Patents

Literature

312results about How to "Prevent overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

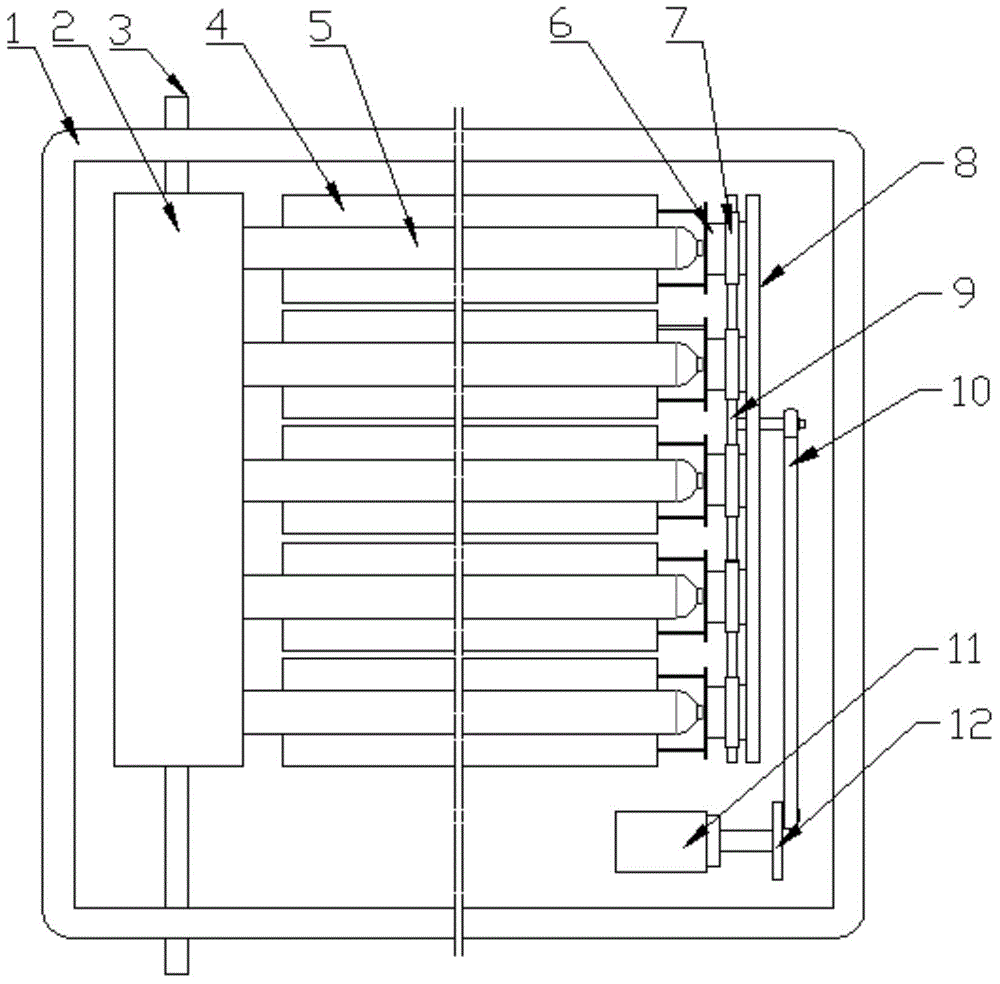

Novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes

ActiveCN104258796APrecisely control the feeding ratioPrevent "overheating"Chemical/physical/physico-chemical processesCapillary TubingEngineering

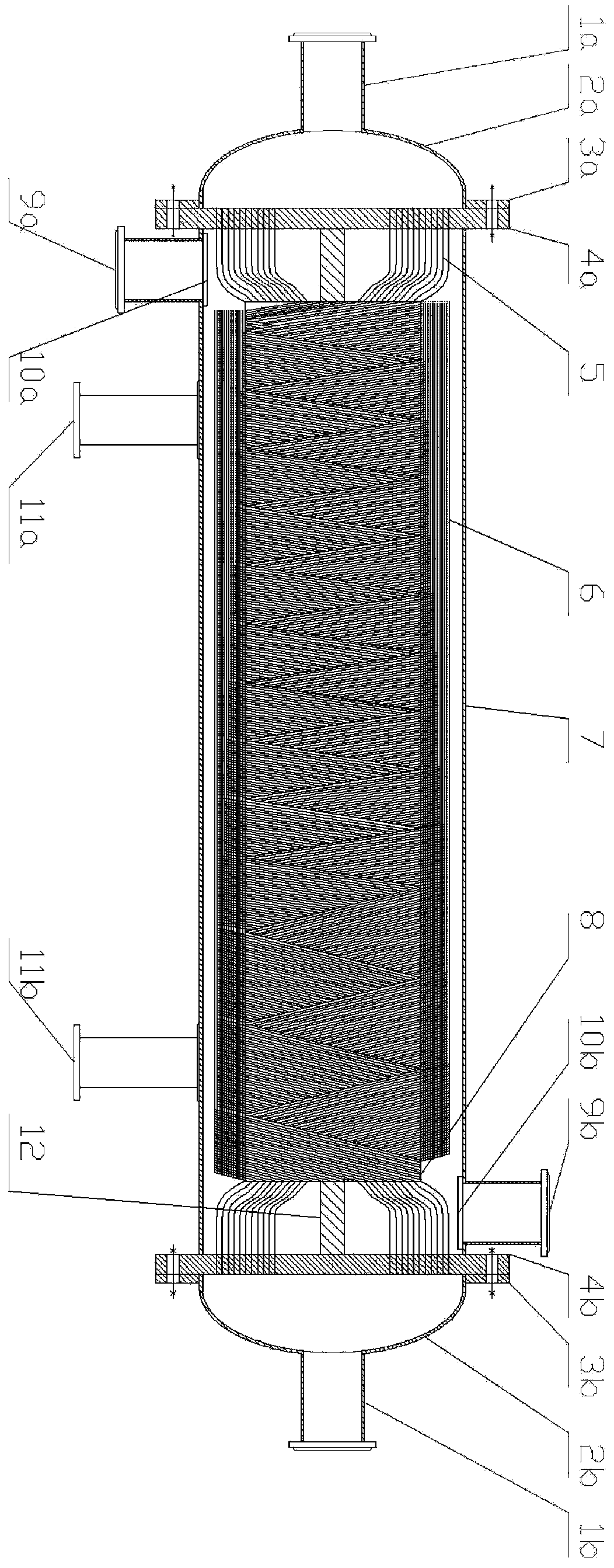

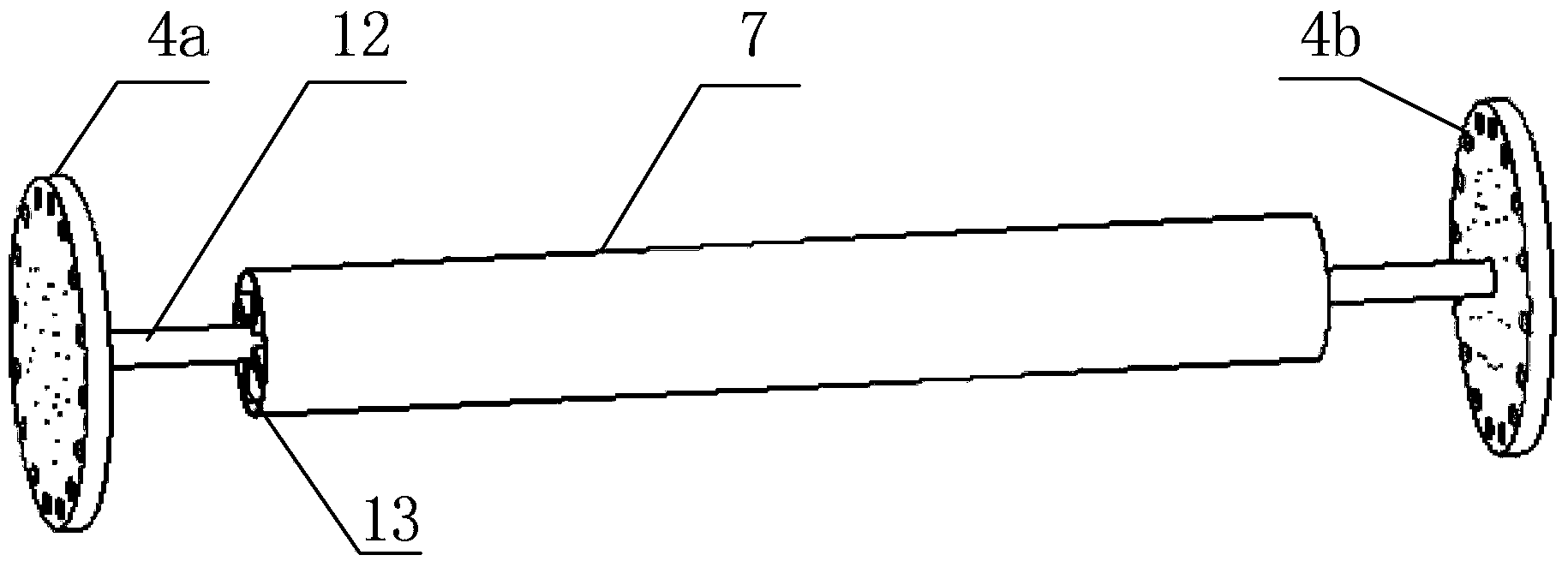

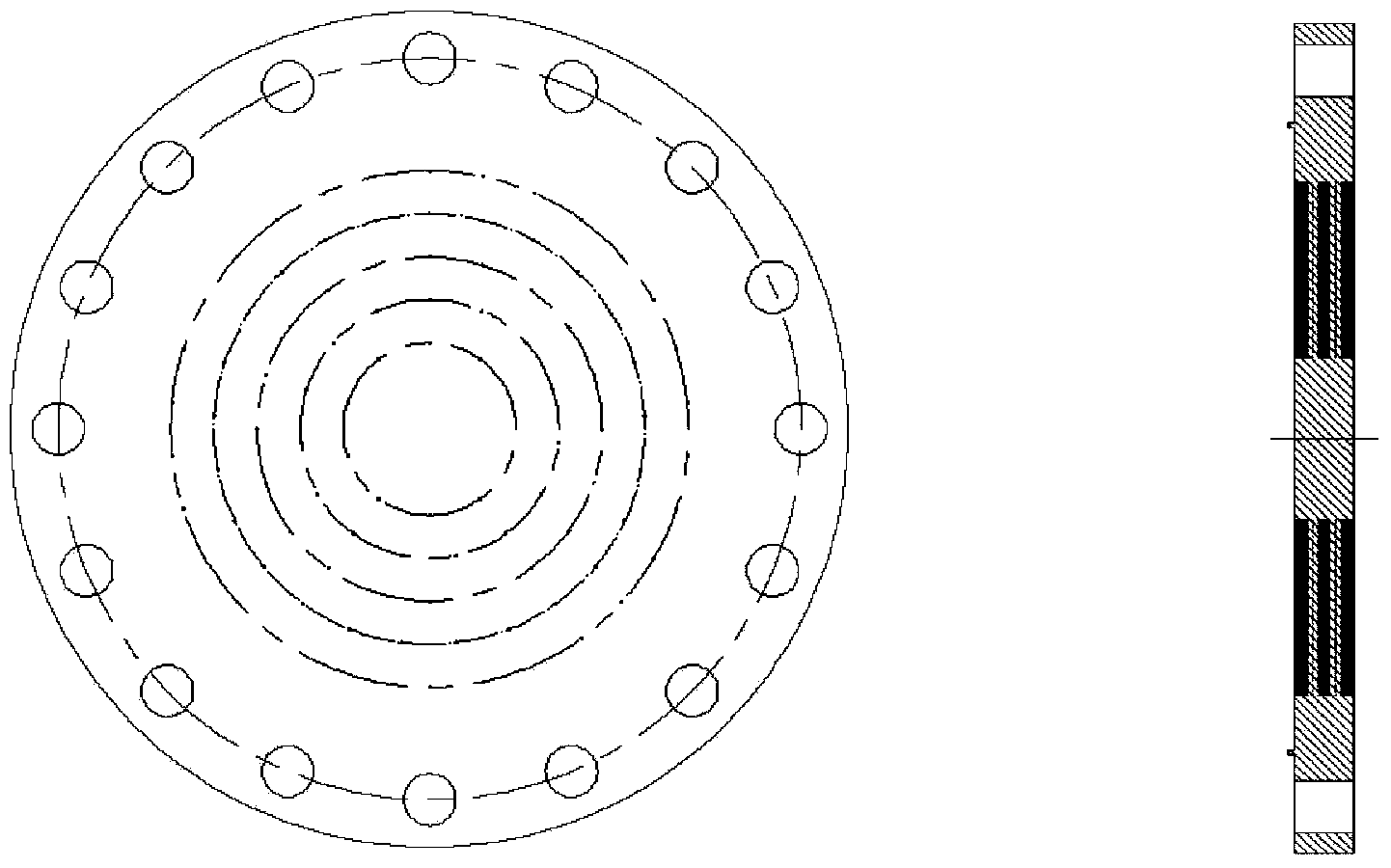

The invention relates to the technical field of the design of chemical reactors and discloses a novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes. The reactor mainly comprises reactant inlet and outlet sections, inlet and outlet glands, flanges, inlet and outlet tube plates, stainless steel capillary tubes, a fixed pad strip, a drum, a winding drum, constant-temperature medium inlet and outlet sections, baffles, left and right supports, a central support tube and a support piece, wherein two ends of the central support tube are connected with the inlet and outlet tube plates, and the winding drum and the central support tube are located on a same axis and welded and connected through the support piece; the stainless steel capillary tubes spirally wind around the winding drum in a multi-layer manner, spiral directions of adjacent winding layers are opposite, multiple reaction tube bundles which take the winding drum as the circle center and have different circle diameters are formed, and two ends of each stainless steel capillary tube are connected onto the inlet and outlet tube plates respectively; the inlet and outlet glands are connected with the inlet and outlet tube plates respectively through the flanges. The reactor has the advantages of high throughput, high heat transfer capacity, high synthetic rate, safety, high efficiency, low machining cost, capability of realizing continuous production, easiness in parallel enlargement and the like.

Owner:NANJING UNIV OF TECH

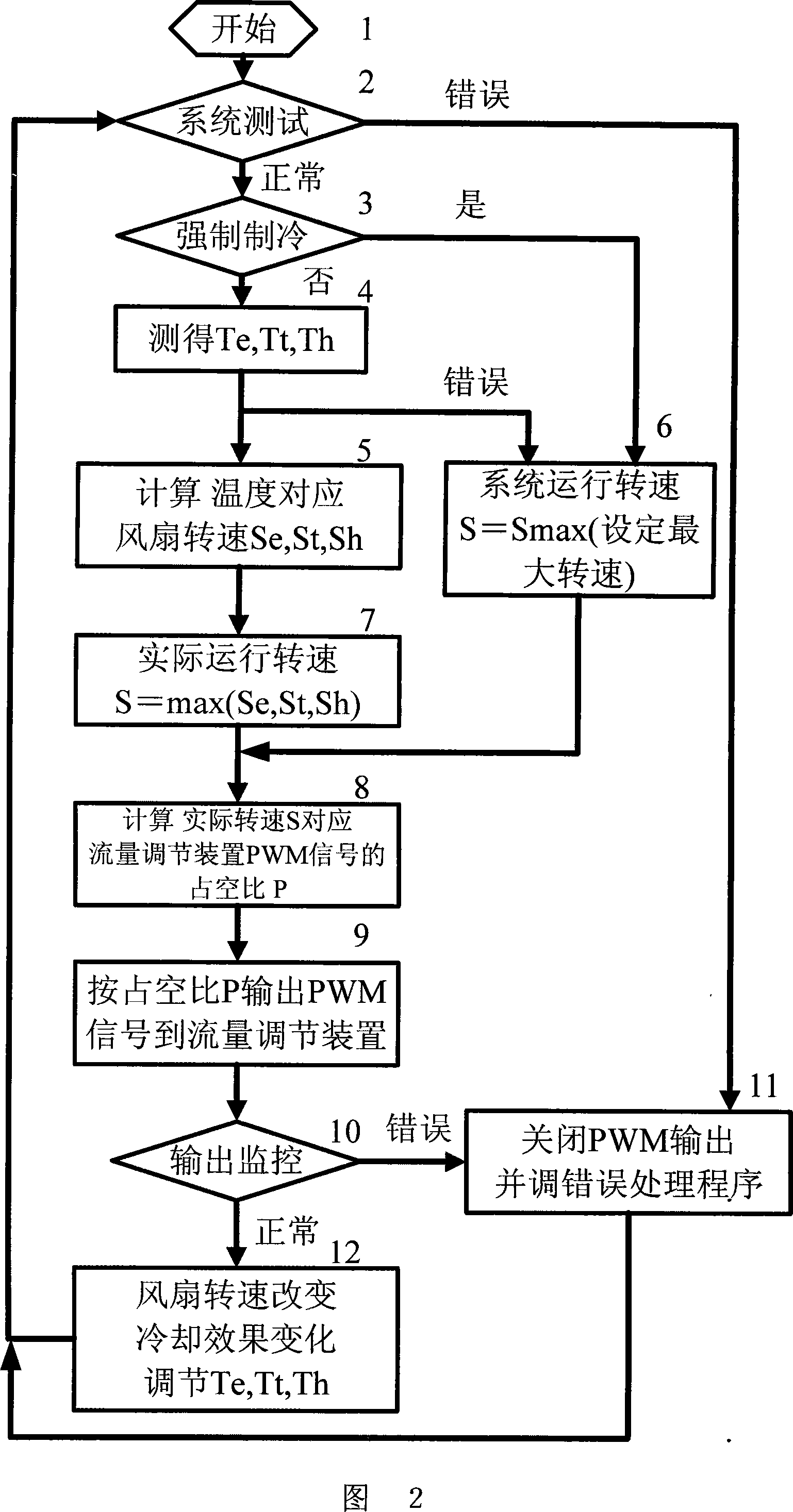

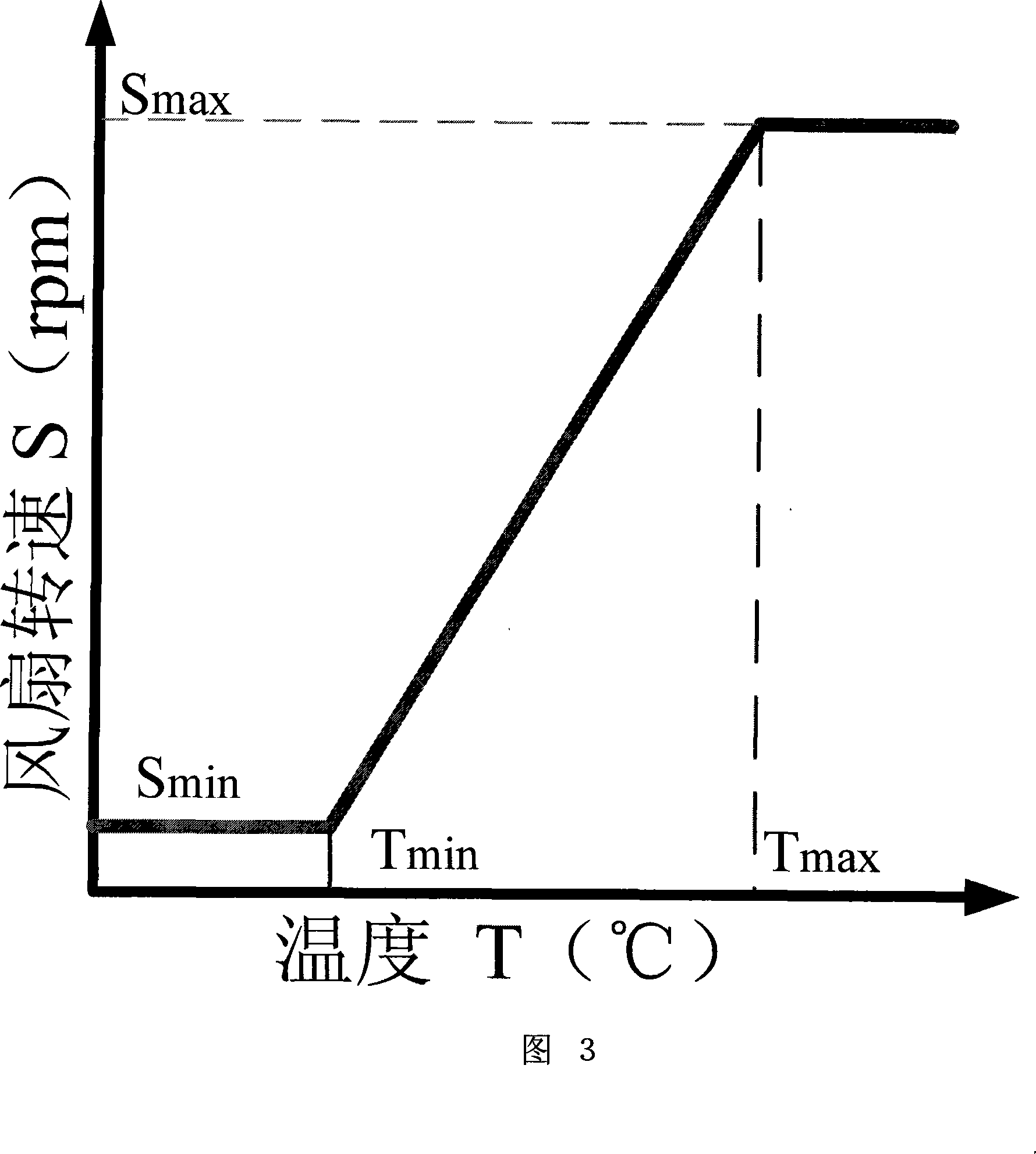

Cooling fan control device and method

ActiveCN101216042APrevent overheatingGuaranteed temperatureCoolant flow controlPump controlCooling fluidDuty cycle

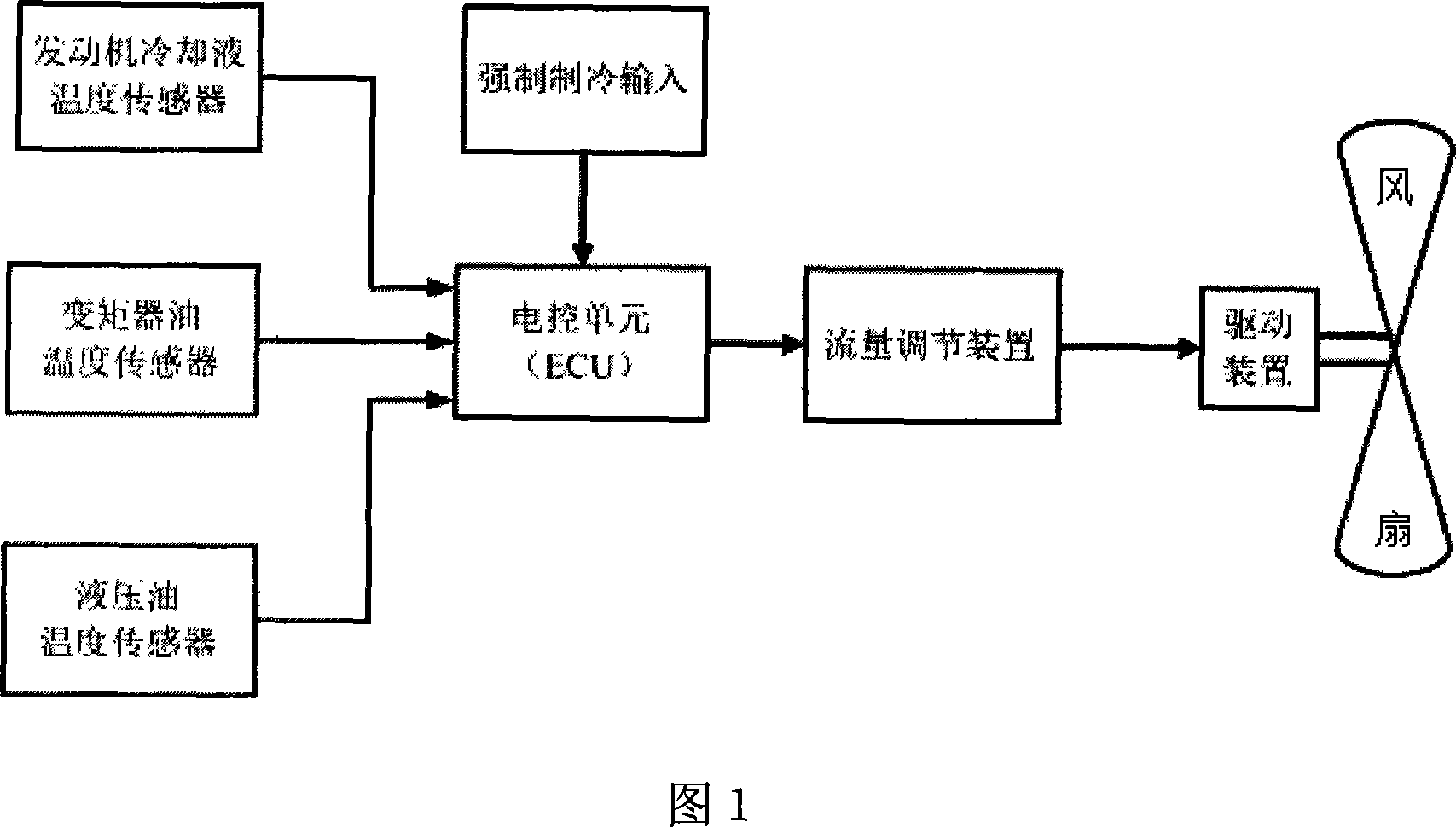

The invention provides a cooling fan control device, which comprises an engine coolant temperature probe, a torque converter oil temperature sensor, a hydraulic oil temperature sensor, an electric control unit, a forced cooling switching input, a flow regulator, a driving device and a fan. A monitoring sensor and a setting amount signal input are connected with the input end of the electric control unit. The output port of the electric control unit is connected with the flow regulator. The flow regulator is connected with the driving device. The driving device is connected with the fan. The invention provides a control algorithm of the device. According to the method, relevant system signal or other incoming signal is collected and processed; the control signal is output and acts on the flow regulator; the driving power output to the driving device is regulated through changing the duty ratio of the output pulse-width signal, thus regulating the rotation speed of the fan. The system is effectively ensured to work within the optimal temperature range all along; the service life of the system or components is improved; energy consumption is reduced; work efficiency is improved; and noise resulting from the fan is reduced.

