Patents

Literature

150results about How to "Avoid flying temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

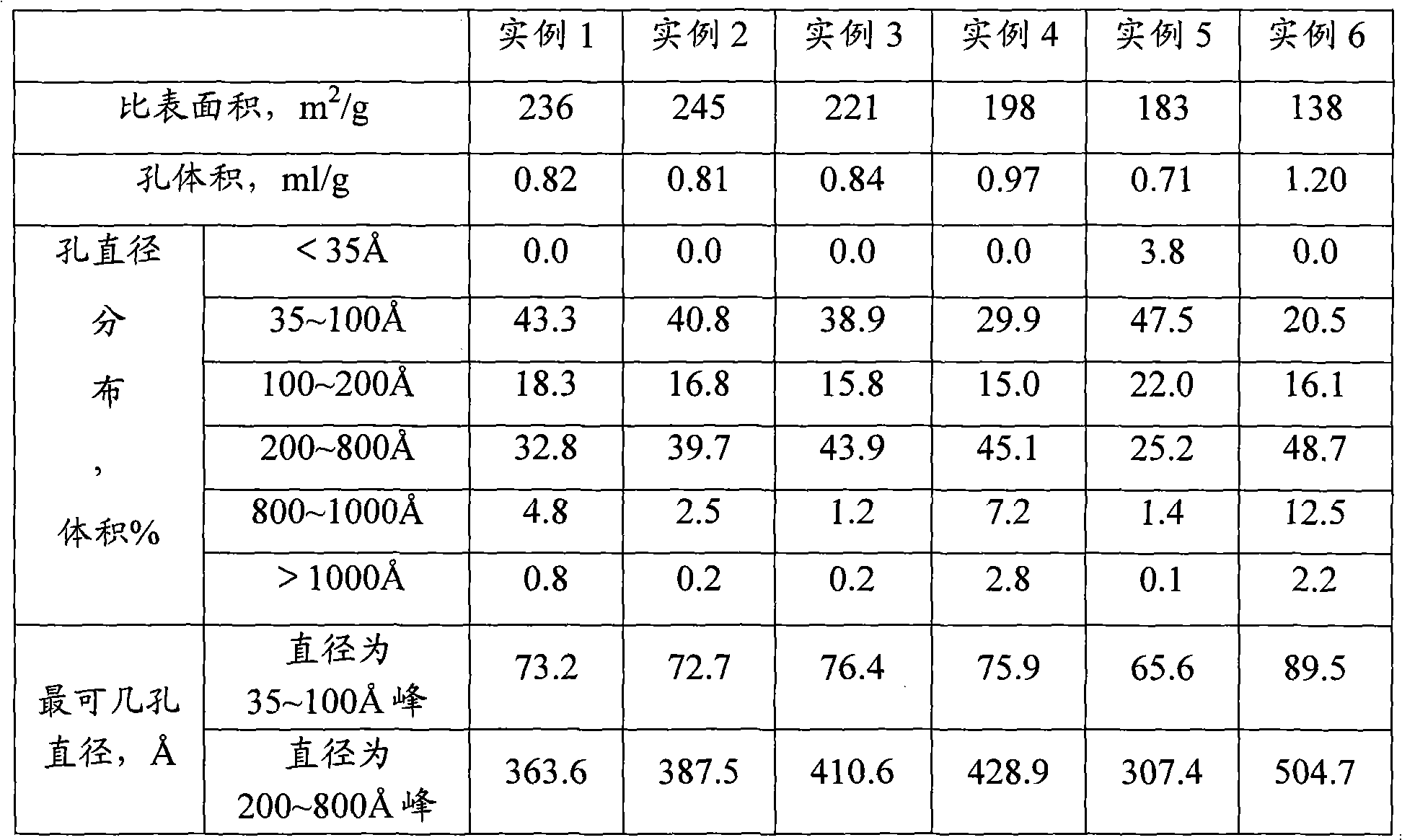

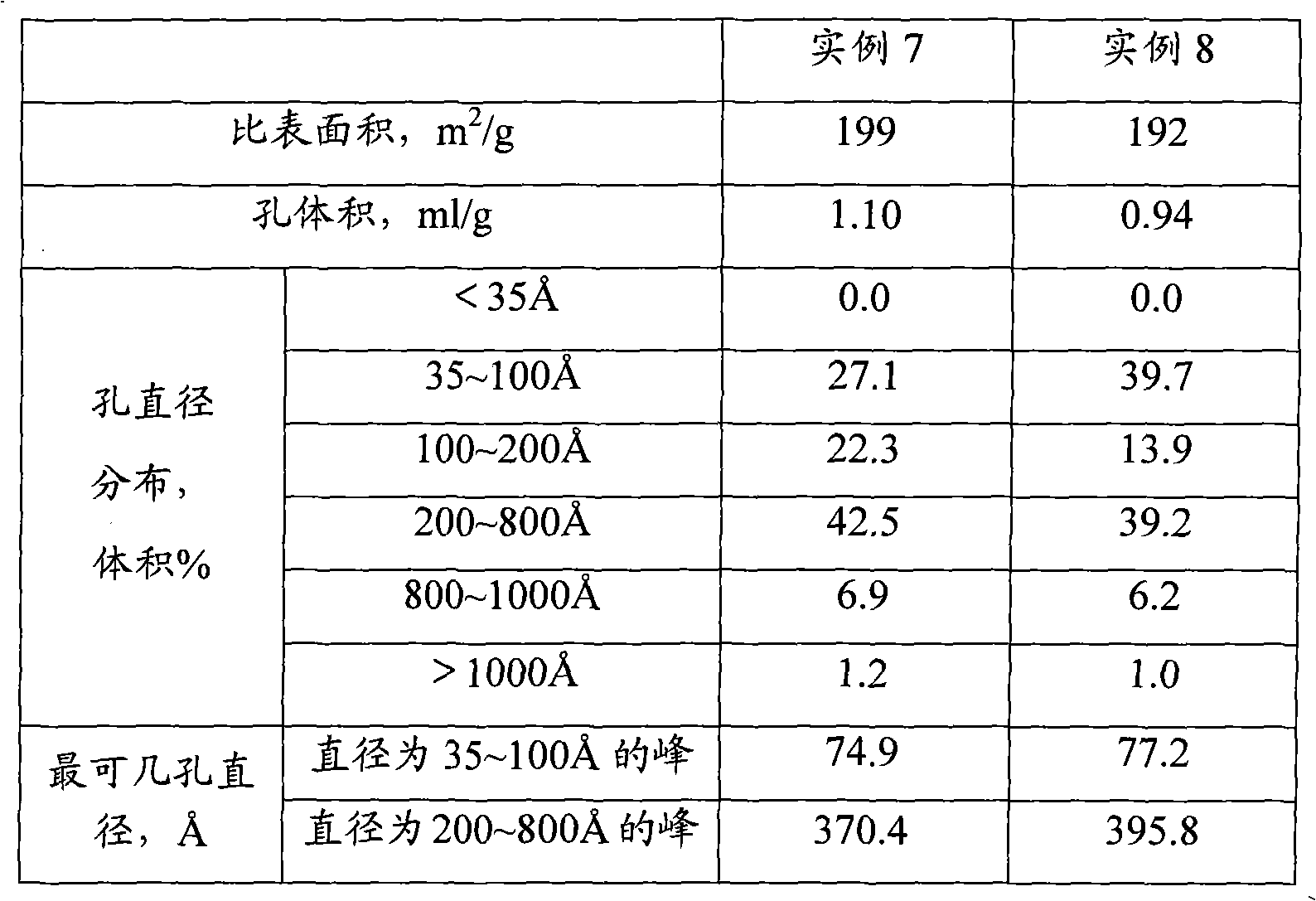

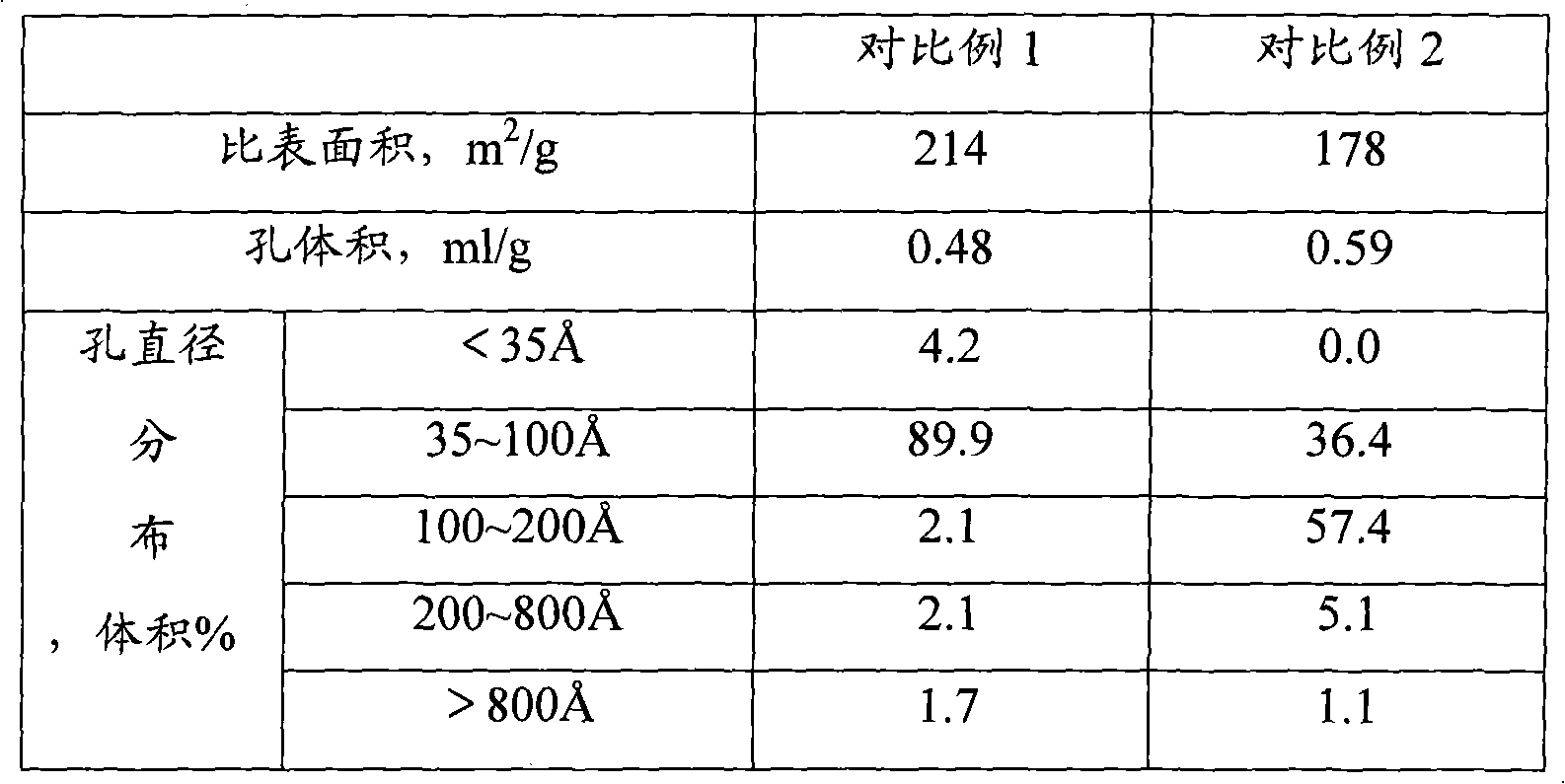

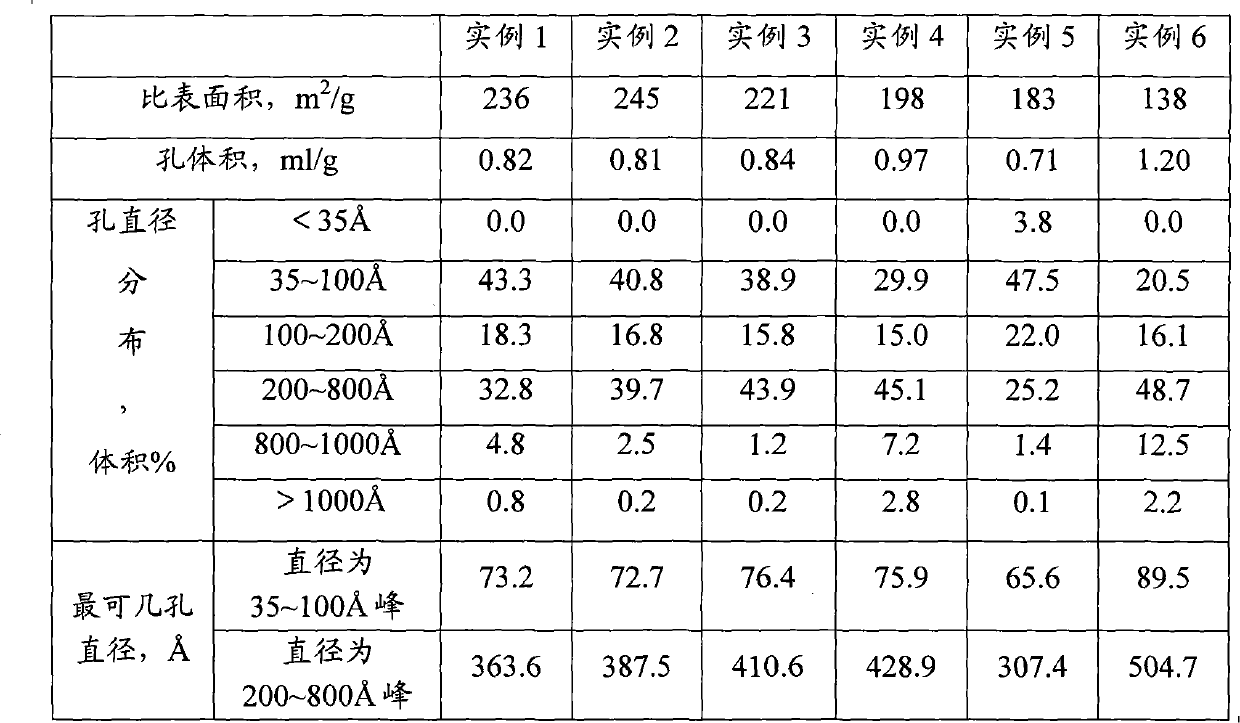

Macroporous aluminum oxide with bimodal pore distribution and preparation method thereof

ActiveCN102030351AAvoid flying temperatureReduce manufacturing costAluminium oxides/hydroxidesPore distributionOrganic solvent

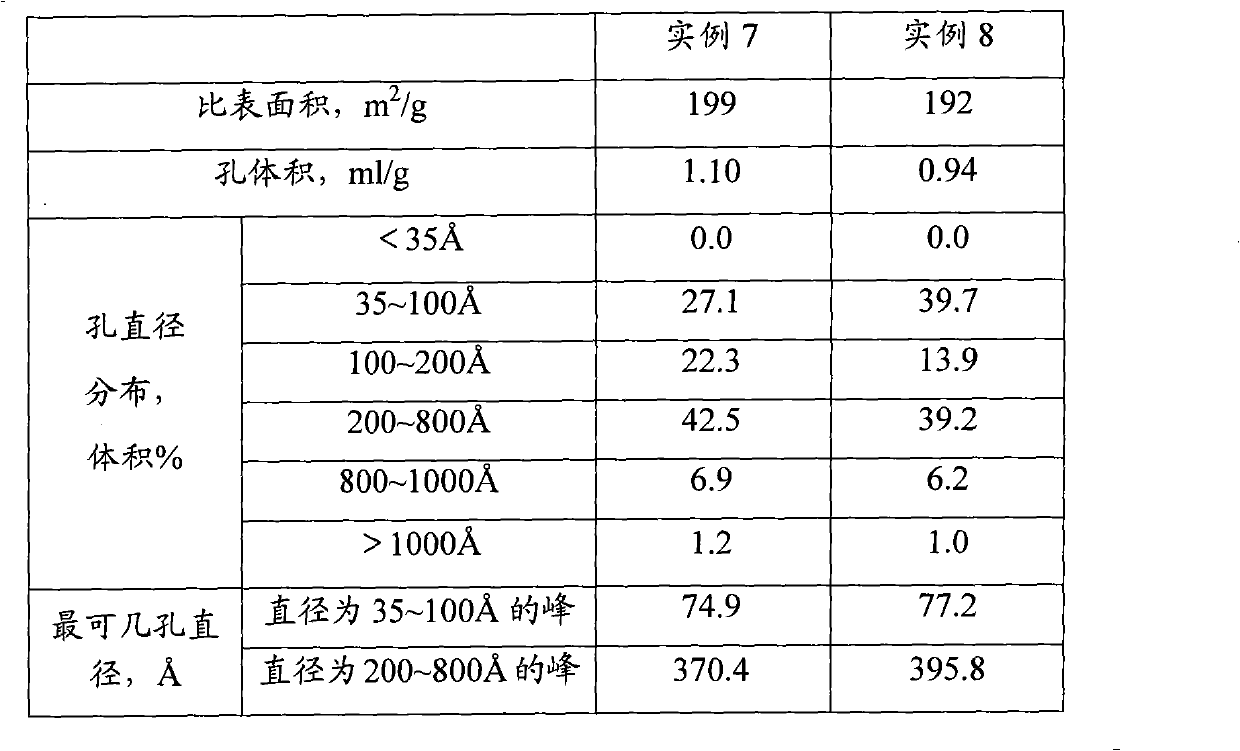

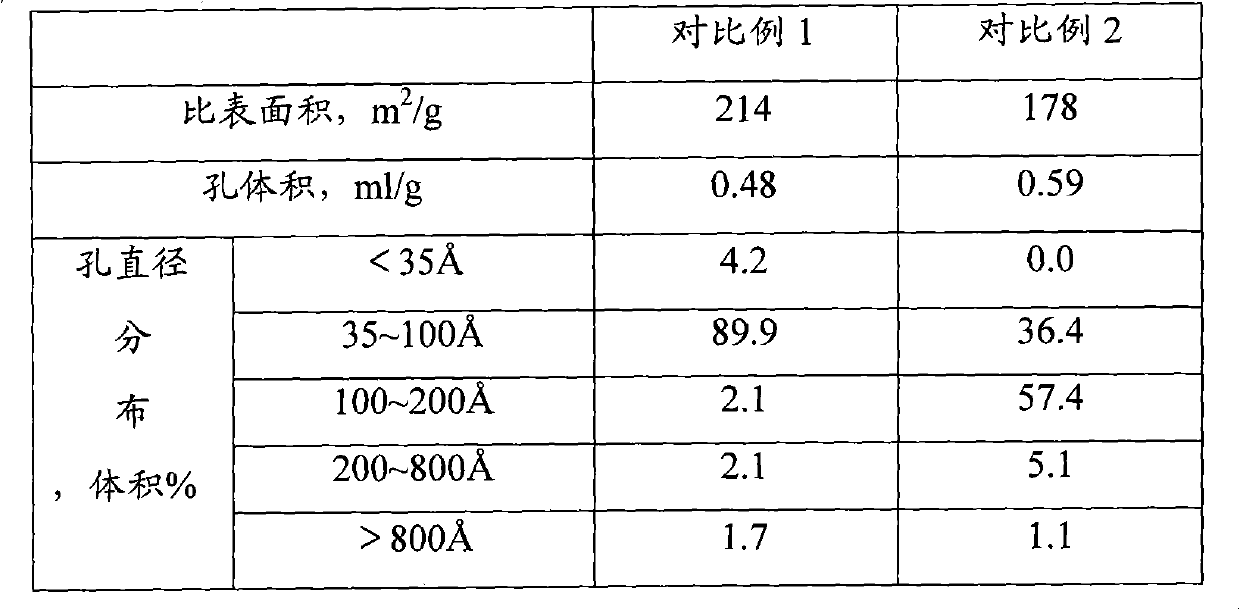

The invention discloses macroporous aluminum oxide with bimodal pore distribution. The pore volume of the macroporous aluminum oxide is 0.6 to 3.0ml / g, the specific surface area is 90 to 300sq.m / g, wherein the pores with aperture of between 35 and 100 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 50 and 90; and the pores with aperture of between 200 and 800 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 300 and 600. The aluminum oxide is prepared by a two-section aging method without a hole expansion agent or an organic solvent, so the raw materials are saved, the flow is simplified, and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

