Annular welding method

A technology of annular welding and welding current, applied in welding equipment, laser welding equipment, plasma welding equipment, etc., can solve the problems of air leakage at the interface, surface clamping damage, poor neutrality, etc., to prevent over-burning or burn-through , to ensure the effect of welding sealing and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

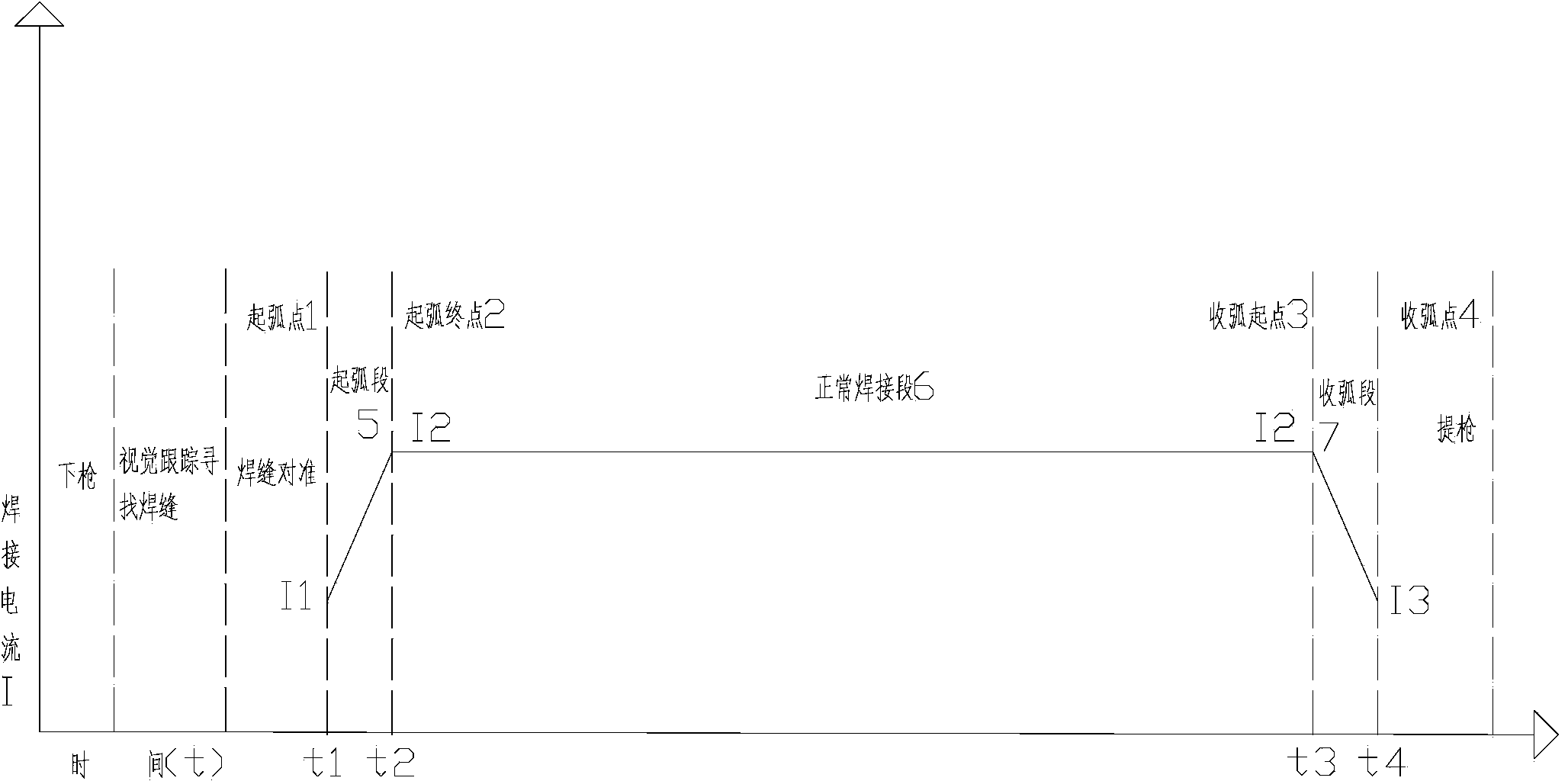

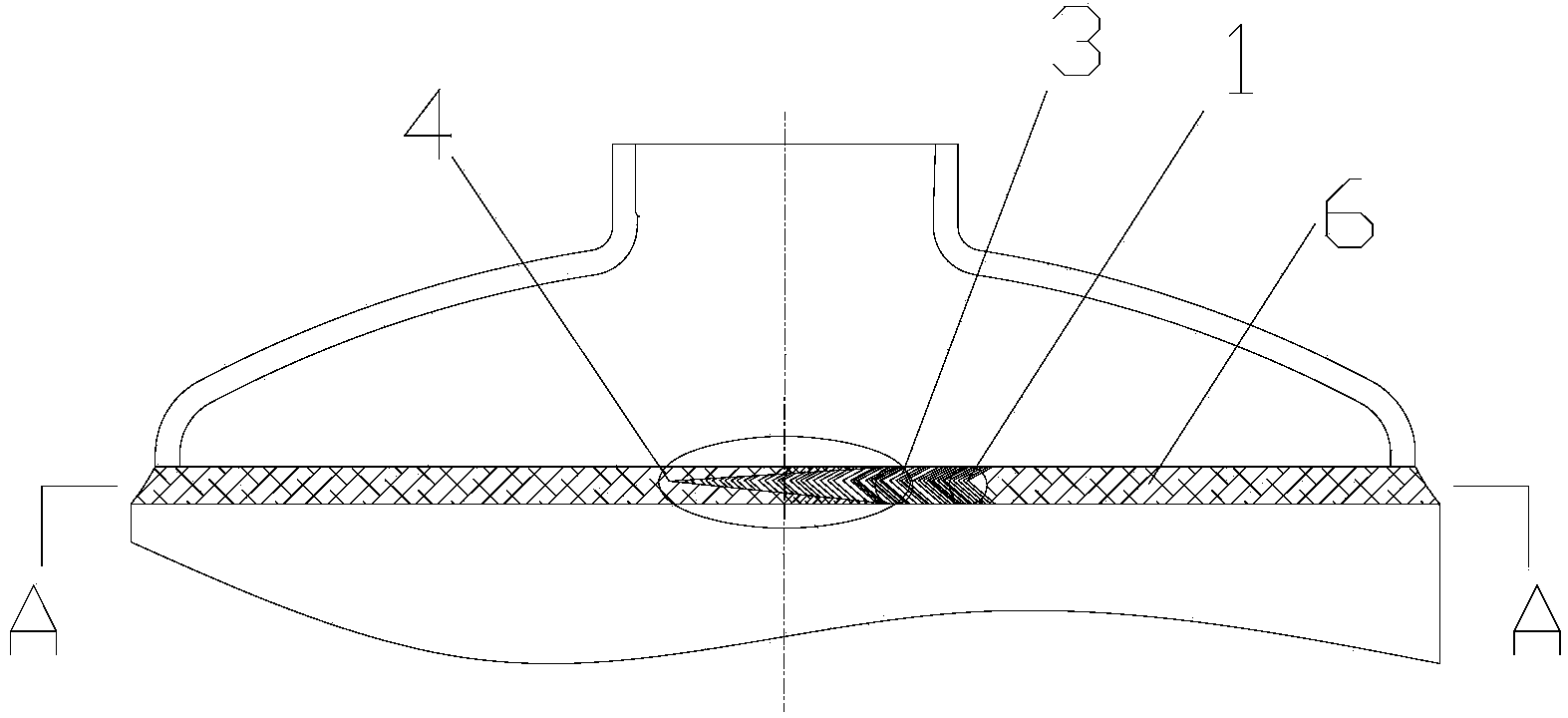

[0036] process such as Figure 5 As shown, the production equipment such as Image 6 shown. First, when the welding workpiece 11 is installed on the welding machine, the tooling module of the welding machine starts to detect whether the welding workpiece 11 is in place, whether the clamping welding workpiece 11 is completed, starts to drive the welding workpiece 11 to rotate, and the welding torch 8 begins to descend and align. At this time, the camera mechanism 611 starts to collect signals, and the visual control module 612 starts to identify the welding seam and the arc starting point and controls the welding torch 8 to align with the welding seam. The welding power supply module 613 controls the welding current of the welding torch 8, press figure 1 The welding curve is welded.

