Macroporous aluminum oxide with bimodal pore distribution and preparation method thereof

A technology of macroporous alumina and bimodal pores, which is applied in the field of alumina with bimodal pore distribution and its preparation, can solve the problems of complex separation and recovery process, high production cost, unfavorable for large-scale industrial production, and the like, and achieves a high technological Simple, saving raw materials, and easy to achieve the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The method for preparing macroporous alumina provided by the present invention includes the following steps:

[0016] (1) Prepare the precursor of alumina into a suspension or sol with a solid content of 2-20% by mass, and age it at 10-90°C.

[0017] (2) The solid content of the aging slurry in step (1) is concentrated to 25-45% by mass, aged at 100-220°C, then dried and calcined.

[0018] The step (1) of the above method is a section of aging of the suspension or sol prepared from the precursor of alumina, the precursor of alumina is selected from boehmite, pseudo-boehmite or boehmite and pseudo-boehmite A mixture of boehmite. Before aging, add water to the alumina precursor to make a suspension with a specified solid content, or add an appropriate amount of inorganic or organic acid to the suspension to make it a sol. The pH of the suspension or sol before aging is 3-9, the pH of the suspension is 7-9, and the pH of the sol is 3-6. The acid used for preparing the sol can ...

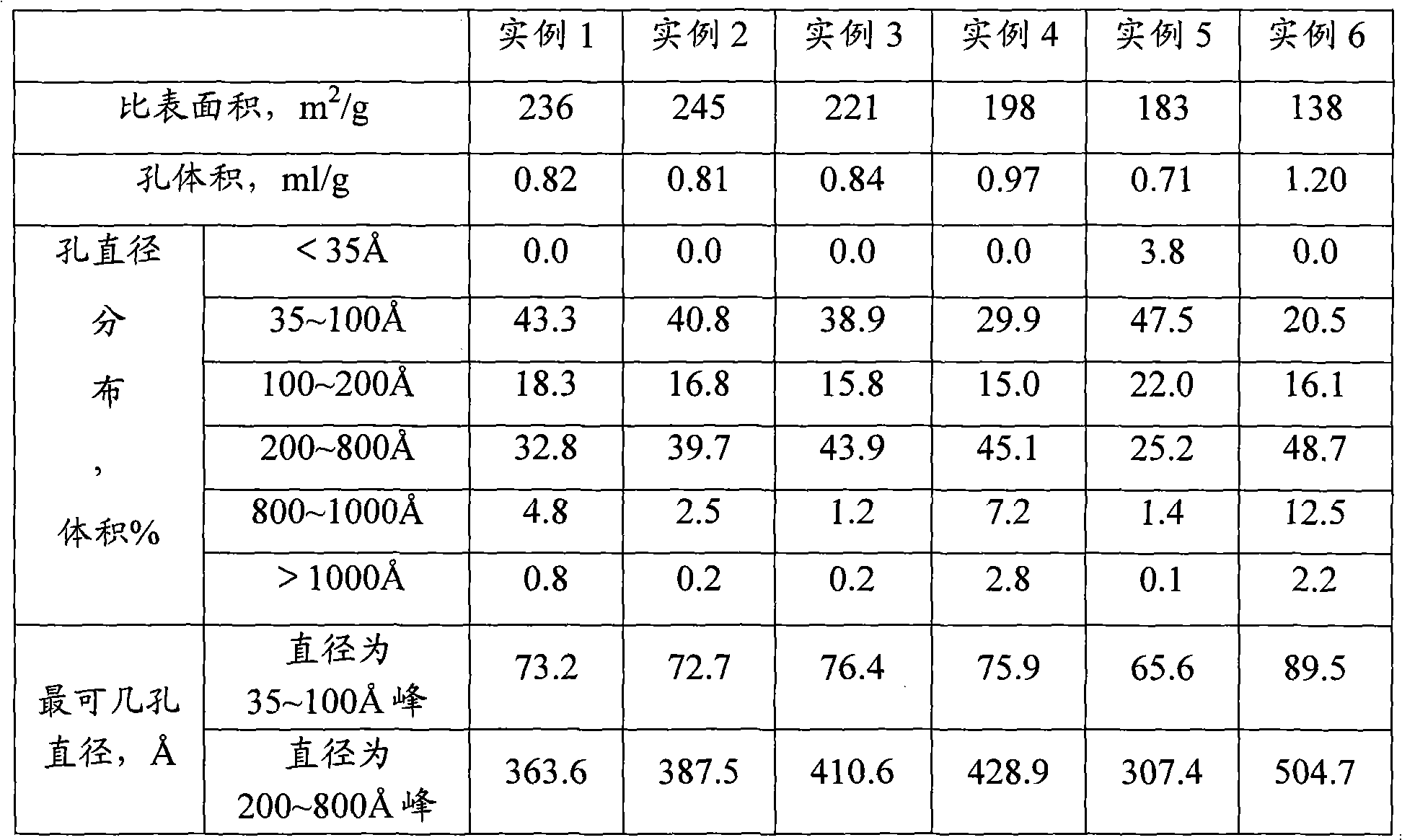

example 1

[0026] Take 100g pseudo-boehmite powder (produced by Changling Catalyst Factory, 70% alumina content) into a 1-liter three-necked flask, add 483.3g deionized water, stir to form a suspension with a solid content of 12.0% by mass, pH value 9.0, aging at 60°C for 12 hours. Heat and evaporate 350 g of deionized water, and transfer the obtained slurry with a solid content of 30.0% by mass to a 250 ml stainless steel pressure tank lined with polytetrafluoroethylene, and heat to 120° C. for aging for 12 hours. The obtained boehmite is dried at 120°C for 6 hours and calcined at 600°C for 6 hours to obtain γ-Al 2 O 3 A, the specific surface area, pore volume and pore distribution are shown in Table 1.

example 2

[0028] Prepare γ-Al according to the method of Example 1 2 O 3 The difference is that the first stage of aging is carried out at 30°C for 12 hours, and the second stage of aging is carried out at 150°C for 12 hours. The resulting boehmite is dried and calcined to obtain γ-Al 2 O 3 B, the specific surface area, pore volume and pore distribution are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com