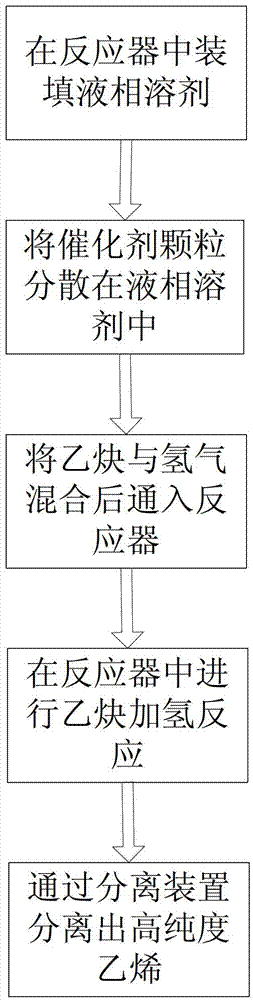

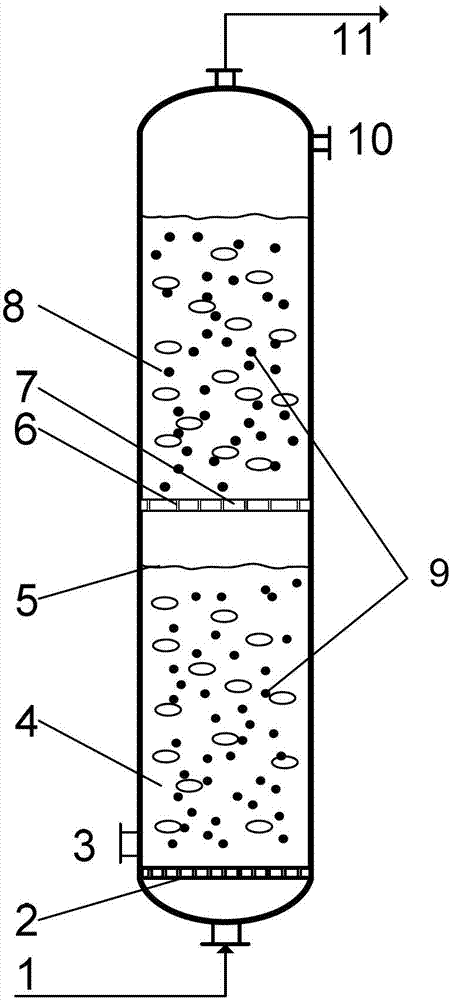

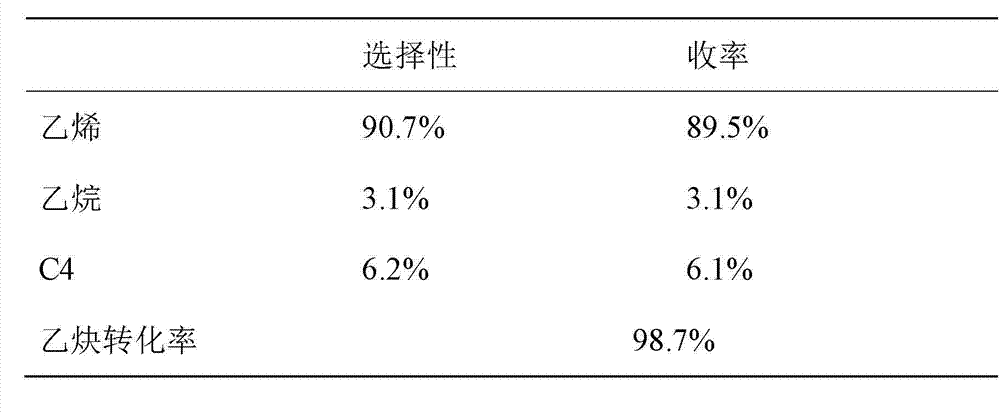

Method for preparing ethylene through liquid-phase selective hydrogenation of acetylene in slurry reactor

InactiveCN103044179AImprove conversion rateHigh yieldHydrocarbon by hydrogenationBulk chemical productionSolubilitySlurry reactor

The invention belongs to the technical field of chemical material preparing methods, and particularly relates to a method for preparing ethylene through liquid-phase selective hydrogenation of acetylene in a slurry reactor. A liquid-phase solvent with high selective solubility for acetylene and low selective solubility for ethylene is introduced into a gas-solid catalytic system, and the relative solubility coefficient of the solvent is larger than 8; a catalyst is dispersed evenly in the liquid-phase solvent, and process coupling is achieved through the high selective solubility of the liquid-phase solvent for acetylene, so that the selectivity of ethylene is improved; and ethylene is prepared and separated through an hydrogenation reaction of acetylene. According to the method, the concentration of ethylene on the surface of the catalyst is reduced through the process coupling, therefore a path of ethane generation through deep hydrogenation is blocked to a certain extent, and the selectivity of ethylene can be improved remarkably. Simultaneously, the liquid-phase dilution thermal effect can accelerate heat transfer in the slurry reactor, and temperature runaway is avoided. The method is not only used for preparing ethylene from acetylene obtained from natural gas pyrolysis, but also is an efficient method in a process for removing acetylene in ethylene.

Owner:TSINGHUA UNIV

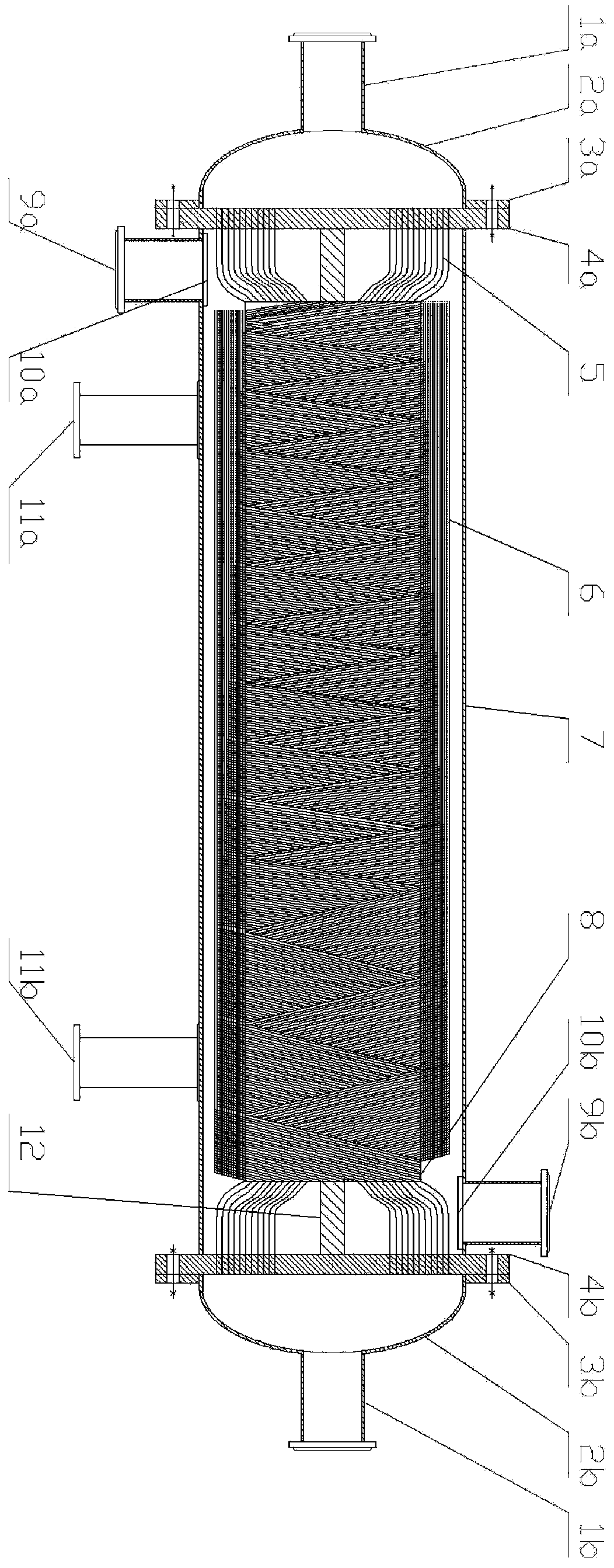

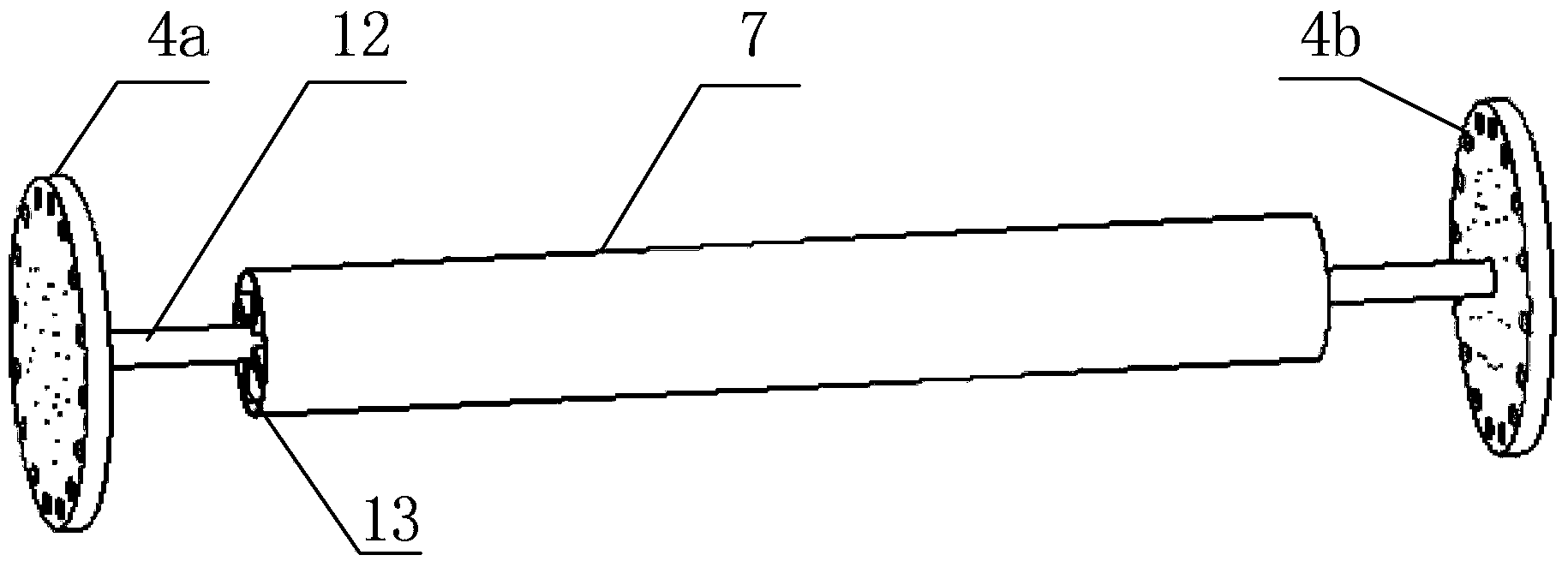

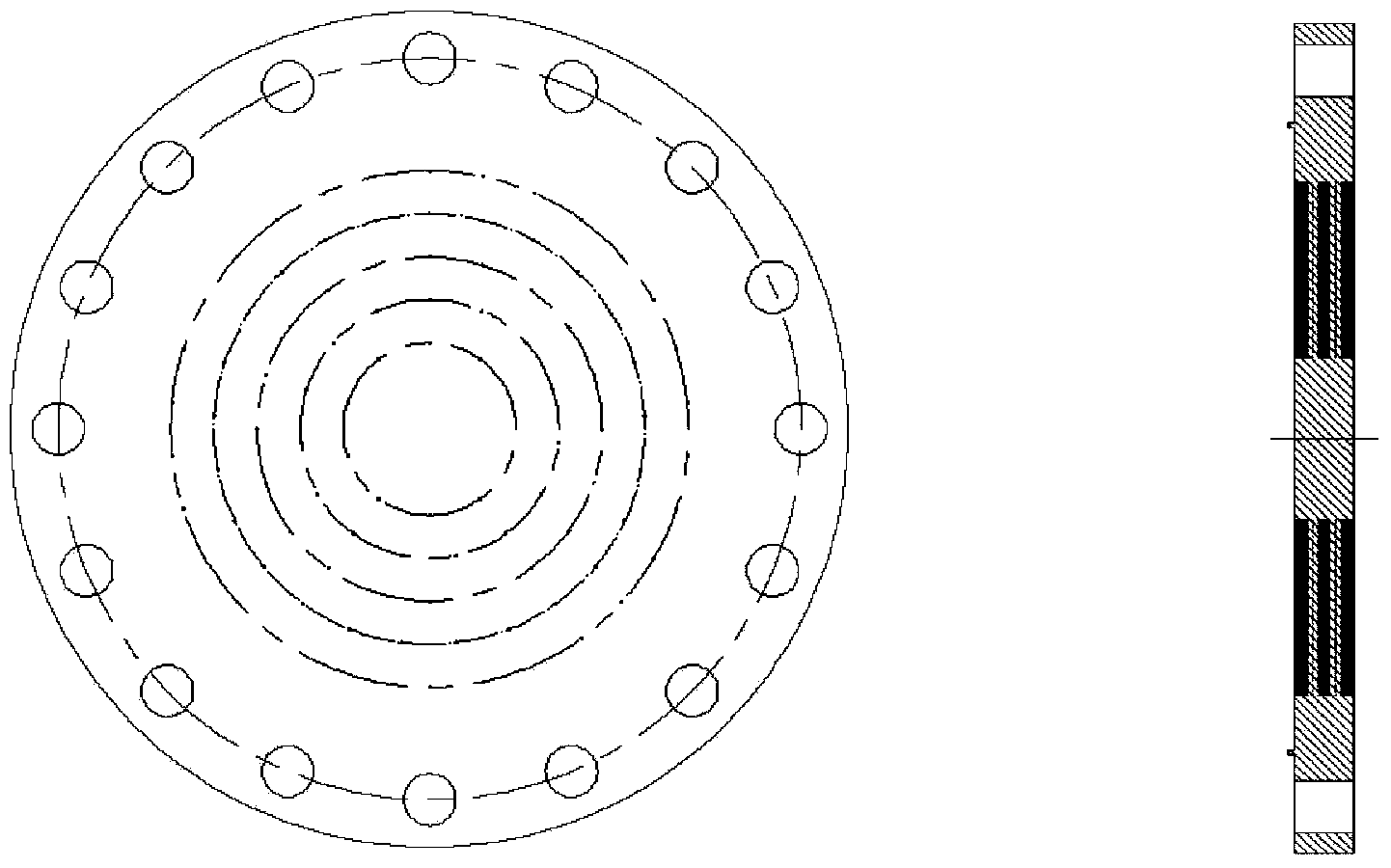

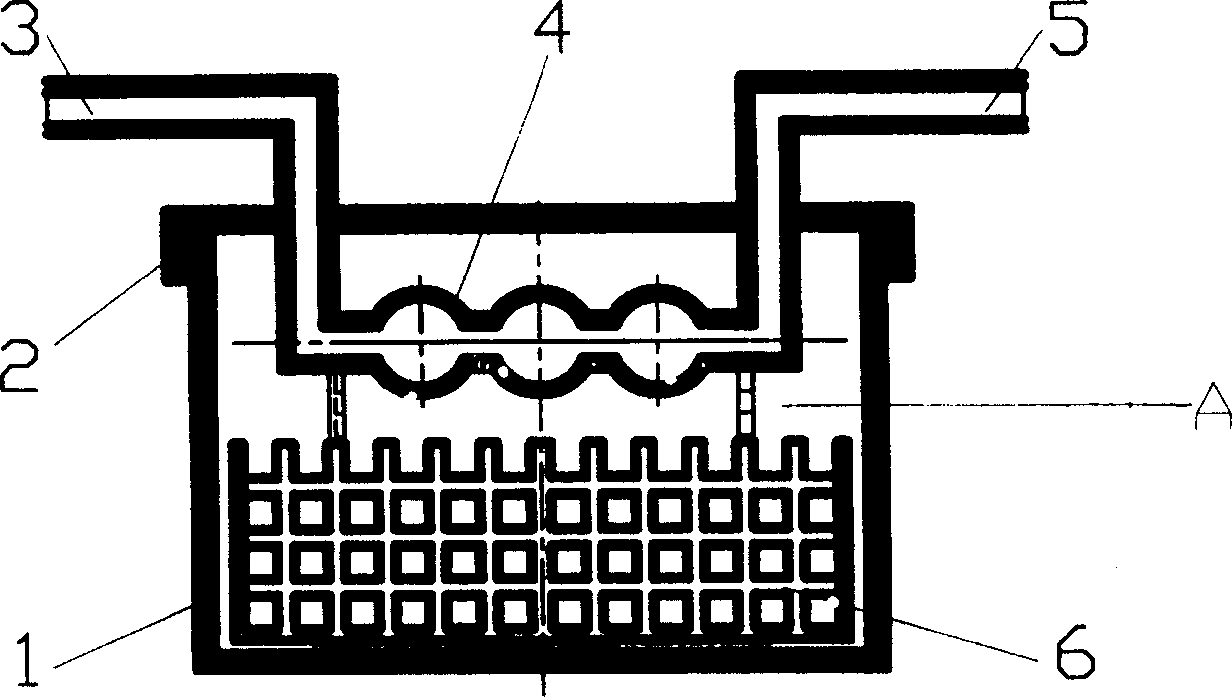

Novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes

ActiveCN104258796APrecisely control the feeding ratioPrevent "overheating"Chemical/physical/physico-chemical processesCapillary TubingEngineering

The invention relates to the technical field of the design of chemical reactors and discloses a novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes. The reactor mainly comprises reactant inlet and outlet sections, inlet and outlet glands, flanges, inlet and outlet tube plates, stainless steel capillary tubes, a fixed pad strip, a drum, a winding drum, constant-temperature medium inlet and outlet sections, baffles, left and right supports, a central support tube and a support piece, wherein two ends of the central support tube are connected with the inlet and outlet tube plates, and the winding drum and the central support tube are located on a same axis and welded and connected through the support piece; the stainless steel capillary tubes spirally wind around the winding drum in a multi-layer manner, spiral directions of adjacent winding layers are opposite, multiple reaction tube bundles which take the winding drum as the circle center and have different circle diameters are formed, and two ends of each stainless steel capillary tube are connected onto the inlet and outlet tube plates respectively; the inlet and outlet glands are connected with the inlet and outlet tube plates respectively through the flanges. The reactor has the advantages of high throughput, high heat transfer capacity, high synthetic rate, safety, high efficiency, low machining cost, capability of realizing continuous production, easiness in parallel enlargement and the like.

