Patents

Literature

83results about How to "Strong centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

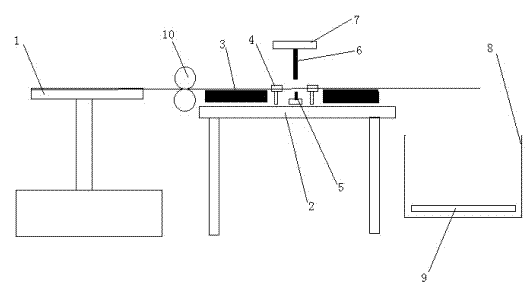

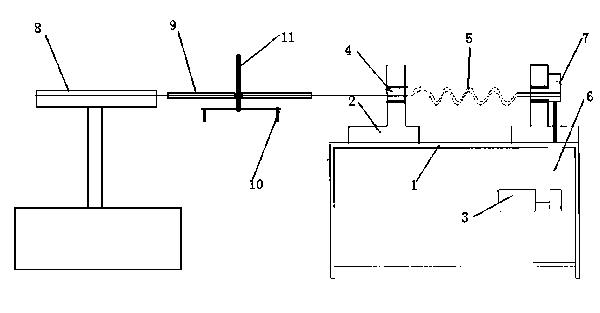

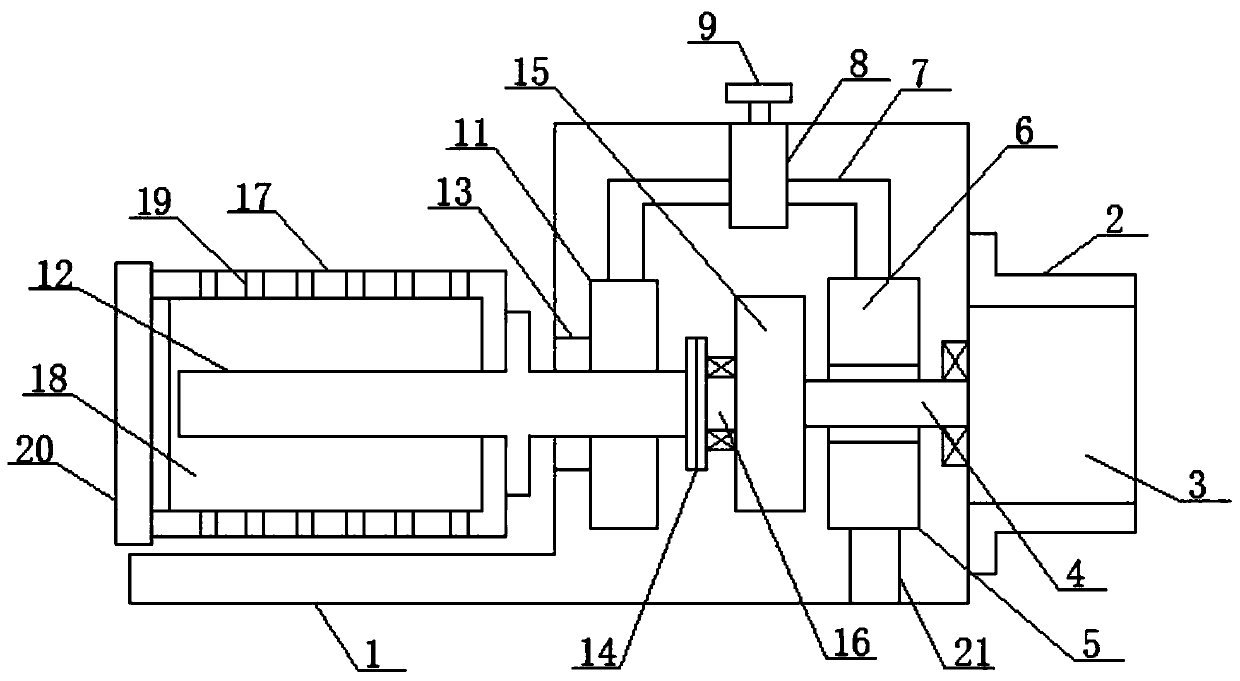

Metal wire production method

The invention discloses a metal wire production method. The metal wire production method comprises such steps as wire coiled material production, wire coiled material cutting, wire straightening, barreling polishing and packaging warehousing; a wire coiled material is produced through wire drawing equipment and returning equipment, and is put on an active emptying tray of a metal wire cutting device; the active emptying tray is horizontally mounted on the side surface of a frame of the cutting device; two transmission rollers are arranged between the active emptying tray and the frame for emptying assistance; the cutting is performed; after the cutting is finished, the straightening is performed; the barreling and the polishing are performed for straightened metal wires; then, the final checking is performed for the metal wires; and the qualified metal wires are packaged and warehoused. When the metal wires are cut by the metal wire production method, the metal wires are automatically cut without being damaged; meanwhile, when the metal wires are straightened, the straightening precision is largely improved; one motor is needed to provide high-speed rotating power, so that the energy consumption is largely reduced; and the working efficiency is higher.

Owner:DONGQING TECH

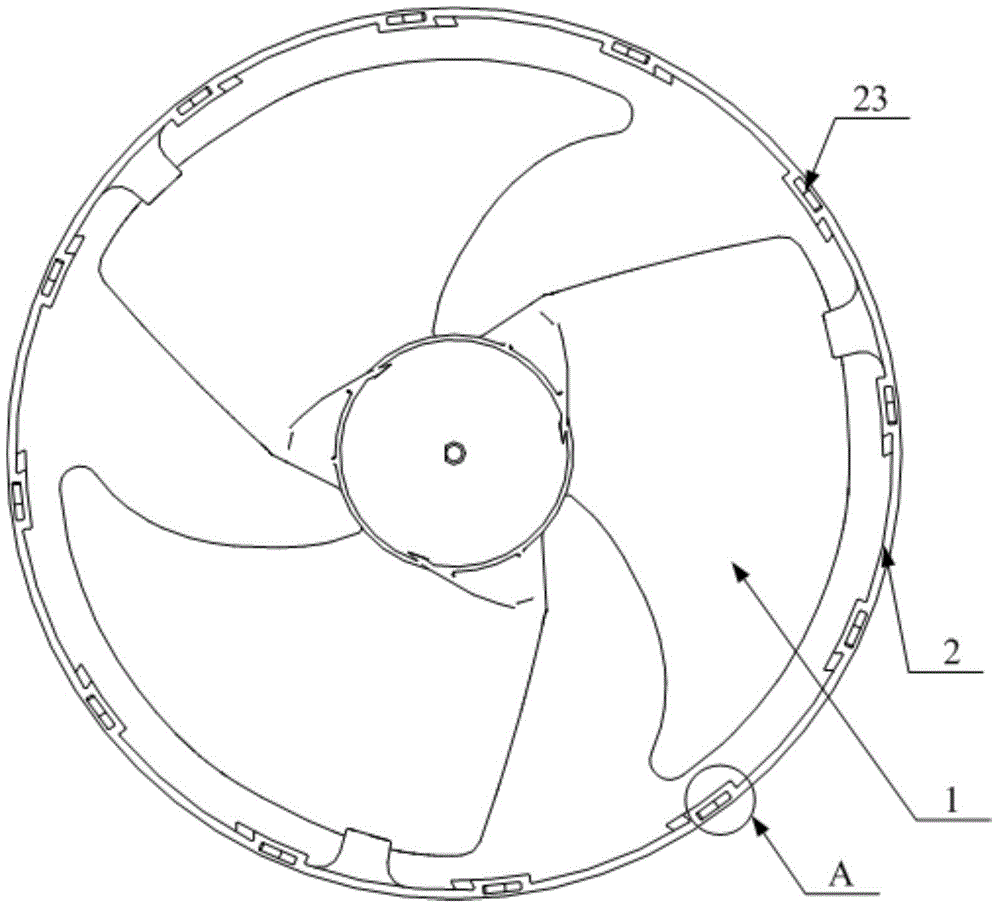

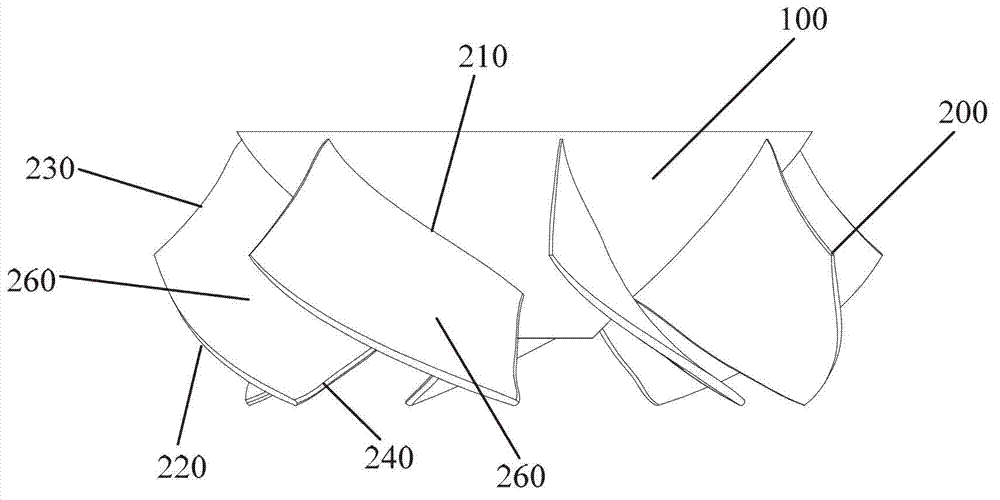

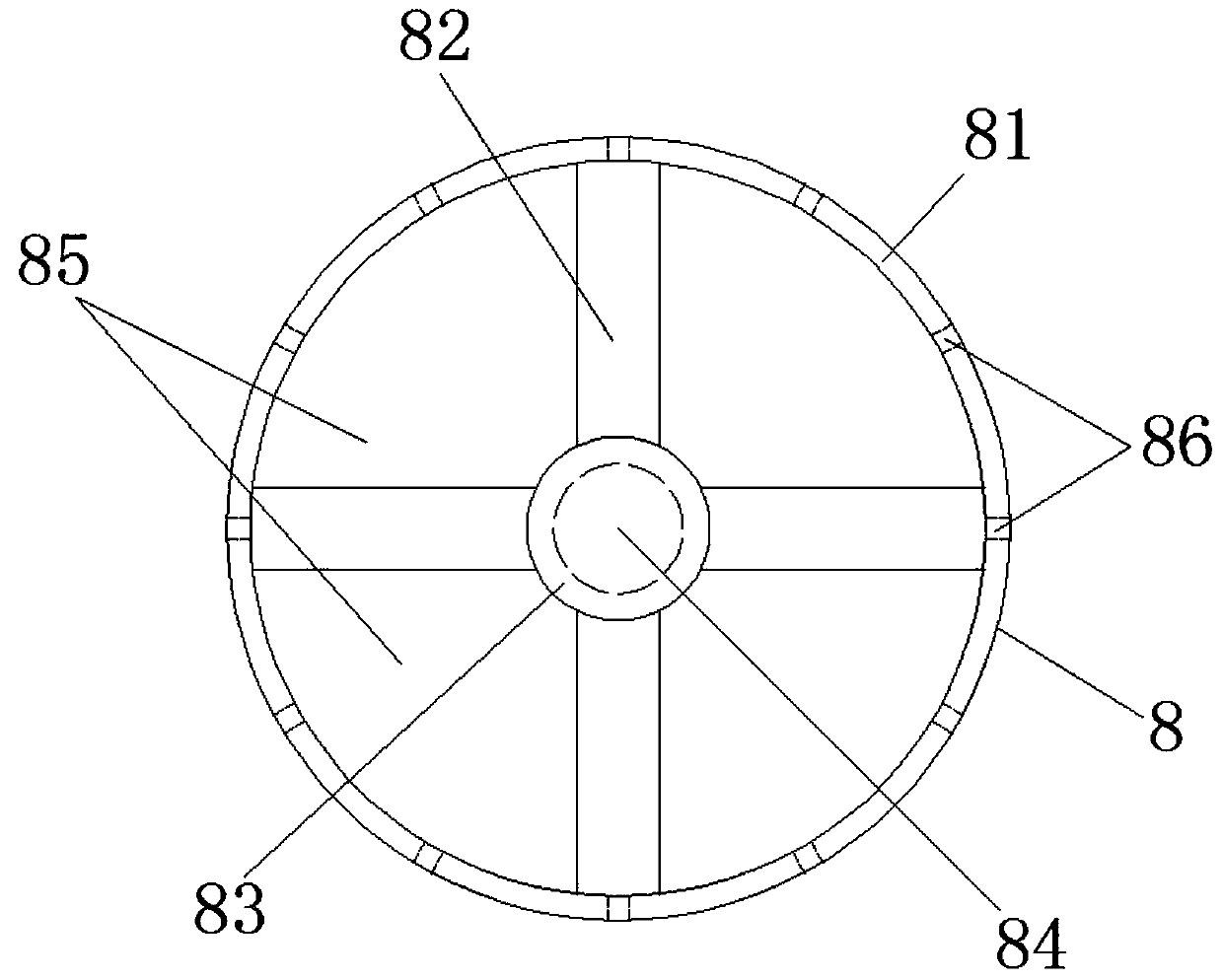

Axial flow fan and window type air conditioner

ActiveCN104948494AIncrease water volumeImprove cooling effectPump componentsLighting and heating apparatusImpellerEngineering

The invention discloses an axial flow fan and a window type air conditioner. The axial flow fan comprises impellers and a water beating ring connected with outer edges of the impellers, wherein a water beating channel is formed in the water beating ring and penetrates through the water beating ring in the wind direction of the axial flow fan. According to the axial flow fan, condensate water can enter the water beating channel when the water beating ring rotates along with the impellers, the condensate water in the water beating channel is thrown to the air outlet side of the axial flow fan under the action of centrifugal force, the water beating capacity is improved, the cooling effect of a condenser is improved, the energy efficiency of the window type air conditioner is improved, and the use cost of the window type air conditioner is reduced. The centrifugal force borne by the condensate water is large due to the fact that the water beating channel penetrates through the water beating ring in the wind direction of the axial flow fan, the distribution range of the condensate water on the air outlet side of the axial flow fan is increased, the cooling area of the condenser is increased, and the cooling effect of the condenser and the energy efficiency of the window type air conditioner are further improved. The window type air conditioner is provided with the axial flow fan.

