Patents

Literature

130 results about "Sodium Molybdate Dihydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

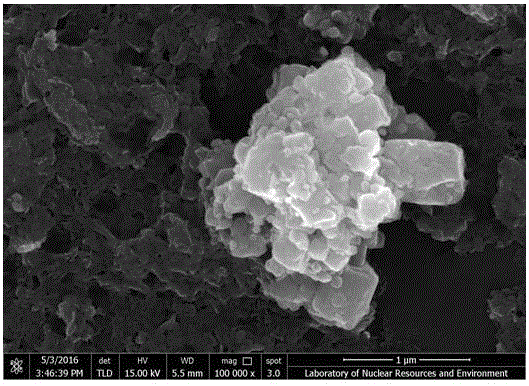

Preparation method of molybdenum disulfide/copper sulfide/cuprous oxide nano-composite material

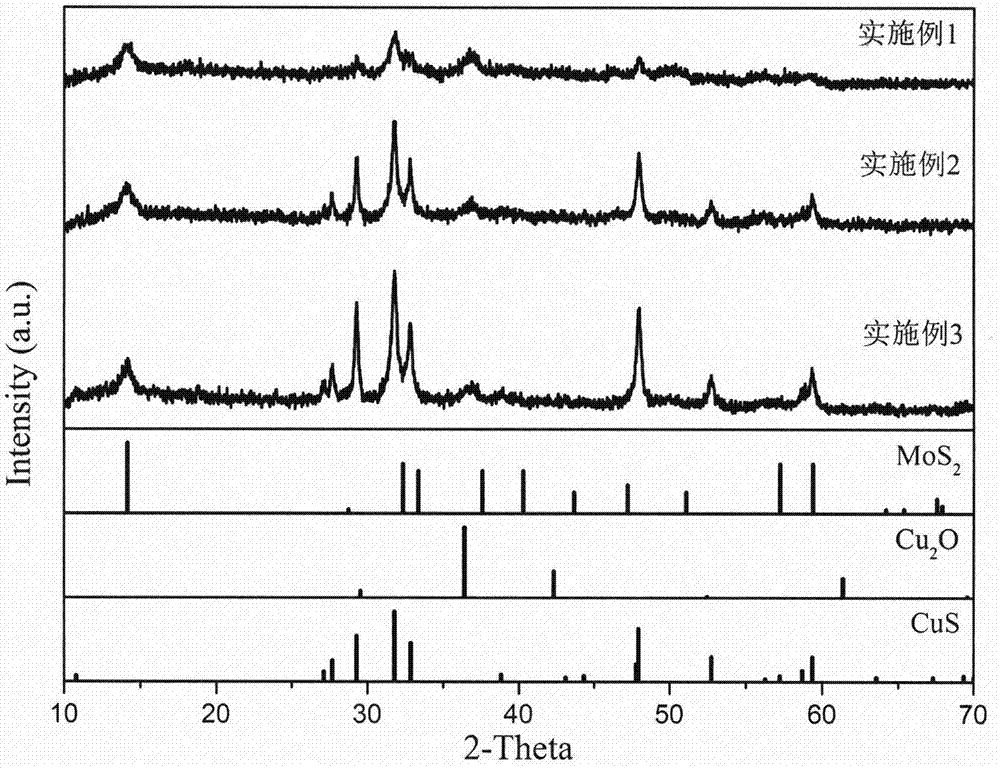

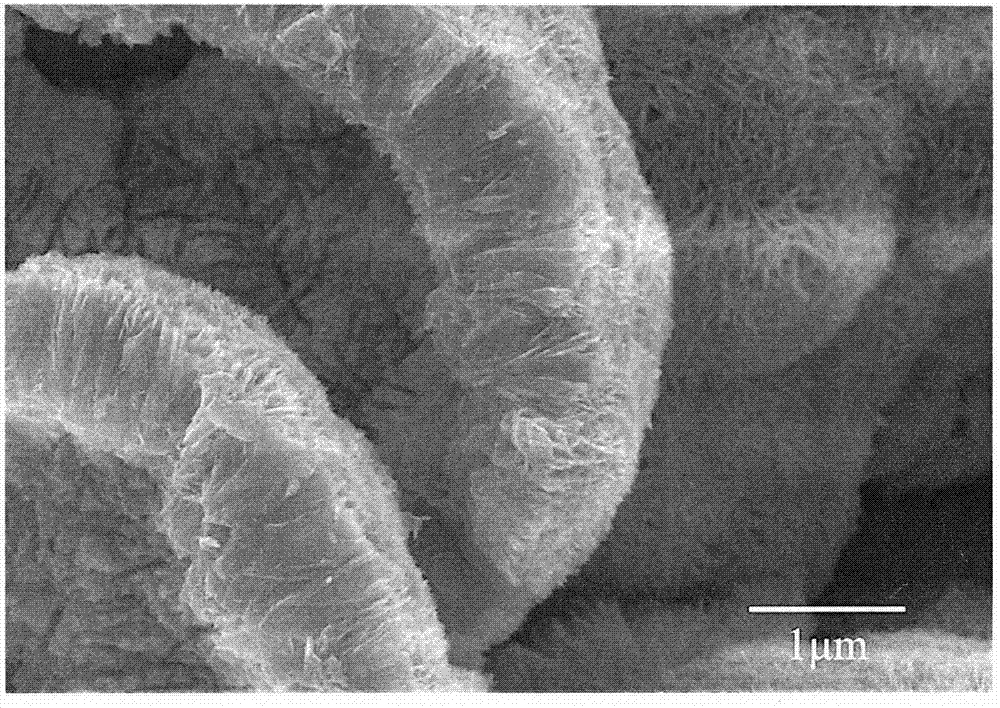

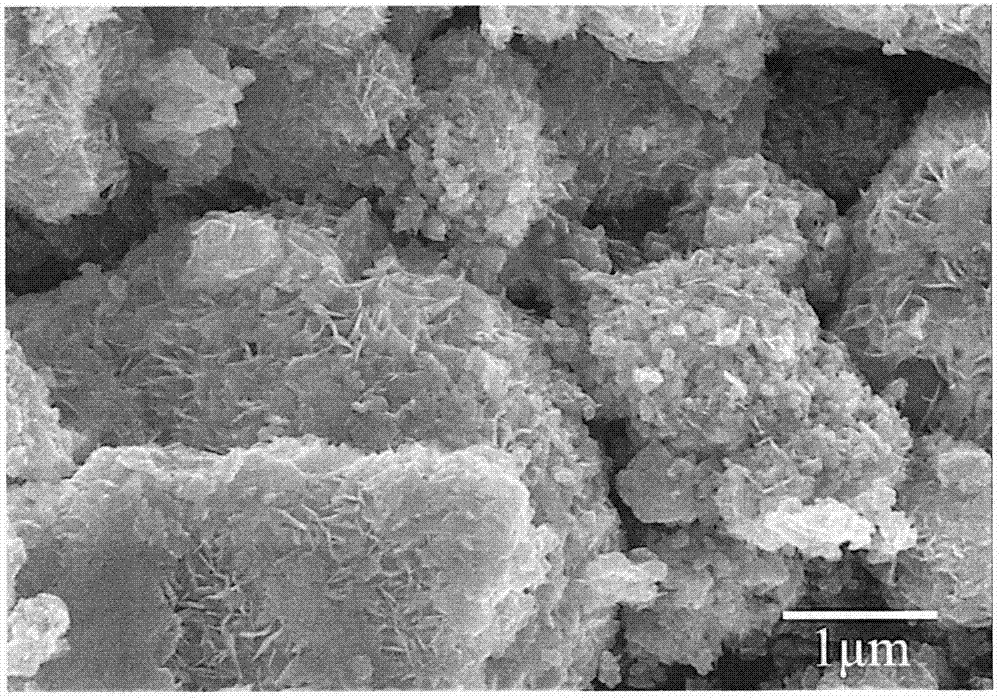

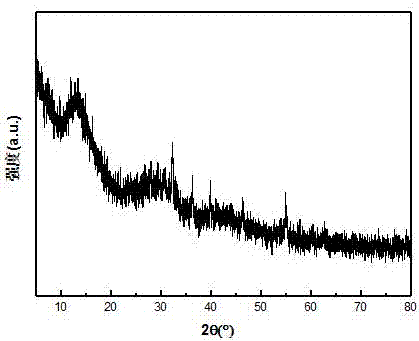

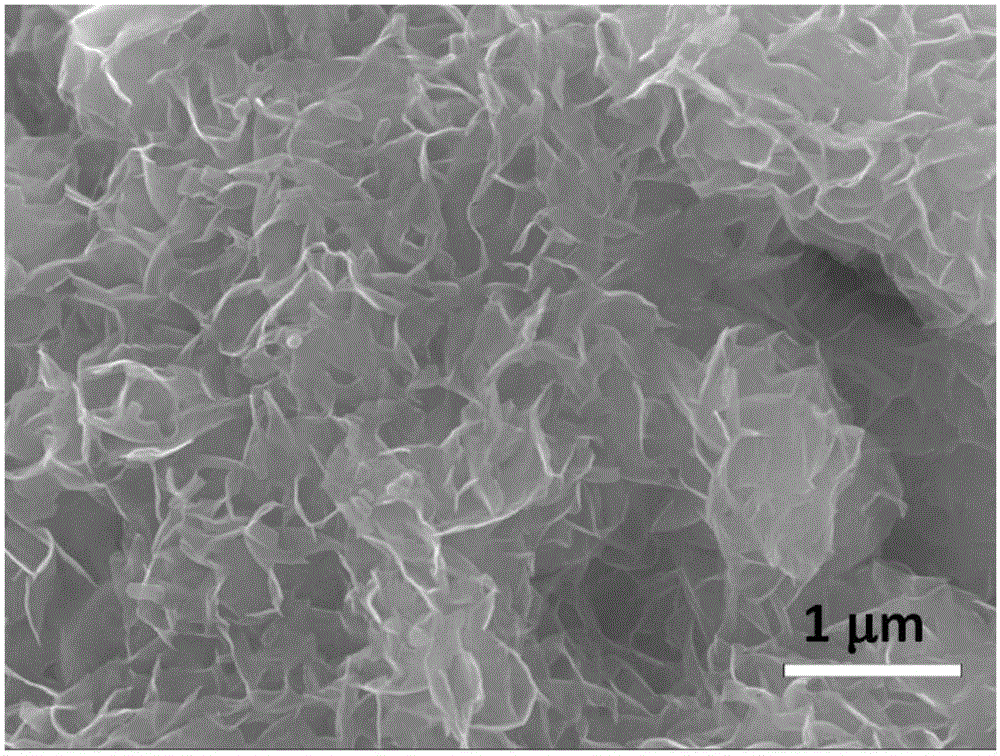

InactiveCN107089683AHigh crystallinitySimple processMaterial nanotechnologyPhysical/chemical process catalystsHeterojunctionThiourea

The invention discloses a preparation method of a molybdenum disulfide / copper sulfide / cuprous oxide nano-composite material. The preparation method comprises the steps of adding copper oxide into deionized water, stirring to form a mixture, adding sodium molybdate dihydrate, thiourea and CTAB, maintaining the temperature of a sample at a hydrothermal temperature of 220 DEG C for 24 hours, washing a product for five times by virtue of deionized water and ethanol, putting the product into a vacuum drying oven, and drying at a temperature of 60 DEG C, so as to obtain the molybdenum disulfide / copper sulfide / cuprous oxide nano-composite material. The molybdenum disulfide / copper sulfide / cuprous oxide nano-composite material prepared by virtue of a hydrothermal method has the characteristics of simple preparation process, good material crystallinity, high sample uniformity and the like. A formed nano-composite structure has semiconductor heterojunction features and is capable of inhibiting the compounding of light-generated electrons and holes and promoting the separation of the electrons and the holes, so that the nano-composite material has wide application prospects in the fields of photocatalysis and photovoltaic cells.

Owner:CHINA JILIANG UNIV

Composite hydrogen evolution electro-catalysis material and preparation method

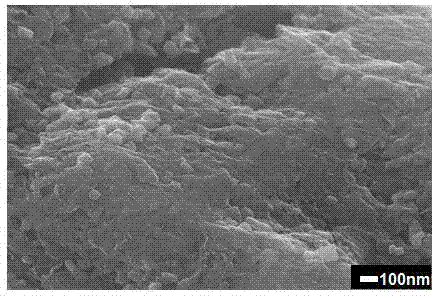

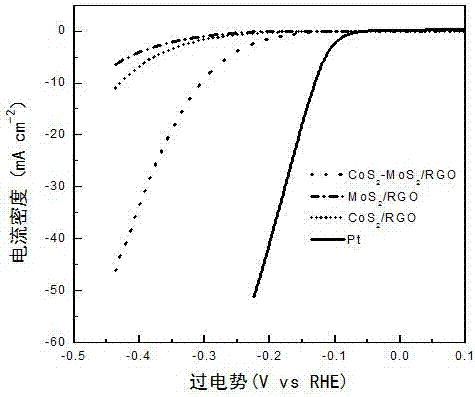

ActiveCN107881529AOvercome instabilityIncrease contact areaElectrodesElectronic transmissionThiourea

The invention relates to a molybdenum disulfide-cobalt disulfide / graphene composite hydrogen evolution electro-catalysis material and a preparation method and belongs to the field of electro-catalysishydrogen evolution. The molybdenum disulfide-cobalt disulfide / graphene composite hydrogen evolution electro-catalysis material is mainly prepared through the following steps that firstly, an advancedHummers method is adopted to prepare graphene oxide; then with sodium molybdate dihydrate, cobalt nitrate hexahydrate, thiourea, graphene oxide and deionized water as raw material, and through a one-step solvent thermal reaction method under 200 DEG C, the ternary molybdenum disulfide-cobalt disulfide / graphene composite hydrogen evolution electro-catalysis material is prepared; and the electro-catalysis hydrogen evolution performance is analyzed. The preparation method has the beneficial effects of being easy to operate, low in energy consumption and the like; transition metal of cobalt and molybdenum for use is low in price, and it is hopeful that the material is applied in industrial production; and besides, a electro-catalysis hydrogen evolution performance test shows that the preparedmolybdenum disulfide-cobalt disulfide / graphene composite hydrogen evolution electro-catalysis material is large in electronic transmission rate and good in hydrogen evolution performance.

Owner:JIANGSU UNIV

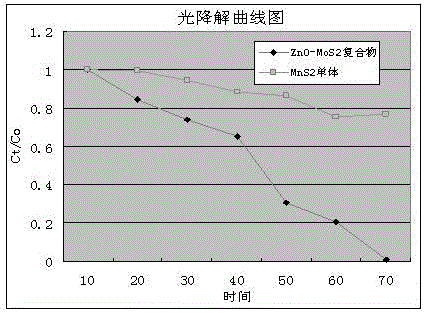

Preparation method of ZnO/MoS2 nanosheet compound photocatalyst

InactiveCN106391059AIncrease profitCompletely degradedPhysical/chemical process catalystsWater/sewage treatment by irradiationSodium molybdateWastewater

The invention relates to a preparation method of a ZnO / MoS2 nanosheet compound photocatalyst. The photocatalyst with low price and high efficiency is obtained by doping a small amount of zinc oxide into molybdenum disulfide; specifically the photocatalyst is prepared by reacting the zinc oxide, sodium molybdate dehydrate and thioacetamide through a hydrothermal method. The ZnO / MoS2 nanosheet compound in the invention can quickly degrade organic pollutants, particularly dye organic pollutes, in waste water into non-pollution substances such as H2O and CO2 under normal temperature, normal pressure and illumination, and the ZnO / MoS2 nanosheet compound has lasting photocatalytic activity.

Owner:NANCHANG HANGKONG UNIVERSITY

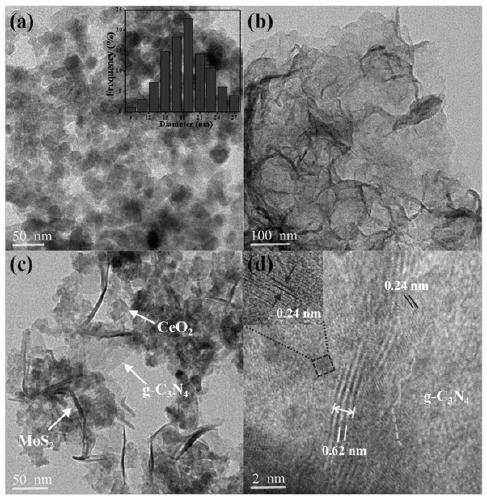

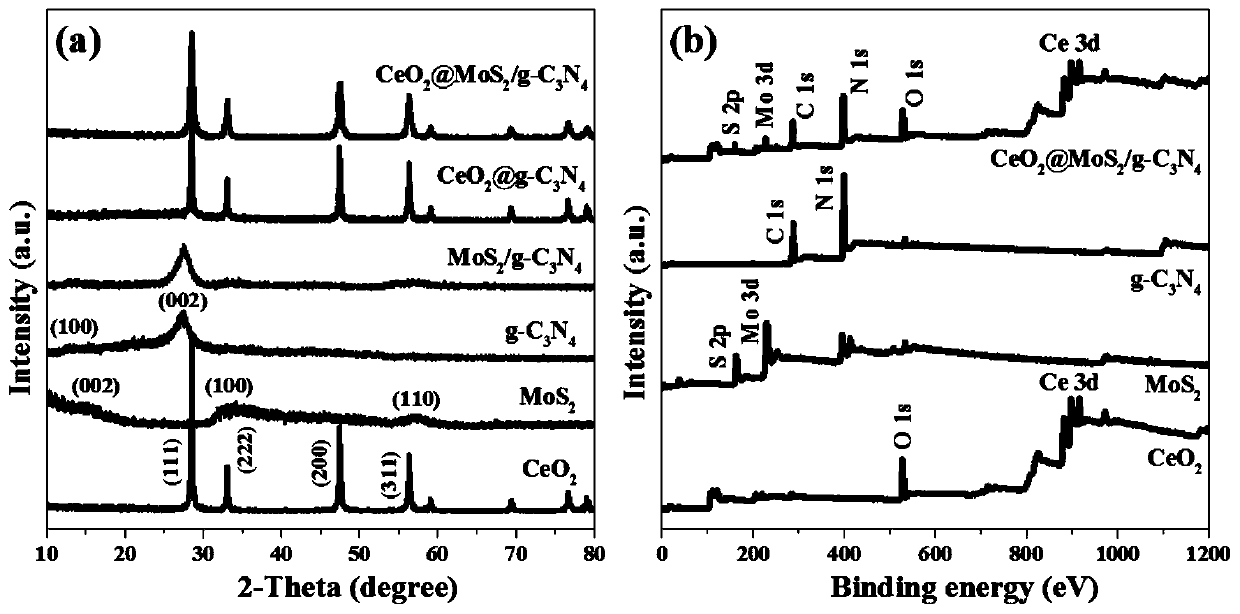

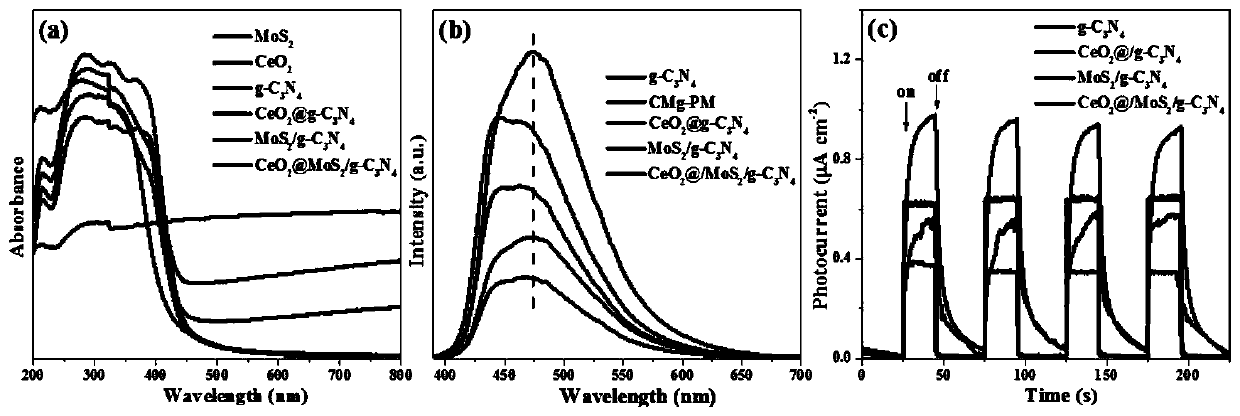

CeO2@MoS2/g-C3N4 ternary composite photocatalyst and preparation method thereof

ActiveCN110152711AImprove light responsivenessUnique two-dimensional nanostructureMaterial nanotechnologyWater/sewage treatment by irradiationNitrogen gasControllability

The invention belongs to the field of nano-material preparation, and discloses a CeO2@MoS2 / g-C3N4 composite photocatalysis material and a preparation method thereof. The preparation method comprises the following steps: (1) adding cerium oxide hexahydrate to a mixed solution of butylamine and toluene, carrying out hydrothermal treatment on the obtained mixed solution, and calcining the obtained reaction product to obtain CeO2 nanocrystals; (2) ultrasonically dispersing sodium molybdate dihydrate and g-C3N4 nanosheets in a mixed solution of L-cysteine and dimethyl sulfoxide, and carrying outhydrothermal treatment on the obtained mixed solution to obtain MoS2 / g-C3N4 nanosheets; (3) ultrasonically dispersing the CeO2 nanocrystals and MoS2 / g-C3N4 in a methanol solution, volatilizing the methanol, and collecting the obtained product to obtain a CeO2-MoS2 / g-C3N4 composite material; and (4) placing the CeO2-MoS2 / g-C3N4 composite material in a tubular furnace, and calcining in a nitrogen atmosphere to obtain the CeO2@MoS2 / g-C3N4 ternary composite photocatalyst. The preparation method of the invention is simple and has strong controllability, and the obtained composite photocatalyst hasan excellent photocatalytic degradation performance.