Owner:NANJING UNIV OF TECH

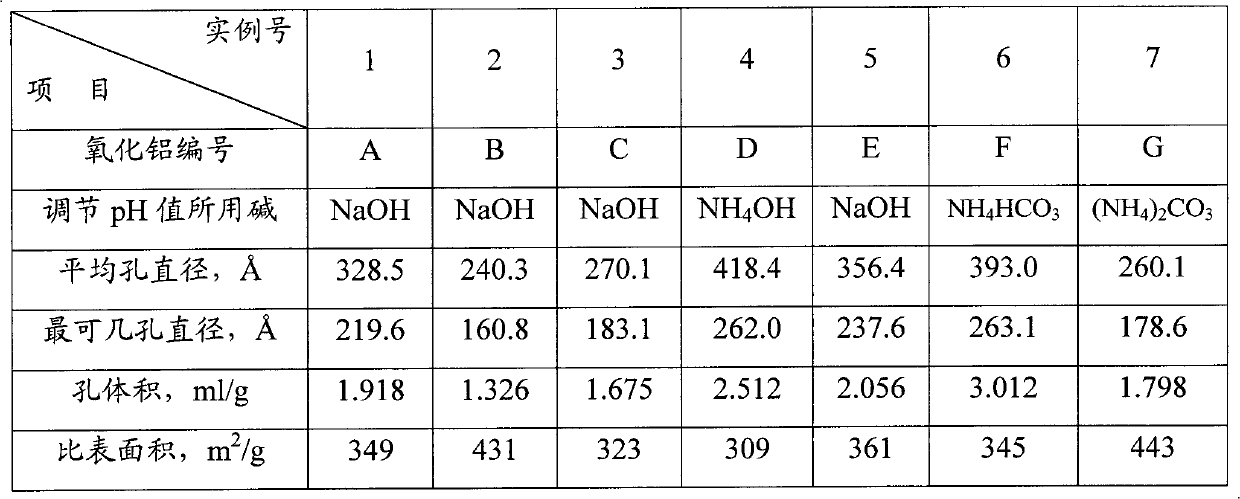

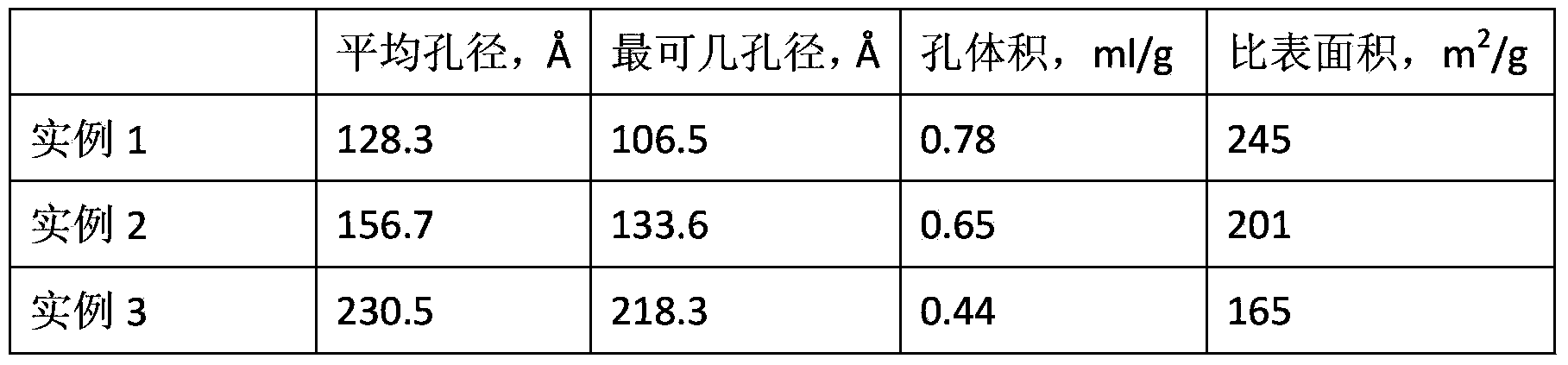

Macro-porous aluminum oxide and preparation method thereof

ActiveCN102795647AHigh specific surface areaHigh purityAluminium oxides/hydroxidesAverage diameterAge method

The invention provides macro-porous aluminum oxide. The average diameter of holes is the diameter of a most probable hole; the size of the holes is 1.1-3.5 ml / g; and the specific surface area is 150-450 m<2> / g. The aluminum oxide is prepared by a two-section ageing method; the first section of ageing comprises the following steps of: adding an alkaline compound or an acidic compound into an aluminum hydroxide suspension solution to adjust the pH (Potential of Hydrogen) value of the suspension solution and then ageing; and the second section of ageing comprises the following steps of: adding fatty alcohol; after ageing, separating out the fatty alcohol; and drying and roasting slurry without the fatty alcohol to obtain the aluminum oxide with a large hole diameter, a large specific surface area and a large hole volume. The aluminum oxide is suitable for a carrier of a hydrocarbons conversion catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

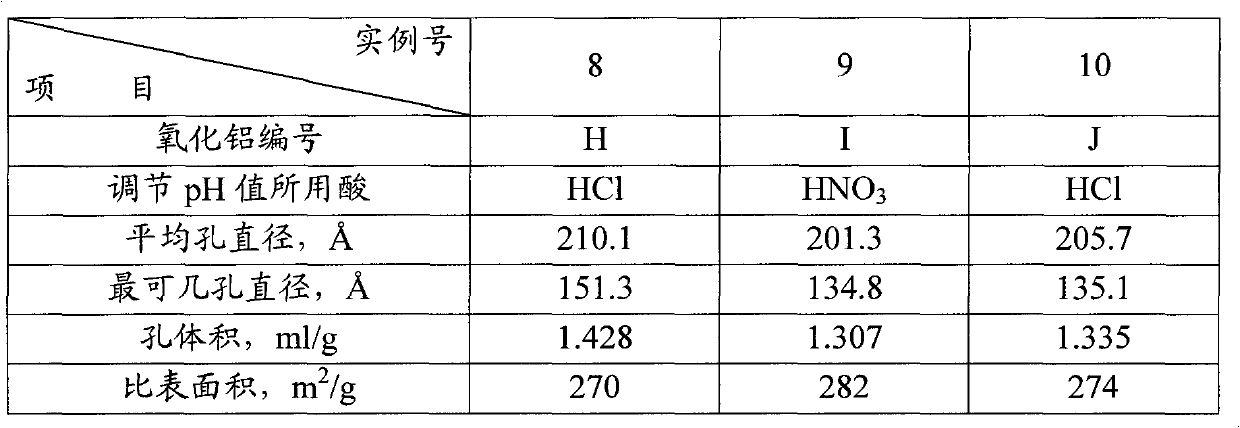

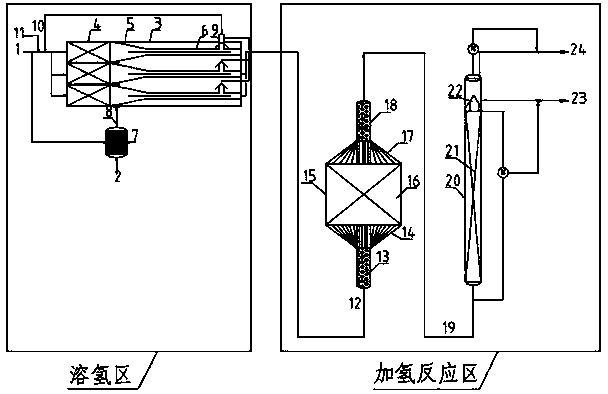

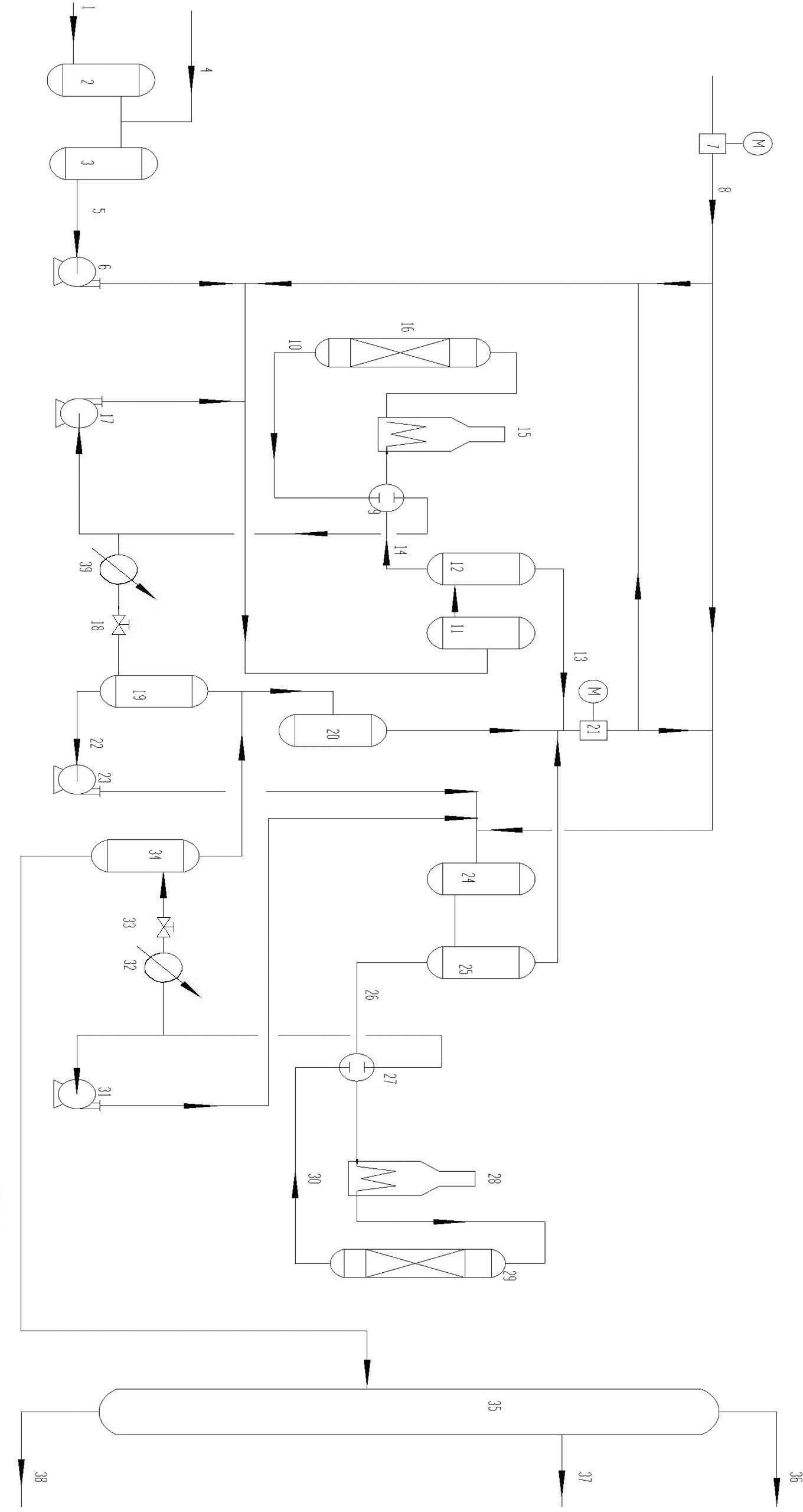

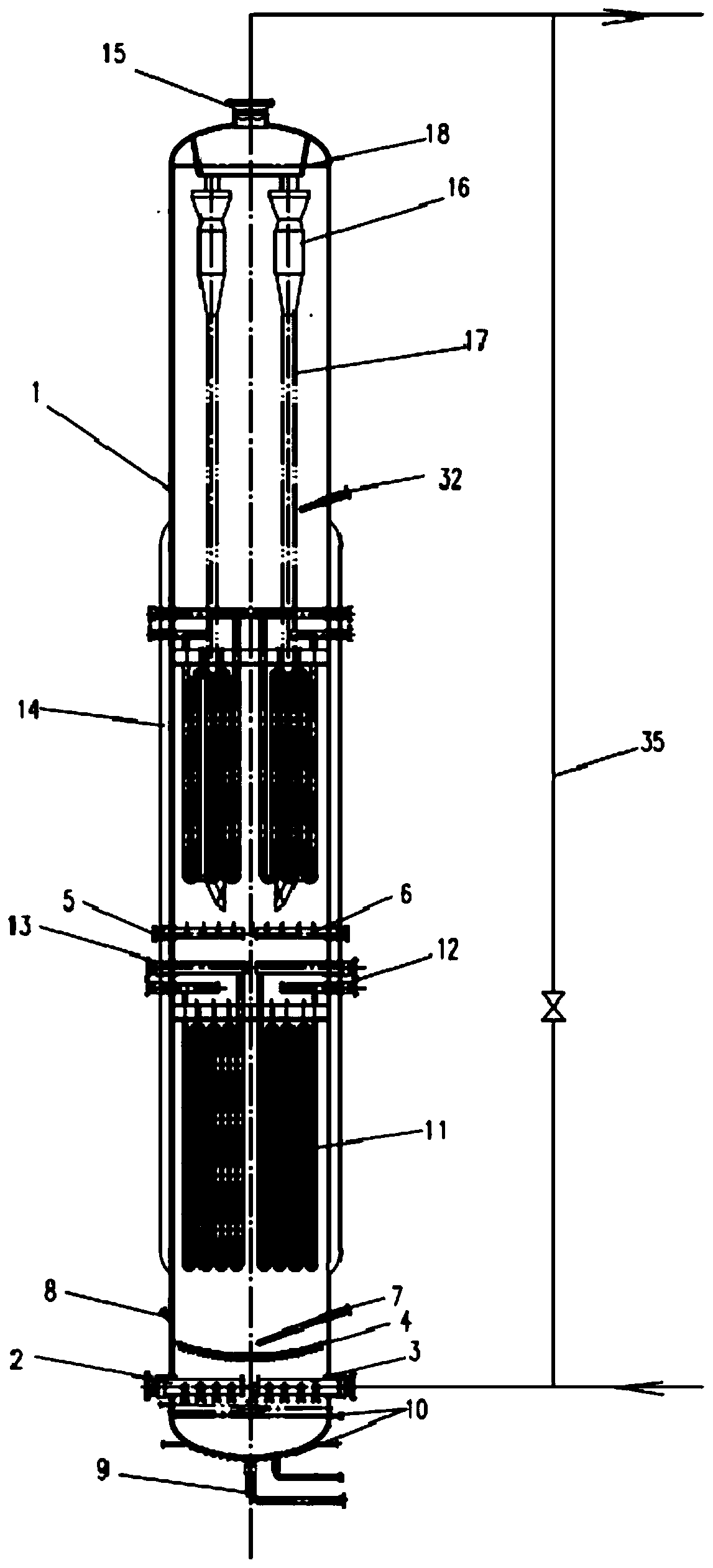

Liquid phase hydrogenation system and method

ActiveCN109679690AAvoid flying temperatureReduced service lifeTreatment with hydrotreatment processesStable stateHydrogenation reaction

The invention discloses a liquid phase hydrogenation system and method. The liquid phase hydrogenation system comprises a hydrogen dissolving area and a hydrogenation reaction area; the hydrogen dissolving area is internally provided with a plurality of hydrogen dissolving devices which comprise hydrogen dissolving device shells; a plurality of hydrogen dissolving assemblies which are connected inparallel are included in the hydrogen dissolving device shells; and the hydrogenation reaction area comprises a fixed bed reactor and one or more up-flow-type tubular reactors, wherein the fixed bedreactor and the one or more up-flow-type tubular reactors are connected in series. Fresh raw oil and hydrogen form a 'gas-in-oil' type gas-liquid mixed fluid with the stable state in the hydrogen dissolving area firstly and then enter the hydrogenation reaction area to generate a liquid phase hydrogenation reaction; and according to the method, the 'gas-in-oil' type gas-liquid mixed fluid formed in the hydrogen dissolving area is adopted as a fed material of the liquid phase hydrogenation reaction, the supplementary hydrogen-to-oil ratio in the hydrogenation reaction process can be greatly decreased, the hydrogenation reaction speed is increased, the hydrogenation reaction efficiency is improved, the hydrogen utilization rate is increased, hydrogen consumption and energy consumption are lowered, and deep hydrogenation is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