Owner:GREE ELECTRIC APPLIANCES INC

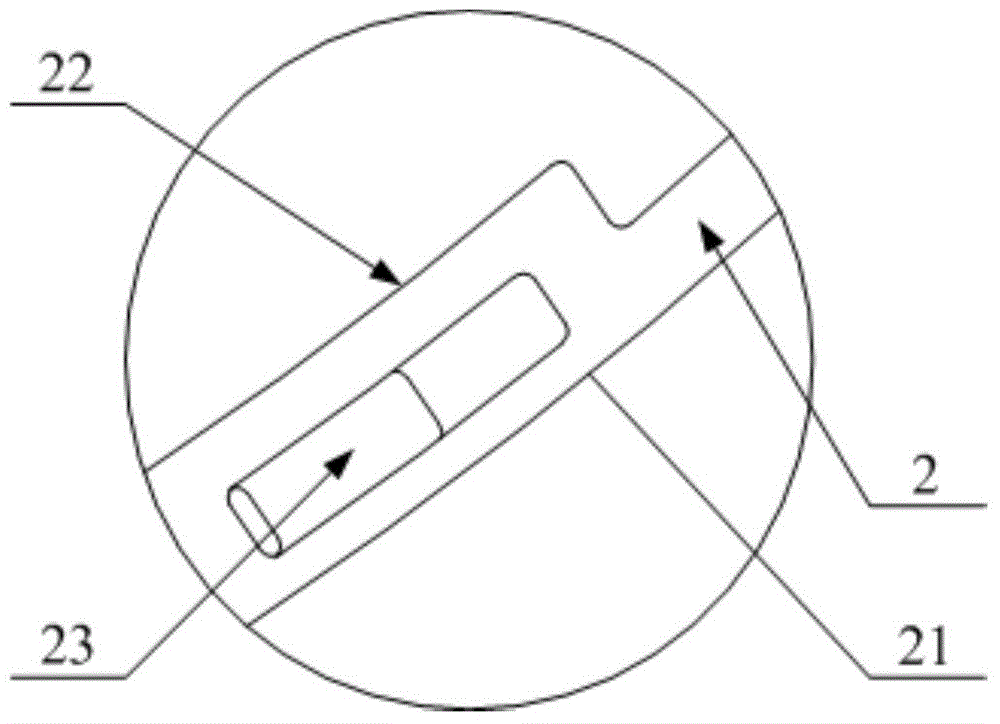

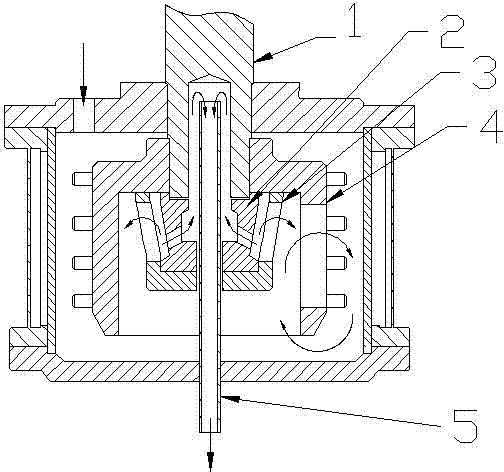

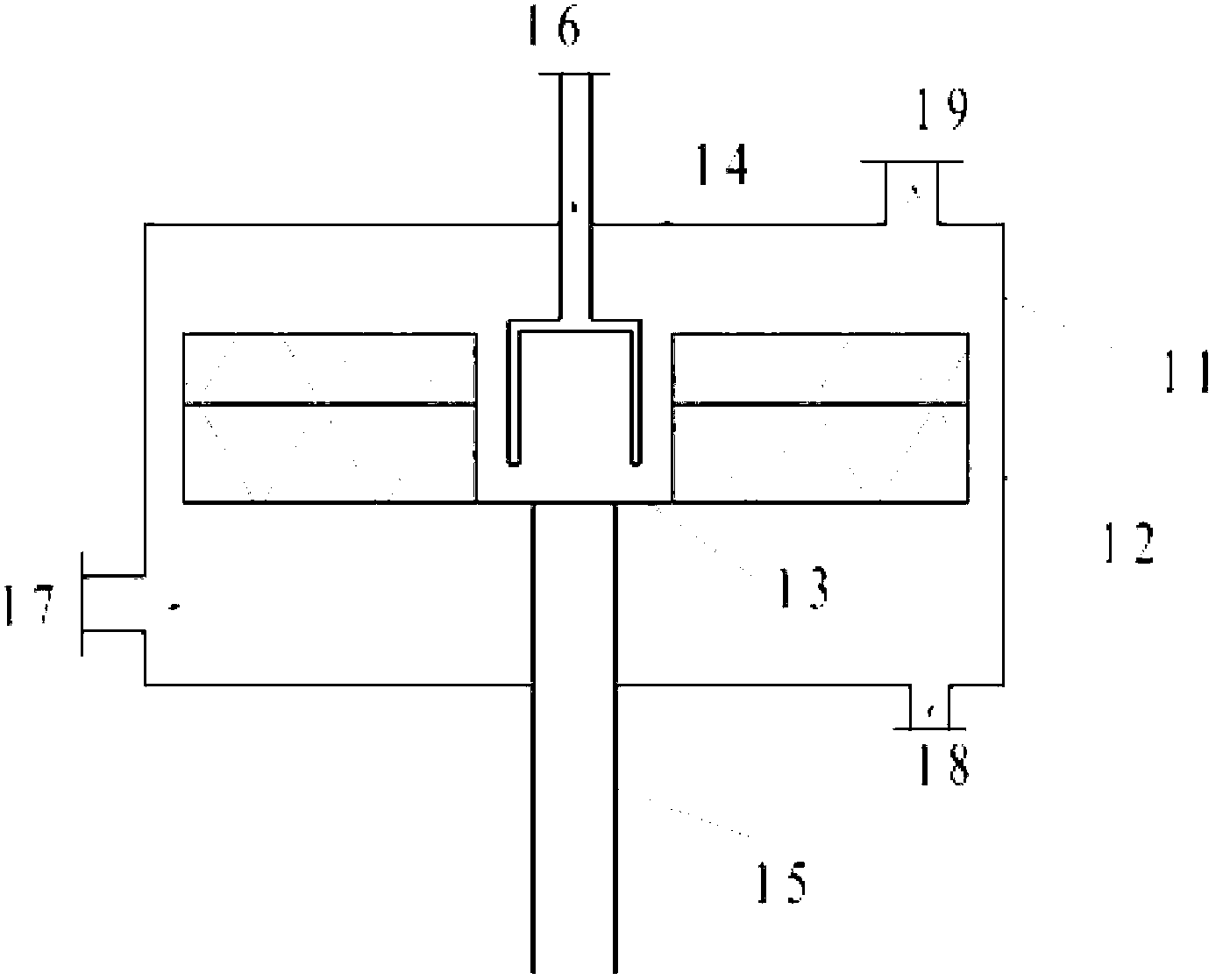

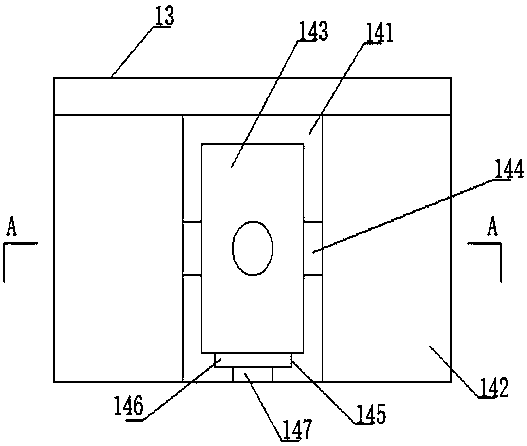

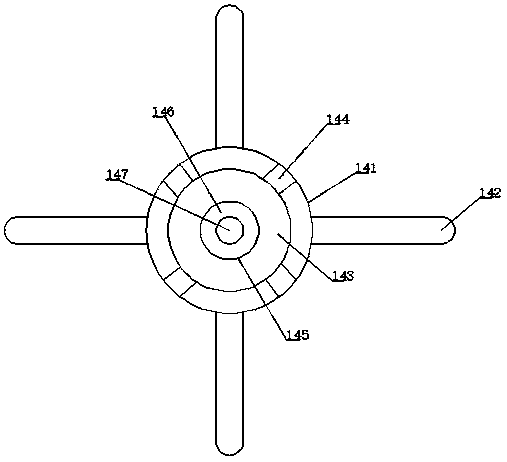

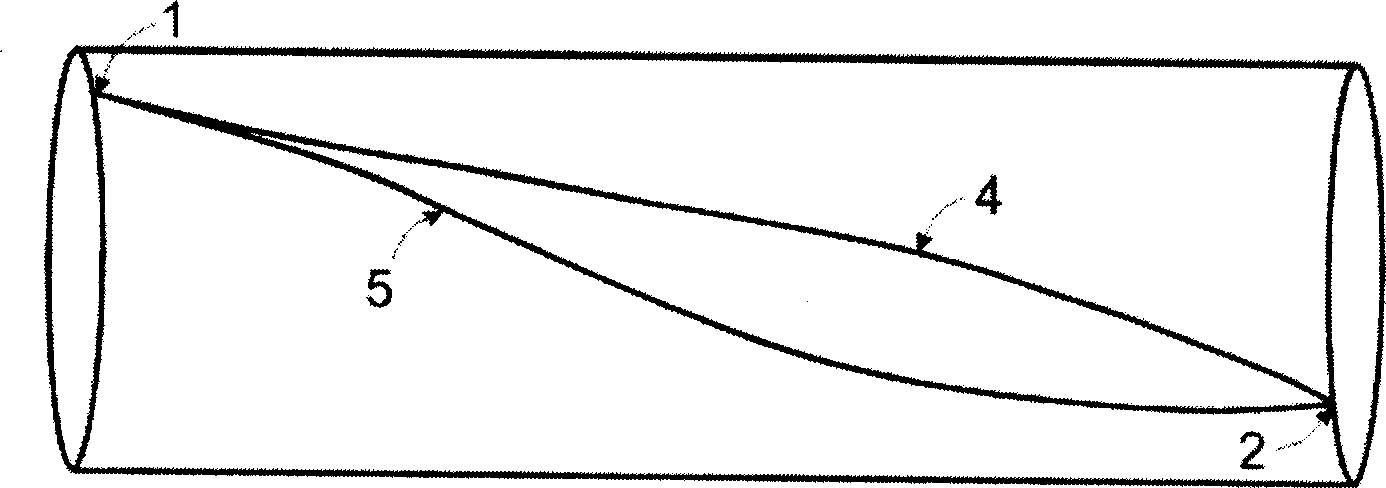

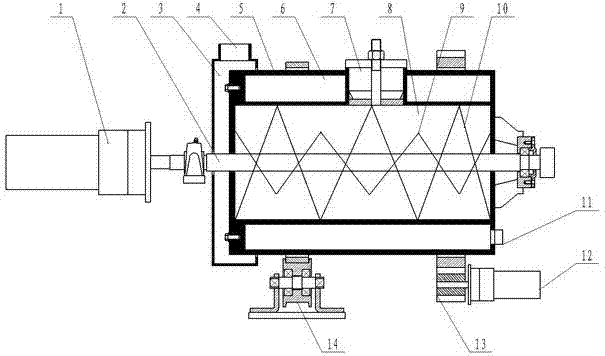

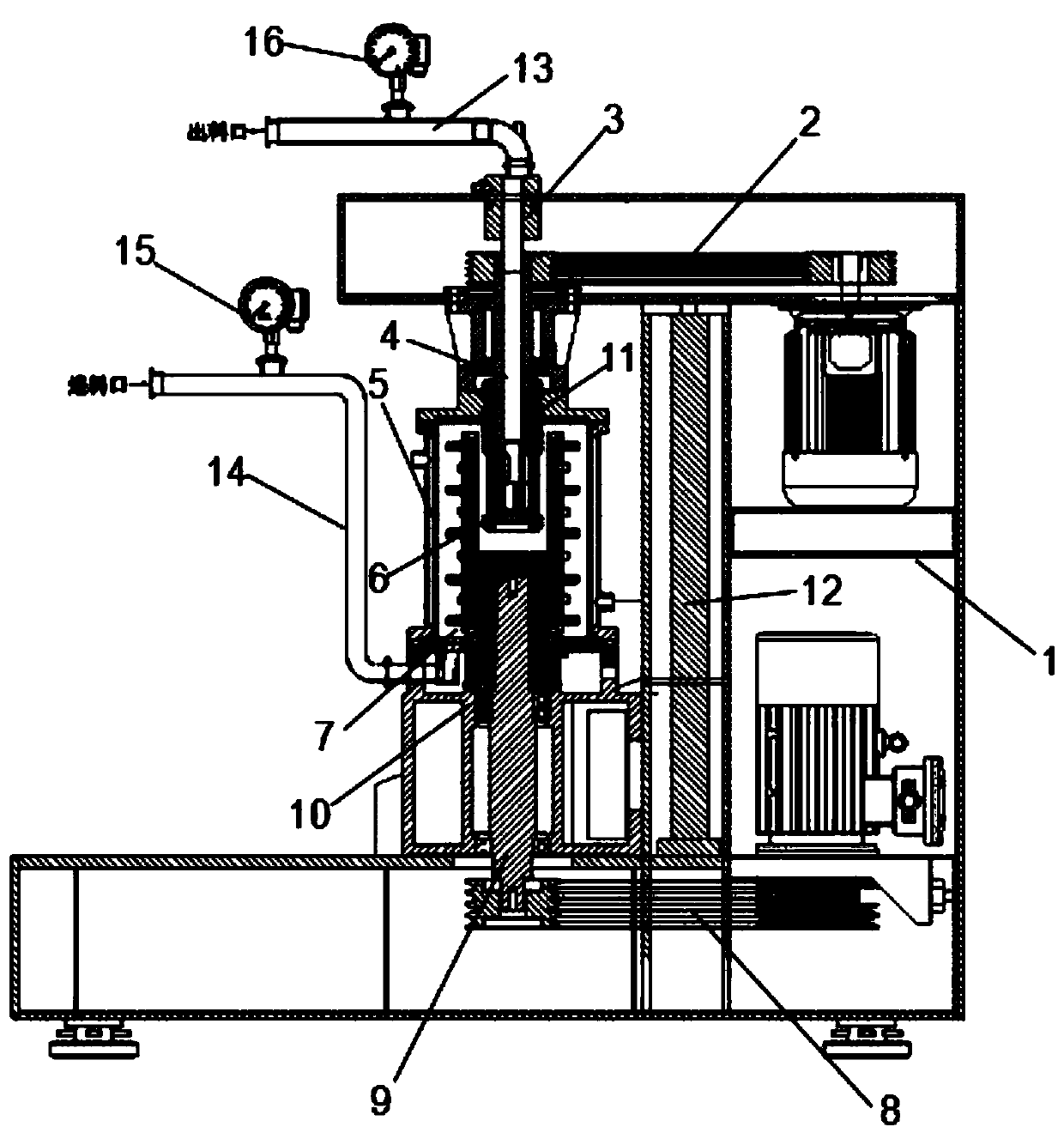

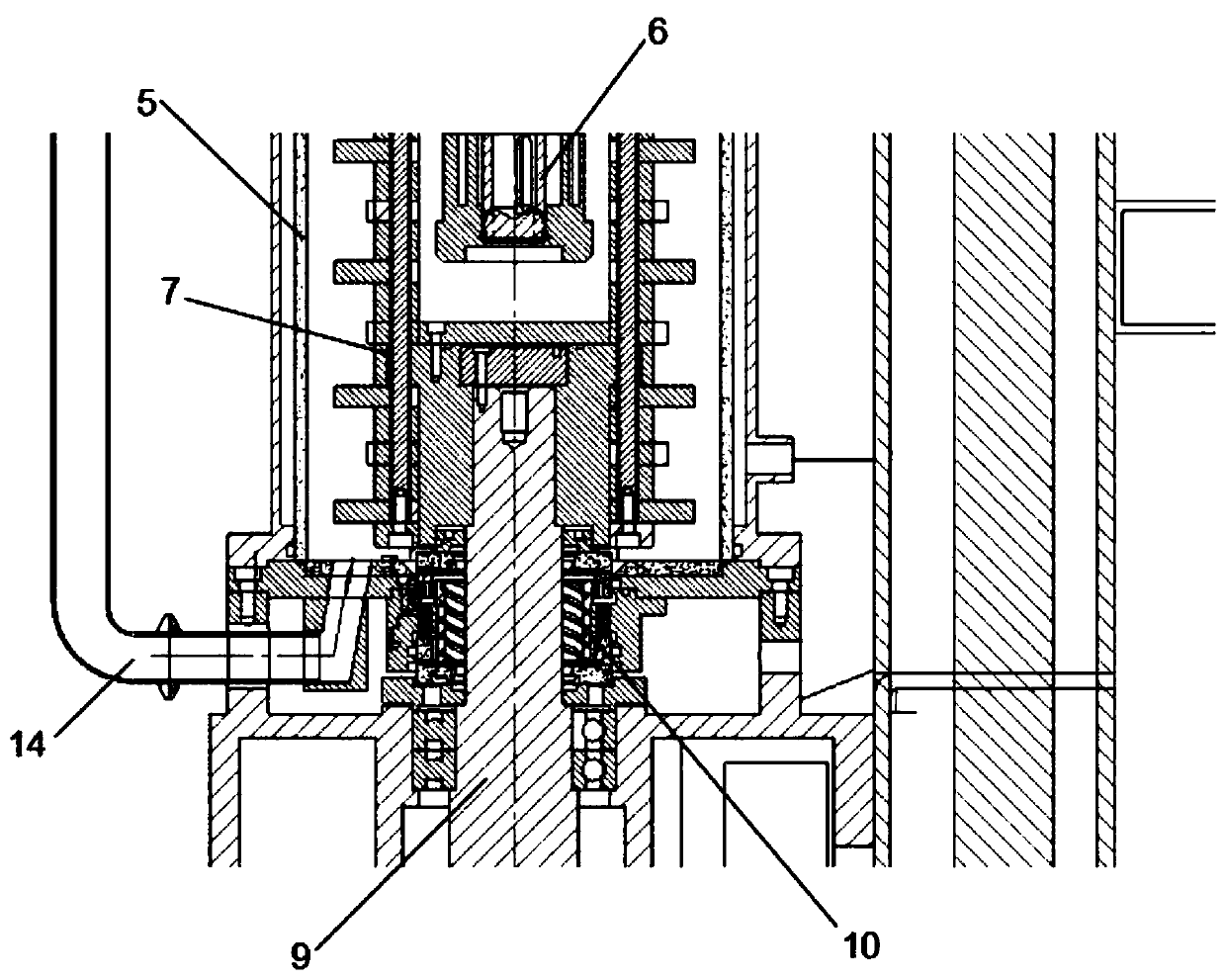

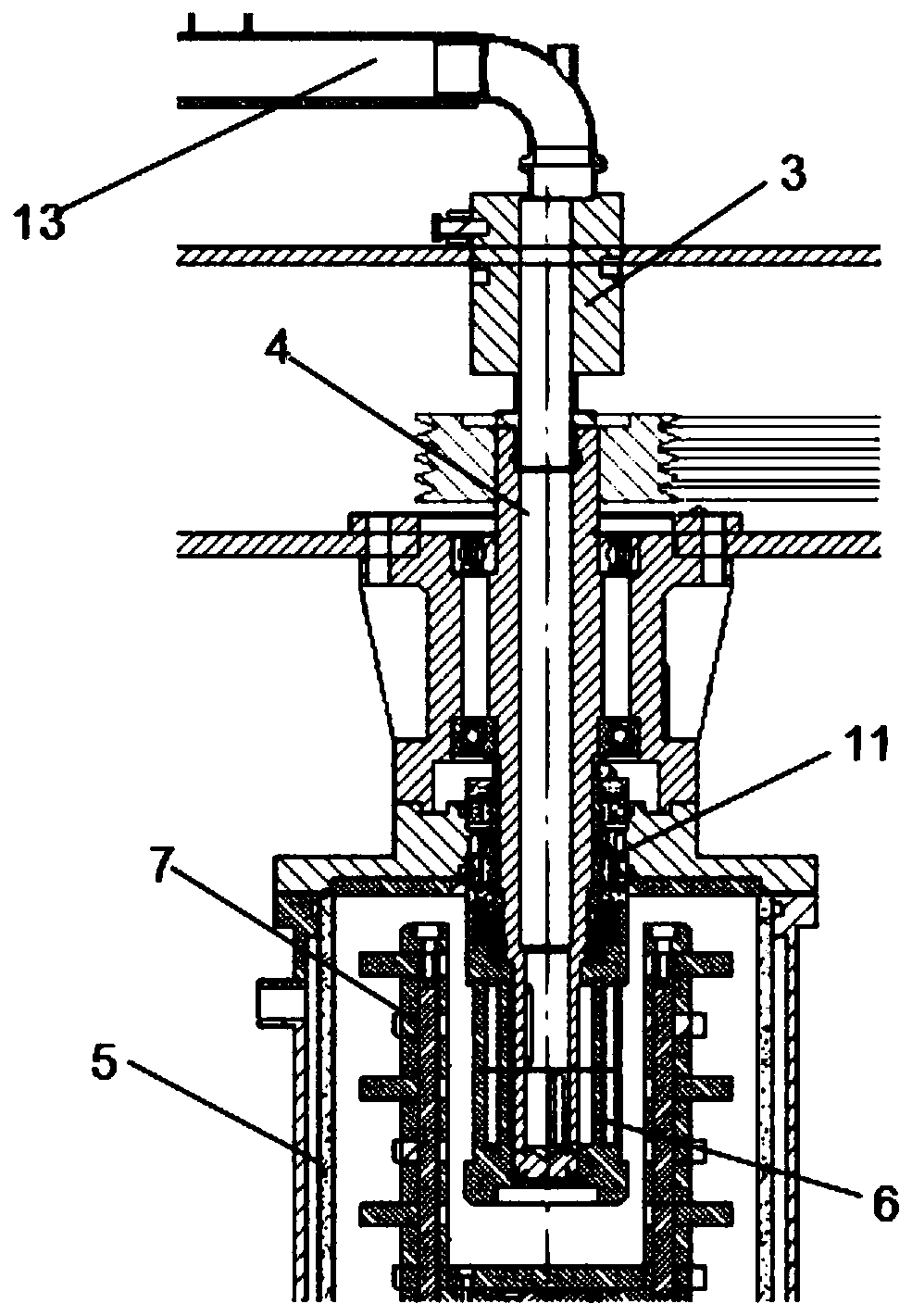

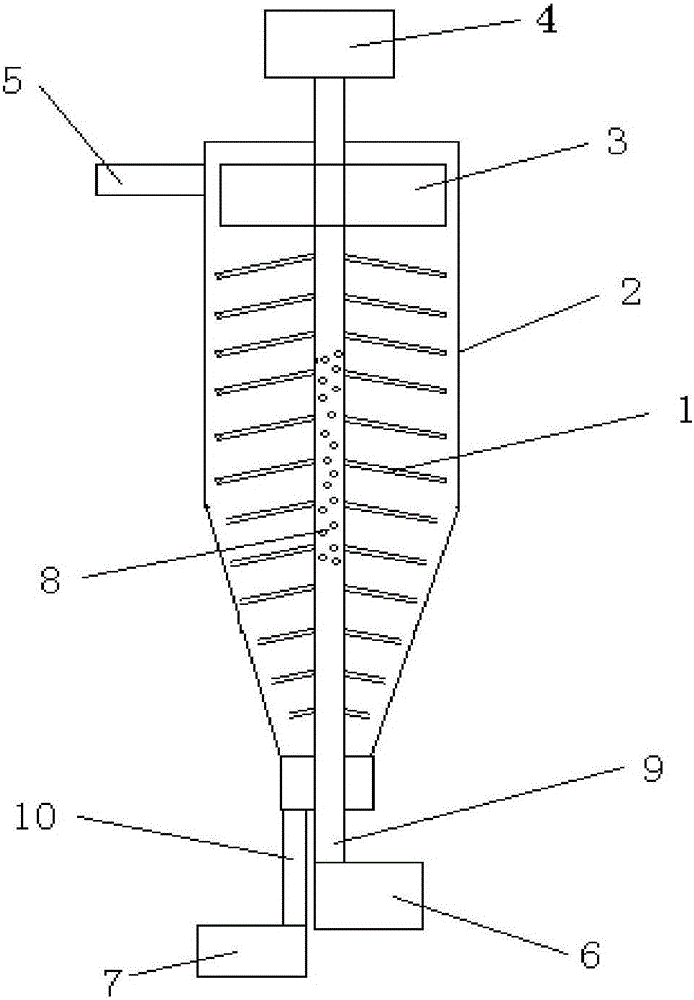

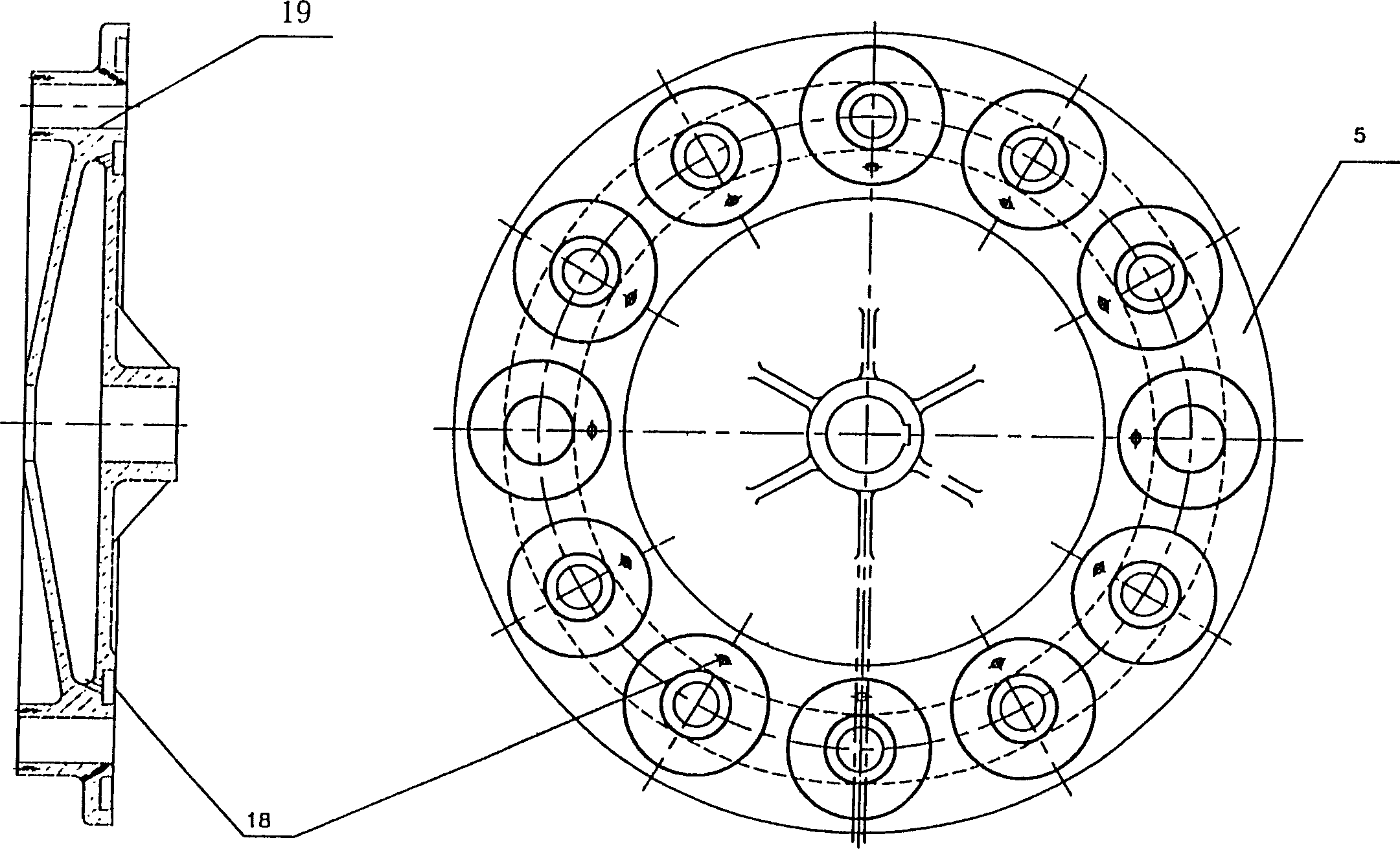

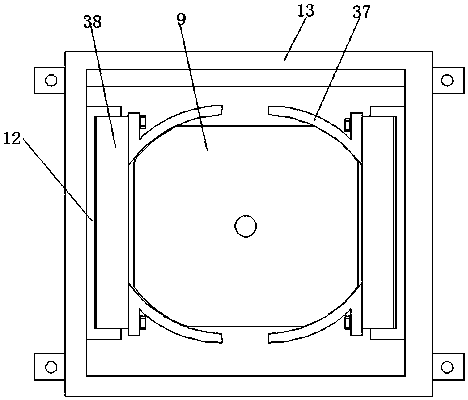

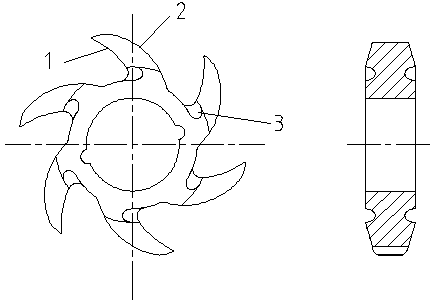

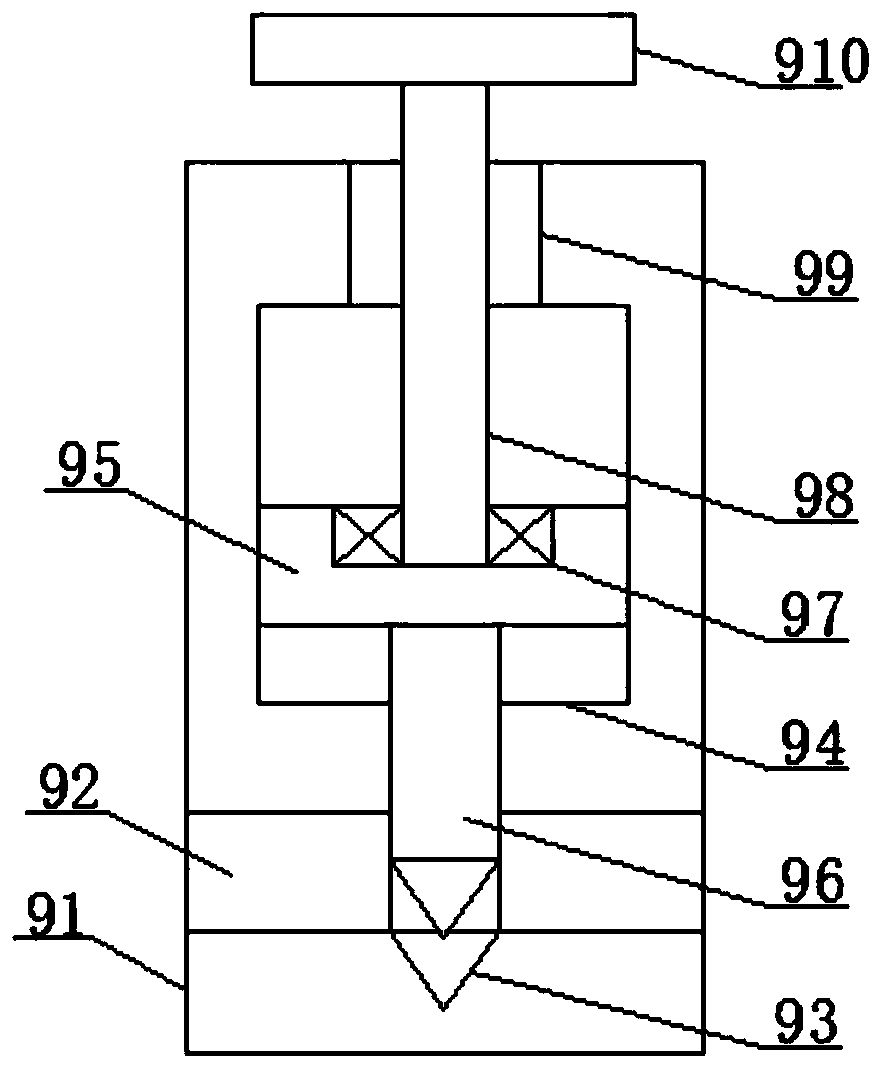

Centrifugal type partition-net-free material bead separator for media stirring mill

InactiveCN103357489AAchieve separationStrong centrifugal forceGrain treatmentsTurbine wheelEngineering

The invention discloses a centrifugal type partition-net-free material bead separator for a media stirring mill. The centrifugal type partition-net-free material bead separator comprises a main shaft (1), a discharge shaft head (2), a separation turbine wheel (3), a rotor (4) and a discharge pipe (5), wherein the discharge shaft head is provided with a plurality of chutes which are communicated and tangent with an inner circle so as to form a turbine, the turbine is assembled with the separation turbine wheel, the rotor and the main shaft so as to form small, middle and large packaging turbines which generate powerful centrifugal force in a rotating process; milling beads and grinding materials with large particle diameters are thrown out of an outer layer, the grinding materials with small particle diameters bear small centrifugal force so as to overcome the centrifugal force of the turbine under the pressure effect of a pump to enter the discharge pipe to be discharged, the effective segregation of the material beads is ideally realized, and the influence of the diameter sizes of the milling beads is free. The designed separator provided by the invention has the advantages that the manufacturing cost is low, the grinding and dispersion efficiency is greatly improved, the particle diameter of a product after primary grinding is obviously reduced, and compared with a traditional same type grinding machine, the centrifugal type partition-net-free material bead separator has the advantage that the yield is increased by 40-100%.