Owner:NANJING UNIV +1

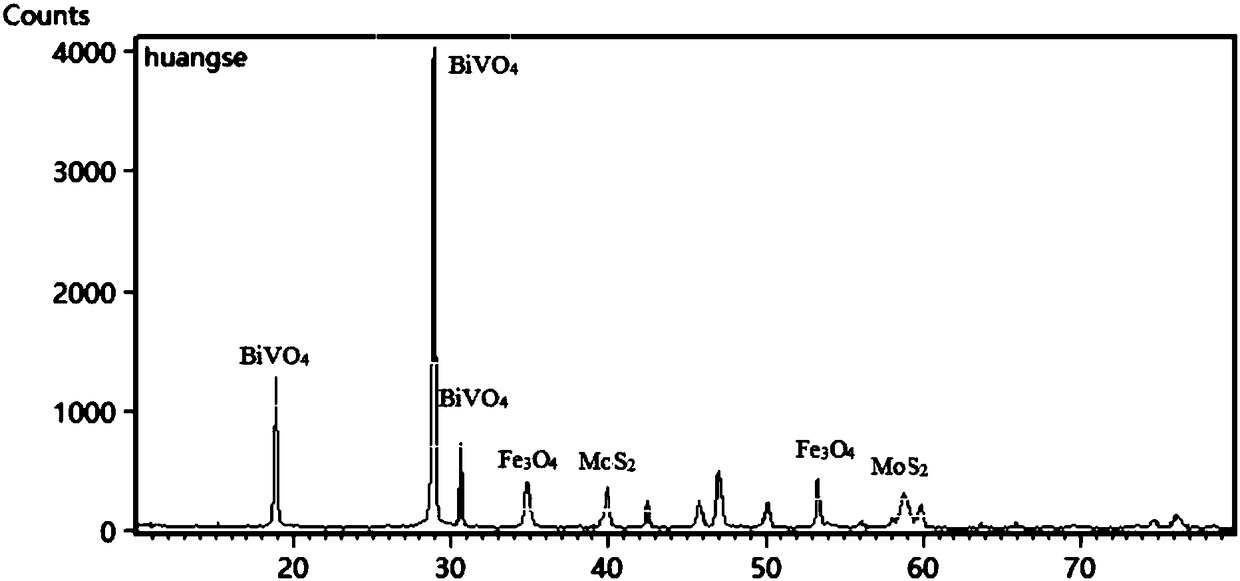

Fe3O4/MoS2/BiVO4 material preparing method, product and application of product

InactiveCN108355679AHigh reuse rateEasy to recycleWater/sewage treatment by irradiationWater treatment compoundsSodium acetateThiourea

The invention discloses a Fe3O4 / MoS2 / BiVO4 material preparing method, a product and an application of the product. The method comprises the steps: firstly, dissolving ferric chloride hexahydrate, sodium acetate and polyethylene glycol in ethylene glycol, carrying out a reaction at the temperature of 180-200 DEG C for 8-9 h, and thus obtaining ferric oxide; then, mixing sodium molybdate dehydrate,sodium molybdate tetrahydrate and thiourea evenly, adding ferroferric oxide, and carrying out a reaction for 22-24 h at the temperature of 180-200 DEG C, to obtain a Fe3O4 / MoS2 material; finally, dissolving bismuth nitrate pentahydrate and ammonium metavanadate in deionized water, adding the Fe3O4 / MoS2 material, mixing evenly, carrying out a reaction for 15-17 h at the temperature of 160-170 DEG C, and thus obtaining a Fe3O4 / MoS2 / BiVO4 composite material. When the composite material is used as a photocatalyst for treating tetracycline hydrochloride wastewater, the degradation rate can reach 90% or more, and the photocatalytic efficiency can be improved. At the same time, because of the presence of Fe3O4, the photocatalyst can be recovered more conveniently and simply for repeated experiments, the recovery cost of the photocatalyst is reduced, and the repeated utilization rate of the photocatalyst is improved.

Owner:CHANGAN UNIV

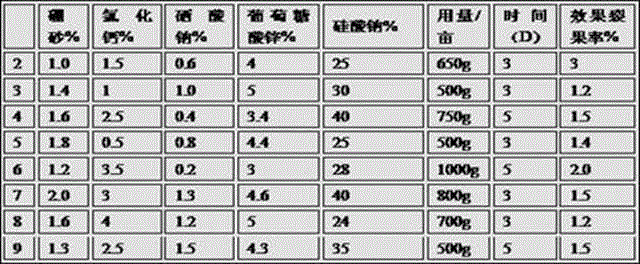

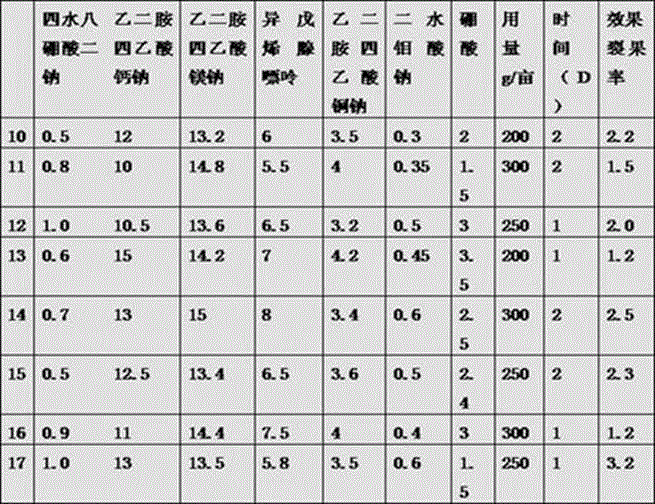

Method for preventing fruit cracking of melons

ActiveCN103329745APrevent fruit crackingImprove qualityHorticulture methodsFertilizer mixturesNucleotideGluconic acid

The invention discloses a method for preventing fruit cracking of melons. The method comprises the following steps of: spraying equal mass solutions of 800-1000 times of nucleotides and 800-1000 times of cytokinins on the melons and leaves per 3-5 days; or spraying anti-cracking agents on the melons per 3-5 days on the basis of 500-1000g / mu, wherein the anti-cracking agents are composed of 1-2 weight parts of sodium borates, 0.5-4 weight parts of CaCl2, 0.2-1.5 weight parts of sodium selenate, 3-5 weight parts of zinc gluconate, 20-40 weight parts of sodium silicate and the balance of water; or spraying the anti-cracking agents on the melons and the leaves per 1-2 days on the basis of 200-300g / mu, wherein the anti-cracking agents are composed of the following components by weight percent: 0.5%-1% of disodium octaborate tetrahydrate, 10%-15% of EDTA (ethylene diamine tetraacetic acid) calcium complex disodium salt, 13%-15% of EDTA magnesium complex disodium salt, 5-8% of isopentennyladenine, 3%-4% of disodium EDTA-copper, 0.3%-0.6% of sodium molybdate dihydrate, 1.5-3.5% of boric acids and the balance of water. According to the method provided by the invention, the fruit cracking is effectively prevented and the yield and quality are both high.

Owner:JIANGSU YANTENG AGRI DEV

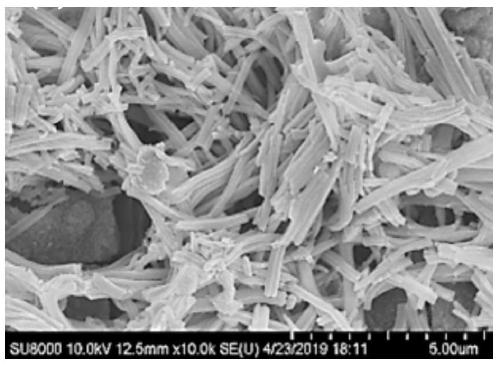

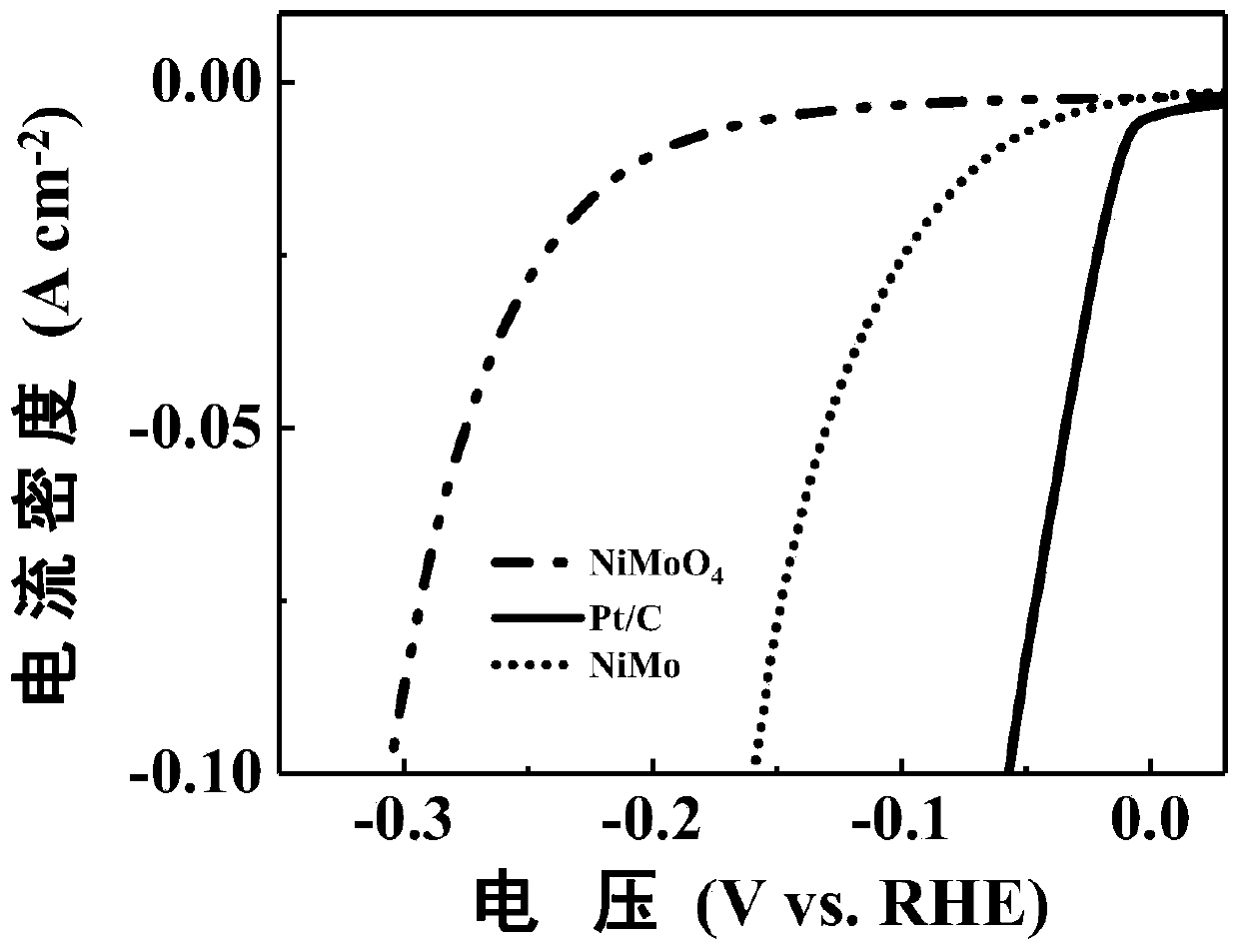

Preparation method of NiMo hydrogen evolution electrocatalyst

ActiveCN110227480APrecise Control of CompositionPerformance changes continuouslyMetal/metal-oxides/metal-hydroxide catalystsElectrodesNitrogen gasHeat treated

Belonging to the field of electrocatalytic hydrogen evolution, the invention discloses a preparation method of a NiMo hydrogen evolution electrocatalyst. The method includes: firstly preparing nickelnitrate hexahydrate and sodium molybdate dehydrate respectively into solutions; then transferring the two solutions into a reaction kettle, adding foamed nickel into the solutions, and carrying out hydrothermal reaction to obtain a nickel molybdate precursor material; then placing the prepared nickel molybdate precursor in a tubular furnace, and performing heat treatment in nitrogen atmosphere toobtain nickel molybdate; and finally, adopting nickel molybdate as the working electrode, taking a lithium sheet or sodium sheet as the counter electrode, using lithium hexafluorophosphate or sodium hexafluorophosphate as the electrolyte, conducting assembling to obtain a lithium battery or sodium battery, standing the battery for a set period of time, and then discharging the battery, thus obtaining the NiMo hydrogen evolution electrocatalyst. The method provided by the invention has no need for high temperature and strong reductant, has relatively mild process, and can precisely control thematerial composition.

Owner:HUAZHONG AGRI UNIV

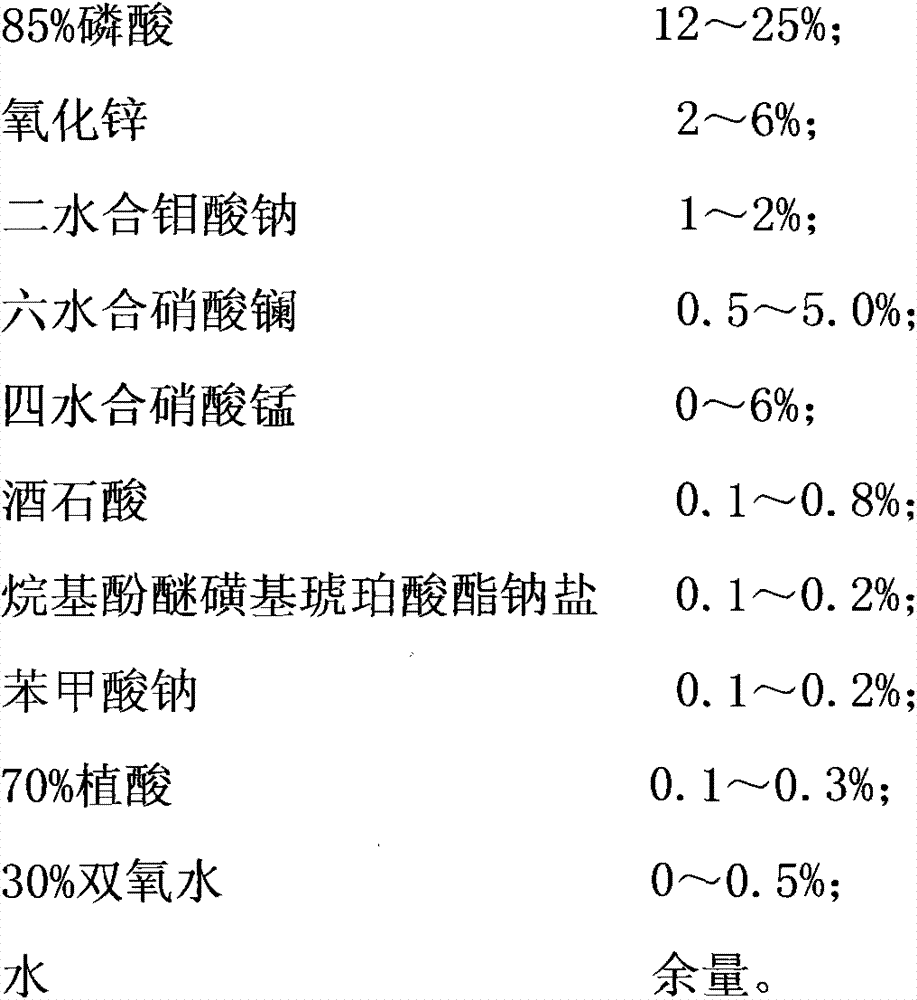

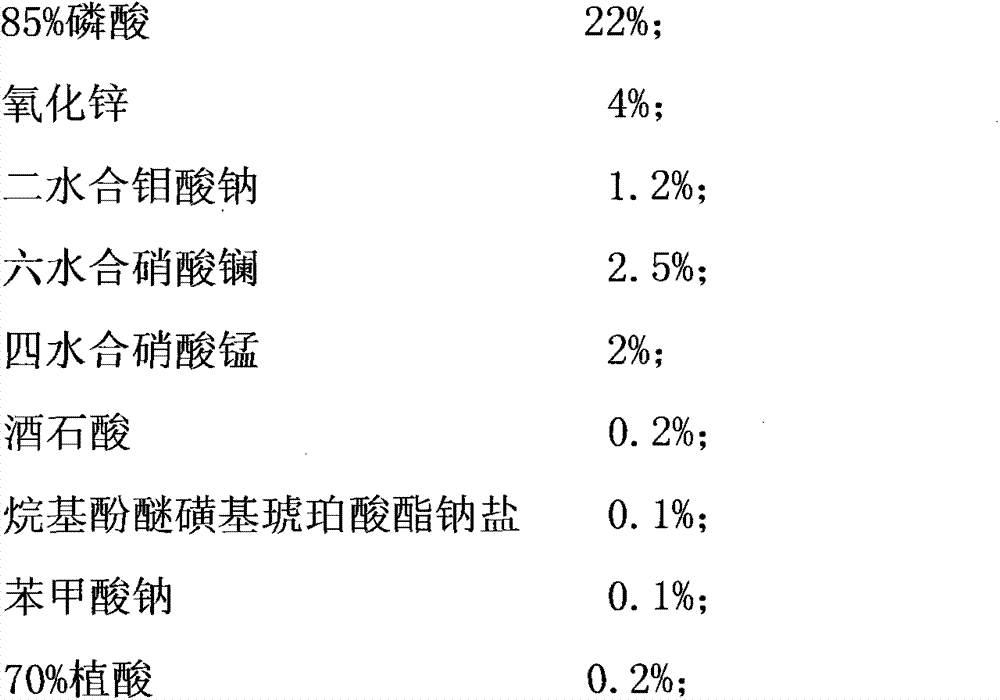

Washing-free normal-temperature phosphating solution after steel workpiece phosphating and preparation method thereof

ActiveCN103114282AImprove wettabilityImprove permeabilityMetallic material coating processesPhytic acidAlkylphenol

The invention relates to a steel surface treating agent, particularly a washing-free normal-temperature phosphating solution after steel workpiece phosphating, which is prepared by mixing the following raw materials in percentage by mass: 12-25% of 85% phosphoric acid, 2-6% of zinc oxide, 1-2% of sodium molybdate dihydrate, 0.5-5.0% of lanthanum nitrate hexahydrate, 0-6% of manganous nitrate tetrahydrate, 0.1-0.8% of tartaric acid, 0.1-0.2% of alkylphenol ether sulfosuccinate sodium salt, 0.1-0.2% of sodium benzoate, 0.1-0.3% of 70% phytic acid, 0-0.5% of 30% oxydol and the balance of water. The preparation method comprises the following steps: adding zinc oxide into 2 times by mass of water, stirring into paste, adding 85% phosphoric acid, and stirring to a uniform transparent state; while stirring, sequentially adding phytic acid and tartaric acid which is dissolved in water, lanthanum nitrate hexahydrate and manganous nitrate tetrahydrate which are respectively dissolved in water, sodium molybdate dihydrate which is dissolved in water, the other raw materials except sodium benzoate, and sodium benzoate dissolved in hot water; regulating the pH value of the solution to 2.0; and adding water to the required amount.

