Patents

Literature

39results about How to "Alleviate chalking problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-based composite material, preparation method thereof, and lithium-ion battery

InactiveCN110010861AImprove conductivityImprove structural stabilityCell electrodesSecondary cellsCarbon layerIn situ polymerization

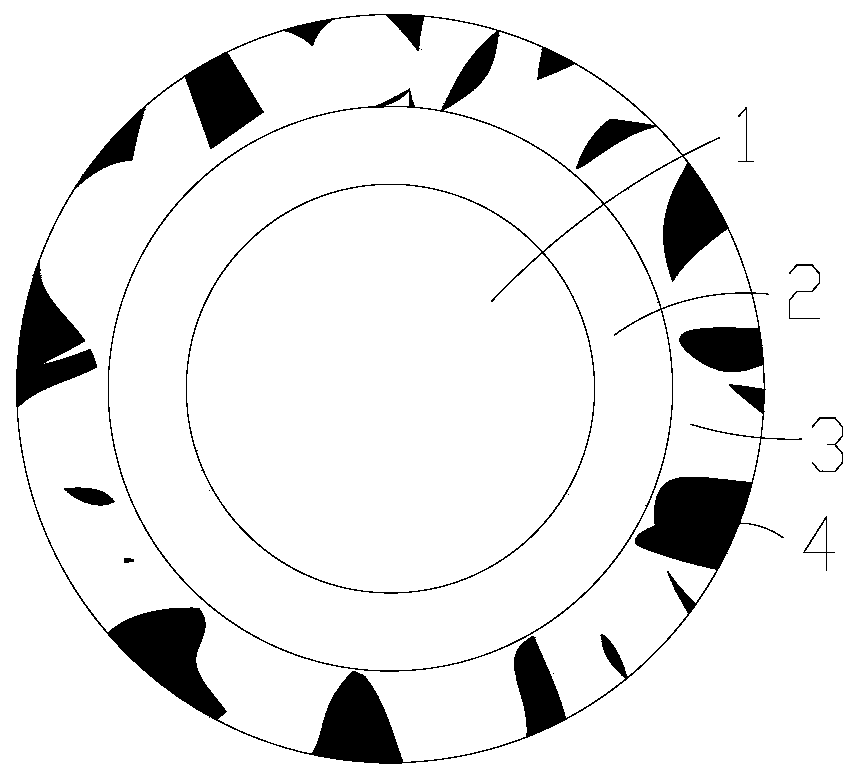

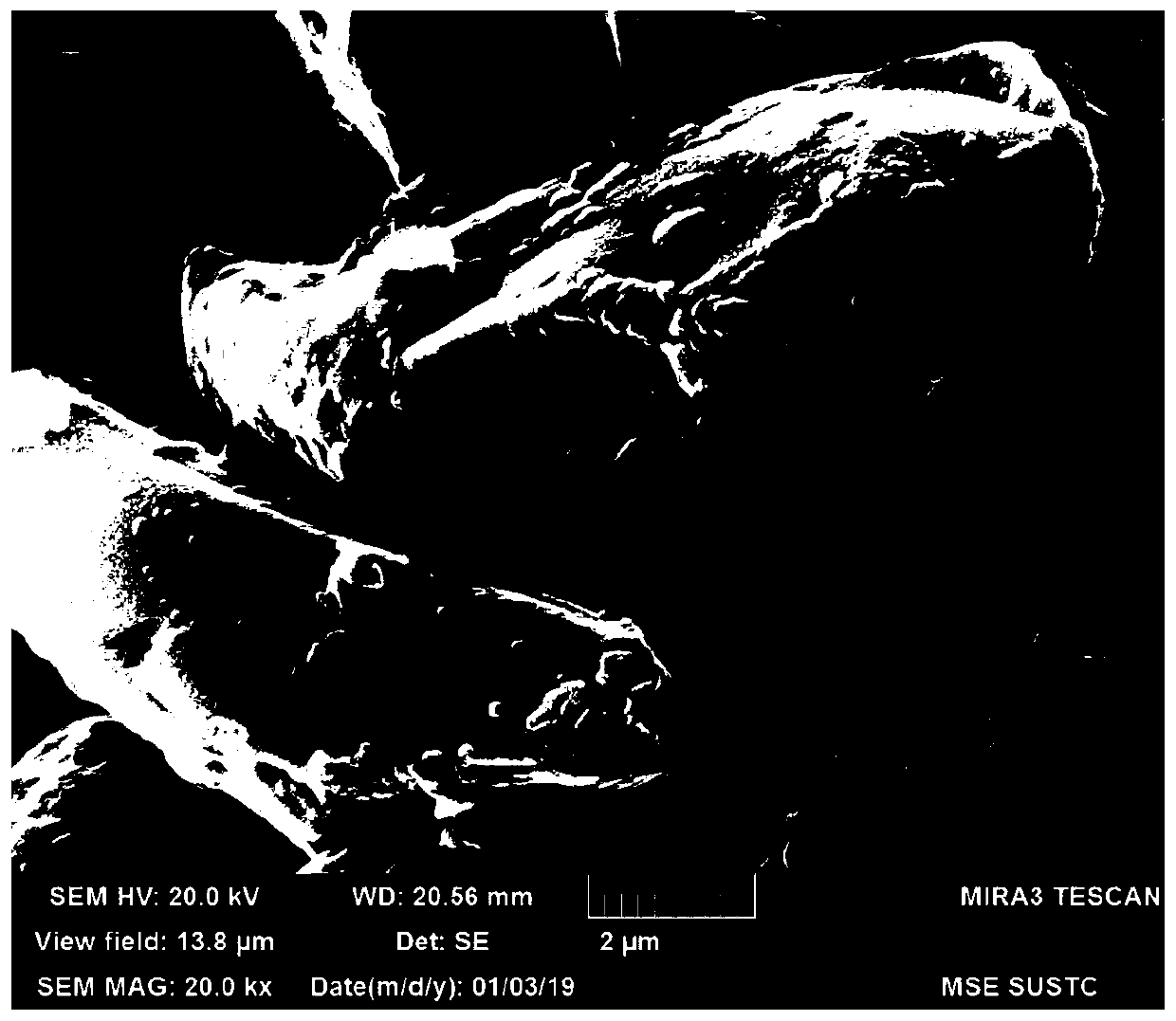

The invention provides a silicon-based composite material, a preparation method thereof and a lithium-ion battery. The preparation method comprises a step of mixing SiOx and a carbon source to obtaina SiOx@carbon source mixture, a step of curing and carbonizing the SiOx@carbon source mixture under an inert atmosphere to obtain SiOx@carbon, a step of dispersing the SiOx@carbon in a solution with oxidant, simultaneously adding a conductive polymer monomer and a conductive carbon material, uniformly dispersing, and polymerizing in situ to obtain the silicon-based composite material. The silicon-based composite material is a double-shell core-shell structure material, an outer shell layer is a conductive polymer layer, an inner shell layer is a carbon layer, and the conductive carbon materialis embedded into the conductive polymer monomer. The silicon-based composite material obtained by the method can effectively improve the electrochemical performance of the lithium-ion battery when the silicon-based composite material is used as a negative electrode material of the lithium-ion battery.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Silicon-carbon composite material of closed cage structure and preparation method of silicon-carbon composite material of closed cage structure

ActiveCN107863513AExtend your lifeImprove buffering effectMaterial nanotechnologyCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite material of a closed cage structure and a preparation method of the silicon-carbon composite material of the closed cage structure. The silicon-carboncomposite material of the closed cage structure is a hollow filled structure material in a closed cage form; the core of the hollow filled structure material is a silicon material-filled porous carbon material; the porous carbon material is filled with a silicon material; the silicon material has the void content of 50-95% in the porous carbon material; and a carbon material coats the outside ofthe silicon material-filled porous carbon material and the specific component of the carbon material is (SiOx)yC, wherein x is smaller than or equal to 2 and greater than or equal to 0 and y is smaller than or equal to 1 and greater than 0. When the silicon-carbon composite material of the closed cage structure is used as a negative electrode of a battery, contact of the silicon material and an electrolyte is isolated, the life of the battery is prolonged and the capacity performance and the cycle performance of the battery are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

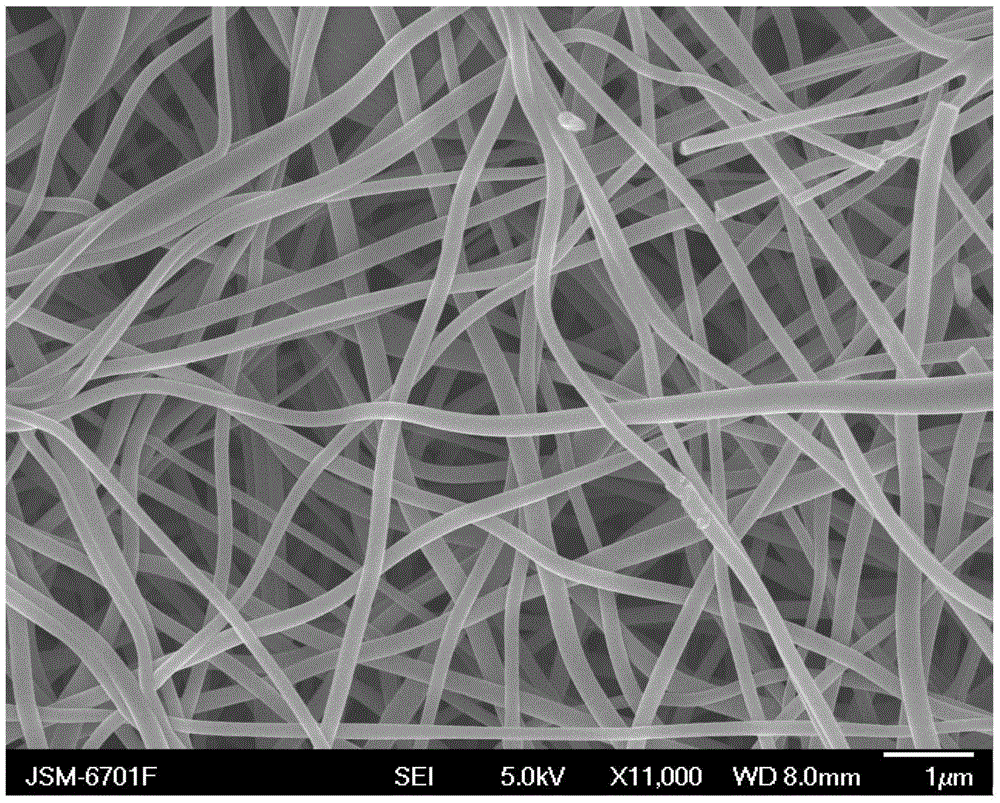

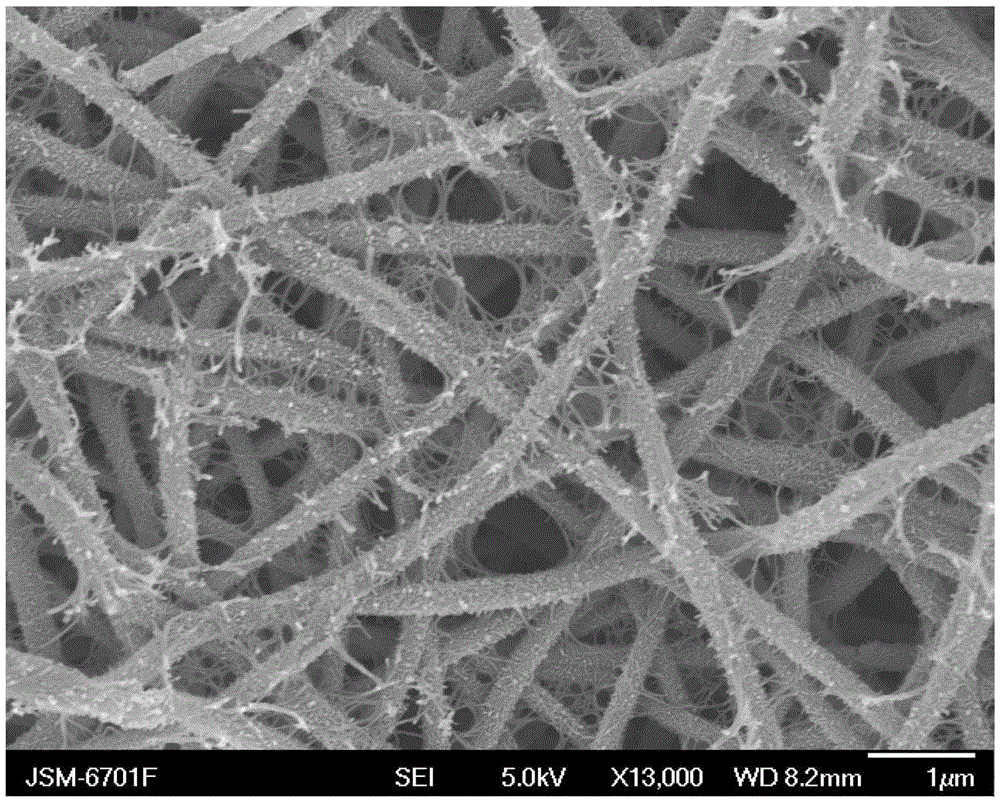

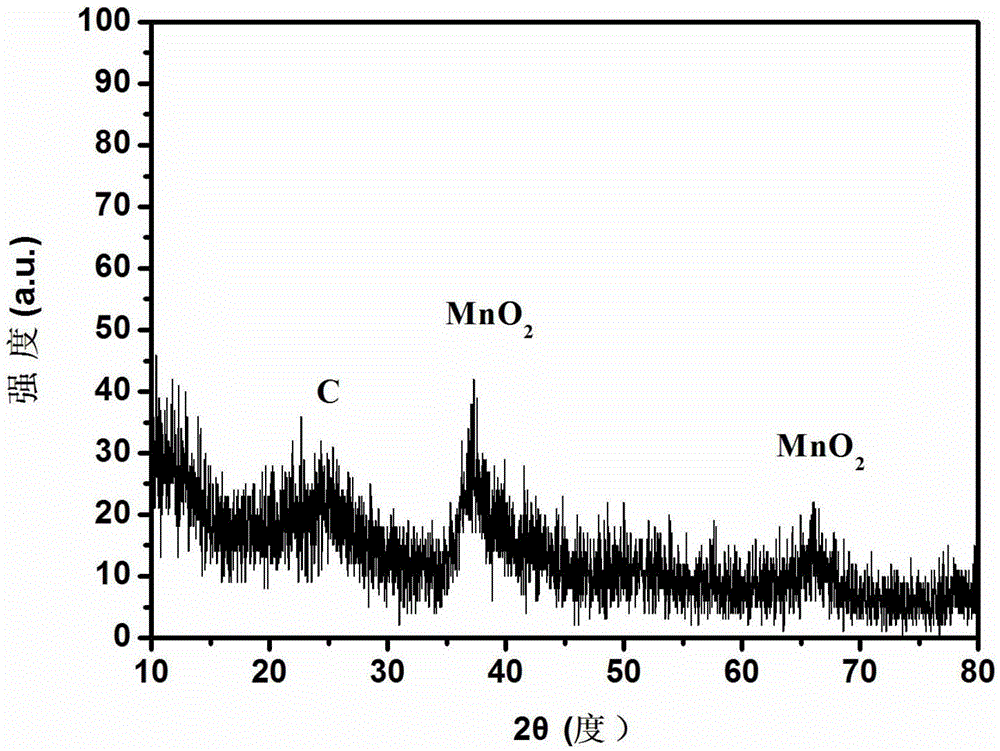

Flexible negative electrode with MnO2 attached onto carbon fiber of lithium ion battery and preparation method of flexible negative electrode

InactiveCN105552342ALithium extraction and extraction potential is lowImprove cycle performanceCell electrodesSecondary cellsFiberCarbon fibers

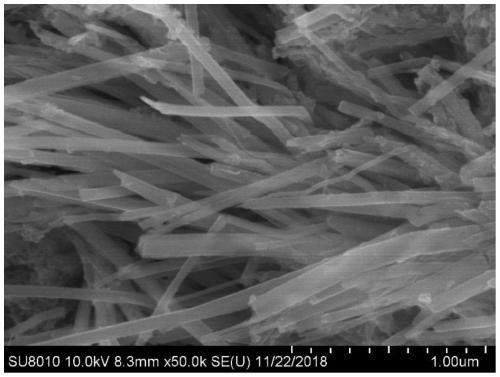

The invention relates to a flexible negative electrode with MnO2 attached onto carbon fibers of a lithium ion battery and a preparation method of the flexible negative electrode. A metal oxide in the prior art is wrapped inside the carbon nanofibers, and thus, the contact of the metal oxide serving as an active substance with an electrode and the de-intercalation process of the metal oxide with lithium ions are not promoted; and further, the metal oxide is Fe2O3, Fe3O4, Co3O4 and the like, and such metal oxide has a defect of relatively high de-intercalation lithium potential. The preparation method is characterized by comprising the following steps of firstly, preparing a flexible carbon nanofiber net, which comprises electrostatic spinning, pre-oxidation of a polymer nanofiber net and high-temperature calcination; secondly, preparing a flexible composite fiber thin film with an MnO2 nanowire attached onto the surfaces of the carbon nanofibers, placing the flexible carbon nanofiber net in a KMnO4 solution, and completing high-temperature reaction under process conditions of a reaction temperature of 150-200 DEG C and reaction time of 30-60 minutes; and finally, cutting the flexible carbon nanofiber net into the flexible negative electrode with MnO2 attached onto the carbon fibers of the lithium ion battery.

Owner:CHANGCHUN UNIV OF SCI & TECH

Composite binder, silicon-based negative electrode plate and preparation method thereof

ActiveCN110350196AFix stability issuesImproved magnification performanceNegative electrodesSecondary cellsCarbon compositesOrganic solvent

The invention provides a composite binder, a silicon-based negative electrode plate and a preparation method thereof. The preparation method of the silicon-based negative electrode plate comprises thefollowing steps of carrying out mixing on polyvinylidene fluoride of different molecular weights through a ball mill, so as to obtain a composite binder; dissolving the composite binder in an organicsolvent to obtain a binder glue solution; dispersing a conductive agent in the binder glue solution to obtain a conductive glue solution; adding silicon-carbon composite material powder and the organic solvent into the conductive glue solution to prepare electrode slurry; coating the electrode slurry on a negative current collector, and carrying out vacuum high-temperature desolventizing treatment on the current collector coated with the electrode slurry; and carrying out roll pressing on the obtained negative electrode plate to obtain the silicon-based negative electrode plate. According tothe prepared silicon-based negative electrode plate, the performance of a lithium battery electrode material can be effectively improved, the rate performance of the battery is improved, and the cyclelife of the battery is prolonged.

