Patents

Literature

33results about How to "Improved size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monitoring devices and processes based on transformation, destruction and conversion of nanostructures

InactiveUS20110003279A1Small sizeImprove responseMaterial nanotechnologyMeasured value indication by color changeMonitor equipmentNanostructure

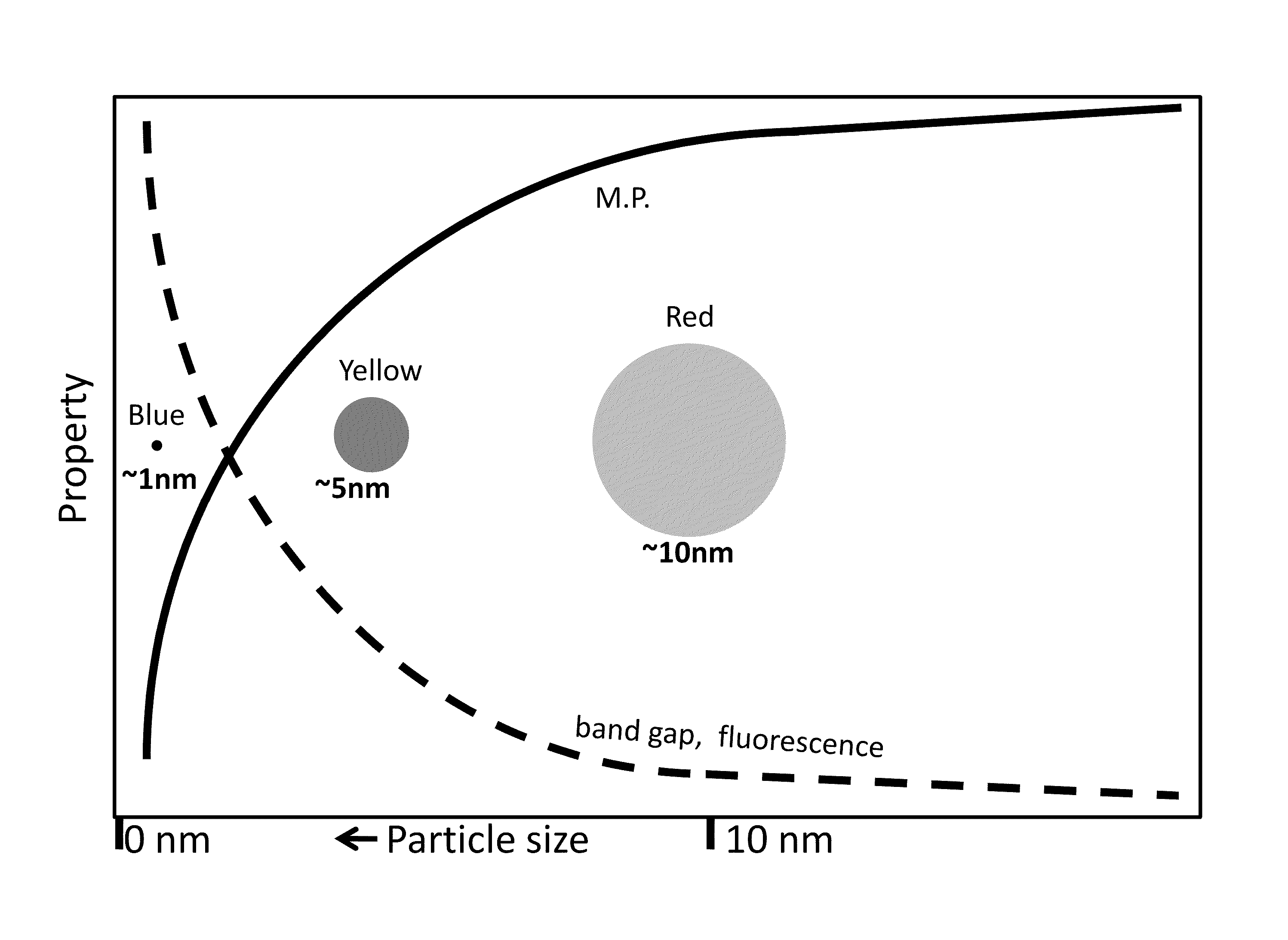

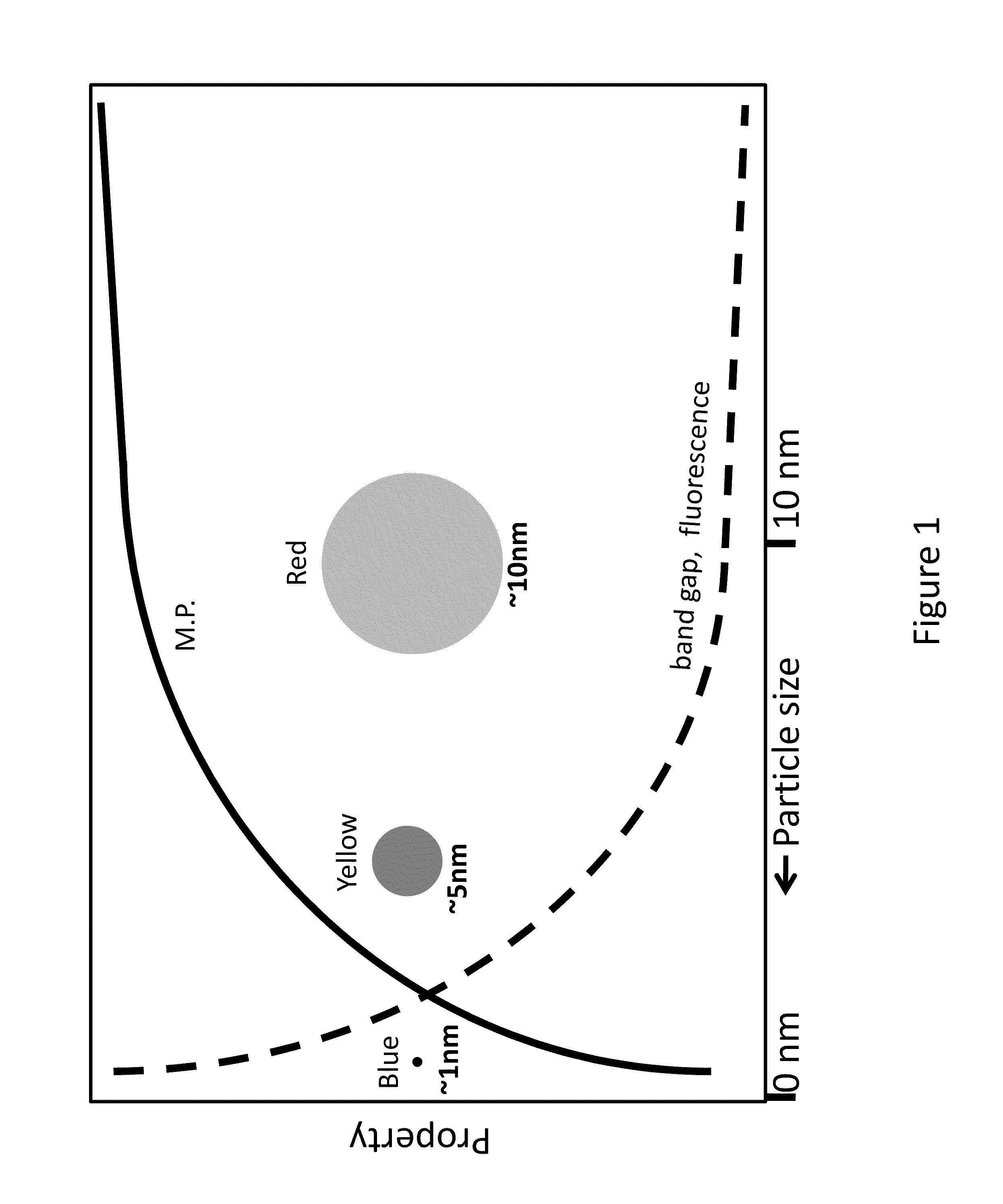

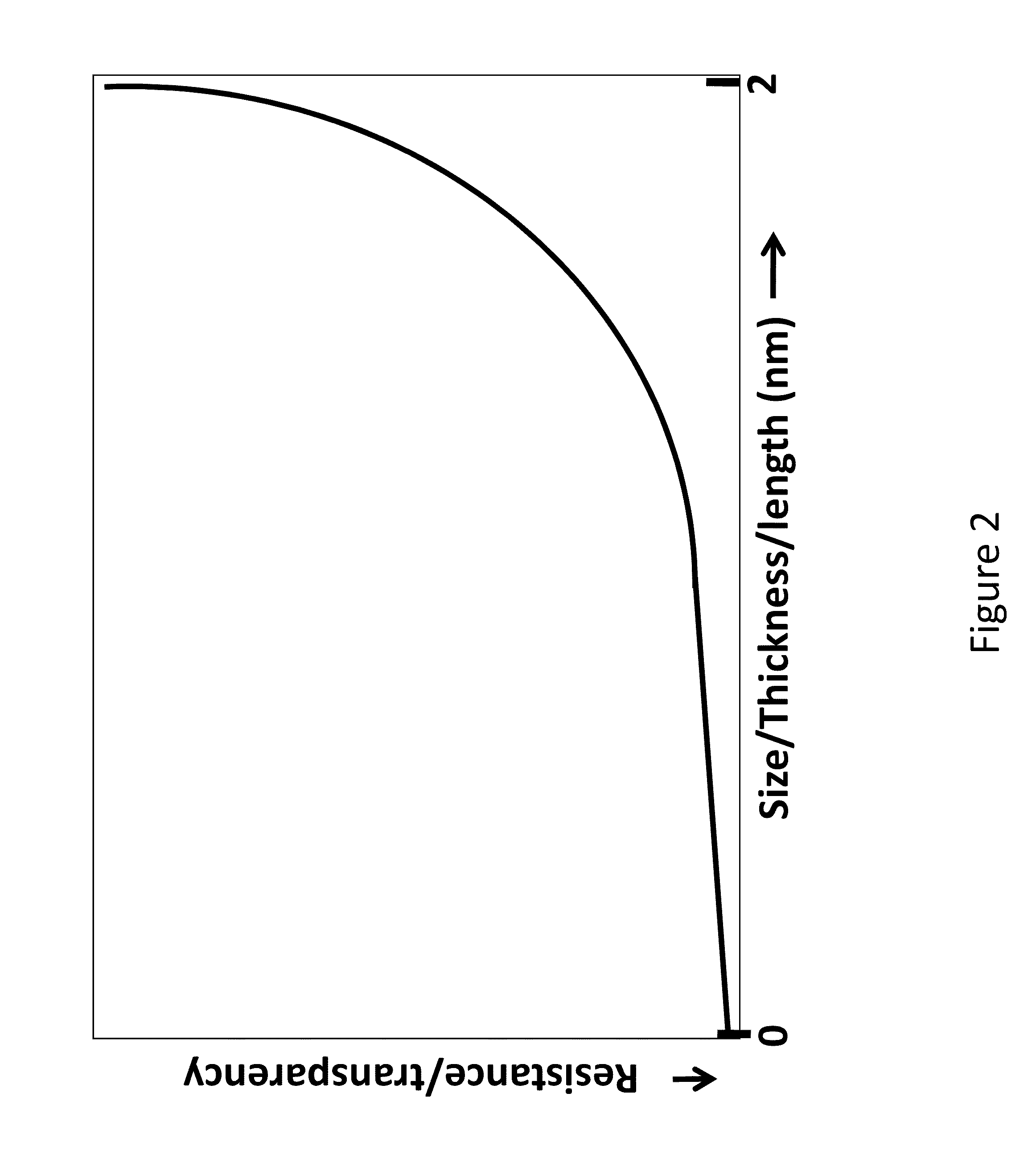

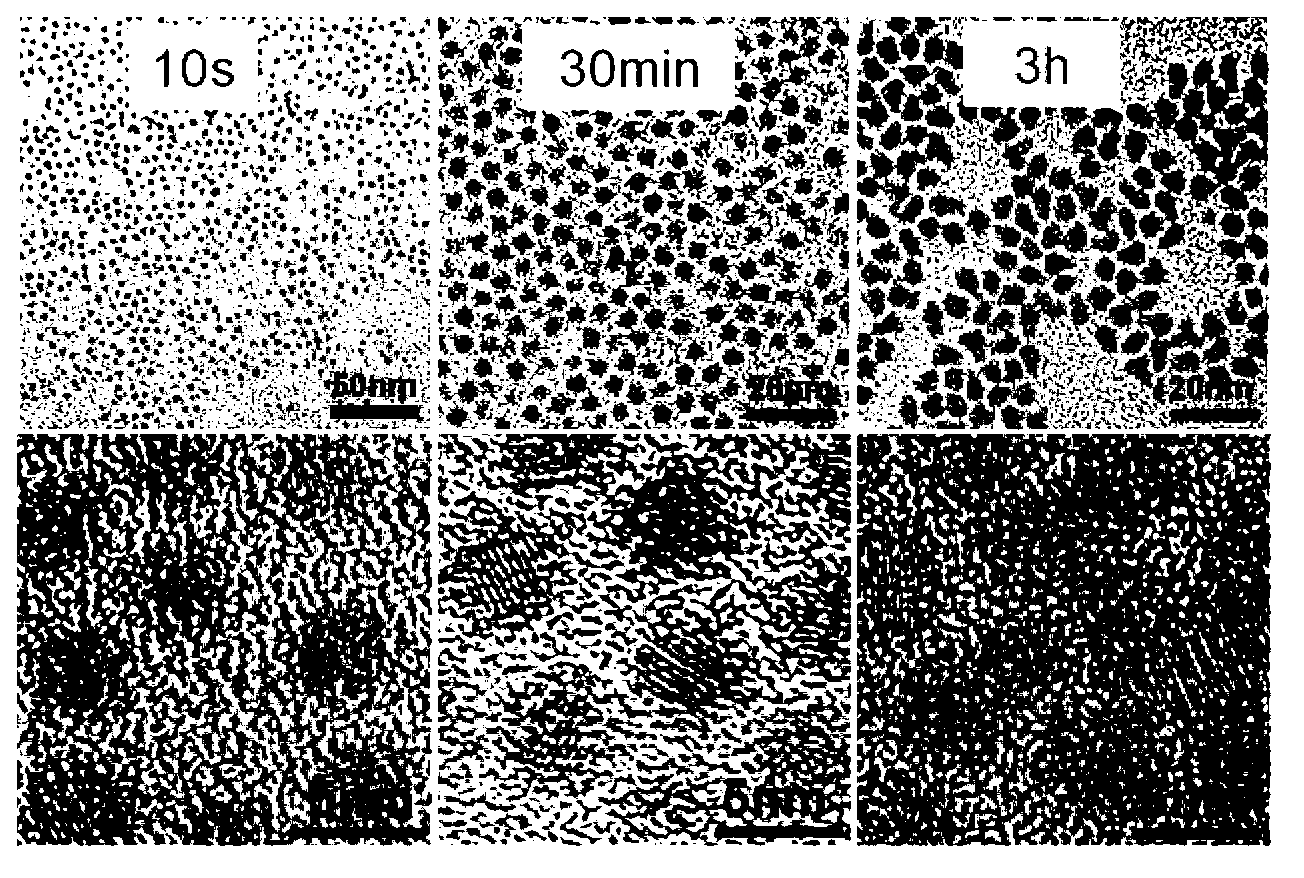

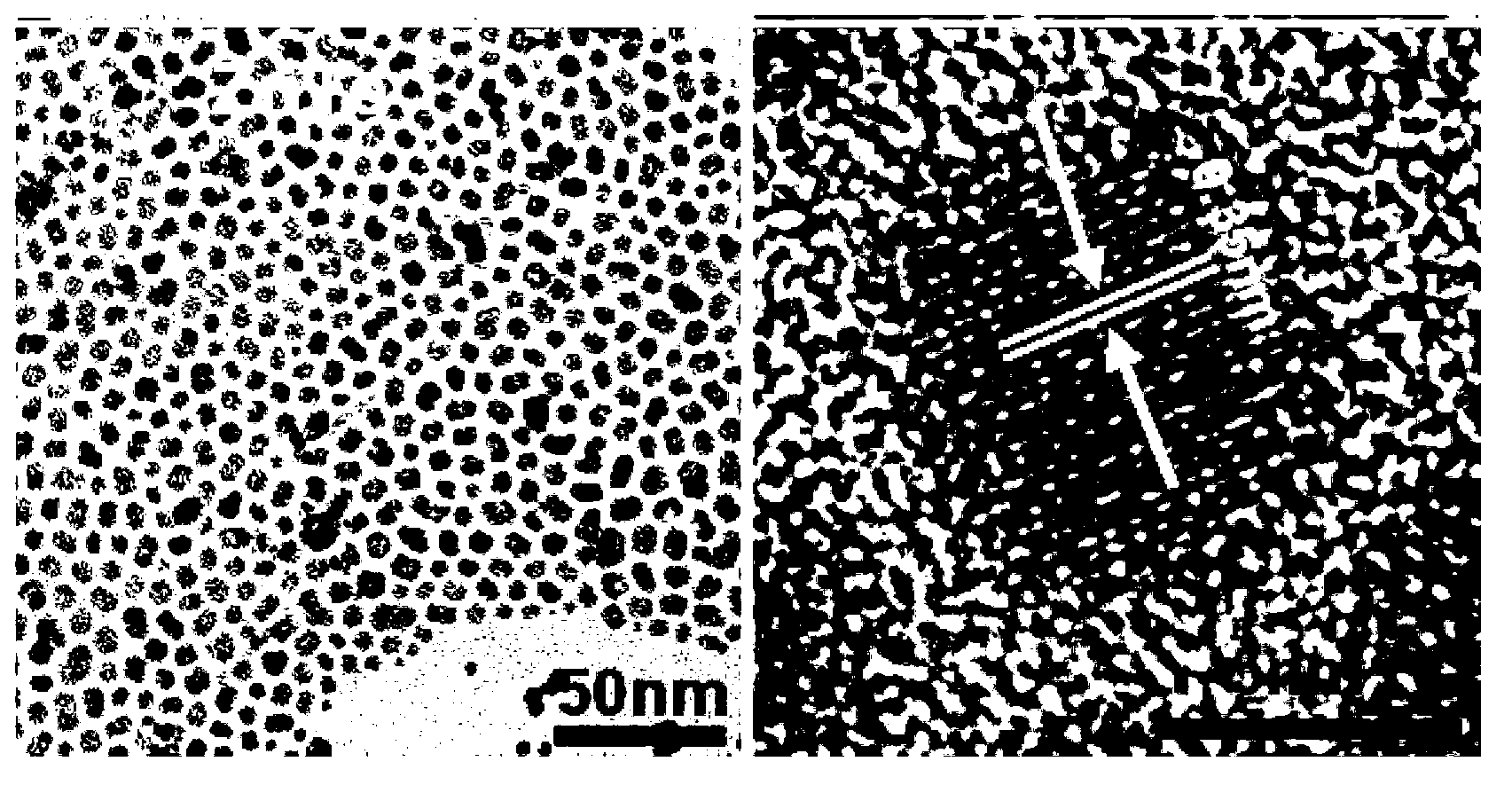

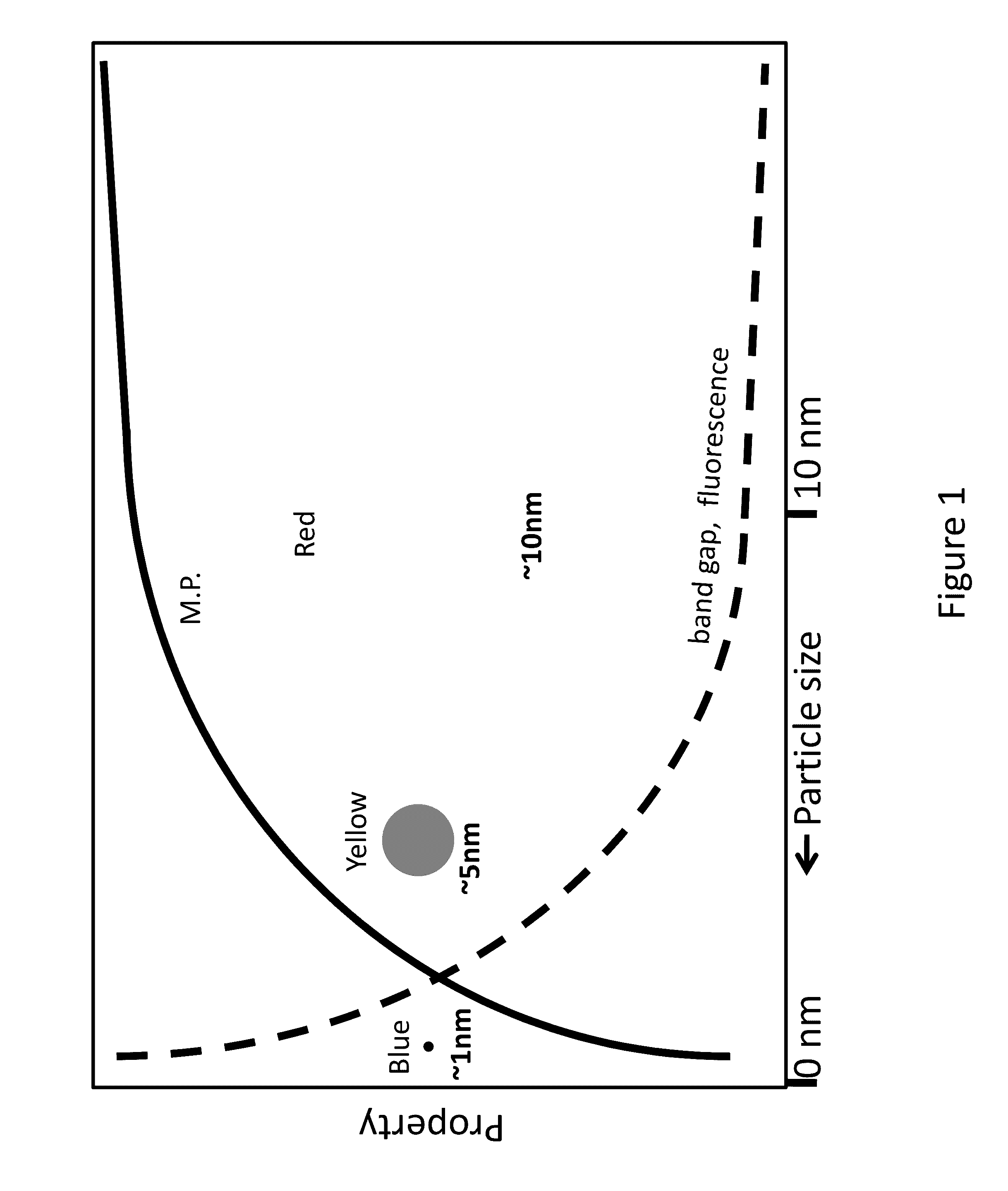

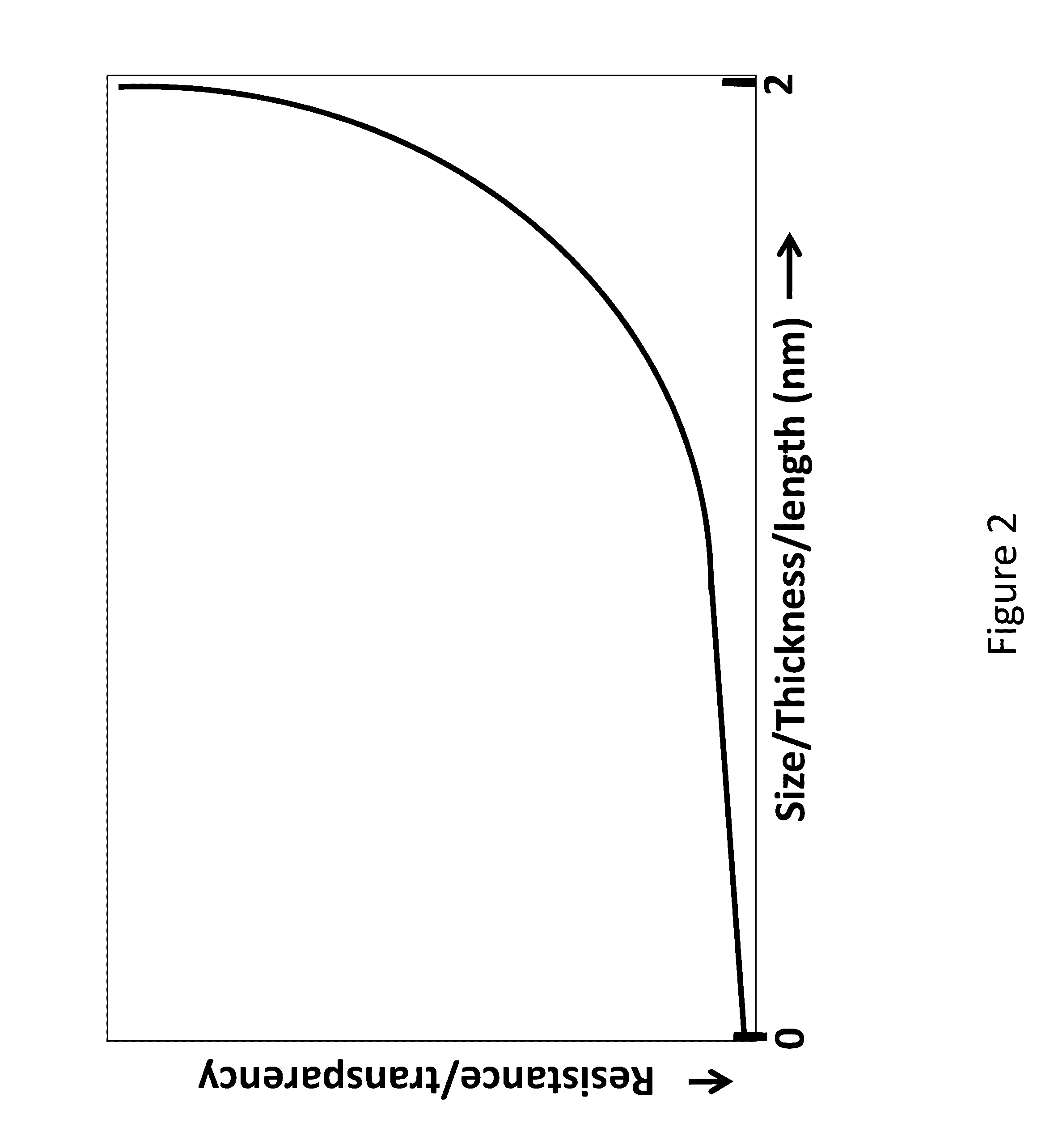

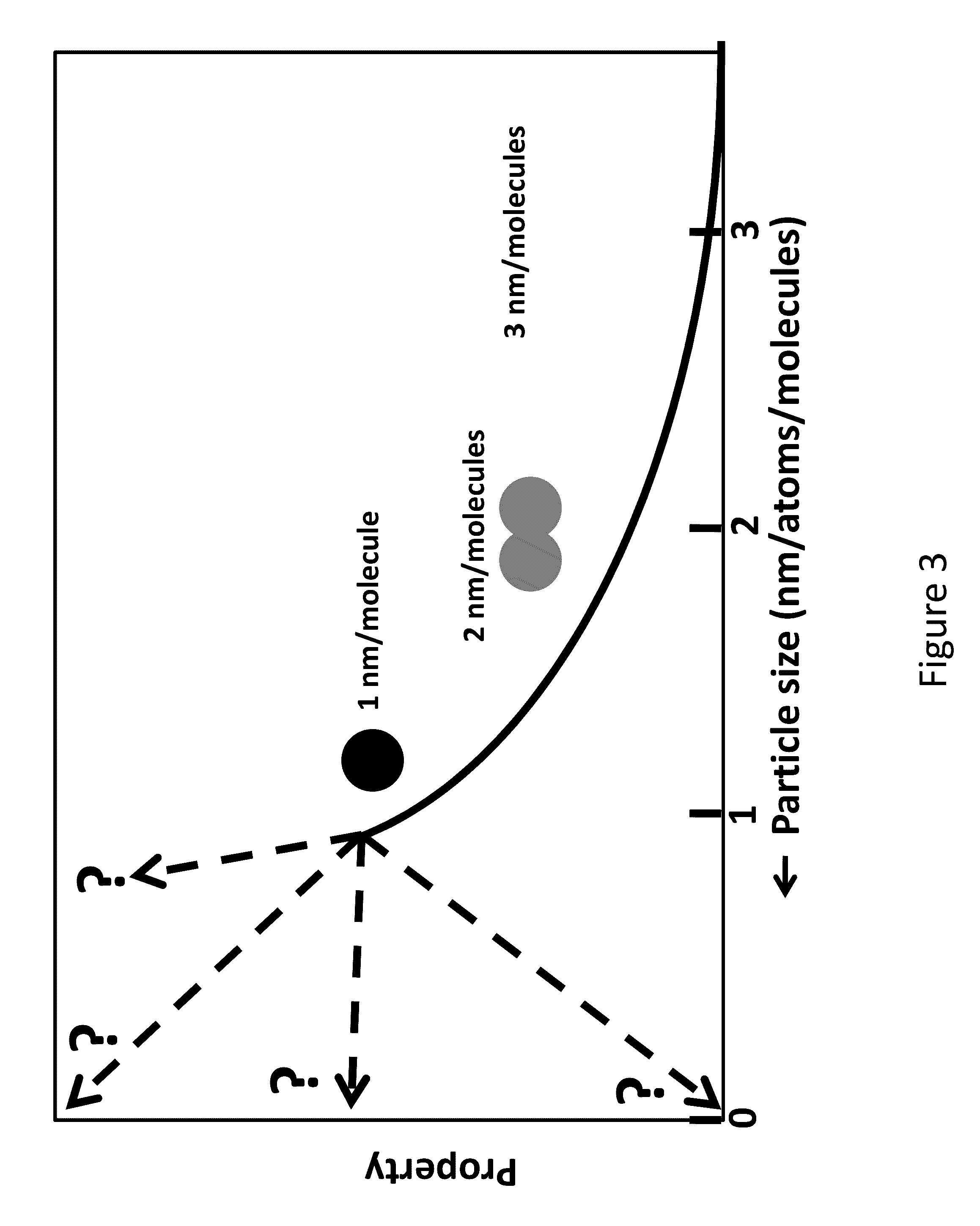

A large number of properties of nanostructures depend on their size, shape and many other parameters. As the size of a nanostructure decreases, there is a rapid change in many properties. When the nanostructure is completely destroyed, those properties essentially disappear. Systems based on changes in properties of nanostructures due to the destruction of nanostructures are proposed. The systems can be used for monitoring the total exposure to organic, inorganic, organometallic and biological compounds and agents using analytical methods.

