Preparation method of copper, cobalt and sulfur micropowder

A copper-cobalt-sulfur ultra-fine powder technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of no copper-cobalt-sulfur ultra-fine powder reports, limited copper-cobalt-sulfur research reports, cumbersome experimental procedures, etc. , to achieve the effects of easy large-scale industrial production, large reversible charge and discharge capacity, and simple product separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of copper cobalt sulfur superfine powder, it comprises the following steps:

[0038] (1) Weigh 0.1997g copper acetate hydrate (Cu(CH 3 COO) 2 ·H 2 O, purity ≥99.0%), 0.4982g of cobalt acetate hydrate (Co(CH 3 COO) 2 4H 2 O, purity ≥99.5%) and 0.3045g of thiourea (CH 4 N 2 S, purity ≥ 99.0%), dissolved in 60ml of ethylene glycol, stirred to form a solution;

[0039] (2) Transfer the solution obtained in step (1) to a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, and react for 12 hours at 200°C to obtain a black product after the reaction;

[0040] (3) Wash the obtained black product with absolute ethanol, centrifuge and wash it three times, and then dry it under vacuum at 80°C for 12 hours, so as to obtain black copper-cobalt-sulfur ultrafine powder.

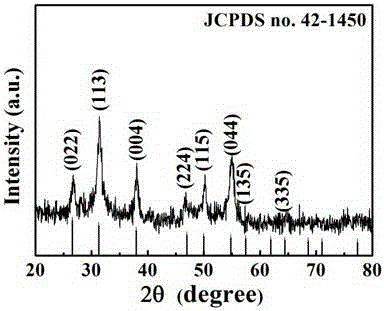

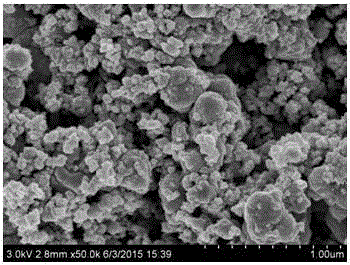

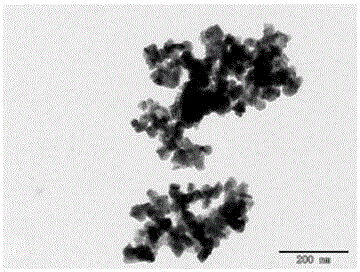

[0041] As attached to the manual Figure 1-7 As shown, the obtained copper-cobalt-sulfur ultrafine powder is tested and it can be seen that: the copper-cobalt-sulfu...

Embodiment 2

[0043] A preparation method of copper cobalt sulfur superfine powder, it comprises the following steps:

[0044] (1) Weigh 0.2491g copper nitrate hydrate (Cu(NO 3 ) 2 ·3H 2 O, purity ≥99.5%), 0.5821g of cobalt nitrate hydrate (Co(NO 3 ) 2 ·6H 2 O, purity ≥99.0%) and 0.3045g of thiourea (CH 4 N 2 S, purity ≥ 99.0%), dissolved in 60ml of ethanol, stirred to form a solution;

[0045] (2) Transfer the solution obtained in step (1) to a 100ml stainless steel reactor lined with polytetrafluoroethylene, and react at 220°C for 6 hours;

[0046] (3) The product obtained in step (2) was washed with absolute ethanol and centrifuged for three times, and then dried under vacuum at 80°C for 12 hours to obtain black copper-cobalt-sulfur ultrafine powder.

[0047] As attached to the manual Figure 8 As shown, the copper-cobalt-sulfur ultrafine powder prepared in this example is a nano-flower morphology composed of nano-sheets.

Embodiment 3

[0049] A preparation method of copper cobalt sulfur superfine powder, it comprises the following steps:

[0050] (1) Weigh 0.1997g copper acetate hydrate (Cu(CH 3 COO) 2 ·H 2 O, purity ≥99.0%), 0.4982g of copper acetate hydrate (Co(CH 3 COO) 2 4H 2 O, purity ≥99.5%) and 0.4846g of L-cysteine (C 3 h 7 NO 2 S, purity ≥ 98.5%), dissolved in 60ml of ethylene glycol, stirred to form a solution;

[0051] (2) Transfer the solution obtained in step (1) to a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, and react at 180°C for 20 hours;

[0052] (3) The product obtained in step (2) was washed with absolute ethanol and centrifuged for three times, and then dried under vacuum at 80°C for 12 hours to obtain black copper-cobalt-sulfur ultrafine powder.

[0053] As attached to the manual Figure 9 As shown, the copper-cobalt-sulfur ultrafine powder prepared in this example has the morphology of nanoparticle stacking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com