Owner:谢小飞

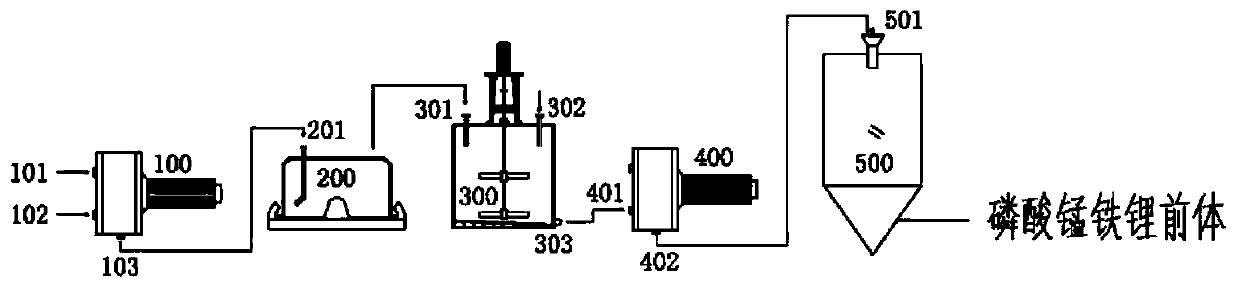

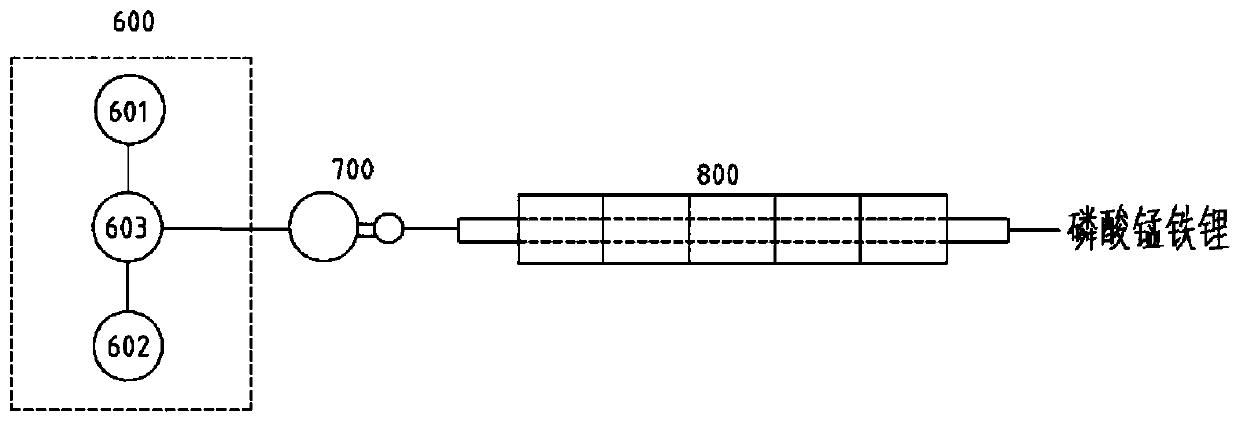

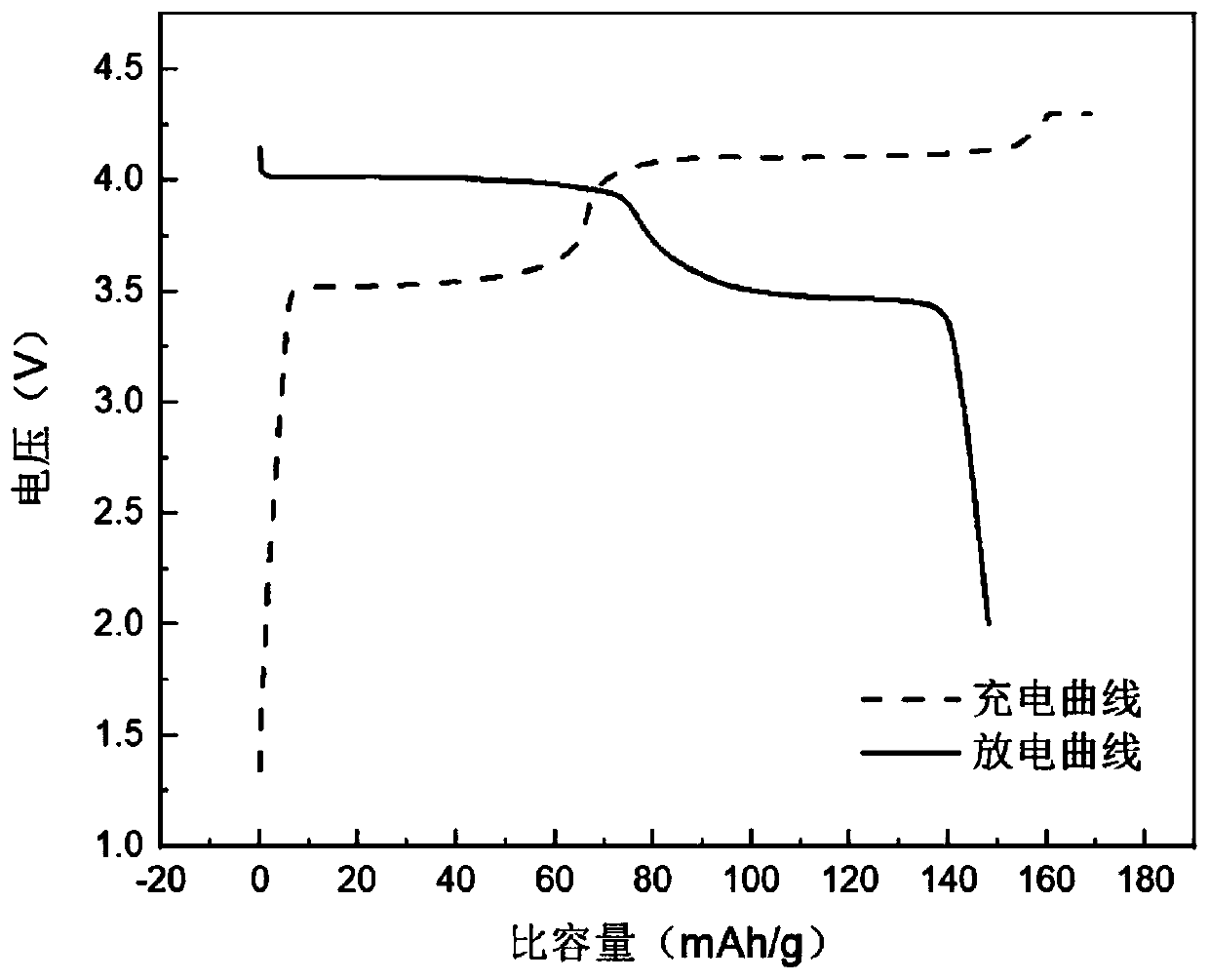

Method for preparing lithium iron manganese phosphate precursor and method for preparing lithium iron manganese phosphate

PendingCN110980682AFine and uniform particle sizeFast manufacturingMaterial nanotechnologyOrganic compound preparationCarbon coatingOXALIC ACID DIHYDRATE

The invention relates to a method for preparing a lithium iron manganese phosphate precursor and a method for preparing lithium iron manganese phosphate. The method for preparing the lithium iron manganese phosphate precursor comprises the following steps: (1) preparing a liquid material A and a liquid material B, wherein the liquid material A is a mixed solution of a manganese salt and an iron salt, and the liquid material B is an oxalic acid or phosphoric acid solution; (2) carrying out a coprecipitation reaction on the liquid material A and the liquid material B in a supergravity rotating bed to obtain a first slurry; (3) washing and filtering the first slurry to obtain a filter cake; (4) mixing the filter cake with water, adding a carbon source, and uniformly stirring to obtain a second slurry; (5) homogenizing the second slurry; and (6) drying the homogenized second slurry to obtain the lithium iron manganese phosphate precursor. The particle size of the lithium iron manganese phosphate precursor prepared by the method is smaller and more uniform than that of a precursor prepared by a traditional method using a reaction kettle, the preparation speed is increased, and carbon coating is uniform.

Owner:JIANGSU LITHITECH CO LTD

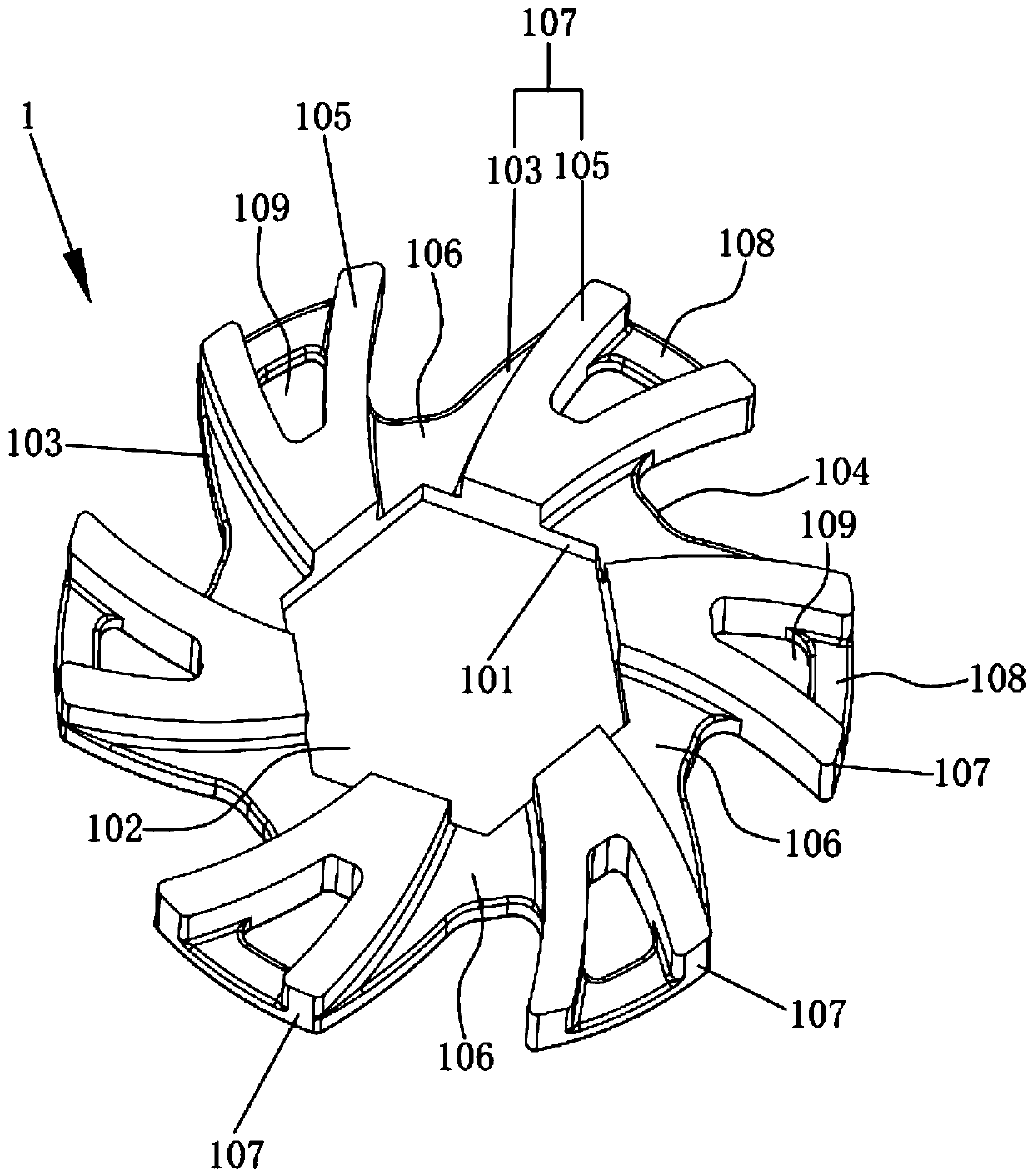

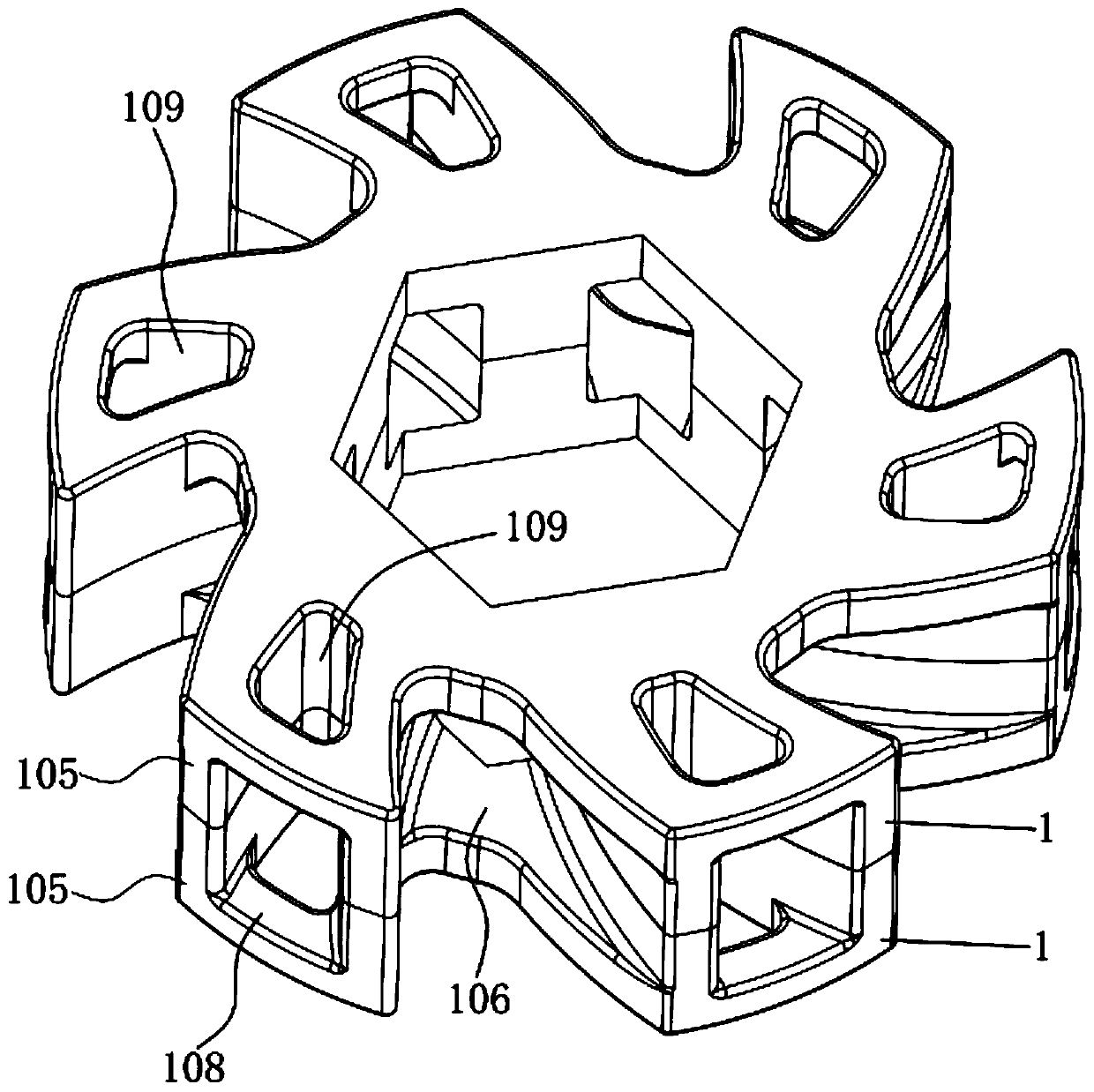

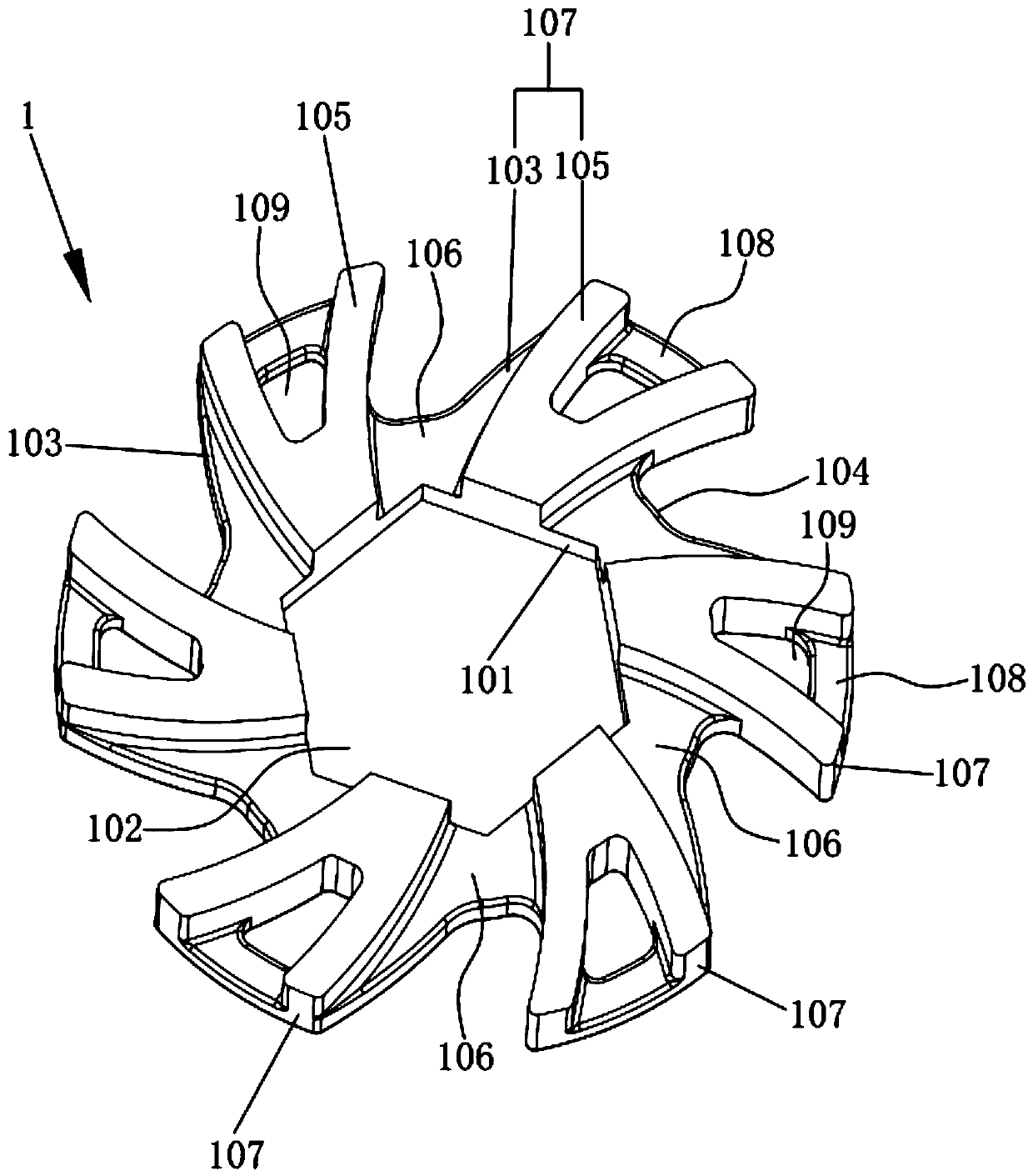

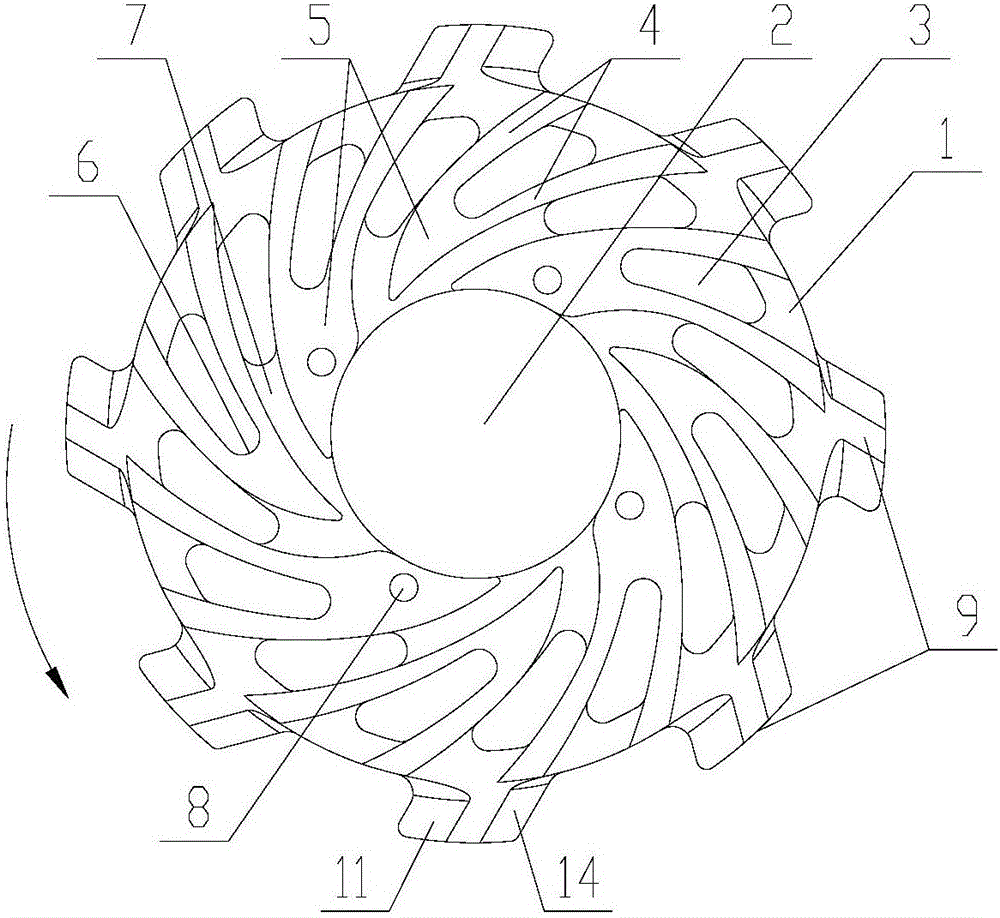

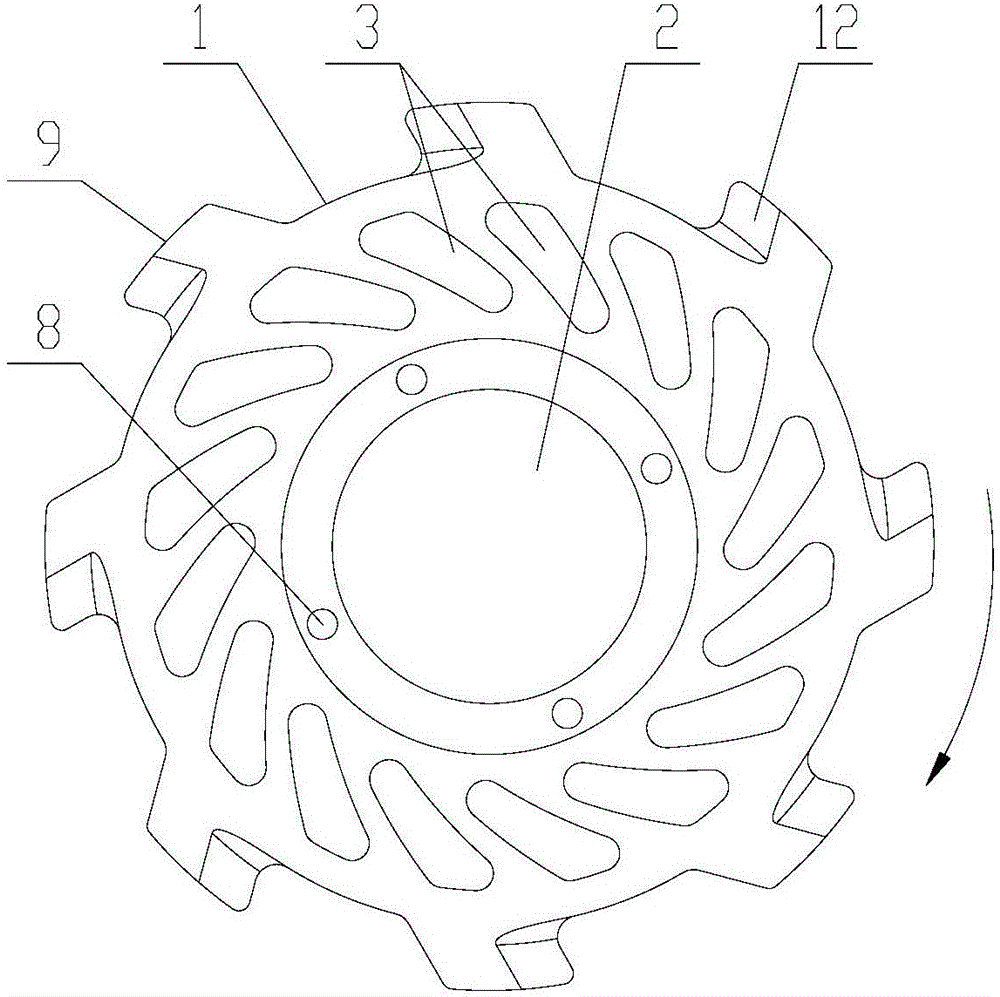

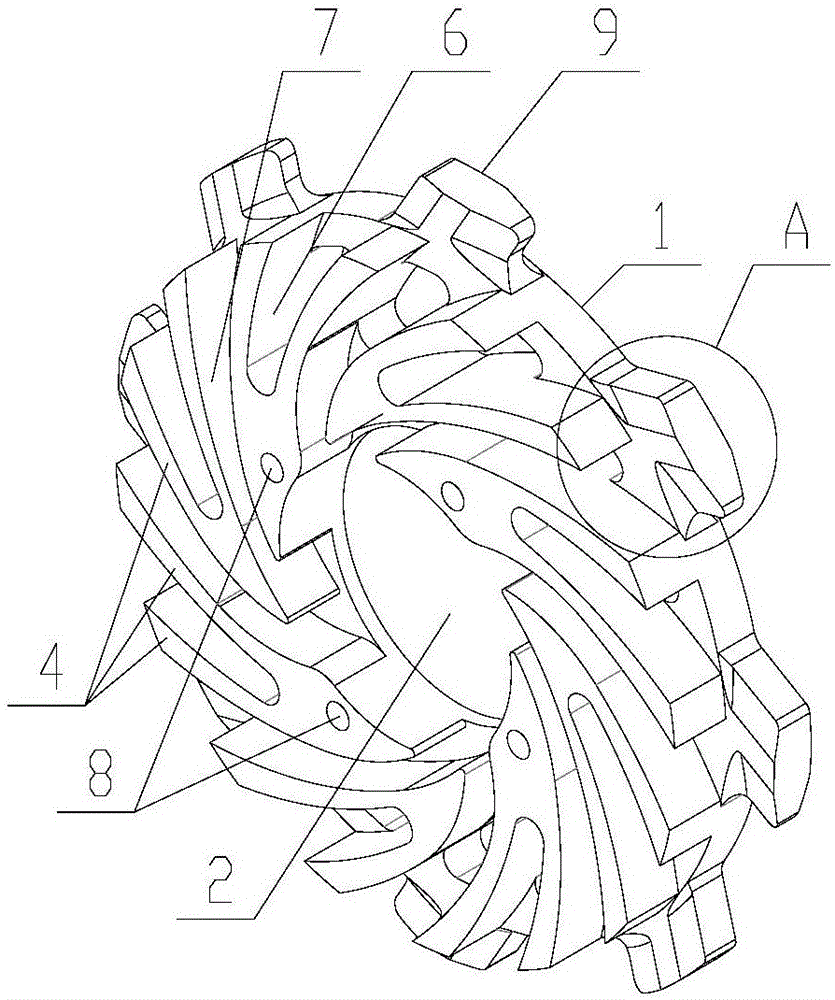

Turbine blade, grinding turbine and grinding device

The invention discloses a turbine blade, a grinding turbine and a grinding device. The turbine blade comprises a turbine body and grinding teeth. A center through hole formed in the axial direction ofthe turbine body is formed in the middle of the turbine body, multiple convex pins being convex outwards are formed in the circumferential direction of the periphery of the turbine body, and an opengroove is formed between every two adjacent convex pins. The multiple grinding teeth are arranged on at least one surface of the turbine body in the circumferential direction of the center through hole. The multiple grinding teeth are formed on the multiple convex pins in one-to-one correspondence. A radial hollowed channel allowing a grinding medium to flow in or out of the center through hole inthe radial direction of the turbine body is formed on one surface of the turbine body by every two adjacent grinding teeth. The radial hollowed channels of the turbine blade have no end faces stopping outflow motion of the grinding media, kinetic energy losses are low in the process that the grinding media flow out, grinding of the grinding media is more sufficient in the radial direction, exchange of the grinding media at different positions is more frequent, and grinding efficiency is greatly improved.