Owner:PATEL GORDHANBHAI NATHALAL

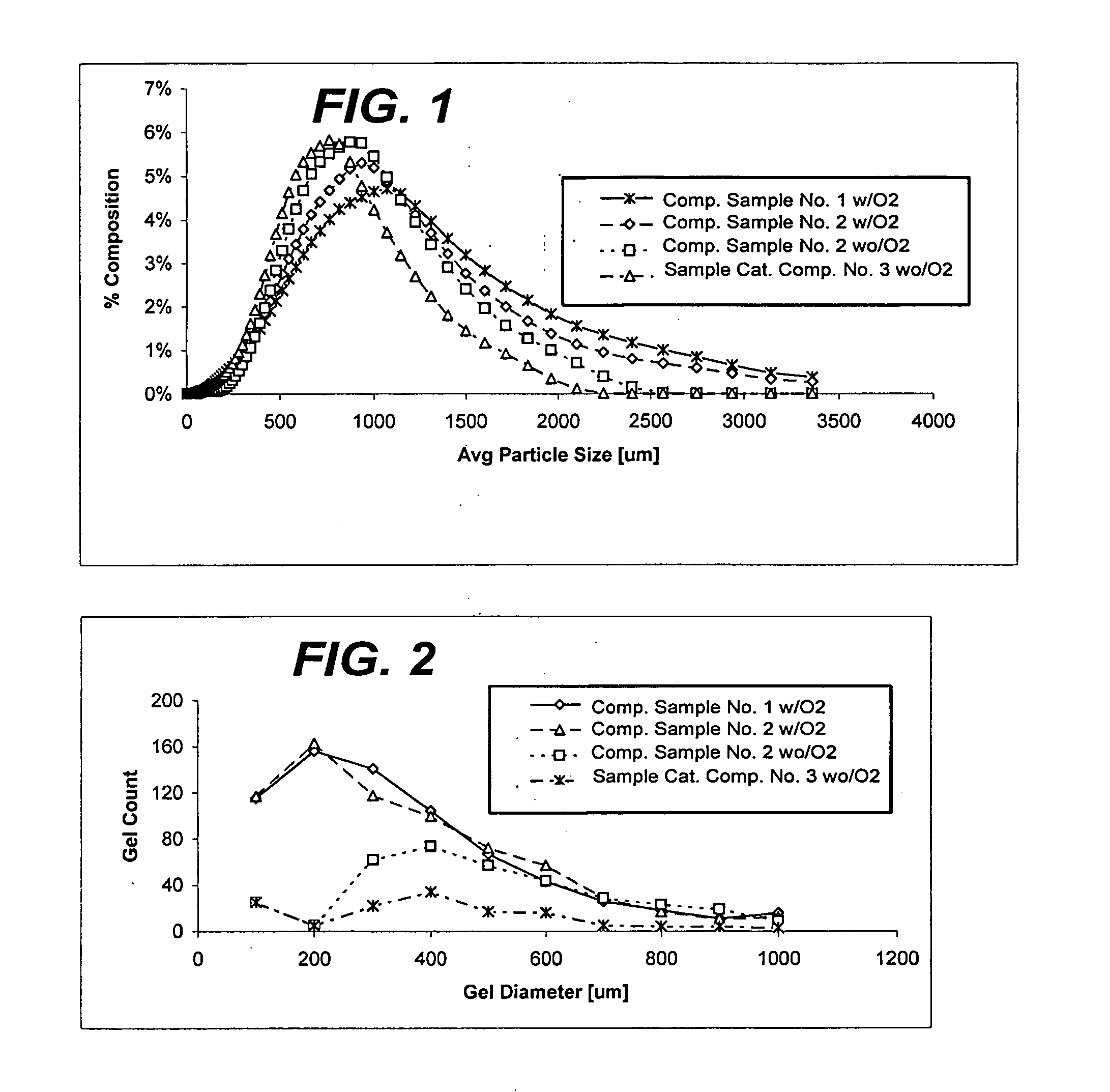

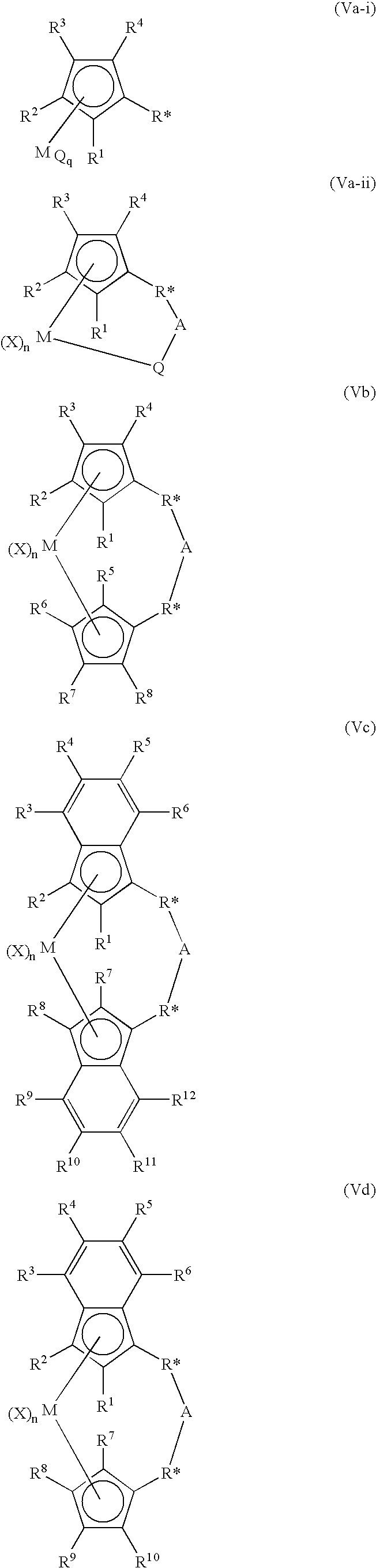

Catalyst compositions comprising support materials having an improved particle-size distribution

A catalyst composition that includes a support material having an improved particle-size distribution is provided. Processes for producing polyolefin composition also are provided. Polymers and films also are provided. An example of a catalyst composition is a supported multi-transition-metal catalyst composition that includes: (a) at least two catalyst components selected from the group consisting of: a nonmetallocene catalyst component and a metallocene catalyst component; (b) a support material that has a D50 of less than about 30 microns and a particle size distribution having a D90 / D10 ratio of less than about 6; and (c) an activator.

Owner:UNIVATION TECH LLC

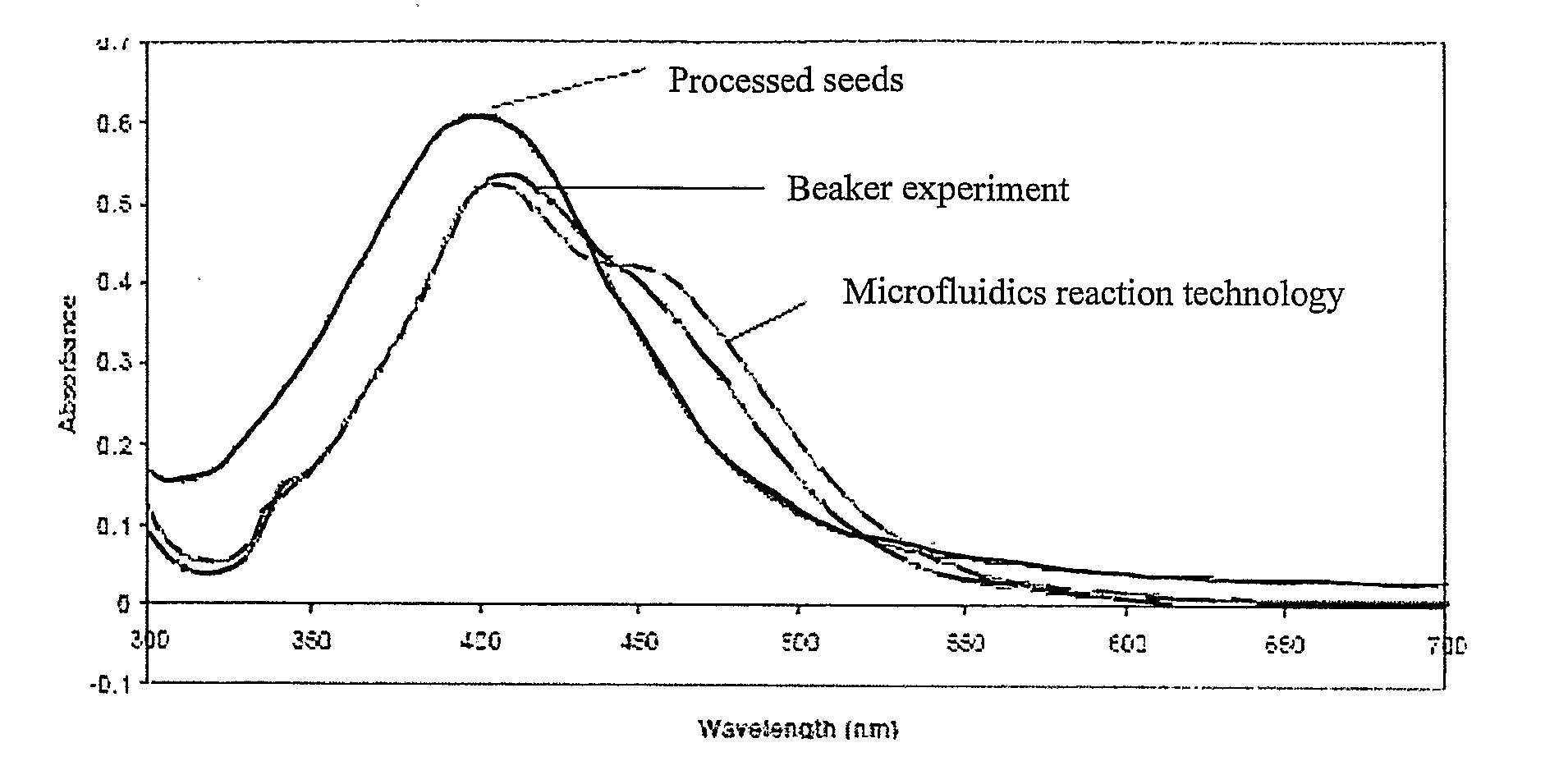

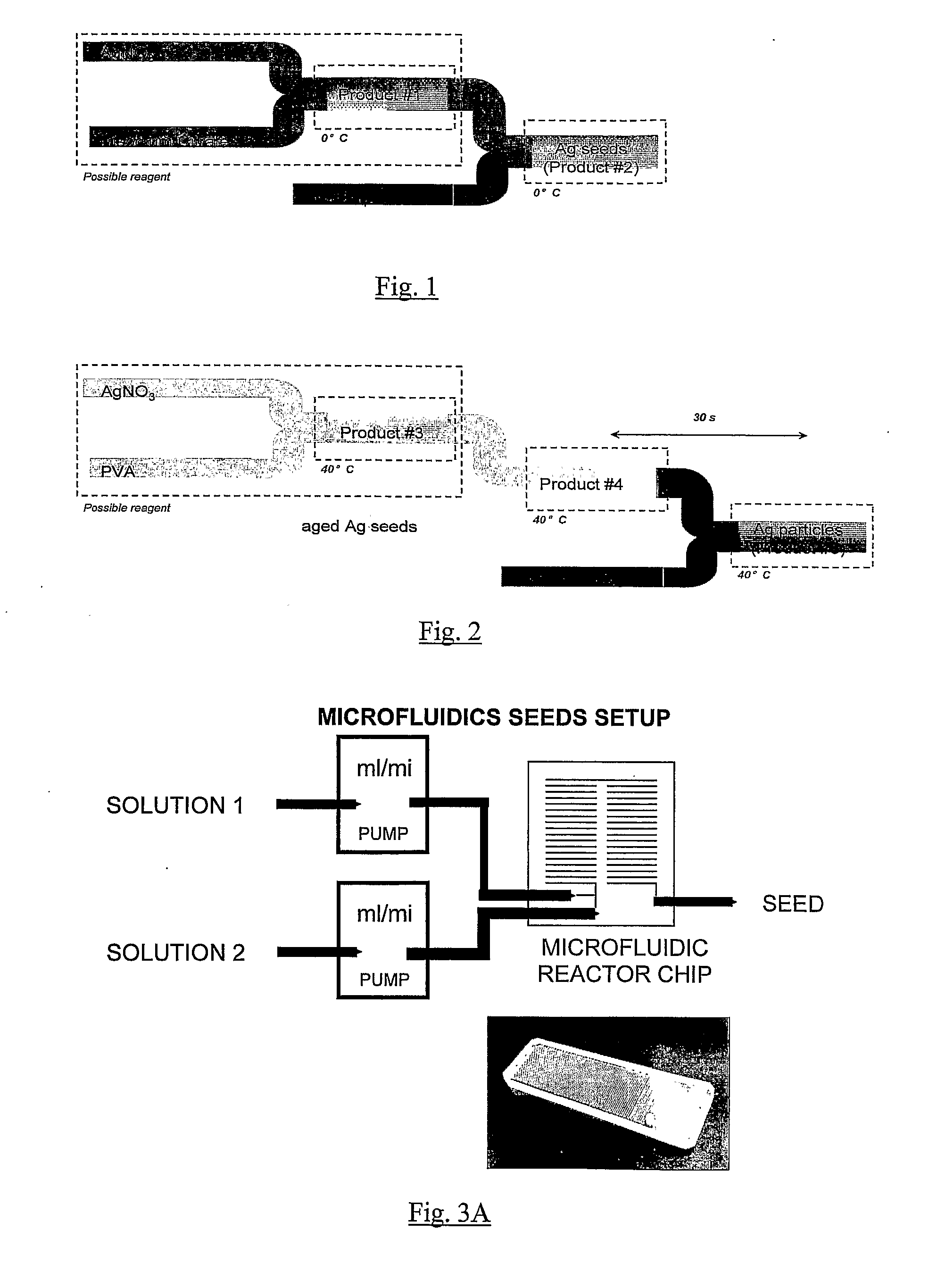

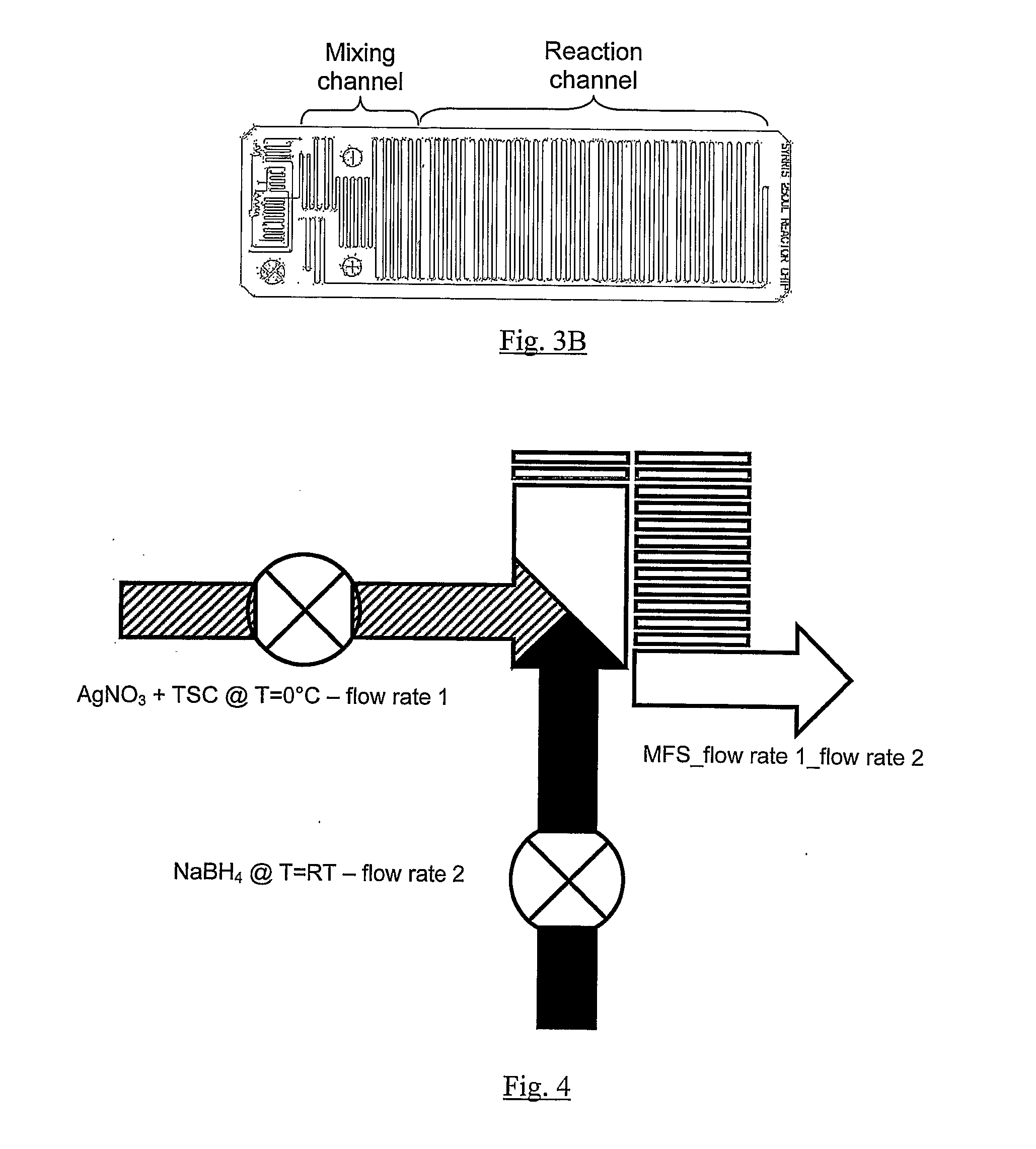

A process for synthesising silver nanoparticles

InactiveUS20100224026A1Improved physical propertyHigh uniformityTransportation and packagingMetal-working apparatusMicro fluidicNanometre

Owner:TRINITY COLLEGE DUBLIN +1

Polyimide foam plastic and preparation method thereof

ActiveCN103275319AImprove mechanical propertiesGood flexibilityAdhesivesPolymer scienceHeat resistance

The invention provides a preparation method of polyimide foam plastic. The method comprises the steps as follows: firstly, after dianhydride is mixed with low-level aliphatic alcohol, an esterification reaction is performed, and a diacid diester solution is obtained; then the obtained diacid diester solution is mixed with polymerized monomer amine and polyamic acid powder to obtain a mixed solution; and finally, the obtained mixed solution is sequentially subjected to foaming and thermal imidization after concentration to obtain the polyimide foam plastic. The invention further provides the polyimide foam plastic and the preparation method thereof, and the method comprises the step that polyamic acid powder is added when dianhydride and isocyanate are used for preparing the polyimide foam plastic. According to the invention, the polyamide acid powder serves as a nucleating agent, so that a cell of an objected formed by foaming of polyimide is fine and smooth, that is, the size distribution of the cell is improved, the cell uniformity is better, then the flexibility performance and the like of the polyimide foam plastic are improved; meanwhile, the heat resistance is not influenced; and besides, the preparation method of the polyimide foam plastic is concise in processing, and low in energy consumption and production cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

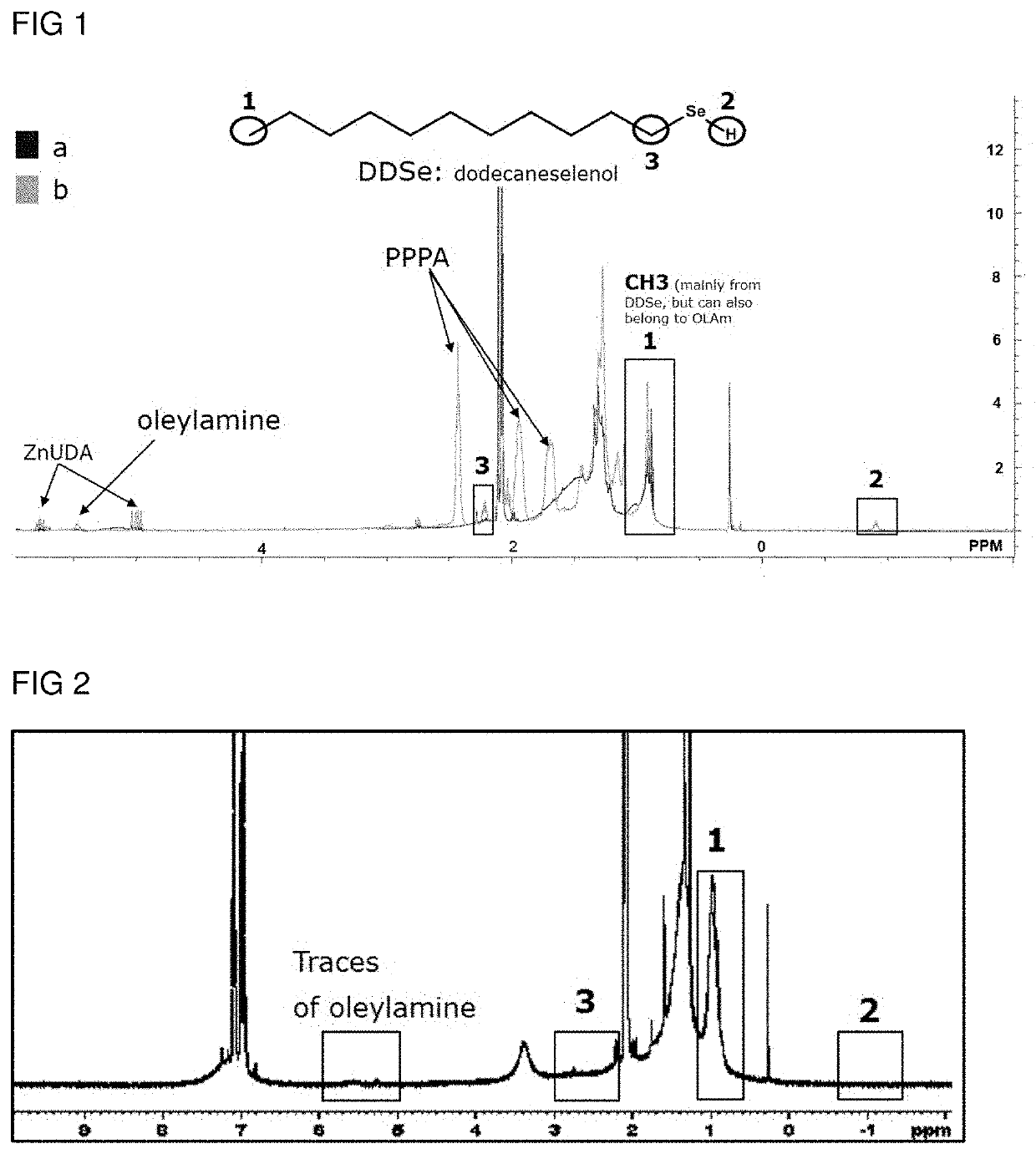

New method for preparing semiconductor nano-crystals containing tellurium, selenium or sulfur

InactiveCN102976289AQuality improvementOperational securityMaterial nanotechnologyBinary selenium/tellurium compoundsTrioctylphosphineTe element

The invention especially relates to a method for preparing nano-crystals containing tellurium, selenium or sulfur, wherein the method uses stable phosphine-containing organic compounds (such as dioctylphosphine oxide and the like) having similar structures as a novel solvent of tellurium powder, selenium powder or sulfur powder and uses a novel tellurium, selenium or sulfur solution as a precursor to prepare a plurality of nano-crystals containing tellurium, selenium or sulfur. The method avoids high cost and high risk caused by a case that tributylphosphine (TBP) or trioctylphosphine (TOP) is commonly and internationally used at present to dissolve tellurium, selenium or sulfur in order to generate the tellurium, selenium or sulfur precursor. The synthetic method has the advantages of safe operation, easy operation, and good repeatability, and medicines used in the method are routine and stable and have low toxicities. The nano-crystals containing tellurium, selenium or sulfur reaches even exceeds nano-crystals containing tellurium, selenium or sulfur synthesized through using flammable and explosive compounds comprising TOP / TBP and the like in quality. The method has very high application values in the laboratory field and the industrial production field.

Owner:HENAN UNIVERSITY

Monitoring devices and processes based on transformation, destruction and conversion of nanostructures

InactiveUS20160349088A1Small sizeImprove responseMaterial nanotechnologyMeasured value indication by color changeNanostructureMaterials science

A large number of properties of nanostructures depend on their size, shape and many other parameters. As the size of a nanostructure decreases, there is a rapid change in many properties. When the nanostructure is completely destroyed, those properties essentially disappear. Systems based on changes in properties of nanostructures due to the destruction of nanostructures are proposed. The systems can be used for monitoring the total exposure to organic, inorganic, organometallic and biological compounds and agents using analytical methods.