Owner:GUANGXI DAHUA DESHENG THERMAL MANAGEMENT SCI TECH

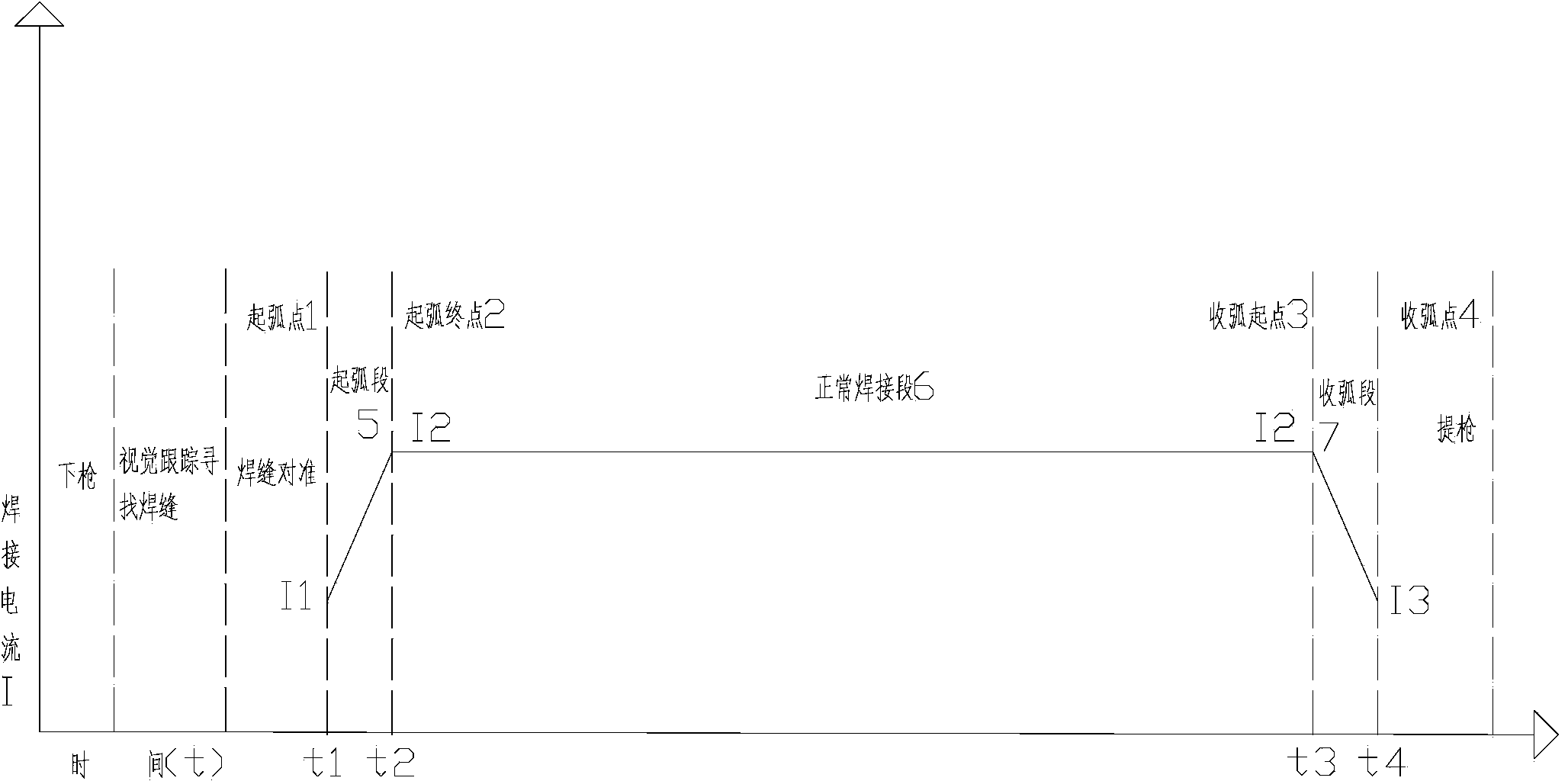

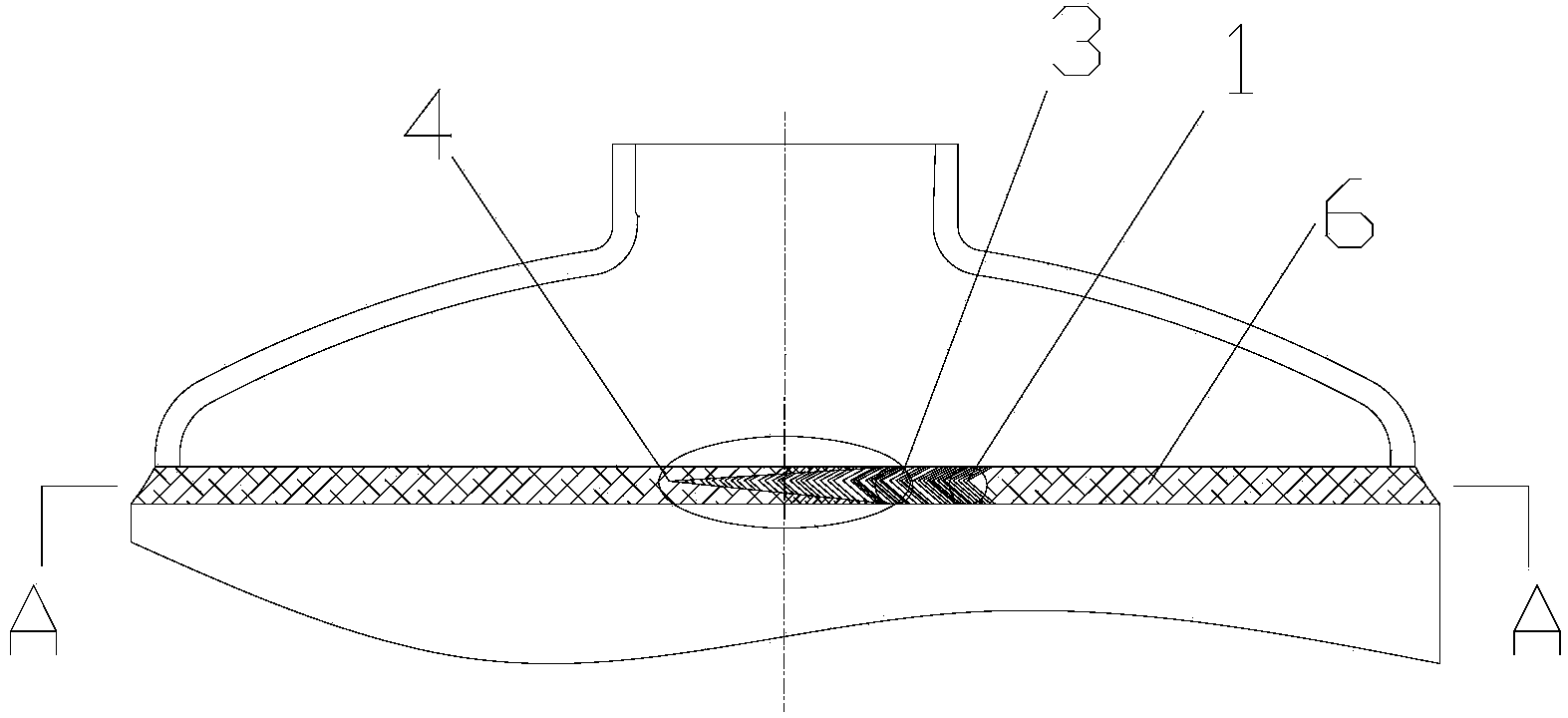

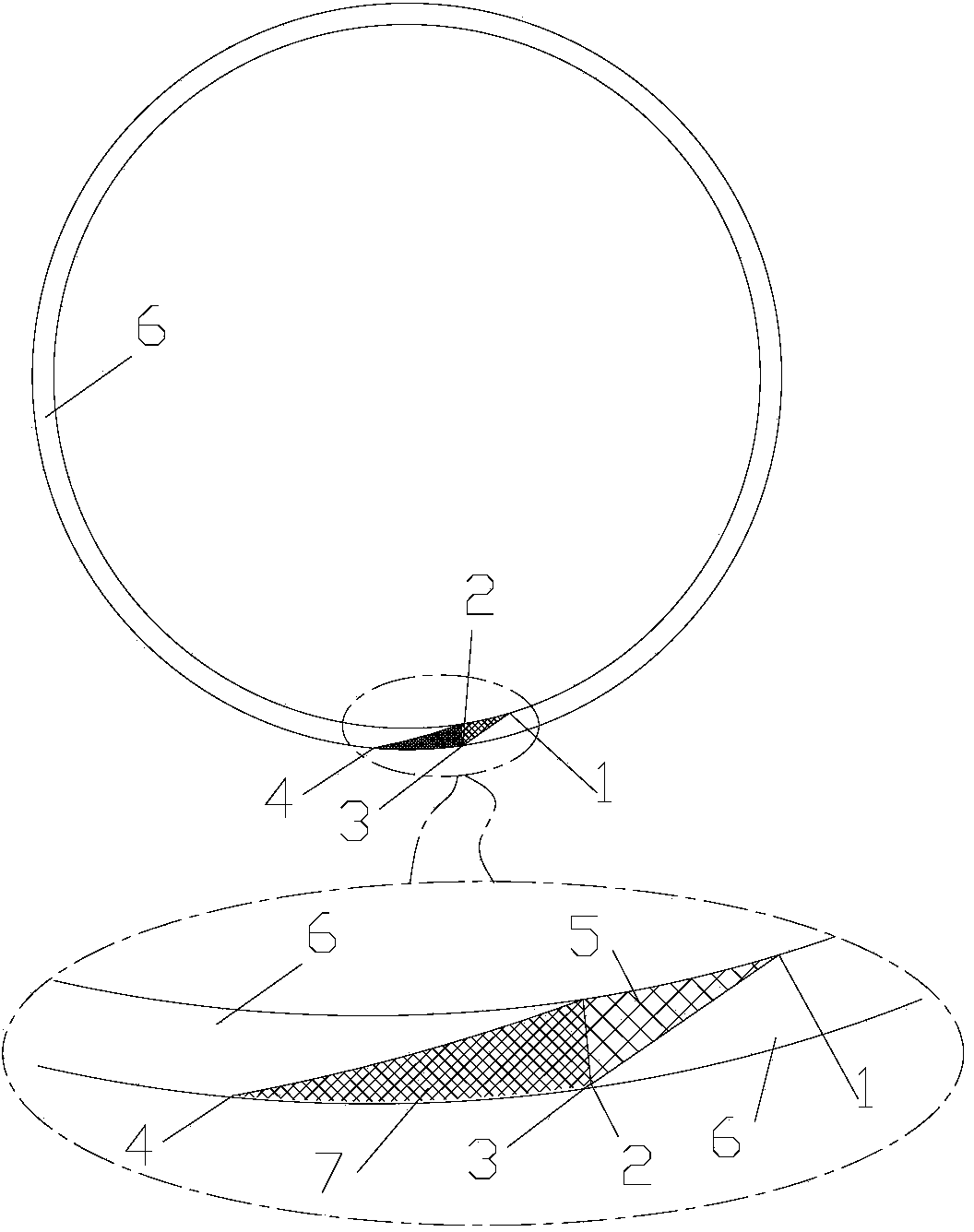

Annular welding method

ActiveCN103846528AQuality improvementGuaranteed weld tightnessElectrode supporting devicesPlasma welding apparatusEngineeringMechanical engineering

The invention relates to an annular welding method. A welding gun is adopted to realize welding; a welding line of a workpiece is annular. The annular welding method is characterized in that welding comprises arc striking, normal welding and arc stopping; the welding current of an arc striking section between an arc striking point and an arc striking end point and the welding current of an arc stopping section between an arc stopping start point and an arc stopping point are lower than that of the normal welding; furthermore, the welding line of the welding line from the arc striking point to the arc stopping point rotates around an angle which is larger than 360 degrees. Due to a research, the quality of the annular welding line is greatly improved by changing welding technical parameters by the adoption of soft arc striking and soft arc stopping, so that the welding sealing property of end-to-end overlapped sections of the welding line formed in the arc striking and the arc stopping is guaranteed; the problem of welding missing is avoided; meanwhile, the phenomenon of burnthrough during welding is avoided, and the end-to-end overlapped section of the welding line is smoothly transitioned. The annular welding method is particularly suitable for welding on a barrel body or a pipe body with a high sealing requirement.

Owner:佛山晓世科技服务有限公司

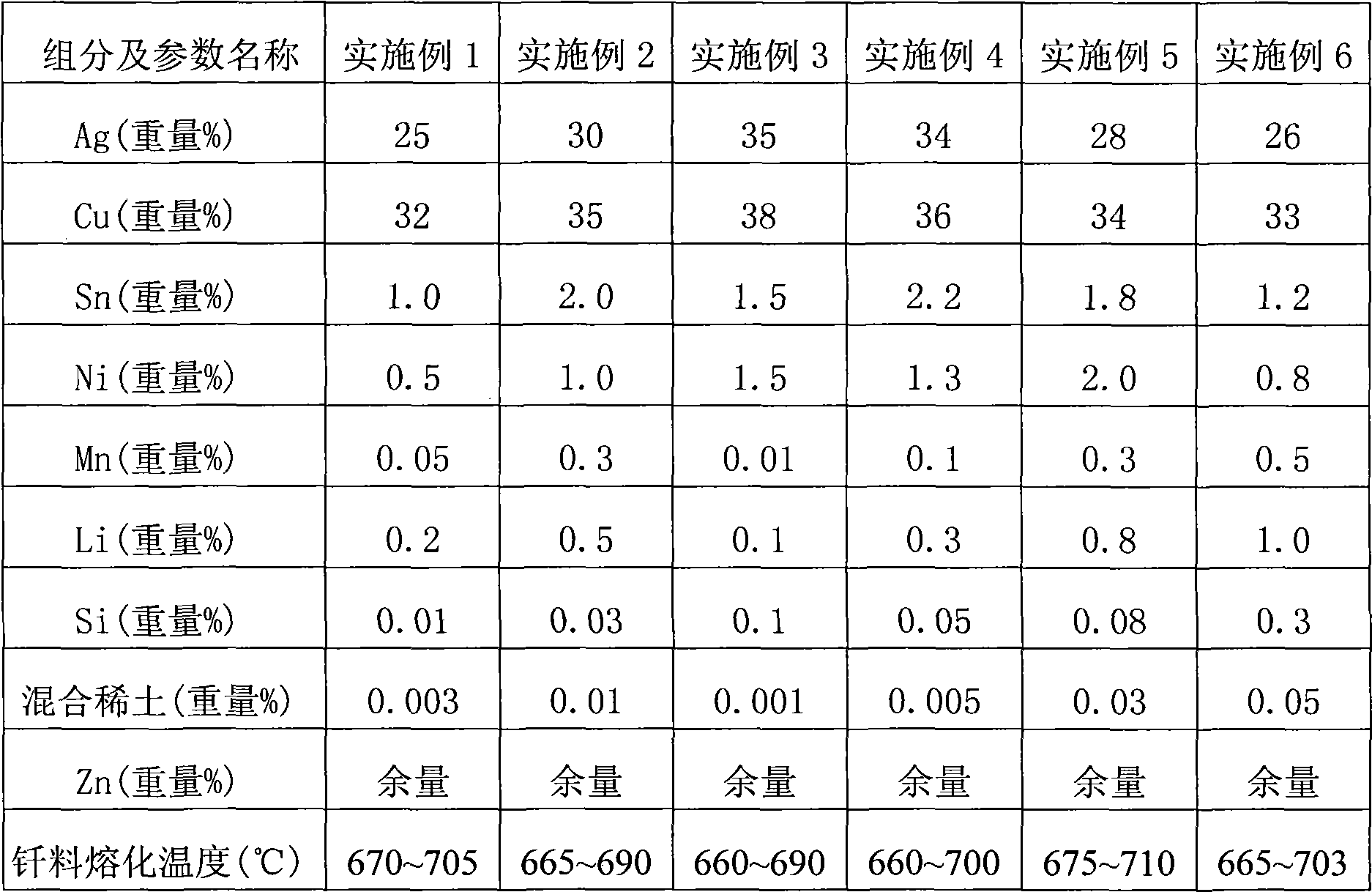

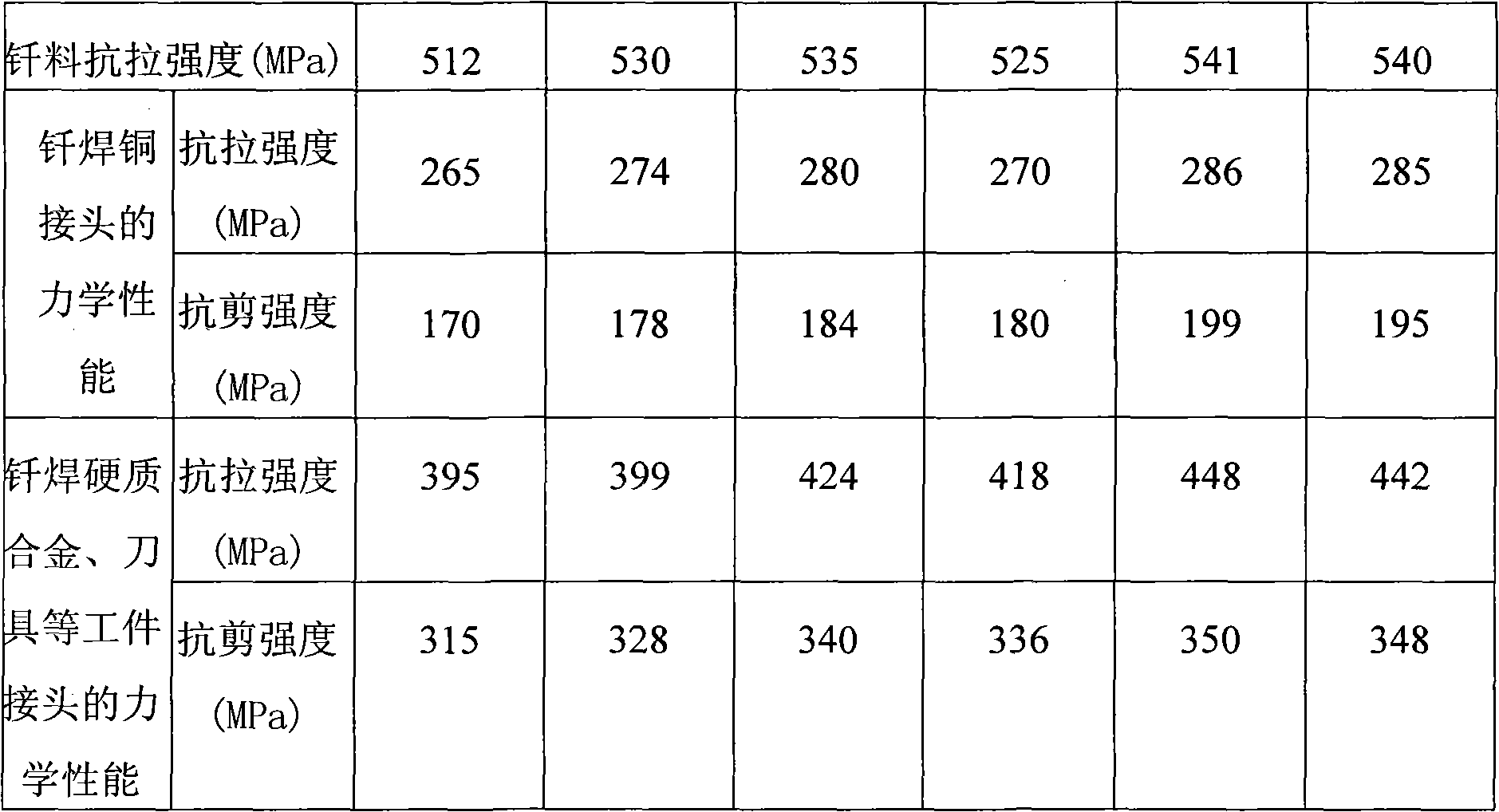

Special rare earth alloy silver-brazing filler metal

ActiveCN101780613AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaCeriumLanthanum

The invention relates to a special rare earth alloy silver-brazing filler metal applied to the brazing of the metal workpieces such as copper and copper alloy, cemented carbide, carbon steel, stainless steel, nickel-based alloy and the like, and belongs to a moderate temperature brazing material. At present, no silver-brazing filler metal has excellent performance and low price, so that the development of the brazing field is obstructed. The special rare earth alloy silver-brazing filler metal comprises the following components in percentage by weight: 25 to 35 percent of Ag, 32 to 38 percent of Cu, 1 to 2.5 percent of Sn, 0.5 to 2.0 percent of Ni, 0.01 to 1 percent of Mn, 0.1 to 1.0 percent of Li, 0.01 to 0.5 percent of Si, 0.001 to 0.1 percent of mixed rare earth, and the balance of Zn, wherein the mixed rare earth consists of lanthanum and cerium. The special rare earth alloy silver-brazing filler metal has the advantages of high cost performance, low fusion temperature of brazing filler metals, good wettability and fluidity, high mechanical strength of soldered joint, and good soldering technological property.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

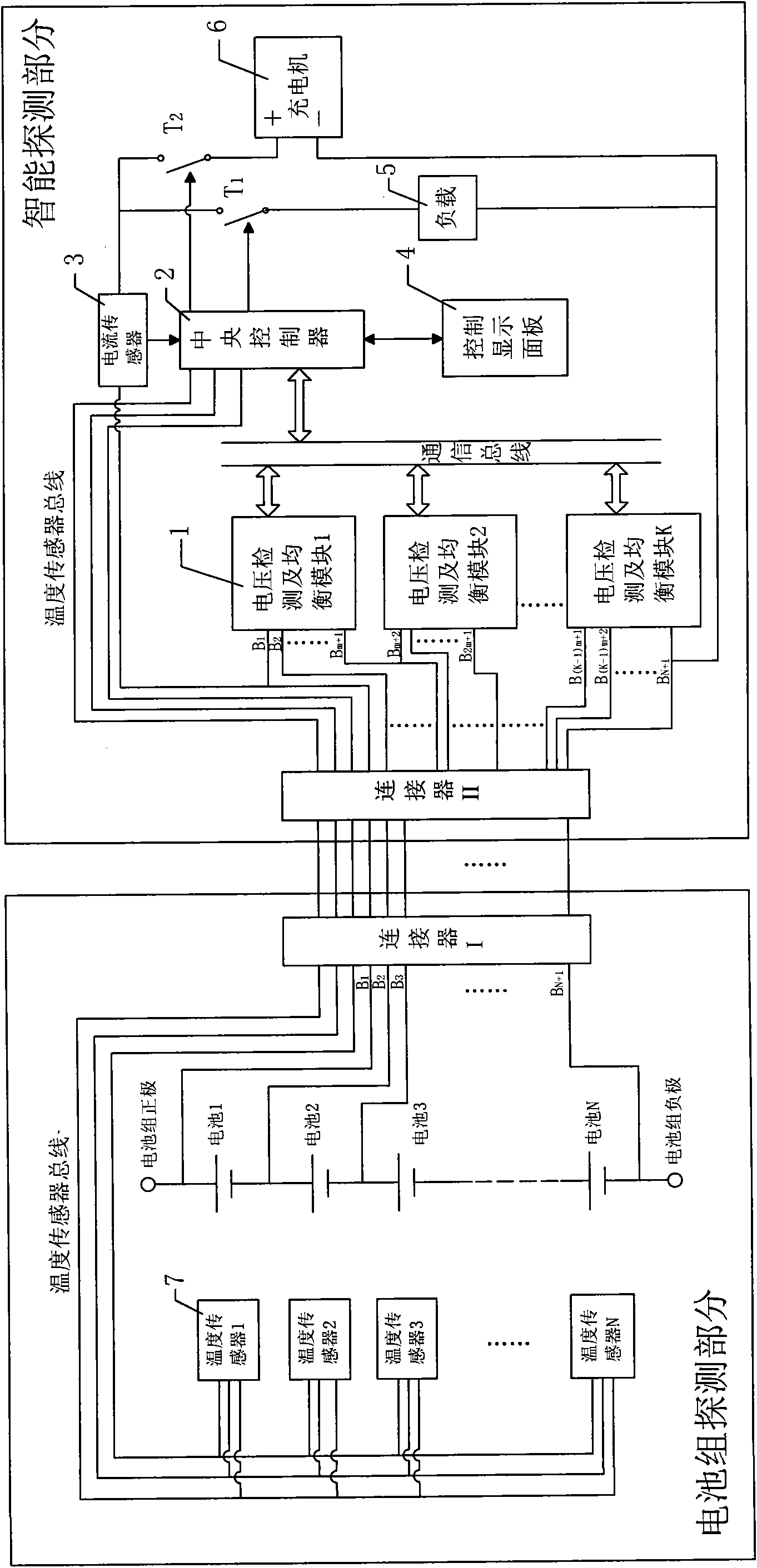

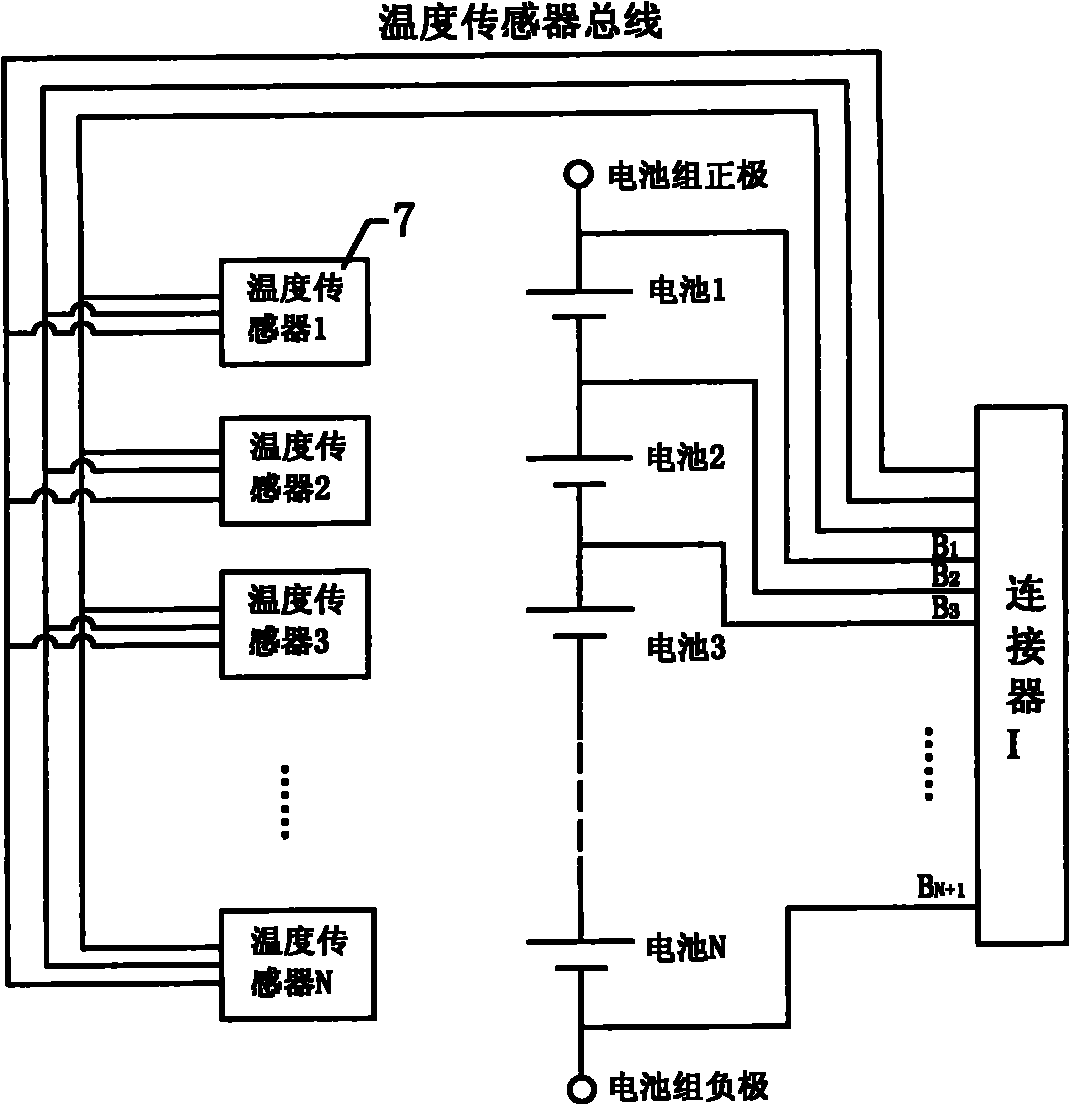

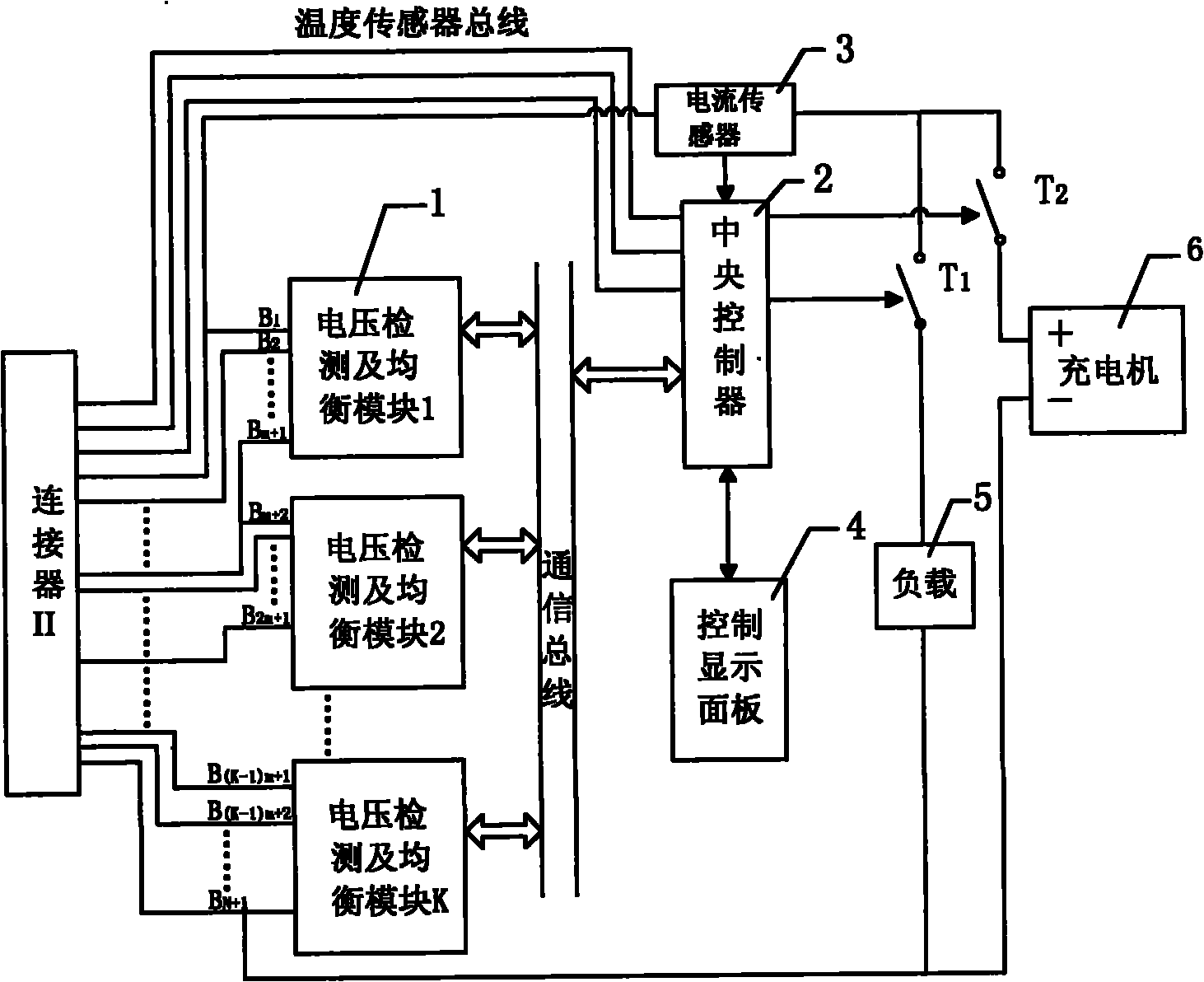

Power battery pack detecting, evaluating and equalizing charge system and applying method thereof

InactiveCN101917028AImprove performanceExtended working hoursBatteries circuit arrangementsElectrical testingPower batteryComputer module

The invention discloses a power battery pack detecting, evaluating and equalizing charge system and an applying method thereof. The power battery pack detecting, evaluating and equalizing charge system is characterized by comprising a battery pack detection part and an intelligent control part, wherein the battery pack detection part comprises a connector I and a plurality of voltage detection lines; the intelligent control part comprises a connector II, a plurality of voltage detecting and equalizing modules (1), a central controller, a current inducer (3), a control display panel (4), a load (5) and a charger (6); and the system is used for measuring voltage and temperature information of a power battery pack and measuring charge and discharge currents of the battery pack. The inventioncan be used for carrying out detecting, evaluating and equalizing charge on the power battery pack, helps a user know the current state of the power battery pack, improves the property of the power battery pack, and prolongs the service life.

