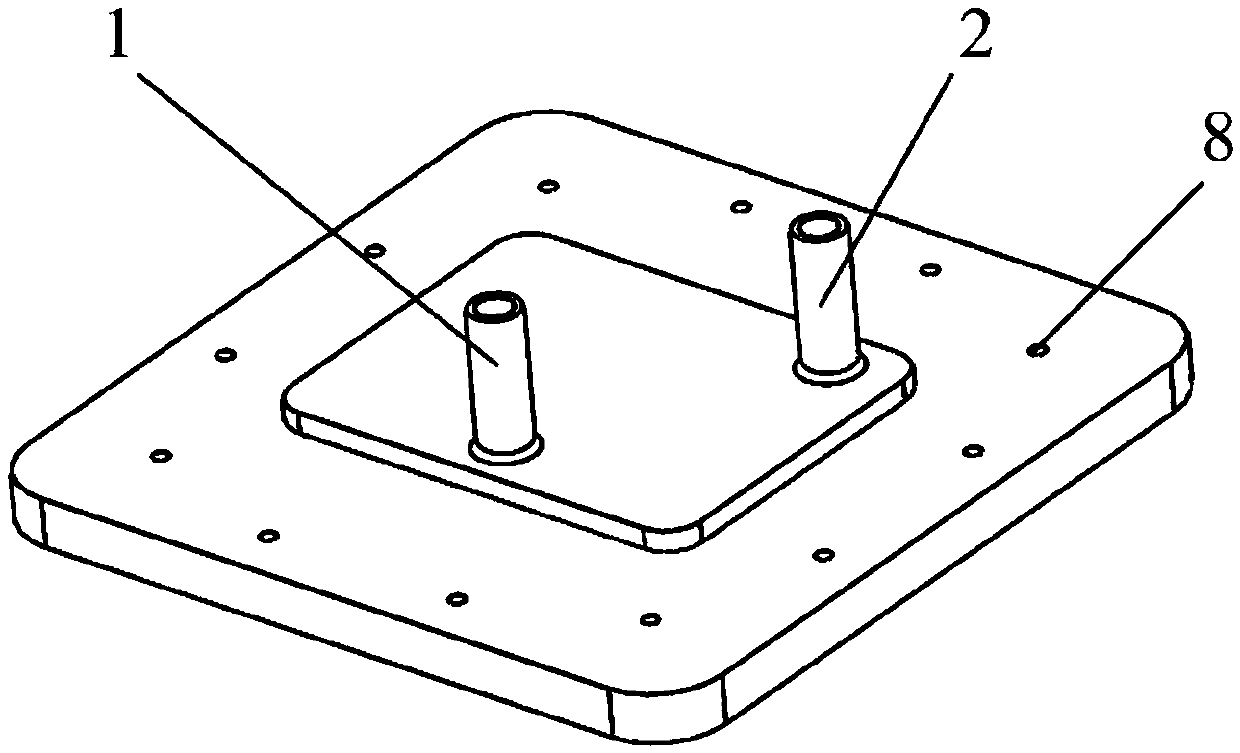

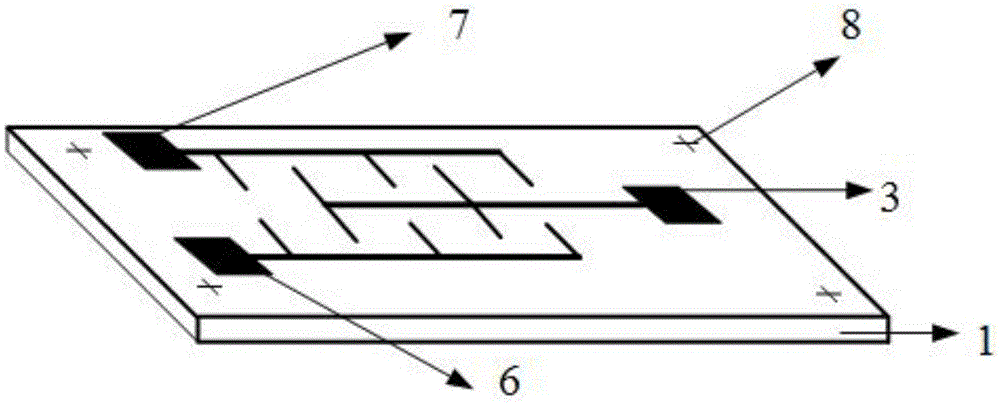

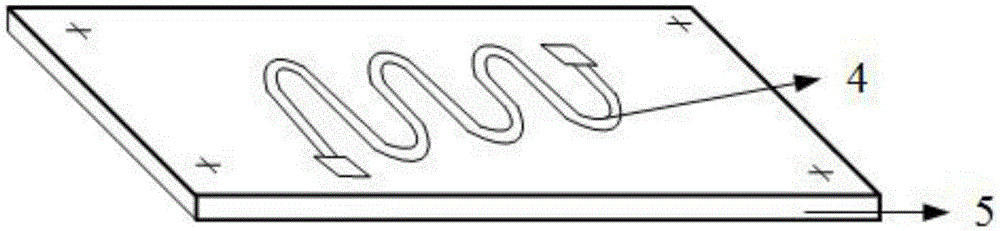

Novel piezoelectric driving microfluid mixer and preparation technology thereof

InactiveCN103768985ASubstantial noveltyWell mixedPrecision positioning equipmentSoldering apparatusElectricityHigh volume manufacturing

The invention belongs to the technical field of microfluid control and in particular relates to a novel piezoelectric driving microfluid mixer and a preparation technology thereof. The microfluid mixer consists of a base body, a base plate, a top plate and a circular piezoelectric vibrator, wherein the base body comprises an inlet, an inlet cavity, a passive mixing unit, a conical inlet end opening, a lower pump cavity, a conical series end opening, a horizontal series channel, a vertical series channel and an upper pump cavity. According to the novel piezoelectric driving microfluid mixer, the upper pump cavity and the lower pump cavity form a serially connected structure and share the circular piezoelectric vibrator; the passive mixing unit consists of a plurality of groups of staggered tri-prism bulges. The novel piezoelectric driving microfluid mixer has the main advantages that a main mixing function and a pumping function for fluid are structurally combined together, and the pumping process of microfluid is also the full mixing process of microfluid; due to the serially connected pump structure, the pumping flow and the pumping pressure are obviously increased; the main structure is prepared by a micro injection molding technology for a thermoplastic polymer material; the novel piezoelectric driving microfluid mixer has the characteristics of low cost, high biological compatibility, suitability for batch production and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

