Patents

Literature

37results about How to "Reduce external resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

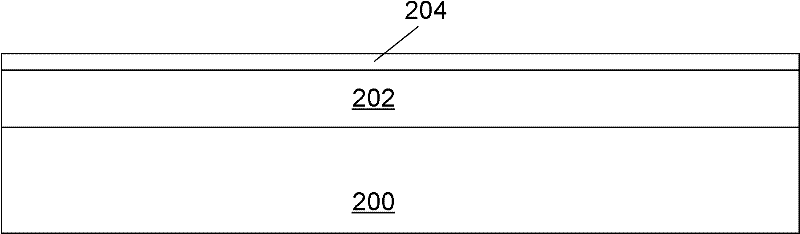

Metal oxide semiconductor devices having implanted carbon diffusion retardation layers and methods for fabricating the same

InactiveUS20100012988A1Reduce the probability of spreadingPromote activationTransistorSemiconductor/solid-state device manufacturingCarbon ionImpurity

Semiconductor devices and methods for fabricating semiconductor devices are provided. One exemplary method comprises providing a silicon-comprising substrate having a first surface, etching a recess into the first surface, the recess having a side surface and a bottom surface, implanting carbon ions into the side surface and the bottom surface, and forming an impurity-doped, silicon-comprising region overlying the side surface and the bottom surface.

Owner:GLOBALFOUNDRIES INC

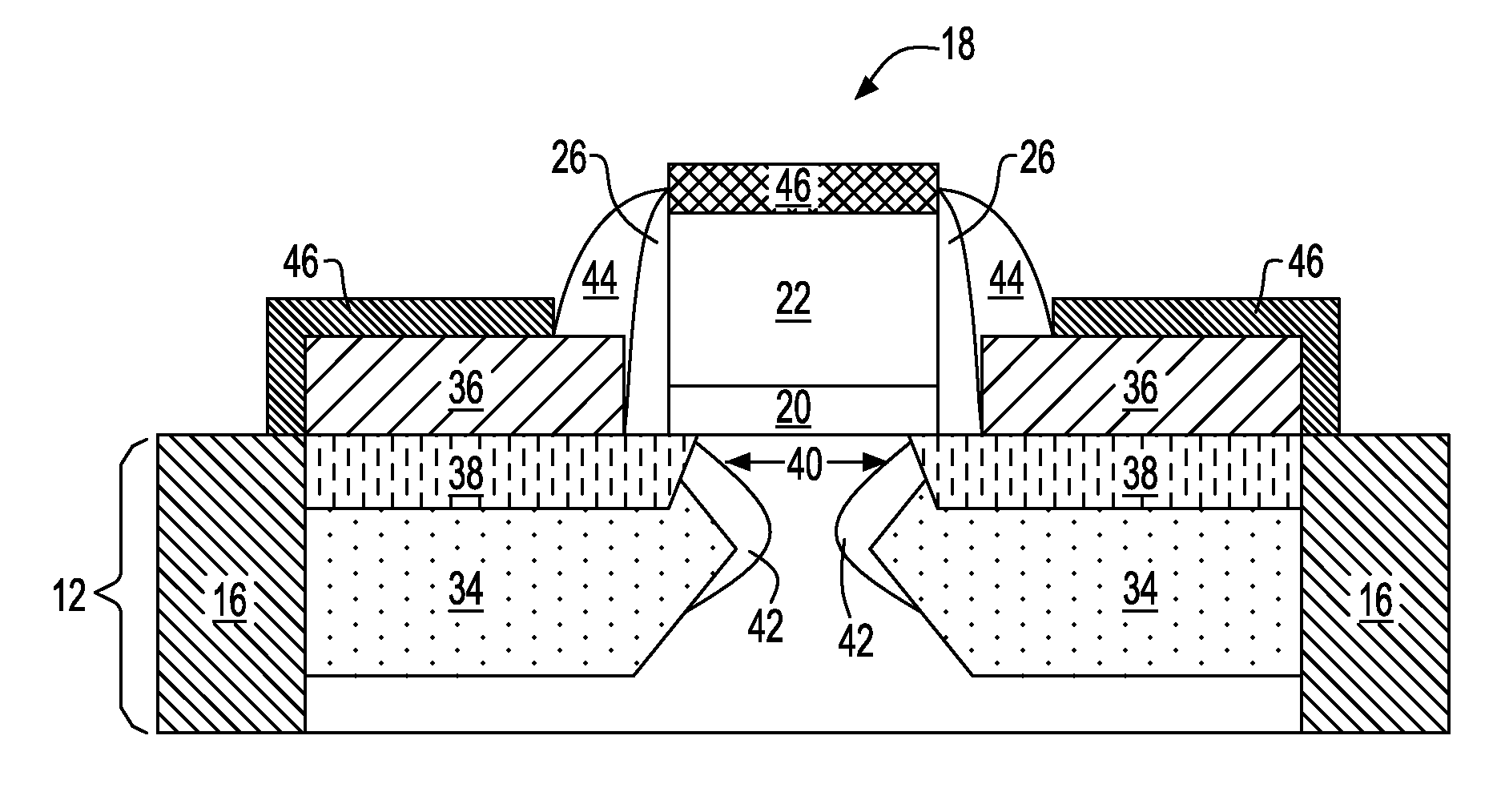

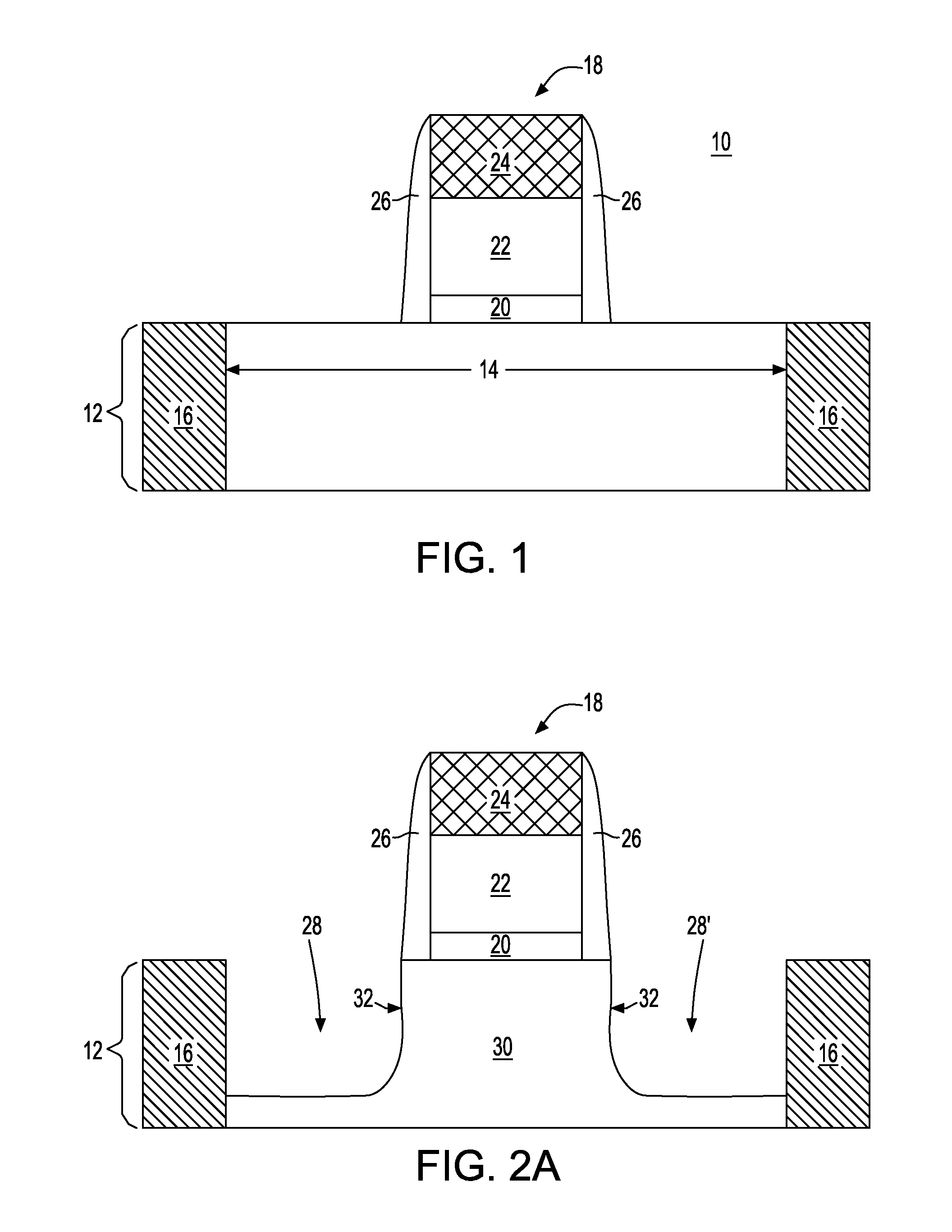

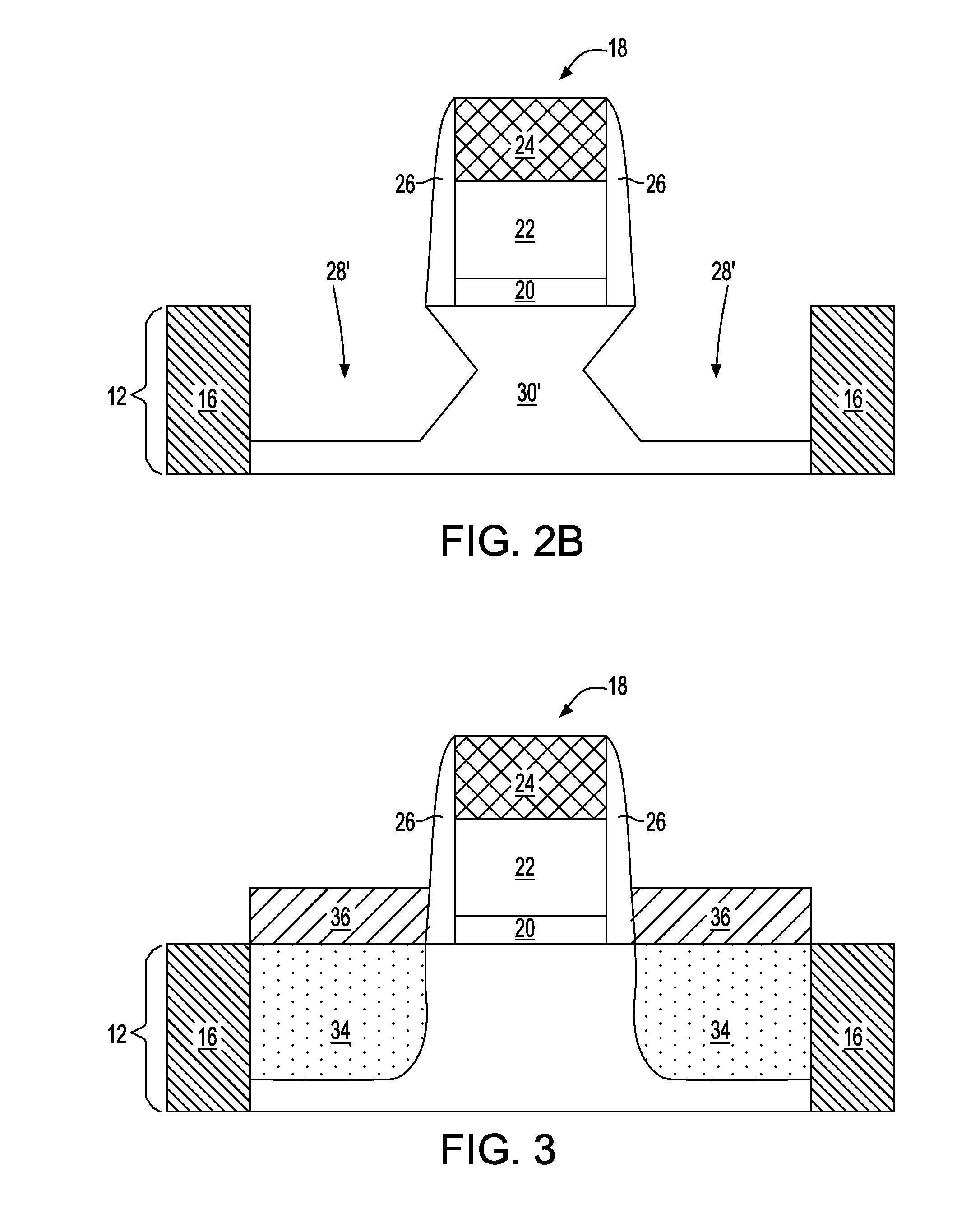

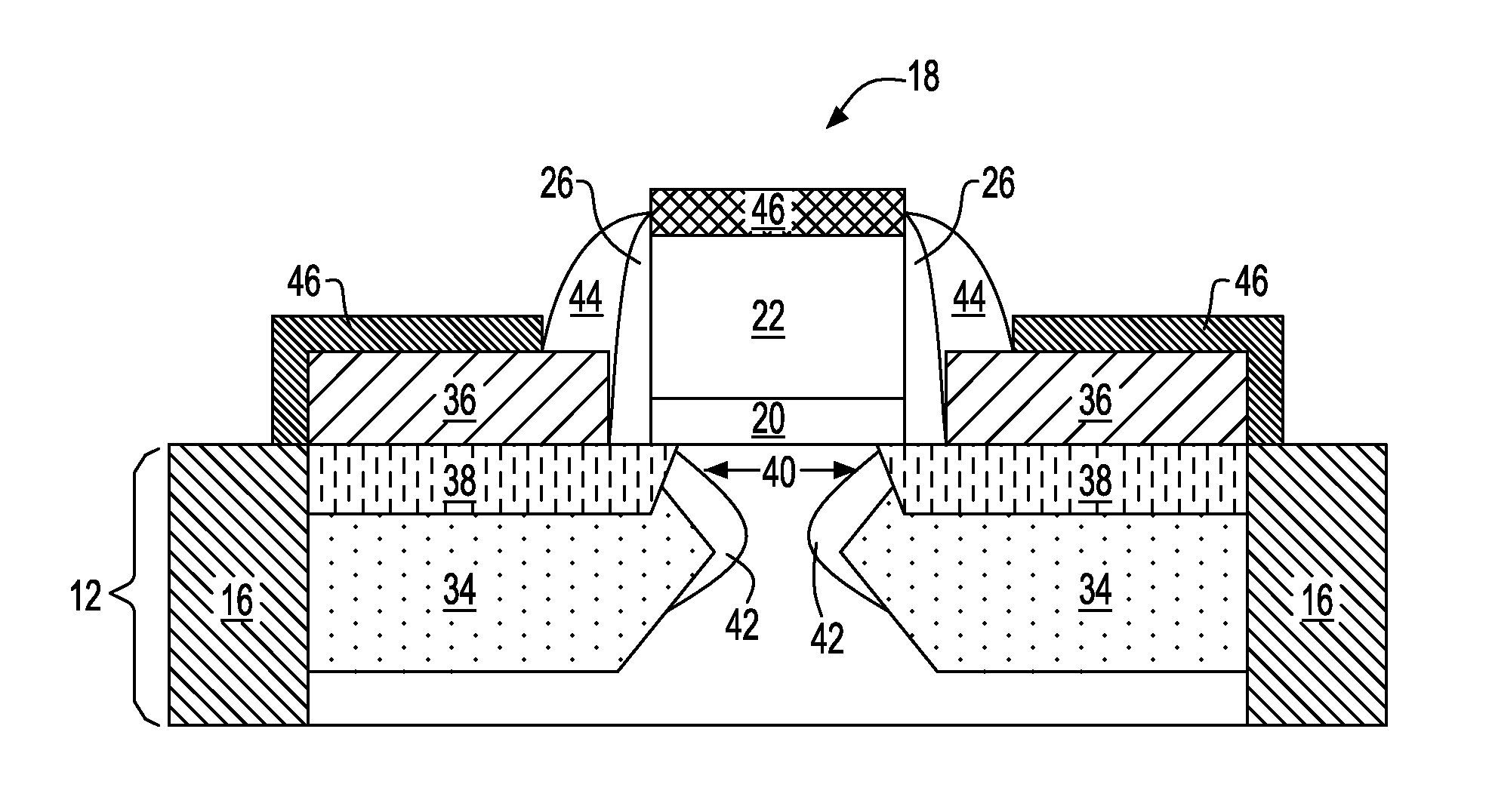

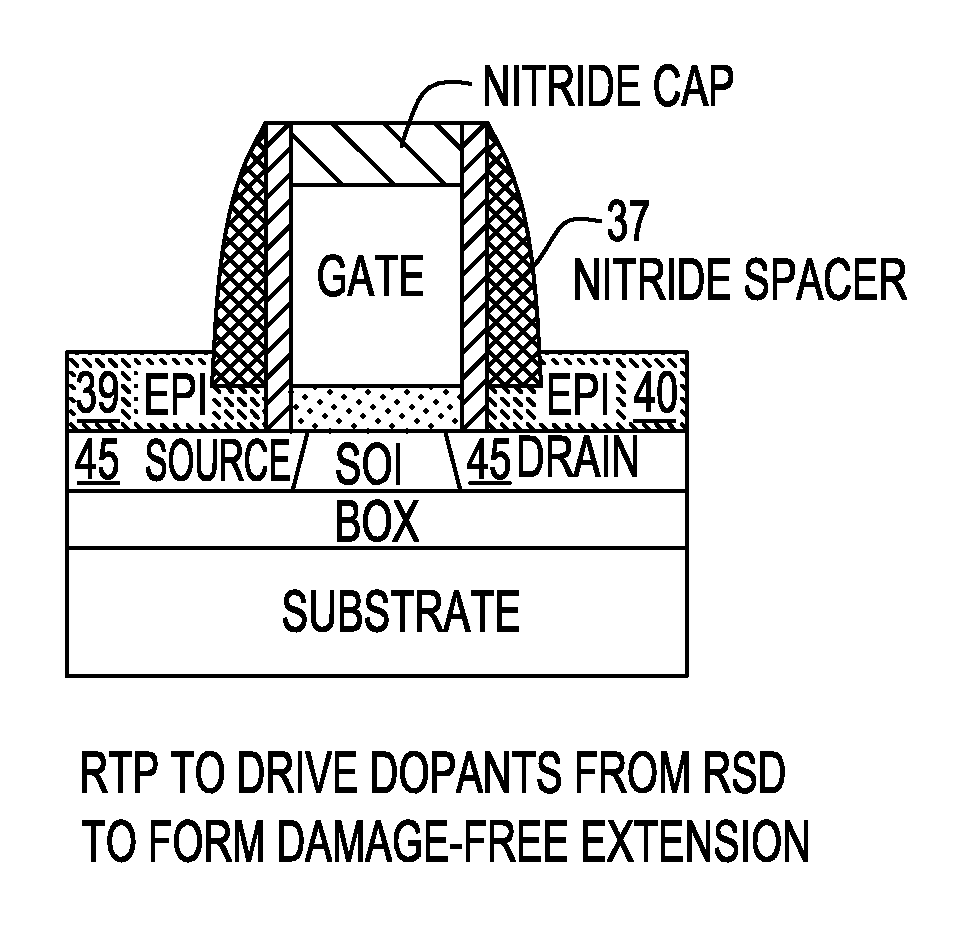

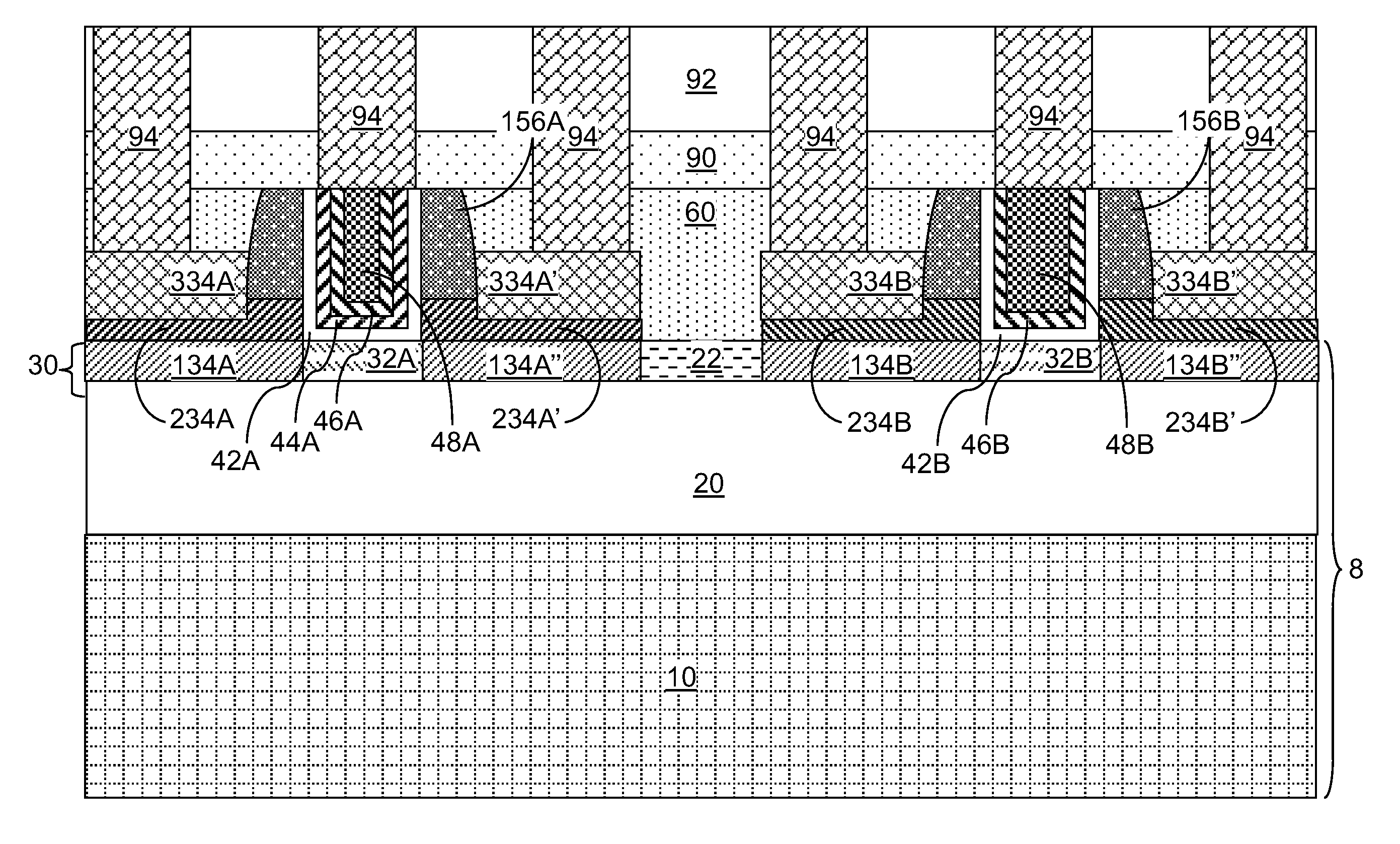

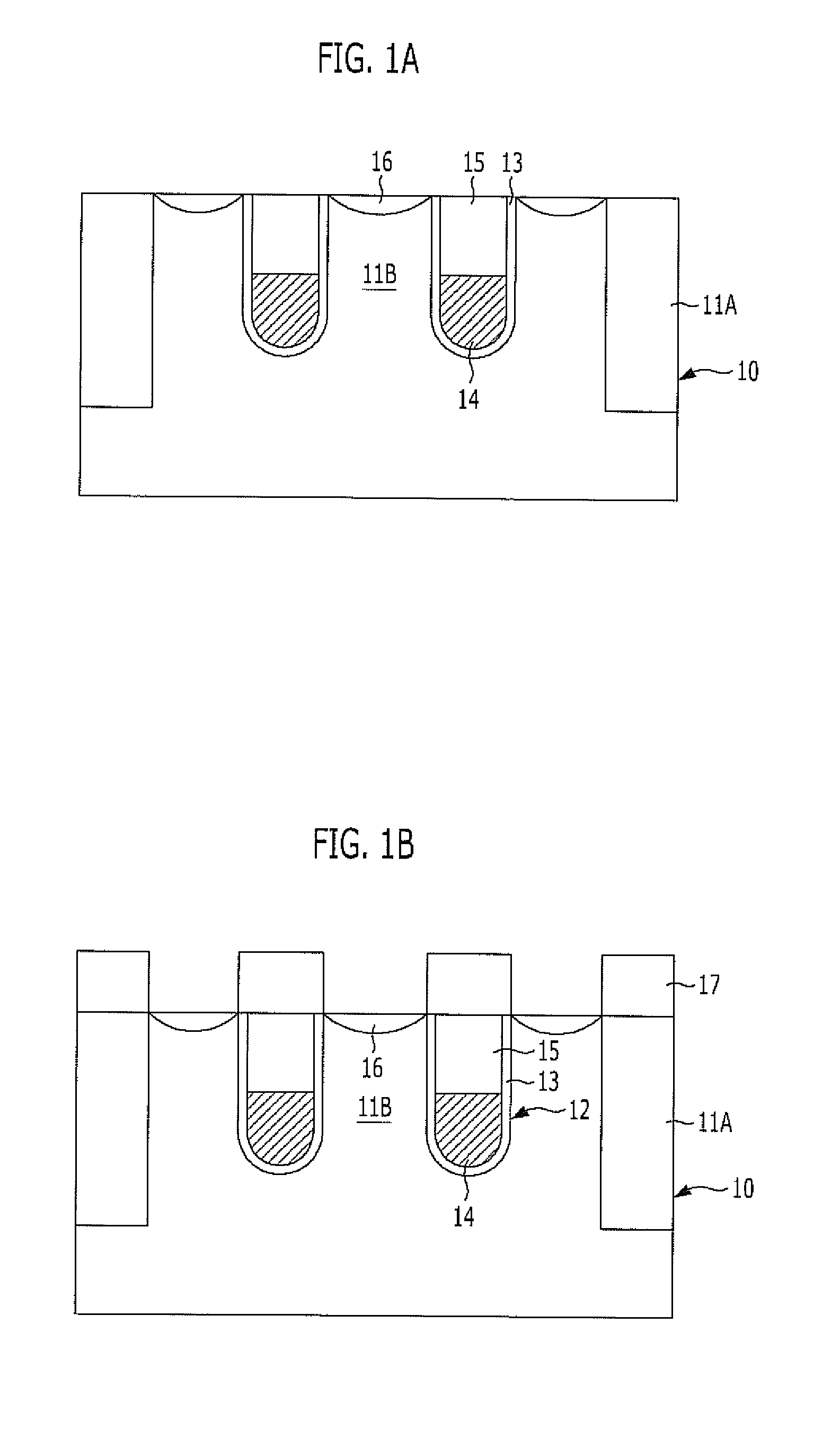

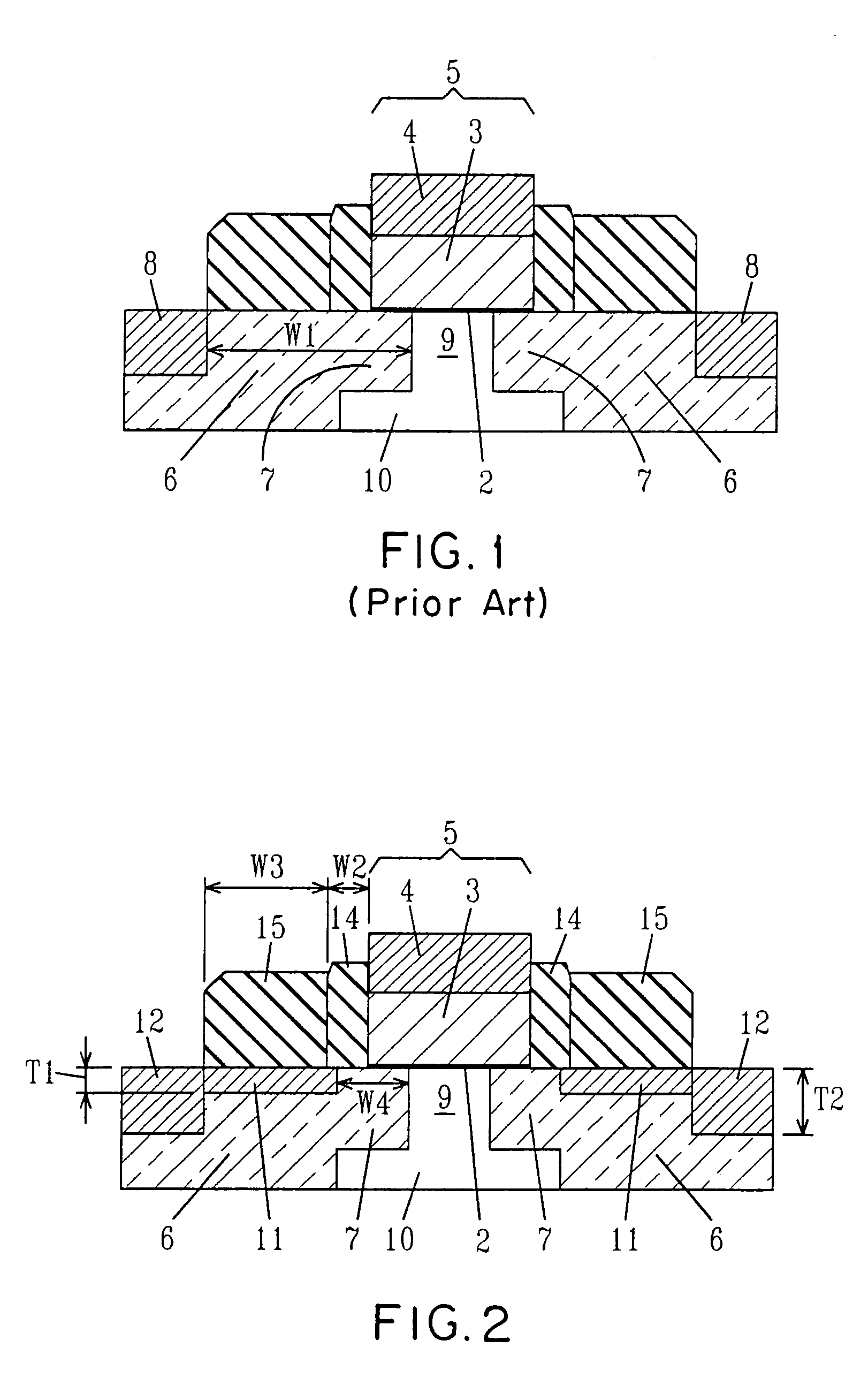

METHOD AND STRUCTURE FOR FORMING HIGH-PERFOMANCE FETs WITH EMBEDDED STRESSORS

ActiveUS20110068396A1Superior short channel controlReduce external resistanceTransistorSemiconductor/solid-state device manufacturingEngineeringGate stack

A high-performance semiconductor structure and a method of fabricating such a structure are provided. The semiconductor structure includes at least one gate stack, e.g., FET, located on an upper surface of a semiconductor substrate. The structure further includes a first epitaxy semiconductor material that induces a strain upon a channel of the at least one gate stack. The first epitaxy semiconductor material is located at a footprint of the at least one gate stack substantially within a pair of recessed regions in the substrate which are present on opposite sides of the at least one gate stack. A diffused extension region is located within an upper surface of said first epitaxy semiconductor material in each of the recessed regions. The structure further includes a second epitaxy semiconductor material located on an upper surface of the diffused extension region. The second epitaxy semiconductor material has a higher dopant concentration than the first epitaxy semiconductor material.