Owner:SUN YAT SEN UNIV +1

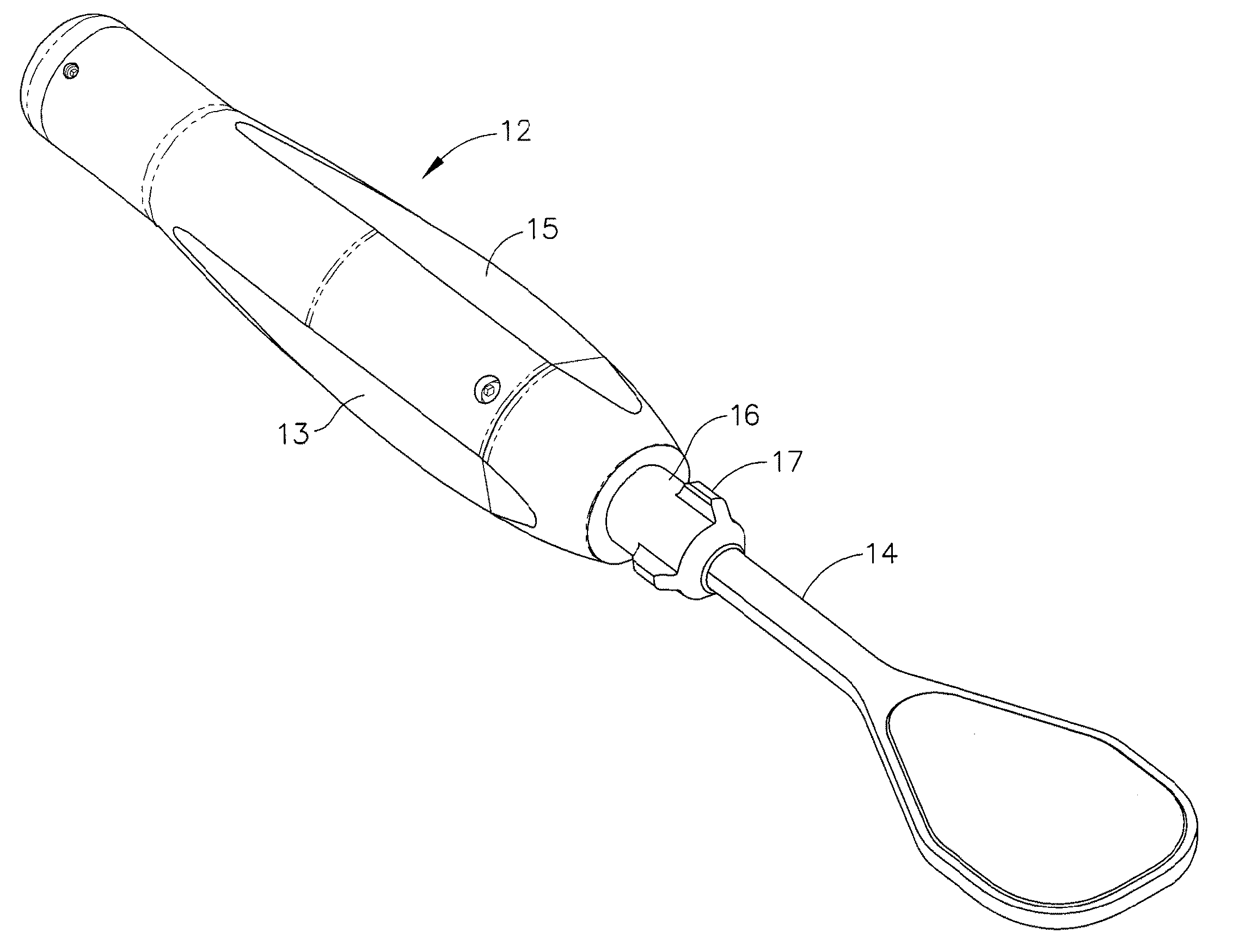

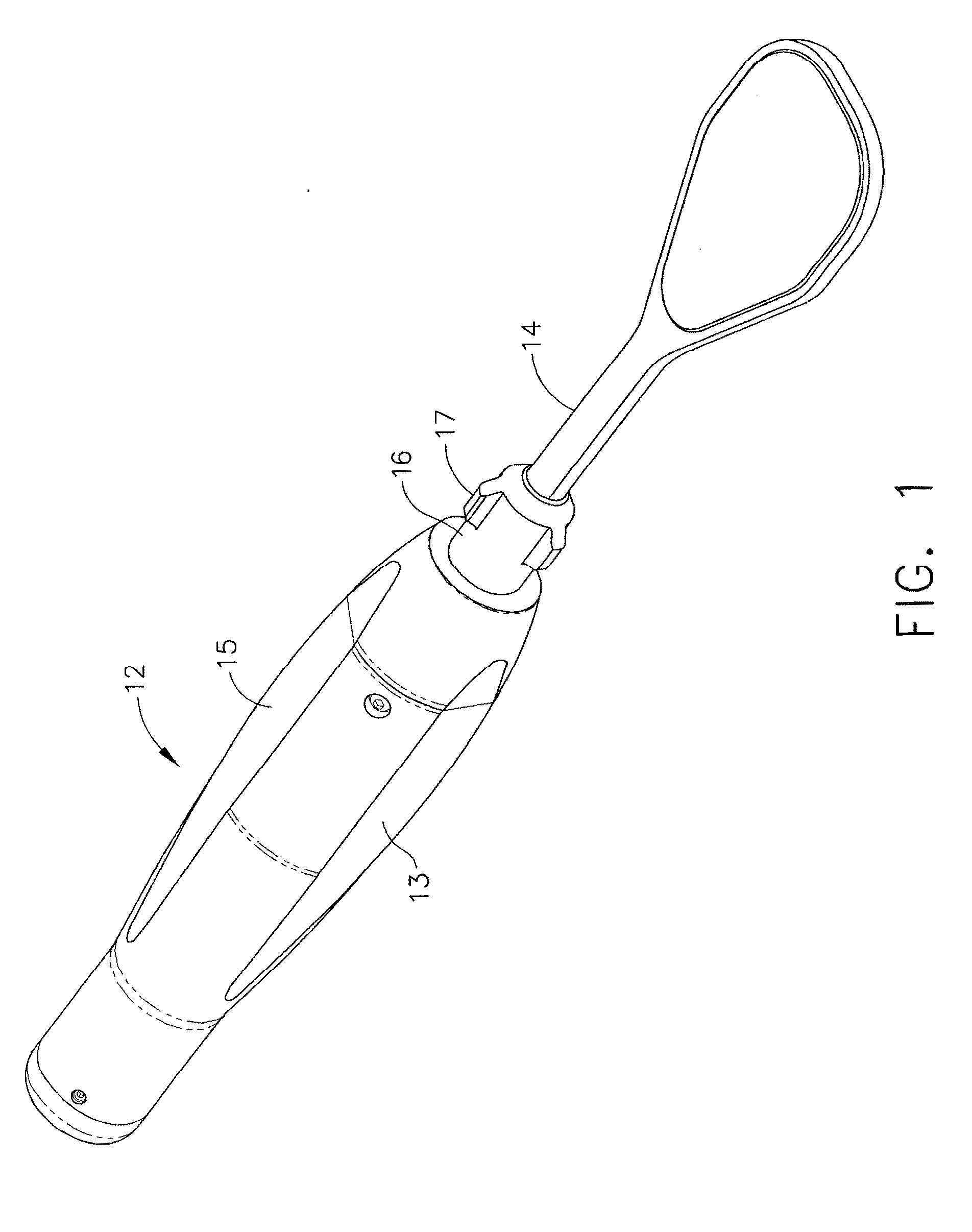

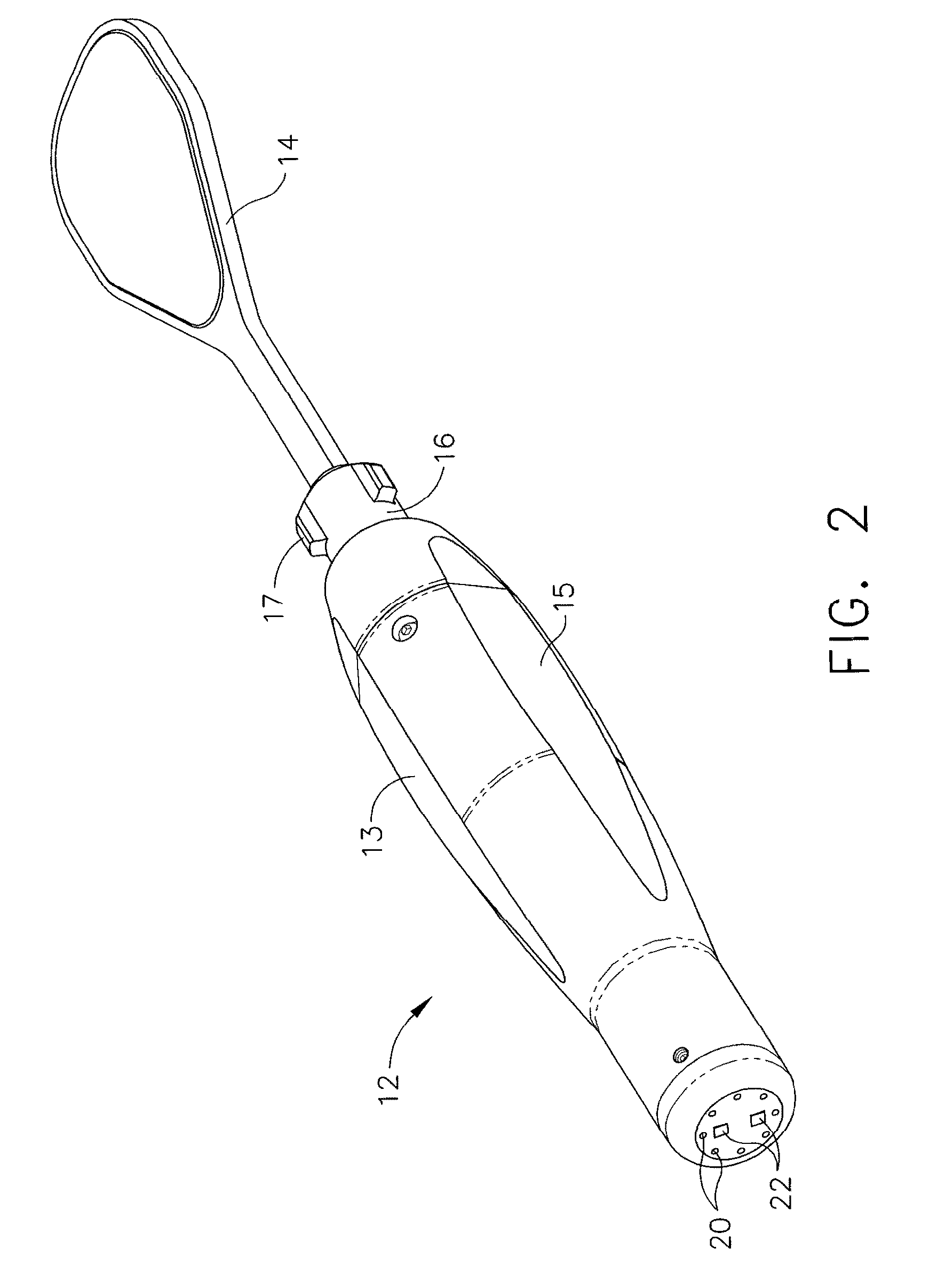

Skin Abrasion Apparatus and Method

InactiveUS20070293795A1Effective and easy removalLess rednessSurgeryChiropractic devicesAfter treatmentMedicine

A handheld apparatus including an internal motor and a removable treatment paddle. The removable treatment paddle is designed for connection with the internal motor, and typically has a first surface and a second surface. The first surface typically includes an abrasive material formed into or attached to the surface for skin exfoliation, and the second surface is typically a relatively less abrasive surface than the first surface, for aid in infusing at least one topical active into the skin after treatment with the first surface. The improved device also includes a multi-sided handpiece having a plurality of flat sides for ease of handling, and at least one ventilation hole to prevent overheating of the device during operation. The handpiece can also include a fan for proper ventilation through the ventilation holes. In one embodiment, the handpiece includes an insulating sleeve to protect the user's hand from the heat generated from the device, as well as to provide an improved gripping surface for the handpiece and to decrease the level of noise production from the handpiece.

Owner:MR CARROLL TIMOTHY

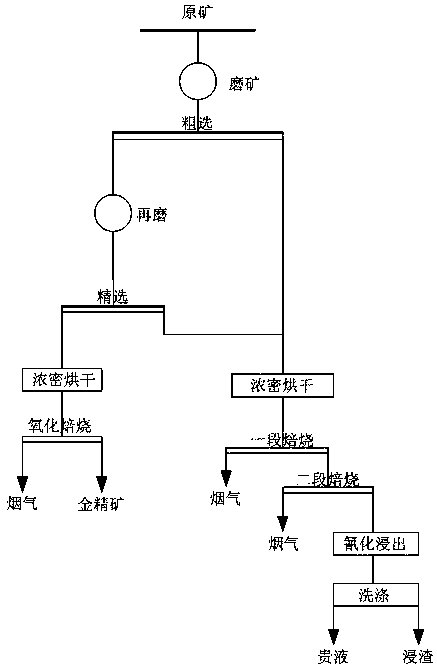

Beneficiation method for high-carbon micro-fine particle sub-microscopic gold ore

ActiveCN107326172AHigh recovery rateImprove leaching rateSolid separationProcess efficiency improvementHigh carbonPyrite

The invention discloses a beneficiation method for high-carbon micro-fine particle sub-microscopic gold ore, and belongs to the technical field of mineral processing. Roasted ore, namely, concentrated gold ore, is obtained by performing flotation after gold ore is ground, grinding and selecting the floated concentrated gold ore again, and performing oxidizing roasting on the floated concentrated gold ore. The content of carbon and sulphur in the floated concentrated gold ore is high; and when iron pyrite in the floated concentrated gold ore is enriched to a certain degree, the gold grade is difficult to improve. The concentrated gold core with high quality can only be obtained through the oxidizing roasting. Two-section oxidizing roasting is performed on floated tailings so as to prevent over-roasting or under-roasting, and a sulphide which coats the gold is damaged through roasting so that cracks appear on a gold-loaded mineral structure to inhibit negative impact of organic carbon on subsequent cyaniding gold extracting process; and therefore, the purpose of remarkably improving the leading rate of gold is achieved. The method has the characteristics of low production cost, high gold recovery rate, high adaptability, wide application range and the like; and recycling and utilization of the ore are realized.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

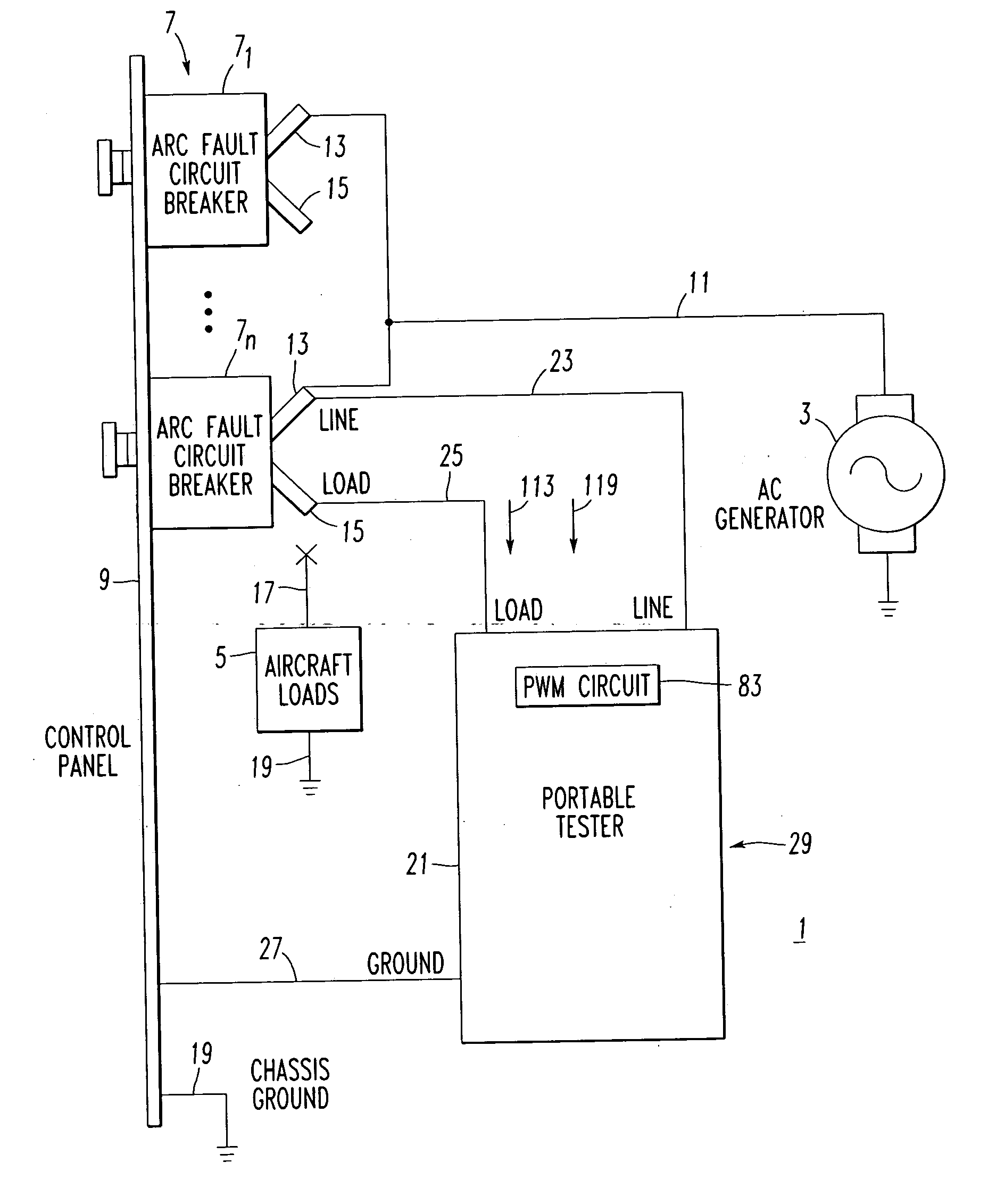

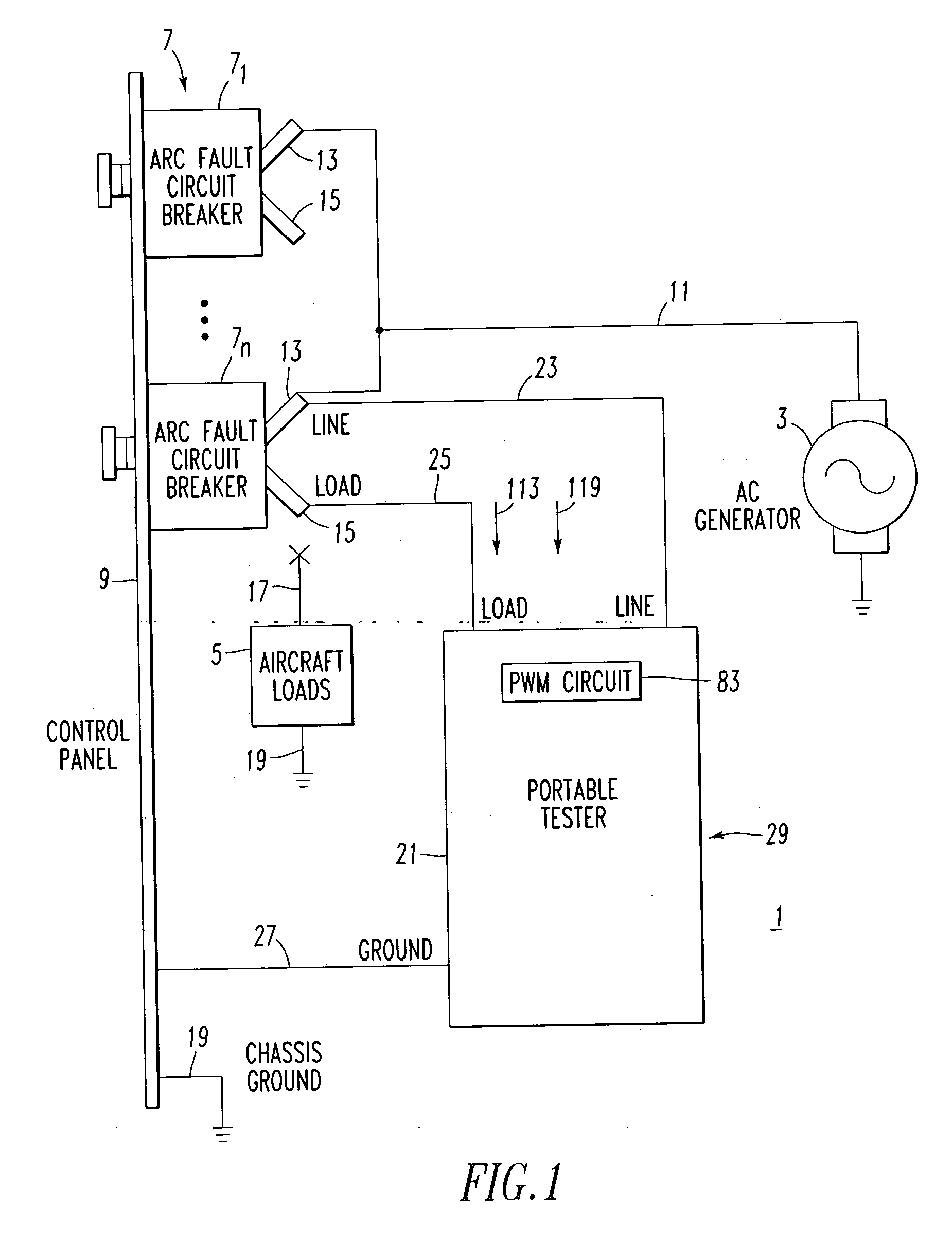

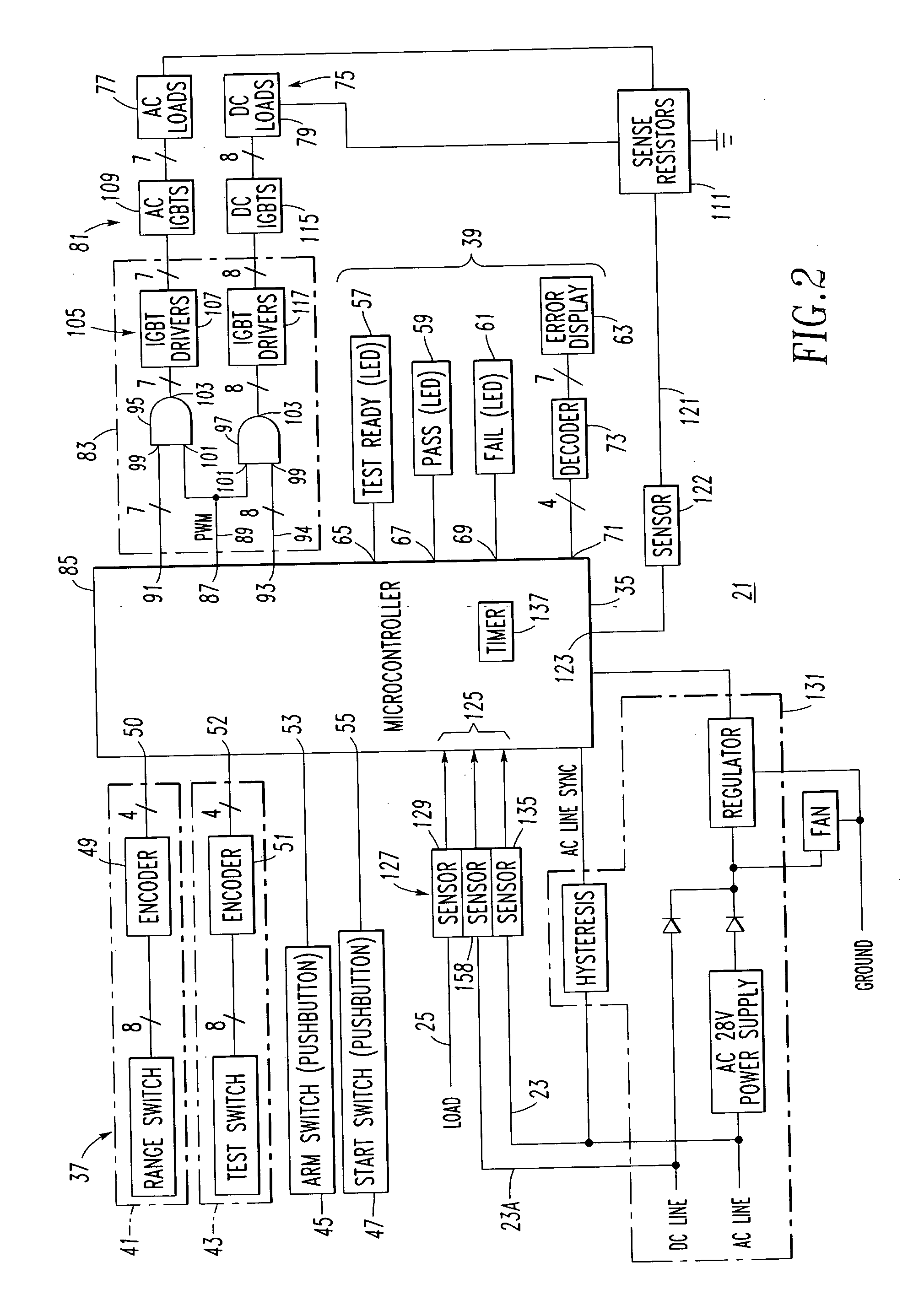

Circuit breaker tester including a pulse width modulation circuit

ActiveUS20070047161A1Prevent overheatingAvoid overall overheatingEmergency protective arrangement detailsEmergency protective arrangements for automatic disconnectionElectricityTester device

A tester for testing a circuit breaker includes a plurality of load elements each having a nominal fixed impedance and an electronic switch associated with each load element. The electronic switch, when turned on, electrically connects a corresponding load element in series with a circuit breaker load terminal and in parallel with none or with a number of other load elements. A controller turns on a number of the electronic switches selected to draw through a corresponding number of the load elements a test current selected as a function of a designated rated current for the circuit breaker and sufficient to trip open the same. A pulse width modulation circuit cooperates with the controller and with the electronic switches. The pulse width modulation circuit provides a constant magnitude of the test current to accommodate variations of the nominal fixed impedance or variations of the voltage of the load terminal.