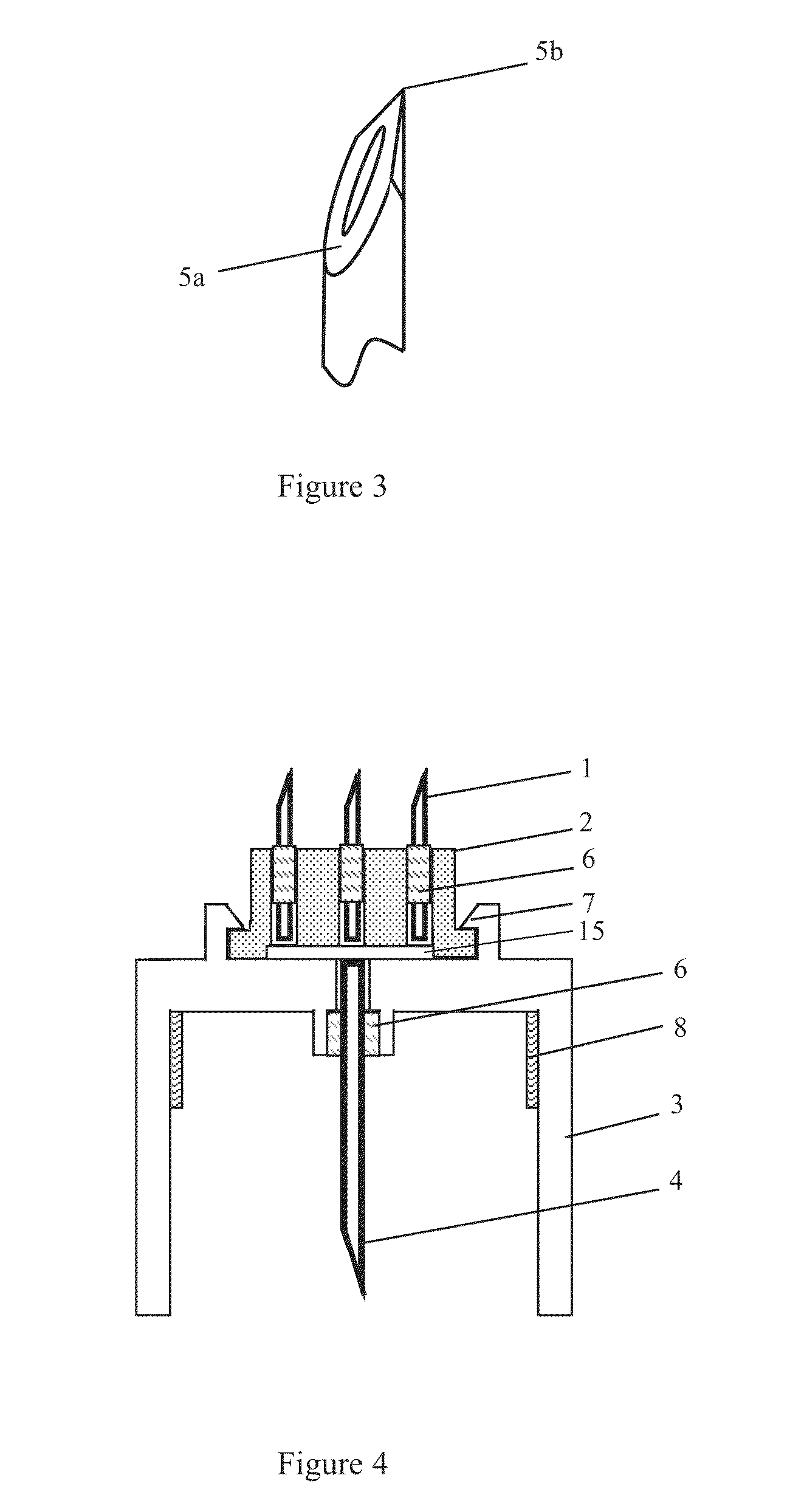

Disposable Array-Type Micro Injection Needle Head And Pre-Filling Injector Thereof

ActiveUS20140257190A1Avoiding muscle injectionCompact structureMicroneedlesMedical devicesTreatment effectPrefilled Syringe

The invention discloses a disposable array-type micro injection needle head which comprises a lower needle seat which is configured as a cylindrical column opening at one end and having a top cap at the other end and which is configured to be connected with an injection reservoir; an upper needle seat which is located above the top cap of the lower needle seat with a cavity formed between the upper needle seat and the top cap; a through-hole formed in the top cap which is configured for communicating the cylindrical column with the cavity, wherein a pipetting needle is mounted in the through-hole which has one end communicated with the cavity and the other end located in the cylindrical column and which is configured for extracting injection from the injection reservoir into the cavity; and at least two needle tubes mounted in the upper needle seat, each of which has one end comprising a needle tip for puncturing and for injecting the injection and the other end for mounting on the upper needle seat and for communicating with the cavity. The needle head can be used directly on existing insulin pen, or the cylindrical column can be provided inside it with an injection reservoir to form a disposable prefilled syringe. By using a plurality of thin, short needle tubes for injecting simultaneously, vertical hypodermic injection of medicines such as insulin can be preformed rapidly, leakproof, painlessly, safely and conveniently at various sites of a human body, without needing to pinch skin, while a potential trouble that the medicines be injected into muscles can be avoided. Patient adherence to the treatment regimen and the treatment effect are improved.

Owner:TSINGHUA UNIV

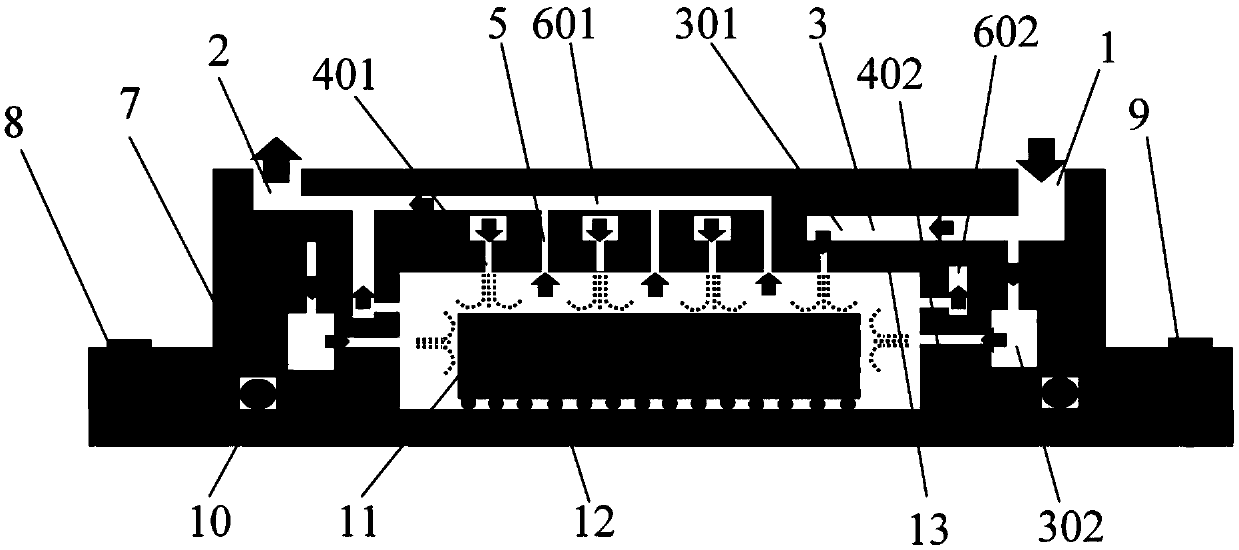

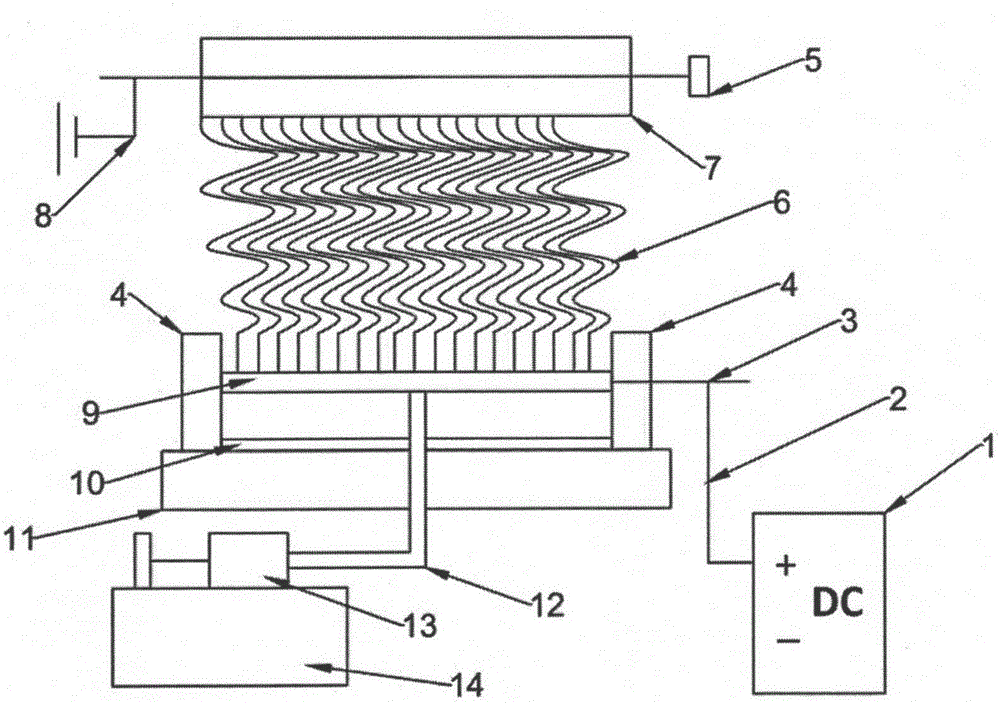

Submerged jet micro-injection direct liquid cooling heat dissipating device

ActiveCN109637987AReduce mutual interferenceThe cooling effect is weakDigital data processing detailsSemiconductor/solid-state device detailsJet flowDirect liquid cooling

The invention belongs to the field of heat dissipation of electronic devices, and discloses a submerged jet micro-injection direct liquid cooling heat dissipating device, wherein the bottom of the heat dissipating device is provided with a first groove to form a sealed space with the circuit board of an object to be cooled, a second groove is arranged in the first groove for placing the object tobe cooled, the coolant enters from the inlet pipe to the nozzle through the liquid separation cavity, and the coolant sprays from the nozzle on the surface of the object to be cooled; the coolant enters from the liquid pumping hole into the outlet pipe through the collecting cavity, and then flows out from the outlet pipe, thereby realizing the collection of the cooling liquid; a plurality of nozzles and a liquid pumping hole are disposed on each surface of the second groove, the liquid pumping hole is arranged on a center line extension line of the connection of the two nozzles, and the liquid pumping hole is higher than the nozzles to avoid interference on the coolant sprayed from adjacent nozzles. Through the invention, the heat dissipation area of the chip is effectively improved, thetemperature of the chip is lowered, and the uniformity of the temperature of the chip is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