Owner:GLOBALFOUNDRIES US INC

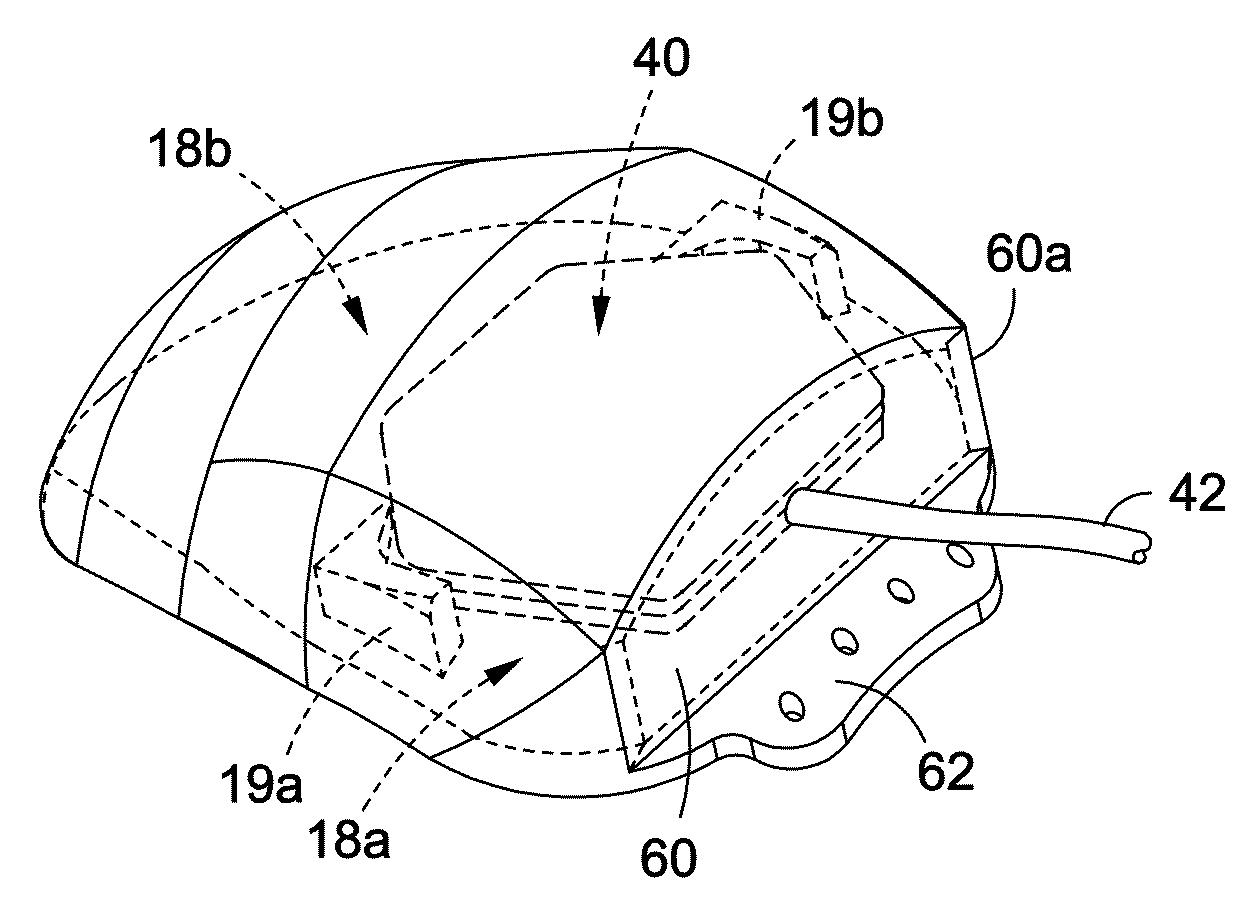

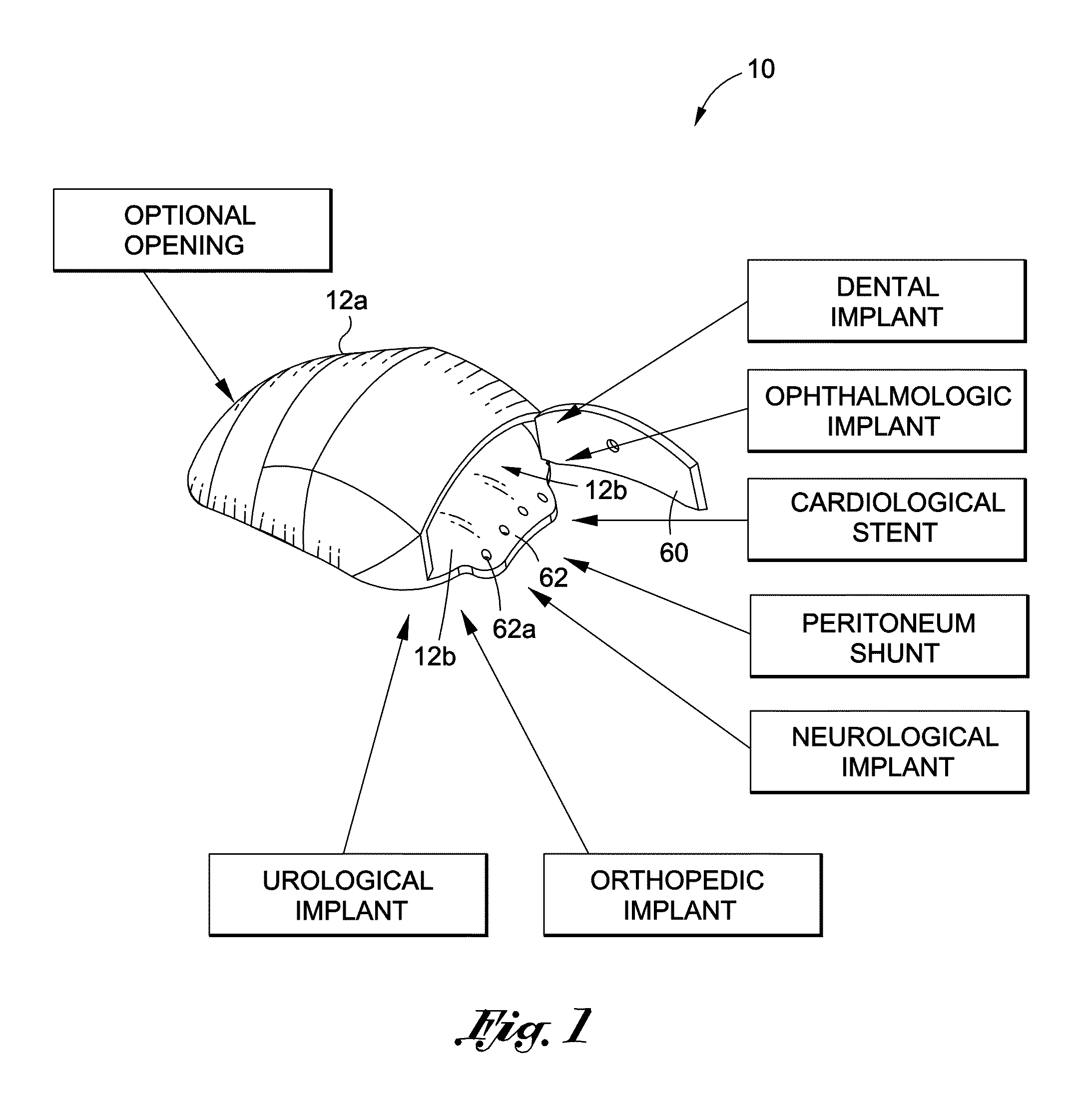

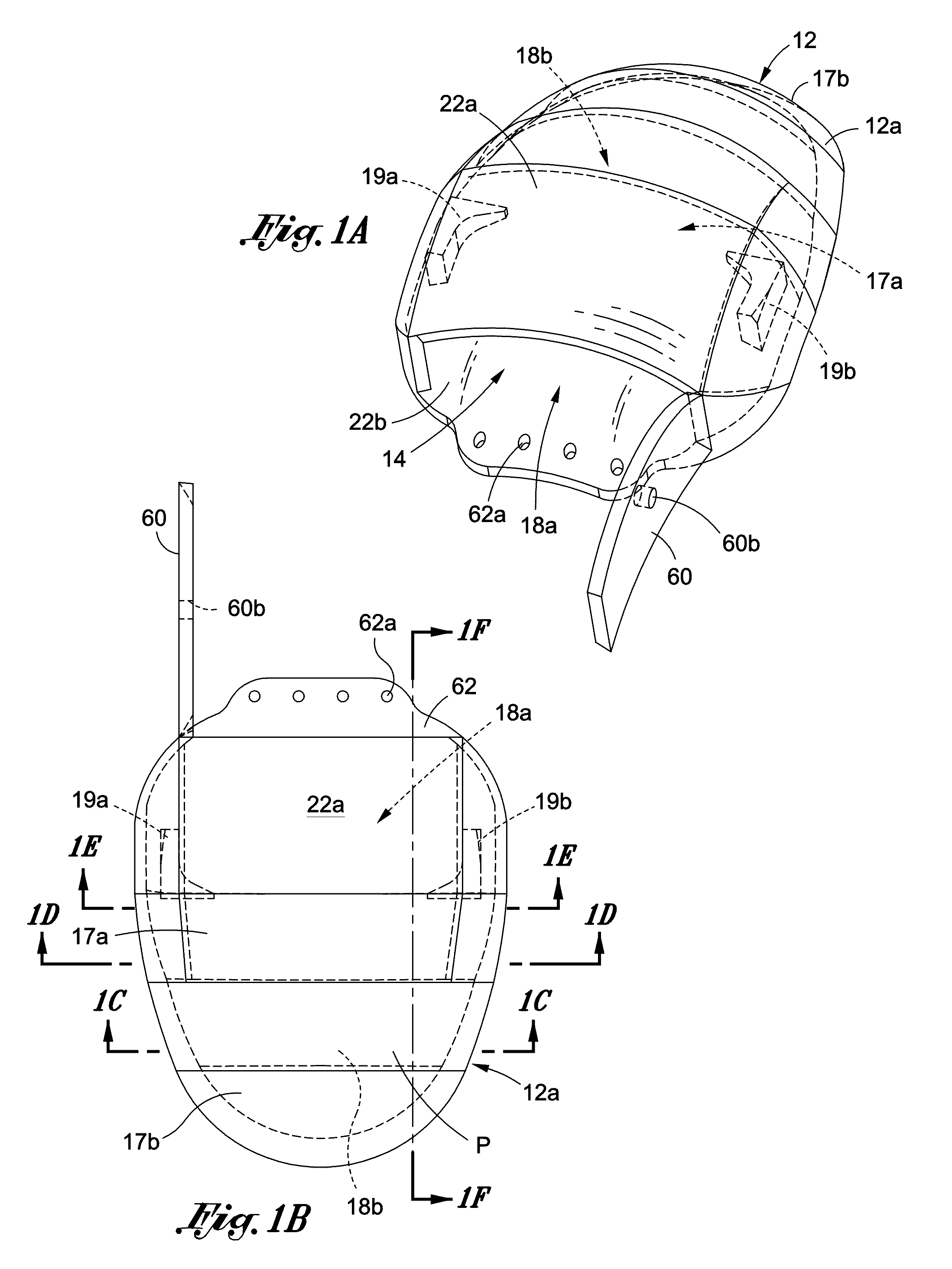

Implantable medical assembly and methods

ActiveUS8632489B1High speedReduce resistanceAdditive manufacturing apparatusEye surgeryBody fluidMedical device

An implantable medical assembly includes a cover having a porous chamber. Enclosed within the chamber is a medical device through which aqueous body fluid flows from an outlet of the device into the chamber. The chamber is formed at least in part from a porous material that promotes vascularization and inhibits fibrotic encapsulation upon implantation and that allows aqueous body fluid in the chamber to flow through the porous material into body tissue in which the assembly is implanted. The chamber has a pair of walls that are spaced apart at a first portion of the chamber at or near the outlet and converge at a second portion of the chamber downstream of the outlet.

