Molybdenum disulfide/tin disulfide/graphene composite and preparation method thereof

A technology of tin disulfide and molybdenum disulfide, which is applied in the field of molybdenum disulfide/tin disulfide/graphene composite materials and its preparation, can solve the problems of large volume change rate, poor high-rate performance, self-structural damage, etc., to achieve Inhibit agglomeration, improve electrical conductivity, and relieve pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

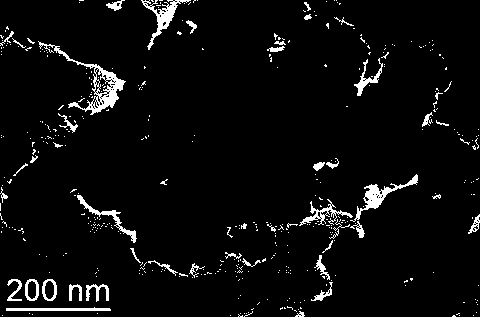

Image

Examples

Embodiment 1

[0033] Take 800mg of graphite powder and 800mg of sodium nitrate in a magnetic stirrer and dissolve them in 50mL of concentrated sulfuric acid in an ice-water bath in turn, and continue to stir to dissolve them completely; after heating up to 30°C, add 4g of potassium permanganate and continue to stir for 4 hours; continue to stir Next, 100 mL of deionized water and 5 mL of hydrogen peroxide were sequentially added, washed four times with 0.5 M dilute hydrochloric acid and deionized water, respectively, and freeze-dried for 12 hours to obtain graphene oxide.

[0034] Take 20 mg of the graphene oxide prepared by the above method and add it into 60 mL of deionized water, and disperse it ultrasonically for 30 minutes; then add 710 mg of tin tetrachloride pentahydrate under magnetic stirring, and keep stirring for 1 hour to completely dissolve it; add 242 mg of dihydrate under constant stirring Sodium molybdate, and continue to stir for 1 h to completely dissolve; add 700 mg of thi...

Embodiment 2

[0037] Take 800mg of graphite powder and 800mg of sodium nitrate in a magnetic stirrer and dissolve them in 50mL of concentrated sulfuric acid in an ice-water bath in turn, and continue to stir to dissolve them completely; after heating up to 30°C, add 4g of potassium permanganate and continue to stir for 4 hours; continue to stir Next, 100 mL of deionized water and 5 mL of hydrogen peroxide were sequentially added, washed four times with 0.5 M dilute hydrochloric acid and deionized water, respectively, and freeze-dried for 12 hours to obtain graphene oxide.

[0038]Take 40 mg of the graphene oxide prepared by the above method and add it into 60 mL of deionized water, and ultrasonically disperse for 30 minutes; then add 710 mg of tin tetrachloride pentahydrate under magnetic stirring, and continue stirring for 1 hour to completely dissolve; add 242 mg of dihydrate under constant stirring Sodium molybdate, and continue to stir for 1 h to completely dissolve; add 700 mg of thioac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com