Owner:PATEL GORDHANBHAI

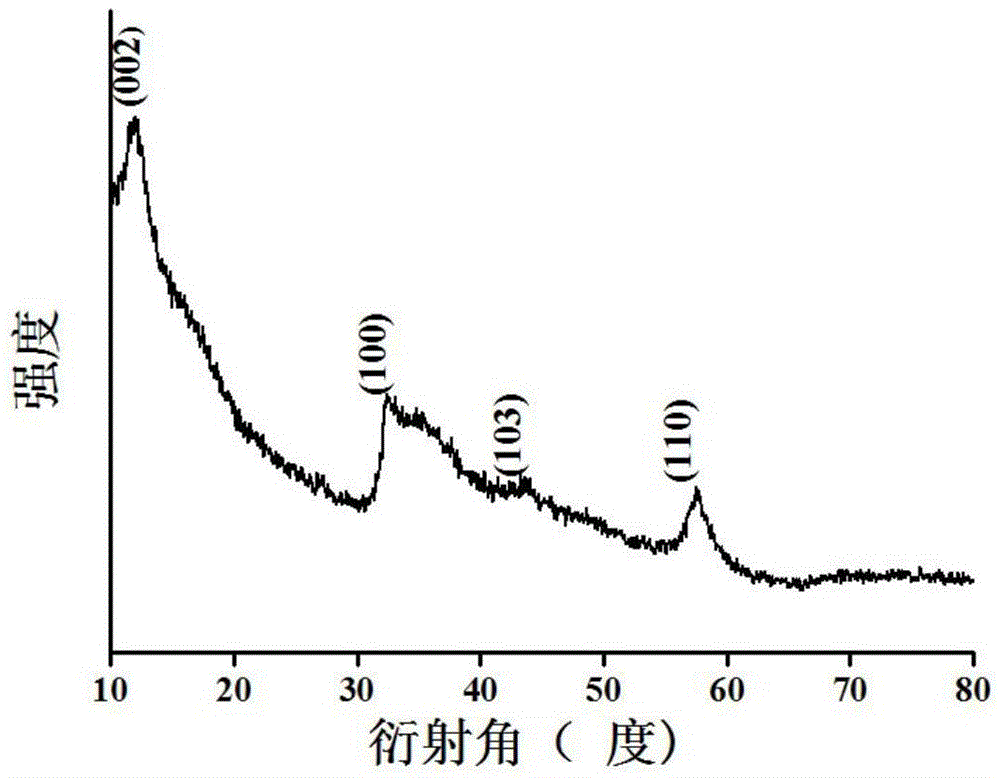

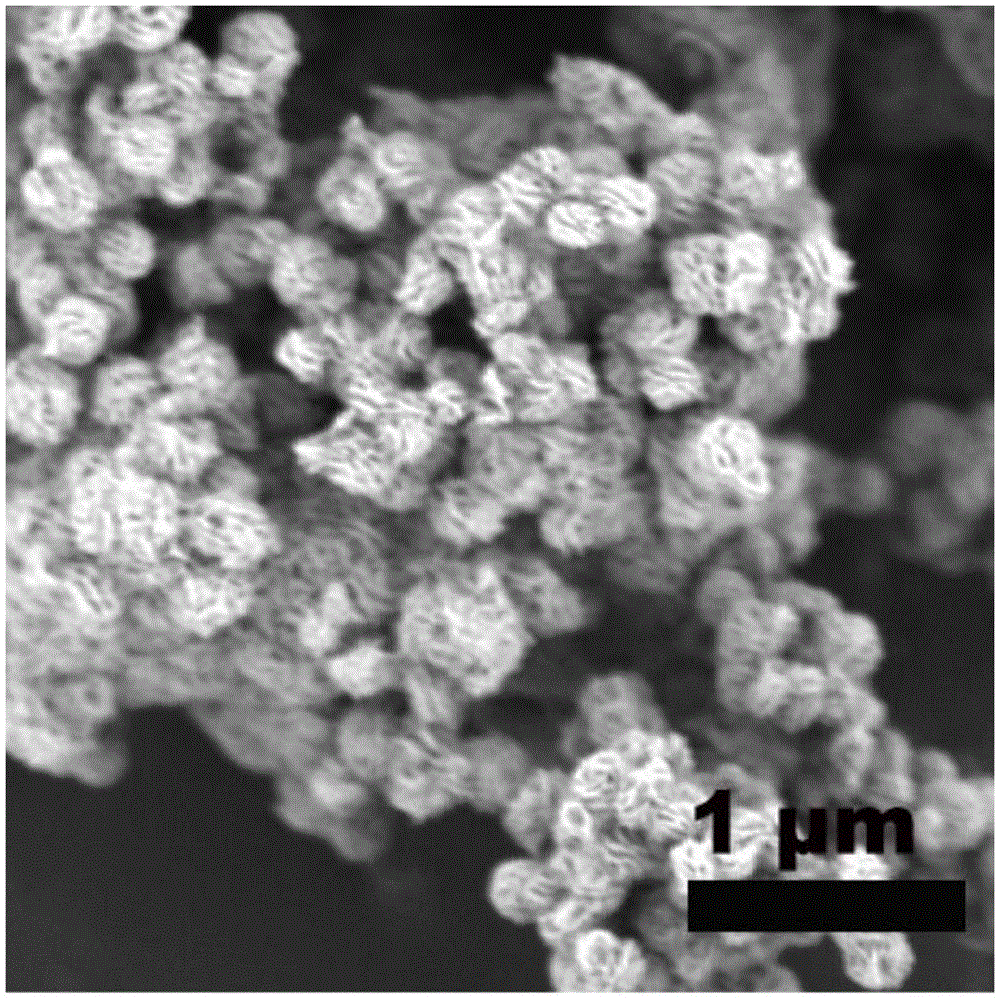

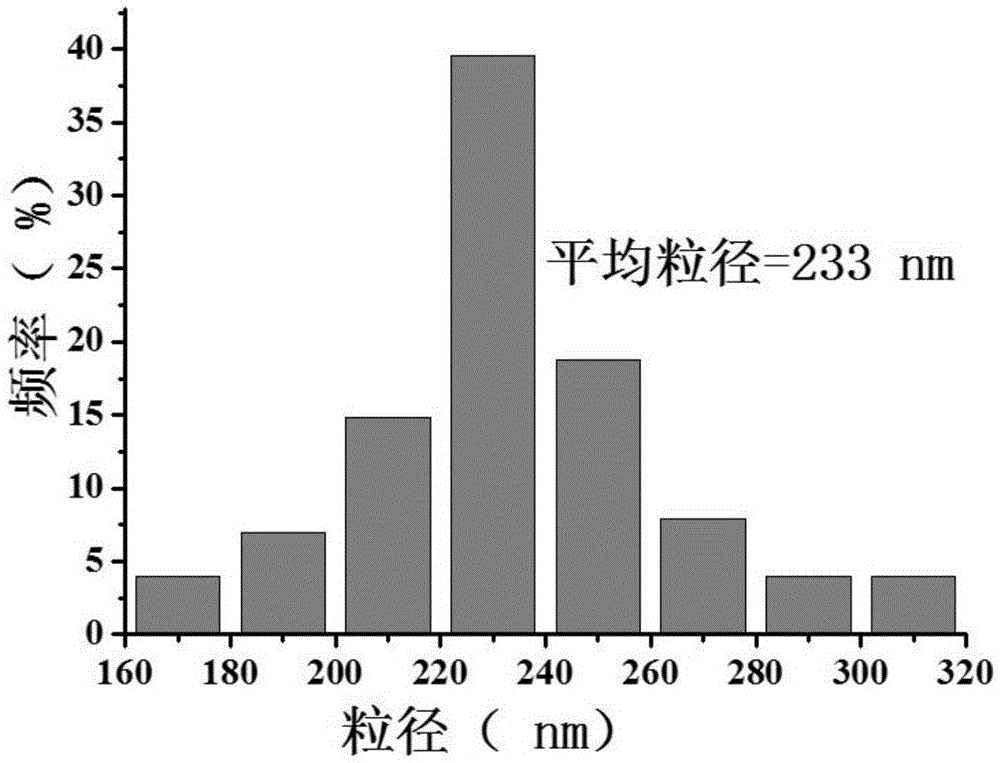

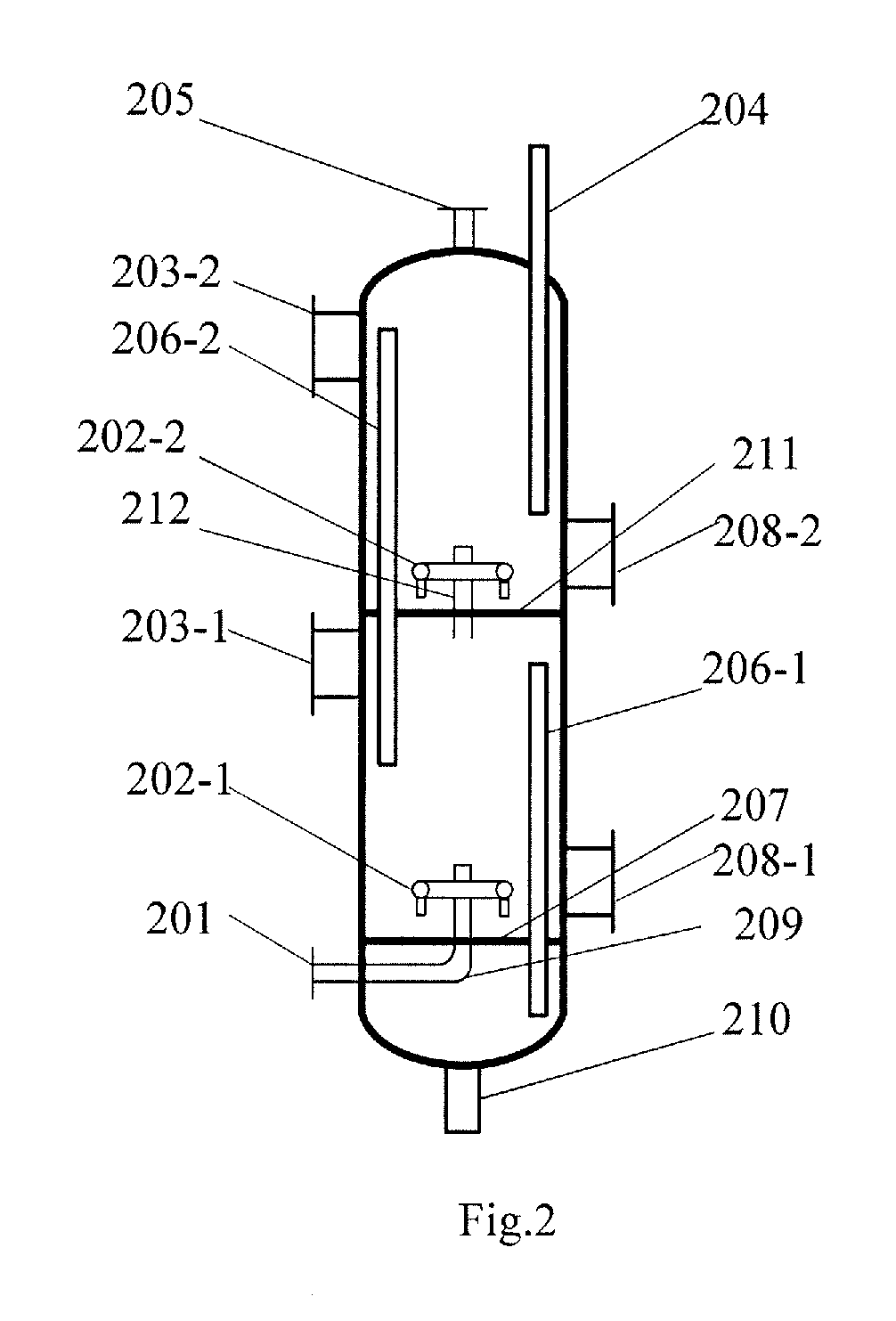

Preparation method for multi-level structured molybdenum disulfide microsphere negative electrode material of lithium battery

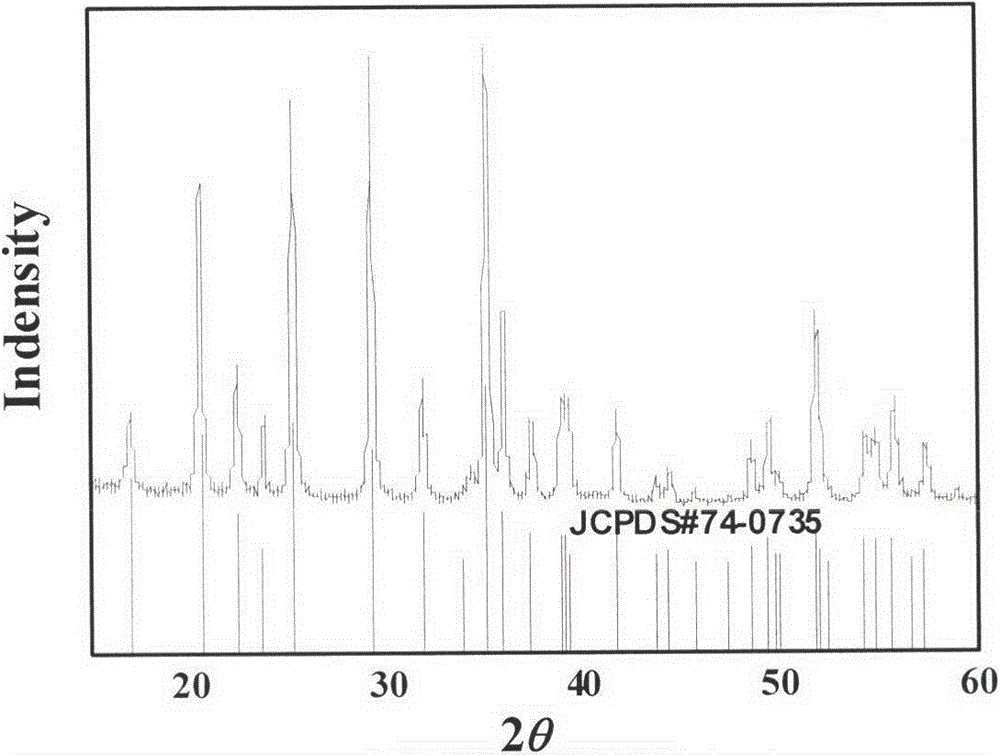

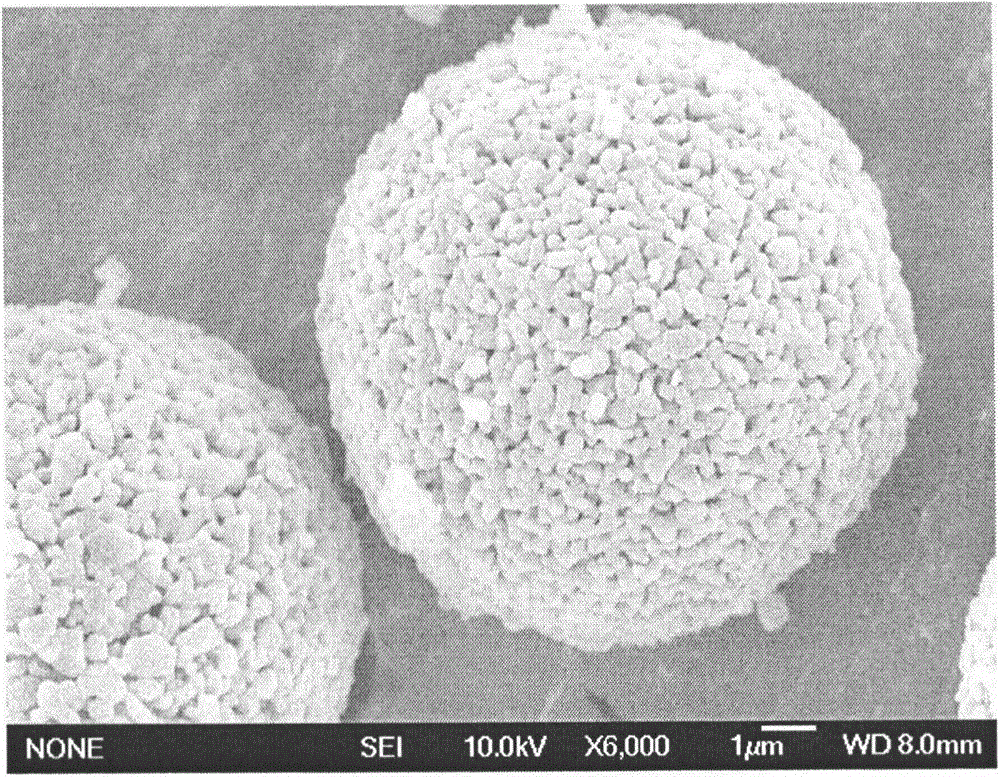

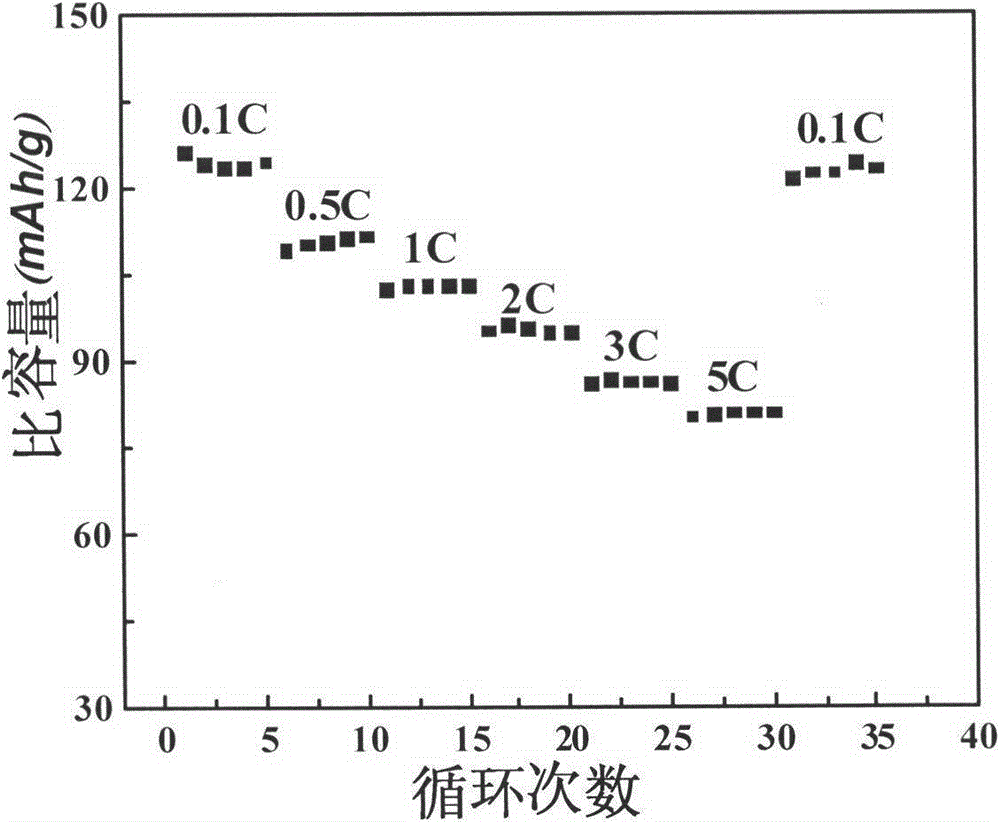

InactiveCN105609769AExcellent electrochemical performanceImproved size distributionCell electrodesSecondary cellsIonSodium Molybdate Dihydrate

The invention relates to a preparation method for a multi-level structured molybdenum disulfide microsphere negative electrode material of a lithium battery. The method comprises the following steps of firstly, dissolving sodium molybdate dehydrate and urea in deionized water, and stirring the mixed solution for 15-60 minutes; secondly, dropwise adding hydrochloric acid to adjust a pH value to be 0-1, transferring the mixed solution in a reaction kettle taking polytetrafluoroethene as a substrate, preserving the mixed solution at 150-250 DEG C for 1 to 40 hours, naturally cooling the mixed solution to a room temperature, taking out the mixed solution after reaction, washing sediments after centrifugal separation, placing the mixed solution in an electrothermal blowing dry box for drying, taking out the mixed solution and placing the mixed solution in a mortar to grind into fine powder; and finally preparing the multi-level structured molybdenum disulfide microsphere negative electrode material of the lithium battery. With the adoption of a simple test method and process steps, the multi-level structured molybdenum disulfide microspheres with relatively small grain sizes (200-250 nanometers) and which are uniformly distributed are prepared, and the negative electrode material has excellent electrochemical performance.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

High-performance methanol synthesis catalyst and preparation method thereof

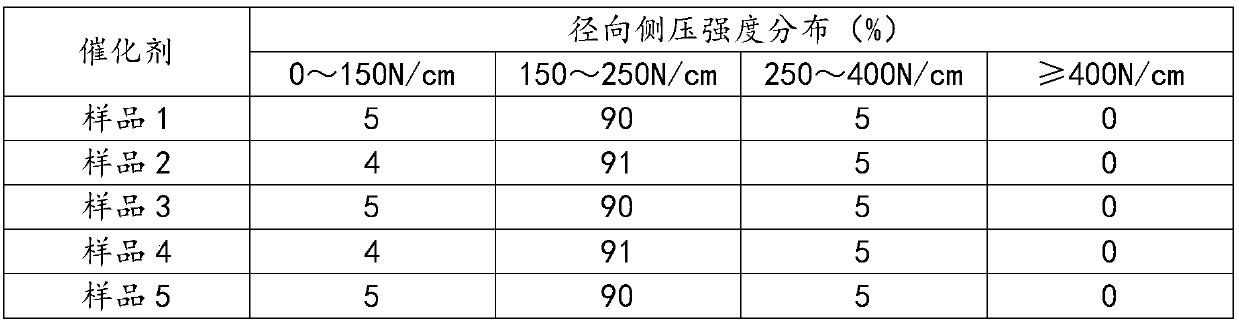

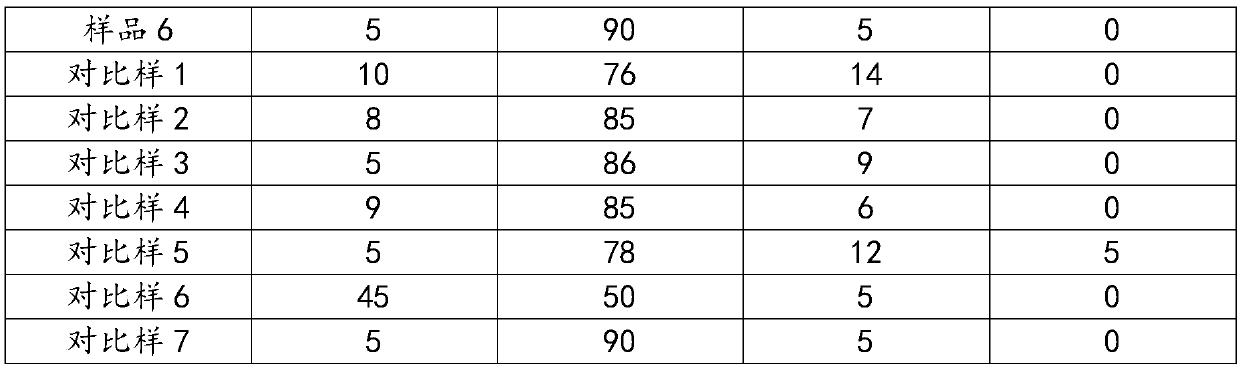

InactiveCN107930644APerformanceEvenly dispersedOrganic compound preparationHeterogenous catalyst chemical elementsManganeseCopper oxide

The invention provides a high-performance methanol synthesis catalyst and a preparation method thereof and belongs to the technical field of methanol catalysts. The catalyst comprises 50-80 parts by mass of copper-zinc-aluminum active component oxide and 25-40 parts by mass of a carrier compound, wherein the copper-zinc-aluminum active component oxide comprises 40-70 parts by mass of copper oxide,10-40 parts by mass of zinc oxide and 0-20 parts by mass of aluminum oxide; and the carrier compound comprises 80-100 parts by mass of zinc metaaluminate, 0-20 parts by mass of magnesium metaaluminate, 0-8 parts by mass of manganese metaaluminate, 0-7 parts by mass of calcium metaaluminate, 0-5 parts by mass of strontium metaaluminate and 0-5 parts by mass of barium metaaluminate. The invention further provides the preparation method of the methanol catalyst. The high-performance methanol synthesis catalyst and the preparation method thereof, provided by the invention, have the beneficial effects that as the catalyst preparation process and a carrier compound adding mode are optimized, the high-performance methanol synthesis catalyst is a high-performance catalyst suitable for industriallarge-scale methanol synthesis; the prepared catalyst by the preparation method provided by the invention has better high and low temperature activity, heat resistance and aging resistance and has higher physical strength distribution, methanol space-time yield, methanol selectivity and stability.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

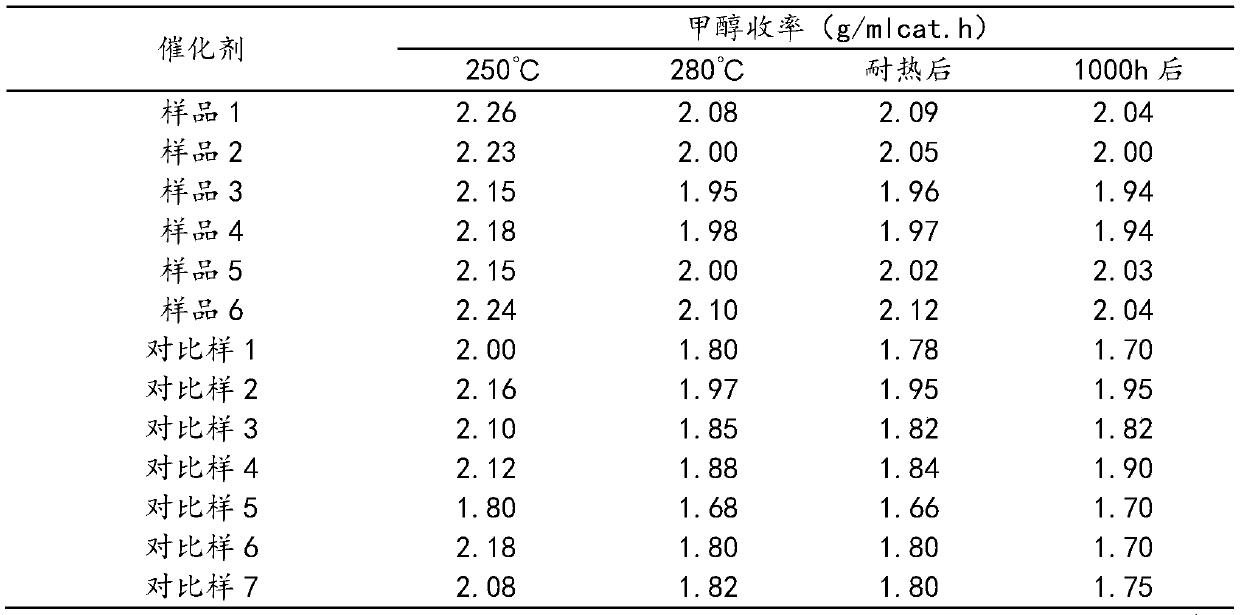

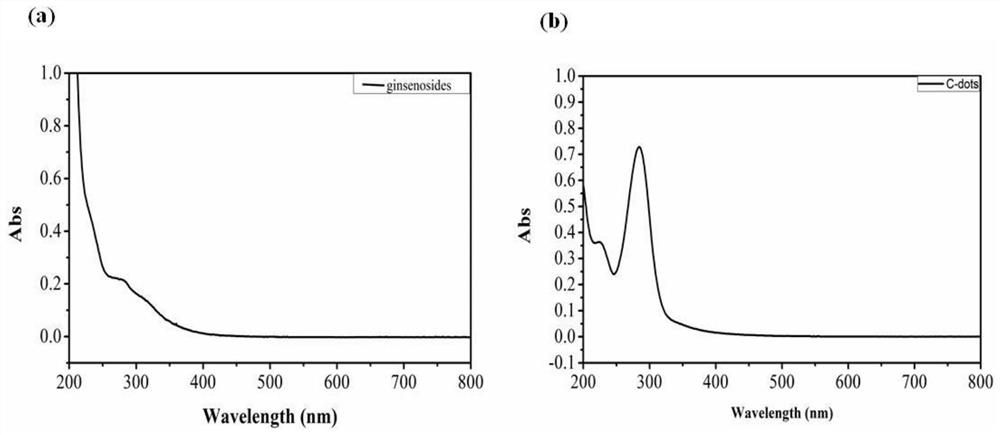

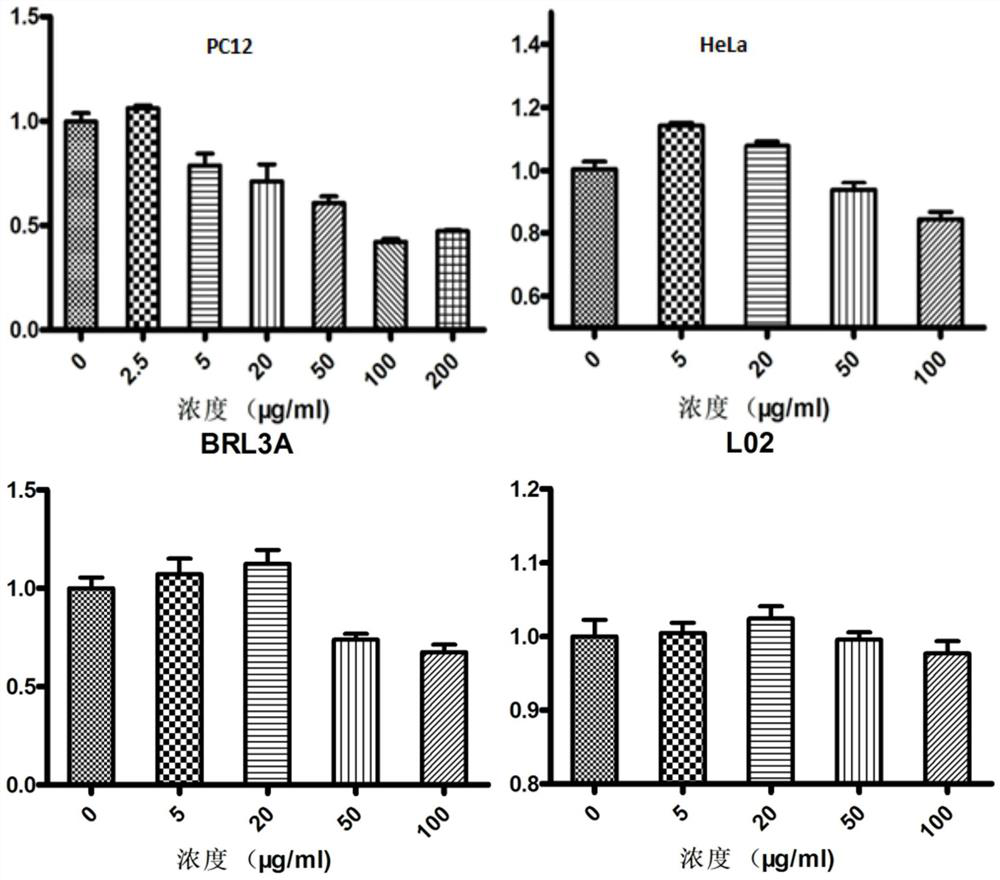

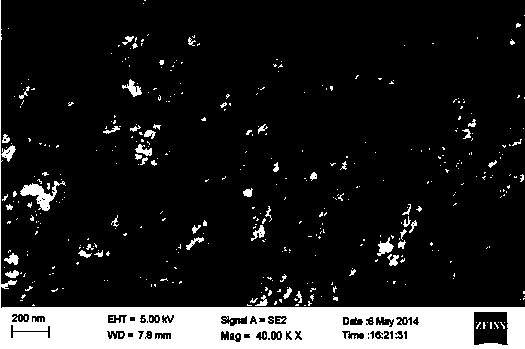

Traditional Chinese medicinal material bio-based carbon nanodot, preparation method thereof, fluorescent probe, traditional Chinese medicinal material medicinal preparation and application

ActiveCN111778018AGood biocompatibilityGood fluorescence stabilityNanoopticsFluorescence/phosphorescenceFluoProbesRat Adrenals

The invention provides a traditional Chinese medicinal material bio-based carbon nanodot. The bio-based carbon nanodot is a ginseng total saponin carbon nanodot. The carbon dot surface of the total ginsenoside is rich in alcohol / phenolic hydroxyl, amino, carboxyl and other structures, the surface groups are rich, subsequent modification and compounding are facilitated, and the total ginsenoside has good time, pH value and salt stability; various cell fluorescence imaging experiments prove that the total ginsenoside carbon dots can be used as a biological fluorescence probe; meanwhile, the obtained total ginsenoside carbon dots have a specific inhibition effect on rat adrenal pheochromocytoma cells (PC12 cells), and have no obvious proliferation or inhibition effect on other cells (HeLa cells, BRL3A cells and LO2 cells); meanwhile, the total ginsenoside carbon dots can be used as fluorescent probes and can be taken by various cells (BRL3A cells, LO2 cells and QGY7703 cells).

Owner:CHANGCHUN UNIV OF CHINESE MEDICINE

Preparation method of self-lubrication material nanometer calcium fluoride for ceramic cutting tool

InactiveCN104229853AHigh purityComplete crystal formMaterial nanotechnologyCalcium/strontium/barium fluoridesPolyethylene glycolCeramic knife

The invention relates to a preparation method of a self-lubrication material nanometer calcium fluoride for a ceramic cutting tool. The preparation method comprises the following steps: (1) weighing calcium nitrate and ammonium fluoride, respectively placing in a beaker, adding distilled water and anhydrous ethanol, to obtain a calcium nitrate liquid with content of calcium nitrate being 1mol / l, and an ammonium fluoride liquid with content of ammonium fluoride being 2.2-3.2mol / l; (2) weighing a certain amount of polyethylene glycol (PEG6000) dispersing agent with molecular weight of 6000, adding the ammonium fluoride liquid so that the mass fraction of the polyethylene glycol in the liquid is 1-2%; performing ultrasonic dispersion for 10-15min, thoroughly dissolving, to obtain a polyethylene glycol-ammonium fluoride complex liquid; and (3) placing the polyethylene glycol-ammonium fluoride complex liquid into a magnetic stirrer, setting the reaction temperature of 15-50DEG C, dropping the calcium nitrate liquid in the polyethylene glycol-ammonium fluoride complex liquid through a separating funnel, appropriately adjusting the speed to be close to flow-in speed (drop-in speed is 1-30ml / min), wherein the stirring frequency under which no liquid is splashed is the best. The prepared nanometer calcium fluoride powder is high in purity, complete in crystal form, high in crystal degree, uniform in size distribution, and good in dispersity.

