Patents

Literature

958results about How to "Ease of large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lady beer and production technology thereof

The invention relates to a beer produced from materials of 1-7 degree beerwort produced with a common beer production method, fresh fruit and vegetable juice, healthcare plant juice, traditional Chinese medicine extract, vitamins, a microelement mineral preparation, a foam stabilizer, and ethanol, which are blended according to a certain weight ratio. The lady beer provided by the invention has characteristics of digestion and absorbance promoting, beautifying, toxin expelling, freckle reducing, weight reducing, aging resisting, fatigue resisting, bowel loosening, constipation relieving, metabolism balancing, endocrine regulating, blood sugar reducing, and blood fat reducing. The contents of beerwort and ethanol in the beer are low. With the lady beer, original flavors of beer are preserved, abundant nutrients are provided, beer belly is not caused with long-term drinking, obesity is not caused, and a good healthcare effect is provided. The application scope of the lady beer is wide, and the lady beer is especially suitable for ladies.

Owner:张华

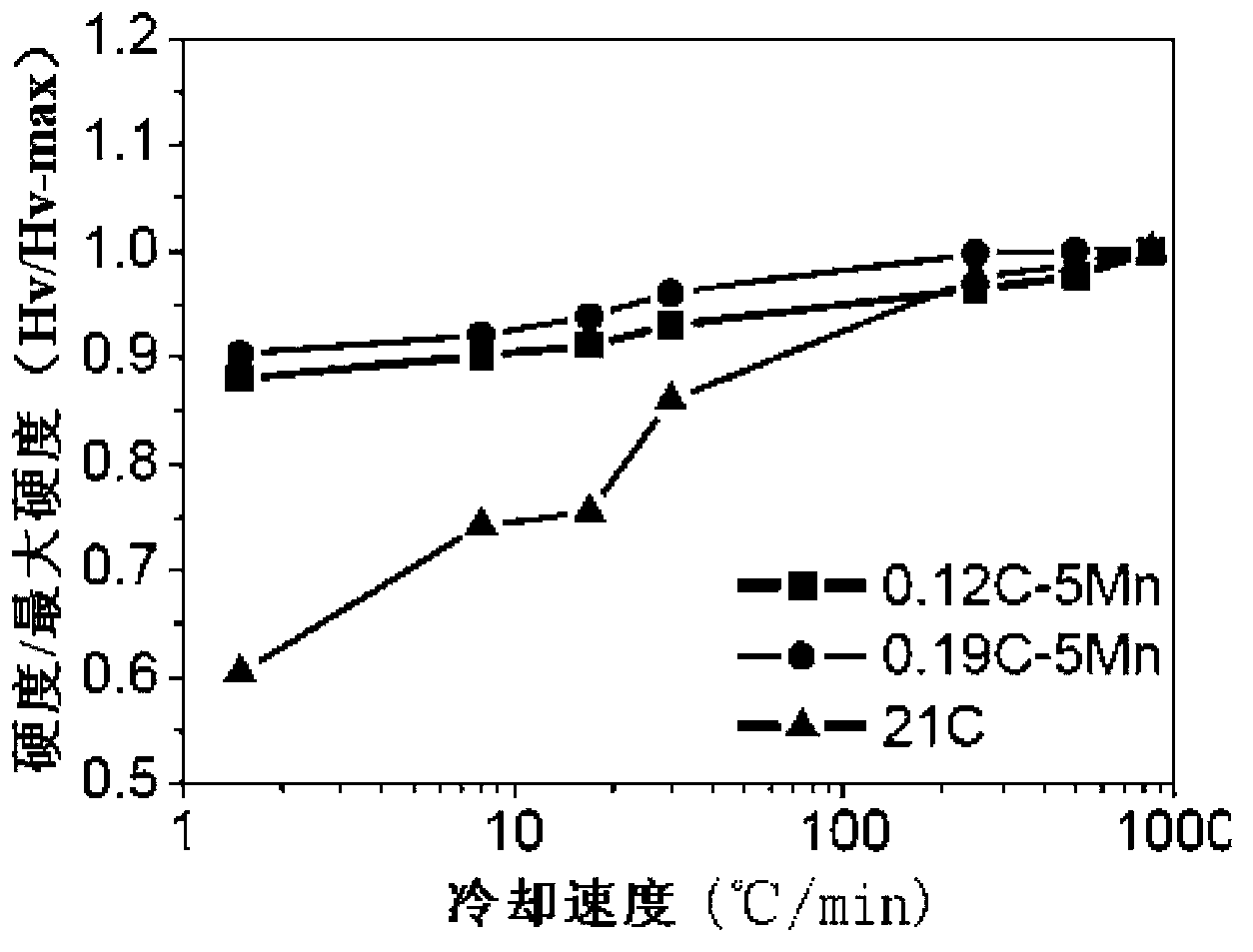

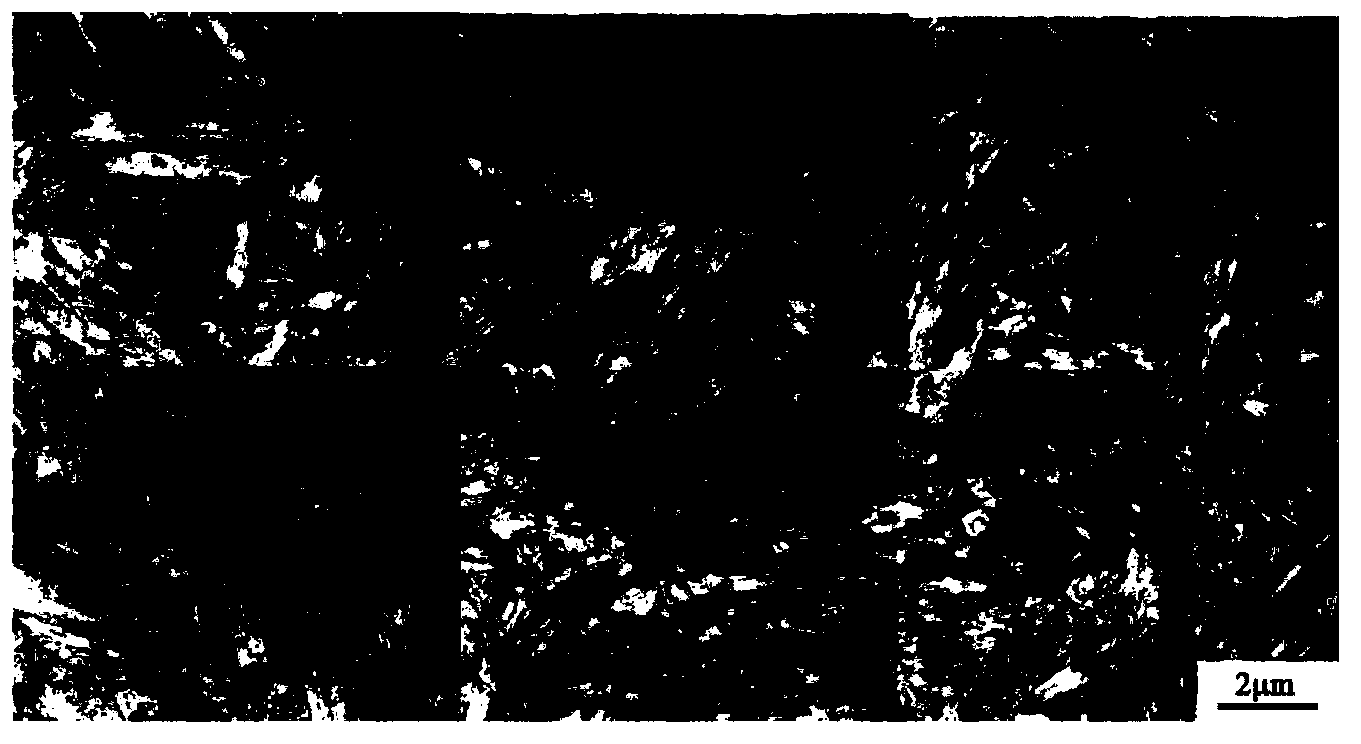

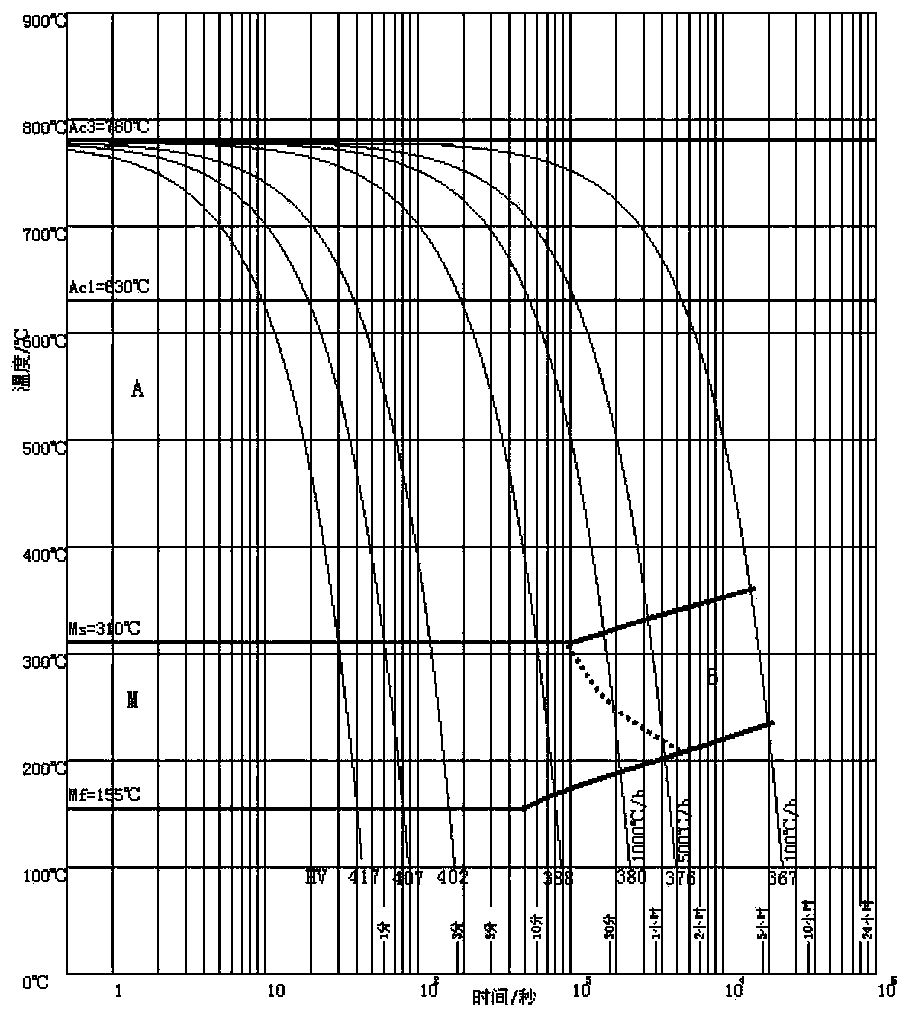

Martensite series wear-resistant steel and preparation method thereof

The invention relates to martensite series wear-resistant steel and a preparation method thereof, belonging to the technical field of wear-resistant steel. The steel comprises the following chemical components: 0.05-0.51wt% of C, 2.0-10wt% of Mn, 0-1.5wt% of Al, 0-1.5wt% of Si, 0-1.5wt% of Cr, 0-1.5wt% of Cu, 0-1.5wt% of Ni and the balance of Fe and inevitable impurities, wherein the Mn / C ratio is not less than 9. Based on this, the following one or more composite elements can be optionally added: 0.02-0.50wt% of Mo, 0.02-0.50wt% of V, 0.02-0.50wt% of Nb, 0.01-0.5wt% of Ti, 0.02-0.50wt% of B and 0.02-0.50wt% of RE. The wear-resistant steel provided by the invention is easy to produce, low in cost and high in performance. The invention is applicable to the technical field of wear-resistant materials for mines, energy, transportation, agricultural machinery, engineering machinery and other industries.

Owner:CENT IRON & STEEL RES INST

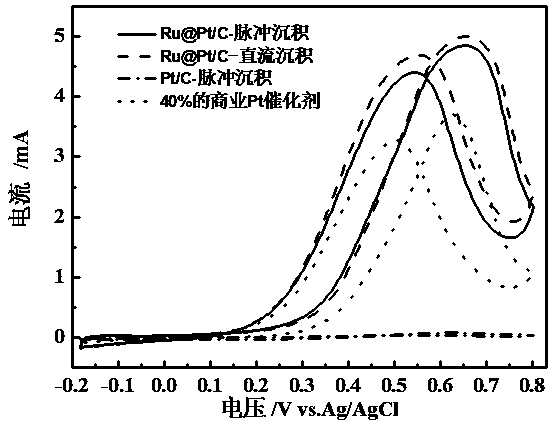

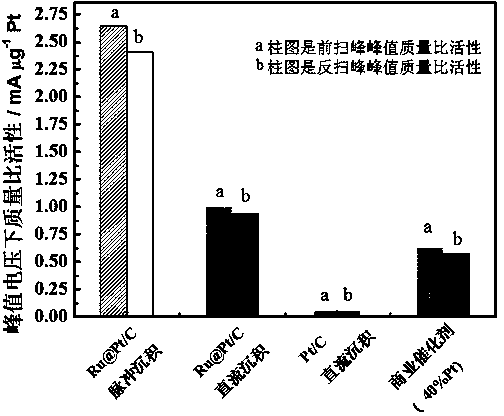

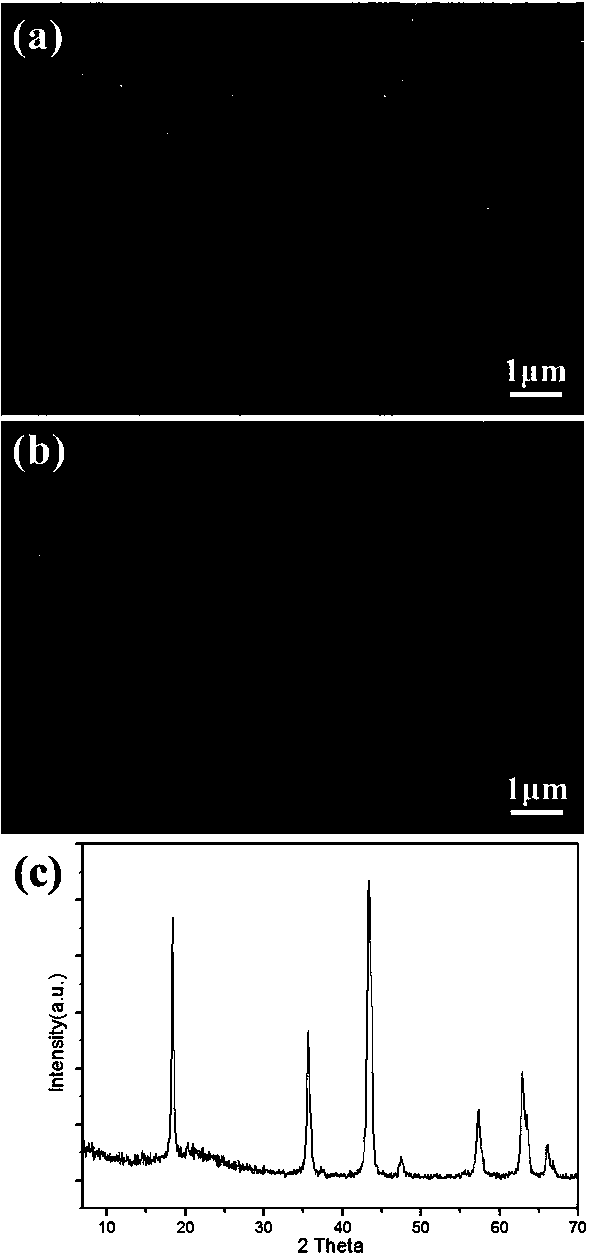

Core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method

ActiveCN103638925AIncrease profitReduce usageCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPlatinumPtru catalyst

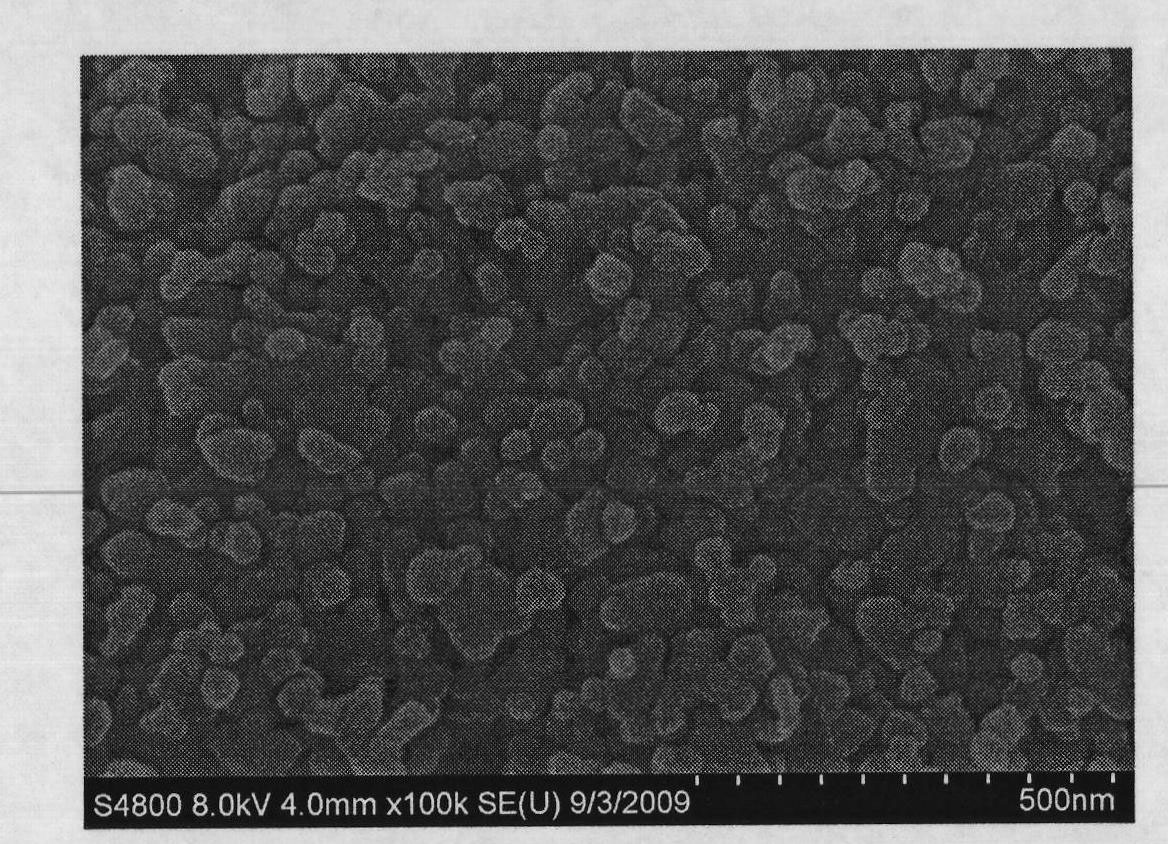

The invention discloses a core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method. The active component of the catalyst is a nanoparticle with a core-shell structure, and an active metal is cladded in the form of an ultrathin shell on the surface of a carbon carrier loaded metal or alloy nanoparticle serving as a core. The catalyst takes a non-platinum noble metal or transition metal as the core, and adopts more than one of Pt, Ir or Au as the shell. The preparation method includes: preparation of the nanoparticle serving as the core, making of a working electrode for pulse electrodeposition, and preparation of the catalyst by pulse electrodeposition. The catalyst can be used as an anode or cathode catalyst of a low temperature fuel cell. The obtained catalyst has very high stability. Compared with underpotential deposition, the method is simple to operate, has no need for inert atmosphere protection, and is more suitable for large-scale industrial production, also can greatly reduce the noble metal consumption of fuel cells, and greatly reduce the cost of fuel cells, thus having great significance in promoting the commercialization process of fuel cells.