Owner:DONGHUA UNIV

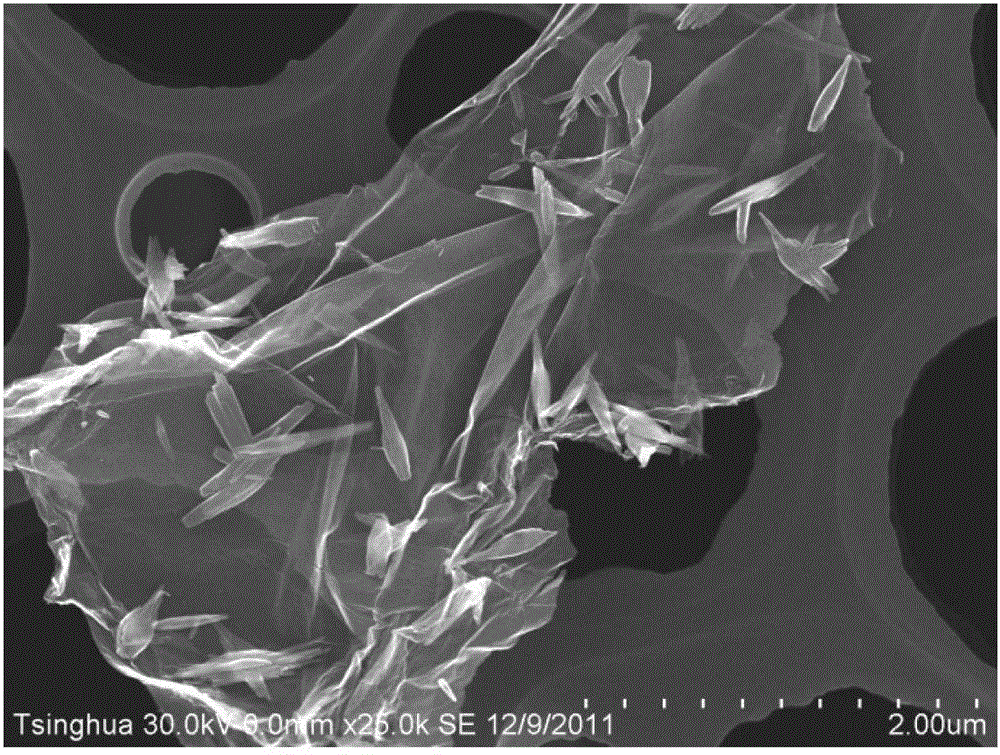

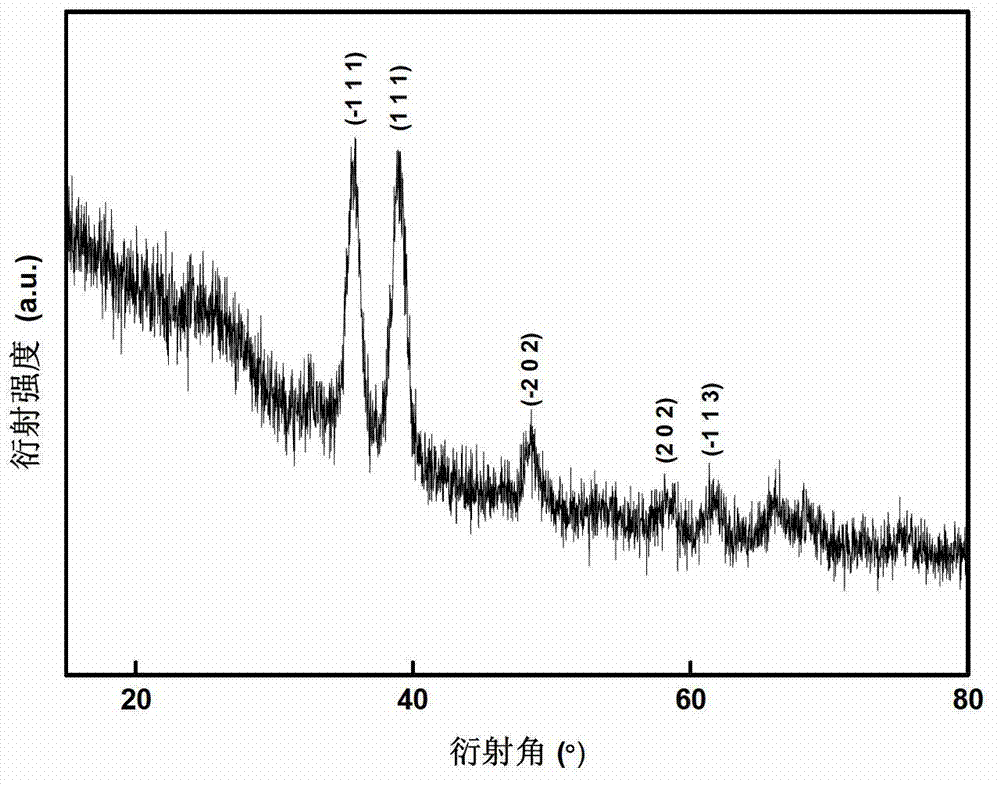

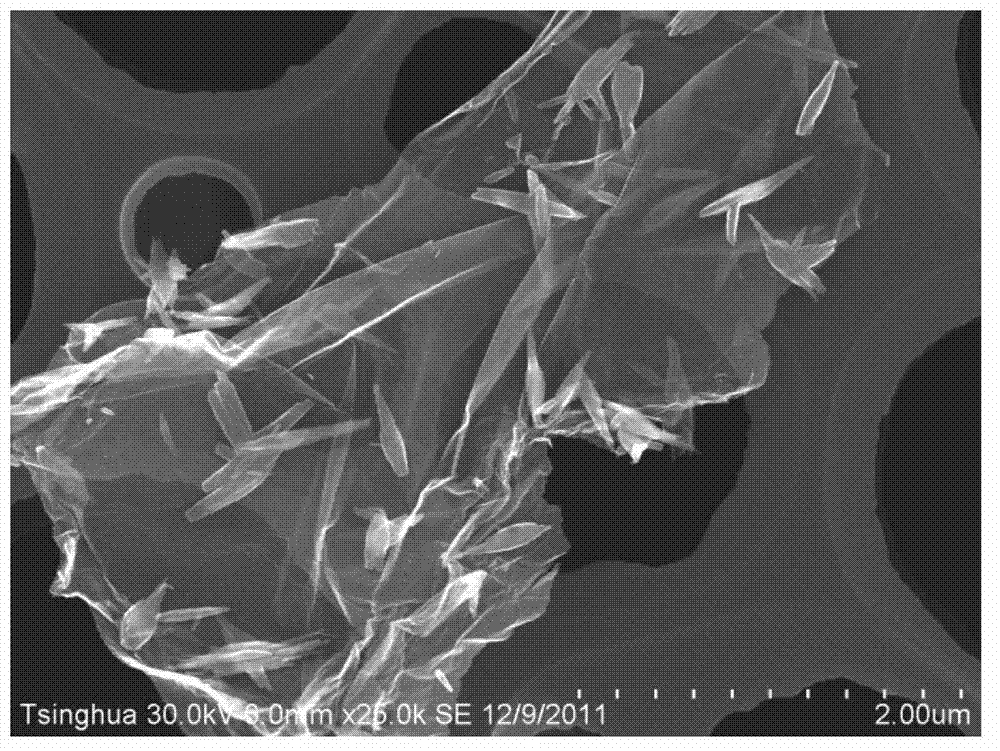

Graphene-coated copper oxide composite cathode material and method for manufacturing same

ActiveCN102916195AAlleviate chalking problemsPromote migrationCell electrodesComposite cathodeSynthesis methods

The invention discloses a graphene-coated copper oxide composite cathode material and a method for manufacturing the same. The graphene-coated copper oxide composite cathode material comprises, by mass, from 20% to 90% of copper oxide and from 10% to 80% of graphene. The method includes uniformly mixing copper salt solution and graphene oxide solution at first, and stirring the copper salt solution and the graphene oxide solution at a constant temperature for 15 minutes to 1 hour to obtain mixed solution; dripping sodium hydroxide solution into the mixed solution, continuously stirring the mixed solution added with the sodium hydroxide solution for 0.5 hour to 2 hours and allowing the mixed solution added with the sodium hydroxide solution to stand for 2 to 24 hours; and performing centrifuging and hydrothermal processing for the mixed solution added with the sodium hydroxide solution to obtain a product, and drying the product at the temperature of 120 DEG C for 12 hours to obtain the graphene-coated copper oxide composite cathode material. The graphene-coated copper oxide composite cathode material and the method have the advantages that the synthesis method is simple, the manufactured graphene-coated copper oxide composite cathode material is good in performance, and technical problems of poor conductivity of a copper oxide electrode and decrease of capacity due to gradual chalking in charge and discharge processes are solved.

Owner:TSINGHUA UNIV

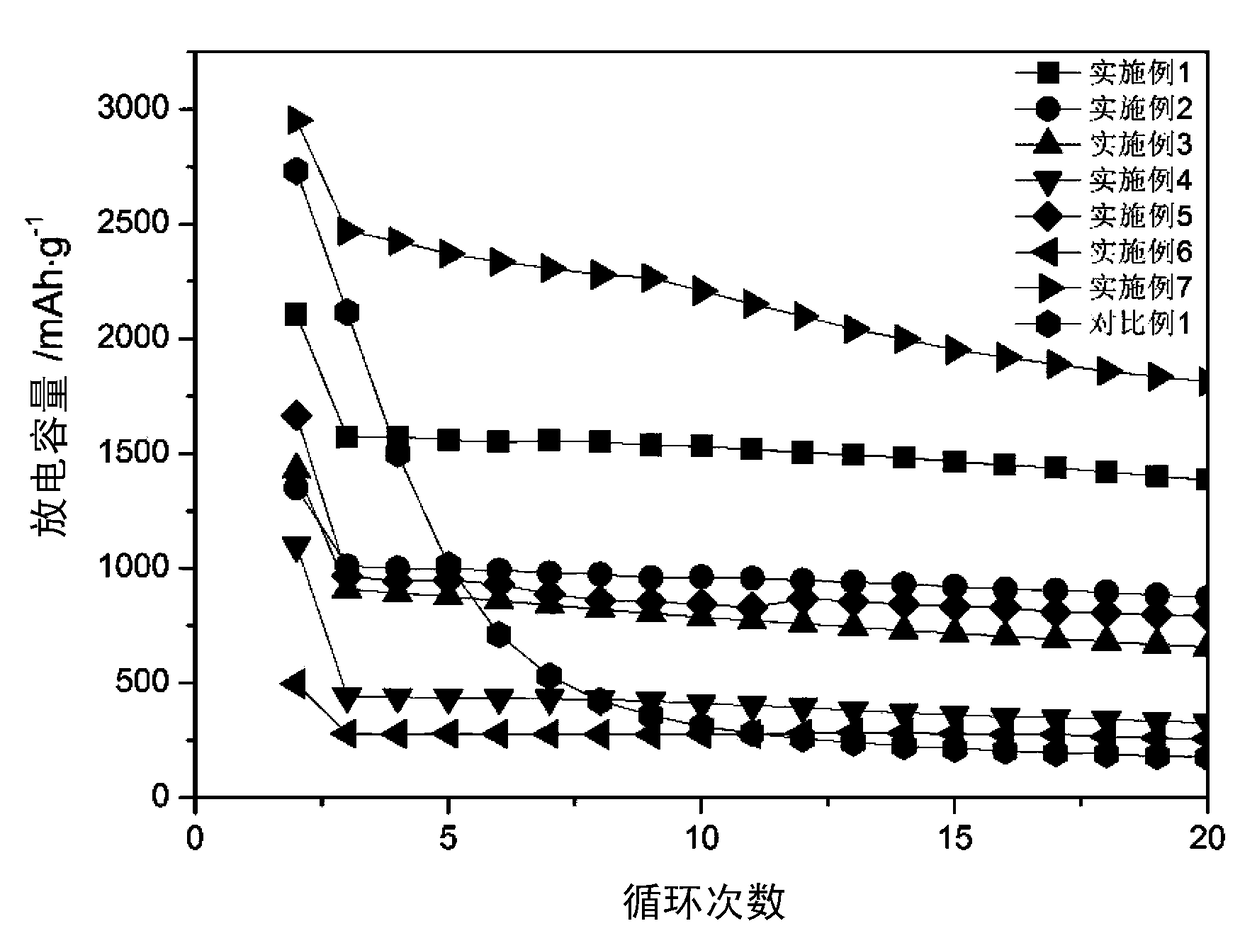

SiOx/carbon composite material and preparation method thereof, and lithium ion battery

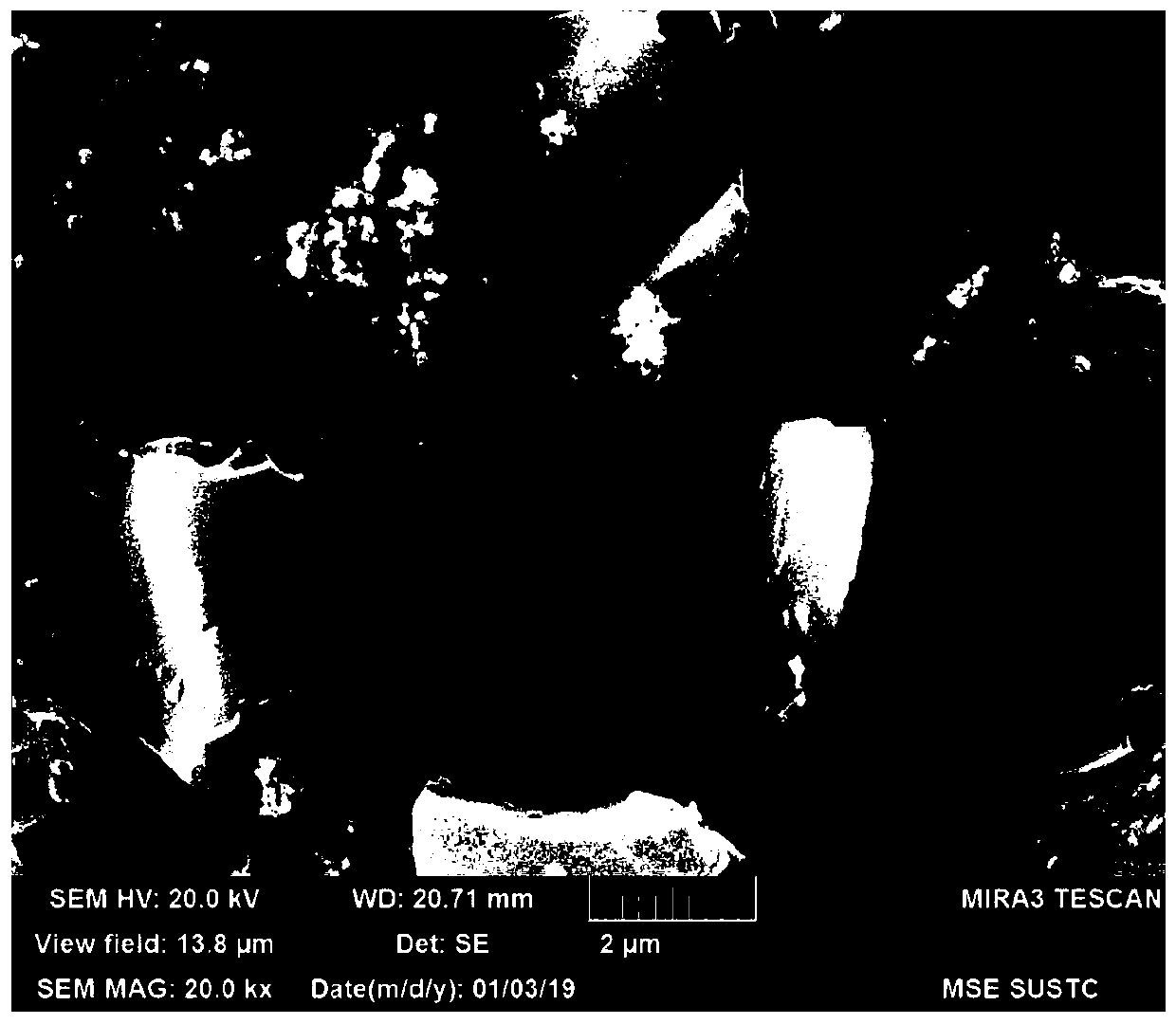

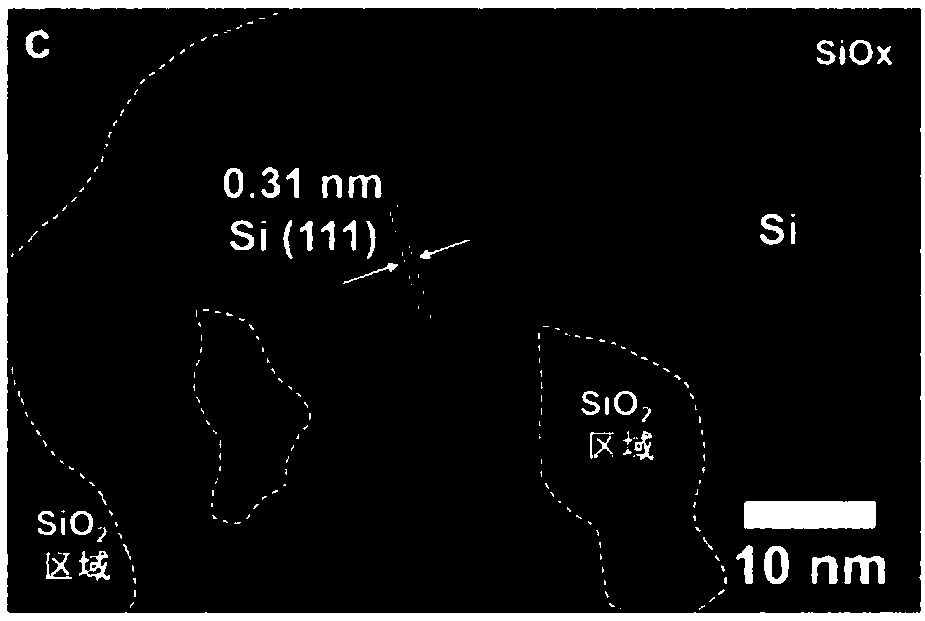

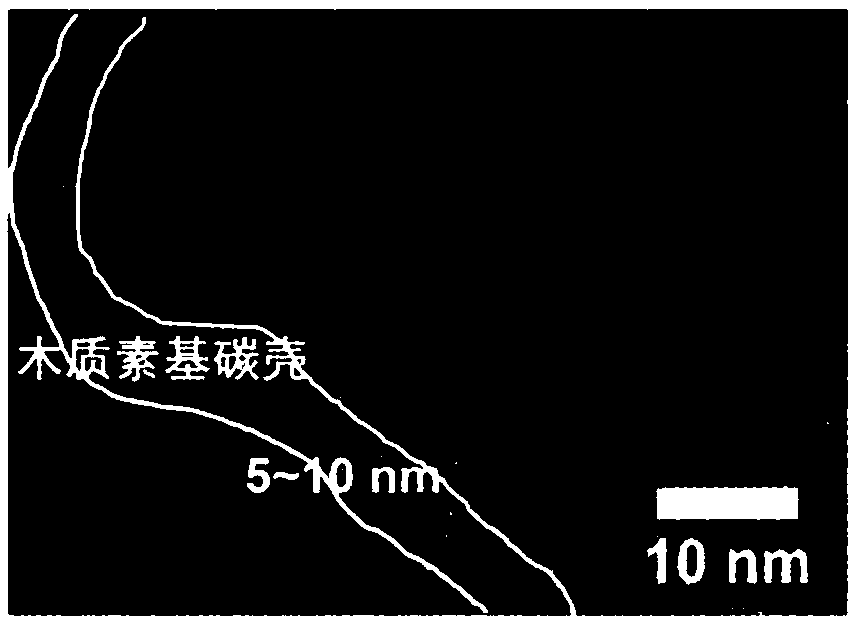

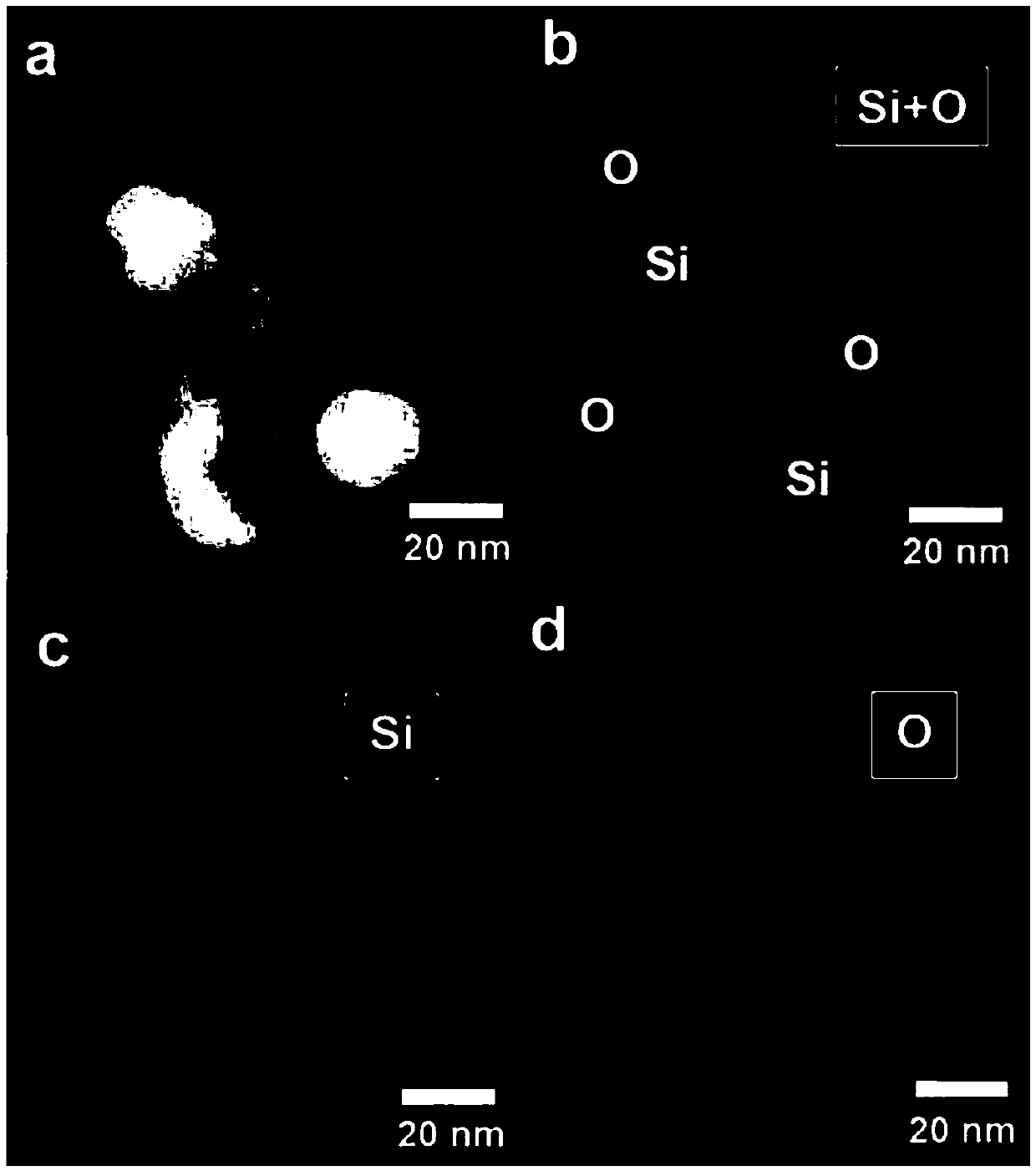

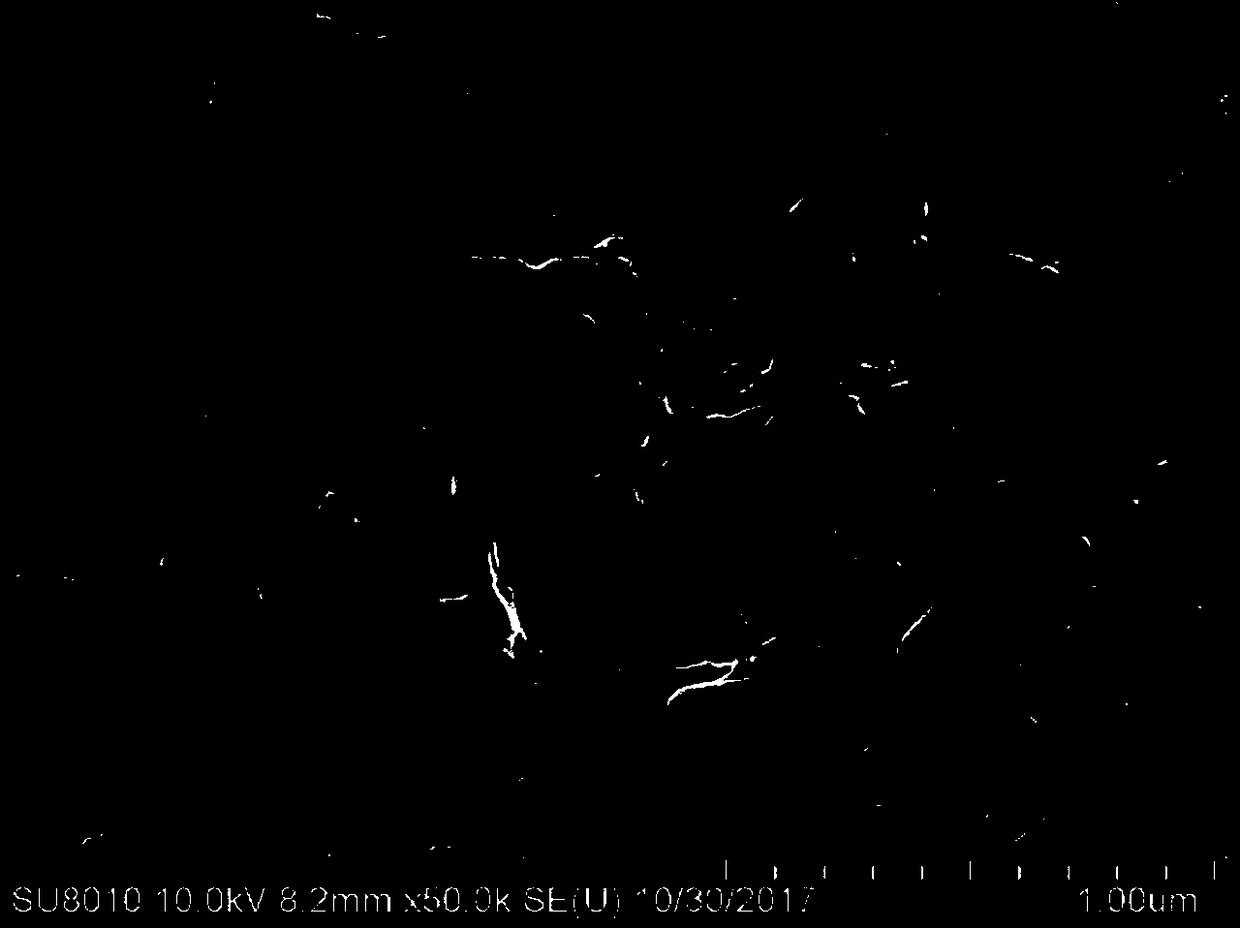

InactiveCN110085811AHigh degree of graphitizationRealize resource utilizationMaterial nanotechnologyCell electrodesCarbon compositesCarbonization