Owner:QILU UNIV OF TECH

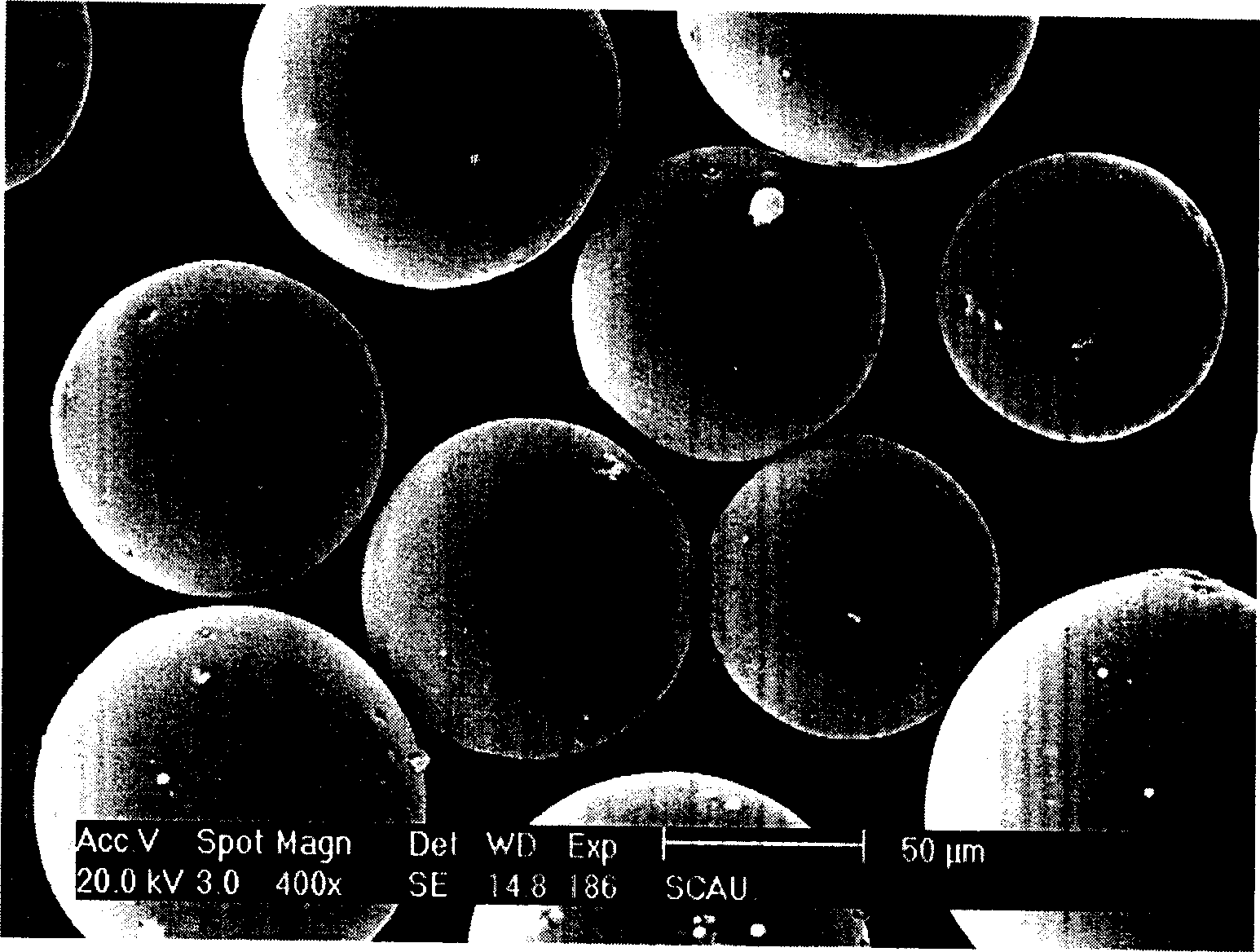

Process for preparing magnetic polymethyl methacrylate microsphere by two-step method

The invention relates to a method for manufacturing magnetic polymethyl methacryate microsphere, which comprises two steps: first, preparing polymethyl methacryate microsphere; second, preparing magnetic polymethyl methacryate microsphere. Compared with existing technology of one step, the invention divides process into two steps. The first step controls particle size and purity of microsphere, while the second step embeds ferrous powder into polymethyl methacryate microsphere. The invention can get magnetic polymethyl methacryate microsphere with adaptive particle size, good monodisperse, mechanic stability and so on.

Owner:SOUTH CHINA UNIV OF TECH

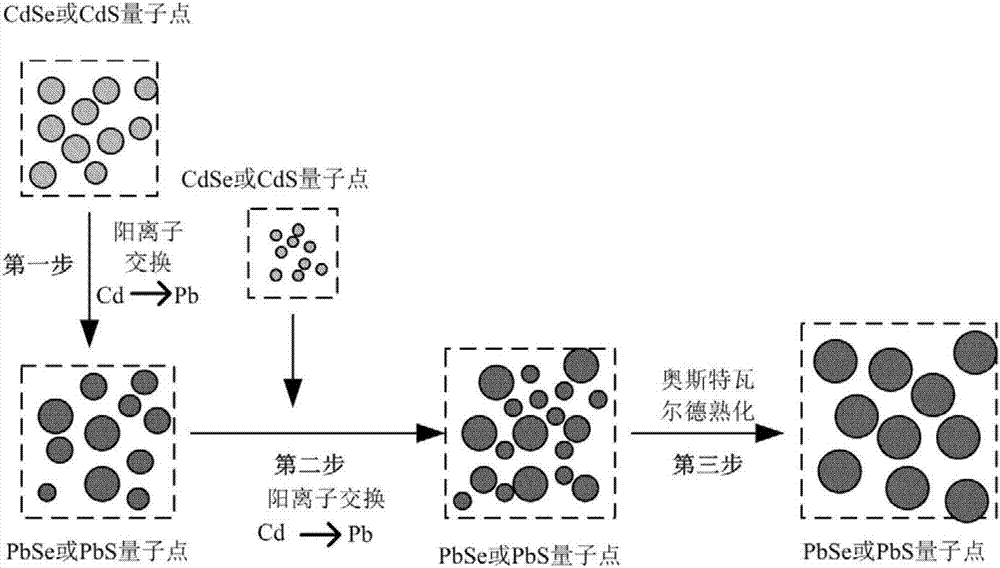

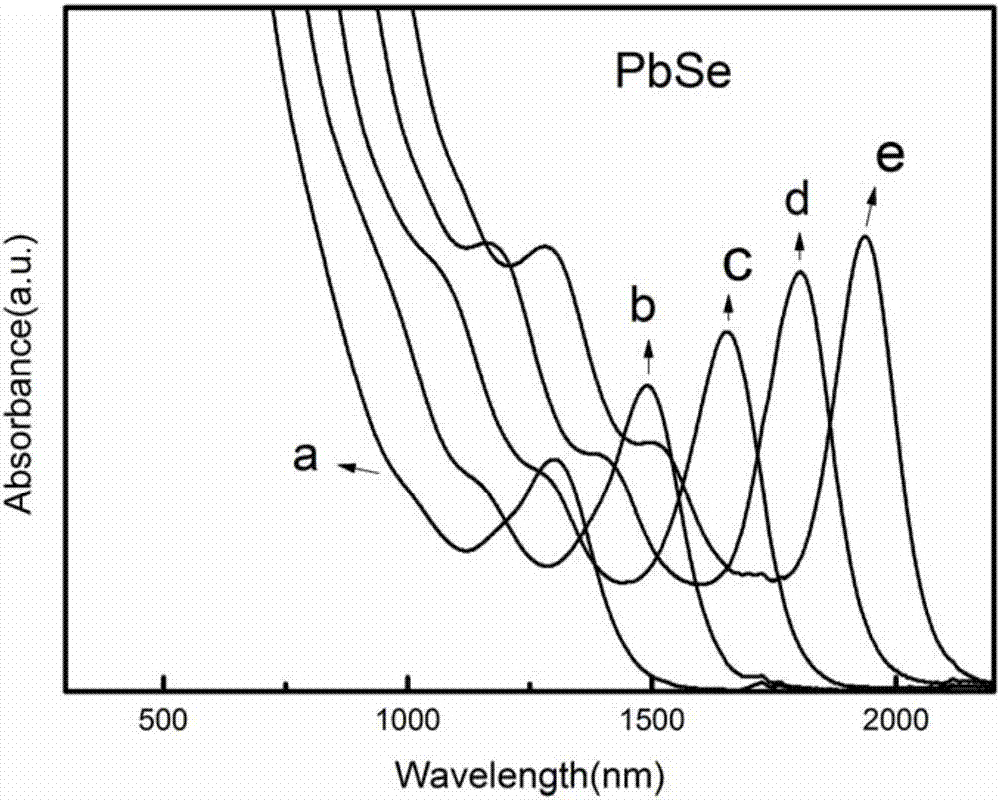

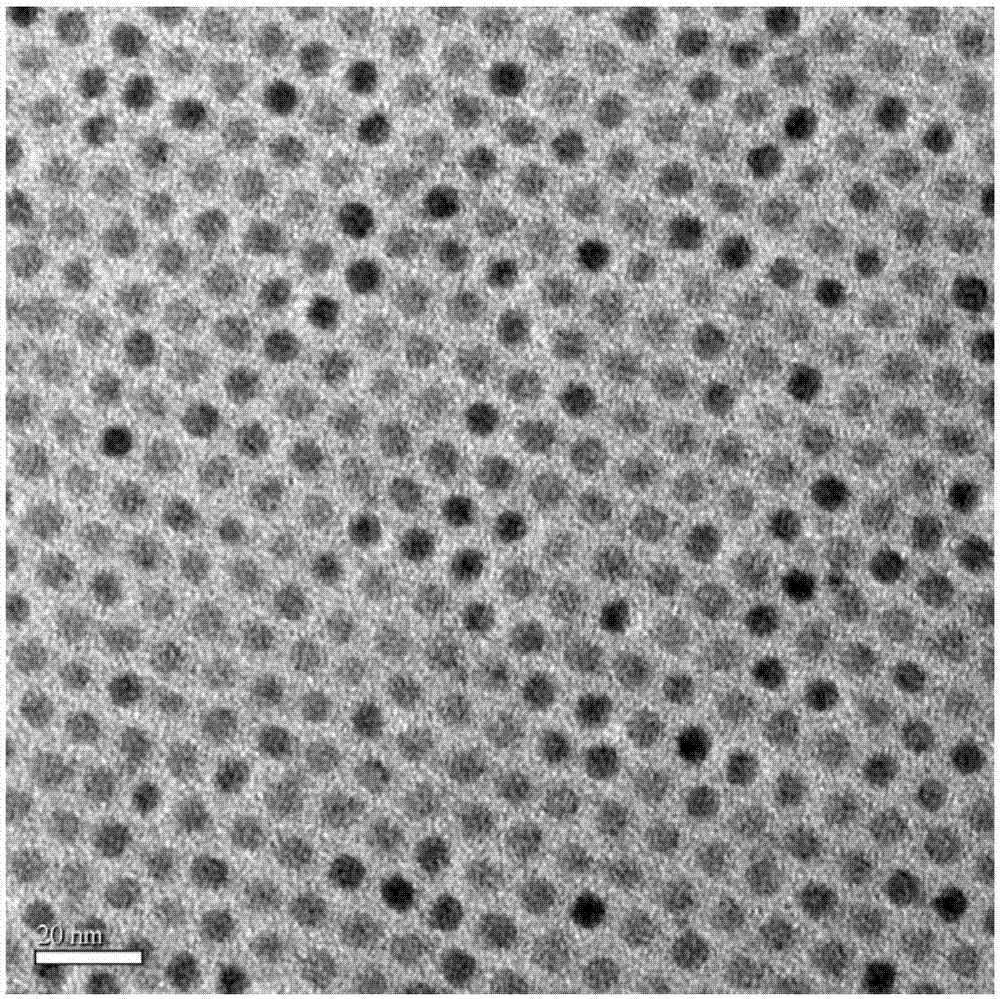

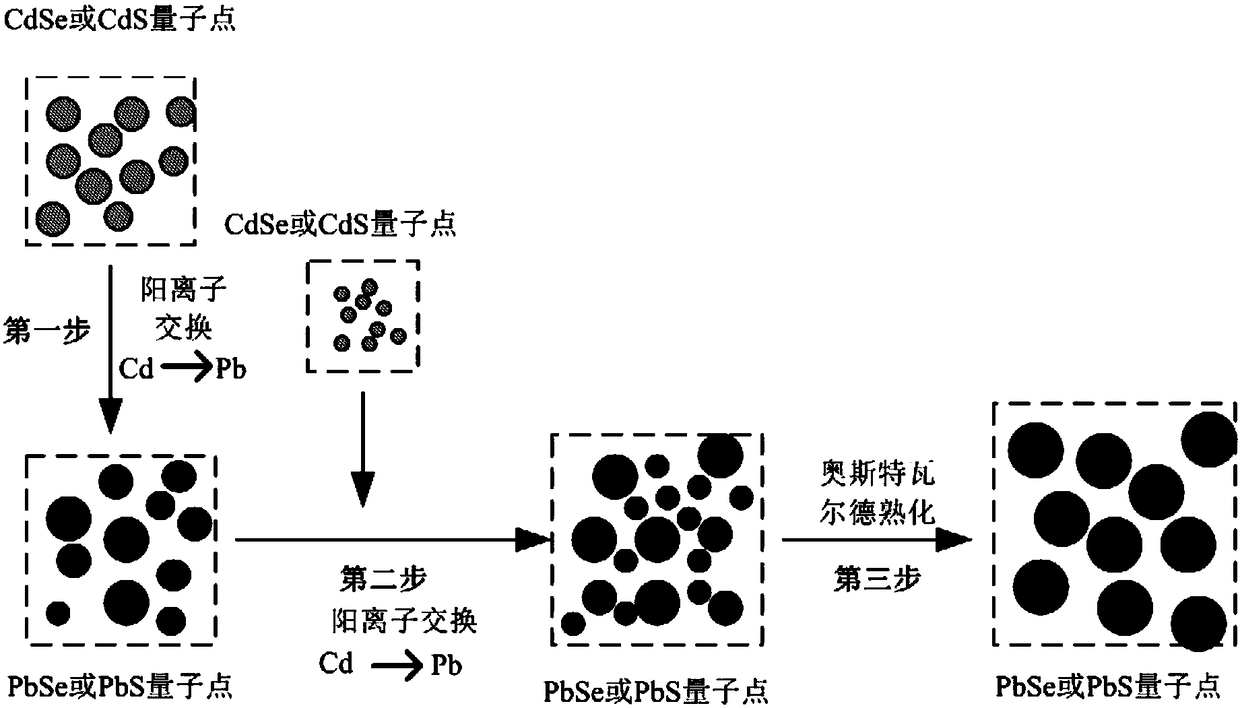

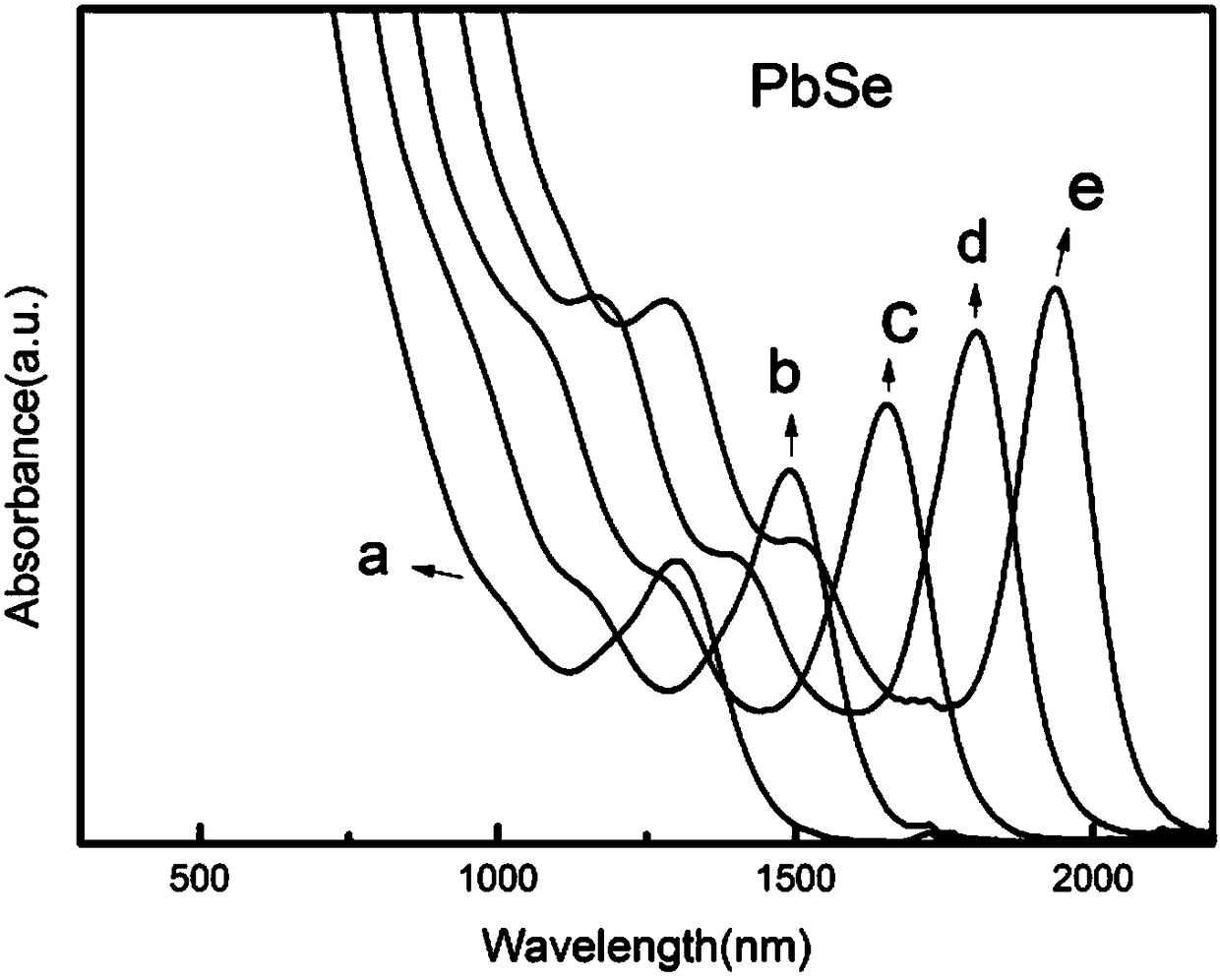

Method for controlling PbS or PbSe quantum dot size distribution

InactiveCN106882837ALow costThe preparation process is matureMaterial nanotechnologyLead sulfidesCation exchange reactionQuantum dot

The invention discloses a method for controlling PbS or PbSe quantum dot size distribution. The method comprises the following steps that: (1) first, CdSe (or CdS) quantum dots with larger sizes are injected into a precursor of lead, and PbSe (or PbS) quantum dots with larger sizes are obtained through a cation exchange reaction at the moment; (2) then, CdSe (or CdS) quantum dots with smaller sizes are continuously injected, and the PbSe (or PbS) quantum dots with smaller sizes are obtained through the cation exchange reaction at the moment; (3) finally, the size distribution of the PbSe (or PbS) quantum dots becomes narrower and narrower under the action of Ostwald ripening effect, so that the size distribution of the PbSe (or PbS) quantum dots is controlled. Through the method, various sizes of the PbSe (or PbS) quantum dots with extremely good size distribution can be obtained; moreover, the PbSe (or PbS) quantum dots are specifically stable in air; the method is low in cost, easy to operate, and not strict in environment requirement.

Owner:HUAZHONG UNIV OF SCI & TECH +1

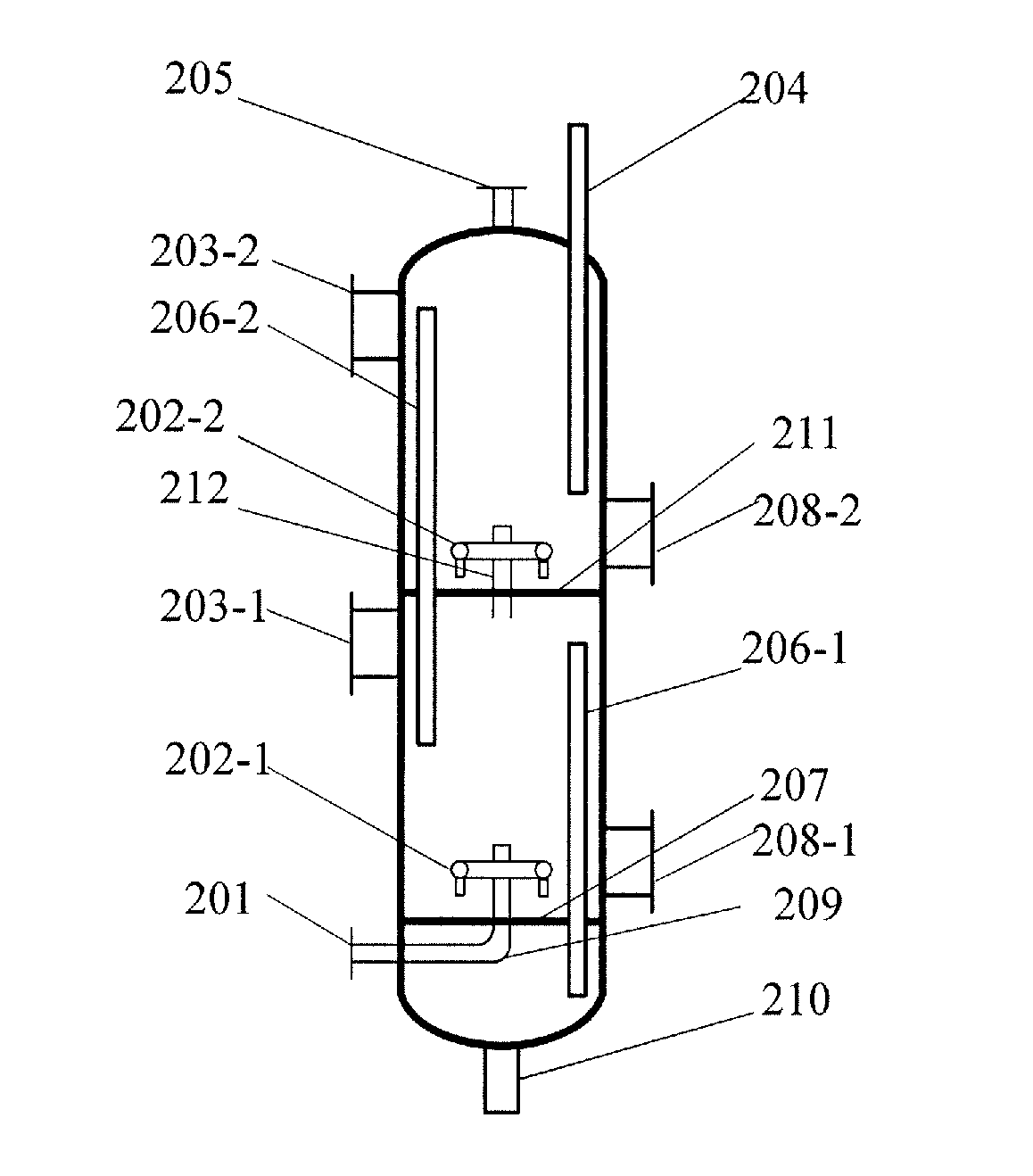

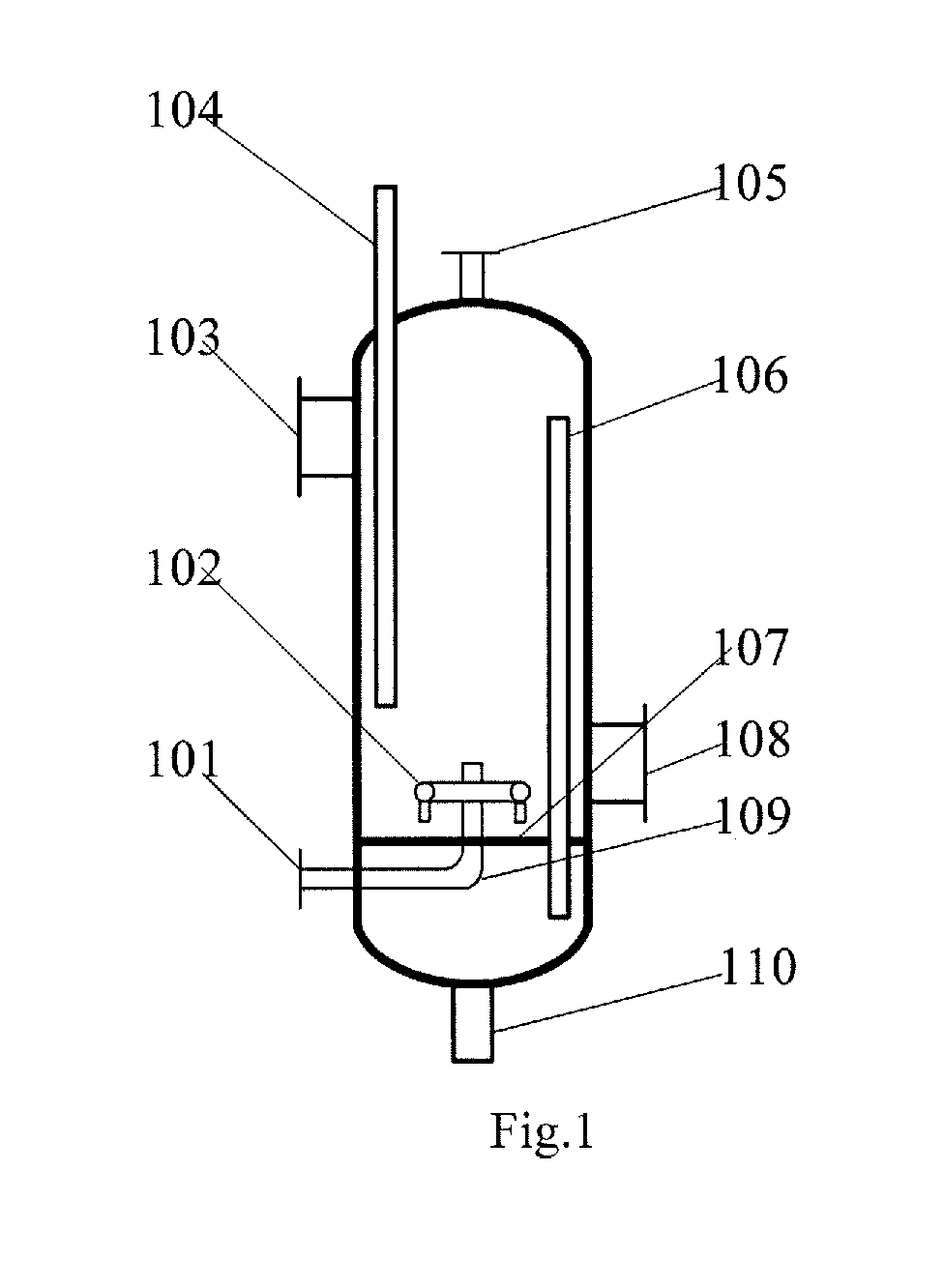

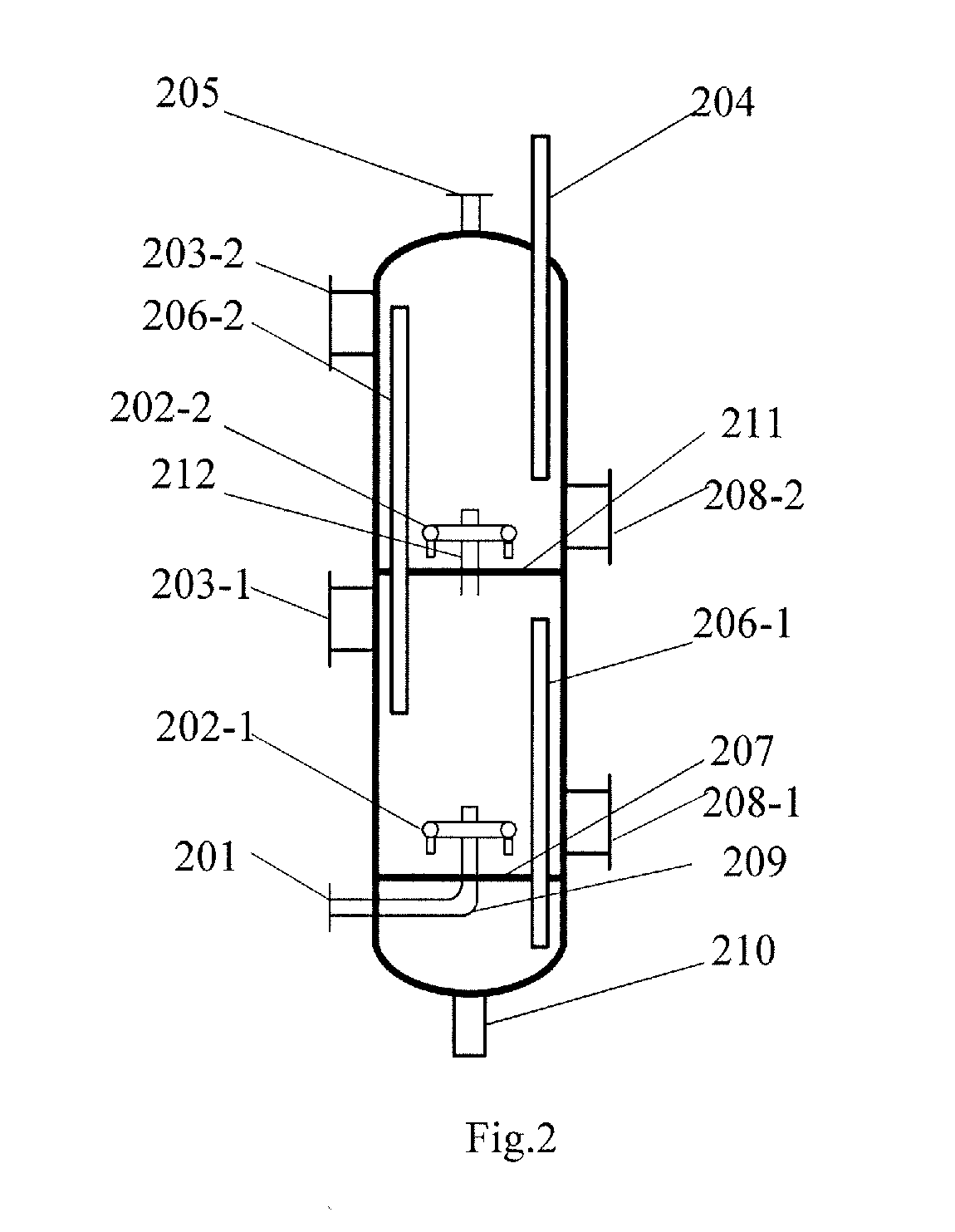

Fluidized Bed Reactor and Method for Preparing Polyoxymethylene Dimethyl Ethers from Dimethoxymethane and Paraformaldehyde