Owner:AHMED A MATEEN

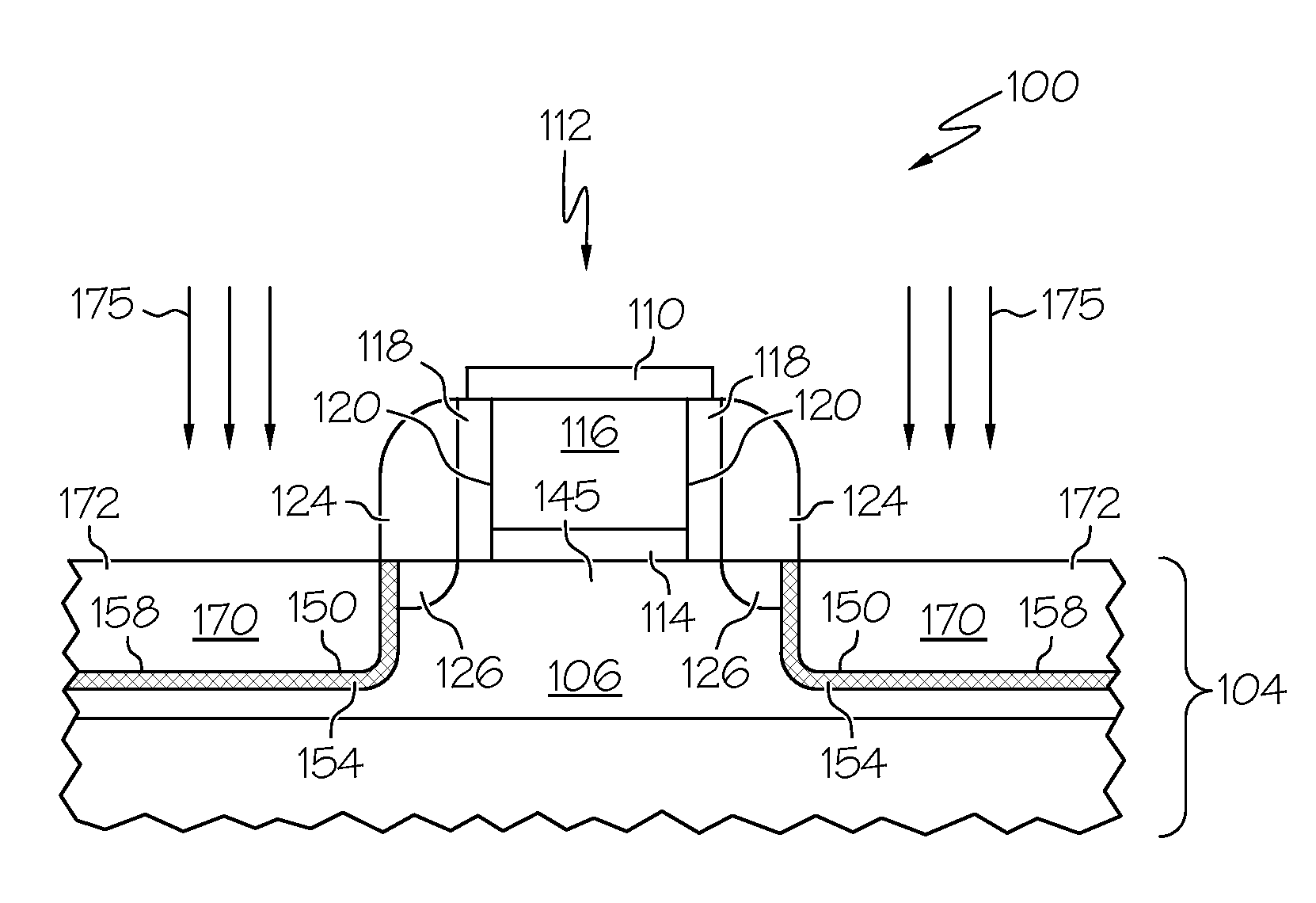

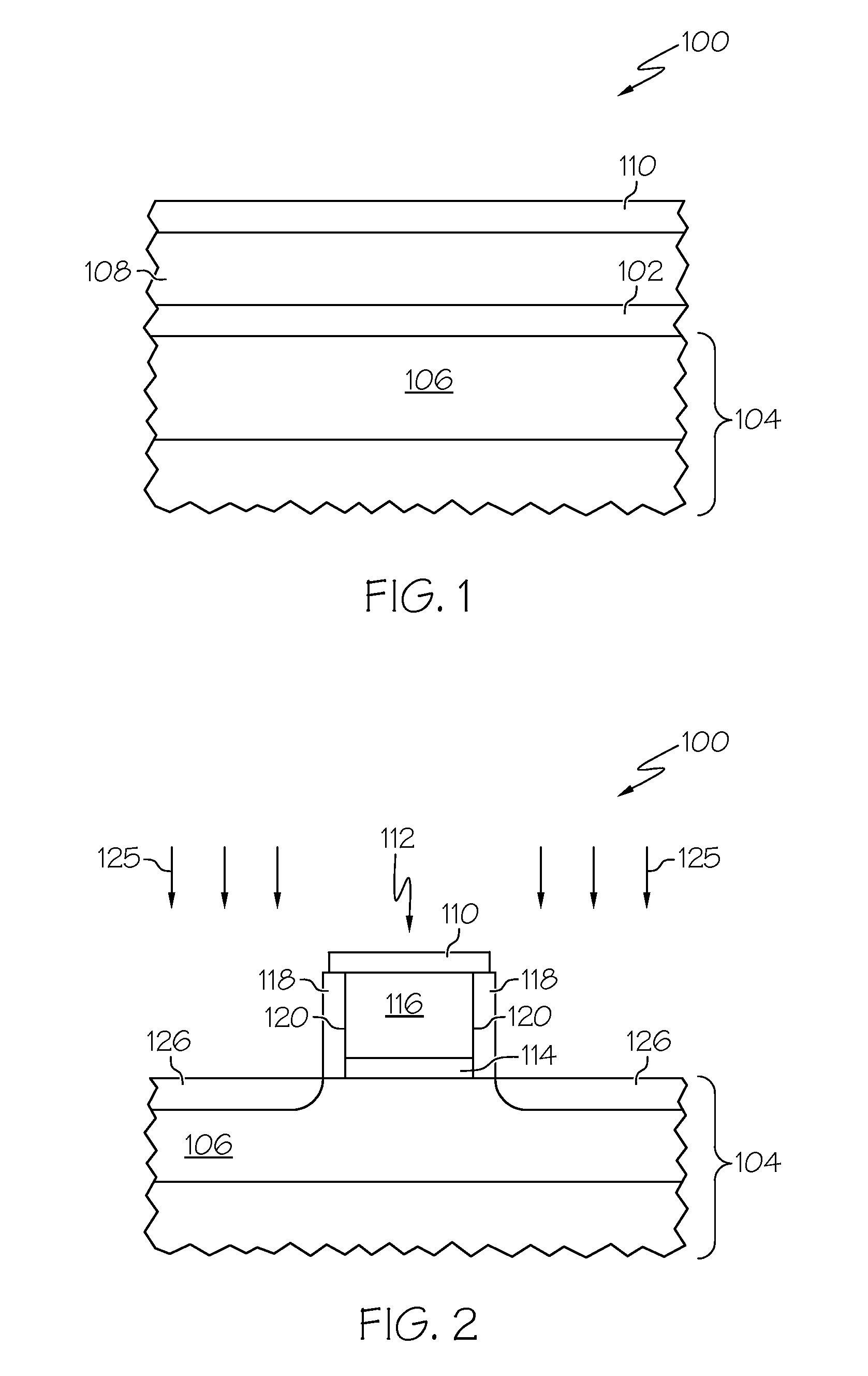

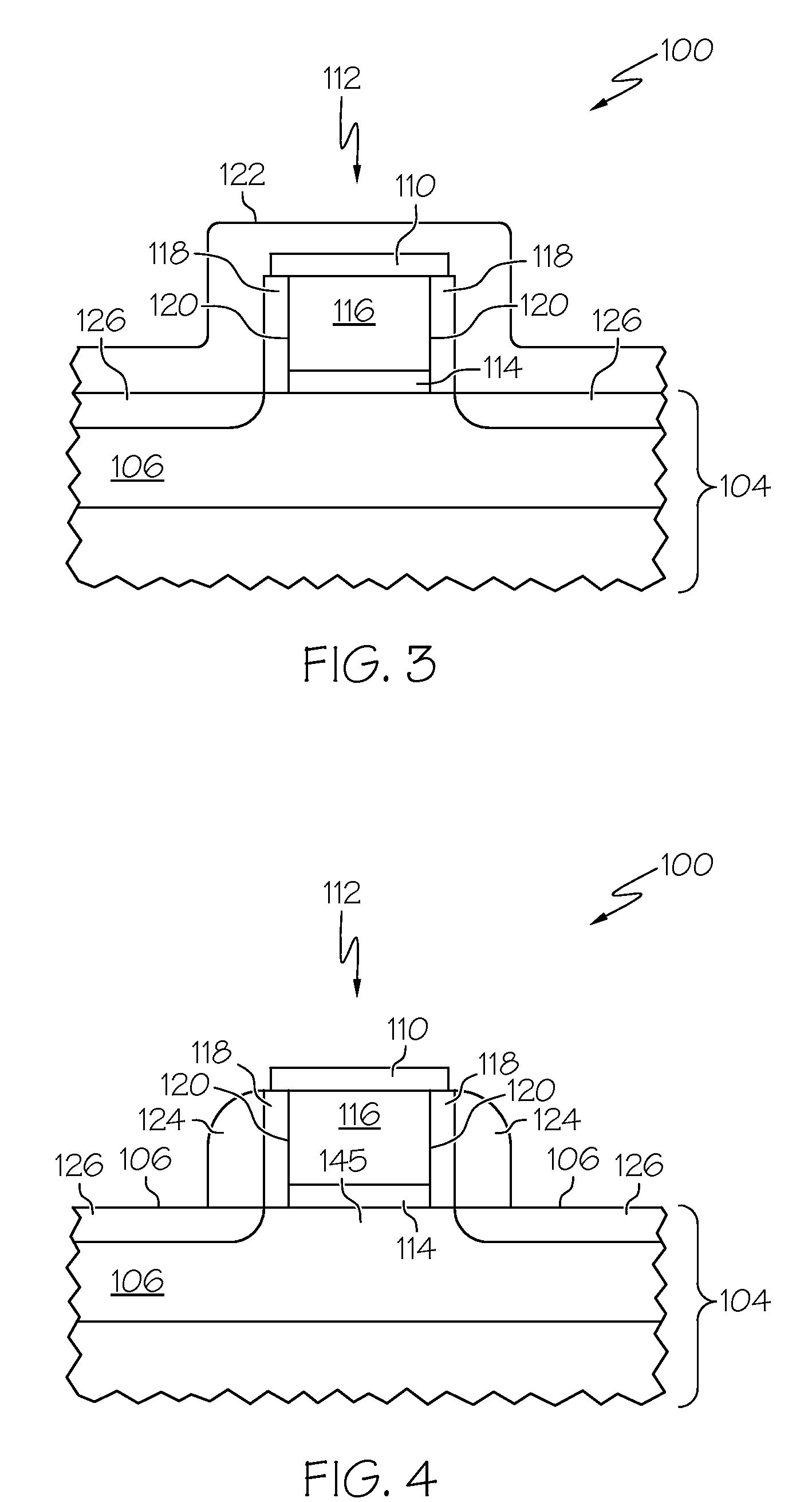

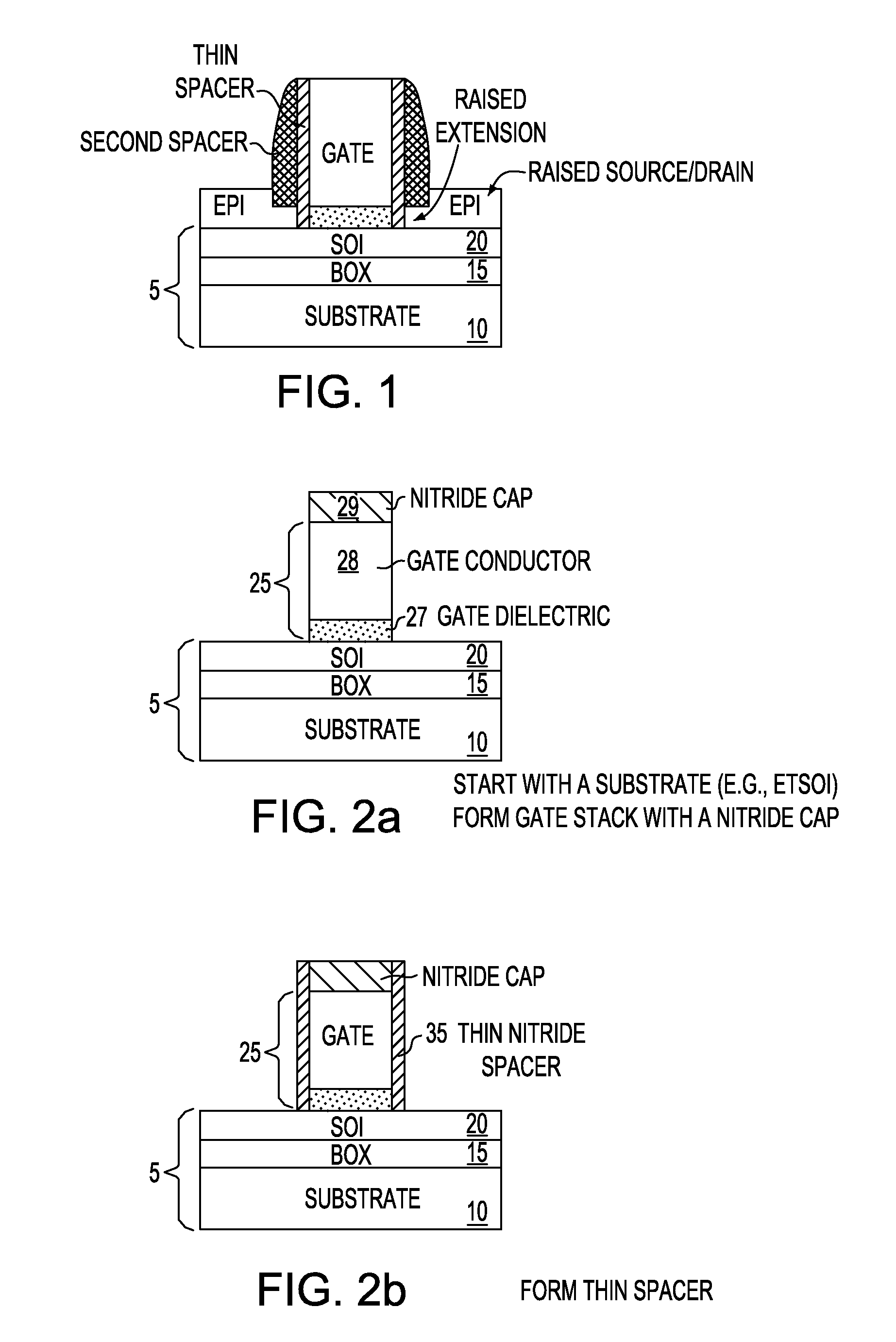

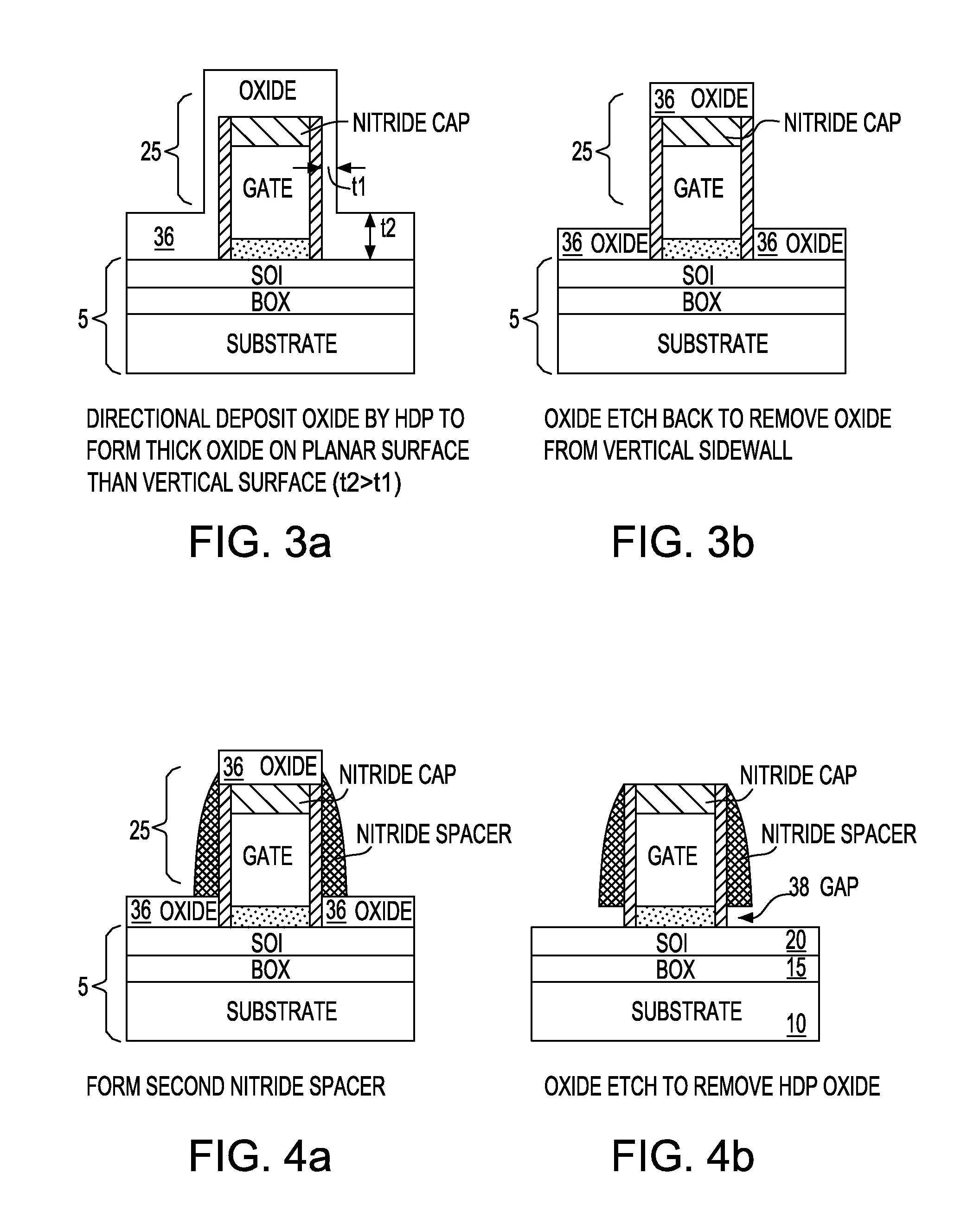

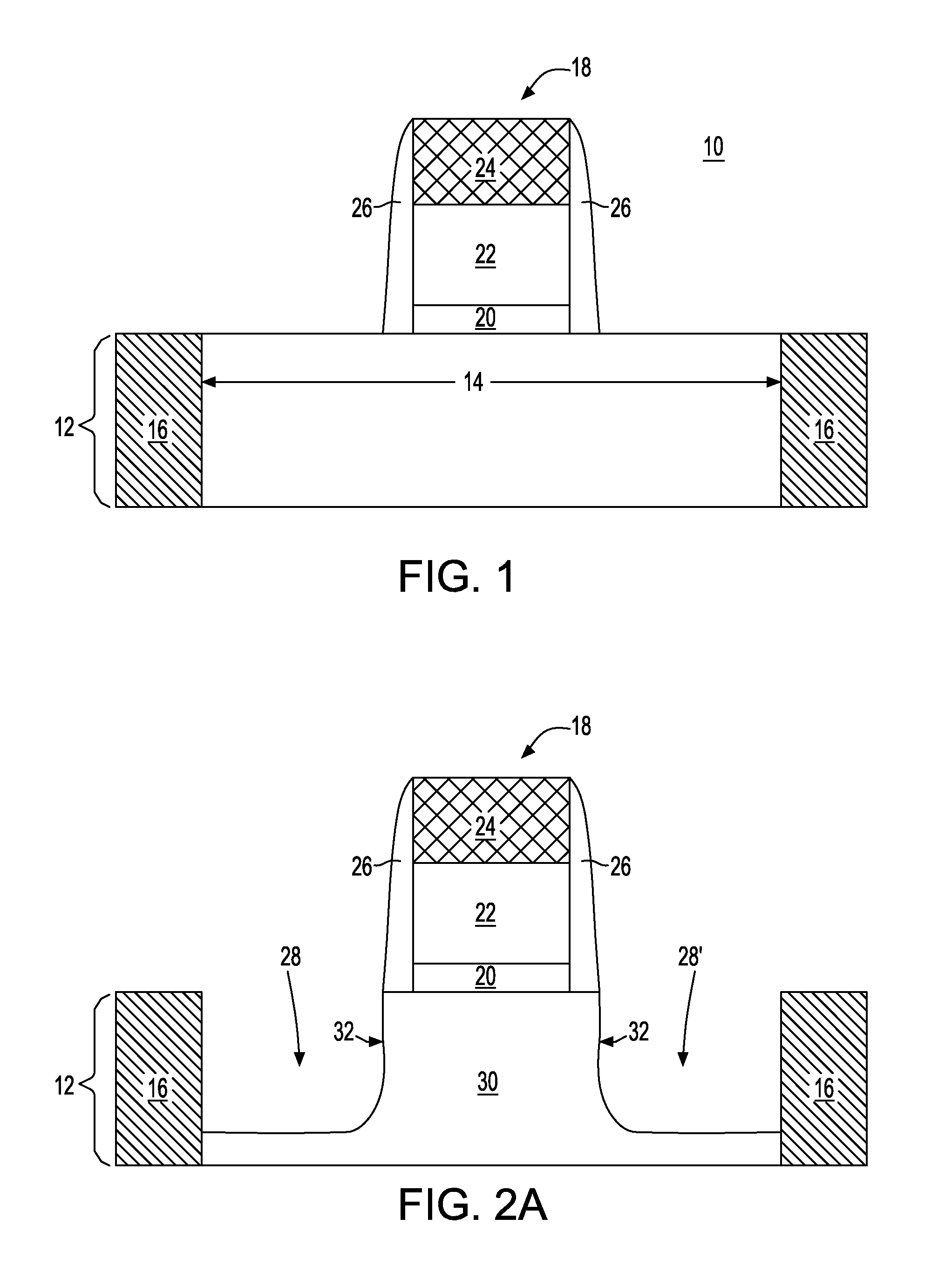

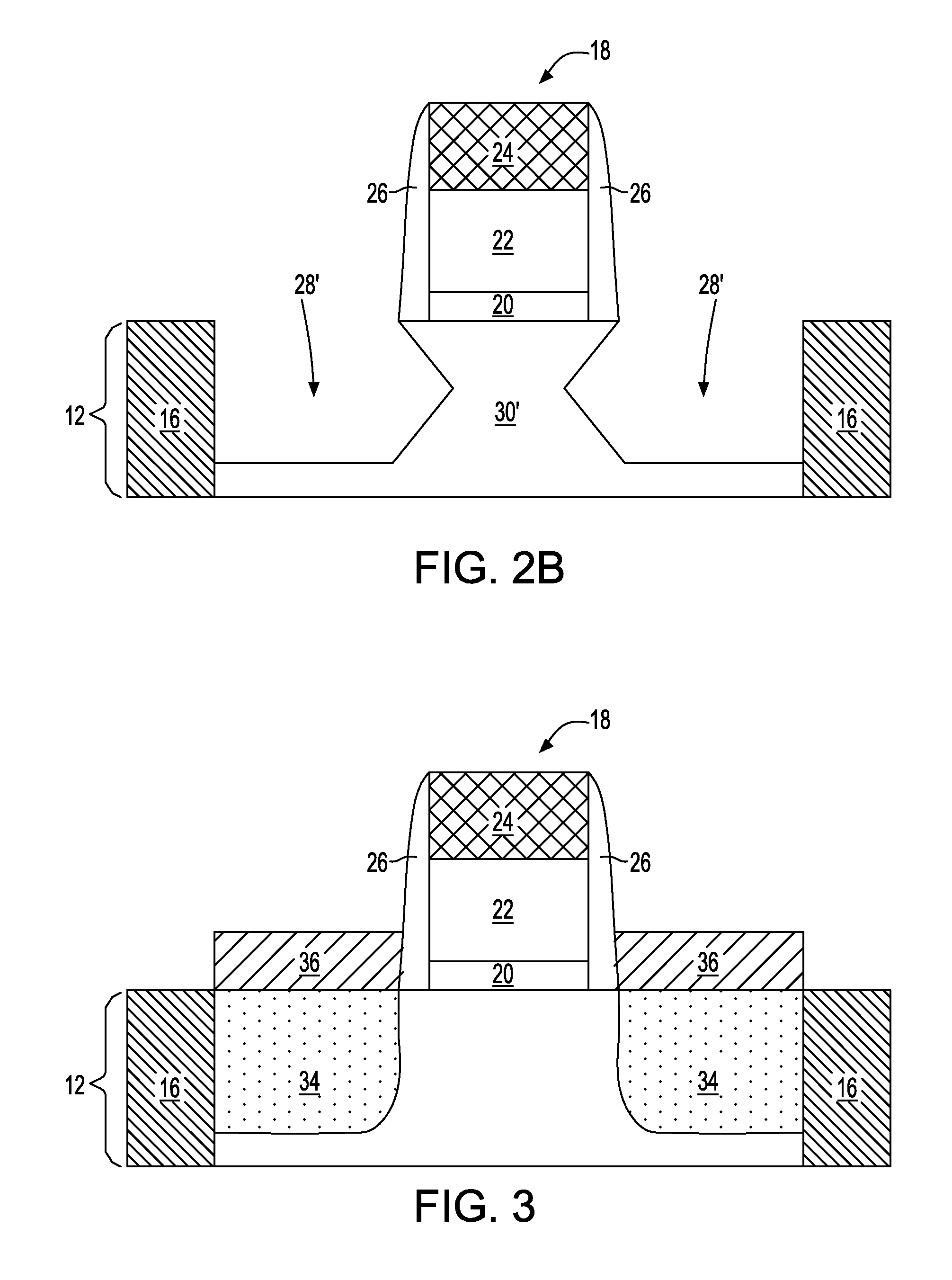

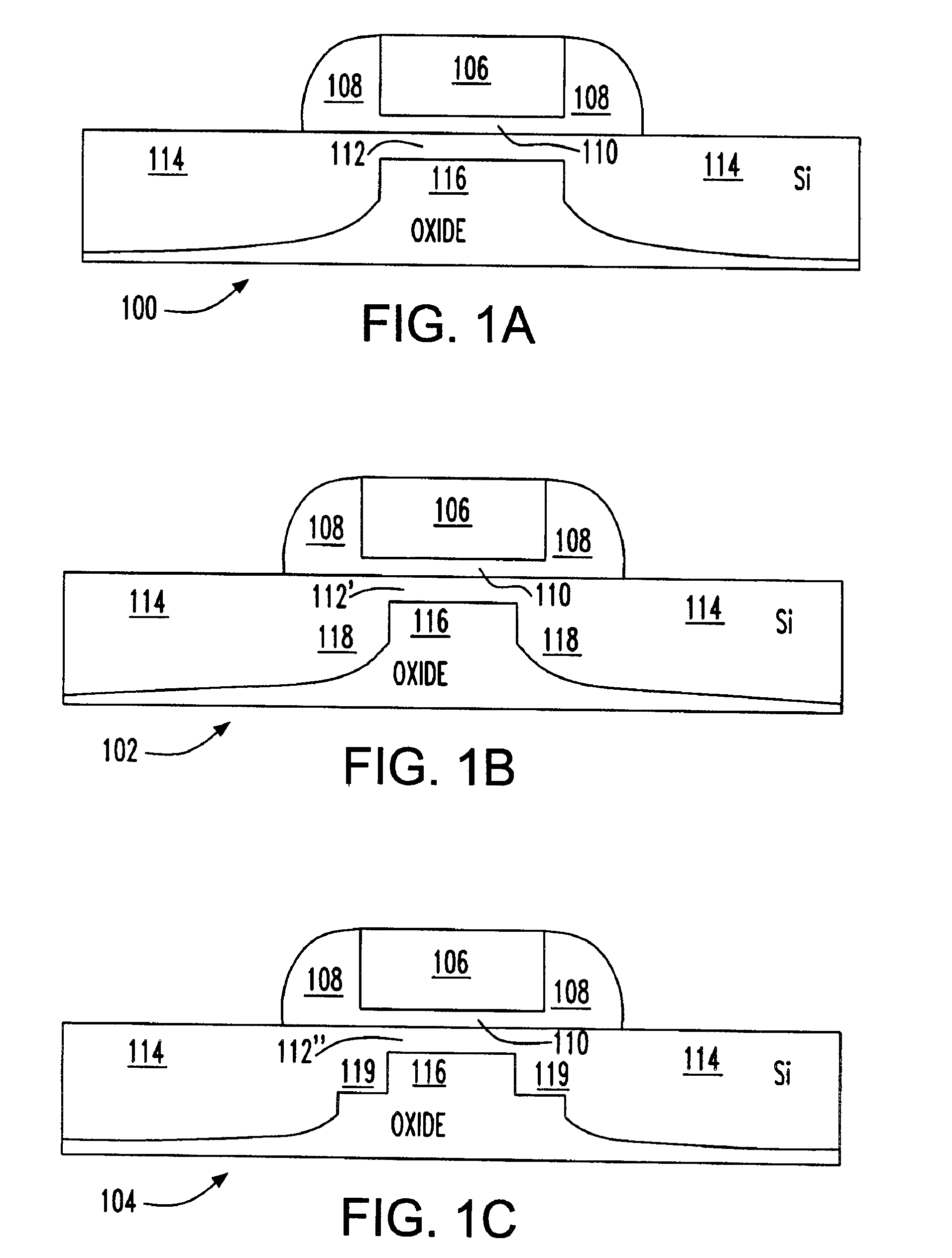

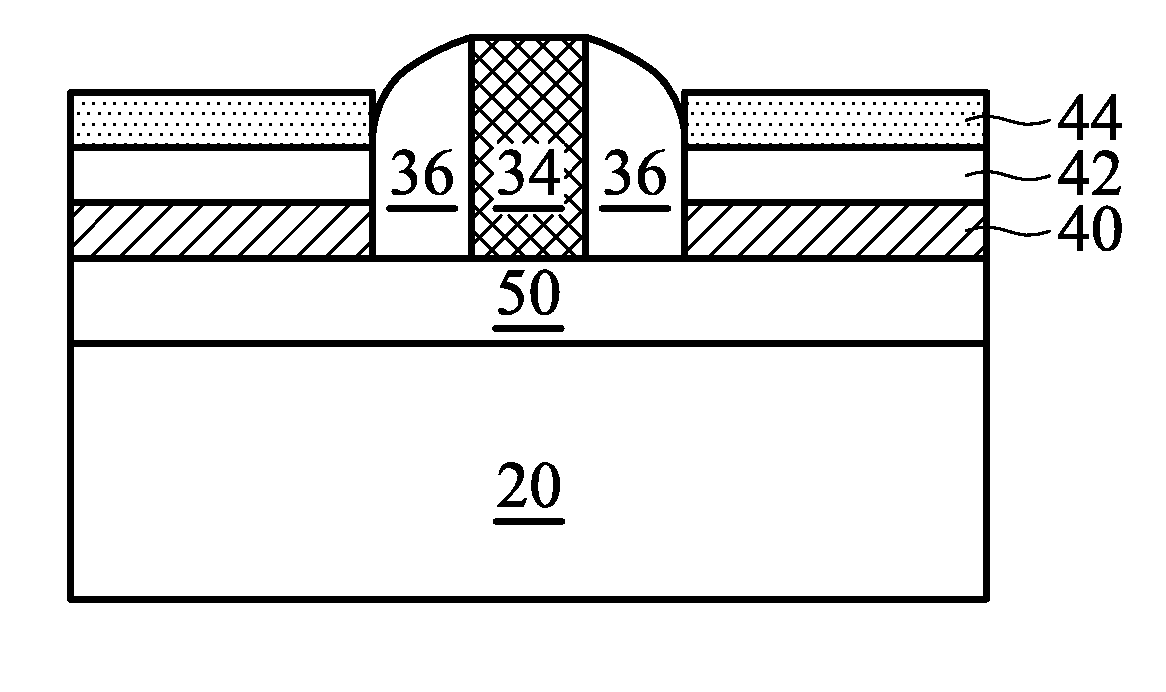

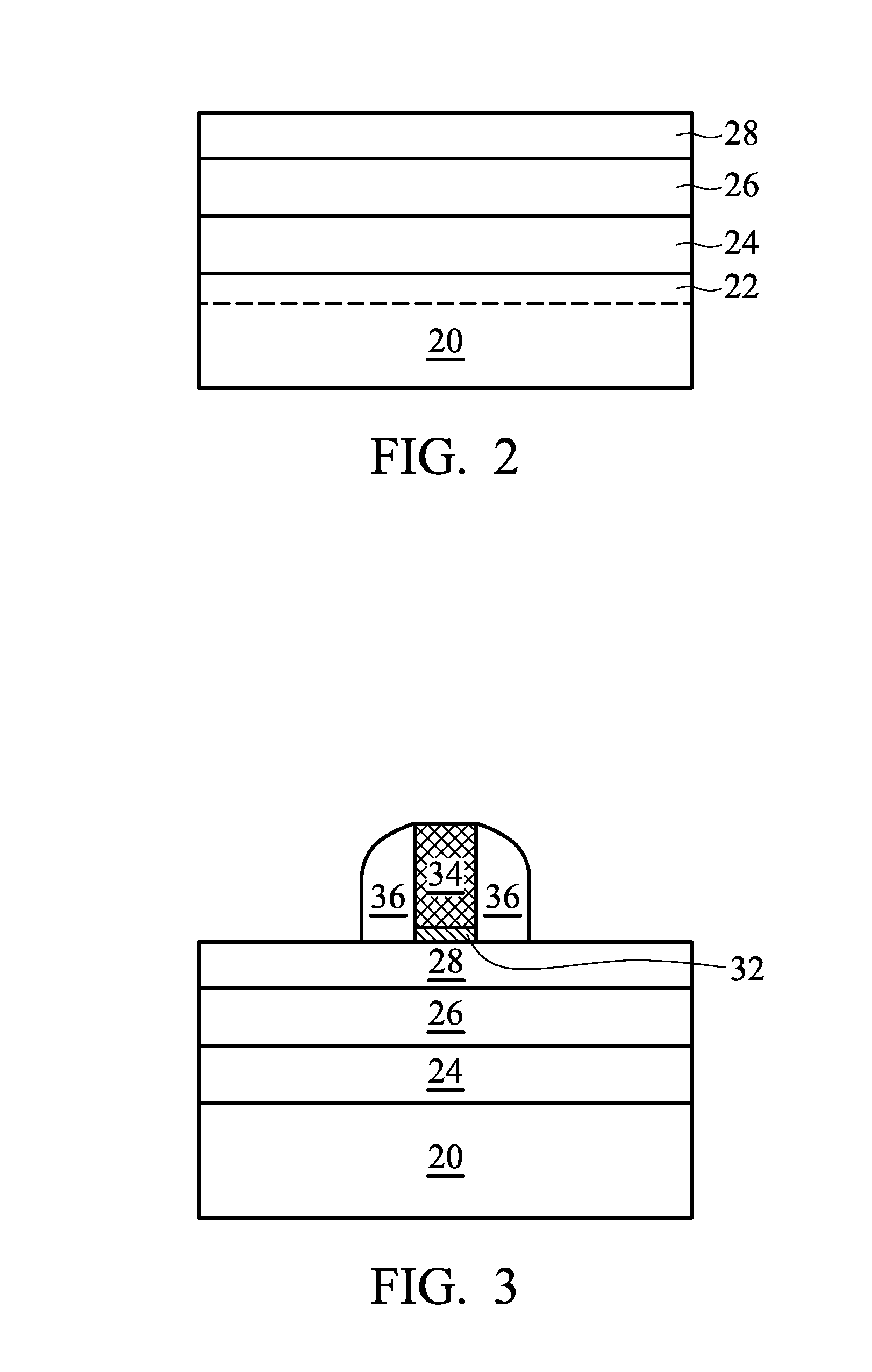

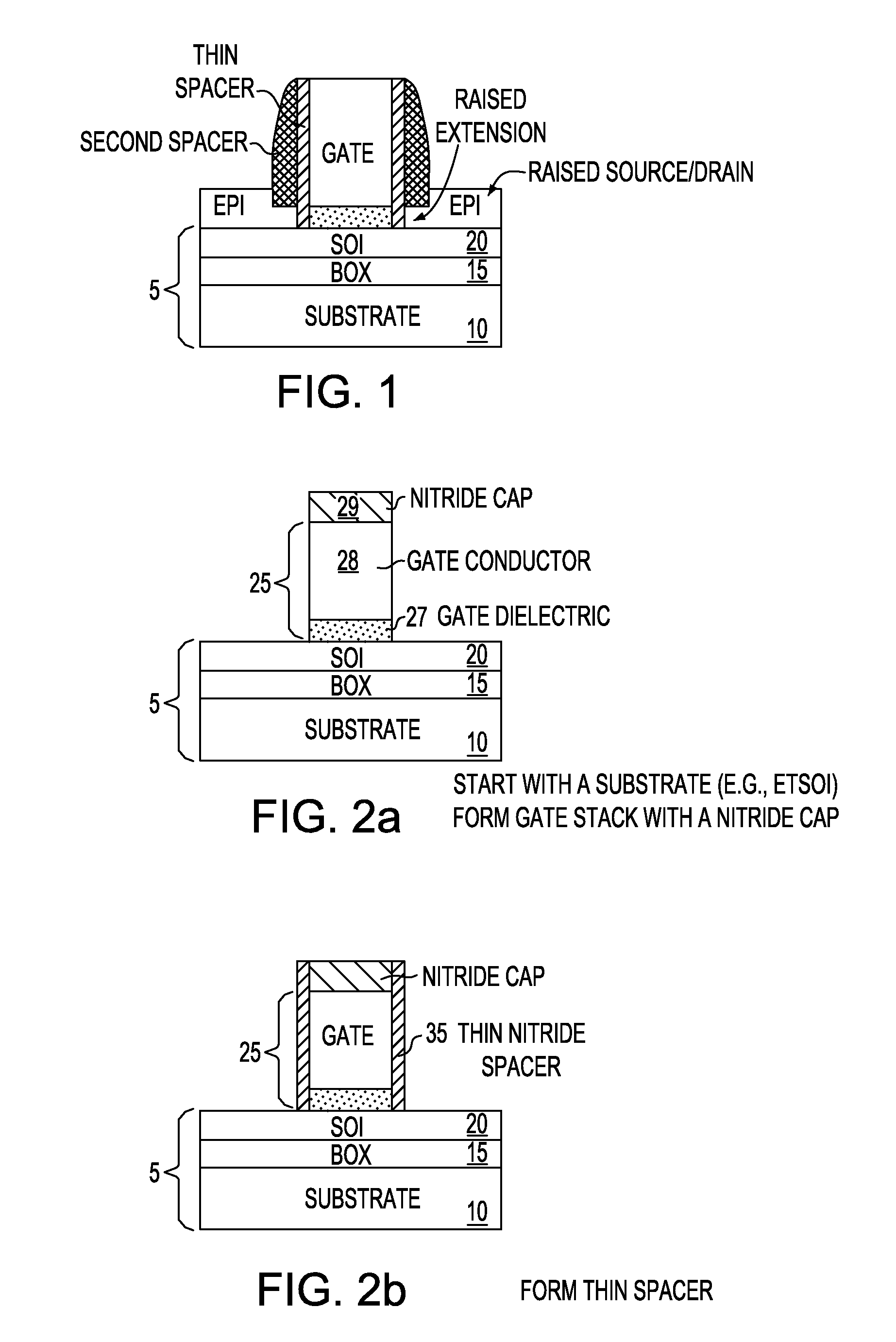

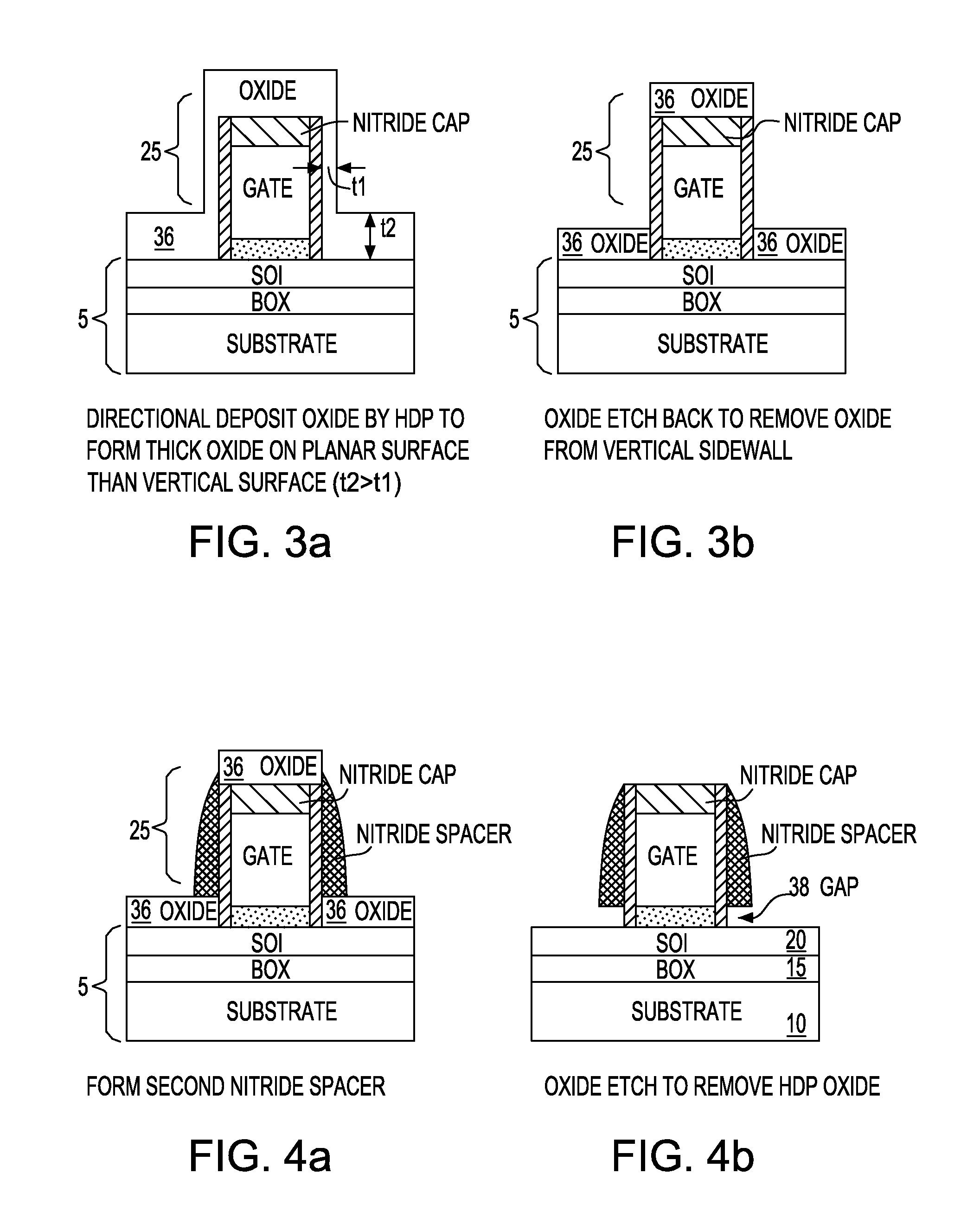

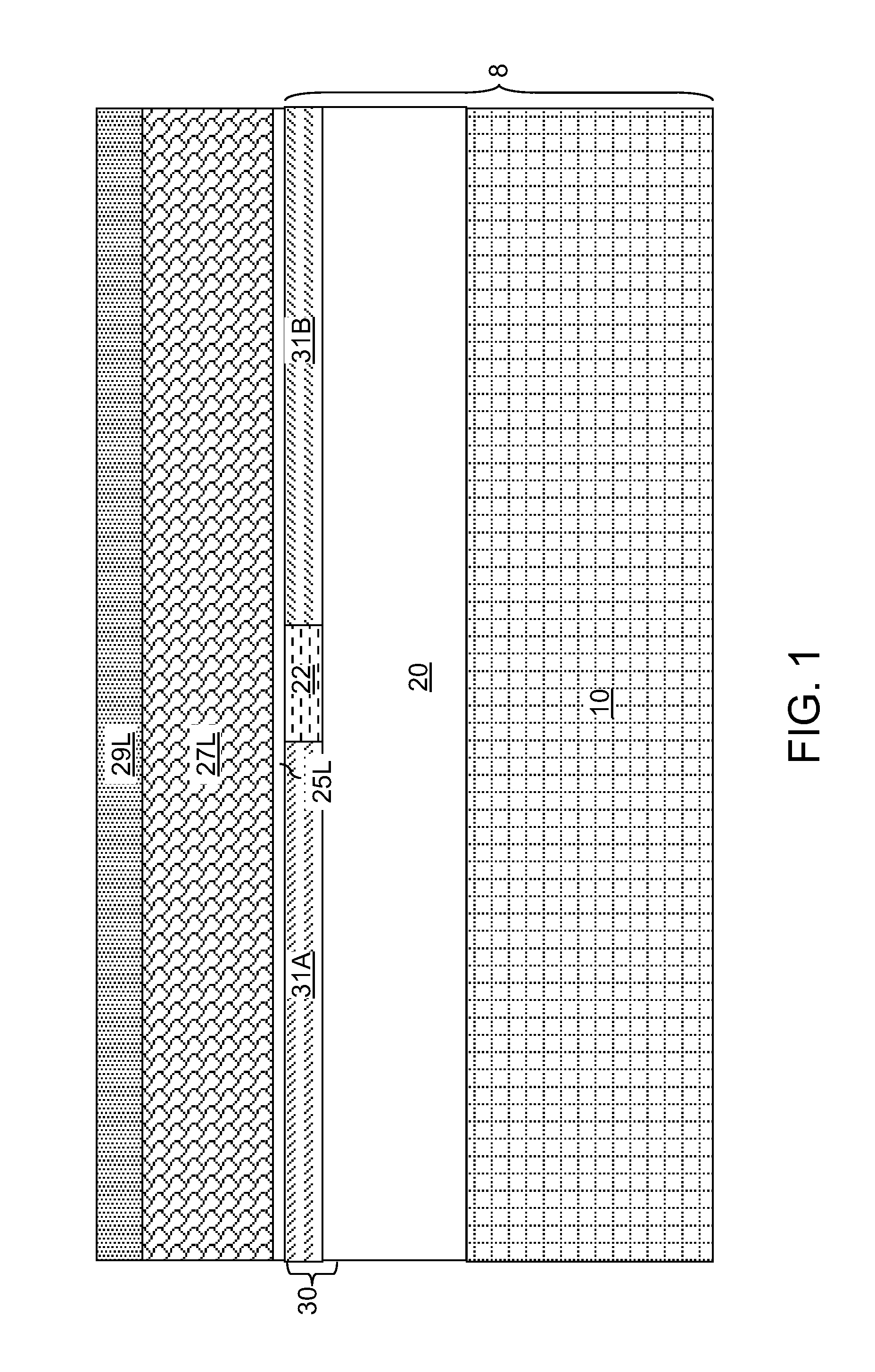

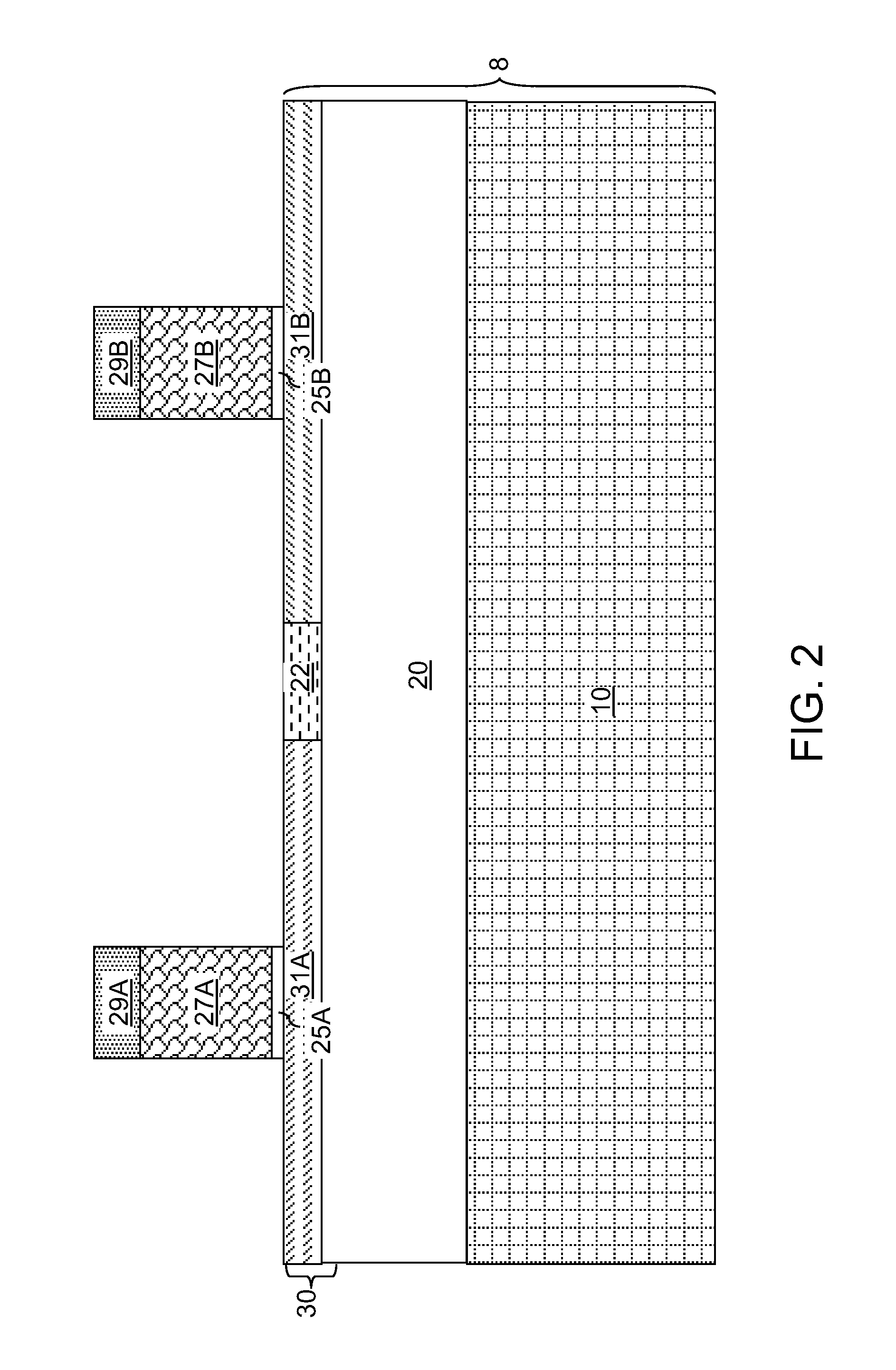

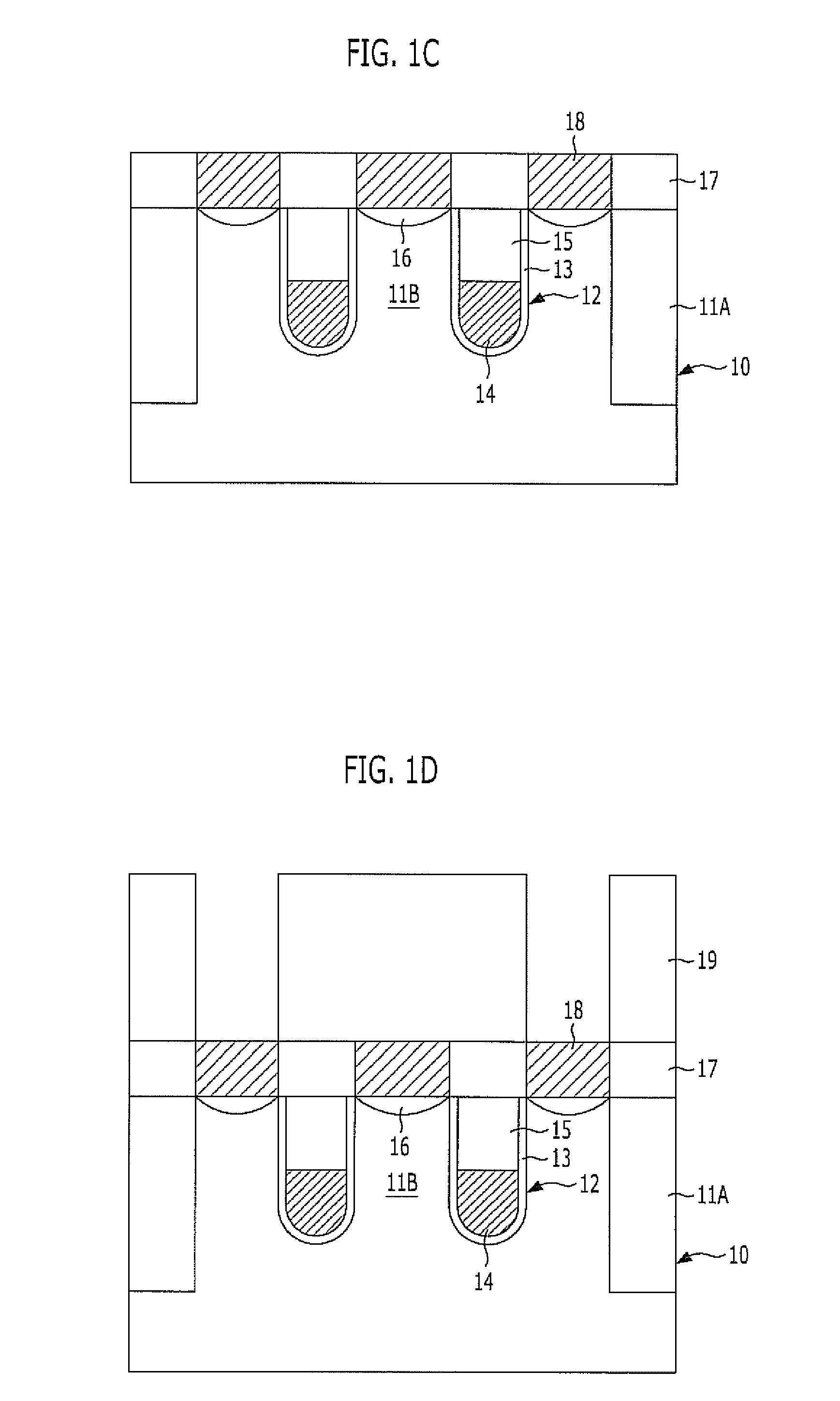

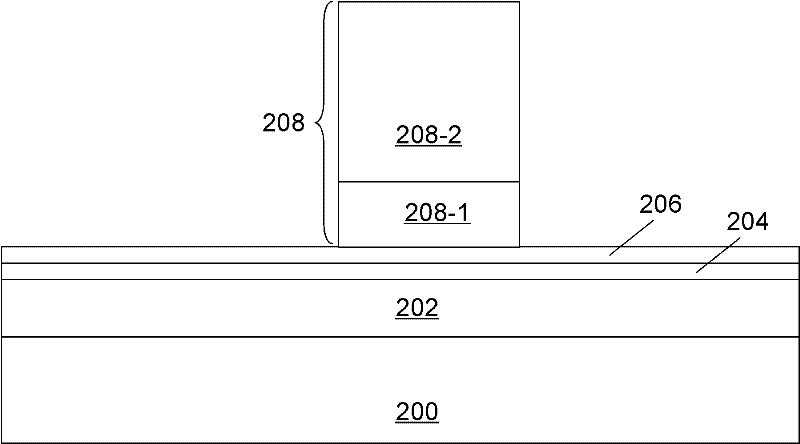

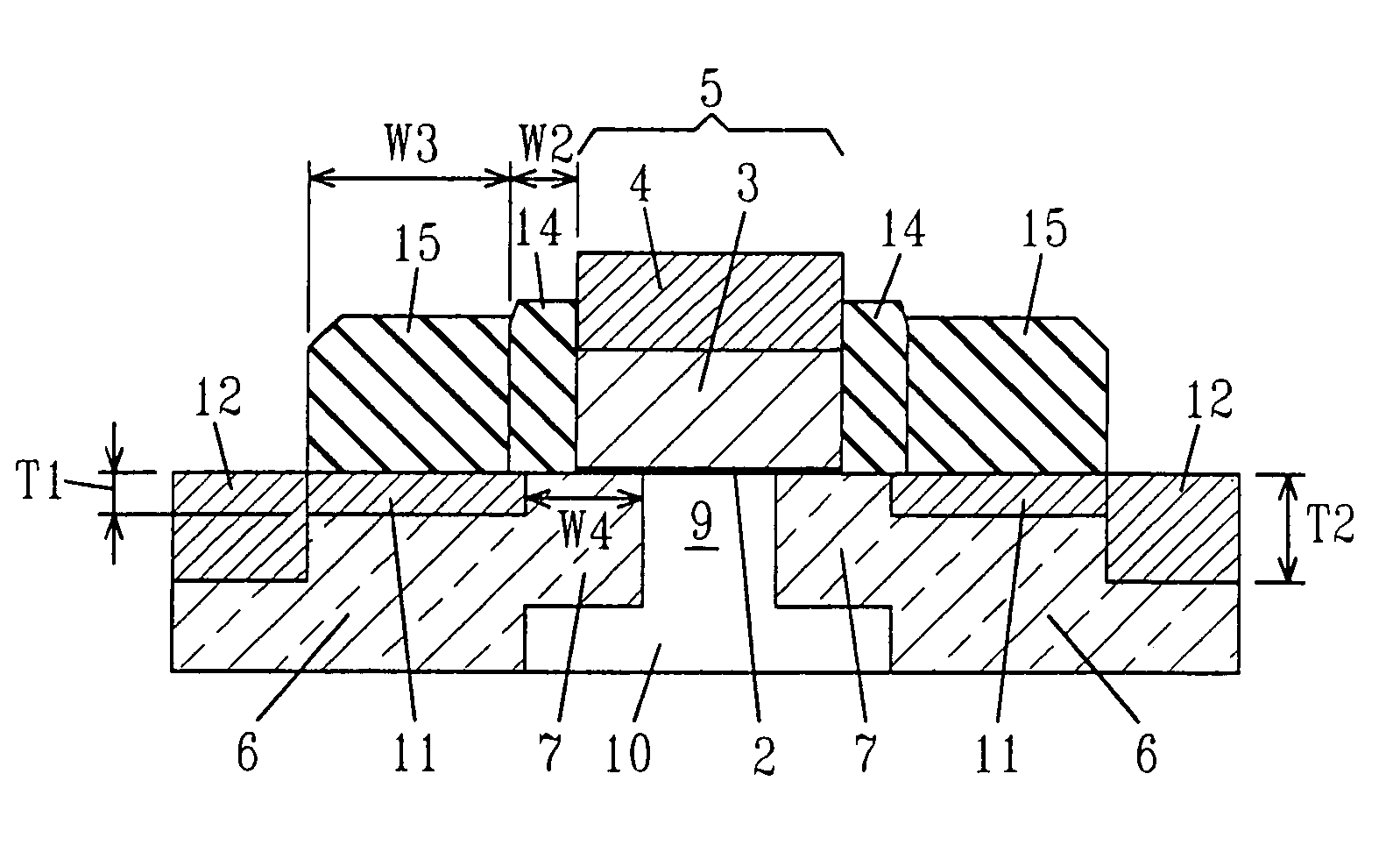

Extremely Thin Semiconductor-on-Insulator (ETSOI) FET Having a Stair-Shape Raised Source/Drain and a Method of Forming the Same

ActiveUS20120061759A1Lower extension resistanceIncrease parasitic resistanceTransistorSolid-state devicesMOSFETSoi substrate

A MOSFET device is formed on top of a semiconductor-on-insulator (SOI) substrate having a semiconductor layer with a thickness ranging from 3 nm to 20 nm. A stair-shape raised extension, a raised source region and a raised drain region (S / D) are formed on top of the SOI substrate. The thinner raised extension region abuts at a thin gate sidewall spacer, lowering the extension resistance without significantly increasing the parasitic resistance. A single epitaxial growth forms the thinner raised extension and the thicker raised S / D preferably simultaneously, reducing the fabrication cost as well as the contact resistance between the raised S / D and the extension. A method of forming the aforementioned MOSFET device is also provided.