Owner:SOUTH CHINA UNIV OF TECH

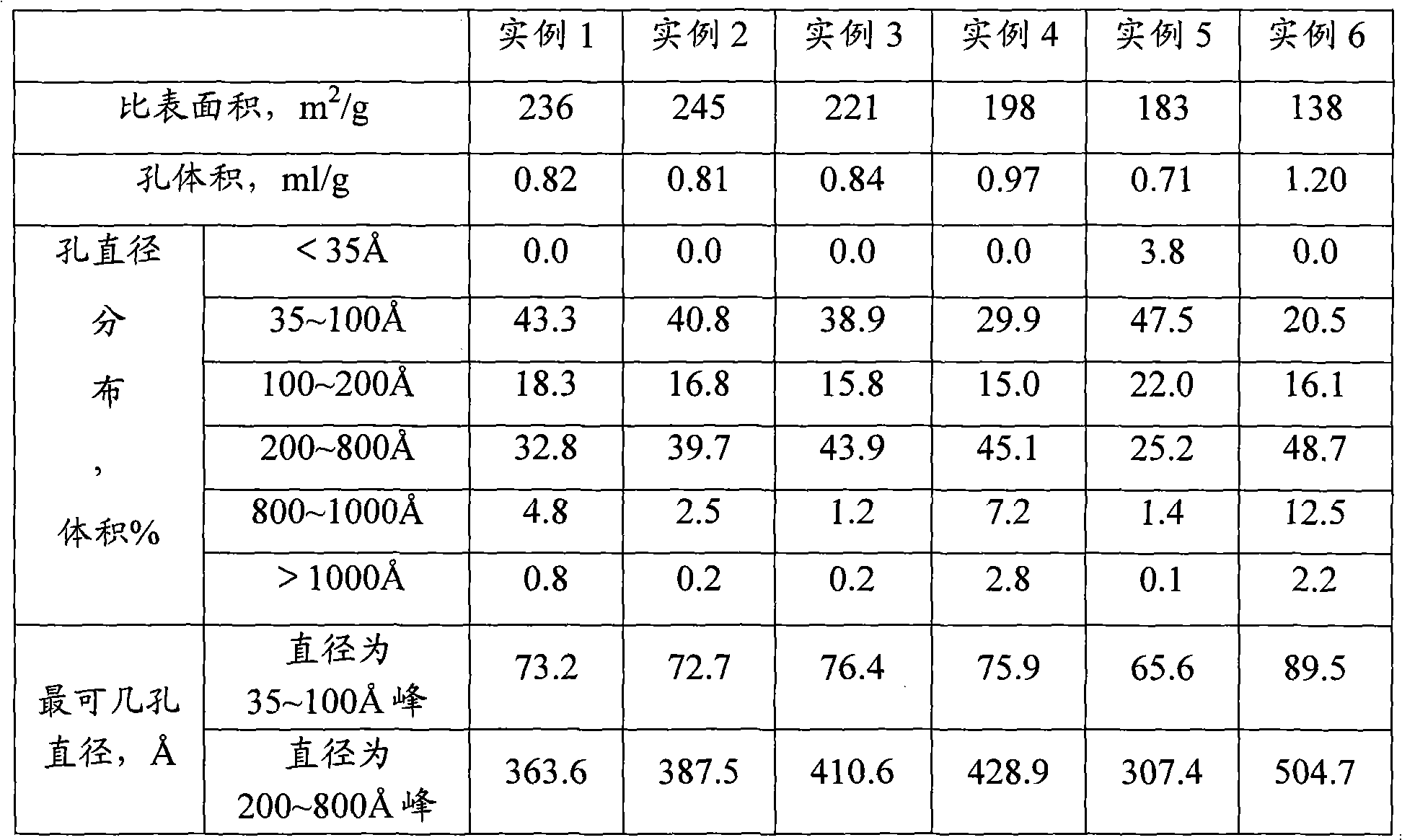

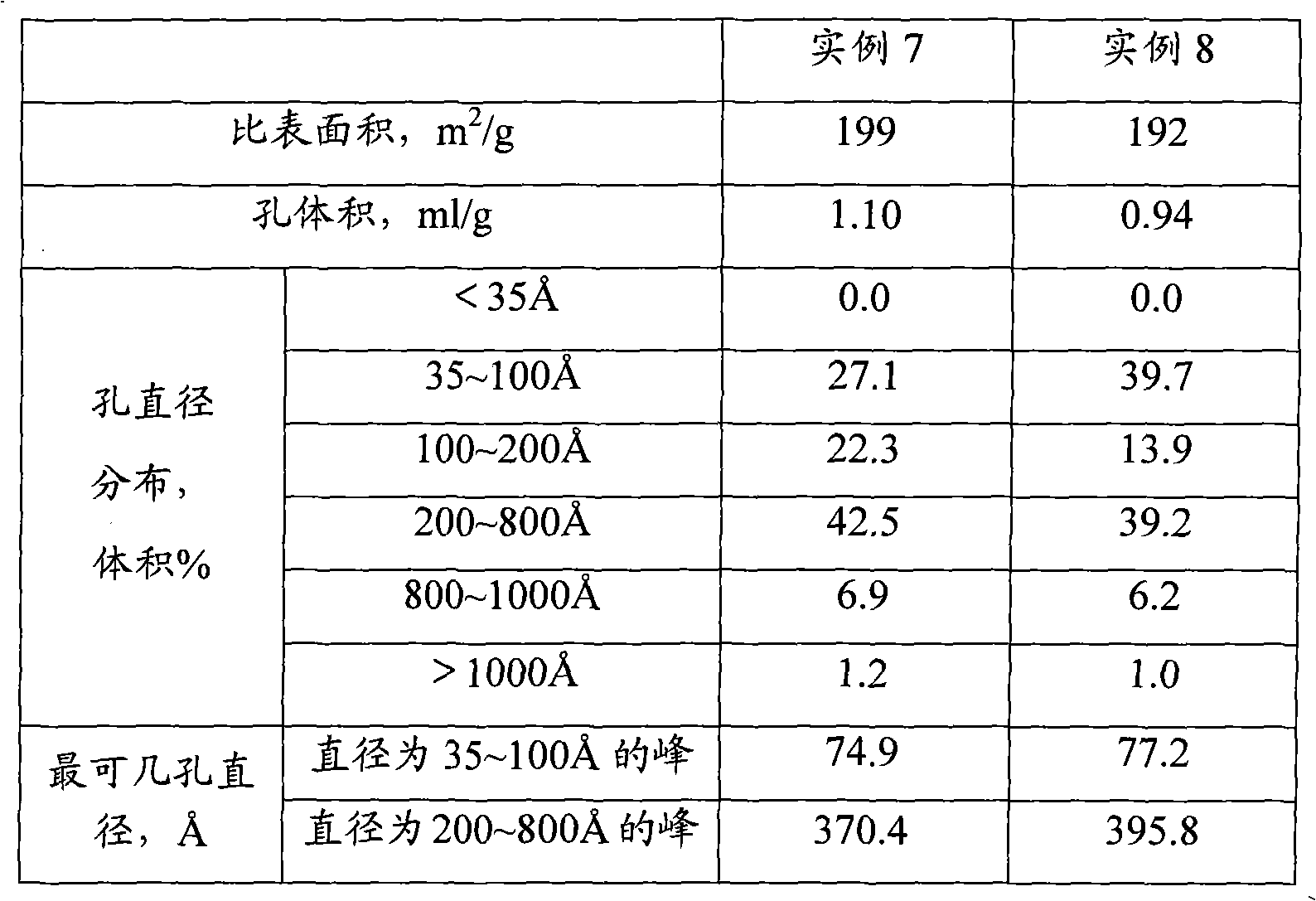

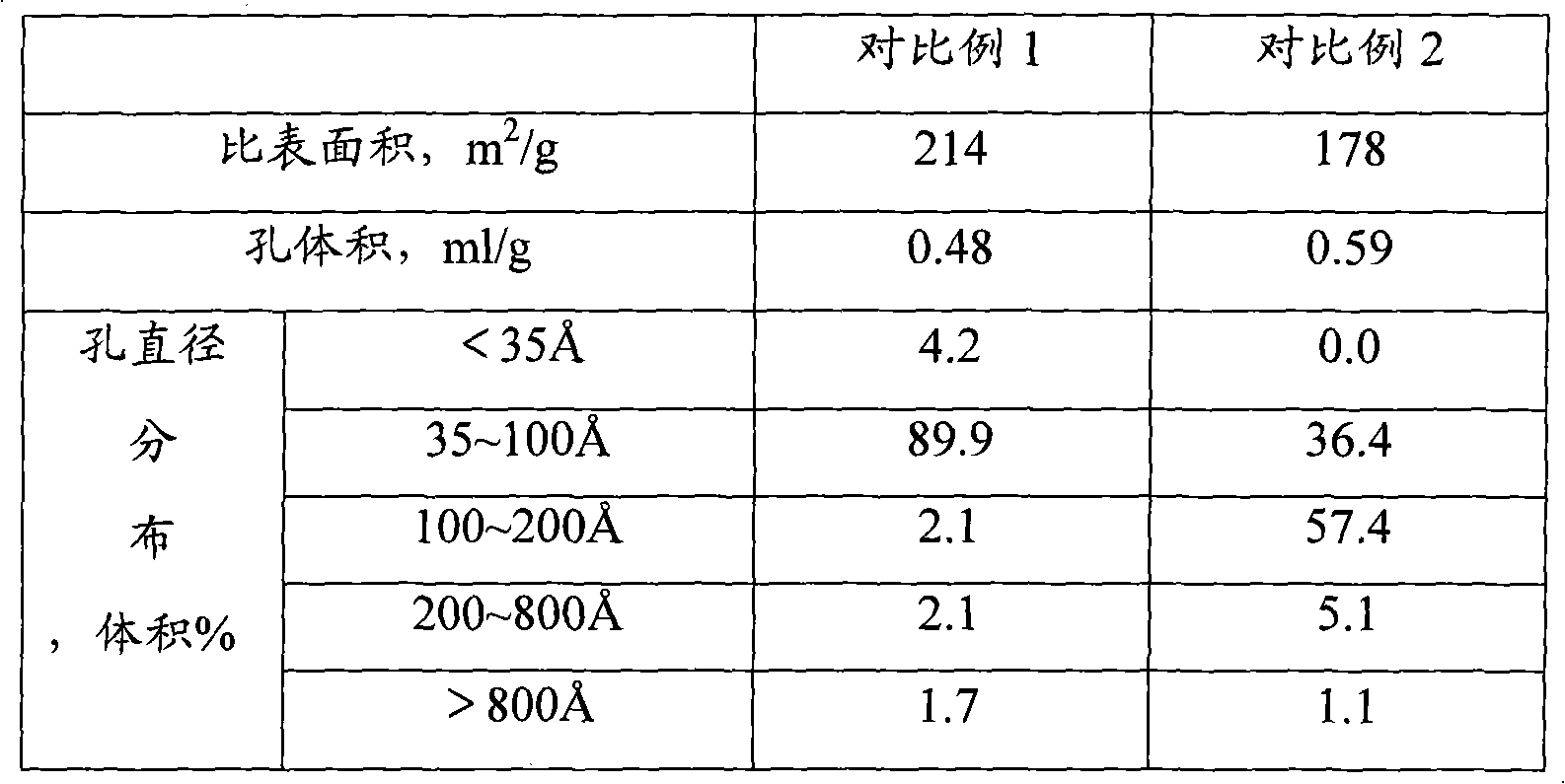

Macroporous aluminum oxide with bimodal pore distribution and preparation method thereof

ActiveCN102030351AAvoid flying temperatureReduce manufacturing costAluminium oxides/hydroxidesPore distributionOrganic solvent

The invention discloses macroporous aluminum oxide with bimodal pore distribution. The pore volume of the macroporous aluminum oxide is 0.6 to 3.0ml / g, the specific surface area is 90 to 300sq.m / g, wherein the pores with aperture of between 35 and 100 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 50 and 90; and the pores with aperture of between 200 and 800 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 300 and 600. The aluminum oxide is prepared by a two-section aging method without a hole expansion agent or an organic solvent, so the raw materials are saved, the flow is simplified, and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

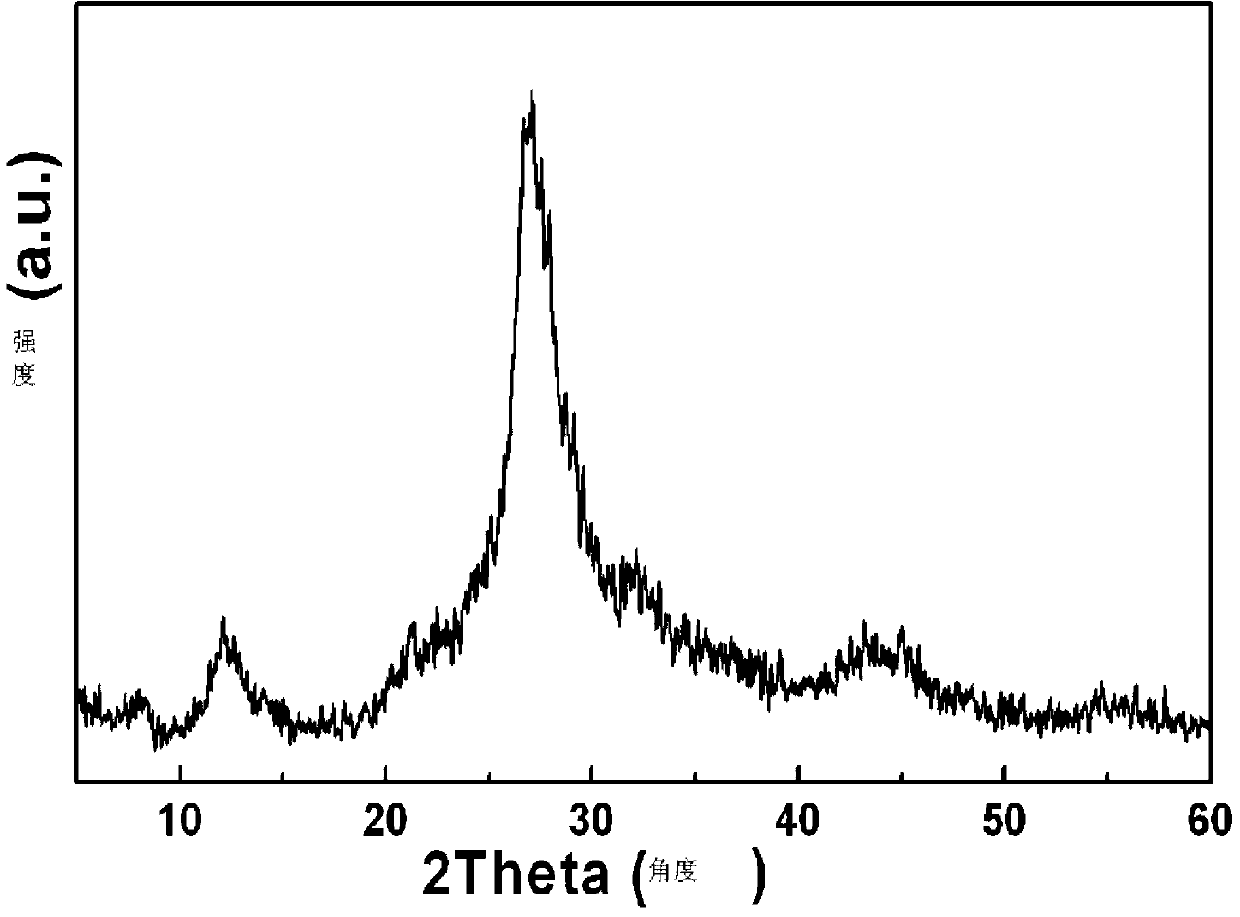

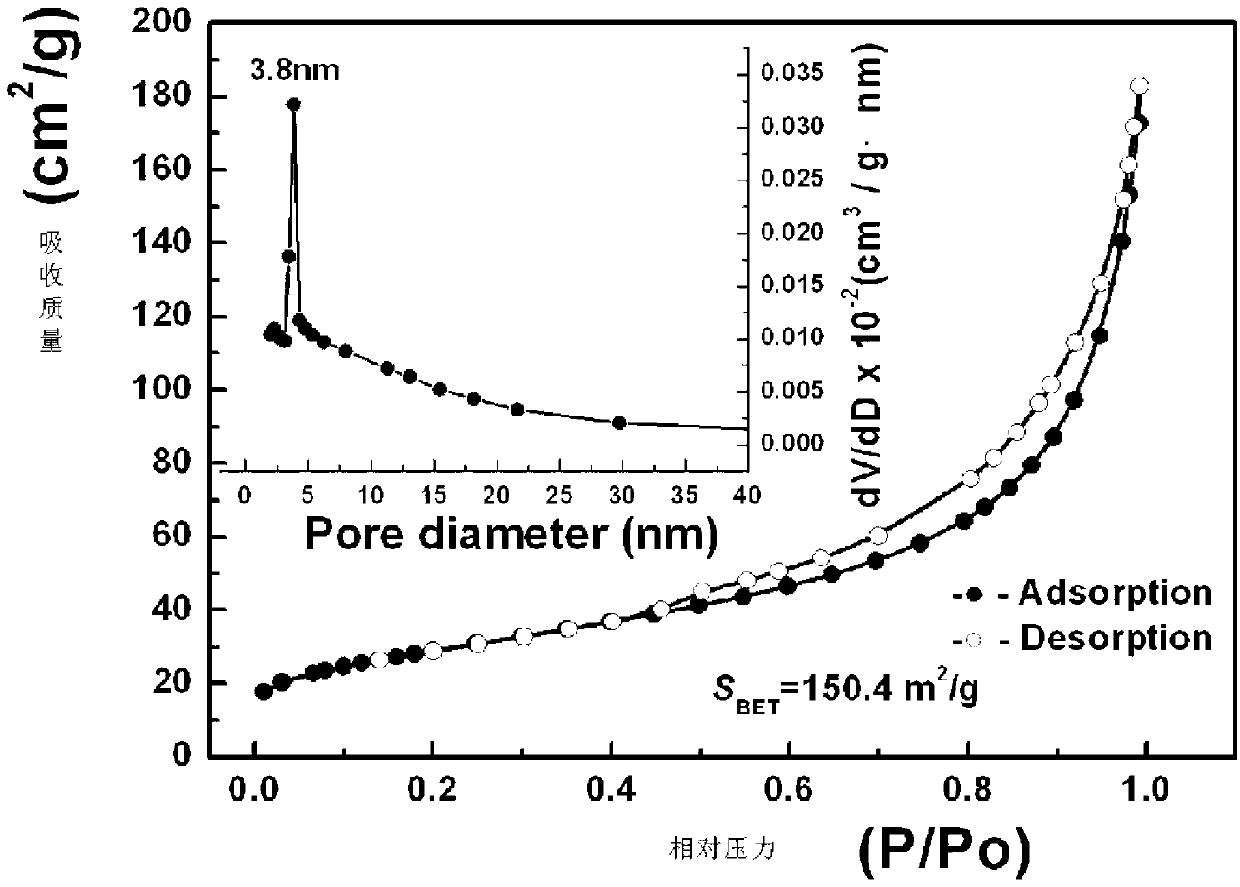

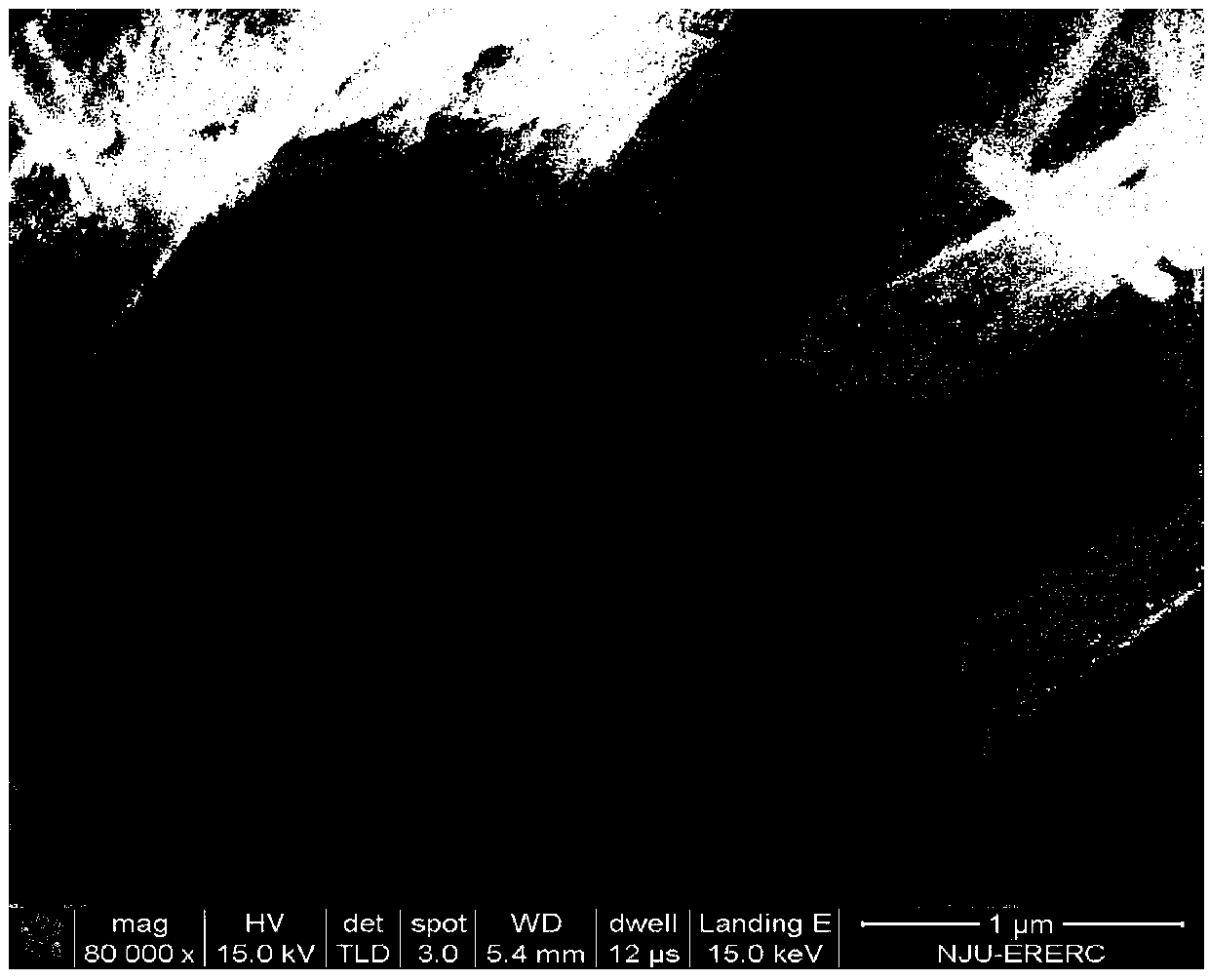

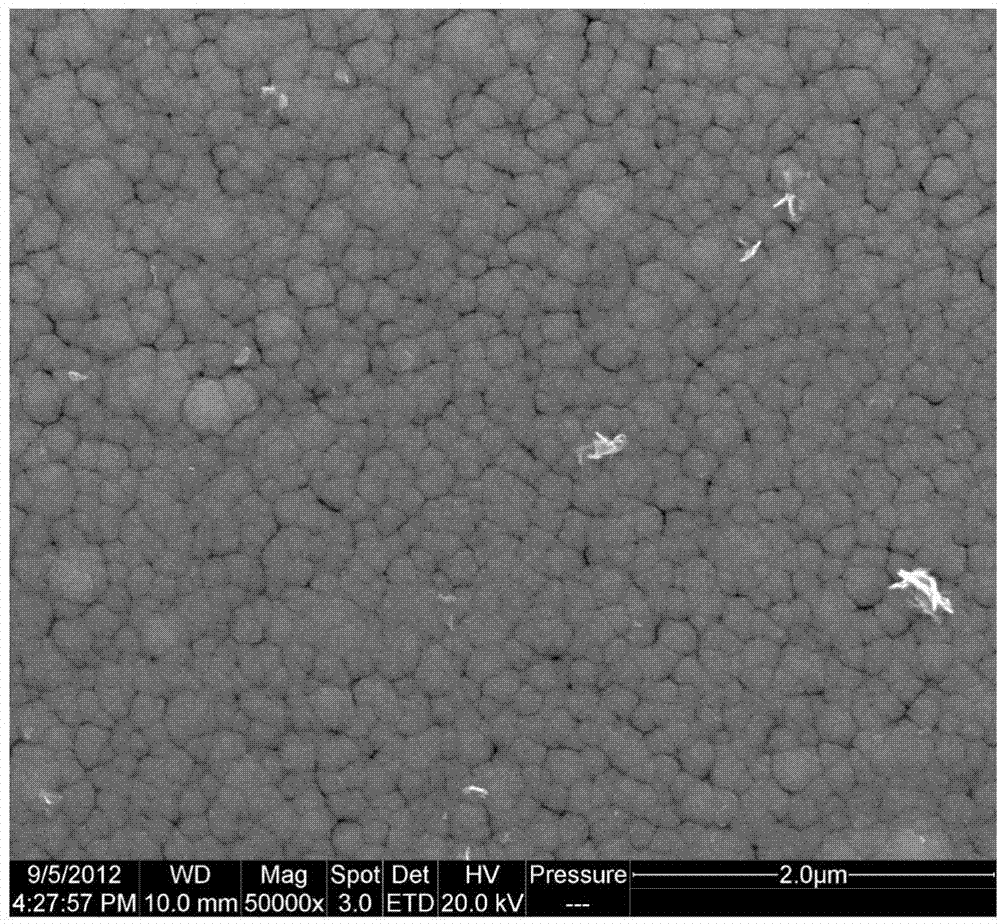

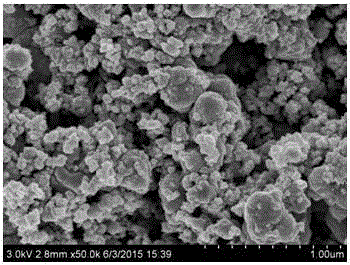

Mesoporous C3N4 photocatalytic material prepared by using molten salt method and application thereof in photocatalysis field

InactiveCN102992282AEase of mass productionEase of large-scale industrial productionPhysical/chemical process catalystsNitrogen and non-metal compoundsMuffle furnaceBlocking layer

The invention discloses a mesoporous C3N4 photocatalytic material prepared by using a molten salt method and a preparing method thereof. The method comprises the following steps that water-soluble low-melting-point molten salt is fully mixed with melamine, small molten salt drops are used as a blocked layer under the melting temperature of the molten salt, C3N4 grows in a way of being coated with the small drops, and the molten salt is recycled by water washing after reaction, so as to obtain the C3N4 photocatalytic material. The C3N4 photocatalytic material is in a wormlike mesoporous structure, the mesoporous size is within 3.8+ / -1nm, and the forming mechanism of the mesoporous C3N4 photocatalytic material is that the small molten salt drops are used as the growth blocked layer. When the material is prepared, water-soluble low-melting-point chloride salt is used as the molten salt and is fully mixed with melamine to obtain a mixture, the mixture is subjected to the heat treatment in a muffle furnace for 1-5h under the temperature being 400-680 DEG C to obtain samples, and the samples after the heat treatment are washed by water to recycle the molten salt, so as to obtain the mesoporous C3N4 photocatalytic material. In the whole process, a template is not introduced, and the operation is easy and feasible, so that the large-scale industrial production can be realized easily.