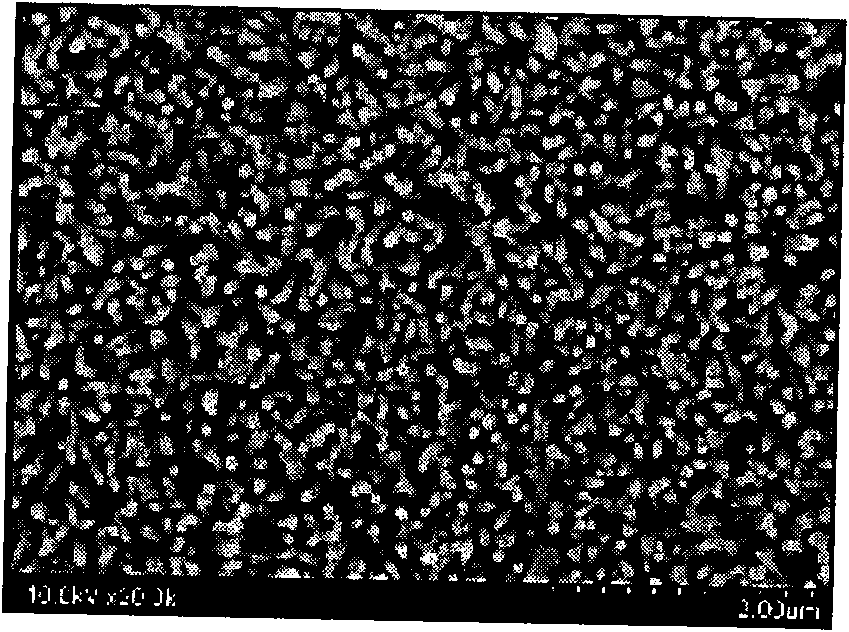

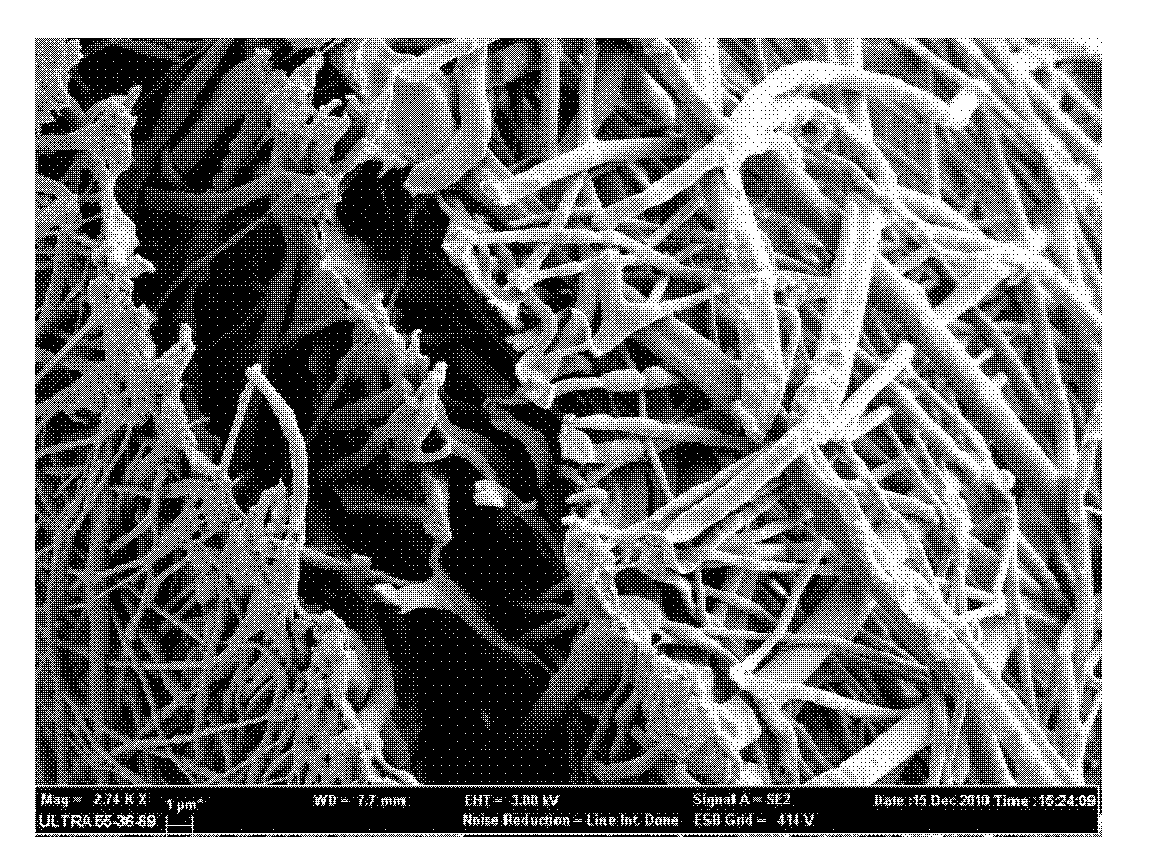

Preparation method of micro-channel vertical-growth TiO2-clading ZnO nano rod array

InactiveCN101774537ALarge specific surface areaAvoid reunionNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsAlcoholAmmonium hydroxide

Owner:DONGHUA UNIV

Method and dedicated chip for preparation of micron calcium alginate filament based on microfluidic chip

ActiveCN102974410AStable and uniform formationControllable arrangementProductsReagentsControl systemCalcium alginate

The present invention provides a method and a dedicated chip for preparation of micron calcium alginate filaments based on a microfluidic chip. By using the chip and the method, calcium alginate microfilament with a minimum diameter of 20 [mu]m can be prepared, calcium alginate microfilaments interiorly including a dispersed phase of spherical structure of other materials can be prepared, and calcium alginate microfilaments with special morphology can be prepared. By using an independent fluid path and a gas path control system of the microfluidic chip, combined with a micro-injection pump and a gas pump valve system, the diameter of the calcium alginate microfilaments can be controlled; the material dispersed phase with the special structure in the microfilaments, including pitch, size, composition and sequence, can be highly-controlled arranged; and the special structure of the filaments can be adjusted. The method and the platform provided by the present invention can highly-controlled prepare calcium alginate filaments, the preparation process is stable, and morphology of the product is homogeneous, and the method is simple.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Linear tank-shaped needleless electrostatic spinning device and spinning method

InactiveCN106048749ARealize automatic and precise supplyRealize industrial preparationFilament/thread formingFiberCollection system

The invention relates to a linear tank-shaped needleless electrostatic spinning device and a spinning method. The device comprises a solution supply system, a spray head system, a solution recycling device and a nanofiber collection system. The solution supply system supplies a solution by controlling an injector through a micro-injection pump; spray heads are linear tank-shaped copper bars; the solution recycling device is a solution tank with the equal length as the copper bar spray heads; the nanofiber collection system is a grounded cylindrical metal roller driven by an adjustable-speed motor. According to the device, the high polymer solution can be automatically and precisely supplied by adopting the micro-injection pump solution supply system; through the linear tank-shaped spray head structure, the problems that when a traditional single needle is adopted, the solution is prone to block, and the nanofiber yield is low are avoided, the purpose of simultaneously forming multiple pieces of jet flow can be achieved, the nanofiber yield in unit time is greatly increased, continuous nanofiber preparation is achieved, and an industrial nanofiber production prospect is achieved.

