Light driven micro-fluid pump

A microfluidic and light-driven technology, which is applied in pumps, machines/engines, liquid displacement machinery, etc., can solve the problem of small driving force of electrostatic-driven micropumps, low operating frequency of heat-driven micropumps, limited output flow and Problems such as back pressure, to achieve the effect of large driving capacity, high operating frequency and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

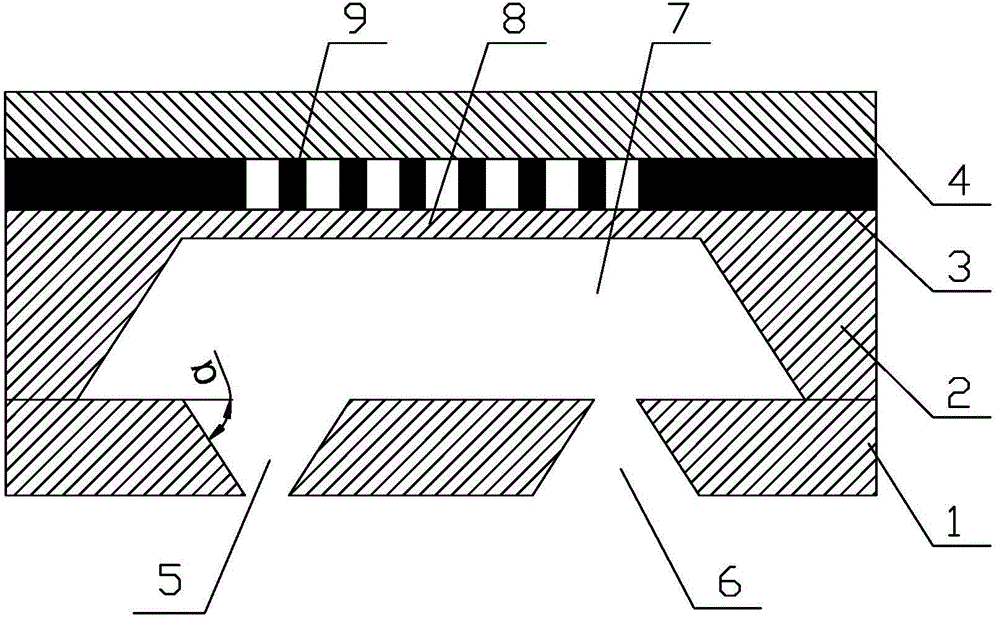

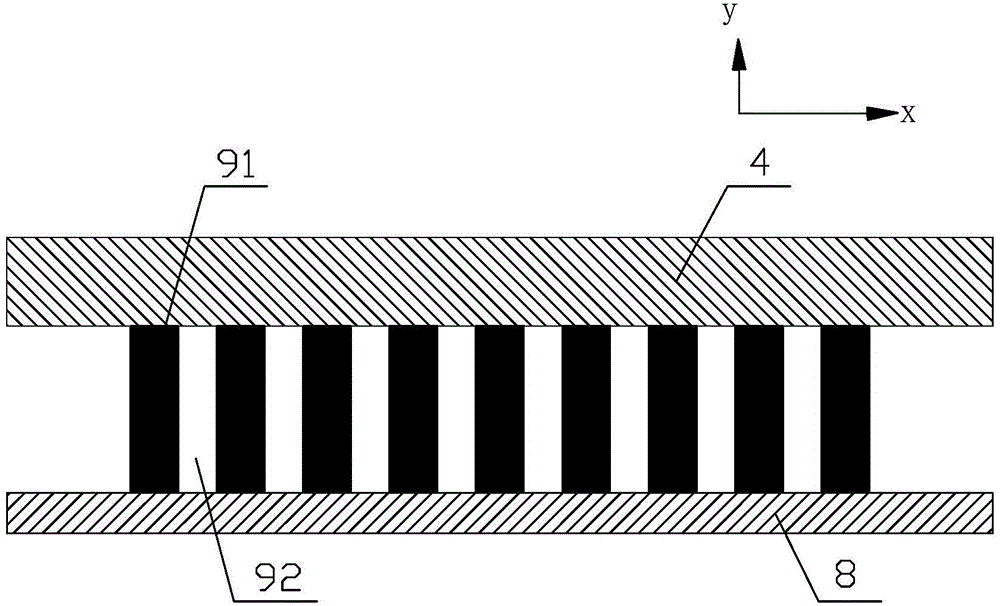

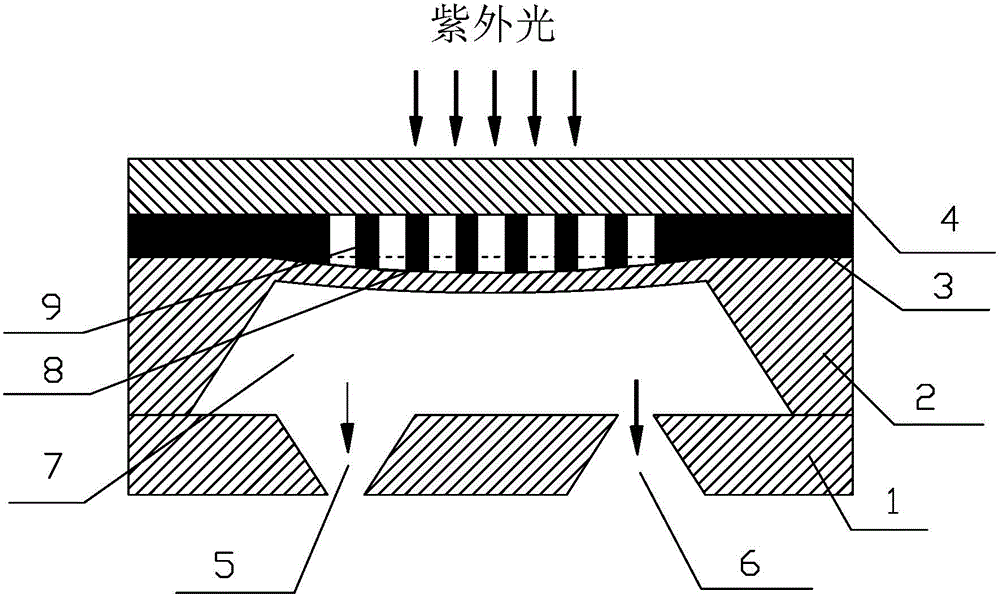

[0031] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0032] Such as figure 1 As shown, it is a schematic diagram of an embodiment of the light-driven microfluidic pump of the present invention. The present invention includes an inlet and outlet layer 1, a pump chamber layer 2, a micro wire grid array driving unit 3 and a substrate 4 in sequence from bottom to top.

[0033] The inlet and outlet layer 1 provides an inlet 5 and an outlet 6 for transferring liquid. The inlet 5 is a tapered mouth with a wide top and a narrow bottom, and the outlet 6 is just the opposite. It is a tapered mouth with a narrow top and a wide bottom. The shape of the inlet 5 and outlet 6 , the same size, but upside down, as follows figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com