Owner:GLOBALFOUNDRIES US INC

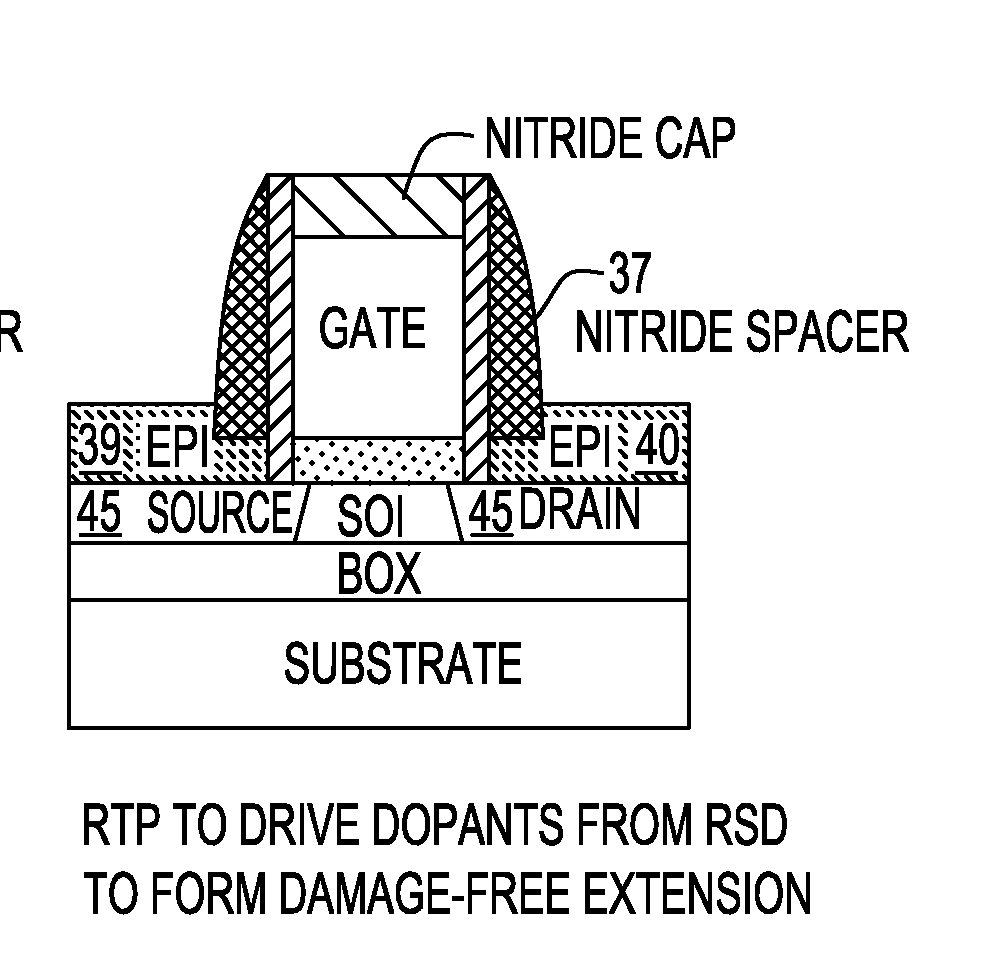

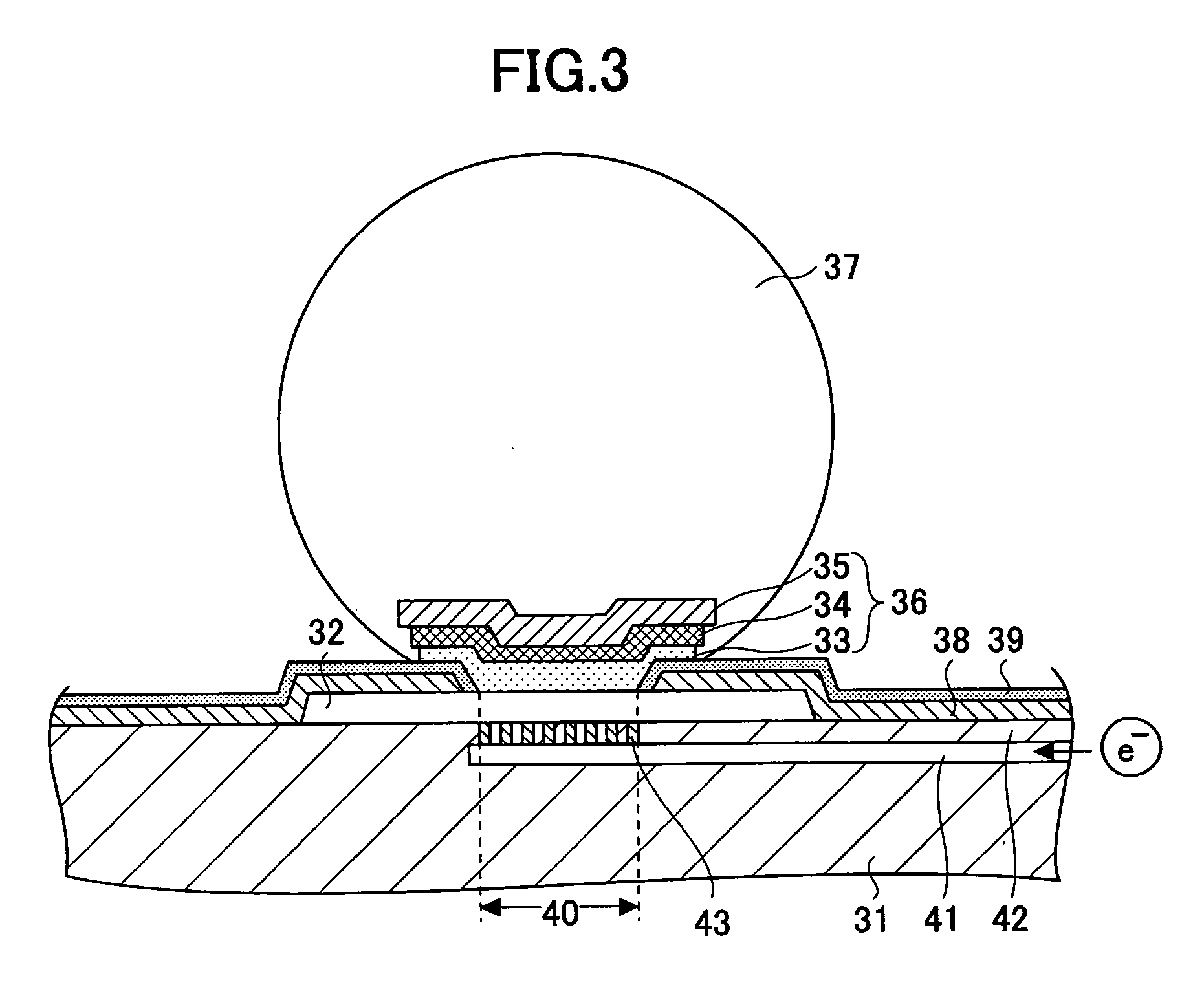

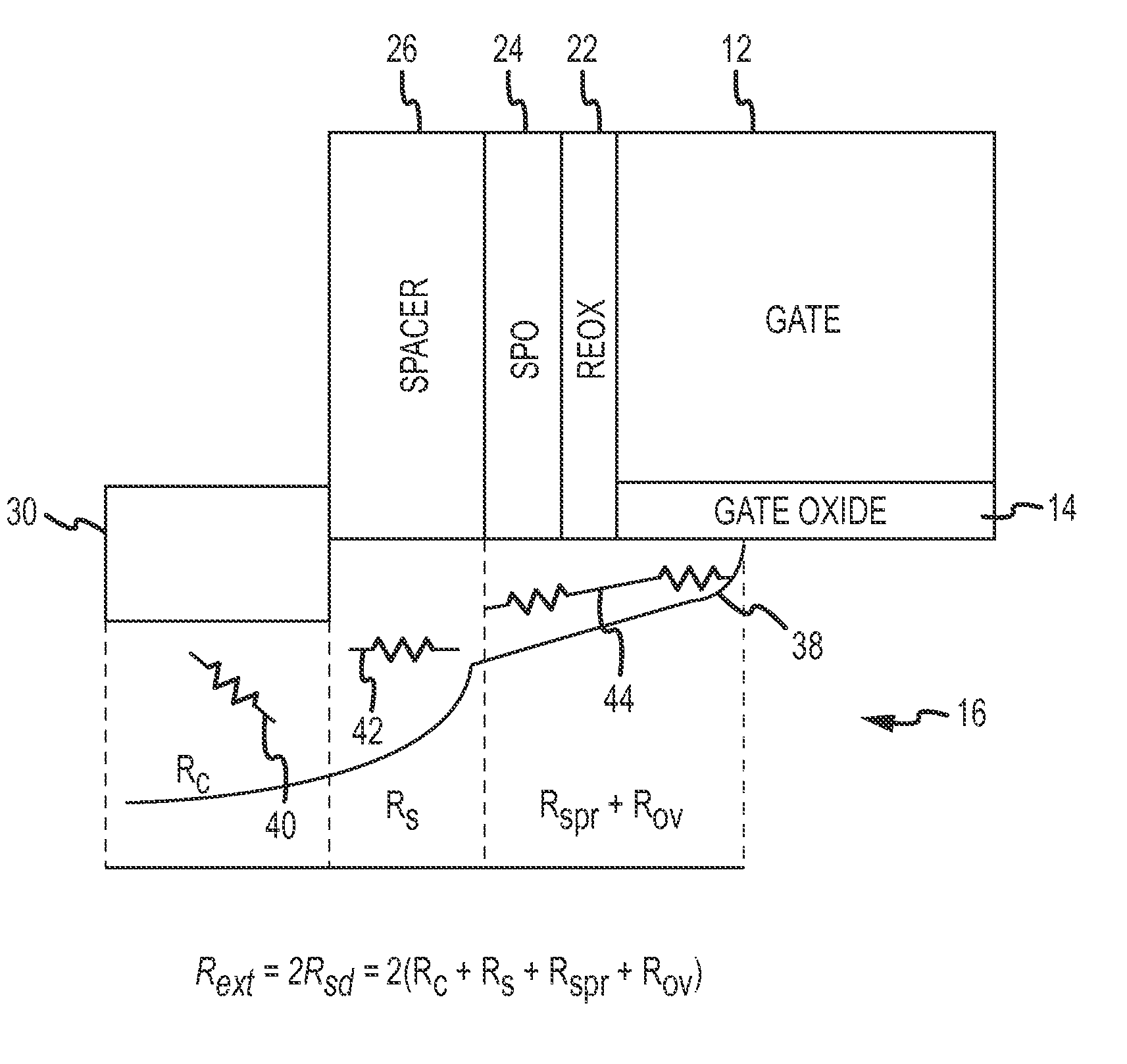

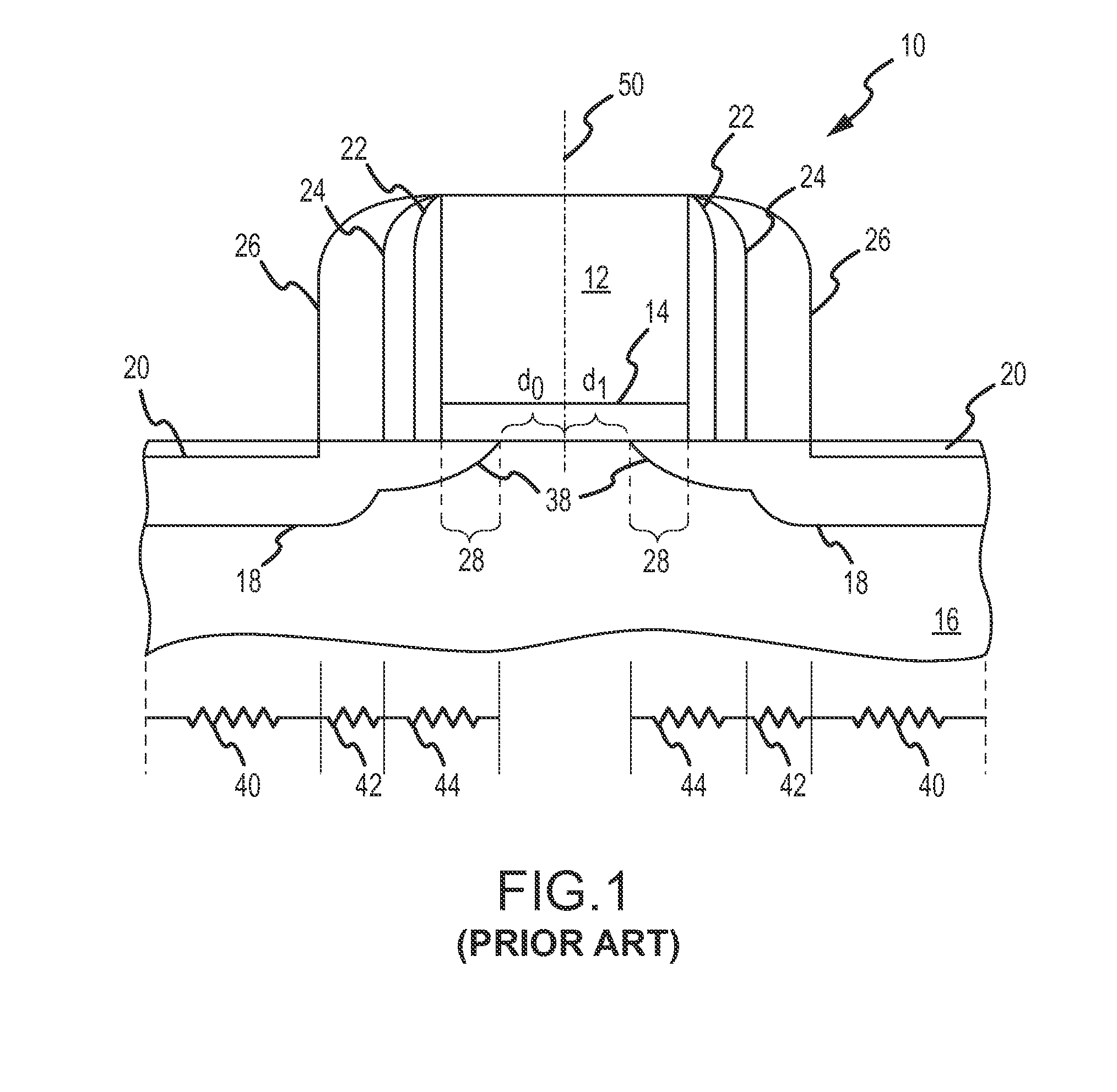

High-performance FETs with embedded stressors

ActiveUS8022488B2High dopant activationSuperior short channel controlTransistorSemiconductor/solid-state device manufacturingDopantSemiconductor materials

A high-performance semiconductor structure and a method of fabricating such a structure are provided. The semiconductor structure includes at least one gate stack, e.g., FET, located on an upper surface of a semiconductor substrate. The structure further includes a first epitaxy semiconductor material that induces a strain upon a channel of the at least one gate stack. The first epitaxy semiconductor material is located at a footprint of the at least one gate stack substantially within a pair of recessed regions in the substrate which are present on opposite sides of the at least one gate stack. A diffused extension region is located within an upper surface of said first epitaxy semiconductor material in each of the recessed regions. The structure further includes a second epitaxy semiconductor material located on an upper surface of the diffused extension region. The second epitaxy semiconductor material has a higher dopant concentration than the first epitaxy semiconductor material.

Owner:GLOBALFOUNDRIES U S INC

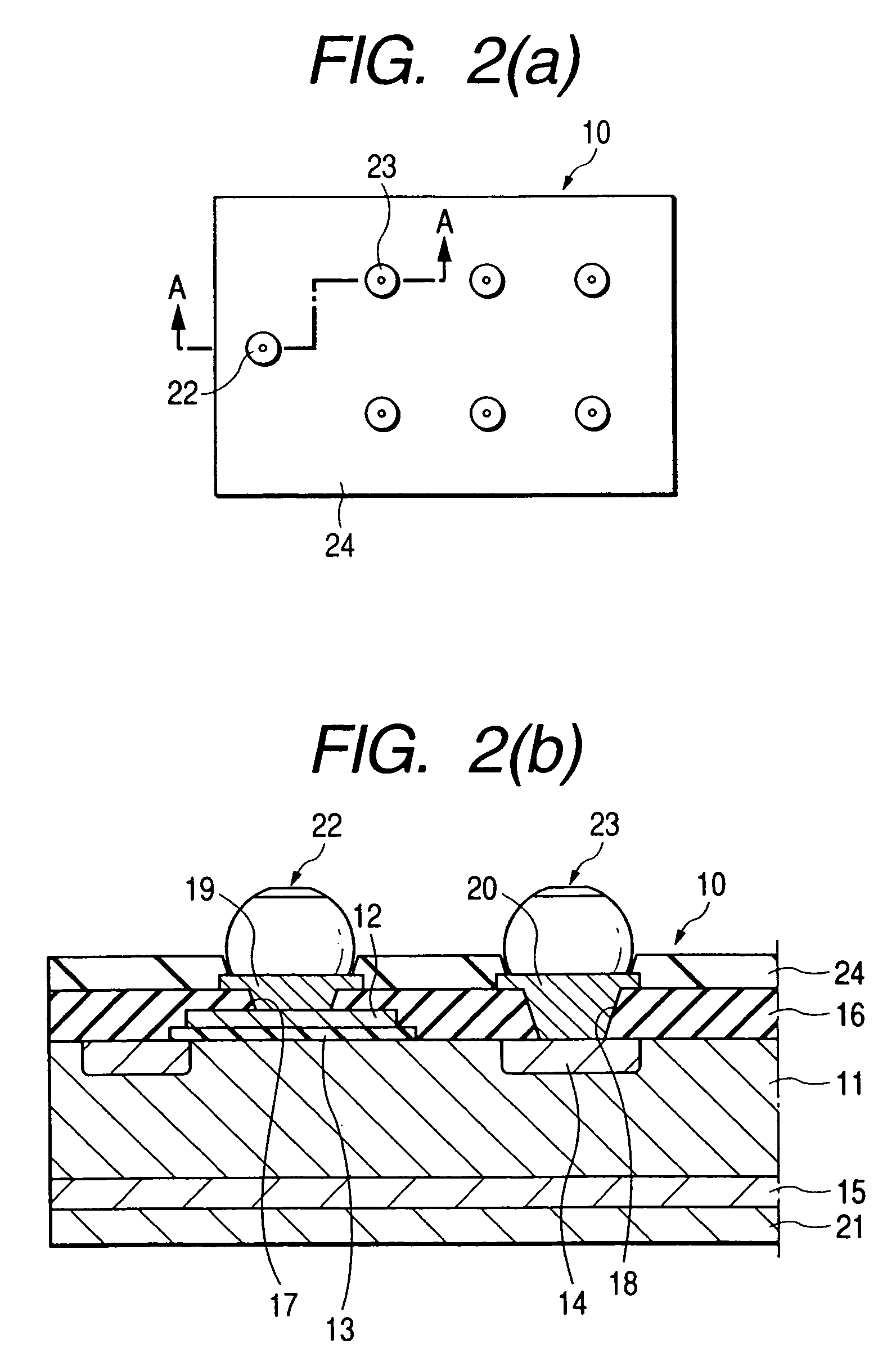

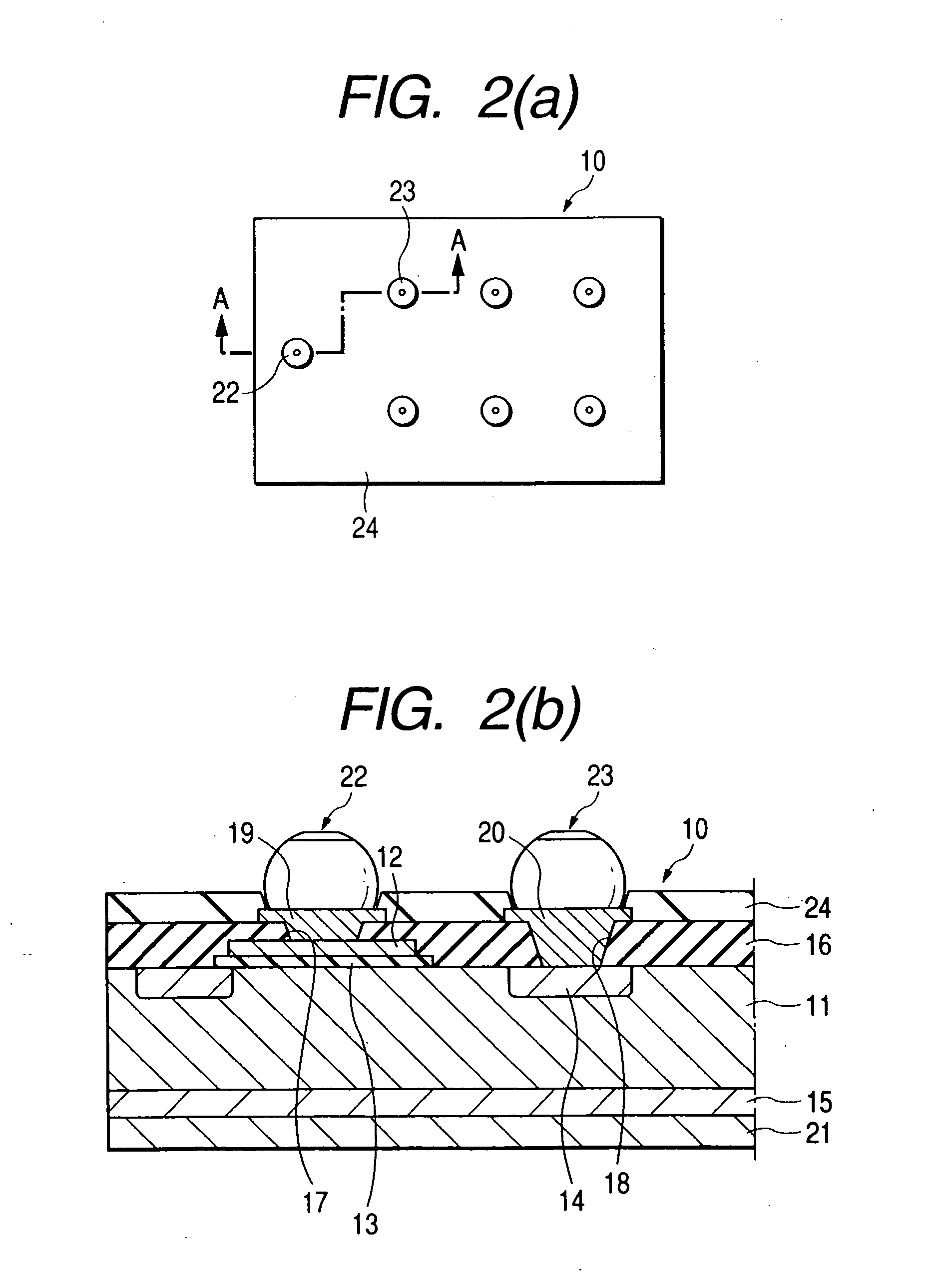

Semiconductor device

InactiveUS20070001317A1Reduce external resistanceLower Reliability RequirementsSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A wiring layer is provided on a semiconductor substrate and extends in a predetermined direction. An external connection electrode terminal is provided on the wiring layer through a plurality of column-shaped conductors. The column-shaped conductors are located under the external connection electrode terminal. A density of arrangement of the column-shaped conductors is varied according to a direction of extension of the wiring layer.

Owner:SOCIONEXT INC

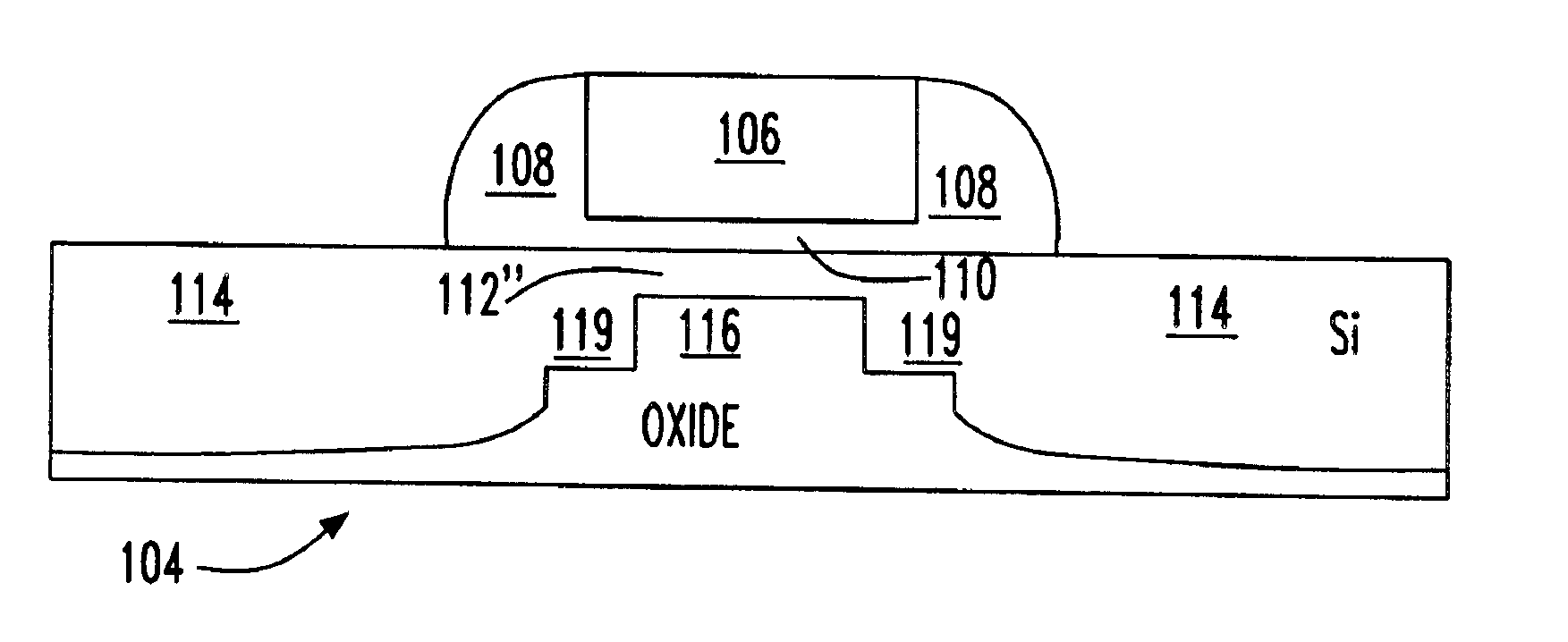

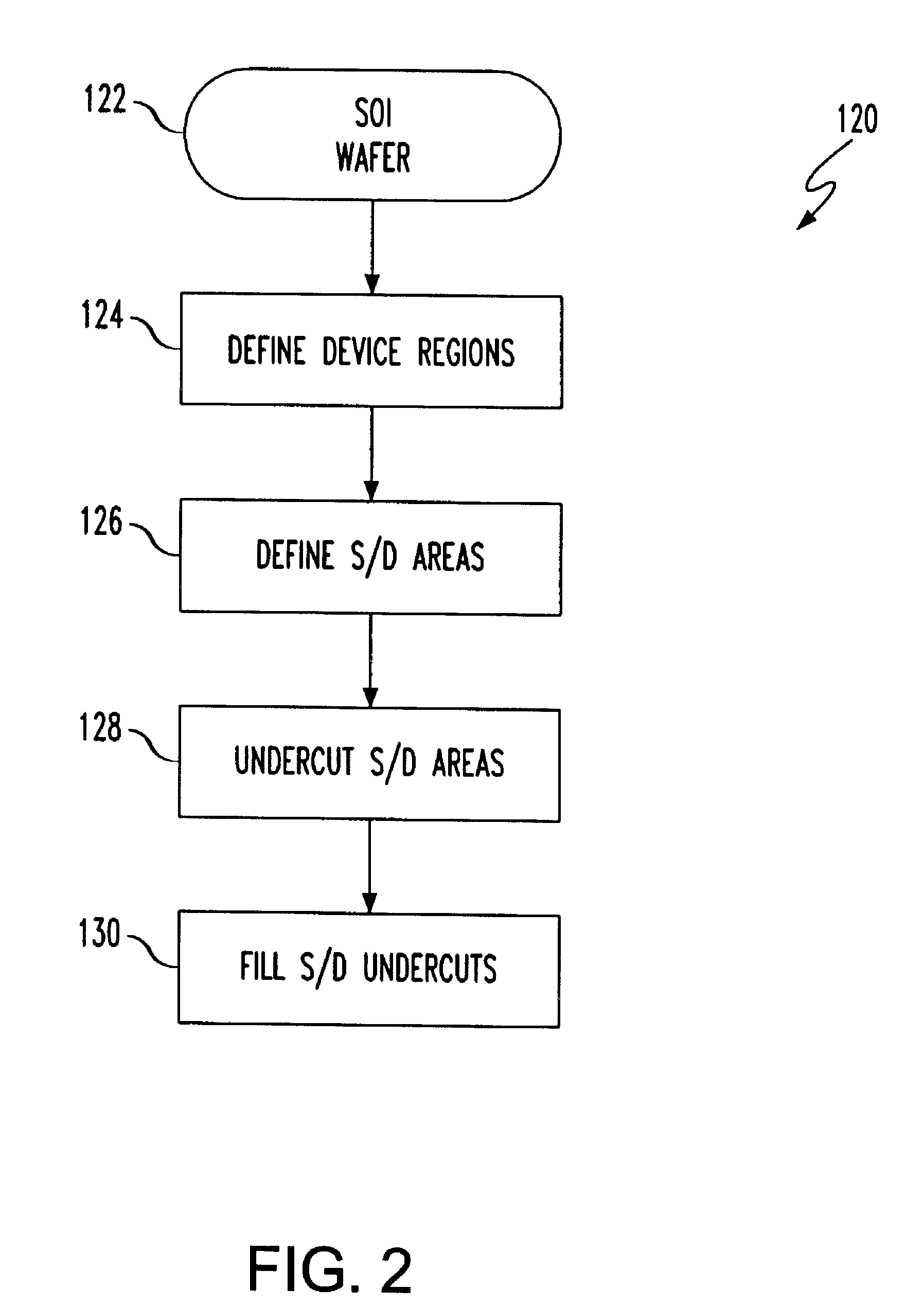

Thin channel FET with recessed source/drains and extensions

InactiveUS6924517B2Improve performanceReduce external resistanceTransistorSolid-state devicesField-effect transistorSilicon on insulator

A field effect transistor (FET), integrated circuit (IC) chip including the FETs and a method of forming the FETS. The devices have a thin channel, e.g., an ultra-thin (smaller than or equal to 10 nanometers (10 nm)) silicon on insulator (SOI) layer. Source / drain regions are located in recesses at either end of the thin channel and are substantially thicker (e.g., 30 nm) than the thin channel. Source / drain extensions and corresponding source / drain regions are self aligned to the FET gate and thin channel.

Owner:IBM CORP

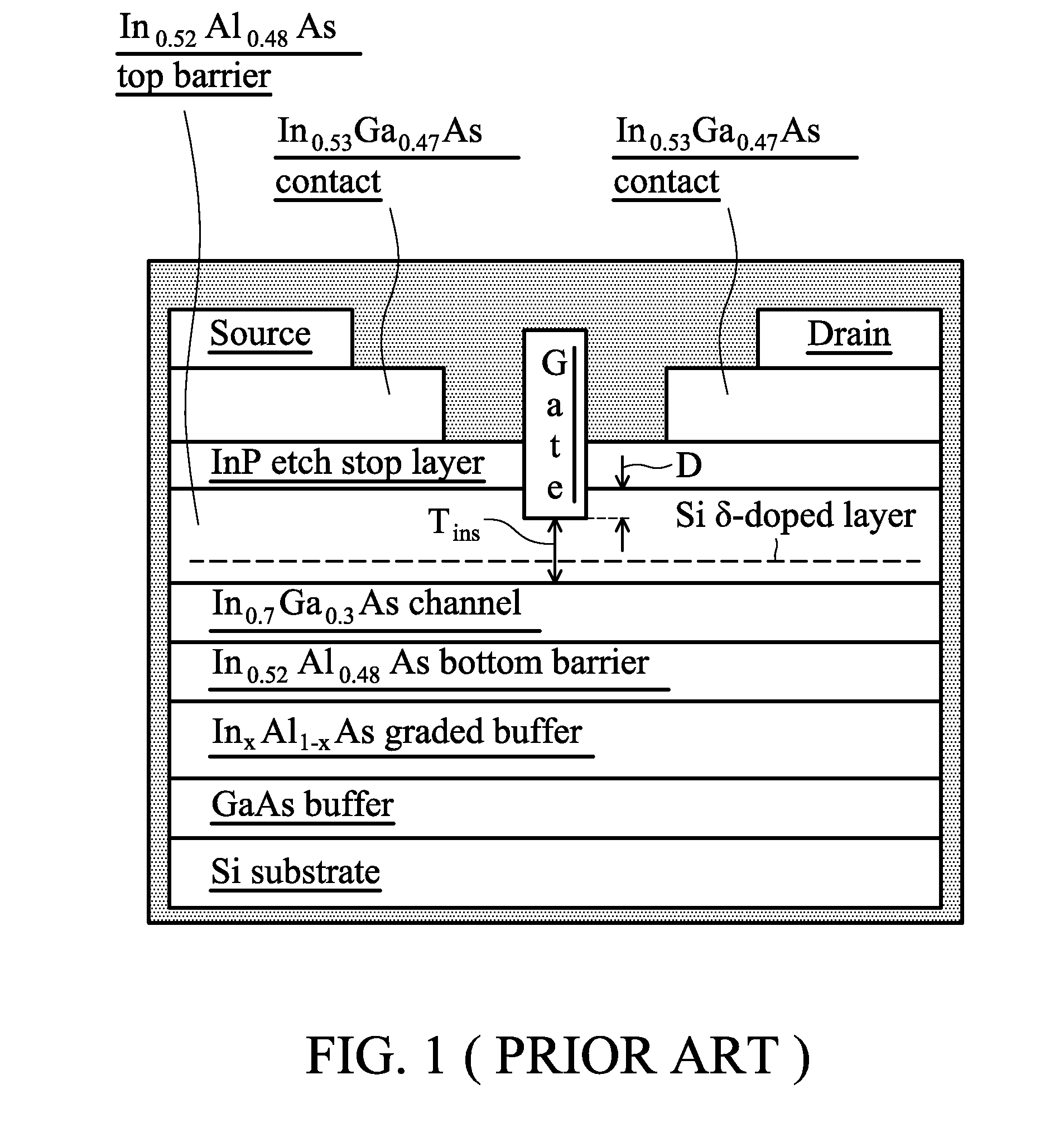

Source/Drain Re-Growth for Manufacturing III-V Based Transistors

ActiveUS20100301392A1Improved short channel controlReduce external resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesIntegrated circuitEngineering

A method of forming an integrated circuit structure includes providing a substrate, and epitaxially growing a first semiconductor layer over the substrate. The first semiconductor layer includes a first III-V compound semiconductor material formed of group III and group V elements. The method further includes forming a gate structure on the first semiconductor layer, and forming a gate spacer on at least one sidewall of the gate structure. After the step of forming the gate structure, a second semiconductor layer including a second III-V compound semiconductor material is epitaxially grown on the first semiconductor layer.