Owner:DONGHUA UNIV +1

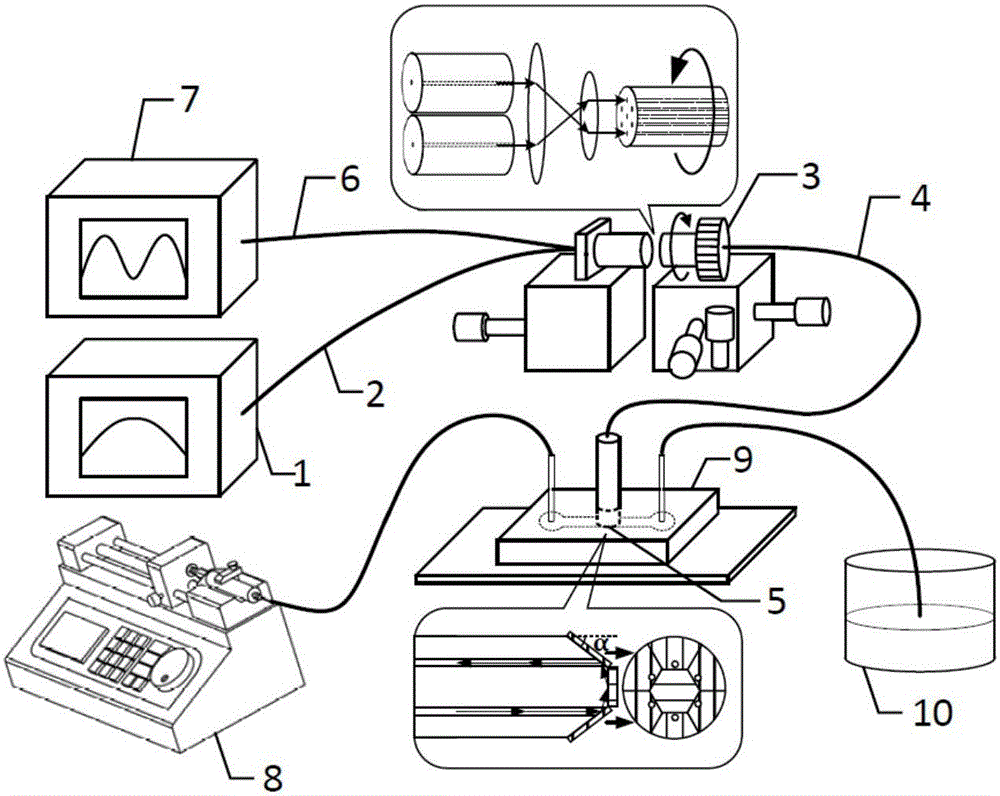

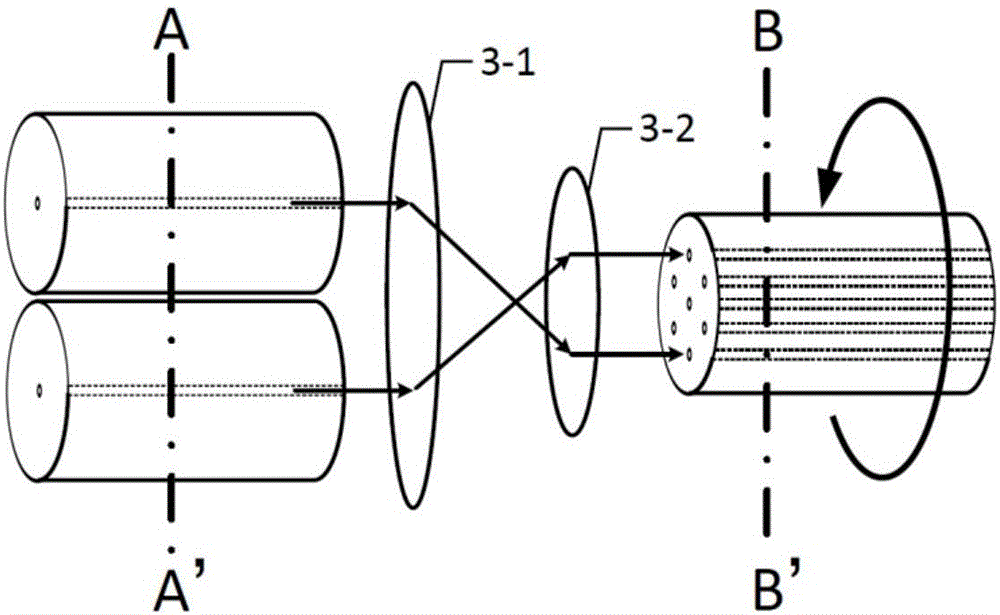

Three-channel SPR (surface plasma resonance) sensor based on seven-core optical fiber

ActiveCN106596474AAdjustable grinding angleAvoid overlapping, difficult to identify problemsPhase-affecting property measurementsFiberSpectrometer

The invention provides a three-channel SPR (surface plasma resonance) sensor based on a seven-core optical fiber. The three-channel SPR sensor comprises a supercontinuum light source, a light injection optical fiber, a seven-core optical fiber coupling device, the seven-core optical fiber, a seven-core optical fiber SPR sensing probe, a receiving optical fiber, a spectrometer, a micro-injection pump, a microfluidic chip and a waste fluid pool, wherein source light is fed into the light injection optical fiber and is then injected into a light injection core of a pair of symmetrical cores of the seven-core optical fiber; switching between three groups of symmetrical fiber cores of the seven-core optical fiber can be realized by a precision rotator of the coupling device; light is subjected to three times of total reflection at symmetrical cone angle structures of the SPR probe at an end part of the seven-core optical fiber and subjected to SPR; reflected light of the probe enters a reflection core of the group of fiber cores, enters the receiving optical fiber through the coupling device and is fed into the spectrometer, an echo attenuation spectrum is collected, a to-be-detected solution is injected into the microfluidic chip by the micro-injection pump, and a waste fluid obtained after measurement flows into the waste fluid pool. The three-channel SPR sensor based on the seven-core optical fiber can realize multi-channel detection and can solve the problem about simultaneous detection of multiple analytes in a mixture in the same sensing area. An SPR segmented detection technology is realized by three groups of cone angle structures with different grinding angles of the seven-core optical fiber, and ultrasensitive SPR segmented optical fiber sensor can be constructed and has very good application prospect in the fields of biology, chemistry and medical treatment.

Owner:CHONGQING THREE GORGES UNIV

Polymer micro-fluidic chip and preparation method thereof

InactiveCN105548315AAvoid uniformityAvoid continuityDecorative surface effectsChemical vapor deposition coatingAntigenPolymer science

The invention discloses a polymer micro-fluidic chip and a preparation method thereof. The preparation method comprises the following steps: providing a first polymer substrate, wherein an electrode is arranged on a first surface of the first polymer substrate in a raised form; adopting a UV-LIGA technique for preparing and forming a micro-channel mould, and then utilizing the micro-channel mould to prepare a second polymer substrate including a micro-channel by a micro-injection mode, wherein the micro-channel is concaved on a second surface of the second polymer substrate; and sealing the first and second surfaces, causing the electrode to be at least locally exposed in the micro-channel and realizing the packaging of the polymer micro-fluidic chip. According to the invention, the UV-LIGA technique is adopted for preparing the micro-fluidic detection chip based on the polymer substrate; the high-efficient preparation for the high-precision high aspect ratio micro-fluidic chip structure can be realized; the technique is simple and the cost is low; the polymer micro-fluidic chip can be easily produced in batches and has a huge market application potential; and the acquired polymer micro-fluidic chip is used for detecting the trace matters, such as, detecting the trace heavy metal ions, antigens and antibody organisms in water.