Owner:NANJING UNIV

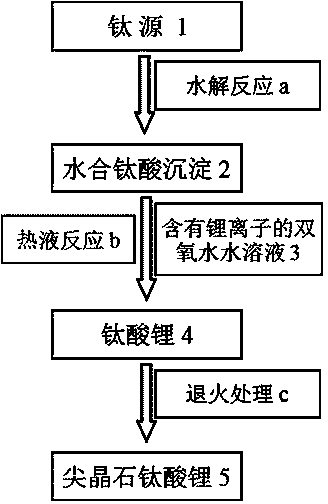

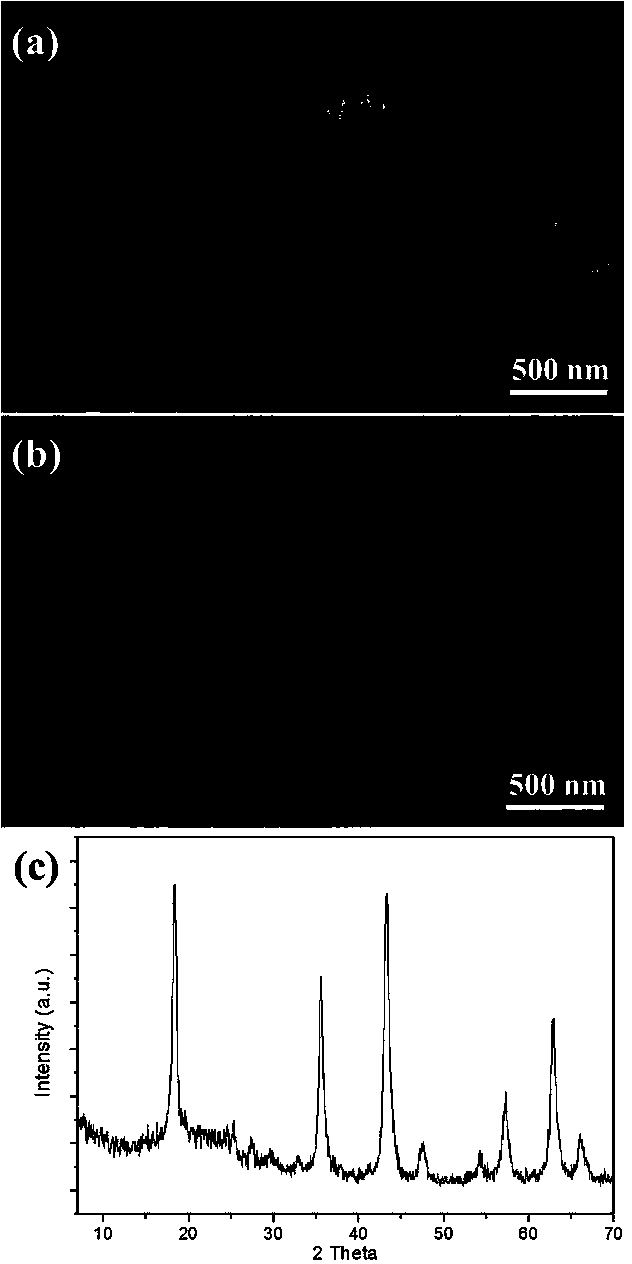

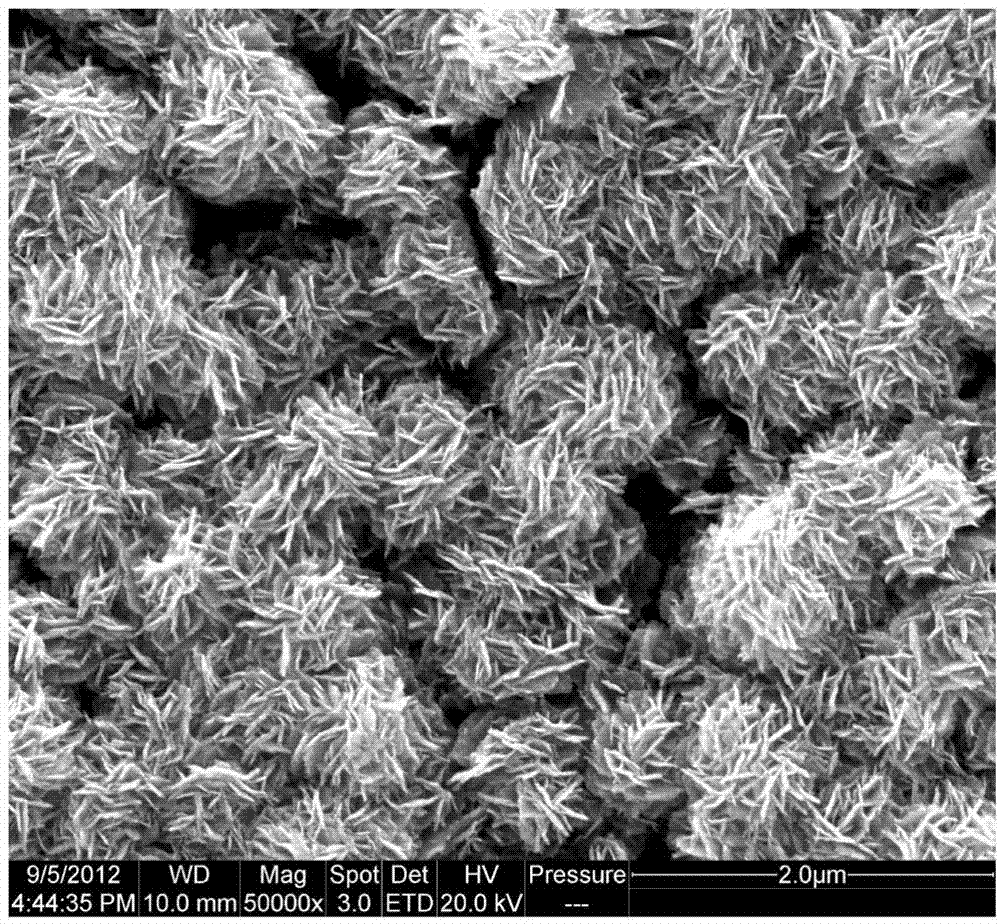

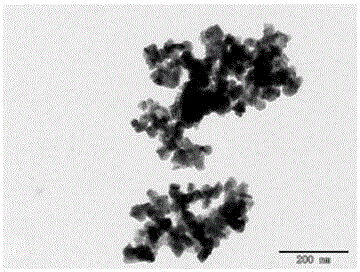

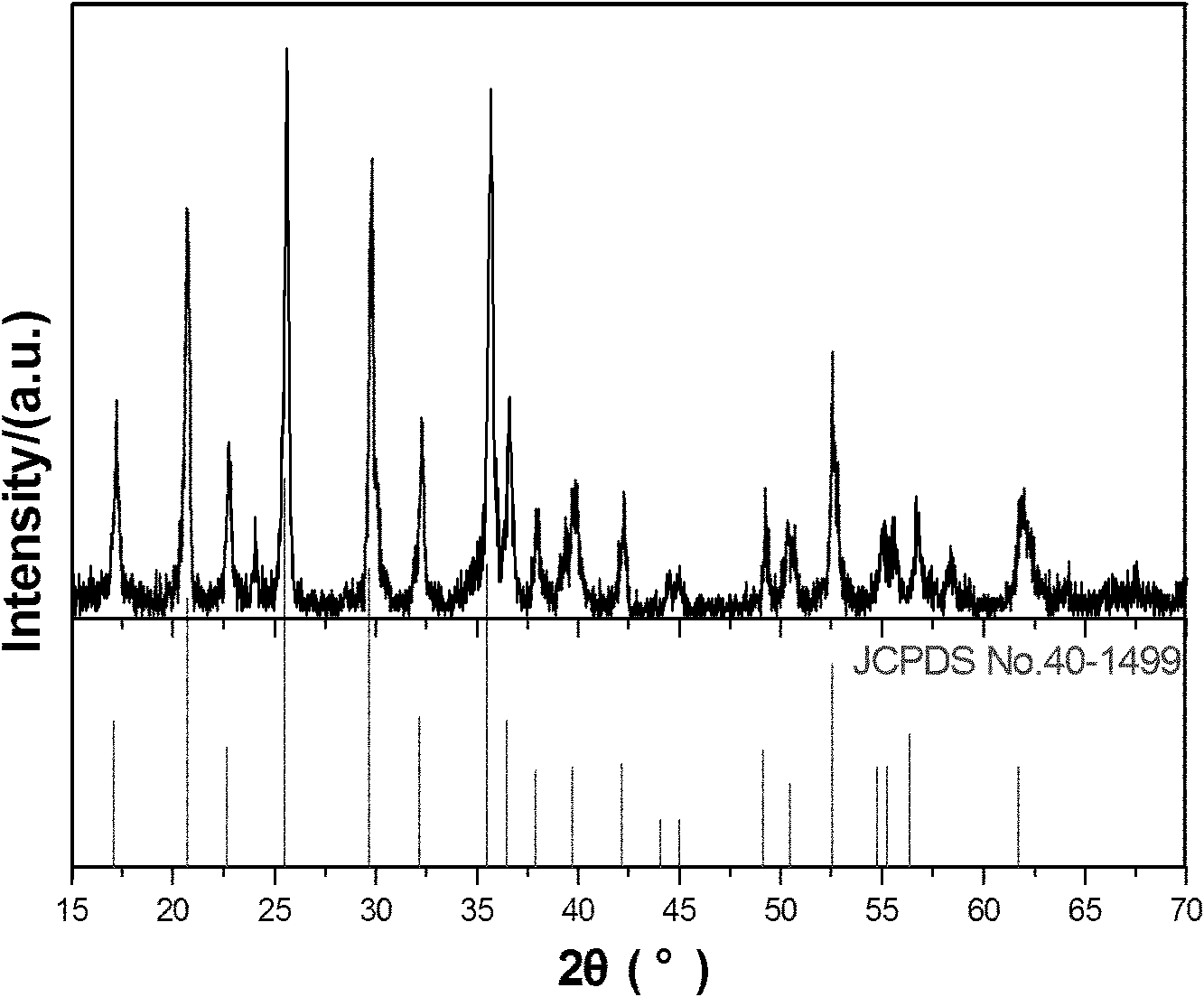

Method for preparing spinel lithium titanate

InactiveCN104201364AOvercome conductivityLow priceMaterial nanotechnologyAlkali titanatesLithiumNanowire

The invention discloses a method for preparing spinel lithium titanate. The method is characterized by comprising the steps of S1, performing hydrolysis reaction on a titanium source to obtain hydrated titanium acid sediments; S2, dispersing the hydrated titanium acid sediments into lithium ion-containing hydrogen peroxide aqueous solution to obtain a mixture; S3, performing hydrothermal reaction on the mixture to obtain nanowire type lithium titanate and / or lithium titanate with a nano differential level structure; S4, annealing the nanowire type lithium titanate and / or the lithium titanate with the nano differential level structure to obtain nanowire type spinel lithium titanate and / or the spinel lithium titanate with the nano differential level structure. According to the method, both spinel lithium titanate nanowires and the spinel lithium titanate with the nano differential level structure can be prepared.