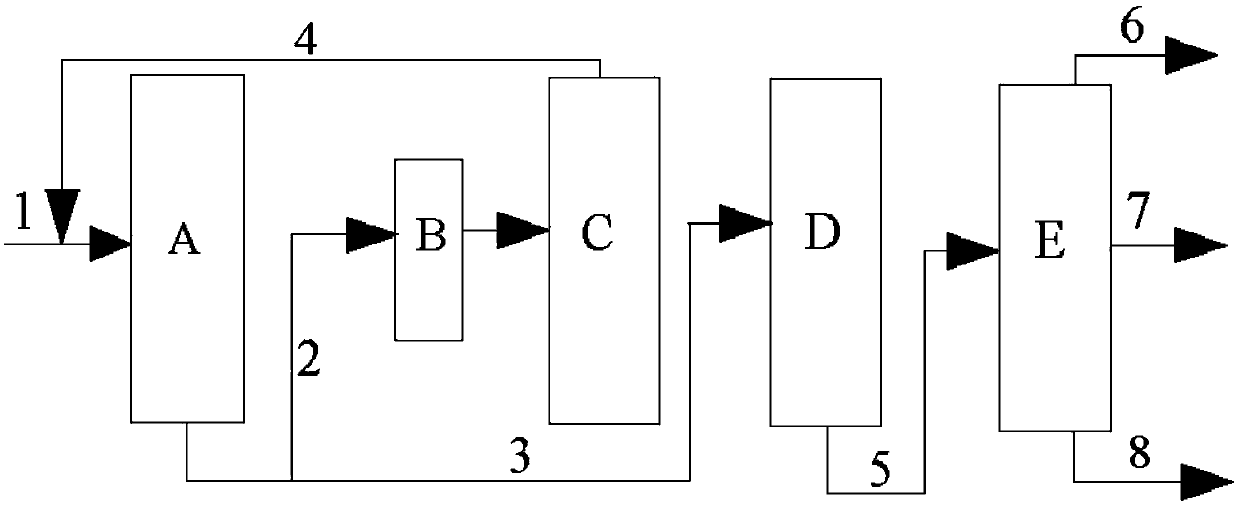

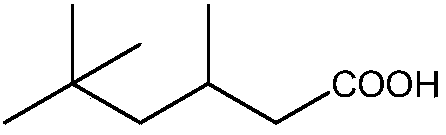

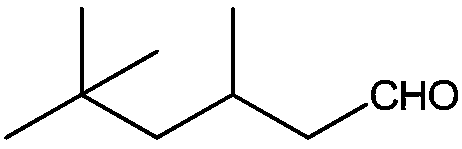

System and method for preparing isononanoic acid and method for preparing metal organic skeletal catalyst

ActiveCN108047027AHigh selectivityPromote decompositionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionMetal-organic framework

The invention provides a system and method for preparing isononanoic acid and a method for preparing a metal organic skeletal catalyst. The system includes an oxidation reactor used for oxidizing isononylaldehyde to isononanoic acid; a cooler used for cooling a part of material flow that flows out of the oxidation reactor; a metal ion separator used for separating excessive metal ions from the material flow that flows out of the cooler; a peroxide decomposition reactor used for decomposing a peroxide in the other part of the material flow that flows out of the oxidation reactor; and a rectification apparatus used for separating the material flow that flows out of the peroxide decomposition reactor to obtain the isononanoic acid product, wherein the material outlet of the metal ion separator is connected to the material inlet of the oxidation reactor. The invention further provides an isononanoic acid preparation method that is good in selectivity and safety and high in yield.

Owner:WANHUA CHEM GRP CO LTD

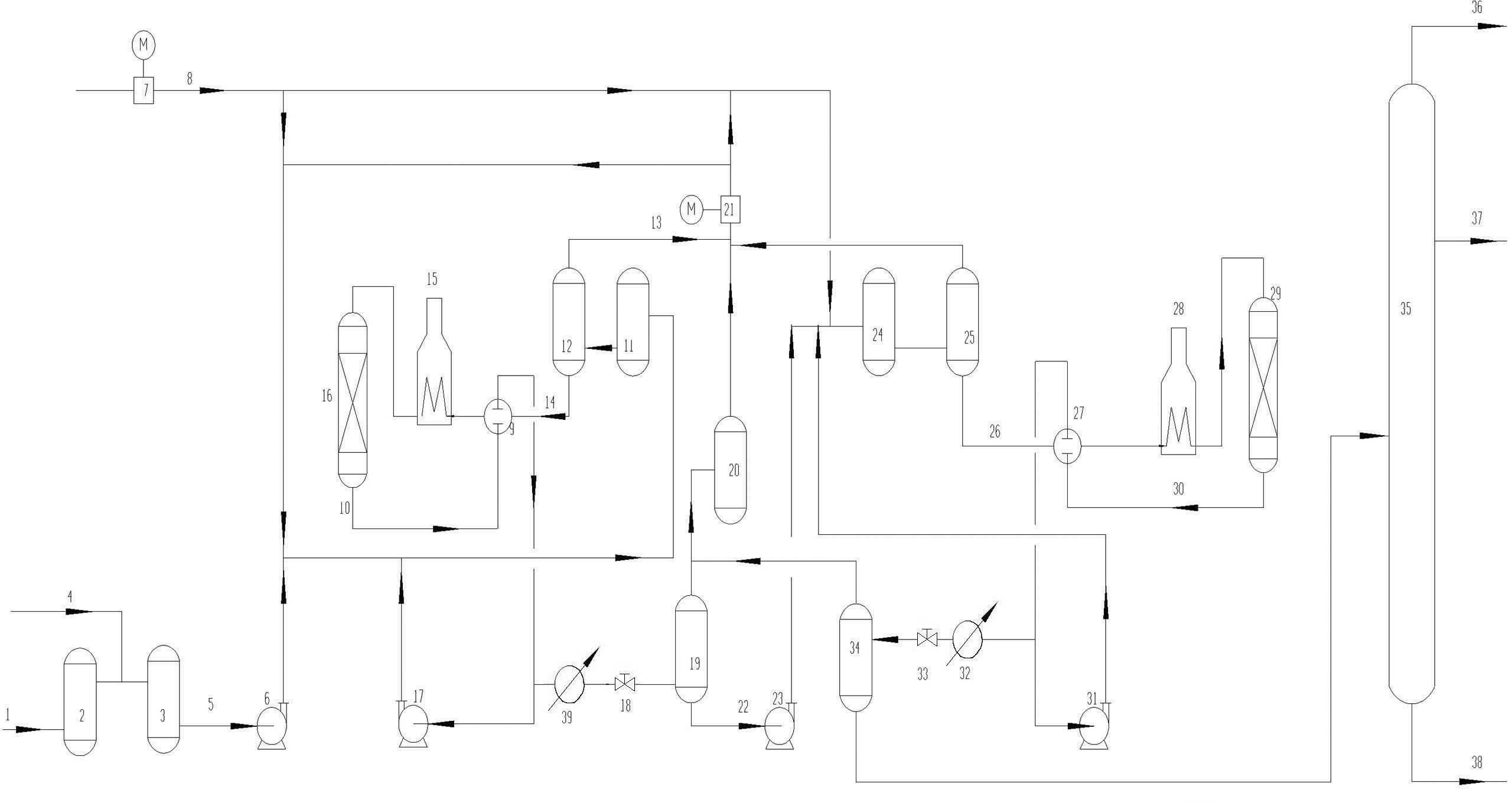

Full liquid phase hydrogenation method of coal tar

ActiveCN102585899ALess investmentRealize long cycle operationTreatment with hydrotreatment processesNaphthaFluid phase

The invention discloses a full liquid phase hydrogenation method of coal tar, which is characterized by comprising the following steps that coal tar raw materials respectively perform full liquid phase pre-hydrogenation reaction and full liquid phase main hydrogenation reaction, and main hydrogenation generated oil respectively generates naphtha products, diesel products and tail oil products through oil gas-liquid separation and distillation. The full liquid phase hydrogenation method enables the coal tar to perform the pre-hydrogenation reaction and the main hydrogenation reaction under the full liquid phase. The method can be suitable for hydrogenation modification of full fraction coal tar of any one or more of high-temperature coal tar, middle-temperature coal tar and low-temperature coal tar. During hydrogenation, coking can be effectively inhibited, reaction heat is controlled, energy loss is reduced, long-period running of a coal tar hydrogenation device is achieved, hydrogen consumption of the whole hydrogenation device can be reduced, investment of a compressor is reduced, and clean naphtha, diesel and tail oil products with sulfur nitrogen contents smaller than 400 parts per million (ppm) can be obtained.

Owner:CHANGLING PETRO CHEM ENG DESIGN

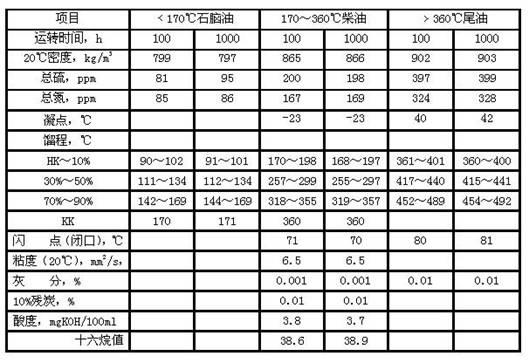

Anthracene oil hydrogenation method

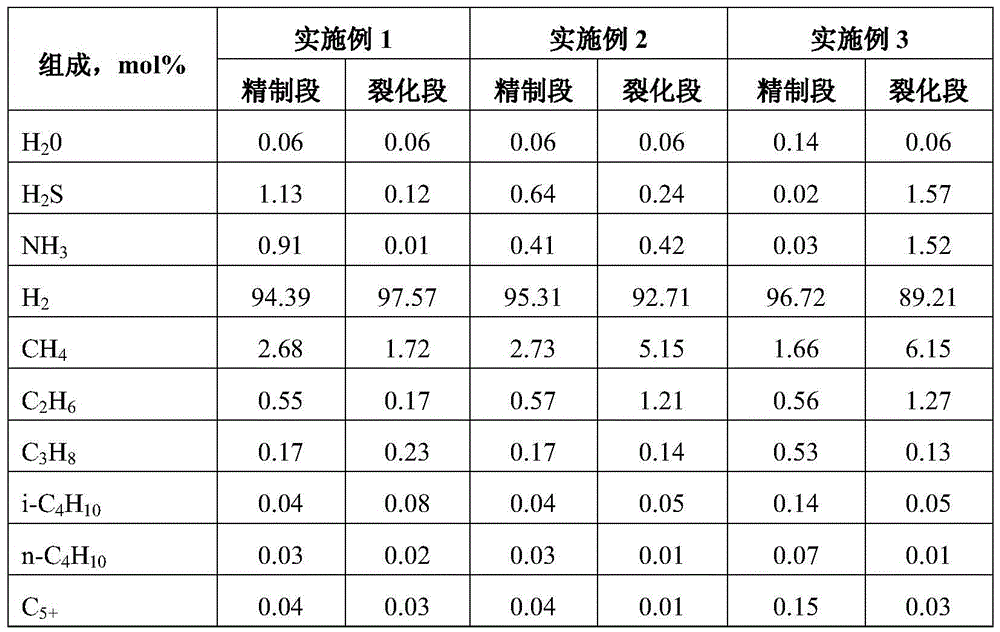

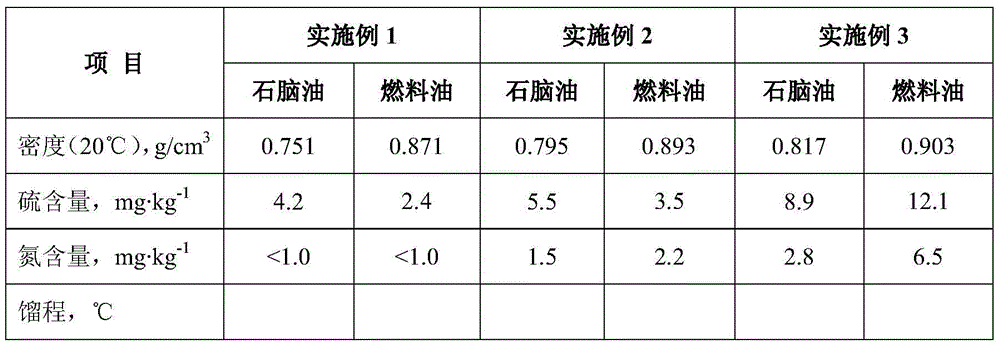

ActiveCN105462610AAdd depthIncrease liquid collectionTreatment with hydrotreatment processesAnthraceneHydrogen purity

The invention discloses an anthracene oil hydrogenation method. According to the method, anthracene oil is diluted with hot low-pressure segregator oil, and then the diluted oil and inlet hydrogen are mixed to undergo hydrofining so as to obtain a hydrofining product; the hydrofining product is separated to obtain refined hot low-pressure segregator oil; part of the refined hot low-pressure segregator oil and inlet hydrogen are mixed, and new hydrogen is supplemented to carry out hydrocracking so as to obtain a hydrocracking product; the hydrocracking product is separated to obtain cracked cold high-pressure segregator oil; the cracked cold high-pressure segregator oil and refined cold high-pressure segregator oil are mixed and separation is then carried out to obtain cold low-pressure segregator oil; and the cold low-pressure segregator oil undergoes fractionation so as to obtain a product. by the method of introducing inlet hydrogen in the hydrofining stage and supplementing new hydrogen in the hydrocracking stage, the hydrogen circulatory system and new hydrogen joint point are adjusted, hydrogen purity and hydrogen partial pressure in the hydrogen circulatory system are guaranteed, hydrofining and hydrocracking depth is enhanced, liquid yield of the product is raised, and tail oil quantity is reduced. The method has advantages of simple technological flow, high conversion rate and stable plant operation.

Owner:HUADIAN HEAVY IND CO LTD

Method for preparing modification aluminoxane

InactiveCN102190678AHigh reaction yieldIncrease productivityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsAluminoxaneAluminium alkyl

The invention discloses a preparation method for modification aluminoxane, comprising the following steps: a) preparing an inertia solvent solution of aluminium alkyl under the protection of an inert gas; b) mixing water, a modifier and an inertia solvent to prepare a hydrolysis agent under the protection of an inert gas; c) mixing the inertia solvent solution of aluminium alkyl and the hydrolysis agent in a T-type pipe reactor at a temperature of between -10 DEG C and -50 DEG C, flowing the mixture into a kettle reactor, heating the mixture to a temperature of between 10 to 100 DEG C and reacting for 1 to 10 hours; d) obtaining a reaction solution by filtering, reducing pressure to remove the solvent to obtain alkylauminoxane. According to the method of the invention, the interacting effect of the modifier and water is utilized to control the local concentration of water and the composition and concentration of the modifier are used to influence the composition of the generated aluminoxane so as to improve the storage stability and usage effect of the alkylauminoxane.

Owner:NORTHEAST GASOLINEEUM UNIV

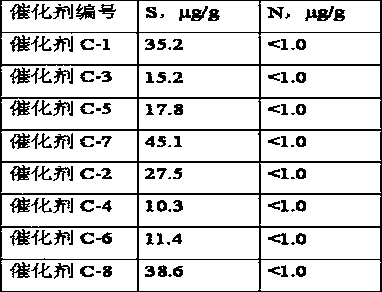

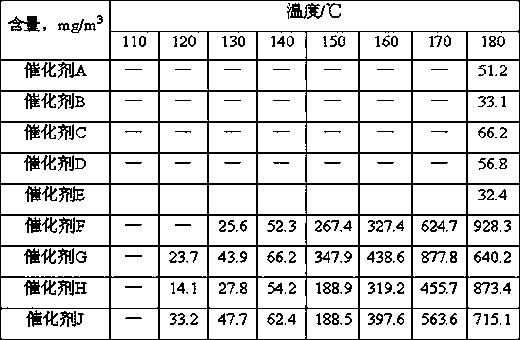

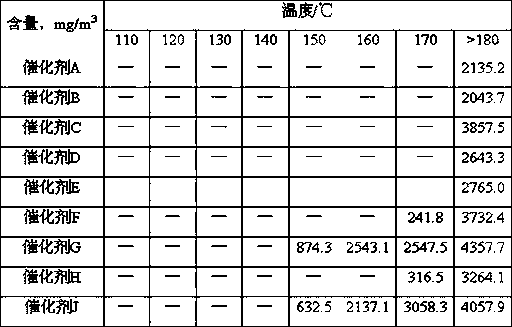

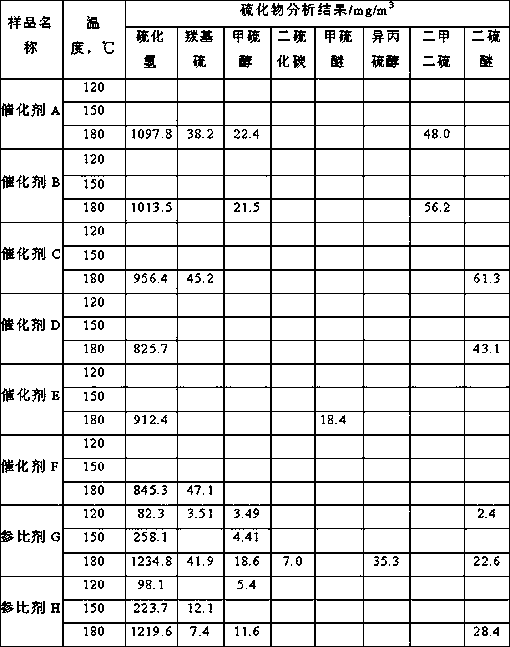

Deactivated catalyst regeneration method

ActiveCN109926103AGuarantee vulcanization qualityReduce dosageCatalyst regeneration/reactivationRefining to eliminate hetero atomsOrganic sulfide compoundBurn treatment

The invention provides a deactivated catalyst regeneration method, which comprises: (1) making a to-be-regenerated hydrogenation catalyst contact an oxygen-containing gas, and carrying out charcoal burning treatment to obtain a catalyst A; (2) making the catalyst A contact an organic compound solution, and carrying out heat treatment to obtain a catalyst B; and (3) introducing an organic sulfide and hydrazine hydrate into the catalyst B, and carrying out heat treatment to obtain a regenerated catalyst. The regeneration method of the present invention can increase the activity of the regenerated catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