Owner:SUZHOU FUYI ELECTRONICS TECH CO LTD

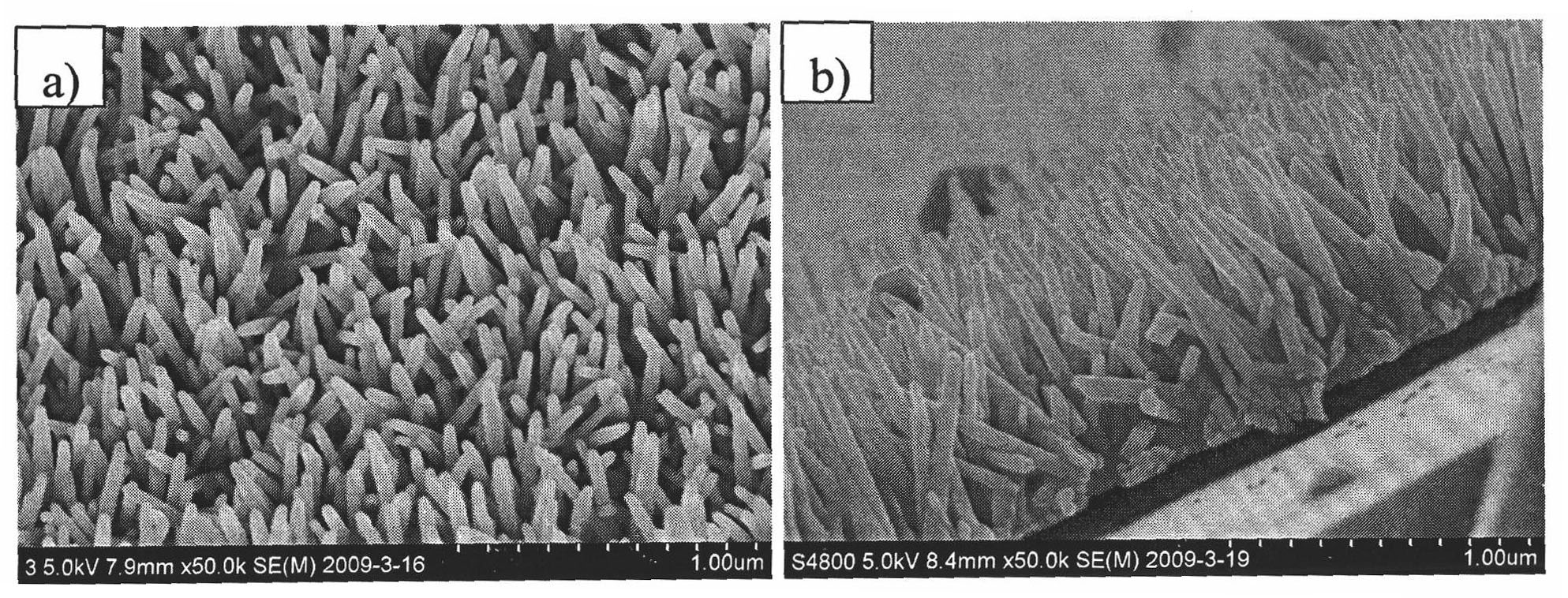

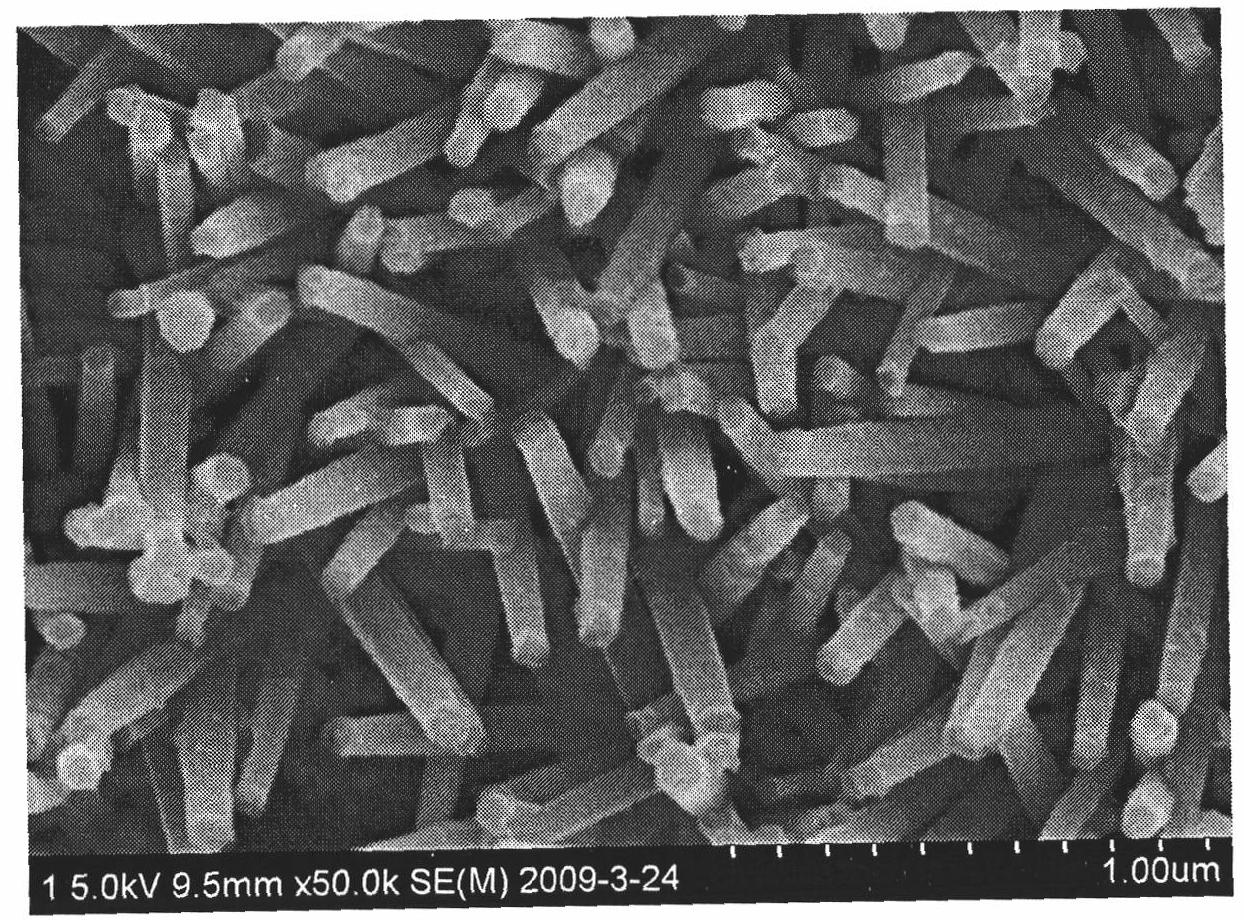

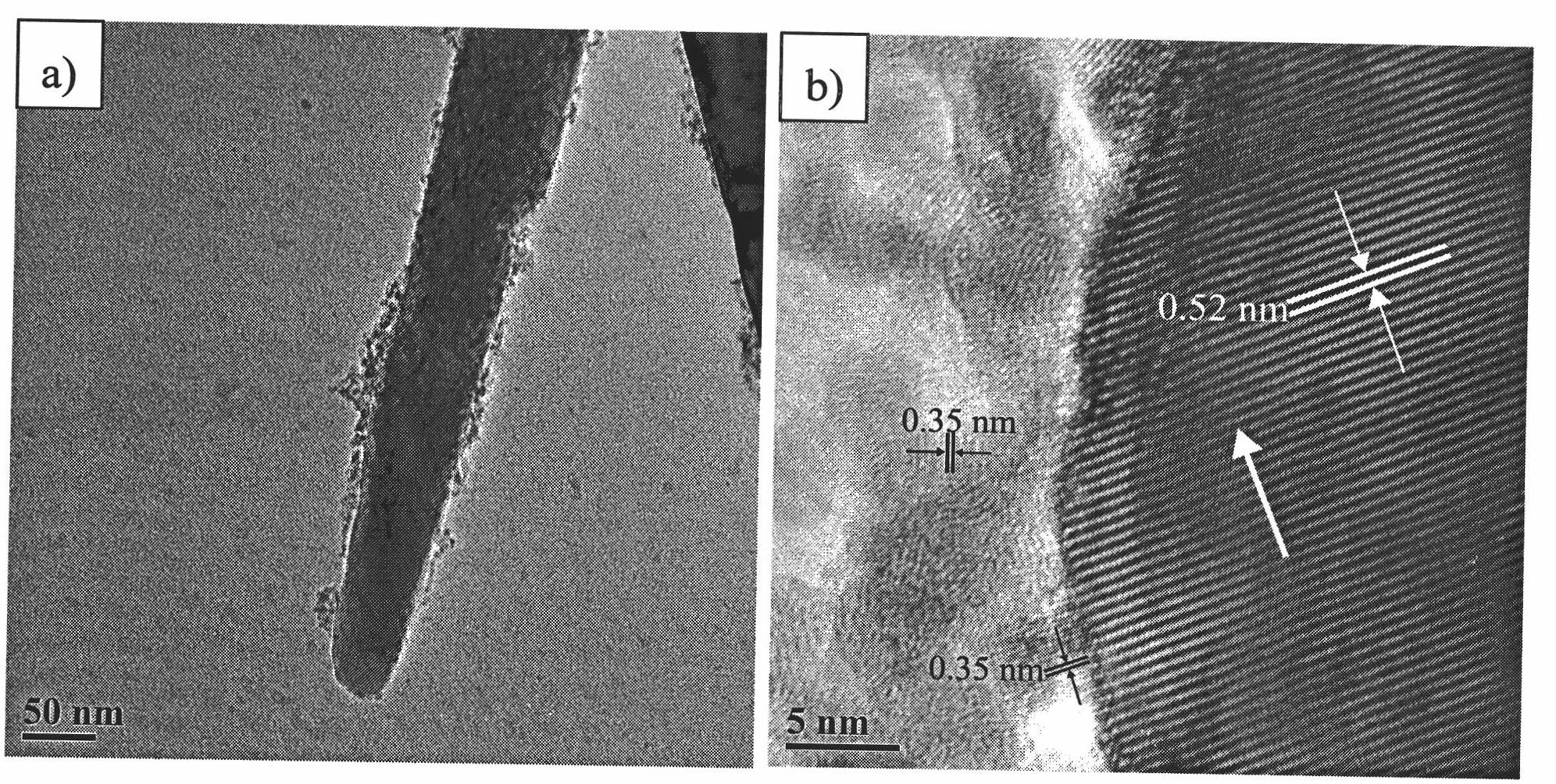

Microchannel type photocatalytic microreactor based on nanorod array and preparation method thereof

InactiveCN101670260AIncrease contact areaSolve the problem of time-consuming and laborious separationPhysical/chemical process catalystsEnergy based chemical/physical/physico-chemical processesMicroreactorEngineering

The invention relates to a microchannel type photocatalytic microreactor based on a nanorod array and a preparation method thereof. The photocatalytic microreactor uses a quartz capillary as a photocatalytic region microchannel, uses a semiconductor nanorod array which vertically grows on the inner surface of the microchannel as a photocatalyst, uses a polytetrafluoroethylene micropipe as a fluidconveying and receiving channel, uses an ultraviolet lamp as a light source, and uses a micro-injection pump to convey organic substances into the microchannel, thereby achieving the purpose of continuous, quick and efficient photocatalytic degradation of the organic substances. By adjusting the pushing speed of the micro-injection pump, the complete degradation of the organic substances is realized; and moreover, the microchannel type photocatalytic microreactor still has high photocatalytic activity after being continuously used for 100 hours, and the degradation rate for the organic substances is still more than 80%.