Owner:GUANGZHOU HONGKAI MACHINERY CO LTD

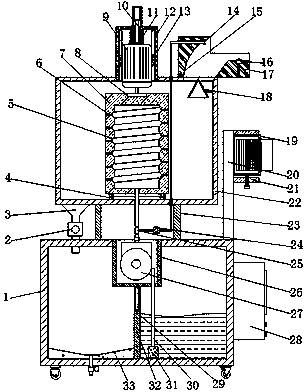

Enhanced oxidization device and method used for organic wastewater treatment

InactiveCN103011377AImprove mass transfer efficiencyReduce waste water treatment timeWater/sewage treatment by centrifugal separationWater contaminantsMass transferEngineering

The invention relates to an enhanced oxidization device and method used for organic wastewater treatment. The device comprises a shell, wherein a rotary drum is arranged in the inner cavity of the shell, a cylindrical rotary filler is arranged in the rotary drum, a liquid distributor is arranged at the central position of the inner cavity of the shell and is disposed in the inner ring of the rotary filler with a gap from the inner ring of the rotary filler, the lower part of the rotary drum is provided with a rotary shaft, the rotary shaft is concentrically connected with the rotary drum, and the lower end of the rotary shaft runs through the shell and is connected with a rotary power mechanism. The device disclosed by the invention is provided with two structural forms consisting of gas-liquid contact and liquid-liquid contact. The enhanced oxidization equipment disclosed by the invention provides strong centrifuge power under high-speed rotation condition, and the liquid materials are torn to be fine liquid drips, liquid films and liquid wires under the action of the centrifuge power, thus the gas liquid reaction mass-transfer efficiency is higher and the oxidant and the organic waste water can be mixed more evenly.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

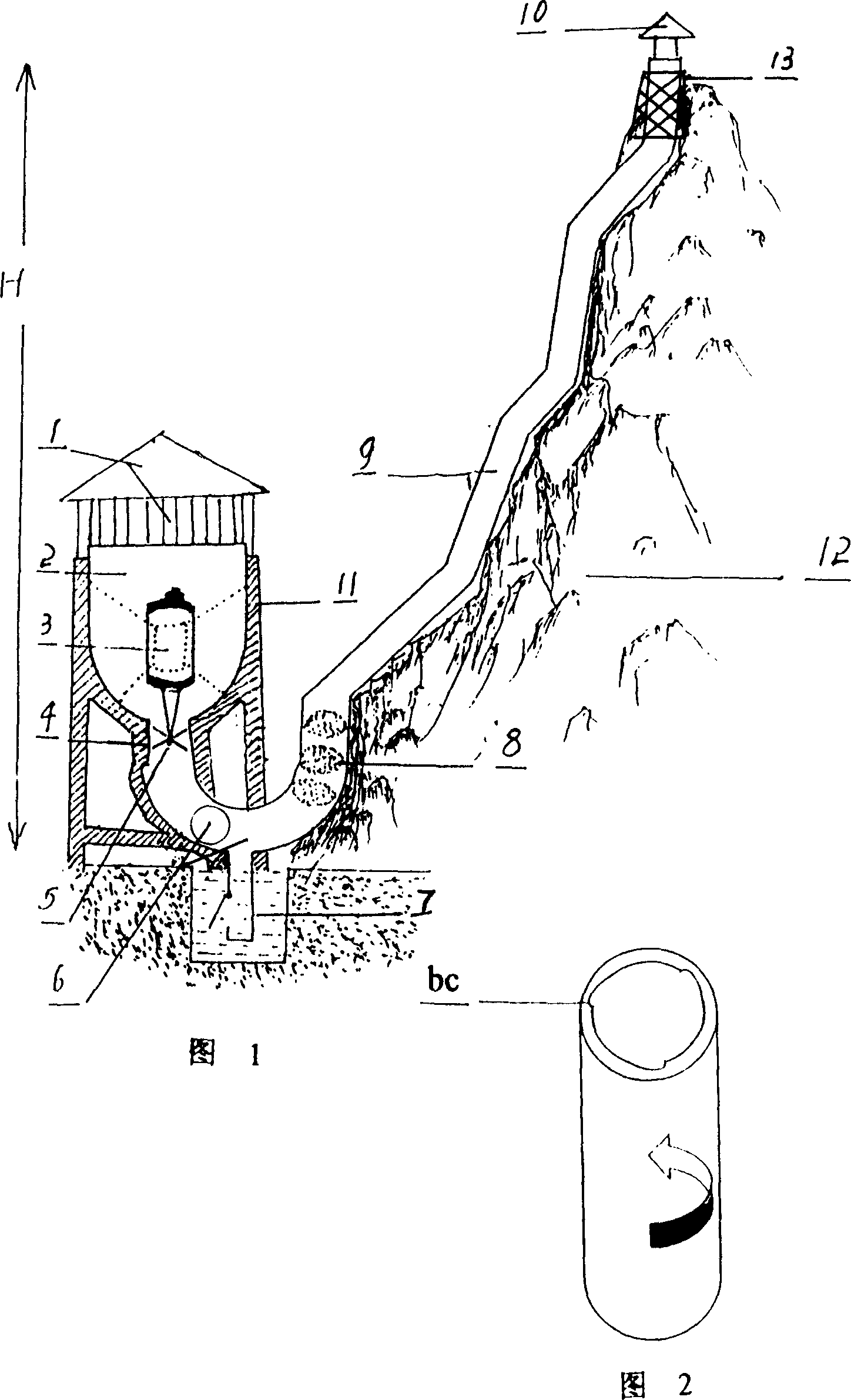

Earth gravity and atmospbere gradient temperature difference comprehensive electric generating method and its device

InactiveCN1619143AIncrease upward momentumSolve supply problemsMachines/enginesMotorsAtmospheric airTemperature difference

The present invention disclosed a comprehensive electric generation method by using terrestrial gravity and atmospheric gradient temperature difference. It is characterized by that on a steep hill body whose vertical height is above 1500 m an internal spiral pipeline system is laid, its bottom end is communicated with an air reservoir by means of 'U'-shaped pipe. Said invention also provides its working principle for implementing electric generation.

Owner:梁和平

Solid-liquid separation device for primary sewage treatment

InactiveCN107935108AEasy dischargeImprove filtering effectWater/sewage treatment by centrifugal separationMoving filtering element filtersCentrifugationEngineering

The invention discloses a solid-liquid separation device for primary sewage treatment. The device comprises a bottom hollow case and a top hollow case, wherein the bottom of the bottom hollow case isprovided with a plurality of connecting plates through screw bolts; one support rod is arranged in the center of the bottom of each connecting plate. The centrifugal force principle is used to realizethe filtering effect; by using the device, the bottom hollow case and the top hollow case can be freely combined or dismounted, so that inside filtered sundries can be conveniently discharged. In addition, through a centrifugal filtering rotating mechanism arranged in the device, when inside sewage rotates to generate an eddy current phenomenon, the eddy current enables impurities in the sewage to generate the centrifugation phenomenon, so that the impurities can move towards the outer side; liquid in the sewage can enter the inside of a hollow structure for the centrifugal filtering rotatingmechanism through a filter hole for the centrifugal filtering rotating mechanism; under the gravity effect, the liquid in the sewage can be discharged out through a main liquid discharging pipeline;when an electric motor rotates faster, when the generated centrifugal force effect is stronger, the filtering effect is better; the practicability is higher.

Owner:湖南涟钢建设有限公司

Supersonic wing of supersonic spiral natural-gas separator

InactiveCN1896184AEliminate shock waveReduce disturbanceSolidificationLiquefactionCycloneProduct gas

A supersonic wing of supersonic cyclone natural-gas separator is the critical part. Bottom of supersonic wing is cylindrical or circular platform face, which fits the internal wall of wing sectional pipe and is fixed on the internal wall. The mean camber line of base is para-curve, wing thickness of bottom varies by three-time polynomial law, cylindrical supersonic-wing bottom shape is determined by bottom mean camber line and bottom wing thickness variation model, top of wing aggregates on one point, which is supersonic wing vertex, two sides are concave and convex faces, which are constituted by vertex and bottom boarder line connection; low-temperature supersonic natural gas homogeneous axial flow formed by thermal-insulating expansion is converted into supersonic cyclone, mixture flow of gas and condensate liquid in supersonic cyclone separating area passes by supersonic tail wing at supersonic speed, to form high-speed cyclone field, and gas-liquid separation is finished through tremendous centrifugal force produced by cyclone.

Owner:曹学文 +1

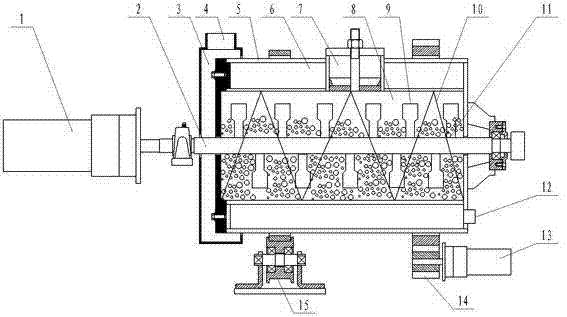

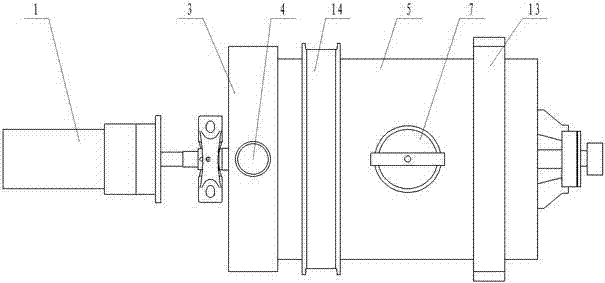

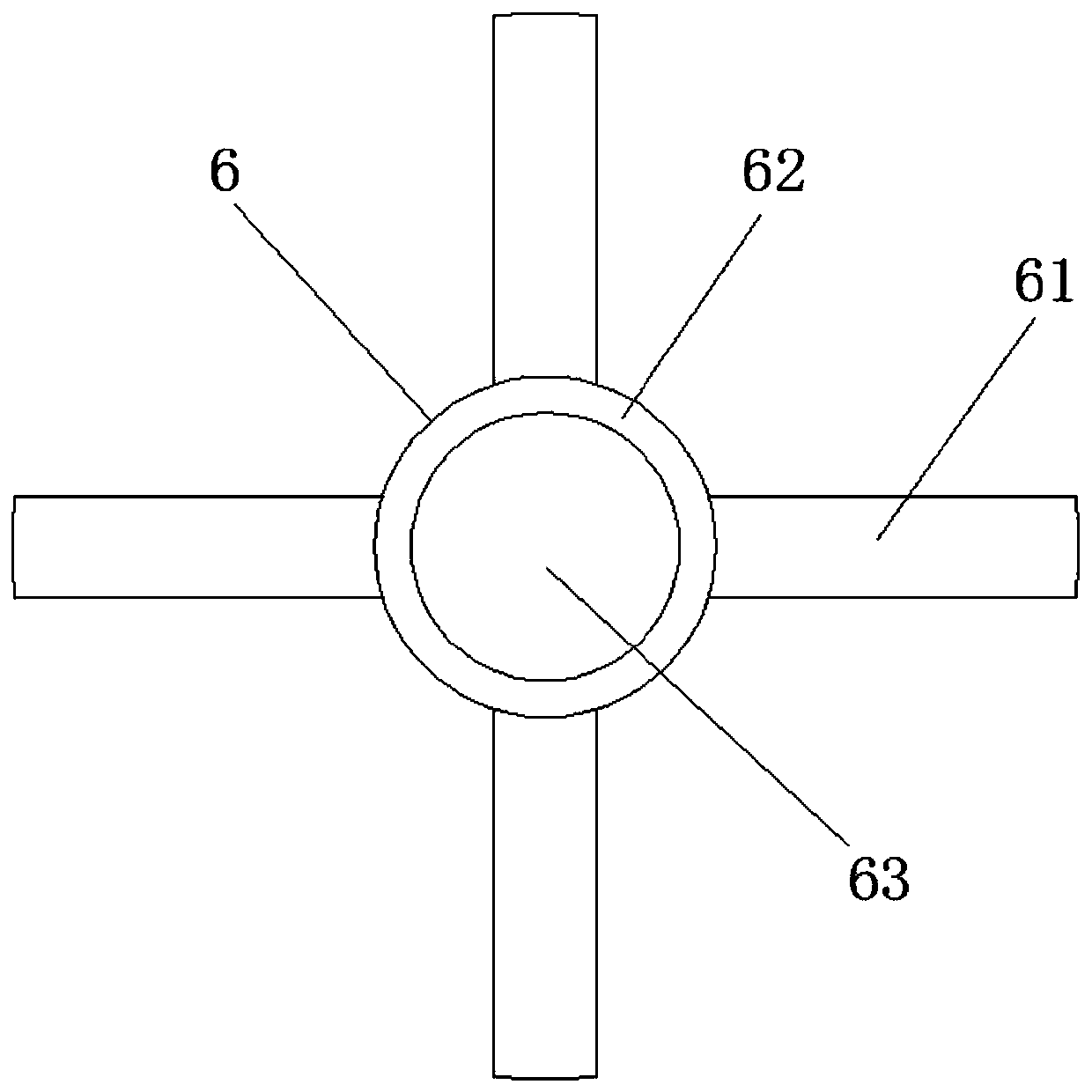

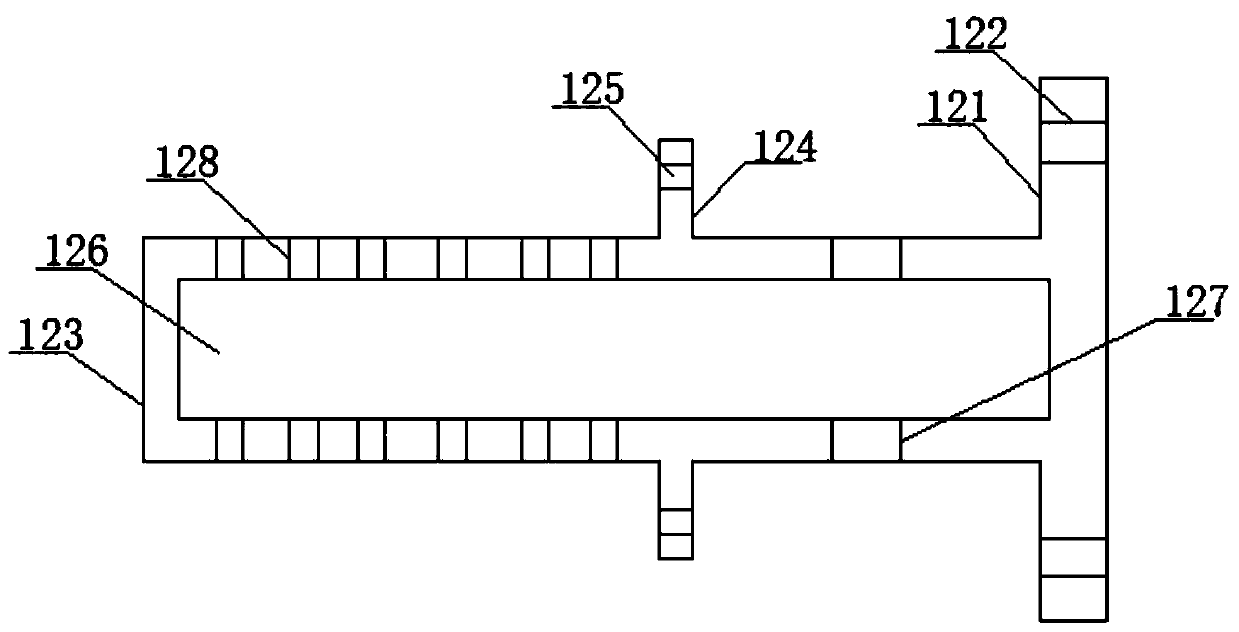

Mechanical activation reactor capable of enhancing polysaccharide high polymer modification

InactiveCN104492557AThe material reacts evenlyFast surface renewalRotary stirring mixersTransportation and packagingHigh polymerRaw material

The invention discloses a mechanical activation reactor capable of enhancing polysaccharide high polymer modification. An outer barrel is in a horizontal structure and a grinding inner barrel is arranged in the outer barrel; a speed reducer I is connected with a stirring shaft by a shaft coupler; the stirring shaft penetrates through a through hole in an end cover of the outer barrel and is inserted into the grinding inner barrel; the stirring shaft is fixed at the two ends of the outer barrel by bearing seats at the two ends; a jacket is arranged outside the grinding inner barrel; a material inlet / outlet is formed in the outer barrel and is communicated with the grinding inner barrel; the grinding inner barrel is internally provided with grinding balls; the stirring shaft is provided with paddles and a material scraping screw belt; the paddles are mounted on the stirring shaft in a staggered manner; and the material scraping screw belt is mounted on the stirring shaft. The mechanical activation reactor is provided with the paddles and the material scraping screw belt so that the grinding balls in the grinding inner barrel can be driven by the paddles and the material scraping screw belt to move back and forth, and the disturbance of the grinding balls is enhanced, and furthermore, materials can react more uniformly and the surface updating is more rapid; and the reaction time is effectively shortened, the loss of the raw materials is reduced and the quality of a product is improved.

Owner:GUANGXI UNIV +1

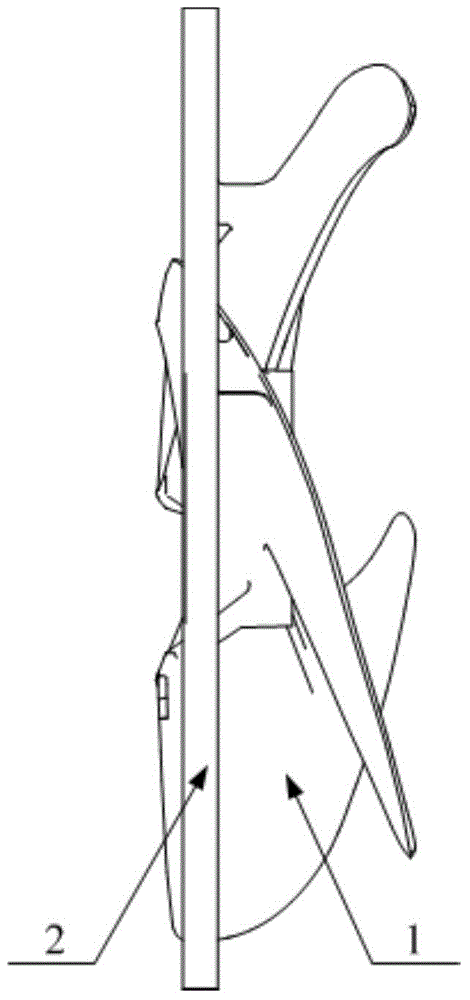

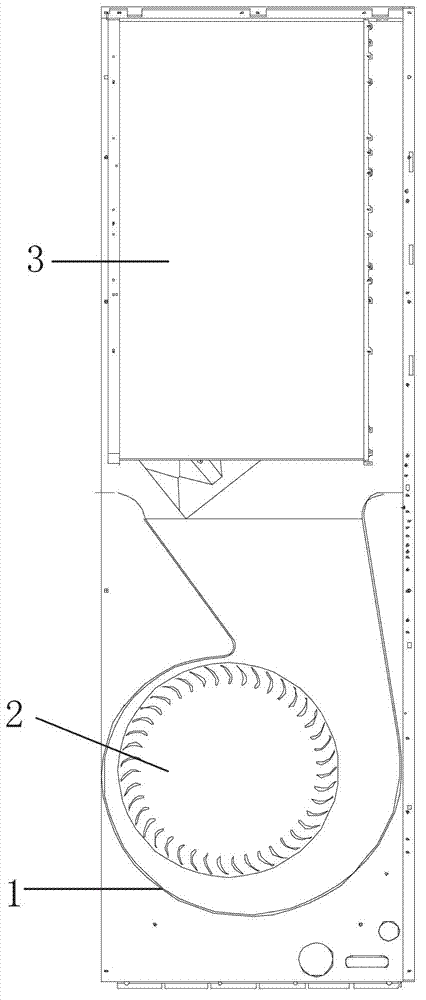

Floor type air conditioner and oblique flow fan thereof

The invention discloses a floor type air conditioner and an oblique flow fan thereof. The oblique flow fan comprises a hub which can be rotationally driven and a plurality of blades arranged around the hub; the hub comprises a head part and a tail part; the outer size of the hub is gradually decreased from the head part to the tail part; each blade comprises a blade root connected with the hub, a blade top far away from the hub, an air outlet end close to the head part and an air inlet end close to the tail part; and when the blades rotate around the axis of the hub, the ratio of the diameter of the rotating circumference in which the air inlet ends of the blade roots are positioned to the diameter of the rotating circumference in which the air inlet ends of the blade tops are positioned is an air inlet end hub ratio, the ratio of the diameter of the rotating circumference in which the air outlet ends of the blade roots are positioned to the diameter of the rotating circumference in which the air outlet ends of the blade tops are positioned is an air outlet end hub ratio, and the air inlet end hub ratio is less than the air outlet hub ratio. The oblique flow fan disclosed by the invention has the characteristics of axial air feeding and oblique air discharging; when the air feed distance is ensured, the air output is increased and the air feeding efficiency is improved.