Owner:湖南中皖骏环保科技有限公司

Molybdenum disulfide/tin disulfide/graphene composite and preparation method thereof

InactiveCN108539175AInhibition of agglomerationImprove conductivityCell electrodesGrapheneSulfurCvd graphene

The invention discloses a molybdenum disulfide / tin disulfide / graphene composite and a preparation method thereof. Molybdenum disulfide / tin disulfide grows on the surface of graphene in a manner of horizontal interface contact growth; with graphene oxide as a carbon source, tin chloride pentahydrate as a tin source, sodium molybdate dihydrate as a molybdenum source and thioacetamide as a sulfur source, the carbon source, tin source, molybdenum source and sulfur source are added sequentially into deionized water and heated at 200 DEG C for 16h to synthesize the molybdenum disulfide / tin disulfide / graphene composite. The molybdenum disulfide / tin disulfide / graphene composite has a stable structure and high electrical conductivity, and has the advantages of large specific surface area and excellent electrochemical performance; the preparation method has low requirements on reaction conditions, simple operation, high yield and good repeatability.

Owner:CHINA JILIANG UNIV

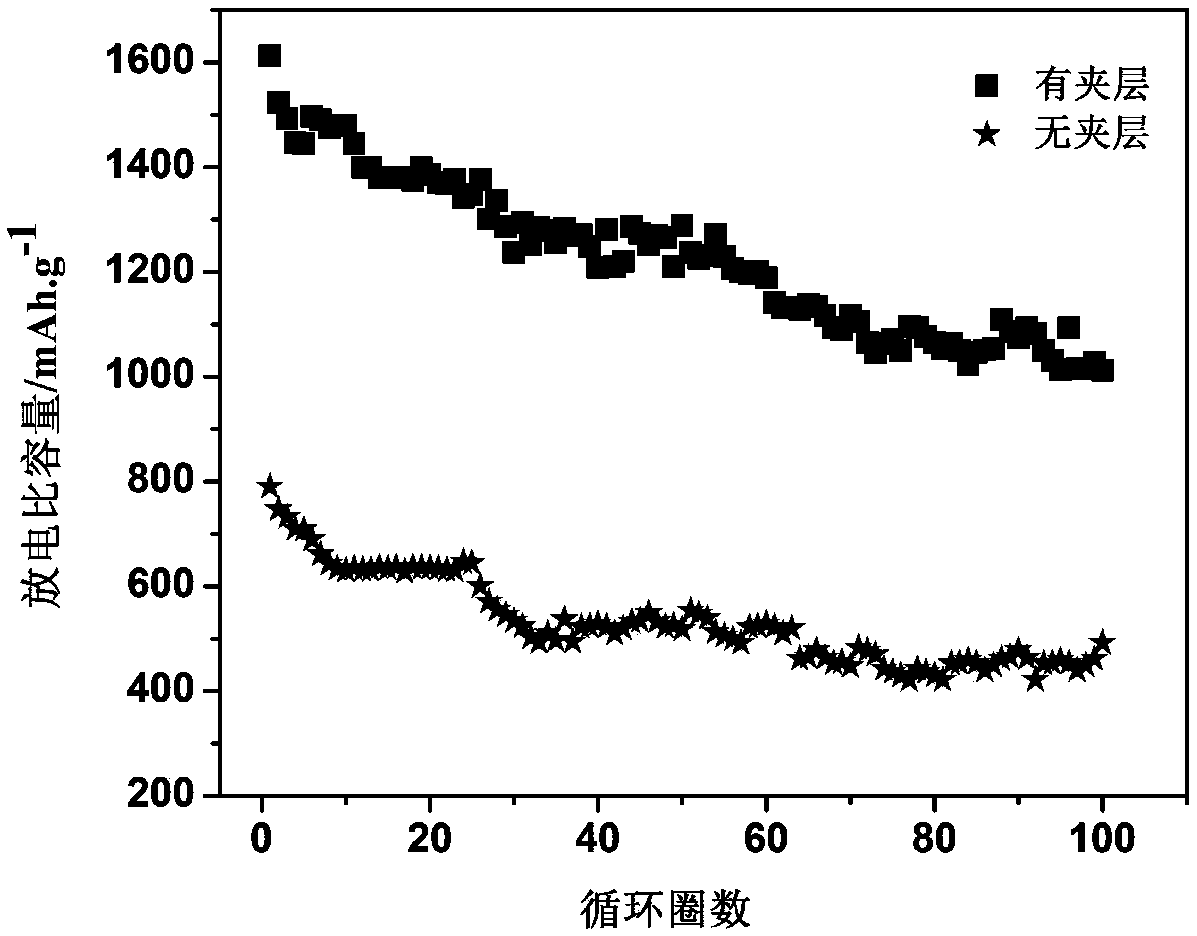

Preparation method of lithium-sulfur battery sandwich layer material

ActiveCN108598410ASmall particle sizeEvenly distributedCell electrodesSecondary cellsIonSodium Molybdate Dihydrate

The invention discloses a preparation method of a lithium-sulfur battery sandwich layer material. The preparation method comprises the following steps of (1) enabling sodium molybdate dihydrate and thiourea to be added to deionized water to prepare into a mixed solution A; in addition, enabling copper chloride dihydrate (and thiourea) to be added to deionized water to obtain a solution B; and (2)enabling the A solution to be mixed with the B solution to obtain a solution C, enabling the solution C to be added to a GO solution to be mixed to obtain a mixed solution D; and transferring the mixed solution D to a reaction kettle which takes polytetrafluoroethylene as a substrate, putting the reaction kettle into a drying oven, and performing heat preservation at a temperature of 180-220 DEG Cfor 2-30h to obtain the lithium-sulfur battery sandwich layer material. By adoption of the preparation method, the shortcomings of obvious "shuttle effect" of polysulfide in the lithium-sulfur battery prepared in the prior art, high volume expansion effect of the lithium-sulfur battery, instable electrochemical performance of the battery and the like are overcome, and the production process is simplified.

Owner:HEBEI UNIV OF TECH +1

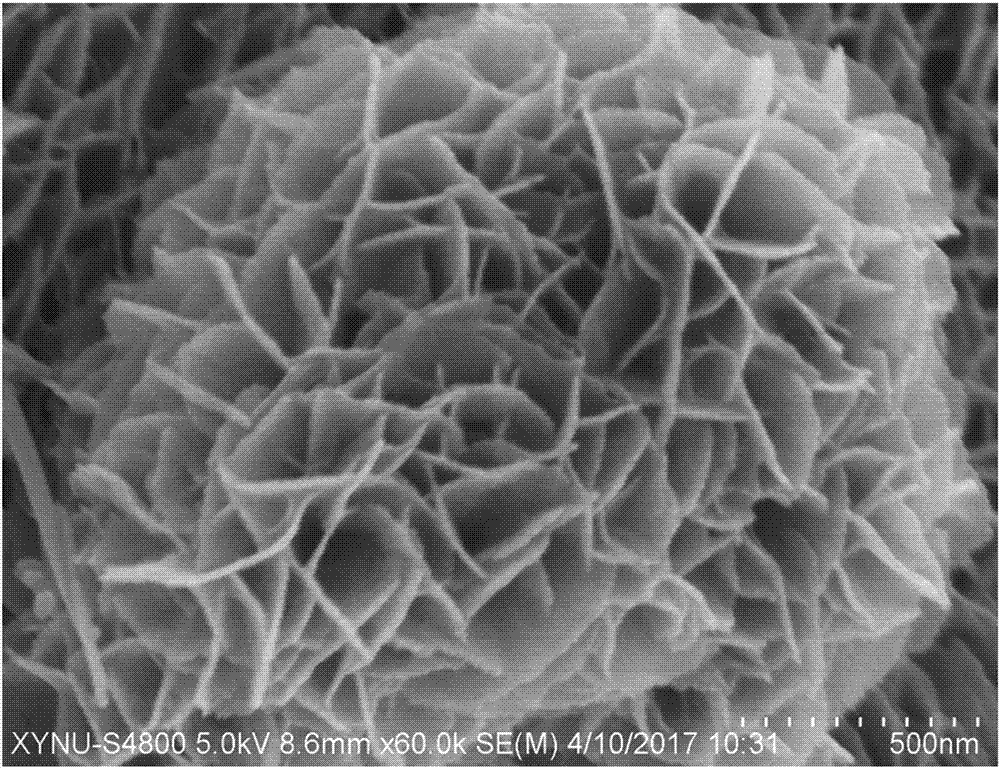

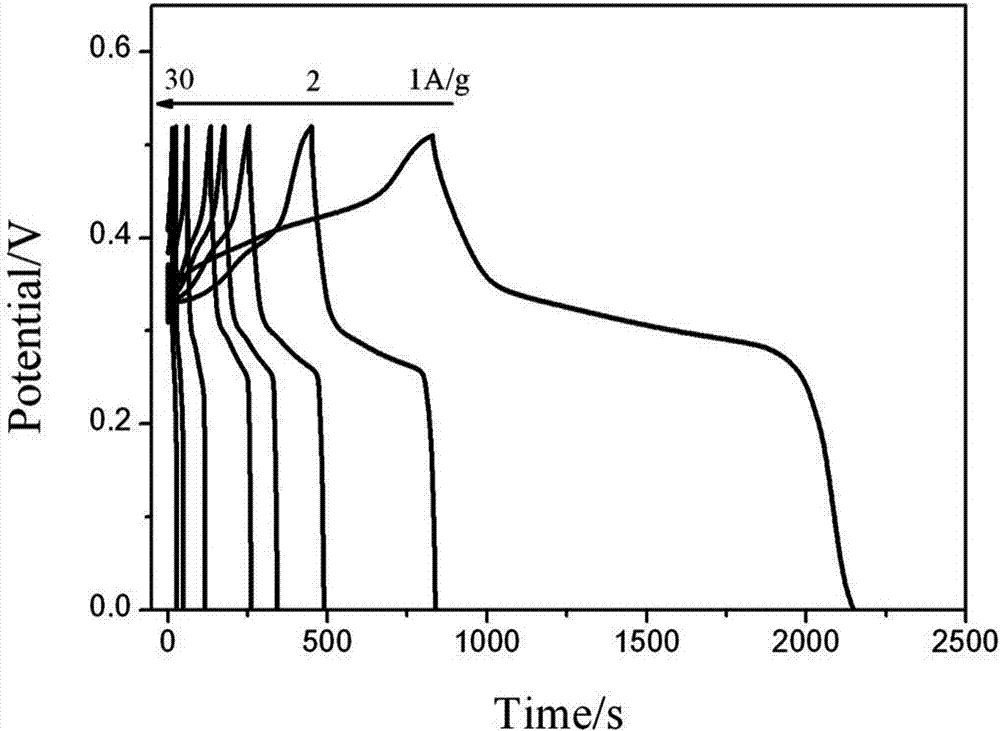

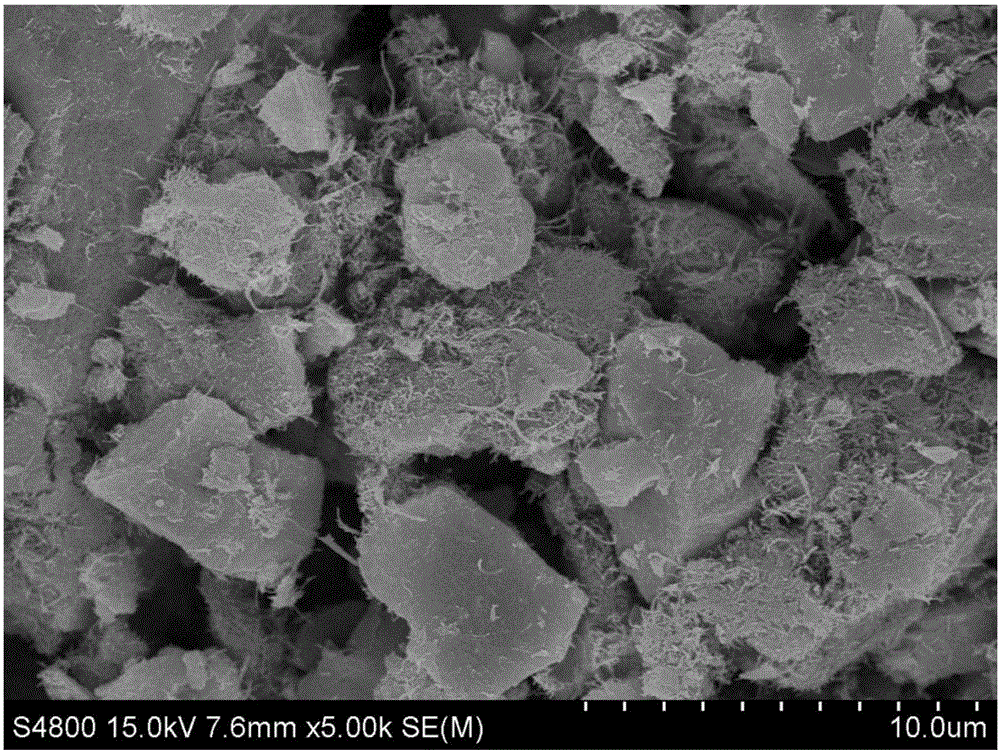

Preparation method of supercapacitor electrode material multilayer petal-shaped nickel molybdate

InactiveCN107978460AImprove electrochemical stabilityLower internal resistanceMaterial nanotechnologyHybrid capacitor electrodesArgon atmosphereInternal resistance

The present invention discloses a preparation method of supercapacitor electrode material multilayer petal-shaped nickel molybdate. The preparation method comprises the following steps of: (1) preparing precursor solution by employing nickel nitrate hexahydrate, sodium molybdate dihydrate, deionized water and 15ml of 95% ethanol; (2) stirring the solution by employing a glass bar for 15-20 minutes, employing a supersonic cleaner to perform ultrasonic acceleration dissolution for 30-35 minutes, then transferring the solution into a high-pressure reaction vessel inner container, sealing the high-pressure reaction vessel inner container, and putting the high-pressure reaction vessel inner container into a constant temperature air dry oven for hydro-thermal synthesis reaction; (3) taking out the completely reacted solution to perform natural cooling to a room temperature, and performing centrifugal cleaning of the solution by rotating distilled water and absolute ethyl alcohol at a certainrotating speed in a high-speed centrifuge; (4) putting cleaned yellow-green substances into a vacuum drying box for cleaning; and (5) performing calcining of products in a tube furnace argon atmosphere in a certain heating rate and a certain temperature, and obtaining target products. The electrode materials are relatively good in electrochemical stability, has multi-layer structure capable of reducing internal resistance, is rapid in charge, is energy saving and environmentally friendly, and has a great research value and application prospect.