The invention provides a preparation method of a SiOx / carbon composite material. The method comprises steps that silica and magnesium powder are subjected to ball milling under ball milling conditions, the silica and the magnesium powder are subjected to magnesium thermal reaction, washing is then performed with hydrochloric acid till no magnesium ions are detected in the eluate, washing with thedeionized water is performed till the solution is neutral, and SiOx is obtained; the SiOx, lignin, iron source and organic solvent are mixed and sonicated to obtain SiOx / carbon precursor; the SiOx / carbon precursor is placed in a reducing atmosphere for calcination treatment, the iron source is reduced to iron, moreover, the iron plays a catalytic role in the carbonization process of lignin, the graphitization degree of the lignin is increased upon carbonization, the acid solution is utilized for several washing treatments, the iron is removed, and the SiOx / carbon composite material is obtained. The method is advantaged in that the SiOx / carbon composite material obtained by the method can improve electrochemical performance of the lithium ion battery.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

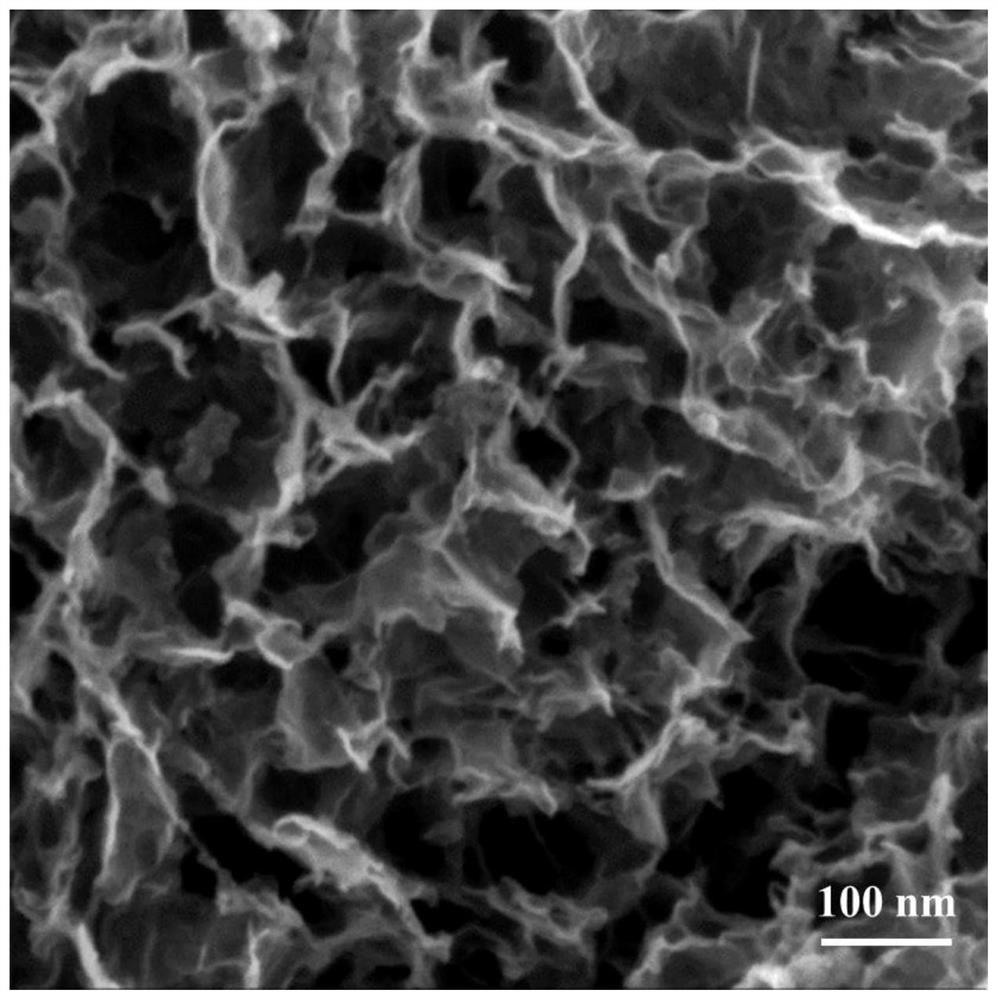

Molybdenum disulfide/tin disulfide/graphene composite and preparation method thereof

InactiveCN108539175AInhibition of agglomerationImprove conductivityCell electrodesGrapheneSulfurCvd graphene

The invention discloses a molybdenum disulfide / tin disulfide / graphene composite and a preparation method thereof. Molybdenum disulfide / tin disulfide grows on the surface of graphene in a manner of horizontal interface contact growth; with graphene oxide as a carbon source, tin chloride pentahydrate as a tin source, sodium molybdate dihydrate as a molybdenum source and thioacetamide as a sulfur source, the carbon source, tin source, molybdenum source and sulfur source are added sequentially into deionized water and heated at 200 DEG C for 16h to synthesize the molybdenum disulfide / tin disulfide / graphene composite. The molybdenum disulfide / tin disulfide / graphene composite has a stable structure and high electrical conductivity, and has the advantages of large specific surface area and excellent electrochemical performance; the preparation method has low requirements on reaction conditions, simple operation, high yield and good repeatability.

Owner:CHINA JILIANG UNIV

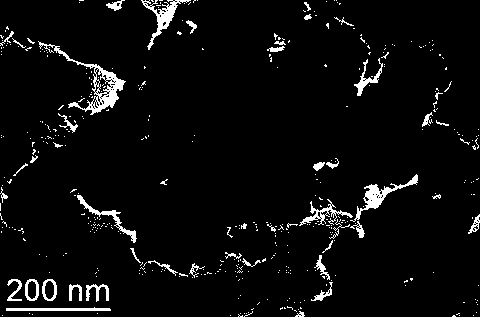

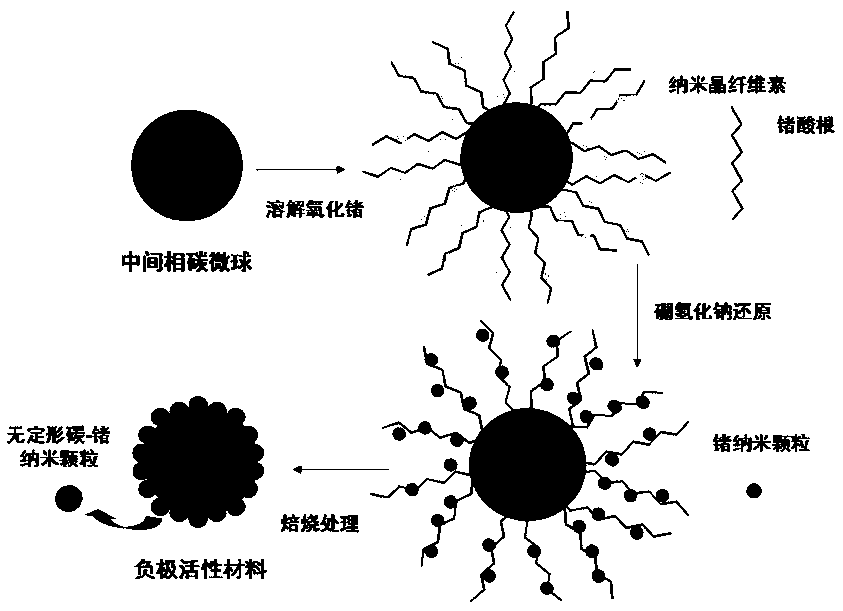

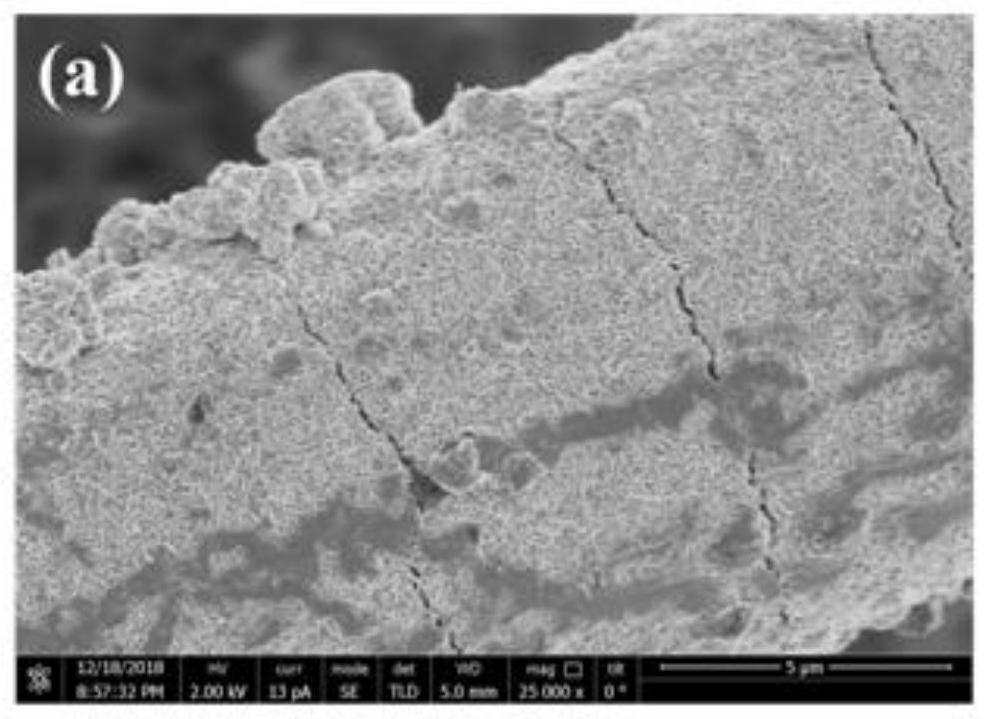

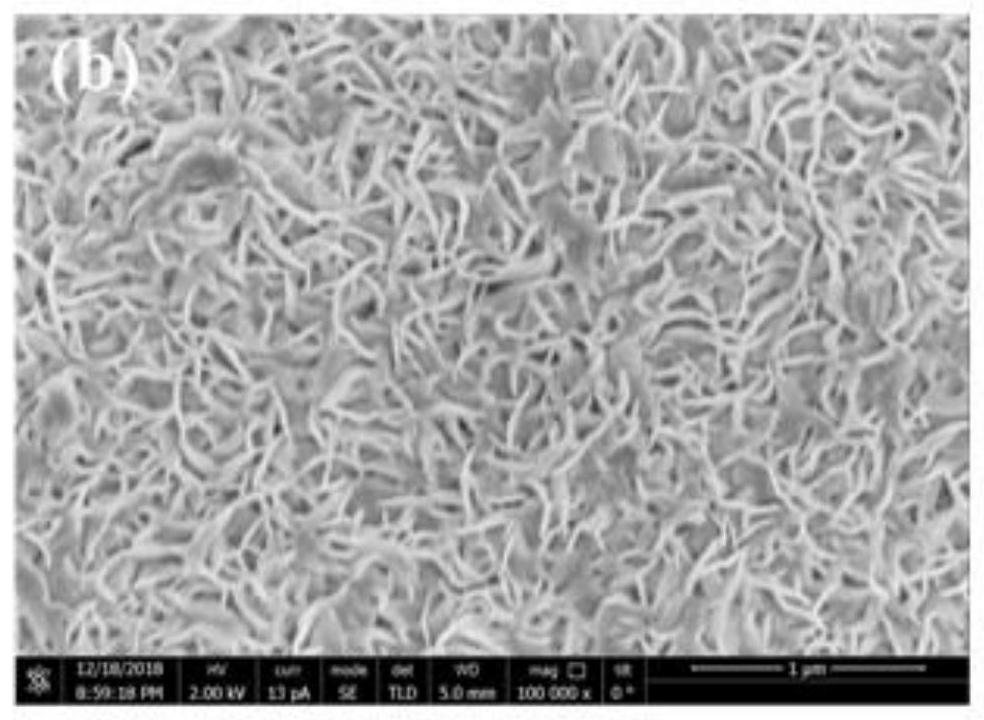

Lithium-ion battery germanium/carbon composite negative electrode material and preparation method and application thereof

ActiveCN110085847AImprove cycle stabilityAvoid reunionNegative electrodesSecondary cellsCelluloseCarbon composites

The invention discloses a lithium-ion battery germanium / carbon composite negative electrode material and a preparation method and an application thereof. The composite negative electrode material includes germanium nanoparticles, mesocarbon microbeads and amorphous carbon. The preparation method comprises the steps of (1) dissolving GeO2 in an alkaline solution, adding nanocrystalline cellulose, adjusting the pH-value of the obtained first suspension, adding the mesocarbon microbeads and stirring to form a second suspension, and transferring the second suspension to a water bath; (2) preparingan NaBH4 solution, adding the heated second suspension, stirring for reaction in the water bath, washing wafer vacuum filtration, then carrying out vacuum drying, roasting the dried solid in an inertgas or reducing atmosphere to obtain the product. The composite negative electrode material disclosed by the invention has high mass capacity and volume specific capacity, can effectively alleviate the volume change and pulverization of germanium, is high in cycle stability and good in compatibility with a propylene carbonate containing electrolyte, has the advantages of good low-temperature electrochemical performance and the like and can be applied to lithium-ion batteries.

Owner:NAT UNIV OF DEFENSE TECH

Silicon-based negative electrode slurry for lithium batteries, and preparation method thereof

InactiveCN109860596AImprove cycle performanceAlleviate chalking problemsCell electrodesCyclic processSlurry

The invention discloses silicon-based negative electrode slurry for lithium batteries, and a preparation method thereof. The slurry includes 40-100 parts of a silicon-based active substance, 0.1-10 parts of a conductive agent, 0.5-10 parts of a cross-linking type binder, and 20-200 parts of deionized water. The active substance in the slurry can be uniformly dispersed in a binder crosslinking network, so that the problems of pole piece pulverization and poor cycle performance caused by volume expansion of a silicon-based negative electrode material during a charging and discharging cyclic process can be effectively improved.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

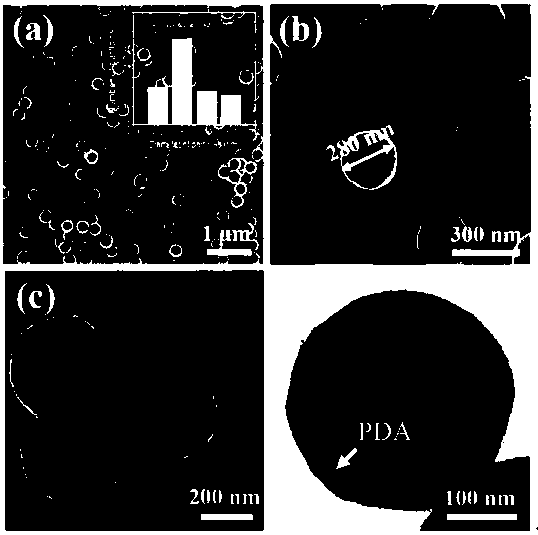

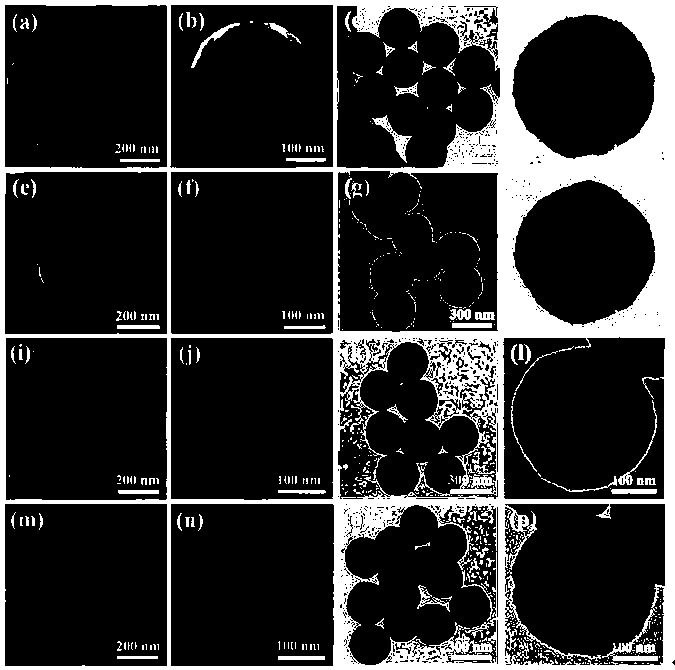

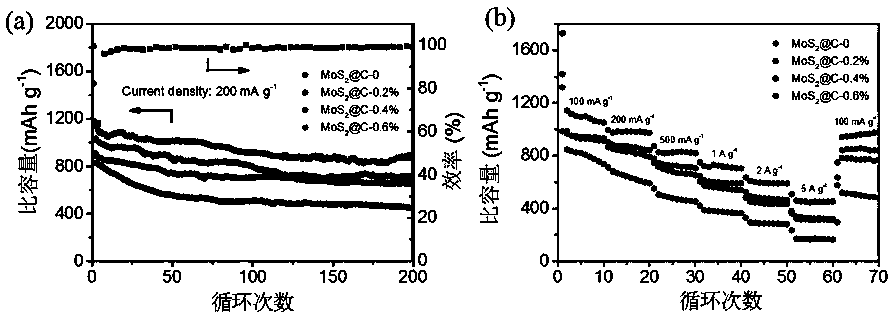

Preparation method of yolk-shell structure molybdenum disulfide@ carbon electrode material

InactiveCN108039459AUniform sizePrevent reaggregationCell electrodesSecondary cellsYolkCarbonization

The invention relates to a preparation method of a yolk-shell structure molybdenum disulfide@ carbon electrode material. The preparation method includes: utilizing molybdenum disulfide precursor solvothermal ethylene glycol to obtain monodisperse molybdenum disulfide nanospheres; allowing dopamine to self-polymerize on the interfaces of molybdenum disulfide particles to obtain a molybdenum disulfide@ polydopamine core-shell structure, and performing high-temperature carbonization on molybdenum disulfide@ polydopamine to obtain core-shell structure molybdenum disulfide@ carbon nanoparticles; dispersing molybdenum disulfide@ carbon in a hydrogen peroxide solution for hydrogen peroxide etching to obtain the yolk-shell structure molybdenum disulfide@ carbon material. A gap between molybdenum disulfide and a carbon shell can be well regulated by adjusting concentration of hydrogen peroxide. When the concentration of hydrogen peroxide is 0.4vol%, discharging specific capacity of a prepared yolk-shell structure molybdenum disulfide@ carbon lithium ion battery cathode in the second circle is up to 1167mAh g-1, discharging specific capacity after being circulated for 200 circles is 880mAh g-1, capacity retaining rate is 75.4%, and rate performance is outstanding.

Owner:FUDAN UNIV

Sodium-ion battery negative electrode material and preparation method and application thereof

InactiveCN112436113AHigh specific capacityImprove cycle lifeNegative electrodesSecondary cellsElectrical batterySodium-ion battery

The invention discloses a preparation method and application of a sodium-ion battery negative electrode material. The preparation method comprises the following steps of synthesizing WS2 / MoS2-G, synthesizing WS2 / MoS2-G@C and applying the WS2 / MoS2-G and the WS2 / MoS2-G@C to a sodium-ion battery. The WS2 / MoS2-G is subjected to hydrothermal synthesis to generate WS2, MoS2 and heteroatom-doped grapheneare uniformly cross-linked and compounded together, recompression of graphene is reduced due to existence of sulfide, and good specific surface area and conductivity of graphene are reserved; the flexible graphene can slow down volume expansion, inhibit sulfide aggregation, introduce nanometer size, increase electrochemical activity, increase Na<+> adsorption and obtain more ion storage sites; and the WS2 / MoS2-G@C final product has multiple advantages of sulfide and graphene, the carbon precursor powder is carbonized to generate amorphous carbon with good interlayer spacing, the microstructure of the whole composite material is almost layered, weak Van der Waals' force combination is achieved, large Na<+> can be contained for back-and-forth de-intercalation, and good charging and discharging performance is achieved.

