Conductive binder material and preparation method thereof, negative pole piece and lithium ion battery

A technology of conductive binder and raw materials, applied in non-aqueous electrolyte battery electrodes, batteries, negative electrodes, etc., can solve the problems of poor conductivity, bonding failure, and easy pulverization of silicon-based materials, and achieves alleviation of pulverization and mitigation. Bond failure, high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

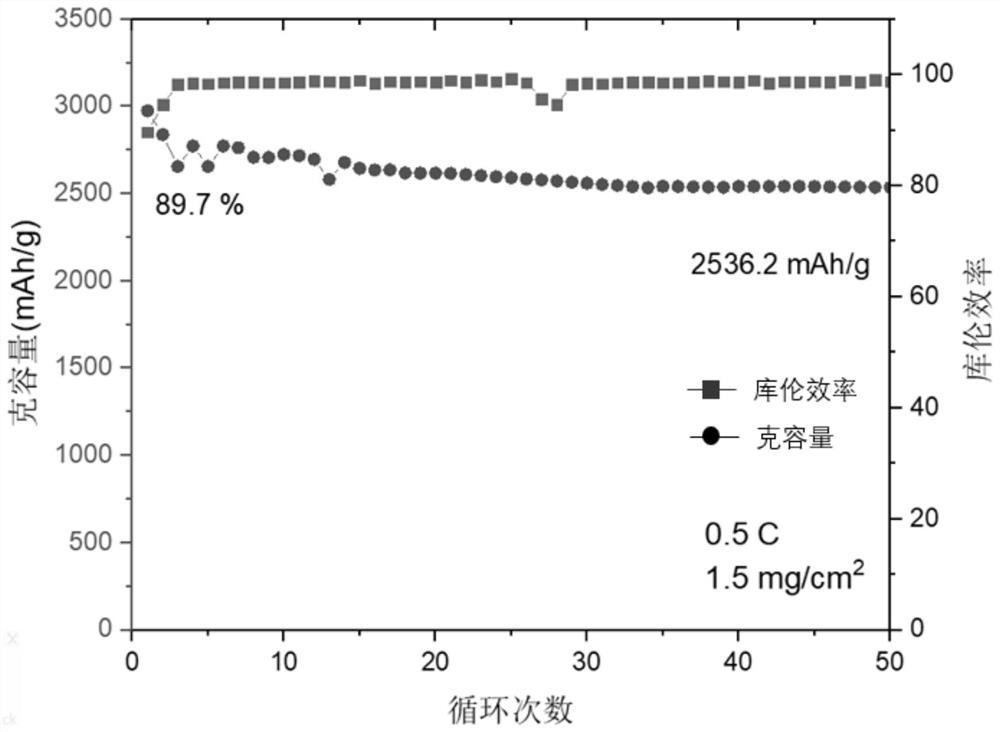

Embodiment 1

[0052] S1) Preparation of binder material A1:

[0053] Prepare 10ml of 5% polyvinyl alcohol aqueous solution, put the polyvinyl alcohol aqueous solution into a 50ml polytetrafluoroethylene-lined hydrothermal kettle, place the hydrothermal kettle in an oven at 160°C, take it out after 6h, and place it in the air for natural cooling , that is, to obtain the binder material, denoted as A1.