Owner:XINYANG NORMAL UNIVERSITY

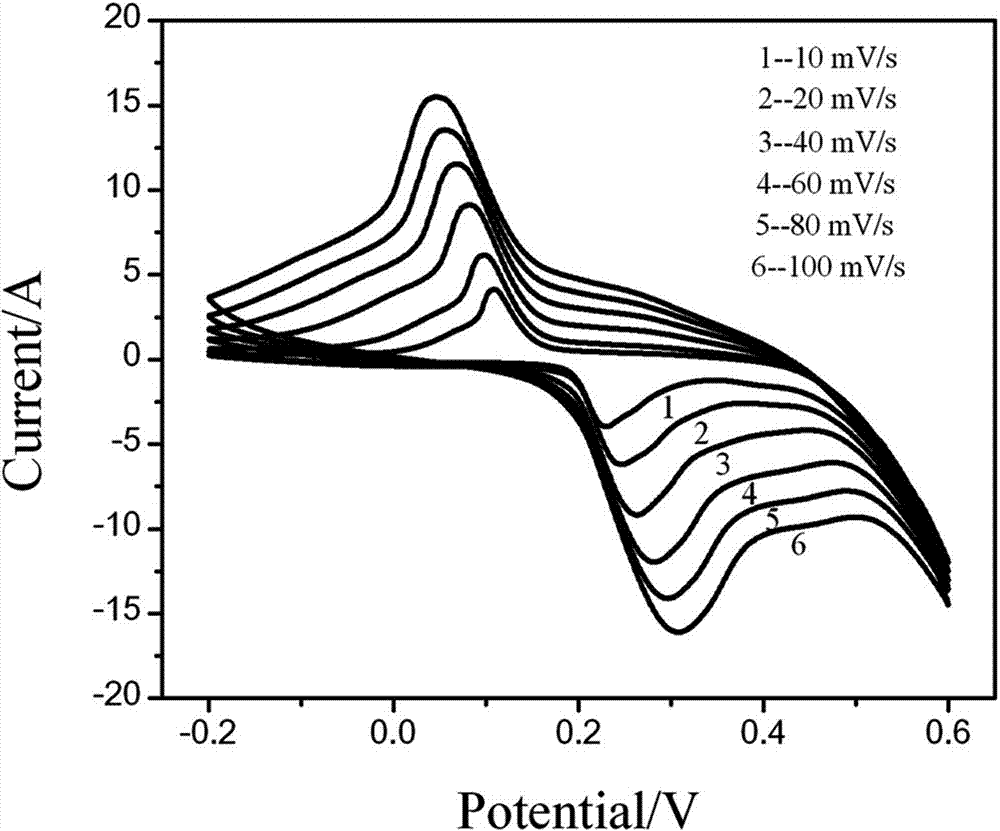

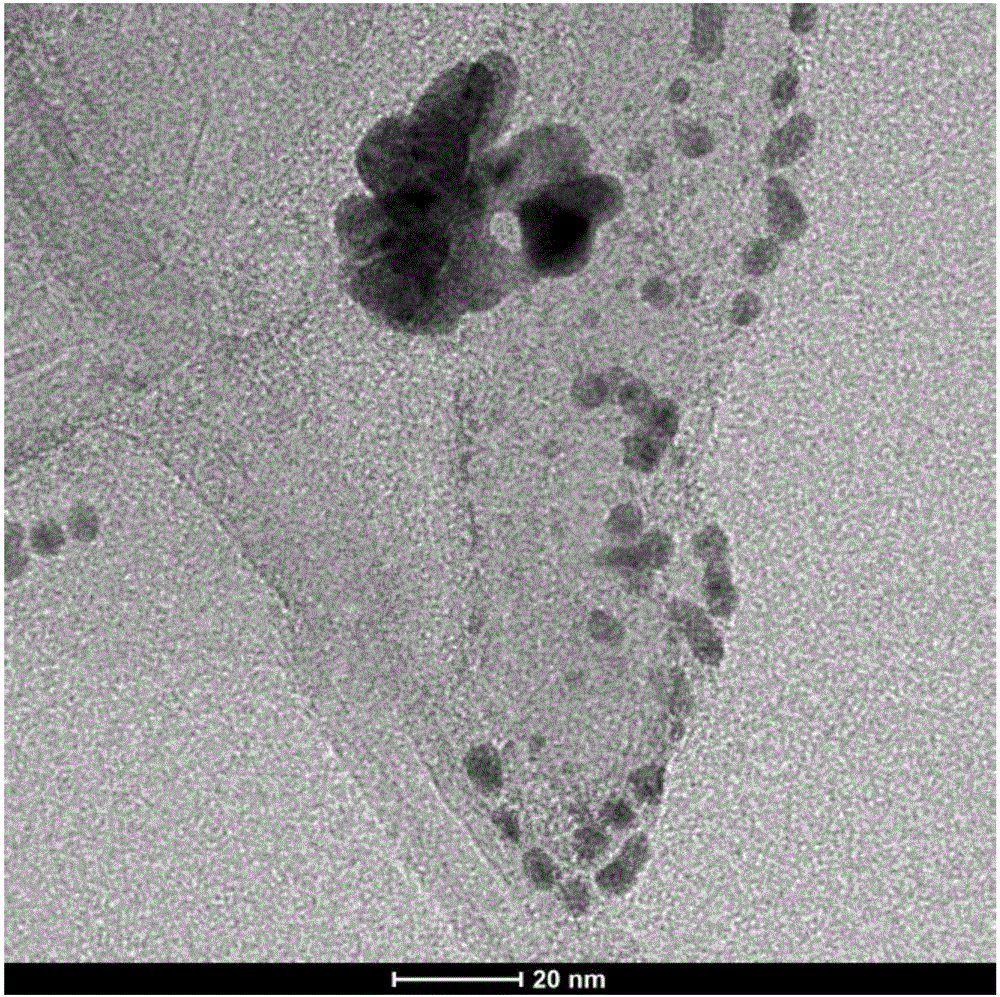

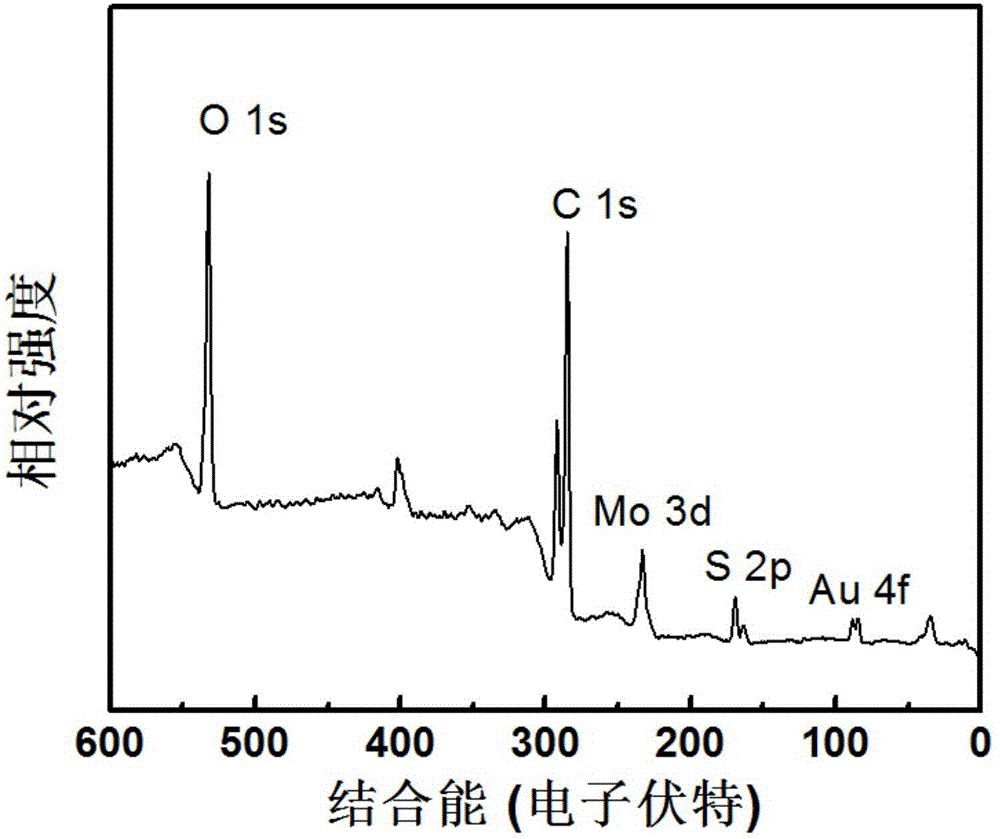

Molybdenum sulfide multi-walled carbon nanotube gold modified glassy carbon electrode

InactiveCN106770548AImprove catalytic performanceReasonably control the amount of depositionMaterial electrochemical variablesElectrolysisThiourea

The invention discloses a molybdenum sulfide multi-walled carbon nanotube gold modified glassy carbon electrode. A preparation method comprises the following steps of dispersing a multi-walled carbon nanotube into a solution of thiourea and a sodium molybdate dihydrate, uniformly agitating an obtained first mixture, and then transferring the first mixture into a high-pressure reaction kettle to carry out a reaction; centrifugally separating an obtained reaction product, and then washing the reaction product by using ethyl alcohol and deionized water; oven-drying the reaction product to obtain a molybdenum sulfide multi-walled carbon nanotube finished product; taking and dispersing a molybdenum sulfide multi-walled carbon nanotube compound in mixed liquor of water, ethyl alcohol and perfluorosulfonic acid, and dropwise coating the clean surface of a glassy carbon electrode with an obtained second mixture; naturally air-drying the glassy carbon electrode, and then using the glassy carbon electrode as a working electrode to form a three-electrode system with a platinum wire and a saturated calomel electrode; putting the three-electrode system in a sulfuric acid solution containing chloroauric acid, and carrying out constant-potential electrolysis, so as to obtain a molybdenum sulfide multi-walled carbon nanotube gold nano compound modified glassy carbon electrode. Proven by a result, a molybdenum sulfide multi-walled carbon nanotube gold nano compound can be used for the effective catalytic oxidation of nitrite, is used for detecting the nitrite conveniently and quickly, is high in sensitivity and is wide in concentration detection range.

Owner:YANGZHOU UNIV

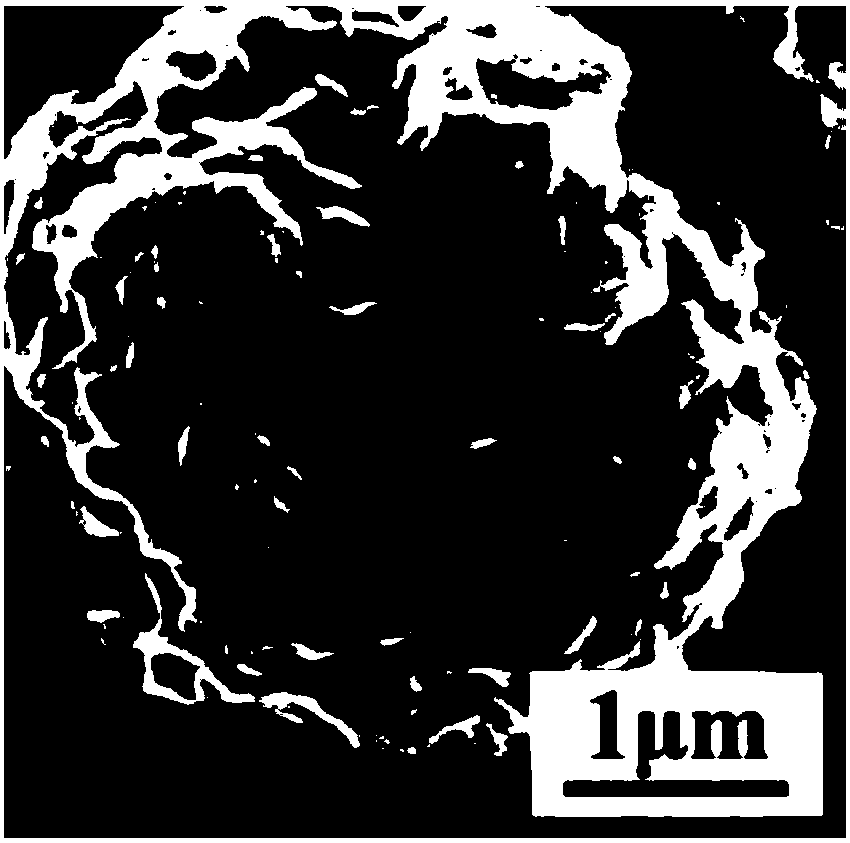

Hollow hybrid microsphere for negative electrode material of lithium ion battery and preparation method

ActiveCN109449399AAvoid damageIncrease contactCell electrodesSecondary cellsMicrosphereCarbonization

The invention belongs to the field of new materials, and particularly relates to a hollow hybrid microsphere for a negative electrode material of a lithium ion battery and a preparation method thereof. The hybrid microsphere takes monodisperse polystyrene microspheres as a template; and hydrolysis of tetrabutyl titanate on the surface of the microsphere, polymerization of dopamine on the surface of the microsphere, hydrothermal treatment in the presence of sodium molybdate dihydrate and a high-temperature carbonization process are carried out in sequence so as to prepare a TiO2 / C / MoS2 hollow hybrid microsphere. When the microsphere is used as a negative material of a lithium ion battery, high reversible capacity, excellent rate performance and excellent cycling stability are presented, anda wide application prospect is shown in the field of lithium ion batteries.

Owner:ZHENGZHOU UNIV

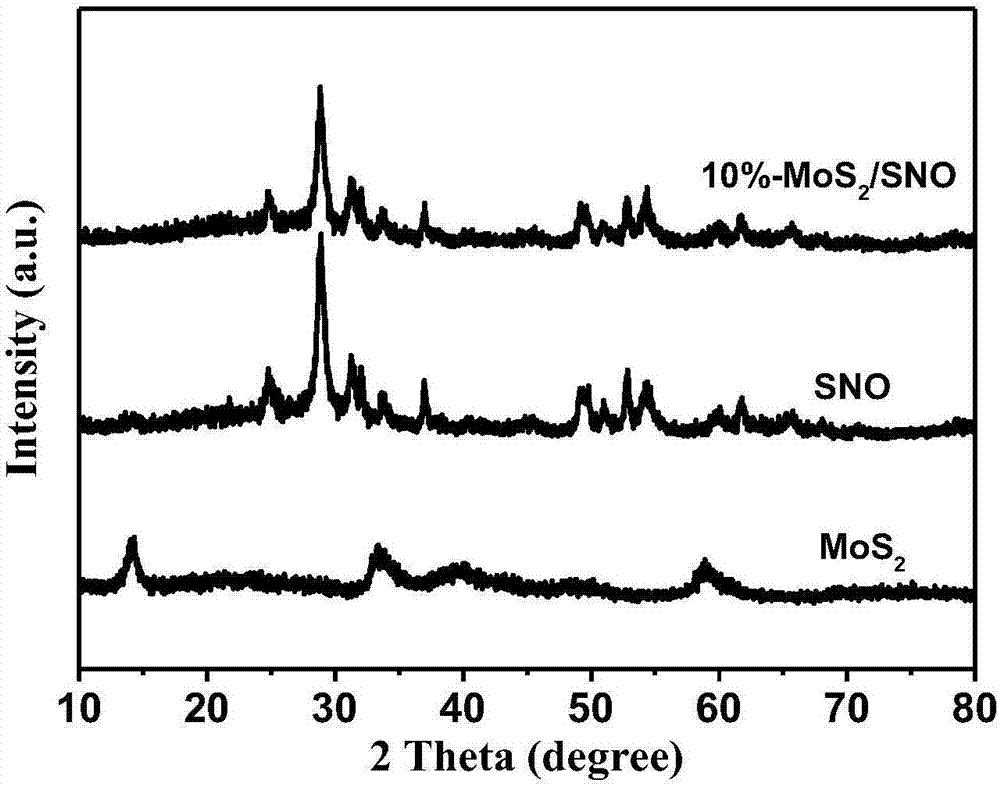

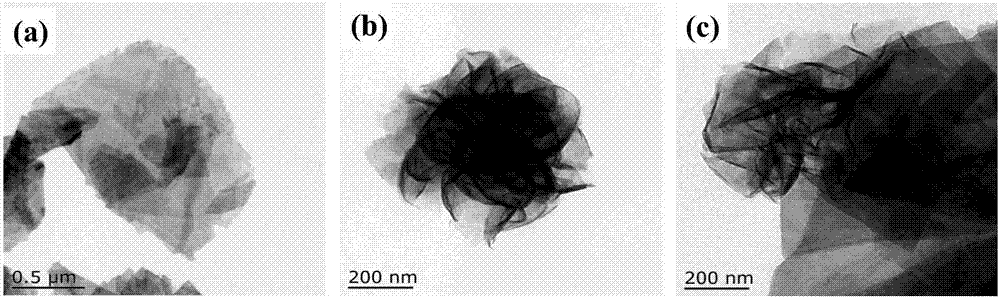

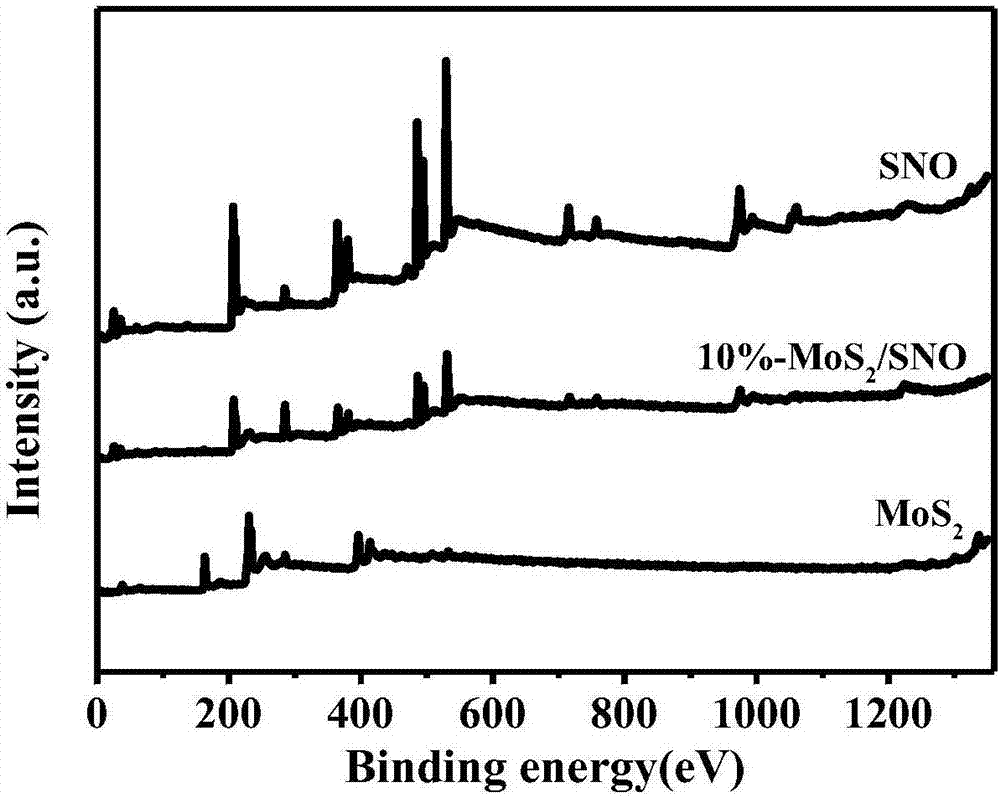

Molybdenum disulfide/tin niobate composite nanomaterial and application thereof

ActiveCN107224986AEasy to operateReduce manufacturing costPhysical/chemical process catalystsHydrogen productionThioureaClean energy

The invention aims at the problem of low catalytic efficiency of visible light catalysis of single two-dimensional molybdenum disulfide, provides a simple preparation method of molybdenum disulfide / tin niobate composite nanomaterial, is mainly used in the technology of hydrogen production realized through photocatalytic decomposition of water, and belongs to the technical field of composites and the field of clean energy. The MoS2 / SnNb2O6 composite is prepared by weighing and dissolving SnNb2O6 in deionized water, magnetically stirring for the first time, conducting ultrasonic dispersion, weighing sodium molybdate dihydrate and thiourea again, dissolving the sodium molybdate dihydrate and the thiourea into the solution, magnetically stirring for the second time, transferring a reaction liquid into a reaction kettle after the reactants are evenly mixed, putting the reaction kettle into an oven, conducting a hydrothermal reaction, centrifuging after naturally cooling to a room temperature, washing with water and washing with alcohol for a plurality of times, and drying, wherein a liner of the reaction kettle is made of teflon. The sheet MoS2 is dispersed on an SNO nanosheet.

Owner:JIANGSU UNIV

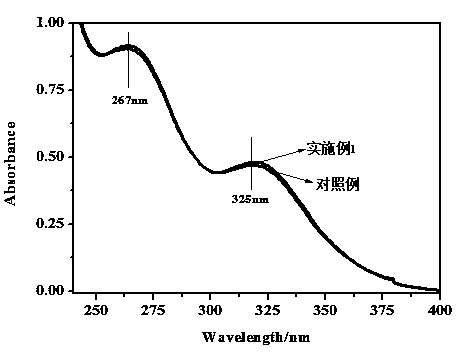

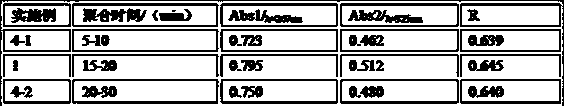

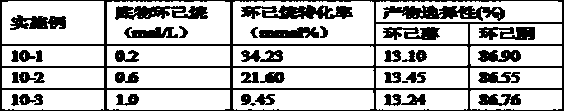

Preparation method for molybdenum-doped quaternary ammonium decatungstate high-efficiency photocatalyst

ActiveCN108993590ARaw materials are easy to getEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationBENZYL ALCOHOL/WATER

The invention relates to the field of photocatalyst synthesis, and discloses a preparation method for a molybdenum-doped quaternary ammonium decatungstate high-efficiency photocatalyst and a transformation system for efficiently catalyzing molecular oxygen to oxidize an organic matter selectively in visible light based on the molybdenum-doped quaternary ammonium decatungstate high-efficiency photocatalyst serving as a catalyst. A series of molybdenum-doped quaternary ammonium decatungstate high-efficiency photocatalysts are synthesized by heating and polymerizing by taking dehydrate sodium tungstate and dehydrate sodium molybdate as raw materials and taking hydrochloric acid as an acidifying agent, and performing exchange by using quaternary ammonium cations. The synthesized target catalyst can efficiently catalyze molecular oxygen to oxidize cyclohexane, methylbenzene, ethylbenzene and benzyl alcohol to synthesize corresponding oxygen-containing organic matters in acetonitrile, particularly, in an acidic water-containing acetonitrile medium, under the irradiation of visible light.