Owner:TAIWAN SEMICON MFG CO LTD

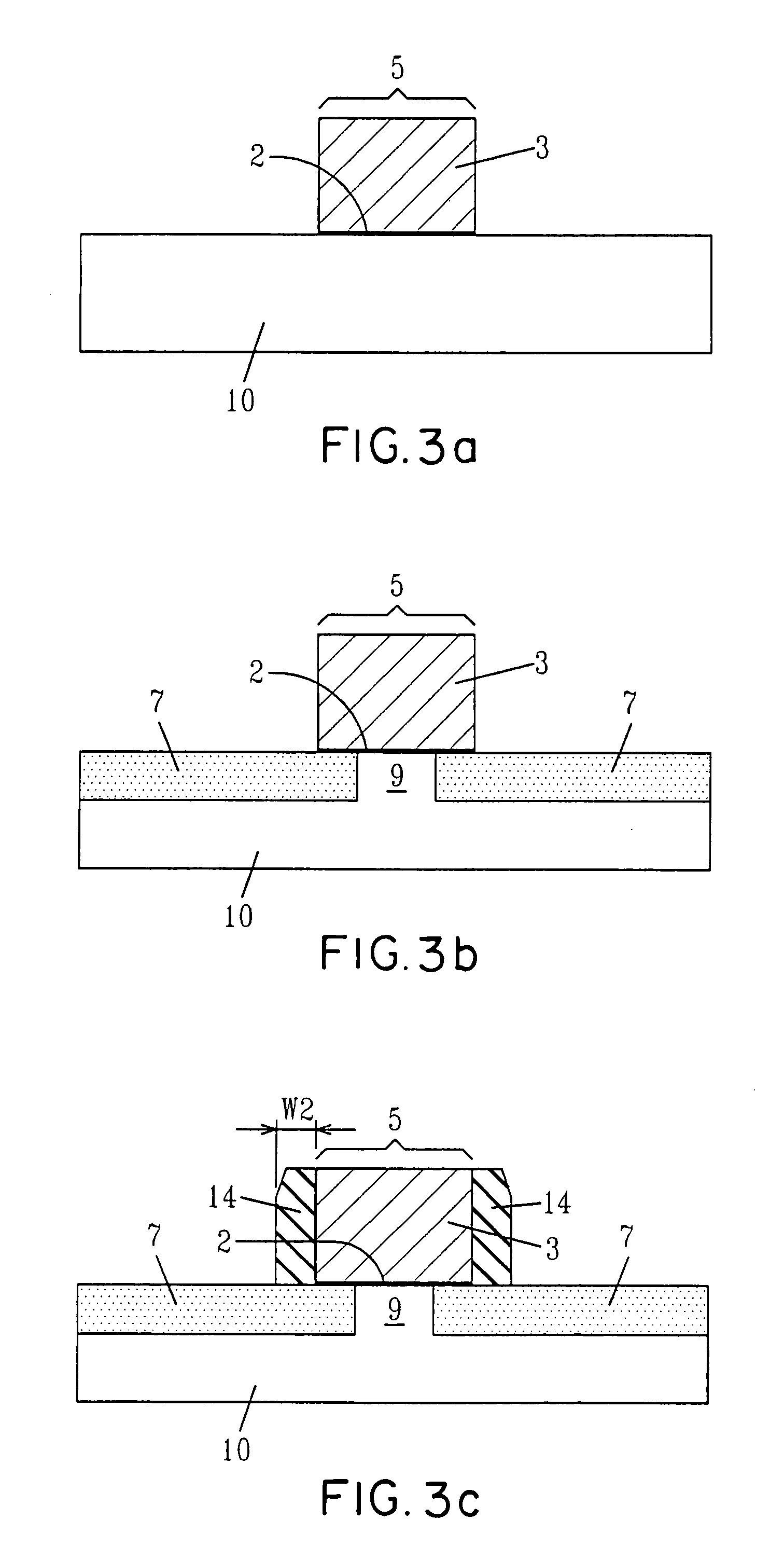

Method of forming an extremely thin semiconductor insulator (ETSOI) FET having a stair-shaped raised source/drain

ActiveUS8574970B2Increase parasitic resistanceReduce resistanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETSoi substrate

A MOSFET device is formed on top of a semiconductor-on-insulator (SOI) substrate having a semiconductor layer with a thickness ranging from 3 nm to 20 nm. A stair-shape raised extension, a raised source region and a raised drain region (S / D) are formed on top of the SOI substrate. The thinner raised extension region abuts at a thin gate sidewall spacer, lowering the extension resistance without significantly increasing the parasitic resistance. A single epitaxial growth forms the thinner raised extension and the thicker raised S / D preferably simultaneously, reducing the fabrication cost as well as the contact resistance between the raised S / D and the extension. A method of forming the aforementioned MOSFET device is also provided.

Owner:GLOBALFOUNDRIES US INC

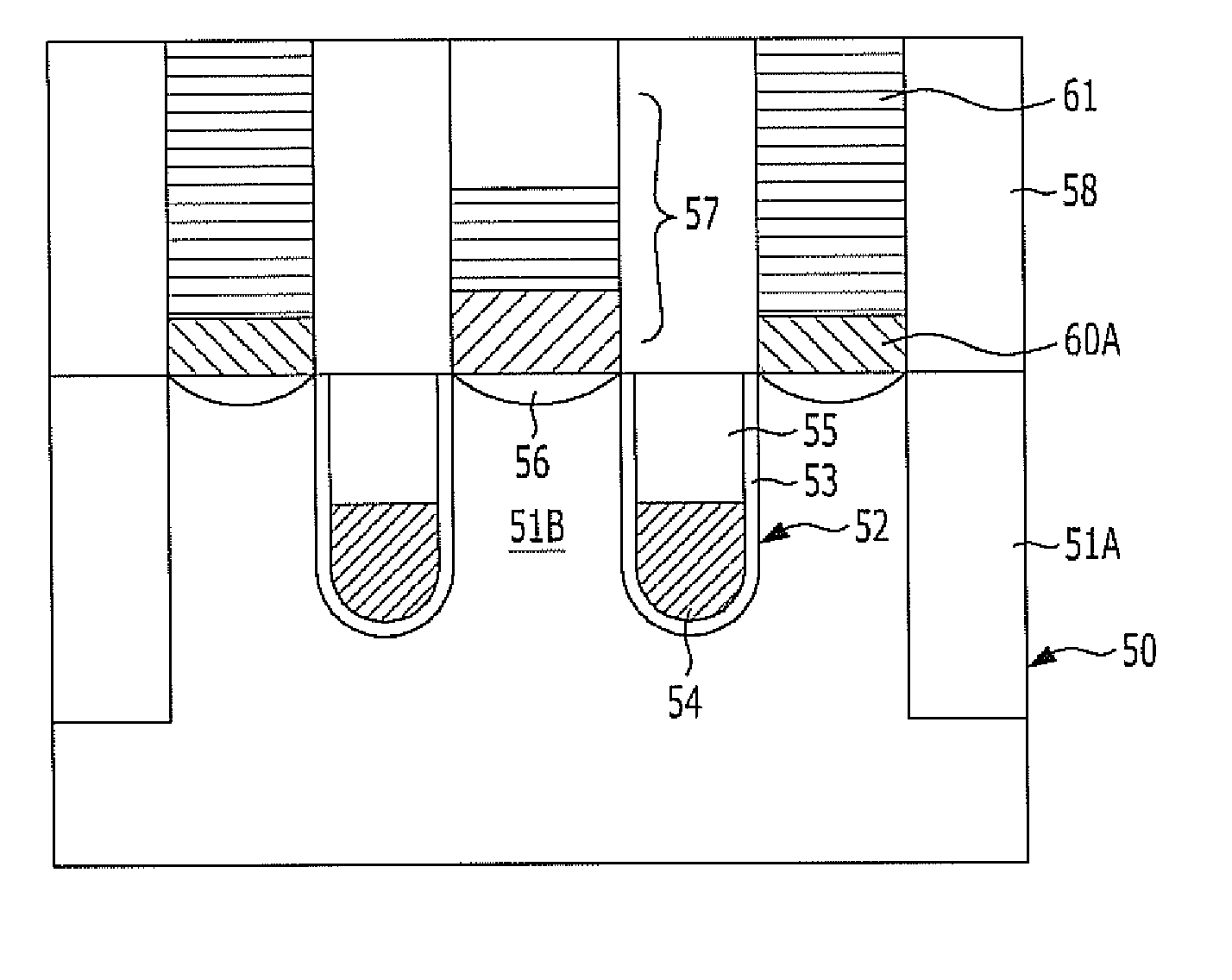

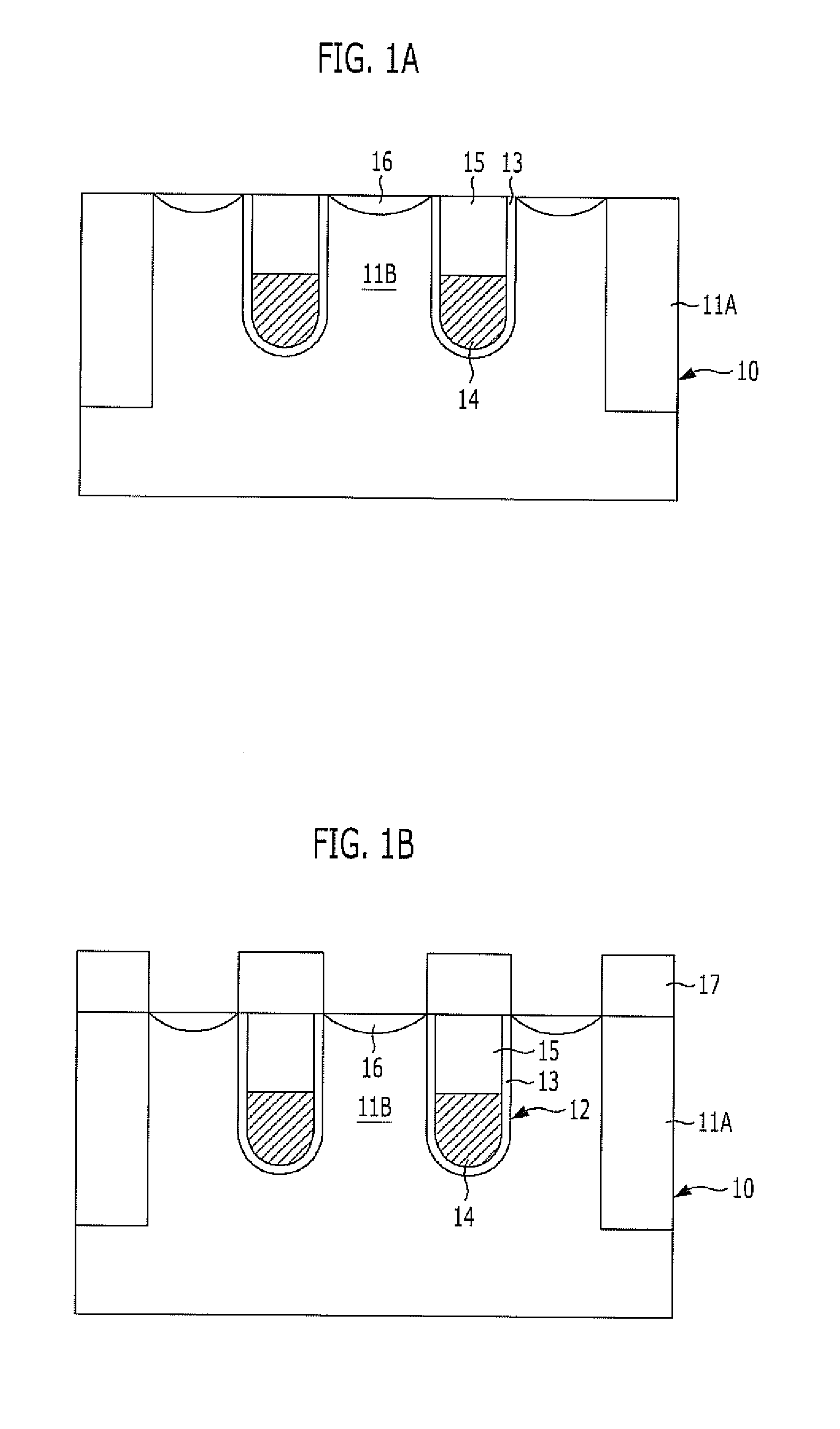

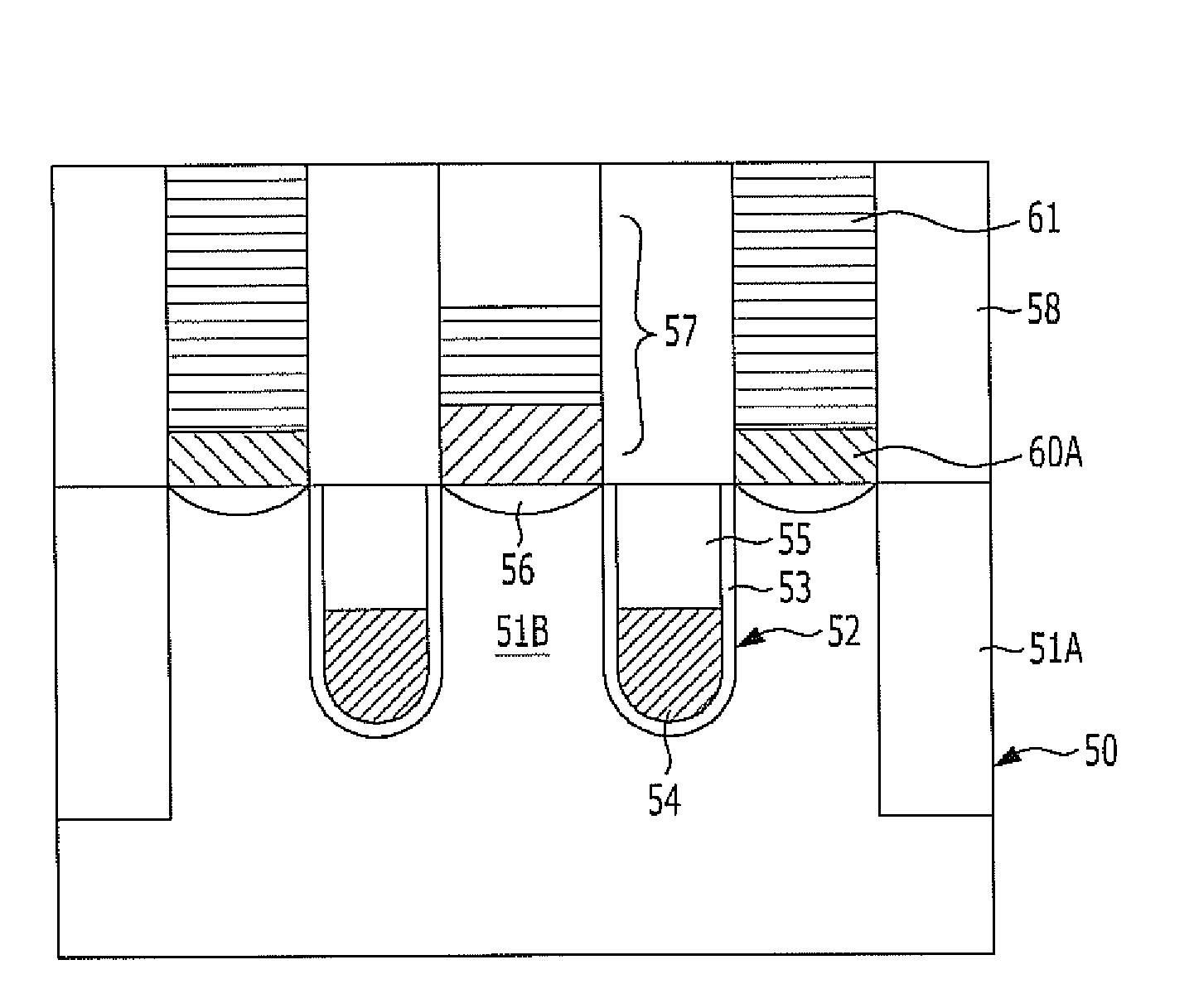

Method for fabricating semiconductor device

ActiveUS20110212607A1Reduce external resistanceSolid-state devicesSemiconductor/solid-state device manufacturingBit lineEngineering

A method for fabricating a semiconductor device includes forming junction area for a bit line contact (BLC) and a junction area for a storage node contact (SNC) by performing ion implantation in a substrate having a buried gate; forming a first insulation pattern having an opening to expose the junction areas; forming a buffer layer to fill the openings; forming a second insulation pattern over the first insulation pattern after filling the openings, wherein the second insulation pattern has openings to expose the buffer layer in an area of the buffer layer that lies over the junction area for the SNC; and forming an SNC to fill the opening of the second insulation patterns.

Owner:SK HYNIX INC

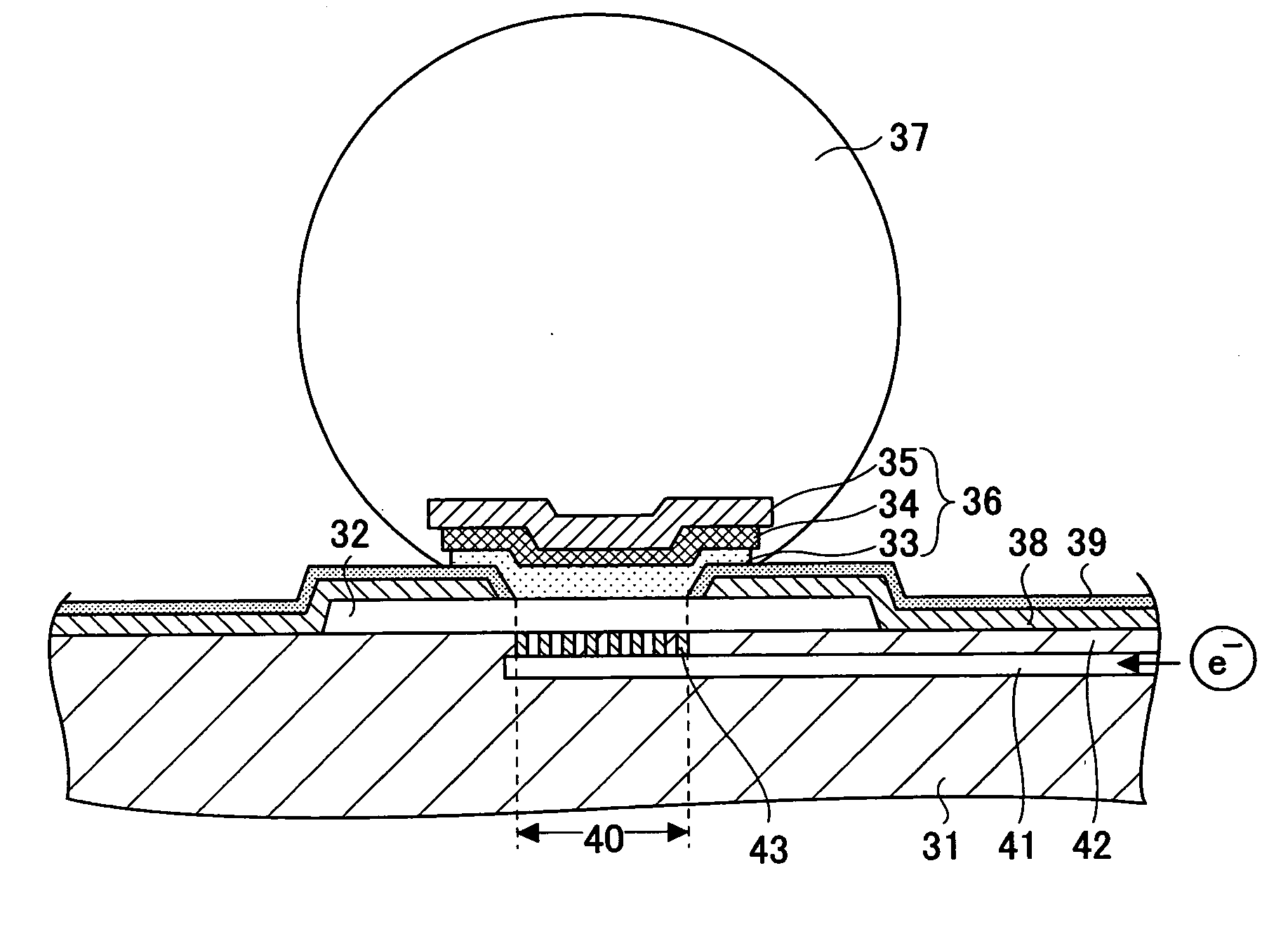

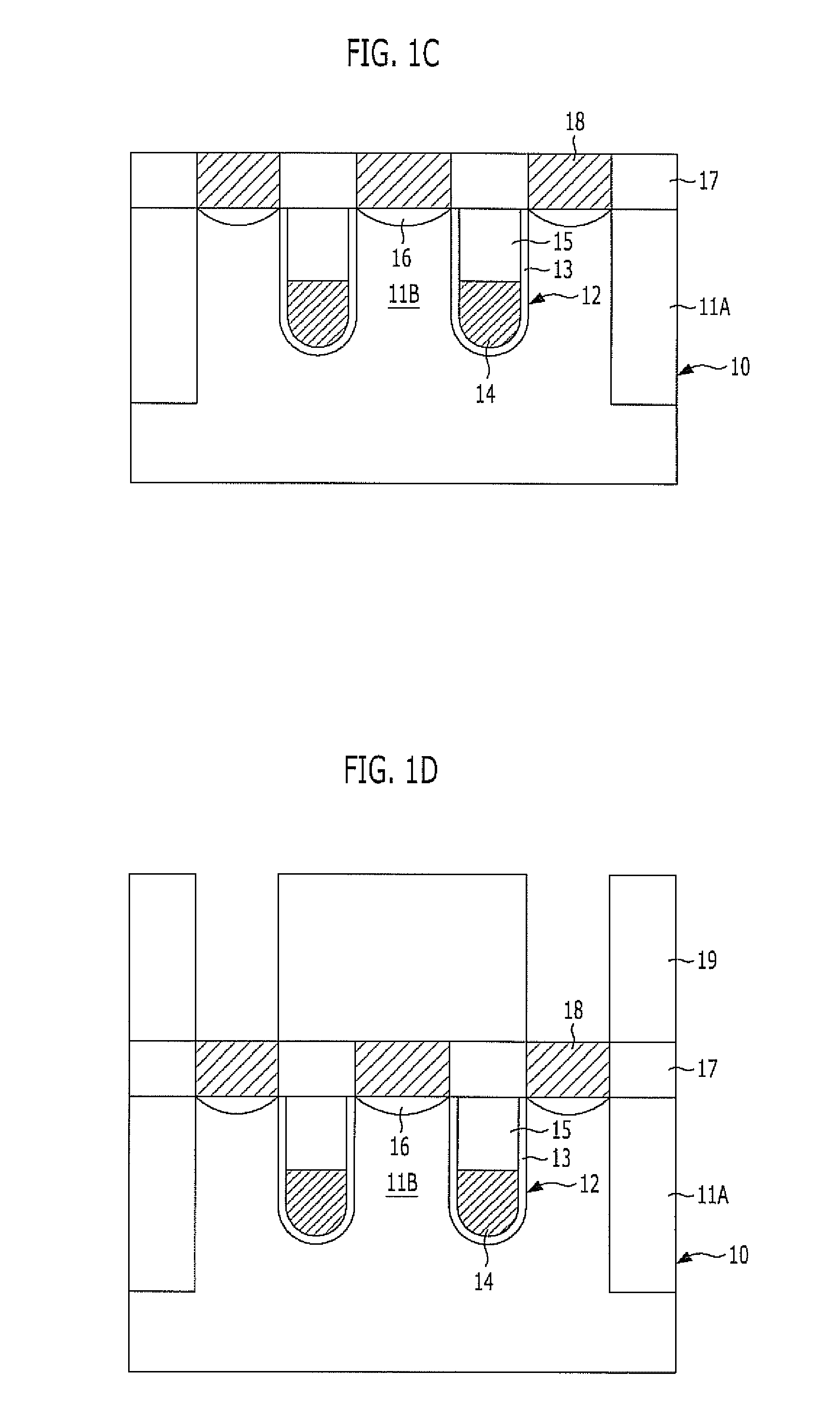

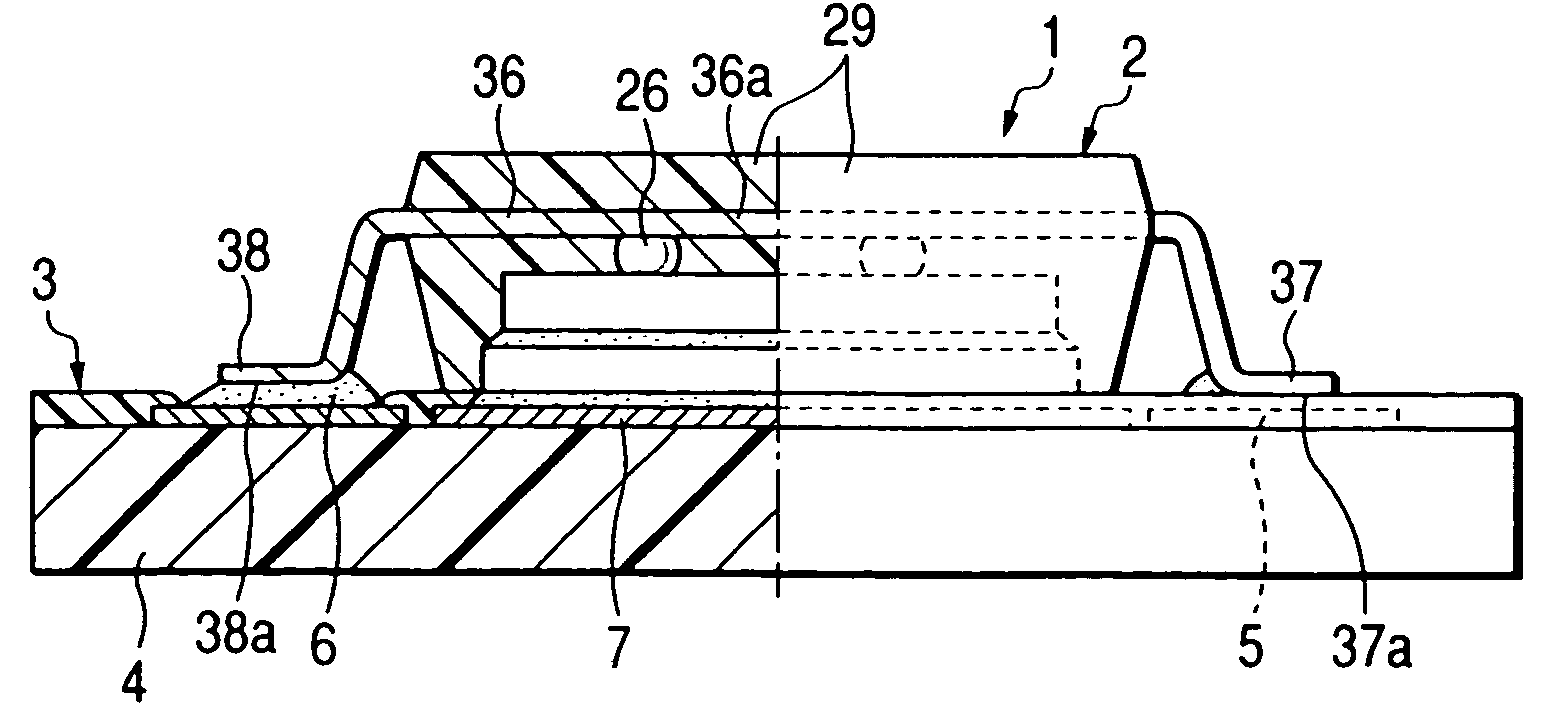

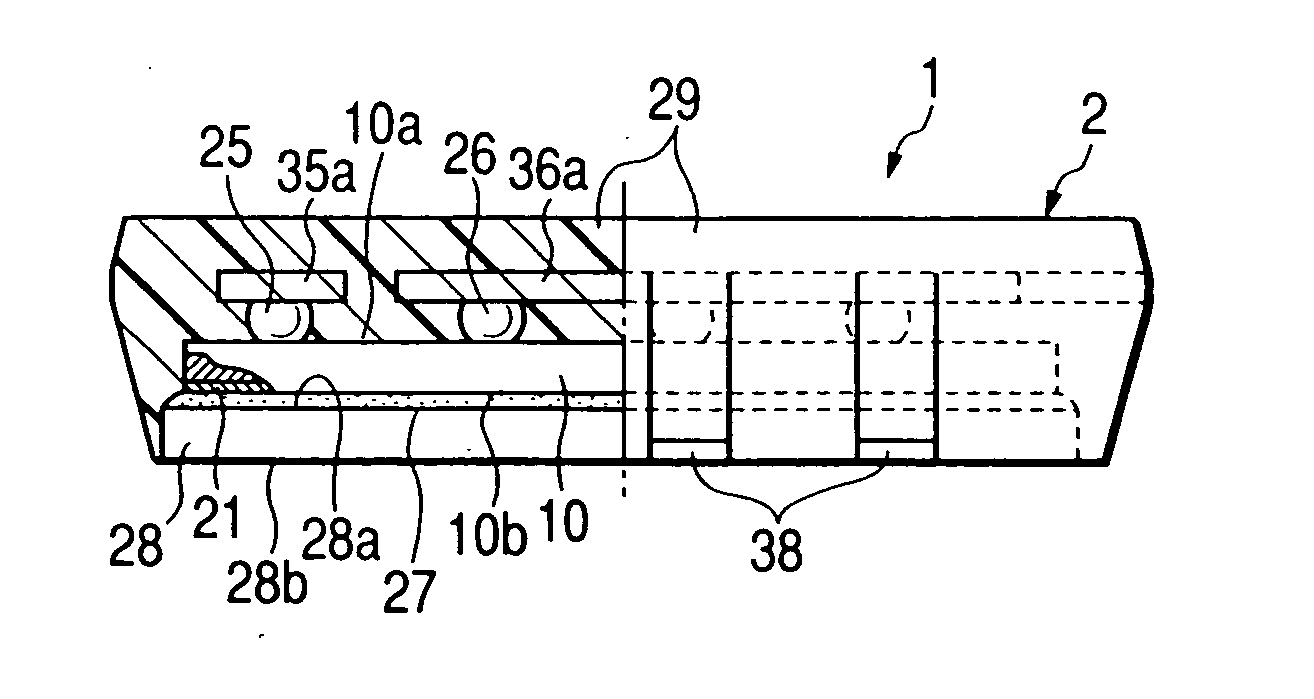

Semiconductor device and a method of manufacturing the same

InactiveUS7160760B2Lower resistanceReduce external resistanceSemiconductor/solid-state device detailsSolid-state devicesMOSFETSemiconductor chip

A semiconductor device and method having high output and having reduced external resistance is reduced and improved radiating performance. A MOSFET (70) has a connecting portion for electrically connecting a surface electrode of a semiconductor pellet and a plurality of inner leads, a resin encapsulant (29), a plurality of outer leads (37), (38) protruding in parallel from the same lateral surface of the resin encapsulant (29) and a header (28) bonded to a back surface of the semiconductor pellet and having a header protruding portion (28c) protruding from a lateral surface of the resin encapsulant (29) opposite to the lateral surface from which the outer leads protrude, wherein the header (28) has an exposed surface (28b) exposed from the resin encapsulant (29); the outer leads (37), (38) are bent; and the exposed of the outer leads (37), (38) are provided at substantially the same height.

Owner:RENESAS ELECTRONICS CORP

Low external resistance etsoi transistors

InactiveUS20130214358A1Reduce external resistanceTransistorSolid-state devicesGate dielectricSemiconductor materials

A disposable dielectric structure is formed on a semiconductor-on-insulator (SOI) substrate such that all physically exposed surfaces of the disposable dielectric structure are dielectric surfaces. A semiconductor material is selectively deposited on semiconductor surfaces, while deposition of any semiconductor material on dielectric surfaces is suppressed. After formation of at least one gate spacer and source and drain regions, a planarization dielectric layer is deposited and planarized to physically expose a top surface of the disposable dielectric structure. The disposable dielectric structure is replaced with a replacement gate stack including a gate dielectric and a gate conductor portion. Lower external resistance can be provided without impacting the short channel performance of a field effect transistor device.