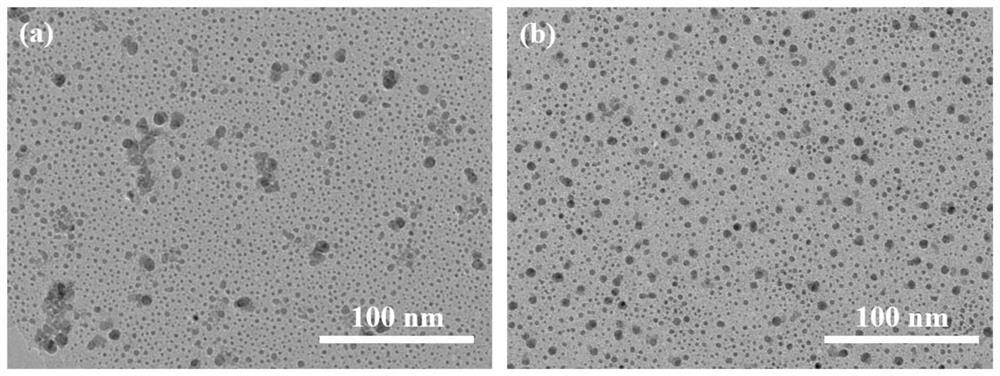

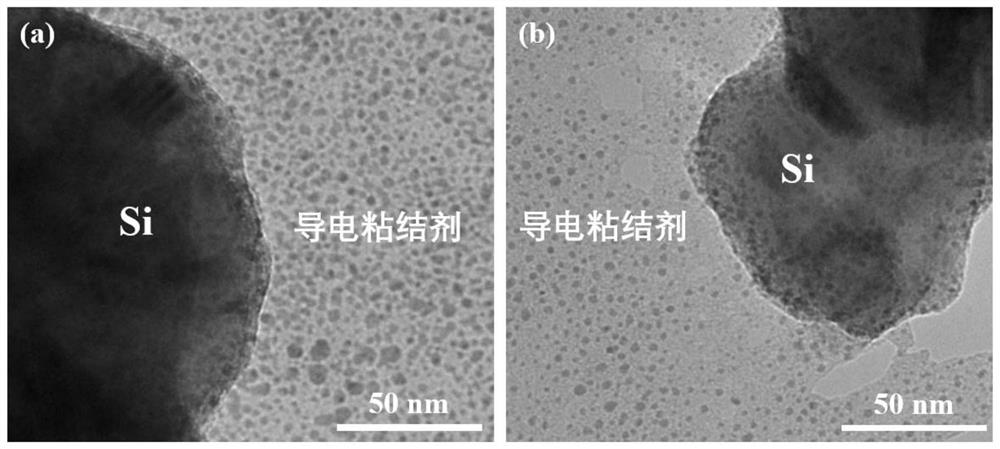

[0054] S2) making of pole piece N1:

[0055] Mix 1 mass part of A1 and 9 mass parts of active material nano-silicon with a mortar, add 0.2ml of deionized water to obtain negative electrode slurry, and coat the negative electrode slurry on copper foil. The solid coating quality is 1mg / cm 2 , and then dried in a vacuum oven at 100°C for 12 hours, cut into pieces, and weighed. The obtained pole piece is designated as N1.

[0056] S3) Preparation of lithium-ion half-cell C1:

[0057] The separator is a 25 μm polypropylene film;

[0058] The electrolyte is composed of non-aqueous organic solv...

Embodiment 2

[0061] S1) Preparation of binder material A2:

[0062] Prepare 10ml of 8% polyvinyl alcohol aqueous solution, put the polyvinyl alcohol aqueous solution into a 100ml polytetrafluoroethylene-lined hydrothermal kettle, place the hydrothermal kettle in an oven at 200°C, take it out after 24 hours, and place it in the air for natural cooling , that is, to obtain the binder material, denoted as A2.

[0063] S2) making of pole piece N2:

[0064] 1 mass part of A2 and 9 mass parts of active material nano-silicon were mixed evenly with a mortar, and 0.2ml deionized water was added to obtain the negative electrode slurry, which was coated on the copper foil, and the solid coating mass was 1mg / cm 2 , and then dried in a vacuum oven at 100°C for 12 hours, cut into pieces, weighed, and the obtained pole piece was recorded as N2.

[0065] S3) Preparation of lithium-ion half-cell C2:

[0066] The separator is a 25 μm polypropylene film;

[0067] The electrolyte is composed of non-aqueo...

Embodiment 3

[0070] S1) Preparation of binder material A3:

[0071] Prepare 50ml of 20% polyvinyl alcohol aqueous solution, put the polyvinyl alcohol aqueous solution into a 200ml polytetrafluoroethylene-lined hydrothermal kettle, place the hydrothermal kettle in an oven at 250°C, take it out after 12h, and place it in the air for natural cooling , that is, to obtain the binder material, denoted as A3.

[0072] S2) making of pole piece N3:

[0073] 1 mass part of A3 and 9 mass parts of active material nano-silicon were mixed evenly with a mortar, and 0.2ml deionized water was added to obtain the negative electrode slurry, which was coated on the copper foil, and the solid coating mass was 1mg / cm 2 , and then dried in a vacuum oven at 100°C for 12 hours, cut into pieces, and weighed. The obtained pole piece is designated as N3.

[0074] S3) Preparation of lithium-ion half-cell C3:

[0075] The separator is a 25 μm polypropylene film;

[0076] The electrolyte is composed of non-aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com