Owner:HUNAN NORMAL UNIVERSITY

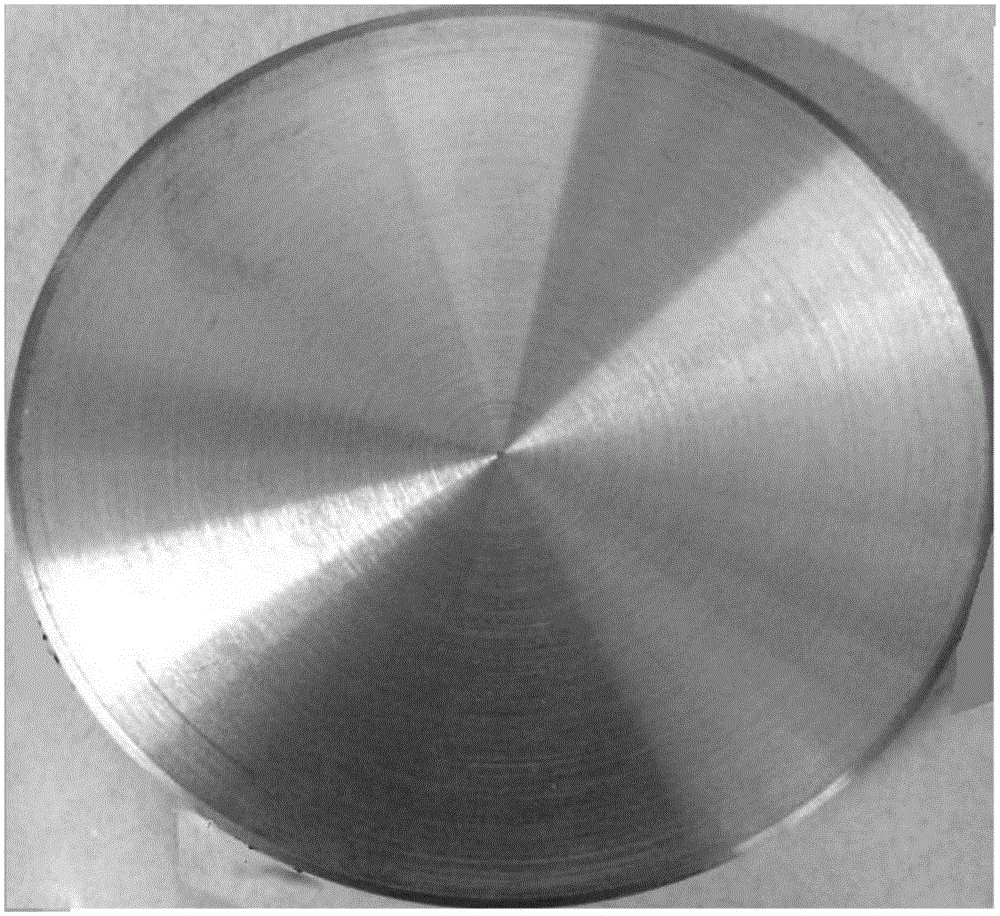

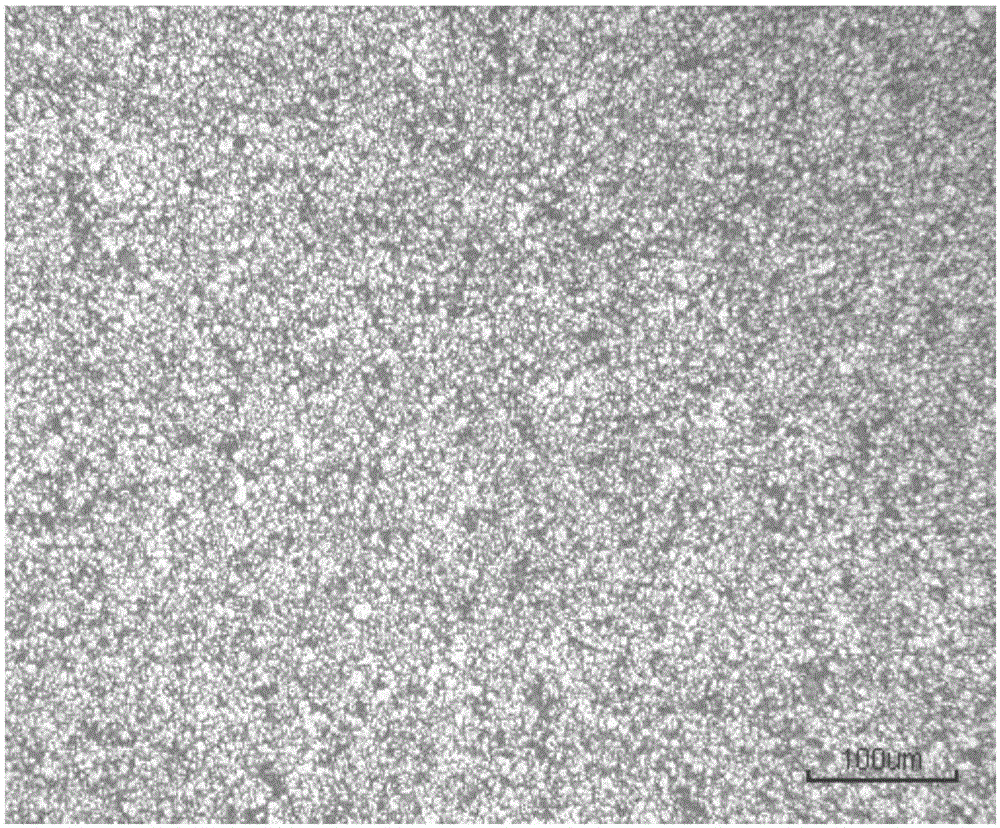

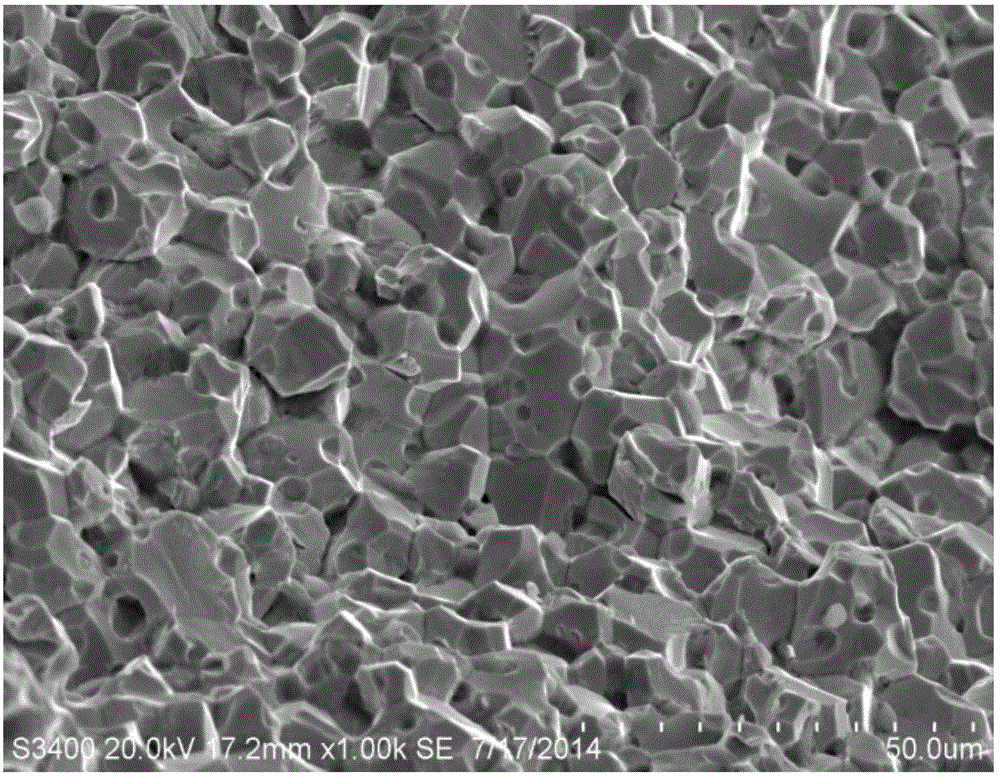

Method for preparing Na-doped molybdenum planar targets

ActiveCN105112859AUniform particle sizeUniform sizeVacuum evaporation coatingSputtering coatingSodium molybdateMaterials science

The invention discloses a method for preparing Na-doped molybdenum planar targets. The method comprises the steps of firstly, stirring mixed powder of molybdenum powder and sodium molybdate dehydrate with deionized water uniformly, and performing spray drying to obtain Na-doped molybdenum particles; secondly, loading the Na-doped molybdenum particles into an isostatic cool pressing mold and sealing the mold, then performing isostatic cool pressing, and removing the isostatic cool pressing mold after pressing to obtain plate blank; thirdly, jacketing the plate blank and performing vacuumizing and sealing; and fourthly, performing hot-pressed sintering on the plate blank and then performing jacket removal treatment to obtain the Na-doped molybdenum planar targets. According to the method, the preparation cost is low, the material use rate is high, the content of Na in the targets and the structure are controllable, the product consistency is good, and the requirement for the Na-doped molybdenum planar targets for industrial production can be well met.

Owner:JINDUICHENG MOLYBDENUM CO LTD

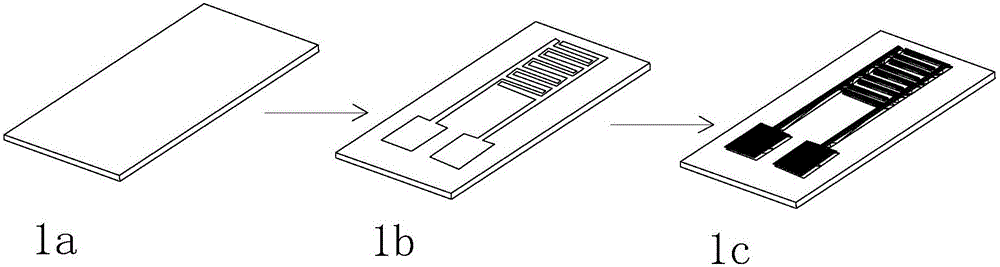

Pyrolytic carbon/molybdenum disulfide nanosheet/graphene composite material patterned micro-electrode and micro-processing technology thereof

InactiveCN106044703AImprove electrochemical performanceHigh area to capacityDecorative surface effectsChemical vapor deposition coatingThioureaMass ratio

The invention relates to a pyrolytic carbon / molybdenum disulfide nanosheet / graphene composite material patterned micro-electrode and a micro-processing technology thereof. The pyrolytic carbon / molybdenum disulfide nanosheet / graphene composite material patterned micro-electrode comprises the steps of 1) mixing graphene, sodium molybdate dihydrate, thiourea and water uniformly according to a mass ratio of 1-10:400:600-700:1000-30000, then putting the mixture in a reaction kettle for hydro-thermal synthesis reaction, centrifuging the mixture after subjected to the hydro-thermal synthesis reaction, drying to obtain a solid product, and grinding the solid product to obtain a molybdenum disulfide nanosheet / graphene material; and 2) mixing photo-resist with the molybdenum disulfide nanosheet / graphene uniformly, then coating the mixture on a substrate for drying, then performing ultra-violet lithography, development and washing for the substrate, and finally performing high-temperature pyrolytic reaction to obtain the pyrolytic carbon / molybdenum disulfide nanosheet / graphene composite material patterned micro-electrode. The obtained micro-electrode has good electrochemical performance and has good application foreground in the fields such as micro-sensors and tiny energy storage devices.

Owner:WUHAN UNIV OF TECH

Culture solution composition capable of efficiently culturing chlorella

ActiveCN105316237ASolve concentrationSolve pollutionUnicellular algaeMicroorganism based processesDipotassium phosphateCobalt

The invention provides a culture solution composition capable of culturing chlorella. The culture solution composition is characterized by being prepared from, by weight, 0.01%-0.02% of naphthalene acetic acid, 70%-75% of urea, 3.5%-4.5% of sodium nitrate, 3.5%-4.5% of anhydrous calcium chloride, 9%-12% of magnesium sulfate heptahydrate, 4%-5% of dipotassium phosphate, 0.8%-0.9% of ammonium ferric citrate, 0.8%-0.9% of citric acid, 2%-3% of anhydrous sodium carbonate, 0.1%-0.2% of ethylenediaminetetraacetic acid disodium, 0.3%-0.4% of boric acid, 0.2%-0.3% of tetrahydrate manganese chloride, 0.02%-0.04% of zinc sulfate heptahydrate, 0.04%-0.06% of sodium molybdate dihydrate, 0.01%-0.02% of copper sulfate pentahydrate and 0.005%-0.007% of cobalt nitrate hexahydrate.

