Core-shell structure catalyst for fuel cells and its pulse electrodeposition preparation method

A technology of pulse electrodeposition and core-shell structure, which is applied in the direction of battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of no significant improvement in the quality and activity of core-shell structure catalysts, which is not conducive to the catalytic performance of noble metals in the shell , Can not realize the use of precious metals in the shell, etc., to achieve the effects of easy large-scale industrial production, good catalytic performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

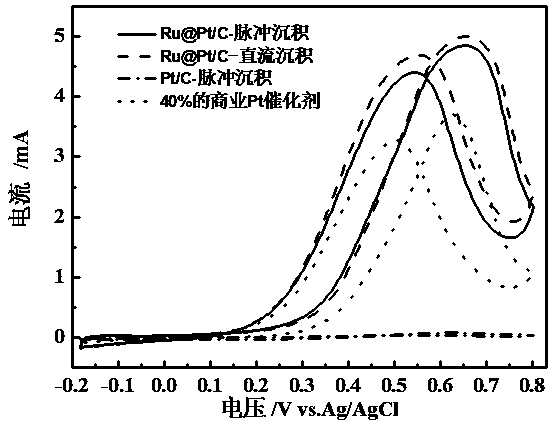

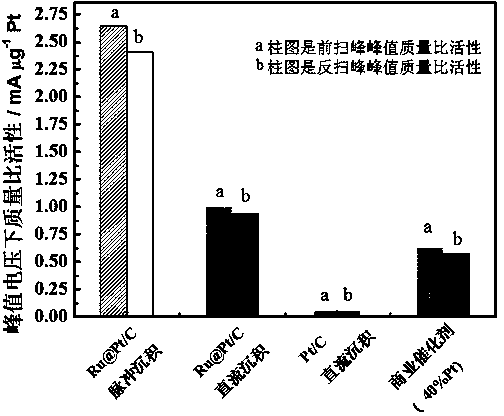

[0046] Example 1: RuPt / C catalyst

[0047] (1) Preparation of Ru / C as core

[0048] (A) Toner XC-72 pretreatment:

[0049] Weigh 10 g of Vulcan XC-72 toner (Cabot Corp., BET: 237 m 2 / g, abbreviated as C), add 500 mL of acetone and stir at room temperature for 8 h to remove oxides and organic impurities in the carbon powder, filter and wash with secondary water, and then vacuum dry at 70 ℃; the dried carbon Transfer the powder to a tube furnace and roast at 500°C for 2 hours under the protection of nitrogen atmosphere to remove organics and other impurities; then transfer the carbon powder to a 500 mL three-necked flask and add 200 mL 10% HNO 3 And 100 mL 30% H 2 O 2 The mixed solution was heated to reflux at 80°C for 6 hours, filtered and washed with water to neutrality, then dried in a 80°C oven under vacuum for 12 hours, and then ground for use.

[0050] (B) Preparation of Ru / C by high pressure organosol method

[0051] Add 385 mg of ground sodium citrate to 9 mL of ruthenium trich...

Embodiment 2

[0082] Example 2: RuPt / C catalyst

[0083] (1) Preparation of 20% Ru / C as the core: same as in Example 1.

[0084] (2) Preparing RuPt / C by constant current pulse method:

[0085] Except for the following two points, the others are the same as in Example 1.

[0086] (A) Shell metal salt solution (chloroplatinic acid, concentration 50 mM, containing 0.1 M sodium sulfate, 0.125 M sodium citrate);

[0087] (B) The pulse current density is 1 mA / cm 2 , The pulse on time is 0.1 ms, the off time is 0.5 ms, and the number of pulses is 1300.

[0088] (C) The platinum content of the catalyst is 2.5 wt%.

[0089] (3) The catalyst performance test and characterization are the same as in Example 1, and the results are shown in column 2 of Table 1.

Embodiment 3

[0090] Example 3: IrPt / CNTs catalyst

[0091] Except for replacing XC-72R carbon black with carbon nanotubes and replacing ruthenium trichloride with iridium trichloride, the other preparation and testing methods are completely the same as those in Example 1. The results are shown in column 3 of Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com