Method for preparing polydimethylsiloxane (PDMS) micro-fluidic chip

A microfluidic chip, glass microtechnology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of high equipment requirements, complex preparation process, high cost, etc., and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

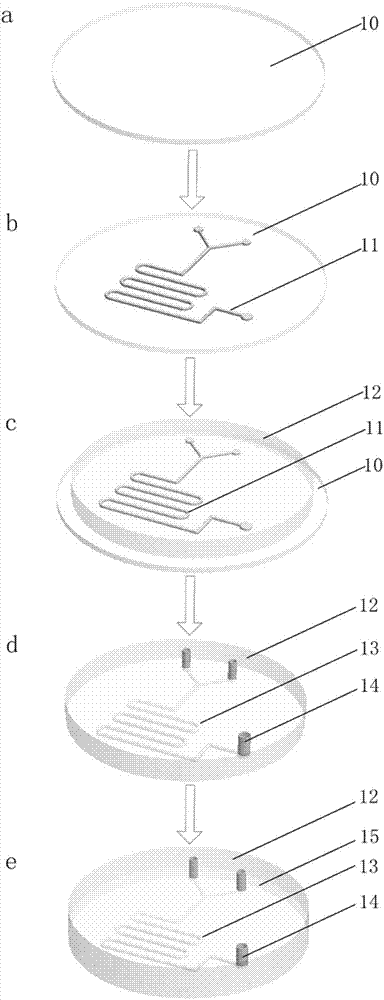

[0029] The preparation of the paraffin positive model 11 of the PDMS microfluidic chip, the specific steps are as follows:

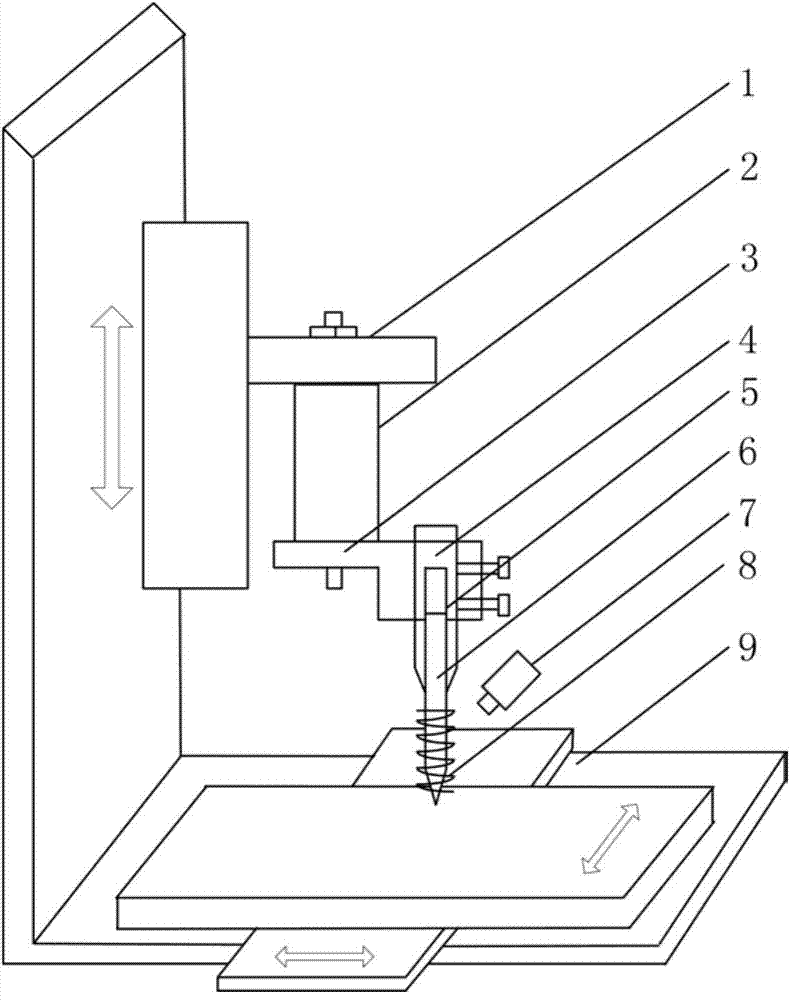

[0030] Step 1 Preparation of the internally structured biconical glass micronozzle 5 : the internally structured biconically shaped glass micronozzle 5 was prepared by adopting the above method for preparing the internally structured biconically shaped glass micronozzle with an outlet diameter of 120 μm.

[0031] Step 2 Cleaning of the glass substrate 10: Put the glass piece into a beaker, pour in an appropriate amount of concentrated sulfuric acid, heat it on a heating furnace for 10 minutes, then take it out and cool it for 10 minutes, and rinse the remaining concentrated sulfuric acid with deionized water. Dry it with a cotton ball, put it into a beaker containing acetone, put it into an ultrasonic cleaner and shake it for 10 minutes, take it out, rinse it with deionized water, and blow dry the surface moisture with nitrogen.

[0032] In step 3, the s...

Embodiment 2

[0035] The preparation of the paraffin positive model 11 of the PDMS microfluidic chip, the specific steps are as follows:

[0036] Step 1 Preparation of the internally structured biconical glass micronozzle 5 : the internally structured biconically shaped glass micronozzle 5 was prepared with the internally structured biconically shaped glass micronozzle having an outlet inner diameter of 180 μm.

[0037] Steps 2 and 3 are identical to steps 2 and 3 described in Example 1

[0038] Step 4 Step 4 Set the driving voltage amplitude of the piezoelectric actuator 2 to 60V, the driving frequency to 2Hz, set the motion parameters of the three-dimensional workbench 9 so that the droplet overlap is 60%, the Z-axis deposition times are 2, and the workbench moves Pattern selection for dual-way micro-mixing patterns for microfluidic chips. Drive the internal double-conical glass micro-nozzle 3, and at this time, the internal double-conical glass micro-nozzle 5 is surrounded by a heating ...

Embodiment 3

[0040] The preparation of the paraffin positive model 11 of the PDMS microfluidic chip, the specific steps are as follows:

[0041] Step 1 Preparation of the internally structured biconical glass micronozzle 5 : the internally structured biconically shaped glass micronozzle 5 was prepared by adopting the above described method for preparing the internally structured biconically shaped glass micronozzle.

[0042] Steps 2 and 3 are identical to steps 2 and 3 described in Example 1

[0043] Step 4 Set the driving voltage amplitude of the piezoelectric actuator 2 to 80V, the driving frequency to 2Hz, set the motion parameters of the three-dimensional table 9 so that the droplet overlap is 80%, the Z-axis deposition times are 6, and the motion pattern of the table is selected Two-way micro-mixing patterns on a microfluidic chip. Drive the internal double-conical glass micro-nozzle 5, and at this moment, the internal double-conical glass micro-nozzle 5 is surrounded by a heating ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com