Owner:内蒙古杉杉科技有限公司

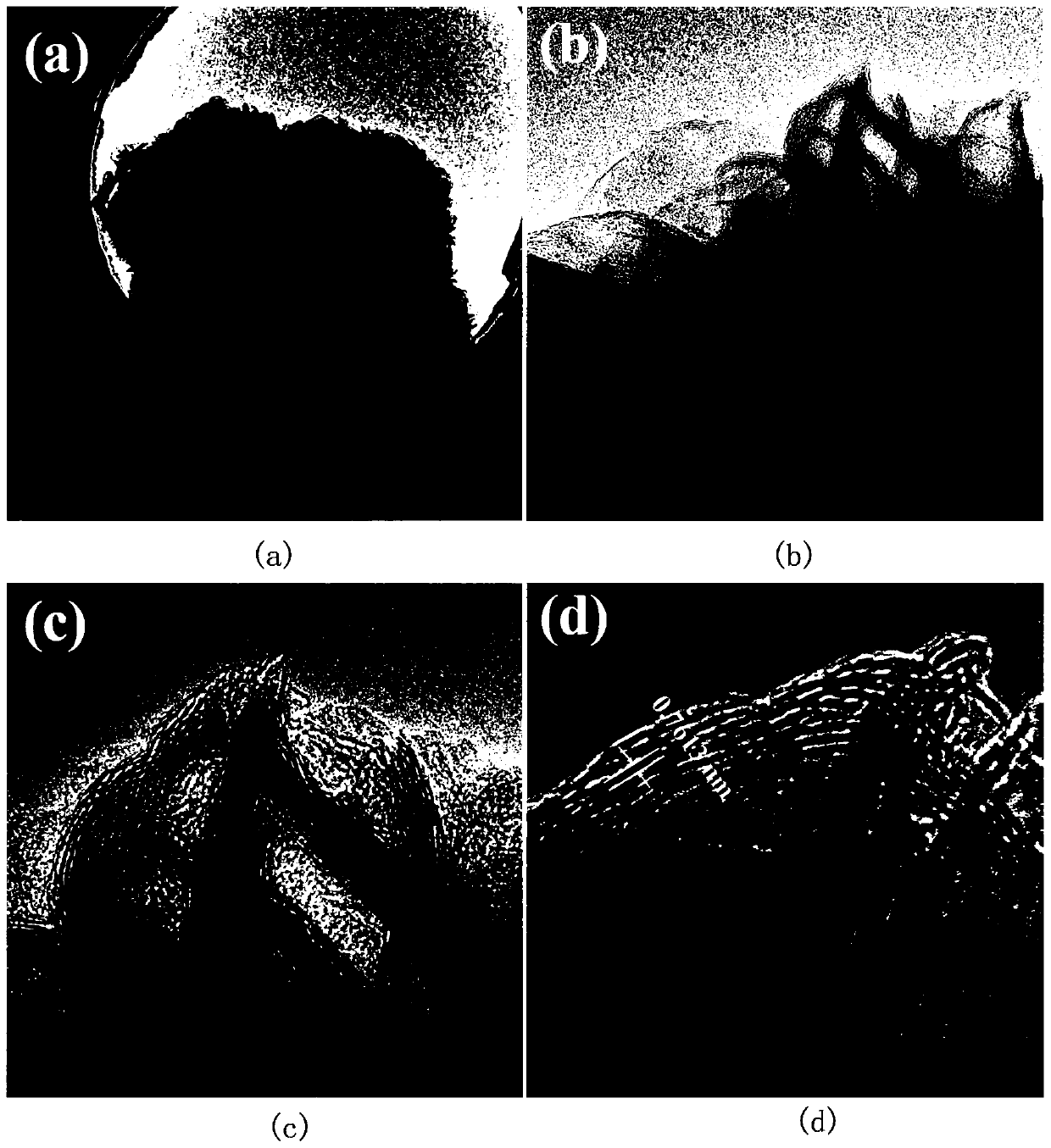

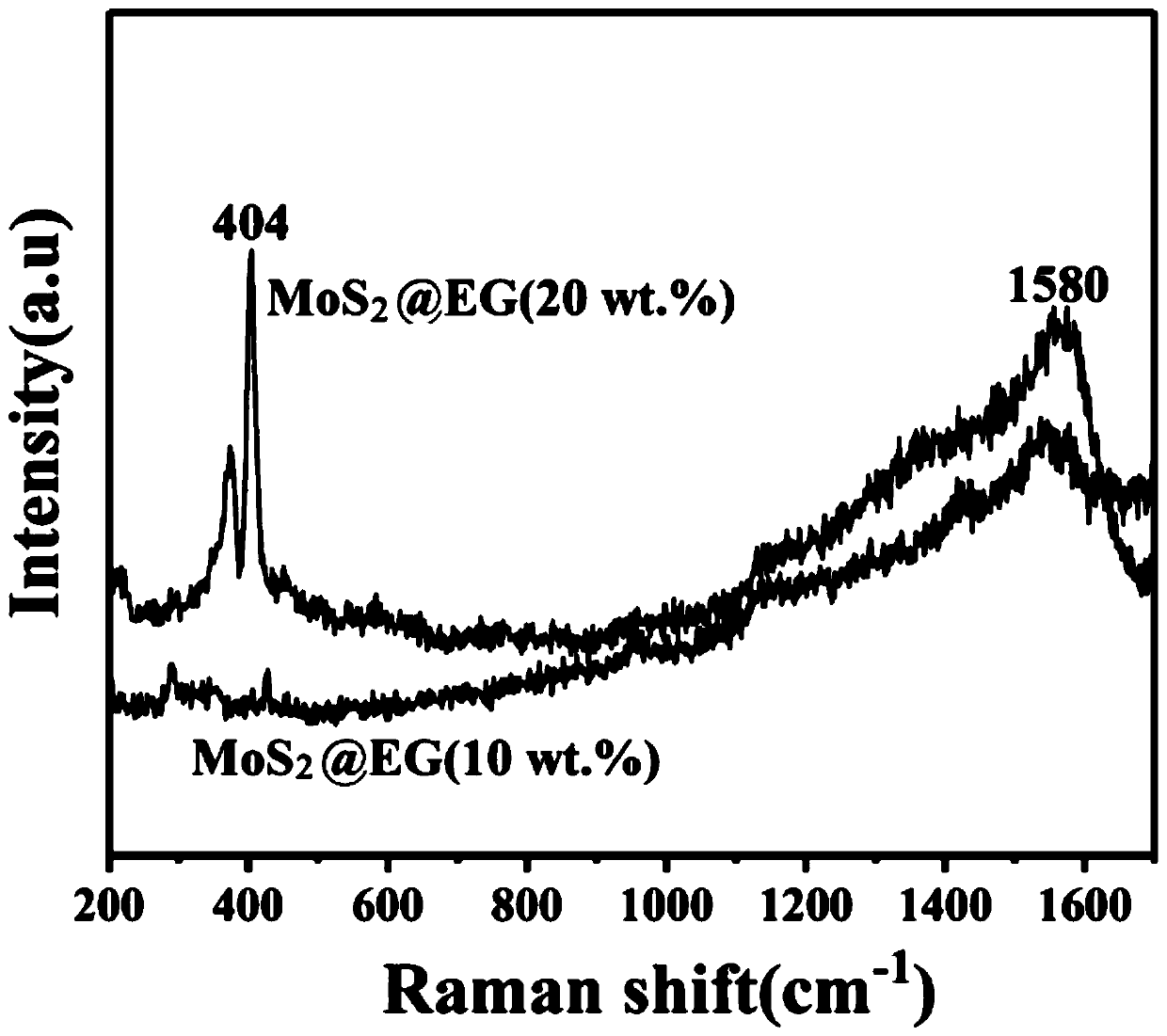

MoS2@EG magnesium-lithium double-salt ion battery positive electrode material and construction method thereof

InactiveCN110311117AImprove structural stabilityImprove mechanical propertiesMaterial nanotechnologySecondary cellsElectrical batteryDouble salt

The invention discloses a MoSe2@EG magnesium-lithium double-salt ion battery positive electrode material and a construction method thereof. a layer of high-activity nanoflower-like two-dimensional nanomaterial MoS2 is loaded in situ on the surface of EG with good conductivity by one-step hydrothermal method, efficient saturated intercalation and de-intercalation of Li+ in the positive electrode material can be effectively promoted with the help of the high conductivity of EG and the high activity and layered structure characteristics of MoS2, and the capacity and rate characteristic of double-salt batteries are improved. In addition, MoSe2@EG can effectively alleviate a problem of material pulverization caused by volume expansion and contraction of the positive electrode material due to the intercalation and de-intercalation of Li+, thereby improving the cycle stability of the magnesium-lithium double-salt ion batteries, and prolonging the battery life.

Owner:SHAANXI UNIV OF SCI & TECH

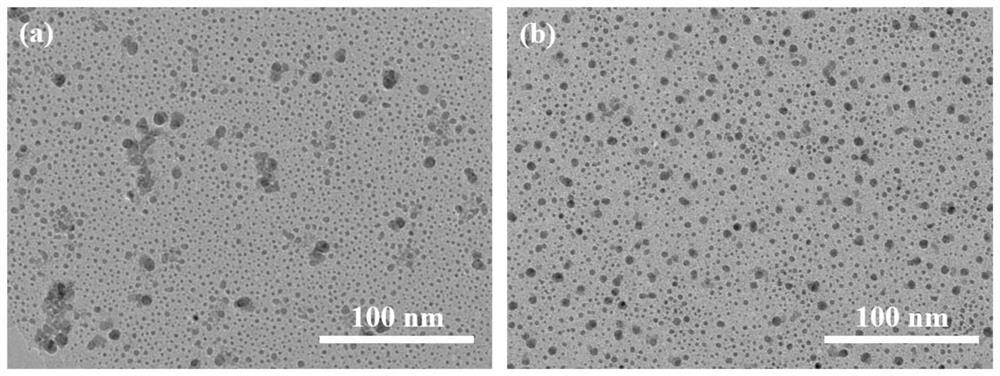

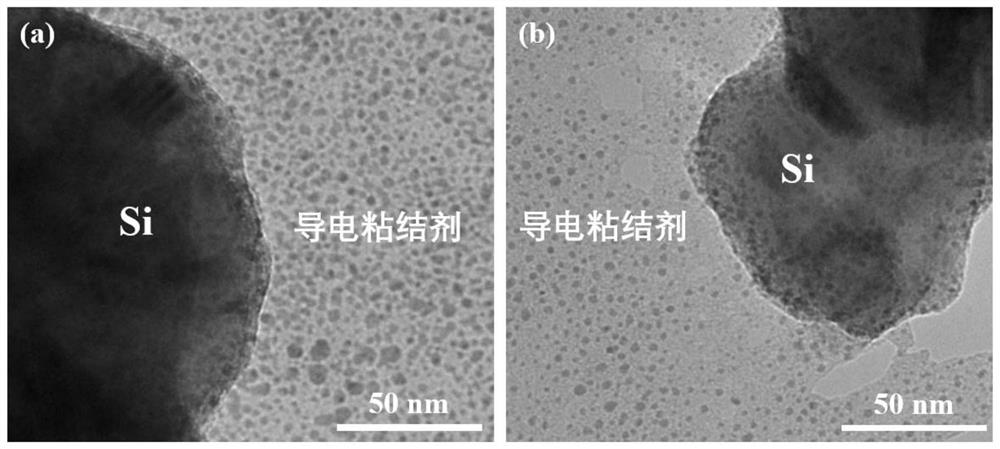

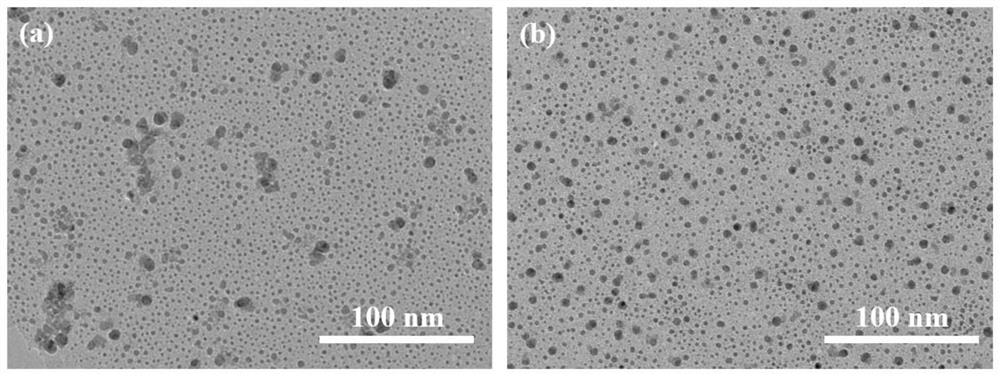

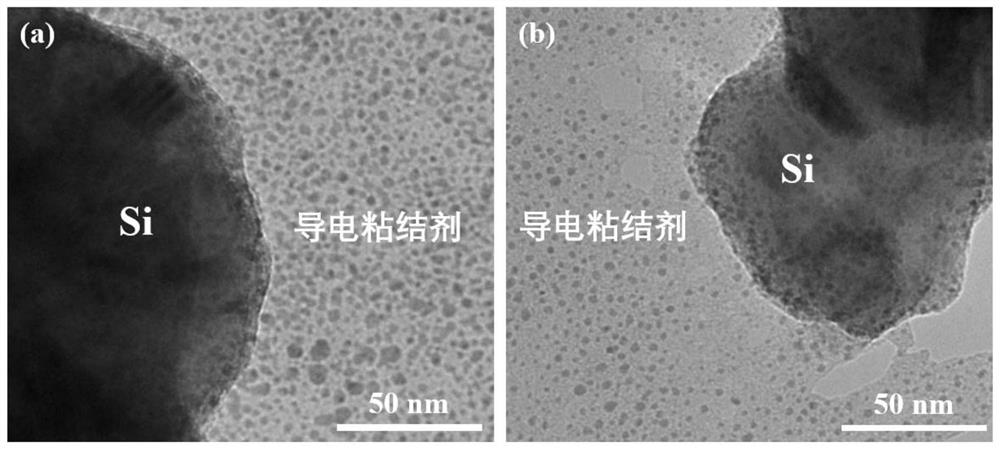

Conductive binder material and preparation method thereof, negative pole piece and lithium ion battery

ActiveCN112072106AImprove electrical conductivityImproved stability and energy densityNegative electrodesSecondary cellsSodium carboxymethylcellulosePoly ethylene

The invention provides a conductive adhesive material and a preparation method thereof, a negative pole piece and a lithium ion battery, and relates to the field of batteries. The conductive adhesivematerial comprises polyvinyl alcohol, sodium carboxymethyl cellulose, sodium alginate, chitosan, polyethyleneimine and other polymers rich in hydroxyl groups, carboxyl groups and amino groups as raw materials, and a polymer carbon dot aqueous solution is prepared through high-temperature and high-pressure or microwave treatment. By utilizing a conductive binder material, the problems that in the prior art, when a silicon-based material is used as a negative electrode active material, the silicon-based material is poor in conductivity and is easy to fall off from a pole piece can be solved, andthe purposes of improving the conductivity of the pole piece and the binding power of the pole piece material so as to improve the energy density of the silicon negative electrode pole piece are achieved.

Owner:ZHEJIANG UNIV

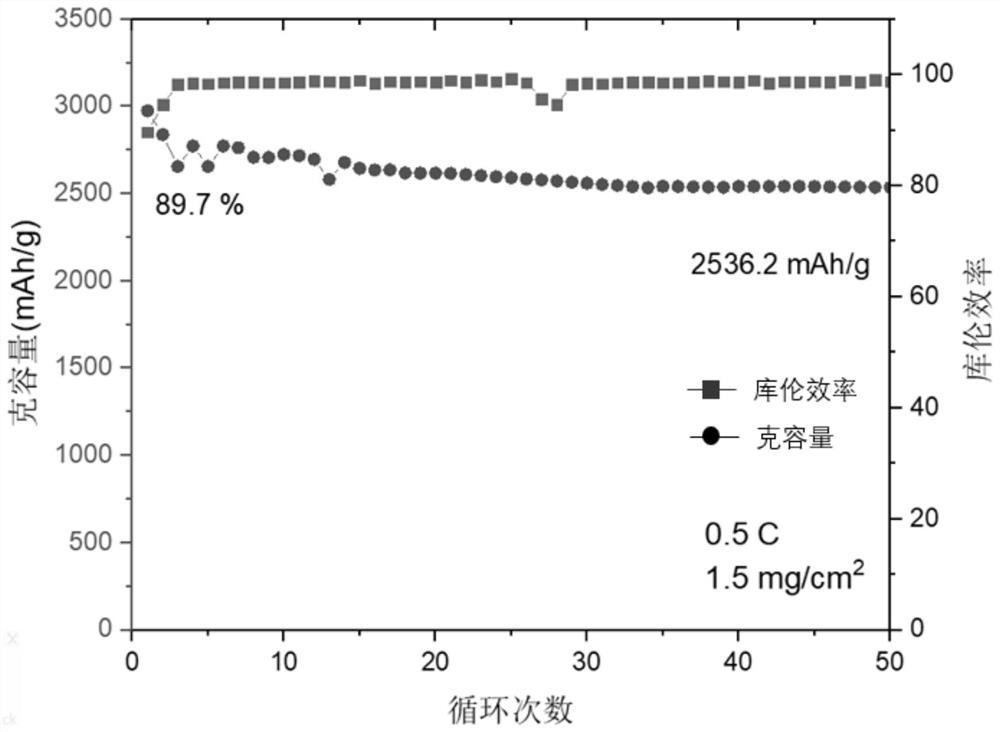

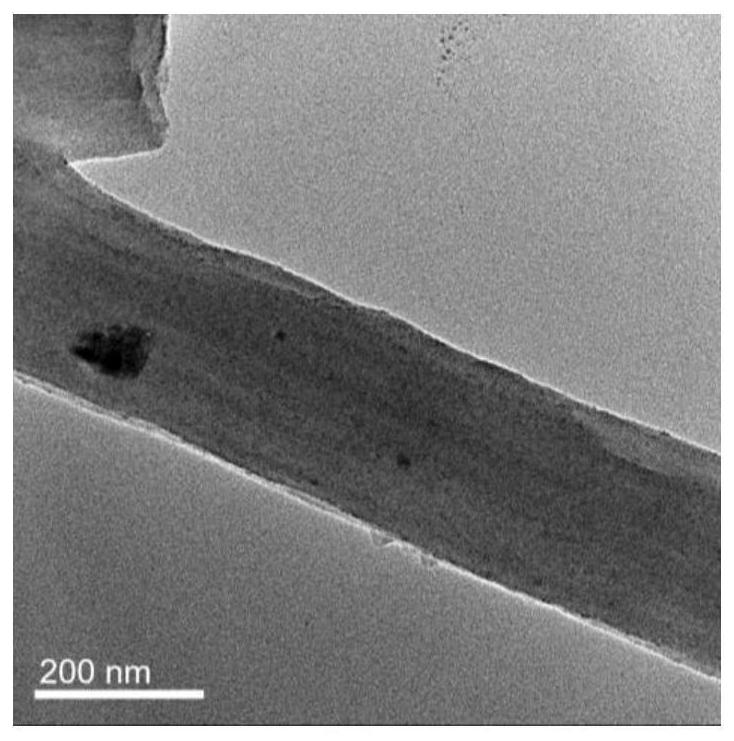

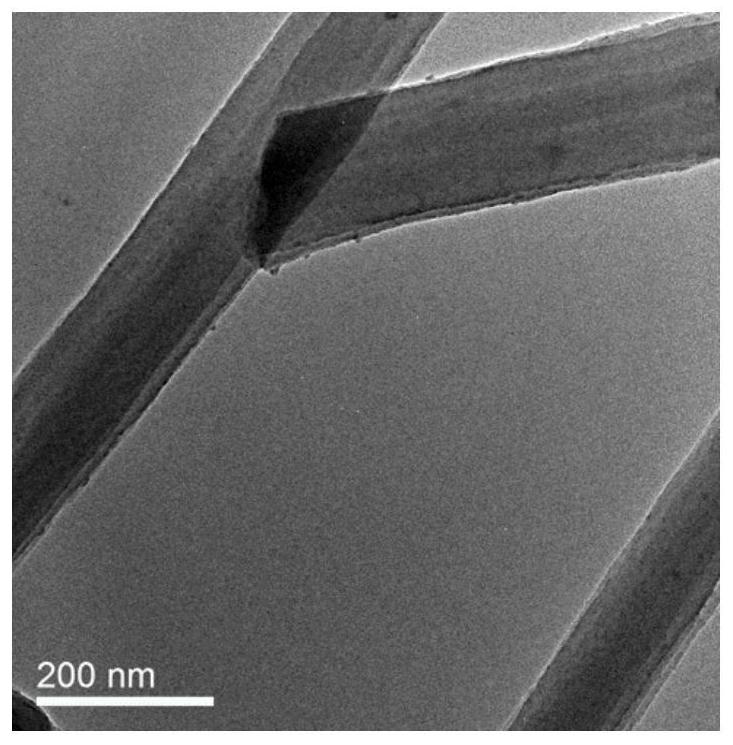

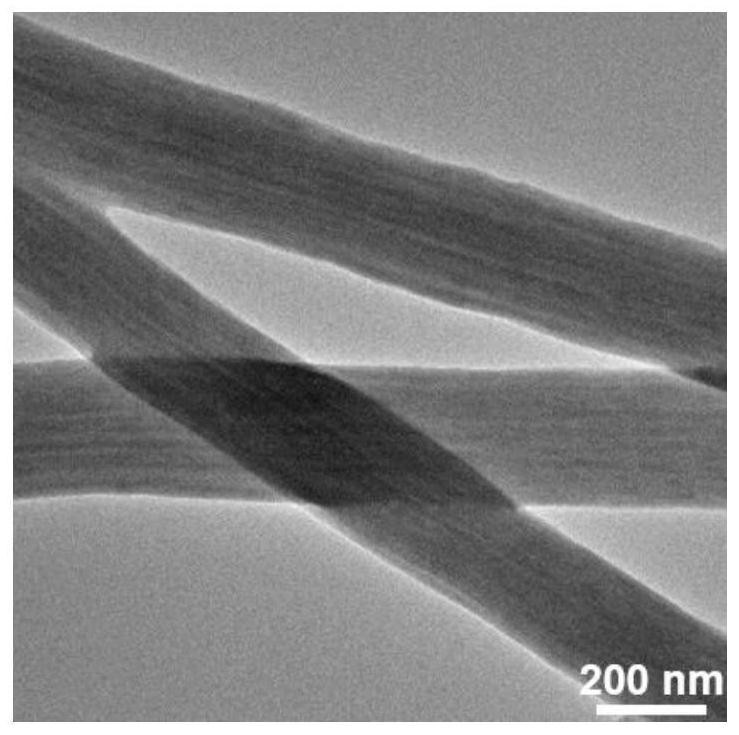

Preparation method and application of high-dispersion metal oxide/carbon nanofiber composite material

PendingCN111740099ALow costSimple processNegative electrodesSecondary cellsSpinningPolyvinyl alcohol

The invention discloses a preparation method and application of a high-dispersion metal oxide / carbon nanofiber composite material. The method is characterized by comprising the following steps: dissolving a metal precursor, a dispersing agent and polyacrylonitrile in dimethylformamide, and uniformly mixing to prepare a spinning solution; putting the spinning solution into an electrostatic spinningdevice, and preparing a fiber precursor membrane through electrostatic spinning; performing high-temperature carbonization treatment on the fiber precursor membrane in a nitrogen atmosphere to obtainthe high-dispersion metal oxide / carbon nanofiber composite material, wherein the dispersing agent is any one of malic acid, citric acid, polyvinyl alcohol, polyvinylpyrrolidone and gelatin. The high-dispersion metal oxide / carbon nanofiber composite material prepared by the invention is used as a self-supporting sodium ion battery negative electrode material; the problems that an existing composite material is large in metal oxide particle, low in dispersity, serious in agglomeration or pulverization in the charging and discharging process and the like are solved; and the composite material has the advantages of being simple in preparation process method, low in preparation cost, good in metal oxide dispersity, high in charging and discharging specific capacity, good in cycling stability and the like and has wide application prospects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