Owner:EATON INTELLIGENT POWER LIMITED

Low silver copper base medium temperature brazing filler metal

ActiveCN101524798AConserve limited resourcesReduce use costWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to a low silver copper base medium temperature brazing filler metal applicable to braze welding of workpieces such as copper and copper alloy, copper and steel, belonging to the field of medium temperature brazing material. The formula and content of the low silver copper base medium temperature brazing filler by weight percentage is as follows: Ag: 1.8-5%, P: 5.5-7.5%, In: 0.5-2.5%, Ni: 0.01-1%, the rest: Cu. The invention has the advantages of rational design of formula, low manufacture cost, relatively low melting temperature of the brazing filler metal when welding copper and copper alloy and copper and bundy tubes, good wetting property and fluidness, smooth and bright surface of soldered connection, high mechanical strength, fine processing property of braze welding, stable quality and good uniformity and capability of replacing noble metal silver brazing filler metal BAg25CuZnSn.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

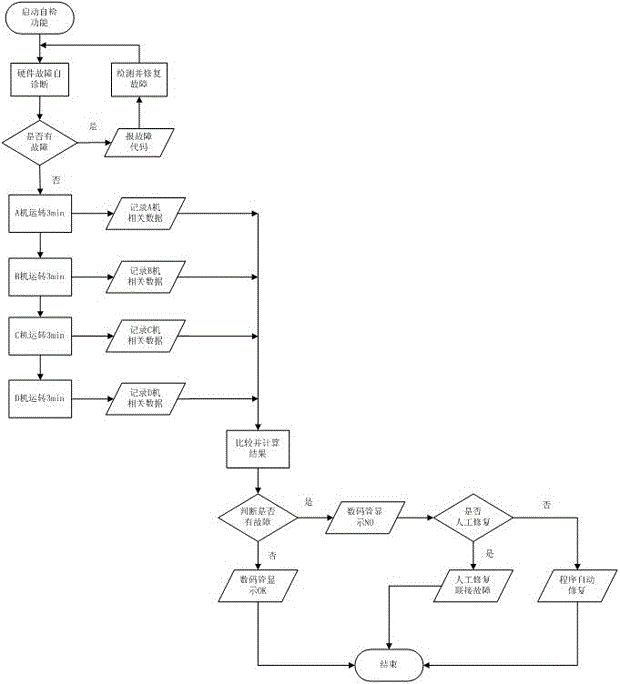

Multitube variable frequency multi-split air conditioner self-inspection method

ActiveCN106247530AImprove accuracyAvoid overheatingMechanical apparatusSpace heating and ventilation safety systemsLookup tableWind speed

The invention discloses a multitube variable frequency multi-split air conditioner self-inspection method. The multitube variable frequency multi-split air conditioner self-inspection method comprises the following steps of computing of self-inspection operation parameters and self-inspection, wherein the self-inspection steps comprises the substeps that (1) an air conditioner is controlled to start the self-inspection mode; (2) all online indoor units are forcefully started in sequence and operated for set time; (3) the current outdoor environment temperature is detected, and the indoor unit air speed corresponding to the current outdoor environment temperature is looked up from a compressor frequency-outdoor environment temperature lookup table; and (4) an indoor unit is operated at low air speed after startup; (5) the liquid pipe temperature T'liq and coil temperature T'coil of the an indoor unit operating currently are detected; (6) whether abnormality exists or not is judged; and (8) judgment results are displayed. The multitube variable frequency multi-split air conditioner self-inspection method has the advantages and positive effects that the online indoor units can be accurately inspected, the failed unit can be accurately determined when a failure occurs, and the accuracy of inspection is improved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

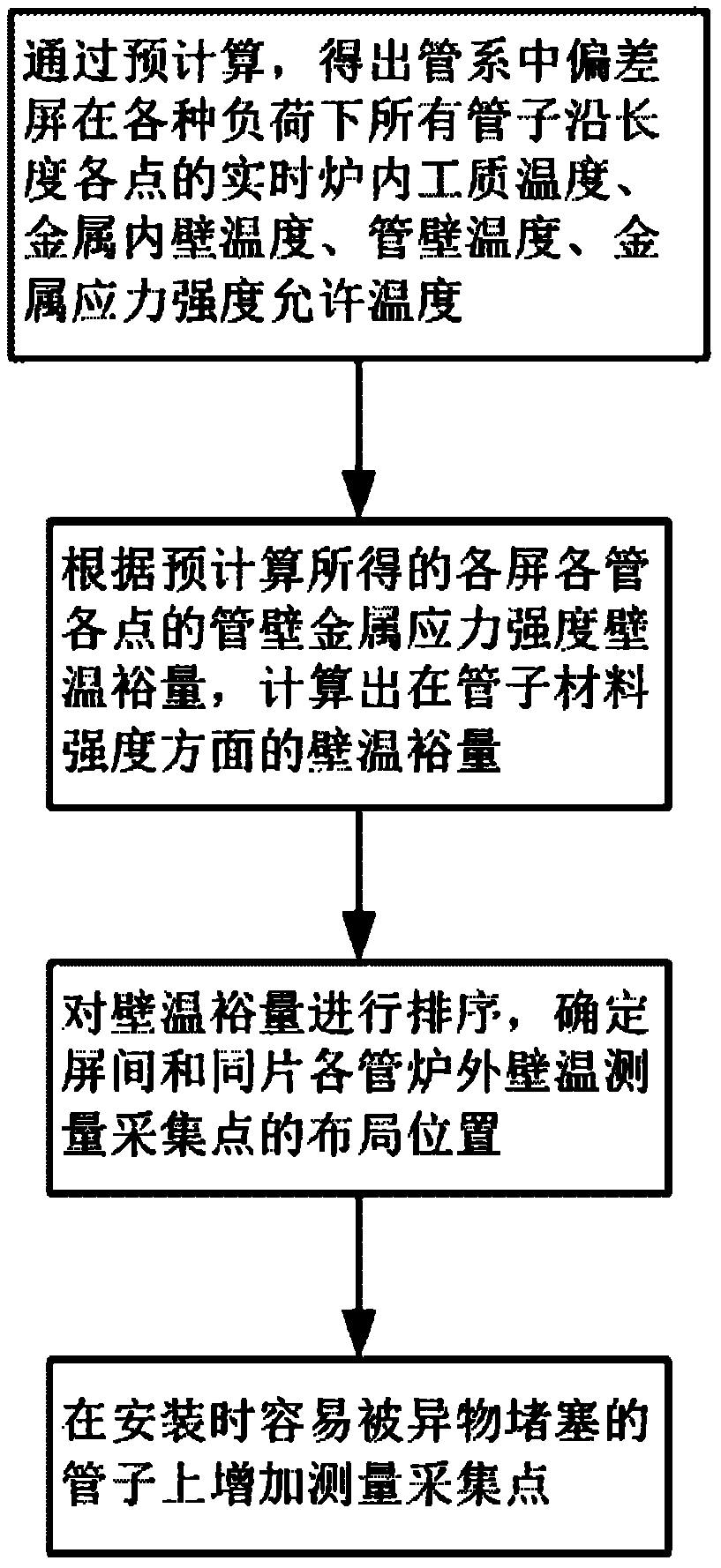

Method for distributing external wall temperature measuring acquisition points of high-temperature piping system of power station boiler

ActiveCN102494323APrevent strength from overheatingPrevent overheatingBoiler controlPipingSuperheater

The invention relates to a method for distributing external wall temperature measuring acquisition points of a high-temperature piping system of a power station boiler in the technical field of power station boilers. The method comprises the following steps of: precalculating the temperature of a working medium in a furnace, the temperature of a pipe metal inner wall, the temperature of a pipe wall and a metal stress intensity allowable temperature value of each point of each pipe of each screen of each piping under various loads; calculating the allowance of intensity wall temperature according to the wall temperature and the allowable temperature value of each point of each pipe of each screen; sorting the allowance of the wall temperature, and determining layout positions of the external wall temperature measuring acquisition points among the screens and on each pipe in the same sheet; and arranging the measuring acquisition points additionally on the pipes which are easy to plug by foreign bodies during installation. According to the method, an on-line monitoring system detects and calculates the minimum allowance of wall temperature in the furnace in all pipes in real time to determine the pipes which are most dangerous in pipe blast due to overtemperature, so the piping systems of a superheater and a reheater of the power station boiler are safe and economic in running, and the direct data support is provided for the state overhauling of the boiler.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

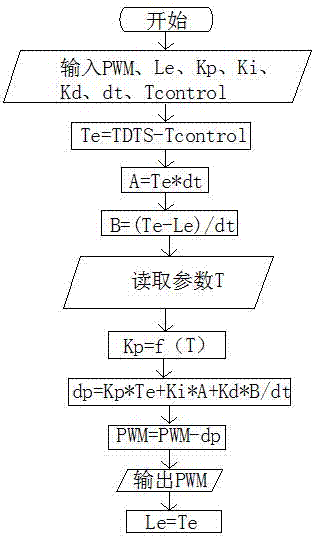

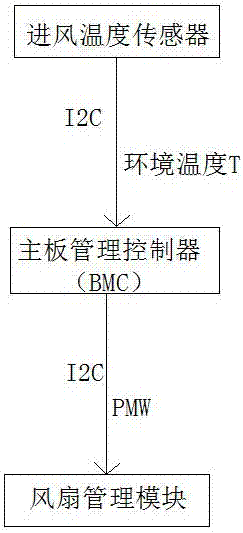

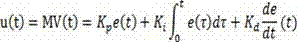

PID fan regulation and control strategy implement method and system based on environment temperature

InactiveCN107269567APrevent overheatingRealize dynamic adjustmentDigital data processing detailsDesign optimisation/simulationInlet temperatureEngineering

The invention discloses a PID fan regulation and control strategy implement method and system based on the environment temperature and belongs to the technical field of CPU heat dissipation. According to the PID fan regulation and control strategy implement method and system, a Kp value is changed along with the change of the environment temperature, and the environment temperature is dynamically regulated through a fan regulation and control strategy. The technical scheme comprises (1) the PID fan regulation and control strategy implement method based on the environment temperature and (2) the PID fan regulation and control strategy system based on the environment temperature, specifically, according to the method, in the CPU operation process, the current environment temperature is read through an air inlet temperature sensor, the Kp value in the fan regulation and control strategy is determined according to the environment temperature, and the PID fan regulation and control strategy is dynamically regulated; and the system comprises the air inlet temperature sensor, a main board management controller and a fan management module, wherein the air inlet temperature sensor sends data to the main board management controller through an I2C bus, and the main board management controller sends the data to the fan management module through an I2C bus.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

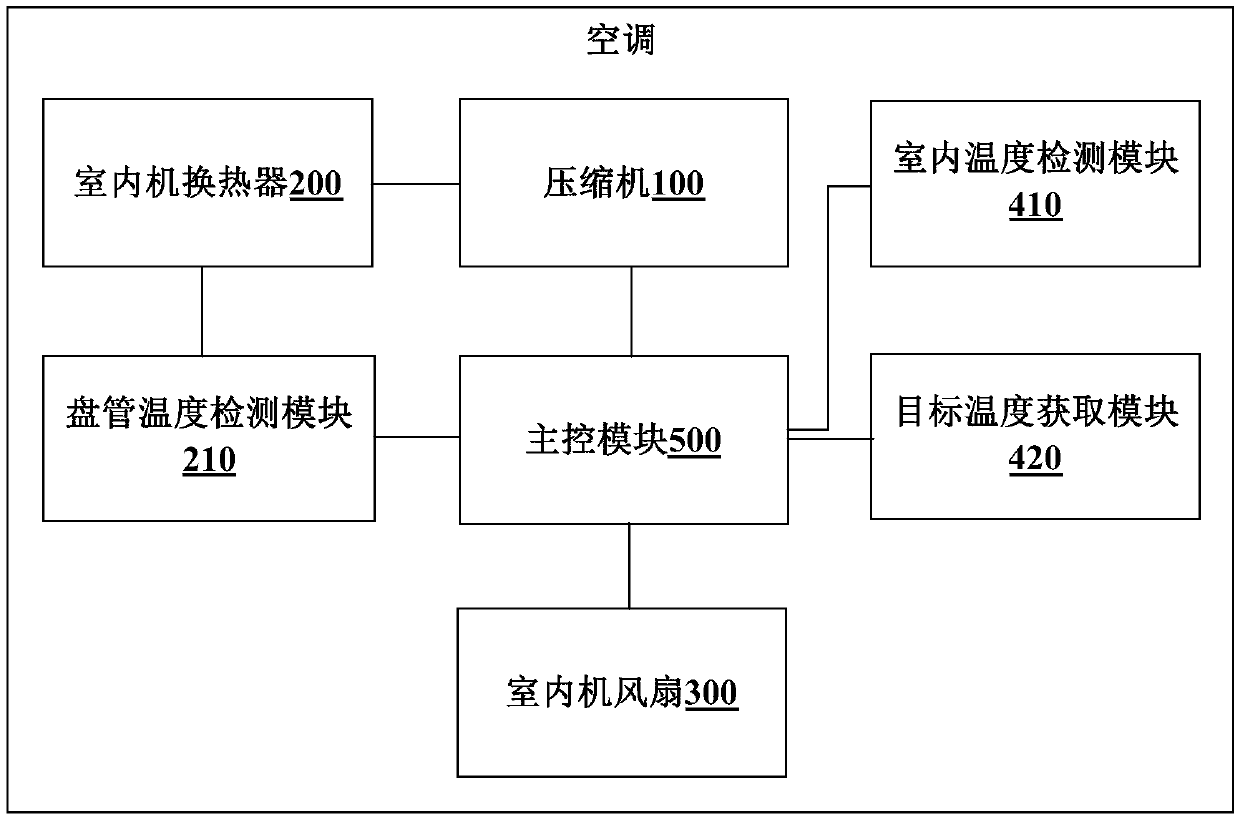

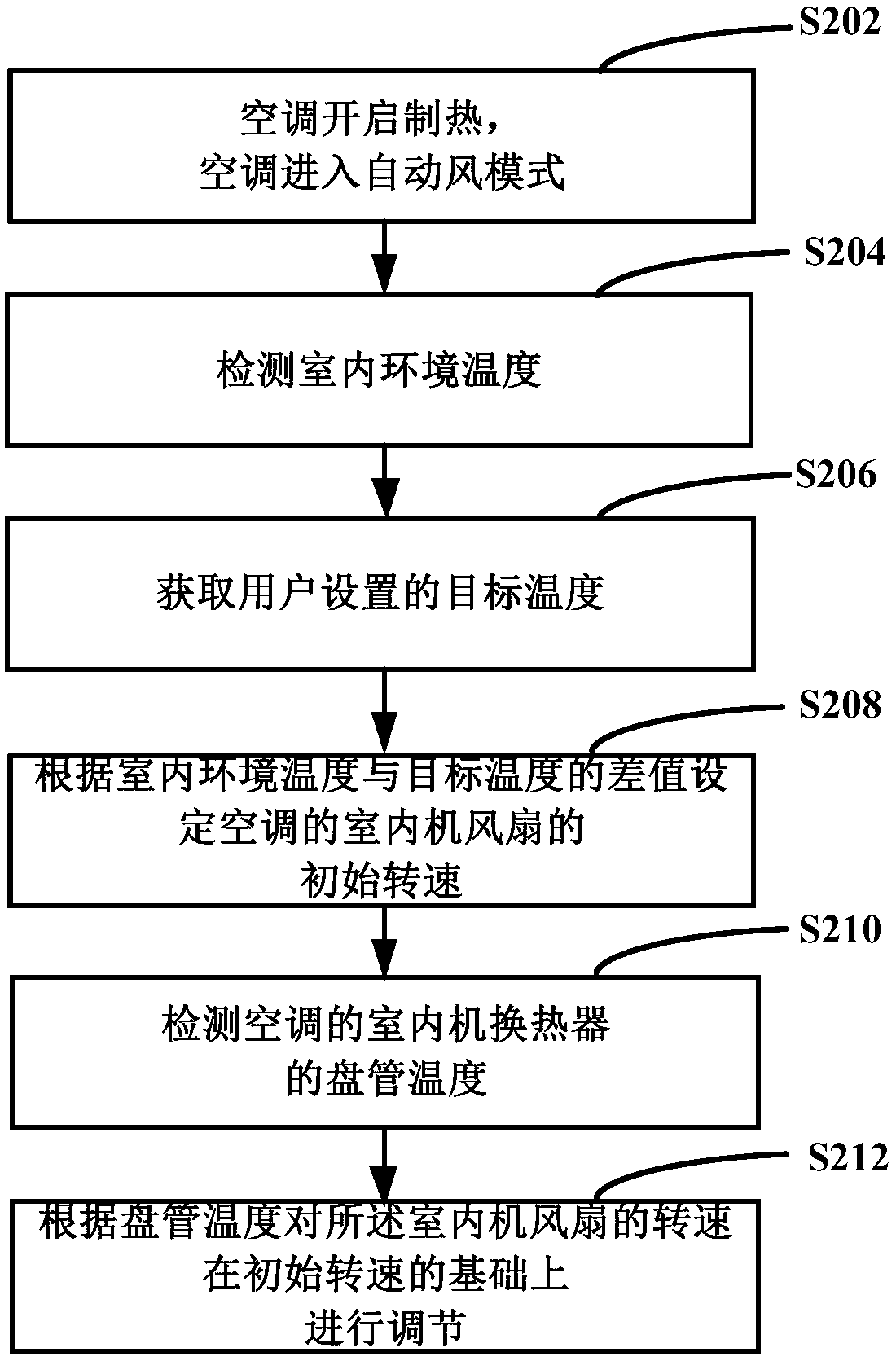

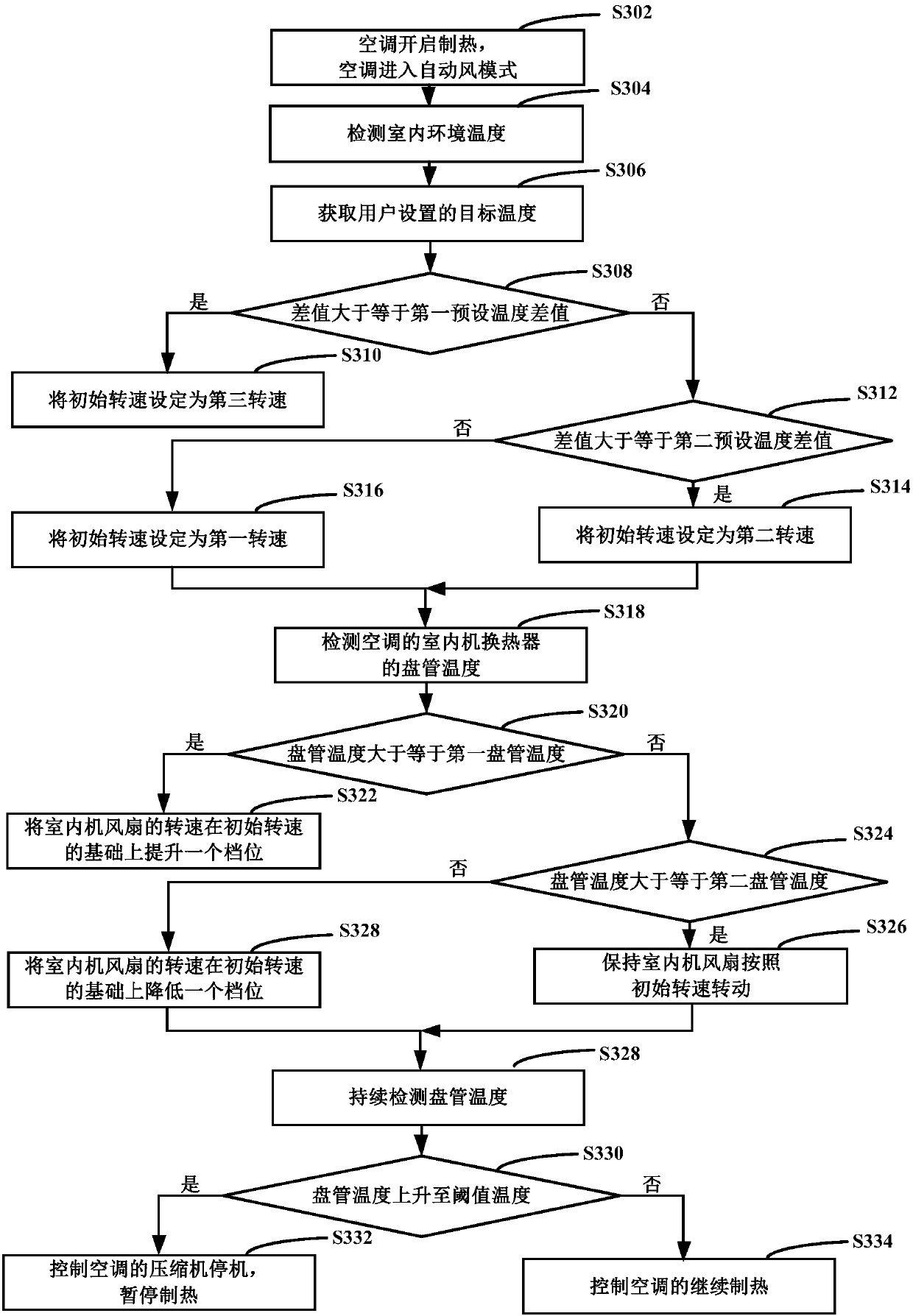

Air conditioner and control method thereof

InactiveCN107940703AImprove user experienceAvoid feeling coldMechanical apparatusSpace heating and ventilation safety systemsEngineeringHeat exchanger temperature

The invention provides an air conditioner and a control method thereof. The control method comprises the steps that the initial rotating speed of a fan of an air conditioner indoor unit is set according to the difference value between the indoor environment temperature and the target temperature; and then the rotating speed of the fan of the indoor unit is further adjusted on the basis of the initial rotating speed according to the temperature of a coil pipe. According to the method, during the heating period of the air conditioner, the heat exchange rate of an indoor unit heat exchanger is controlled by adjusting the rotating speed of the fan of the indoor unit so that the temperature of the indoor unit heat exchanger can be always within a proper temperature range, and the problem of damage to the air conditioner caused by the fact that temperature of the heat exchanger is too high can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Solar thermal collector and method for converting solar energy into mesothermal heat energy by utilizing same

ActiveCN104567026AGood light transmissionGood dustproofSolar heating energySolar heat devicesThermodynamicsTower

The invention discloses a solar thermal collector which comprises a thermal collection pipe, a framework, a reflecting plate and a reflecting plate rotation control device; the reflecting plate is positioned on the back side of the thermal collection pipe, and a focal axis of the reflecting plate is coincident with the axis of the thermal collection pipe; the reflecting plate is used for gathering the solar energy onto a thermal absorbing body of the thermal collection pipe; the reflecting plate rotation control device is used for driving the reflecting plate to rotate by taking the focal axis as a center, so that the reflecting plate can rotate along the change of sunshine. The invention further discloses a method for converting solar energy into mesothermal heat energy by utilizing the solar thermal collector, so that the self tracking of sunshine can be realized, the problems of common tank type, tower type, butterfly type, Fresnel type thermal collection modes are high in cost, and incapable of combining with a factory building and the problem that the non-tracking focusing mode is small in focusing ratio can be solved, 4-20 times of solar focusing ratio can be realized, solar energy is efficiently converted into mesthermal heat energy to obtain a stable mesothermal heat source of 100DEG C-300DEG C.

Owner:NANJING CHENGYUAN SOLAR HEATING

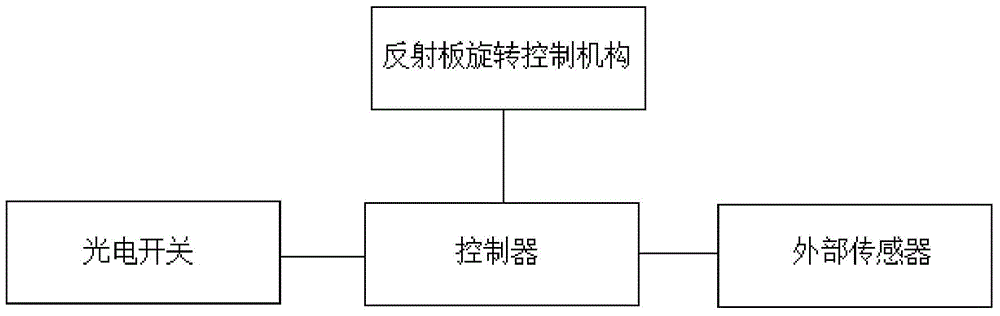

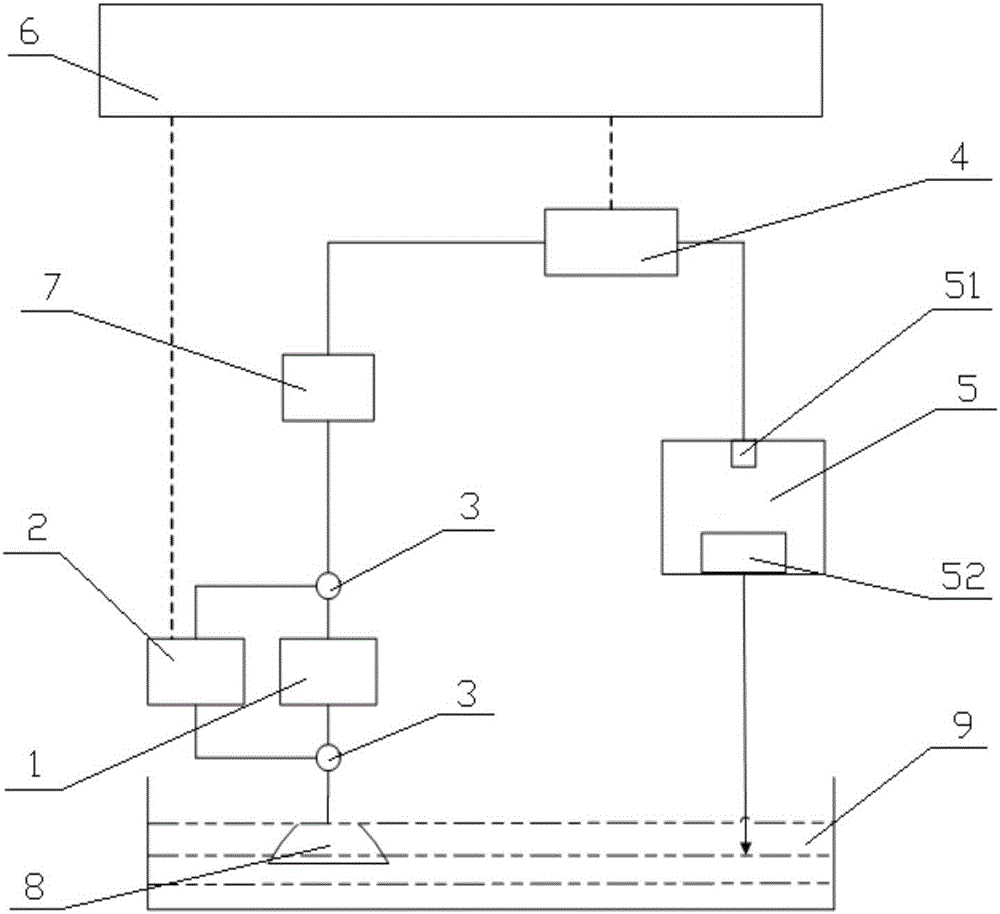

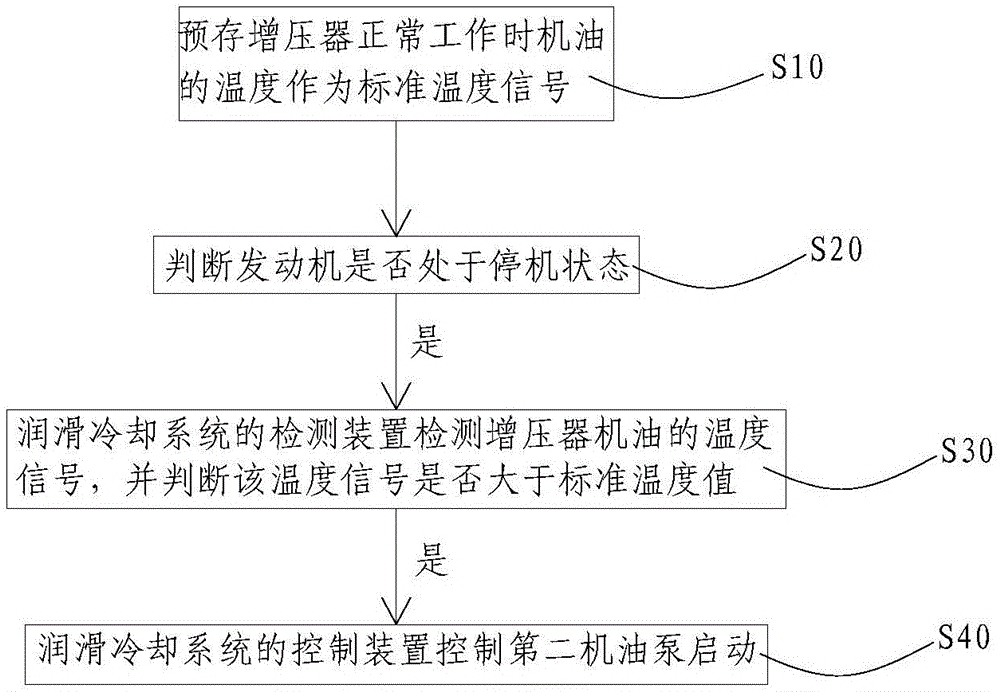

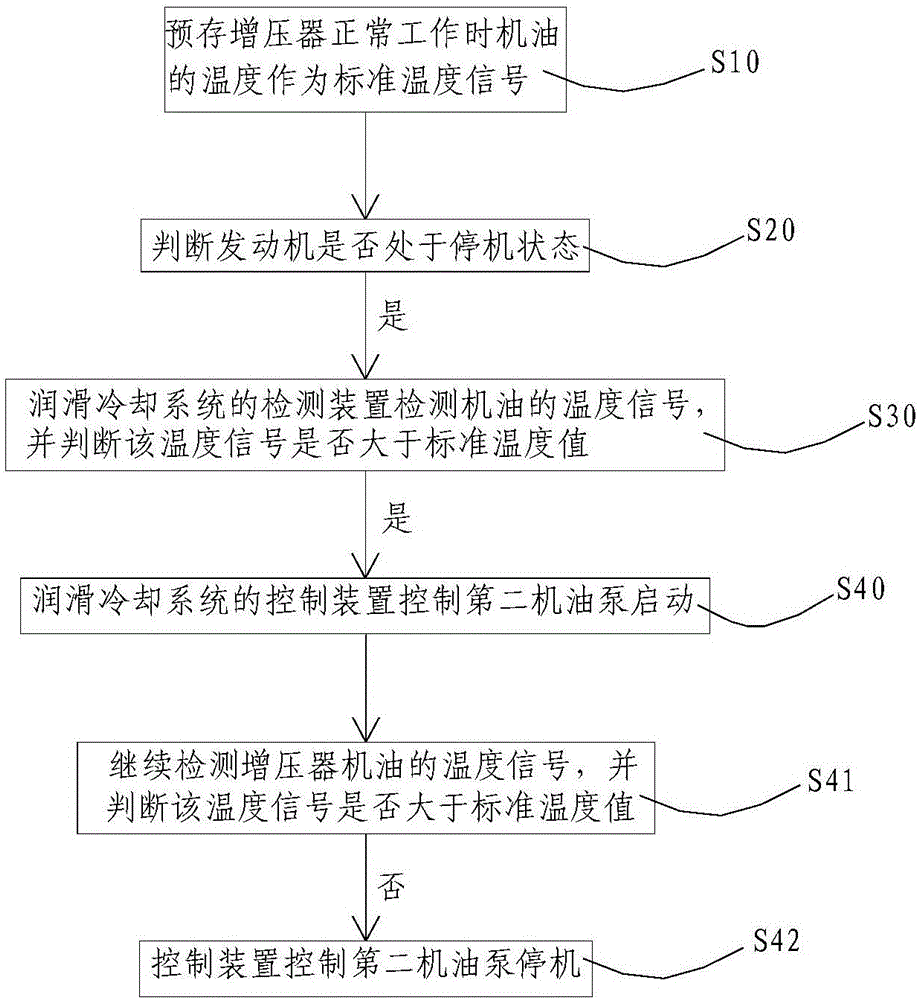

Hybrid power vehicle and lubricating and cooling system and method of supercharger

InactiveCN106368805AHigh working reliabilityExtended service lifeLiquid coolingMachines/enginesOil temperatureHybrid vehicle

The invention discloses a lubricating and cooling system of a supercharger. The lubricating and cooling system comprises a first engine oil pump and further comprises a second engine oil pump, a monitoring device and a control device. The second engine oil pump is connected with the first engine oil pump in parallel. The monitoring device is used for monitoring the temperature signal of engine oil in the supercharger. The control device prestores the engine oil temperature during normal work of the supercharger, and the engine oil temperature during normal work of the supercharger serves as the standard temperature value. When an engine is in a shutdown state and the temperature signal is larger than the standard temperature value, the control device controls the second engine oil pump to be started; and when the engine is in the shutdown state, the second engine oil pump can supply oil to the supercharger, and therefore the supercharger can be cooled, the overheat phenomenon of the supercharger is prevented, and therefore the working reliability of the supercharger is improved, and the service life of the supercharger is prolonged. The invention further discloses a hybrid power vehicle. The invention further discloses a lubricating and cooling method of the supercharger.