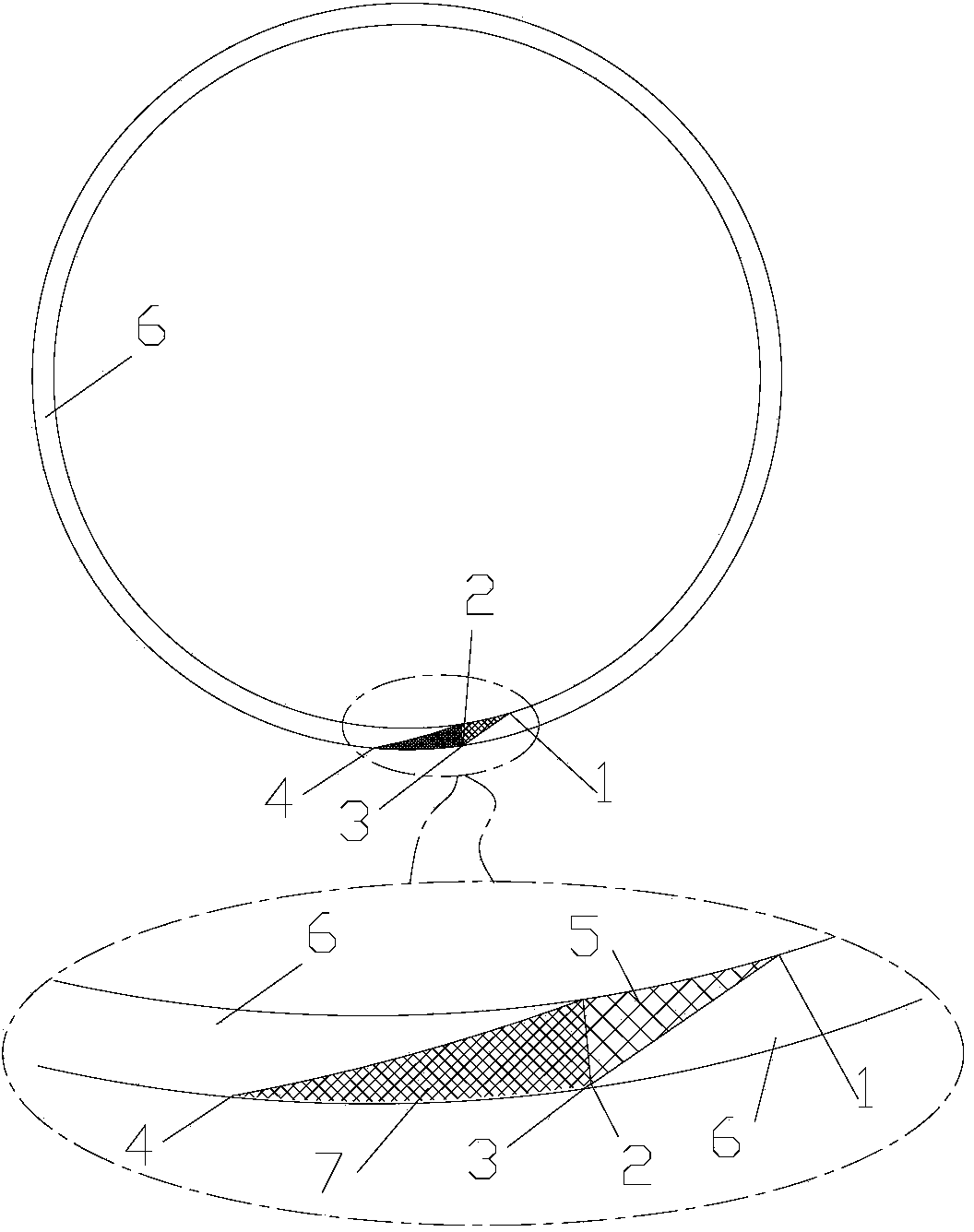

[0037] The welding workpiece 11 rotates slowly, and the visual tracking system captures the welding torch 8 and the weld seam, and adjusts the relative position of the welding torch 8 to complet...

Embodiment 2

[0043] In this example, if Figure 4 As shown, the welding workpiece 11 rotates slowly, the visual tracking system captures the welding torch 8 and the weld seam, and adjusts the relative position of the welding torch 8 to complete the alignment, and then outputs a signal to the welding power source 613 to start the arc. The current at arc starting point 1 is I1, and the time point is t1, the welding workpiece 11 rotates, and after a period of time to time point t2, the position of the welding seam aligned with the welding torch 8 is from the arc starting point 1 to the arc starting end point 2, and the welding current in the arc starting section 5 gradually changes linearly from I1 As large as the normal welding section 6 welding current value I2, where I1 is about 60% of I2;

[0044] The welding workpiece 11 continues to rotate. After a period of time, the time point t3 is reached. At this time, the welding seam is aligned with the position of the welding torch 8 from the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com