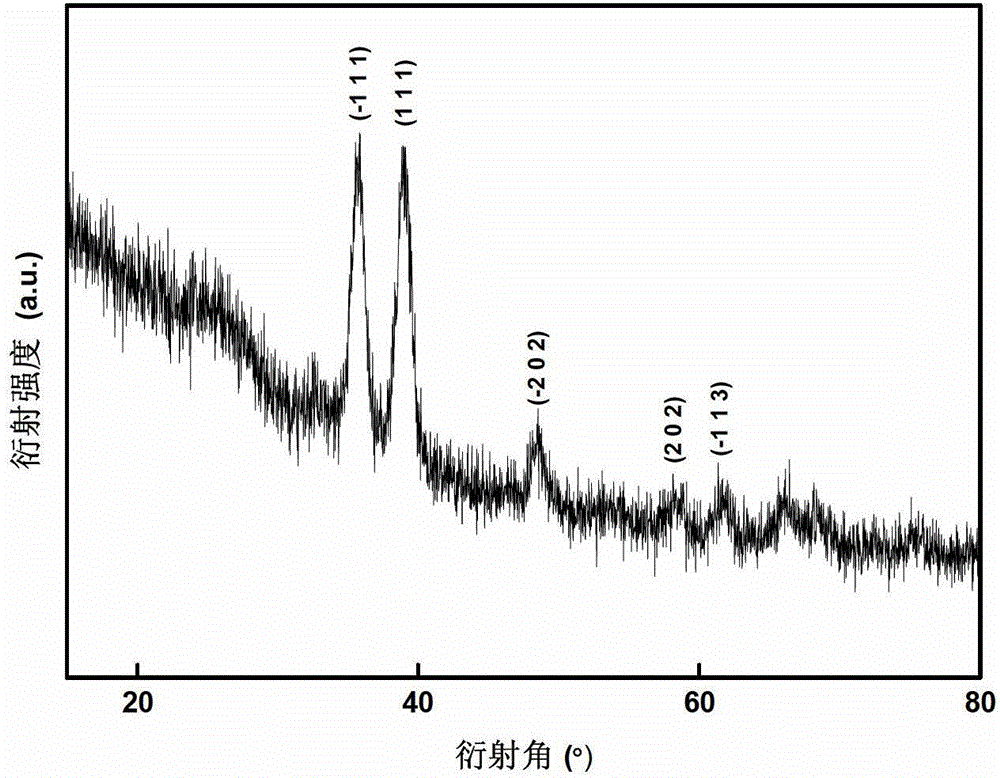

Nano silicon material and preparation method thereof

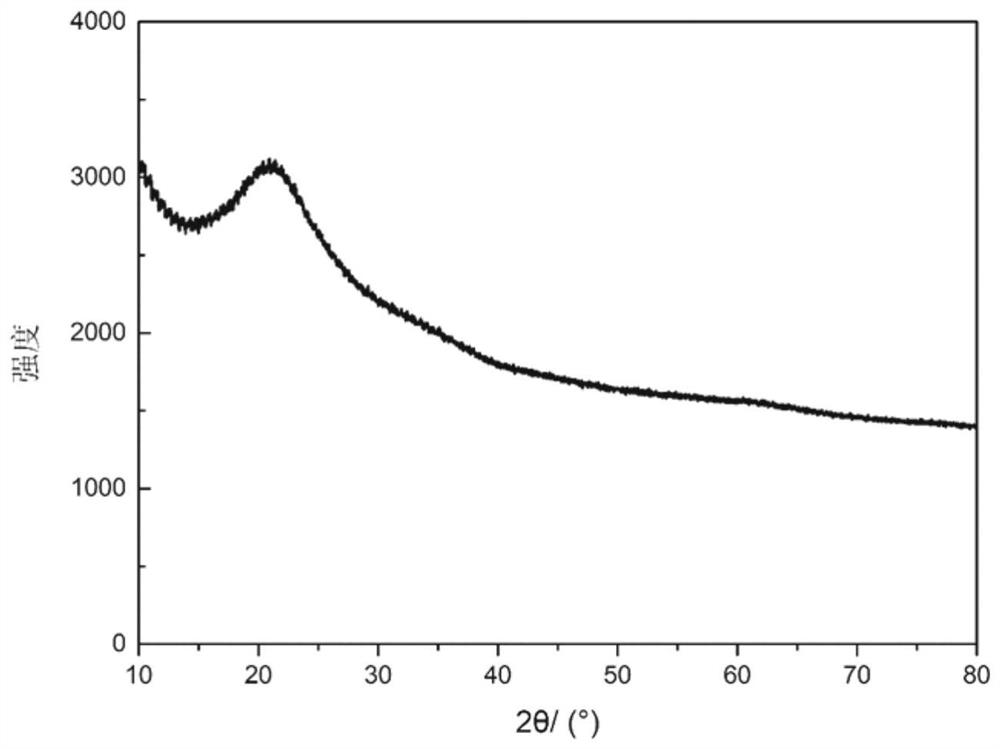

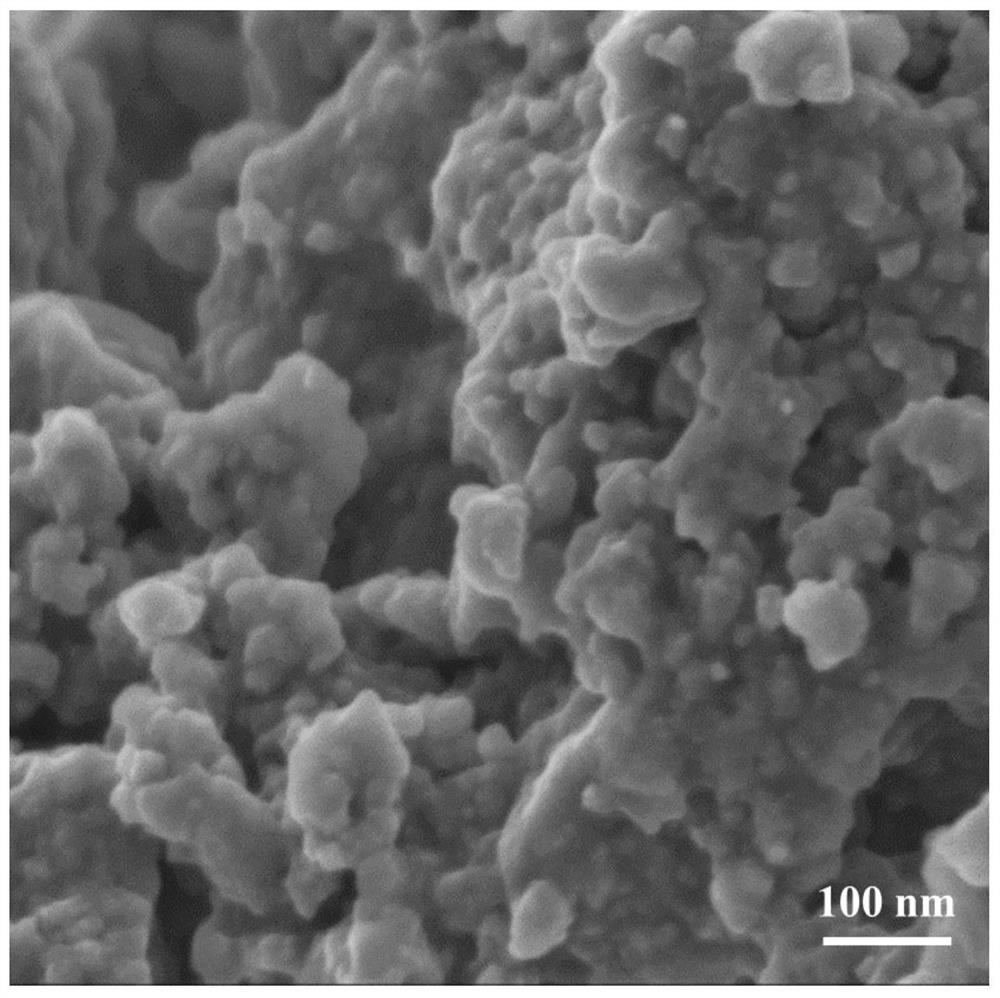

PendingCN113130857ARelieve ruptureAlleviate chalking problemsMaterial nanotechnologySiliconNano siliconSodium-ion battery

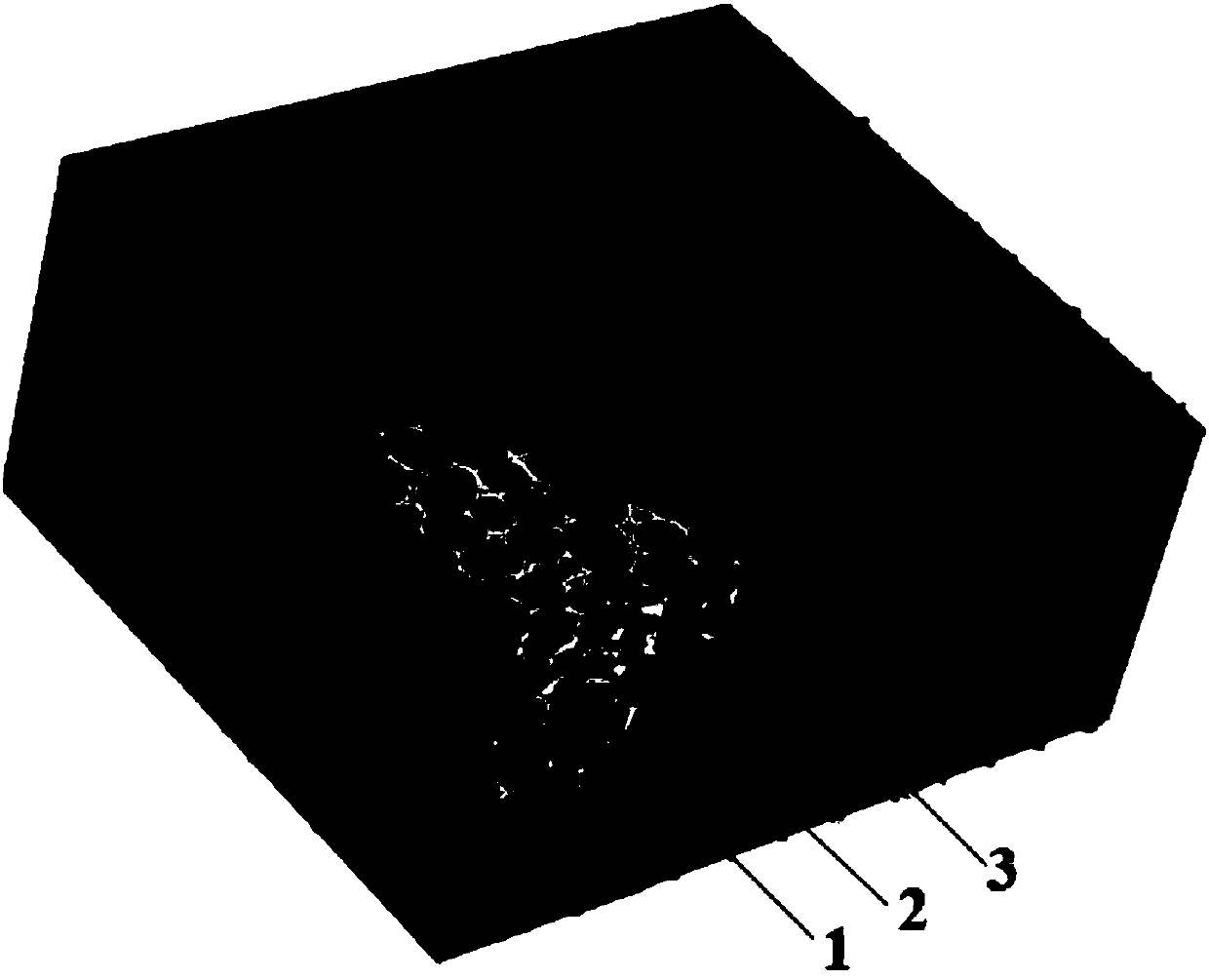

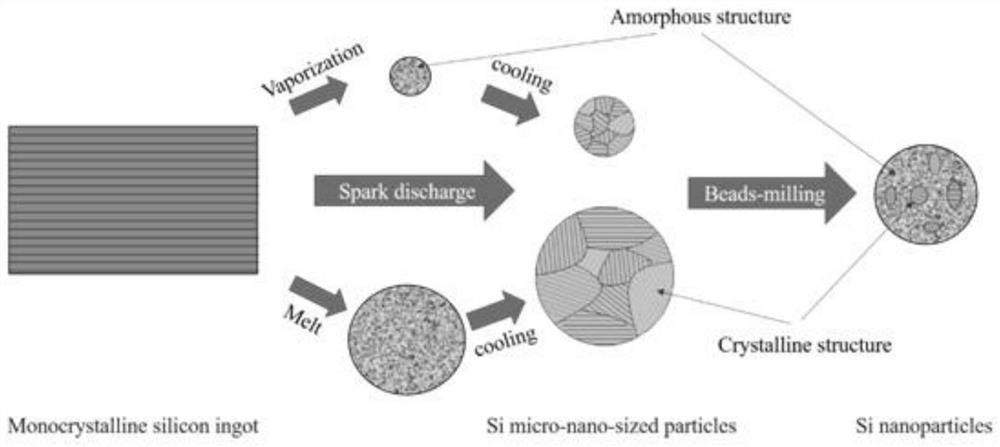

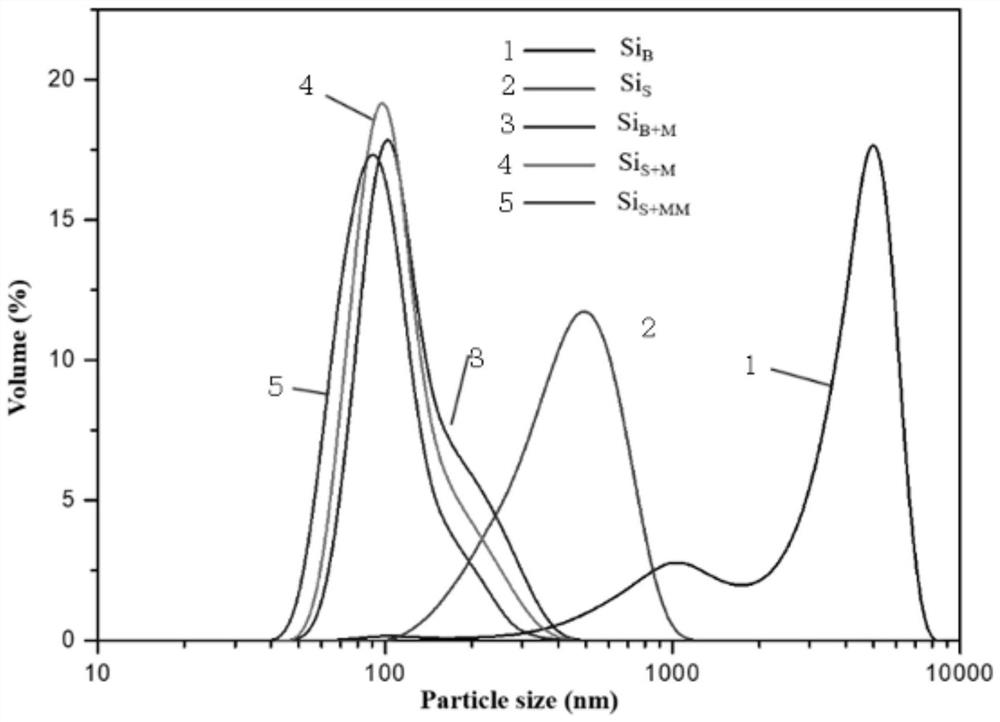

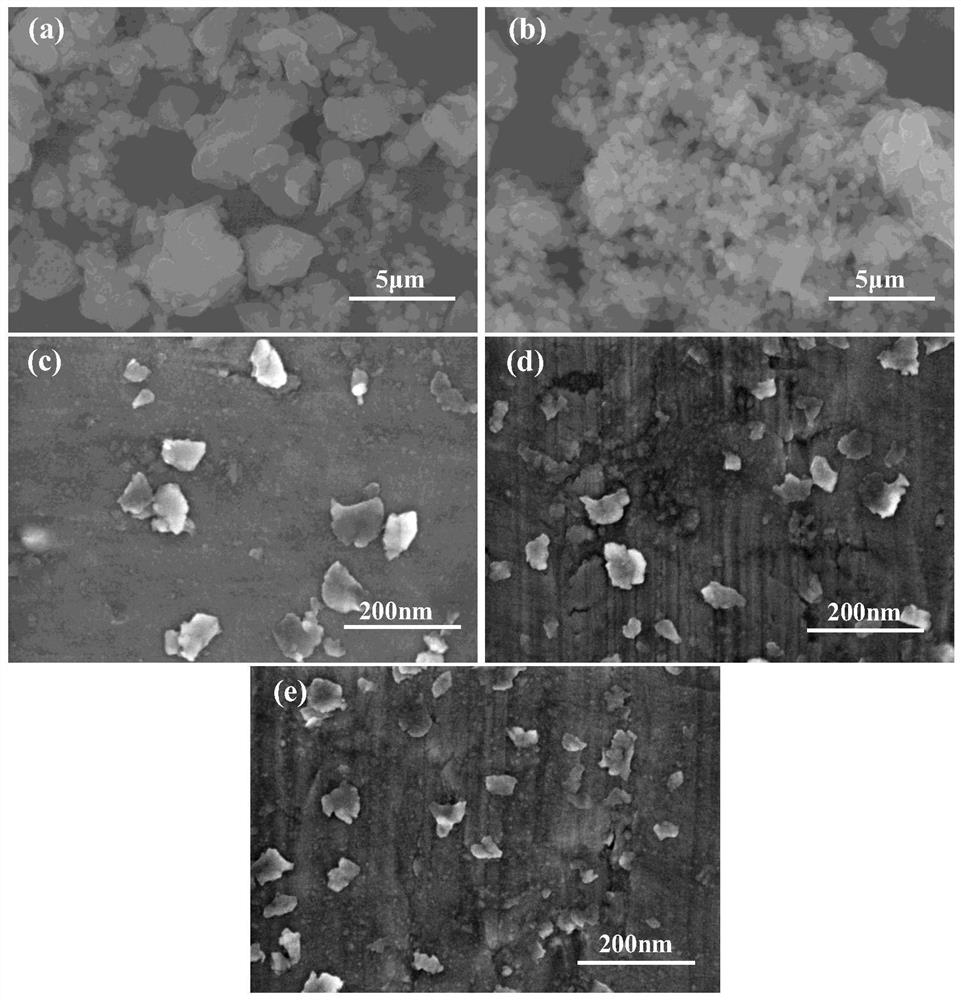

The invention relates to a nano silicon material with an amorphous / nanocrystalline composite structure. In the application of a lithium / sodium ion battery, after lithium / sodium is embedded into a crystalline silicon material for the first time, a composite structure of an amorphous region (silicon-lithium alloy) and a crystalline region (not embedded with lithium) is formed, and volume expansion and structural change are generated; after lithium / sodium removal, volume shrinkage causes structure collapse, i.e., silicon particle fracture and pulverization. In order to provide enough lithium / sodium embedding space in advance and inhibit the volume change of lithium / sodium embedding / removal for the first time, the invention provides an amorphous / nanocrystalline composite structure and a controllable preparation method thereof, i.e., a nano silicon material with the amorphous / nanocrystalline composite structure is prepared by adopting a spark discharge and high-energy ball milling combined process, the amorphous region surrounds the nanocrystalline, the crystal face orientation of the nanocrystalline is randomly distributed, the proportion range of the amorphous region is controllable, and the amorphous region belongs to an isotropic material. In the application of lithium and sodium ion batteries, the structure can effectively relieve the problems of material fracture and pulverization caused by silicon material expansion / shrinkage due to embedding / removal of lithium / sodium, so that the cycle performance of the silicon negative electrode is improved.

Owner:江苏载驰科技股份有限公司

Lithium ion battery with high cycle performance

ActiveCN112599729AImprove hydrophilicityAlleviate chalking problemsCell electrodesSecondary cellsCarbon layerLithium-ion battery

The invention relates to a preparation method of a lithium ion battery negative electrode material, and a lithium ion battery. The preparation method of the negative electrode comprises the followingsteps: adding a certain amount of Ti3AlC2 into a mixed solution of LiF and HCl, and reacting to obtain accordion-shaped Ti3C2; adding Ni salt and acrylic acid into the obtained Ti3C2 turbid liquid, and carrying out irradiation in gamma rays generated by <60>Co; and pouring the turbid liquid into liquid nitrogen for quick freezing, then freeze-drying the obtained product, and finally coating the Ti3C2-NiO with a carbon layer by adopting a CVD method. According to the invention, the prepared composite material NiO particles are uniformly dispersed among three-dimensional accordion-shaped Ti3C2 sheet-shaped gaps, so that material pulverization and structure collapse caused by the volume expansion effect of NiO in the charging and discharging process are effectively relieved, and the conductivity of NiO is effectively improved through the Ti3C2 and CVD carbon layer.

