Preparation method of shell core fibre tectorial membrana endovascular stent

An inner stent and fibrous membrane technology, applied in stents, medical science, surgery, etc., can solve problems affecting treatment goals, achieve good biological safety and mechanical properties, easy industrial production, and prevent blood supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the shell-core fiber-coated intravascular stent of the present invention, the specific steps are as follows:

[0032] (1) dissolving the natural or artificial polymer in a suitable solvent to obtain a homogeneous solution with a concentration of 0.01-0.08 g / ml;

[0033] (2) Dissolving the drug or artificial polymer with the drug and bioactive ingredients in a suitable solvent to obtain a uniform solution or suspension, or preparing the solutions separately and mixing them into a uniform solution or suspension;

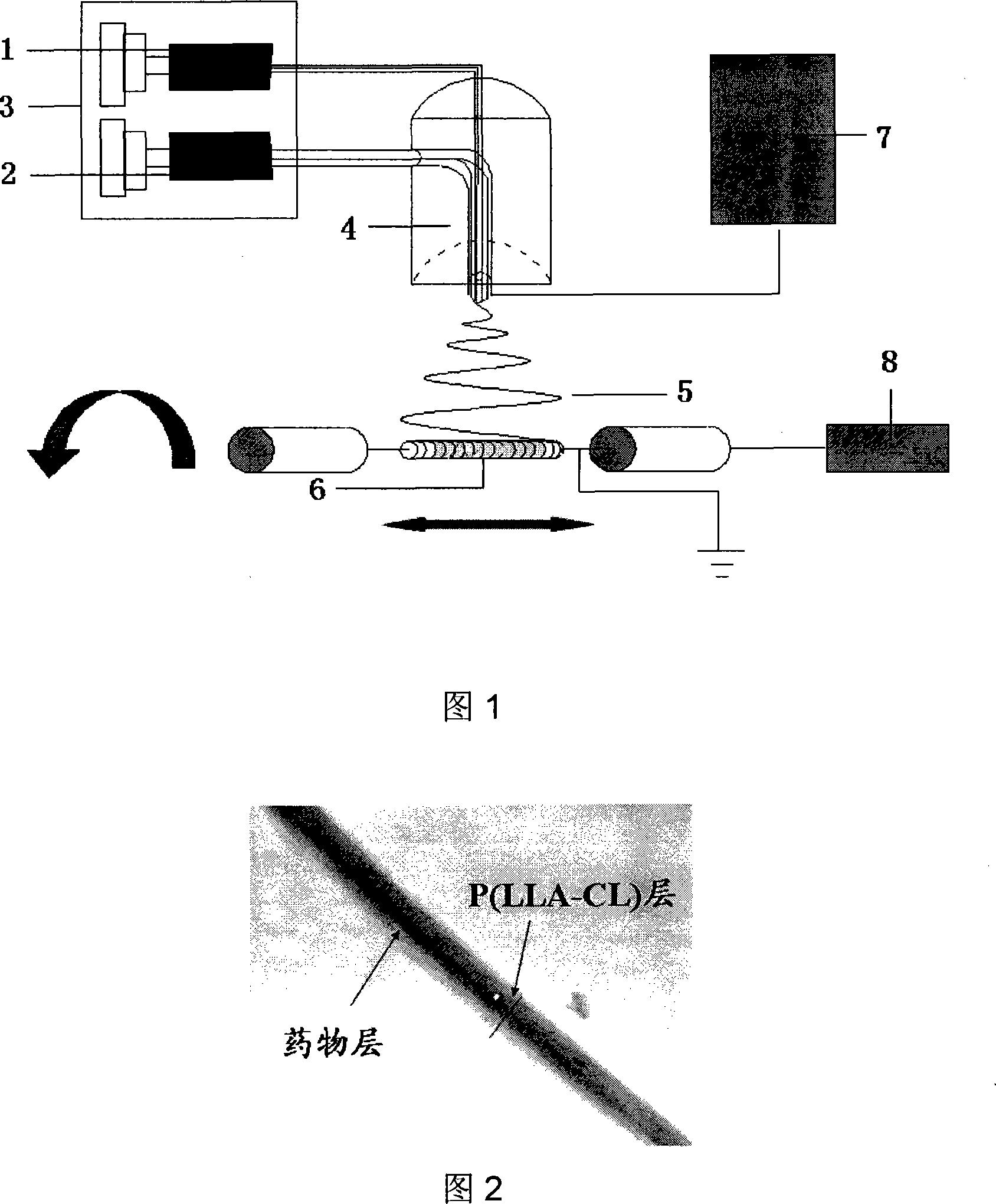

[0034] (3) As shown in Figure 1, add the homogeneous solution of natural or artificial polymer and the solution or suspension of medicine or artificial polymer and medicine, biological activity to two syringes 1 and 2 respectively, and adjust the speed of micro-injection pump 3 0.1-5.0 ml / hour, adjust the high-voltage electrostatic generator 7 so that the voltage is 5000-30000 volts, adjust the receiving device so that the receiving dis...

example 1

[0043] (1) preparing a solution with a heparin concentration of 0.08 g / ml, the solvent used is water;

[0044] (2) Prepare a solution of P(LLA-CL) with a concentration of 0.06 g / ml, and the solvent used is hexafluoroisopropanol.

[0045] (3) Put the heparin solution into the supply syringe of the inner layer, put the P(LLA-CL) solution into the supply syringe of the outer layer, and adjust the supply rate of the inner and outer layers to 0.1 ml / hour and 0.9 ml / hour. Electrospinning is carried out under the action of a propulsion pump and a high-voltage electrostatic generator to obtain heparin-containing fibers with a shell-core structure;

[0046] (4) Fix the intravascular stent on the rotating shaft with a voltage of 20.0 kV, a receiving distance of 20.0 cm, and a motor speed of 50 rpm. After 30 minutes, the intravascular stent is covered with a fibrous membrane with a thickness of about 0.10 mm;

example 2

[0048] (1) the preparation paclitaxel concentration is the solution of 0.01 g / ml, and the solvent used is acetone;

[0049] (2) Prepare a solution of P(LLA-CL) with a concentration of 0.06 g / ml, and the solvent used is trifluoroethanol.

[0050] (3) put the paclitaxel solution into the supply syringe of the inner layer, put the P(LLA-CL) solution into the supply syringe of the outer layer, and adjust the supply rate of the inner and outer layers to be 0.3 ml / hour and 0.9 ml / hour. Electrospinning is carried out under the action of a propulsion pump and a high-voltage electrostatic generator to obtain paclitaxel-containing fibers with a shell-core structure;

[0051] (4) Fix the intravascular stent on the rotating shaft with a voltage of 15.0 kV, a receiving distance of 15.0 cm, and a motor speed of 100 rpm. After 30 minutes, the intravascular stent is covered with a fibrous membrane with a thickness of about 0.10 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com