Owner:MIDEA GRP CO LTD

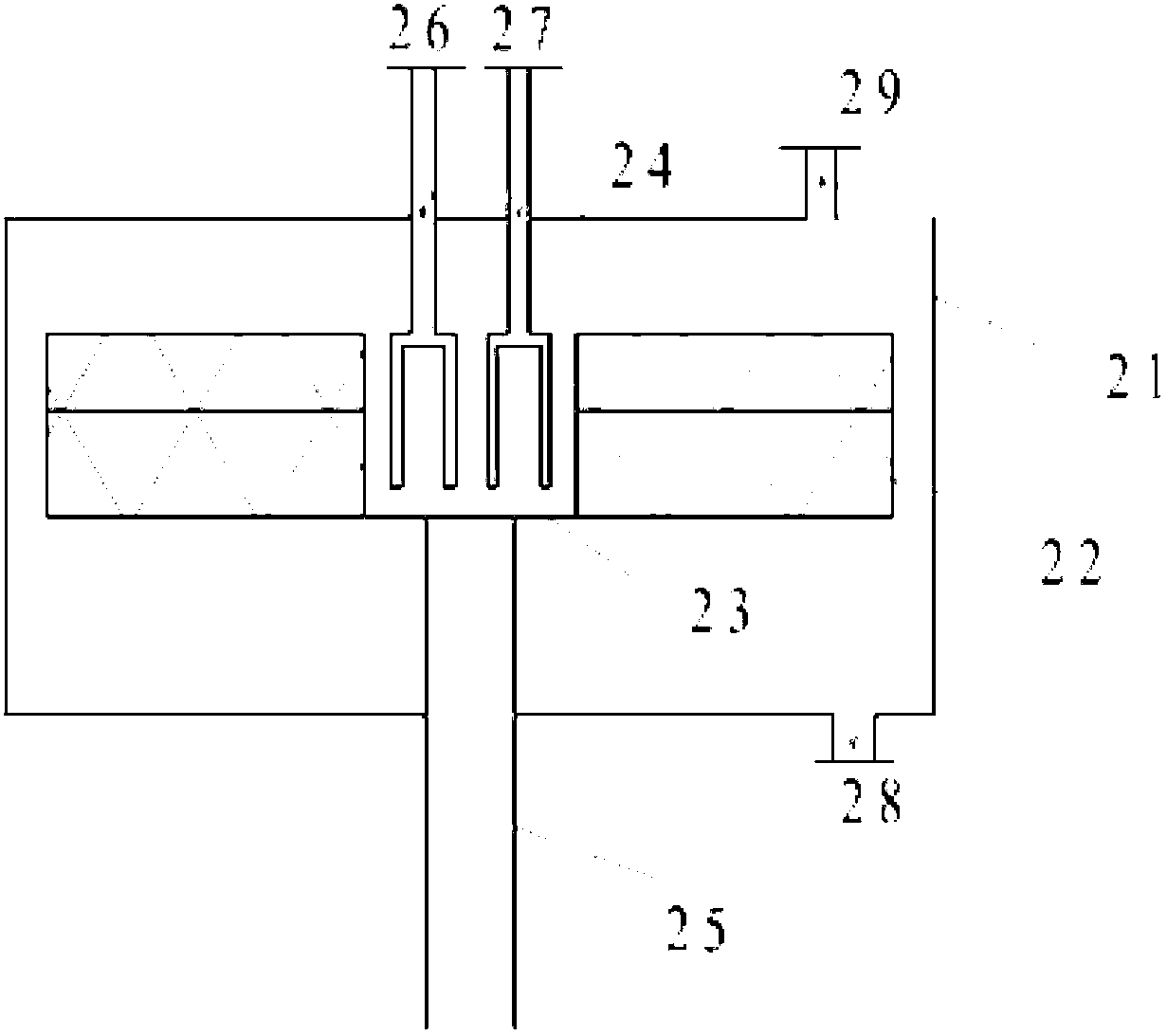

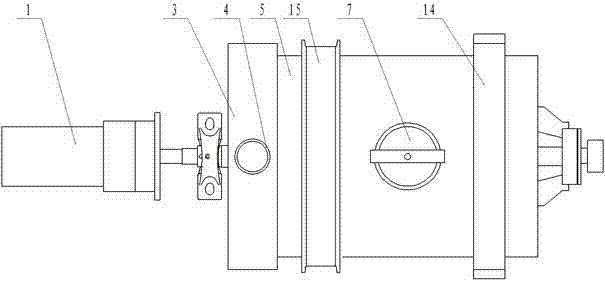

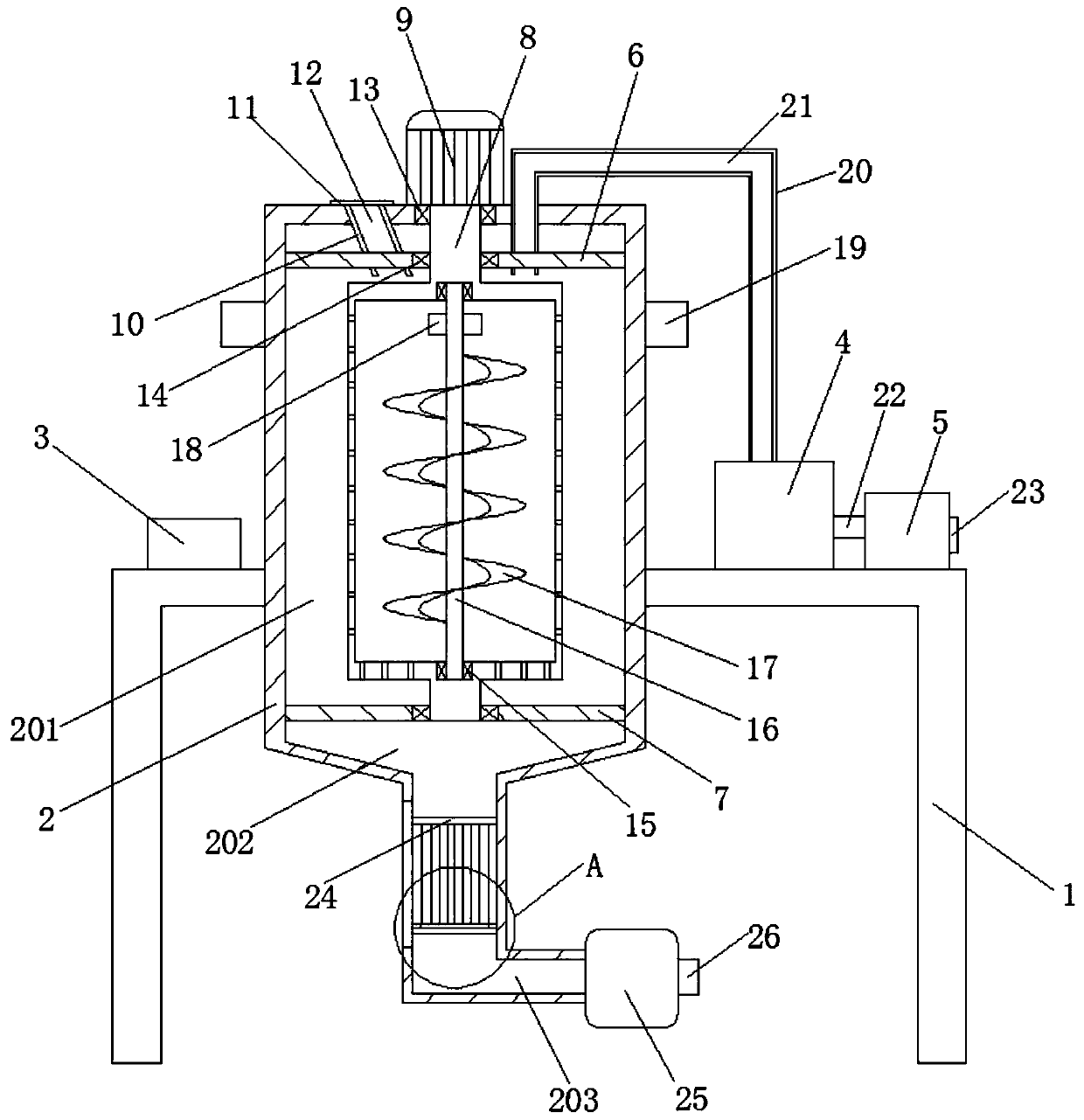

Supergravity reactor for intensifying modification of polysaccharide high polymer

InactiveCN104492362AImprove reaction efficiencyPrevent material agglomerationRotary stirring mixersMixer accessoriesRADIUSMass transfer

The invention discloses a supergravity reactor for intensifying the modification of a polysaccharide high polymer. An outer cylinder body is in a horizontal type structure, the outer cylinder body is internally provided with a reaction inner cylinder, a speed reducer I is connected with a stirring shaft through a coupler, the stirring shaft penetrates through a through hole positioned on an end cover of the outer cylinder body to be inserted into the reaction inner cylinder, and the stirring shaft is fixed on two ends of the outer cylinder body through bearing seats positioned on two ends of the stirring shaft; the outer side of the reaction inner cylinder is provided with a jacket, a main inlet and outlet is arranged on the outer cylinder body, the main inlet and outlet is communicated with the reaction inner cylinder, the stirring shaft is provided with an inner spiral band and an outer spiral band, and the inner spiral band and the outer spiral band are reversely arranged along an axial direction; and the radius of the inner spiral band is smaller than the radius of the outer spiral band. According to the supergravity reactor, the inner spiral band and the outer spiral band move at high speed back and forth to generate strong centrifugal force and shearing force so as to enhance mass transfer and micromixing effect, so that the reaction is intensified, and the reaction time is effectively shortened; in addition, the outer spiral band is capable of scraping to remove a wall-adhering material in time, so that the product quality is enhanced.

Owner:GUANGXI UNIV +1

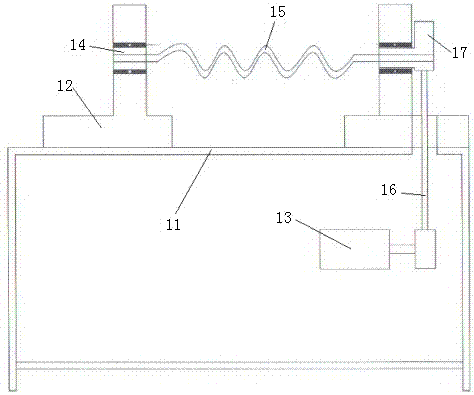

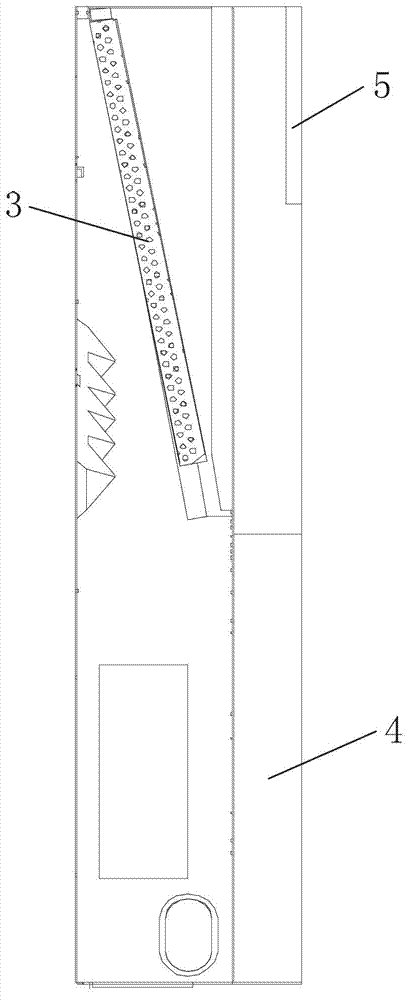

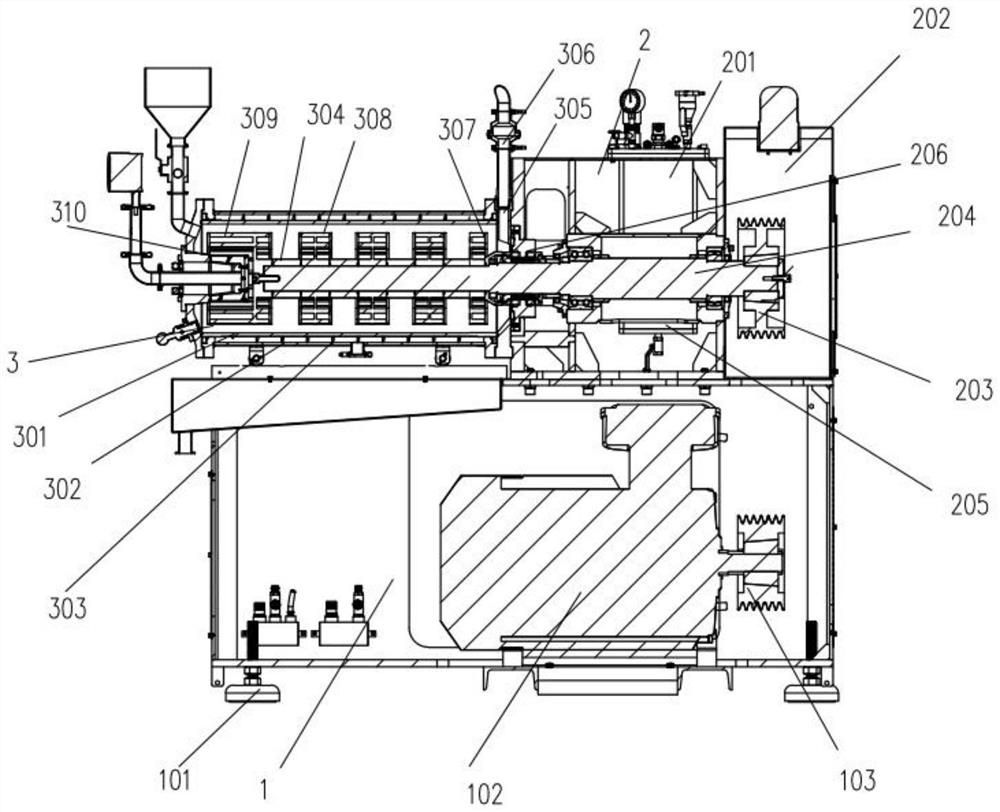

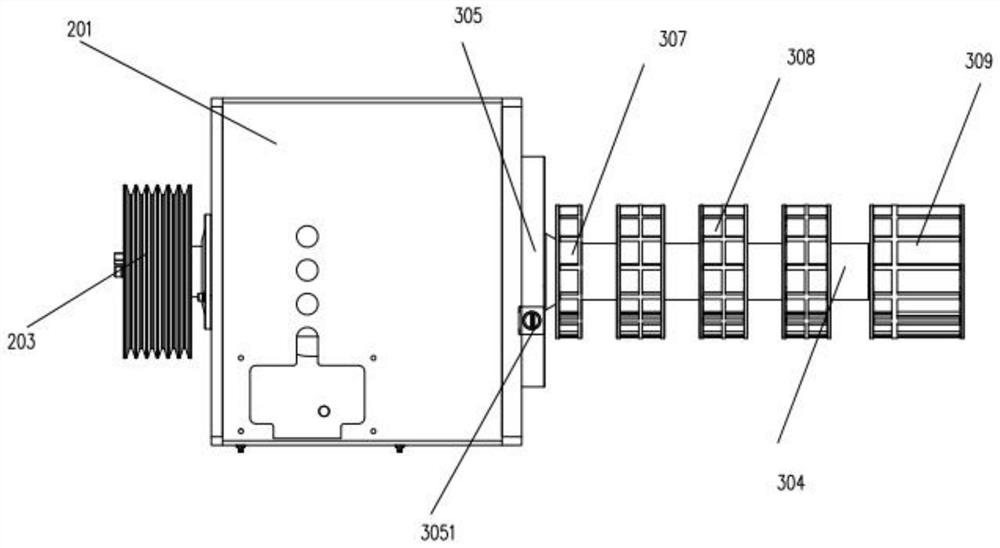

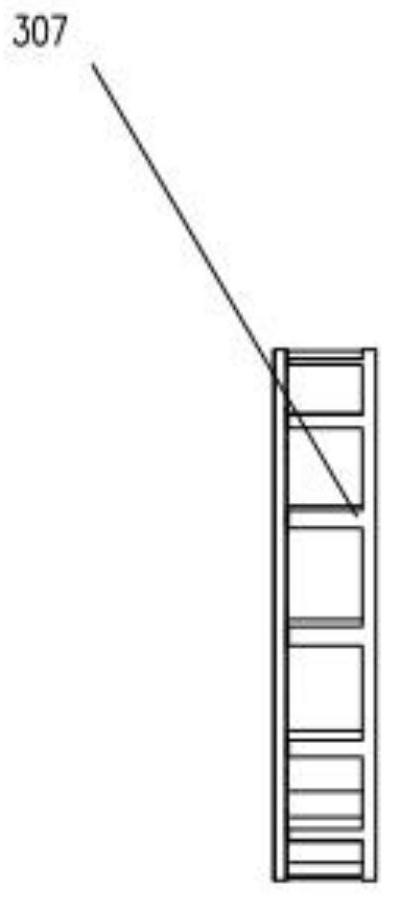

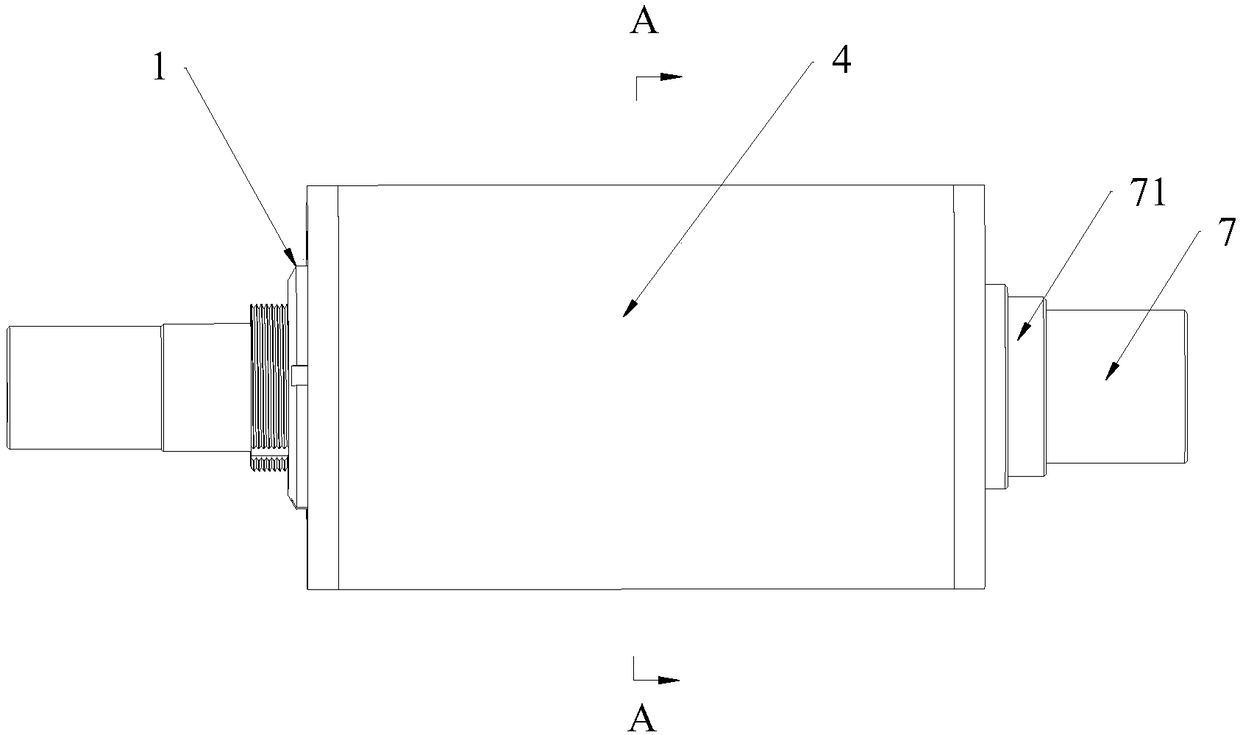

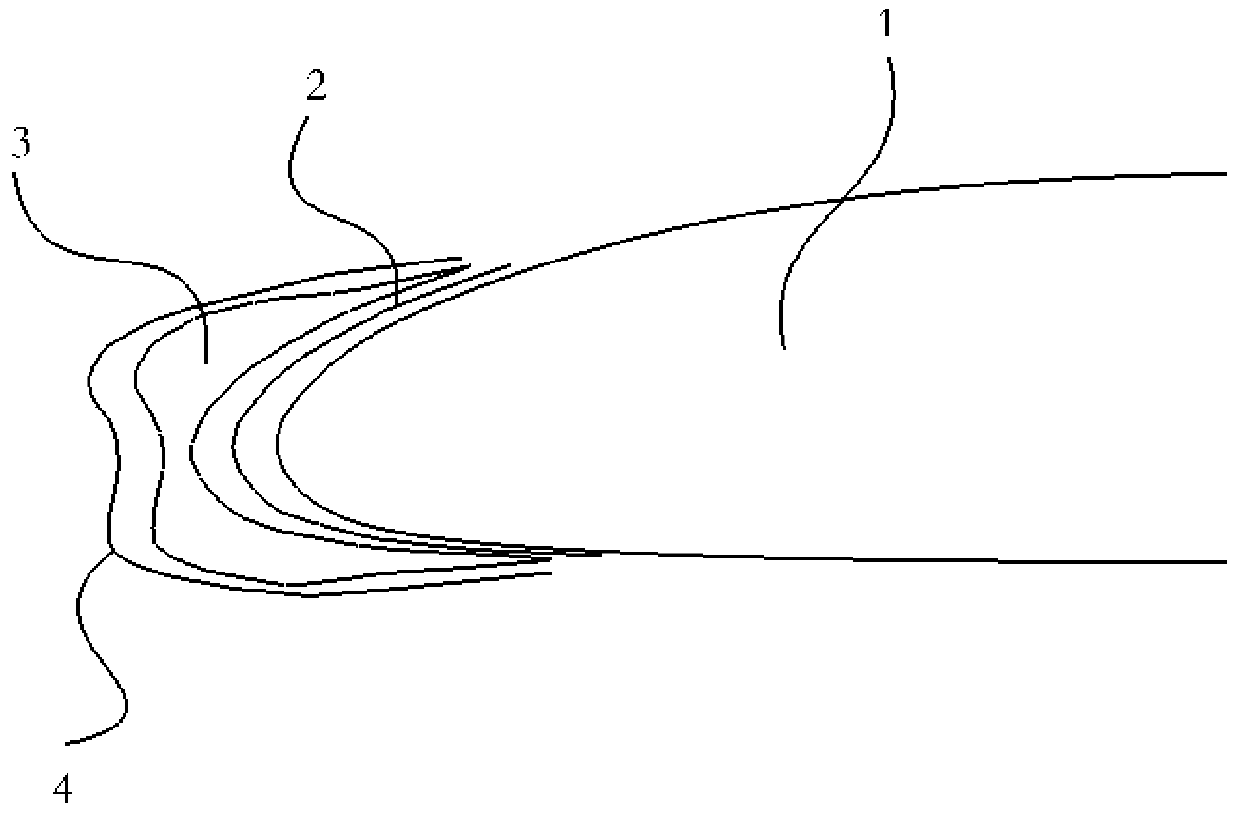

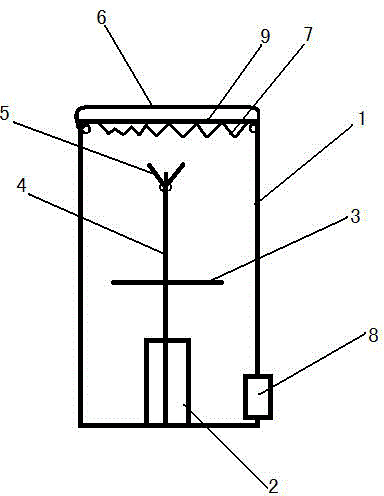

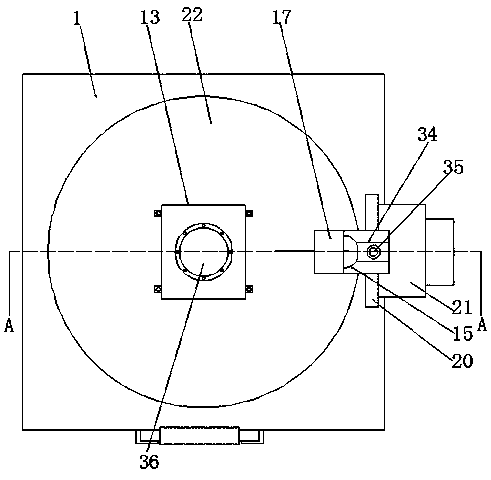

Metal capillary tube straightening device

ActiveCN104015058AWon't hurtFlat cutOther manufacturing equipments/toolsTube shearing machinesRadianEngineering

A metal capillary tube straightening device comprises a feeding mechanism and a straightening mechanism, wherein the straightening mechanism comprises a motor, a base, a bent metal tube and high-speed rotating bearings, the upper surface of the base is provided with two locating supports which are parallel to each other and respectively provided with one high-speed rotating bearing, the bent metal tube penetrates through the two high-speed rotating bearings, the part, between the two high-speed rotating bearings, of the bent metal tube is in a wavy shape by being bent upwards and downwards, all bent radians of the metal tube are the same, and a flexible tube is plugged in the metal tube. According to the metal capillary tube straightening device, the metal tube is driven to rotate at high speed by the high-speed rotating bearings and can generate strong centrifugal force to drive a metal capillary tube to be straightened when rotating at high speed; meanwhile, the rubber flexible tube is specially plugged in the metal tube to protect the metal capillary tube and prevent the damage, caused by collision of the metal capillary tube and the metal tube in a straightening process, of the metal capillary tube.

