Helicopter rotor blade simulating transparent ice structure and integration method

A technology of helicopter rotor and integrated method, which is applied in the field of anti-icing/de-icing performance verification of helicopter rotor blades, and achieves the effect of easy processing and large margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

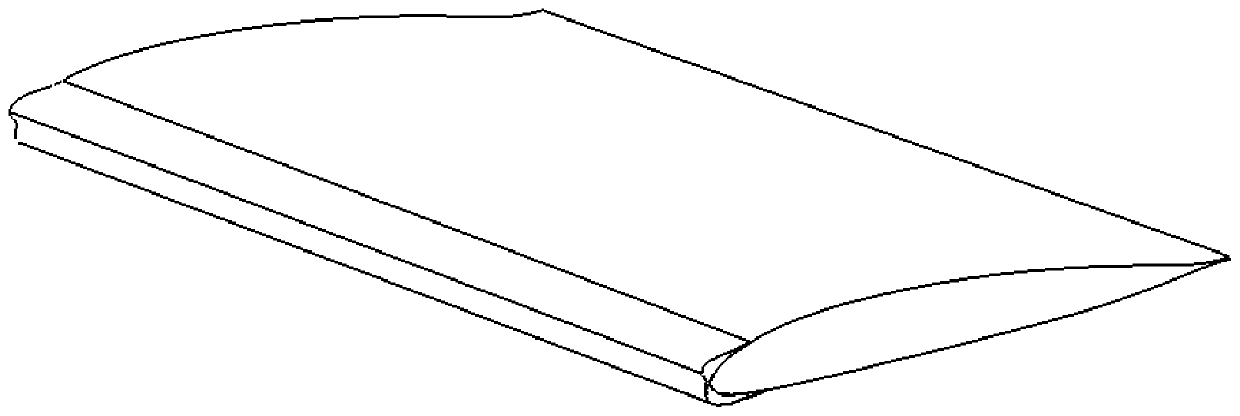

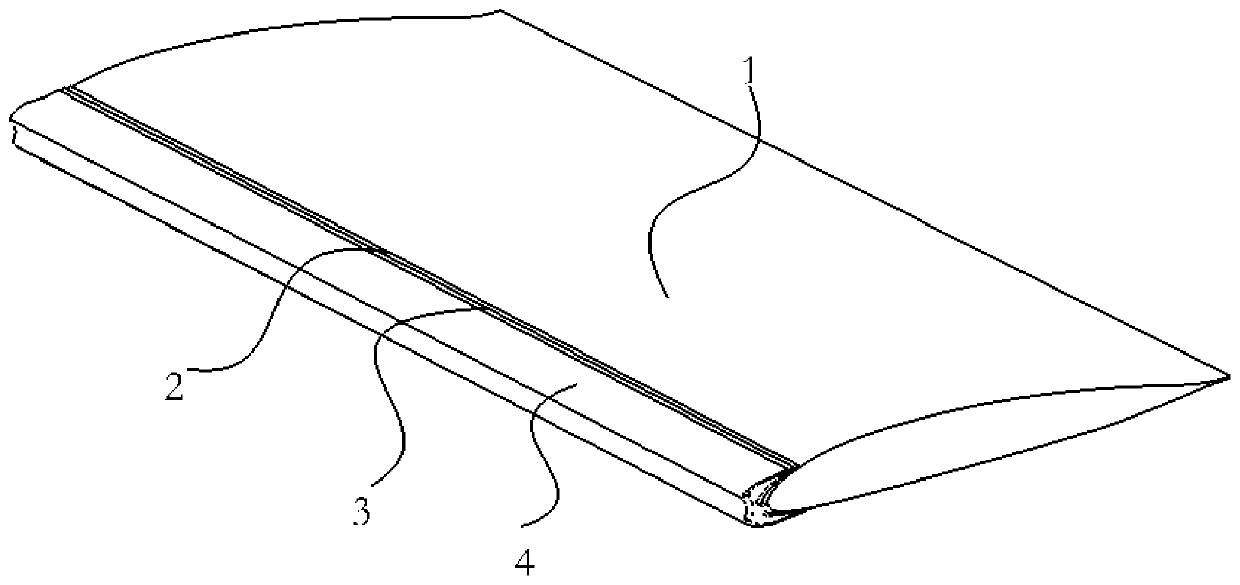

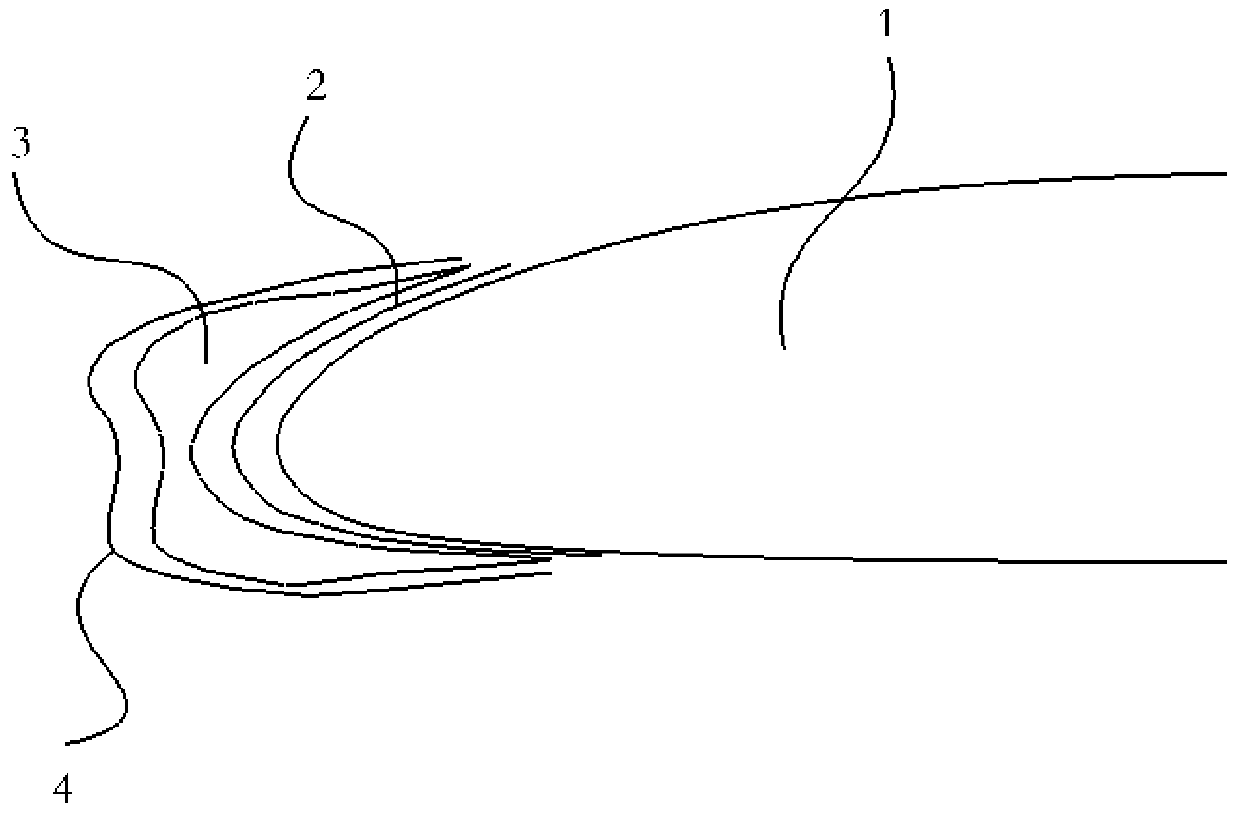

[0038] In the various drawings and the following description, well-known structures and techniques have not been shown in order to avoid unnecessarily obscuring the present invention. see figure 1 , 2 , 3 are the simulated transparent ice structure and integration diagram of the helicopter rotor blade of the present invention. The specific implementation is as follows:

[0039] According to the analysis and calculation of the flow field under specific icing conditions or from the ice wind tunnel test of the ice type, the simulated transparent ice ice type and the transparent ice freezing area are obtained.

[0040] A low-density and high-strength ACCPMI-110 foam is selected as the material for simulating the transparent ice structure. The compressive strength of the material at room temperature is greater than 2.5MPa, the shear strength is greater than 1.5MPa, and the foam density is 110kg / m 3 . According to the previously obtained transparent ice-type digital modeling sim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Foam density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com