Owner:DONGHUA UNIV

Method for preparing polydimethylsiloxane (PDMS) micro-fluidic chip

The invention discloses a method for preparing a polydimethylsiloxane (PDMS) micro-fluidic chip. The method comprises the following steps: preparing a paraffin male die of the PDMS micro-fluidic chip by a droplet micro-injection method; preparing a female die of the PDMS micro-fluidic chip by a molding method; and bonding the female die of the PDMS micro-fluidic chip and a glass substrate together by a reversible bonding mode, thereby preparing the PDMS micro-fluidic chip. The process of preparing the paraffin male die of the PDMS micro-fluidic chip is completed in one step, the cost is low, a specific template is not needed, and a paraffin male die of a PDMS micro-fluidic chip of any graph can be prepared.

Owner:NANJING UNIV OF SCI & TECH

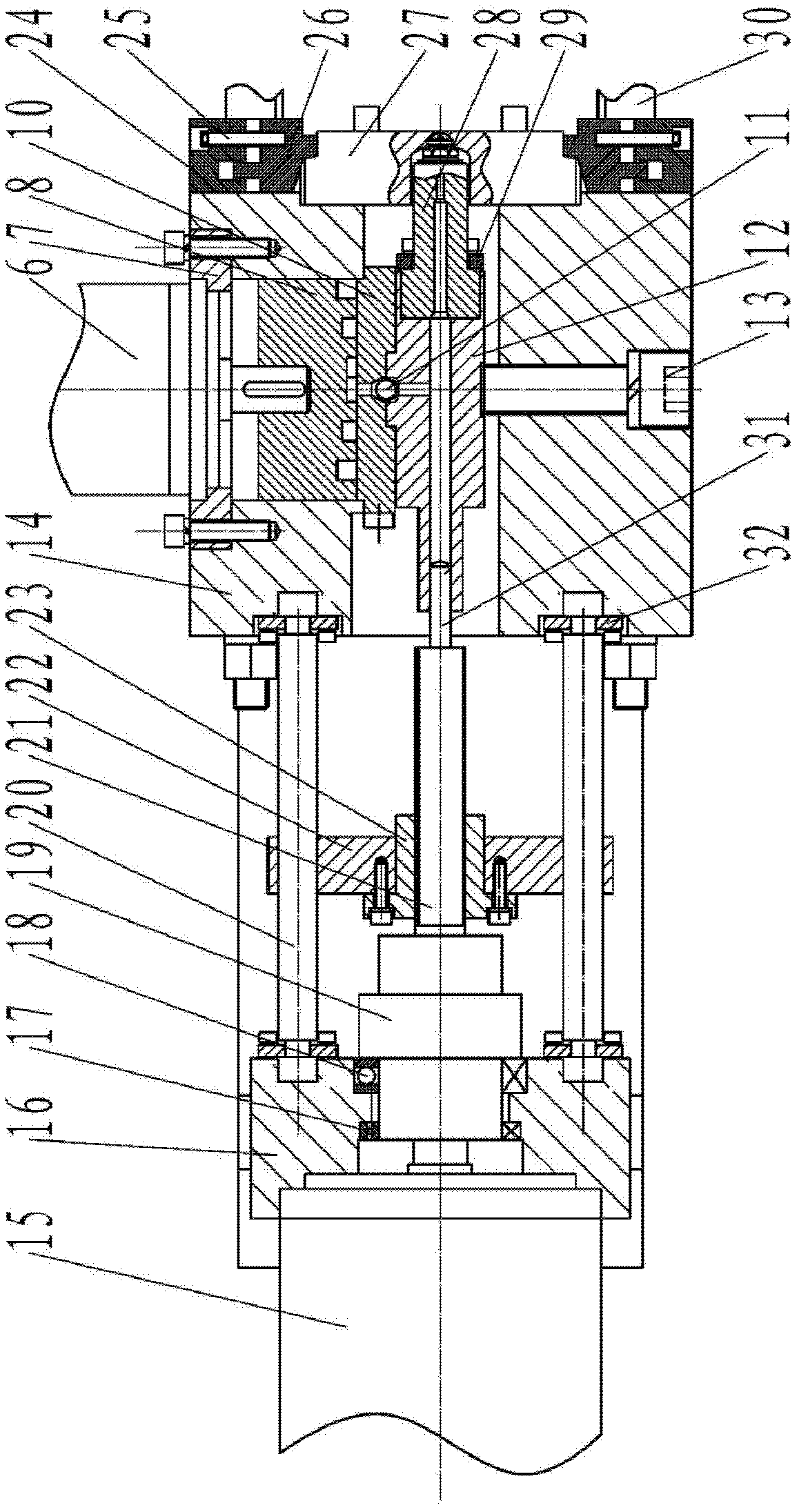

All-electric micro precise injection moulding machine

The invention discloses an all-electric micro precise injection moulding machine, which belongs to the field of high molecular material forming mechanism. The micro precise injection moulding machine mainly consists of an end-face plasticizing part, a plunger injection part, a mold-closing part, a mold and a machine frame. The all-electric micro precise injection moulding machine of the invention adopts the side feeding way; a plunger, a machine cylinder and a hot runner nozzle are arranged on one line; and a check valve is assembled; the injection resistance is low and the pressure loss is less; the end-face spiral disc plasticizing materials are used, so that the problems, such as difficult processing, low intensity and the like, of the traditional small-sized screws are solved basically; a servo motor is used to drive a ball screw pair to inject the plunger and open and close the mold, so that the accurate control of action positions and stepless speed regulation can be realized. The all-electric micro precise injection moulding machine disclosed by the invention combines the advantages of traditional micro injection forming technology, the end-face pre-plastication technology, the hot runner technology and the electric servo driving technology, and has the advantages of well plasticizing and mixed melting effects, high material utilization rate, less pressure loss and relatively simple structure.

Owner:BEIJING UNIV OF CHEM TECH

Method for large-scale production of continuous carbon nano tube fiber

The invention relates to a method for large-scale production of continuous carbon nano tube fiber. The carbon nano tube fiber is continuously prepared by connecting multiple furnaces in series, utilizing airflow in multiple times, and simultaneously stabilizing multiple furnaces. The mixed reaction solution of an ethyl alcohol carbon source, a ferrocene catalyst, a thiophene accelerant and a water assistant is injected by utilizing a micro-injection pump, and guided to a first hydrogen flow furnace via a nozzle, a cylindrical continuous carbon nano tube aggregate is generated at a reaction zone, and the continuous carbon nano tube fiber is obtained via mechanical traction, waterlogged densification and twining by an external spindle; the airflow is guided to a rear furnace once more via a transmission device, the same reaction solution is injected, the hydrogen flow rate and the solution injection speed of the rear furnace are regulated, the cylindrical continuous carbon nano tube aggregate is generated in the rear furnace, and the continuous carbon nano tube fiber is obtained via mechanical traction, waterlogged densification and twining by an external spindle. According to the invention, the multiple furnaces can at least simultaneously stabilize spinning to reach the hectometer level, and the obtained fiber is mainly composed of double-walled carbon nano tubes; the fiber has better degree of crystallinity, certain strength and electrical conductivity, and is similar to fiber prepared through a typical single reactor.

Owner:TIANJIN UNIV

Method for preparing protein-loaded tissue engineering fiber support

InactiveCN102188755AReduce adsorptionImprove stabilitySurgeryFilament/thread formingFiberMagnetic tension force

The invention relates to a method for preparing a protein-loaded tissue engineering fiber support in the technical field of medicaments, which comprises the following steps of: dissolving protein in macromolecular polysaccharide aqueous solution and using as an inner water phase; dissolving sustained-release macromolecules in an organic solvent, adding a suspending aid for dispersing, and using as an outer oil phase; adding the inner oil phase into the outer water phase dropwise, magnetically stirring or homogenizing to form emulsion, adding the emulsion into an injector, and performing electrostatic spinning by using a micro-injection pump and a receiver at room temperature under the condition of applying high-voltage static electricity to form a fiber membrane, or respectively putting the inner water phase and the outer oil phase into a capillary tube subjected to coaxial cospinning, and performing the electrostatic spinning by using the micro-injection pump and the receiver at room temperature under the condition of applying the high-voltage static electricity on inner and outer layers simultaneously; and standing and airing at room temperature to obtain tissue engineering fibers. The tissue engineering fiber support comprises the following components in percentage by weight: 0.5 to 20 percent of protein or polypeptide medicaments, 2 to 20 percent of macromolecular polysaccharides, 0 to 15 percent of suspending aid and 60 to 99 percent of sustained-release macromolecules. By the method, release curves of the protein are improved, the stability in the processes of preparation, storage and release is improved, and the medicament loading capacity of the fibers is increased.