Owner:李建明

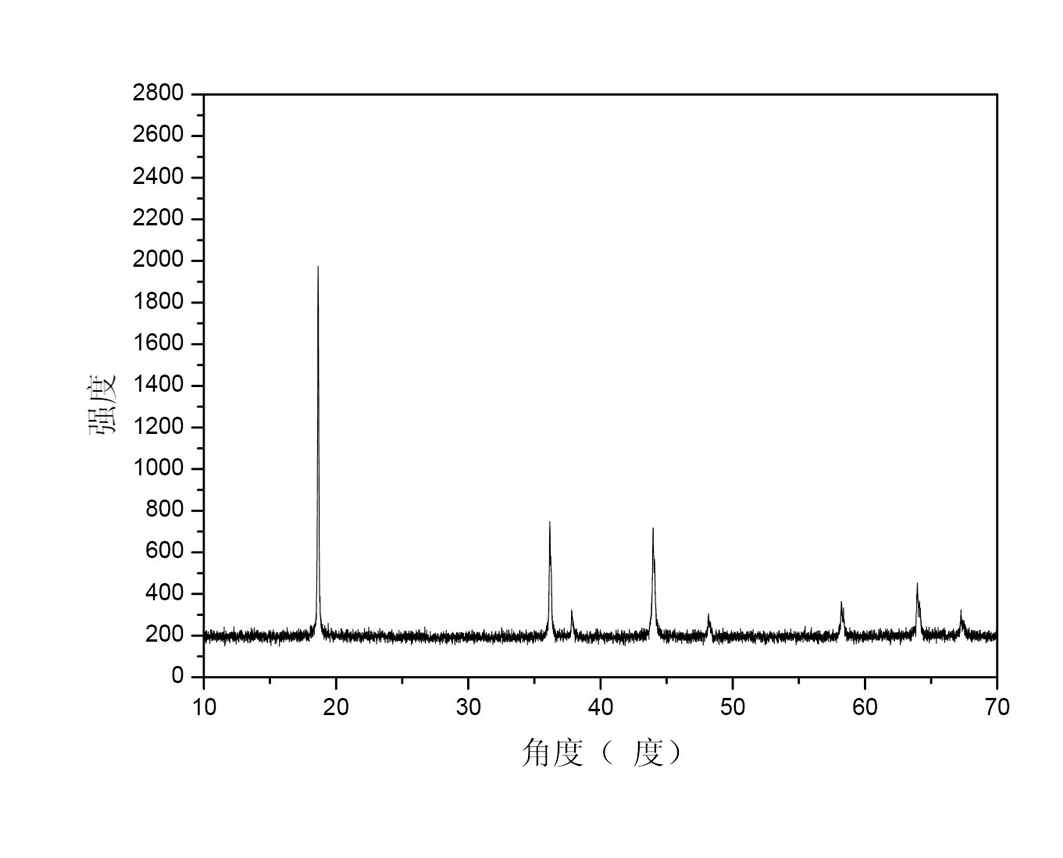

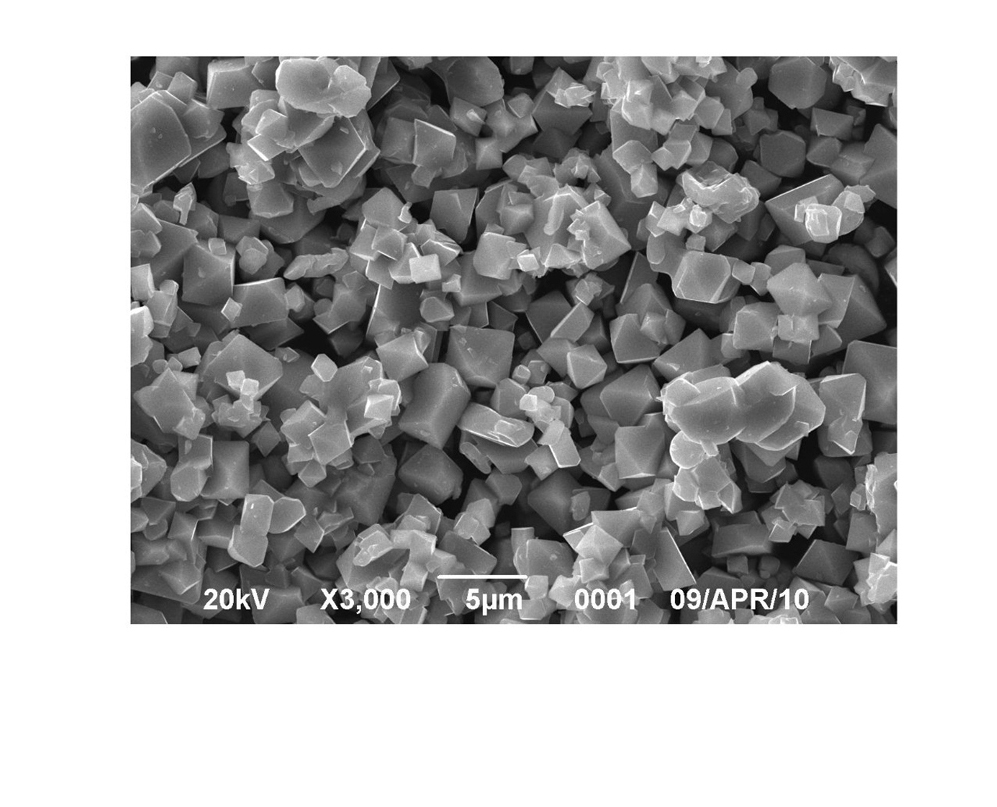

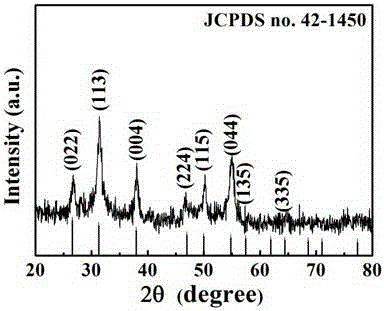

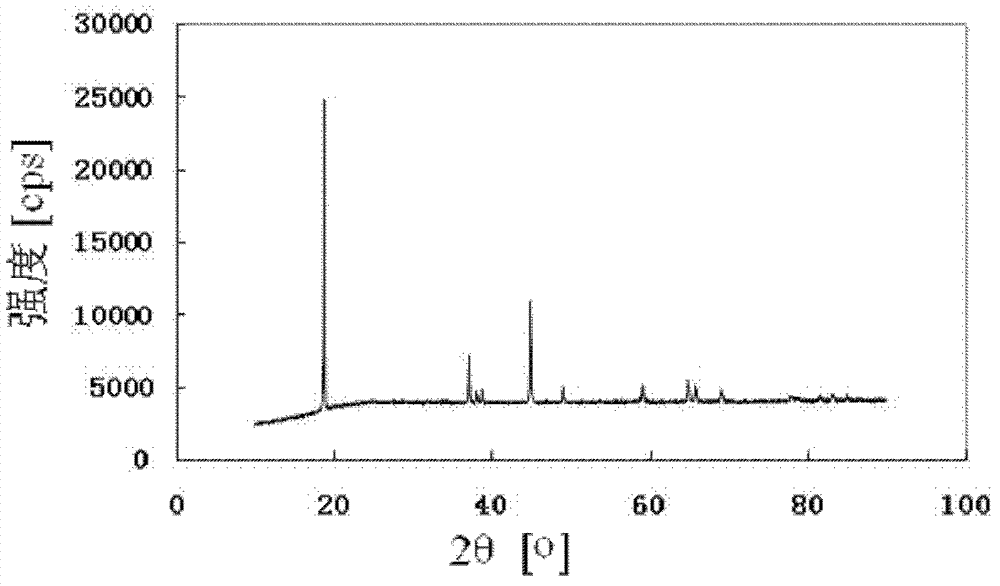

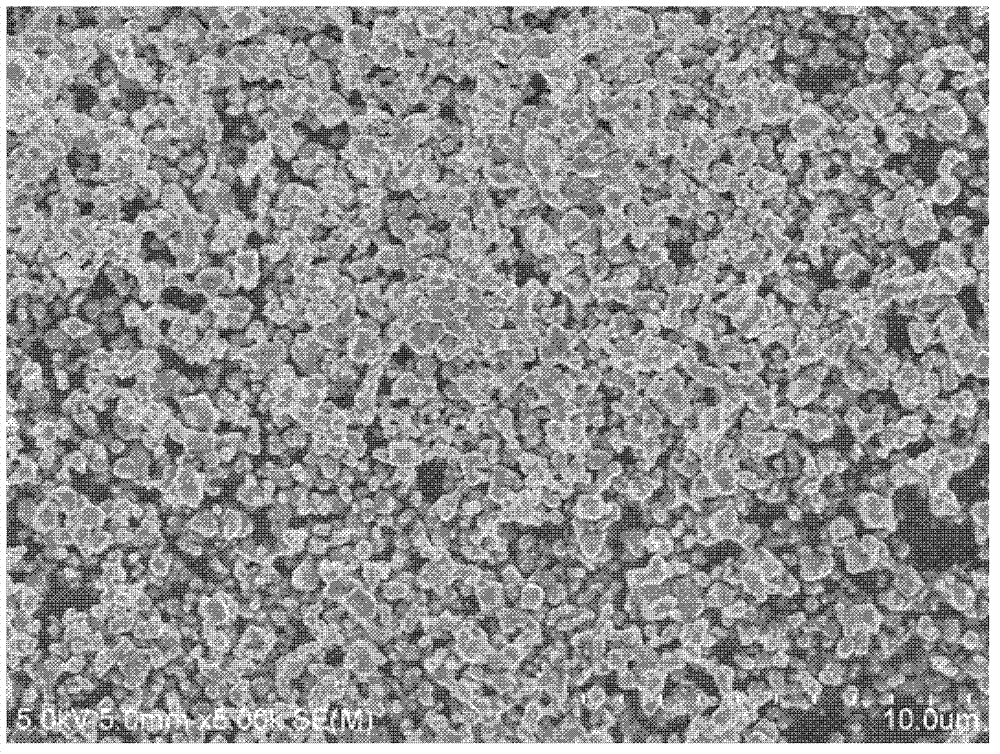

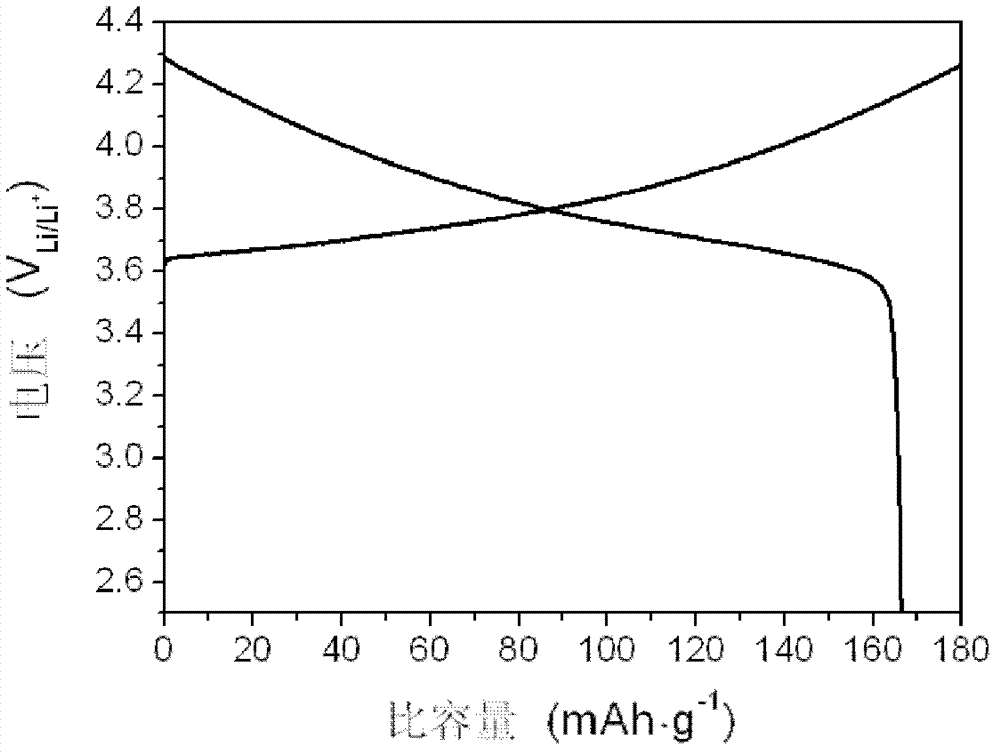

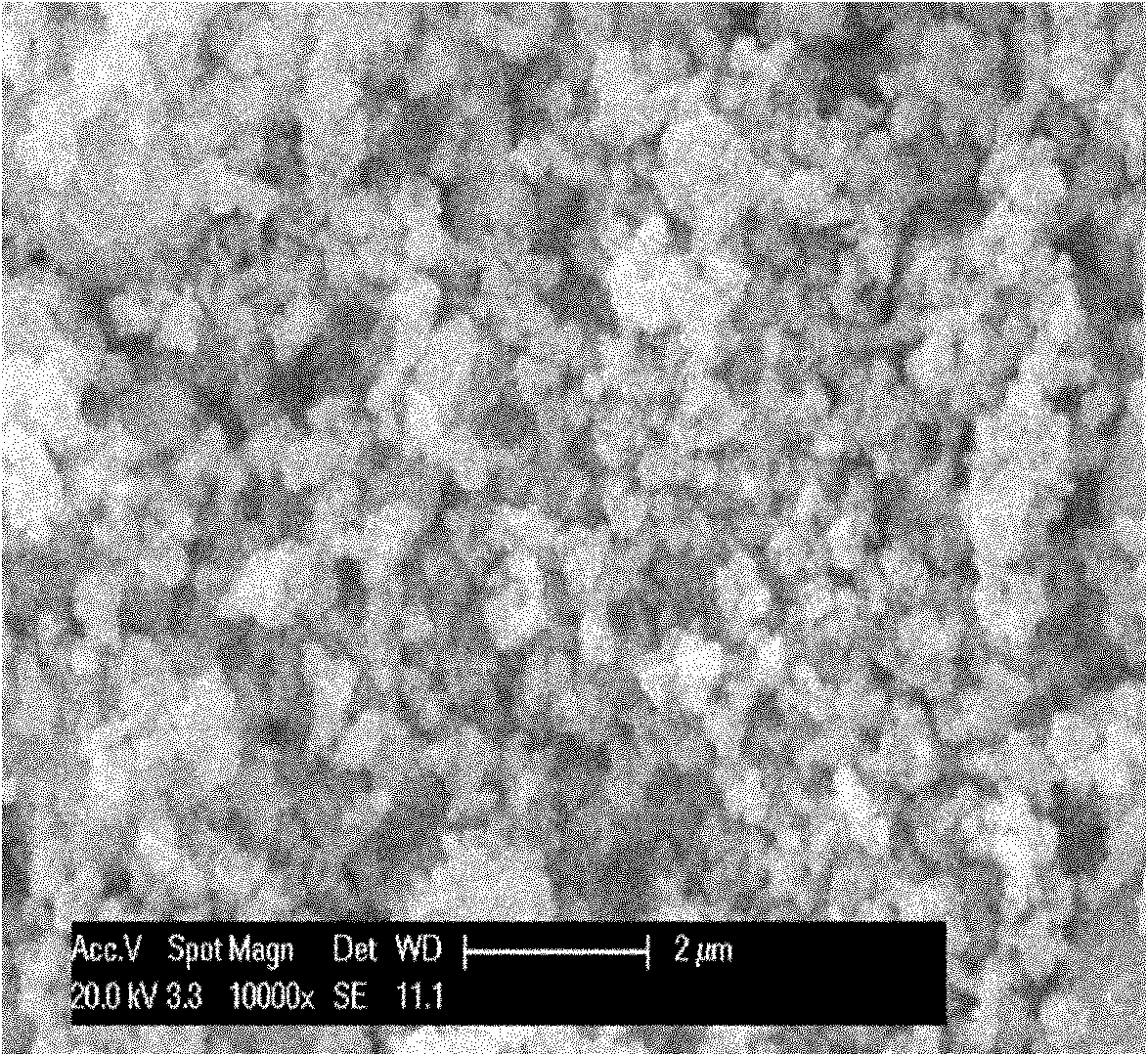

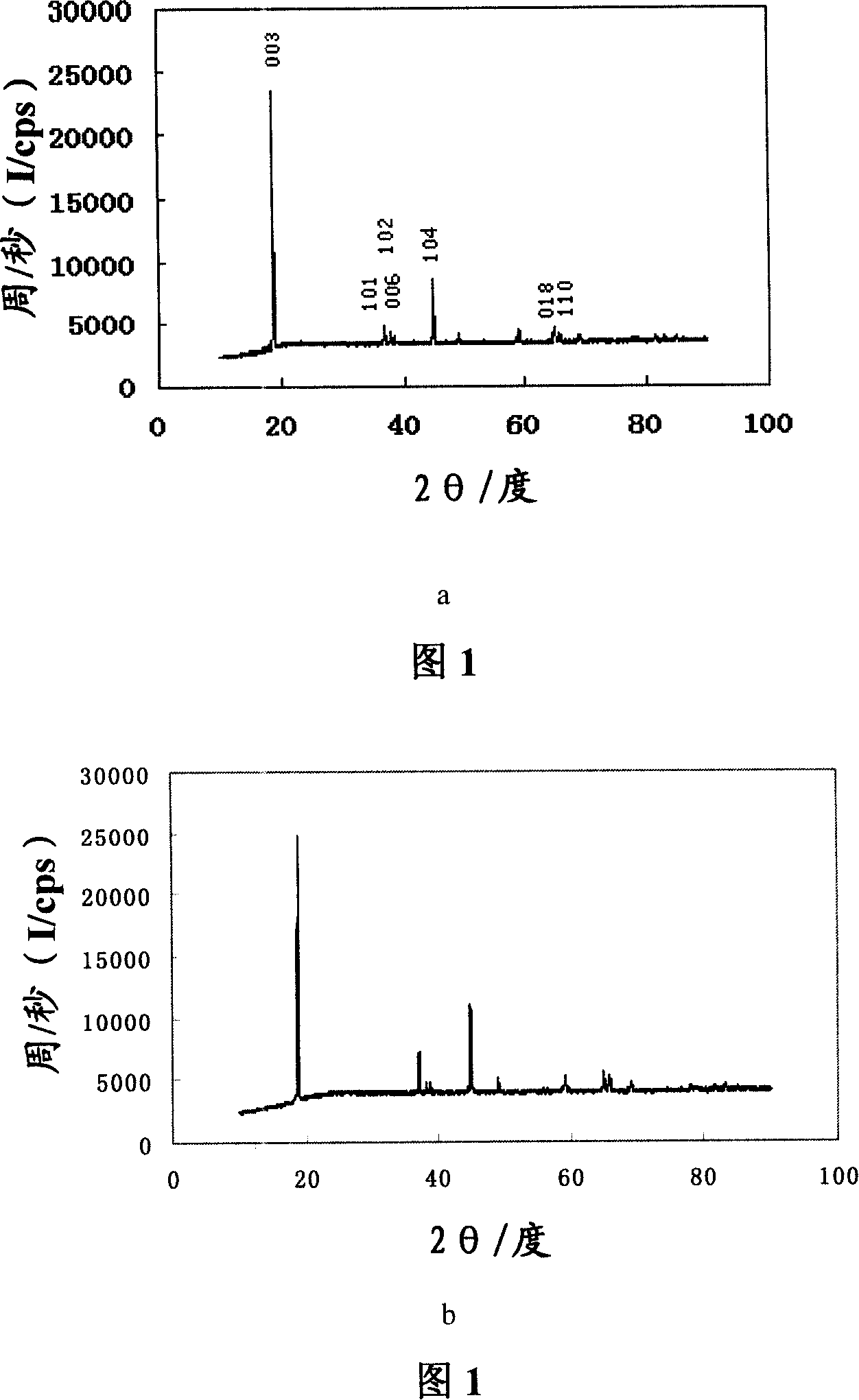

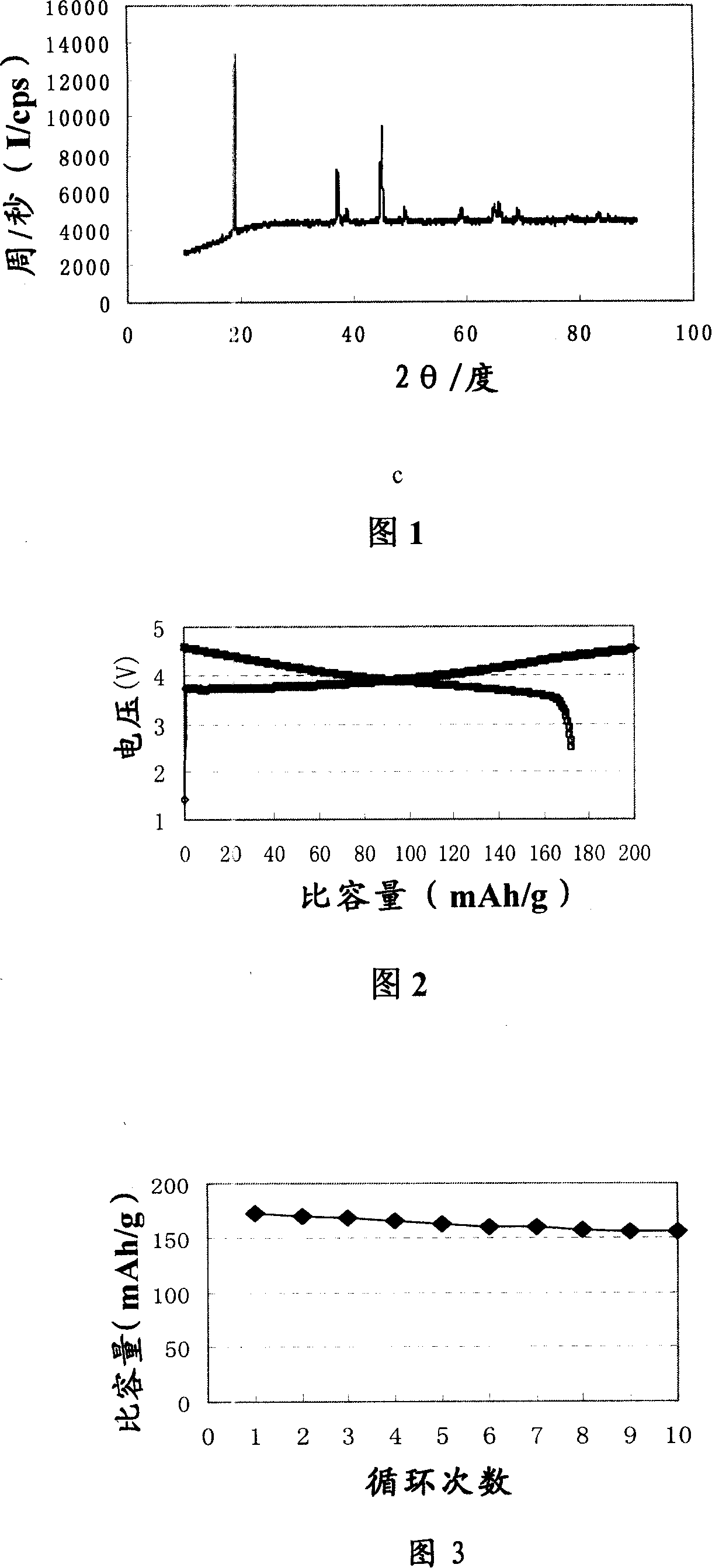

Preparation method of lithium ion battery anode material lithium manganate and automobile lithium ion battery

InactiveCN101964416AUniform bulkGood crystallizationCell electrodesSecondary cellsElectrical batteryManganate

The invention relates to a preparation technology of a battery anode material and a related automobile battery and particularly discloses a preparation method of lithium ion battery anode material lithium manganate. The method comprises the following steps: using lithium source, Mn3O4 and nanoscale doping metal additive as raw materials for proportioning, then presintering Mn3O4 or the Mn3O4 processed by ball milling, mixing the presintered Mn3O4 with the mixture of lithium source and metal additive; performing the first sintering and second sintering to the mixed raw material; and finally classifying and screening the sintering product to obtain the spinel lithium manganate product with the required grain size. The invention also discloses an automobile lithium ion battery which is assembled by using the spinel lithium manganate prepared by the method of the invention as anode and using graphite as cathode. The preparation method of the invention has simple operation and environmental friend; and the prepared lithium manganate product has excellent product performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