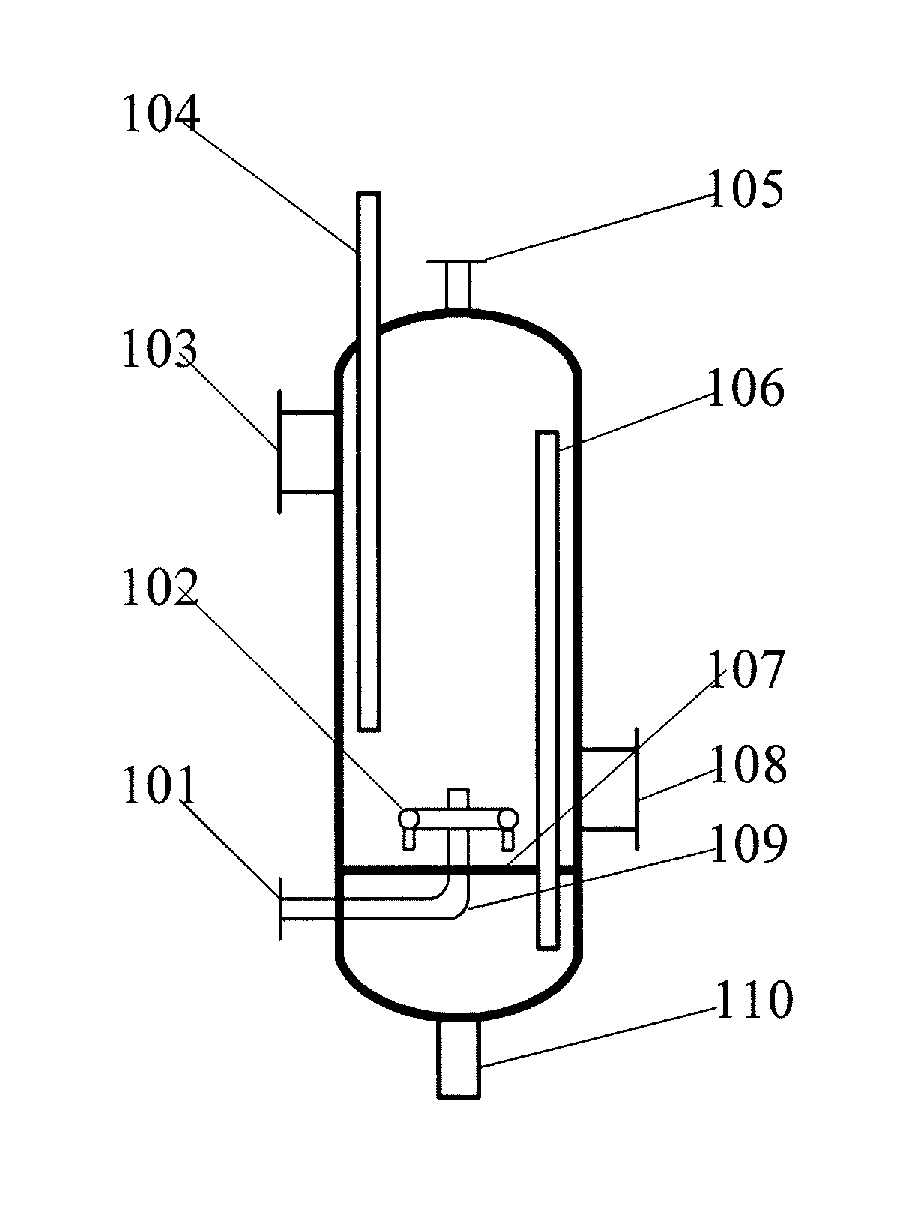

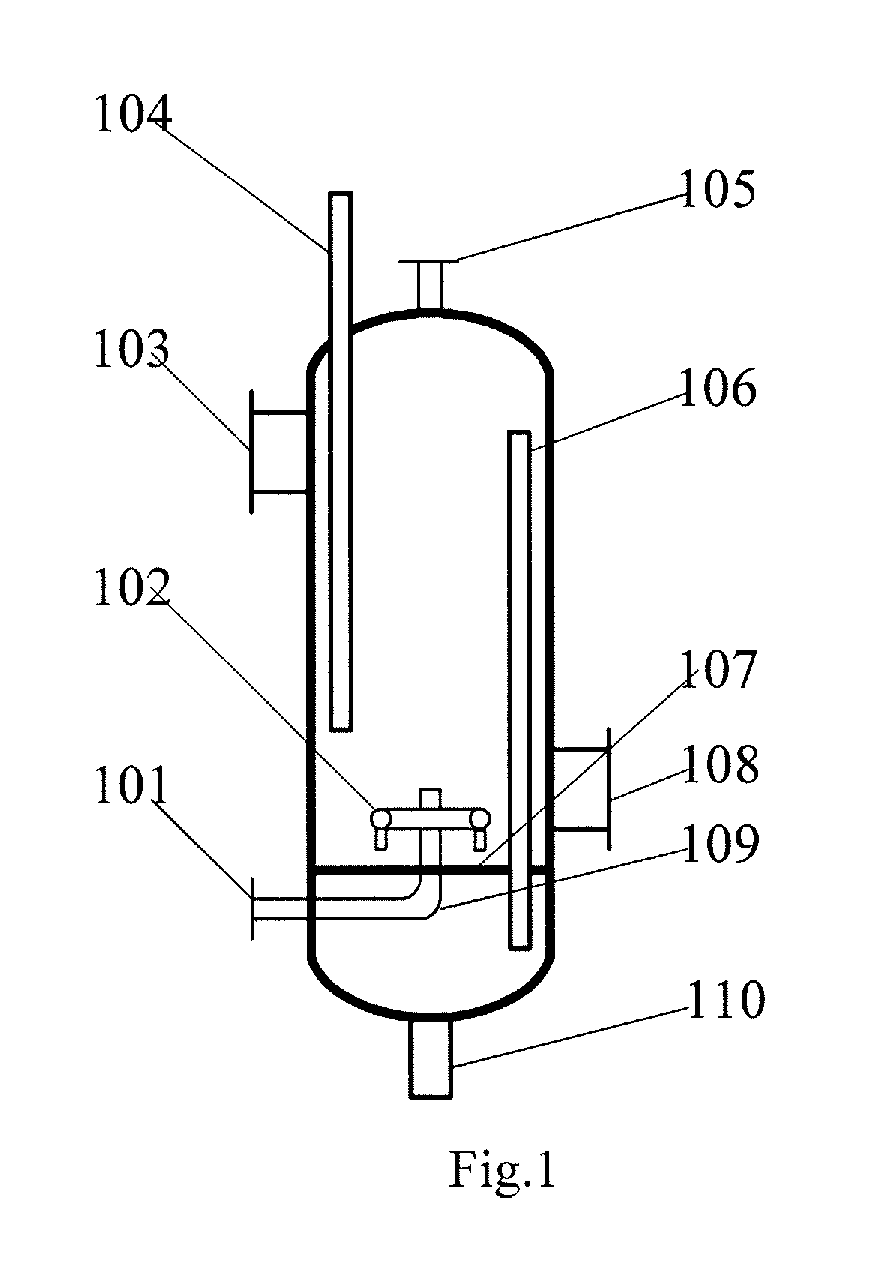

InactiveUS20150273426A1Enhance reaction driving forceImprove product size distributionOrganic chemistryOrganic compound preparationFluidized bedDimethoxymethane

The invention belongs to energy chemical technical field, especially relates to a fluidized bed reactor and a method for preparation of polyoxymethylene dimethyl ethers from dimethoxymethane and paraformaldehyde. The fluidized bed reactor comprises a gas inlet, a gas distributor, a catalyst inlet, a gas outlet, a fluid inlet, a catalyst outlet, a bottom component and an interstage component, a bottom component related gas upward channel, an interstage component related gas upward channel, a fluid outlet, a bottom downcorner and an interstage downcorner. A process for preparation of polyoxymethylene dimethyl ethers comprises the steps of: fluidizing gas is introduced into a bottom bed from the gas inlet via the bottom component related gas upward channel through the gas distributor; the fluidizing gas goes upwards and flows out of the reactor via the gas outlet; paraformaldehyde and dimethoxymethane are introduced into a bed through the fluid inlet; the fluid goes downwards and leaves the reactor via the fluid outlet. Compared with a conventional cannula reactor, the fluidized bed reactor improves the dispersion uniformity of catalyst and conversion of formaldehyde.

Owner:SHANDONG YUHUANG CHEM CO LTD +1

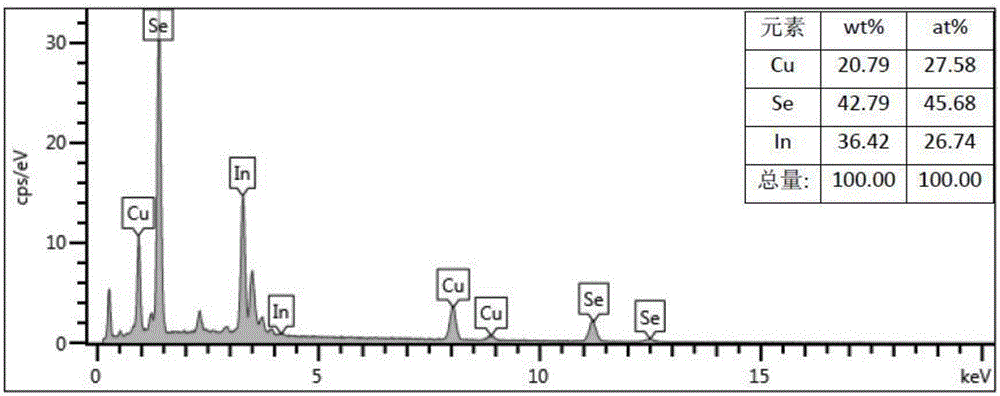

Method for efficiently synthesizing CuInSe2 quantum dots with chalcopyrite structures

ActiveCN106833648ASmall particle sizeParticle size controllableNanotechnologyLuminescent compositionsIndium TrichlorideSolvent

The invention discloses a method for efficiently synthesizing CuInSe2 quantum dot with a chalcopyrite structure. By using a method for dissolving selenium powder by using a mixed solvent of oleylamine and hexadecyl mercaptan instead of oleylamine single solvent, a difficulty problem that high temperature is needed during dissolving the selenium powder by using oleylamine is solved. By using cheap indium trichloride tetrahydrate as an indium source instead of expensive anhydrous indium trichloride or indium acetate and using octadecene as metallic precursor instead of partial oleylamine, the CuInSe2 quantum dot with the chalcopyrite structure is successfully synthesized. Compared with the traditional hot injection method, the method for efficiently synthesizing the CuInSe2 quantum dots with the chalcopyrite structures, disclosed by the invention, has the advantages of low raw material cost, simple operation, easy control, high repeatability and no pollution to environment. The synthesized CuInSe2 quantum dot has the advantages of less defects, high yield, uniform particle size distribution, good dispersion and important industrial application values and can be used for preparing CuInSe2 quantum dot solar cells.

Owner:WUHAN UNIV OF TECH

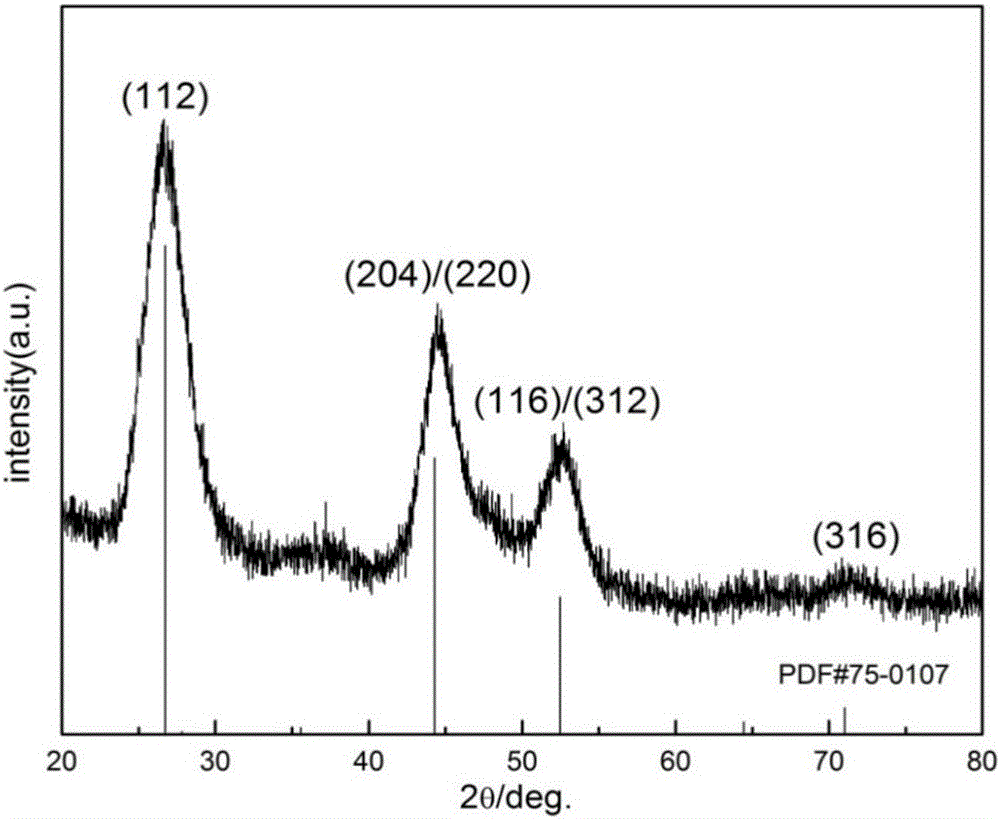

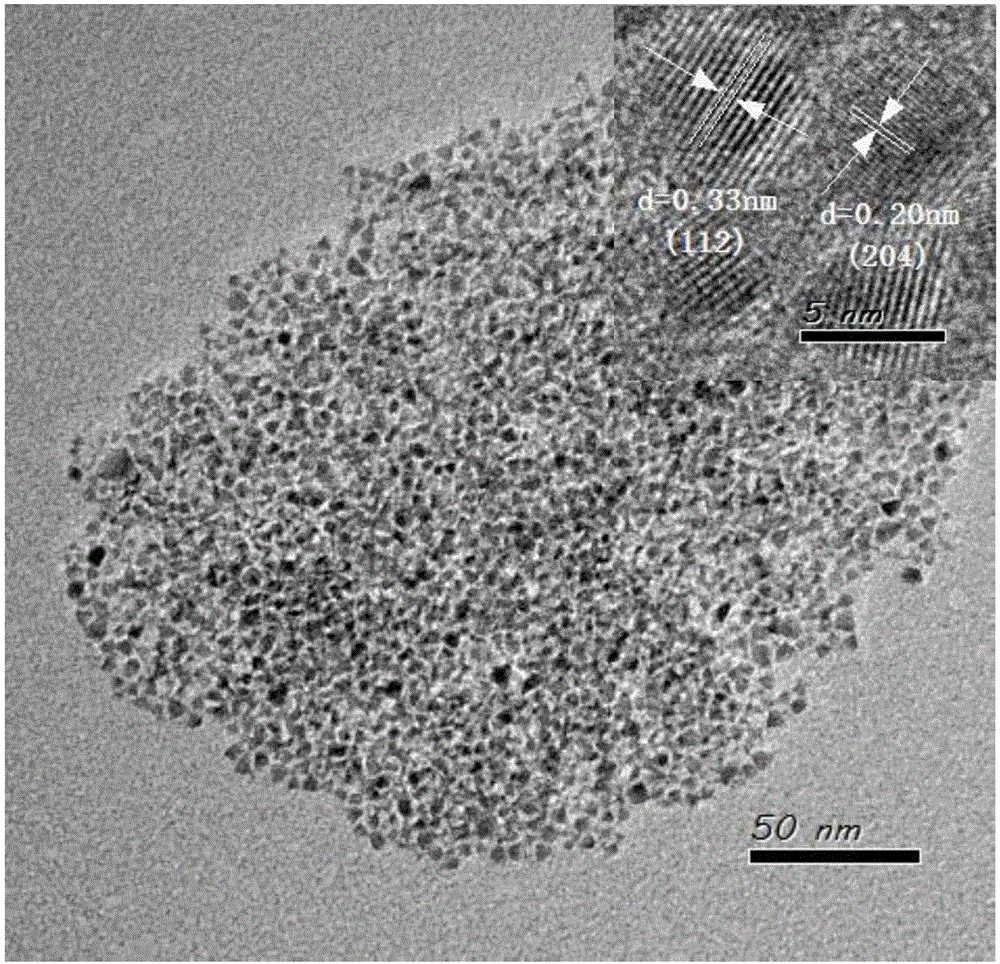

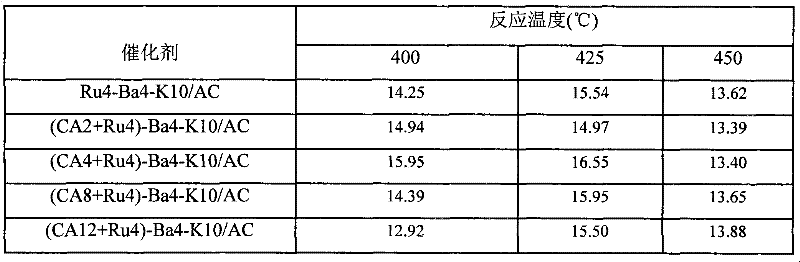

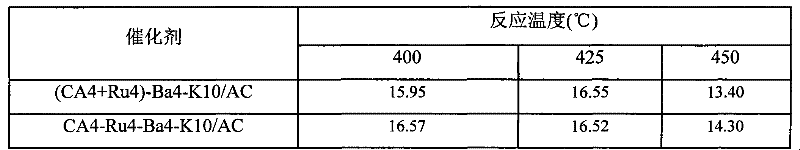

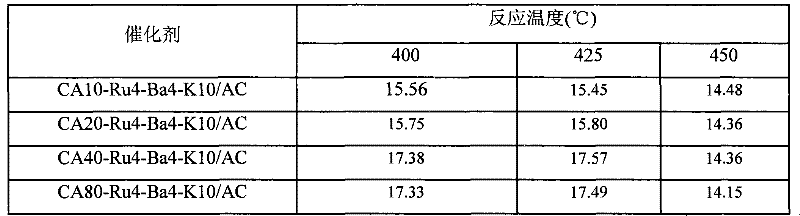

A kind of activated carbon-supported ruthenium-based ammonia synthesis catalyst and preparation method thereof

InactiveCN101322947BImproved size distributionSimple processOrganic-compounds/hydrides/coordination-complexes catalystsBulk chemical productionPtru catalystPotassium hydroxide

Owner:FUZHOU UNIV

Fluidized bed reactor and method for preparing polyoxymethylene dimethyl ethers from dimethoxymethane and paraformaldehyde

InactiveUS9346916B2Increase forceImproved size distributionOrganic chemistryOrganic compound preparationFluidized bedCompound (substance)

The invention belongs to energy chemical technical field, especially relates to a fluidized bed reactor and a method for preparation of polyoxymethylene dimethyl ethers from dimethoxymethane and paraformaldehyde. The fluidized bed reactor comprises a gas inlet, a gas distributor, a catalyst inlet, a gas outlet, a fluid inlet, a catalyst outlet, a bottom component and an interstage component, a bottom component related gas upward channel, an interstage component related gas upward channel, a fluid outlet, a bottom downcomer and an interstage downcomer. A process for preparation of polyoxymethylene dimethyl ethers comprises the steps of: fluidizing gas is introduced into a bottom bed from the gas inlet via the bottom component related gas upward channel through the gas distributor; the fluidizing gas goes upwards and flows out of the reactor via the gas outlet; paraformaldehyde and dimethoxymethane are introduced into a bed through the fluid inlet; the fluid goes downwards and leaves the reactor via the fluid outlet. Compared with a conventional cannula reactor, the fluidized bed reactor improves the dispersion uniformity of catalyst and conversion of formaldehyde.

Owner:SHANDONG YUHUANG CHEM CO LTD +1

Polyimide foam plastic and its preparation method

ActiveCN103275319BImprove mechanical propertiesGood flexibilityAdhesivesPolymer scienceHeat resistance

The invention provides a preparation method of polyimide foam plastic. The method comprises the steps as follows: firstly, after dianhydride is mixed with low-level aliphatic alcohol, an esterification reaction is performed, and a diacid diester solution is obtained; then the obtained diacid diester solution is mixed with polymerized monomer amine and polyamic acid powder to obtain a mixed solution; and finally, the obtained mixed solution is sequentially subjected to foaming and thermal imidization after concentration to obtain the polyimide foam plastic. The invention further provides the polyimide foam plastic and the preparation method thereof, and the method comprises the step that polyamic acid powder is added when dianhydride and isocyanate are used for preparing the polyimide foam plastic. According to the invention, the polyamide acid powder serves as a nucleating agent, so that a cell of an objected formed by foaming of polyimide is fine and smooth, that is, the size distribution of the cell is improved, the cell uniformity is better, then the flexibility performance and the like of the polyimide foam plastic are improved; meanwhile, the heat resistance is not influenced; and besides, the preparation method of the polyimide foam plastic is concise in processing, and low in energy consumption and production cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