Owner:DONGQING TECH

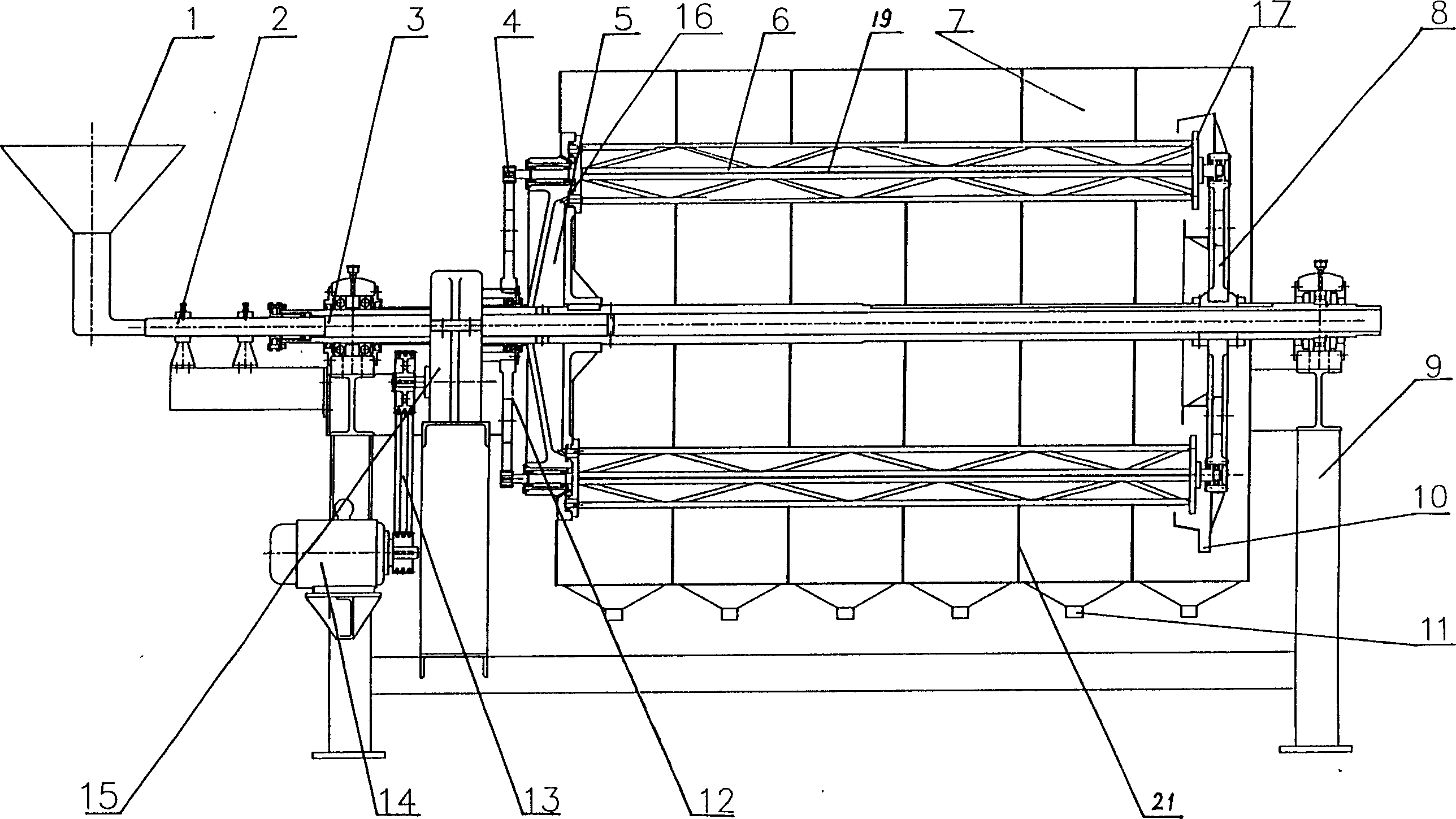

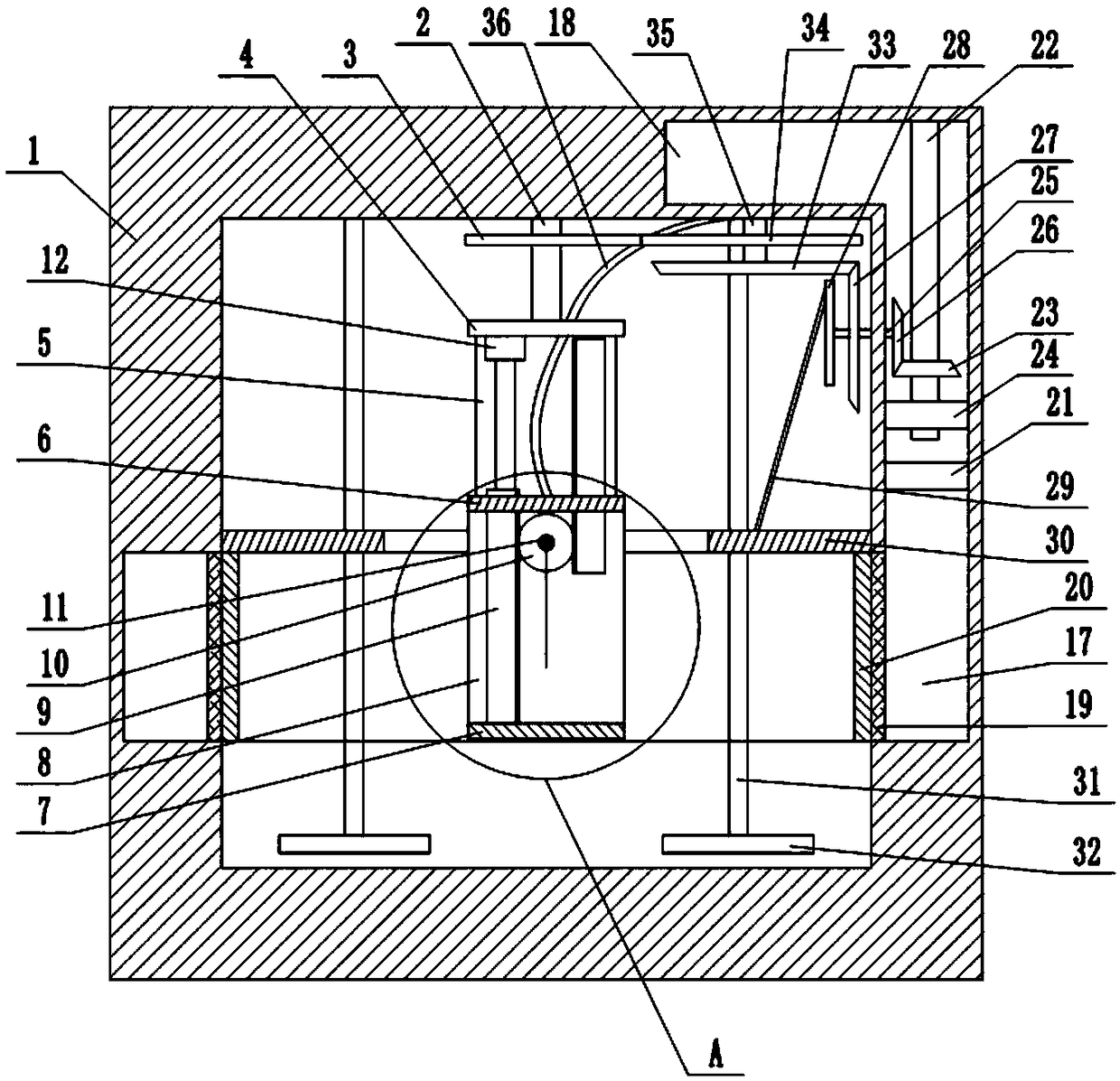

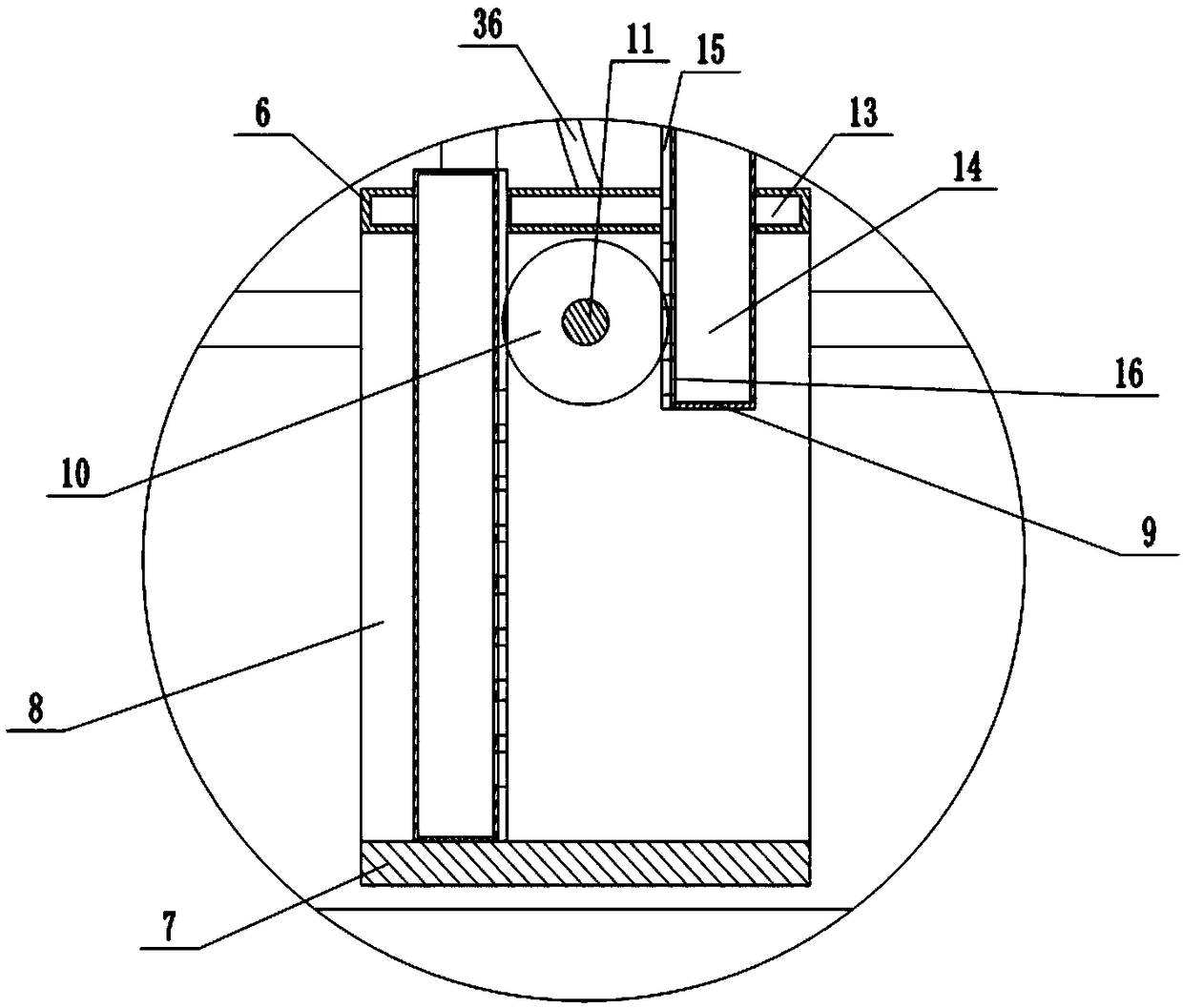

Vertical centrifugal separation discharge grinding system

PendingCN110193408ASimple structureIngenious designGrain treatmentsEngineeringCentrifugal separation

The invention discloses a vertical centrifugal separation discharge grinding system. The vertical centrifugal separation discharge grinding system comprises a grinding cavity, a grinding rotor, and adischarging and separating rotor mechanism, wherein the grinding rotor is in linkage with a second rotating shaft by adopting a splicing structure, the inner side and the outer side of the grinding cavity are sealed through mechanical seal, a hollow structure is adopted at the front end of the grinding rotor, the second rotating shaft is driven by a second driving mechanism to rotate at a high speed, materials enter the grinding cavity from a feeding port through pumping, under the action of the rotation of the grinding rotor, the materials and a grinding medium are driven to collide with andrub with one another, and the materials flow towards a discharging and separating rotor. The vertical centrifugal separation discharge grinding system is simple in structure and ingenious in design, avertical structure, centrifugal separation, and free-net discharging are adopted, a screen is not additionally arranged, so that the problems that in the prior art, the discharging screen is easy toblock, the flow is small, the cleaning is difficult and the ball leakage are solved.

Owner:DONGGUAN LONGLY MACHINERY

Nano-pesticide fine grinding equipment

ActiveCN112742551ASmall particle sizeLarge specific surface areaGrain treatmentsAgricultural engineeringElectric machinery

The invention discloses nano-pesticide fine grinding equipment. A main shaft fixing cavity is fixedly formed in the top surface of a rack; a grinding cylinder is fixedly arranged on the top surface of the rack and located on the left side of the main shaft fixing cavity; a driving cavity is fixedly arranged on the top surface of the rack and located on the right side of the main shaft fixing cavity; a main shaft is arranged inside the grinding cylinder; the right end of the main shaft penetrates through the main shaft fixing cavity and is arranged in the driving cavity; an auxiliary belt wheel is fixedly arranged at the end, in the driving cavity, of the main shaft; a motor is arranged in the rack through a motor mounting base; and a main belt wheel is fixedly arranged at the output end of the motor. In the circulating process of materials in the grinding cylinder, the main shaft drives a dispersion turbine, a grinding turbine and a diffusion turbine to stir a grinding medium, and the materials are continuously crushed and shaped under the comprehensive action of various forces such as impact, shearing and friction of the grinding medium, so that the particle size is continuously reduced, and the specific surface area is continuously increased.

Owner:安徽儒特实业有限公司

Method for preparing oxalate tail gas by purified CO coupling

InactiveCN103768906AIncrease flow rateStrong centrifugal forceDispersed particle separationGas phaseNitric oxide

The invention relates to a method for preparing oxalate tail gas by purified CO coupling. The method mainly solves the technical problem that a removal rate of nitric oxide is low in the prior art. The method comprises the following steps that (a) a tail gas flow, oxygen or air containing nitric oxide and methanol are led in a methanol absorption tower for reaction from a gas inlet and a liquid inlet; a gas phase flow and a liquid phase flow are obtained; and (b) the gas phase flow obtained in Step (a) and an acid urea solution are led in absorption towers or supergravity rotary packed beds; the absorption towers or the supergravity rotary packed beds are connected in series; and the reaction is performed under the conditions that the urea concentration is 5-40%, a pH (power of hydrogen) value is 1-5, the temperature is 20-80 DEG C, the pressure is 0.1-0.5MPa and a liquid-gas ratio is 5-100L / m<3>. With the adoption of the technical scheme, the problem is solved better, so that the method can be used in industrial production of nitric oxide in oxalate tail gas preparation by removed CO coupling.

Owner:CHINA PETROLEUM & CHEM CORP +1

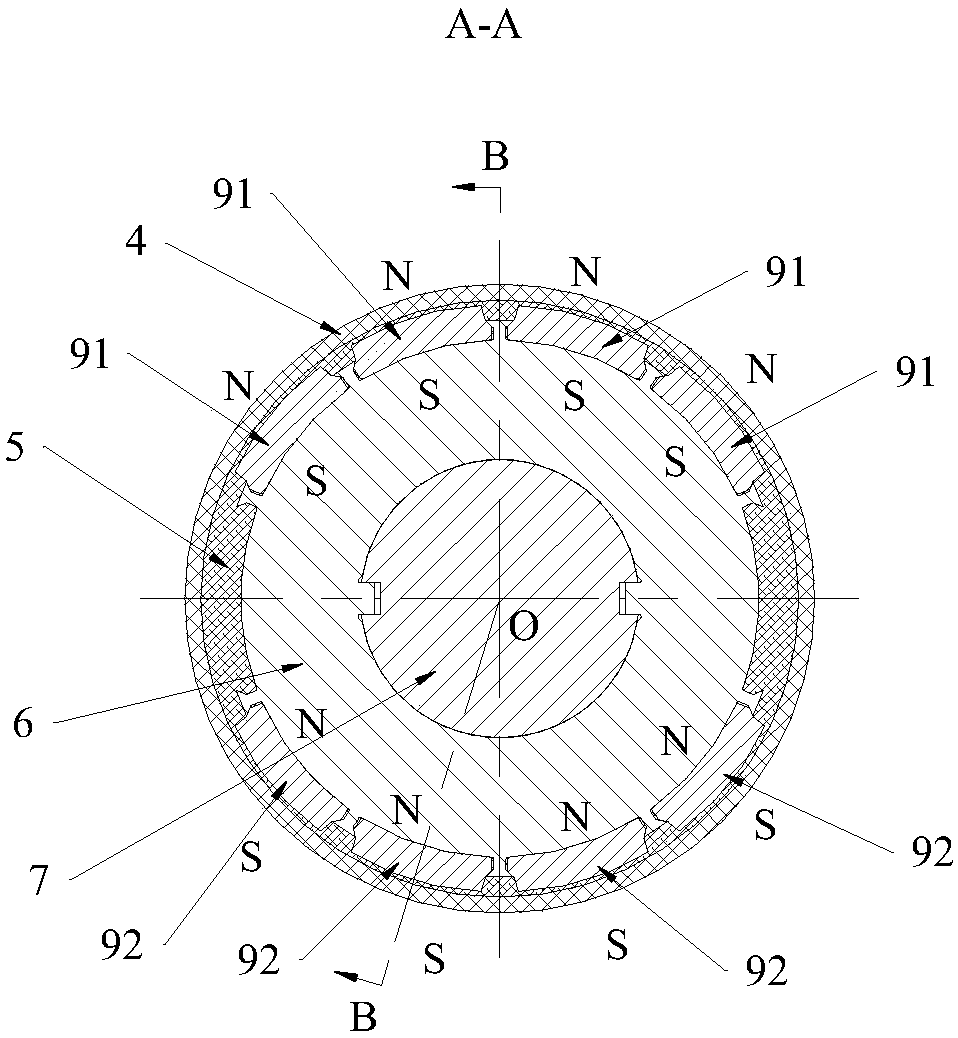

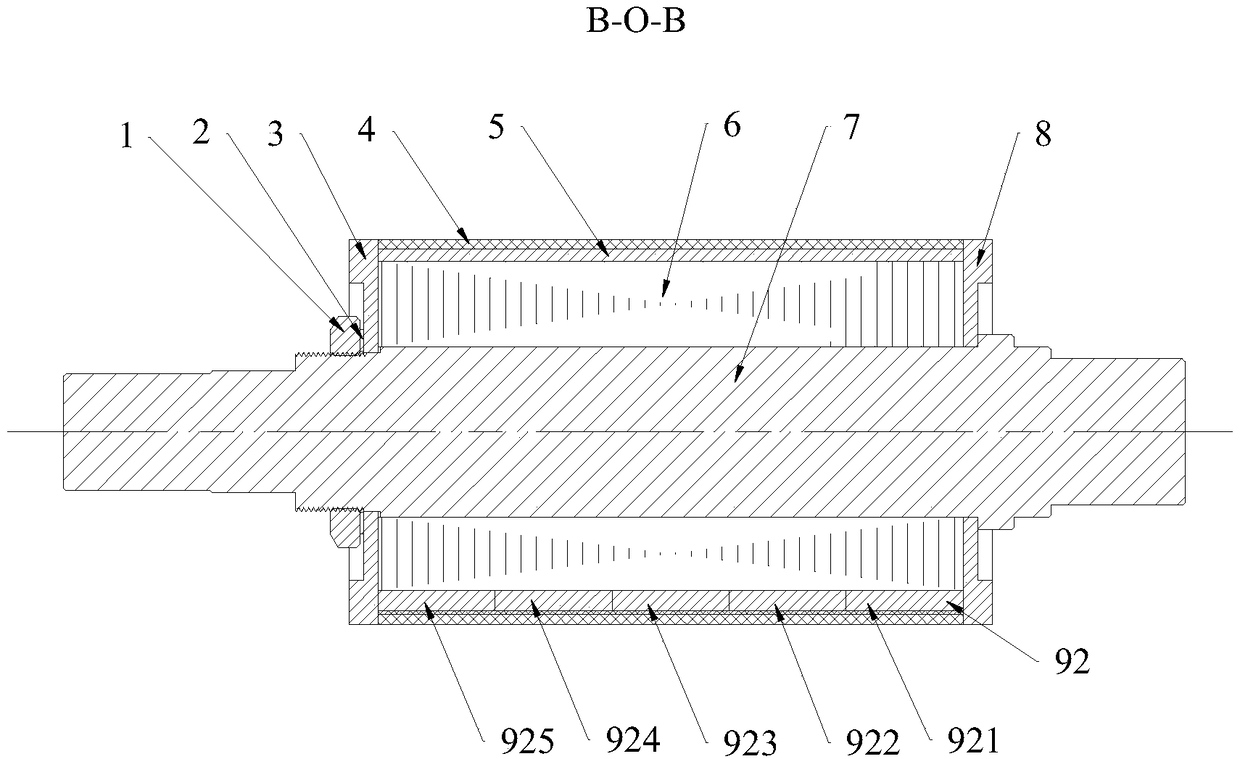

Permanent magnet motor rotor and motor

InactiveCN108494131AReduce performanceStrong centrifugal forceMagnetic circuit rotating partsCooling/ventillation arrangementMagnetic polesPermanent magnet motor

The invention discloses a permanent magnet motor rotor and a motor. The permanent magnet motor rotor comprises a rotor shaft, a rotor iron core, two magnetic poles and a sleeve, wherein the rotor ironcore sleeves the outside the rotor shaft, and a plurality of dovetail grooves are axially formed in the outer surface of the rotor iron core; the magnetic poles are respectively a north pole and a south pole and are symmetrically arranged on the outer surface of the rotor iron core, each magnetic pole comprises at least two permanent magnets, the cross sections of the permanent magnets are matched with the cross sections of the dovetail grooves, and the permanent magnets are embedded into the dovetail grooves; and the sleeve sleeves the periphery of the rotor iron core, and a gap between thesleeve and the rotor iron core is filled with epoxy resin. According to the permanent magnet motor rotor, the permanent magnets can be protected, and the good heat dissipation function of the permanent magnets and the good efficiency of the motor can be guaranteed.