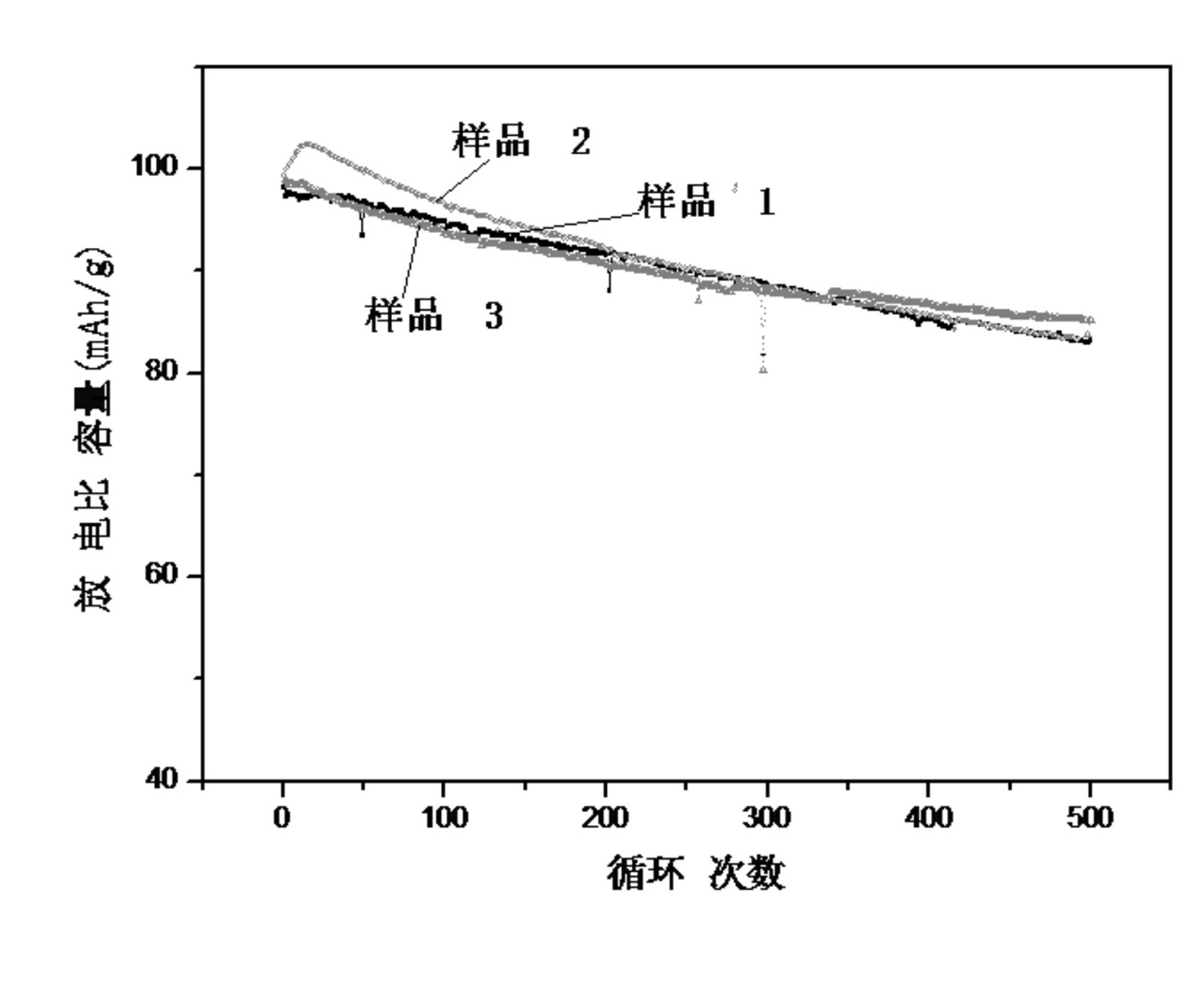

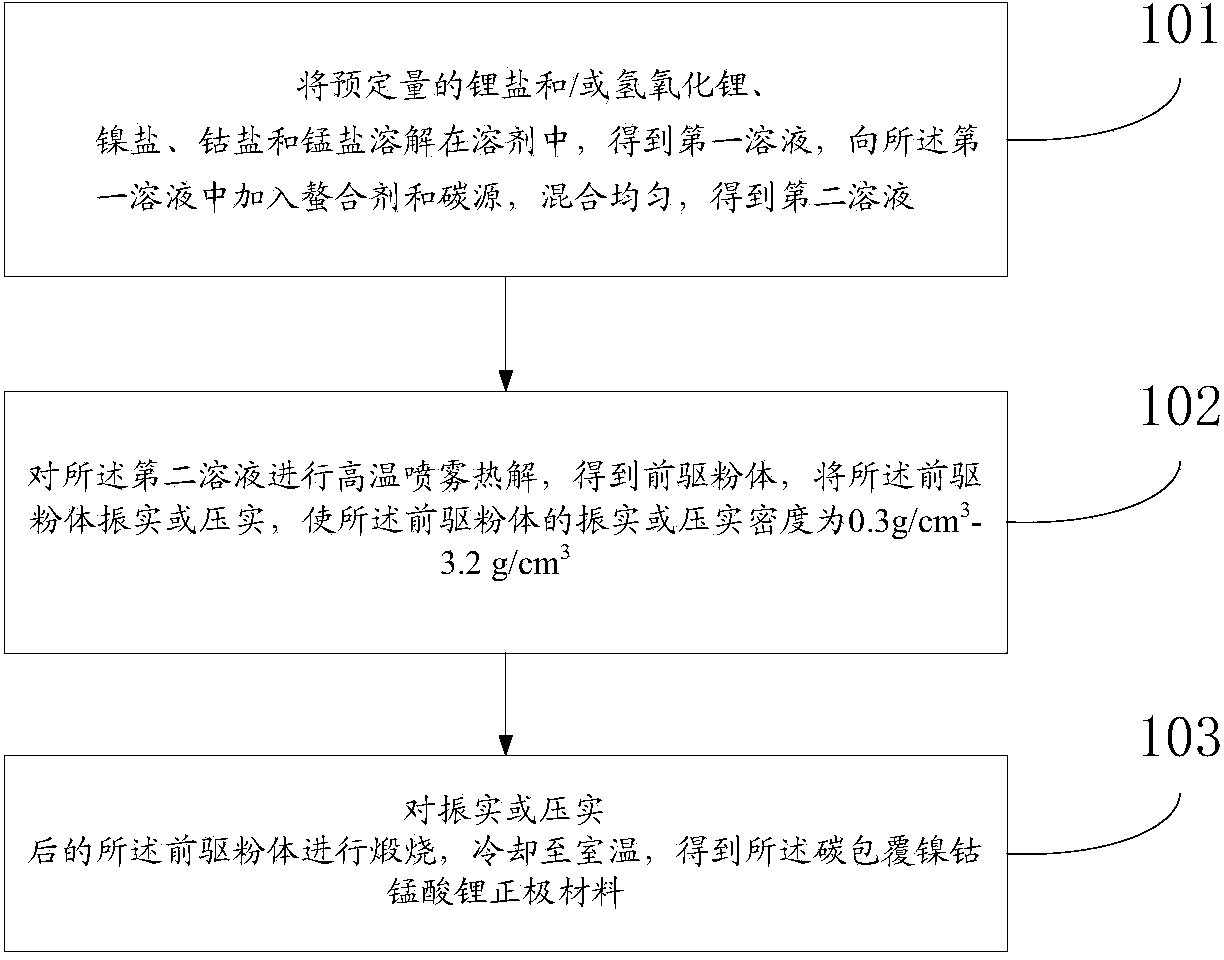

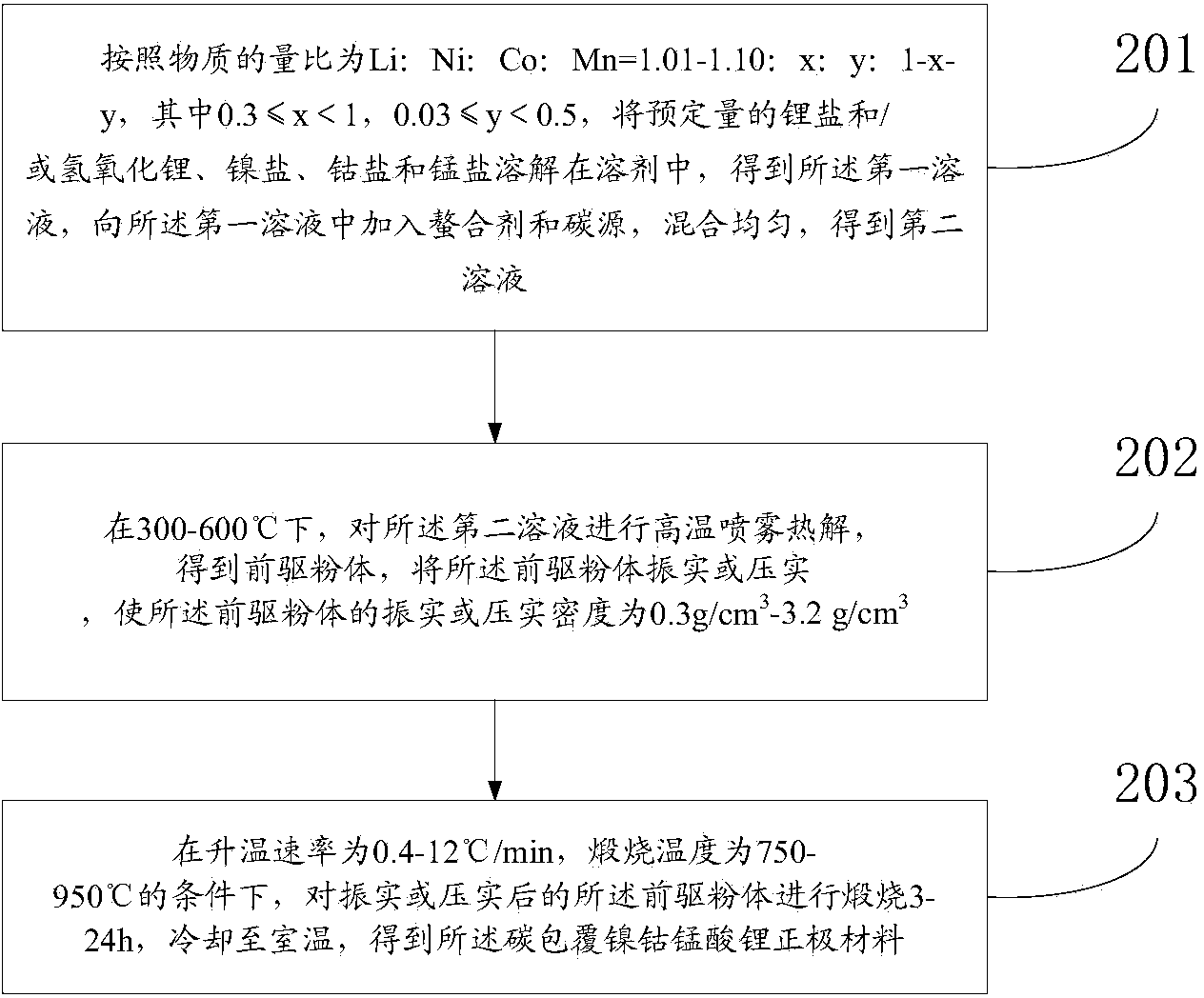

Carbon-coated nickel-cobalt lithium manganate positive electrode material and preparation method thereof

InactiveCN104051724AImprove conductivityImprove cycle stabilityCell electrodesSecondary cellsCarbon coatingNickel salt

The embodiment of the invention discloses a preparation method of a carbon-coated nickel-cobalt lithium manganate positive electrode material, and belongs to the technical field of preparation of a lithium battery positive electrode material. The preparation method comprises the following steps: adding a chelating agent and a carbon source into a solution containing lithium salt, nickel salt, cobalt salt and manganese salt, and performing high-temperature spray pyrolysis to obtain precursor powder; compacting the precursor powder by vibration or pressure, wherein the compaction density by the vibration or the pressure is 0.3-3.2g / cm<3> so that lithium ions, nickel ions, cobalt ions and manganese ions are uniformly dispersed in the powder and are contacted closely; and calcining the precursor powder, and cooling to obtain the carbon-coated nickel-cobalt lithium manganate positive electrode material with the good conductivity and the high cyclic stability. The carbon-coated nickel-cobalt lithium manganate positive electrode material comprises nickel-cobalt lithium manganate and carbon coating the surface of nickel-cobalt lithium manganate. The method disclosed by the embodiment of the invention is easy to operate and easy to control and facilitates the large-scale industrial production.

Owner:CHERY AUTOMOBILE CO LTD

Preparation method of doped zinc oxide nano powder

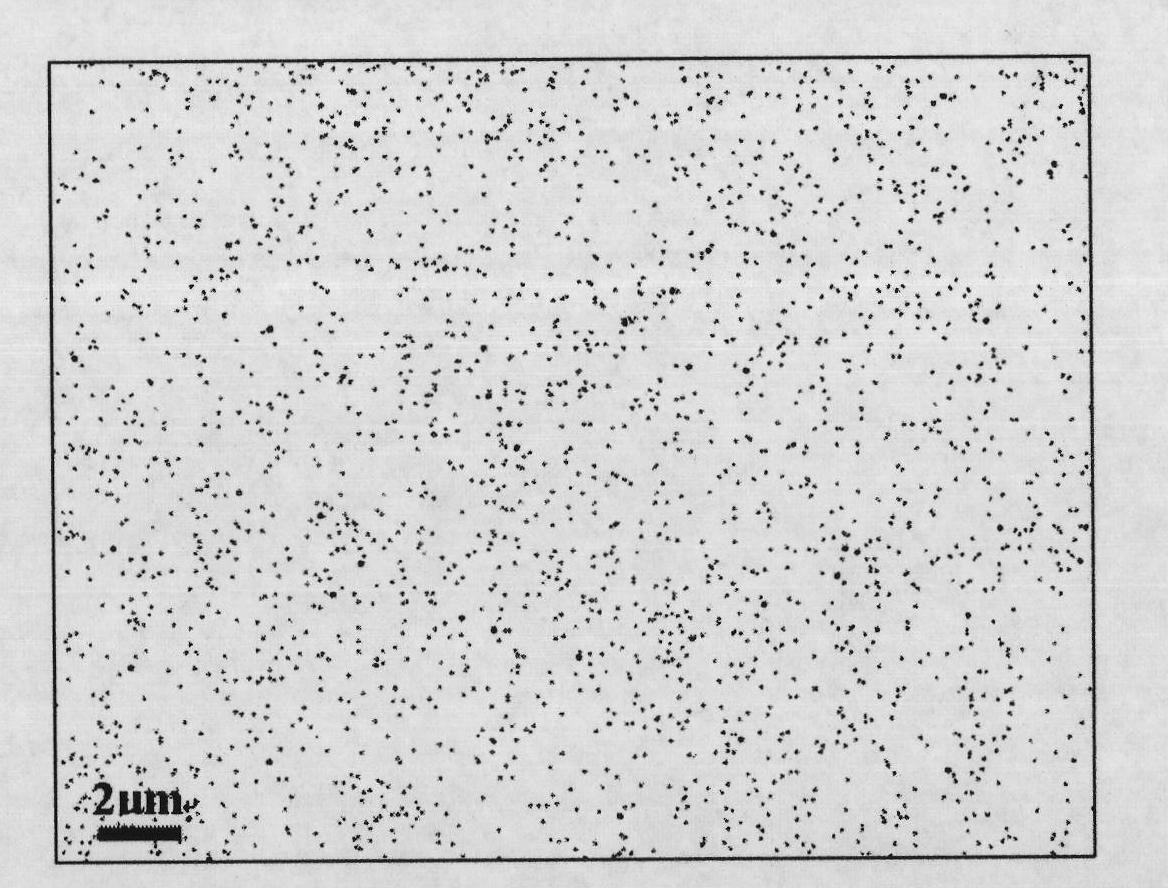

The invention discloses a preparation method of doped zinc oxide nano powder, which comprises the following steps that: doped metal salt and zinc salt are dissolved in water to form salt solution; under intense stirring, the salt solution is uniformly dripped into precipitant solution, the pH value of a mixed system is kept to be 5 to 10 and the temperature is kept to be 10 to 80DEG C during the dripping process to obtain a coprecipitation product; after the coprecipitation product is aged for 10 to 30h, precipitate is sequentially washed by deionzied water and absolute ethyl alcohol and is dried to obtain a white product; and the white product is calcined for 1 to 5h at 400 to 800DEG C to prepare the doped zinc oxide nano powder. The method has the advantages of low cost, simple used equipment and easy large-scale industrial production, and the prepared doped zinc oxide nano powder has the advantages of uniform distribution, high purity and no non-conductive second phase, and can be used for preparing high-quality zinc oxide-based sputtering targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

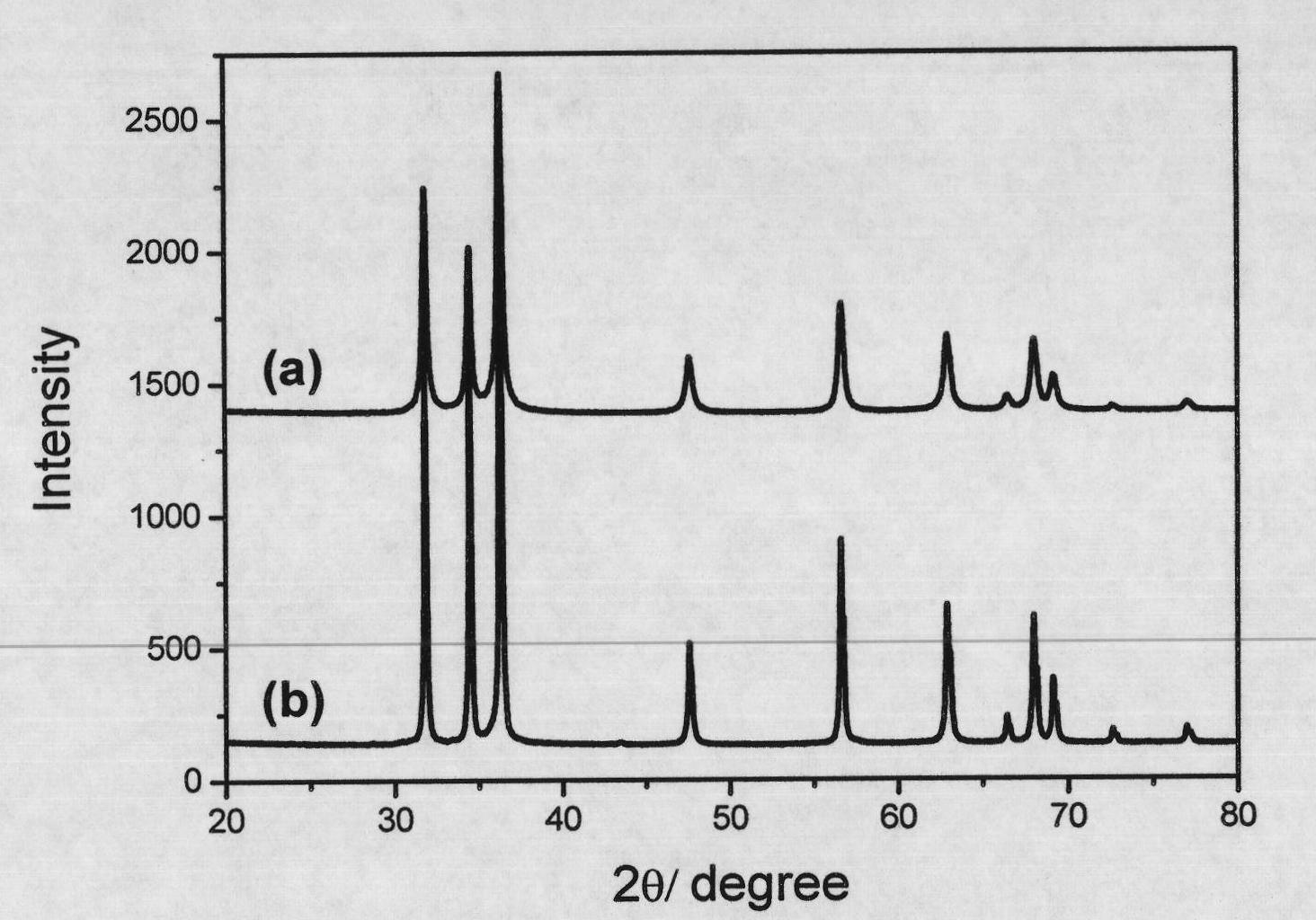

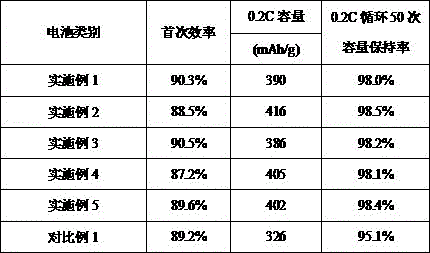

Recycling method for graphite anode material from waste lithium-ion battery

InactiveCN105552468AReduce recycling costsHigh recovery rateWaste accumulators reclaimingBattery recyclingOxalateElectricity

The invention discloses a recycling method for a graphite anode material from a waste lithium-ion battery, and belongs to the technical field of recovering of materials from the waste lithium-ion battery. According to the main points of the technical scheme, the method comprises the following steps: carrying out soaking pretreatment on the graphite material recovered from the waste lithium-ion battery; carrying out ball-mill mixing on pre-calcined and separated graphite powder and a ferrous oxalate or zinc oxalate or ferrous oxalate and zinc oxalate mixture evenly; and finally preparing the battery-grade graphite anode material through high-temperature treatment. The graphite anode material prepared by the method has excellent electrochemical activity and cyclic reversibility; the discharge capacity at 0.2C reaches over 400mAh / g; and the capacity retention rate after 50 cycles is greater than 98.0%. The recycling method can efficiently recover the graphite anode material from the waste lithium-ion battery, further improves the electrical property and achieves recycling of the graphite anode material.

Owner:河南环宇赛尔新能源科技有限公司

Method for manufacturing metal surface self-cleaning high-protection film

ActiveCN104213112AGuaranteed protective effectWith self-cleaning functionMetallic material coating processesComposite filmMolybdate

The invention provides a method for manufacturing a metal surface self-cleaning high-protection film. The method comprises two steps of molybdate solution soaking treatment and plant corrosion inhibitor-low-surface-energy material collaborative modification treatment. According to the molybdate solution soaking treatment step, a composite film which is of a specific micro / nano coarse structure, has the good protection effect and is composed of metallic oxides, molybdenum oxide and metal molybdate can be formed on a metal surface, and therefore according to the plant corrosion inhibitor-low-surface-energy material collaborative modification treatment step, efficient green plant corrosion inhibitors can be introduced into the film, and the protection effect can be obviously improved. Due to the hydrophobization effect of the low-surface-energy material on the film, the film has the self-cleaning function, the pollution can be avoided, the probability of direct contact of metal materials and corrosive media can be reduced, and the protection effect of the film can be further improved. The method has the advantages of being environmentally friendly, simple in process, convenient to operate, capable of being easily and industrially produced in a large-scale mode and the like.

Owner:重庆中昆新材料科技有限公司

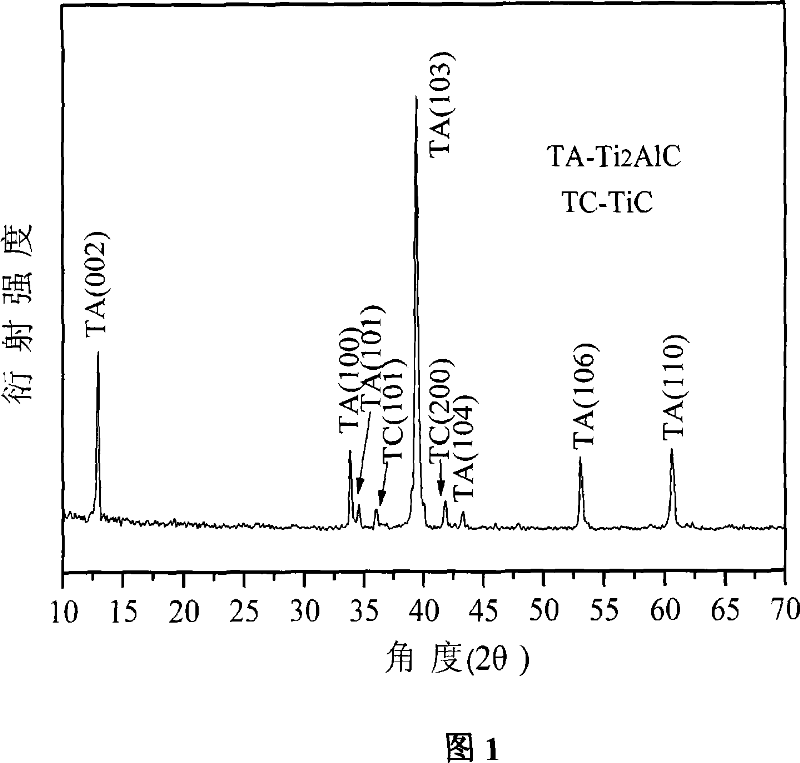

High-purity Ti2AlC powder material and preparing method thereof

The present invention discloses a high pure Ti2AlC powder material and a preparation method of the same. The powder material comprises Ti powder, TiC powder, Al powder and active carbon powder, wherein the mol ratio of which is n(Ti):n(TiC):n(Al):n(C)=(1.15~1.95):(0.5~0.95):1:(0.15~0.95). The preparation method comprises the steps of: feed weighing according to compounding ratio; mixing the raw material powder evenly; tabletting the mixed raw material and putting into the chamber of the microwave sintering device, and sintering in the presence of argon gas; obtaining the powder material after natural cooling. The powder material of the present invention has high purity and small crystal grain. The preparation process has simple raw material, adequately uses the characteristics of microwave sintering technology and the advantages of self-propagating reaction, and has a short synthesis time; besides the Ti2AlC powder material has a high purity, is adapted to industrial production. The application of the material is greatly improved.

Owner:WUHAN UNIV OF TECH

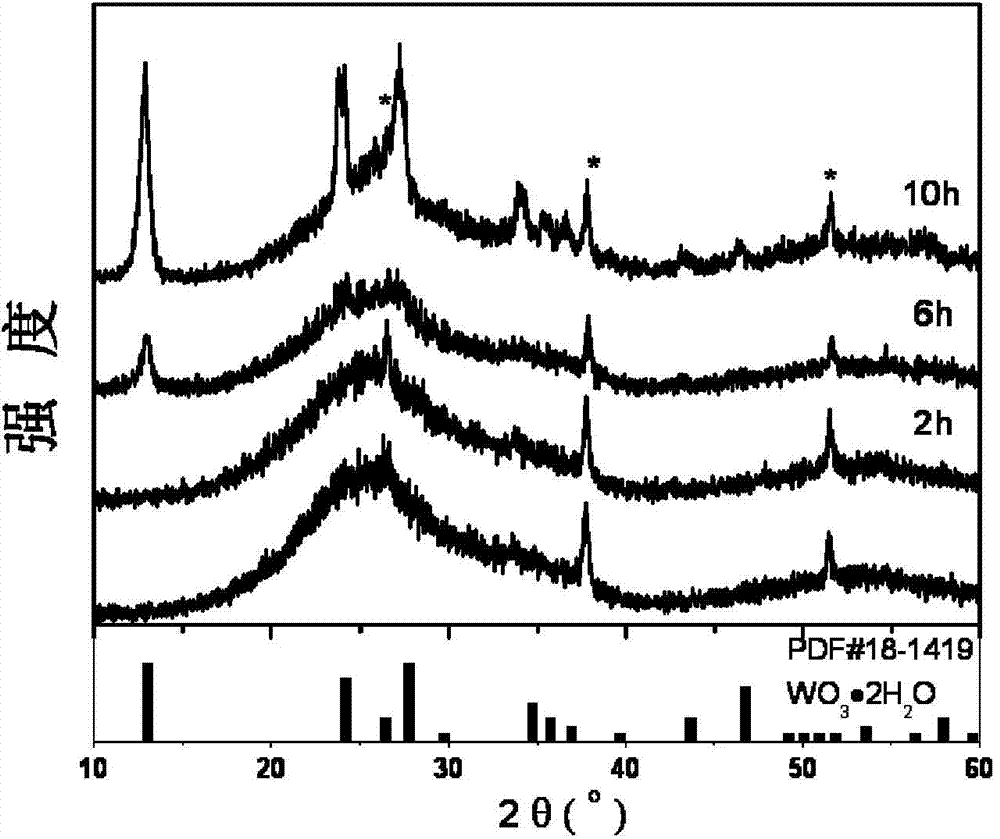

Sheet-like tungsten trioxide photoelectrode and preparation method thereof

InactiveCN104711528ASimple processGood uniformityVacuum evaporation coatingSputtering coatingAmorphous oxideStrong acids

The present invention relates to porous WO3 sheet-like array film preparation, which comprises: firstly utilizing a direct current reaction magnetron sputtering method, adopting Ar gas as sputtering gas, adopting O2 gas as reaction gas, and adopting double metal target co-sputtering to carry out sputtering so as to obtain an amorphous oxide film, wherein the one target is a tungsten target, and the other target is one selected from aluminum, copper and zinc; and immersing the prepared amorphous metal oxide film in a strong acid solution to selectively etch, obtaining a sheet-like porous structure on the substrate, and annealing at a temperature of 450-550 DEG C in air so as to form monoclinic crystal phase WO3, wherein the morphology is well preserved. According to the present invention, the porous tungsten oxide electrode obtained through the method has characteristics of specific surface increase, substantial light absorption property improving, and good adhesion between the material and the substrate; and the preparation method of the present invention has the following advantages that: the mass production can be achieved, the preparation process is simple, the saturated photocurrent of the prepared WO3 electrode is increased by 3 times compared with the saturated photocurrent of the unetched dense WO3 electrode, and the obtained sheet-like tungsten trioxide photoelectrode can further be used for dye-sensitized solar cells, electrochromic devices and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing nitrogen-doped porous carbon material used as sodium ion battery cathode

ActiveCN107331867AImprove cycle stabilityOvercome the disadvantage of low specific capacityCell electrodesSecondary cellsPorous carbonSynthesis methods

The invention provides a method for preparing a nitrogen-doped porous carbon material used as a sodium ion battery cathode, and belongs to a method for preparing nitrogen-doped porous carbon. The nitrogen-doped carbon material is controlled and synthesized by regulating and controlling each parameter in the reacting process by means of a simple and feasible high-temperature solid phase reaction method, and is applied to a sodium ion battery cathode material. The method comprises the following steps: dissolving a selected nitrogen source in a solvent to form a transparent solution A; adding a proper amount of carbon source into the solution A, and constantly adding into solvent to sufficiently disperse the nitrogen source under a stirring state; drying the materials in a lyophilizer for 2-12 hours; putting a proper amount of the materials into a crucible, heating to 300-1100 DEG C and insulating for 1-6 hours in a vacuum tube furnace under an argon atmosphere at a speed of 2-8 DEG C / minute; and separating and purifying the generated product to obtain a product. The preparation method has the advantages of low-price and easily available raw materials, simple synthesis method and high controllability of operation steps, and is easy for expanded production. The nitrogen-doped porous carbon material can be used as a sodium ion battery cathode material, and shows excellent electrochemical performance.