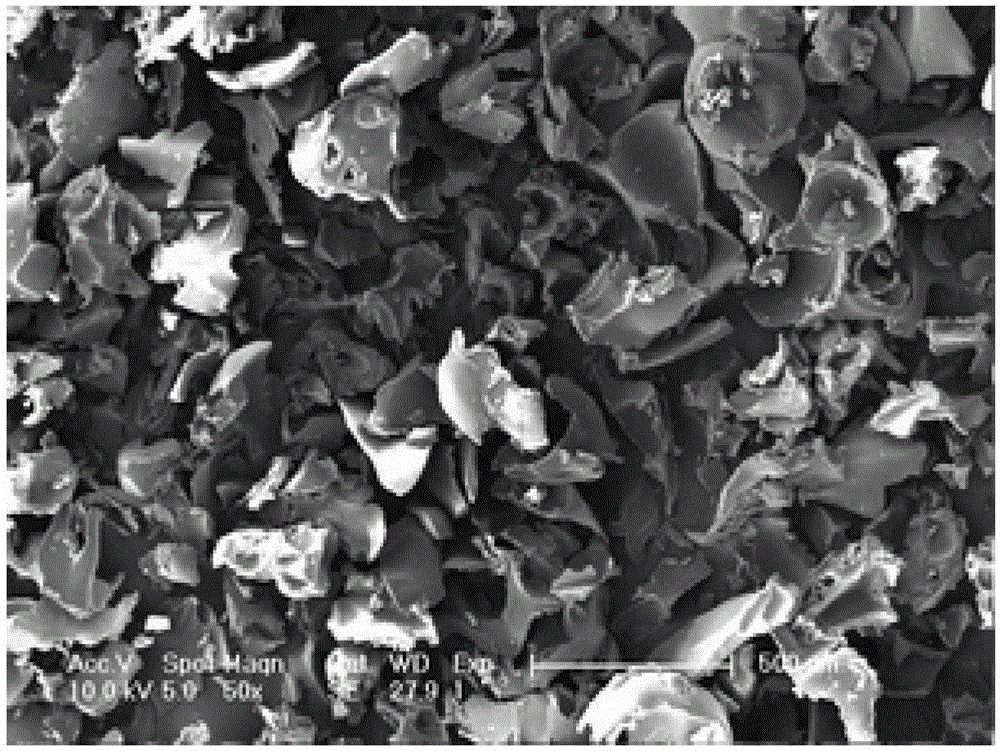

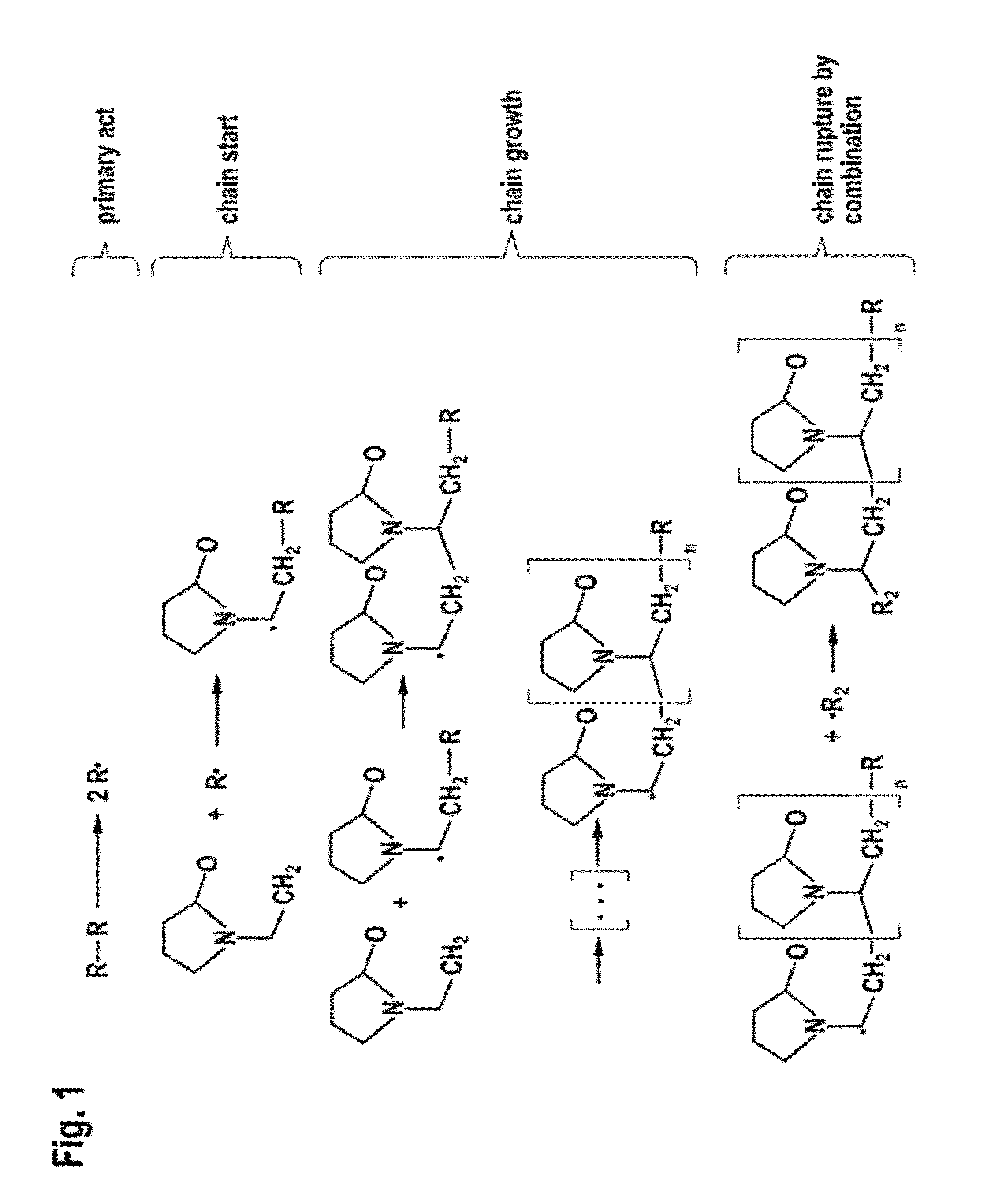

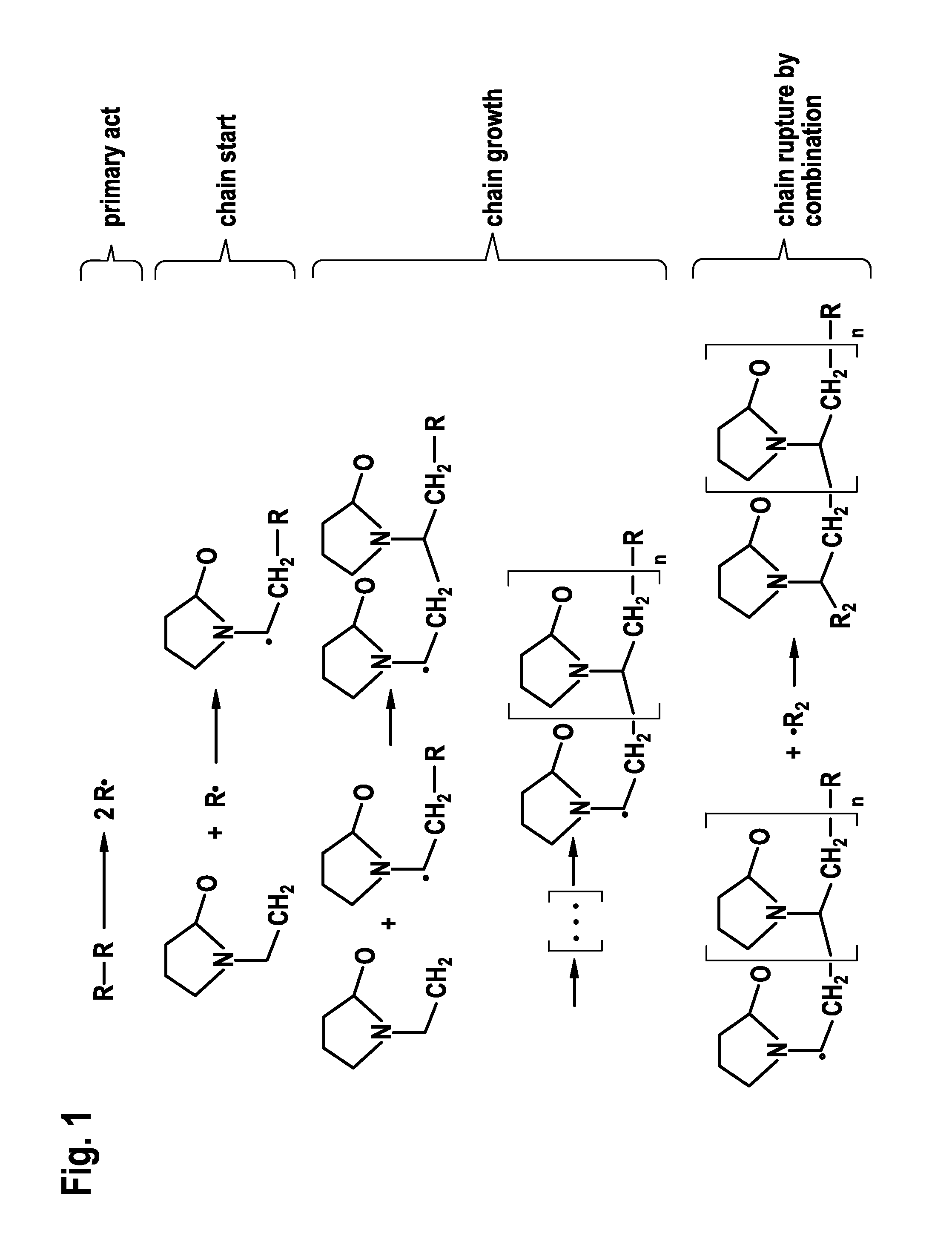

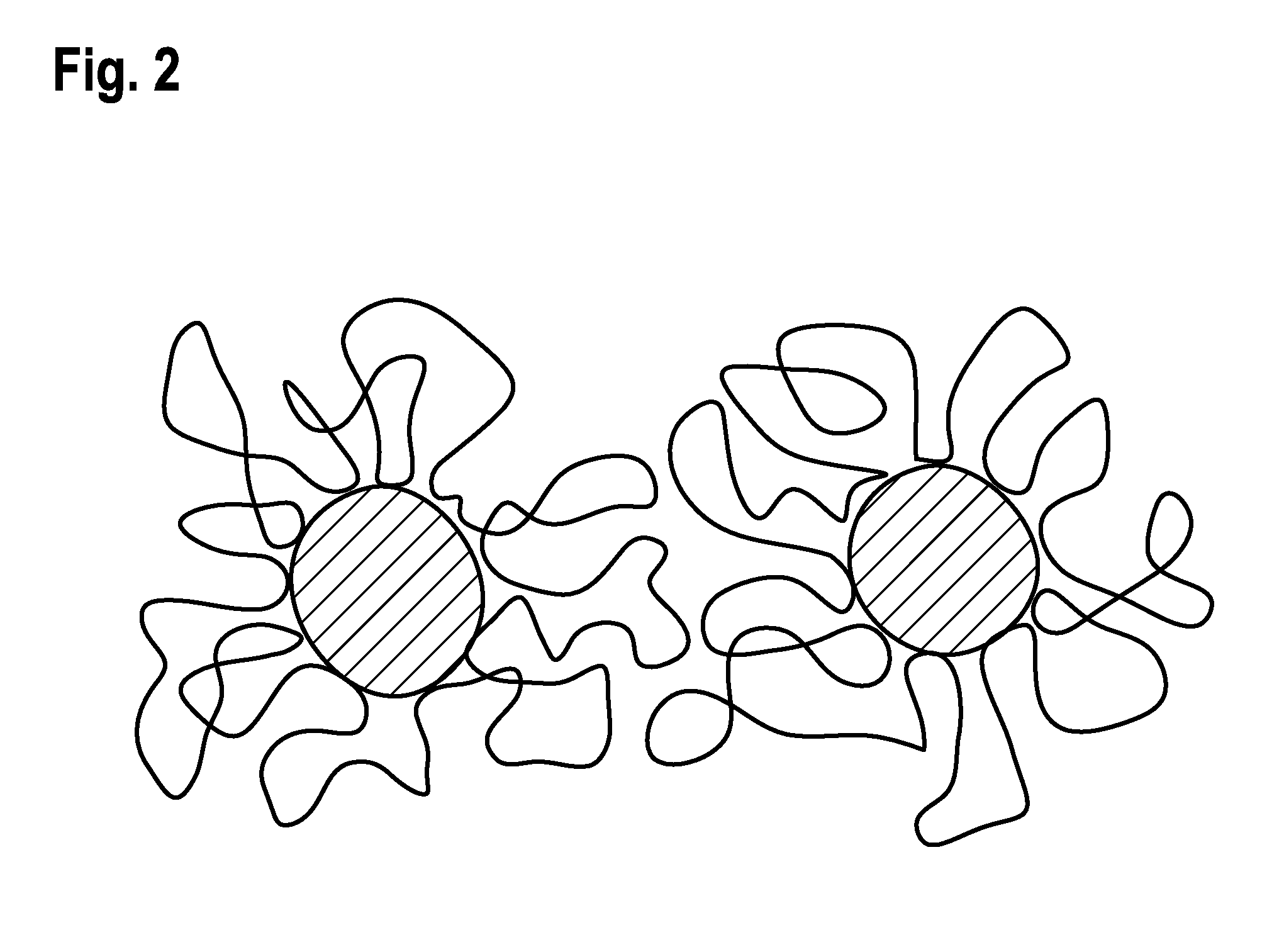

Method for producing hydrophilic poly-n-vinylpyrrolidone and use thereof

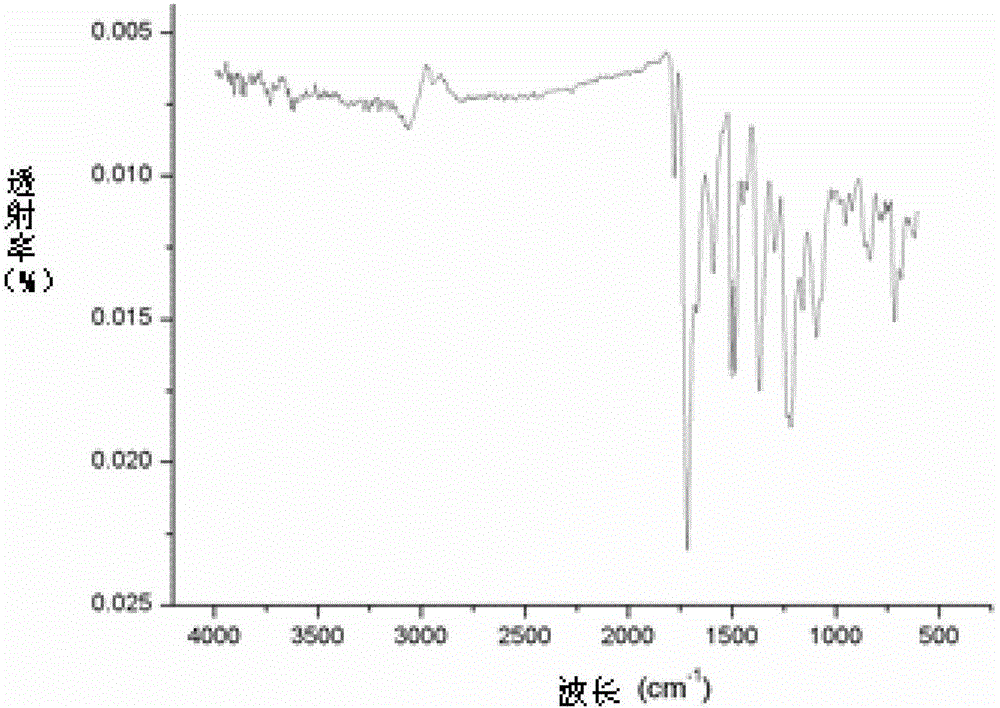

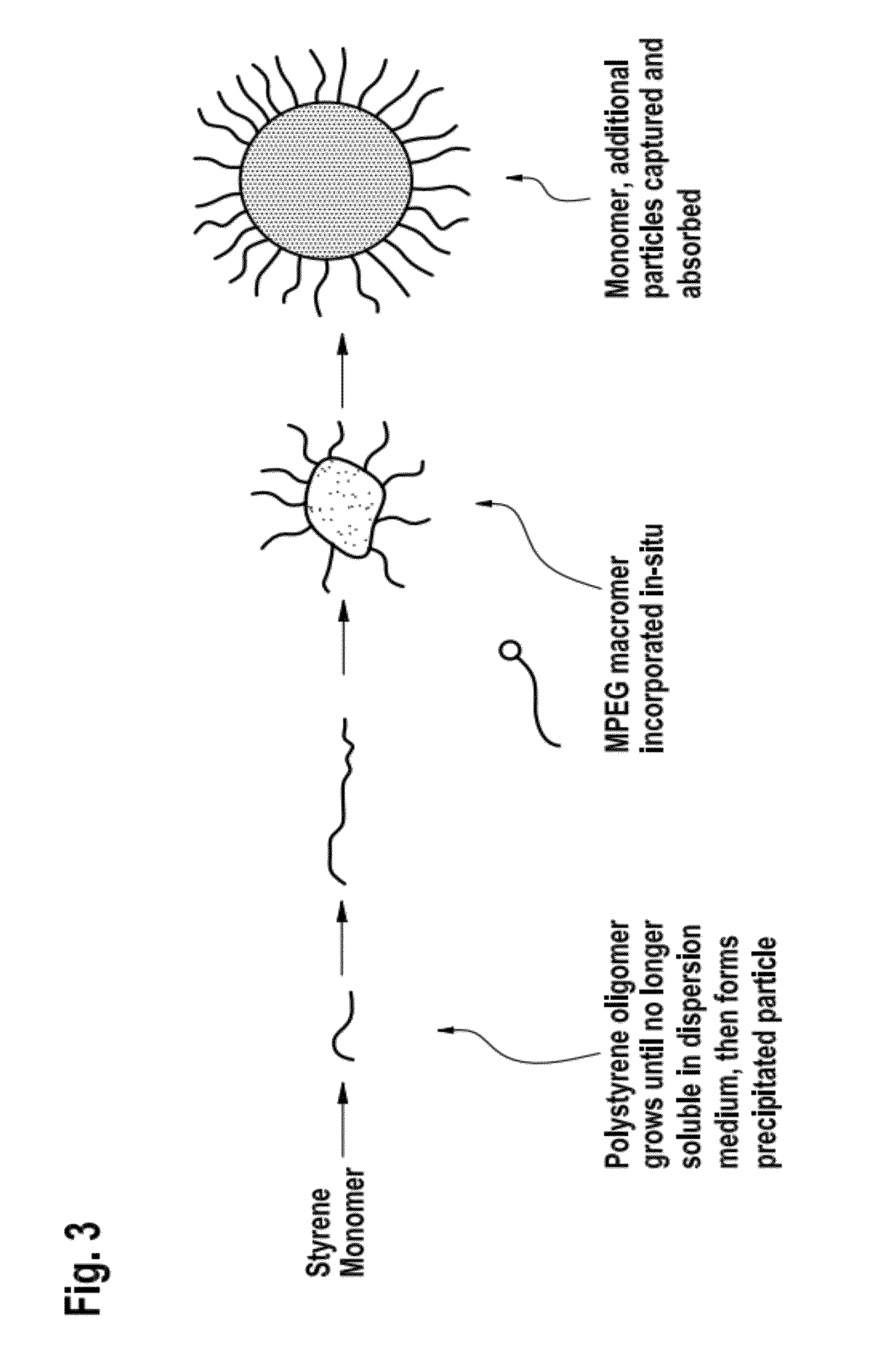

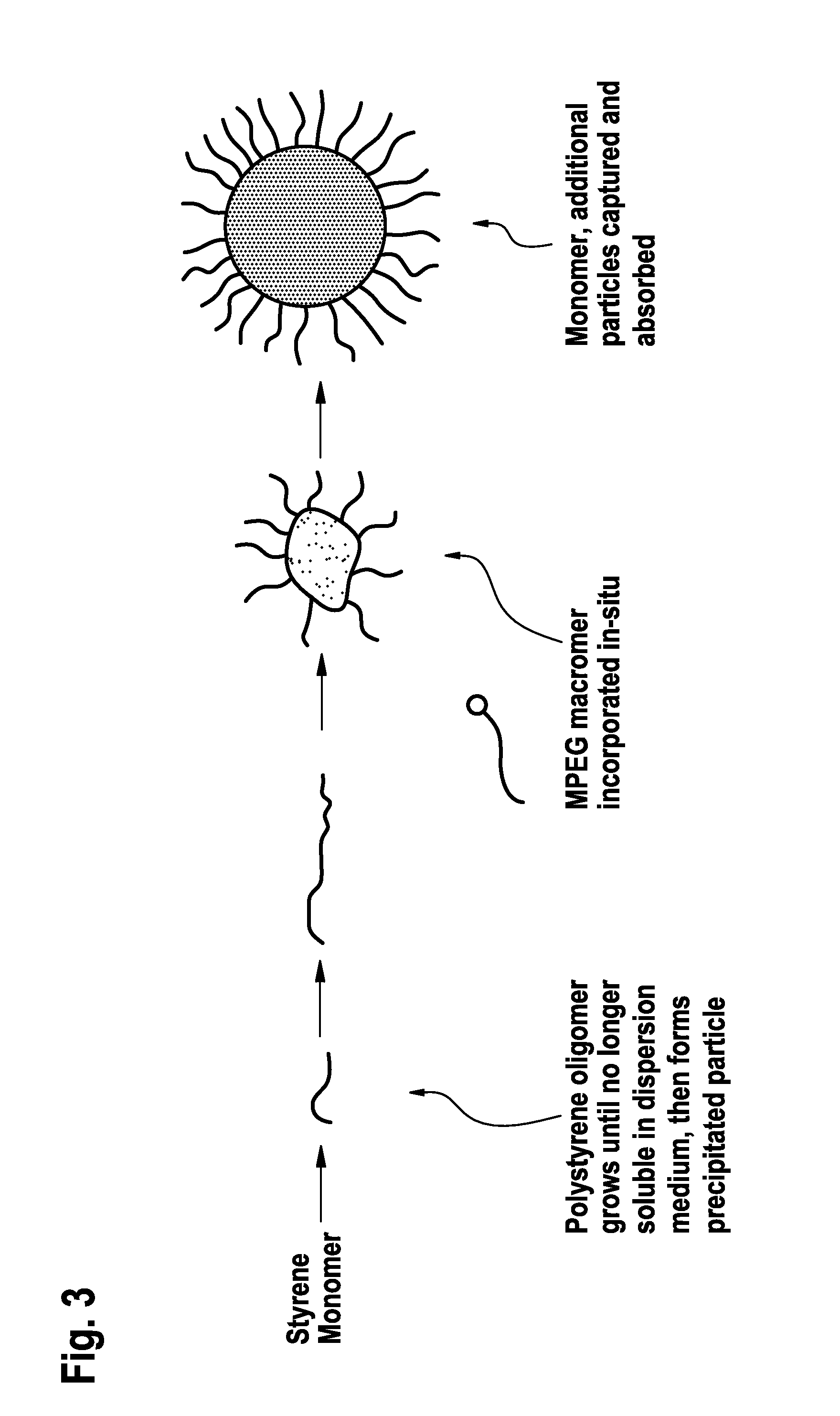

InactiveUS20120053254A1Maintain good propertiesGood chemical stabilityChromatographic separationDispersion polymerization

The present invention relates to a process for the production of the largest possible spherical, monodisperse polyvinylpyrrolidone (PVP) seed particles in the micron range by dispersion polymerisation. The particles obtained in this way represent novel starting materials for the production of macroporous polymer particles, which can in turn be employed in preparative and analytical chromatography for protein preparation. They can also be employed as base material for further reactions.The novel process for the polymerisation of N-vinylpyrrolidone, which is inexpensive to carry out, gives particles having optimised quantities, such as monodispersity, sphericity and particle diameter, which can be employed in further reactions and have advantageous, in particular improved, properties for use in chromatographic separation methods.

Owner:MERCK PATENT GMBH

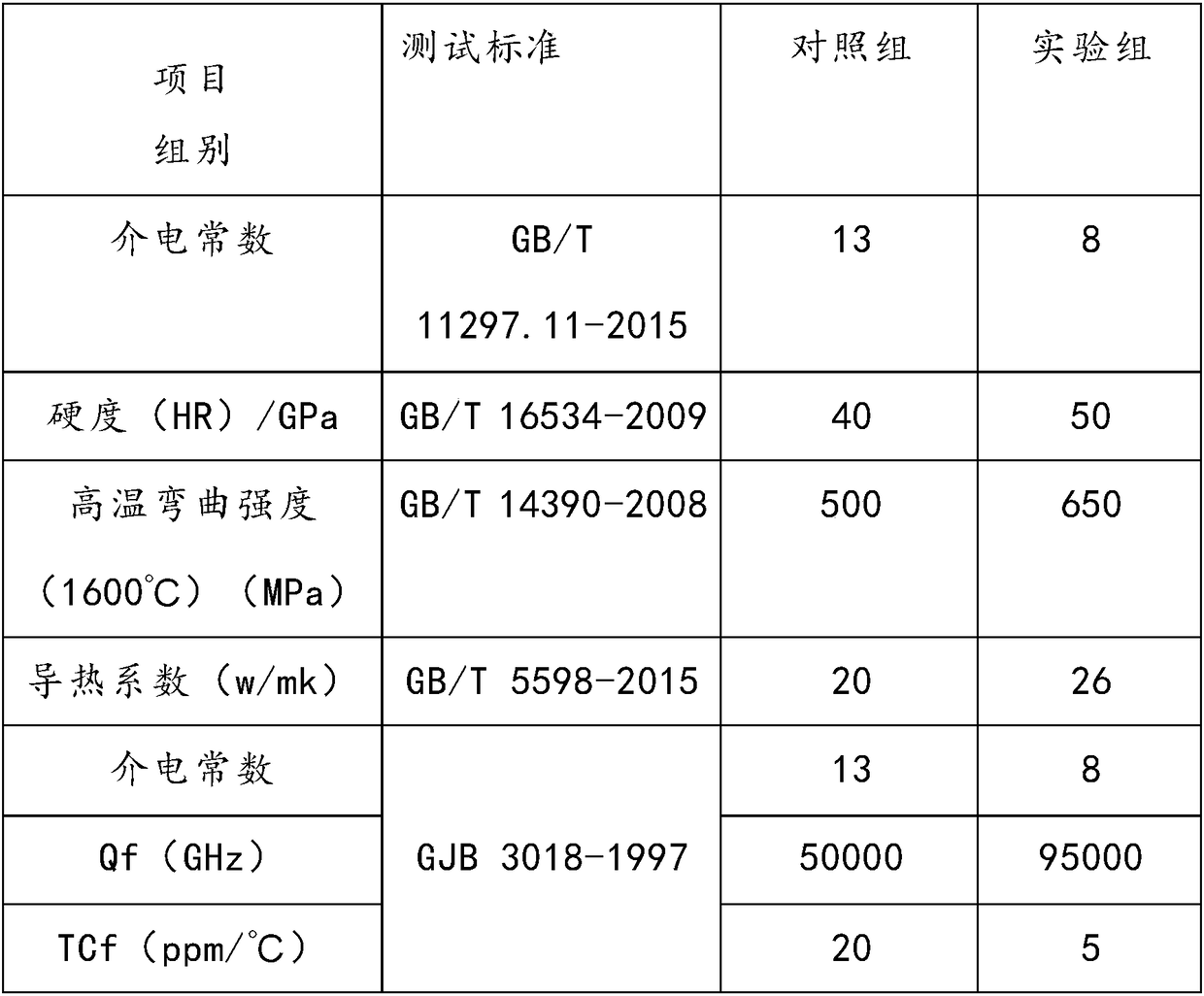

Microwave ferrite material with high dielectric constant as well as preparation method and application of microwave ferrite material

ActiveCN112960977ALower sintering temperatureImproved size distributionInorganic material magnetismInductances/transformers/magnets manufactureDielectricLine width

The invention provides a microwave ferrite material and a preparation method with a high dielectric constant and application thereof. According to the high-dielectric-constant microwave ferrite material, the dielectric constant is increased through synergistic addition of Sn<4+>, Al<3+> and Sm<3>, the saturation magnetization of the obtained material ranges from 1800 Gs to 2000 Gs, and the dielectric constant is 18 or above; through synergistic addition of Bi<3+> and Cu<2+>, the sintering temperature of the material is reduced, so excessive growth of crystal grains caused by too high sintering temperature and too long sintering time is avoided, formation of the ferrite material with good crystal grain size distribution is facilitated, the Curie temperature of the material is 180 DEG C or above, and the resonance line width of the material does not exceed 28 Oe; the preparation method is simple to operate; and through grading, the bonding strength of the material is improved, the porosity in the ferrite material is reduced, and the ferromagnetic resonance line width of finally obtained garnet ferrite is reduced. The ferrite material provided by the invention can meet the requirements of a 5G base station circulator for miniaturization and light weight.

Owner:SUZHOU IND PARK KAYMAX PRECISION ENG

Ceramic material with low dielectric constant and preparation method of ceramic material

InactiveCN108793959AImproved size distributionLower sintering temperatureClaywaresPorosityPyrophyllite

The invention discloses a ceramic material with a low dielectric constant. The ceramic material is prepared from the following materials in parts by weight: kaolin, anorthite, akermanite, sodium carboxymethyl cellulose, calcium titanate, polyvinyl alcohol, nanometer bismuth trioxide, boron oxide, zinc nitrate, magnesium cordierite, fluorite, tremolite, clinochlore, pyrophyllite and yttrium aluminum garnet. Zinc ions in zinc nitrate can substitute magnesium in akermanite; the akermanite having magnesium substituted with the zinc ions can be matched with boron oxide to reduce a sintering temperature, and can be matched with calcium titanate to adjust the temperature stability, thereby avoiding heating fragmentation and reducing the dielectric constant; yttrium ions in the yttrium aluminum garnet can improve particle size distribution and reduce porosity; a special octahedral six-membered rings of magnesium cordierite crystals enable the structure and performance to have adjustability; and the yttrium aluminum garnet can be matched with the magnesium cordierite to further reduce the dielectric constant and increase the stability.