Owner:WEICHAI POWER CO LTD

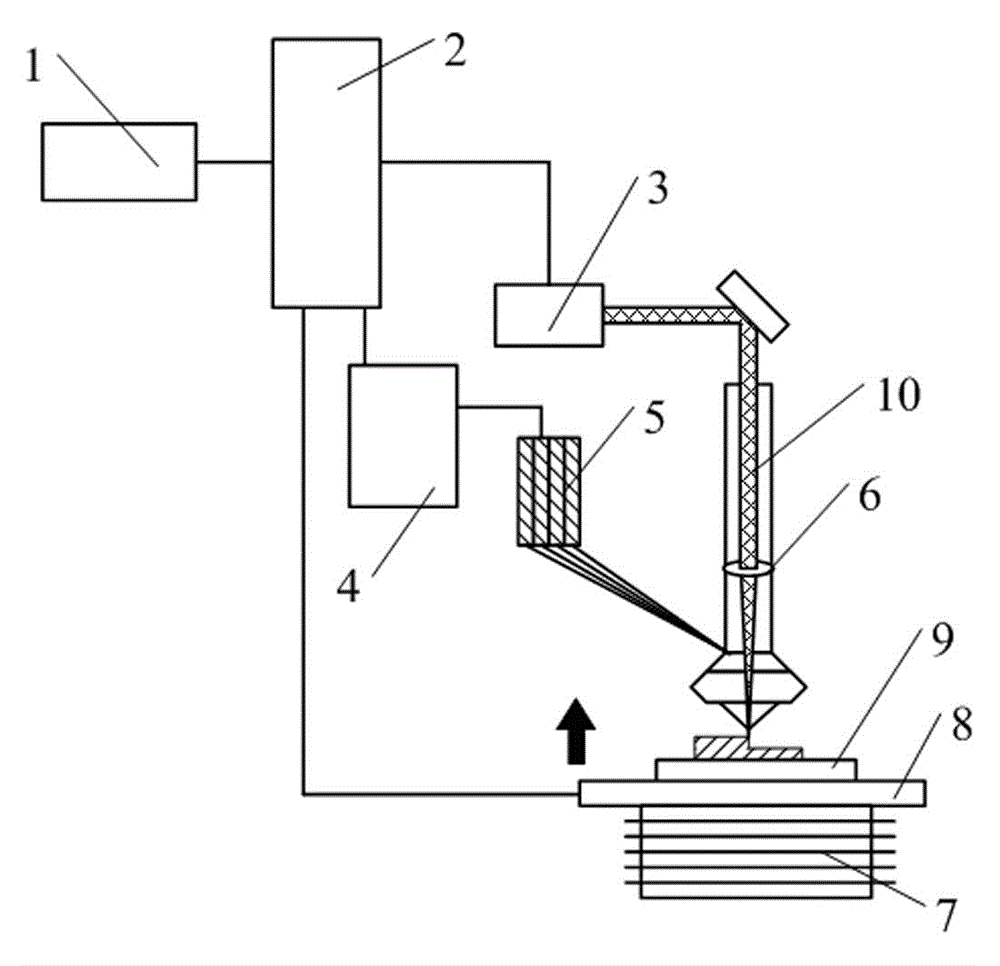

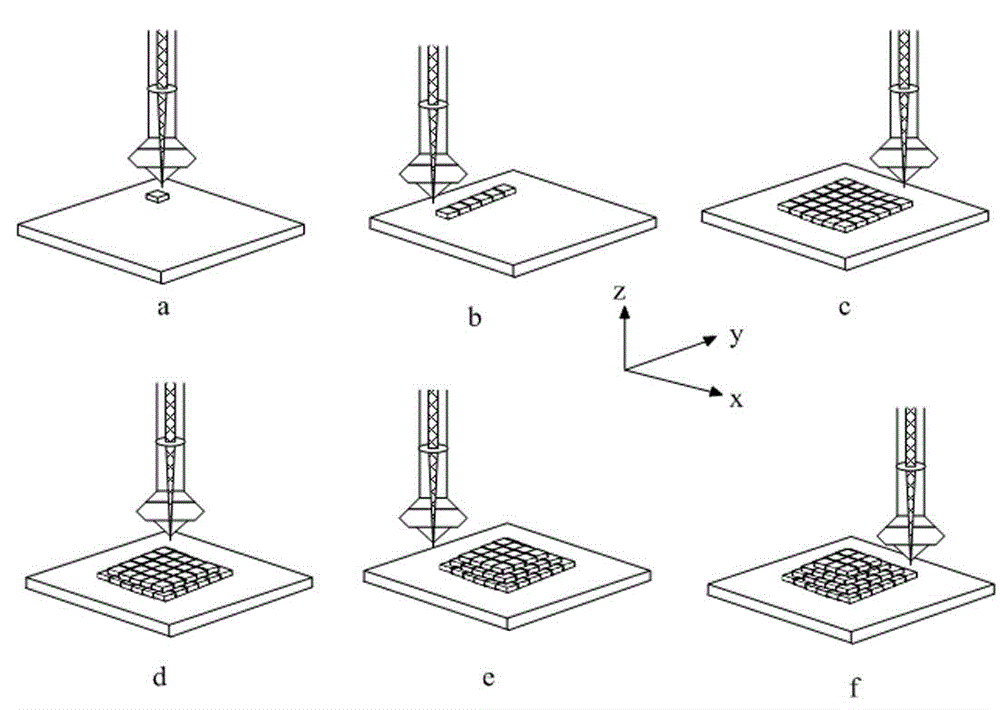

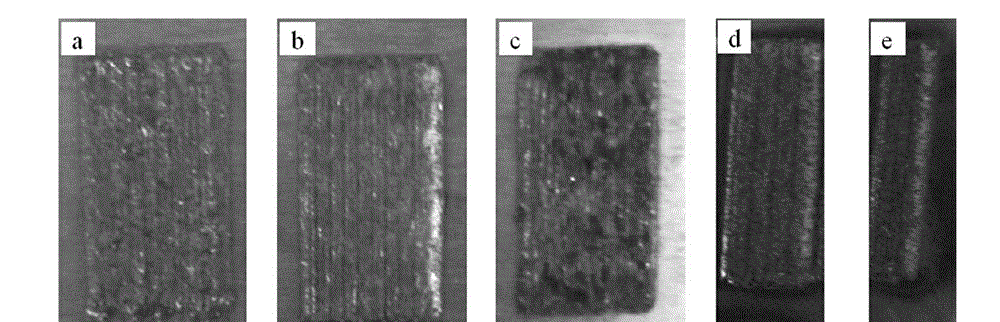

Method for preparing rare earth permanent magnet through laser additive fast forming and sintering in hot isostatic pressing mode

ActiveCN104377027ASave raw materialsReduce production processInorganic material magnetismInductances/transformers/magnets manufactureRare earthHigh pressure

The invention provides a method for preparing a rare earth permanent magnet through laser additive fast forming and sintering in a hot isostatic pressing mode, and belongs to the technical field of materials. The method comprises the following steps that (1), Nd / Pr / Dy-Fe-B micro powder is prepared; (2), programs are compiled in a control computer of a 3D printing device; (3), a base plate is installed on a work table, laser power is adjusted, and the spot size is controlled; (4), high-pressure nitrogen or argon is utilized for blowing the Nd / Pr / Dy-Fe-B micro powder into a feeding pipeline, and the conveying capacity is adjusted; (5), the Nd / Pr / Dy-Fe-B micro powder is sprayed on the base plate, an electromagnet is used for exerting a magnetic field, and laser is irradiated on the Nd / Pr / Dy-Fe-B micro powder on the base plate; scanning and sintering are sequentially carried out according to the programs to obtain a magnet rough blank; (6), the magnet rough blank is sintered in the hot isostatic pressing mode. A product obtained through the method can be directly used after the surface defects such as uneven surfaces and oxide skin are removed through polishing, and post-processing working procedures of slicing, polishing, wire-electrode cutting and the like are not needed.

Owner:NORTHEASTERN UNIV

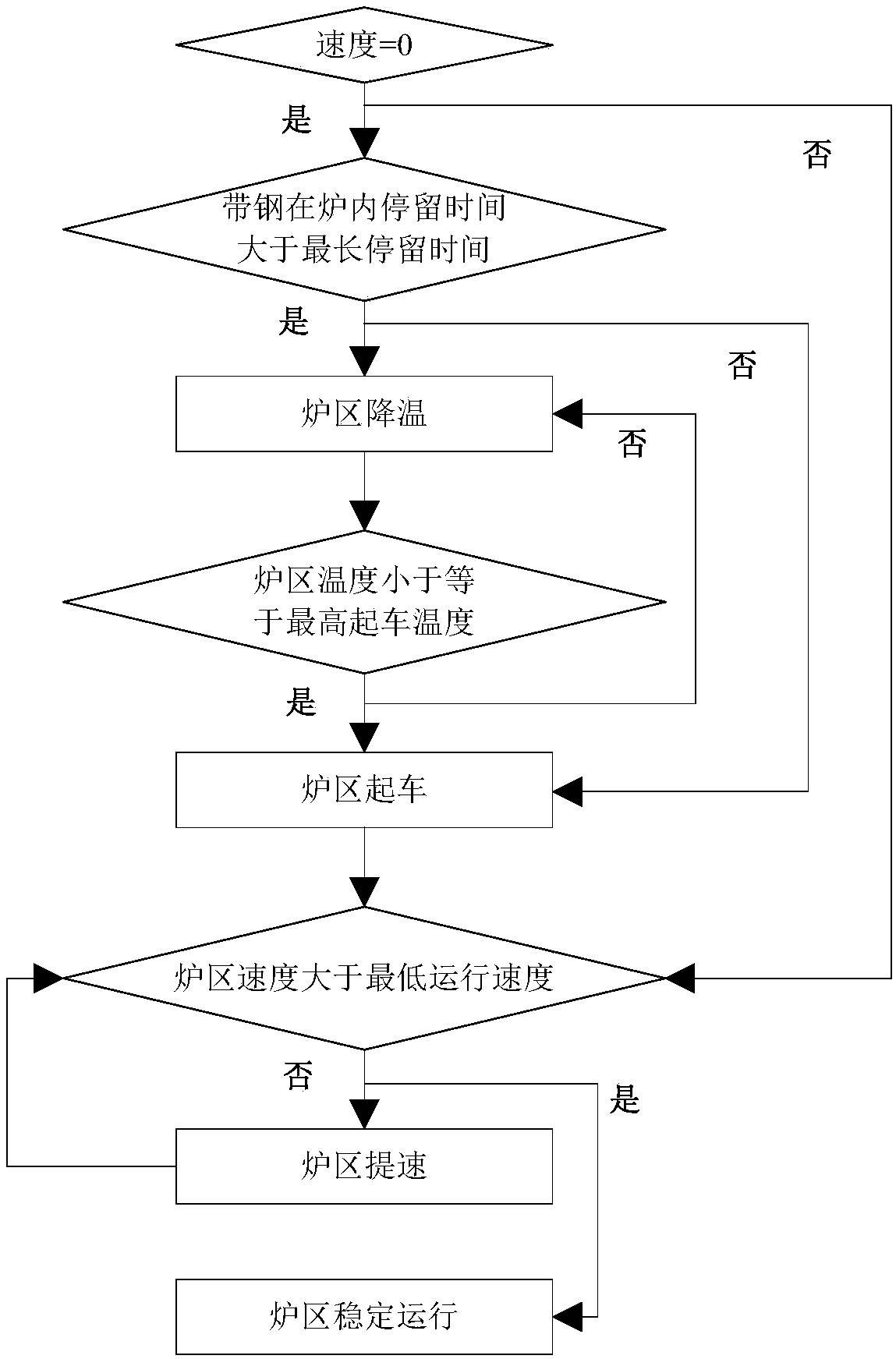

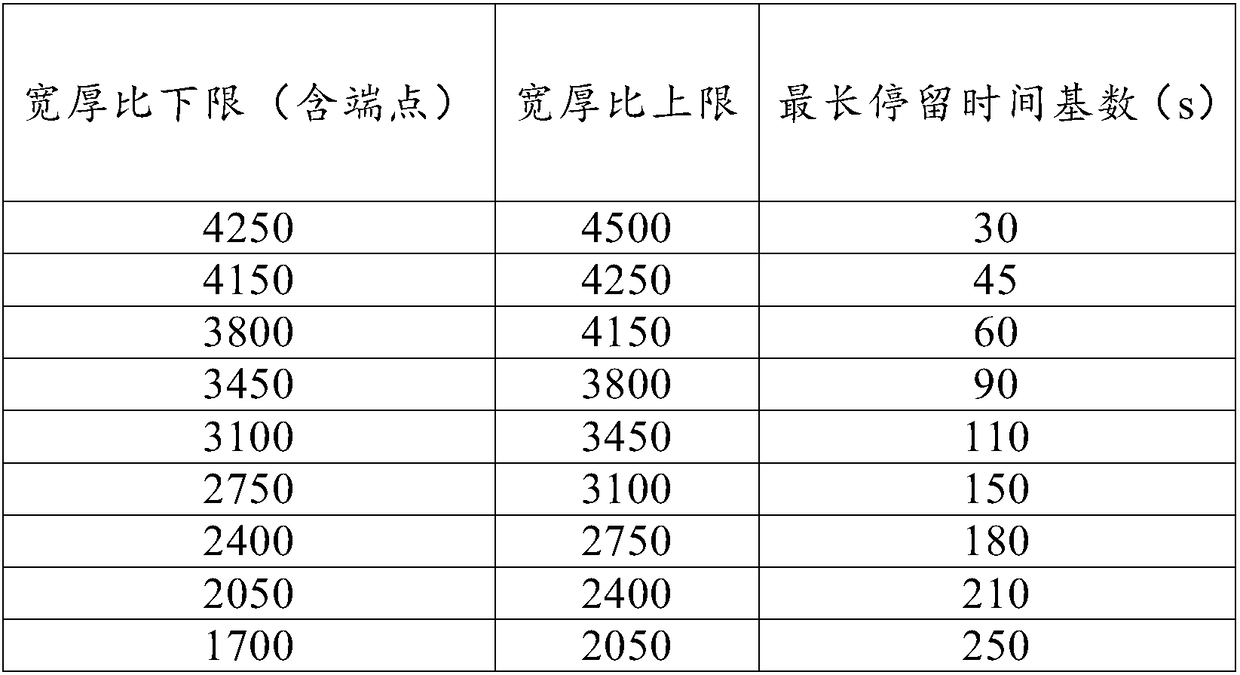

Method for preventing strip steel from buckling in annealing furnace

ActiveCN108384944AAvoid warpingPrevent overheating"Furnace typesHeat treatment process controlStrip steelTemperature coefficient

The invention belongs to the technical field of steel rolling and discloses a method for preventing strip steel from buckling in an annealing furnace. The method for preventing the strip steel from buckling in the annealing furnace includes the steps that the minimum running speed is controlled, and the running speed of the strip steel in the annealing furnace is controlled to be larger than or equal to the minimum running speed; the minimum running speed Vmin= V(w / Thi) X Fv(w) X fv(opt_strip_temp), Fv(w) is a minimum running speed _width coefficient, and fv(opt_strip_temp) a minimum running speed _temperature coefficient; V(w / Thi) is a minimum running speed cardinal number and is solved through V(w / Thi)=(1-sigma / sigma a) x Vmax; and Vmax is a theoretical maximum production speed accordingto the specification, sigma is unit tension, and sigma a is critical tension. The method for preventing the strip steel from buckling in the annealing furnace is provided, it is achieved that the strip steel buckling risk is substantially reduced, and the strip steel quality stability is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

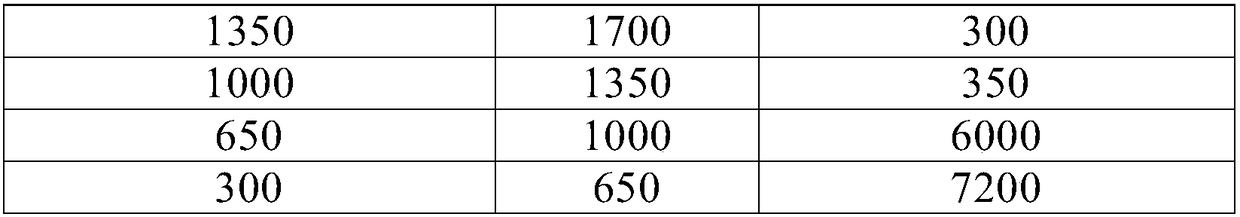

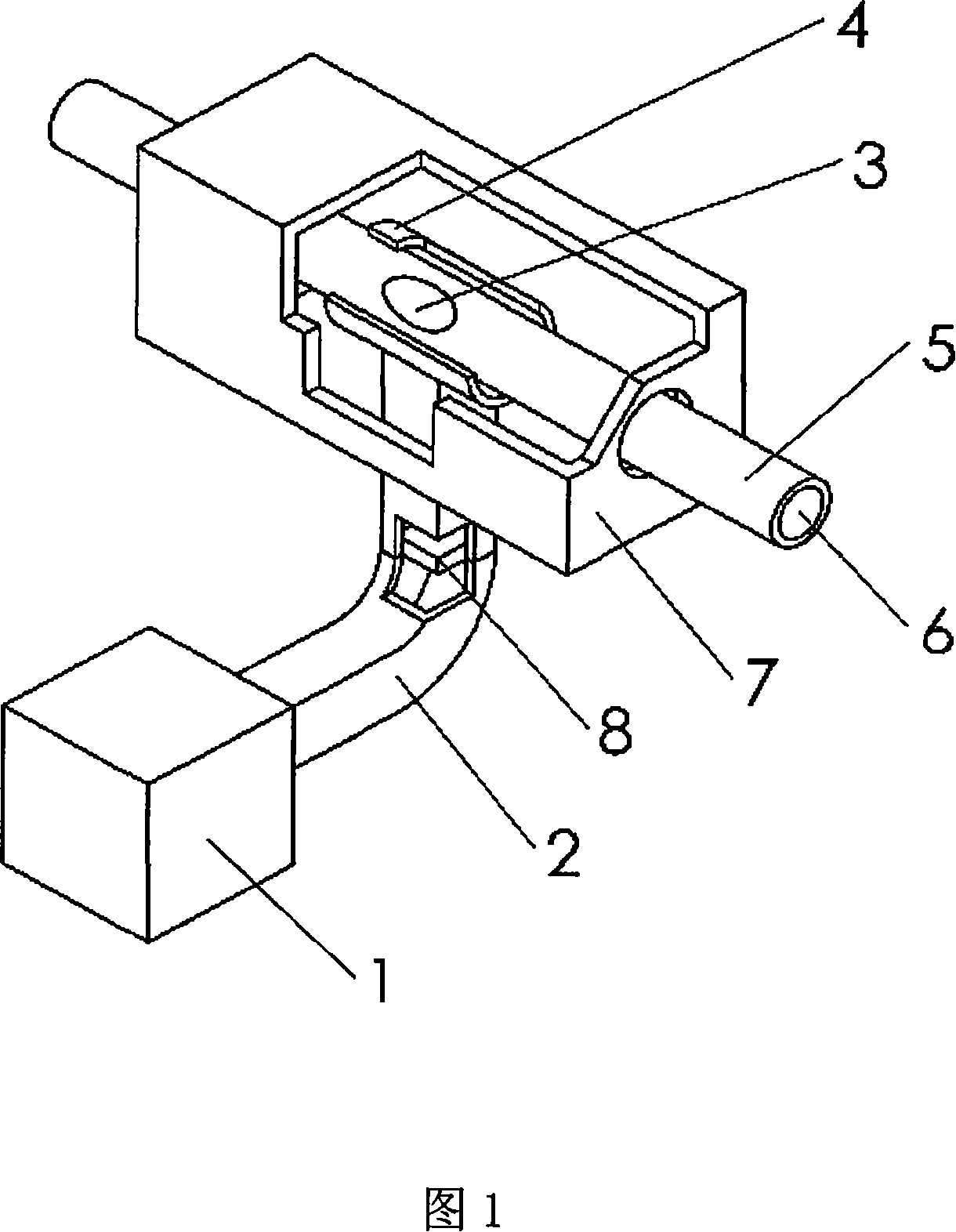

Centrifugal type partition-net-free material bead separator for media stirring mill

InactiveCN103357489AAchieve separationStrong centrifugal forceGrain treatmentsTurbine wheelEngineering

The invention discloses a centrifugal type partition-net-free material bead separator for a media stirring mill. The centrifugal type partition-net-free material bead separator comprises a main shaft (1), a discharge shaft head (2), a separation turbine wheel (3), a rotor (4) and a discharge pipe (5), wherein the discharge shaft head is provided with a plurality of chutes which are communicated and tangent with an inner circle so as to form a turbine, the turbine is assembled with the separation turbine wheel, the rotor and the main shaft so as to form small, middle and large packaging turbines which generate powerful centrifugal force in a rotating process; milling beads and grinding materials with large particle diameters are thrown out of an outer layer, the grinding materials with small particle diameters bear small centrifugal force so as to overcome the centrifugal force of the turbine under the pressure effect of a pump to enter the discharge pipe to be discharged, the effective segregation of the material beads is ideally realized, and the influence of the diameter sizes of the milling beads is free. The designed separator provided by the invention has the advantages that the manufacturing cost is low, the grinding and dispersion efficiency is greatly improved, the particle diameter of a product after primary grinding is obviously reduced, and compared with a traditional same type grinding machine, the centrifugal type partition-net-free material bead separator has the advantage that the yield is increased by 40-100%.

Owner:谢小飞

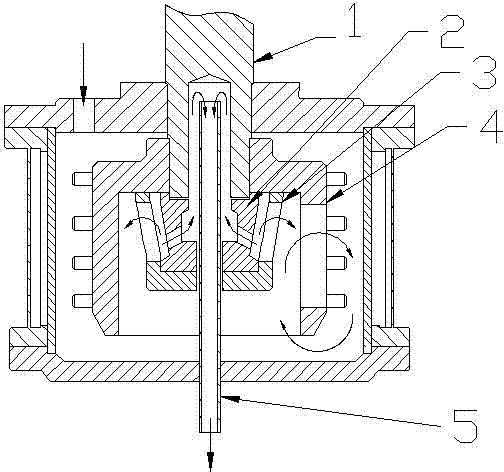

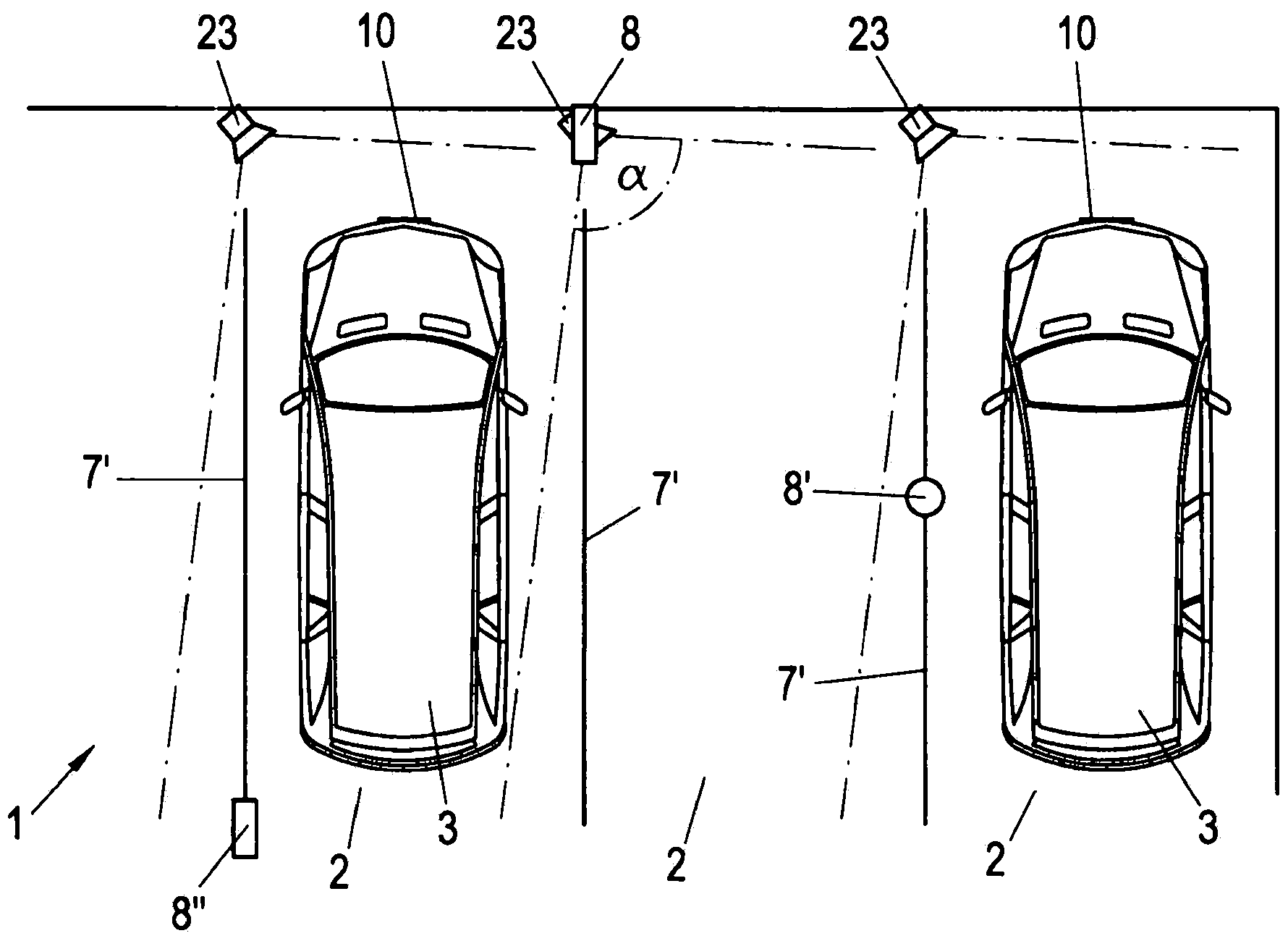

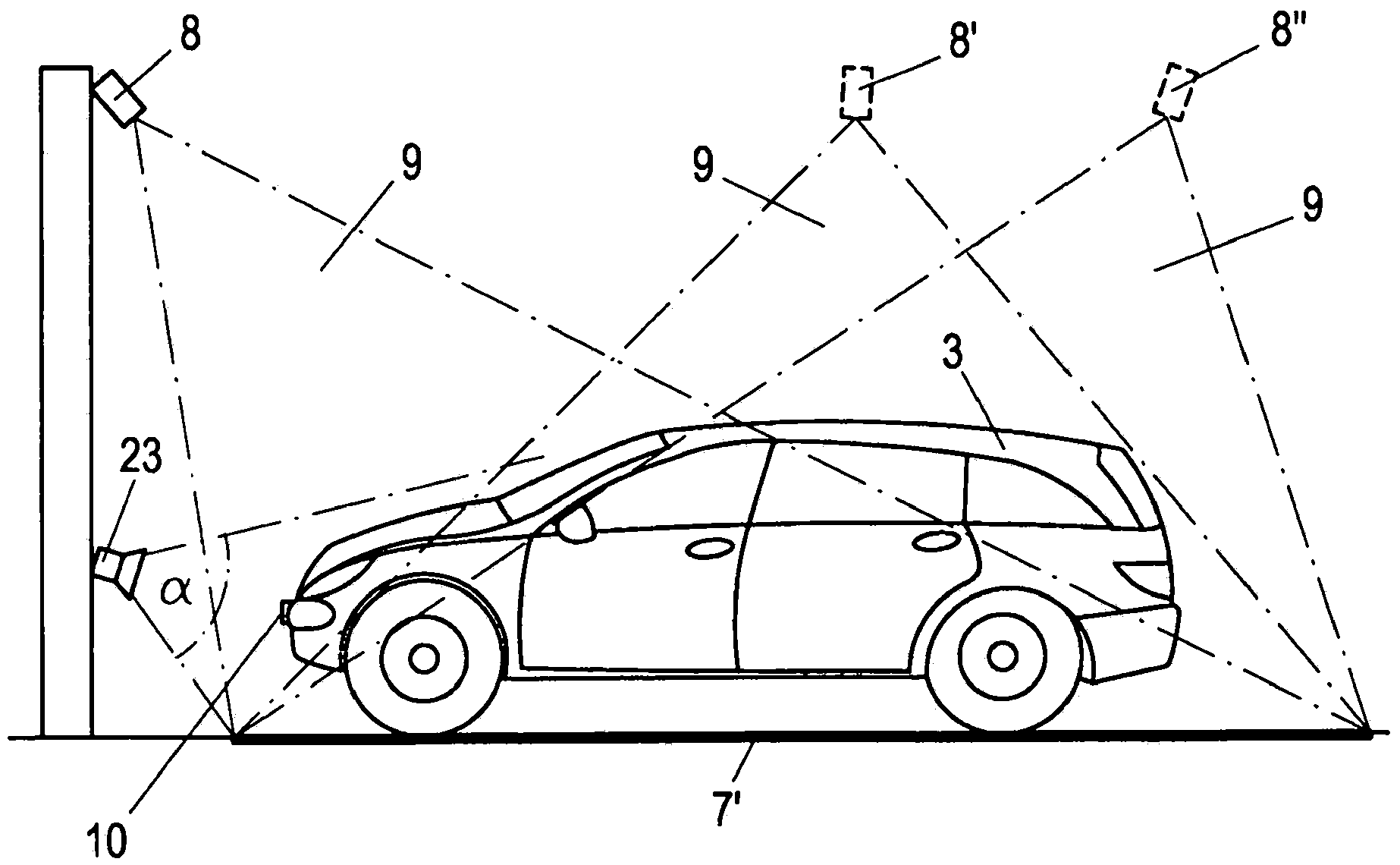

Device for monitoring a vehicle parking place

InactiveCN103430225AReduce the risk of interferenceImprove securityCharging stationsIndication of parksing free spacesParking spaceComputer science

The parking lot (1) has a reservation system having a common radio beacon unit (15) and a camera unit (17) that are provided at an entrance (5) for reading out of radio identifier (14) and vehicle identifier (11) of an entering vehicle (3) respectively. Each parking space (2) is provided with a fixed camera unit (23) for performing optical character recognition (OCR) reading of a vehicle registration plate of parked vehicle. The central computer is adapted to verify whether data read by fixed mounted camera unit is identical to data read by camera unit mounted at entrance.