Owner:IBM CORP

Method for fabricating semiconductor device

ActiveUS8053341B2Reduce external resistanceSolid-state devicesSemiconductor/solid-state device manufacturingBit lineEngineering

A method for fabricating a semiconductor device includes forming junction area for a bit line contact (BLC) and a junction area for a storage node contact (SNC) by performing ion implantation in a substrate having a buried gate; forming a first insulation pattern having an opening to expose the junction areas; forming a buffer layer to fill the openings; forming a second insulation pattern over the first insulation pattern after filling the openings, wherein the second insulation pattern has openings to expose the buffer layer in an area of the buffer layer that lies over the junction area for the SNC; and forming an SNC to fill the opening of the second insulation patterns.

Owner:SK HYNIX INC

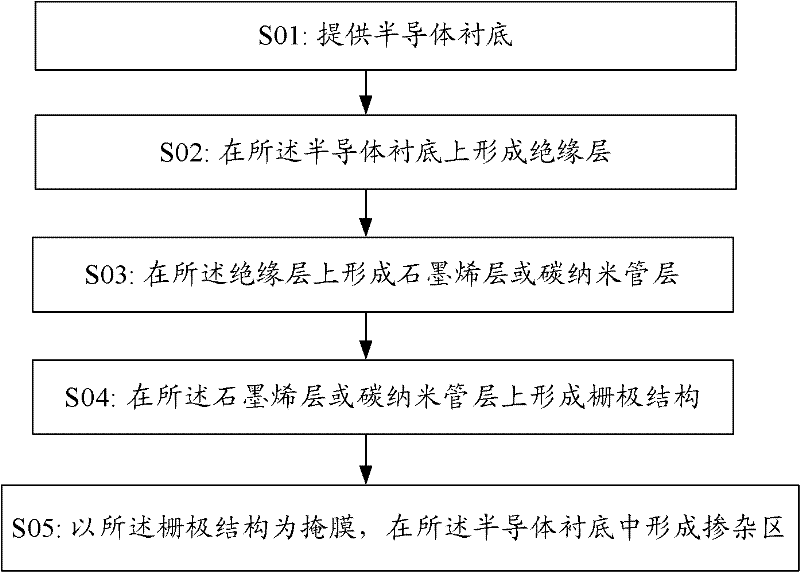

Semiconductor device and manufacturing method thereof

ActiveCN102651397AReduce external resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesExternal resistanceOxide

The invention discloses a semiconductor device and a manufacturing method thereof. The method comprises the following steps of providing a semiconductor substrate; forming an oxide layer on the semiconductor substrate; forming a grapheme layer on the oxide layer; forming a grid medium layer on the grapheme layer; forming a grid electrode on the grid medium layer; patterning the grid electrode; and forming a doping area in the substrate at two sides of the grid electrode. As the doping area is formed in the semiconductor substrate, and then a sensitive doping area is formed on the surface layer of the grapheme layer due to static induction, so as to form doping in the grapheme layer, thus, the decrease of the external resistance of the semiconductor device containing the grapheme layer can be facilitated.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

CMOS device integration for low external resistance

InactiveUS7189644B2Lower resistanceReduce resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETCMOS

The present invention relates to a Complementary Metal Oxide Semiconductor (CMOS) device having a lower external resistance and a method for manufacturing the CMOS device. The inventive MOSFET is produced by forming first suicide regions in a substrate as well as atop surface of a gate region and forming second silicide regions where second silicide thickness is greater than the first silicide thickness. The inventive method produces a low resistance first silicide in close proximity to the channel region of the device, where the incorporation of the first silicide decreases the external resistance of the device while the incorporation of the second silicide produces low sheet resistance interconnects.

Owner:GLOBALFOUNDRIES INC

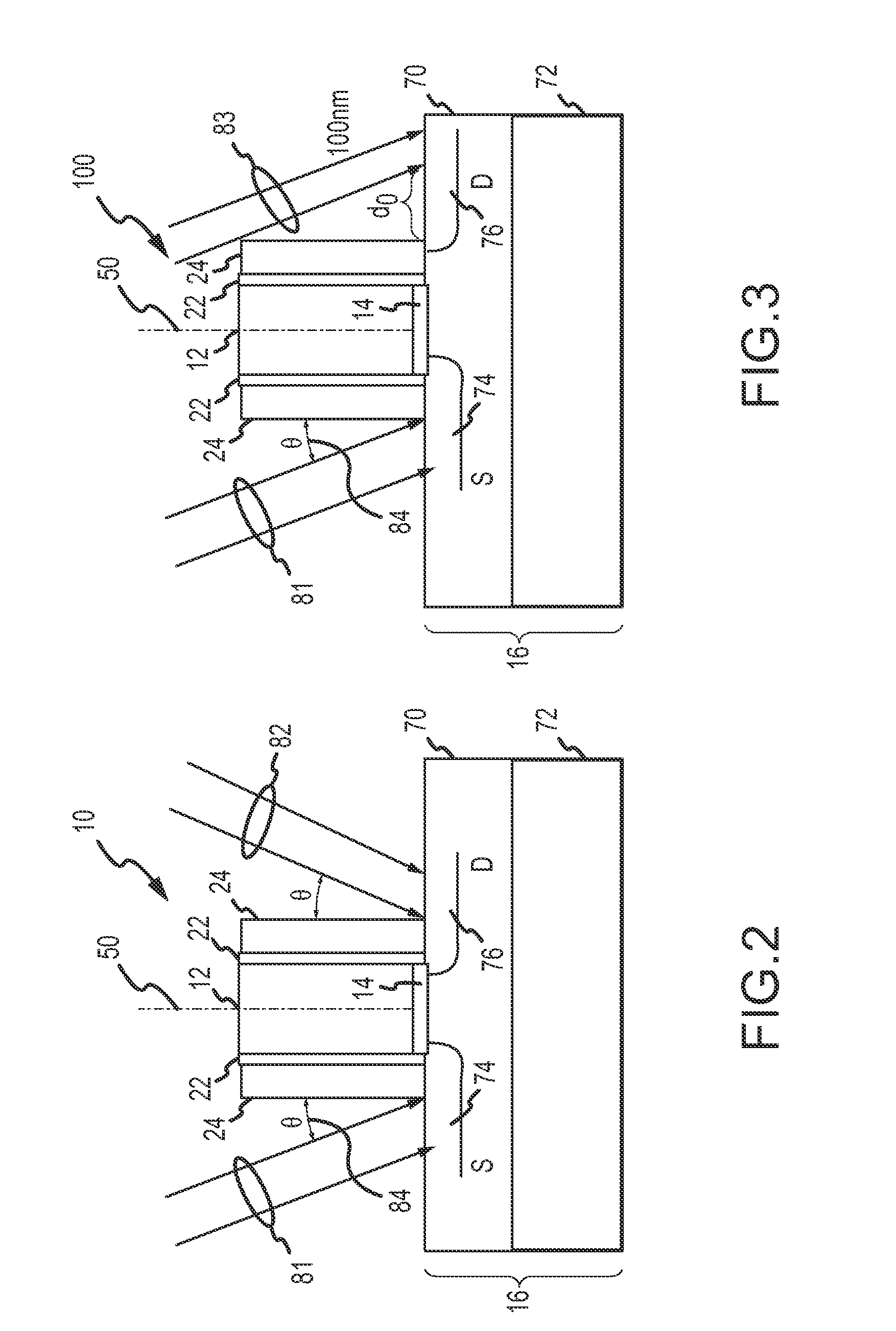

MOSFET with asymmetrical extension implant

ActiveUS7829401B2Reduce external resistanceSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETCondensed matter physics

A method for fabricating a MOSFET (e.g., a PMOS FET) includes providing a semiconductor substrate having surface characterized by a (110) surface orientation or (110) sidewall surfaces, forming a gate structure on the surface, and forming a source extension and a drain extension in the semiconductor substrate asymmetrically positioned with respect to the gate structure. An ion implantation process is performed at a non-zero tilt angle. At least one spacer and the gate electrode mask a portion of the surface during the ion implantation process such that the source extension and drain extension are asymmetrically positioned with respect to the gate structure by an asymmetry measure.

Owner:ADVANCED MICRO DEVICES INC

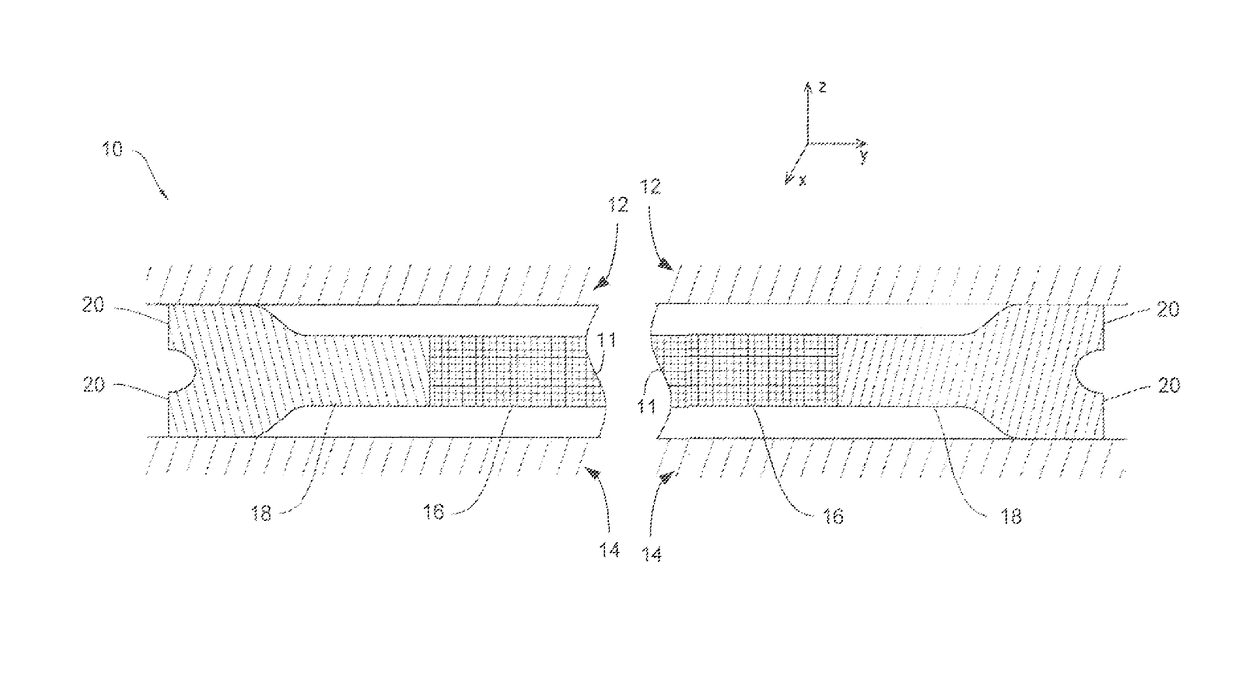

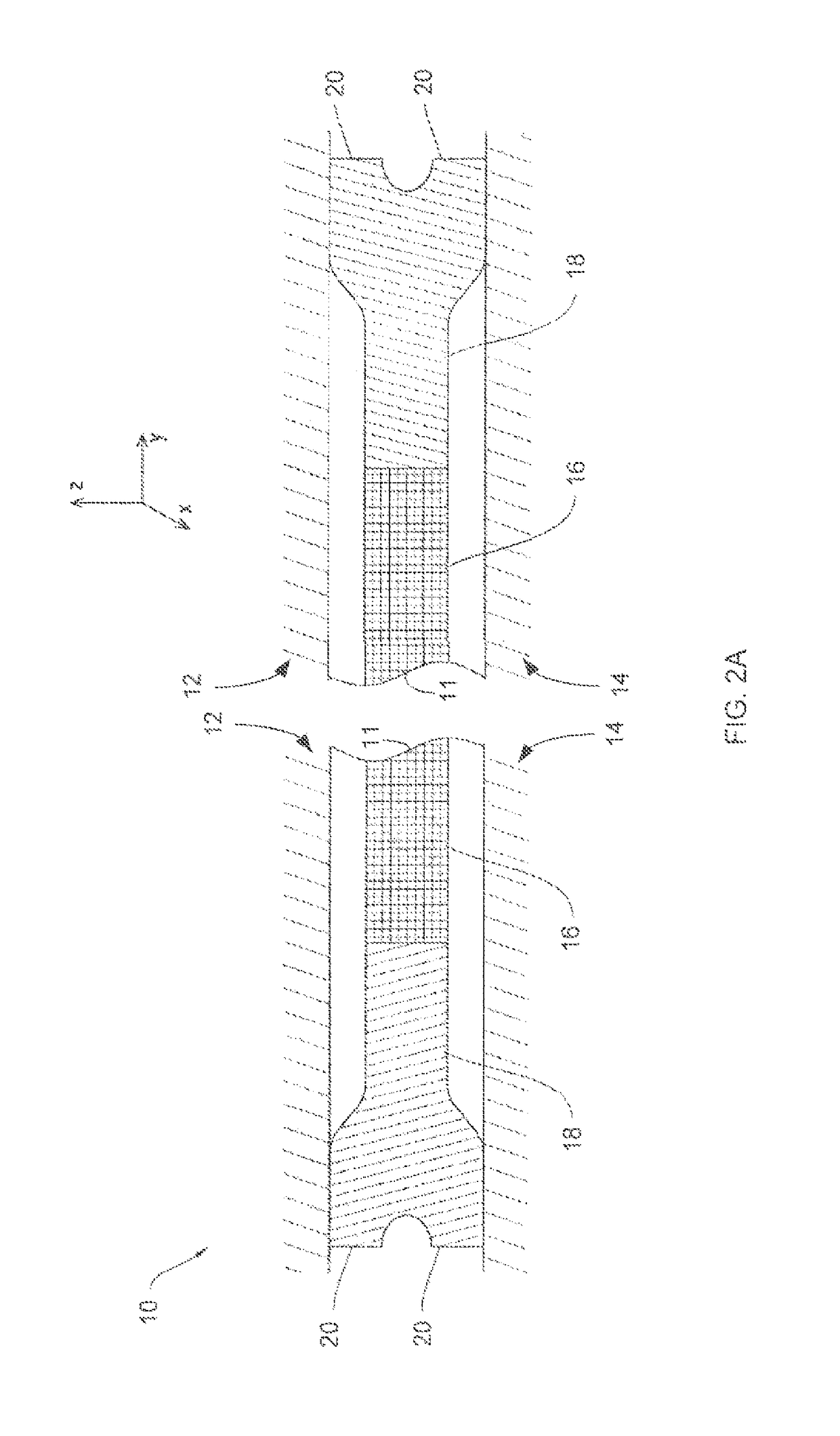

Deflectable conductive gasket with environmental seal

ActiveUS9635790B2Prevent leakageHarm and impede effectivenessLocalised screeningShielding materialsEngineeringElectronic component

A deflectable gasket assembly for EMI shielding and environmental sealing is described. The gasket assembly is formed from an electrically-conductive mesh sheet positioned between adjacent conductive surfaces. A gasket is provided at the outer boundaries of the mesh sheet for environmental protection. The edge of the gasket has a branched sealing element extending above and below the gasket assembly for contacting the adjacent surfaces. The branched sealing element is deformable and can be used on external aircraft electronic components.

Owner:PARKER INTANGIBLES LLC

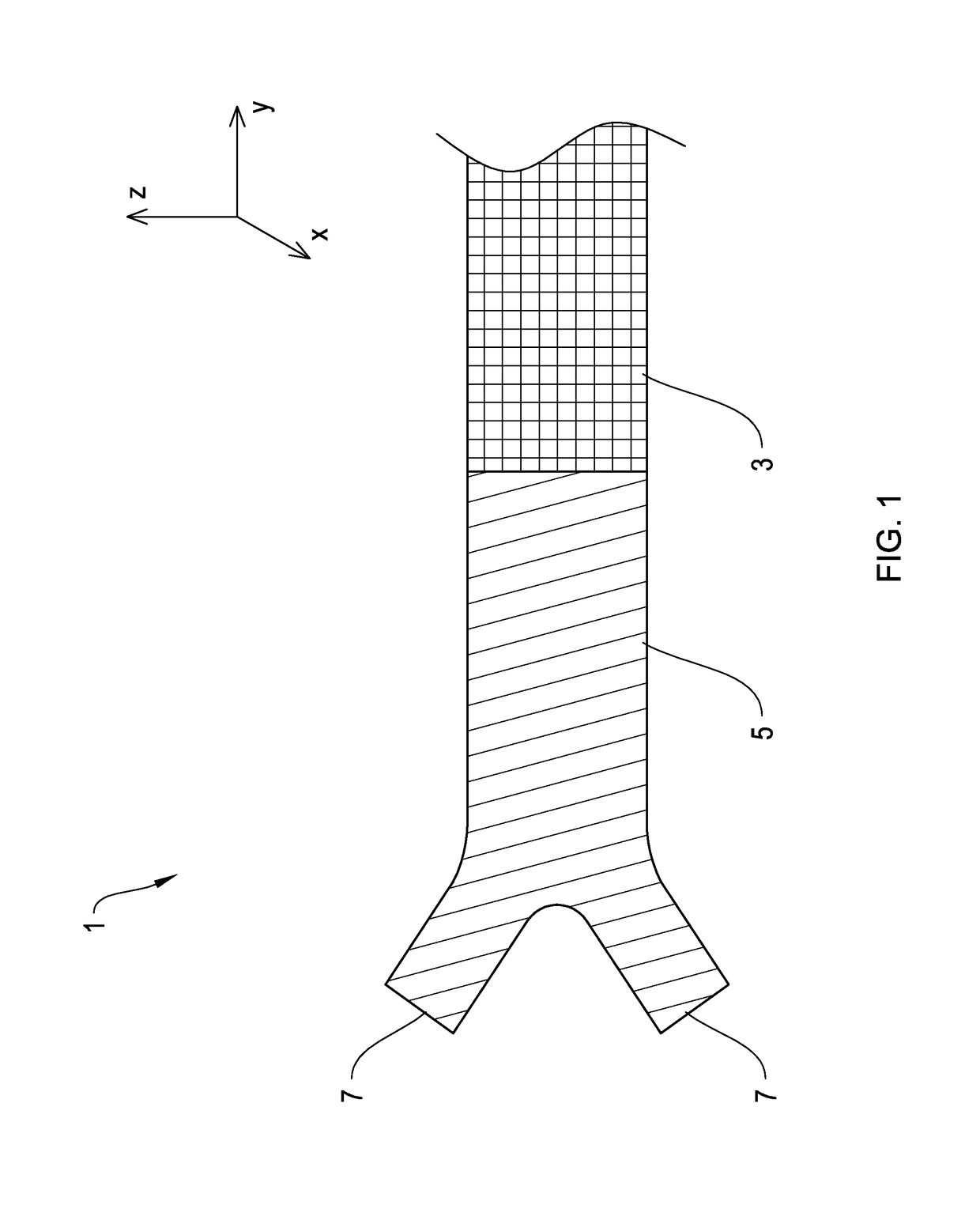

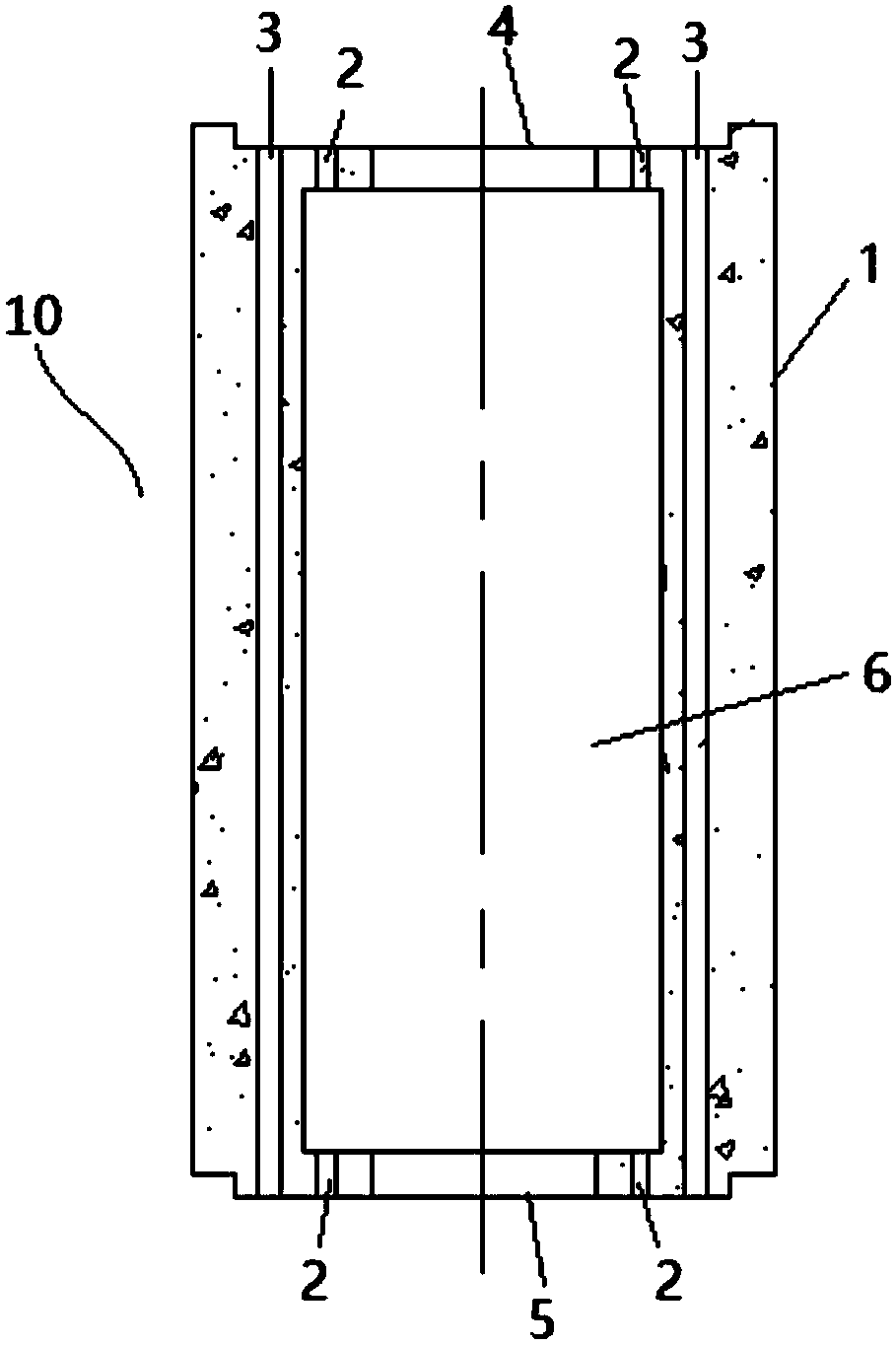

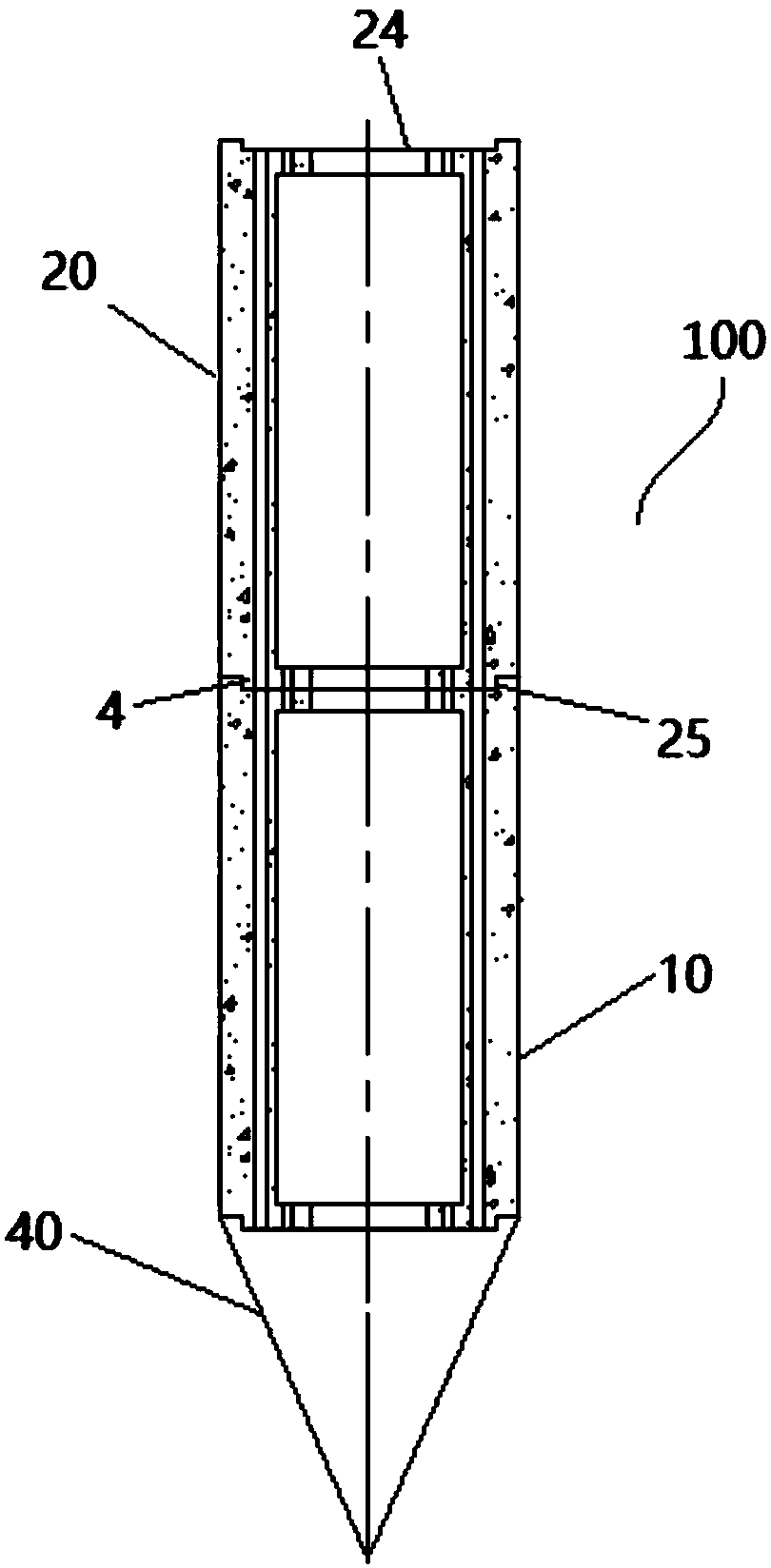

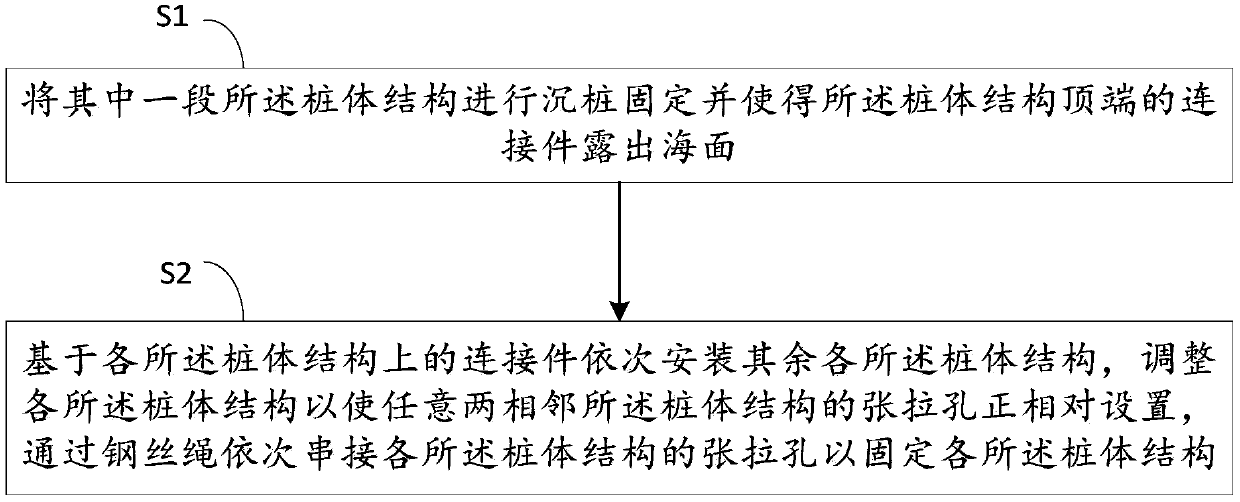

Mounting structure of wind generating set and mounting method of mounting structure

The invention provides a pile body of an offshore wind power generator. The pile body comprises a main body and connecting pieces arranged at two ends of the main body; tensioning holes penetrating through the main body are axially formed in the main body; and the main body is made of concrete. The connecting pieces are arranged at two ends of the main body, so that the pile body is connected withother devices conveniently; and the tensioning holes penetrating through the main body can also be used for connecting the pile body with other devices and stabilizing the pile body. Besides, the main body is made of the concrete, compared with a pile body made of a steel material, the pile body has the advantage that the cost is greatly reduced, and thus the manufacturing cost is relatively low.In addition, the invention further provides a supporting column of the offshore wind power generator, a mounting method of the supporting column, a bearing platform and the offshore wind power generator.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

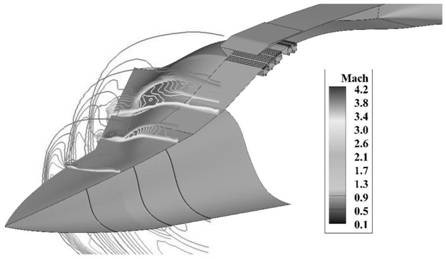

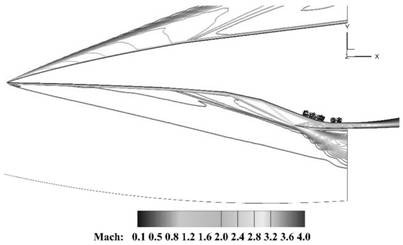

Integrated assembly of binary adjustable air inlet passage and an aircraft forebody and design method

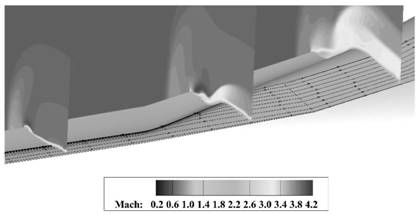

ActiveCN113148192AImprove sideslip performanceImprove compression efficiencyPower plant air intake arrangementsFlight vehicleElectric machinery

The invention discloses an integrated assembly of a binary adjustable air inlet passage and an aircraft forebody. The integrated assembly comprises a first-stage fixed compression wedge surface, a second-stage adjustable compression wedge surface, a throat section, an expansion section, a lip mask, a driving motor, a connecting rod component and a side plate, the aircraft forebody comprises a first-stage bump, a second-stage bump, a transition molded surface and a strake wing. According to the integration method disclosed by the invention, the binary adjustable air inlet channel and the aircraft fuselage are highly fused, so that the external resistance of the aircraft is effectively reduced; the two-stage bulge molded surface of the fuselage not only can effectively eliminate the developed thick boundary layer of the fuselage, but also can decelerate and pressurize the supersonic airflow and improve the performance of the air inlet channel.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

