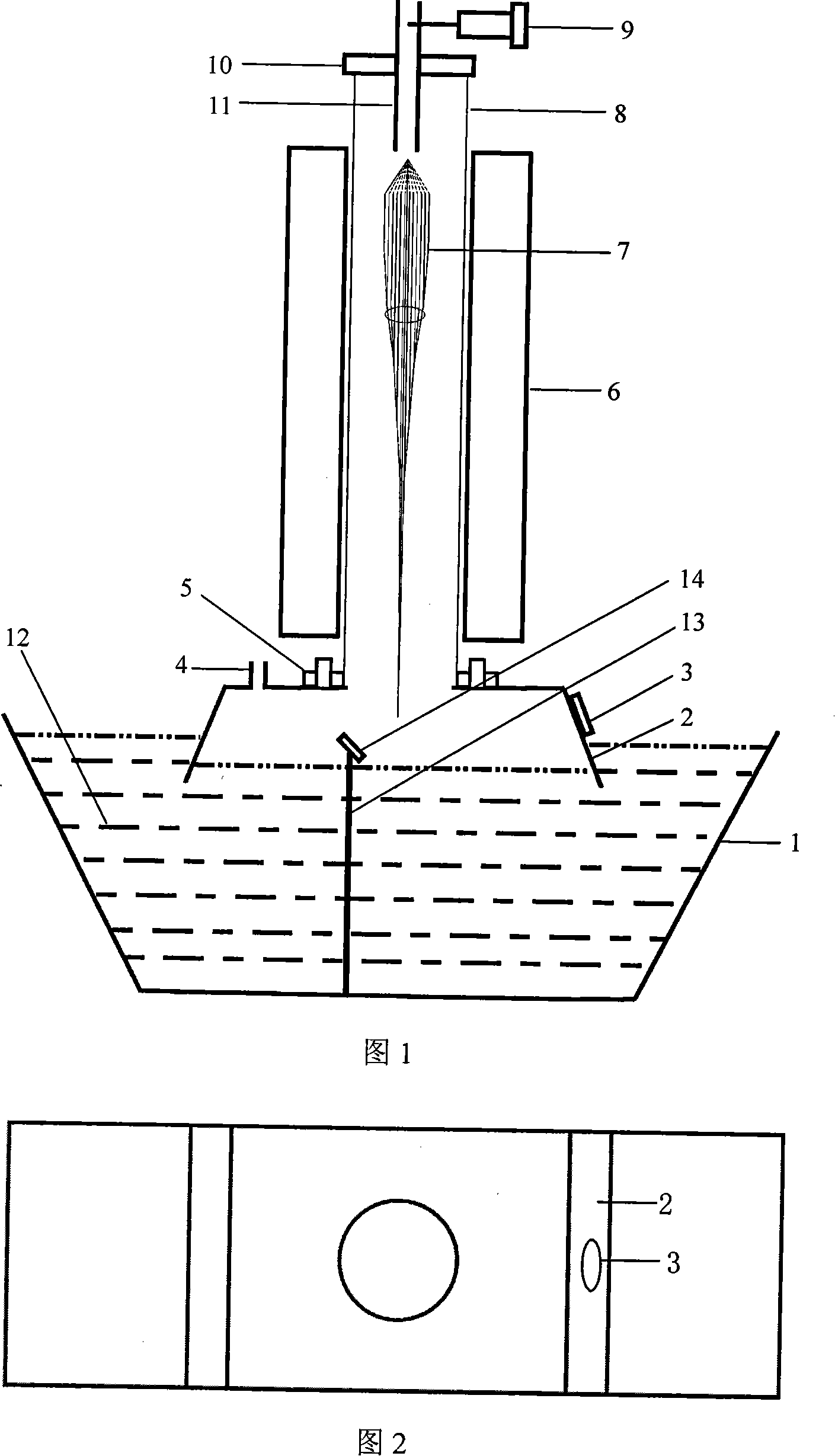

Apparatus and method for producing continuous carbon nano-tube fibre by liquid sealed vapor-phase flow catalytic reaction

A technology of carbon nanotube fiber and gas phase flow catalysis, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve problems such as difficult carbon nanotube fiber, and achieve the effect of wide application and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

