Inflation tire

A technology for pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, transportation and packaging, etc. It can solve the problems of difficulty, deterioration of wet road performance, and easy reduction of residual CF, and achieve uniform rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

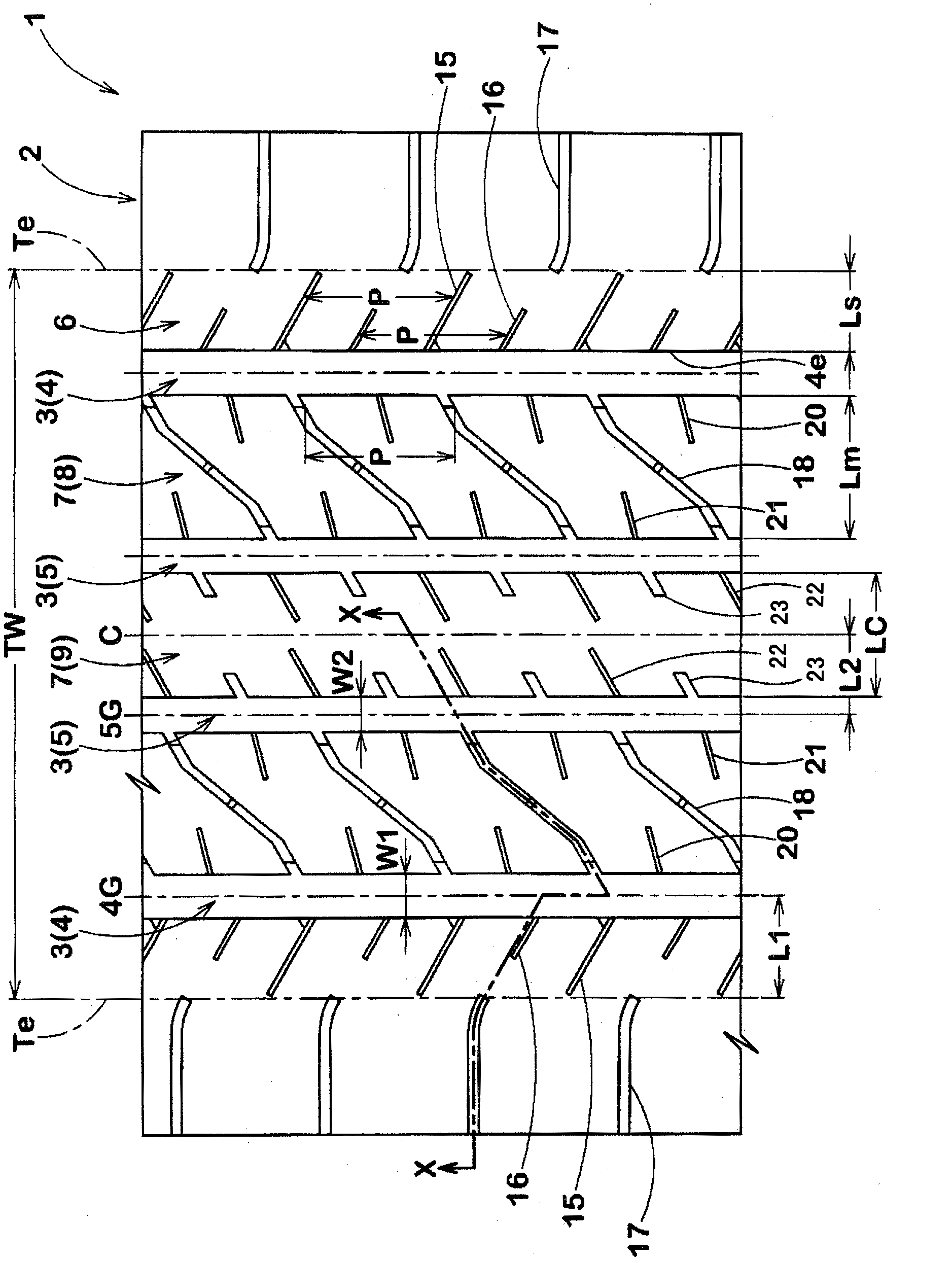

[0059] Manufacturing has figure 1 Pneumatic tires (size: 215 / 55R17) with a tread pattern based on the specifications in Table 1, and their performances were tested. Among them, the common specifications are as follows.