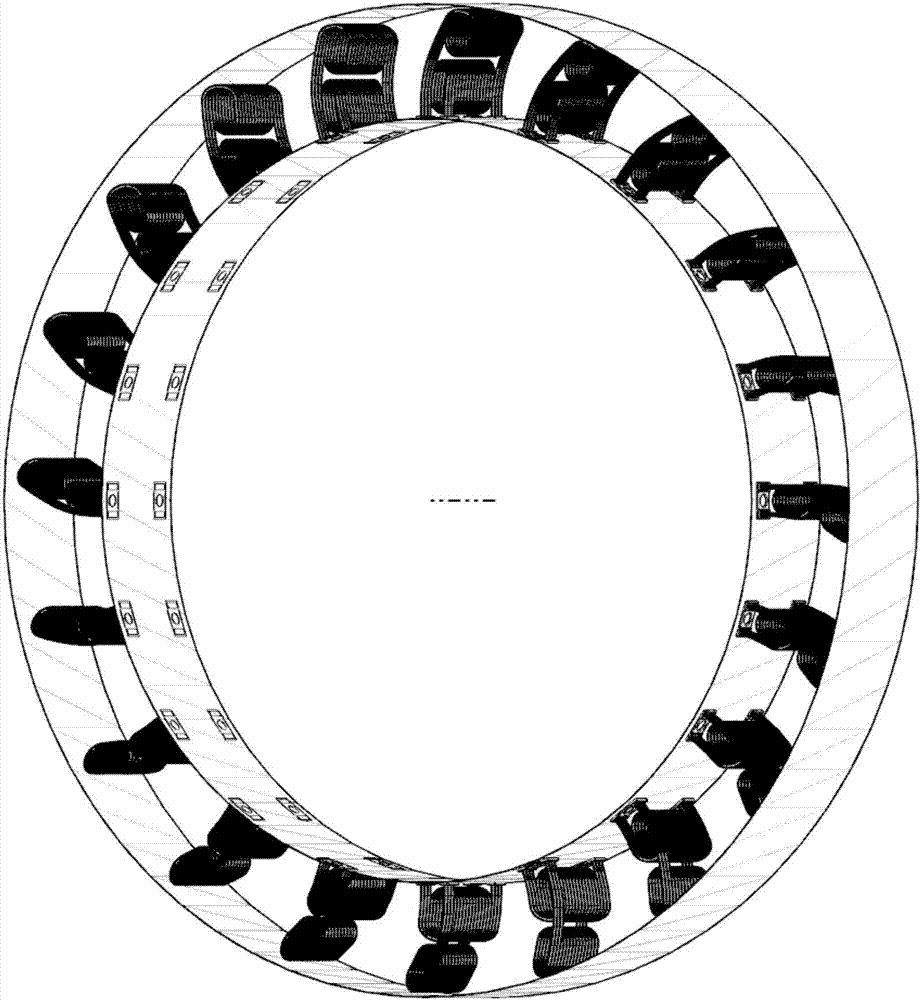

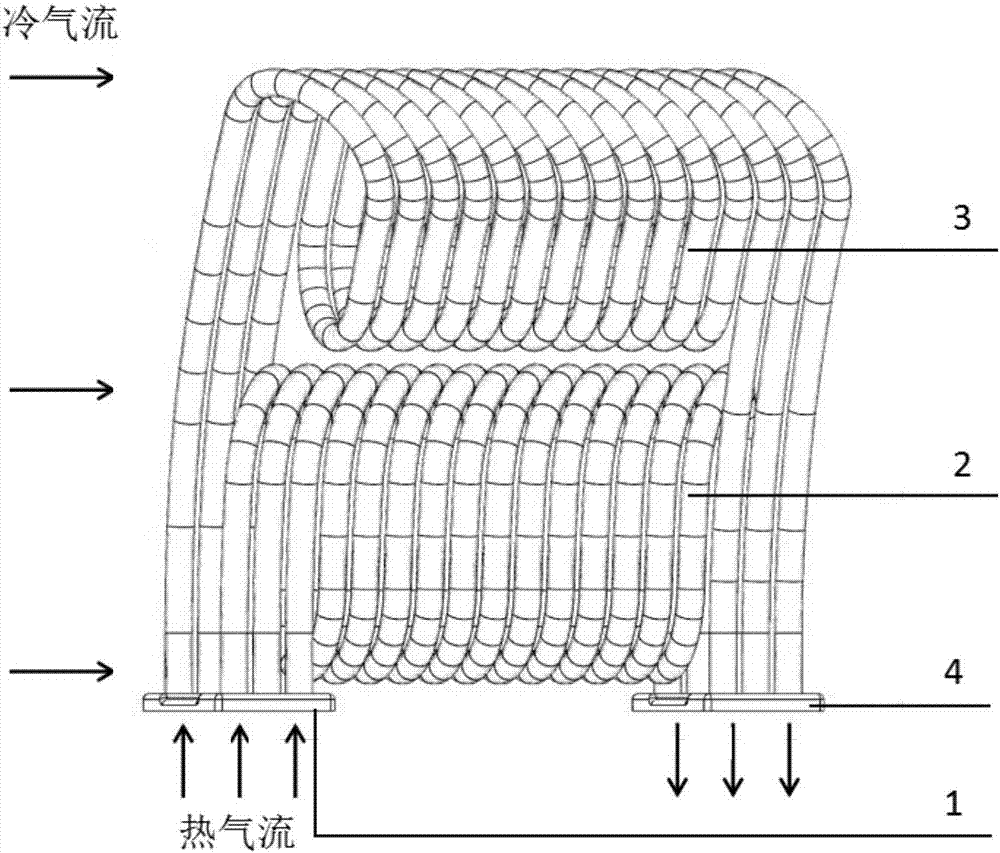

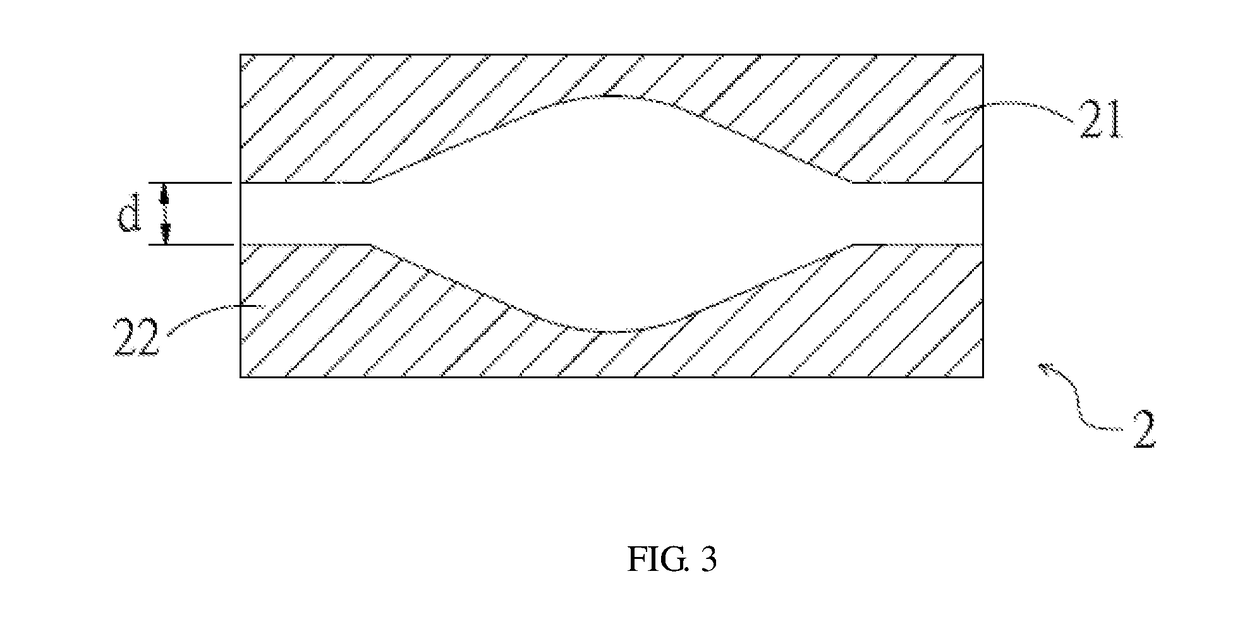

Spiral tube type air-air heat exchanger in circular passage

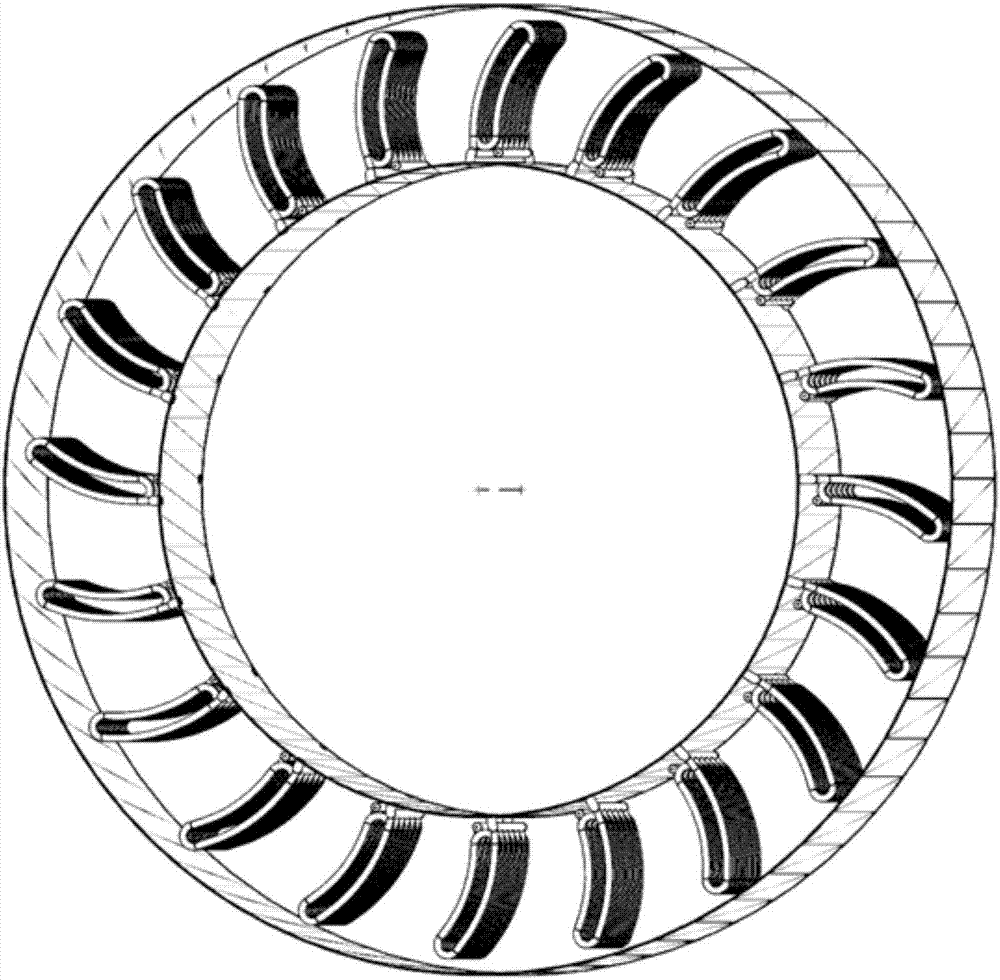

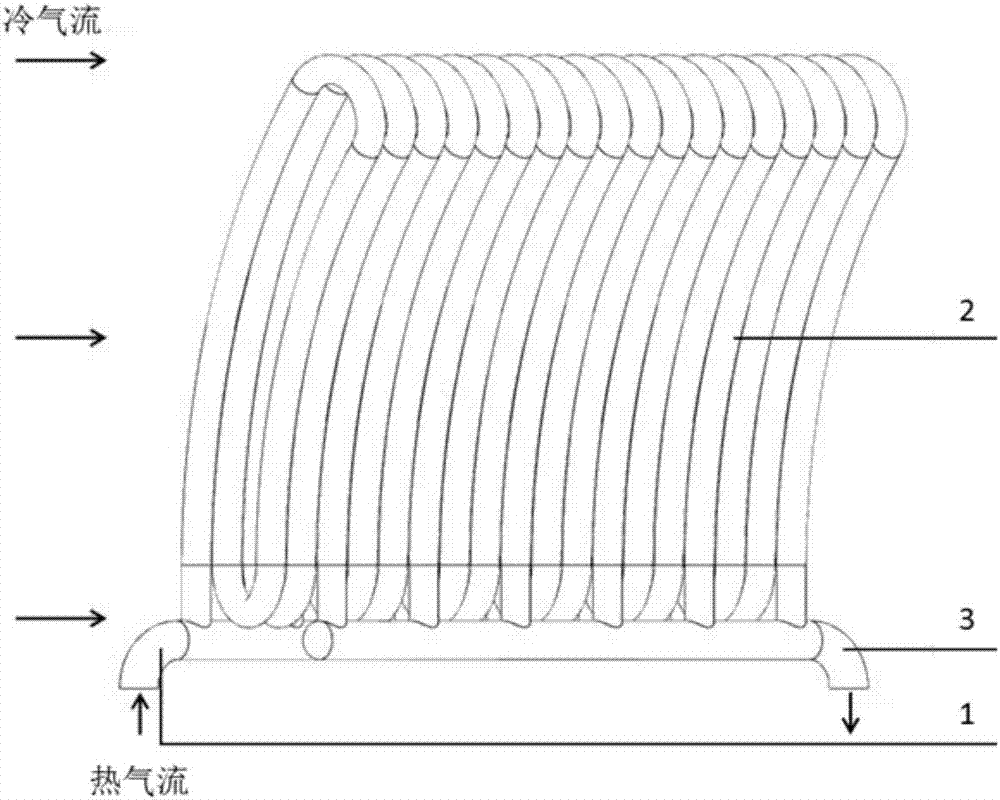

InactiveCN107192279AImprove compactnessGood thermal expansion adaptabilityStationary tubular conduit assembliesCold airPlate heat exchanger

The invention discloses a spiral tube type air-air heat exchanger in a circular passage, and relates to the field of air-air heat exchangers. The spiral tube type air-air heat exchanger in the circular passage comprises a plurality of heat exchanging units which are evenly arranged in the circular passage in the circumferential direction of the circular passage. Cold air flow in the circular passage moves in the axial direction. Each heat exchanging unit comprises a hot air flow inlet air collecting pipe and a hot air flow outlet air collecting pipe which are arranged in the flowing direction of the cold air flow and a plurality of spiral heat exchanging pipes, wherein the two ends of each spiral heat exchanging pipe communicate with the hot air flow outlet air collecting pipe and the hot air flow inlet air collecting pipe correspondingly. The spiral heat exchanging pipes are distributed in sequence in the flowing direction of the cold air flow to form a heat exchanging pipe bundle. An outlet of each hot air flow outlet air collecting pipe and an inlet of each hot air flow inlet air collecting pipe are located at the same end of the corresponding heat exchanging unit and penetrate through the inner wall or the outer wall of the circular passage. The other end of each heat exchanging unit is a free end.

Owner:XI AN JIAOTONG UNIV

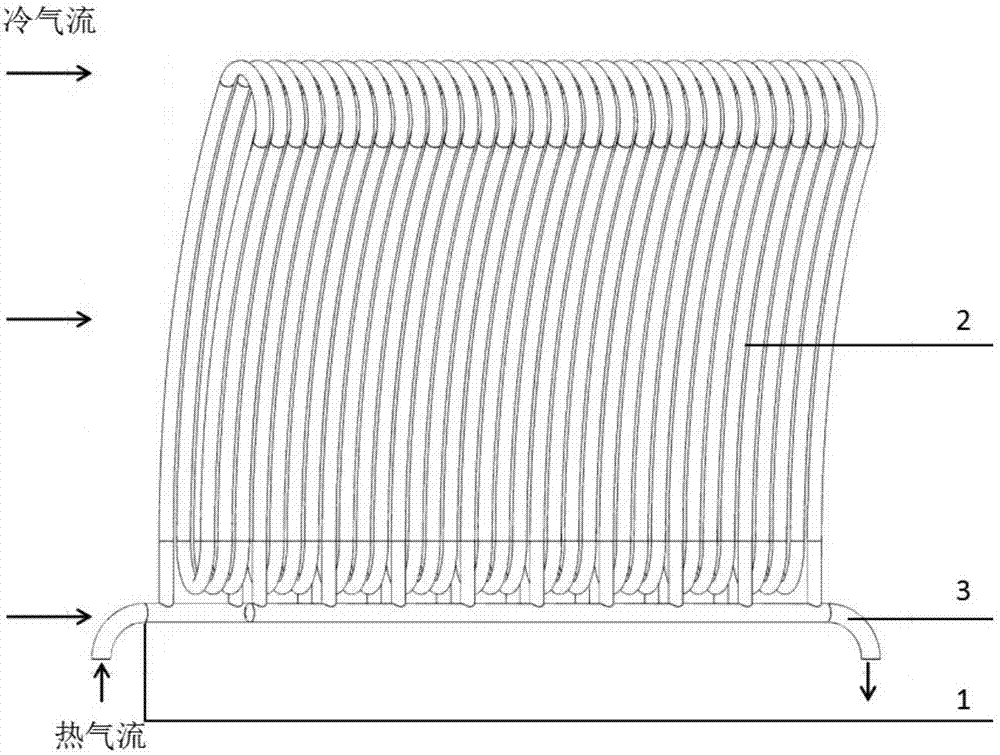

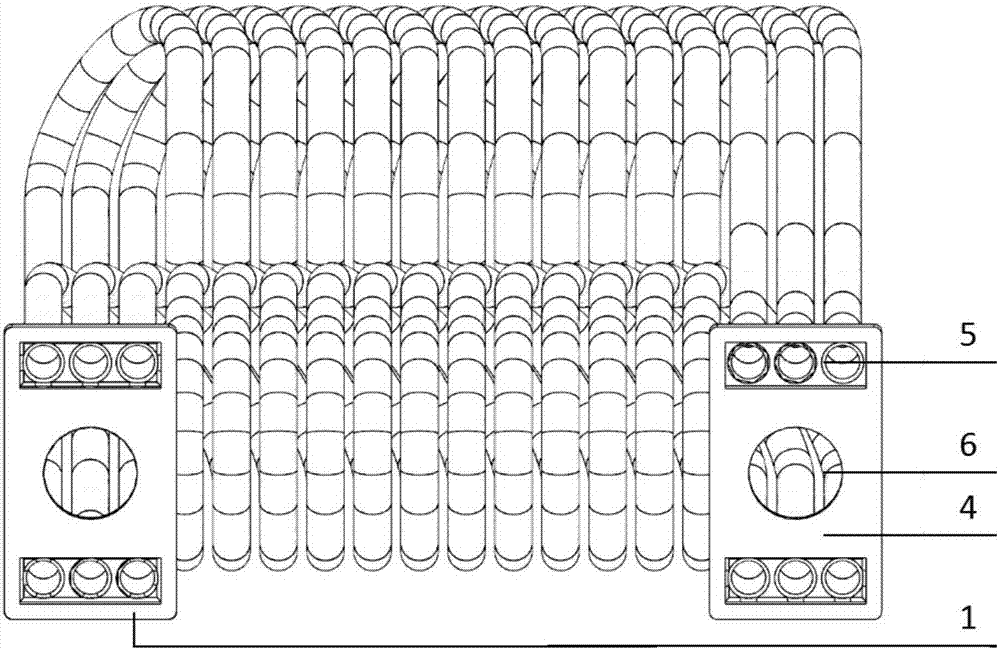

Double-spiral-pipe type gas-to-gas heat exchanger in annular channel

InactiveCN107131776AImprove the heat transfer coefficient in the tubeUniform thermal stress distributionStationary tubular conduit assembliesPlate heat exchangerEngineering

The invention discloses a double-spiral-pipe type gas-to-gas heat exchanger in an annular channel and relates to the field of gas-to-gas heat exchangers. The double-spiral-pipe type gas-to-gas heat exchanger comprises a plurality of heat exchange units evenly arranged in the annular channel in the circumferential direction of the annular channel. Cold airflow in the annular channel moves axially. Each heat exchange unit comprises a hot airflow flow-in gas collection chamber, a hot airflow flow-out gas collection chamber, and a plurality of spiral heat exchange pipes, wherein the hot airflow flow-in gas collection chamber and the hot airflow flow-out gas collection chamber are arranged in the cold airflow flowing direction, and the two ends of the spiral heat exchange pipes communicate with the hot airflow flow-in gas collection chamber and the hot airflow flow-out gas collection chamber correspondingly. Each spiral heat exchange pipe comprises outer spiral heat exchange pipe bodies and inner spiral heat exchange pipe bodies which are arranged at intervals in the radial direction of the annular channel, and the outer spiral heat exchange pipe bodies and the inner spiral heat exchange pipe bodies are sequentially arranged in the cold airflow flowing direction to form heat exchange pipe bundles. An inlet of the hot airflow flow-in gas collection chamber and an outlet of the hot airflow flow-out gas collection chamber are located in the same end of the corresponding heat exchange unit and penetrate through the inner wall or the outer wall of the annular channel, and the other end of the heat exchange unit is a free end.

Owner:XI AN JIAOTONG UNIV

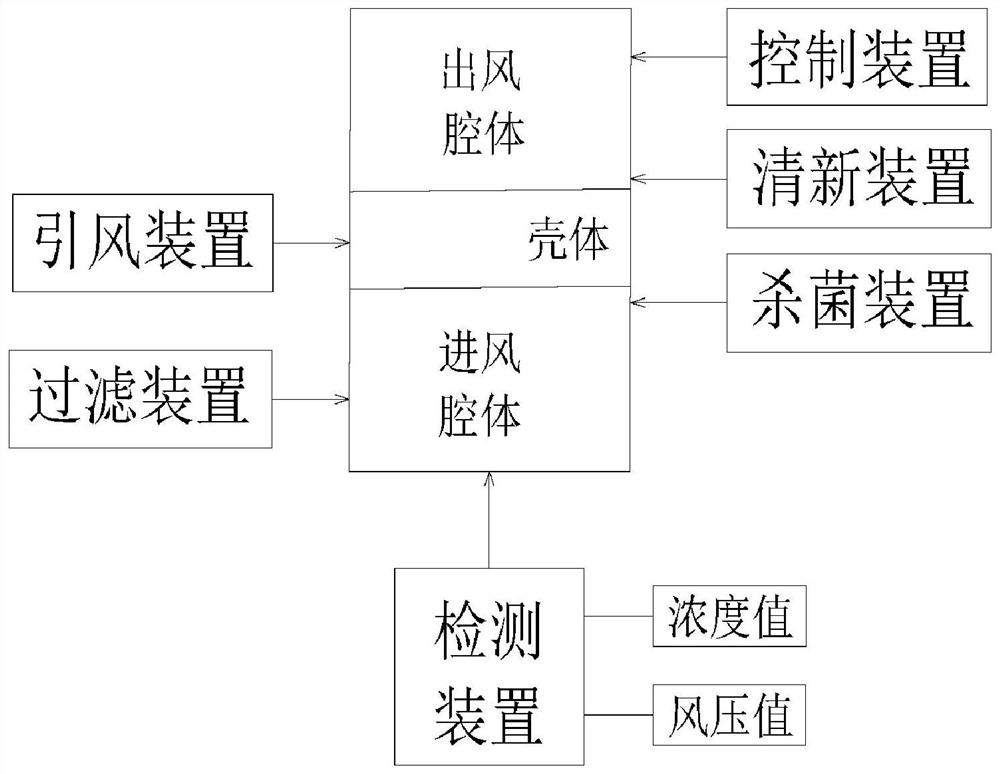

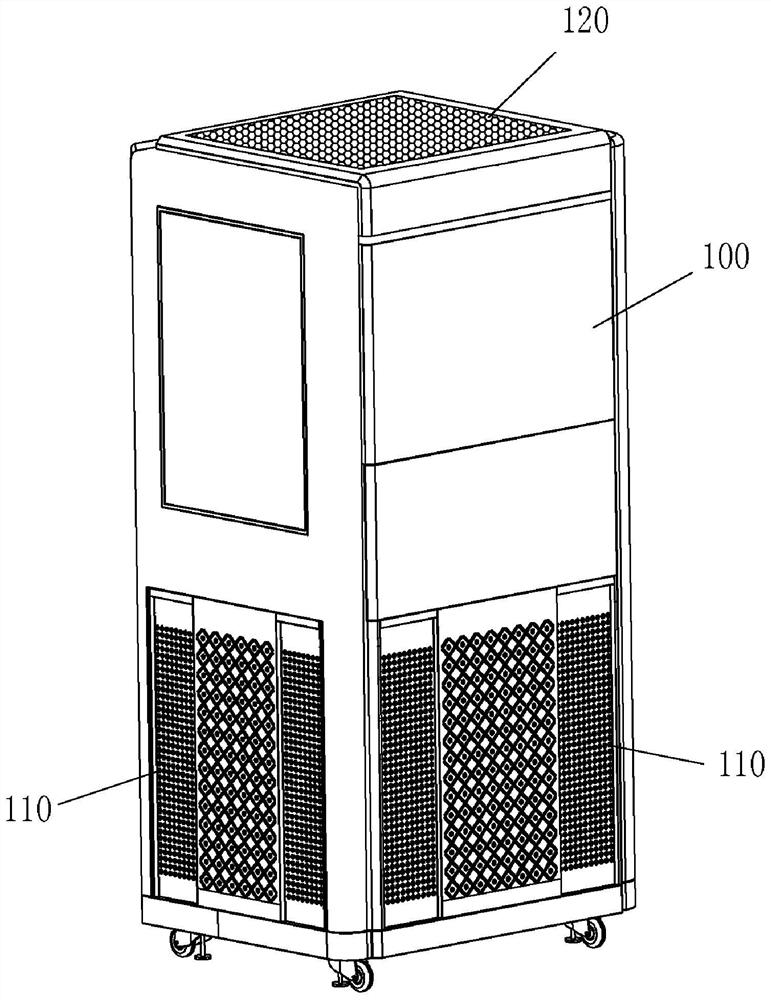

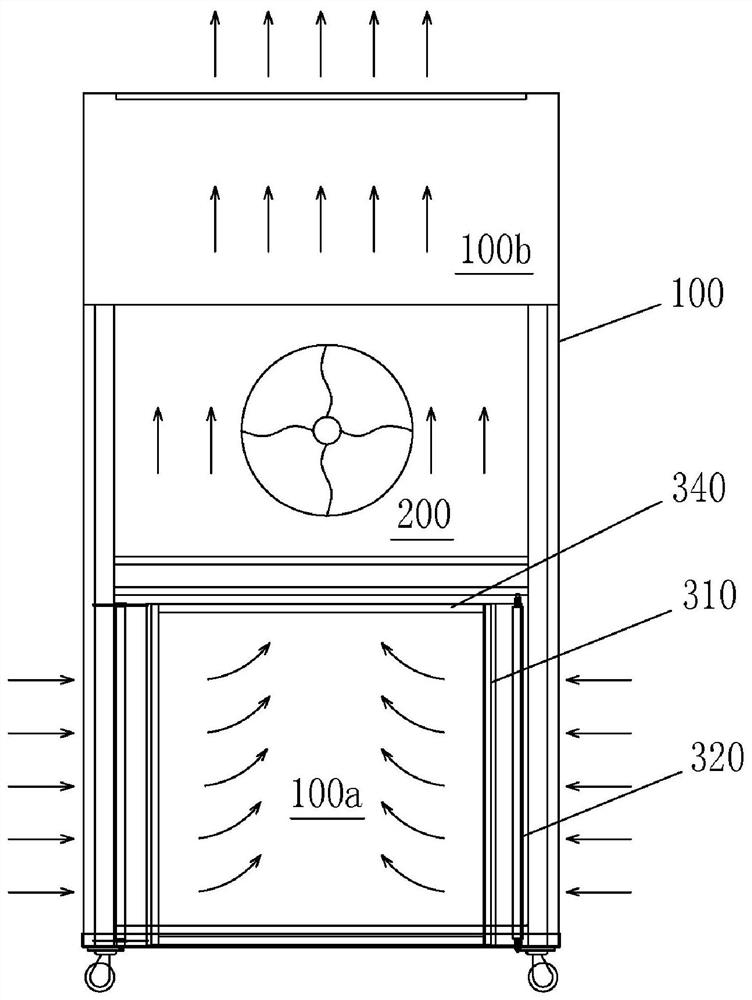

Air purifier

PendingCN111981594AImprove the effectReduce the overall heightMechanical apparatusDispersed particle filtrationAir volumeAir purifiers

The invention provides an air purifier. The air purifier comprises a shell body, an air inducing device, a filtering device and a control device, wherein the shell body is provided with a suction inlet and a blowing outlet of air, the air inducing device sucks the air into the shell body from the suction inlet and blows the air out from the blowing outlet, the filtering device filters and purifiesthe air sucked into the shell body from the suction inlet, the filtering device comprises an inner filtering assembly and an outer filtering assembly, the inner filtering assembly is arranged on theshell body and completely covers the suction inlet, the outer filtering assembly is arranged on the shell body and located on the outer side of the inner filtering assembly, the outer filtering assembly comprises a movable filter screen capable of conducting collecting and winding, the control device controls the air inducing device and the filtering device at the same time, and when the dust accumulation amount of the filtering device is changed, the air inducing device is used for keeping the air amount of the blowing outlet stable. The air purifier has the advantages of being large in air outlet amount and stable in air outlet amount.

Owner:广州九森环保产业有限责任公司

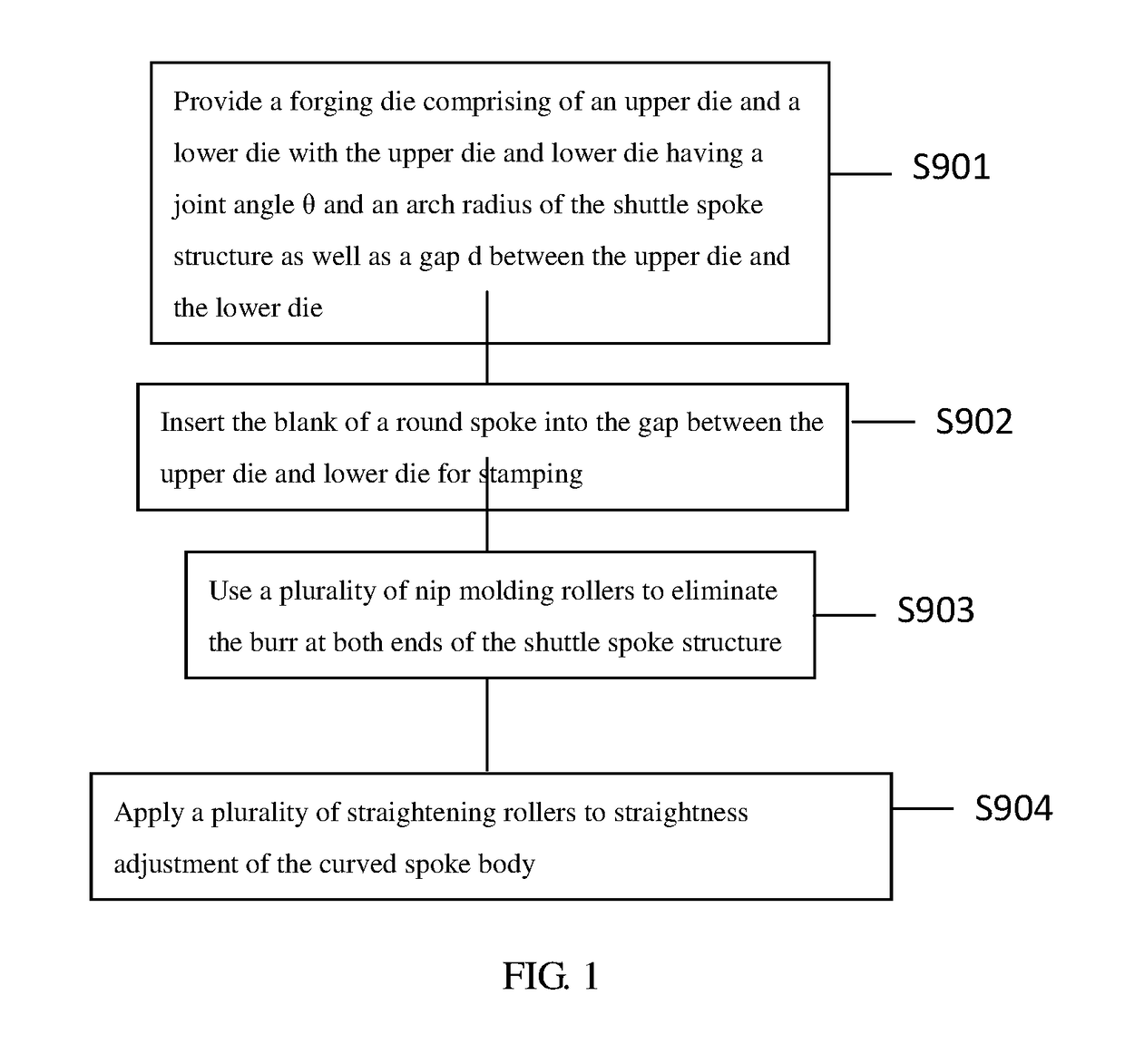

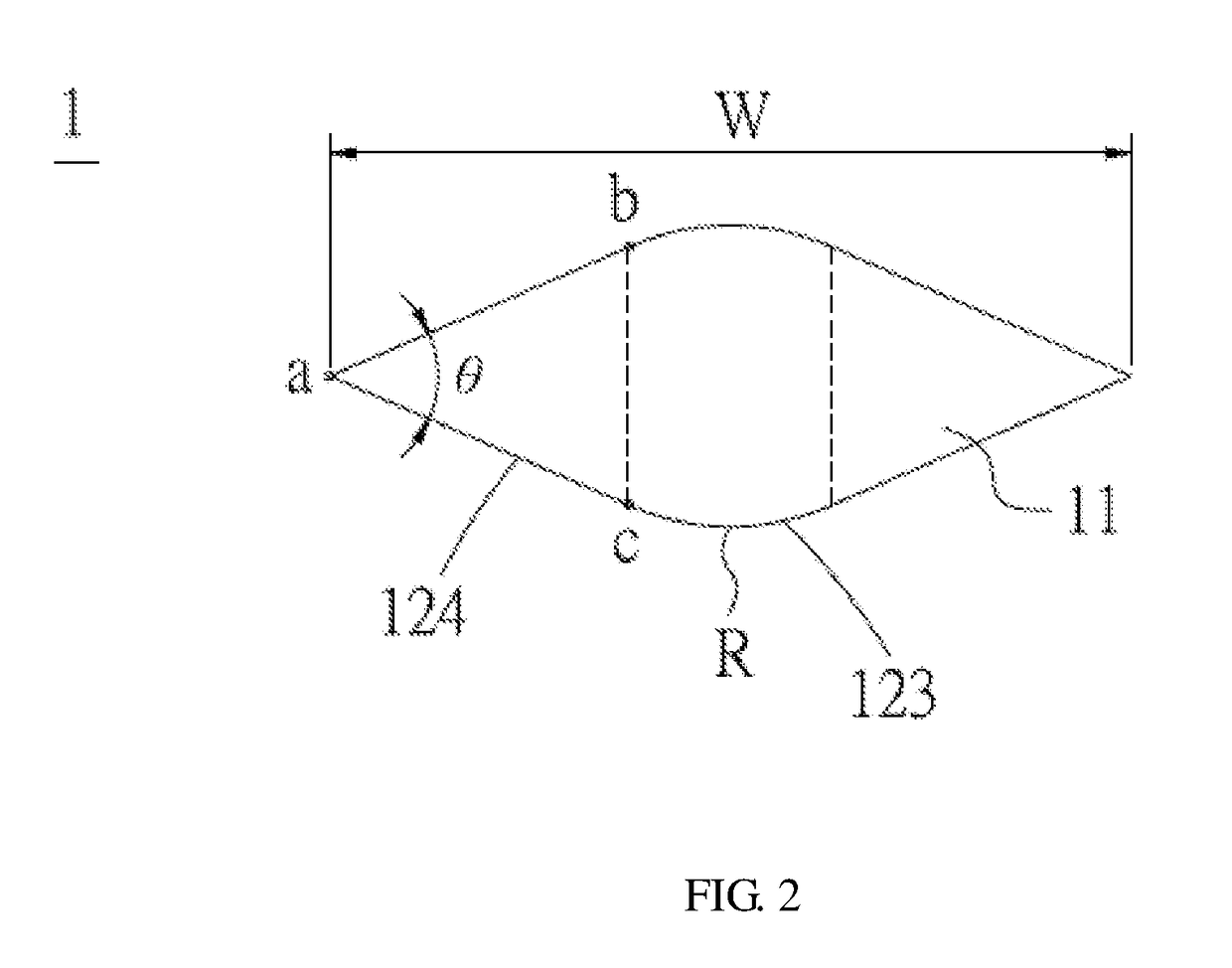

Preparation method of shuttle spokes

InactiveUS20190015891A1Reduce external resistanceOvercome deficienciesMetal-working apparatusSpoked wheelsEngineeringJoint angle

A preparation method of shuttle spokes that includes these steps: providing a forging die comprising of an upper die and a lower die with the upper die and lower die having a joint angle of the shuttle spoke structure and an arch radius as well as a gap between the upper die and the lower die; inserting the blank of a round spoke into the gap between the upper die and lower die for stamping; using a plurality of nip molding rollers to eliminate the burr at both ends of the shuttle spoke structure; and applying a plurality of straightening rollers to straightness adjustment of the curved spoke body so that when the wheel parts are rolling, less air vortex can minimize air resistance.