Owner:福建格林生物科技有限公司 +1

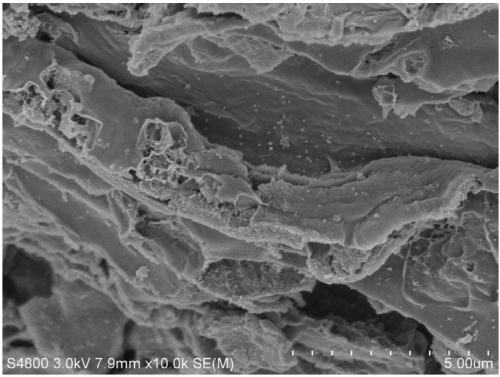

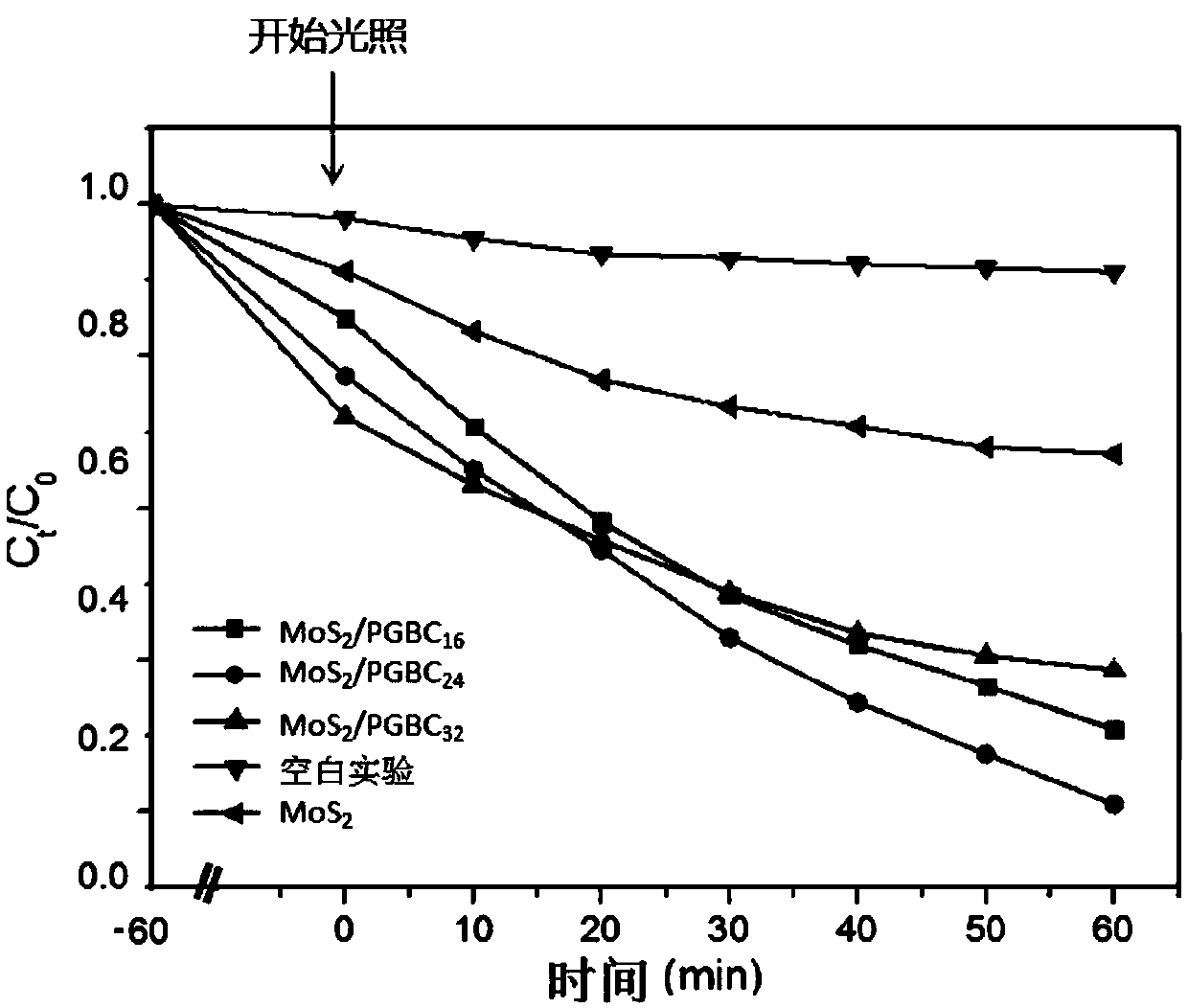

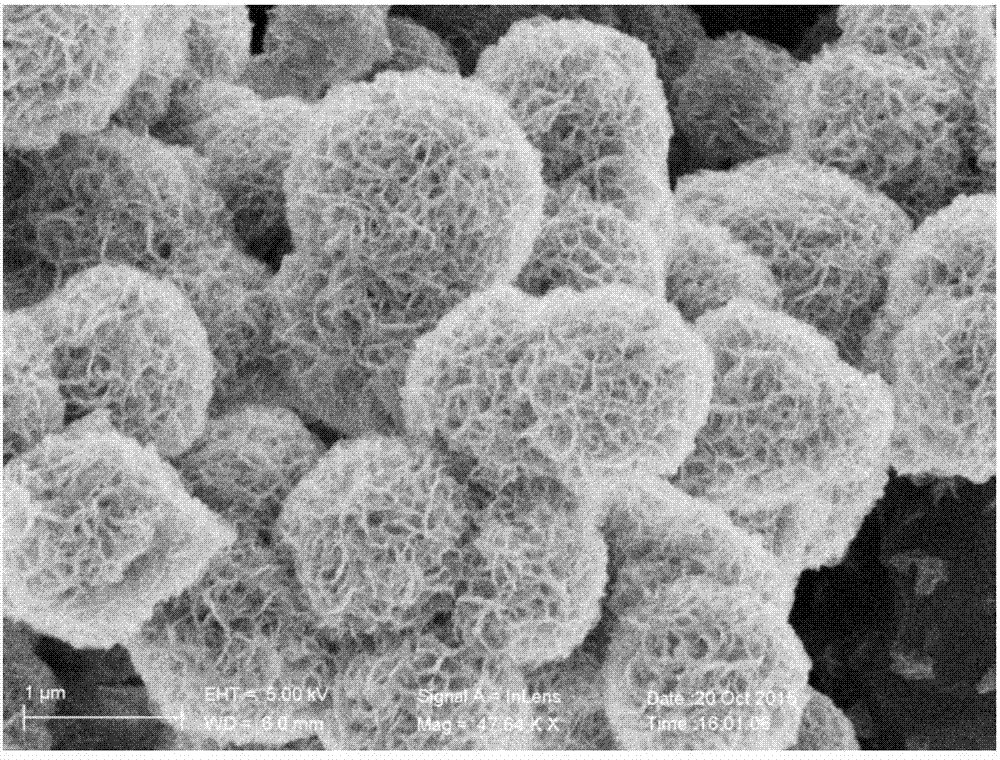

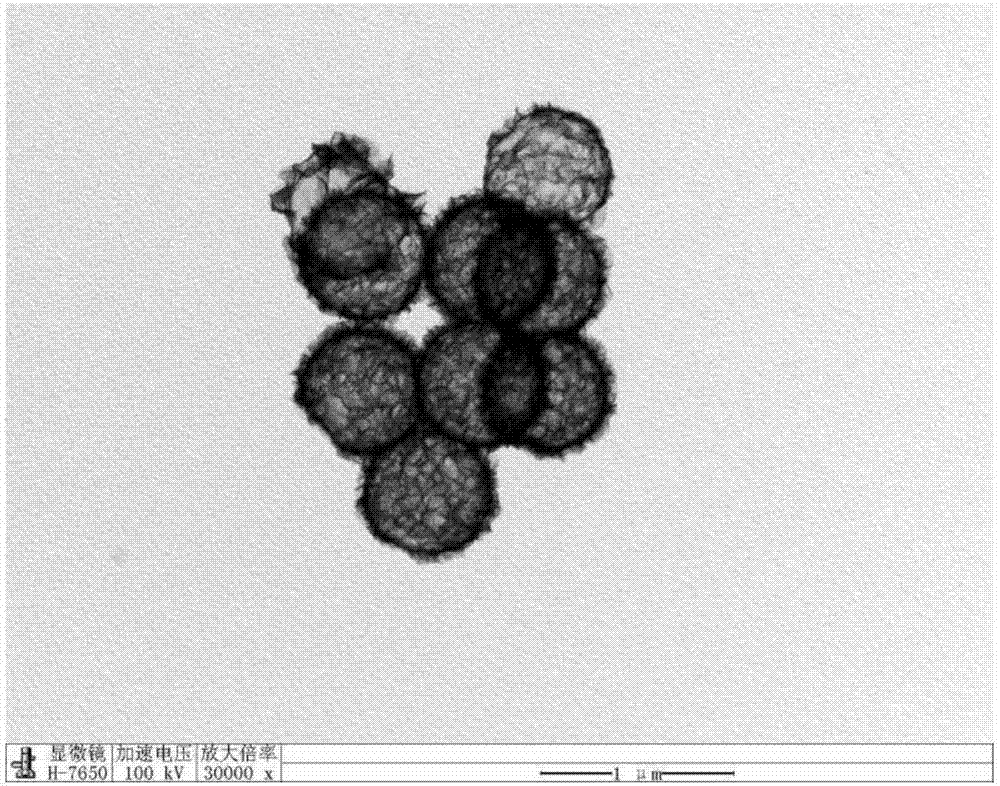

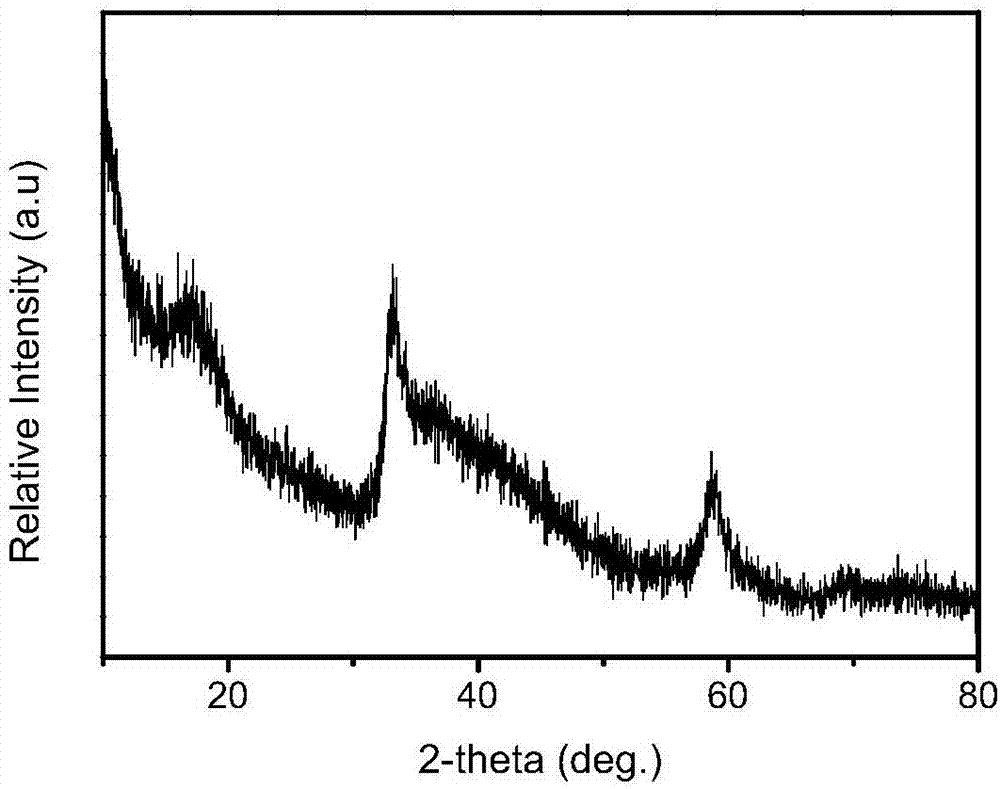

Molybdenum disulfide nanosheet/porous graphitized biocarbon composite material and preparation method and application thereof

ActiveCN109603810ALarge specific surface areaImproved pore distributionWater/sewage treatment by irradiationWater treatment compoundsAntibiotic YBiochar

The invention discloses a molybdenum disulfide nanosheet / porous graphitized biocarbon composite material and a preparation method and application thereof. The composite material takes porous graphitized biocarbon as a carrier, and the surface of the composite material is embedded with a molybdenum disulfide nanosheet. The preparation method comprises the following steps: preparing porous graphitized biochar powder; ultrasonic dispersing the porous graphitized biochar powder in water, adding sodium molybdate dihydrate and thioacetamide for hydrothermal reaction, centrifuging, washing and dryingto obtain the composite material. The composite material has the advantages of large specific surface area, good conductivity, low photogenerated electron-hole pair recombination rate, high photocatalytic activity, high universality and the like, and the preparation method has the advantages of simple process, simple and convenient operation and low cost, environmental protection, and no toxic and harmful by-products, suitability for large-scale preparation, and the method meets the requirement of actual production. The composite material can rapidly and efficiently treat antibiotics in the environment, and has good application value and application prospect.

Owner:HUNAN UNIV

Preparation method for molybdenum disulfide/carbon microsphere negative electrode material of lithium ion battery

InactiveCN107069035AEvenly distributedEasy to prepareSecondary cellsNegative electrodesMicrosphereThiourea

The invention provides a preparation method for a molybdenum disulfide / carbon microsphere negative electrode material of a lithium ion battery, and relates to the technical field of a battery material. The preparation method comprises the steps of dissolving polystyrene microspheres, sodium molybdate dihydrate, thiourea and glucose into deionized water to obtain a mixed solution; putting the mixed solution into a reaction kettle, performing heat preservation at a temperature of 180-230 DEG C for 8-24h and cooling; and next, performing centrifuging, washing, drying and sintering on the reacted mixed solution. The preparation method provided by the invention is simple in method, and industrial production can be realized easily; and in addition, the molybdenum disulfide / carbon microspheres can be uniformly distributed in the prepared molybdenum disulfide / carbon microsphere negative electrode material of the lithium ion battery, and excellent electrochemical performance is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

Culture medium for phalaenopsis amabilis tissue culture

The invention provides a culture medium for phalaenopsis amabilis tissue culture. The culture medium comprises the following components: 1900 mg / L of KNO3; 1650 mg / L of ammonium nitrate; 170 mg / L of potassium dihydrogen phosphate; 370 mg / L of magnesium sulfate heptahydrate; 440 mg / L of calcium chloride dihydrate; 0.60-0.62 mg / L of KI; 4.5-4.8 mg / L of boric acid; 25.0-25.3 mg / L of manganese sulfate tetrahydrate; 7.0-7.2 mg / L of zinc sulfate heptahydrate; 0.20-0.22 mg / L of sodium molybdate dihydrate; 0.025 mg / L of copper sulfate pentahydrate; 0.025 mg / L of cobalt chloride hexahydrate; 37.25 mg / L of Na2.EDTA; 27.85 mg / L of ferrous sulfate heptahydrate; 100 mg / L of inositol; 2 mg / L of glycine; 0.1 mg / L of thiamine hydrochloride; 0.5 mg / L of pyridoxine hydrochloride; 0.5 mg / L of nicotinic acid; 20-22 g / L of sucrose; 5-5.2 g / L of agar; 30-35 g / L of a banana juice; 3-5 g / L of a pear juice; 0.45-0.48 g / L of activated carbon; and a solvent being deionized water. With application of the culture medium to culture phalaenopsis amabilis, the survival rate is more than 96%, the bacteria infection rate is 2.7-2.8%, and the browning degree of the culture medium is 30-40% lower than that of an MS culture medium.

Owner:柳州赛特生物科技研发中心

Environmental-friendly anti-rust metal cleaning agent

The invention discloses an environmental-friendly anti-rust metal cleaning agent, which is prepared from the following raw materials of modified quaternary ammonium salt surfactant, a nonionic surfactant, an anionic surfactant, sodium tungstate, zinc carbonate, acrylic acid-maleic anhydride copolymer sodium salt, sodium polyacrylate, sodium molybdate dihydrate, sodium tetraborate, D-limonene, Schiff base corrosion inhibitors, cosolvents, anti-foaming agents, ethanol and water, wherein the nonionic surfactant is a mixture of alkylphenol ethoxylates, coco fatty acid diethanol amide, sorbitan fatty acid ester and FMEE; the anionic surfactant is a mixture of sodium dodecyl benzene sulfonate and sodium lauryl alcohol polyoxyethylene ether sulfate. The environmental-friendly anti-rust metal cleaning agent provided by the invention has the advantages that the cleaning efficiency is high; the detergency power is strong; after the cleaning, no residue is left; the antirust performance is good;the environmental-friendly effect is achieved.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

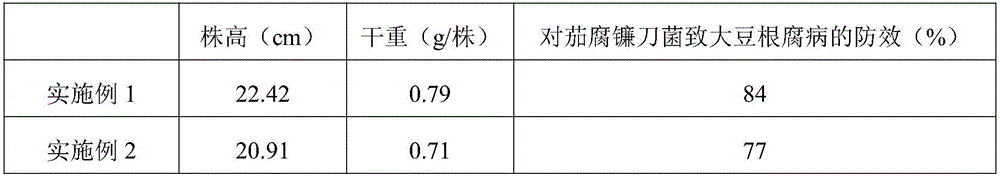

Efficient compound fertilizer and preparation method thereof

InactiveCN106748144APromote growthInhibit root rotSuperphosphatesAlkali orthophosphate fertiliserPhosphateRoot rot

The invention discloses an efficient compound fertilizer and a preparation method thereof. The efficient compound fertilizer is prepared from the following raw materials in parts by weight: 10-20 parts of bone meal, 5-10 parts of sodium molybdate dihydrate, 5-10 parts of monoammonium phosphate, 5-10 parts of ground phosphate rock, 3-5 parts of sodium hydrogen phosphate, 10-20 parts of straws, 3-5 parts of ferrous sulfate, 3-5 parts of potassium sulfate, 5-10 parts of humic acid, 10-20 parts of plant ash, 10-20 parts of cow dung, 5-10 parts of calcium superphosphate, 3-5 parts of ammonium chloride, 10-20 parts of urea, 3-5 parts of weathered coal, 4-6 parts of a potassium mineral powder, 4-6 parts of ethylene diamine tetraacetic acid, 4-6 parts of a rice hull powder and 4-6 parts of a mixed culture powder. The efficient compound fertilizer can not only promote growth of soybeans but also effectively inhibit soybean root rots, is obviously superior to a conventional compound fertilizer, and has prominent substantive features and remarkable advancement.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

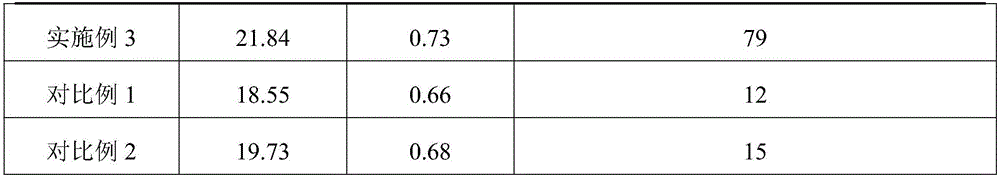

Fertility-enhancing chelating sustained-release fertilizer

InactiveCN102040423AImprove fat retentionImprove water retentionFertilizer mixturesBiotechnologyPhosphate

The invention discloses a fertility-enhancing chelating sustained-release fertilizer. The fertilizer consists of the following raw materials in part by weight: 240 parts of urea, 343 parts of monoammonium phosphate, 250 parts of potassium chloride, 100 parts of humic acid, 40 parts of amino acid, 8 parts of borax, 4 parts of manganous sulfate monohydrate, 2 parts of ferrous sulfate, 4 parts of heptahydrate zinc sulphate, 4 parts of copper sulfate pentahydrate, 2 parts of sodium molybdate dihydrate and 3 parts of filming agent. The fertility-enhancing chelating sustained-release fertilizer is a high-concentration, long-acting and conservation-oriented sustained-release fertilizer.