Owner:深圳派赛科技有限公司

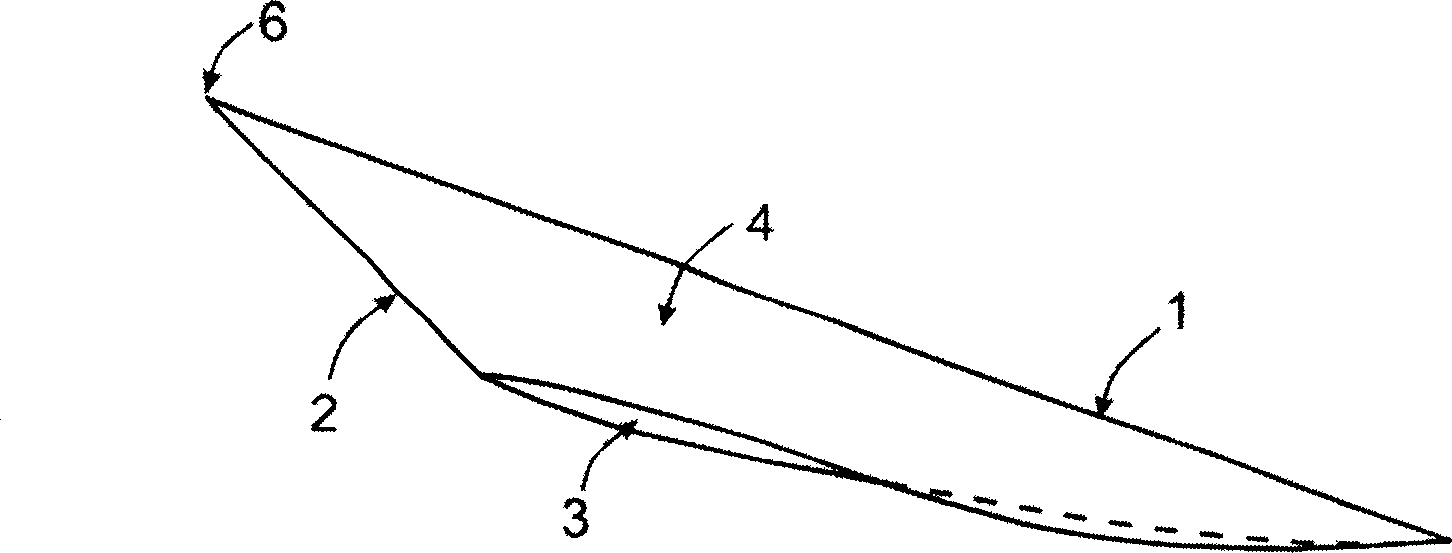

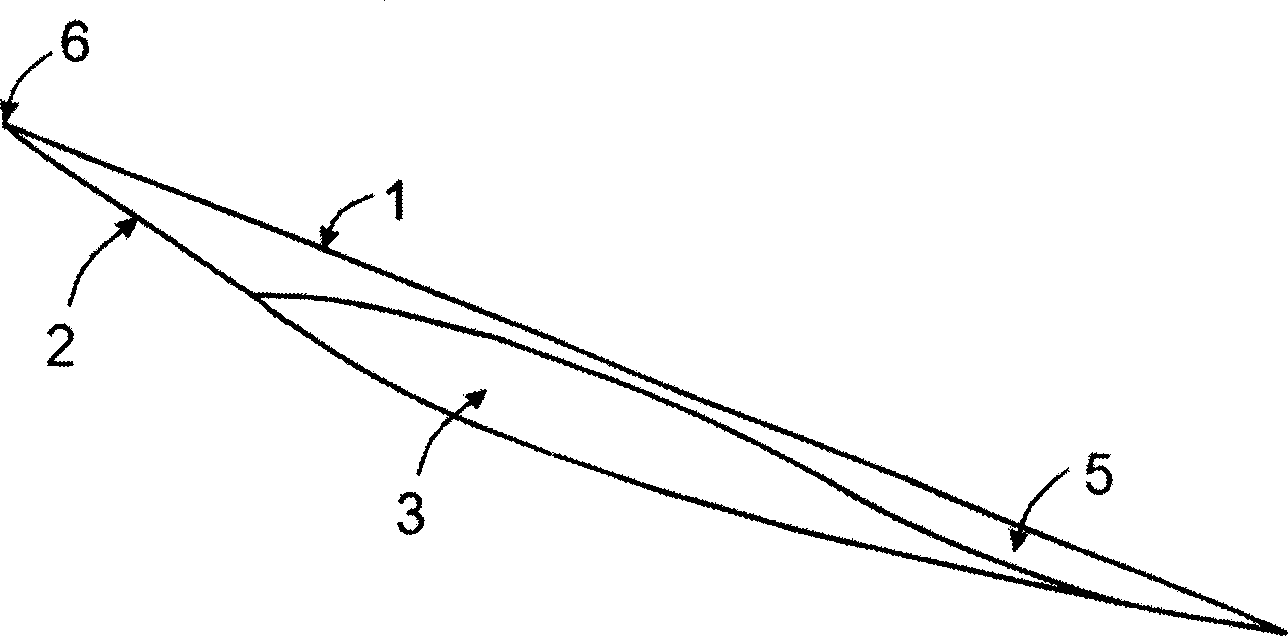

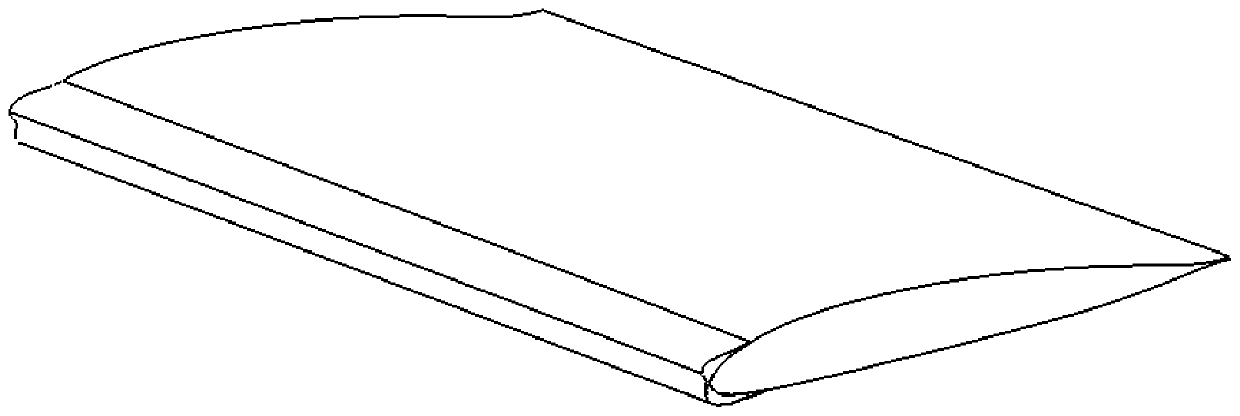

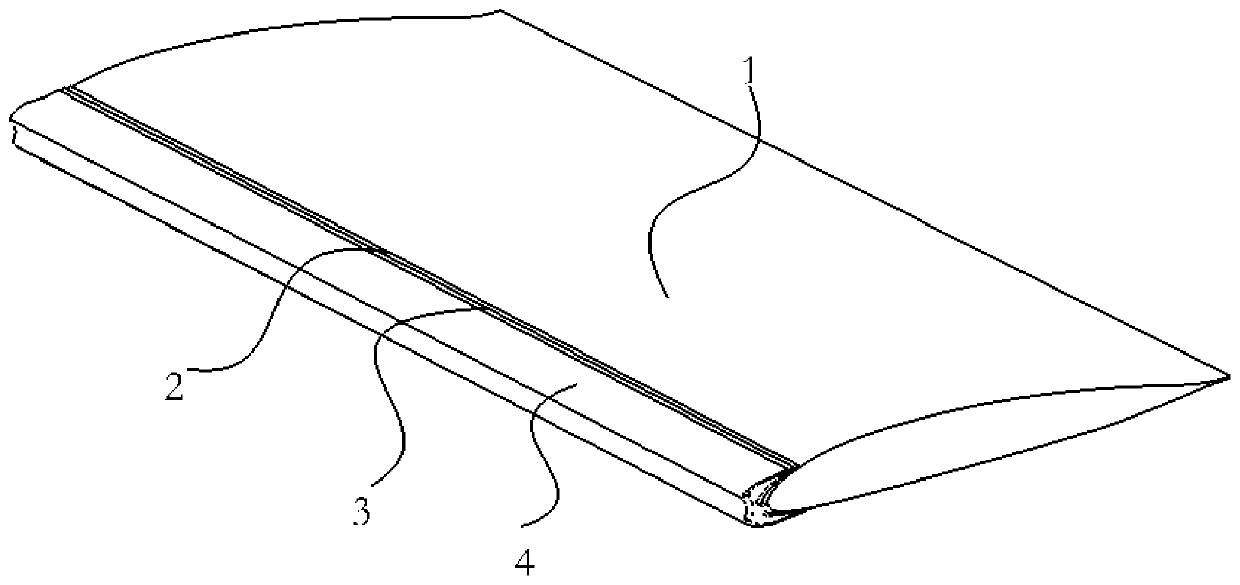

Helicopter rotor blade simulating transparent ice structure and integration method

PendingCN110758767AEasy to process and shapeIncrease marginAircraft components testingSustainable transportationEngineeringIce formation

The invention belongs to the technical field of helicopter rotor blade ice preventing and removing performance verification and relates to a helicopter rotor blade simulating transparent ice structureand an integration method. The helicopter rotor blade simulating transparent ice structure is made of a light high-strength foam material. The material compressing strength under the normal temperature is no smaller than 2.5 MPa, the shearing strength is no smaller than 1.5 MPa, and the foam density is between 70 kg / m3 and 200 kg / m3. The light high-strength foam material is formed into the bladesimulating transparent ice structure. The shape of the inner surface is consistent with that of a blade surface simulating transparent ice area. The shape of the outer surface is obtained by means offlow field analysis and calculation under the specific icing condition or from the ice wind tunnel test of the ice type. The blade simulating transparent ice structure is bonded to the blade surface simulating transparent ice area. By means of the technology, material selecting and manufacturing of the simulating ice type and transparent ice type structure can be achieved, and the structure is integrated with a helicopter rotor blade, and used for simulating icing flight test check of the helicopter rotor blade under the dry air condition.

Owner:HARBIN

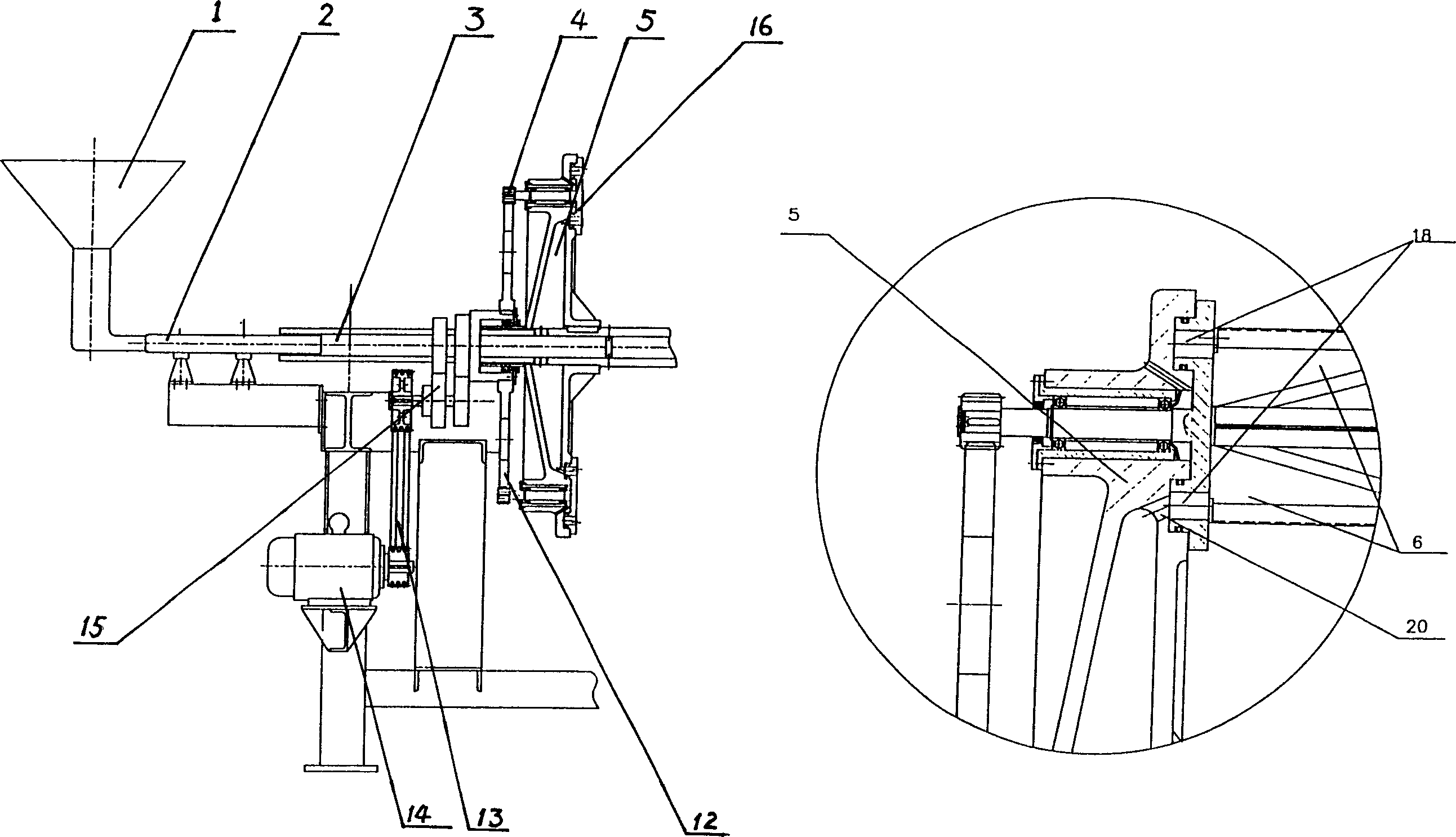

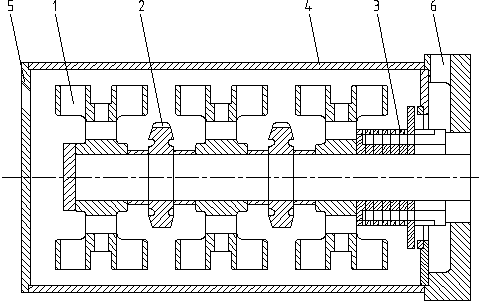

Turbine for sand mill

The invention provides a turbine for a sand mill. The turbine comprises a bottom plate, wherein a plurality of oblique guide holes are uniformly formed in the bottom plate around the circumference; the oblique direction of each guide hole is opposite to the rotary direction of the turbine; a centrifugal blade is arranged on one side face of the bottom plate between every two adjacent guide holes, and the oblique direction of each centrifugal blade is the same as that of the guide hole; a plurality of oblique screws are uniformly distributed on the outer circumference of the bottom plate, the oblique direction of each screw in the cross section of the bottom plate is opposite to the rotary direction of the turbine; and a first section and a second section extending in the radial direction are arranged on two sides of the rear of each screw and are in mirror symmetry to enable the thickness of the screw to be gradually decreased from front to back in the rotary direction. According to the invention, intense centrifugal design that the screws are arranged on the outer circumference of the bottom plate is adopted to thoroughly separate small grinding media from a material, so that grinding is more sufficient; and in addition, the screws are additionally arranged on the circumference of the turbine to improve the grinding efficiency of the turbine sand mill, and the screws adopt bionic shapes to generate stronger bead flows and further reduce energy consumption.

Owner:CHANGZHOU LONGXIN MACHINERY

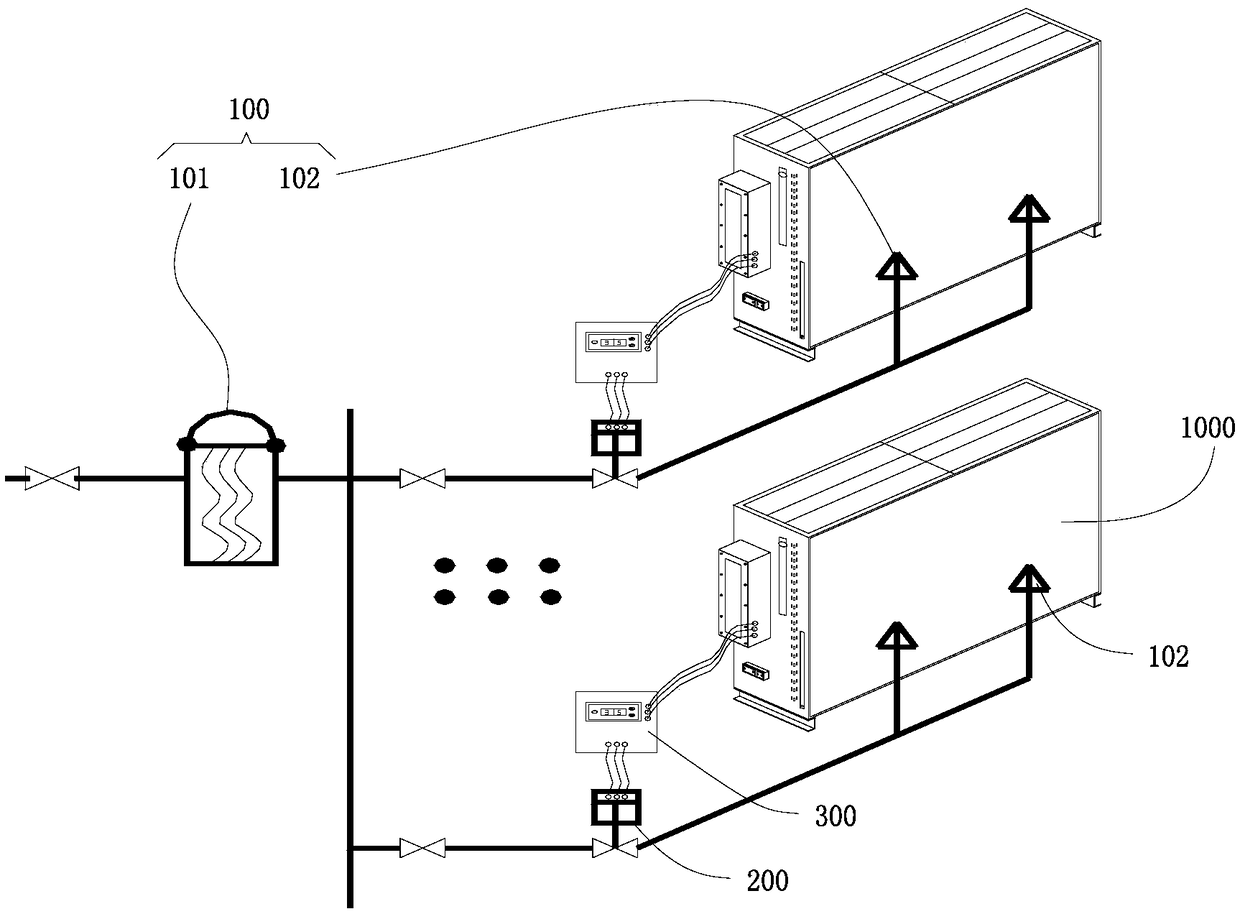

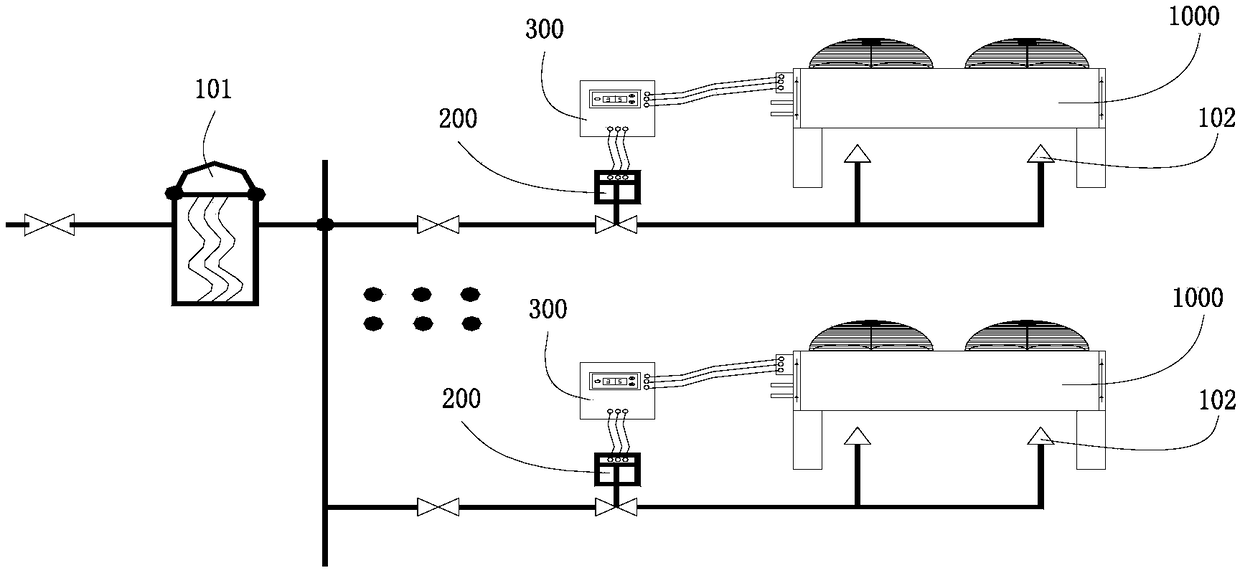

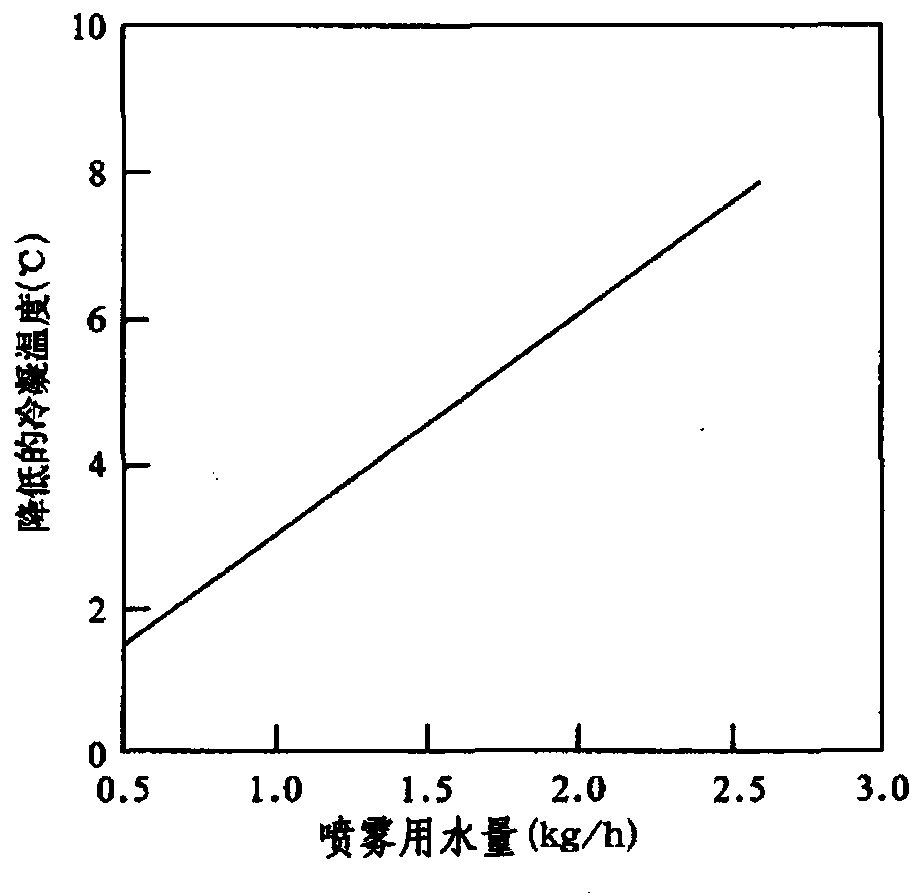

Air conditioner micro-mist cooling energy-saving structure

InactiveCN109282371AImprove cooling effectLess power consumptionEvaporators/condensersAir conditioning systemsWater flowEngineering

The embodiment of the invention discloses an air conditioner micro-mist cooling energy-saving structure. The structure comprises a spraying device and a controller system, wherein a micro-mist main machine in the spraying device sends a pressure pump of to-be-atomized water to a micro-mist nozzle under the controlling of the controller system; high-pressure water flow forms a high-pressure vortexin the micro-mist nozzle so as to generate powerful centrifugal force, and is sprayed out through a micro nozzle in the micro-mist nozzle to generate ultra-fine spiral water mist; and the micro-mist nozzle is arranged at an air inlet of an outdoor unit of an air conditioner. The water mist evaporates to absorb heat from the air, so that the temperature of the environment around an condenser is reduced, the heat dissipation efficiency of the condenser is improved, and the refrigerating effect of the air conditioner is improved; and on the other hand, the temperature difference between the condenser and the air is large, the heat exchange efficiency between the high-temperature and high-pressure gas, namely, freon and the air can be effectively improved, so that the air conditioner works inthe optimal efficiency state, the power consumption of the air conditioner is reduced, and the conditions of high voltage, tripping and the like of the air conditioner are avoided.