Owner:重庆标能瑞源储能技术研究院有限公司

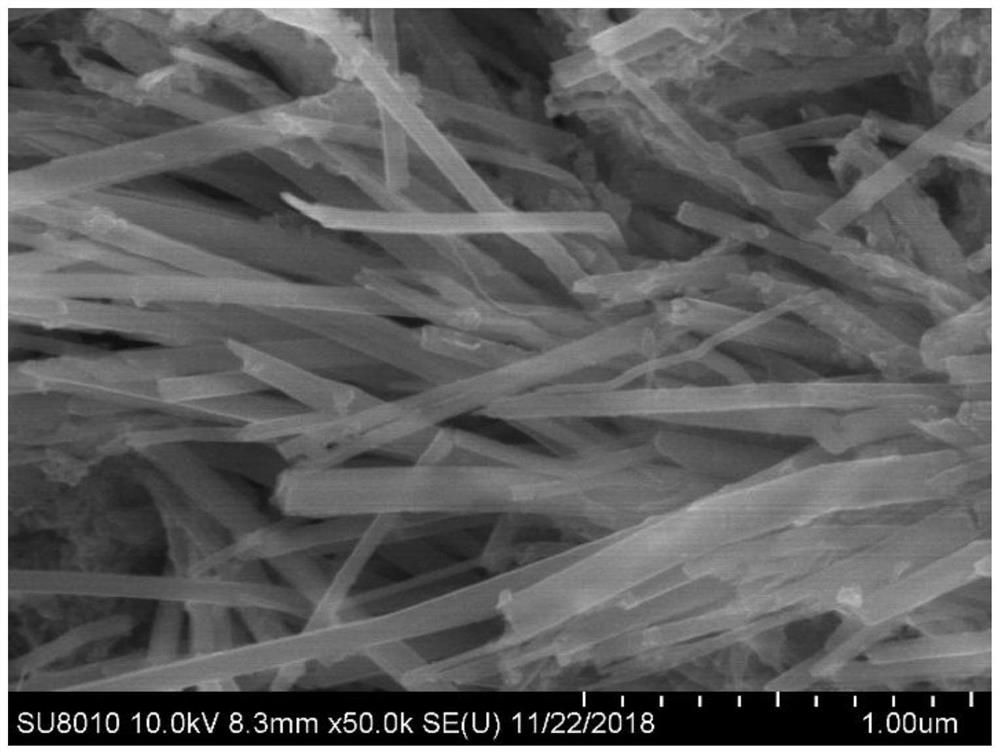

Nanorod-like vanadium tetrasulfide powder and preparation method and application thereof

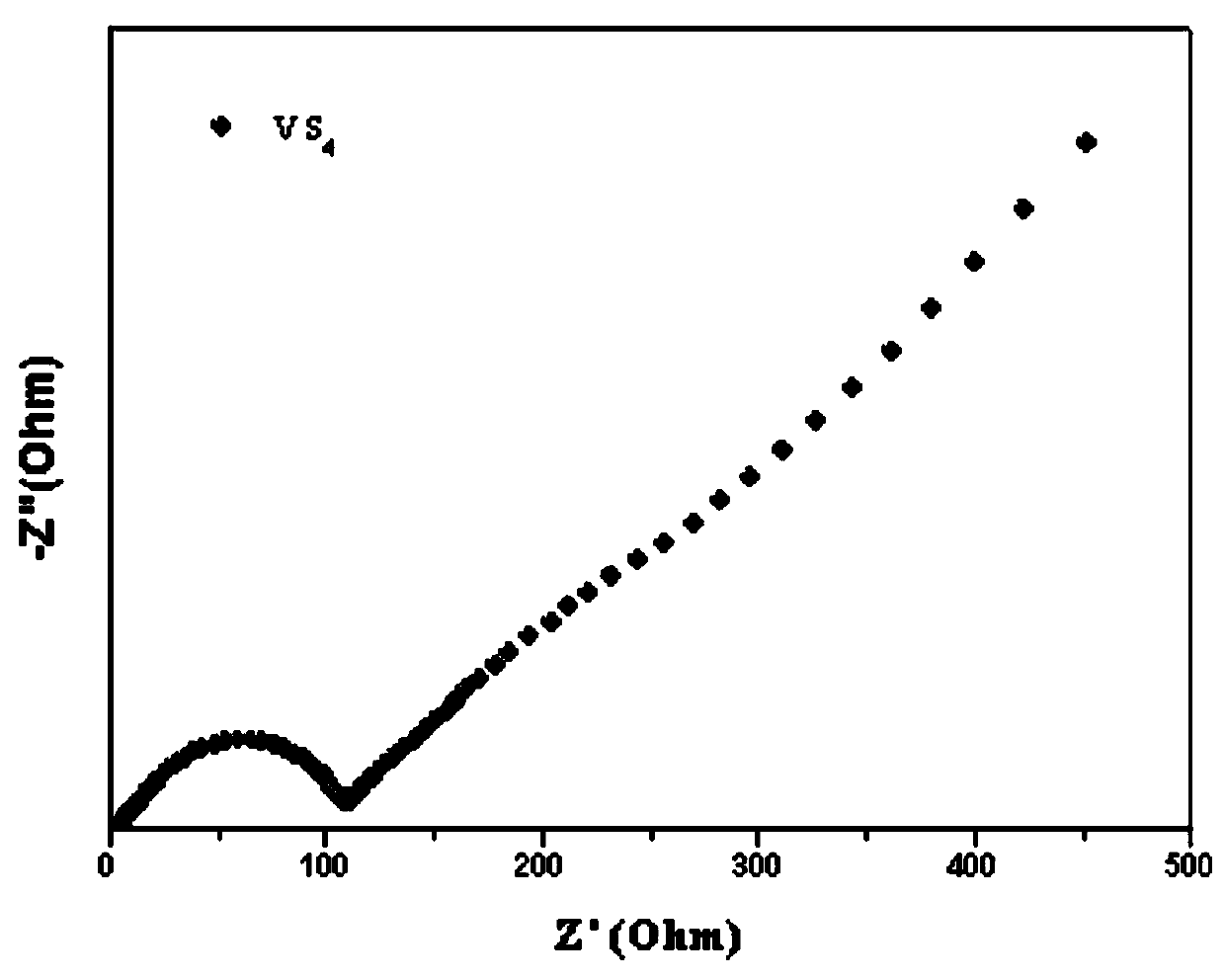

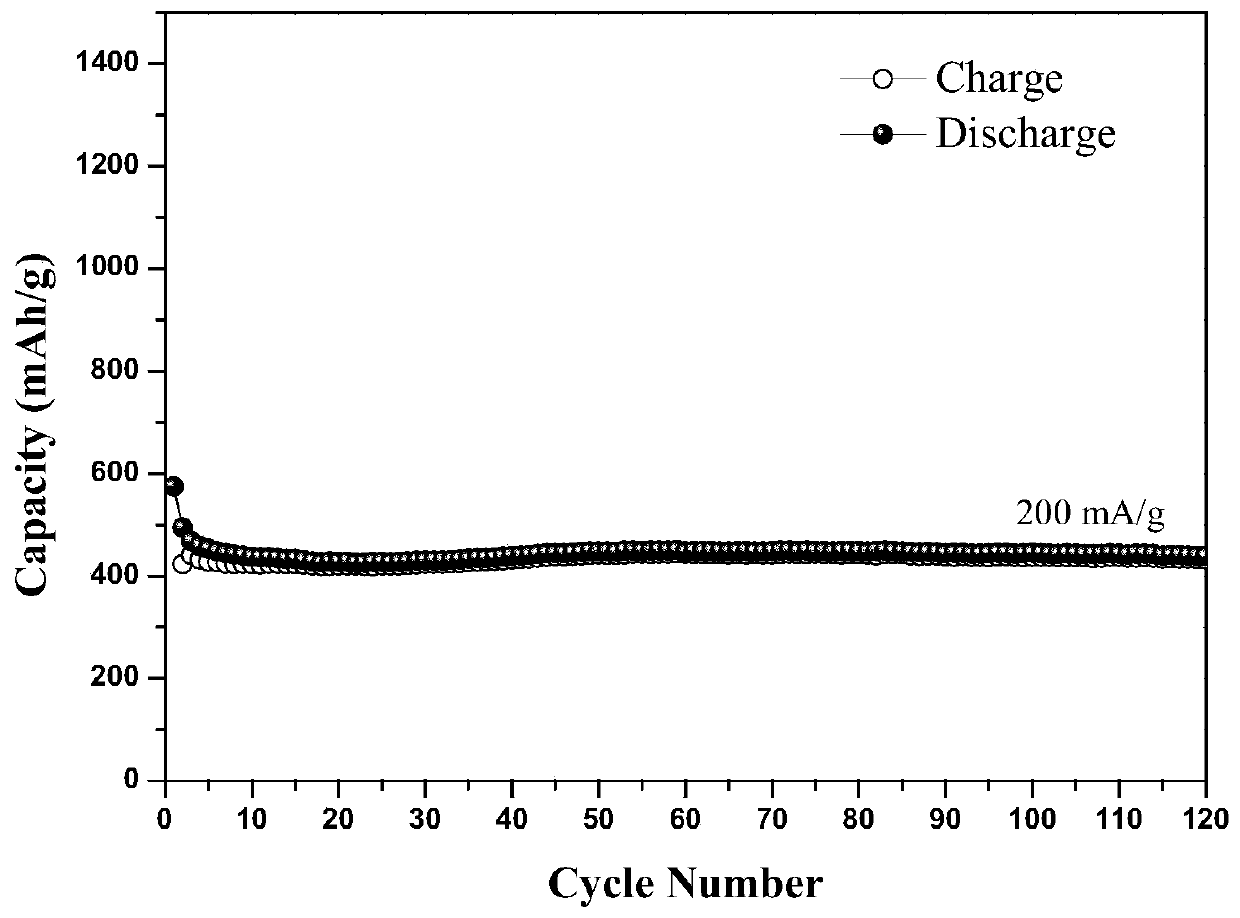

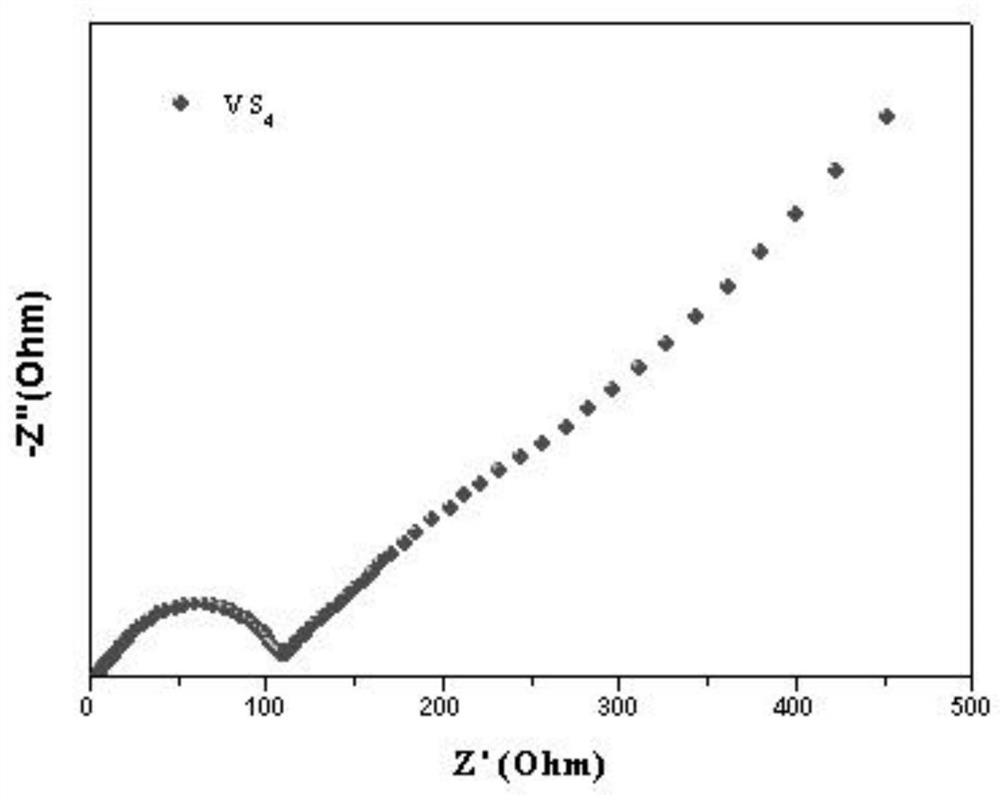

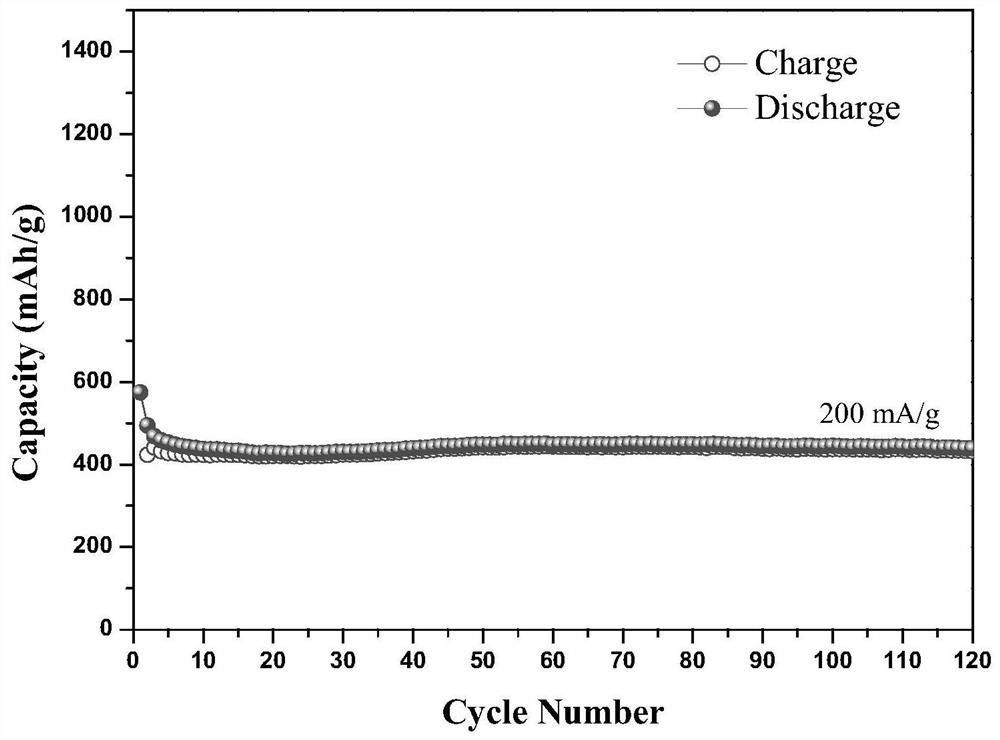

ActiveCN110282660AHigh specific capacityControl growth rateMaterial nanotechnologyCell electrodesChemistryVacuum drying

The invention discloses a preparation method of nanorod-like vanadium tetrasulfide powder. The method comprises the following steps: (1) dissolving thioacetamide in absolute ethyl alcohol, and stirring until whole dissolution is completed to obtain a mixture A; (2) adding ammonium vanadate to the mixture A, and stirring until whole dissolution is completed to obtain a mixture B; (3) dripping dilute hydrochloric acid into the mixture B under stirring conditions to form a transparent solution to obtain a mixture C; (4) transferring the mixture C to a hydrothermal reaction kettle, and carrying out a hydrothermal reaction for 24 to 25 hours; (5) after the reaction is finished, naturally cooling, performing centrifugal washing several times, and then performing vacuum drying to obtain the nanorod-like vanadium tetrasulfide powder. The nanorod-like vanadium tetrasulfide prepared by the method is higher in specific capacity, excellent in cycle stability, long in service life and higher in electrical conductivity.

Owner:CHINA JILIANG UNIV

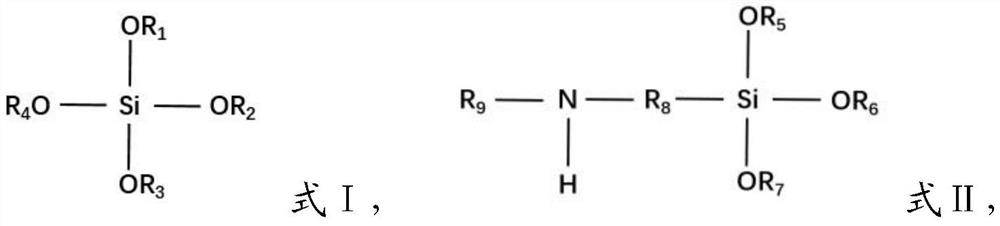

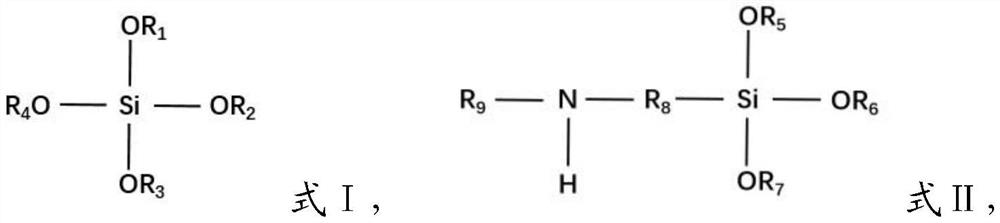

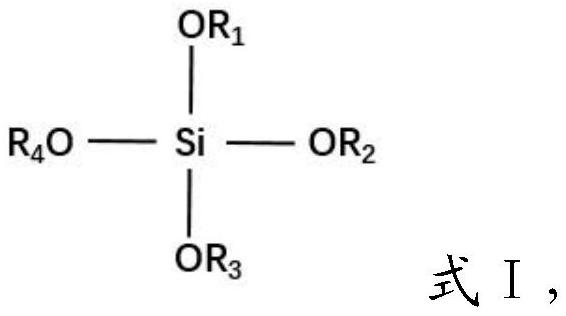

Copper foil composite material, preparation method thereof, negative pole piece and lithium ion battery

InactiveCN112652774AStrong adhesionAlleviate chalking problemsElectrode carriers/collectorsSecondary cellsComposite materialCopper foil

The invention provides a copper foil composite material, a preparation method thereof, a negative pole piece and a lithium ion battery, and relates to the field of batteries. The copper foil composite material comprises a copper foil, and the surface of the copper foil is modified by an amino silane coupling agent. By utilizing the copper foil composite material, the problems that in the prior art, when a silicon-based material is used as a negative electrode active material, the capacity of the silicon-based material is rapidly attenuated in the early cycle and foil leakage occurs in the later cycle can be solved.

Owner:ZHEJIANG UNIV

Graphene-coated copper oxide composite cathode material and method for manufacturing same

ActiveCN102916195BAlleviate chalking problemsPromote migrationCell electrodesComposite cathodeSynthesis methods

The invention discloses a graphene-coated copper oxide composite cathode material and a method for manufacturing the same. The graphene-coated copper oxide composite cathode material comprises, by mass, from 20% to 90% of copper oxide and from 10% to 80% of graphene. The method includes uniformly mixing copper salt solution and graphene oxide solution at first, and stirring the copper salt solution and the graphene oxide solution at a constant temperature for 15 minutes to 1 hour to obtain mixed solution; dripping sodium hydroxide solution into the mixed solution, continuously stirring the mixed solution added with the sodium hydroxide solution for 0.5 hour to 2 hours and allowing the mixed solution added with the sodium hydroxide solution to stand for 2 to 24 hours; and performing centrifuging and hydrothermal processing for the mixed solution added with the sodium hydroxide solution to obtain a product, and drying the product at the temperature of 120 DEG C for 12 hours to obtain the graphene-coated copper oxide composite cathode material. The graphene-coated copper oxide composite cathode material and the method have the advantages that the synthesis method is simple, the manufactured graphene-coated copper oxide composite cathode material is good in performance, and technical problems of poor conductivity of a copper oxide electrode and decrease of capacity due to gradual chalking in charge and discharge processes are solved.

Owner:TSINGHUA UNIV

A kind of nano-rod vanadium tetrasulfide powder and its preparation method and application

ActiveCN110282660BInhibition of agglomerationHigh specific capacityMaterial nanotechnologyCell electrodesPropizochlorThio-

The invention discloses a preparation method of nanorod-shaped vanadium tetrasulfide powder, which comprises the following steps: (1) dissolving thioacetamide into absolute ethanol and stirring until completely dissolved to obtain mixture A; (2) dissolving vanadium tetrasulfide Add ammonium acid to mixture A, stir until completely dissolved to obtain mixture B; (3) drop dilute hydrochloric acid into mixture B under stirring conditions to form a transparent solution to obtain mixture C; (4) transfer mixture C to hydrothermal In the reaction kettle, conduct hydrothermal reaction for 24-25 hours; (5) naturally cool after the reaction, centrifuge and wash several times, and vacuum-dry to obtain nanorod-shaped vanadium tetrasulfide powder. The nanorod vanadium tetrasulfide prepared by the invention has high specific capacity, excellent cycle stability, long service life and high conductivity.

Owner:CHINA JILIANG UNIV

A kind of conductive binder material and preparation method thereof, negative pole sheet and lithium ion battery

ActiveCN112072106BImprove conductivityImprove stabilityNegative electrodesSecondary cellsPolyvinyl alcoholPole piece

The invention provides a conductive binder material, a preparation method thereof, a negative pole piece and a lithium ion battery, and relates to the field of batteries. The conductive adhesive material, including polyvinyl alcohol, sodium carboxymethyl cellulose, sodium alginate, chitosan, polyethyleneimine and other polymers rich in hydroxyl, carboxyl and amino groups, is prepared by high temperature and high pressure or microwave treatment. Aqueous solution of polymer carbon dots. Utilizing the conductive binder material can solve the problem of poor electrical conductivity of the silicon-based material and easy fall off from the pole piece when the silicon-based material is used as the negative electrode active material in the prior art, so as to improve the conductivity of the pole piece and the bonding force of the pole piece material , so as to improve the energy density of the silicon negative pole piece.