Owner:CHINA UNIV OF MINING & TECH

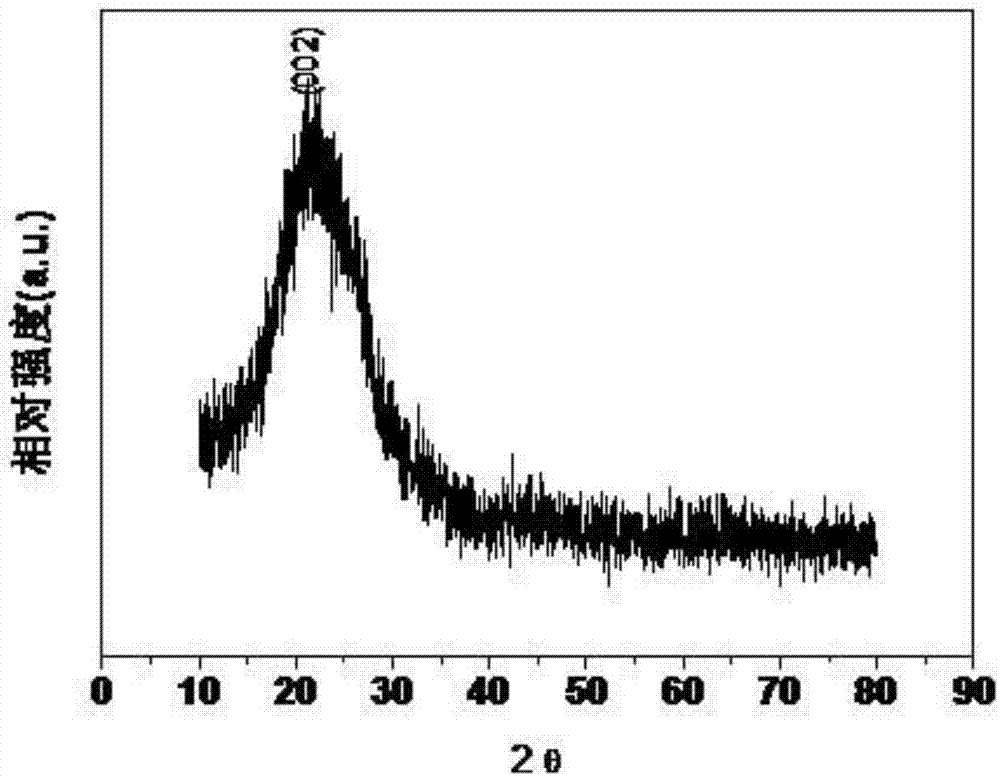

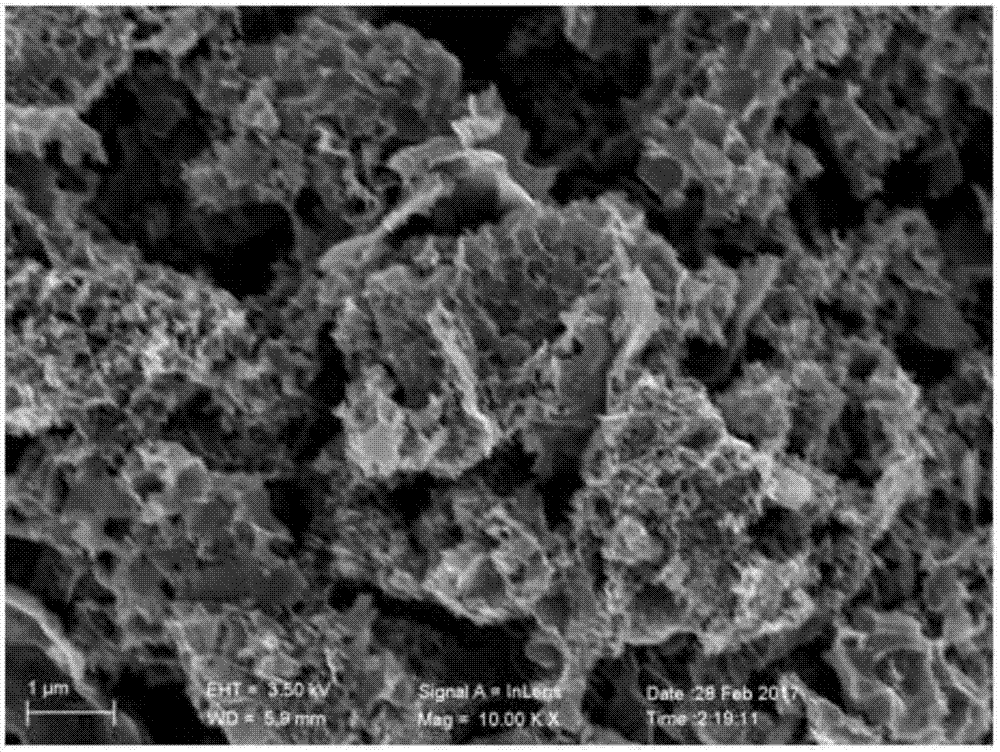

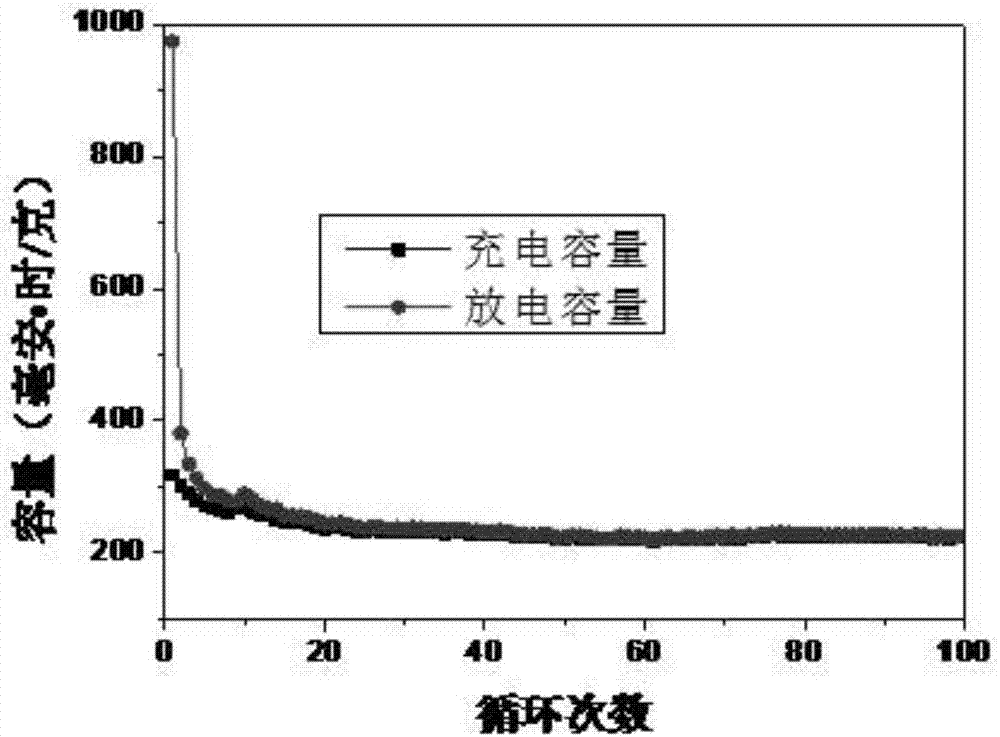

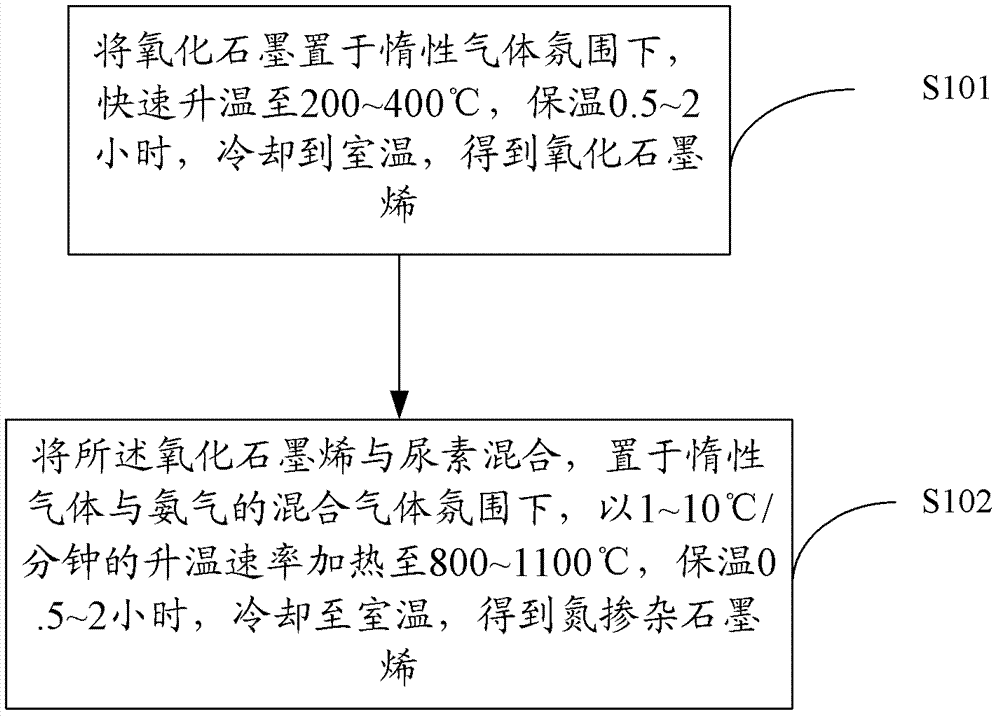

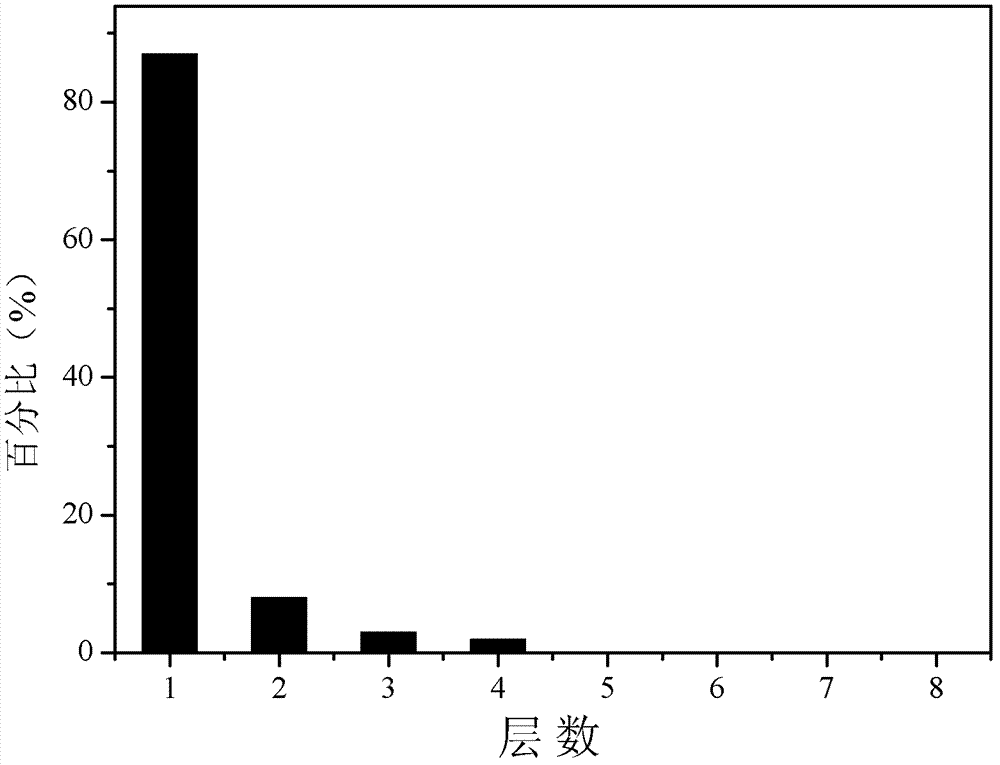

Preparation method of nitrogen-doped graphene

The invention provides a preparation method of nitrogen-doped graphene. The preparation method comprises the following steps of putting graphite oxide in the atmosphere of inert gas, heating the mixture to 200-400 DEG C quickly, preserving heat for 0.5-2 hours, and cooling the product to the room temperature, thus obtaining graphene oxide; and mixing the graphene oxide with urea, putting the mixture in the atmosphere of a mixture of inert gas and ammonia gas, heating the mixture to 800-1100 DEG C at a heating rate of 1-10 DEG C / min, preserving heat for 0.5-2 hours, and cooling the product to the room temperature, thus obtaining the nitrogen-doped graphene. In the preparation method, an oxidative thermal reduction method is utilized to prepare the single-layer nitrogen-doped graphene, so that the preparation is simple in equipment and process, convenient to operate, cheap in raw materials, low in cost and easy in achievement of large-scale industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of copper, cobalt and sulfur micropowder

InactiveCN105355919AGood effectLarge reversible charge and discharge capacityCell electrodesSecondary cellsOrganic sulfide compoundCobalt salt

Owner:SOUTHWEST UNIVERSITY

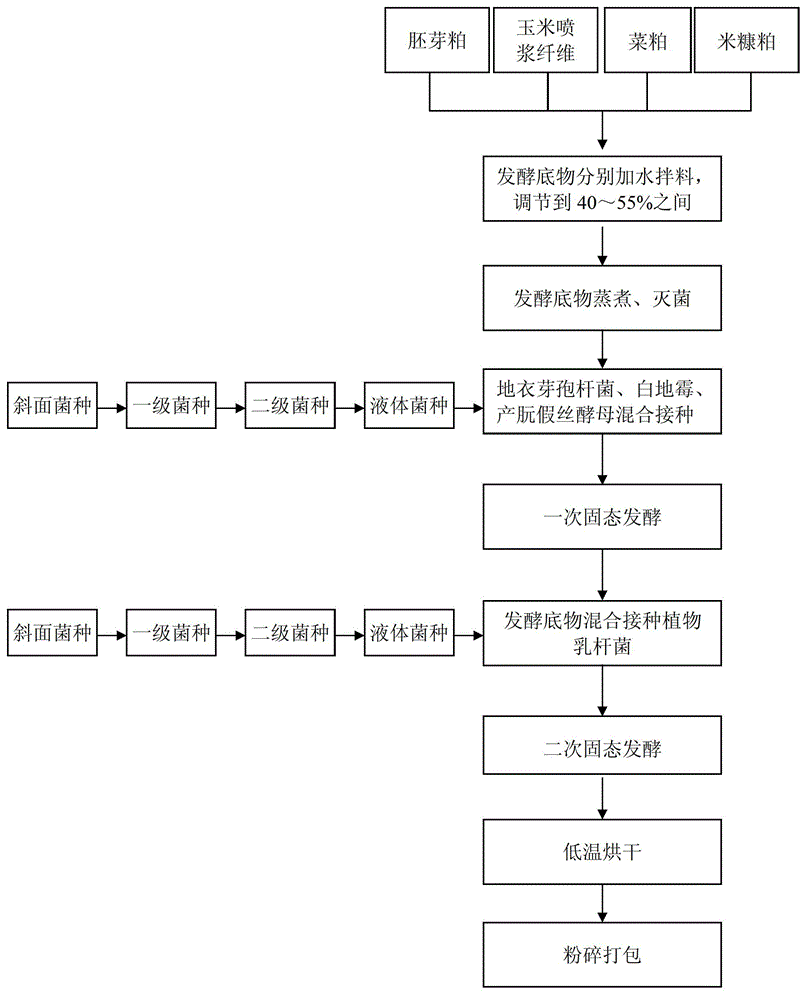

Method for producing microorganism feed additive by utilizing probiotics and mixed meal

ActiveCN102972635AHigh in nutrientsEfficient degradationAnimal feeding stuffBacillus licheniformisFiber

The invention discloses a method for producing a microorganism feed additive by utilizing probiotics and mixed meal. The method comprises the following steps: adding water into fermentation substrates respectively, stirring materials, and then cooking and sterilizing; adding a mixed bacterial liquid into the sterilized fermentation substrates and stirring uniformly after the temperature is lowered to 28-35 DEG C, and carrying out aerobic fermentation under constant temperature; introducing a lactic acid bacterium after the fermentation substrates are fermented and mixed, and then carrying out secondary fermentation; and drying materials after fermentation at a lower temperature, and crushing so as to obtain a microorganism feed additive finished product. The fermentation substrates comprise germ meal, corn spray slurry fibers, rapeseed meal and rice bran meal; the rice mixed bacterial liquid is obtained through mixing bacterial liquids of candida utilis, bacillus licheniformis and cryytococcus neoformans; and the lactic acid bacterium is lactobacillus plantarum, and the inoculum size is 5-10% of the weight of the fermentation substrates.

Owner:张有聪

Nickel-based positive electrode material, and preparation method thereof and battery

ActiveCN103094576AIncrease capacityImprove structural stabilityCell electrodesSecondary cellsMetallurgySlurry

The invention relates to a nickel-based positive electrode material, and a preparation method thereof and a battery. The composition of the nickel-based positive electrode material is LiaNibCocMndMeM'fO2-g / 2Fg (M is at least one selected from Ti, Zr, Al, Fe, Cr, Si, and Cu; M' is at least one selected from Mg, Ca, Sr, Ba, and W; a is no smaller than 0.95 and no greater than 1.2; b is no smaller than 0.2 and no greater than 0.9; c is no smaller than 0 and no greater than 0.4; d is no smaller than 0 and no greater than 0.4; e+f is greater than 0.05and no greater than 0.2; and g is greater than 0.02 and no greater than 0. 1). Anions and cations are used in co-doping. With a synergistic effect, nickel-based positive electrode material capacity, structural stability and circulation performance are greatly improved. The preparation method at least comprises the 4 steps that: (1) corresponding raw materials are weighed according to the molar ratio consistent with LiaNibCocMndMeM'fO2-g / 2Fg; (2) the raw materials are subjected to wet grinding; (3) slurry obtained by grinding is dried; and (4) the dried material is subjected to solid-phase synthesis under a temperature of 500-1100 DEG C. With the process, the raw materials can be more uniformly dispersed, and the obtained product has the advantages of high capacity and good circulation performance. The process is simple, and has the advantages of low cost and suitability for large-scale industrialized productions. With the process, problems such as complicated process and acid and alkali pollution of a wet chemical precursor preparation method are avoided. The invention also relates to a battery with the material as an active substance.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Method for preparing biomass carbon based on waste crop straw

InactiveCN101993701ASolve the problem of the large amount of land required for stackingReduce pollutionBiofuelsSpecial form destructive distillationBiomass carbonRoom temperature

The invention relates to a method for preparing biomass carbon based on waste crop straw. The method comprises the following steps of: (1) cutting the crop straw into straw particles, washing and drying; (2) loading the processed straw particles in a quartz tube of a carbonizing furnace and introducing an inert gas; (3) heating to 350 to 550 DE C from room temperature in an environment with inert gas flow rate of 100mL / min at the heating rate of 25 DEG C / min, maintaining for 1 to 3 minutes, stopping heating, and cooling to the room temperature to obtain solid; and (4) washing and drying the solid obtained in the step (3) to obtain the biomass carbon. The device of the invention is simple in operation, the raw material has low cost and is readily available, and the method is suitable for large-scale industrial production; and the biomass carbon prepared by the method has a high specific area, can be used as a soil modifying agent to improve the fertility of the soil and can also be used as a soil repairing agent to repair the polluted soil, and has good application prospect.