Owner:PING AN TECH (SHENZHEN) CO LTD

Eddy flow dehydration plant

InactiveCN105018135AHigh purityImprove dehydration efficiencyTreatment with plural serial refining stagesImpellerDrive shaft

The invention relates to an eddy flow dehydration plant. The eddy flow dehydration plant comprises a housing, a transmission shaft, a driving page wheel, electrode plates, an liquid inlet pipe, an oil collecting pipe, and a water outlet pipe; the liquid inlet pipe is arranged on the upper part of the housing; the oil collecting pipe and the water outlet pipe are arranged on the lower part of the housing; the transmission shaft is stretched into the housing and is connected with the driving page wheel; the liquid inlet pipe and the driving page wheel are arranged at corresponding positions; one end of the oil collecting pipe is stretched into the housing; the electrode plates are arranged on the oil collecting pipe; a plurality of oil collecting holes are arranged on the oil collecting pipe; the electrode plates and the oil collecting holes are arranged in the housing; and the other end of the oil collecting pipe is stretched out from the housing. According to the eddy flow dehydration plant, eddy flow technology is adopted, oil water separation of crude oil is realized under high speed centrifugal force; dehydrated crude oil is delivered into a machine oil pipe in the housing; oil purity is increased; the eddy flow dehydration plant is small in size, short in dehydration treatment time, and high in dehydration efficiency.

Owner:蔡桂钧

Air filter cleaner

The invention relates to an air filter cleaner comprising a housing. The cleaner is characterized in that the center of the bottom in the housing is provided with a high-speed motor perpendicularly, the rotary shaft of the high-speed motor is connected to a fixed disc, the center of the fixed disc is provided with a tightening rod, in a plugged manner, perpendicular to the fixed disc, the top of the tightening rod is provided with a butterfly-shaped nut in a screwed manner, the upper portion of the housing is connected to an end cover through a hinge, the lower portion of the end cover is provided with an electrical heating lamp, and one side of the lower portion of the housing is provided with a dust discharging port. The cleaner has the advantages of simple structure and convenience for usage.

Owner:丁巧娜

Rotary tapered chute type centrifugal concentrator

InactiveCN1597128AExcellent indicatorsSatisfied with the test resultsWet separationEngineeringMineral deposition

A chute-type centrifugal ore dressing machine features that several groups of tapered chutes are axially installed round a horizontal rotary axle in the bottom-to-bottom mode. When the ore sludge flows through the chutes, the chutes in rotating around the axle at high seed. The generated centrifugal force can deposit the high-density mineral on the bottom of chutes and then discharge it.

Owner:KUNMING UNIV OF SCI & TECH

Centrifugal geotechnical test soil fast-drying device

InactiveCN111322836ASimple structureStrong centrifugal forceDrying solid materials without heatFiltration circuitsSoil scienceElectric machinery

The invention belongs to drying equipment, and particularly discloses a centrifugal geotechnical test soil fast-drying device which comprises a support. The support is welded and fixed on the outer wall of a centrifugal dehydrator, a control box, a drying box and a hot air blower are fixed on the upper surface of the support, the hot air blower is connected with the drying box through an air inletpipe, the drying box is connected with the centrifugal dehydrator through a hot air pipe, a centrifugal barrel is arranged in the centrifugal dehydrator, the centrifugal barrel is fixed inside the centrifugal dehydrator through an upper fixing plate and a lower fixing plate, the top of the centrifugal dehydrator is provided with a stepping motor, the output end of the stepping motor is connectedwith the top end of the centrifugal barrel, a stirring device is arranged in the centrifugal barrel, the stirring device is composed of a stirring shaft and a spiral stirring fan blade, and the tail end of the centrifugal dehydrator is further fixedly provided with an exhaust fan. The device is high in drying speed, high in treatment precision and easy to operate.

Owner:中国机械设备工程股份有限公司 +1

Nursing device for tumor chemotherapy

PendingCN108354847AStrong centrifugal forceAvoid spillingSpittle receiving devicesEngineeringTumor chemotherapy

The invention belongs to the technical field of medical apparatus and instruments, and particularly relates to a nursing device for tumor chemotherapy. For the technical problem that vomit brings cleaning difficulty to a nursing staff and makes the nursing work more tiring, the following scheme is provided, the device comprises a base in a cuboid structure, a cavity is arranged in the base, the top end of the base is embedded with a water pump, a water inlet end of the water pump is screwed with a water inlet pipe, one end, away from the water pump, of the water inlet pipe is sleeved with a filter sleeve, the inner wall of the bottom of the base is welded with a partition baffle, a portion, close to the top, of the partition baffle is embedded with an annular metal frame, a double-layer filter mesh is clamped in the annular metal frame, a supporting tube is welded in the middle of the upper surface of the base, and the top end of the supporting tube is welded with a storage bucket in acylindrical structure. The nursing device for the tumor chemotherapy has the advantages that the water pump sprays cleaning water into a revolving drum to generate strong centrifugal force, then thecleaning water is ejected at a high speed through small holes in a threaded groove, and hits the inner wall of the storage bucket, so that the stain attached to the bucket wall can be cleaned.

Owner:李静

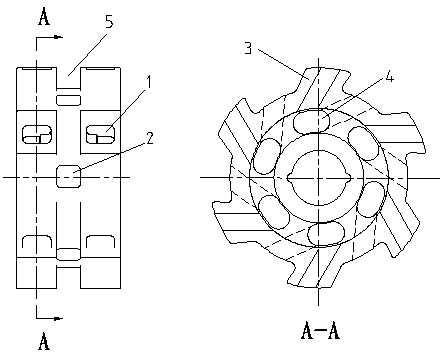

Ball-stirring mill for convex pin turbine

The invention provides a ball-stirring mill for a convex pin turbine. The ball-stirring mill comprises one or more convex pin turbines, zero or more jaw wheels, a material-ball separating assembly, a milling cavity cylinder body, a charging cylinder cover and a discharging room, wherein a plurality of convex pins are arranged on the turbine(s), and the middle parts of the convex pins are hollowed to form vortex grooves; each turbine is provided with a plurality of through holes along the radial direction, and the through holes are communicated with the plurality of middle vortex grooves; and when the turbines run, a sizing agent and a milling media (i.e. milling balls) are driven to circularly move along the peripheral direction and the radial direction, and a high shearing force is generated by the stirring function of the pins. When the jaw wheels rotate, a powerful centripetal driving force is generated. The materials thrown out of the turbine and the milling balls are driven to enter inner holes of the turbines, so that the circular flow can be enhanced. According to the ball-stirring mill, a circular driving force and a stirring force of liquid are enhanced, so that the milling efficiency can be greatly improved, and the granularity of products milled for once can be obviously reduced; and therefore, the ball-stirring mill can be wildly applicable to the field of extra-fine grinding and extra-fine dispersing of materials, and in particular, the ball-stirring mill has preferable effects on the extra-fine grinding and dispersing of prepared nanometer-level products or high-viscosity products.

Owner:深圳市叁星飞荣机械有限公司

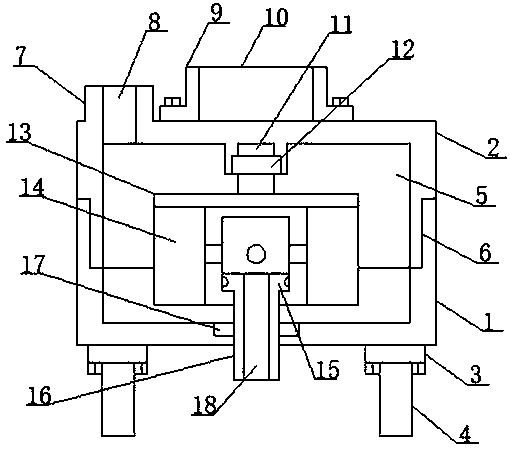

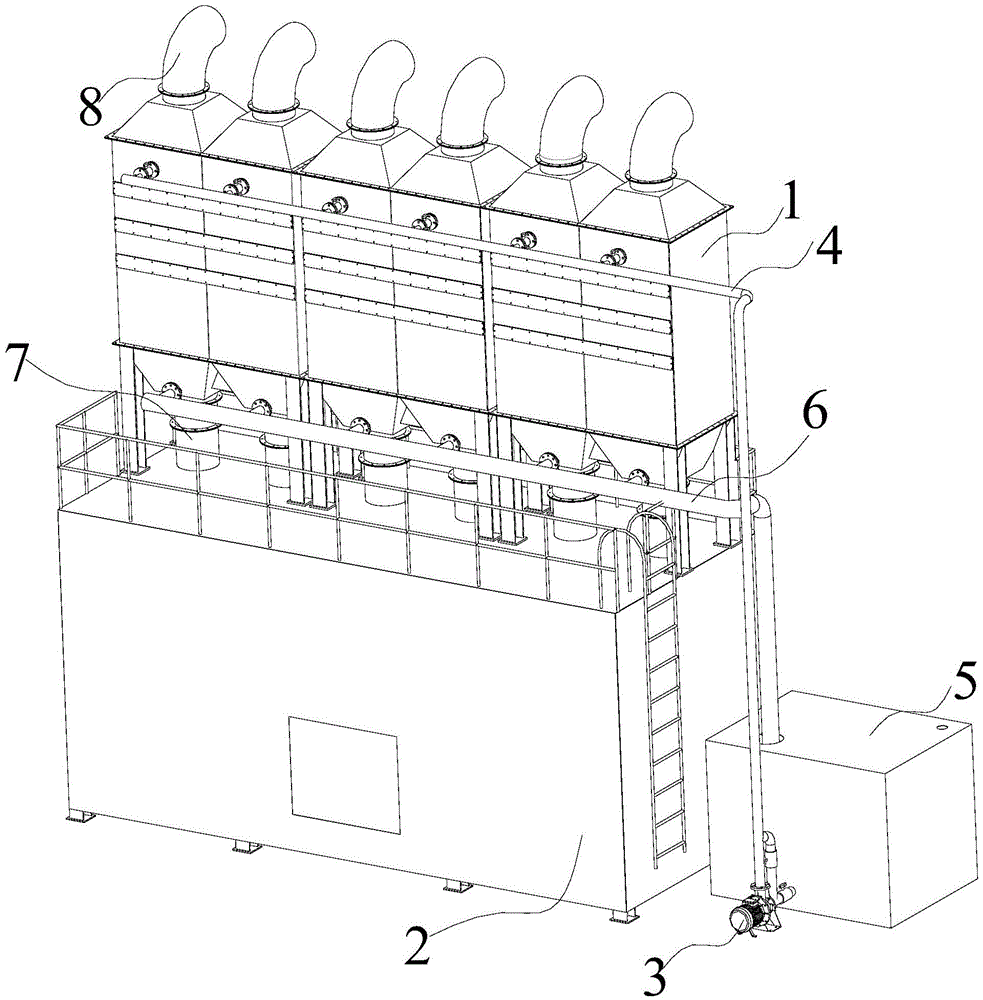

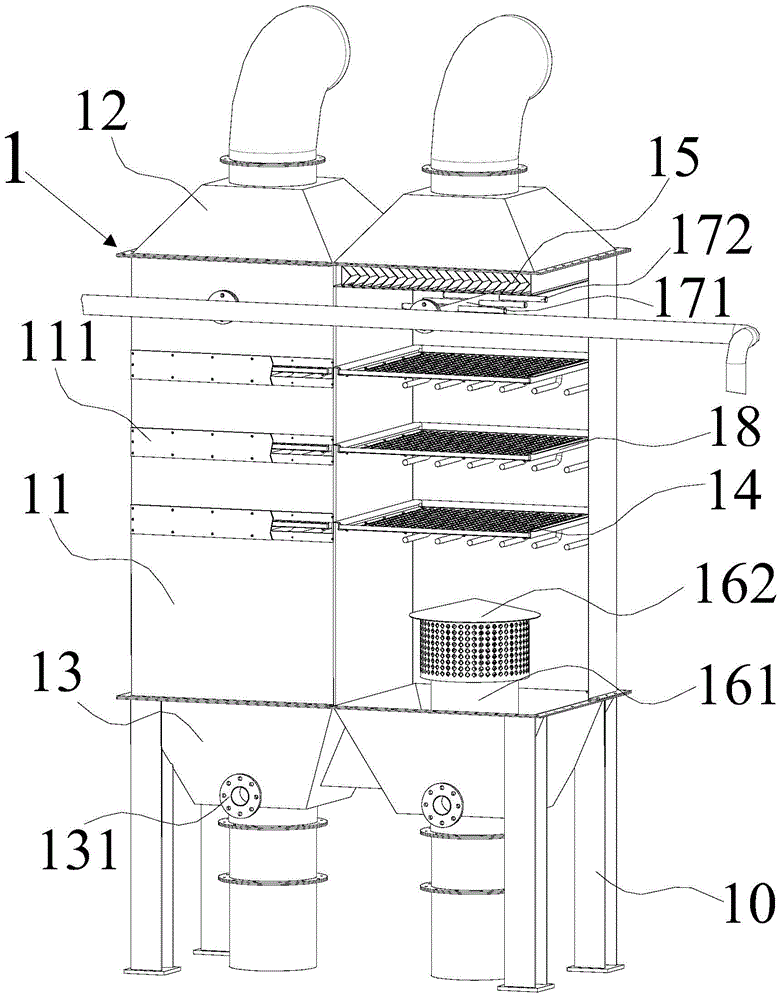

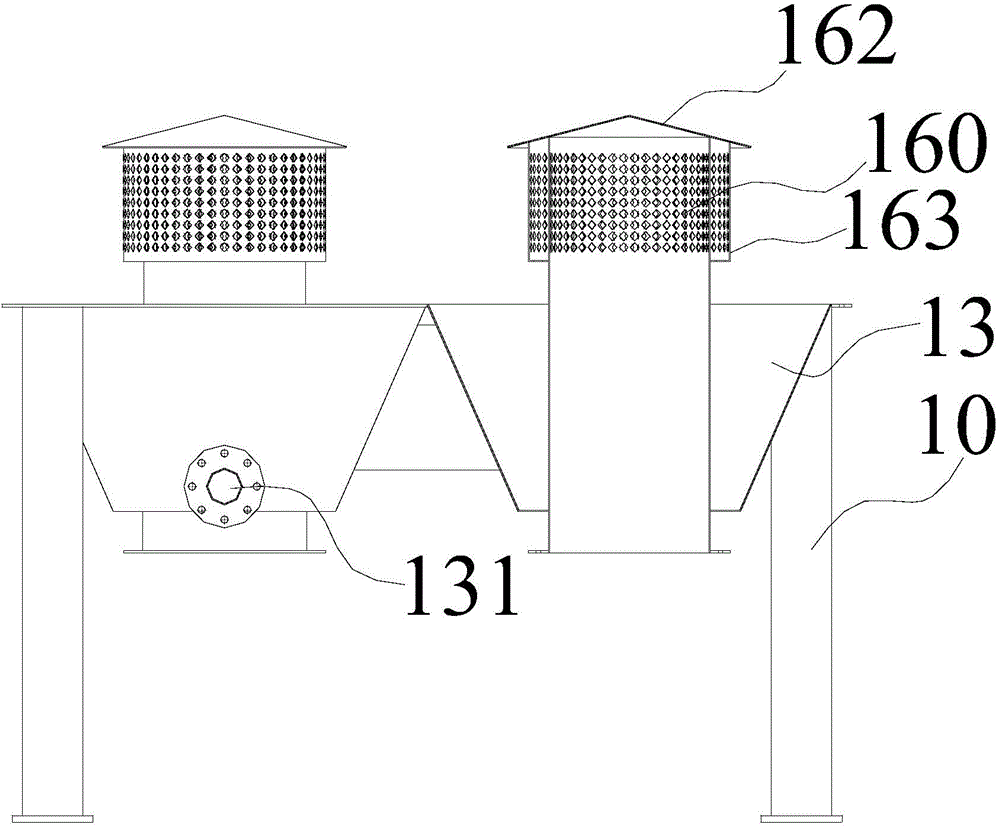

Treatment tower, equipment and system for purifying dust exhaust gas

InactiveCN104785061AStrong centrifugal forceHas a holding effectCombination devicesWastewaterEngineering

The invention relates to the field of exhaust gas purification equipment, and discloses a treatment tower, equipment and system for purifying dust exhaust gas. The treatment tower (1) comprises a tower body (11) and dust removal filtering plates (14) which is horizontally arranged in the tower body (11) to divide an inner cavity of the tower body (11) into multiple chambers, as well as a gas inlet for introducing the dust exhaust gas and an exhaust port for exhausting the filtered gas. The dust exhaust gas introduced from the gas inlet can be filtered by the dust removal filtering plates (14). Moreover, the treatment tower (1) is further provided with liquid inlets for introducing filtrate to form water films on the dust removal filtering plates (14) and drain ports (131) for draining wastewater in the tower body (11). According to the treatment tower (1), a working principle different from that of conventional water film dust removal equipment is adopted, and the power consumption is lower.

Owner:北京钢研新冶环科科技有限公司

Efficient dewatering device for textiles

ActiveCN111089456AControl discharge rateHigh kinetic energy utilizationDrying solid materials with heatDrying solid materials without heatElectric machineryProcess engineering

The invention discloses an efficient dewatering device for textiles. The efficient dewatering device comprises a main body shell. According to the efficient dewatering device, a power source generatedby a driving motor can be utilized for achieving both the effects of generation of high-pressure gas and jet dewatering, and the function of centrifugal dewatering, in this way, the textiles can be subjected to high-pressure air jetting and centrifugal dewatering, and thus the accelerated and effective dewatering effect can be achieved. Moreover, power of the driving motor is effectively and sufficiently utilized, and the utilization rate of kinetic energy is high. Besides, the efficient dewatering device is provided with a rotation-type air flow speed control mechanism of a thread structureso that discharge speed of air can be controlled to form wind power with proper strength. In addition, the efficient dewatering device is provided with a hollow-shaft-type wind power switching and guiding mechanism which can achieve position switching on the space, and the air is converted to the mode of blowing the textiles via wind power to achieve wind-driven dewatering. The efficient dewatering device is furthermore provided with a gear-meshing-type rotation function conversion mechanism, which can increase the rotation speed and then achieve a better centrifugal effect.

Owner:安徽湖晟纺织科技有限公司

Method for extracting honey

The invention relates to the technical field of food processing, and discloses a method for extracting honey. The method comprises the following steps that A, a honey comb completely covered or only covered by 1 / 4 or above is taken out, and bees in the honey comb are driven out by using folium artemisiae argyi to obtain the clean honey comb; B, cover cutting is performed on the honey comb, and honey flowing from the honey comb is brushed off by using a honey brush; C, the honey comb is placed on a positioning frame in a honey extraction device, and the positioning frame is rotated, so that thehoney in the honey comb is flung out under the action of centrifugal force; a negative pressure mechanism is utilized to generate attractive force on the honey in the honey comb and accelerate the fling of the honey; an air blowing mechanism is utilized to generate pushing force on the honey in the honey comb; D, a reversing mechanism is started, so that the originally exposed face of the honey comb is shielded, the originally shielded face of the honey comb is exposed, so that the honey located at the two faces of the honey comb can be all flung out; E, a scraping mechanism is used for scraping the flung honey to the bottom of a bucket body. The method for extracting the honey can greatly improve the efficiency of honey extraction.

Owner:桐梓县巧媳妇农产品开发有限公司

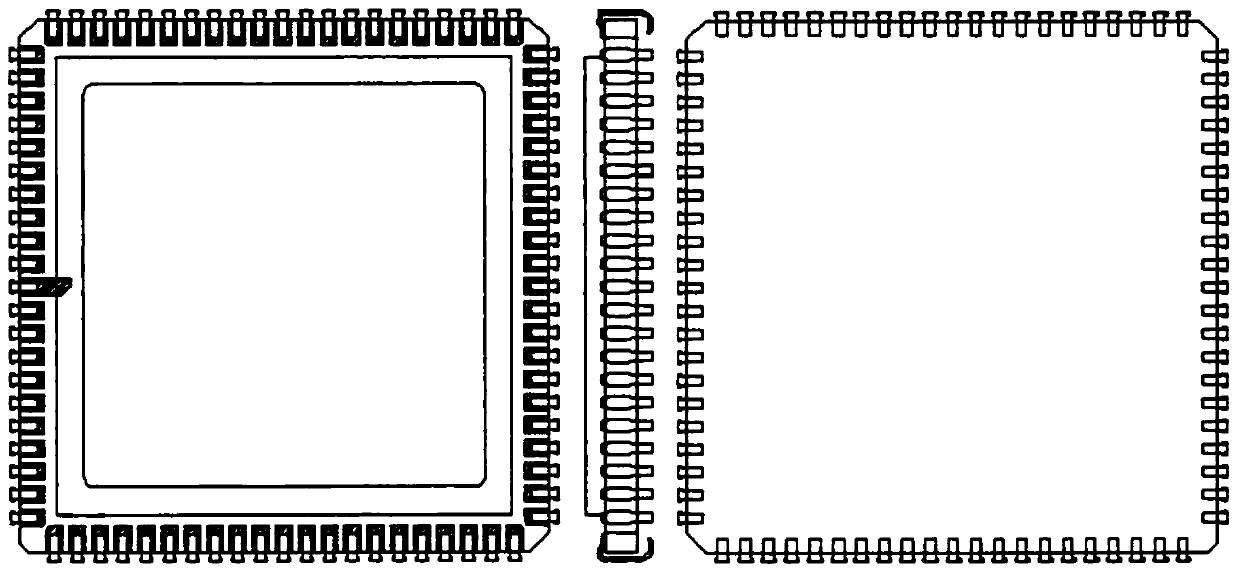

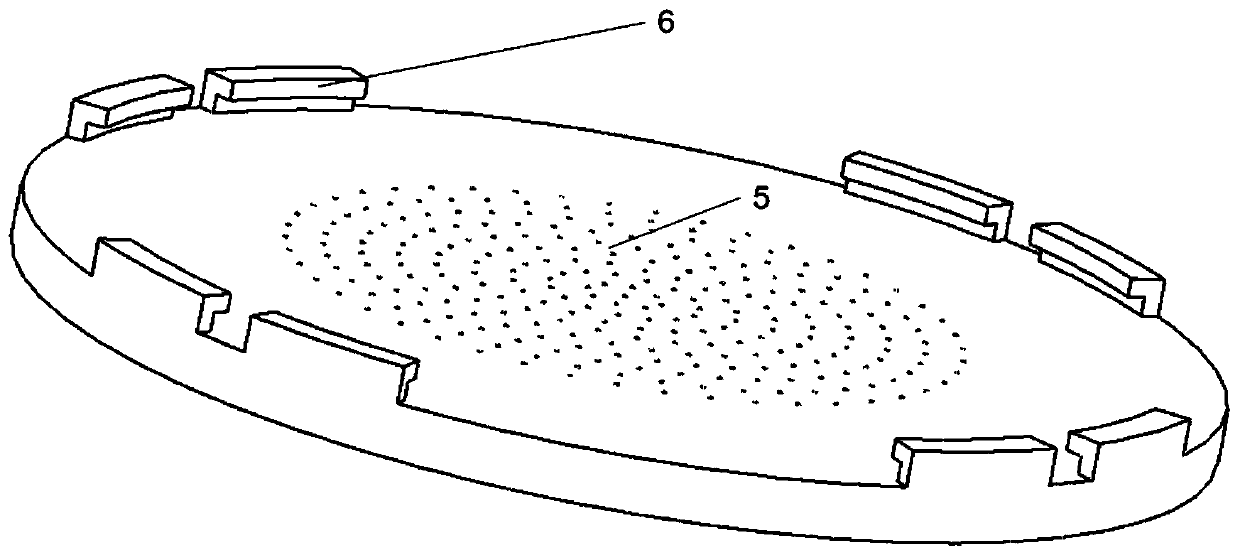

Cleaning tool and method for JLCC image sensor circuit before packaging

ActiveCN111081594AImprove versatilityReduce wearSemiconductor/solid-state device manufacturingCleaning using liquidsHemt circuitsHigh pressure gas

The invention relates to a cleaning tool and method for a JLCC image sensor circuit before packaging. According to the tool, small holes are closely distributed at the central position of a high-speedrotating platform; four safety limiting clamping grooves are uniformly distributed at the edge of the high-speed rotating platform; a circuit positioning tool comprises a substrate and a plurality ofgroups of circuit limiting clamping grooves formed in the substrate; the plurality of groups of the circuit limiting clamping grooves are located on the same circumference; each group of circuit limiting clamping grooves is used for fixing a to-be-cleaned circuit; the circuit positioning tool is installed on the rotating platform; the circuit positioning tool and the rotating platform are fixed in a vacuum adsorption mode through the small holes formed in the rotating platform; the rotating platform drives the to-be-cleaned circuit on the circuit positioning tool to rotate in a cleaning process; a liquid and high-pressure gas channel is communicated with a two-fluid nozzle placed above the rotating platform; two fluids are sprayed to the surface of the to-be-cleaned circuit through the two-fluid nozzle to achieve cleaning.

Owner:BEIJING MXTRONICS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com