[0060] Rim size: 7J

[0061] Tread contact width: 170mm

[0062]

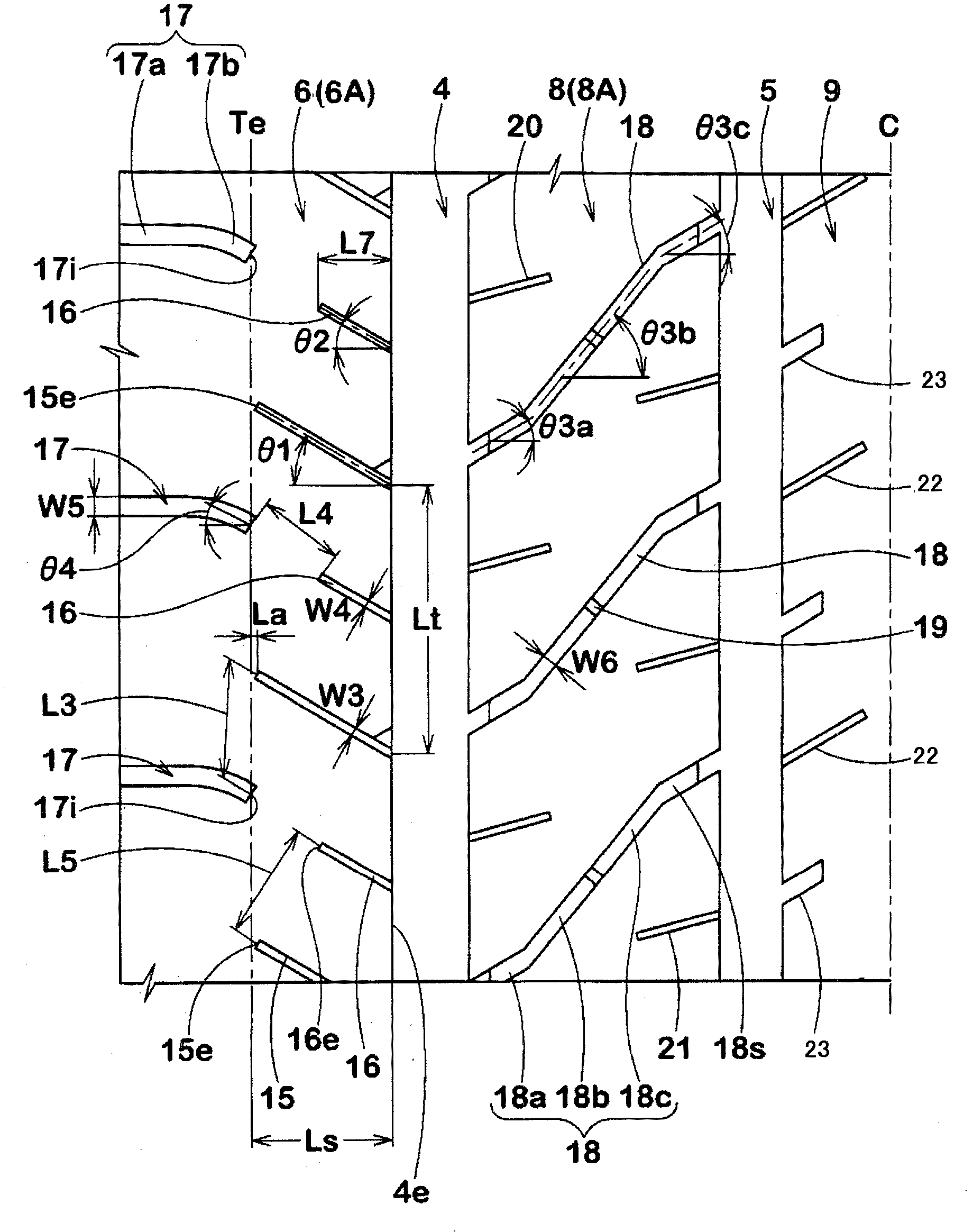

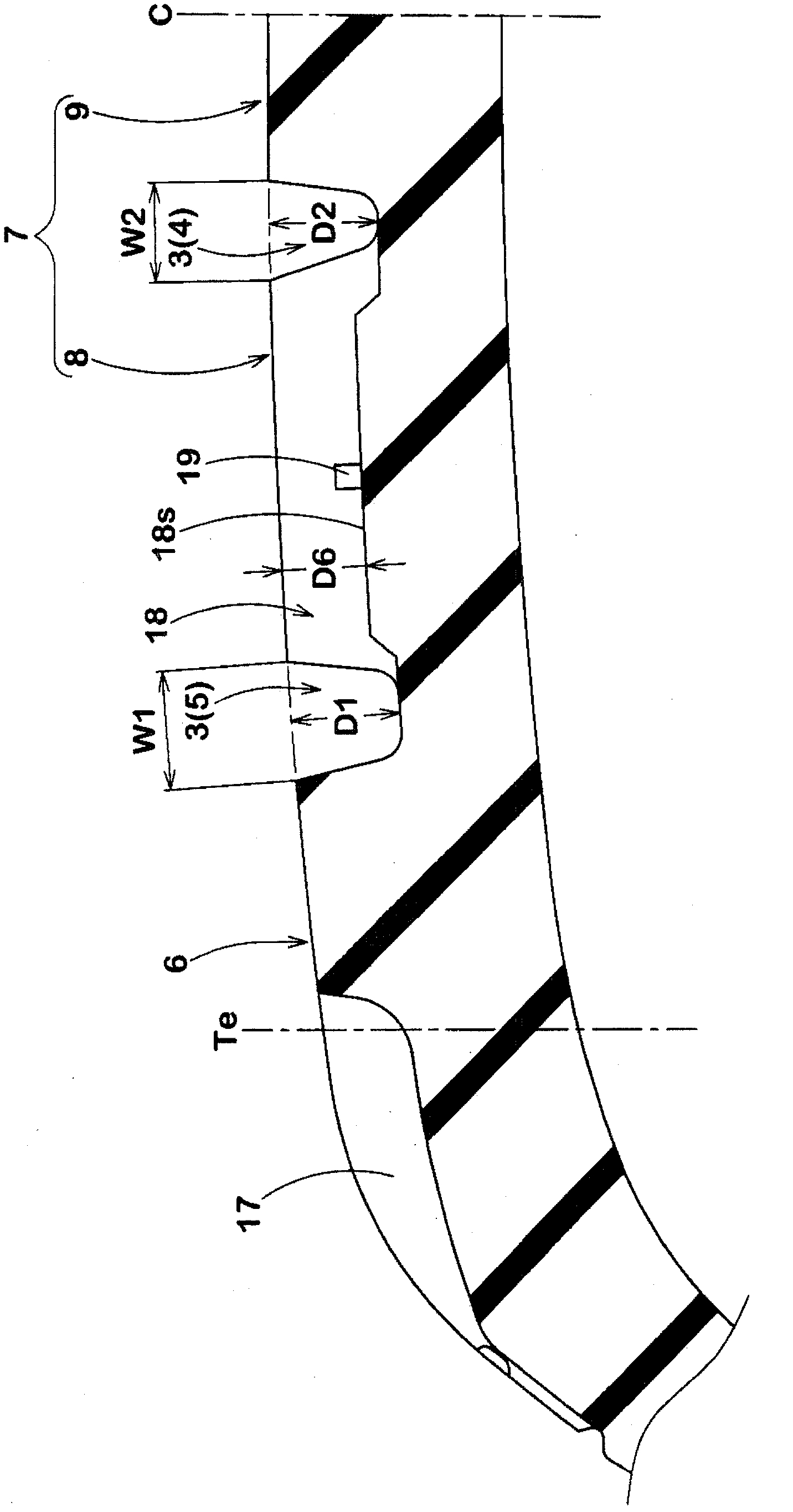

[0063] Groove width W1 / Tread contact width TW: 4.5%

[0064] Groove depth D1: 8.2mm

[0065] Angle relative to tire equator C: 0 degrees

[0066] Installation location: L2 / TW from tire equator C

[0067]

[0068] Groove width W2 / Tread contact width TW: 4.9%

[0069] Groove depth D2: 8.2mm

[0070] Angle relative to tire equator C: 0 degrees

[0071]

[0072] Groove width W3: 0.8mm

[0073] Ditch depth D3: 6.0mm

[0074]

[0075] Groove width W4: 0.6mm

[0076] Groove depth D4: 6.0mm

[0077] Tire axial length L7 / Ls: 40%

[0078]

[0079] Groove width W5: 2.0mm

[0080] Groove depth D5: 6.6mm

[0081]

[0082] Groove width W6: 2.0mm

[0083] Groove depth D6: 6.0mm

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com