Owner:SHANGHAI JIAO TONG UNIV

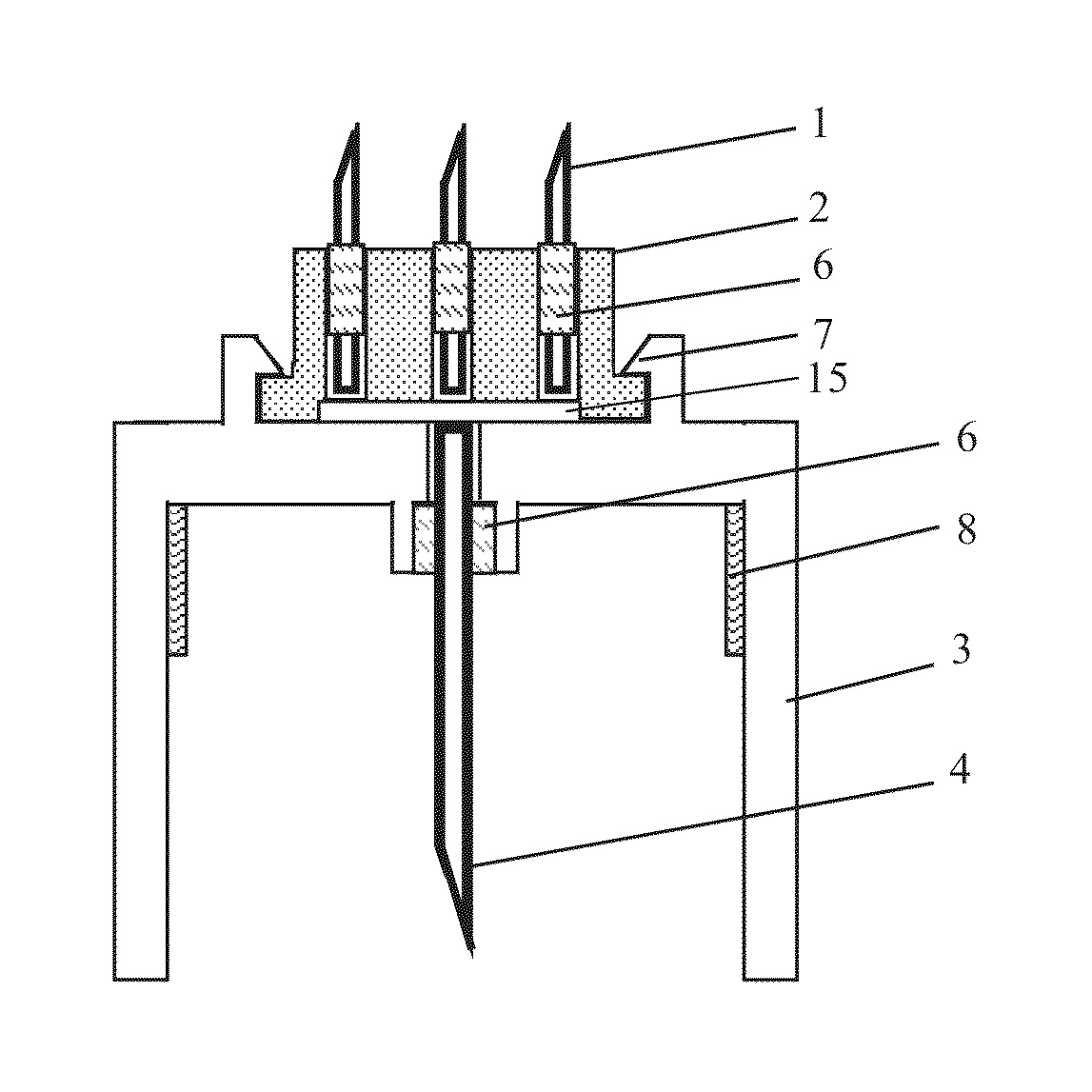

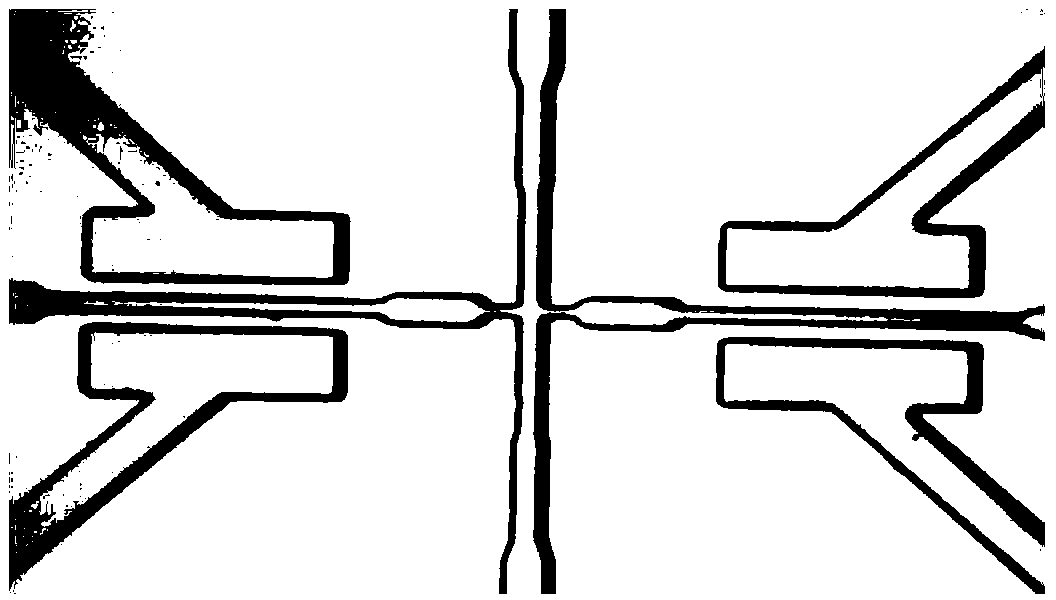

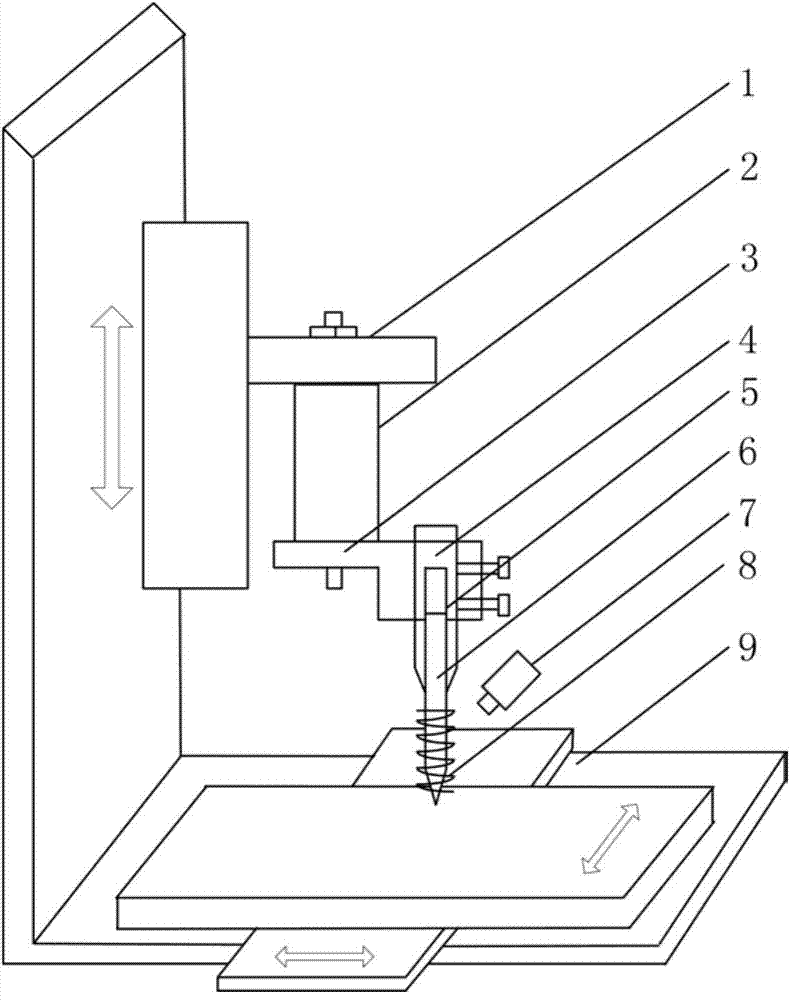

Multi-degree-of-freedom micromanipulator driven by multi-polarization mode piezoelectric actuator