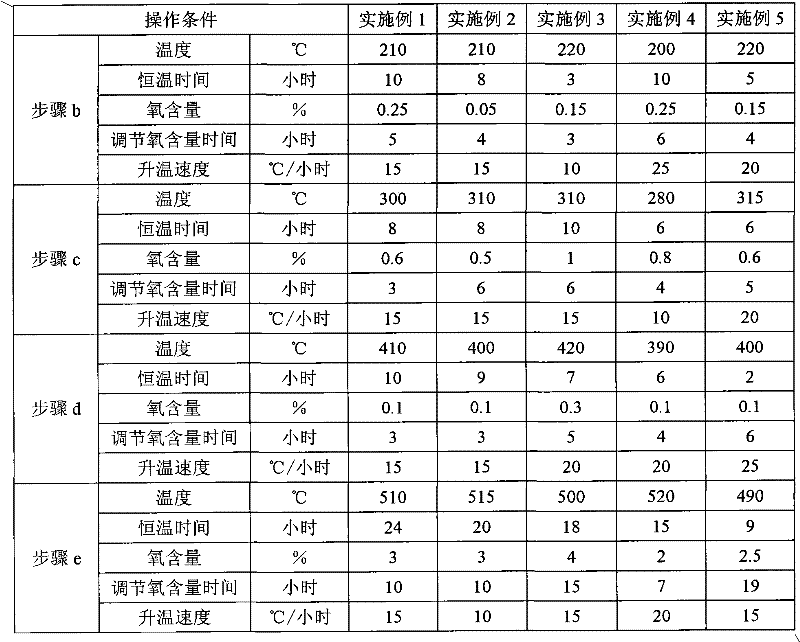

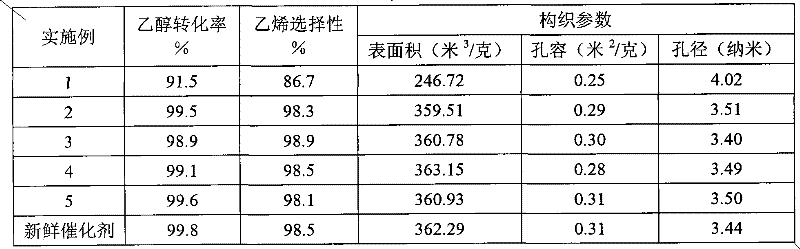

Regeneration method of catalyst for producing diphenylamine with phenylamine continuous condensation

ActiveCN101172262AAvoid lostFlexible switchingMolecular sieve catalystsCatalyst regeneration/reactivationActivity indexNitrogen

The invention relates to a catalyst regeneration method used for preparing diphenylamine by aniline consecutive condensation. The method is a method of coke burning regeneration of nitrogen including oxygen in an adoption device, and comprises the steps of purging the complete system with nitrogen to remove reaction mixture, reducing the temperature of the system and replacing the oxygen gas by nitrogen, wherein, the regenerated temperature and the oxygen content are strictly controlled by adopting a method of multiple step burning regeneration, the operation is simple, the regenerating time is short, and the physicochemical property and the activity index of the regenerated catalyst are basically identical to the fresh catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

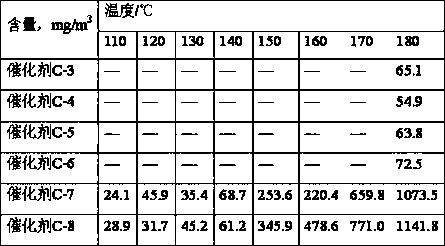

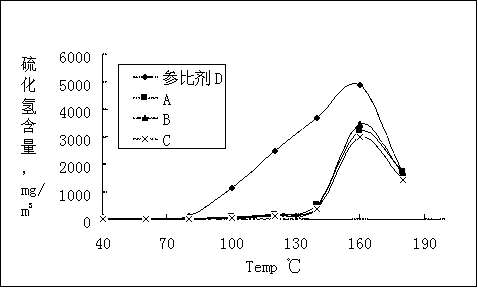

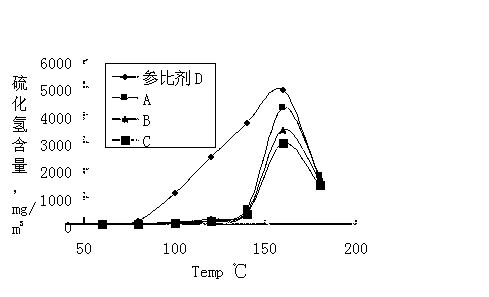

Preparation method of prevulcanization type catalyst

ActiveCN103100444ANo self-heatingNo flammability issuesCatalyst activation/preparationSimple Organic CompoundsVulcanization

The invention discloses a preparation method of a prevulcanization type catalyst. The method consists of: taking an oxidation state catalyst, adding an organic solvent and elemental sulfur, conducting heat treatment, then using an appropriate organic assistant to perform aftertreatment on the catalyst, thus obtaining the final prevulcanization type catalyst. The method enables the organic assistant and sulfur to form an organic compound, which does not decompose at low temperature, thus avoiding untimely contact of hydrogen and sulfur during startup activation, release of a hydrogen sulfide gas and the consequent influence on equipment air tightness. After high pressure air sealing, the compound of sulfur and the organic assistant decomposes. Hydrogen and sulfur react, the formed hydrogen sulfide and an active metal undergo catalyst activation in the pores of the catalyst, thus raising the initial temperature of vulcanization. After high pressure air sealing, activation oil is introduced to take away the heat generated by activation timely, thus avoiding temperature runaway of the catalyst bed and ensuring a smooth startup process. The catalyst prepared by the method involved in the invention is applicable to preparation of a petroleum fraction hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

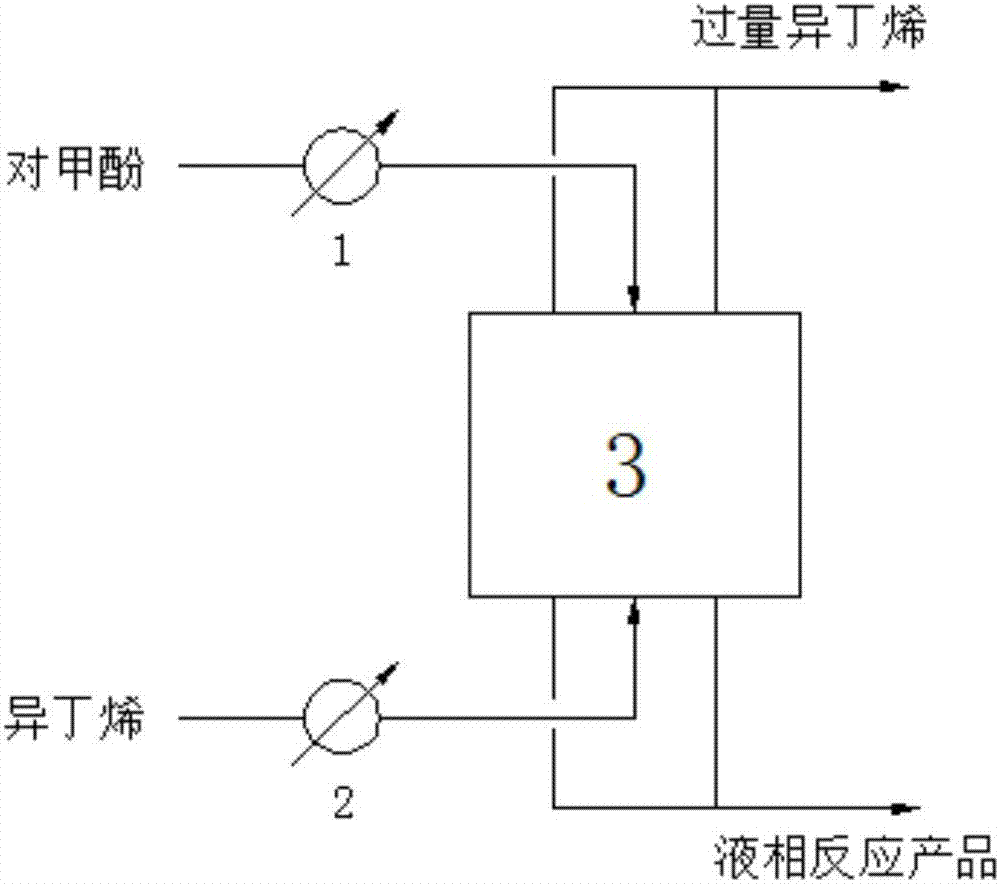

Method for preparing 2,6-ditertbutyl-4 methylphenol by using micro-reaction rectifying plate and device thereof

InactiveCN106866380AImprove conversion rateAvoid flying temperatureOrganic chemistryOrganic compound preparationChemistryBoiling point

The invention relates to a technology method for preparing 2,6-ditertbutyl-4 methylphenol by using a micro-reaction rectifying plate. The method comprises the following steps of preheating p-cresol to 70 to 90 DEG C by a first preheater, and sending into the micro-reaction rectifying plate via an upper center passage; meanwhile, preheating isobutene to 70 to 90 DEG C by a second preheater, and sending into the micro-reaction rectifying plate via a lower center passage; enabling the p-cresol and the isobutene to react in the micro-reaction rectifying plate, so as to generate a liquid-phase product; discharging via a lower side passage of the micro-reaction rectifying plate, and rectifying and separating the liquid-phase reaction product, so as to obtain the 2,6-ditertbutyl-4 methylphenol; crystallizing again, and drying, so as to obtain a finished product; discharging the excessive isobutene and a low-boiling point product from an upper side passage of the micro-reaction rectifying plate. The technology method has the advantages that the conversion rate of the p-cresol is high, the yield rate of the 2,6-ditertbutyl-4 methylphenol is high, the reaction temperature is low, and the temperature runaway is avoided.

Owner:HEBEI UNIV OF TECH

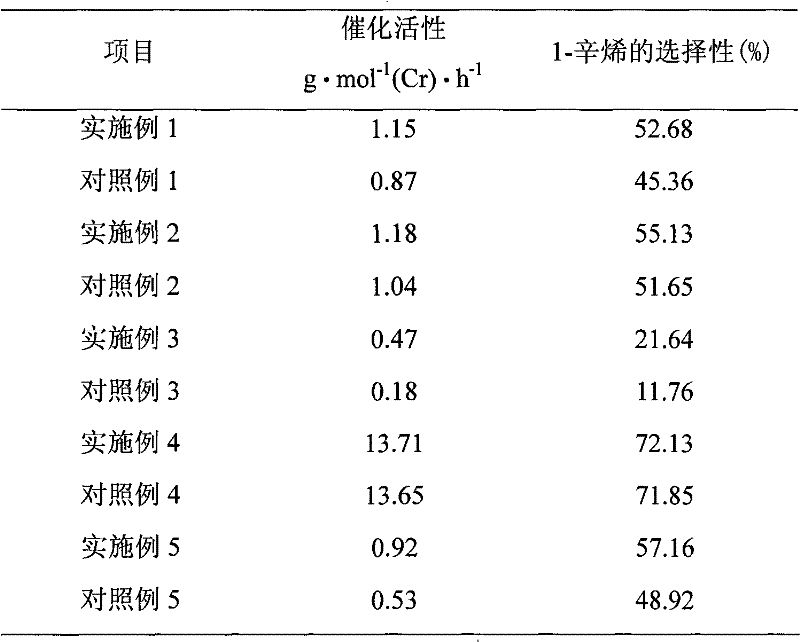

Iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as method

InactiveCN110639553ASimple compositionLow costOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsDiaminodiphenyl etherPtru catalyst

The invention discloses an iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as a method. The catalyst takes carbon coated foam copper as a carrier and loads Fe, Co and noble metal; and the mass contents of the Fe, the Co and the noble metal in the catalyst are sequentially 0.1 to 1.0 percent, 0.1 to 0.8 percent and 0.1 to 0.9 percent. The4,4-diaminodiphenyl ether is continuously produced by adopting the iron cobalt composite carbon copper catalyst, by taking 4,4-dinitrodiphenyl ether as a raw material and by performing nitro hydrogenation reaction on a catalyst bed by a trickle bed, the catalytic reaction efficiency is high, the reaction heat is concentrated, the carbon coated foam copper carrier can disperse the active componentsof the catalyst well, also can rapidly remove reaction heat and guarantees that the reaction is conducted within the proper temperature range rapidly and stably, the raw material conversion rate is 100 percent, the selectivity of target products is more than 99.9 percent, the catalyst property is stable, the catalytic reaction is too simple the catalytic reaction heat is recoverable, the heat energy utilization efficiency is high, and environmental friendliness is realized.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

A preparing method of large-pore diameter aluminium oxide

ActiveCN104340997ALow costAvoid flying temperatureAluminium oxides/hydroxidesAluminium hydroxidePore diameter

The invention relates to a preparing method of large-pore diameter aluminium oxide. The method includes: dissolving boehmite, pseudo boehmite or a mixture of boehmite and pseudo boehmite by any ratio into deionized water to form an aluminium hydroxide suspension liquid; performing stage heating treatment, with an initial temperature being 30-120 DEG C, a temperature gradient being 30-50 DEG C, and the treating time in each temperature state being 2-6 h; subjecting the treated aluminium hydroxide suspension liquid to hydrothermal ageing; and drying and calcinating after ageing is finished to finally obtain a large-pore diameter aluminium oxide product. The average pore size of the product is 90-300 angstroms, the most probable pore diameter is 90-280 angstroms, pore volume is 0.3-1.0 mL / g, and the specific surface area is 100-300 m<2> / g. The product has advantages of a large pore diameter, large pore volume, large specific surface area, easy adjustable product properties, and the like, and can be further processed into a catalyst carrier or an adsorbent having excellent performance.

Owner:PETROCHINA CO LTD

Preparation method and application of eggshell type composite metal catalyst

InactiveCN110420643AImprove catalytic performanceImprove thermal stabilityOrganic compound preparationCarbonyl compound preparationGas phaseMetal catalyst

The invention relates to an eggshell type composite metal oxide catalyst applied to gas phase oxidation of isobutylene / tert-butanol for synthesis of methylacrolein. A spherical carrier and a binder are added during the preparation of the catalyst, so a metal salt undergoes a reaction on the surface of the spherical carrier and adheres onto the surface of the spherical carrier; and a part of the binder is removed by roasting so as to obtain the eggshell type composite metal oxide catalyst. The catalyst provided by the invention is simple in preparation process and low in cost, and has excellentcatalytic performance in the gas phase oxidation of isobutylene / tert-butanol for synthesis of methylacrolein; and the catalyst has long catalytic life and is suitable for industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

