Device and process for decarburization of gas containing high-concentration CO2 and regeneration of amine liquid

An amine liquid and gas technology, which is applied in the field of devices for decarburization of high-concentration CO2 gas and regeneration of amine liquid, which can solve the problems of large loss rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

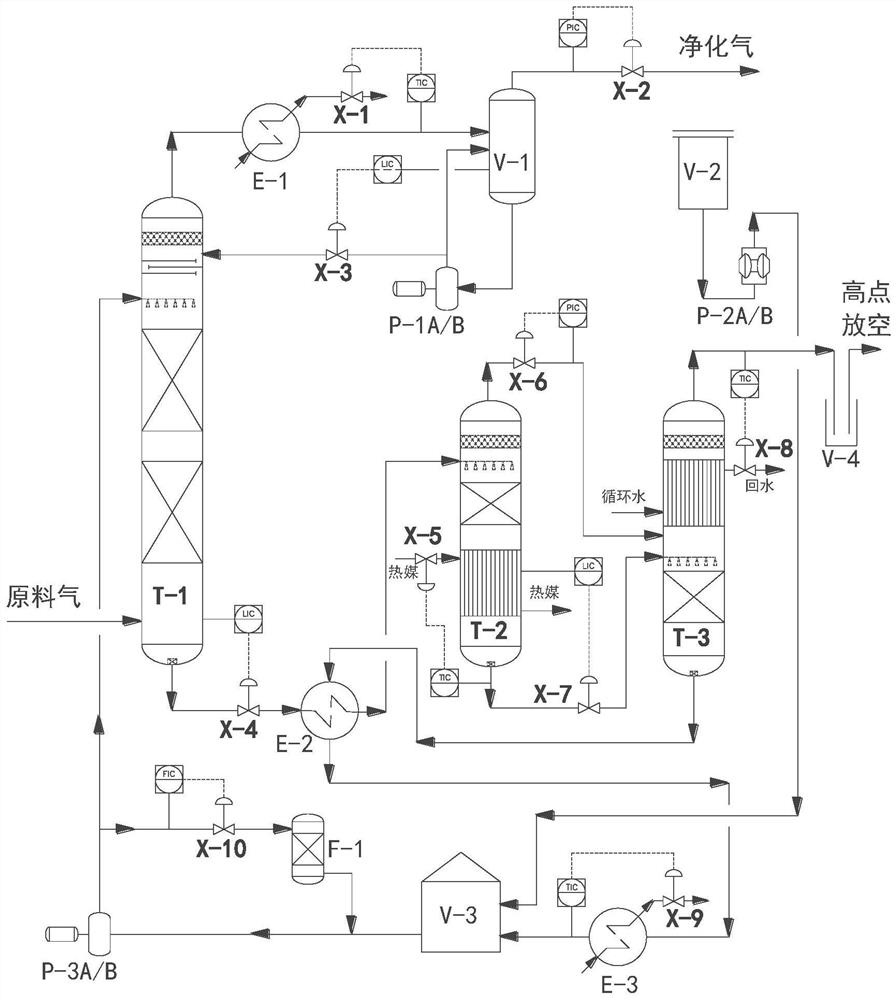

Method used

Image

Examples

Embodiment 1

[0056] (1)CO 2 Absorption: Natural gas with a carbon content of 25% (mole%) and a temperature of about 40°C (the component of the high-acid feed gas is mainly CH 4 , CO 2 , additionally contains a small amount of H 2 or N 2 ) enters from the bottom of the absorption tower T-1, and flows from bottom to top; amine liquid (about 35wt% MDEA aqueous solution) at about 46°C pours from the upper part of the absorption tower T-1 (the volume of high-acid raw material gas and amine liquid The flow ratio is about 30:1), passing through the absorption tower T-1 from top to bottom, after the counter-flowing amine liquid and natural gas fully contact the heat and mass transfer in the tower, the CO in the natural gas 2 Absorbed by amine liquid, output CO from the top of the absorption tower 2 Purified gas whose concentration is reduced to below 2.5% (mole%).

[0057] (2) The purified gas output from the top of the absorption tower T-1 is cooled by the purified gas cooler E-1 (usually to...

Embodiment 2

[0063] (1)CO 2 Absorption: carbon content or CO 2 Synthesis gas with a content of 35% (mole%) and a temperature of about 40°C (the components of the high-acid feed gas are mainly CH 4 , CO 2 , additionally contains a small amount of H 2 or N 2 ) enters from the bottom of the absorption tower T-1, and flows from bottom to top; lean amine liquid (concentration is about 35wt% MDEA aqueous solution; amine liquid spray density is 15-20m 3 / m 2 * between h) from the upper part of the absorption tower T-1 (the volume flow ratio of the high-acid raw material gas to the amine liquid is about 27:1), and pass through the absorption tower T-1 from top to bottom, and the reverse flow of the amine liquid and After the natural gas is fully exposed to heat and mass transfer in the tower, the CO in the natural gas 2 Absorbed by amine liquid, output CO from the top of the absorption tower 2 Purified gas whose concentration is reduced to below 2.5% (mole%).

[0064] (2) The purified gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com