Owner:KAPSCH TRAFFICCOM AG

Plasma resonant cavity waveguide assembly with heat insulating function

ActiveCN101109075AEnhance the effect of cutting off heat radiationPrevent overheatingChemical vapor deposition coatingResonatorThermal radiation

The invention relates to a plasma resonator waveguide device with heat insulation function used for a PCVD optical fiber preform machining tool. The invention comprises a microwave generator, a wave guide and a plasma resonator; wherein, the microwave generator is conducted with the plasma resonator through the wave guide; the plasma resonator is arranged inside a heating furnace; the difference lies in that the waveguide internal cavity channel is provided with a heating separator. The invention can effectively prevent the heat radiation from entering into the microwave generator through the waveguide device without affecting the transmission of the microwave, which avoids the overheated state of the microwave generator and makes the microwave generator operate under a relative lower temperature, thus enhancing the service life of the microwave generator and the components thereof. The plasma resonator waveguide system is capable of working for longer time under a larger power, and further improves the effect of the PCVD process. The invention is simple in structure, easy to operation and convenient to refit the existing equipment.

Owner:YANGTZE OPTICAL FIBRE AND CABLE JOINT STOCK LIMITED COMPANY

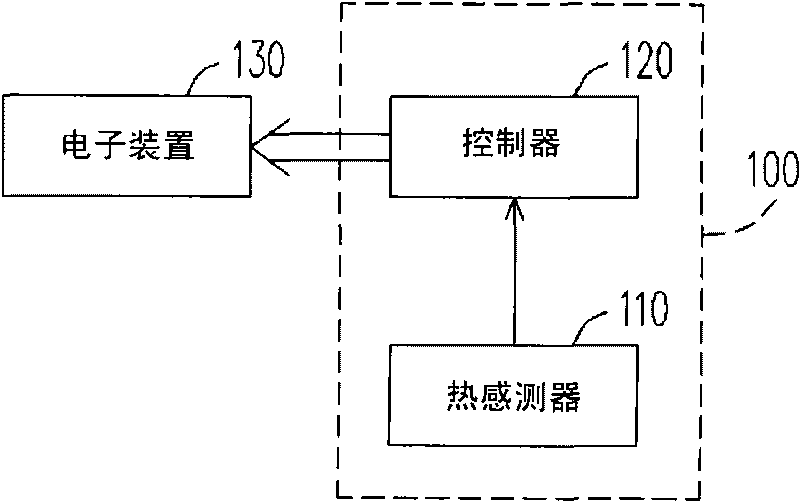

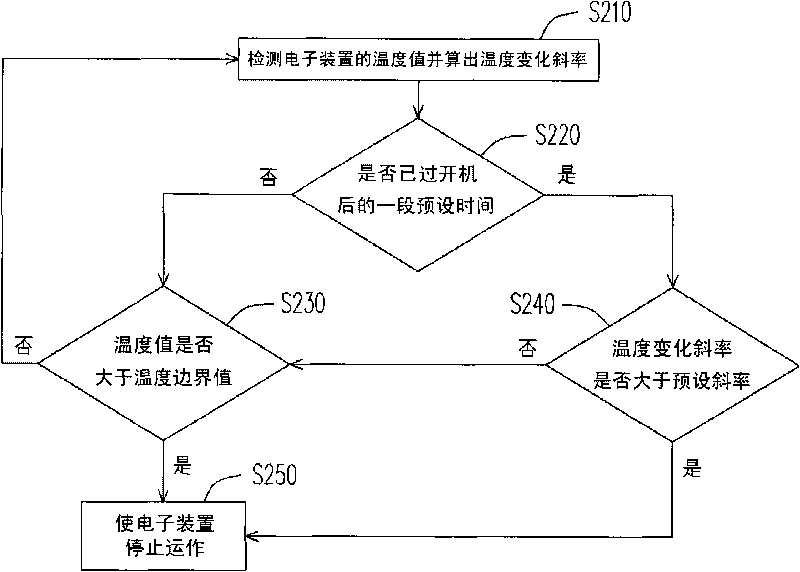

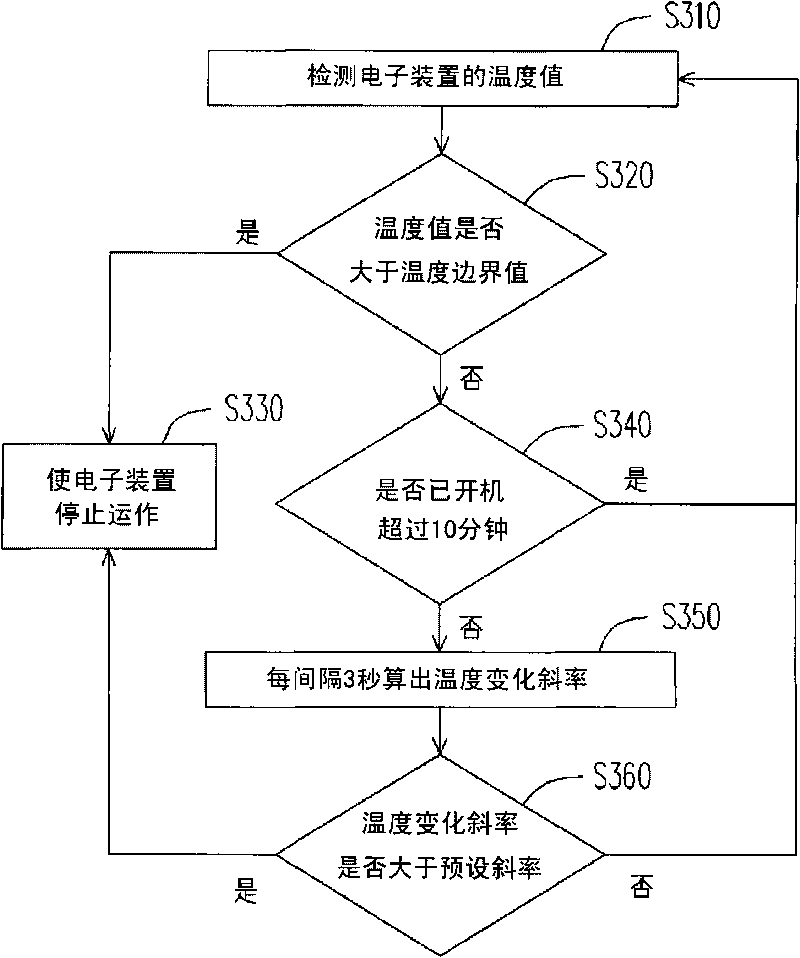

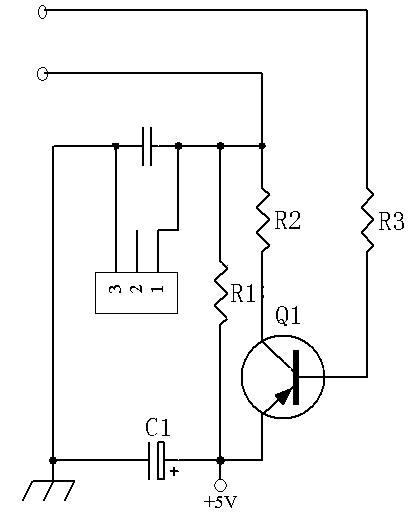

Overheating protection device and method of electronic device

InactiveCN101741067AEarly detection of temperature anomaliesPrevent overheatingThermometers using electric/magnetic elementsUsing electrical meansBoundary valuesEngineering

Owner:INVENTEC CORP

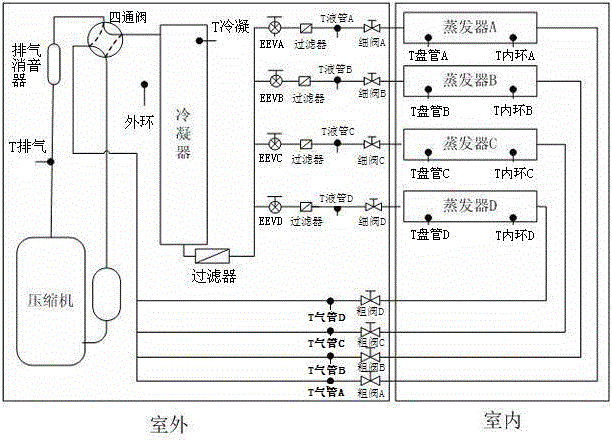

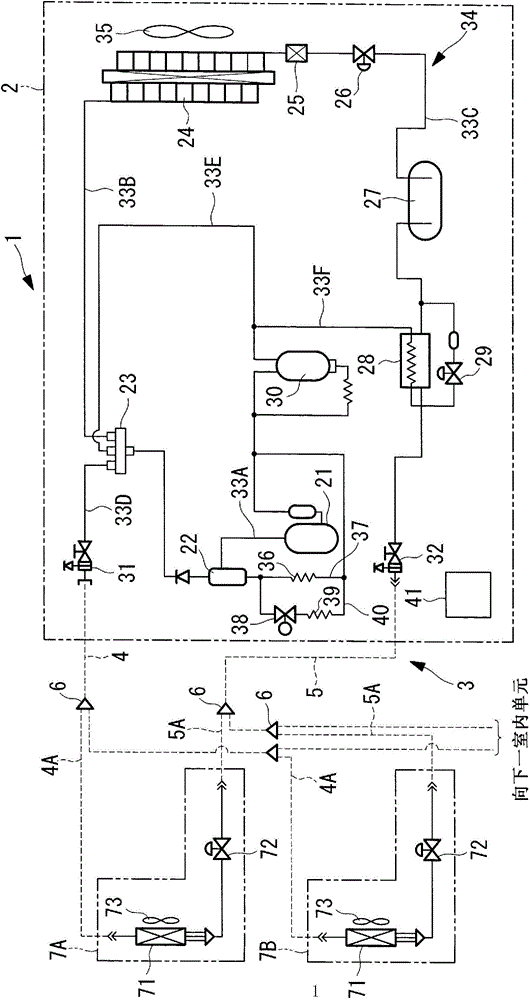

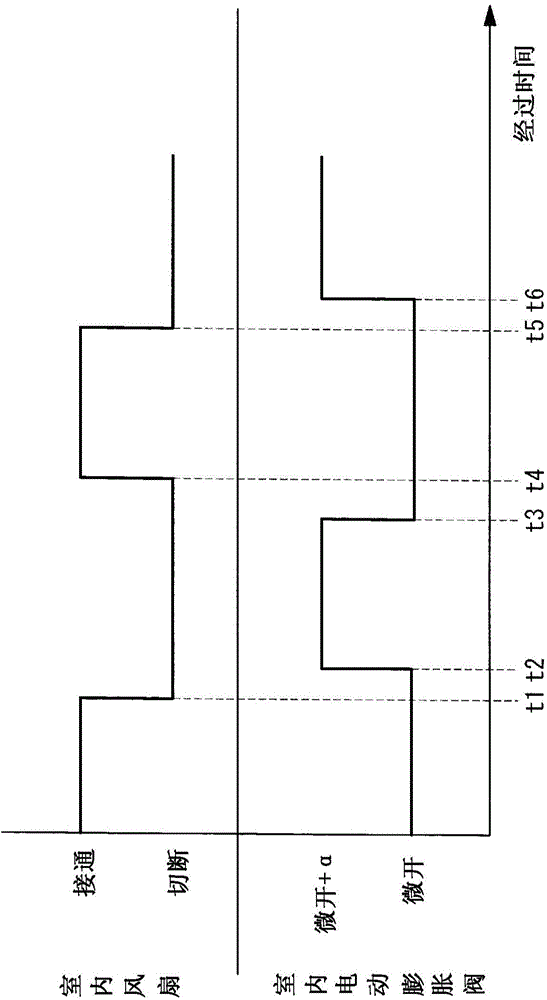

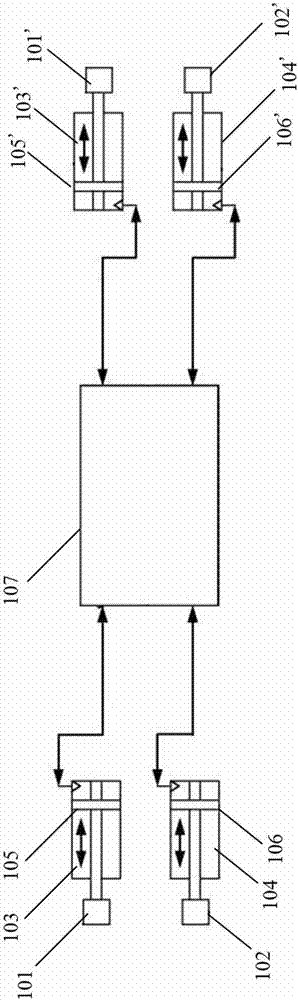

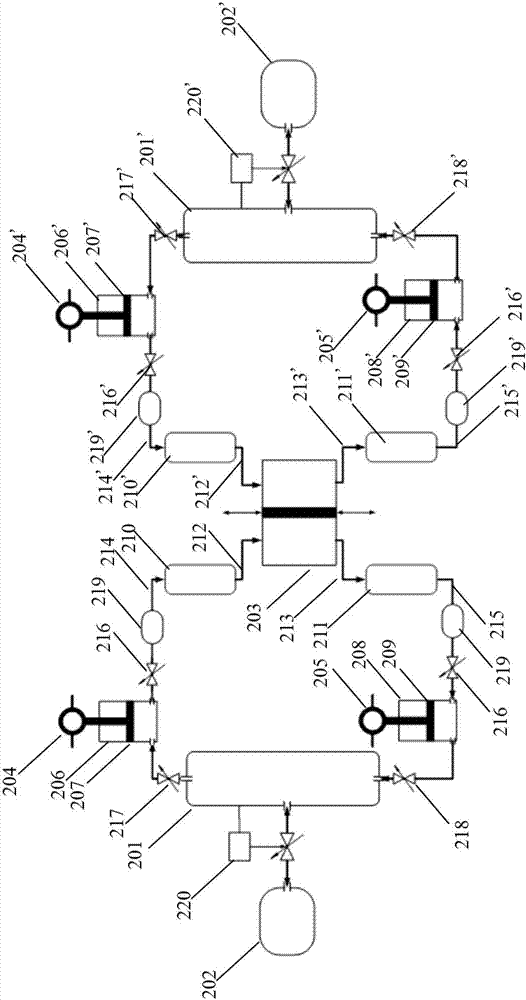

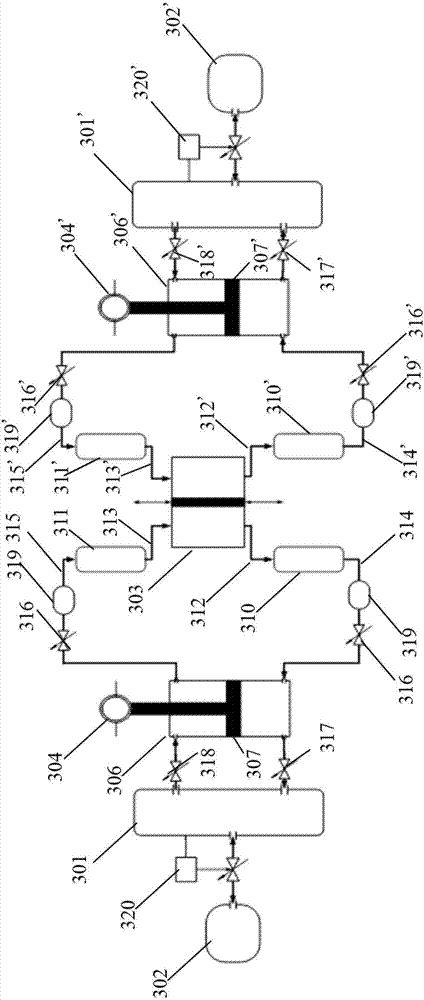

Control device, method, and program, and multi-type air conditioning system comprising same

ActiveCN104067064APrevent overheatingPrevent low breathMechanical apparatusSpace heating and ventilation safety systemsEngineeringThermostat

A control device (41) that prevents excessive heating, prevents low gas, and intermittently operates fans for indoor units in a thermo-off state. The control device (41) controls the operation of a multi-type air conditioning system (1) in which a plurality of indoor units (7) are connected to an outdoor unit (2), and the flowrate for a refrigerant caused to flow through refrigerant piping is adjusted by the degree of opening of an indoor electric expansion valve (72). When the thermostat is off during warming and when the control unit (41) is performing intermittent operation during which an on-off operation is repeated whereby the fans for the indoor units (7) are operated for a prescribed time and then stopped for a prescribed time, the control unit (41) controls the degree of opening of the indoor electric expansion valve (72) during the off period for the fans for the indoor units (7) so as to be larger than the degree of opening during the on period for the fans for the indoor units (7) and to be no more than the degree of opening for noise reduction.

Owner:MITSUBISHI HEAVY IND THERMAL SYST

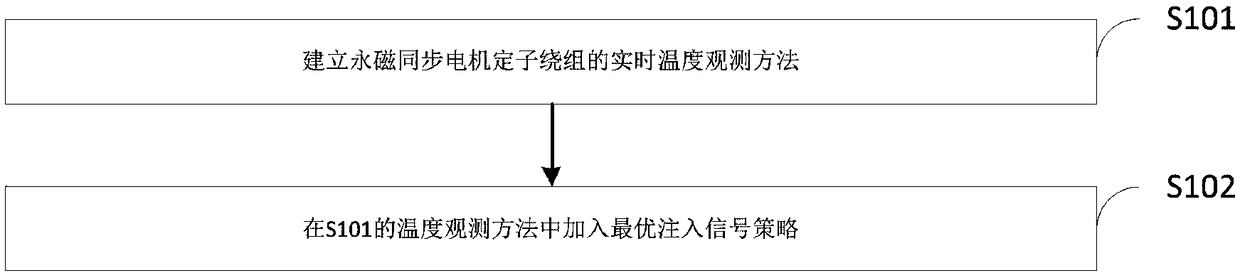

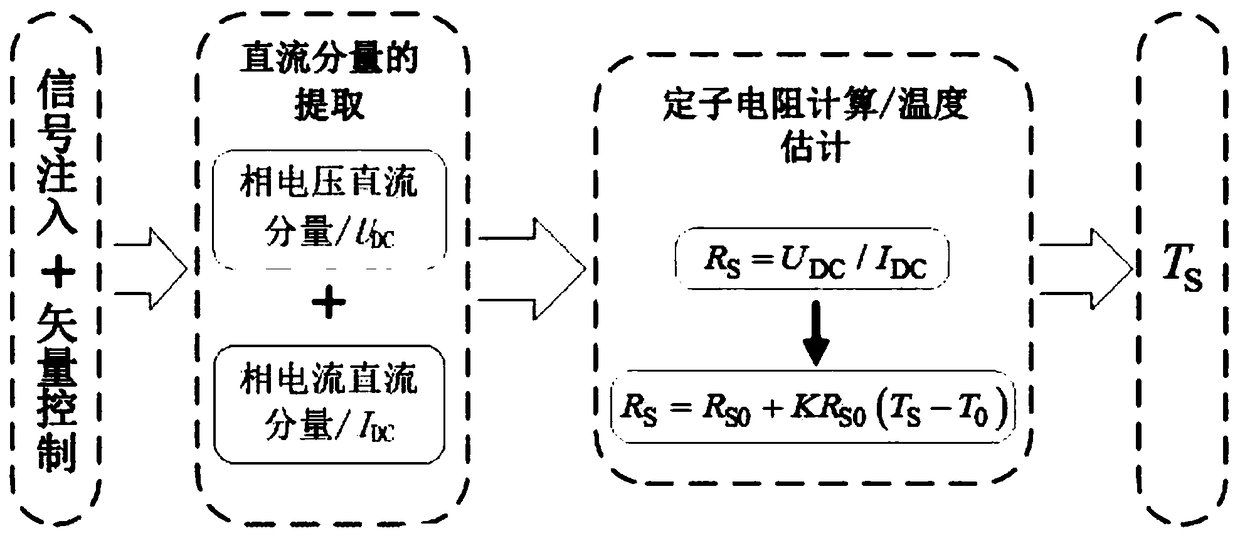

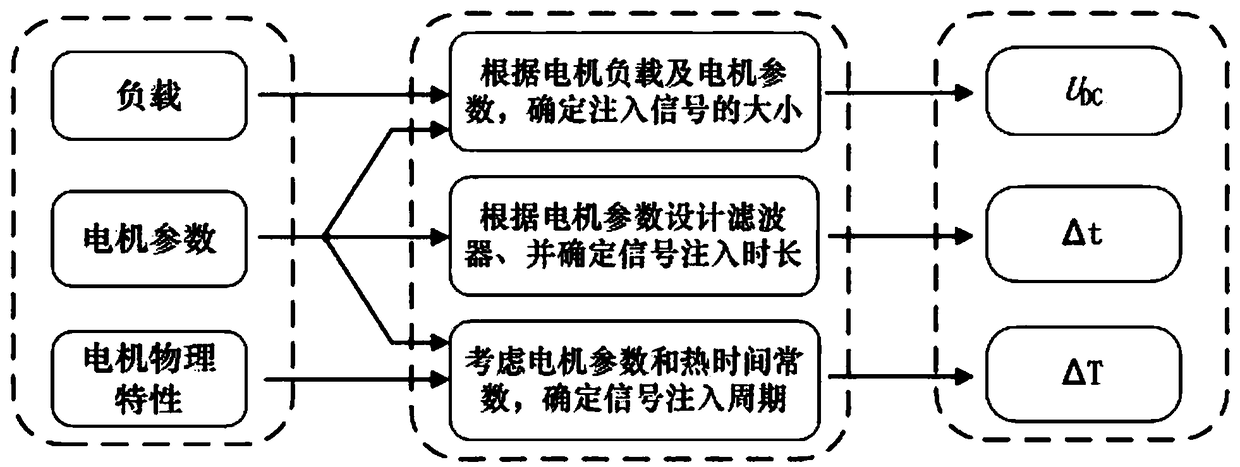

Signal injection-based PMSM stator winding temperature online detection method

InactiveCN108847799AMonitor healthImprove performanceElectronic commutation motor controlAC motor controlElectricityElectrical resistance and conductance

The invention belongs to the technical field of computer systems, and discloses a signal injection-based PMSM stator winding temperature online detection method. The method comprises the steps of establishing a high-performance PMSM stator temperature online calculation method, and adding an optimal signal injection strategy into the online calculation method; adding vector control on the basis ofan existing signal injection method to form a new signal injection method; performing direct current component extraction in the new signal injection method; and calculating the stator resistance andthe estimated temperature and obtaining the real-time temperature observed data. The temperature of the stator winding of a permanent magnet synchronous motor is estimated online, so that the healthcondition of the motor can be monitored, and over-temperature generation can be prevented, and the methods can also be used in motor optimization control such as active heat management and the like, and is beneficial to improving the performance of an electric driving system.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

Four-corner tangential boiler and hearth thereof

InactiveCN104033888AReduce emission contentPrevent overheatingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorPulp and paper industry

The invention relates to a hearth of a four-corner tangential boiler. Four groups of combustors are arranged in the hearth and are respectively arranged at four corners of the hearth; each group of the combustor comprises four groups of primary air nozzles, five groups of secondary air nozzles, a compact overfire air nozzle and a separation overfire nozzle along the height direction of the hearth; the four groups of primary air nozzles and the five groups of secondary air nozzles are arranged at intervals. The uppermost layer of the hearth of the four-corner tangential boiler adopts separation overfire air, and a deflection secondary air technology is adopted for part of the secondary air nozzles, so that the NOx emission content can be reduced, and the combustion efficiency can be improved; a main combustion region on the lower part can enable deflection secondary air to form a layer of air film near a water-cooling wall surface under an oxygen deficient condition, so that the phenomena of slagging and high-temperature corrosion of a water-cooling wall can be prevented; meanwhile, overtemperature pipe explosion of a water-cooling wall pipe is prevented favorably. Furthermore, the invention also relates to the four-corner tangential boiler with the hearth.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