Owner:王通华

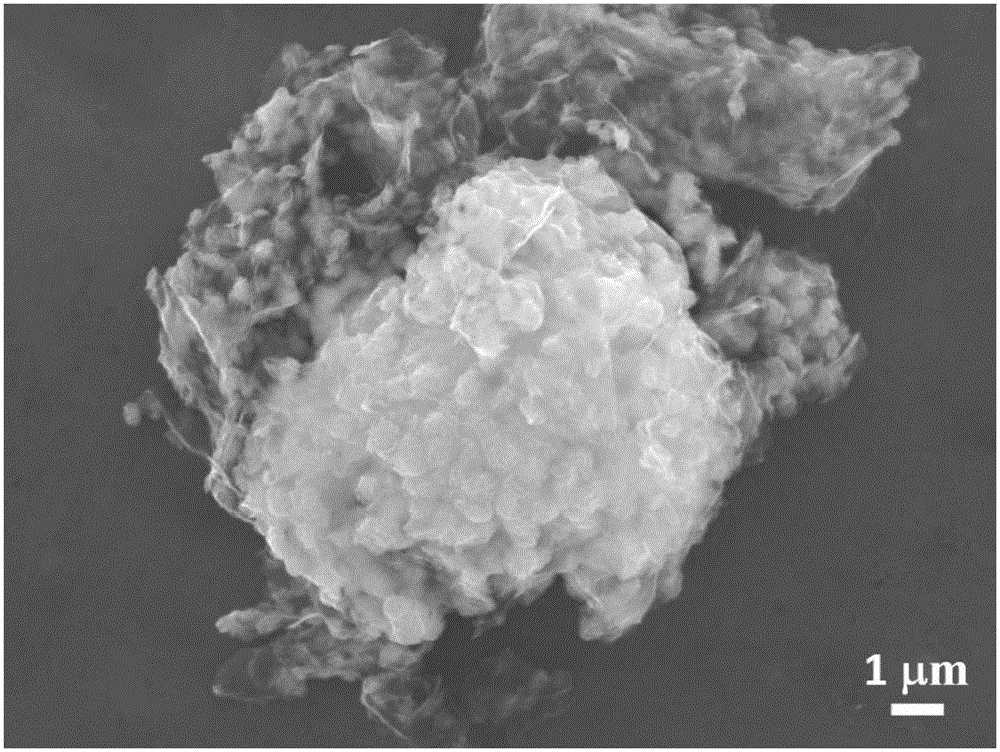

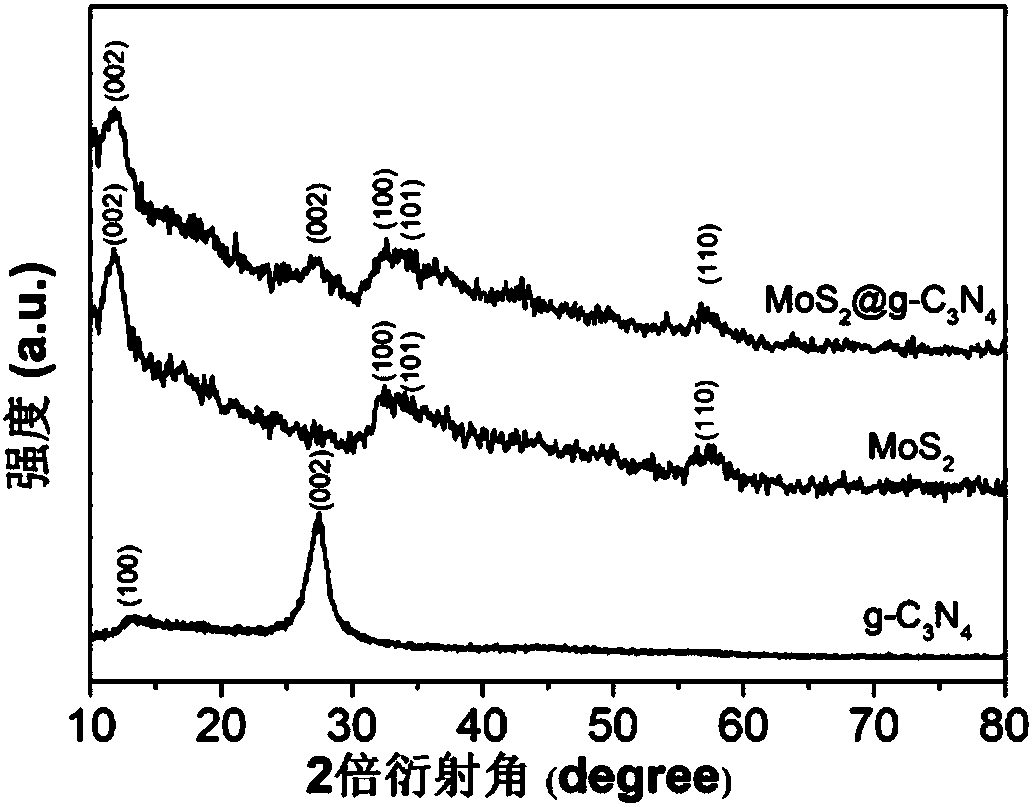

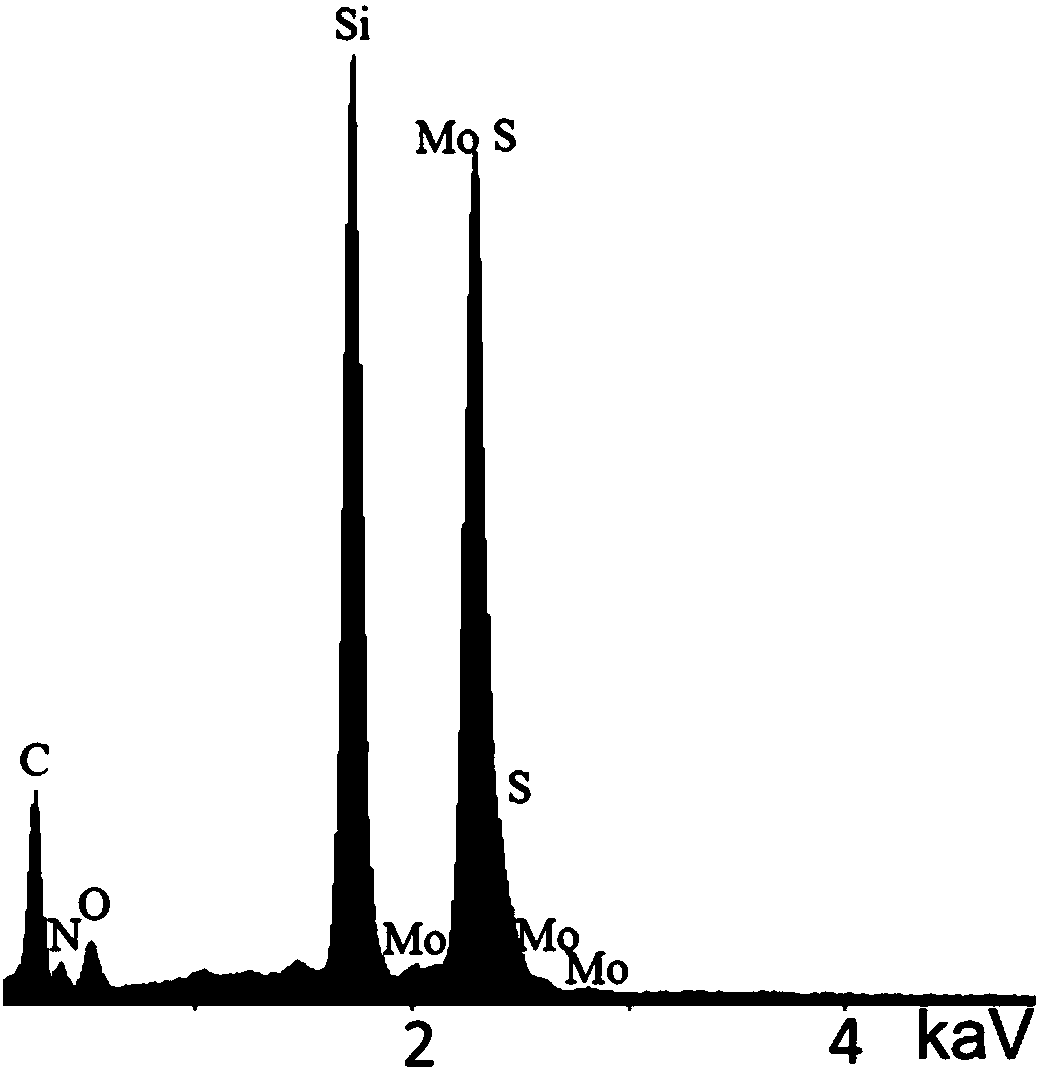

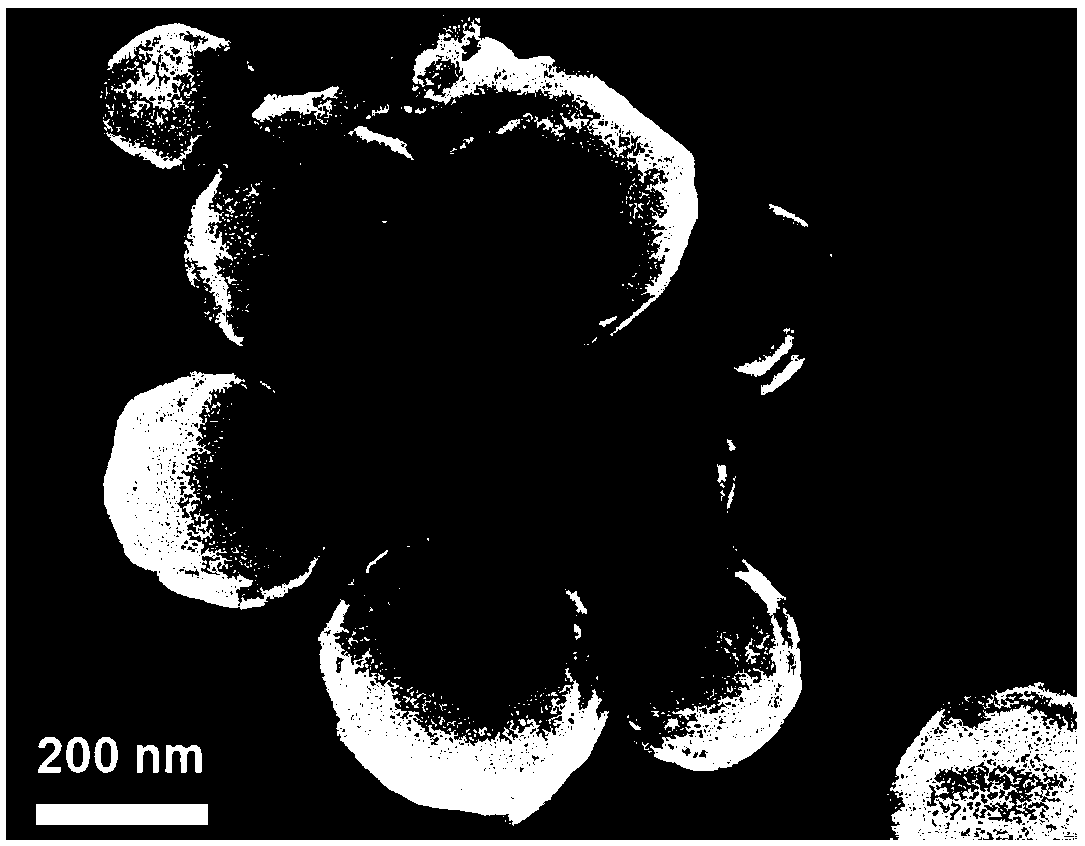

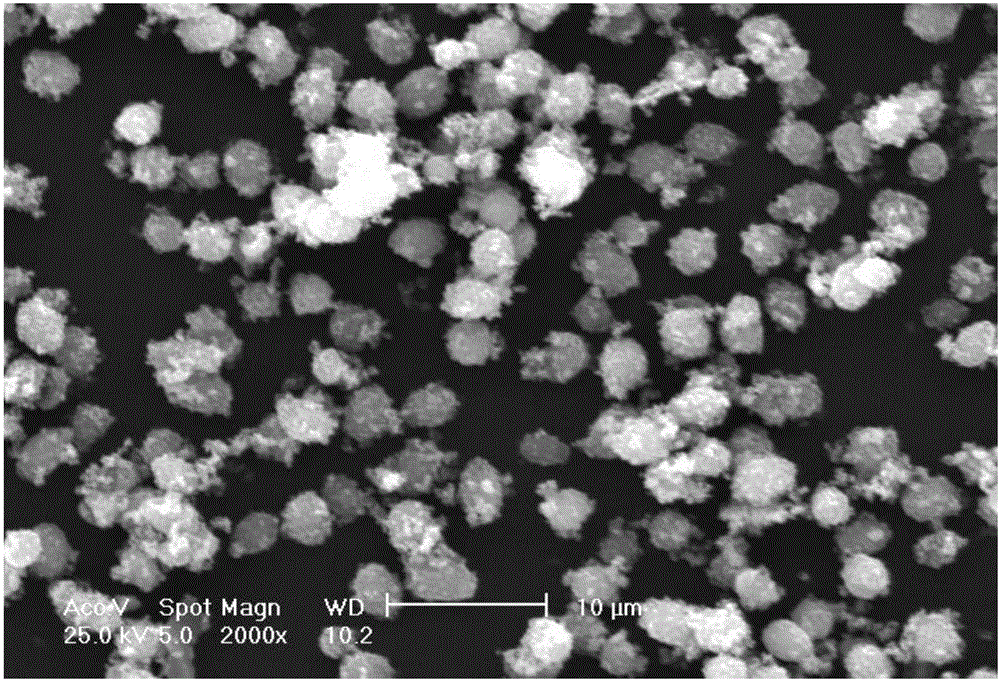

MoS2atg-C3N4 core-shell nanospheres and preparation method thereof

InactiveCN108569721AEasy to operateMild conditionsNitrogen and non-metal compoundsMolybdenum sulfidesUltrasonic dispersionElectrostatic adsorption

The invention provides MoS2atg-C3N4 core-shell nanospheres and a preparation method thereof, and belongs to the technical field of preparation of a catalytic material and a nano material. Firstly, mixed solution is prepared by using sodium molybdate dihydrate, urea and PVP (Polyvinyl Pyrrolidone) as raw materials, and by a hydrothermal reaction, MoS2 nanospheres are obtained; then MoS2 and g-C3N4are subjected to ultrasonic dispersion, an electrostatic adsorption method is adopted, and thus the MoS2atg-C3N4 core-shell nanospheres are obtained. A material consists of the MoS2atg-C3N4 core-shellnanospheres which are uniform in size; the diameter of the core-shell nanospheres is about 240 to 260nm. According to the invention, the used raw materials are cheap and easy to obtain; the preparation method is simple and easy to operate, mild in conditions and low in equipment requirements, and environmentally friendly. The prepared MoS2atg-C3N4 core-shell nanospheres can be used for the fieldsof light, electricity, energy storage, catalysis and the like.

Owner:DALIAN UNIV OF TECH

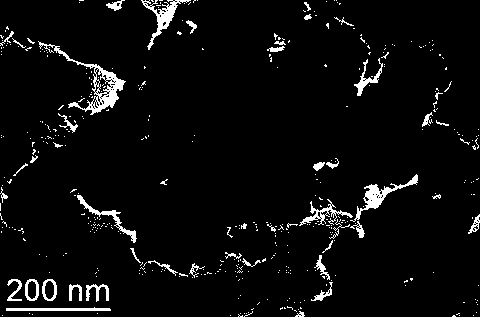

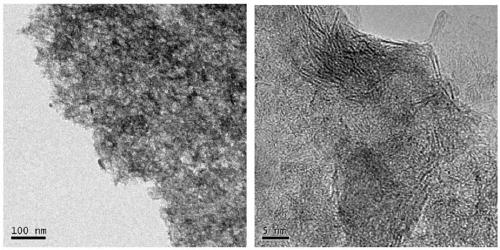

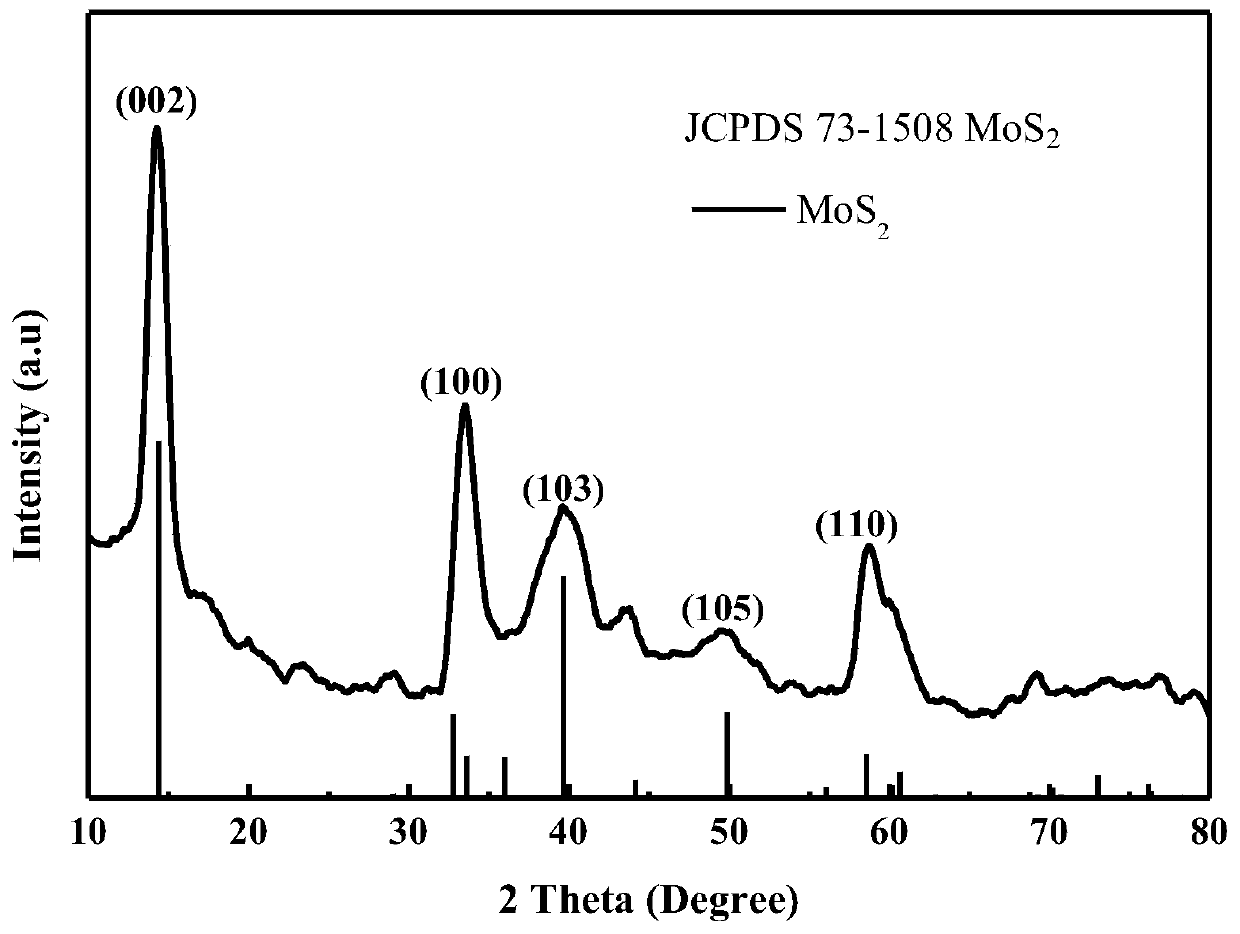

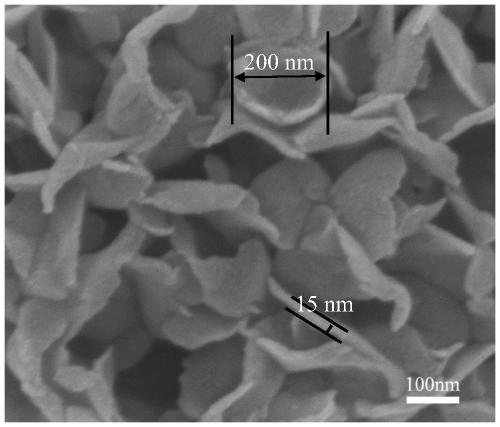

Preparation method of molybdenum disulfide material used for sodium lithium battery anodes

InactiveCN109956500AHigh specific surface areaAgglomeration did not occurCell electrodesSecondary cellsThioureaSodium-ion battery

The invention provides a preparation method of a molybdenum disulfide material used for sodium lithium battery anodes. The preparation method comprises following steps: dissolving sodium molybdenum dihydrate in deionized water and stirring; adding thiourea to a prepared solution for stirring, adding surfactant cetyltrimethylammonium bromide, stirring to obtain a solution; adding dilute hydrochloric acid in the solution dropwise to adjust the pH value to 1 to 7, and stirring continuously; transferring an obtained mixed solution to the lining of a polytetrafluoroethylene hydrothermal reaction kettle for hydrothermal reaction; cooling an obtained mixture to normal temperature in the reaction kettle, taking an obtained reactant out, washing and vacuum drying so as to obtain a molybdenum disulfide material of a nanometer flower shaped structure; introducing the molybdenum disulfide material into a quartz boat, carbonizing in a tube furnace with Ar gas to obtain a nanometer flower shaped structure molybdenum disulfide material with good crystallinity. The nanosheet thickness is 10 to 20 nm and the length is 100 to 200 nm. The small size molybdenum disulfide nanosheet is capable of improving the cycle stability of molybdenum disulfide as a lithium / sodium battery anode material.