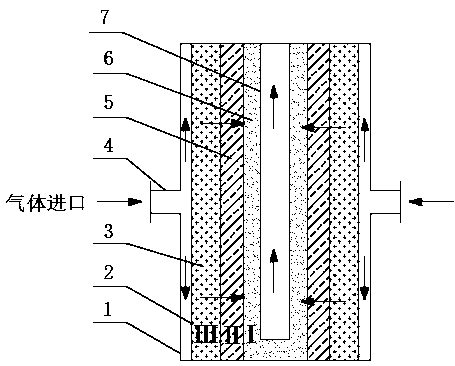

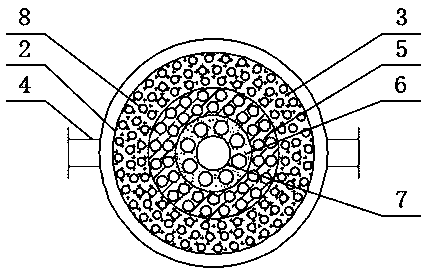

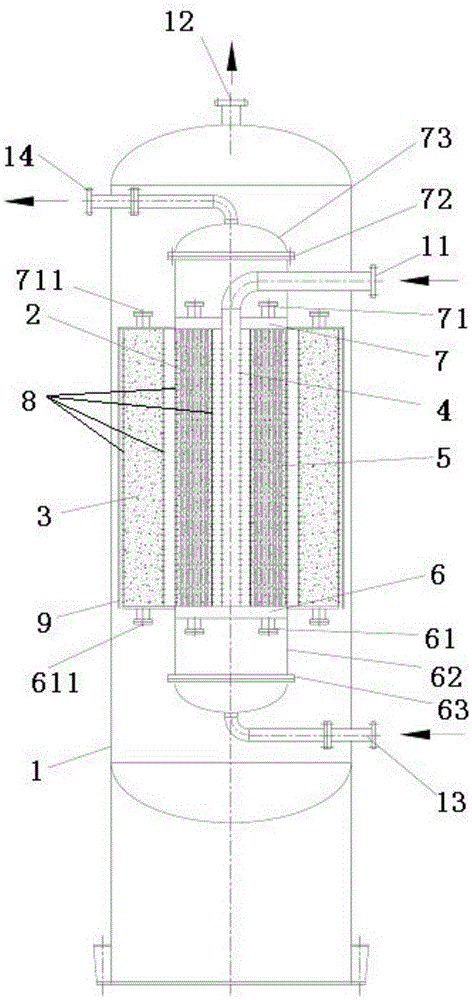

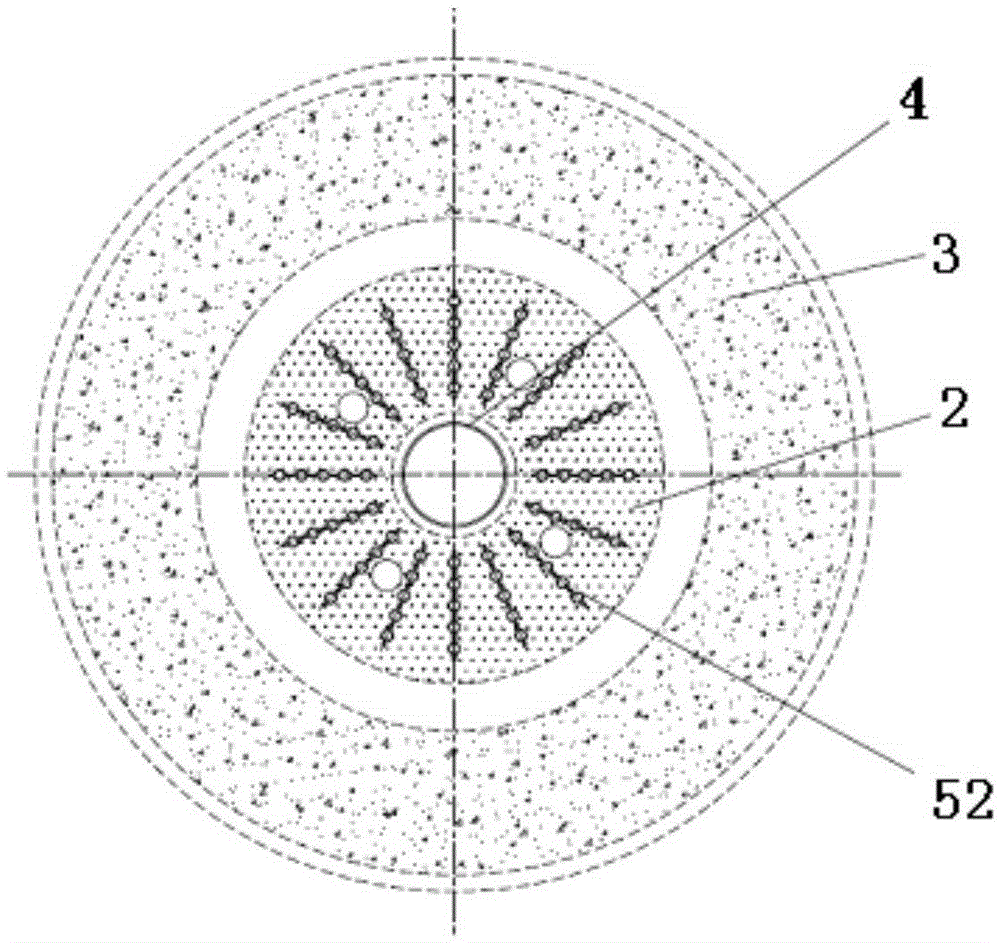

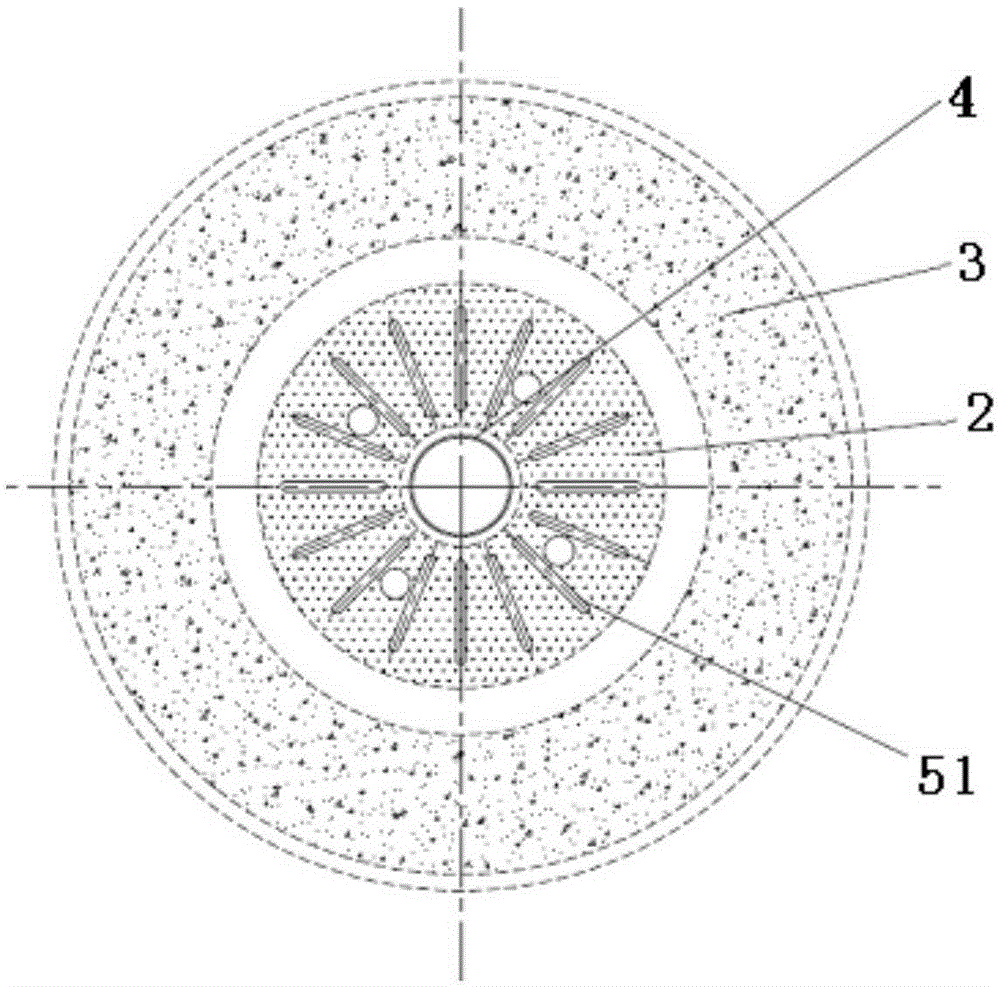

Catalytic reactor suitable for strong exothermic volume reduction

ActiveCN108554321AShorten the pathSmall pressure dropChemical/physical processesRadial positionProcess engineering

The invention provides a catalytic reactor suitable for strong exothermic volume reduction and relates to a catalytic reactor. The axis of the reactor adopts a U-shaped structure; the U-shaped axis isan inner air cylinder; a catalyst bed layer I (6), a catalyst bed layer II (5), a catalyst bed layer III (3), a gas distribution cylinder (2) and an outer air cylinder (1) are arranged at the periphery of the inner air cylinder (7) symmetrically from inside to outside; a gas inlet (4) is formed in the outer part communicated with the outer air cylinder (1); a heat exchange tube (8) is arranged inthe catalyst bed layer III (3); the reaction raw materials enter the catalyst bed layers along the periphery of the reactor and are discharged from the center of the reactor; the change of the gas volume and the flow channel area is matched; the quantity of reaction occurring at different radial positions is regulated and controlled; gradient filling of the catalyst is matched; heat of the tube bundles in the catalyst bed layers is transferred gradiently; and bed layer reaction heat balancing and heat exchange tube bundle heat transfer are completed. The reactor is particularly suitable for places of strong exothermic volume reduction reaction to realize uniformization of bed layer gas flow speed and bed layer temperature.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

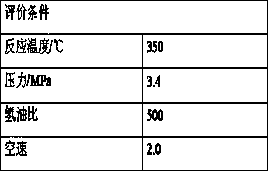

Vulcanization type hydrogenation catalyst starting method

ActiveCN109926100ASuppress overflowGuarantee vulcanization qualityCatalyst activation/preparationRefining to eliminate hetero atomsVulcanizationHydrogenation reaction

The invention discloses a vulcanization type hydrogenation catalyst starting method, which comprises: loading a vulcanization type hydrogenation catalyst composition into a reactor; carrying out nitrogen gas tightness; gradually introducing hydrogen gas after the nitrogen gas tightness is qualified; carrying out hydrogen gas low-pressure gas tightness; increasing the temperature and the pressure after the low-pressure gas tightness is qualified; carrying out high-pressure gas tightness; and after the high-pressure gas tightness is qualified, adjusting the pressure to a reaction pressure untilvulcanization is completed, adjusting the temperature to a reaction temperature, feeding raw material oil, and starting a hydrogenation reaction. With the starting method of the present invention, thevulcanization quality of the catalyst can be ensured, the gas tightness problem of the device can be solved, and the advantages of no environment pollution, economy and environmental protection can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of vulcanization type catalyst

ActiveCN103100395ASimple production processReduce manufacturing costPhysical/chemical process catalystsRefining to eliminate hetero atomsInorganic saltsVulcanization

The invention discloses a preparation method of a vulcanization type catalyst. The method comprises: adopting a dipping solution containing a sulfide precursor of active metal Mo or W and an inorganic salt of Ni or Co to dip a needed catalyst carrier, and then conducting after-treatment under certain vacuum degree and temperature, thus obtaining the vulcanization type catalyst. The method can control vulcanization of the catalyst under an appropriate temperature in a startup activation process, thus avoiding untimely vulcanization of the active metal, release of a hydrogen sulfide gas and the consequent influence on equipment air tightness. Meanwhile, in the after-treatment process, redundant water in catalyst pores are removed to prevent excess water in recycle hydrogen from influencing the catalyst activity during activation and corroding equipment. The catalyst prepared by the method provided in the invention is applicable to preparation of a petroleum fraction hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for preparing water-absorbent resin

The invention discloses a process for preparing absorbent resin comprising, charging water, sodium hydroxide, acrylic acid, N, N'-methylene di-propenamide and potassium peroxodisulfate into stirring still, homogenizing, going through preheating section, reaction section, heat preservation section in sequence, carrying out heat exchange and polymerization reaction.

