Silicon wafer polishing composition and preparation method thereof

A polishing composition, silicon wafer refining technology, applied in the direction of polishing composition containing abrasives, etc., can solve problems such as residue and reduce friction coefficient, and achieve the effects of improving stability, reducing residue, and inhibiting deposition

Inactive Publication Date: 2012-06-27

TSINGHUA UNIV +2

View PDF5 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The above methods have achieved certain effects in controlling the surface defects of silicon wafers, but for the higher requirements of single crystal silicon polishing, the above methods still have problems in further controlling surface defects, residues, improving wafer surface uniformity and reducing friction coefficient. Certain limitations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0033] The present invention will be further described below by way of examples, which certainly should not be construed as limiting the scope of the present invention in any case.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

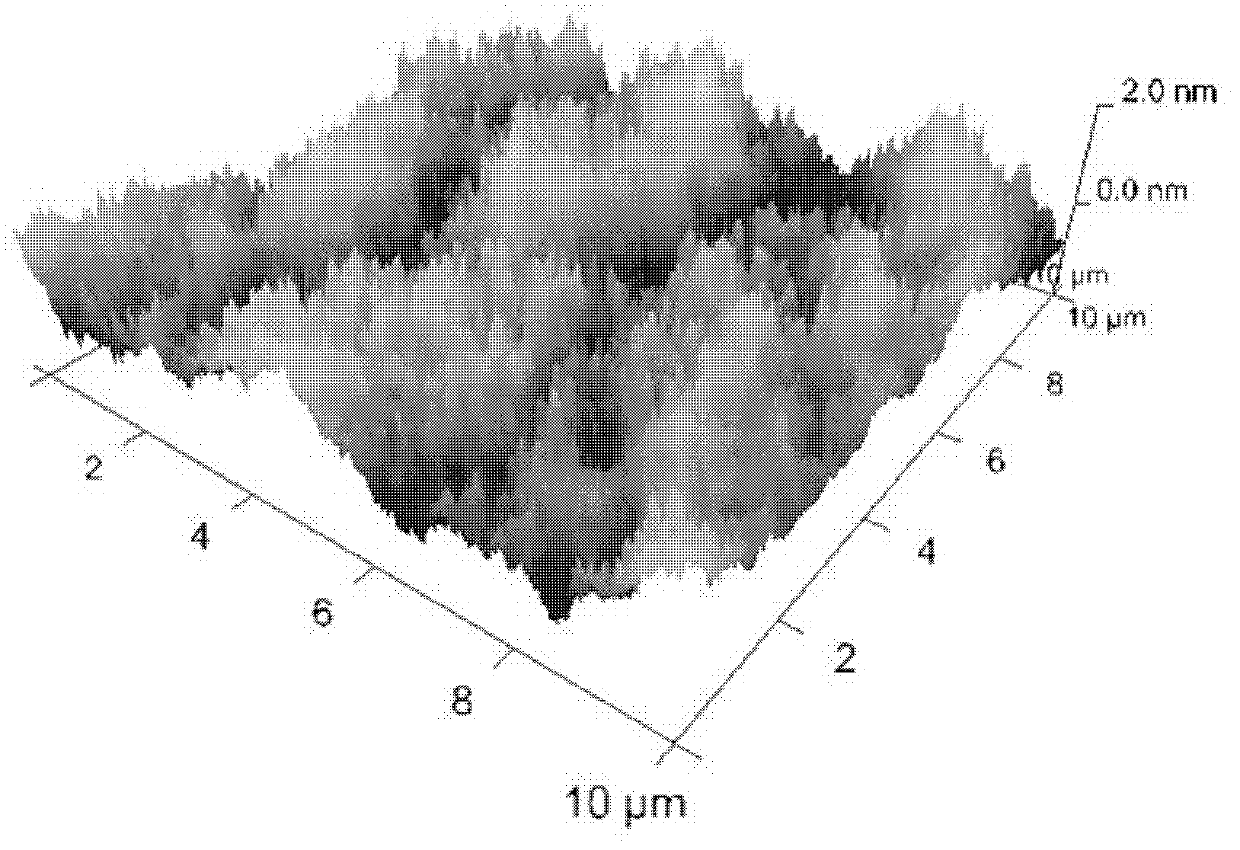

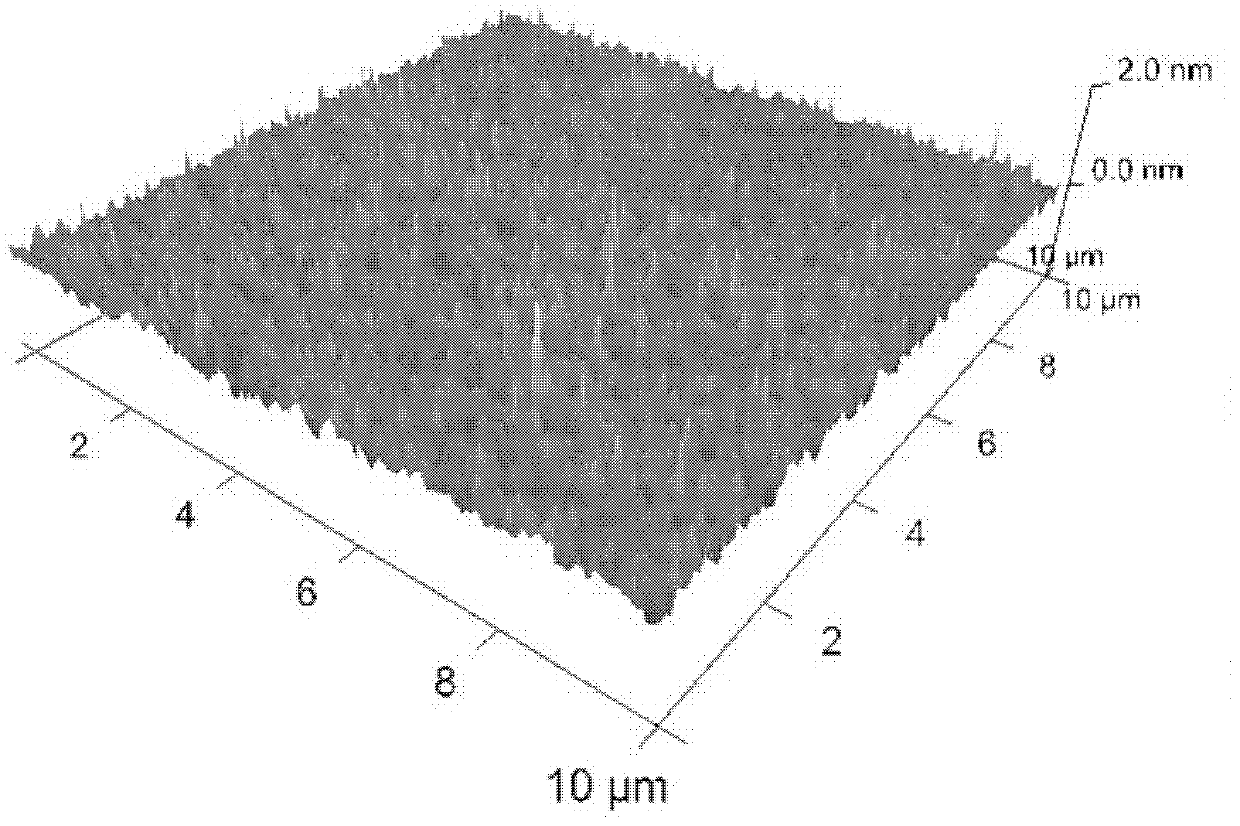

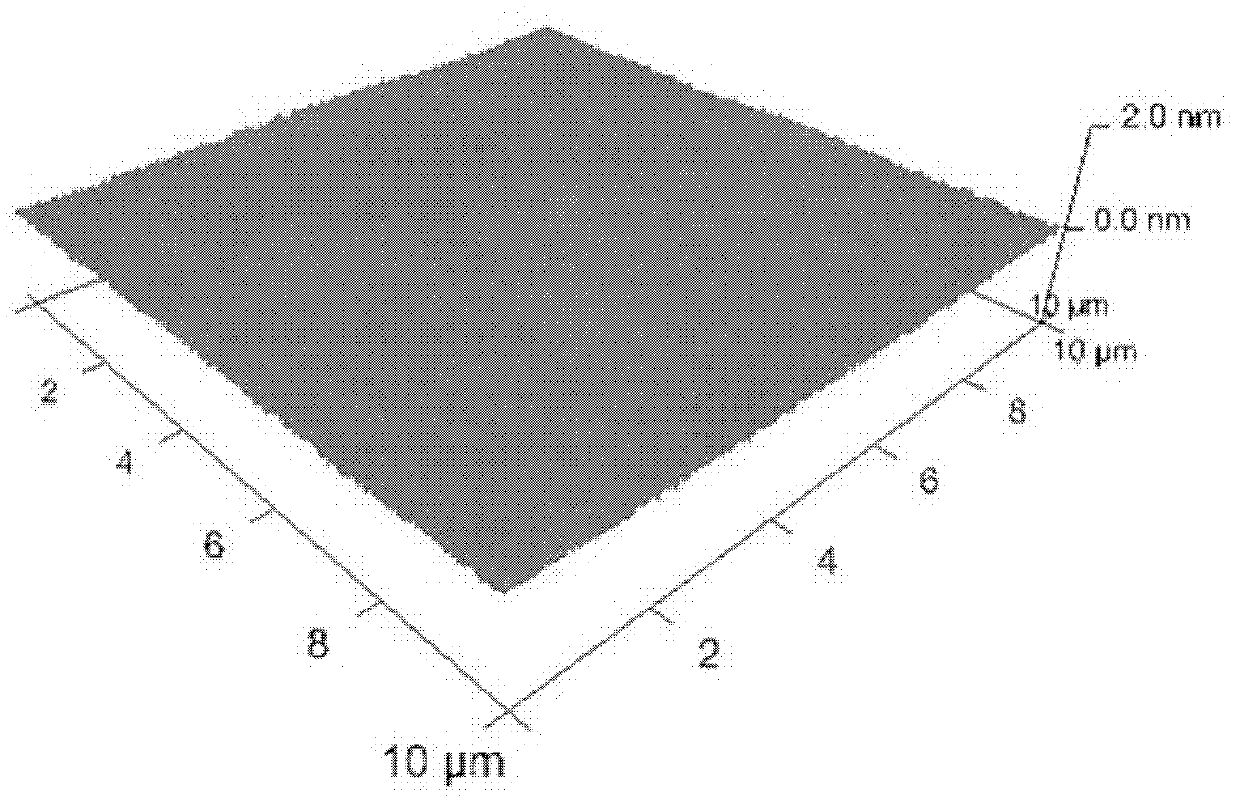

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a silicon wafer polishing composition and a preparation method thereof, and belongs to the field of chemically mechanical polishing (CMP). The silicon wafer polishing composition contains a grinding material, one or more alkaline compounds, 0.001 to 5 wt% of one or more water-soluble polymers, deionized water, 0.001 to 1 wt% of one or more polymer bridging agents and 0.001 to 0.5 wt% of one or more frictional factor conditioning agents, wherein the pH value of the silicon wafer polishing composition is in a range of 8 to 12. The silicon wafer polishing composition is especially suitable for silicon wafer polishing, can improve the stability of a polymer in slurry, can adjust a frictional factor between a silicon wafer surface and a polishing pad, can effectively inhibit the deposition of particles and a polymer, can reduce the scratches on the surface of a silicon wafer, can improve the uniformity of the quality of a polished silicon wafer surface, and can be washed away easily.

Description

technical field [0001] The invention relates to the field of chemical mechanical polishing (CMP), in particular to a polishing composition for fine polishing of silicon wafers and a preparation method thereof. Background technique [0002] Integrated circuit (IC) is the technical basis of the information industry and the core driving force for the development of high-tech. Chemical mechanical polishing technology can effectively take into account the global and local flatness of the processed surface. In the manufacture of VLSI, this technology is widely used to process single crystal silicon substrates. [0003] A traditional CMP system consists of the following three parts: a rotating silicon wafer holding device, a workbench carrying a polishing pad, and a polishing liquid (slurry) supply system. During polishing, the rotating workpiece is applied with a certain pressure on the polishing pad that rotates with the worktable. The polishing liquid flows between the workpiec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02

Inventor 潘国顺顾忠华龚桦邹春莉

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com