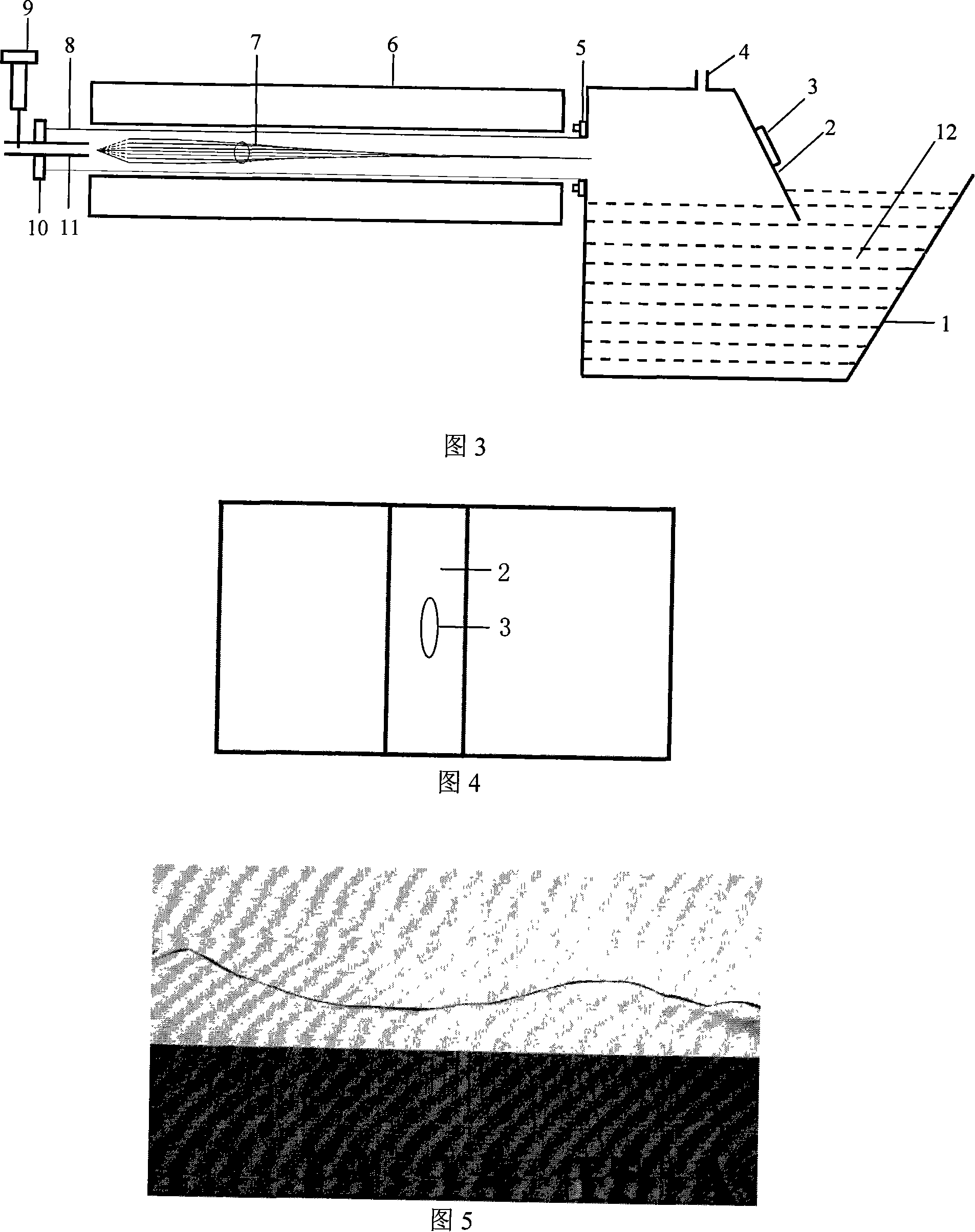

Embodiment 1

[0037] Water is the sealing liquid medium. Mix ethanol (carbon source), ferrocene (catalyst), thiophene (accelerator), and water according to 23.70g, 0.45g, 0.40g, and 0.66g of ultrasonic to form a solution, and inject the solution through a micro syringe at a speed of 7.0ml / h 600ml / minH 2 In the reaction gas flow, the synthesis reaction is carried out in a quartz tube, and the horizontal tube atmosphere furnace is set at 1150° C. as the reaction temperature. After the reaction starts, it can be observed from the observation mirror that misty carbon nanotube fibers are produced in the quartz tube, and with the flow of the carrier gas flow, the fibers become cylindrical continuous carbon nanotube fibers of 0.5-1.5 cm. The formed carbon nanotube fibers can be directly mechanically manipulated through the water-sealed medium. After the carbon nanotube fibers taken out of the reaction zone pass through the water medium, the diameter becomes about 0.1 cm, the strength increases, a...

Embodiment 2

[0039] With 10% HCl solution as the sealing liquid medium. Mix ethanol, ferrocene, thiophene, and water according to 23.70g, 0.45g, 0.40g, and 0.66g ultrasonically to form a solution, and inject the solution into 600ml / min H at a speed of 7.0ml / h through a microinjector 2In the reaction gas flow, the synthesis reaction is carried out in a quartz tube, and the horizontal tube atmosphere furnace is set at 1150° C. as the reaction temperature. After the reaction starts, it can be observed from the observation mirror that misty carbon nanotube fibers are produced in the quartz tube, and with the flow of the carrier gas flow, the fibers become cylindrical continuous carbon nanotube fibers of 0.5-1.5 cm. The formed carbon nanotube fibers can be directly mechanically manipulated through the water-sealed medium. After the carbon nanotube fibers taken out of the reaction zone pass through the water medium, the diameter becomes about 0.1 cm, the strength increases, and the fiber surface...

Embodiment 3

[0041] With 10% HNO 3 The solution is a sealed liquid medium. Mix ethanol, ferrocene, thiophene, and water according to 23.70g, 0.45g, 0.40g, and 0.66g ultrasonically to form a solution, and inject the solution into 600ml / min H at a speed of 7.0ml / h through a microinjector 2 In the reaction gas flow, the synthesis reaction is carried out in a quartz tube, and the vertical tube atmosphere furnace is set at 1150° C. as the reaction temperature. After the reaction starts, it can be observed from the observation mirror that misty carbon nanotube fibers are produced in the quartz tube, and with the flow of the carrier gas flow, the fibers become cylindrical continuous carbon nanotube fibers of 0.5-1.5 cm. The formed carbon nanotube fibers can be directly mechanically manipulated through the water-sealed medium. After the carbon nanotube fibers taken out of the reaction zone pass through the water medium, the diameter becomes about 0.1 cm, the strength increases, and the fiber surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com