Owner:WUHAN UNIV +1

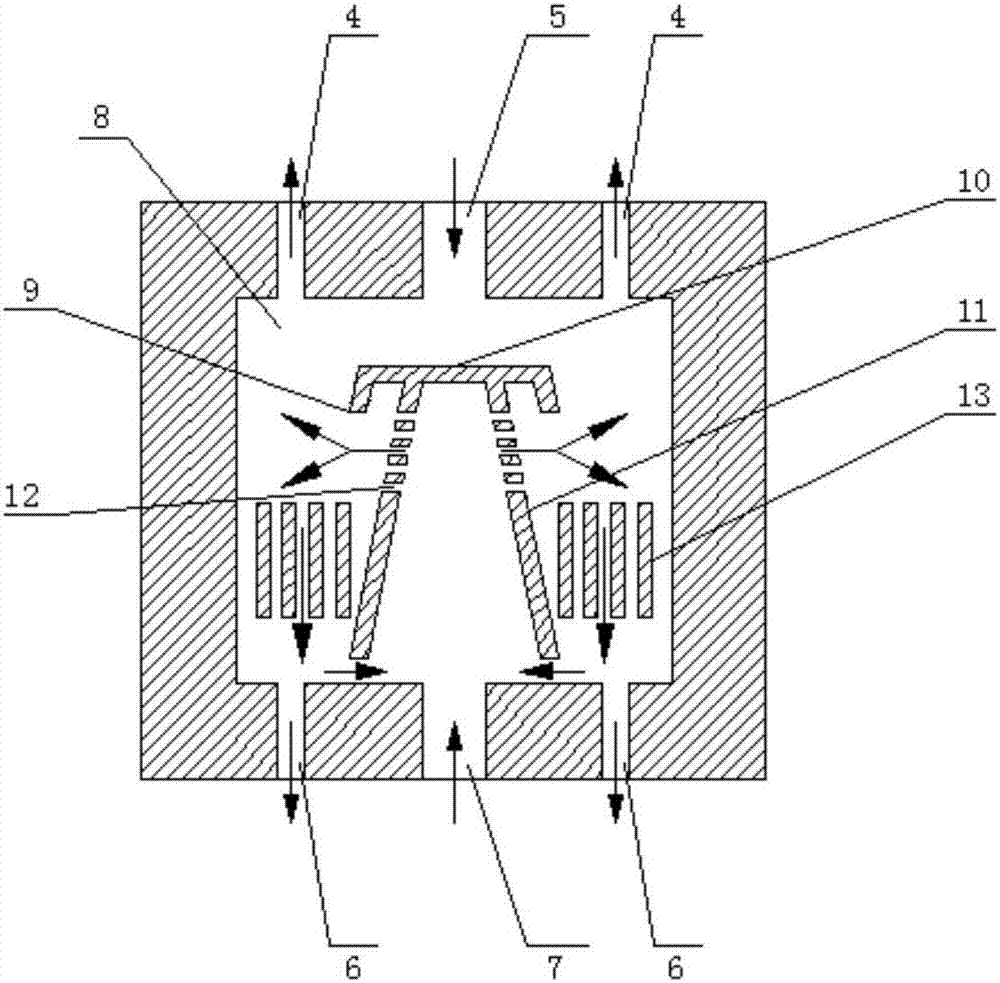

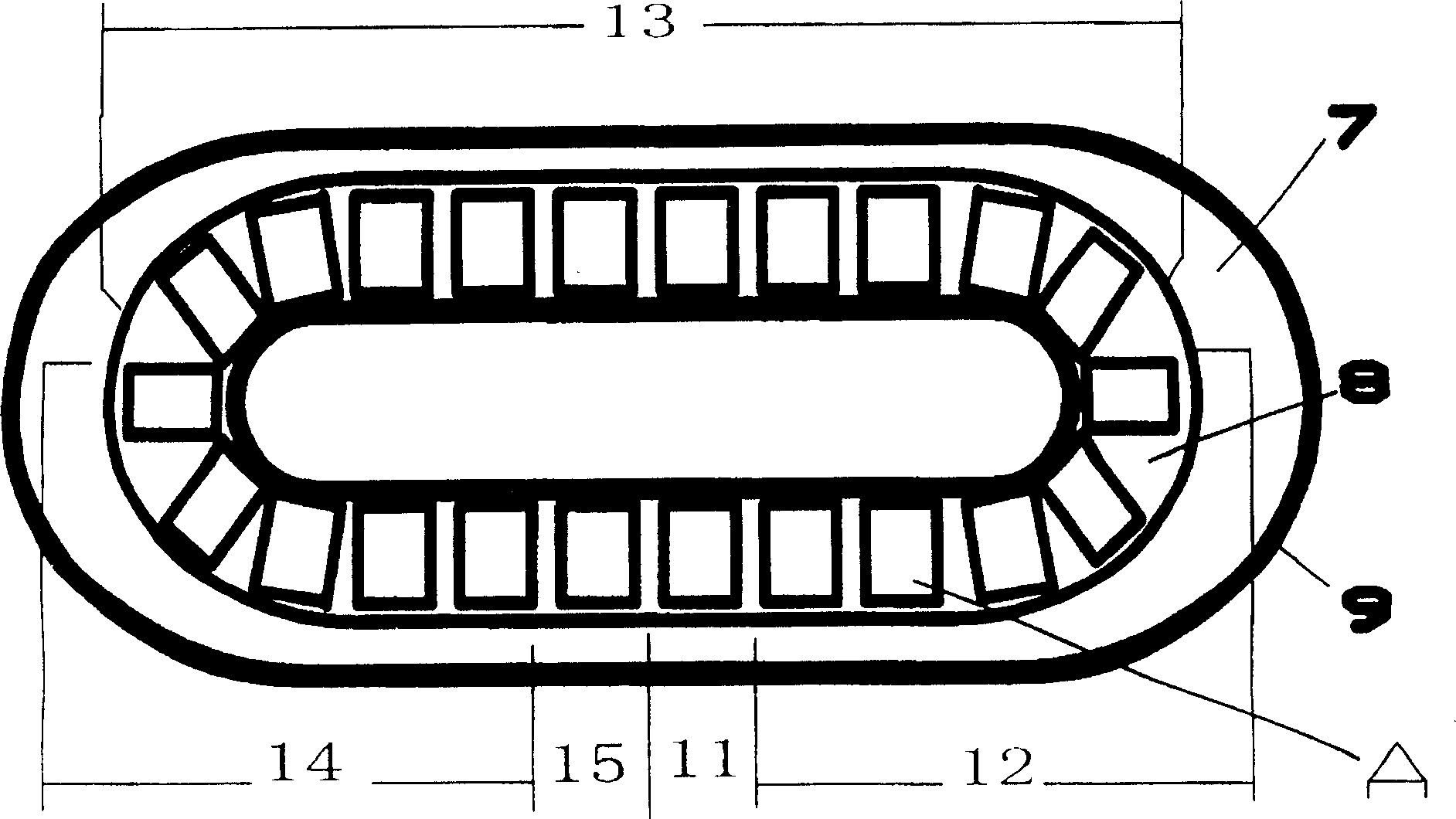

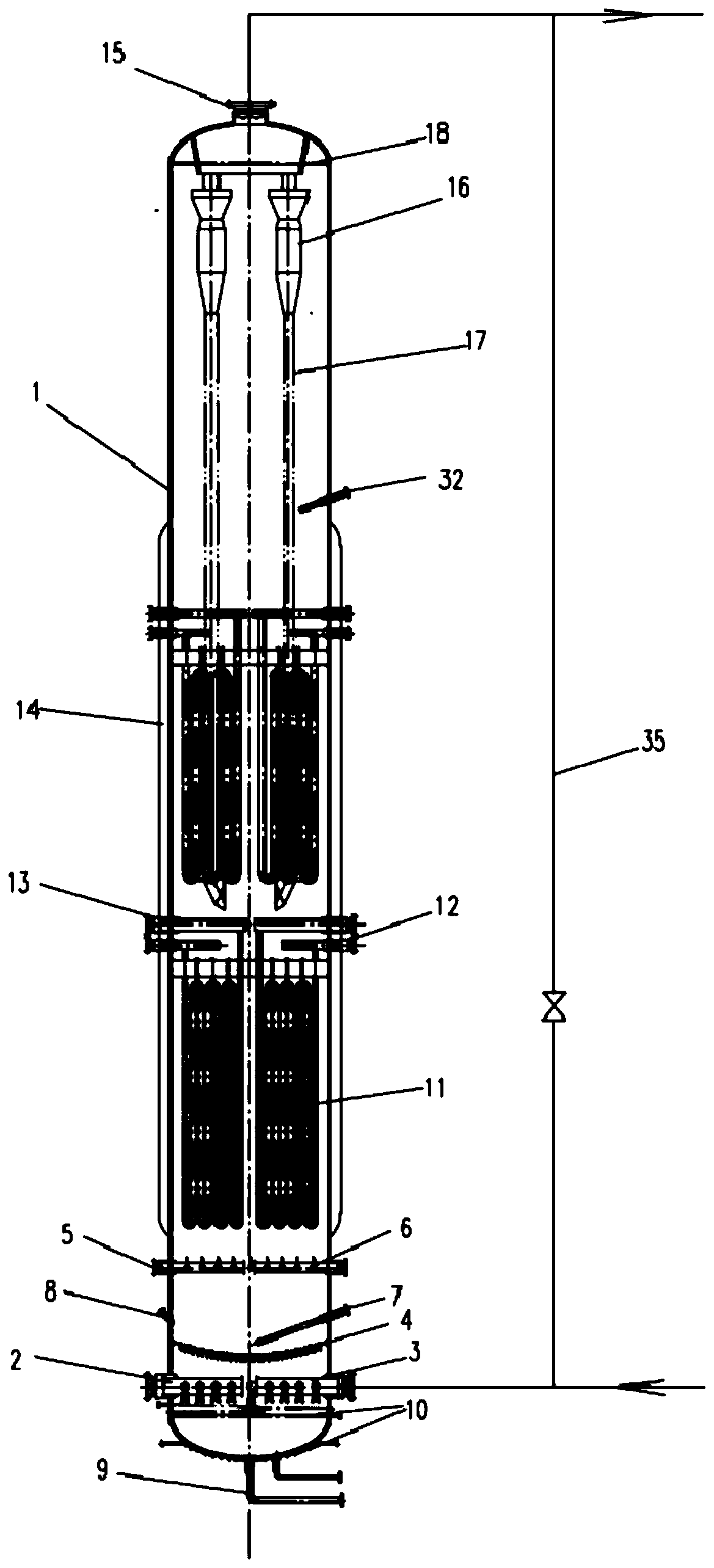

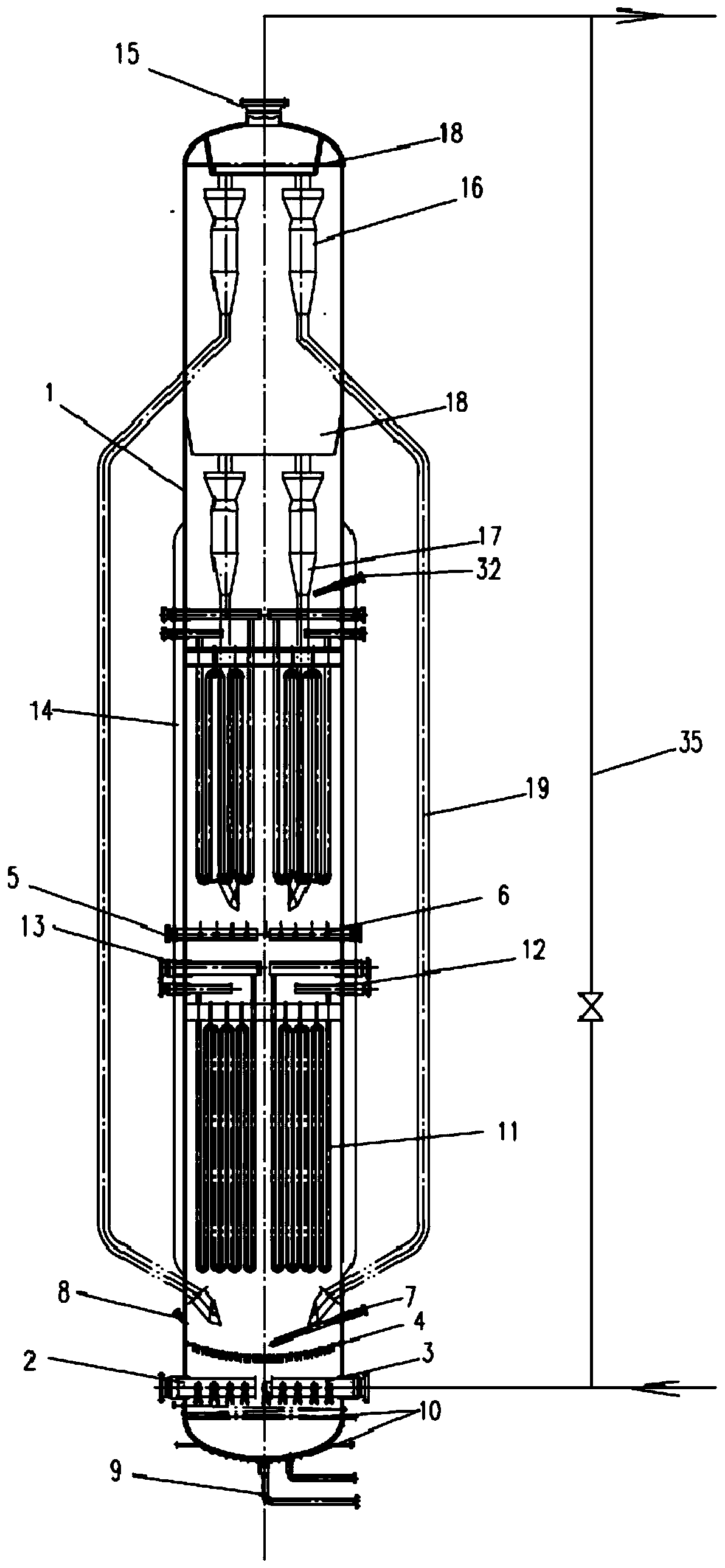

Fischer-Tropsch synthesis fluidized bed reactor

ActiveCN111286355AIncrease disturbancePlay a chilling roleLiquid hydrocarbon mixture productionChemical/physical processesPtru catalystFluidized bed

The invention relates to a Fischer-Tropsch synthesis fluidized bed reactor, wherein the fluidized bed reactor comprises a reactor cylinder and an internal component arranged in the reactor cylinder, and the internal component comprises a gas distribution mechanism, a heat exchange mechanism, a solid catalyst separation and circulation mechanism and a catalyst online feeding and discharging mechanism; the gas distribution mechanism comprises a first-stage gas distributor, a second-stage gas distributor and a third-stage gas distributor which is arranged in a main reaction dense-phase region ofthe fluidized bed reactor; the first-stage gas distributor and the second-stage gas distributor are arranged at the bottom of the reactor cylinder; a gas nozzle of the third-stage gas distributor transversely sprays gas to transversely cut longitudinally rising gas flow. Compared with the prior art, the reactor is reasonable in design structure and layout; the fluidized bed reactor is good in gas-solid contact in the reactor, uniform in fluid distribution, high in system heat transfer efficiency, uniform in temperature distribution, good in gas-solid separation effect, high in system operationflexibility and particularly suitable for design and operation of the large-scale Fischer-Tropsch synthesis fluidized bed reactor, and cavities in the fluidized bed reactor are avoided.

Owner:YANKUANG ENERGY R&D CO LTD

In-vessel regeneration method of zsm-5 zeolite catalyst for ethanol dehydration

InactiveCN102294263APhysical and chemical properties are the sameThe activity index is the sameMolecular sieve catalystsCatalyst regeneration/reactivationCombustionNitrogen gas

The invention relates to an in-device regeneration method for ethanol dehydration ZSM-5 zeolite catalyst, which mainly solves the problem of poor regeneration effect of the regeneration method in the prior art, thus affecting the life of the catalyst, reaction conversion rate and yield, and device shutdown caused by catalyst replacement It takes a long time to affect the output of the device. The present invention adopts the method for regeneration by burning carbon with oxygen-containing nitrogen in the device, including purging the whole system with nitrogen to remove the reaction mixture, stepwise combustion regeneration with oxygen-containing nitrogen, cooling the system and replacing the oxygen-containing gas with nitrogen. The problem is solved, and the method can be used in the industrial production of ethylene prepared by catalyzing ethanol dehydration with ZSM-5 zeolite catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vulcanization type catalyst starting method

ActiveCN109926101AGuarantee vulcanization qualitySolve the airtight problemCatalyst activation/preparationHydrocarbon oil crackingVulcanizationHydrogenation reaction

The invention discloses a vulcanization type catalyst starting method, which comprises: loading a vulcanization type hydrogenation catalyst composition into a reactor; carrying out nitrogen gas tightness; gradually introducing hydrogen gas after the nitrogen gas tightness is qualified; carrying out hydrogen gas low-pressure gas tightness; increasing the temperature and the pressure after the low-pressure gas tightness is qualified; carrying out high-pressure gas tightness; and after the high-pressure gas tightness is qualified, adjusting the pressure to a reaction pressure until vulcanizationis completed, adjusting the temperature to a reaction temperature, feeding raw material oil, and starting a hydrogenation reaction. With the starting method of the present invention, the vulcanizationquality of the catalyst can be ensured, the gas tightness problem of the device can be solved, and the advantages of no environment pollution, economy and environmental protection can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Macroporous aluminum oxide with bimodal pore distribution and preparation method thereof

ActiveCN102030351BAvoid flying temperatureReduce manufacturing costAluminium oxides/hydroxidesOrganic solventAge method

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing glyoxylate

InactiveCN109574843AAvoid excessive oxidationAvoid decompositionOrganic compound preparationCarboxylic acid esters preparationActive componentDehydrogenation

The invention relates to a method for producing glyoxylate. The method comprises the step of enabling oxygen-containing gas to pass through a reactor with a catalyst under the condition of oxidative dehydrogenation. The reactor comprises n sections of catalyst bed layers; the contents of catalyst active components in the n catalyst bed layers from an inlet to an outlet of the reactor are graduallyincreased; and n is an integer between 2 and 10. The method can be used for industrial production of the glyoxylate.

Owner:CHINA PETROLEUM & CHEM CORP +1

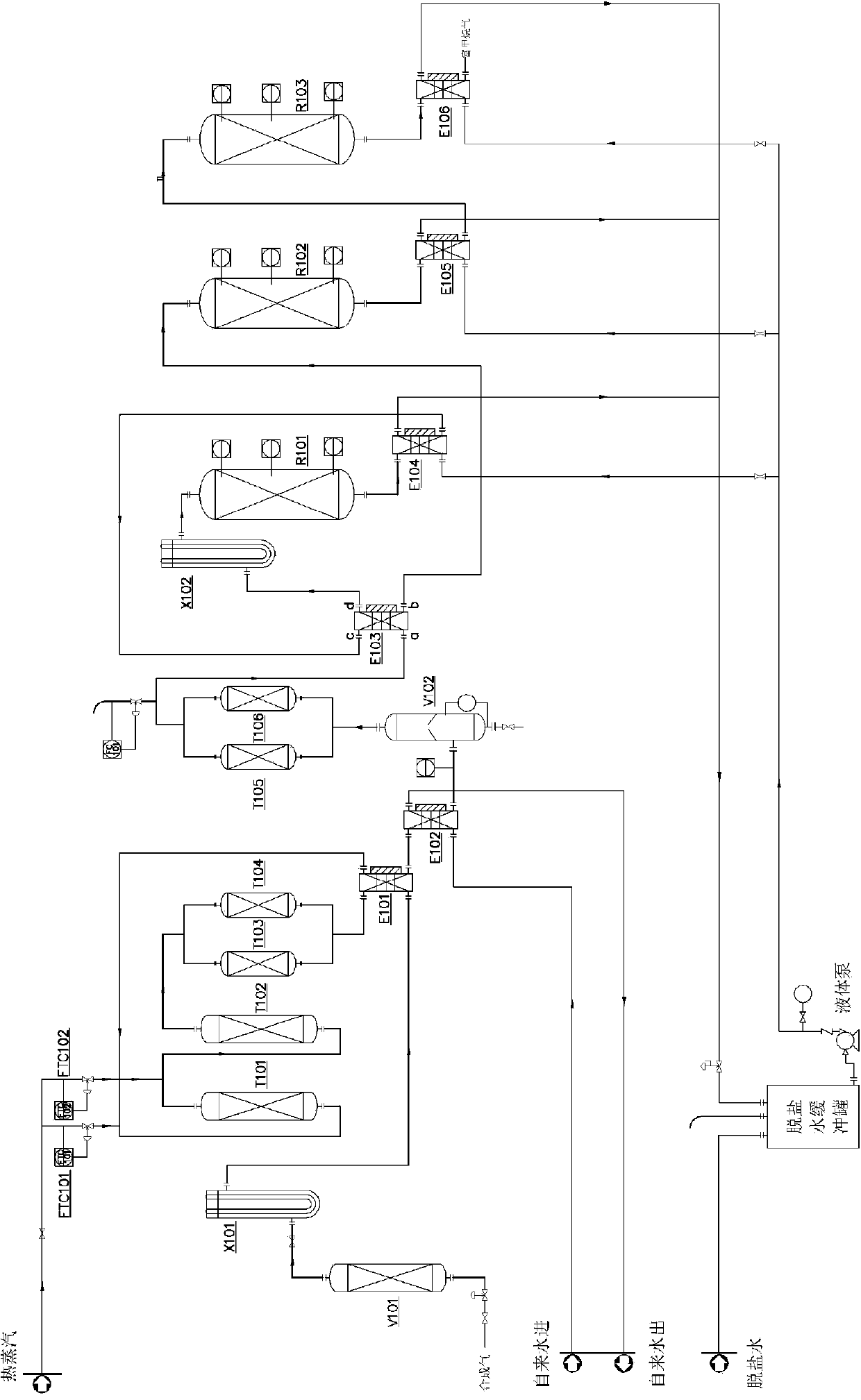

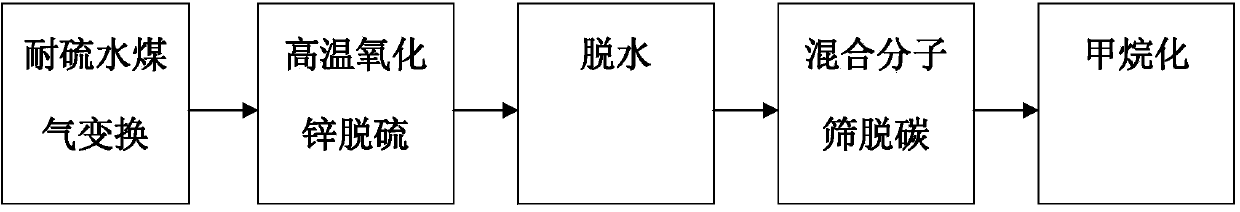

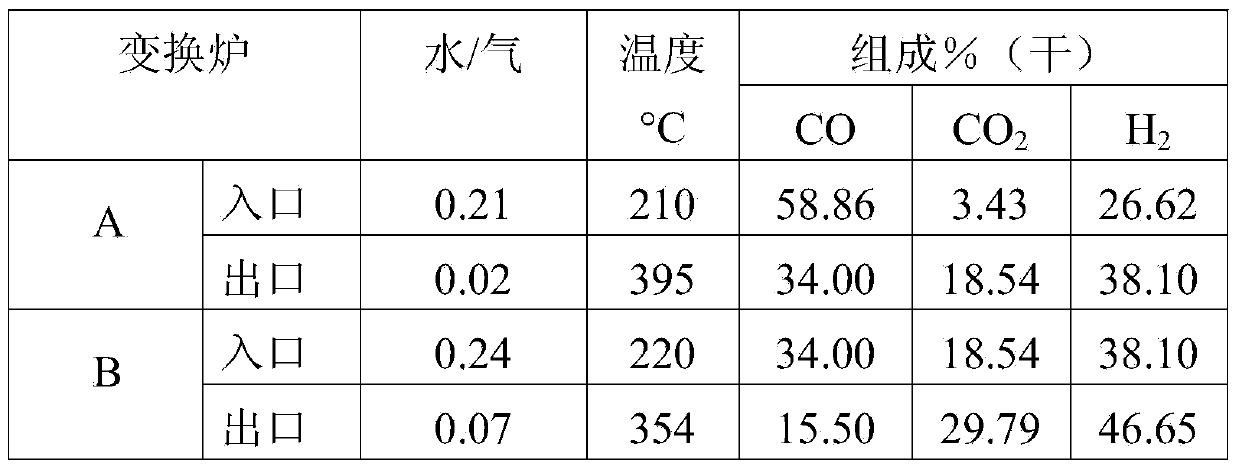

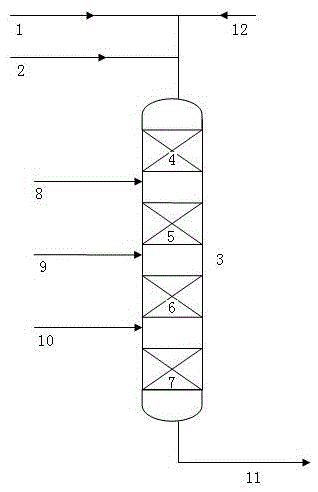

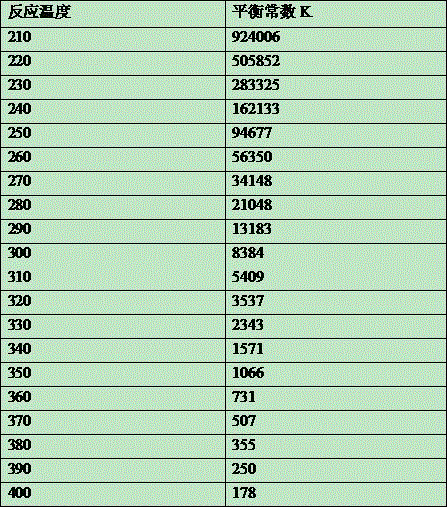

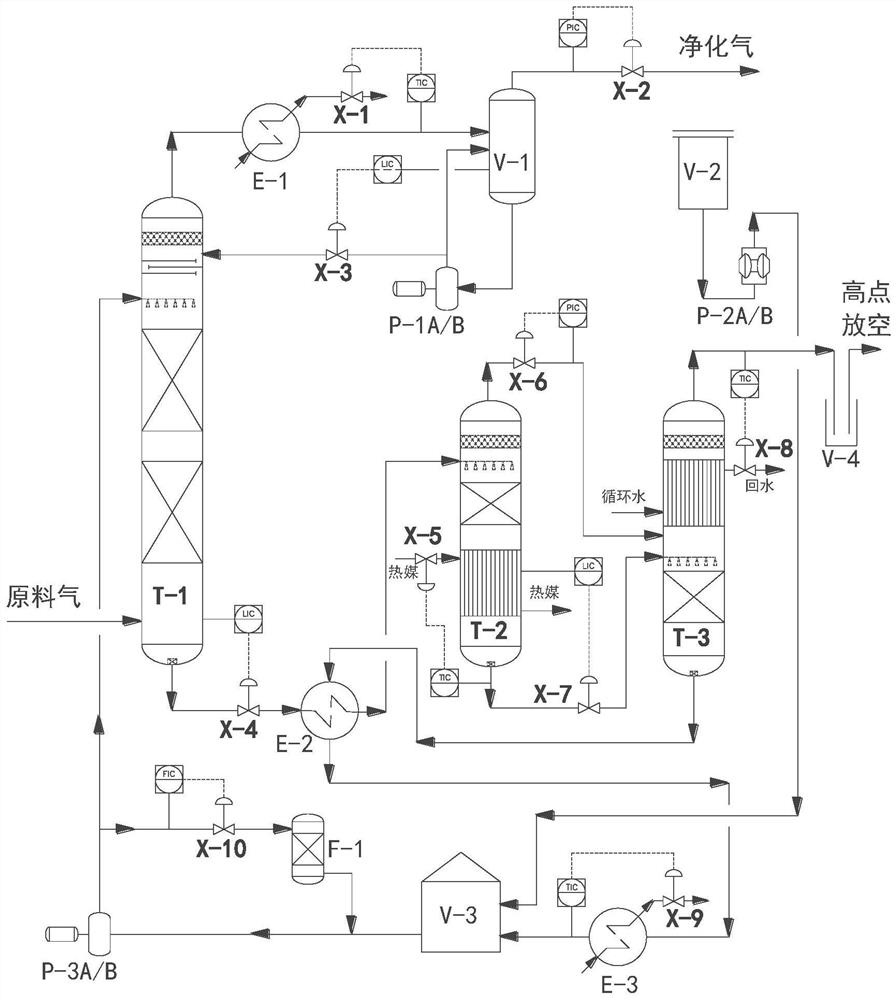

Movable coal synthesis gas metnanation catalyst testing platform and testing method

ActiveCN103468336AImprove applicabilityReasonable design structureHydrogen separation using solid contactGaseous fuelsSulfur waterMethanation

The invention discloses a movable coal synthesis gas metnanation catalyst testing platform and a testing method. The testing platform comprises a gas component conversion and purification part and a gas methanation part which can be transported in a container, wherein the gas component conversion and purification part comprises a sulfur water resistant coal gas conversion device, a moderate temperature zinc oxide desulfurization device, a gas-water separation device, and an NaOH and 5A molecular sieve column decarbonization device; and the gas methanation part is a three-section methanation reactor device. The testing method comprises the steps that 1, the sulfur water resistant coal gas conversion device converts a ratio of hydrogen to carbon monoxide in coal gas into an appropriate value; 2, the moderate temperature zinc oxide desulfurization device reduces sulfur content to below 0.2ppm; 3, the gas-water separation device separates water in the coal gas; 4, the NaOH and 5A molecular sieve column decarbonization device performs decarbonization to enable the content of carbon to be below 20 ppm; and 5, the three-section methanation reactor device performs coal gas methanation reaction. The platform is used for testing an optimal methanation reaction condition of various gas source conditions, adapts to testing of different virgin gas components, different operation conditions and different catalysts, and can test and evaluate a methanation technology, an operation parameter and catalyst performance.