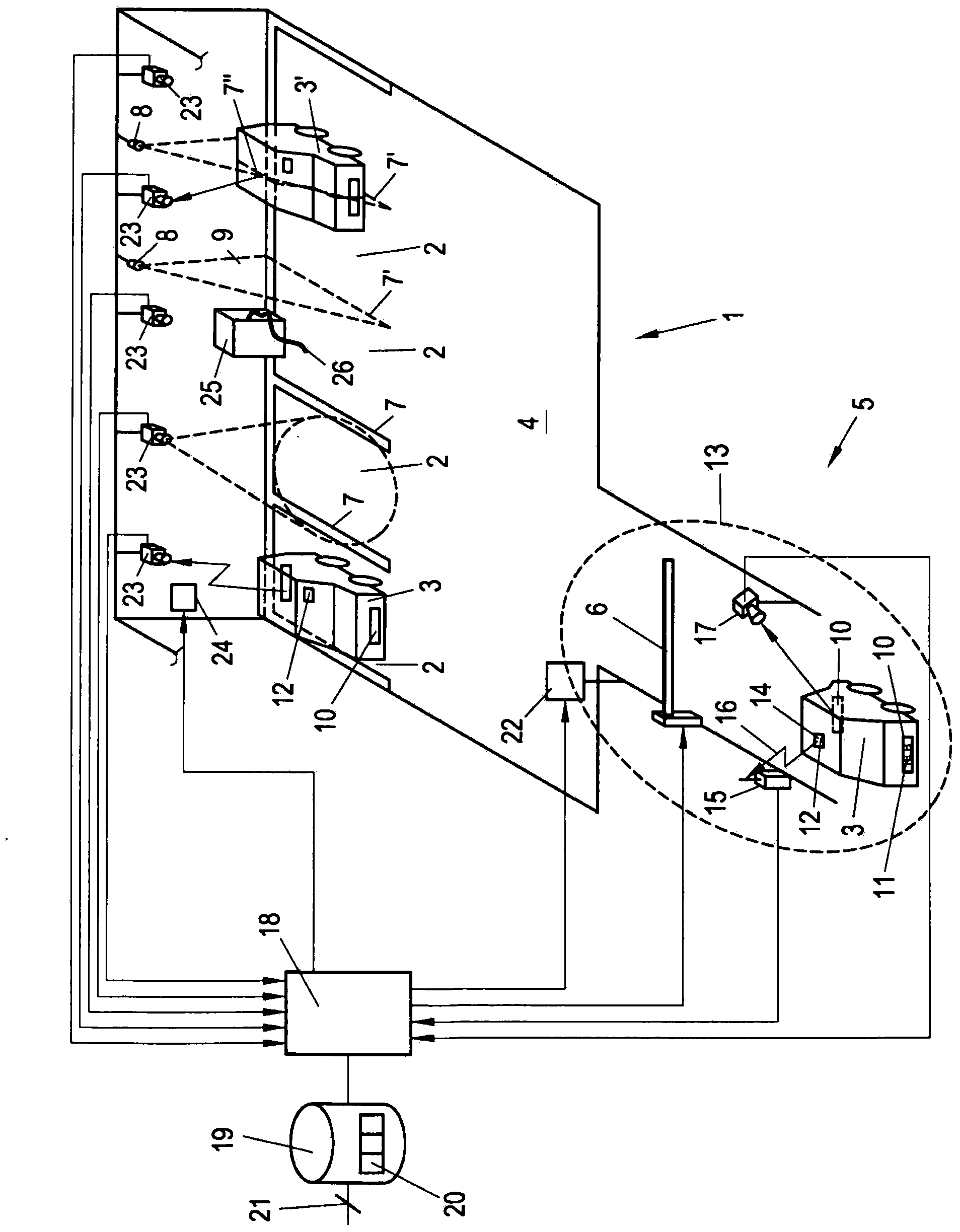

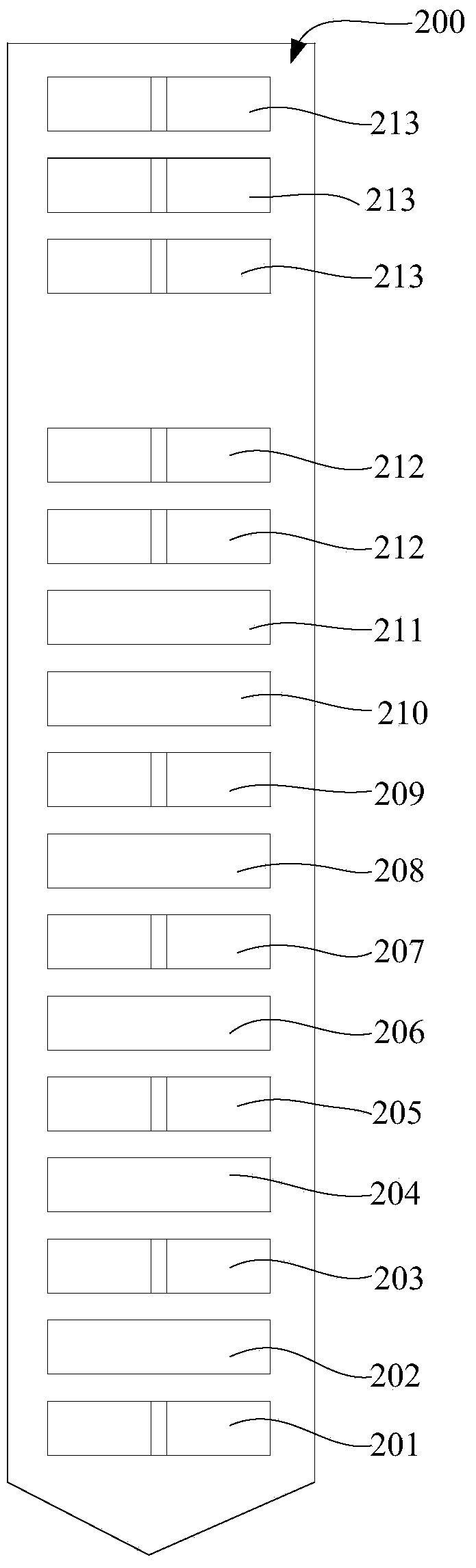

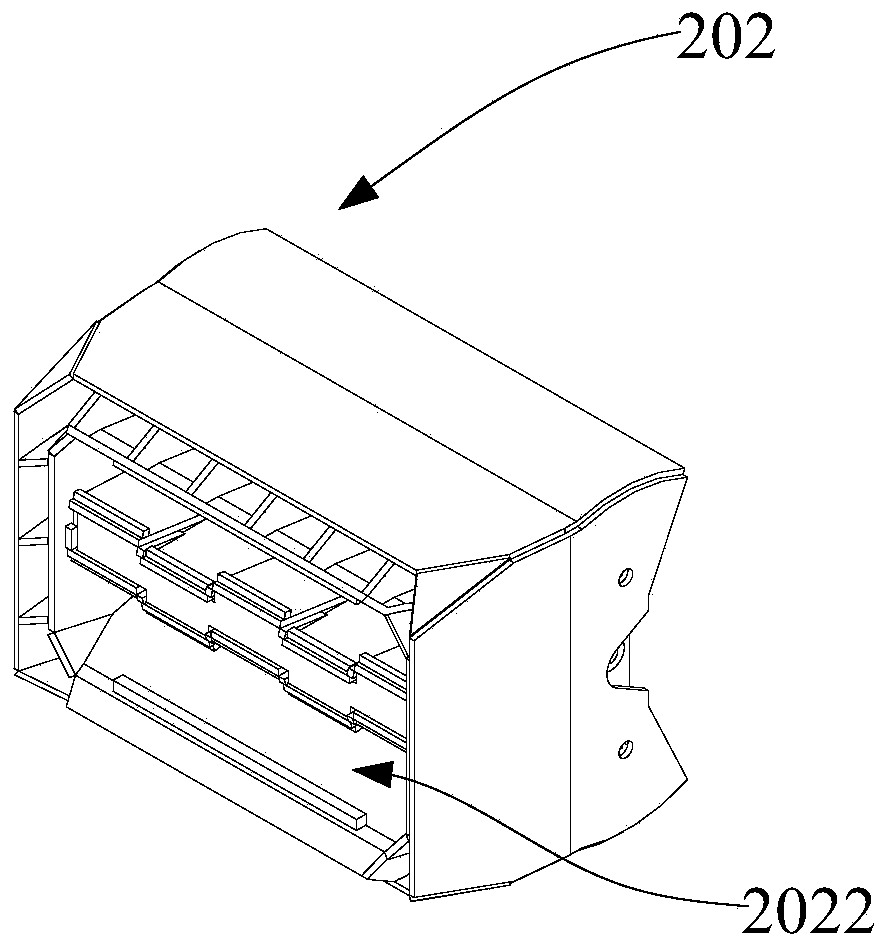

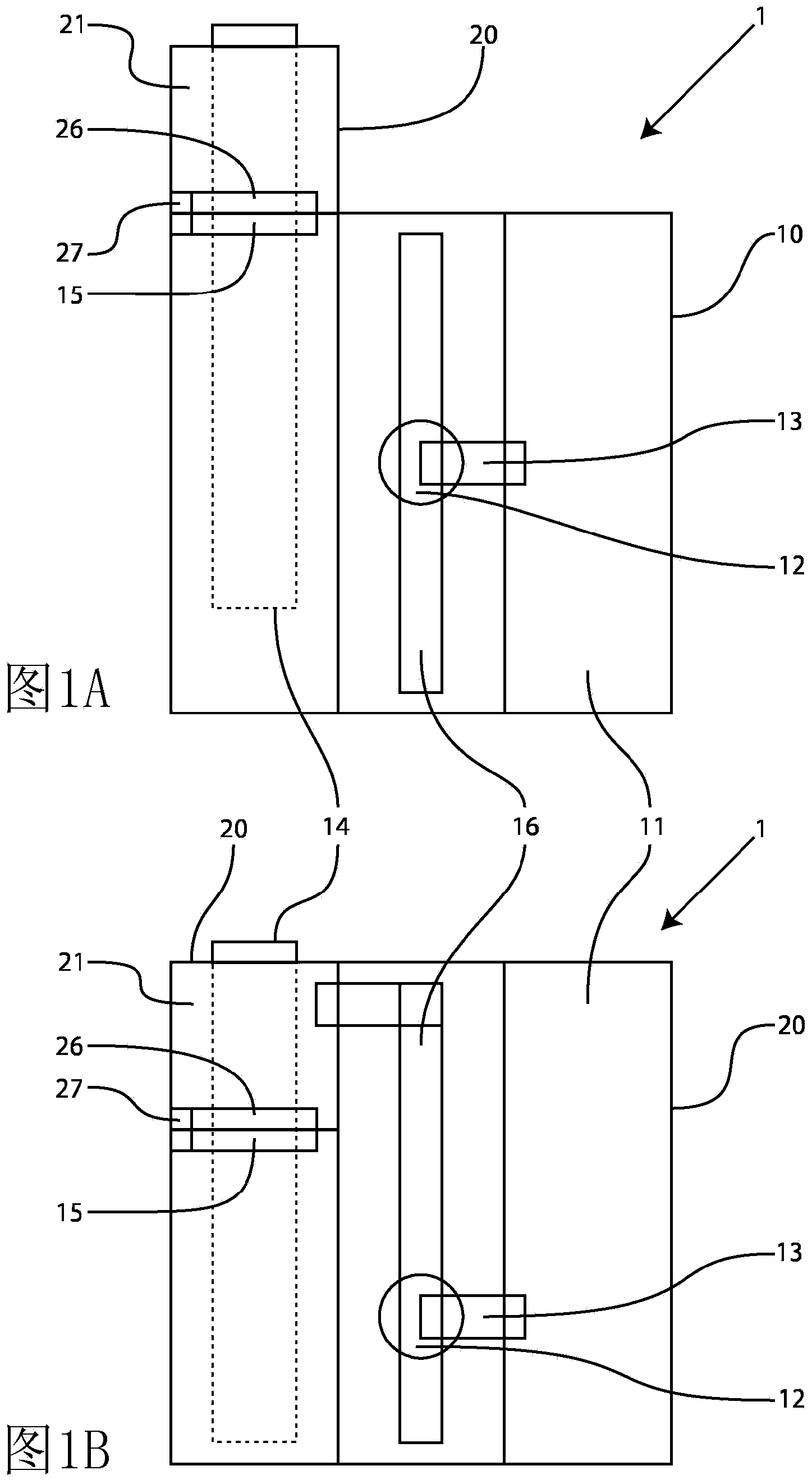

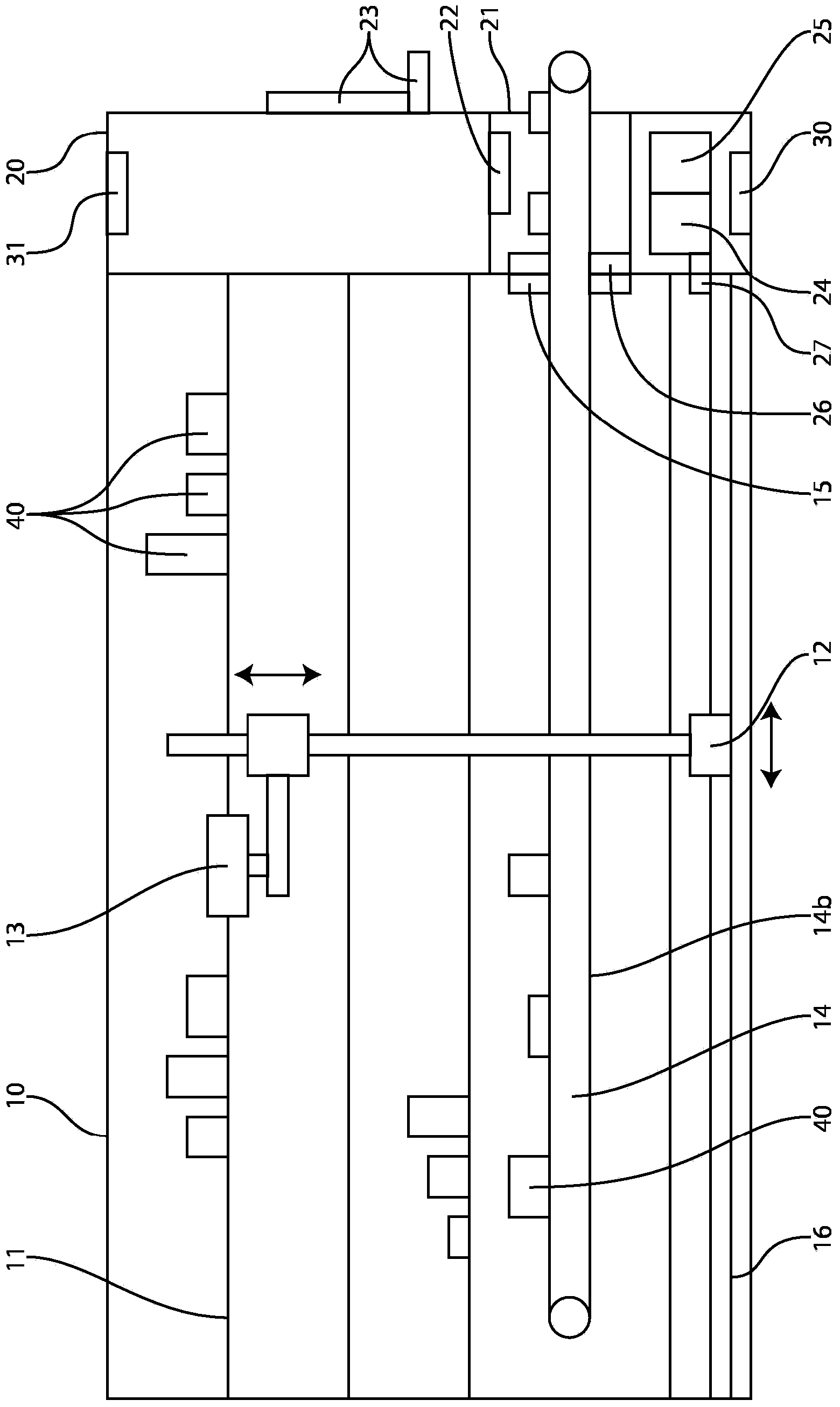

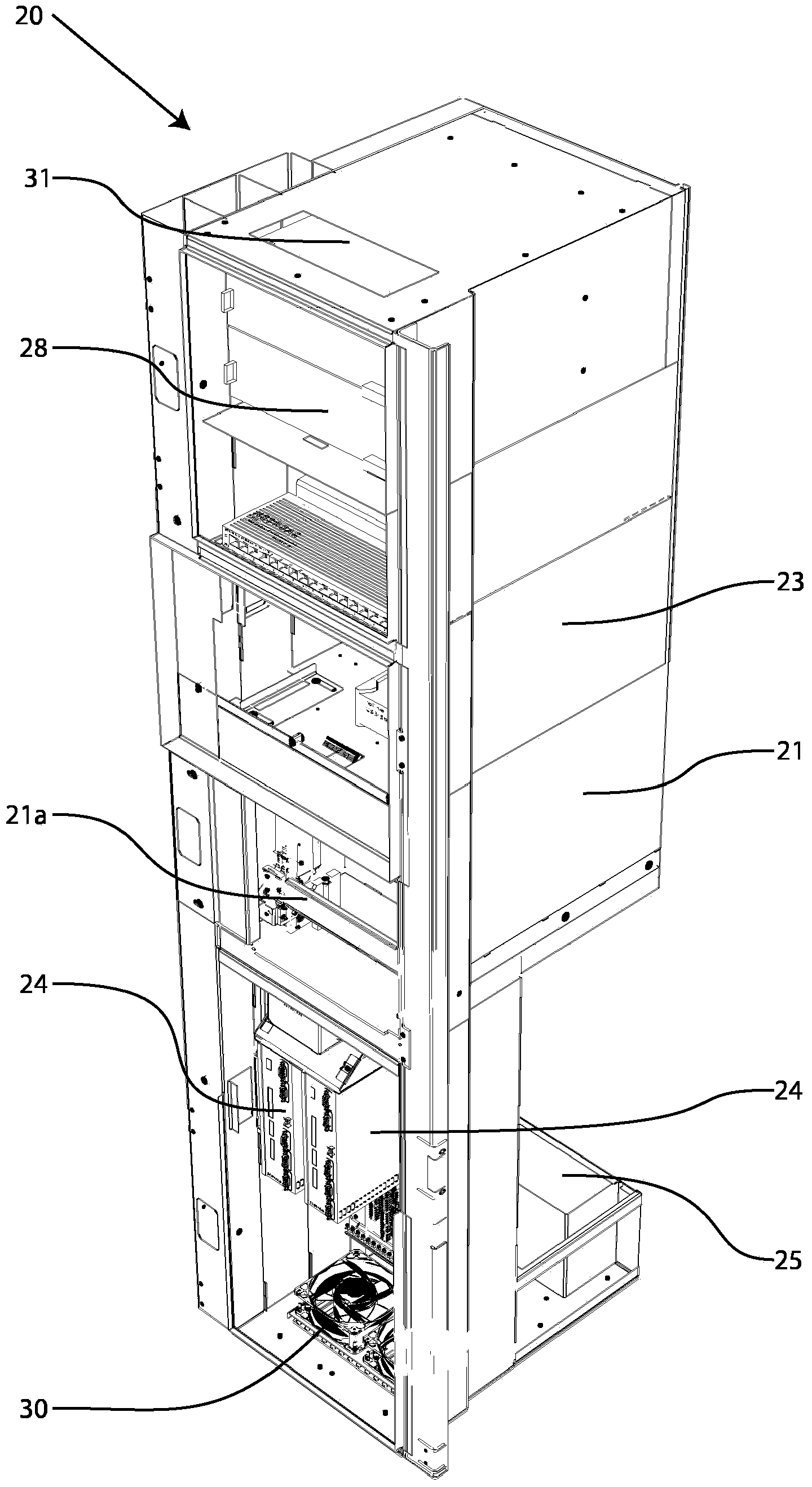

Pharmacy picking device comprising a universal supply-and-control module

The invention relates to a pharmacy picking device (1) comprising a housing (10) with a plurality of shelf bases (11) disposed one above the other, at least one operating device (12), a conveyor device (14), a housing-coupling interface (15), and a universal supply-and-control module (20). This universal supply-and-control module (20) comprises a feed device (21), an identification and measurement device (22), operator input / output devices (23), an electronic controller (24) and a voltage supply assembly (25), as well as a housing-coupling interface (15) and an electrical interface (27), said supply-and-control module (20) being arranged adjacent to the housing (10) such that a mechanical coupling is produced by said housing-coupling interface (15) and module-coupling interface (26), in such a manner that drug packages in or on the supply-and-control module (20), which are to be deposited, are delivered to a position on the conveyor device (14) which is known to the electronic controller.

Owner:BECTON DICKINSON ROWA GERMANY GMBH

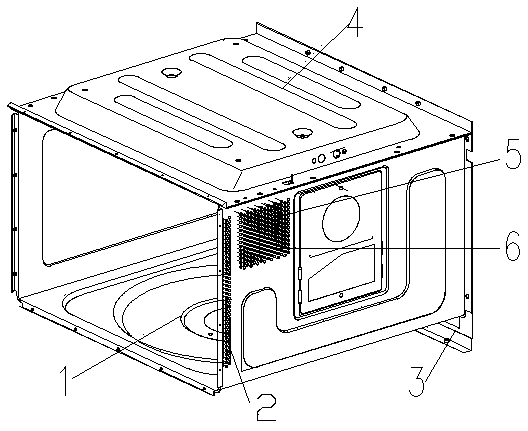

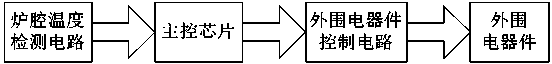

Microwave oven with hot air convection function and control method thereof

ActiveCN104165390APrevent overheatingIncrease hot air convection effectDomestic stoves or rangesLighting and heating apparatusMicrowave ovenProcess engineering

The invention provides a microwave oven with a hot air convection function and a control method thereof. The microwave oven comprises a chamber, a door, a first heating tube arranged on the top plate of the chamber, a cooling fan, a second heating tube and a hot air convection fan both arranged on the rear panel of the chamber, an oven chamber temperature detection circuit and a peripheral electric device control circuit. A furnace lamp and vent holes are respectively arranged on and formed in the side panel of the chamber. The control method comprises the following steps: (1) setting standard oven chamber environment temperature values at different microwave oven set temperatures; (2) enabling the microwave oven to start working and detecting the environment temperature values of the oven chamber in real time; (3) comparing the detected environment temperature of the oven chamber with the standard oven chamber environment temperature values, and controlling the working conditions of the cooling fan, the hot air convection fan, the first heating tube and the second heating tube according to the comparison result. The microwave oven with the hot air convection function is capable of keeping the desired set temperature in the oven chamber accurately for a long time and also avoiding overhigh temperature at the top of the oven chamber.

Owner:WHIRLPOOL CHINA

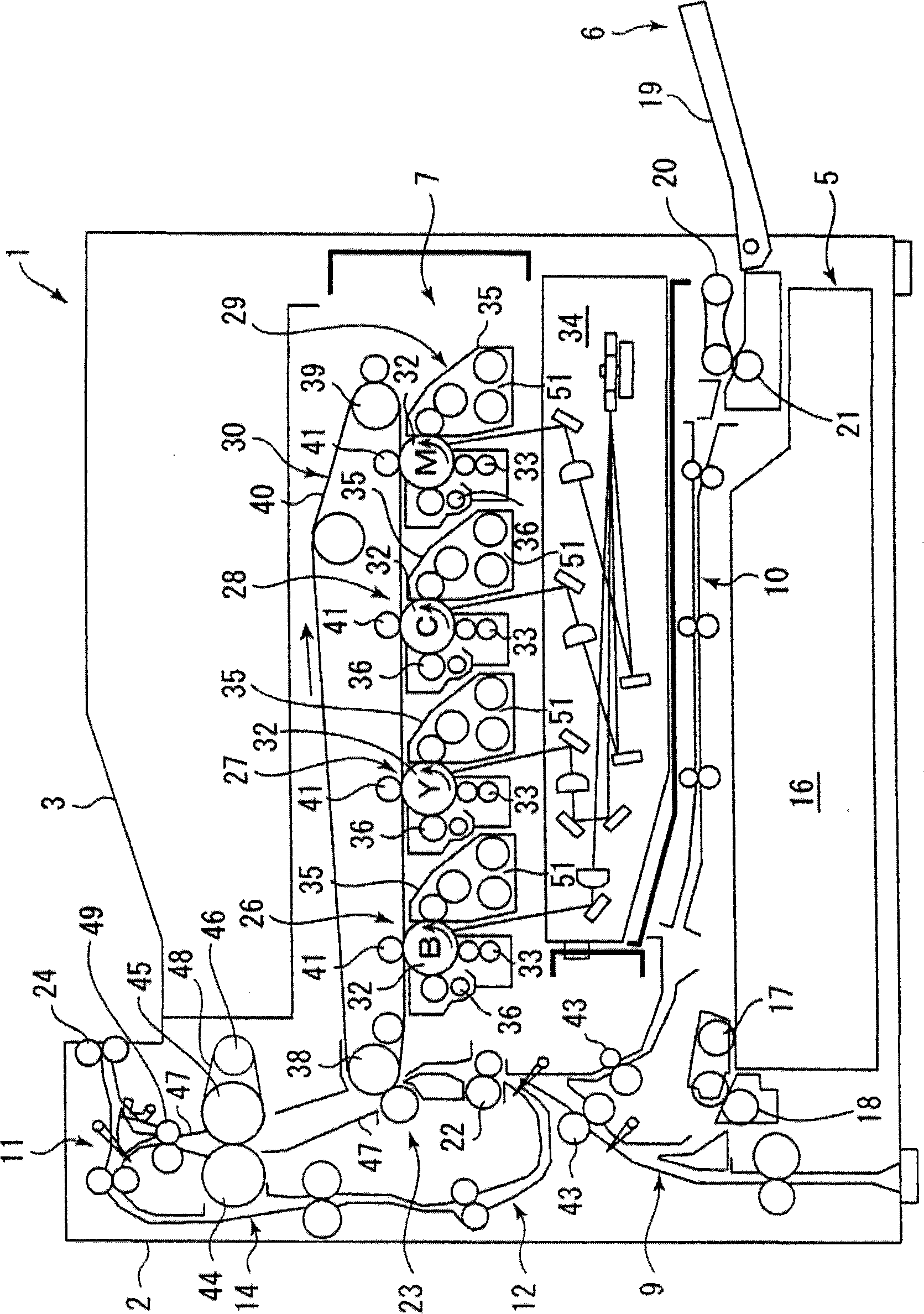

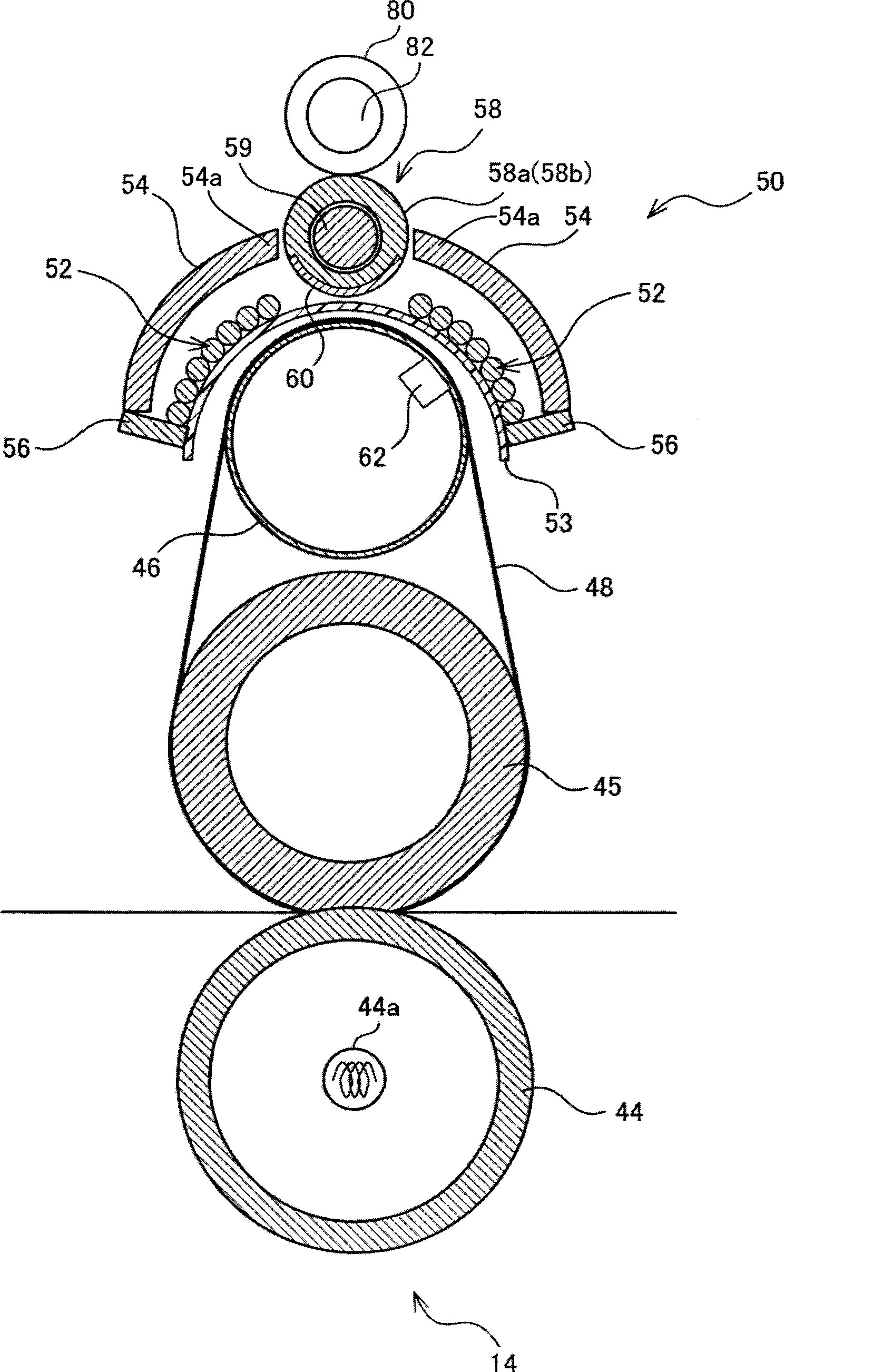

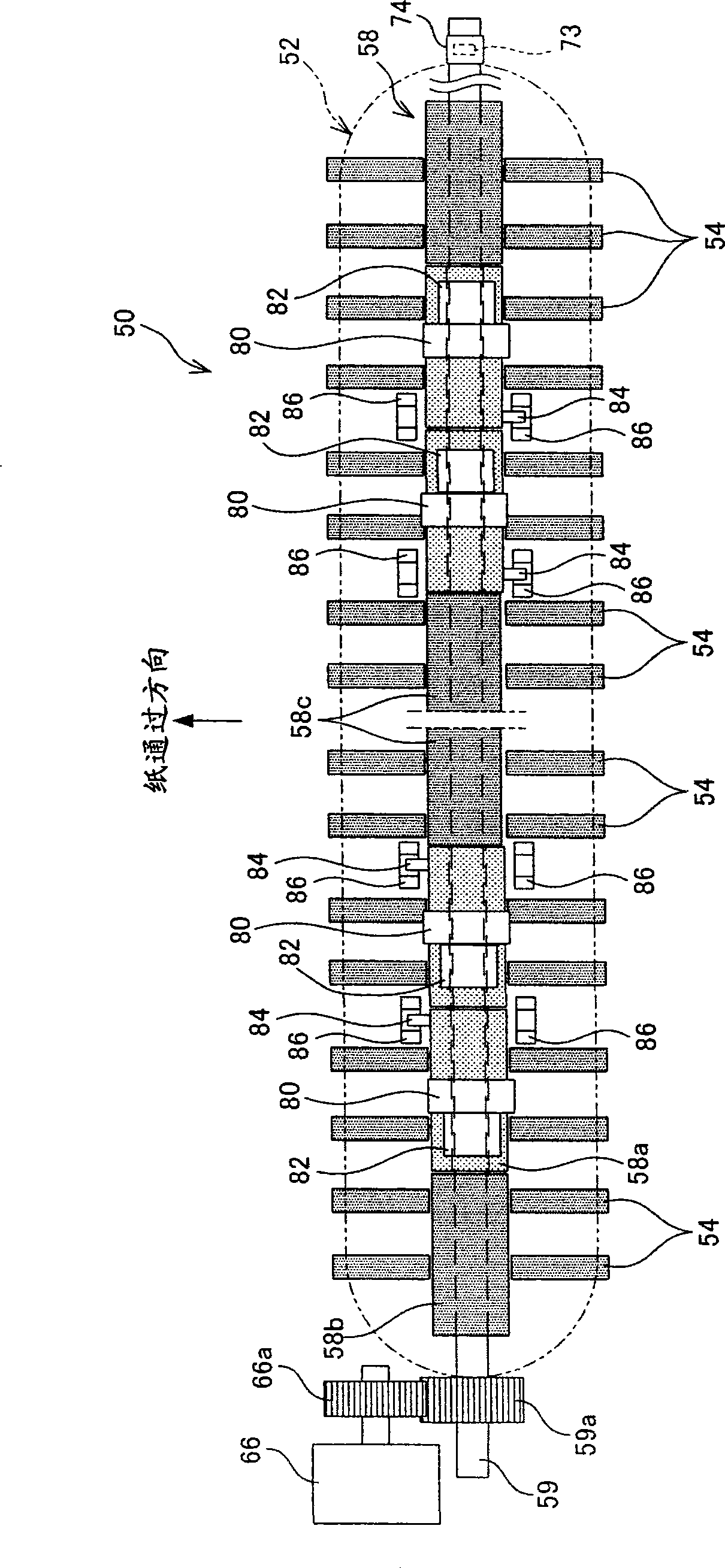

Image forming apparatus

InactiveCN101546167ALow calorific valueInhibition of magnetic fluxElectrographic process apparatusInduction heating apparatusImage formationMagnetic orientation

