Integrated assembly of binary adjustable air inlet passage and an aircraft forebody and design method

A technology for air intakes and aircraft, which is applied in the direction of aircraft parts, air intake combustion of power devices, power devices on aircraft, etc. It can solve the problems of increasing the weight of the airframe and flight resistance, so as to improve the sideslip performance and improve the uniformity. sex, performance-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

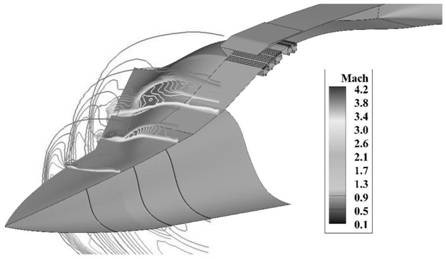

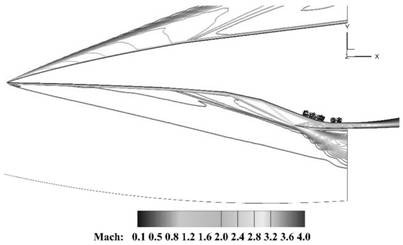

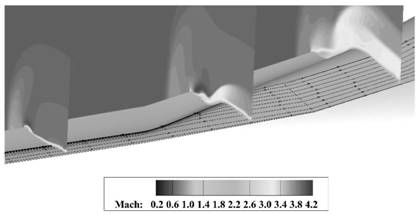

[0045] see Figure 1 to Figure 3 As shown, the binary adjustable air inlet provided by the present invention and the integrated assembly of the aircraft precursor include the inlet of the air inlet, the two-stage adjustable compression wedge surface 4 located at the front of the inlet of the air inlet, and the two-stage adjustable compression wedge surface located at the front of the air inlet. The primary fixed compression wedge surface 3, the throat section 8, the expansion section 9, the connecting rod part 10 and the driving device 11 at the front part of the wedge surface 4. Wherein, the first-stage fixed compression wedge surface 3 is connected with the second-stage bulging trailing edge of the precursor, and its compression angle is 8°; Triangular staircase.

[0046] The front of the primary fixed compression wedge surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com