Owner:DONGHUA UNIV +1

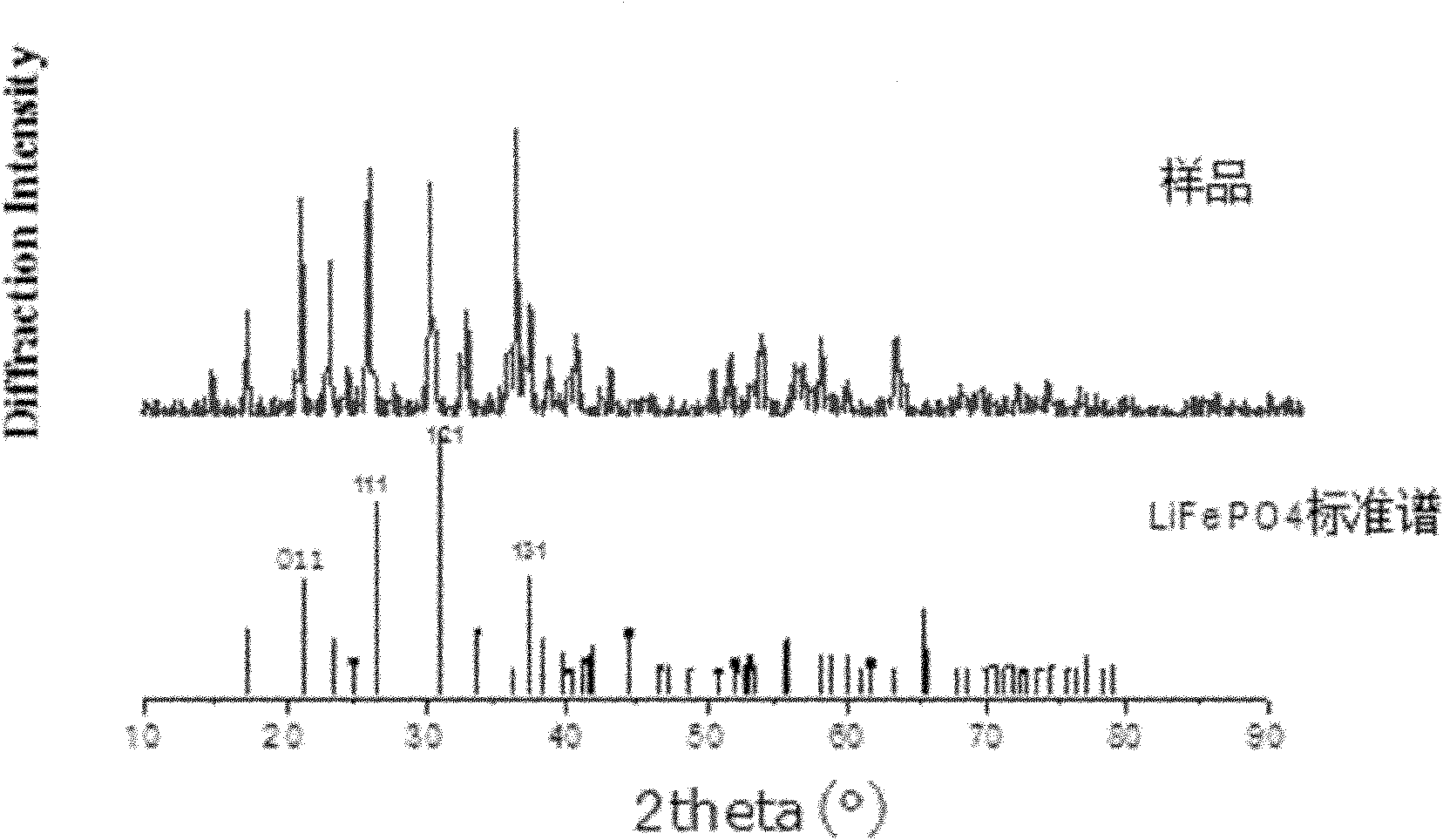

Hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate

InactiveCN102074687AShort tripIncrease the speed of diffusionCell electrodesReaction temperatureMolecular level

The invention discloses a hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate, which belongs to the field of lithium-ion battery anode materials and comprises the following steps of: sequentially adding a phosphorus-source solution, an iron-source solution, a carbon source, a lithium-source solution and a boiling-point elevator into a reaction device in sequence, mixing, then heating to the temperature of 60-180 DEG C for reaction under inert gas, cooling after the reaction, filtering precipitates to obtain a nano-scale lithium iron phosphate precursor, and then sintering the nano-scale lithium iron phosphate precursor at the temperature of 400-600 DEG C under the protection of the mixed gas of the inert gas and hydrogen gas. The combination of lithium, iron, phosphorus and the like on a molecular level is realized by the method, and the grains of a product are quite fine and are uniformly distributed; because the boiling-point elevator is adopted, the reaction temperature and pressure of the reaction kettle are decreased; and the hydrothermal synthesis method has the advantages of simple preparation process, short flow, easiness in operational control, low reaction temperature, short time, low energy consumption and easiness in realizing large-scale industrialized production.

Owner:JIANGSU DELI CHEM

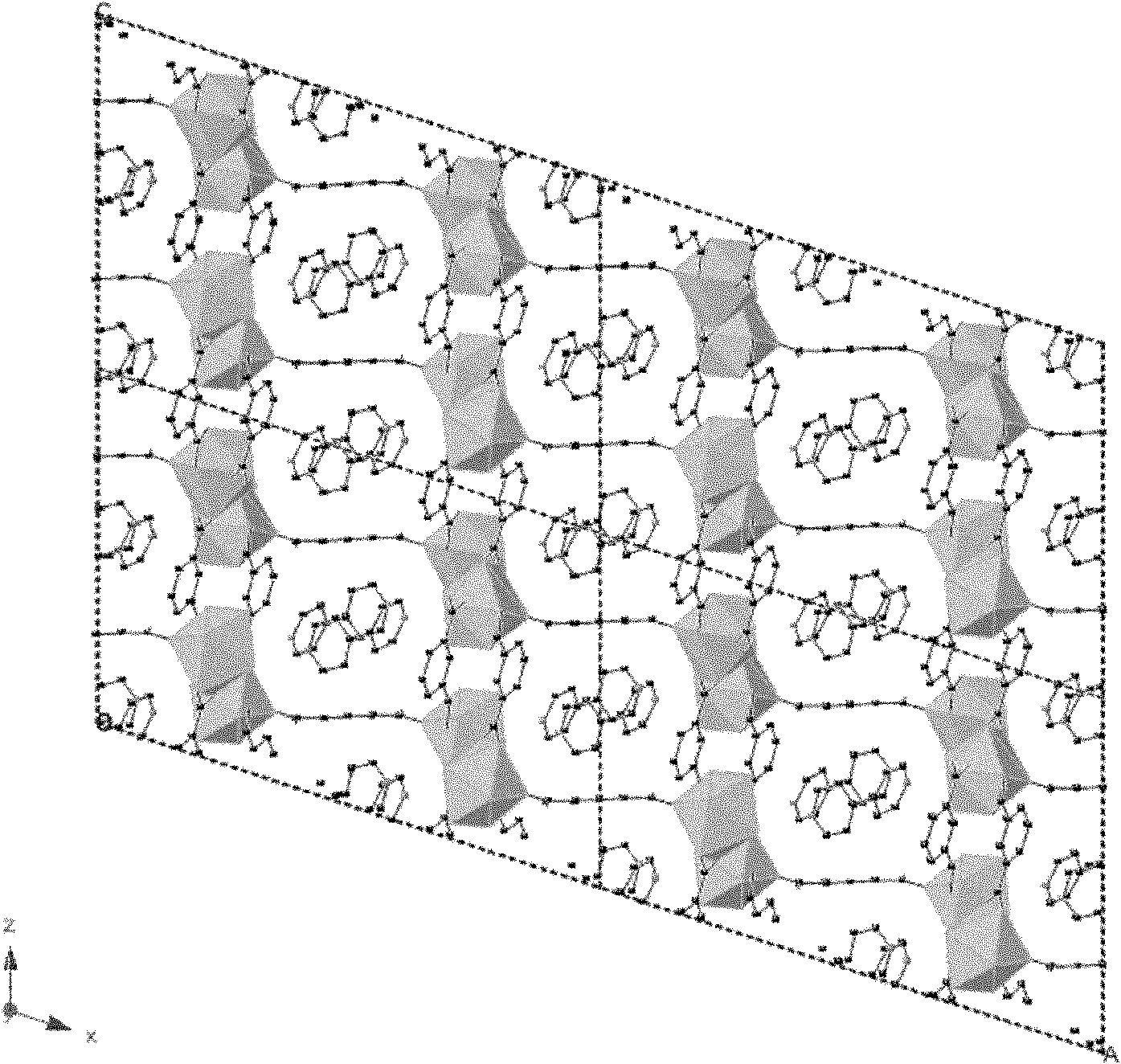

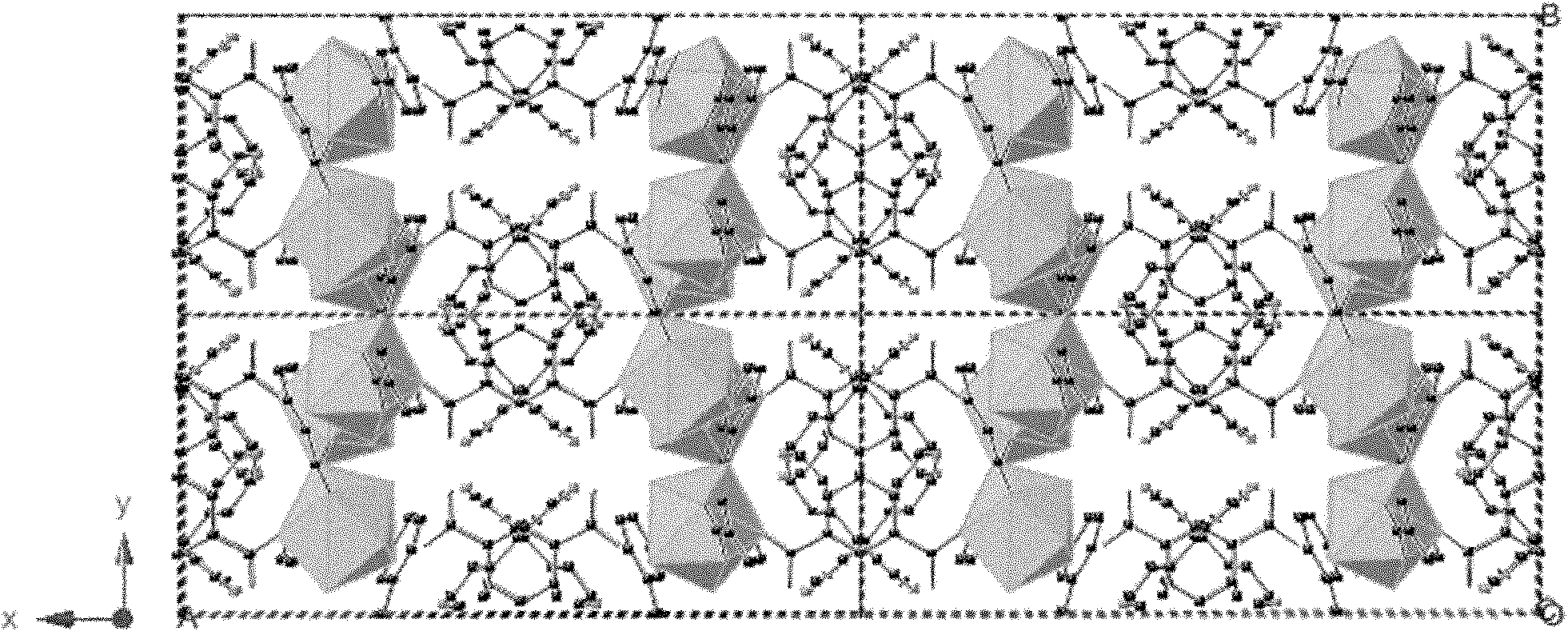

Rare-earth organic coordination polymer taking 4,4'-bipyridyl as template, and preparation method and application thereof

InactiveCN102153578AImprove the coordination effectNovel structureOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsIon exchange

The invention relates to a rare-earth organic coordination polymer, and a preparation method and application thereof. The rare-earth organic coordination polymer has the following chemical formula: {(bpy)[Re(ip)1.5(H2O)4]}n, wherein bpy is 4,4'-bipyridyl, ip is isophthalic acid divalent negative ions, Re is one or more of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc, Y and the like,and n is degree of polymerization. A hydro (solvent)-thermal synthesis method is used for preparing the rare-earth organic coordination polymer, is environment-friendly and easy to operate, low in cost and high in yield, and is suitable for large-scale industrial production. The prepared rare-earth organic coordination polymer has the good application prospects in fields of luminescence, catalysis, adsorption, magnetism, ion exchange, high polymer material aids and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

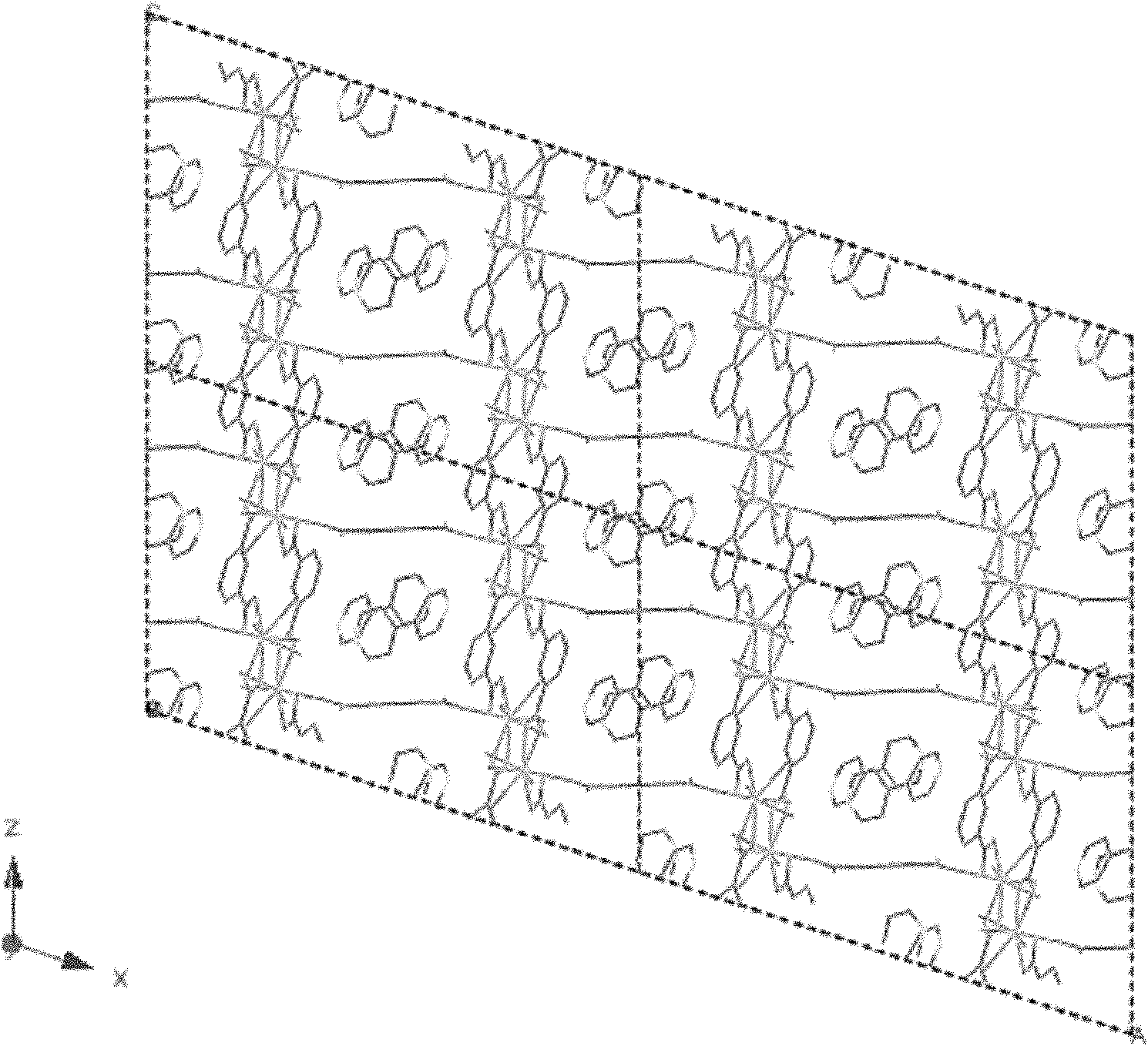

Method for preparing layered lithium, nickel, cobalt and manganese oxide anode material for lithium ion battery

The present invention relates to a method to prepare cathode material of layered lithium-nickel-cobalt-manganese oxide applied to lithium ion battery. The corresponding materials of metal manganese powers, compounds of lithium, metal cobalt or compounds of cobalt and compounds of nickel are weighted according to the molar ratio expressed and required in the chemical formula LiyNixCo1-2xMnxO2. In the formula, x is more than zero but less than 0.5 and y is more than or equal to 0.9 but less than 1.1; a solvent is added in the materials for wetmilling; and to be dried after wetmilling; then the materials is sintered under high temperature and then to be grinded to acquire the cathode material of layered lithium-nickel-cobalt-manganese oxide. The present invention has the advantages that a wetmilling mixing method is adopted which improves the mixing effect of the materials; a solid phase method is adopted to compound which has the advantages of simple technics process and low cost and is suitable for Industrialized mass production and avoids the complex flows of the body of a wet method before preparation; the metal manganese powers are adopted to replace the traditional manganese compound as materials which greatly improves the tap density of products and can realize higher volume capacity.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Graphene/carbon black composite material, preparation method and application thereof

InactiveCN103832997AImprove energy storage capacityReduce reunionElectrolytic capacitorsGrapheneHigh energyCvd graphene

The invention belongs to the field of electrochemical materials, and discloses a graphene / carbon black composite material, a preparation method and an application thereof. The electrode material comprises, by mass, 50-90% of graphene and 10-50% of carbon black. According to the graphene / carbon black composite material, agglomeration of the graphene lamellas is low, such that the high energy storage capacity is provided when the composite material is adopted as the electrochemical capacitor electrode material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Prepn process of dispersed polymer liquid crystal material

InactiveCN1421506ARaise the phase transition temperatureImprove stabilityLiquid crystal compositionsPolymer scienceIndium tin oxide

The preparation process of dispersed polymer liquid-crystal material includes the main steps of: mixing the substrate material and liquid crystal material in the weight ratio of 0.25-1 in a containerthrough stirring, painting the mixture between two conductive glass plates with coated indium tin oxide film, applying DC voltage of 45-65 V across the glass plates to cure the mixture as dispersed polymer liquid crystal material. The dispersed polymer liquid crystal material thus prepared has high phase transferring temperature and high stability. The preparation process is simple, environment friendly, short in preparation period and suitable for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for one-step synthesis of alkyl cyclohexanone from alkylphenol and preparation method thereof

InactiveCN101502800AHigh activityGood dispersionOrganic compound preparationCarbonyl compound preparationCyclohexanoneAlkaline earth metal

The invention relates to a catalyst for synthesizing alkyl cyclohexanone by alkyl phenol in one step and a preparation method thereof. The catalyst comprises an active carbon carrier, and nano active component palladium metal and auxiliary catalytic component alkaline metal or alkaline-earth metal loaded on the active carbon carrier. The preparation method for the catalyst comprises the following steps: after the active carbon is subjected to ultrasonic treatment by nitric acid solution, using deionized water to wash the active carbon to be neutral, adding the active carbon into palladium salt aqueous solution to be ultrasonically soaked, filtering the solution, pulping a filter cake and then reducing the filter cake, evenly distributing nano-scale granules as the active component on the surface of the active carbon carrier, filtering and washing the reactants until no chloride ions exist, then adding the filter cake into alkaline metal or alkaline-earth metal salt solution, pulping, soaking and filtering the filter cake, and drying the filter cake to form a Pd / active carbon catalyst. The preparation method is simple to operate, the palladium / carbon catalyst particles are evenly distributed and are less than 50 nanometers, the catalyst enjoys adjustability, and the catalyst is particularly suitable for the reaction of synthesizing the alkyl cyclohexanone by the alkyl phenol in one step and has high catalytic activity and ketone selectivity.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Graphene/carbon nano-tube composite material, preparation method and application thereof

InactiveCN103832996AConductive mesh is goodImprove energy storage capacityElectrolytic capacitorsCarbon nanotubesHigh energyCarbon nanotube

The invention belongs to the field of electrochemical materials, and discloses a graphene / carbon nano-tube composite material, a preparation method and an application thereof. The electrode material comprises, by mass, 50-90% of graphene and 10-50% of carbon nano-tubes. According to the graphene / carbon nano-tube composite material, agglomeration of the graphene lamellas is low, such that the high energy storage capacity is provided when the composite material is adopted as the electrochemical capacitor electrode material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Catalyst for synthesizing cyclohexene by hydrogenation of benzene ring and preparing method thereof

InactiveCN101549292AEasy to operateShort production cycleHydrocarbon by hydrogenationCatalyst activation/preparationActivated carbonWater soluble

The invention relates to a catalyst for synthesizing cyclohexene by hydrogenation of benzene ring and a preparing method thereof. The catalyst consists of activated carbon carrier, metal ruthenium and promoter; the promoter is one or the mixture of more than two from platinum, palladium, rhodium, cobalt and nickel. The method comprises the following steps: pretreated activated carbon is added into water-soluble compound solution of metal ruthenium or mixed water-soluble precursor solution of the metal ruthenium and the promoter so as to be stirred and soaked, thus obtaining mixed slurry; the PH value of the mixed slurry is regulated by alkali compound aqueous solution, after stirring and filtering, the filter cake is washed to neutrality by water, and then after the filter cake is beaten by water, the PH value of the mixed slurry is regulated by the alkali compound aqueous solution, then a chemical reducer is added to reduce ruthenium carbon catalyst in liquid phase, and after washing, the filter cake is transferred into an oven so as to be dried, thus obtaining the product of the ruthenium carbon catalyst. The catalyst has good catalytic activity and high selectivity and is especially suitable for catalytic hydrogenation for synthesizing cyclohexene by the hydrogenation of benzene ring, and the preparing method has simple operation and short production period.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