The invention provides an image forming apparatus. The image forming apparatus includes a fixing unit. The fixing unit includes a coil configured along the external surface of the heating member for generating magnetic field; a fixed core, separated from the coil at the opposite side of the heating member, for forming a magnetic path, a plurality of movable cores forming a magnetic path together with the fixed core, configured between the fixed core and the heating member on the field direction generated by the coil and arranged along the sheet conveyed region; a shielding member arranged on at least one movable core and shielding magnetism; and a magnetism adjustment unit rotating at least one movable core to switch the position of the shielding member between a shielding position where the shielding member is positioned inside the sheet conveyed region to shield the magnetism and a retracted position where the shielding member is positioned outside the sheet conveyed region to permit pass of the magnetism.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

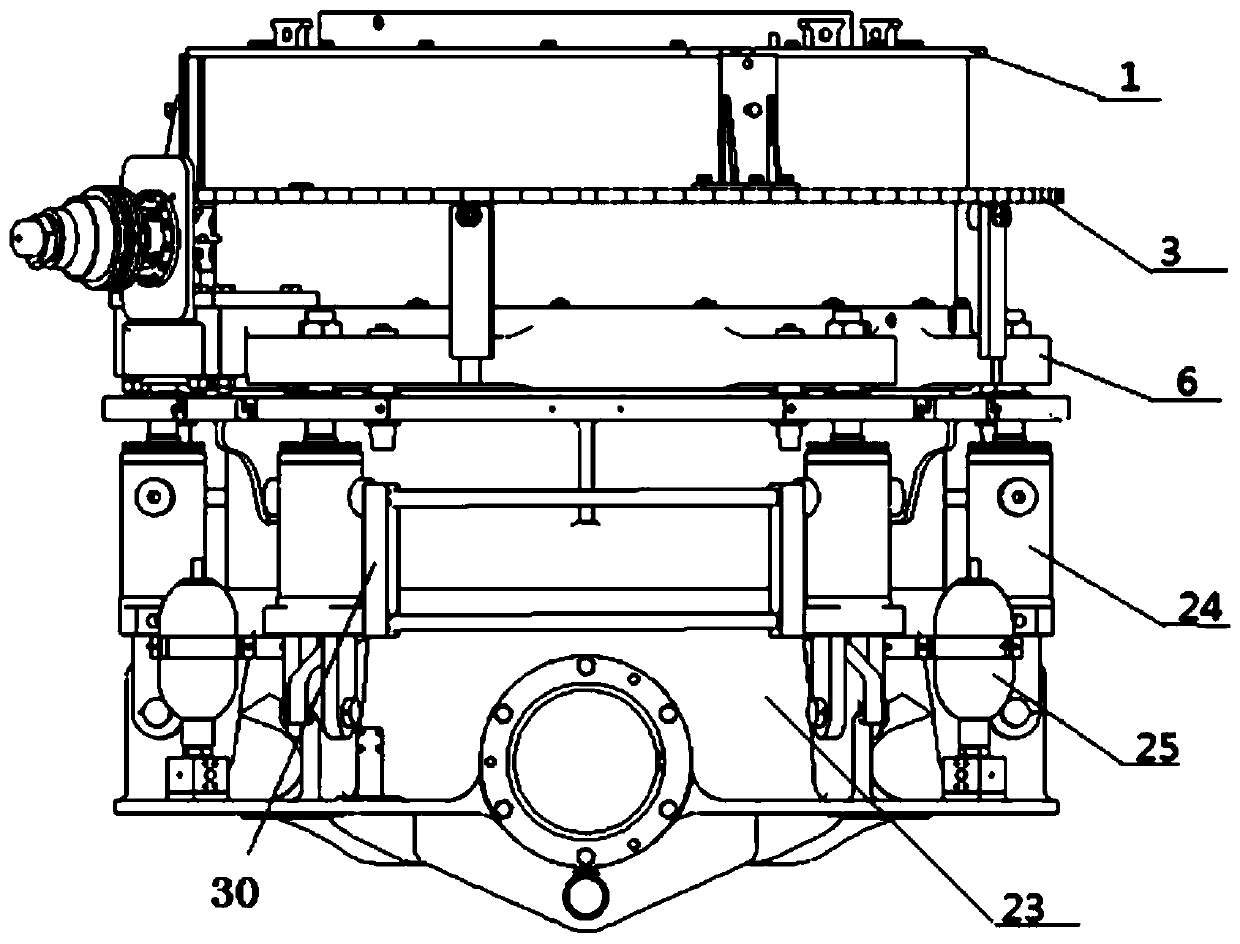

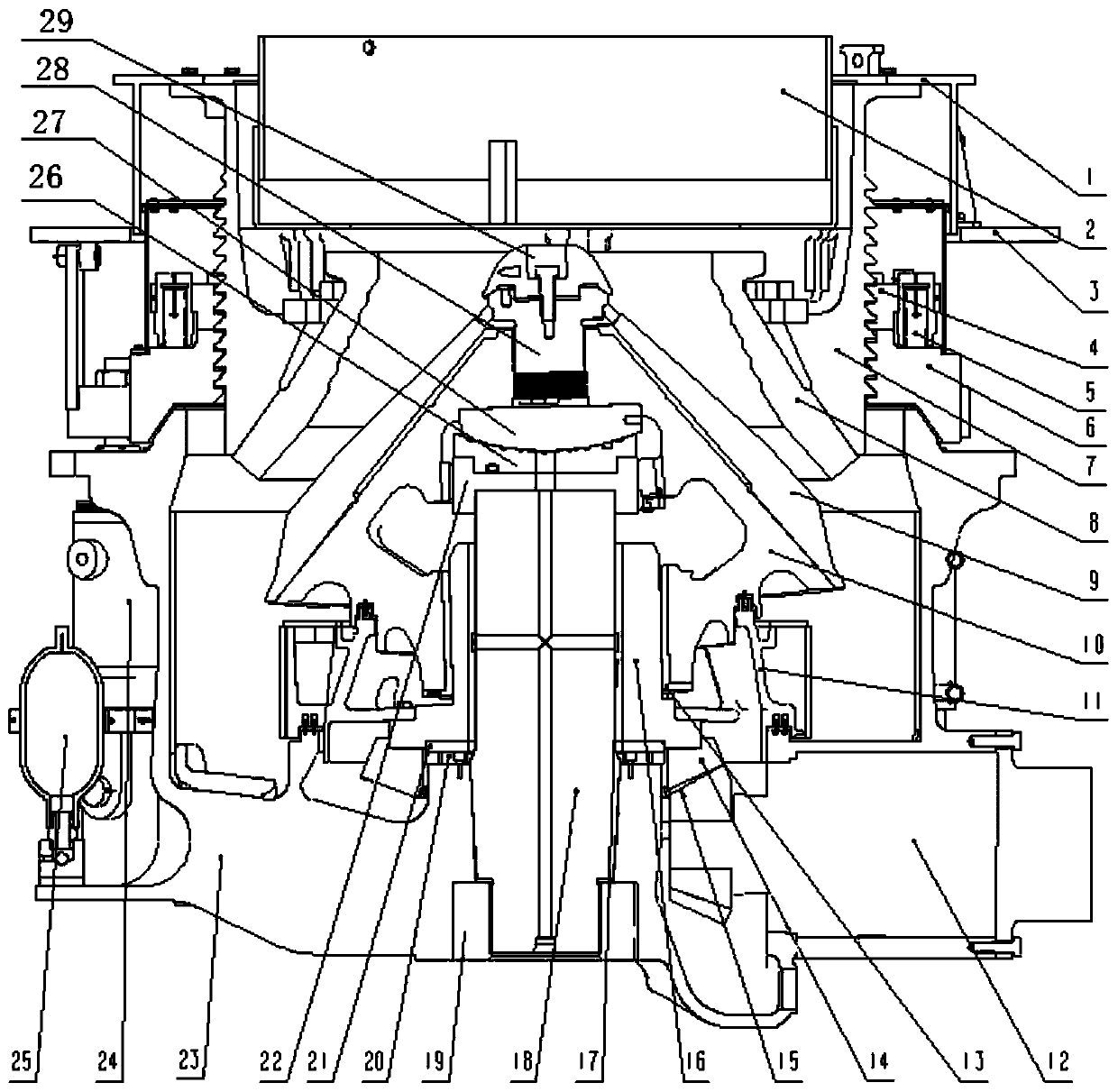

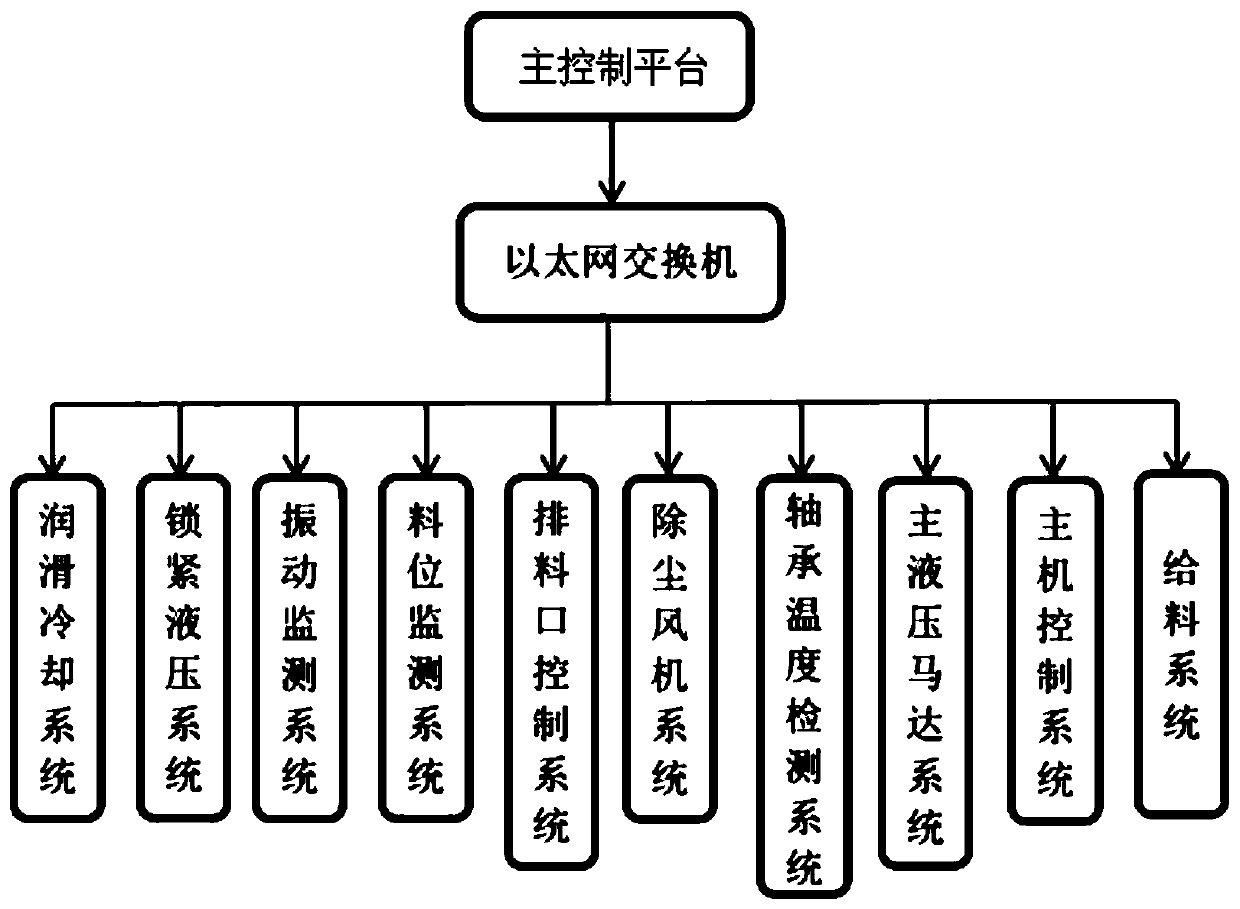

Automatic control system and method of hydraulic multi-cylinder cone crusher

The invention discloses an automatic control system and method of a hydraulic multi-cylinder cone crusher. The system comprises a master control platform. The master control platform is connected witha lubricating and cooling system, a locking hydraulic system, a vibration monitoring system, a material level monitoring system, a discharging opening control system, a dust removal fan system, a bearing temperature detection system, a main hydraulic motor control system, a main engine control system and a feed system through an ethernet switch and a signal line. Through the lubricating and cooling system, it is guaranteed that the crusher does not run in a superheating manner; the vibration monitoring system is used for monitoring the bouncing condition of an adjusting ring, and continuous overload running of the crusher is avoided; the discharging opening control system adjusts a discharging opening liner plate to adjust the size of a discharging opening; and the main drive hydraulic motor system is used for monitoring oil pressure of a main drive motor to monitor loads of the crusher, and the rotating speed of a main engine is adjusted according to the monitored value. The runningcondition of the crusher is monitored, automatic control over running of the crusher is achieved, running is achieved safely, and crushing efficiency is guaranteed.

Owner:南昌矿机集团股份有限公司

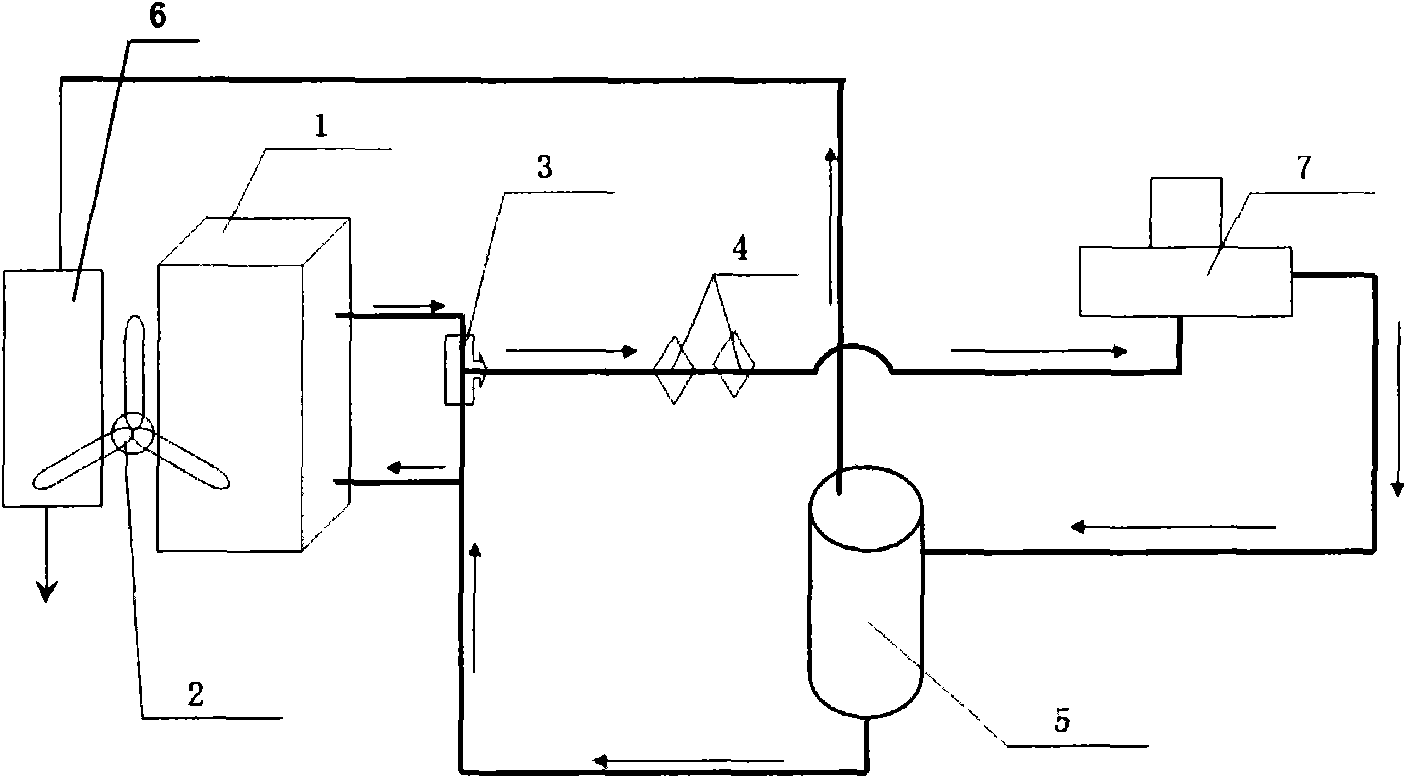

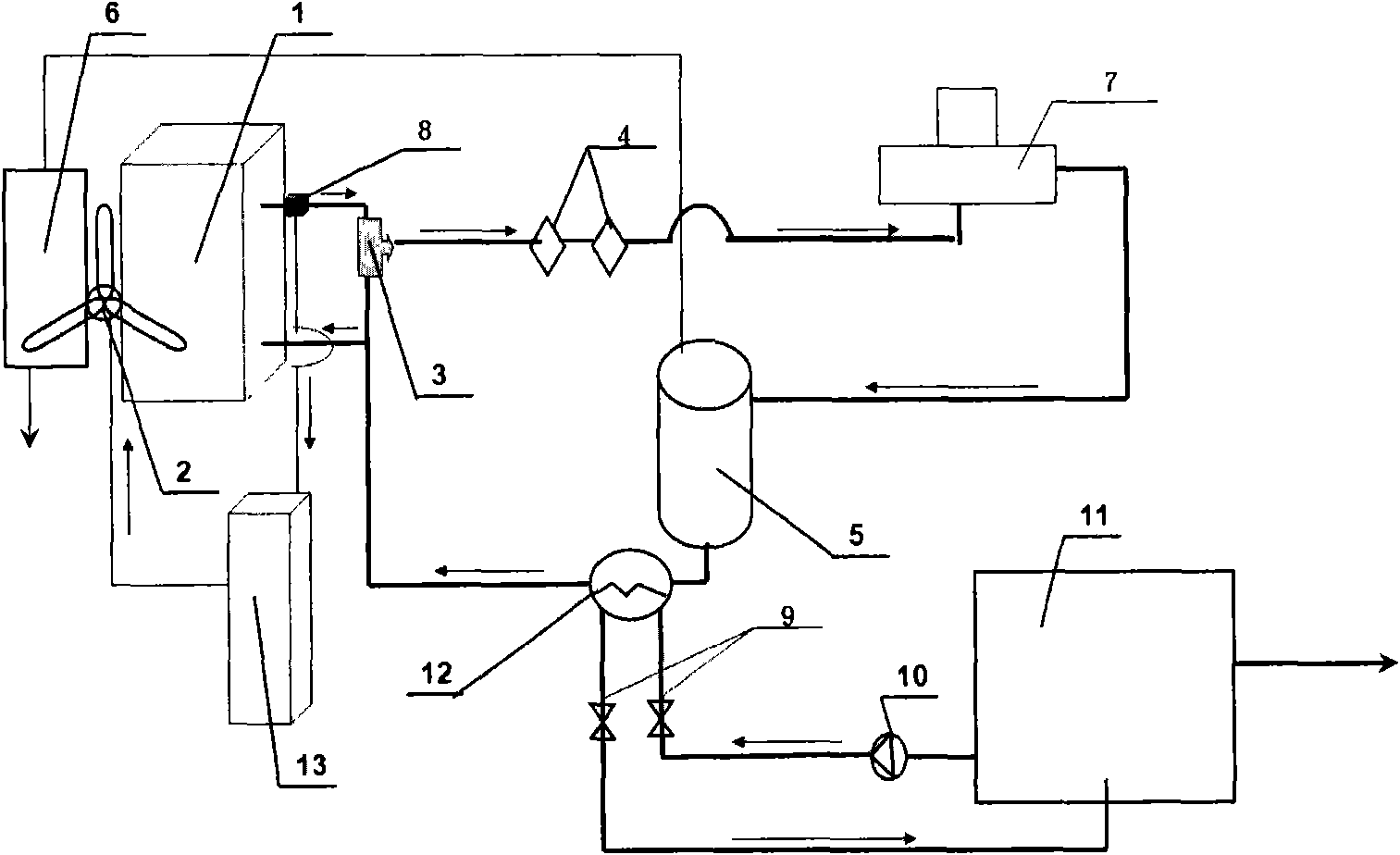

Cooling and afterheat recovering device of air-cooled oil-injected screw air compressor

InactiveCN101871455APrevent overheatingDoes not damage the structureRotary/oscillating piston pump componentsLiquid fuel engine componentsWater pipeComputer fan

The invention belongs to the category of heat exchange devices of air compressors, in particular to a cooling and afterheat recovering device of an air-cooled oil-injected screw air compressor, comprising a radiator fan, an oil heat radiator, a heat exchanger, a cold water pipe, a hot water pipe, a water pump and a valve. The cooling and afterheat recovering device of the air-cooled oil-injected screw air compressor is characterized by comprising a transformer which is provided with a temperature sensor and connected in series in a power supply circuit of the radiator fan of the air compressor, the heat exchanger of a brazing sheet type is connected in series between an oil outlet of an oil-gas separator and an oil inlet of the oil heat radiator of the air compressor, the temperature sensor is arranged on an oil outlet of the oil heat radiator of the air compressor, and the frequency of a current output by the transformer is controlled to change in a range of 15 Hz to 50 Hz according to the temperature of the oil outlet.

Owner:JOHNSON & JOHNSON CN

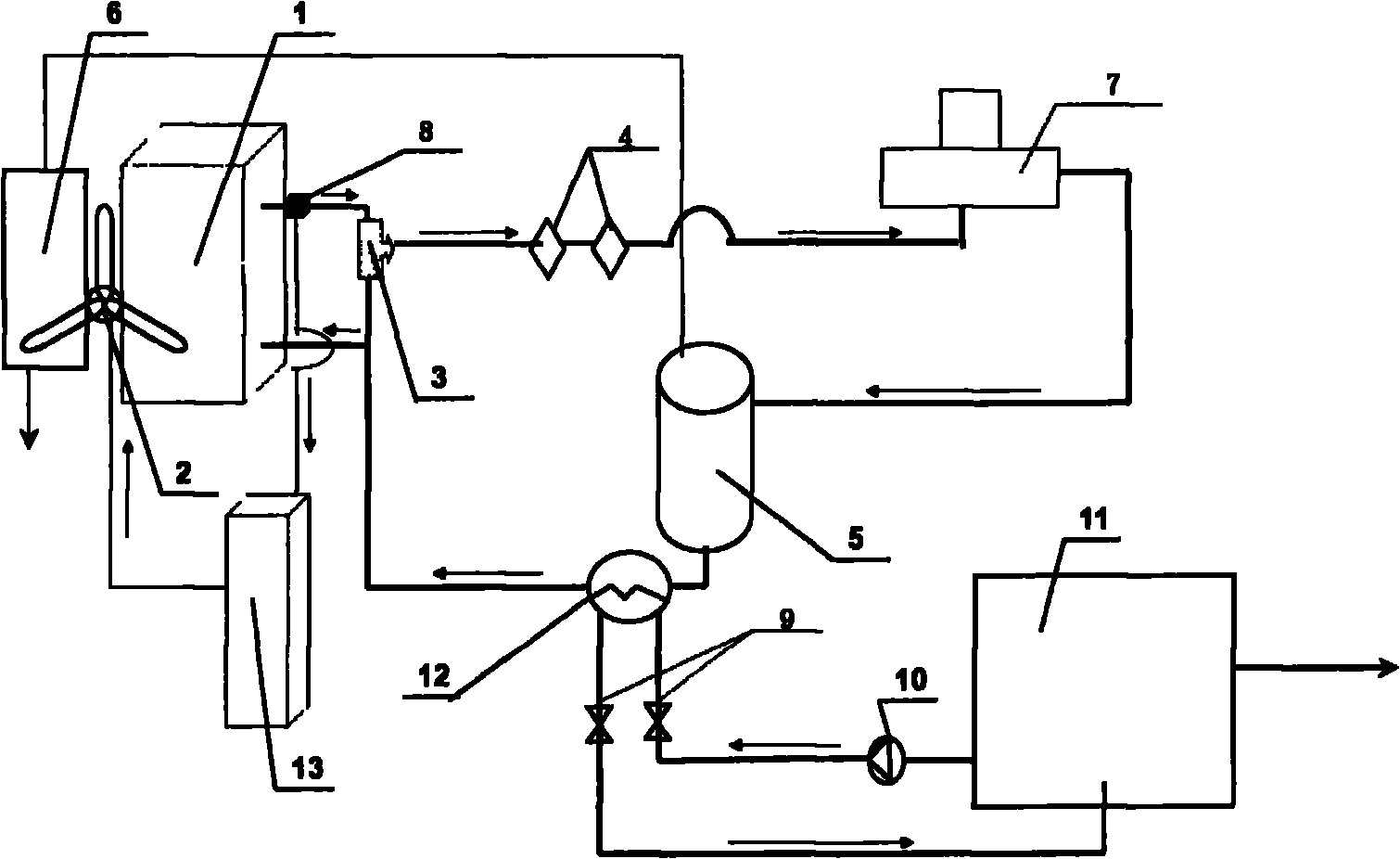

Lithium flow battery system driven by virtue of motor

ActiveCN107403944AImprove securityPrevent overheatingReactant parameters controlElectrolyte stream managementWater vaporEngineering

The invention provides a lithium flow battery system driven by virtue of a motor. The lithium flow battery system comprises a control device, a gas supply part and a battery module part, wherein gas supplied by the gas supply part enters a liquid storage device under the actions of a motor and a piston of the battery module part, independent, synchronous or successive liquid exchange between a positive pole reaction chamber and a negative pole reaction chamber of a battery reactor is completed, and flow rate of the gas supplied by the gas supply part and a rotating speed of the motor of the battery module part are controlled by virtue of the control device, wherein the piston is separated from suspension liquid in the liquid storage device by virtue of the gas. By virtue of the lithium flow battery system provided by the invention, leakage of the suspension liquid of an electrode or contact between the suspension liquid as well as water vapor and oxygen in the air can be effectively prevented, so that safety of the battery system is improved, and mechanical friction intensification and shortening of life of a mechanical structure which are caused by direct contact between a mechanical part and the suspension liquid of the electrode are also avoided. Besides, the invention also provides a working method of the lithium flow battery system driven by virtue of the motor.

Owner:南京竞予能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com