Self-mixing downflow fluidized bed rapid pyrolysis process for solid organics

A solid organic, self-mixing technology, applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, special forms of dry distillation, etc., can solve the problems of increasing investment costs and difficulty in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

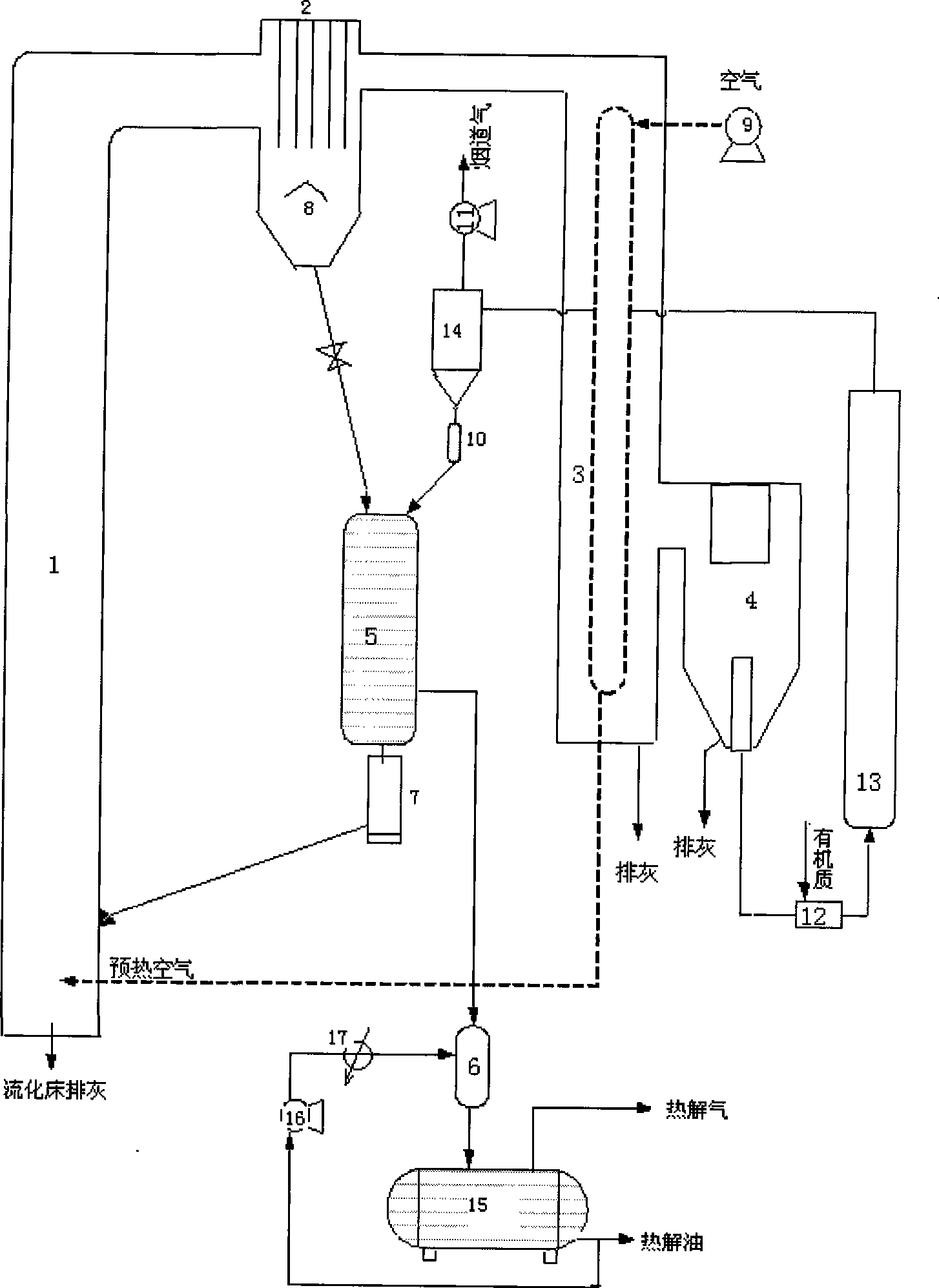

[0014] Below in conjunction with accompanying drawing, the present invention is described in detail: in actual design and manufacture, the present invention is to enter self-mixing fluidized-bed descending reactor (5) through conveying by screw conveyer (10) through the solid organic matter after the drying pulverization Inlet, contact, mix and react with the high-temperature regeneration agent entering from another inlet in the self-mixing downward fluidized bed reactor (5), and leave the reaction section quickly; the gas phase passes through the self-mixing downward fluidized bed reactor (5) The outlet of the gaseous phase enters the quench cooler (6) to condense and separate into pyrolysis oil and pyrolysis gas, which are separated by the oil tank (15), and part of the pyrolysis oil is pumped back to the water cooler (17) by the liquid circulation pump (16) to cool and then made It is the cooling source of the quench cooler (6); the solid phase enters the fluidized bed regen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com