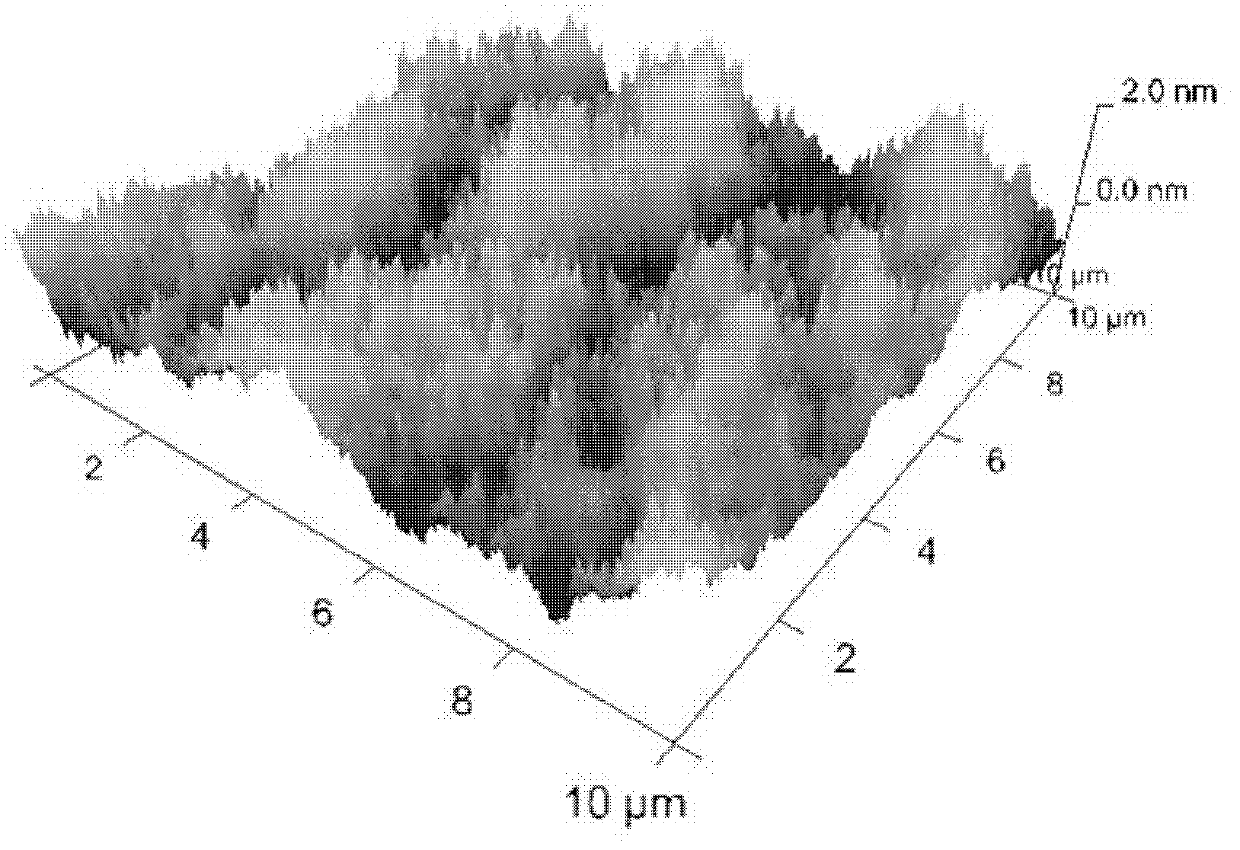

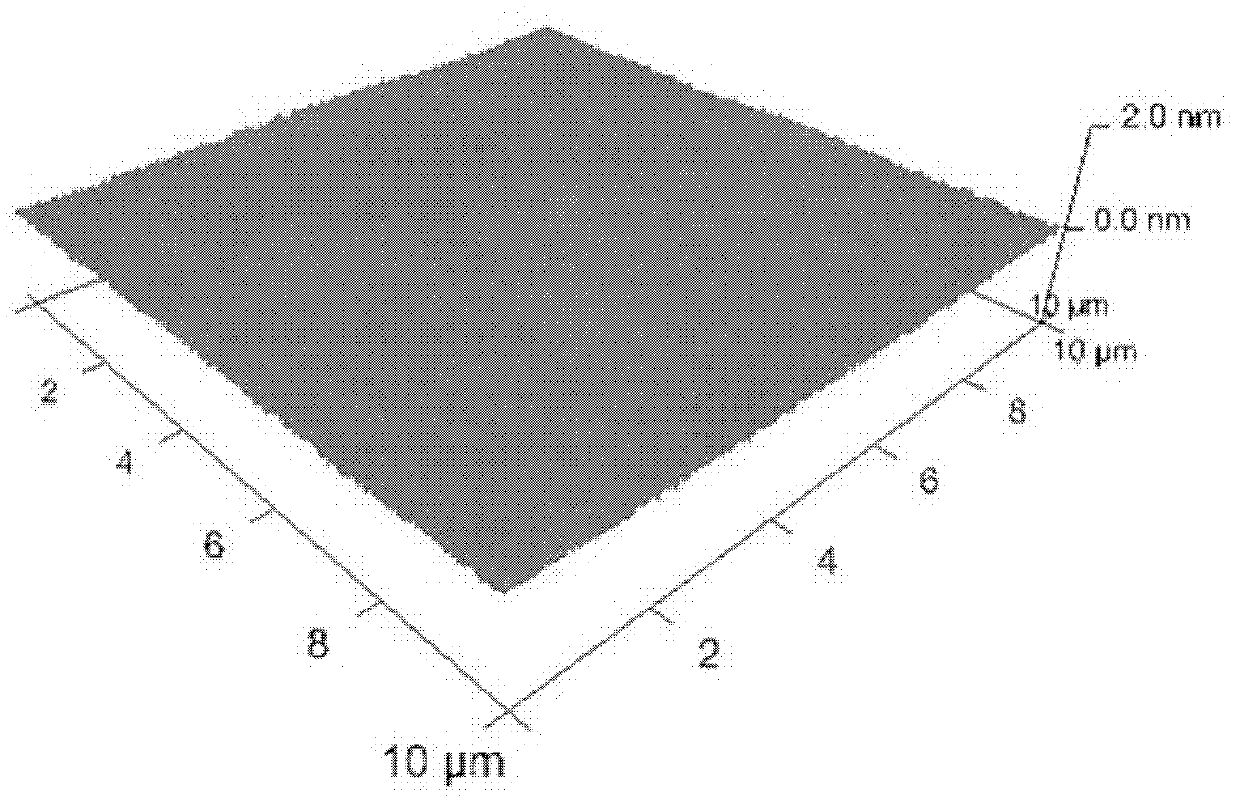

Silicon wafer polishing composition and preparation method thereof

InactiveCN102516873AImprove stabilityFunction increasePolishing compositions with abrasivesSlurryWater soluble

The invention discloses a silicon wafer polishing composition and a preparation method thereof, and belongs to the field of chemically mechanical polishing (CMP). The silicon wafer polishing composition contains a grinding material, one or more alkaline compounds, 0.001 to 5 wt% of one or more water-soluble polymers, deionized water, 0.001 to 1 wt% of one or more polymer bridging agents and 0.001 to 0.5 wt% of one or more frictional factor conditioning agents, wherein the pH value of the silicon wafer polishing composition is in a range of 8 to 12. The silicon wafer polishing composition is especially suitable for silicon wafer polishing, can improve the stability of a polymer in slurry, can adjust a frictional factor between a silicon wafer surface and a polishing pad, can effectively inhibit the deposition of particles and a polymer, can reduce the scratches on the surface of a silicon wafer, can improve the uniformity of the quality of a polished silicon wafer surface, and can be washed away easily.

Owner:TSINGHUA UNIV +2

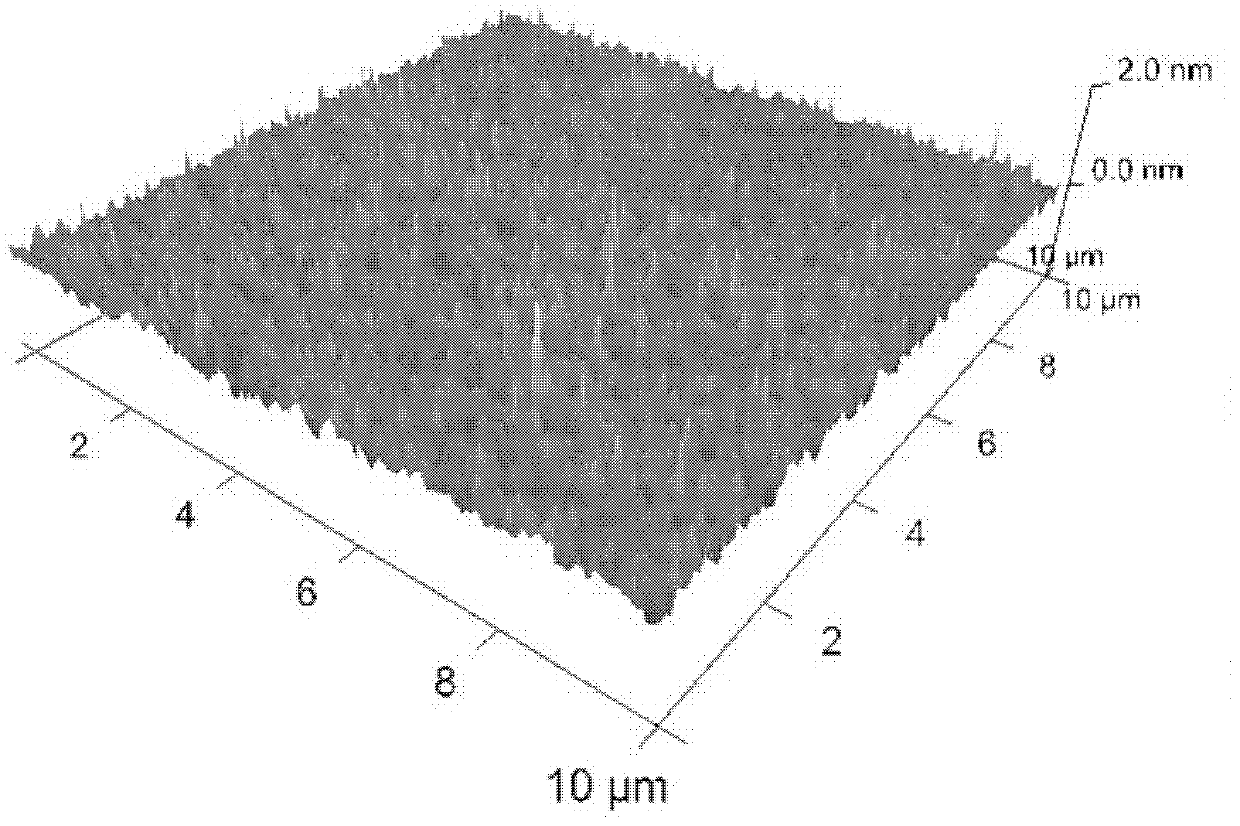

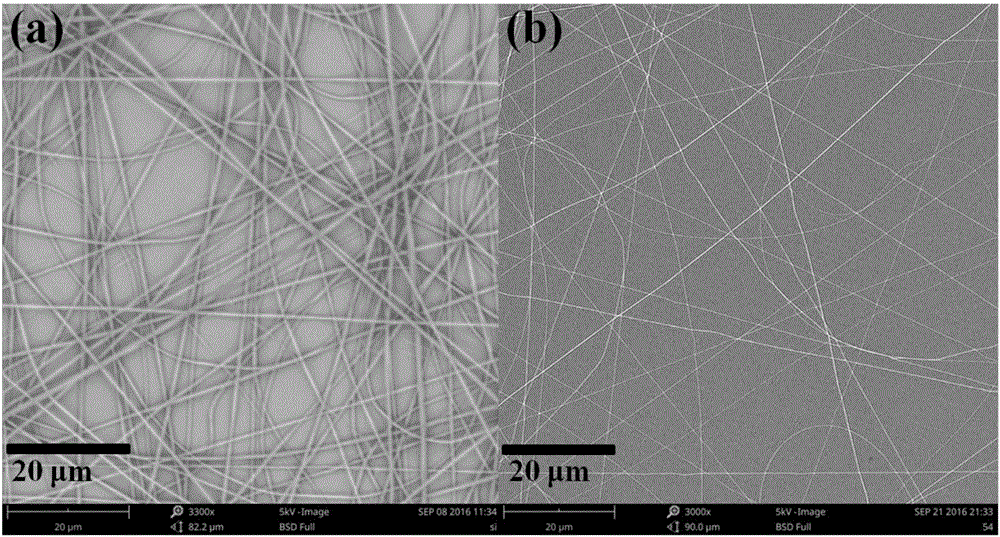

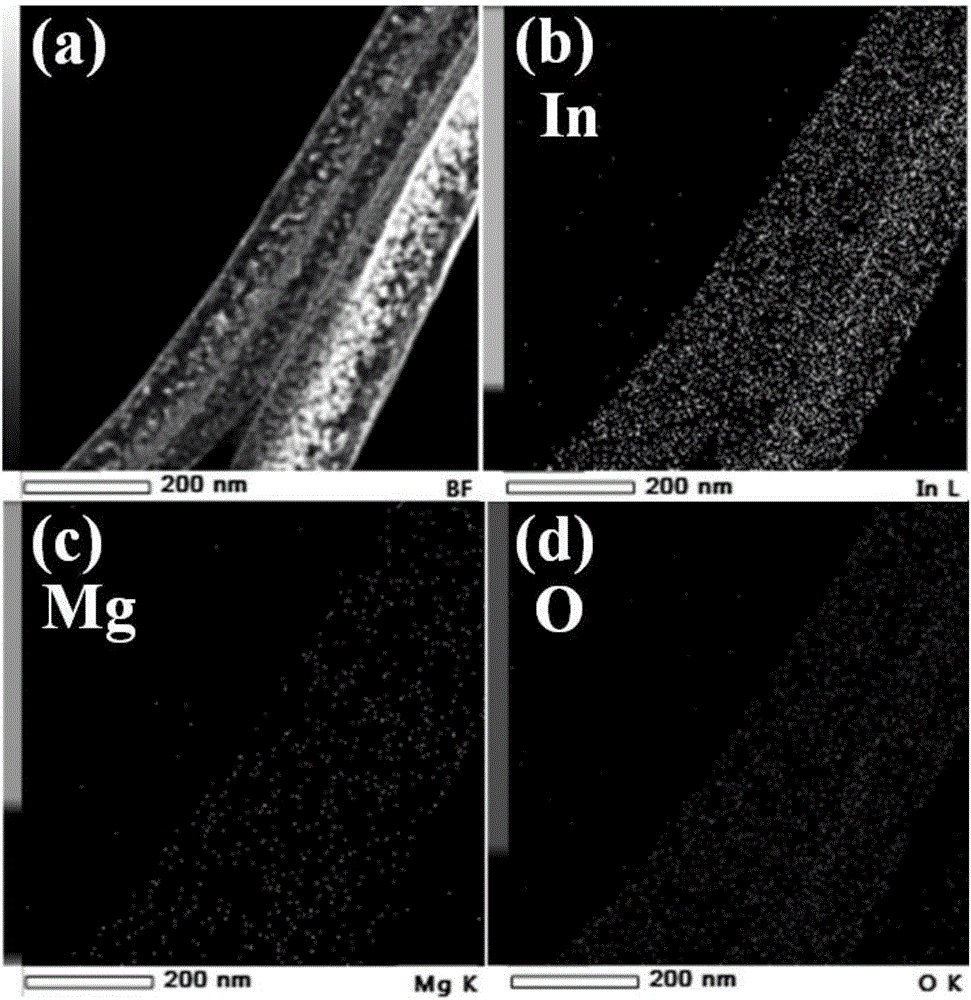

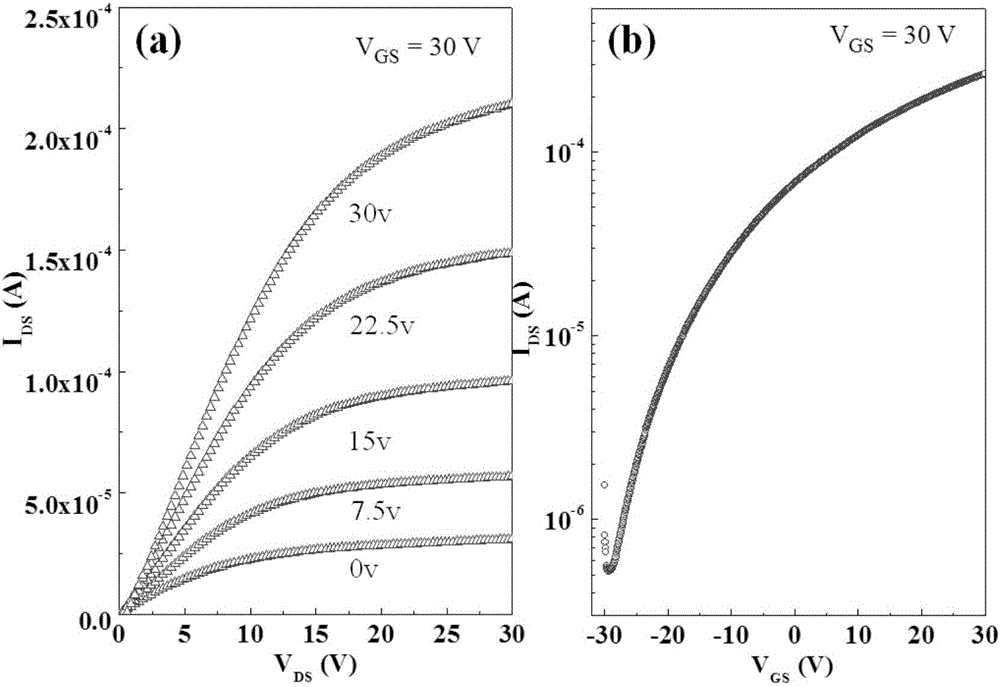

Regulation and control method for electrical property of indium oxide nanofiber field effect transistor

InactiveCN106486541ARegulation transmissionReduce concentrationInorganic material artificial filamentsNanoinformaticsIndiumElectrospinning

The invention belongs to the regulation and control technical field of electrical property of a transistor, and relates to a regulation and control method for electrical property of an indium oxide nanofiber field effect transistor. In<2>O<3> nanofibers are prepared through a simple, convenient and low-cost electrospinning technology; the electrical property of the In<2>O<3> nanofiber field effect transistor is regulated and controlled through simple and feasible metal doping so as to regulate and control the electrical property, such as a threshold voltage, an off-state current, a switching ratio and the like, of the In<2>O<3> nanofiber field effect transistor in a simple and convenient, efficient and low-cost manner, in order to obtain the excellent-performance and metal-doped In<2>O<3> nanofiber field effect transistor; the preparation process is simple, convenient, and safe, and the principle is reliable, and the production cost is low; and the prepared In<2>O<3> nanofibers and the metal-doped In<2>O<3> nanofibers have wide application prospect in the fields of an electronic switching device, a display, biological and chemical sensors and the like, and large-scale industrial production can be performed easily.

Owner:QINGDAO UNIV

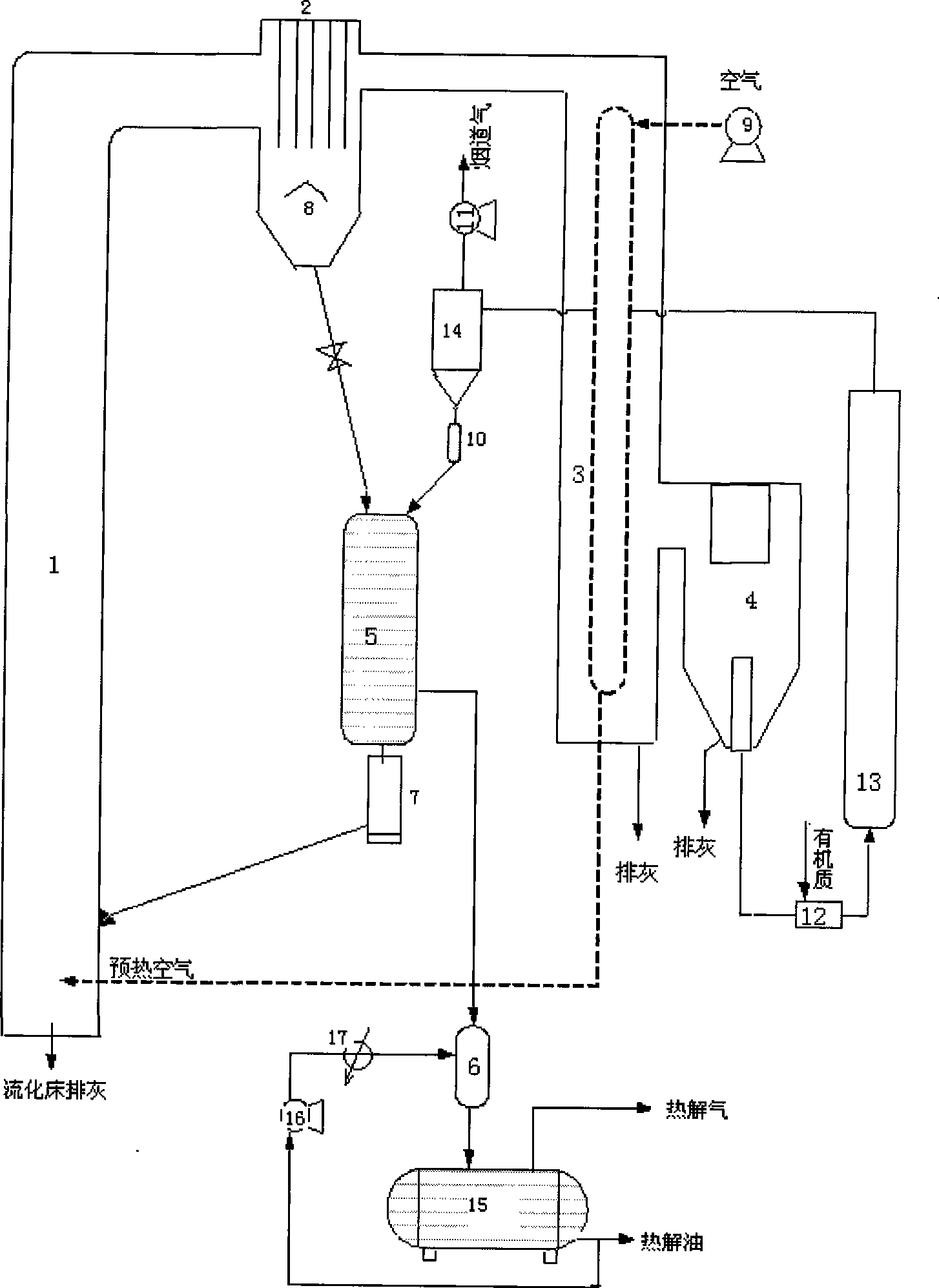

Self-mixing downflow fluidized bed rapid pyrolysis process for solid organics

ActiveCN101481619AHigh recovery rateReduce the temperatureEnergy inputLiquid hydrocarbon mixture productionHeat carrierResource utilization

The invention provides a solid organic matter self-mixing descending fluidized bed fast thermolysis technique. A reaction regeneration cycle system is formed by leading fast thermolysis and scorch to be carried out in different systems and circularly coupling solid heat carriers, thus ensuring pyrolytic reaction to be carried out continuously and the regenerated heat to be reasonably utilized; furthermore, pyrolytic gas and oil with high quality can be produced, so that the resource utilization rate is improved. The invention mainly comprises a self-mixing descending reactor, a fluidized bed reactivator, etc.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com