Owner:ZHEJIANG UNIV

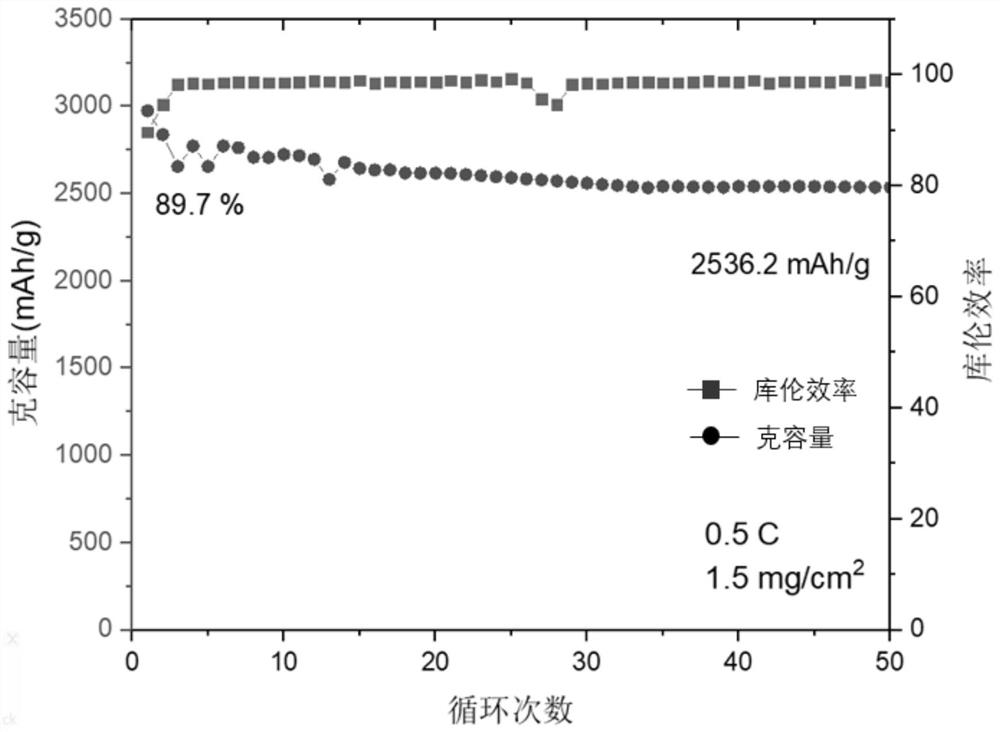

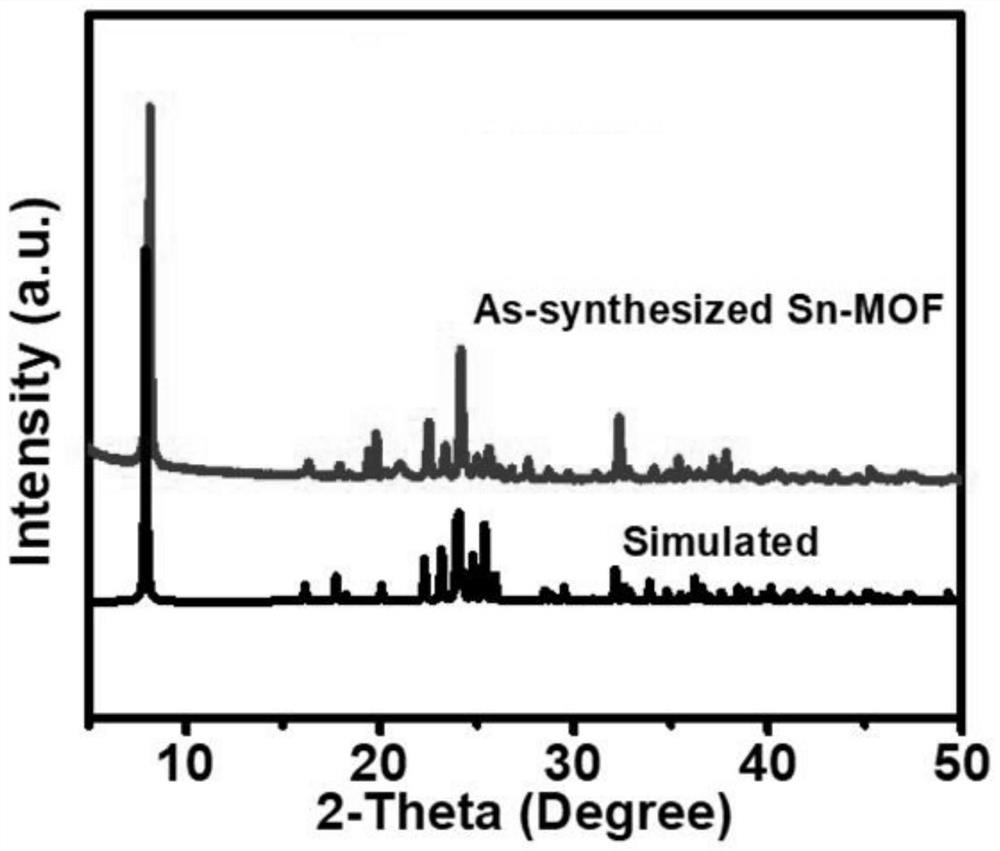

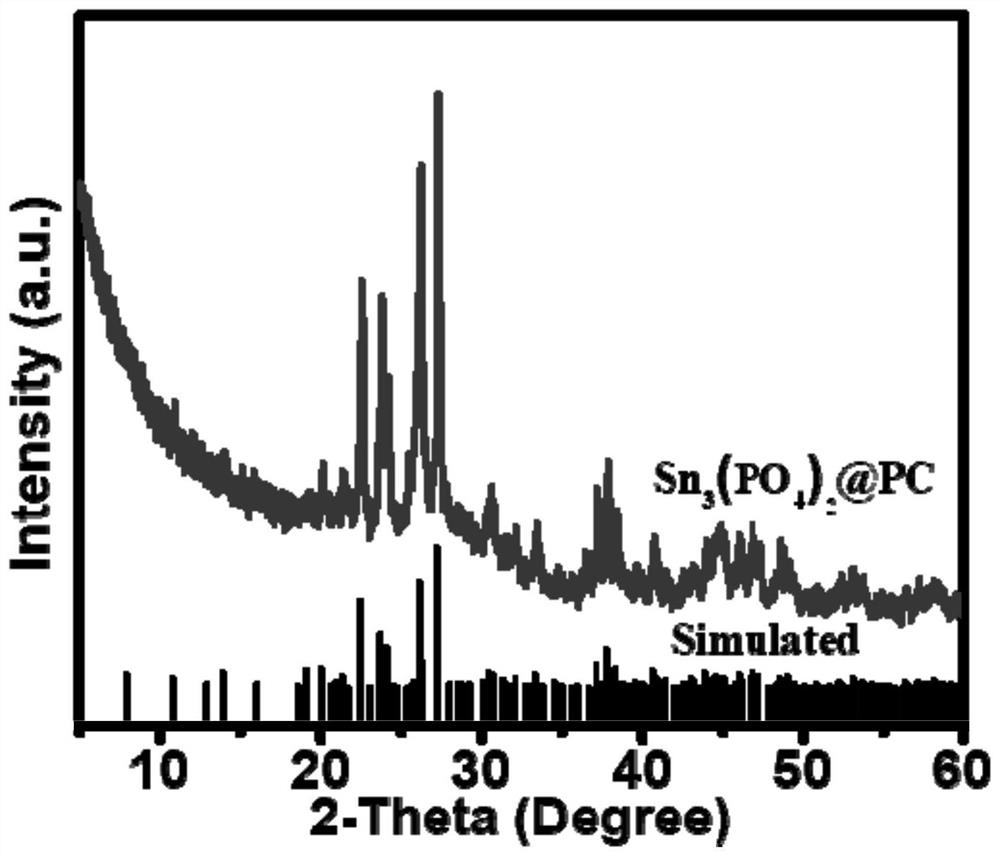

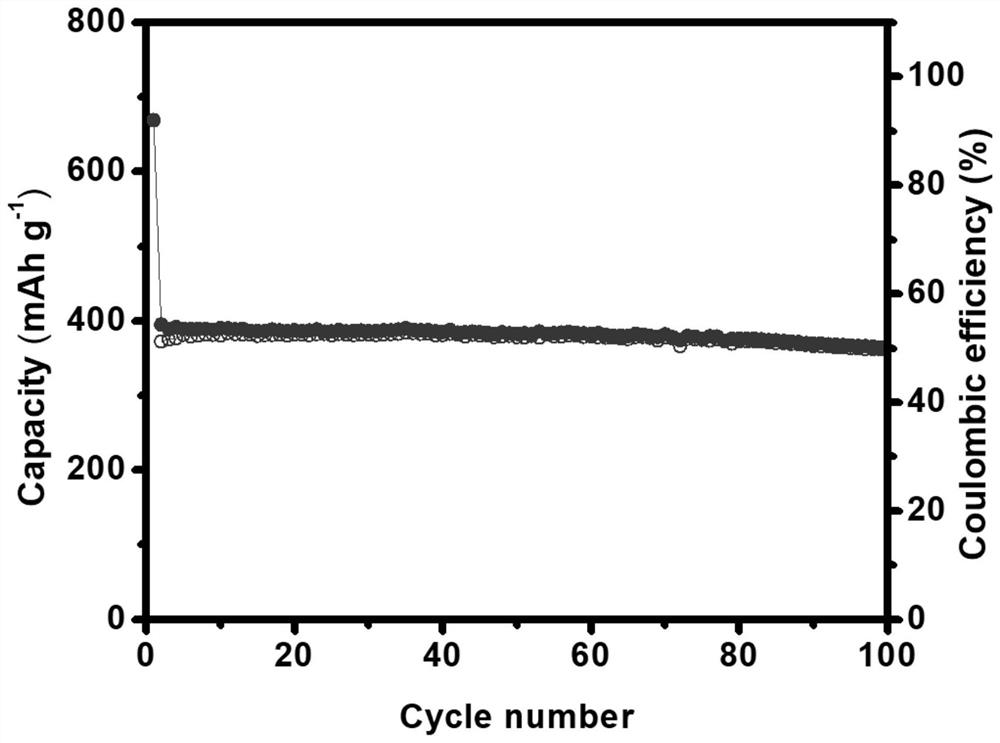

Negative electrode material of stannous phosphate battery as well as preparation method and application of negative electrode material

ActiveCN114284490AImprove conductivityThe preparation method is simple and controllableCell electrodesSecondary cellsElectrical batteryNew energy

The invention relates to the technical field of new energy materials, in particular to a stannous phosphate battery negative electrode material and a preparation method and application thereof. The invention provides a preparation method of a stannous phosphate battery negative electrode material, which specifically comprises the following steps: obtaining a tin-containing phosphonic acid metal organic framework (MOF) through a one-step hydrothermal method or a solvothermal method, namely taking the tin-containing phosphonic acid MOF material as a single precursor; then a composite negative electrode material with Sn3 (PO4) 2 uniformly dispersed in a phosphorus-doped carbon skeleton, namely the Sn3 (PO4) 2-atPC negative electrode material, is finally prepared through one-step calcination heat treatment, and the negative electrode material is uniform and controllable in morphology and well inherits the microstructure of the precursor; anions in Sn3 (PO4) 2 can be used as a matrix for buffering volume change to prevent pulverization of the electrode material, so that the cycle life is prolonged; after calcination, the carbon skeleton has good conductivity, and the cycling stability of the Sn3 (PO4) 2-atPC negative electrode material is enhanced; and meanwhile, when the material is applied to a sodium ion battery or a potassium ion battery, the material has relatively high charge-discharge specific capacity and good cycle stability.

Owner:QILU UNIV OF TECH

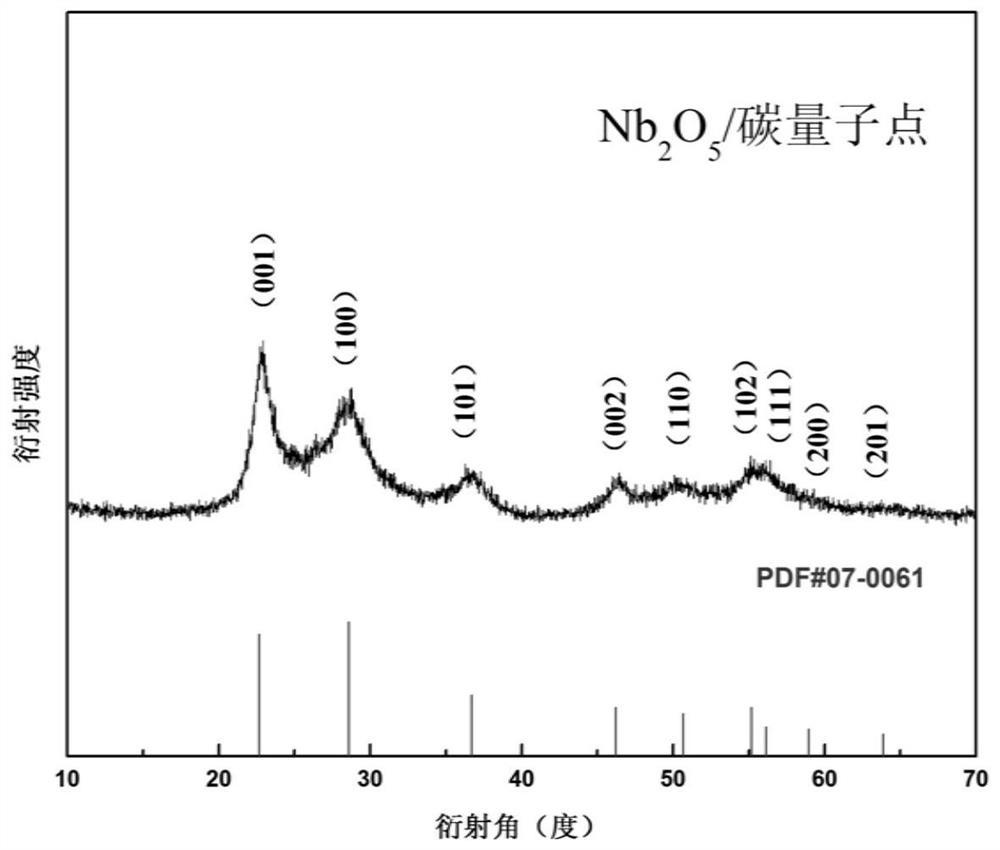

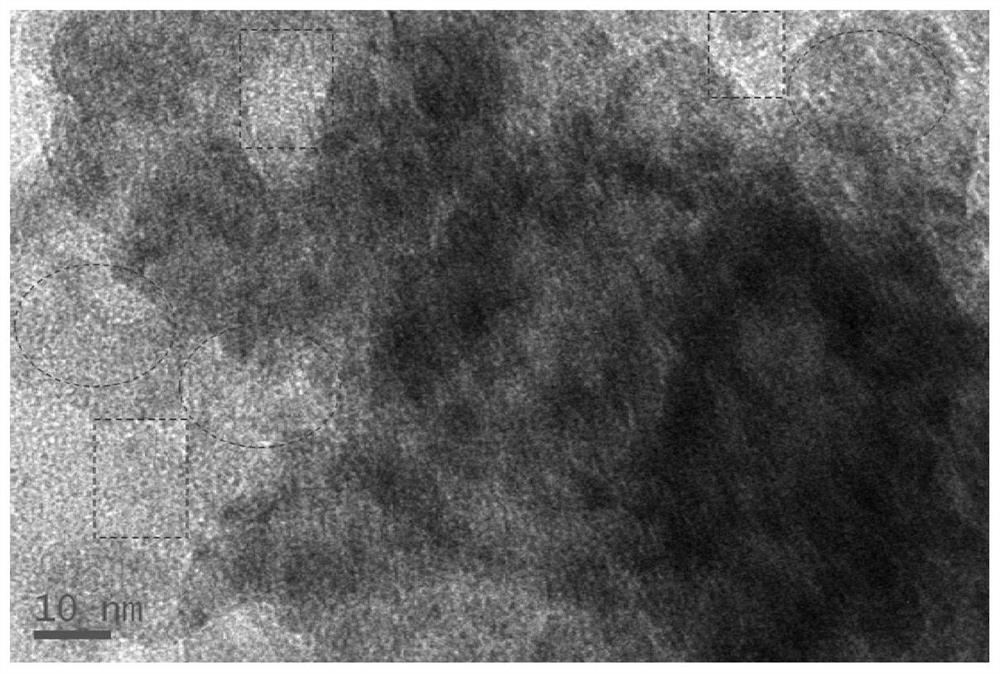

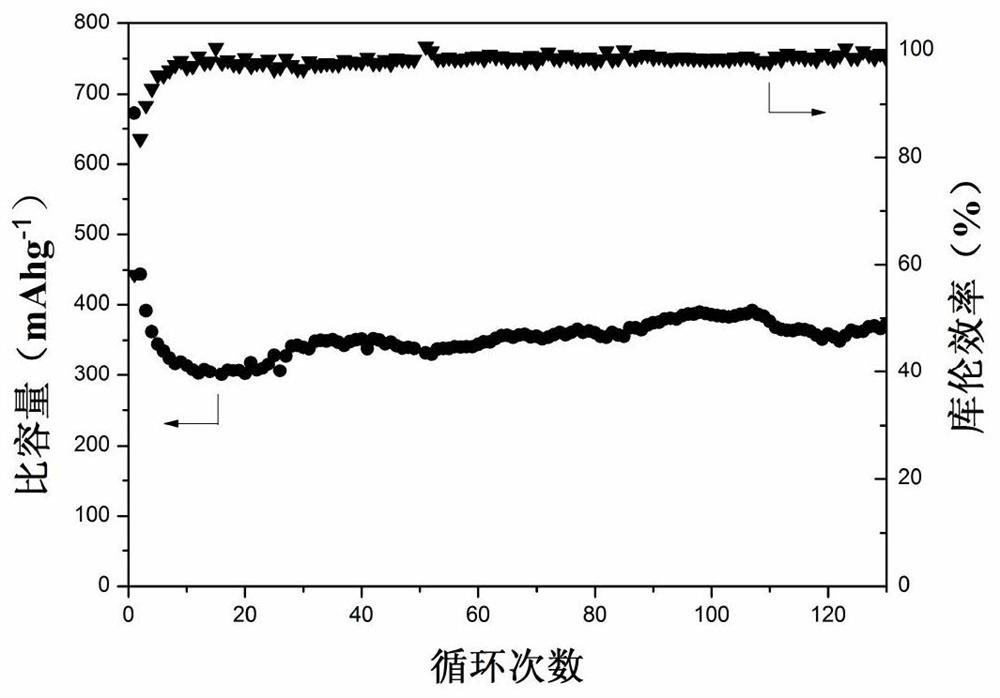

A kind of niobium pentoxide/carbon double quantum dot nanocomposite material and its preparation method and application

ActiveCN108448104BImprove cycle stabilityAlleviate chalking problemsMaterial nanotechnologySecondary cellsElectrolytic agentArgon atmosphere

The invention discloses a niobium pentoxide / carbon double quantum dot nanocomposite material, a preparation method and an application thereof. The composite material is composed of niobium pentoxide and carbon double quantum dots, and the niobium pentoxide quantum dots and carbon quantum dots are closely combined; the mass fraction of the carbon quantum dots in the composite material is 20-40% . There are gaps between the niobium pentoxide / carbon double quantum dot particles, and the specific surface area is relatively large. This structure is not only conducive to the full contact between the electrolyte and the active material, but also effectively adapts to the volume expansion of the material during charge and discharge, thereby greatly improving its electrochemical performance when used as a negative electrode material for lithium-ion batteries. In the invention, the precursors of niobium and carbon quantum dots are firstly synthesized by a hydrothermal method, and then calcined in an argon atmosphere to obtain a nanocomposite material of niobium pentoxide / carbon double quantum dots. The preparation method is easy to operate, the reaction conditions are controllable, and it is easy to scale up experiments.