Owner:TIANJIN UNIV

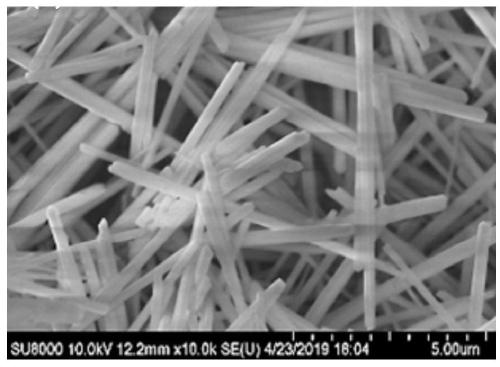

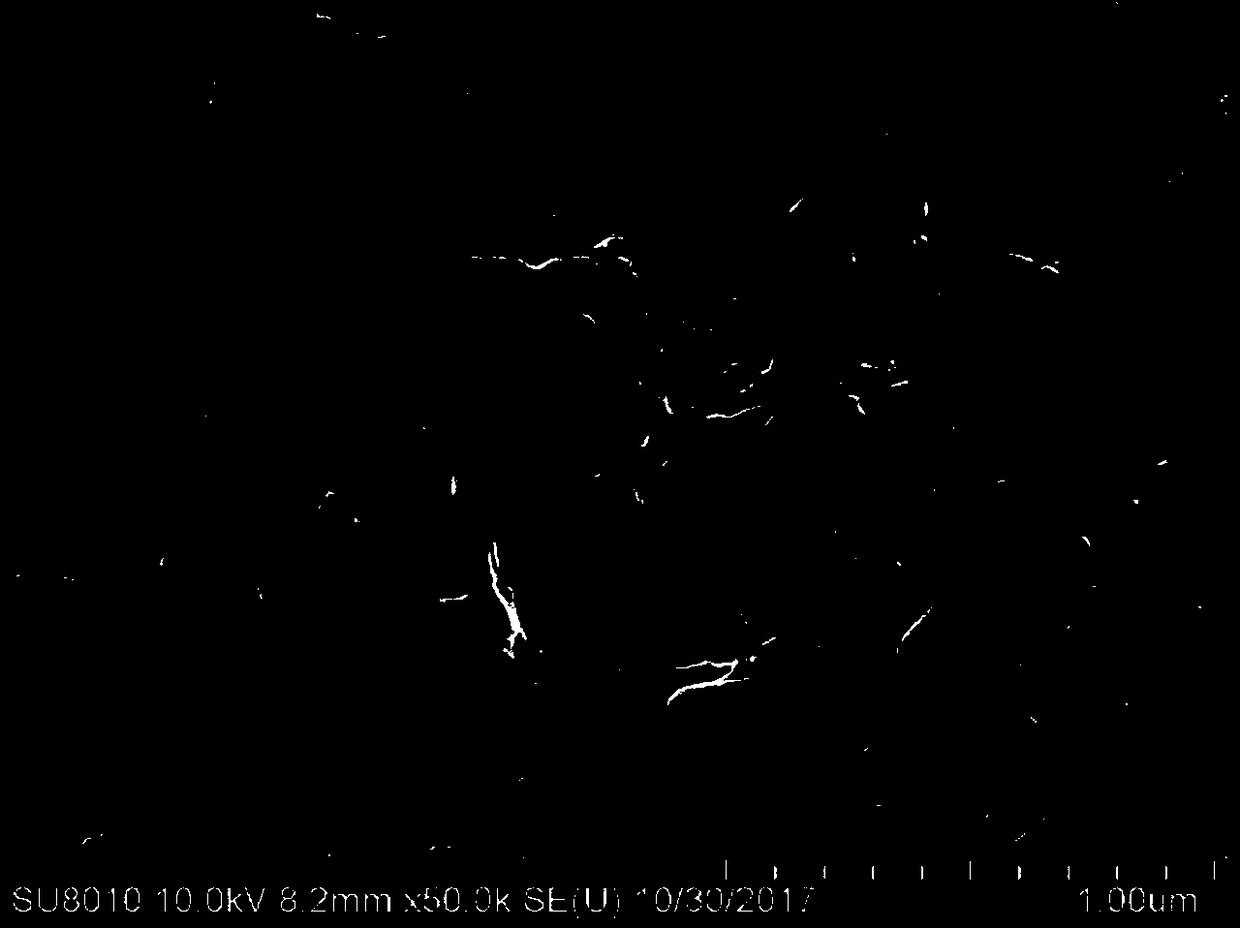

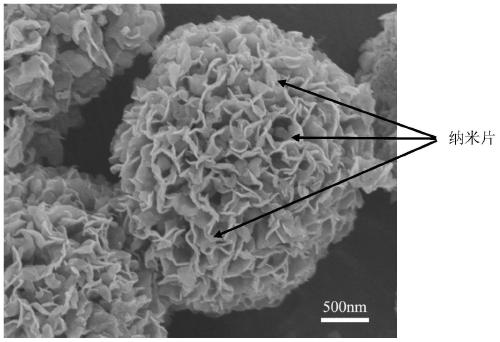

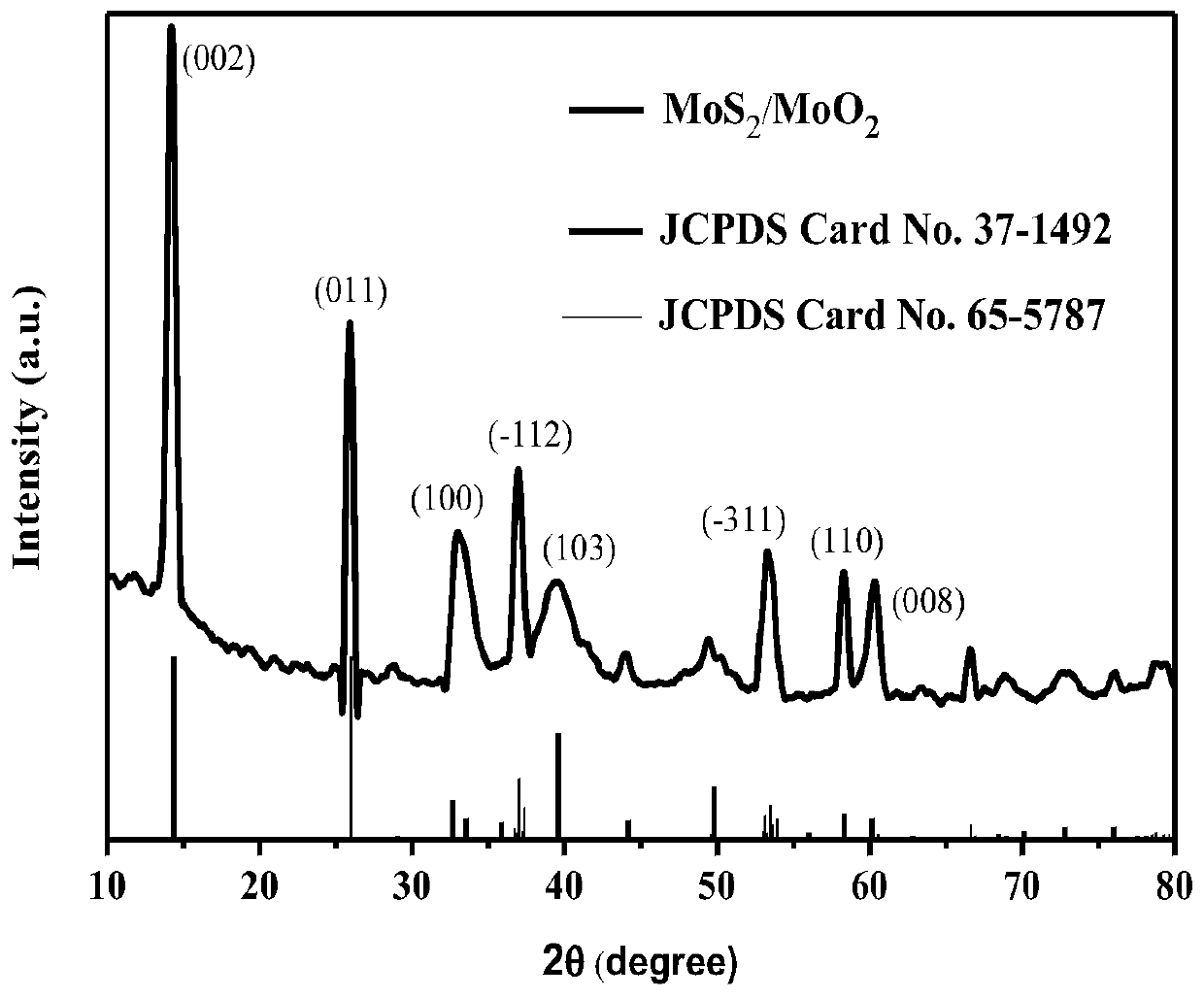

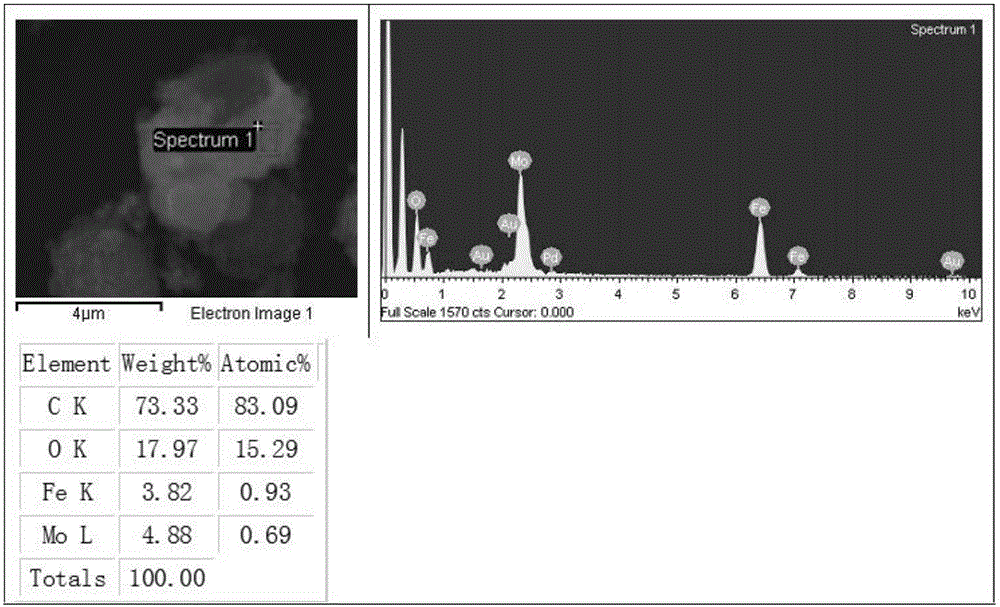

Method for preparing molybdenum disulfide/molybdenum dioxide composite material used for sodium ion negative electrode material

The invention provides a method for preparing a molybdenum disulfide / molybdenum dioxide composite material used for a sodium ion negative electrode material; the method comprises the steps of adding sodium molybdate dihydrate into deionized water, and performing stirring to obtain a sodium molybdate solution; sequentially adding thiourea and CTAB into the sodium molybdate solution, sufficiently stirring, and transferring into a hydrothermal reaction kettle; and separating the precipitate, washing and drying to obtain a nano-sheet assembled molybdenum disulfide / molybdenum dioxide heterogeneousmaterial. The material is made of molybdenum disulfide / molybdenum dioxide heterostructure nano-sheets, wherein the thickness of the nano-sheets ranges from 10nm to 20nm, and the length of the nano-sheets is 0.8-1.0[mu]m. The nano-sheets of the heterostructure have the advantages that the stability of the structure is greatly improved, the nano-sheets of the heterogeneous structure do not have agglomeration, and the nano-sheets are lap jointed into flower shape, so that the specific surface area is greatly enlarged, and the cycling stability of the molybdenum disulfide / molybdenum dioxide sodiumion battery negative electrode material is improved.

Owner:TIANJIN UNIV

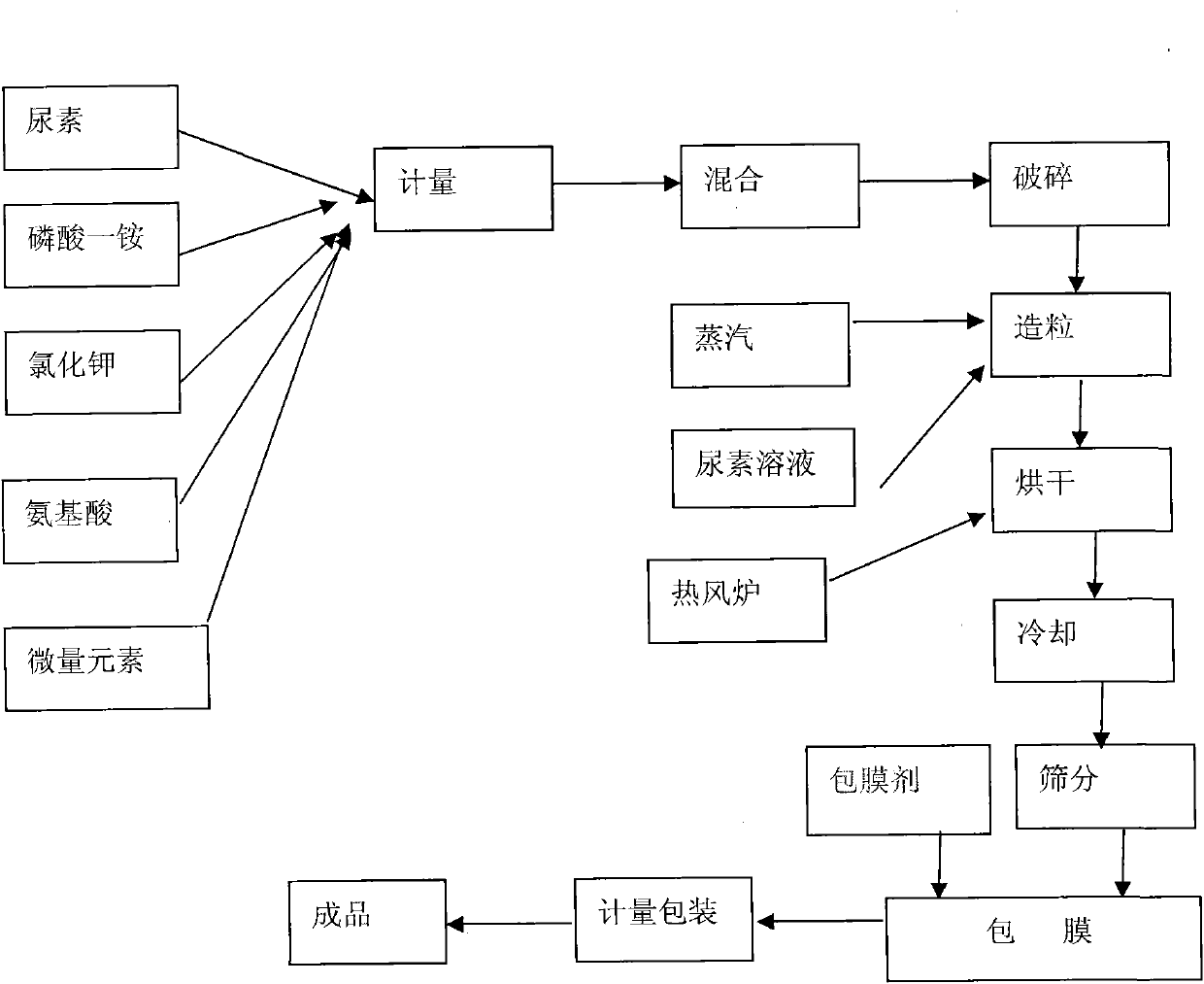

Professional sustained-release fertilizer for honeysuckle flower

InactiveCN103387442AIncrease profitImprove resistance to pests and diseasesFertilizer mixturesSodium Molybdate DihydrateHumic acid

The invention relates to a professional sustained-release fertilizer for honeysuckle flowers. The fertilizer is prepared from the raw materials of, by weight: 50 parts of urea, 15 parts of ammonium carbonate, 5 parts of potassium chloride, 5 parts of humic acid, 3 parts of manganese sulfate monohydrate, 3 parts of amino acid, 3 parts of calcium superphosphate, 1 part of calcium-magnesium-phosphorous, 2 parts of potassium sulfate, 2 parts of zinc sulfate, 2 parts of manganese sulfate, 2 parts of aluminum silicate, 2 parts of borax, 1 part of ferrous sulfate, 1 part of zinc sulfate heptahydrate, 1 part of copper sulfate pentahydrate, 1 part of sodium molybdate dihydrate, and 1 part of a coating agent. The fertilizer provided by the invention assists in enhancing the utilization rates of other fertilizers to honeysuckle flowers, improving fertilizing effect, reducing fertilizer dose, improving honeysuckle flower disease resistance, resisting pests and diseases, resisting lodging, resisting frost damage, improving soil, accelerating honeysuckle flower growth, enhancing photosynthesis, accelerating root system growth, increasing root system coverage, enhancing drought resistance, improving honeysuckle flower yield, and improving honeysuckle flower quality.

Owner:习水县同心中药材有限责任公司

Biological carbon sphere supported FeMoO4 Fenton catalyst, preparation method and application

InactiveCN105056965AImprove adsorption capacityReduce ferrous ion valenceCatalyst carriersWater contaminantsSodium molybdateChloride

Owner:CHANGAN UNIV

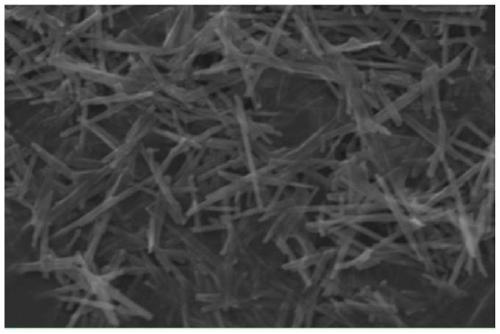

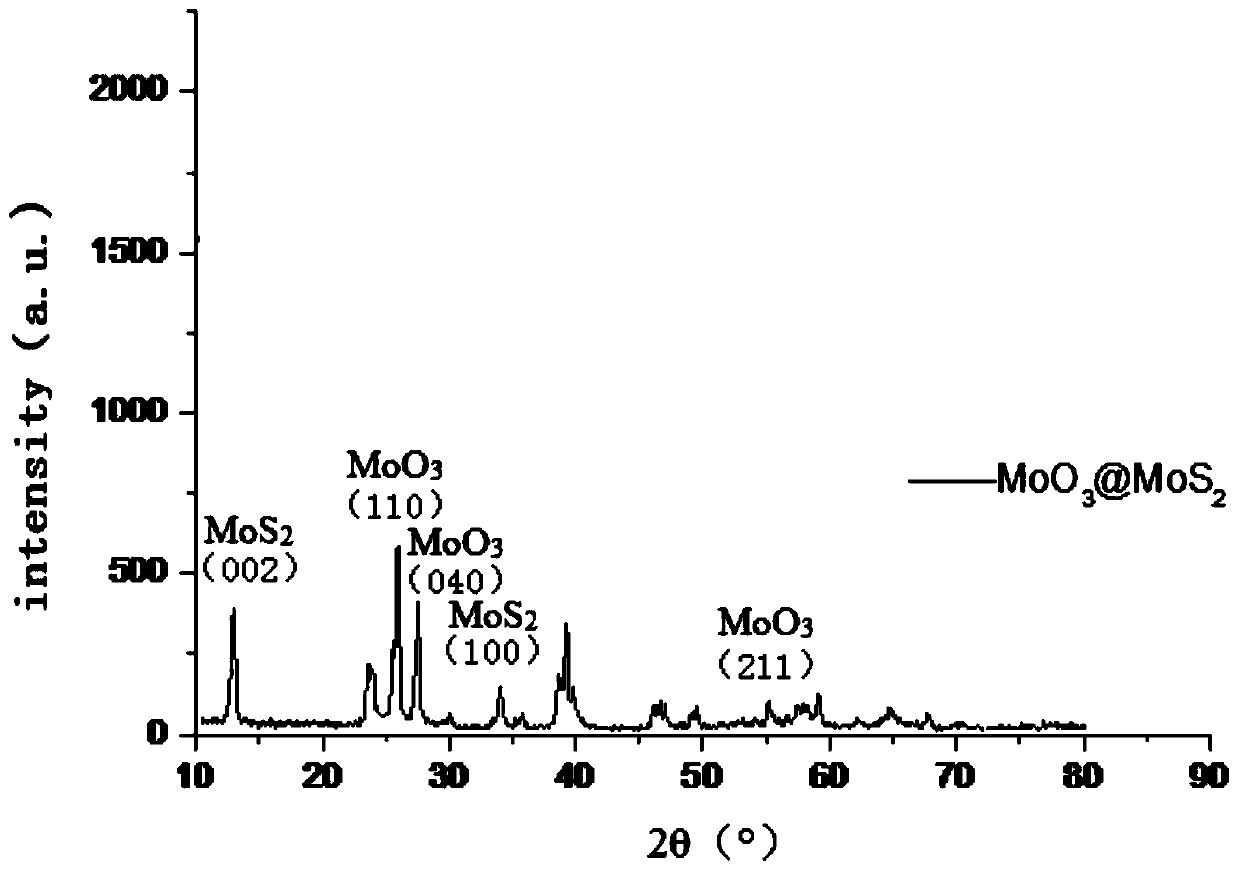

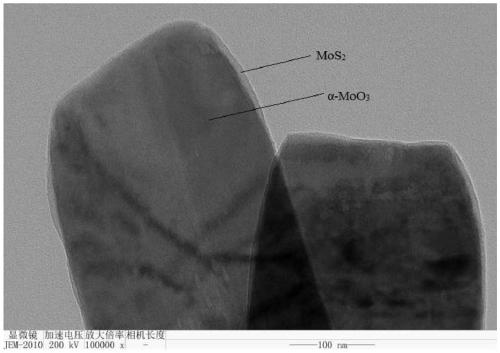

Alpha-molybdenum trioxide@molybdenum disulfide material as well as preparation method and application thereof

ActiveCN110479316ABroaden the response rangeImprove efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationThioureaDissolution

The invention discloses an alpha-molybdenum trioxide@molybdenum disulfide material as well as a preparation method and application thereof, and belongs to the technical field of photocatalytic materials. The alpha-molybdenum trioxide@molybdenum disulfide material is of a rod-like shell-core structure, a core is composed of alpha-MoO3 of a rod-like structure, and a shell is a film composed of MoS2.The preparation method comprises the following steps: adding sodium molybdate dihydrate into water, carrying out ultrasonic dissolution, adding concentrated nitric acid, carrying out a stirring reaction, and carrying out a hydrothermal reaction to obtain an alpha-MoO3 precursor; adding an alpha-MoO3 precursor, a surfactant, sodium molybdate dihydrate and thiourea into acetonitrile, and stirring for reaction to obtain alpha-MoO3 slurry; subjecting the alpha-MoO3 slurry to a hydrothermal reaction to obtain the alpha-MoO3@MoS2 material. The alpha-MoO3@MoS2 material has the advantages of accessible raw materials, low cost and simple preparation technique, and has great popularization and application values in the fields of photocatalytic materials and the like.

Owner:陕西华钼实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com