Owner:冯嘉豪

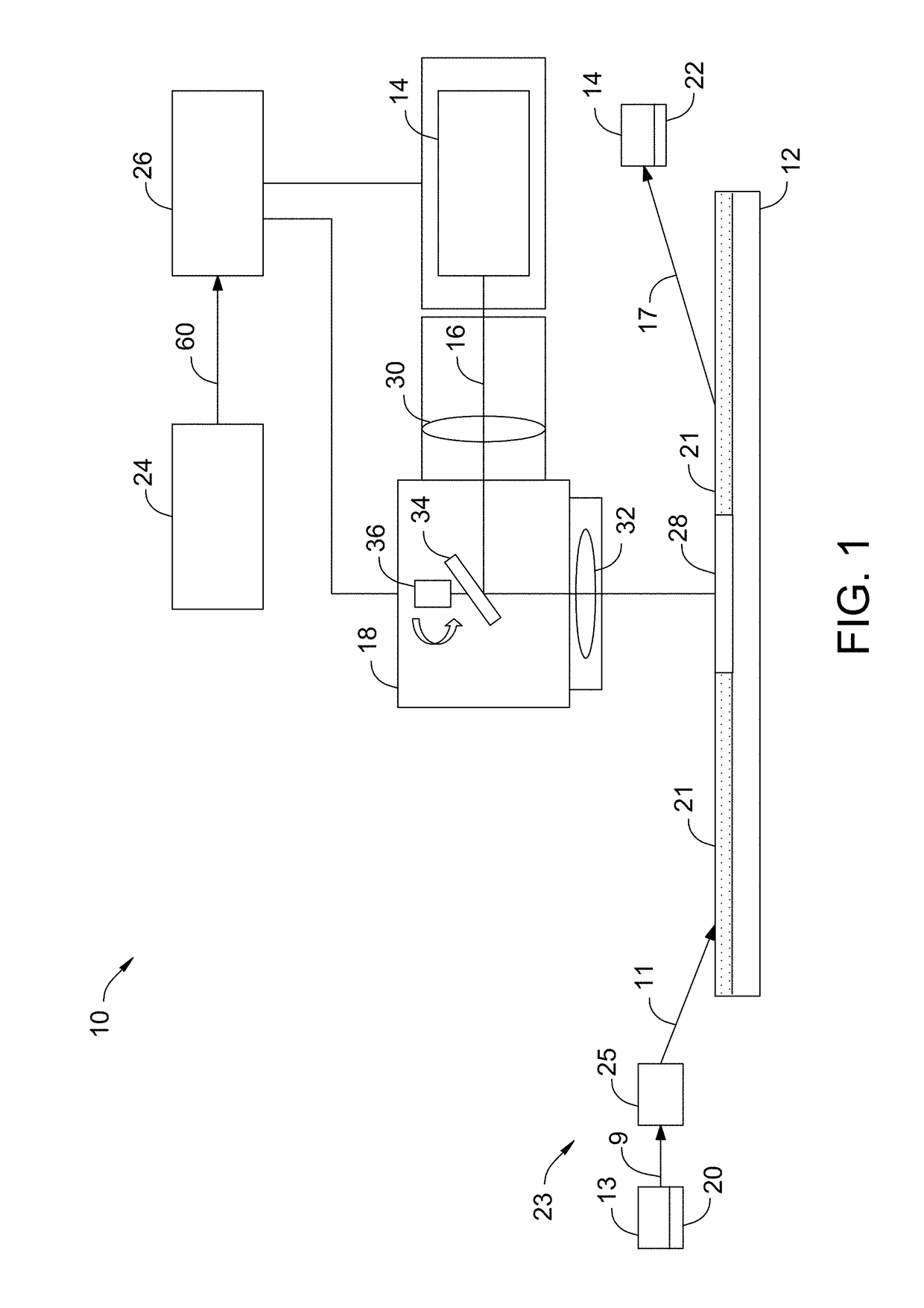

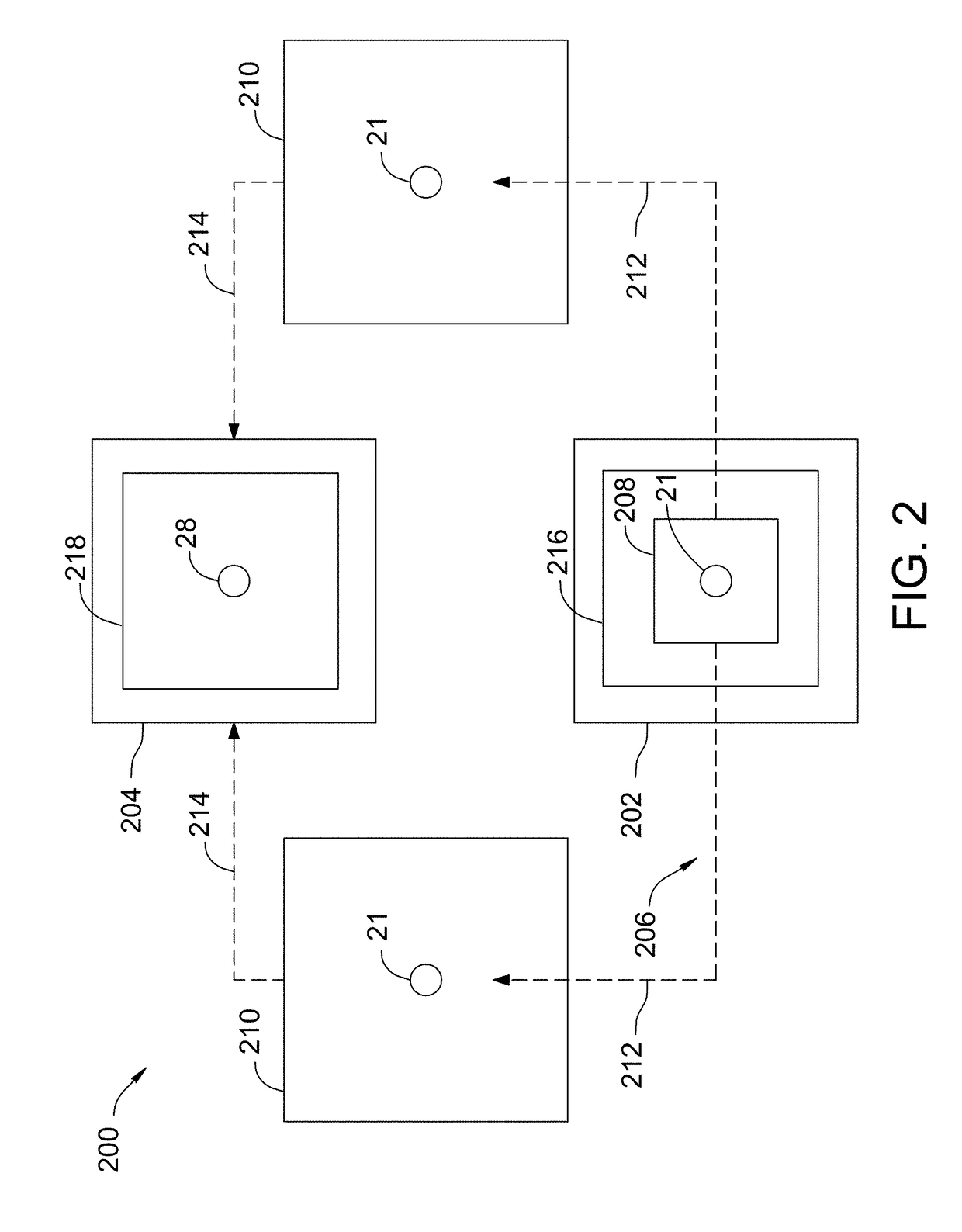

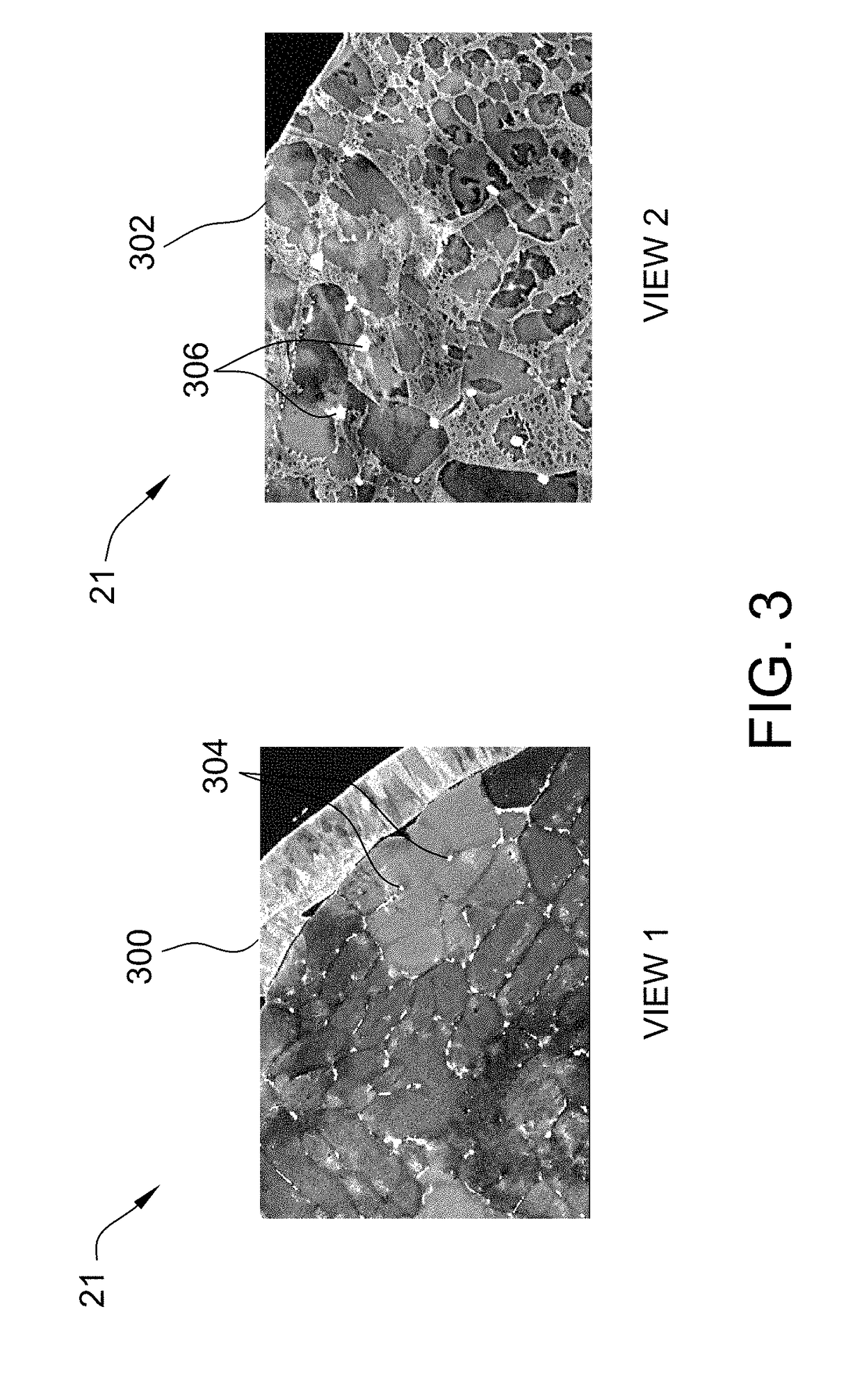

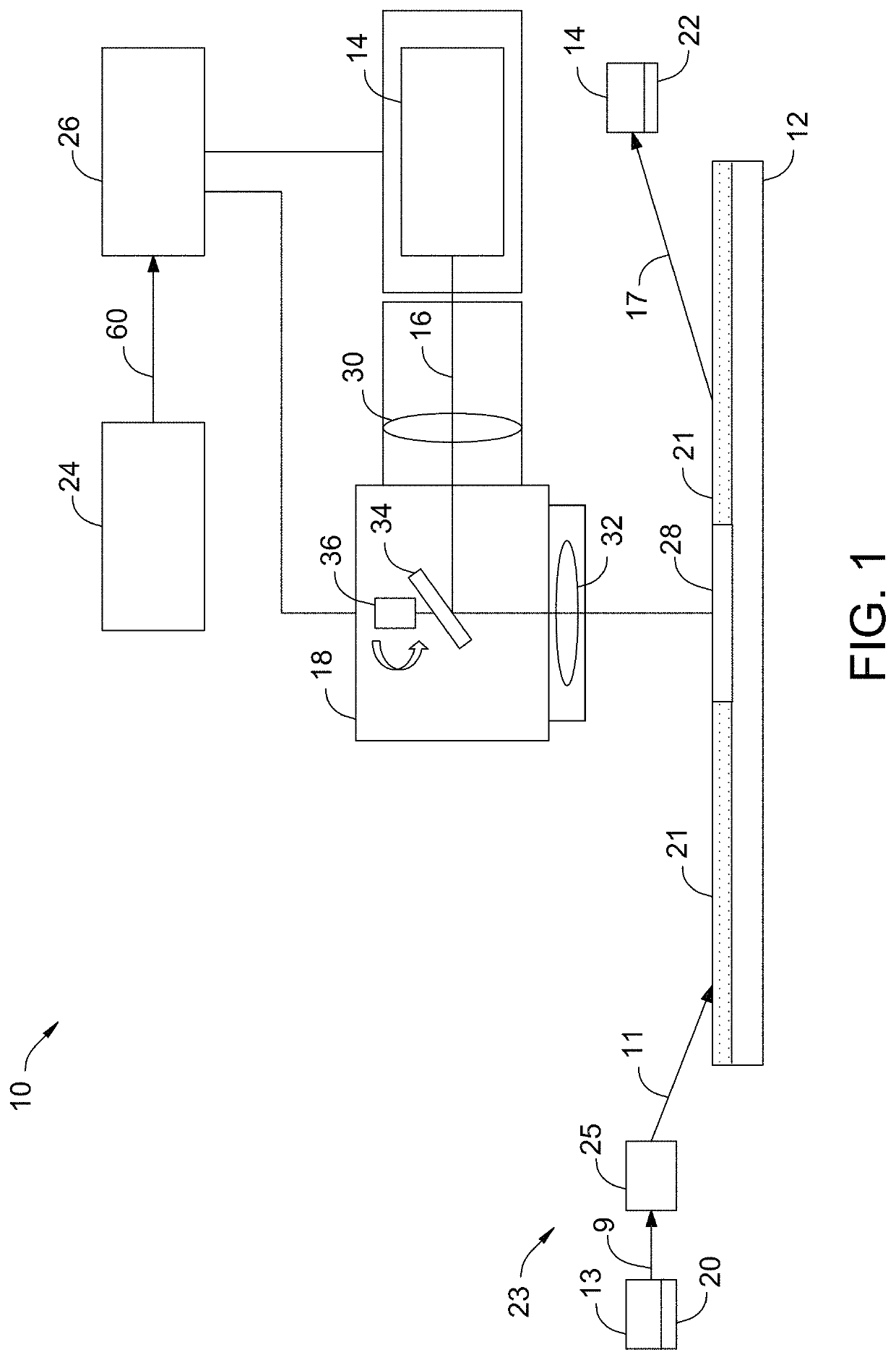

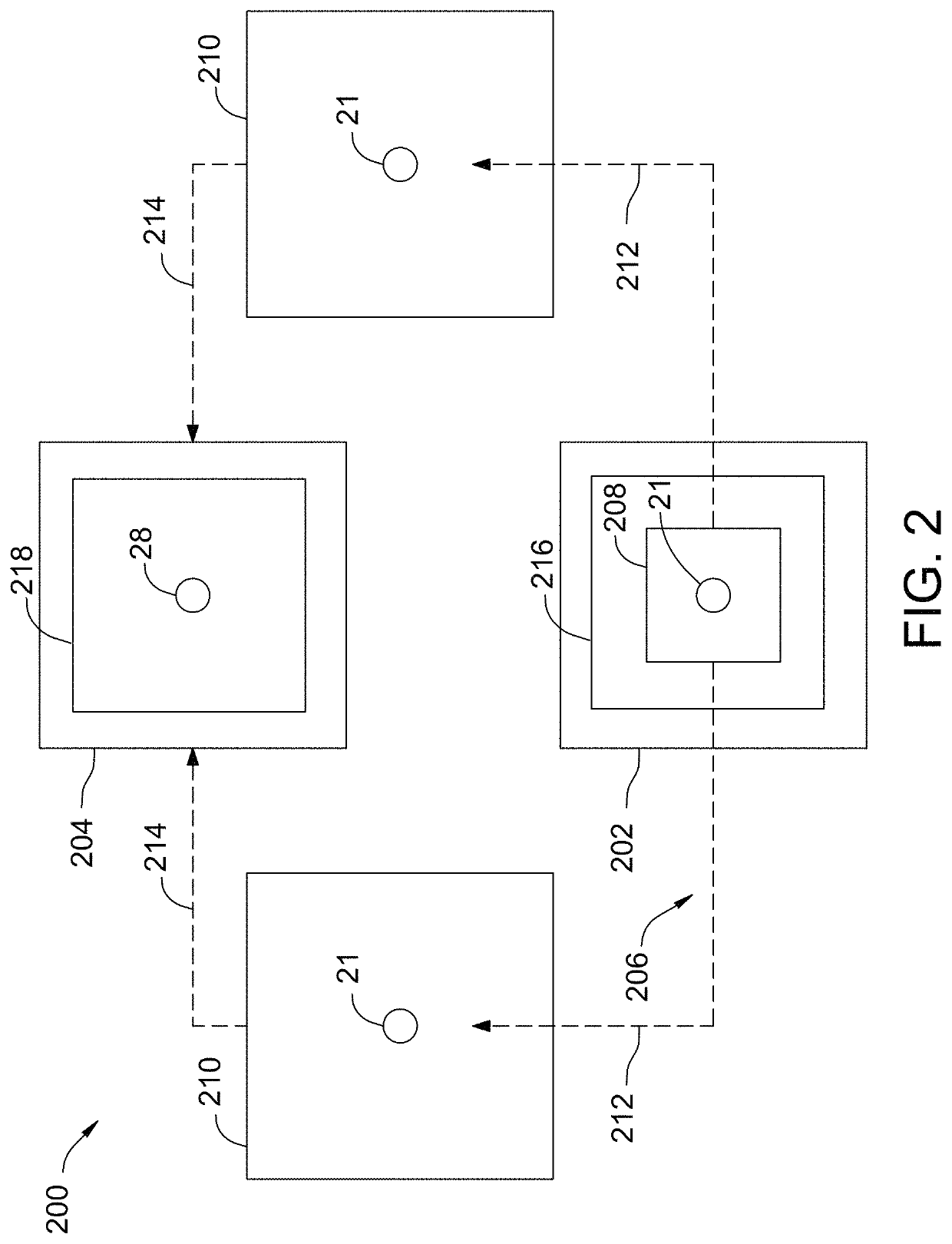

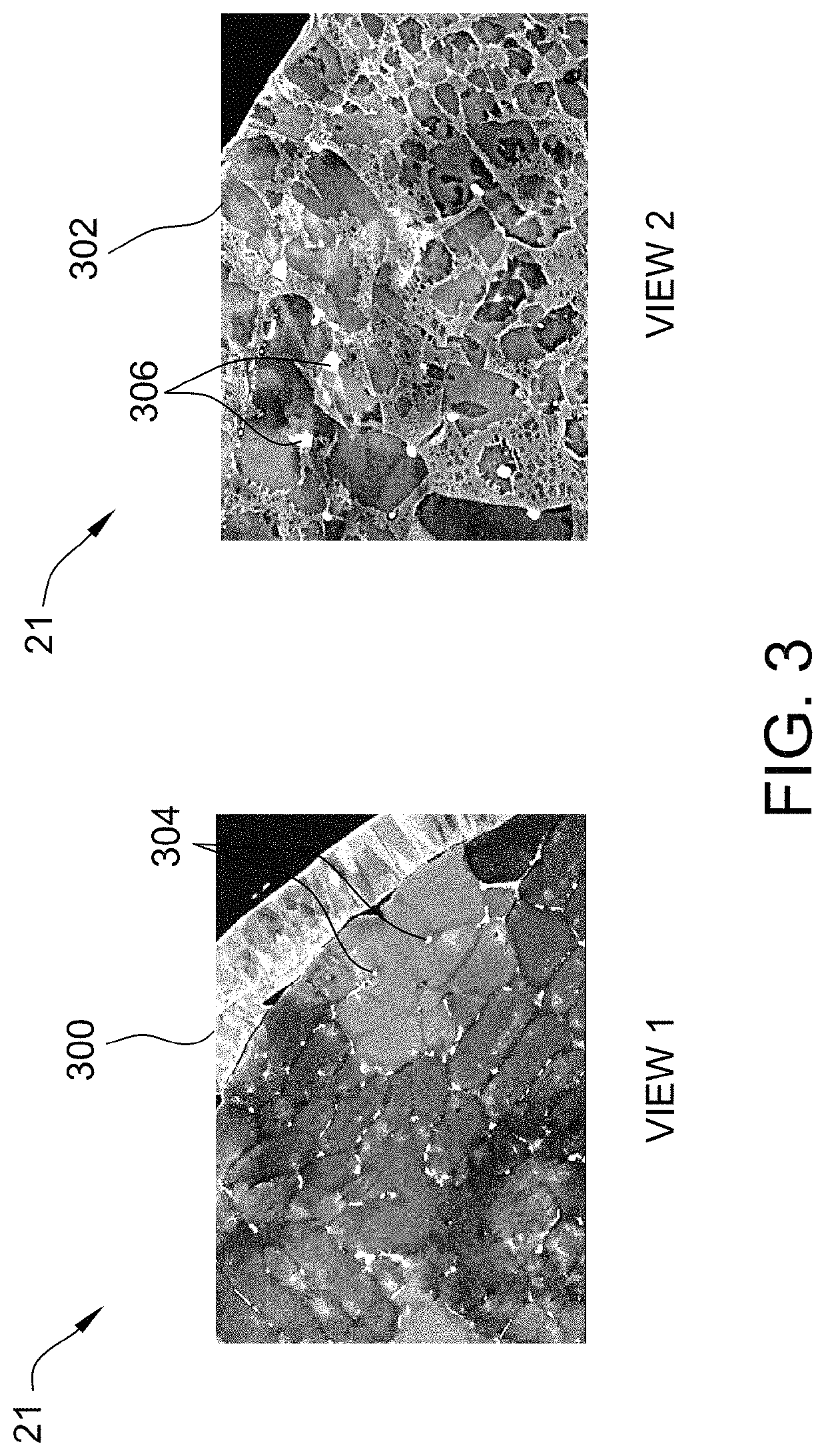

Systems and methods for powder pretreatment in additive manufacturing

ActiveUS20180369907A1Improved size distributionAdditive manufacturing apparatusTransportation and packagingParticulatesNominal size

A method of processing a powdered feedstock to form a fabricated component is provided. The fabricated component includes a plurality of grains having a nominal grain size. The method includes providing the powdered feedstock material having a population of phase particulates with a first nominal size distribution disposed within a host matrix material. The method includes building a consolidated component from the powdered feedstock material in an additive manufacturing process, and fabricating the fabricated component from the consolidated component. The first nominal size distribution of the population of phase particulates is sized such that at least a portion of the population of phase particulates persists throughout the additive manufacturing process and is present as a processed population of phase particulates in the consolidated component. In addition, the processed population of phase particulates has a second nominal size distribution effective to produce the nominal grain size of the fabricated component.

Owner:GENERAL ELECTRIC CO

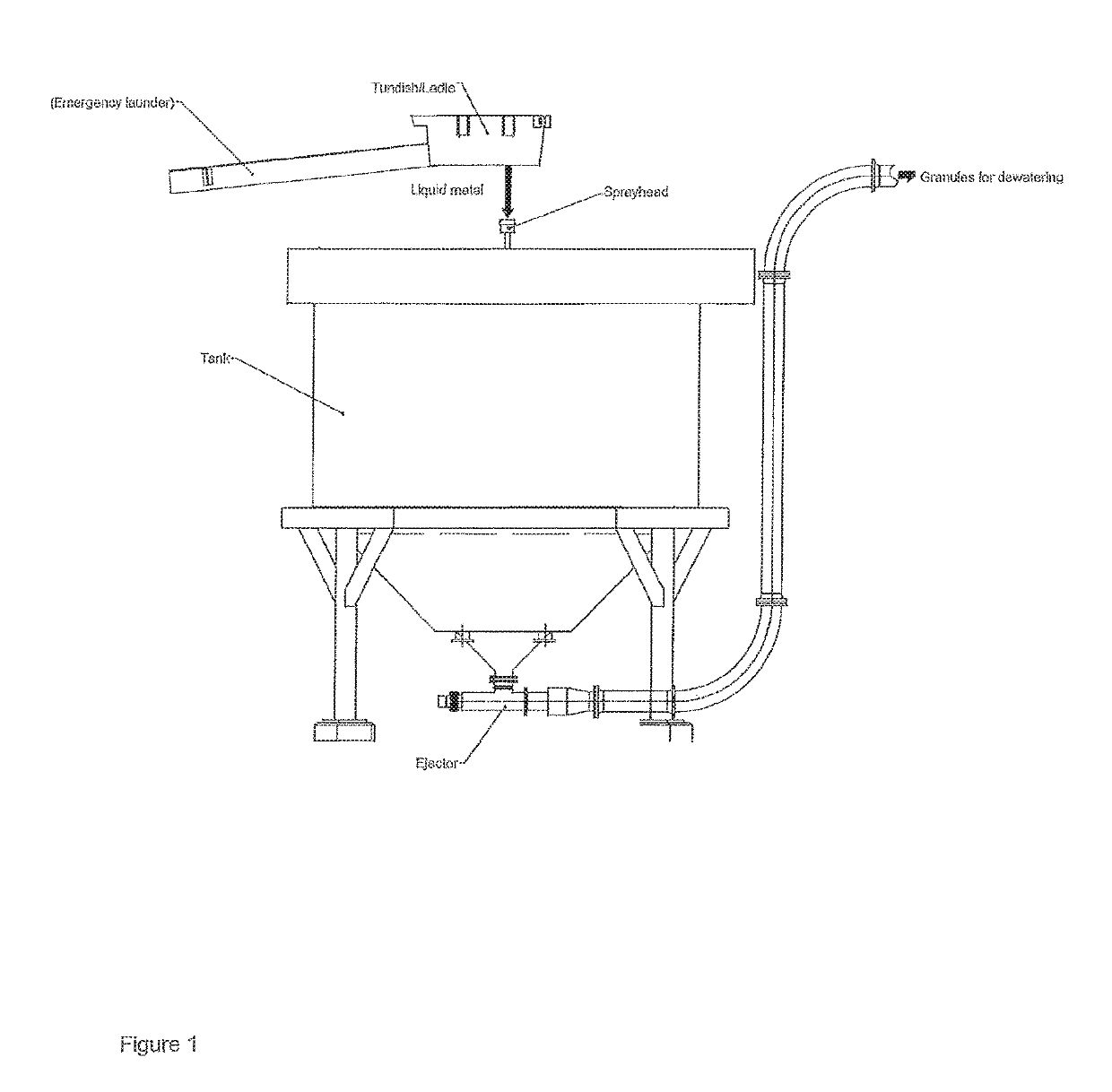

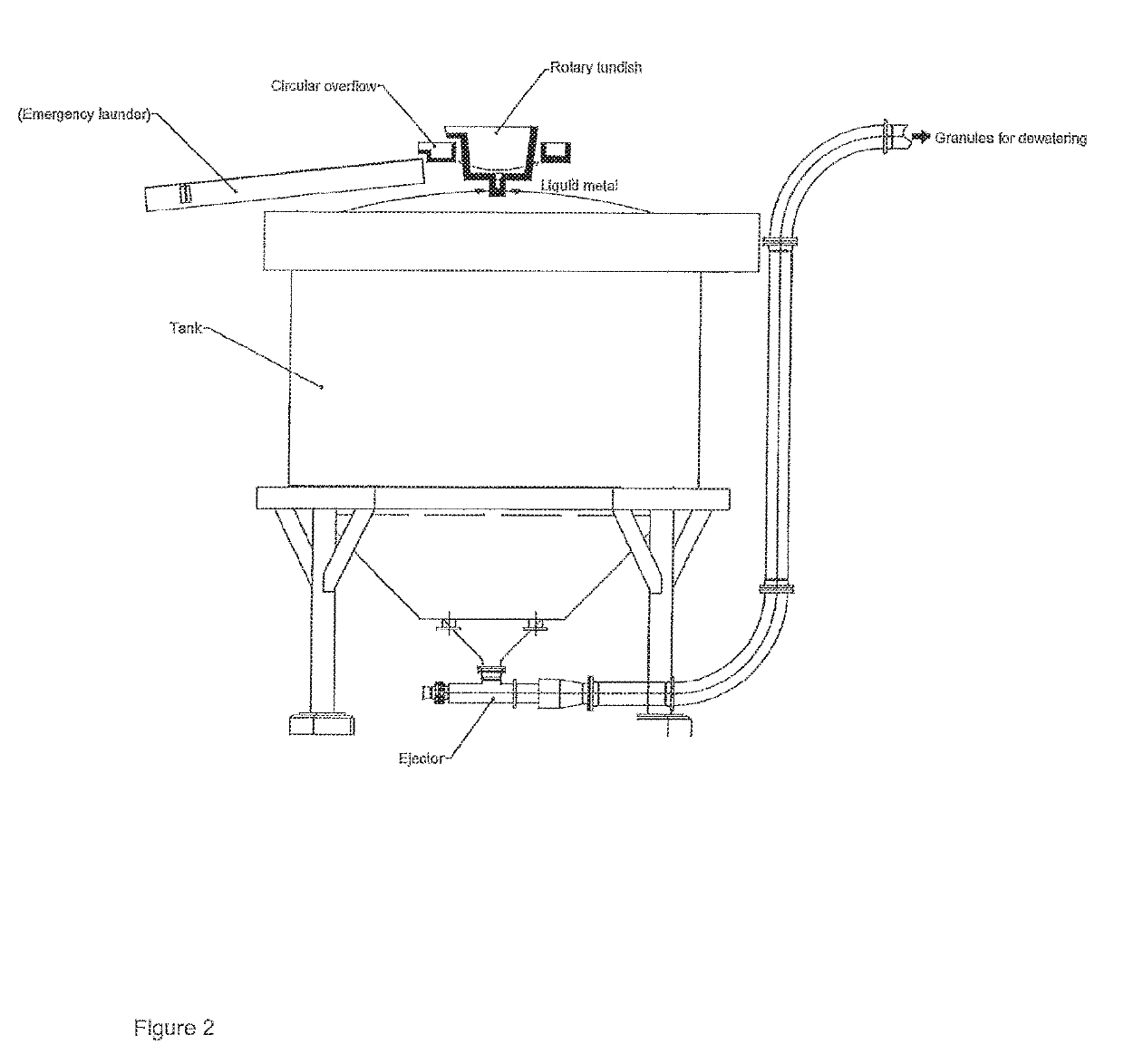

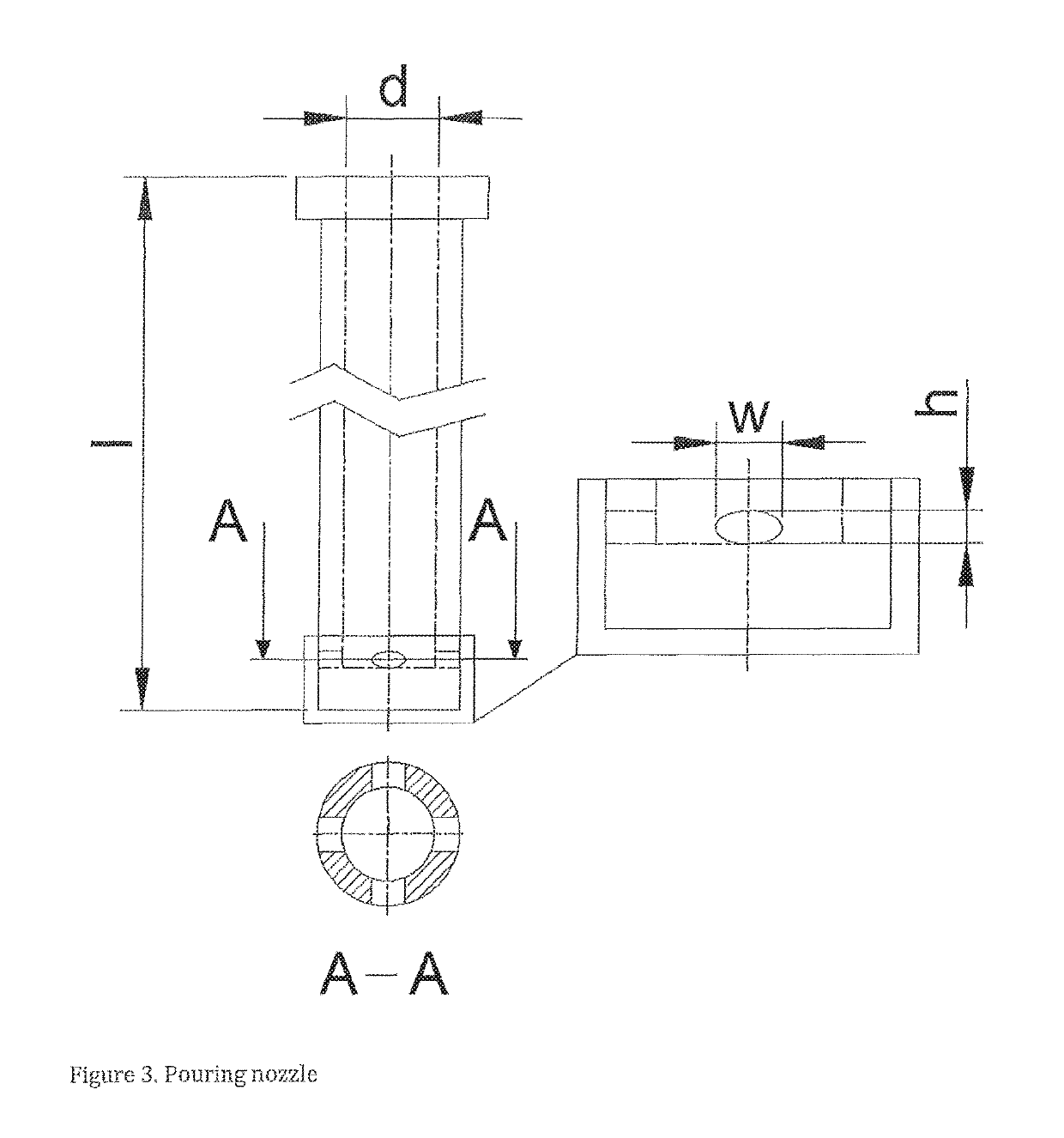

Nozzle and a tundish arrangement for the granulation of molten material

A nozzle, a tundish arrangement used for the production of granulated material, and a method and apparatus for the production of a granulated material with an improved size distribution are provided. The grain size and grain size distribution is controlled by a nozzle having a specific design. The nozzle comprises an upper inlet opening, sidewalls forming a channel, a bottom and at least one outlet opening or at least one row of outlet openings at the lower end of the channel. The outlet opening(s) in the channel have a size of at least 5 mm in the smallest dimension. A cross sectional area of the channel at the inlet AC is at least 3 times bigger than the total area of the outlet openings AT.

Owner:UVAN HLDG

Systems and methods for powder pretreatment in additive manufacturing

ActiveUS10758976B2Improved size distributionAdditive manufacturing apparatusTransportation and packagingMetallurgyHost material

A method of processing a powdered feedstock to form a fabricated component is provided. The fabricated component includes a plurality of grains having a nominal grain size. The method includes providing the powdered feedstock material having a population of phase particulates with a first nominal size distribution disposed within a host matrix material. The method includes building a consolidated component from the powdered feedstock material in an additive manufacturing process, and fabricating the fabricated component from the consolidated component. The first nominal size distribution of the population of phase particulates is sized such that at least a portion of the population of phase particulates persists throughout the additive manufacturing process and is present as a processed population of phase particulates in the consolidated component. In addition, the processed population of phase particulates has a second nominal size distribution effective to produce the nominal grain size of the fabricated component.