Owner:CHEN WEN HSUAN

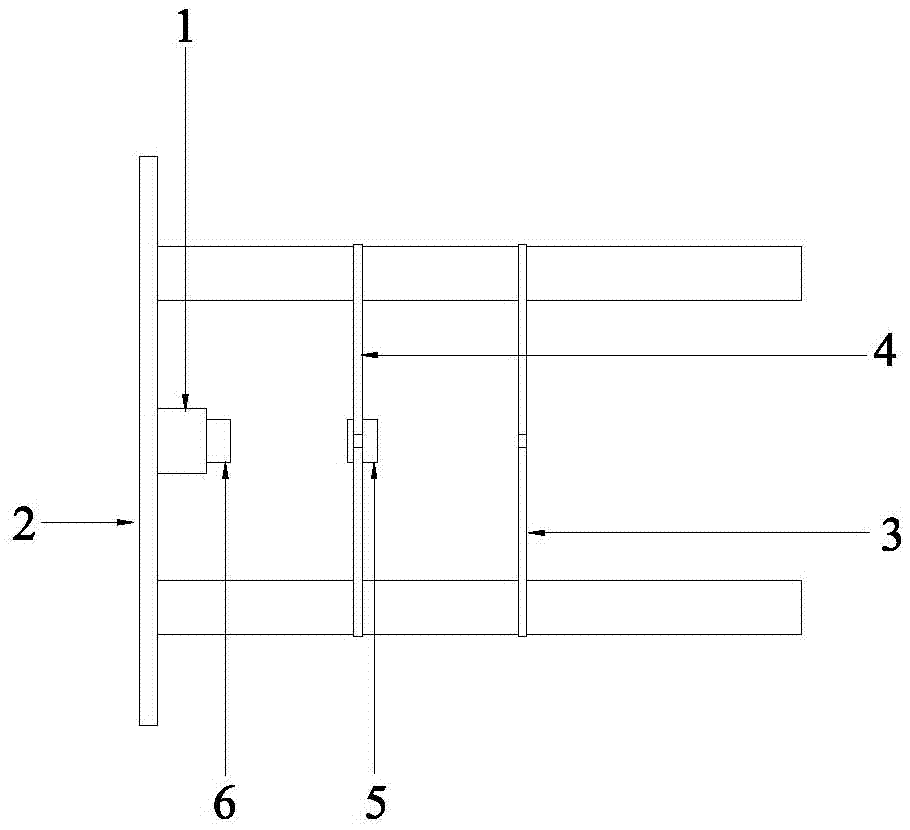

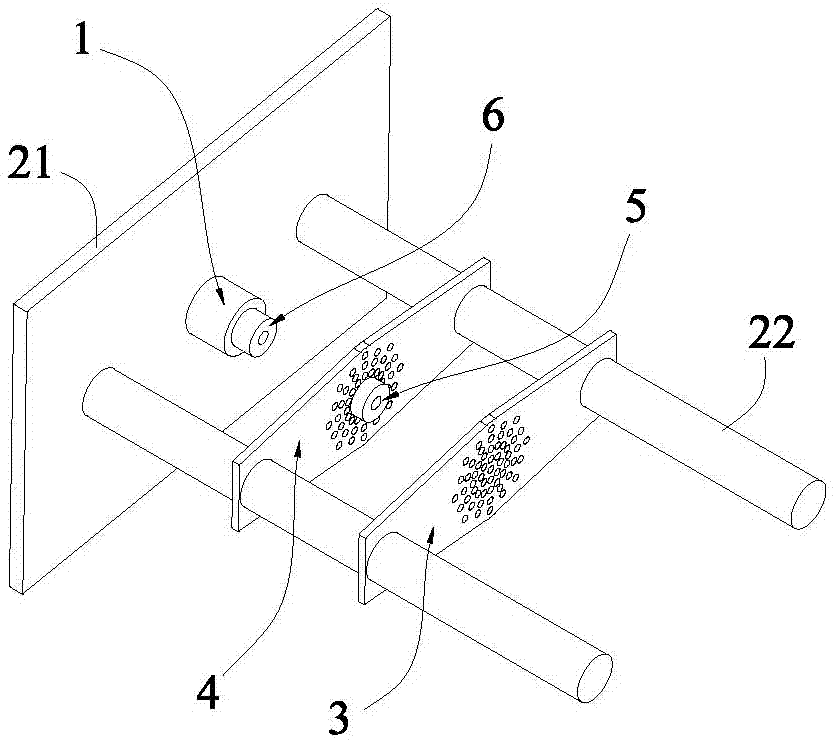

Composite stranding high-speed wire-stranding machine

ActiveCN107221392AReduce contact gapMeet production requirementsCable/conductor manufactureEngineeringCore set

The present invention discloses a composite stranding high-speed wire-stranding machine. The composite stranding high-speed wire-stranding machine comprises a wire-stranding host, a mounting rack, a front distributor plate, a back distributor plate, a first stranded wire die and a second stranded wire die. The mounting rack is arrange at the stranded wire port near the wire-stranding host, the front distributor plate and the back distributor plate are arranged on the mounting rack at intervals in order, the first stranded wire die is arranged at the back distributor plate, and the second stranded wire die is arranged at the stranded wire port; the front distributor plate and the back distributor plate are employed to perform uniform arrangement distribution of a plurality of single branches, the first stranded wire die is employed to perform concentration of the single branches located at center area positions to form a core set, and the single branches located at the surrounding area positions pass through back branching holes on the back distributor plate and then perform arrangement once again to allow the single branches located at the surrounding area positions to be uniformly distributed. The composite stranding high-speed wire-stranding machine effectively reduce the external resistance to allow laying tension to be balanced, the diameters of single branches is not easy to become small through pulling, and the single branches are subjected to uniform composite stranding on the core set through the second stranded wire die so as to reach the composite stranding effect, allow the wire material products after the composite stranding to be smooth and rounding and effectively ensure the quality of products.

Owner:广州和理新金属科技有限公司

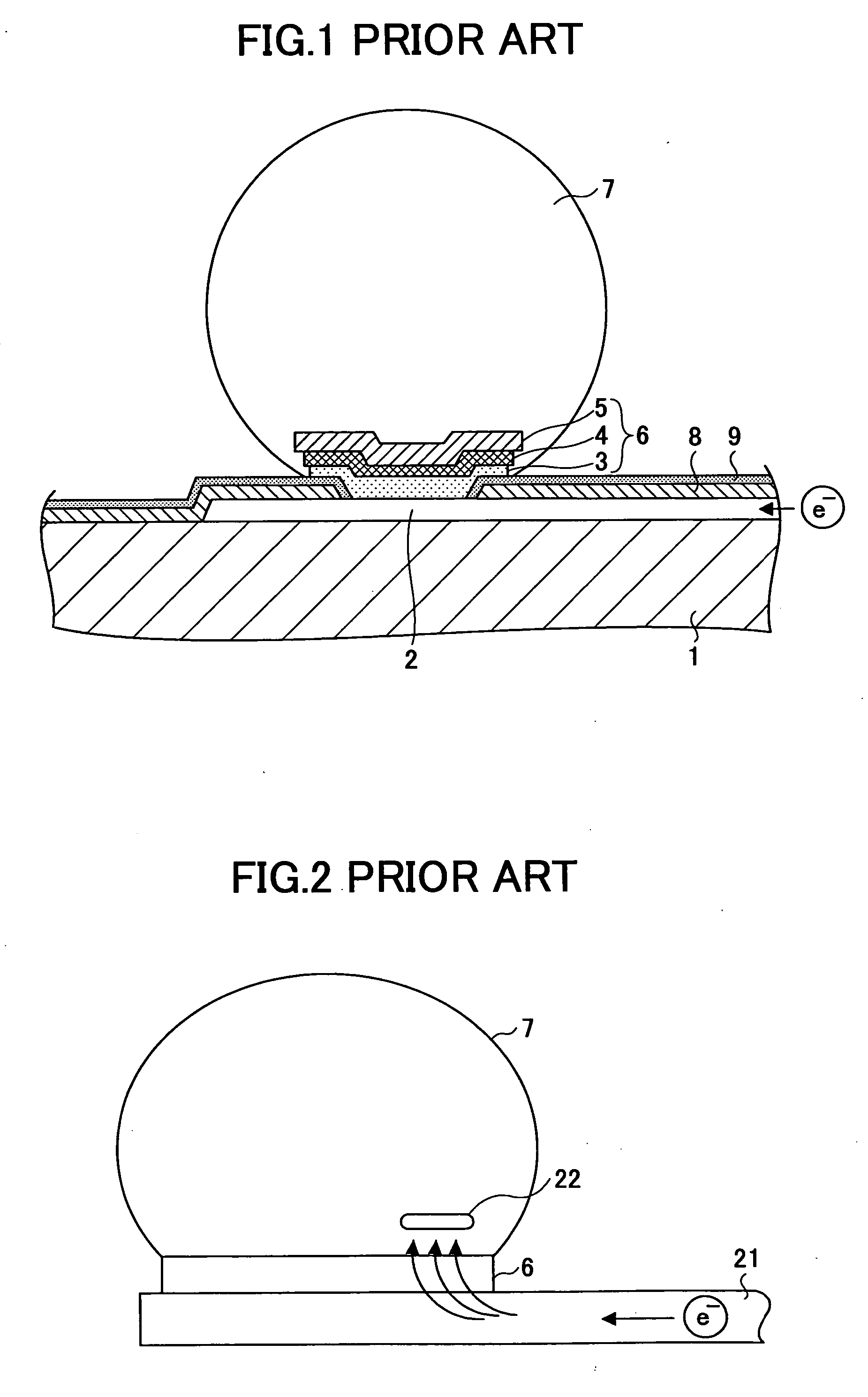

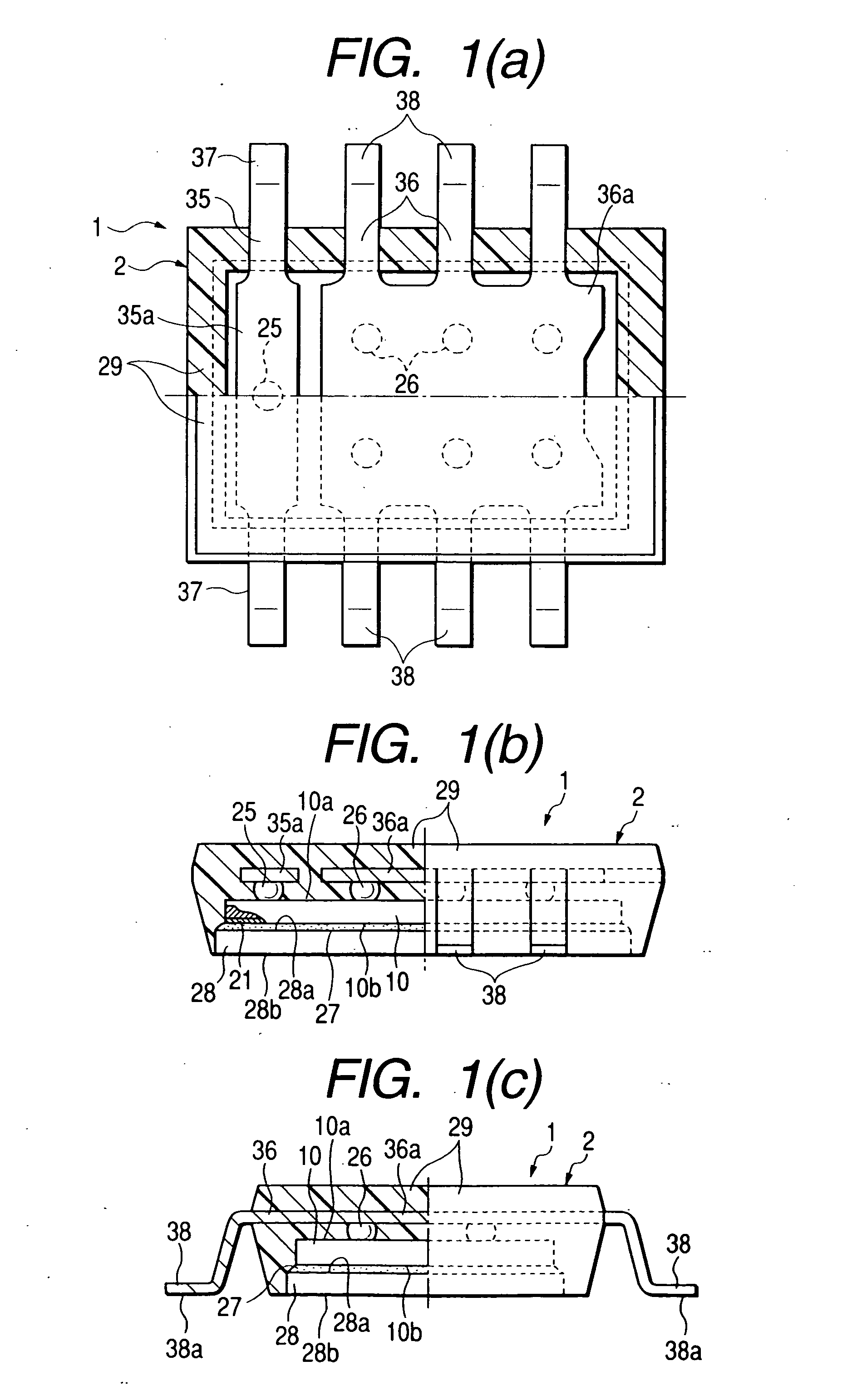

Semiconductor device and a method of manufacturing the same

InactiveUS20050023671A1Reduce external resistanceLower resistanceSemiconductor/solid-state device detailsSolid-state devicesMOSFETSurface electrode

A semiconductor device having high output and a method of manufacturing the same are disclosed in which external resistance is reduced and radiating performance is improved. A MOSFET (70) comprises a plurality of inner leads electrically connected to a surface electrode of a semiconductor pellet having a field effect transistor on a principal surface thereof, a connecting portion for electrically connecting the surface electrode of the semiconductor pellet and the inner leads, a resin encapsulant (29) formed by encapsulating the semiconductor pellet with resin, a plurality of outer leads (37), (38) protruding in parallel from the same lateral surface of the resin encapsulant (29) and a header (28) bonded to a back surface of the semiconductor pellet and having a header protruding portion (28c) protruding from a lateral surface of the resin encapsulant (29) opposite to the lateral surface from which the outer leads protrude, wherein the header (28) has an exposed surface (28b) exposed from the resin encapsulant (29); the outer leads (37), (38) are bent; and the exposed of the outer leads (37), (38) are provided at substantially the same height.

Owner:RENESAS ELECTRONICS CORP

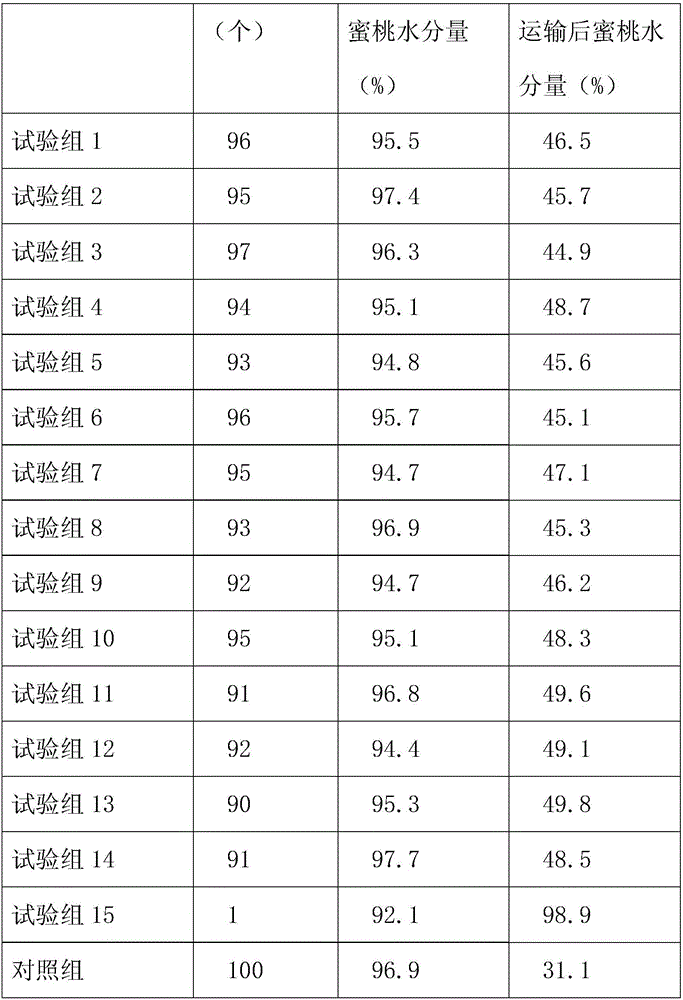

Anticorrosive traditional Chinese medicine spray for fruit/vegetable transportation

InactiveCN106135396ANo residueEnhanced inhibitory effectFruit and vegetables preservationNatural extract food ingredientsBULK ACTIVE INGREDIENTActive ingredient

The invention discloses an anticorrosive traditional Chinese medicine spray for fruit / vegetable transportation, belonging to the technical field of agricultural product preservation. In the anticorrosive traditional Chinese medicine spray for fruit / vegetable transportation disclosed by the invention, natural green plant components are adopted such as bamboo leaves, lens culinaris and hickory leaves; through mutual cooperation of the plant components, the problem that the fruit and vegetables are susceptible to fungus invasion and easily get rotted during transportation is solved; the oxidation resistance and antibacterial ability of the fruit / vegetable cells are enhanced, the fruit / vegetable storage time is prolonged, and the moisture content in the fruit / vegetables is increased; and moreover, the active ingredients of various plants are all extracted by a water extraction method, and any harmful chemical reagent residue is avoided.

Owner:黄云波

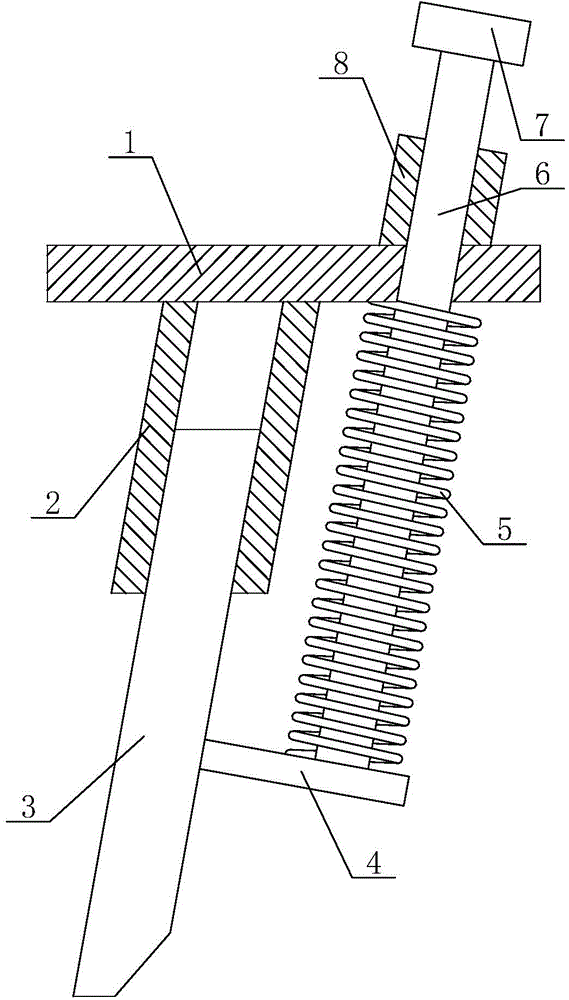

Self-adaptable spring stern door of asphalt pavement milling machine

The invention discloses a self-adaptable spring stern door of an asphalt pavement milling machine. The self-adaptable spring stern door comprises a rack, a door plate, a guide groove, a spring and a sliding shaft, wherein the guide groove is fixedly formed in the lower side of one end of the rack; the door plate is arranged in the guide groove in a sliding manner; a guide sleeve is fixedly arranged on the upper side of the other end of the rack; the sliding shaft is arranged in the guide sleeve in a sliding manner; a limiting baffle block is fixedly arranged at the upper end of the sliding shaft; the spring sleeves the sliding shaft; the lower end of the sliding shaft is fixedly connected with one end of a fixed connection plate; and the other end of the fixed connection plate is fixedly connected with the door plate. The self-adaptable spring stern door has the characteristics of reasonable design, relatively low cost, good economical efficiency, constant stern door grounding pressure and high control reliability, does not relate to hydraulic and electric control systems, and can adapt within a small range; the operation efficiency and quality of the pavement milling machine can be improved; and the recovery rate of milled materials is improved.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

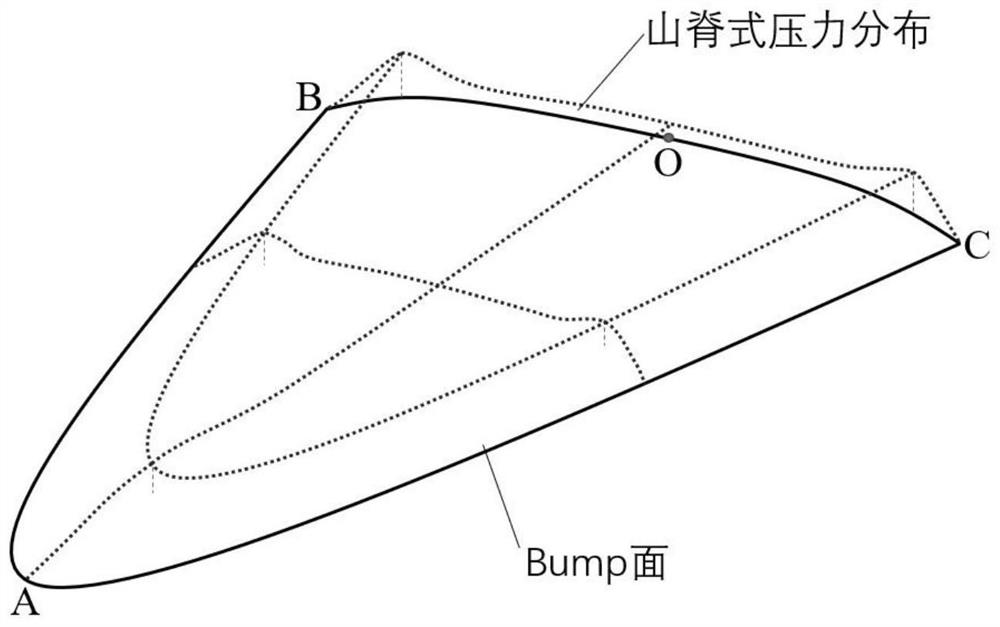

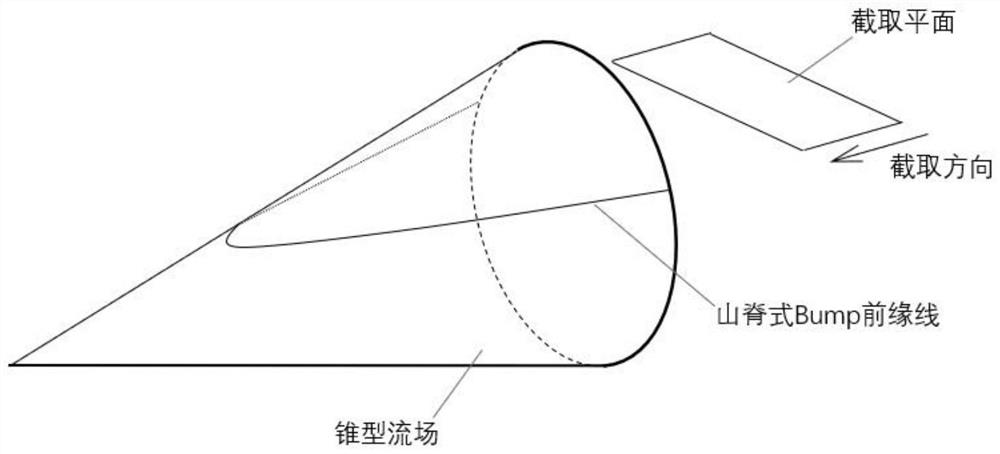

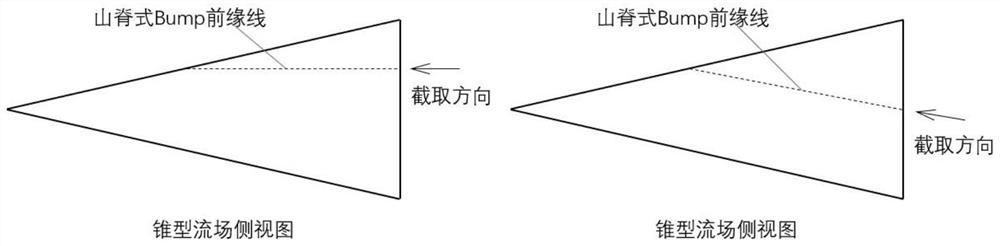

Inlet Precursor of High Velocity Inlet Based on Integral Controlled Ridge Pressure Distribution

ActiveCN111824431BEfficient displacementReduce resistanceGeometric CADSustainable transportationEngineeringMechanical engineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Power grid data acquisition equipment management method

PendingCN114330768AReduce external resistanceStay highOffice automationResourcesAcquisition apparatusPower grid

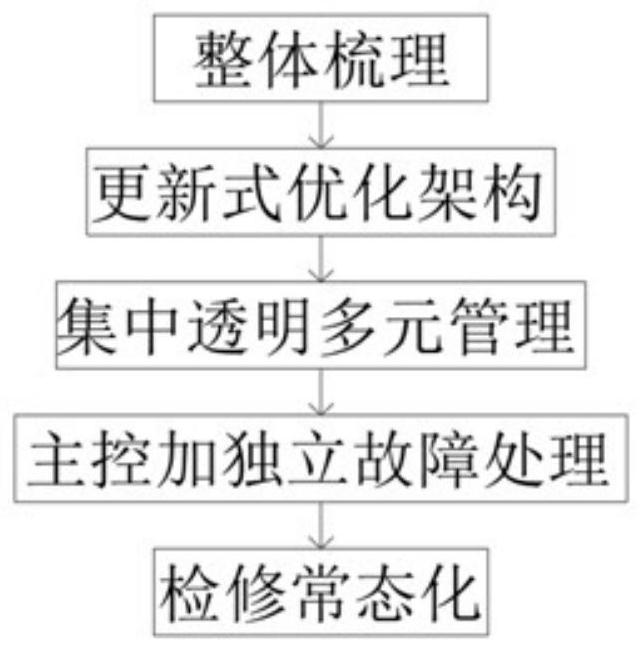

The invention discloses a power grid data acquisition equipment management method, which comprises the following steps: during acquisition equipment management, old equipment in a management range, old team departments in the management range and old management modes in the management range need to be sorted; topographic conditions, equipment distribution and management difficulty points in a management range are sorted, and overall sorting is preferentially carried out, so that the scientific premise of equipment management is kept. According to the method, on the premise of keeping equipment management scientificity through overall carding, an updated optimization architecture and concentrated transparent multi-element management are executed, the main control excellent point is high in responsibility, problem responsibility pushing and delayed processing are reduced, a radiation type execution point has independent fault processing capacity, fault maintenance and elimination can be carried out while reporting is carried out, and the fault processing efficiency is improved. Maintenance normalization not only refers to maintenance of acquisition equipment, but also refers to continuous optimization and screening of management personnel, so that scientific advancement and timely fault handling are jointly kept.

Owner:国网天津市电力公司营销服务中心 +2

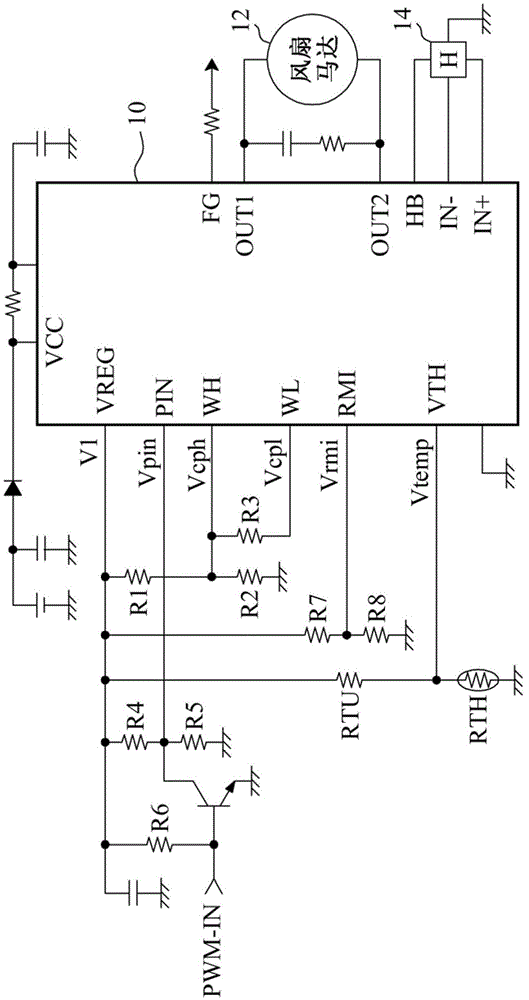

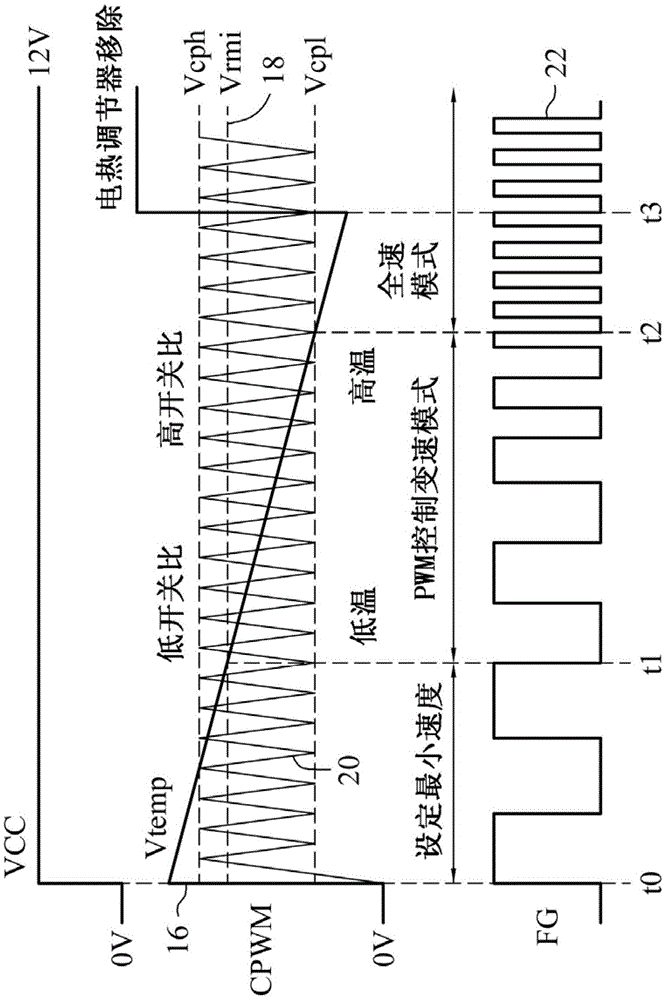

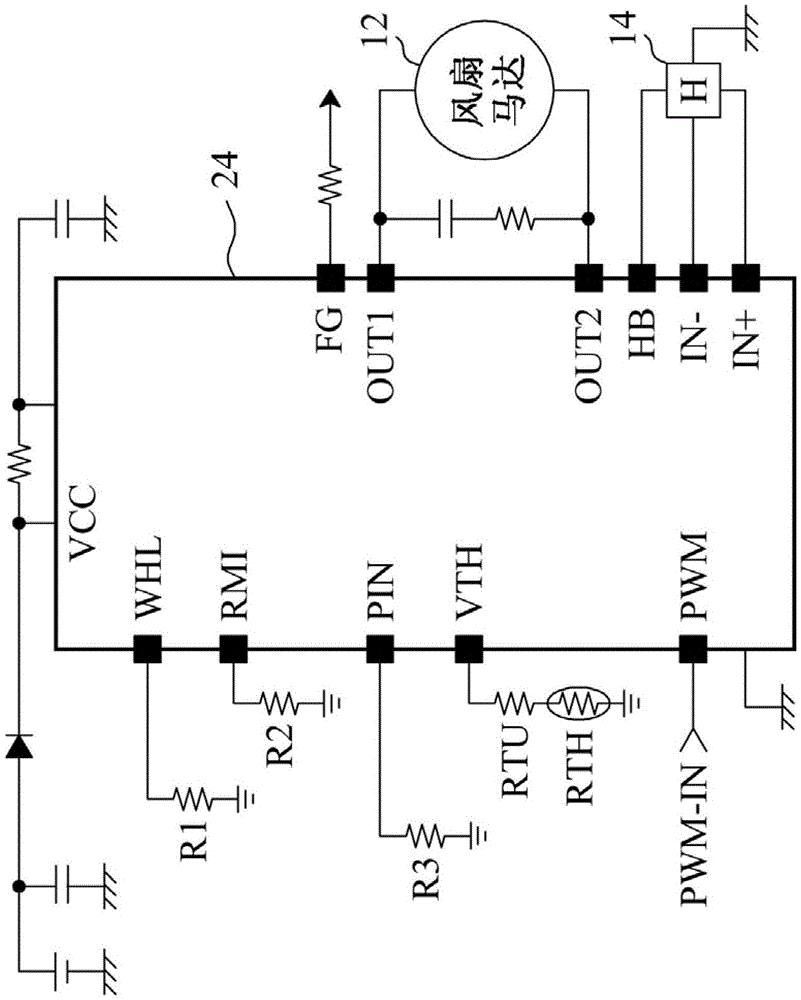

Fan motor driver, method for generating pulse width modulation signal and control circuit

ActiveCN103368482BLow costReduce external resistanceField or armature current controlMotor controlControl circuit

The embodiment of the invention discloses a fan motor driver used for providing a pulse-width modulation signal in order to decide the rotating speed of a fan. The fan motor driver controls the duty ratio the pulse-width modulation signal according to the resistance value of a multiple external resistors connected with the pins of the fan motor driver, rather than the voltage on the multiple pins. As a result, a fan motor control circuit established on the basis of the fan motor driver is capable of reducing the number of external resistors and material cost. The embodiment of the invention also discloses a fan motor control circuit.

Owner:RICHTEK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com