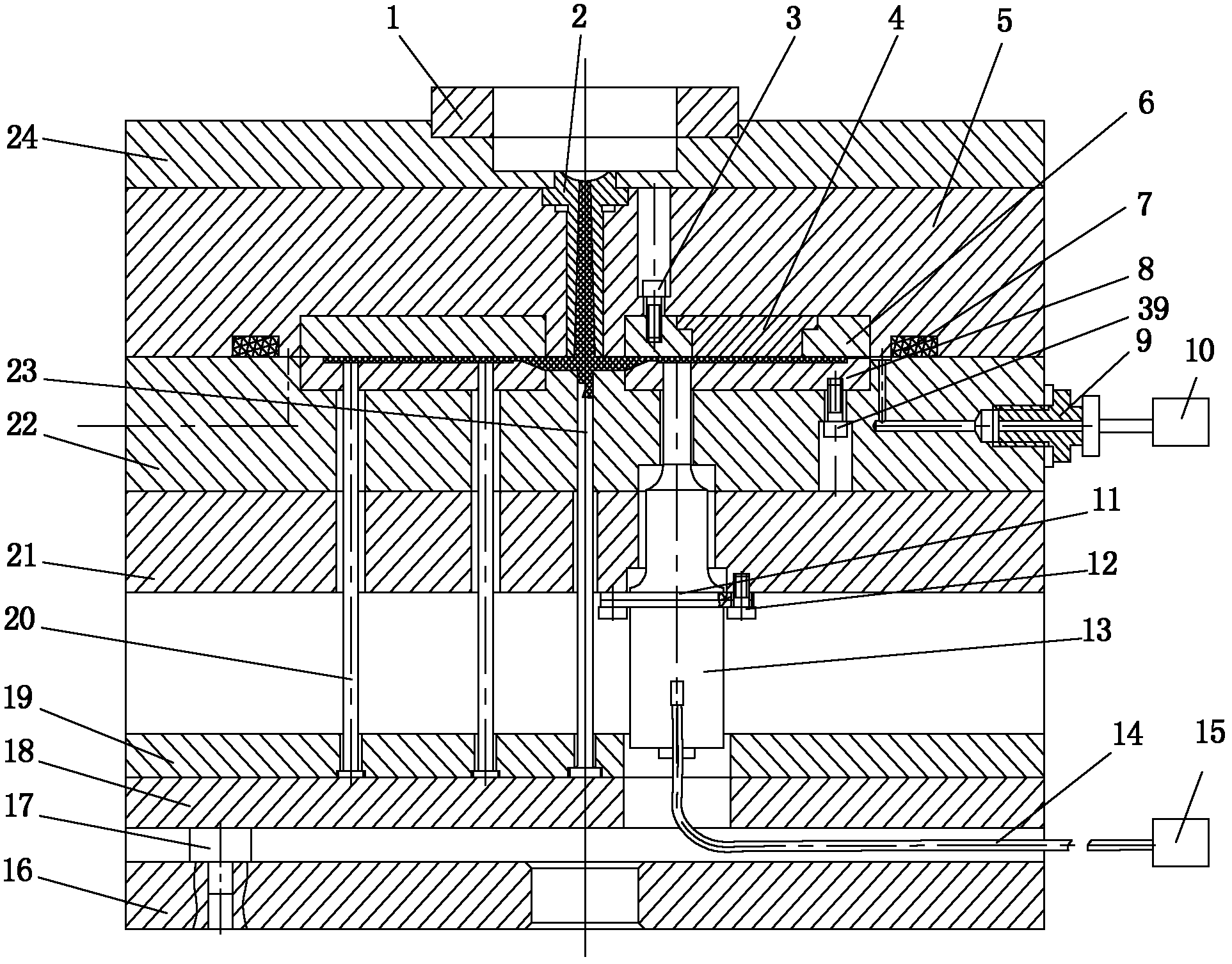

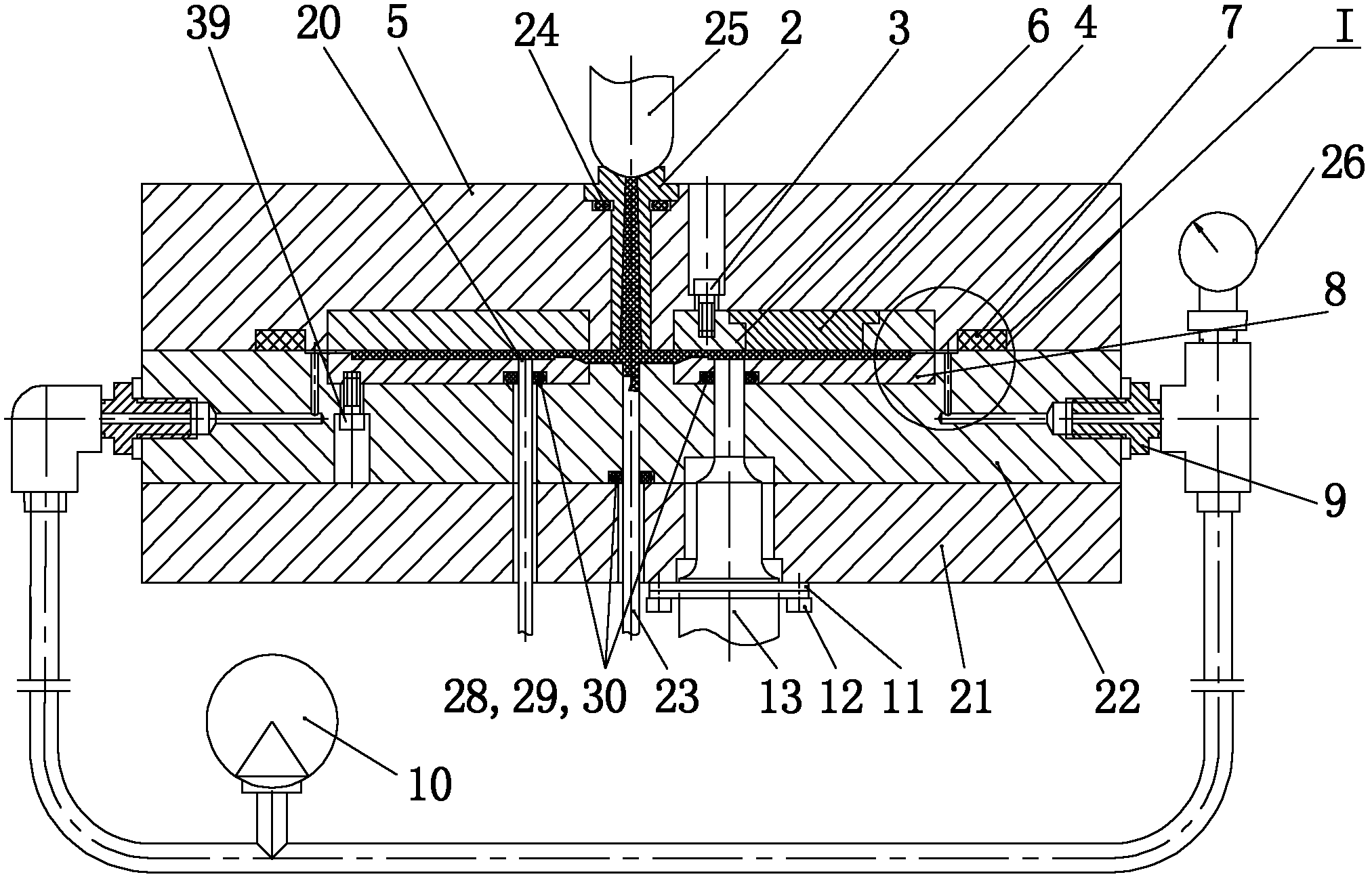

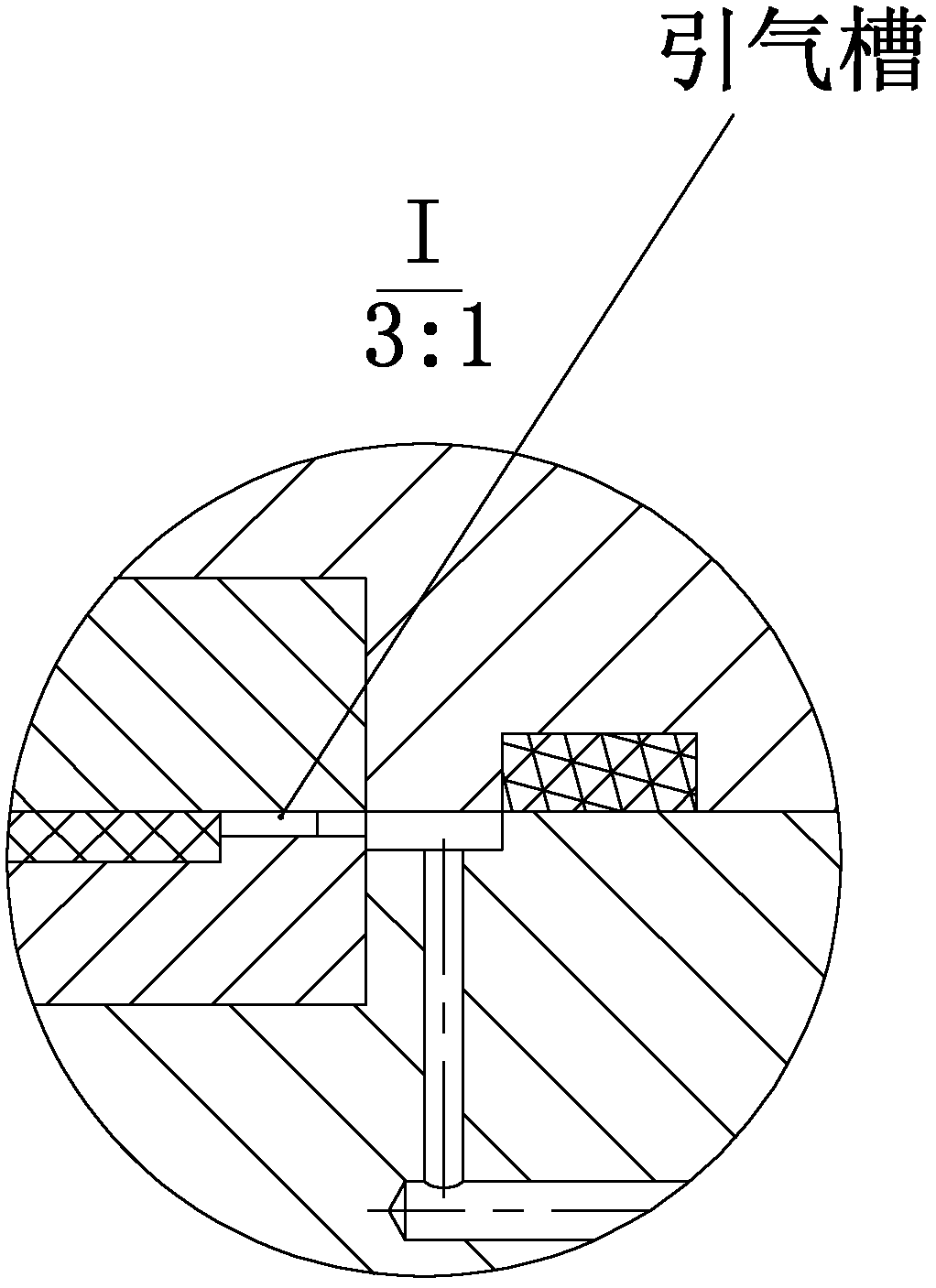

Ultrasonic vibration and vacuumizing integrated micro injection mold and molding method

An ultrasonic vibration and vacuuming technology, which is applied in the field of micro-injection molding and its molds, can solve the problems of difficulty in the flow of melt filling, unsatisfactory filling of micro-plastic parts, and poor exhaust of micro-cavities, so as to improve the degree of automation and production. Efficiency, reduced requirements, energy and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] When the melt temperature is 210°C and the mold temperature is 65°C, injection molding of micro-cylindrical array plastic parts is carried out;

[0030] Without vacuum and ultrasonic vibration, the filling height of the micro cylinder is 174μm;

[0031] When vacuum was applied but without ultrasonic vibration, the filling height of the micro cylinders was 183 μm; an increase of 9 μm;

[0032] After applying ultrasonic vibrations and vacuuming, the filling height of the micropillars increased to 213 μm; an increase of 30 μm.

Embodiment 2

[0033] Example 2 When the melt temperature is 240°C and the mold temperature is 80°C, the micro-cylindrical array plastic part is injection-molded. It is measured that the micro-cylindrical filling height reaches 276 μm without vacuuming and ultrasonic vibration;

[0034] When the melt temperature was lowered to 230°C and the mold temperature was still at 80°C, vacuum exhaust injection molding was performed without ultrasonic vibration, and the measured filling height of the micro cylinder was still 276 μm;

[0035] When the melt temperature is still maintained at 230°C and the mold temperature drops to 75°C, ultrasonic vibration and vacuum exhaust are performed simultaneously, and the measured filling height of the micro cylinders can still reach 276 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com