InactiveCN102497129ARealize three-dimensional translationRealize high-precision micro-movementPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamPiezoelectric actuators

The invention discloses a multi-degree-of-freedom micromanipulator which is driven by a multi-polarization mode piezoelectric actuator. The micromanipulator comprises a substrate, a nested x and y axis translation micromotion mechanism, a Z axis translation micromotion mechanism, a Z axis turning micromotion mechanism and an end executive mechanism, wherein three-dimensional translation is realized by using a piezoelectric pile actuator with a piezoelectric strain constant d33 driving a flexure hinge; Z axis turning is realized by using a piezoelectric turning actuator with a piezoelectric strain constant d15 driving a reverse arm; and the end executive mechanism is a micro clamp holder consisting of a piezoelectric double-chip cantilever beam based on a piezoelectric strain constant d31 or a micro injection probe. High accurate micromotions such as the three-dimensional translation, turning around with a Z axis and swing around with an X axis are realized by the drive of the piezoelectric actuator in different polarization modes, and operations such as clamping, transport, probing, injection and the like are realized by different end executive arms. The micromanipulator has the advantages of freedom decoupling, compact structure, flexible operation, convenient control, high motion precision and the like, and the micromanipulator can be applied in the fields of biomedicine, micro electro mechanical engineering and the like.

Owner:ZHEJIANG UNIV

Light driven micro-fluid pump

InactiveCN104481850AQuick responseIncrease working frequencyFlexible member pumpsPositive-displacement liquid enginesLight energyMechanical energy

The invention relates to a light driven micro-fluid pump. The light driven micro-fluid pump converts between light energy and mechanical energy. The light driven micro-fluid pump comprises an outlet / inlet layer, a pump cavity layer, a micro-wire grid array drive unit and a substrate in sequence from the bottom to top; the outlet / inlet layer is provided with an inlet and an outlet; the pump cavity layer comprises a pump cavity and a deformable vibrating diaphragm; the micro-wire grid array drive unit comprises a micro-wire grid array of which the period is hundreds of nanometers, the micro-wire grid array is composed of grid ridges and grid valleys, and the micro-wire grid array is a shape memory material azobenzene liquid crystal elastomer. The light driven micro-fluid pump periodically changes the irradiation light type and light intensity and is capable of precisely controlling the periodic change of the pump cavity volume of the micro-fluid pump so as to generate continuous differential flow. The light driven micro-fluid pump has advantages of fast respond speed, high working frequency, small energy consumption, large drive quantity and the like; the light driven micro-fluid pump is capable of precisely controlling the flow rate and capable of being used for the cell separation, micro-feeding of fluid, micro-injection of medicine, micro-chemical analysis and the like fields; the apparatus manufacturing can use an MEMS processing technique compatible with an IC manufacturing technique, and the apparatus manufacturing is suitable for batch production.

Owner:CHANGZHOU UNIV

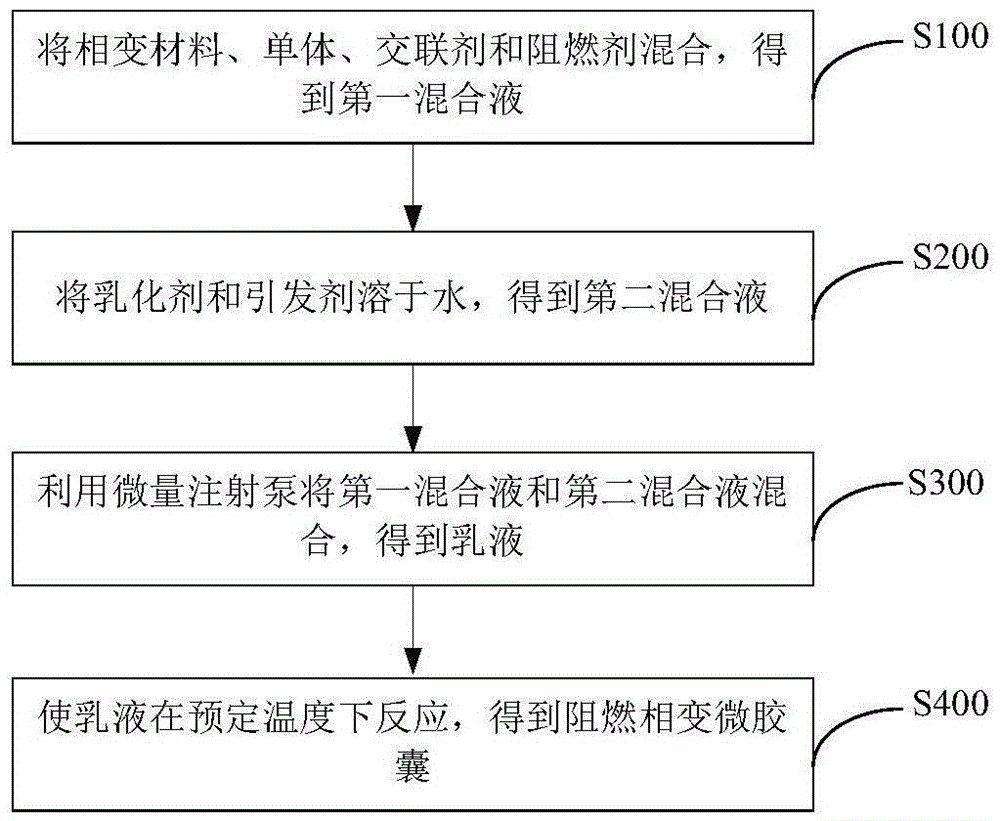

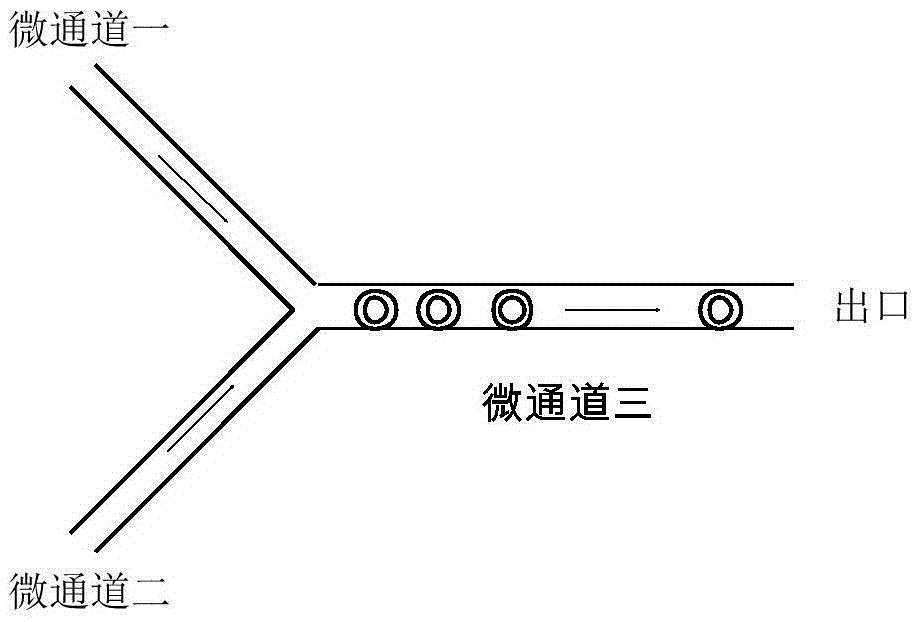

Flame retardant phase change microcapsule and its preparation method and use

InactiveCN105542721AImprove flame retardant performanceGood dispersionSecondary cellsHeat-exchange elementsCross-linkEmulsion

The invention provides a flame retardant phase change microcapsule and its preparation method and use. The preparation method of the flame retardant phase change microcapsule comprises 1, mixing a phase change material, a monomer, a cross-linking agent and a fire retardant to obtain a first mixed solution, 2, dissolving an emulsifier and an initiator in water to obtain a second mixed solution, 3, mixing the first mixed solution and the second mixed solution through a micro-injection pump to obtain an emulsion and 4, carrying out a reaction process on the emulsion at a preset temperature to obtain the flame retardant phase change microcapsule. The preparation method realizes fast and effective preparation of the flame retardant phase change microcapsules with uniform particle size distribution, good monodispersity and ideal flame resistance.

Owner:BEIJING ELECTRIC VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com