Owner:GENERAL ELECTRIC CO

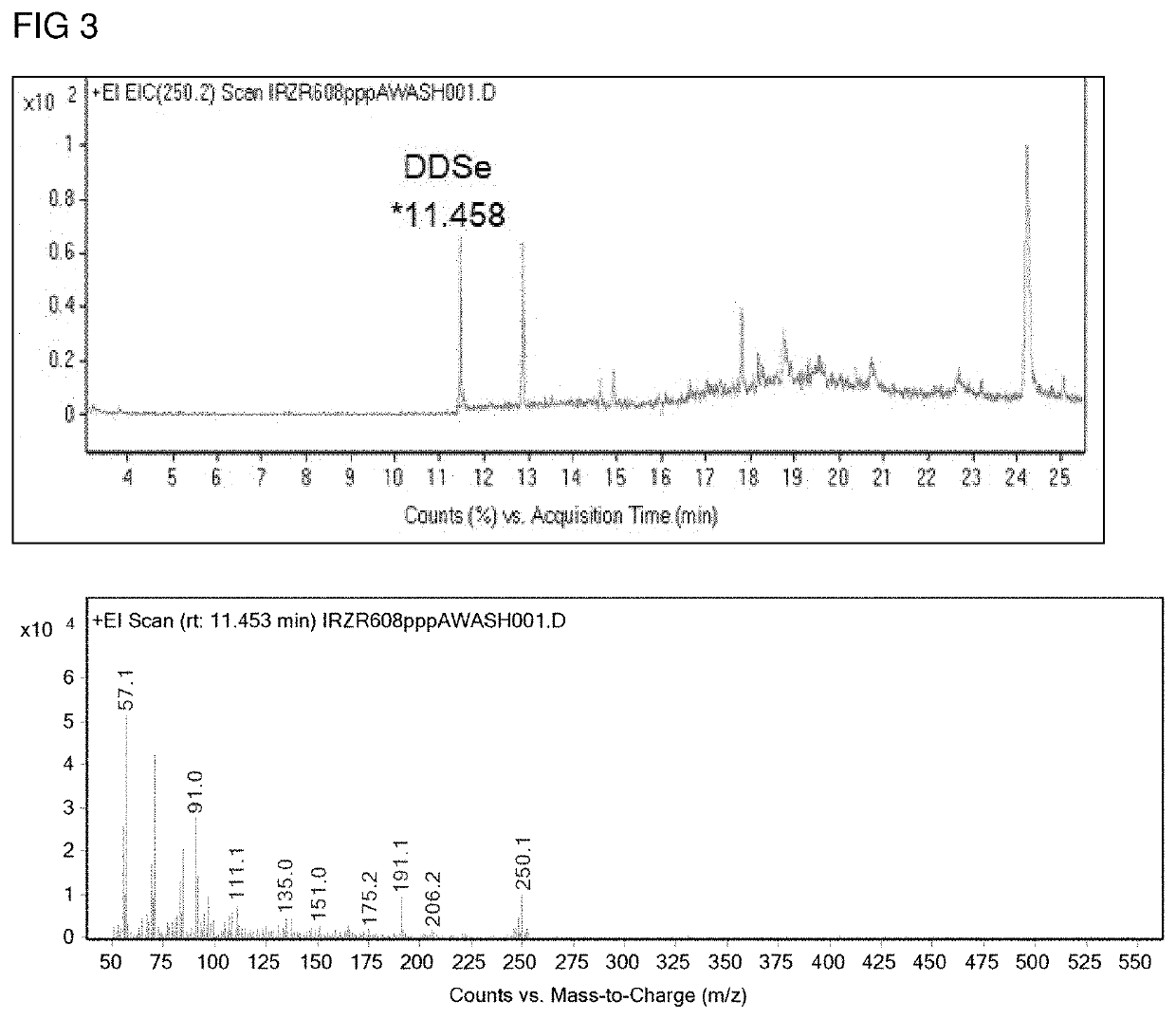

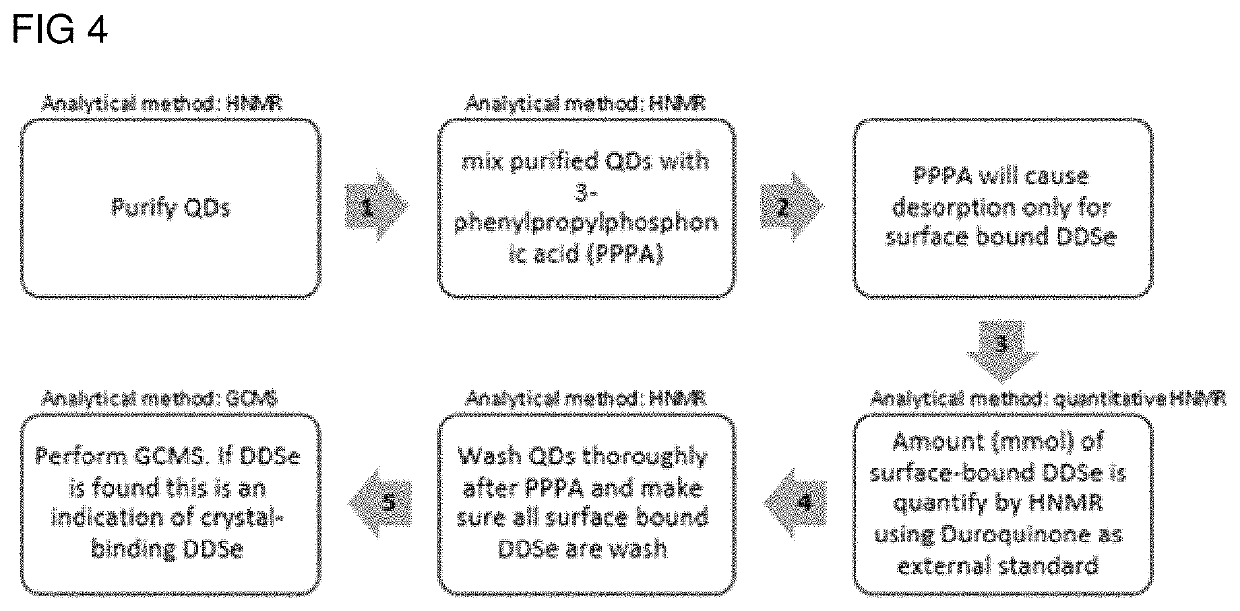

Nanoparticle

PendingUS20220298411A1Increase valueLarge particle sizeNanotechnologyLuminescent compositionsNanoparti cles

The present invention relates to a semiconducting nanoparticle; and a process for synthesizing the nanoparticle.

Owner:MERCK PATENT GMBH

A method of controlling the size distribution of pbs or pbse quantum dots

InactiveCN106882837BLow costThe preparation process is matureMaterial nanotechnologyLead sulfidesCation exchange reactionQuantum dot

The invention discloses a method for controlling PbS or PbSe quantum dot size distribution. The method comprises the following steps that: (1) first, CdSe (or CdS) quantum dots with larger sizes are injected into a precursor of lead, and PbSe (or PbS) quantum dots with larger sizes are obtained through a cation exchange reaction at the moment; (2) then, CdSe (or CdS) quantum dots with smaller sizes are continuously injected, and the PbSe (or PbS) quantum dots with smaller sizes are obtained through the cation exchange reaction at the moment; (3) finally, the size distribution of the PbSe (or PbS) quantum dots becomes narrower and narrower under the action of Ostwald ripening effect, so that the size distribution of the PbSe (or PbS) quantum dots is controlled. Through the method, various sizes of the PbSe (or PbS) quantum dots with extremely good size distribution can be obtained; moreover, the PbSe (or PbS) quantum dots are specifically stable in air; the method is low in cost, easy to operate, and not strict in environment requirement.

Owner:HUAZHONG UNIV OF SCI & TECH +1

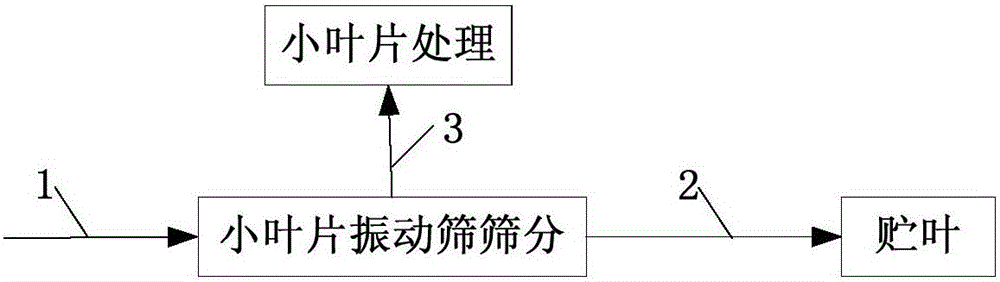

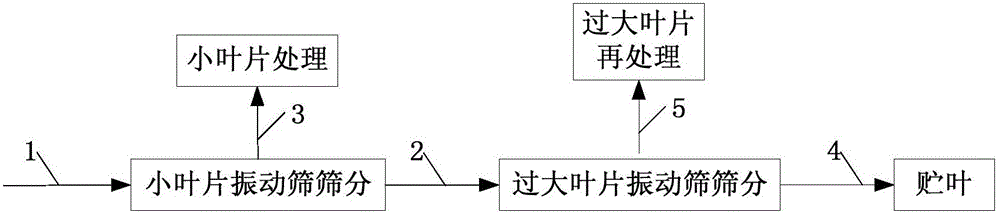

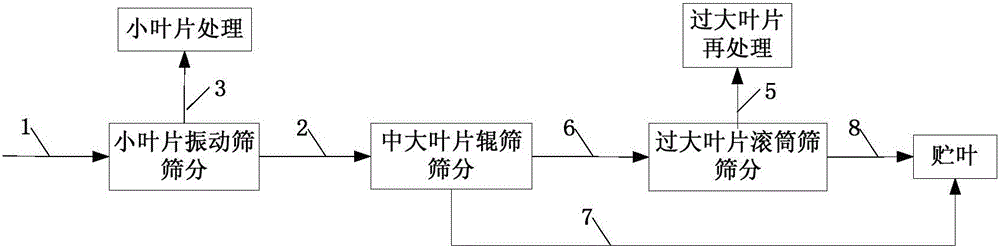

A combined screening method and device for blades after beating

The invention provides a threshed leaf combination sieving method and device. The method comprises the following steps: 1 feeding threshed and stemmed leaves to a vibration sieve to sift out small leaves; 2, feeding leaves on the vibration sieve to a roller sieve to sift out middle leaves; 3, feeding the leaves on the roller sieve to a drum sieve to divide the leaves into large leaves and overlarge leaves. Due to the adoption of the method, the overlarge threshed leaves can be accurately sieved out for reprocessing, so as to improve the size distribution of the threshed leaves.

Owner:CHINA TOBACCO FUJIAN IND

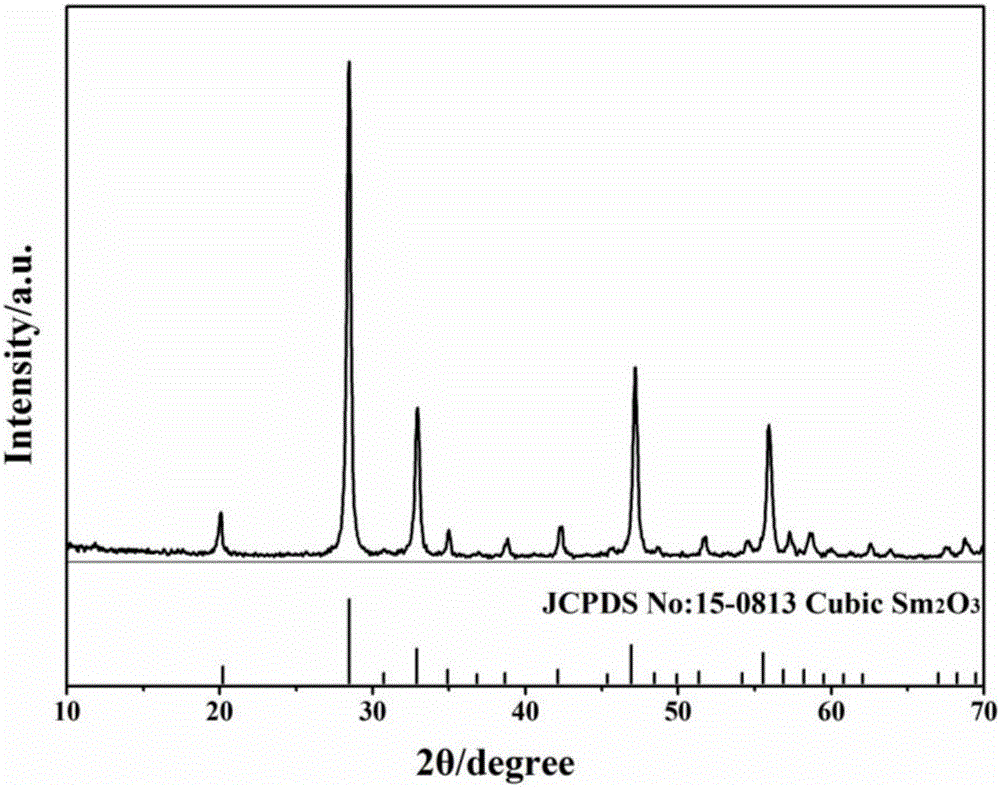

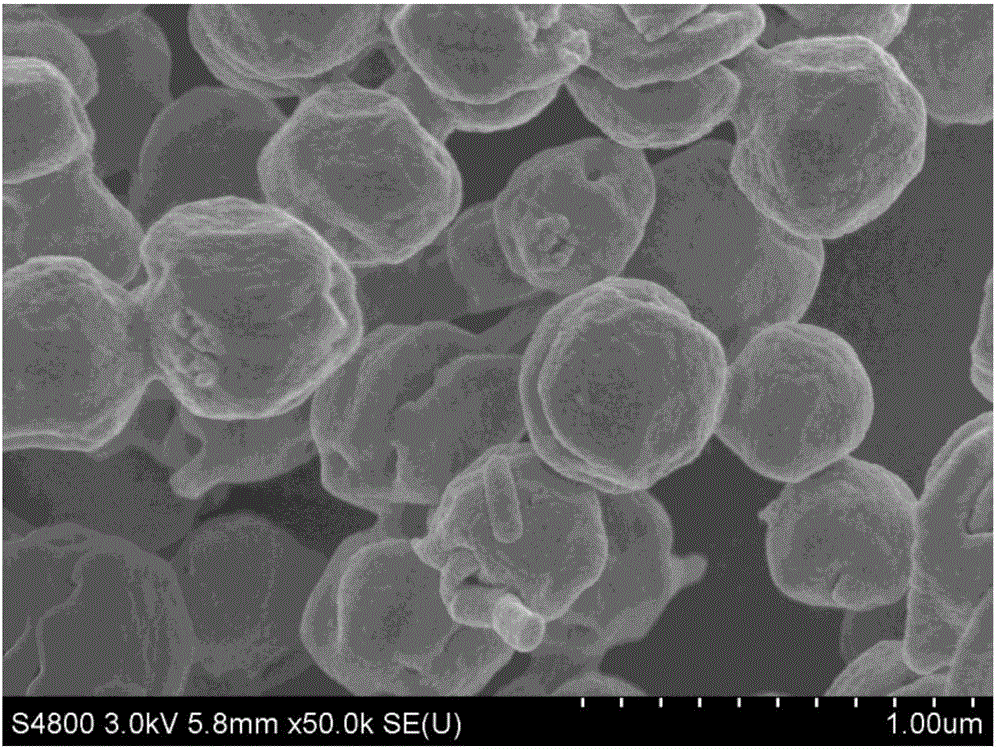

a sm 2 o 3 Preparation method of nanocrystal

InactiveCN105858707BHigh purityHigh crystallinityRare earth metal oxides/hydroxidesDispersityRoom temperature

The invention relates to a preparing method for Sm2O3 nanocrystalline. The preparing method includes the steps that a Sm(NO3)3 solution and a CO(NH2)2 solution are mixed uniformly to form a reaction precursor solution, wherein the molar ratio of Sm(NO3)3 to CO(NH2)2 is (0.02-0.06):(0.01-0.03); the reaction precursor solution reacts at the temperature of 120-180 DEG C to generate precipitate, and the reaction product is naturally cooled to the room temperature after reaction is finished; the precipitate is separated, washed and dried to obtain a precursor; the precursor is calcined at the temperature of 450-600 DEG C for 1-2 h to obtain the Sm2O3 nanocrystalline. Sm(NO3)3 is used as a samarium source, CO(NH2)2 is used as an alkali source, pure cubic-phase spherical Sm2O3 nanocrystalline is prepared at the low heat treatment temperature of 450-600 DEG C through a hydrothermal-heat treatment method, energy consumption is low, and surfactant for controlling morphology is not needed. The obtained Sm2O3 nanocrystalline is high in purity and crystallinity, uniform in size distribution and good in dispersity.

Owner:SHANGLUO UNIV

Method for producing hydrophilic poly-N-vinylpyrrolidone and use thereof

InactiveUS8735496B2Good chemical stabilityImprove solubilityChromatographic separationDispersion polymerization

The present invention relates to a process for the production of the largest possible spherical, monodisperse polyvinylpyrrolidone (PVP) seed particles in the micron range by dispersion polymerisation. The particles obtained in this way represent novel starting materials for the production of macroporous polymer particles, which can in turn be employed in preparative and analytical chromatography for protein preparation. They can also be employed as base material for further reactions.The novel process for the polymerisation of N-vinylpyrrolidone, which is inexpensive to carry out, gives particles having optimised quantities, such as monodispersity, sphericity and particle diameter, which can be employed in further reactions and have advantageous, in particular improved, properties for use in chromatographic separation methods.

Owner:MERCK PATENT GMBH

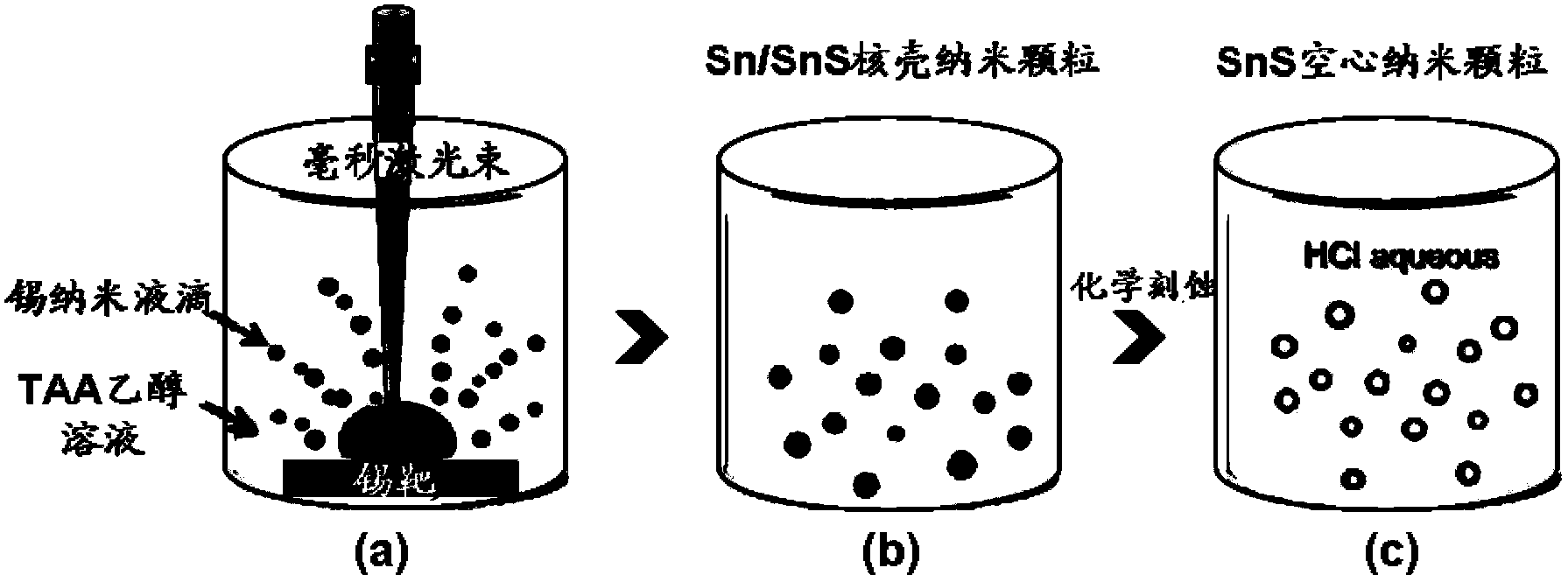

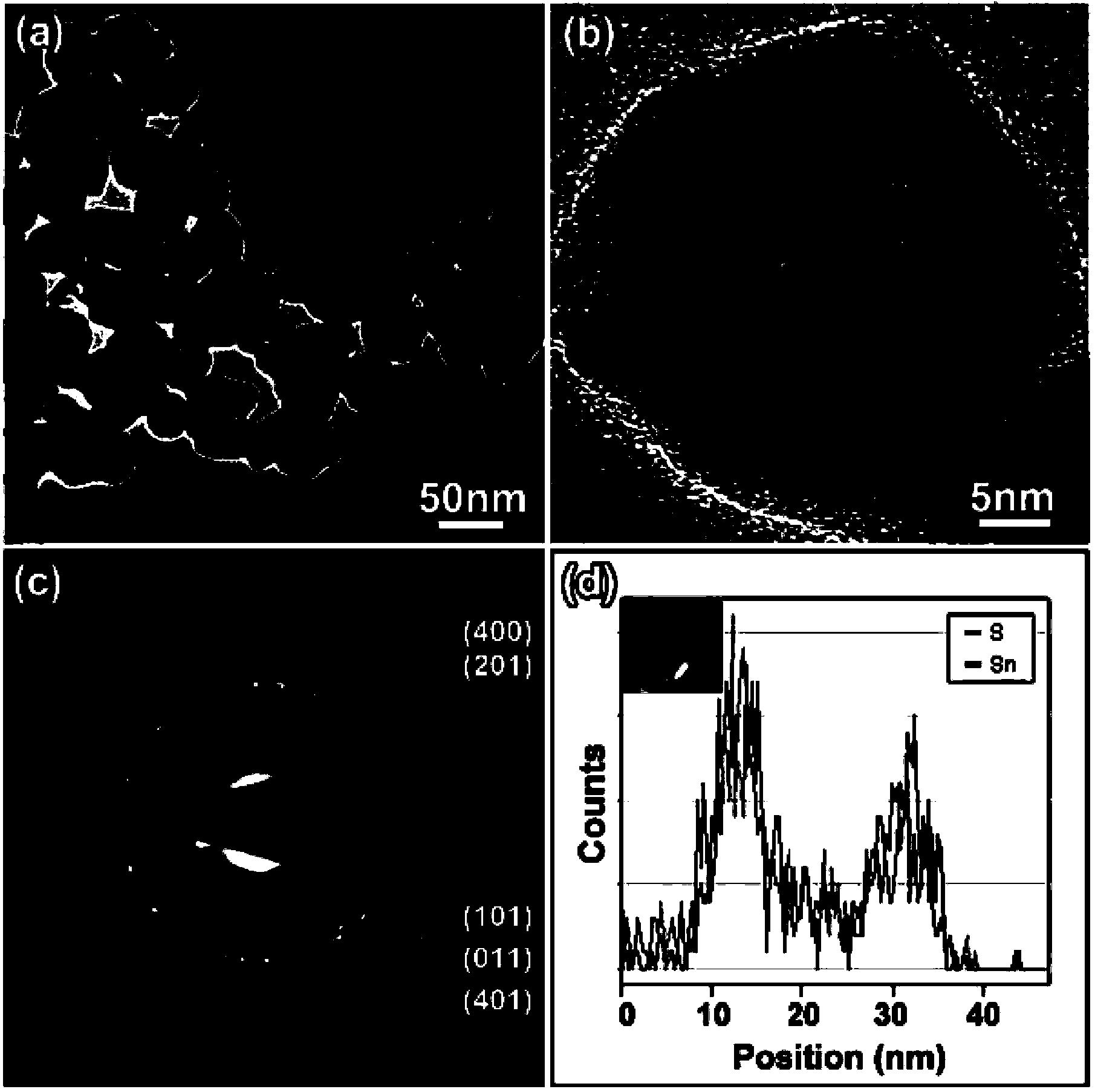

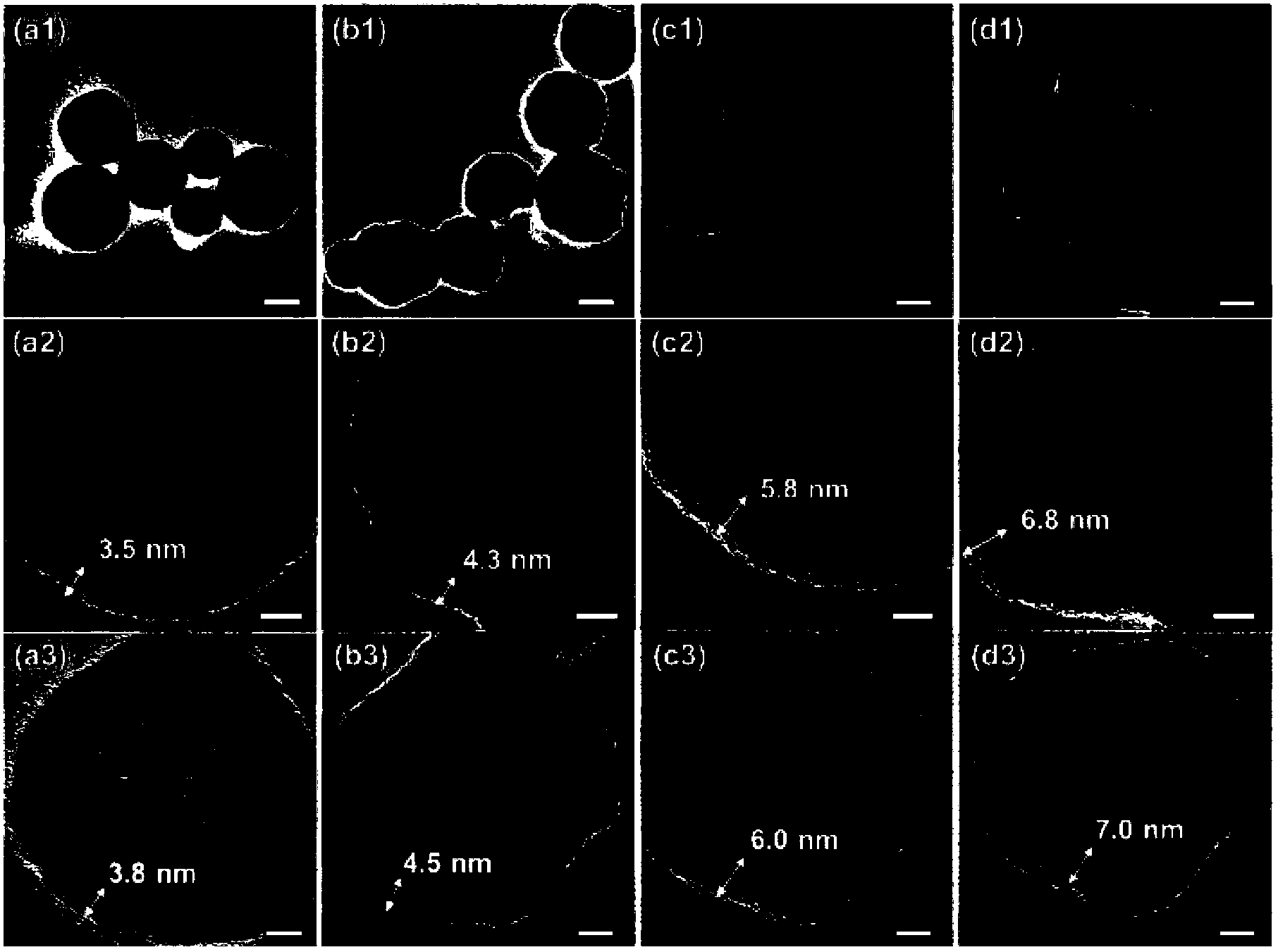

Preparation method for colloidal stannic sulfide hollow nanoparticles

The invention discloses a preparation method for colloidal stannic sulfide hollow nanoparticles. The preparation method comprises the steps as follows: taking a block-shaped metal tin target as a raw material; placing the block-shaped metal tin target into a sulfur source-containing ethanol solution; and controllably synthesizing the high-purity colloidal stannic sulfide (SnS) hollow nanoparticles by utilizing a millisecond laser and chemical etching method in a liquid phase according to the characteristic of the surface reaction of the sputtered metal nanometer liquid drops and the surrounding liquid medias in the long-pulse millisecond laser liquid phase ablation technology. The preparation method is simple in process, convenient to operate and easy to control, doesn't have byproducts and impurities, belongs to normal pressure and temperature synthesis, and is an environment-friendly green synthesis process.

Owner:TIANJIN UNIV

Preparation method of spherical lithium manganese phosphate/carbon composite material

InactiveCN104916838ASize limitWell mixedMaterial nanotechnologyCell electrodesCarbon compositesHigh energy

The invention relates to a preparation method of a spherical lithium manganese phosphate / carbon composite material, wherein the lithium manganese phosphate material comprises all lithium manganese phosphate base materials which accord with the molecular formula LiMn1-xMxPO4. The preparation method comprises the following steps: using a manganese source compound, a phosphorus source compound, a lithium source compound, a doped compound and a small organic molecule carbon source as raw materials to prepare a lithium manganese phosphate precursor, and carrying out heat treatment on the precursor by the controlled crystallization roasting technology to obtain primary nano-particles of the lithium manganese phosphate / carbon composite material. By addition of the small organic molecule carbon source, electronic conductivity of the lithium manganese phosphate material is improved, and high current charge-discharge capability of the material is effectively enhanced. By introduction of doped ion, lattice distortion caused by Jahn-Teller effect is effectively inhibited, and cycle performance of the lithium manganese phosphate material is improved. The prepared spherical lithium manganese phosphate / capacitor carbon composite material has advantages of high energy density, high power density and good cycle performance.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com