Owner:HUANENG CLEAN ENERGY RES INST +1

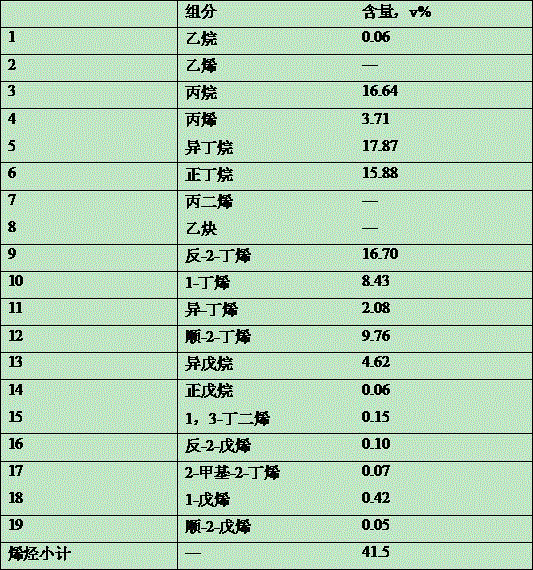

Method for preparing ethylene cracking feed by hydrogenation of liquefied gas

ActiveCN106753561AReduce reaction temperature rise"warm bag" gentleGaseous mixture working upHydrocarbon oils treatment productsHydrogenation reactionReaction temperature

The invention discloses a method for preparing ethylene cracking feed by hydrogenation of liquefied gas. Liquefied gas and hydrogen pass through a hydrogenation reactor in a parallel flow manner and is in contact with hydrogenation catalysts for reaction; two or more hydrogenation catalyst bed layers are arranged in the hydrogenation reactor; the hydrogen enters the two or more hydrogenation catalyst bed layers from different feeding openings respectively; the amounts of the hydrogen entering all the hydrogenation catalyst bed layers are 5 to 95 volume percent of chemical hydrogen consumption required by reaction separately; except the last hydrogenation catalyst bed layer, the sum of total amounts of the hydrogen entering other hydrogenation catalyst bed layers is smaller than the required chemical hydrogen consumption. According to the method disclosed by the invention, by controlling partial pressures of the hydrogen entering different catalyst bed layers, the reaction speed is effectively controlled, and accurate control over the conversion rate is realized, so that reaction temperature rise of all sections of catalyst bed layers in the reactor is reduced, further the carbon deposit speed of the catalyst is retarded, and the single-pass service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined type fixed bed reactor and device formed thereby

ActiveCN105413592AIncrease profitPromote absorptionChemical/physical processesRetention timeDevice form

The invention provides a combined type fixed bed reactor. The combined type fixed bed reactor comprises a shell, an isothermal reaction bed layer, a heat insulation reaction bed layer, a gas distributor and a gas guiding structure, wherein the gas distributor, the isothermal reaction bed layer and the heat insulation reaction bed layer are sequentially arranged in a sleeving way, and gaps are formed between every two of the gas distributor, the isothermal reaction bed layer and the heat insulation reaction bed layer; a heat exchange structure is arranged in the isothermal reaction bed layer and comprises a plurality of heat exchange pieces which penetrate through the isothermal reaction bed layer along the axial direction. According to the combined type fixed bed reactor provided by the invention, and a process gas flows along the radial direction after entering a catalyst bed layer; for a reaction of which the gas flow is increased, the gas flow speed is prevented from being increased through an external expansion type flowing way, the retention time of the process gas in the catalyst bed layer is prolonged, the reaction can be promoted to proceed completely, and the utilization rate of a catalyst is increased; meanwhile, since the heat insulation reaction bed layer is arranged at the outer part of the isothermal reaction bed layer, heat of the isothermal reaction bed layer is facilitated to be absorbed, on one hand, the heat exchange amount is reduced, and on the other hand, a heat insulation reaction is promoted to proceed.

Owner:BEIJING EDGEIN TECH

Device and process for decarburization of gas containing high-concentration CO2 and regeneration of amine liquid

PendingCN111849578ASimple processReduced calorie intakeDistillation regulation/controlGaseous fuelsCirculator pumpEngineering

The invention discloses a device and a process for decarburization of gas containing high-concentration CO2 and regeneration of amine liquid. The device comprises an absorption tower, an amine liquidprimary flash tower, an amine liquid secondary flash tower, a purified gas cooler, a lean / rich amine liquid heat exchanger, a lean amine liquid cooler, an amine liquid filter, an absorption tower cleaning pump, a charging pump, an amine liquid circulating pump, a purified gas-liquid separator, a charging tank, a solution buffer tank, a liquid seal tank and a regulating valve. The device is suitable for the process for regenerating the amine liquid after decarburization of high-acid natural gas or synthetic gas with the acid gas content of 35% (mol%), and the carbon content of the purified gasis controlled to be not higher than 2.5% (mol%). According to the device, the amine liquid primary flash tower and the amine liquid secondary flash tower are used for replacing a regeneration tower, only part of heat is provided for the lower portion of the primary flash tower, the heat taking amount is greatly reduced, and energy consumption of the device is reduced; a traditional amine-rich liquid flash tank is replaced by the primary flash tower, and a carbon dioxide gas-liquid separator and a regeneration tower reflux pump do not need to be arranged in the process due to the secondary flash tower, so that the quantity of equipment is greatly reduced, and the process is greatly simplified.

Owner:XINDI ENERGY ENG TECH

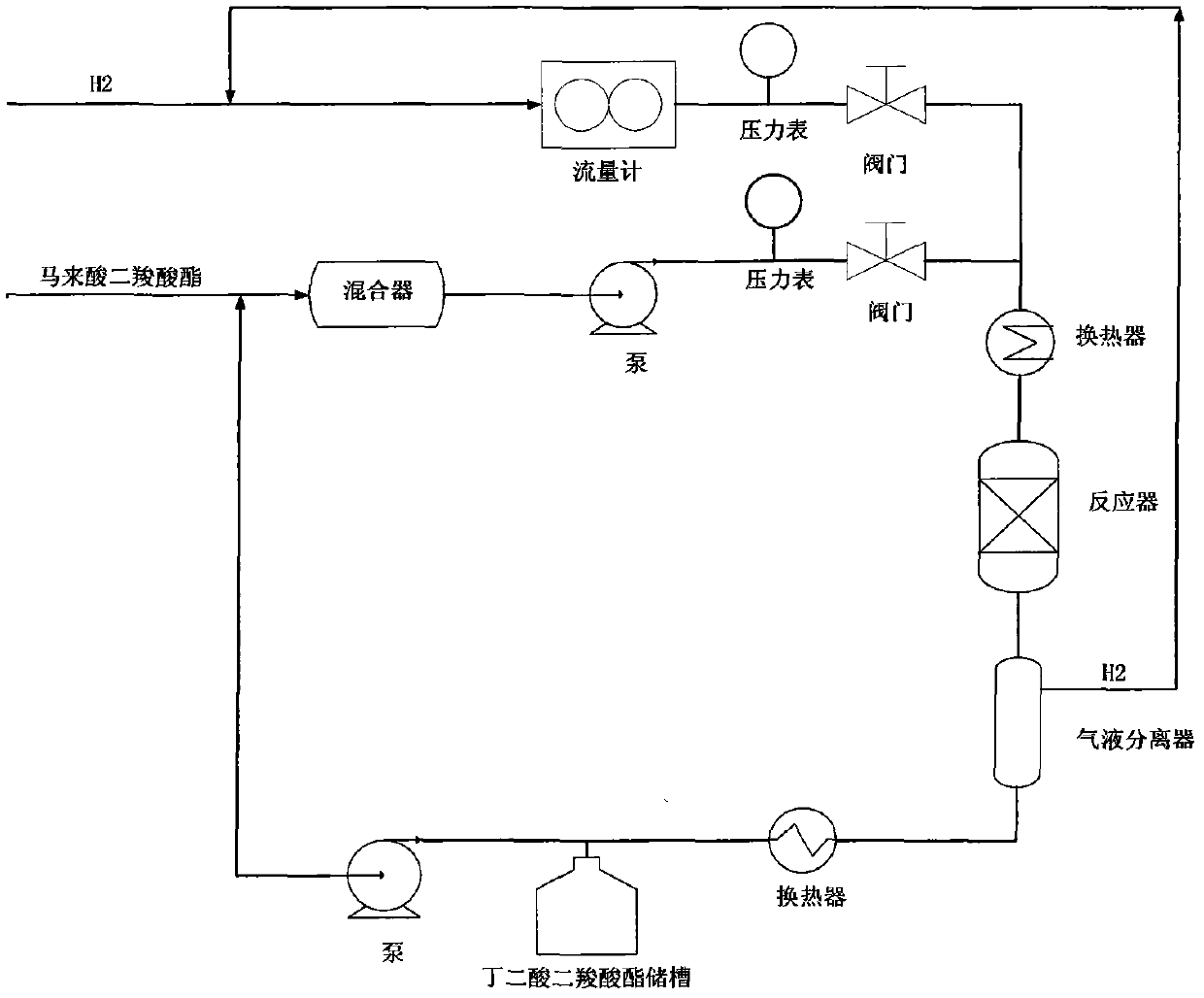

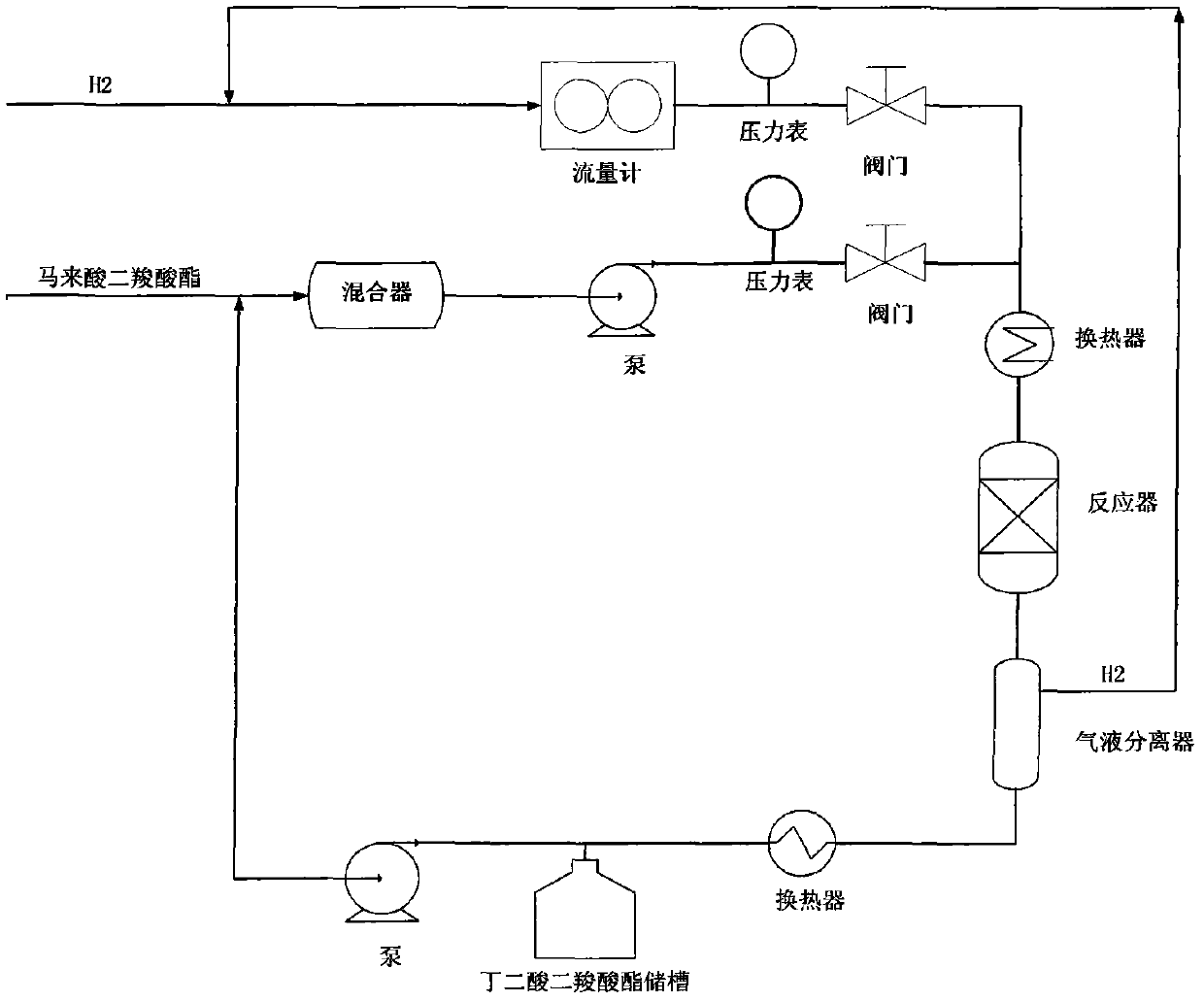

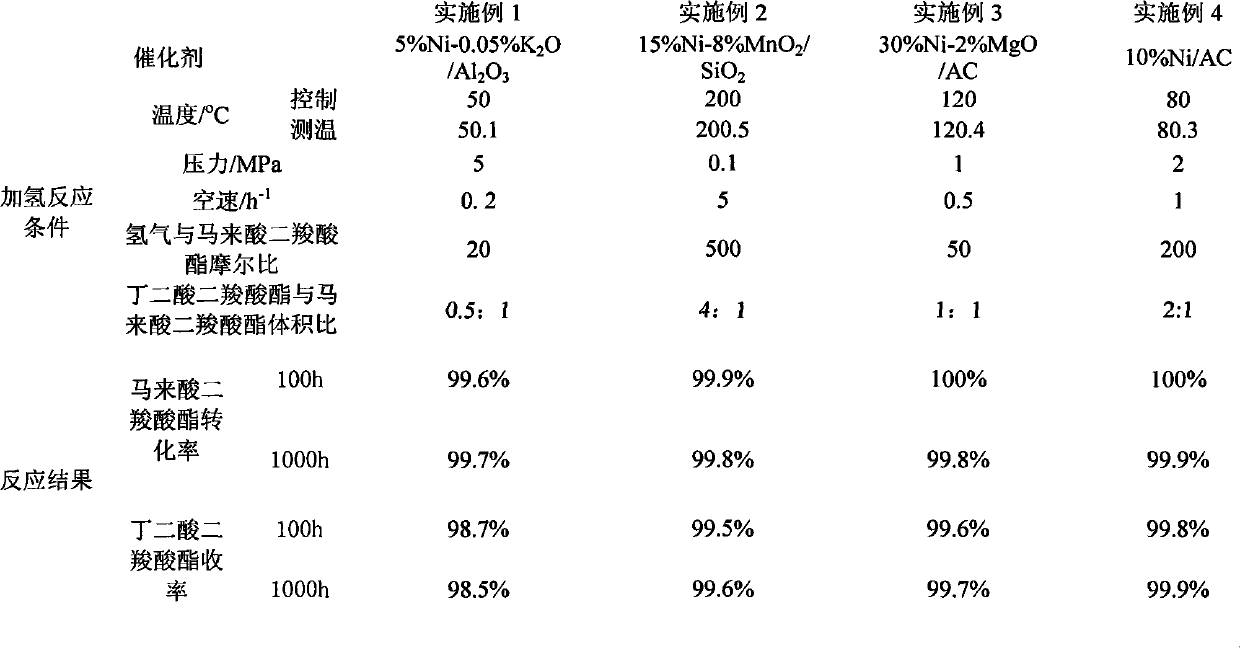

Method for preparing succinate

ActiveCN102001939AExtended service lifeHigh activity and selectivityOrganic compound preparationCarboxylic acid esters preparationBy-productFixed bed

The invention discloses a method for preparing succinate. The method comprises the following steps of: mixing hydrogen and maleic acid ester, and performing hydrogenation with a fixed bed reactor filled with a hydrogenation catalyst to obtain the succinate; and partially circulating the generated succinate, mixing with the maleic acid ester to obtain raw materials, and feeding a product subjectedto hydrogenation into a gas-liquid separator to obtain succinate with content of over 99.6 percent, wherein the separated hydrogen can be recycled. The method has the advantages that: raw materials are diluted in a reaction product circulation mode, so that temperature runaway caused by hydrogenation heat release can be effectively avoided, by-products of the reaction is very few, and the servicelife of the catalyst is prolonged and the stability of the catalyst is improved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com