Owner:CENT SOUTH UNIV

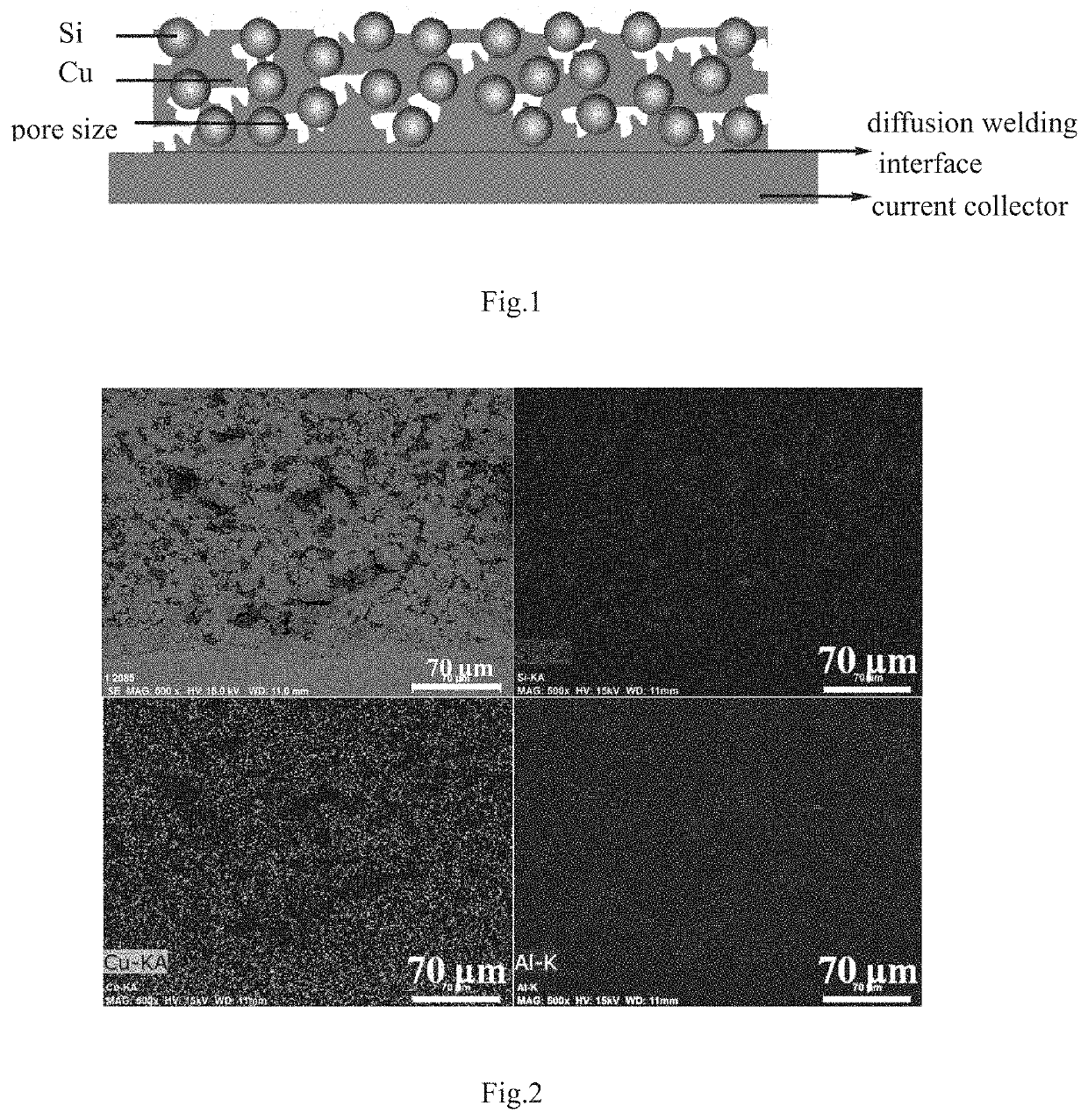

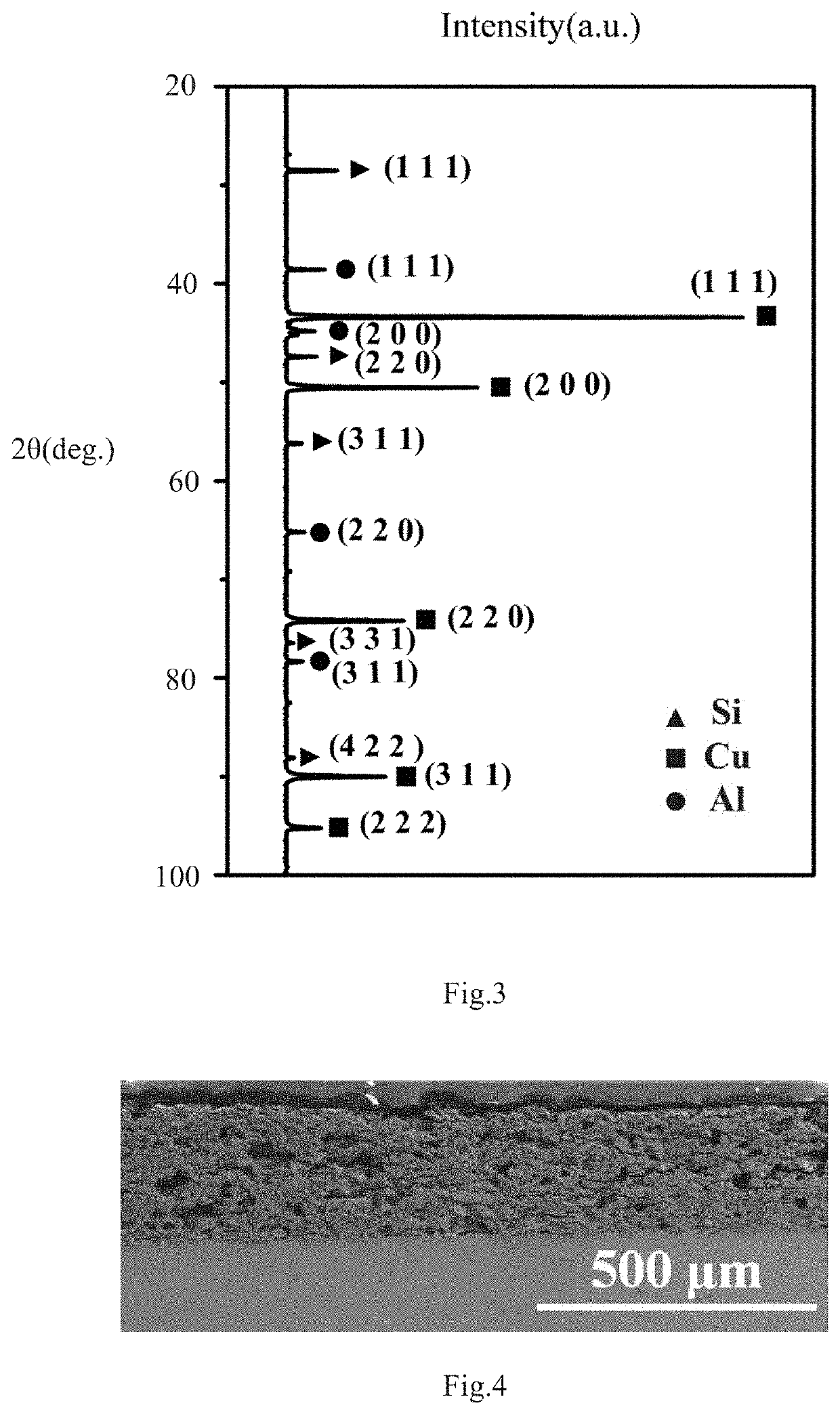

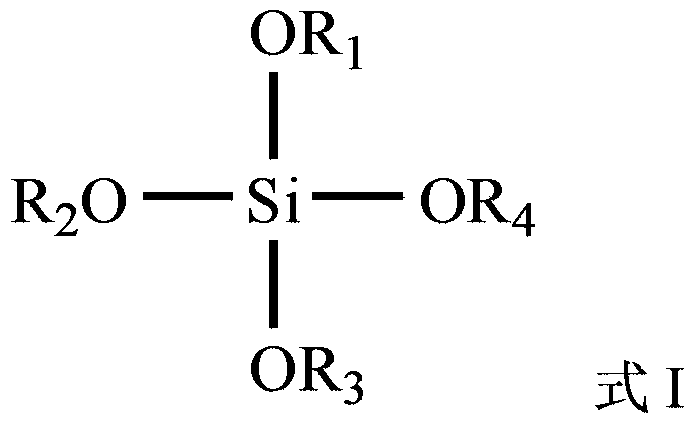

Porous structure Si Cu composite electrode of lithium ion battery and preparation method thereof

ActiveUS11063264B2Alleviate chalking problemsImprove performanceElectrode thermal treatmentElectrode carriers/collectorsAl powderElectrolytic agent

The present disclosure discloses a porous structure Si / Cu composite electrode of a lithium ion battery and a preparation method thereof. The composite electrode comprises an active substance, a bulk porous Cu and a current collector, wherein the active substance Si is embedded into the bulk porous Cu, and the bulk porous Cu is in metallurgical bonding with the current collector and plays a dual role of “binder” and “conductive agent”, which not only relieves the pulverization and the shedding of the active substance Si particles but also improves electron transmission efficiency; and meanwhile, the porous structure increases the contact area between the active substance Si and electrolyte and increases the reaction efficiency of lithium insertion combination. The method of preparing the composite electrode comprises: with Si, Cu and Al powders as raw materials, preparing a Si—Cu—Al precursor alloy on the Cu current collector by powder metallurgy and diffusion welding technology; and removing Al element in the Si—Cu—Al precursor alloy by using a chemical de-alloying method to obtain a Si / Cu composite electrode with a porous-structure.

Owner:BEIJING UNIV OF TECH

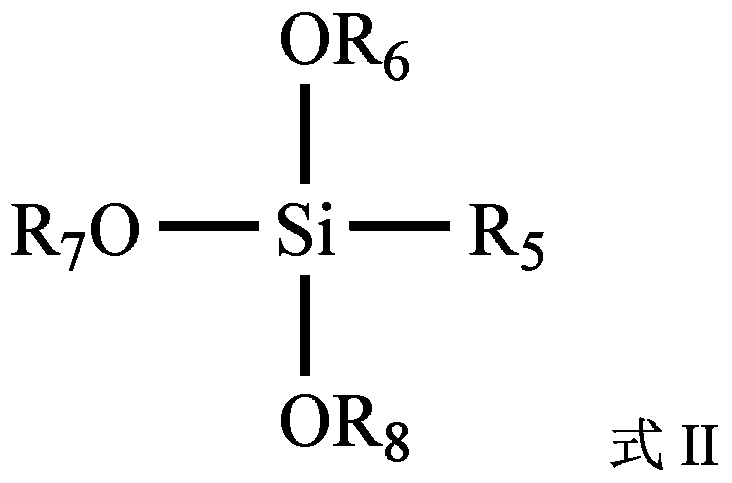

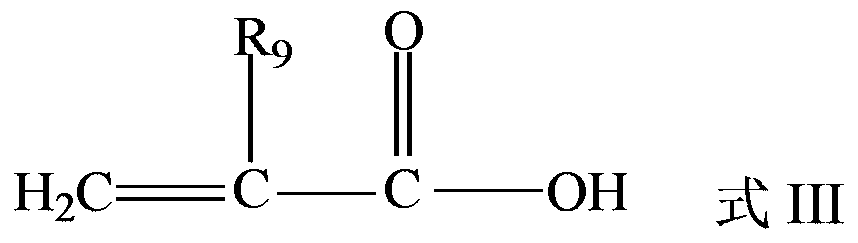

A kind of silicon-based composite material, its preparation method and application

ActiveCN104934606BAlleviate chalking problemsGood self-adhesiveCell electrodesSecondary cellsElectrical batteryBattery cell

The application discloses a silicon-based composite material which comprises a silicon-based material, wherein the surface of the silicon-based material is modified by an organosilicon compound containing amino and / or carboxyl. The silicon-based composite material is applied to a lithium ion secondary battery, during a battery cycle process, the pulverization of an electrode membrane can be effectively relieved, and battery stability can be improved. When the silicon-based composite material is used with a carboxylic acid binding agent, a polycarboxylate binding agent or a polyimide binding agent in a matching way, hydrogen bonds can be formed by the silicon-based composite material and a polymer in the bonding agent, the adhesion force is enhanced, the incapability of the silicon-based material in contact with the binding agent and a conductive agent due to volume expansion / contraction during the battery cycle process is prevented, and therefore, energy density and cycle performance of the lithium ion secondary battery are effectively improved.

Owner:NINGDE AMPEREX TECH

A cnfs load mos 2 Magnesium-lithium double-salt battery cathode material and construction method thereof

ActiveCN110165155BImprove cycle stabilityExtend your lifeMaterial nanotechnologyCell electrodesCarbon fibersPhysical chemistry

A CNFs loaded MoS 2 Novel magnesium-lithium double-salt battery cathode material and its construction method, CNFs account for x=20-40wt%, MoS 2 Flower-like nanomaterials account for 60-80wt%, and the construction methods include carbon fiber pretreatment, solution preparation, surfactant addition, pH value adjustment, hydrothermal synthesis and product collection, and the final product is one-step hydrothermal synthesis of CNTs in situ loaded MoS 2 Nanocomposite CNFs@MoS 2 , the invention improves the capacity and rate characteristics of the double-salt battery, thereby improving the cycle stability of the magnesium-lithium double-salt battery and improving the battery life.

Owner:SHAANXI UNIV OF SCI & TECH

Lithium-ion battery germanium/carbon composite negative electrode material and its preparation method and application

ActiveCN110085847BImprove cycle stabilityAvoid reunionSecondary cellsNegative electrodesCarbon compositesElectrolytic agent

The invention discloses a lithium-ion battery germanium / carbon composite negative electrode material and a preparation method and an application thereof. The composite negative electrode material includes germanium nanoparticles, mesocarbon microbeads and amorphous carbon. The preparation method comprises the steps of (1) dissolving GeO2 in an alkaline solution, adding nanocrystalline cellulose, adjusting the pH-value of the obtained first suspension, adding the mesocarbon microbeads and stirring to form a second suspension, and transferring the second suspension to a water bath; (2) preparingan NaBH4 solution, adding the heated second suspension, stirring for reaction in the water bath, washing wafer vacuum filtration, then carrying out vacuum drying, roasting the dried solid in an inertgas or reducing atmosphere to obtain the product. The composite negative electrode material disclosed by the invention has high mass capacity and volume specific capacity, can effectively alleviate the volume change and pulverization of germanium, is high in cycle stability and good in compatibility with a propylene carbonate containing electrolyte, has the advantages of good low-temperature electrochemical performance and the like and can be applied to lithium-ion batteries.

Owner:NAT UNIV OF DEFENSE TECH

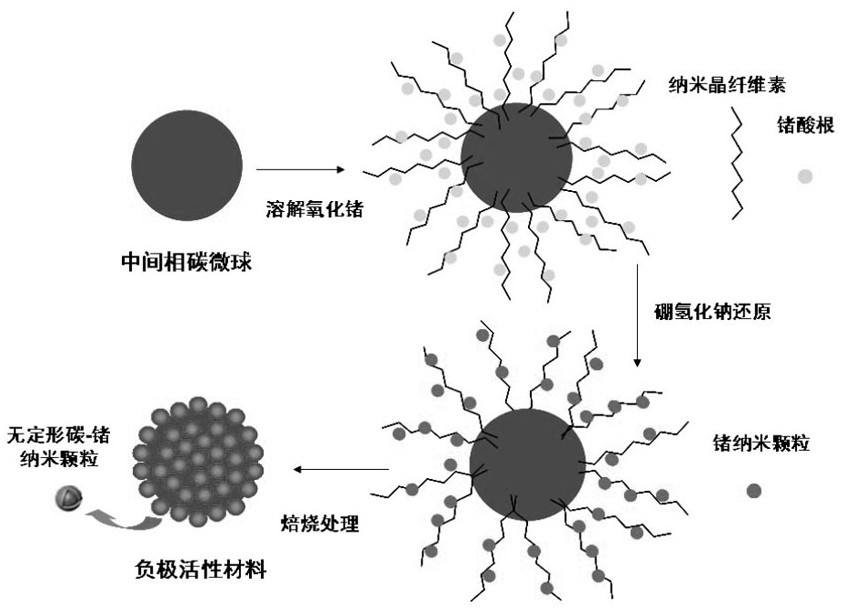

Pod-shaped MoS2-SnO2 magnesium-lithium hybrid ion battery positive electrode material as well as synthesis method and application thereof

PendingCN111403742AExtend your lifeAlleviate chalking problemsMaterial nanotechnologyFinal product manufactureElectrical batteryPhysical chemistry

The invention relates to a pod-shaped MoS2-SnO2 magnesium-lithium hybrid ion battery positive electrode material as well as a synthesis method and application thereof, the synthesis method comprises the following steps: step 1, dissolving SnCl2. 2H2O in a mixed solution composed of absolute ethyl alcohol and DMF to obtain a solution A; 2, dissolving PVP in the solution A, and a solution B is obtained; 3, adding nano flower-like MoS2 and mineral oil into the solution B, and stirring to obtain a precursor solution C for electrostatic spinning; and 4, setting the flow rate of an injection pump tobe 8mL. H <-1 >, and spraying the solution C, performing high-voltage electrostatic spinning, collecting the thin film on the silk collecting plate after the electrostatic spinning is finished, performing annealing treatment in air, and naturally cooling the thin film to room temperature to obtain a powdery pod-shaped MoS2-SnO2 magnesium-lithium hybrid ion battery positive electrode material sample. The charging and discharging capacity and dynamic characteristics of the magnesium-lithium double-salt battery and the cycling stability of the magnesium-lithium double-salt battery are improved,and the service life of the battery is prolonged.

Owner:SHAANXI UNIV OF SCI & TECH

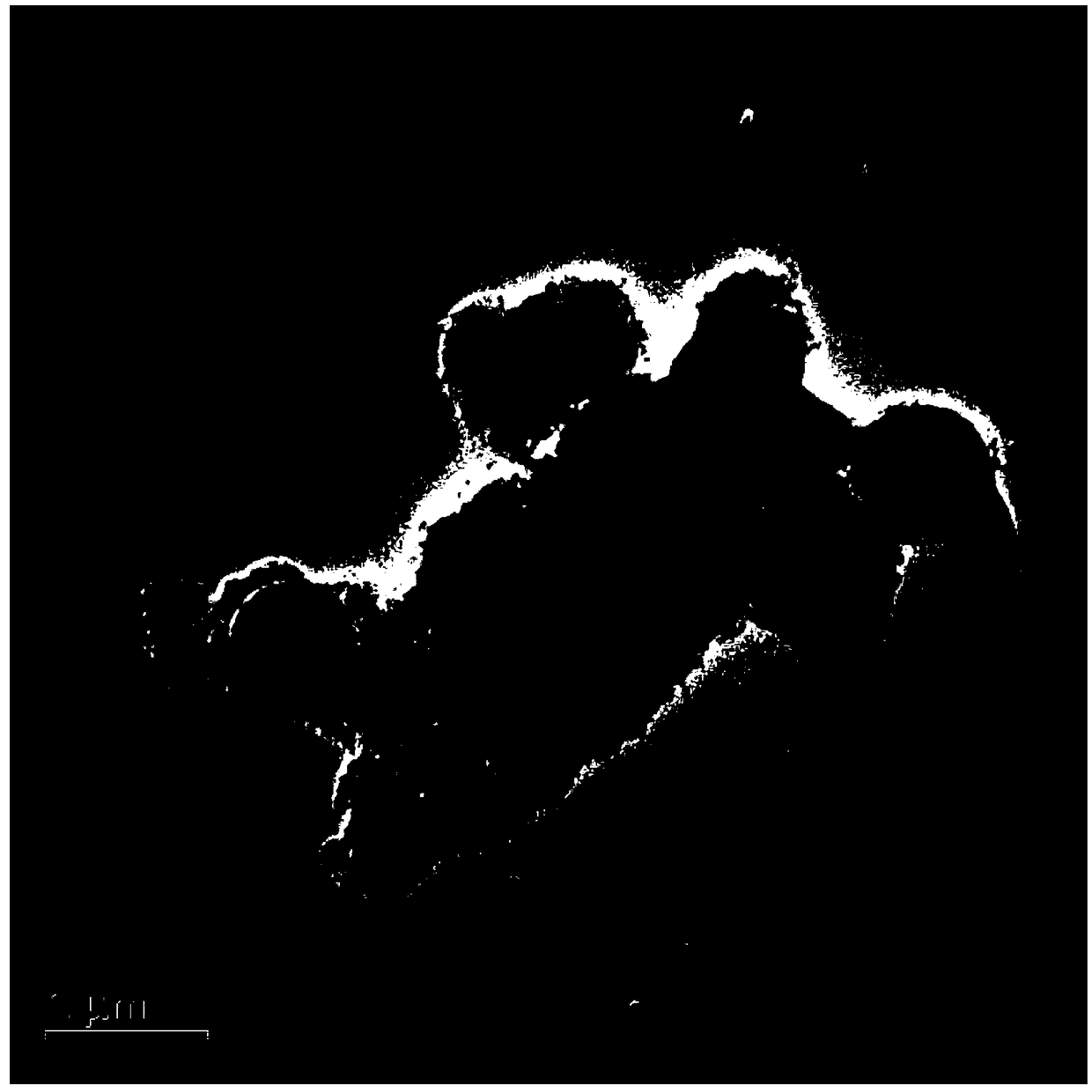

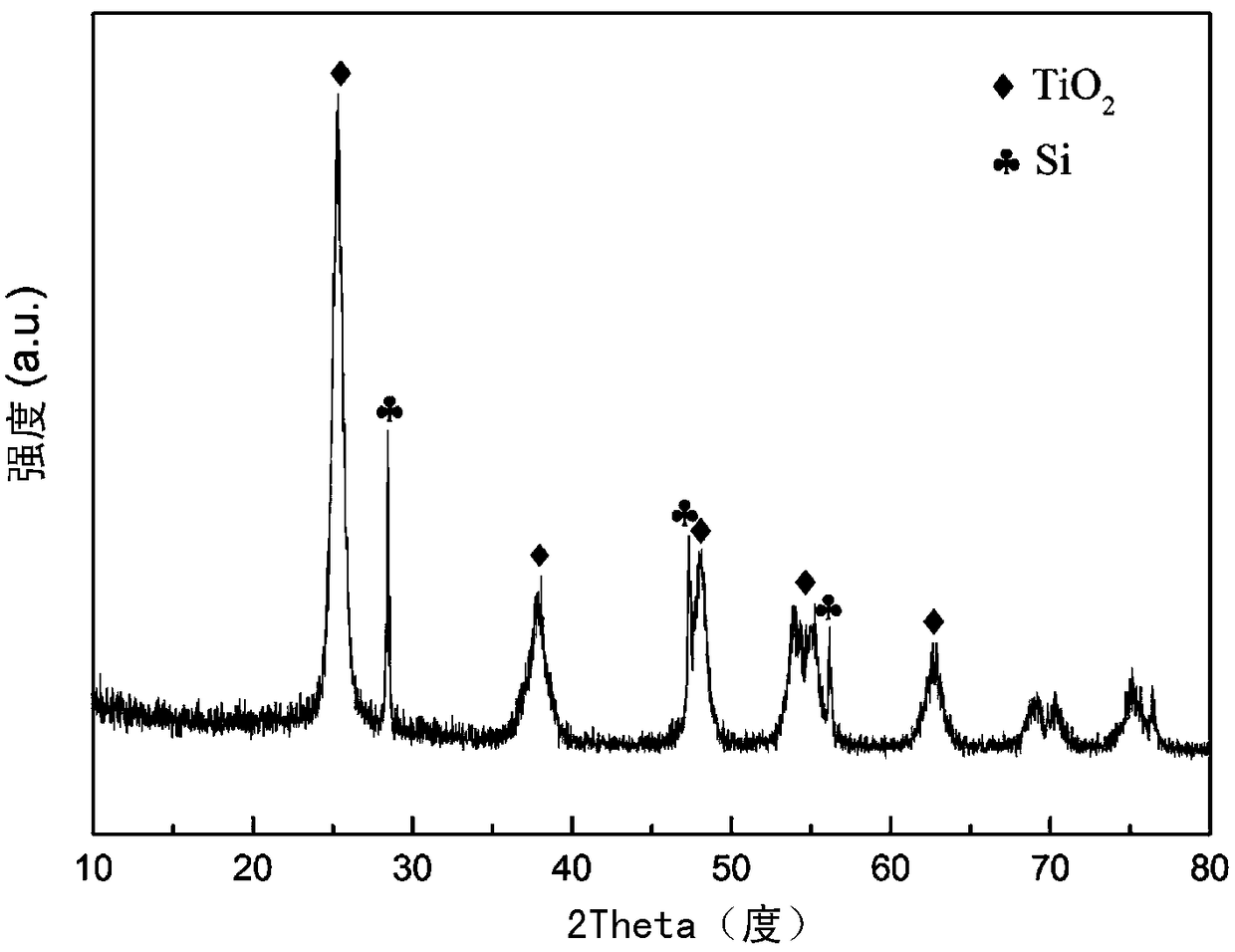

A kind of si/tio2 composite material with multi-sphere packing structure and its preparation method

ActiveCN105185964BActive range that limits volume expansionAlleviate chalking problemsCell electrodesSecondary cellsInternal stressSilicon

The invention relates to a multi-sphere stack-structured Si / TiO2 composite material and a preparation method therefor. The Si / TiO2 composite material comprises Si spheres, and a plurality of TiO2 spheres densely stacked around the Si spheres; and the grain diameter of the Si spheres is larger than that of the TiO2 spheres. In the multi-sphere stack-structured Si / TiO2 composite negative electrode material, silicon active granules are protected by a titanium dioxide nano-particles dense stacked layer; the internal stress generated from volume expansion is fully relieved by taking advantage of the dense stacking characteristic of the Si / TiO2 composite negative electrode material, so that the electrochemical performance and the stacking density of the silicon negative electrode material can be improved, the circulation reversibility of the electrode and the utilization rate of active materials are effectively improved, and the cycle life of the battery is prolonged.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of red phosphorus/nitrogen-doped graphene composite negative electrode material and its preparation method and application

ActiveCN108376767BUnique Mechanical PropertiesImprove mechanical propertiesCell electrodesSecondary cellsElectrolytic agentNitrogen doped graphene

The invention relates to a red phosphorus / nitrogen-doped graphene composite negative electrode material and its preparation method and application. Firstly, nitrogen-doped graphene and red phosphorus are mixed uniformly according to the mass ratio of (2-4):(8-6) , to obtain a mixture; under a protective atmosphere, the obtained mixture is ball-milled to obtain a red phosphorus / nitrogen-doped graphene composite negative electrode material. The present invention utilizes the nitrogen-doped graphene material with good electronic conductivity as the base material, and through ball milling with red phosphorus, the insulating red phosphorus particles can be well dispersed in the conductive nitrogen-doped graphene material during the ball milling process , the complex has a large specific surface area, improves the overall electrical conductivity and increases the contact area with the electrolyte, alleviates the collapse and pulverization of the structure caused by the volume expansion of phosphorus-based materials during the deintercalation of potassium ions, and increases the Potassium ion diffusion rate; as a negative electrode material for potassium ion batteries, it has high reversible capacity, excellent rate performance and cycle stability.

Owner:咸阳瞪羚谷新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com