Shaft unloading device for coiling mechanism of double-needle-bar double-width warp knitting machine

A warp knitting machine and double needle bed technology, applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of heavy burden on staff, affecting enterprise benefits, low shaft unloading efficiency, etc. The effect of high efficiency and lightening of the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

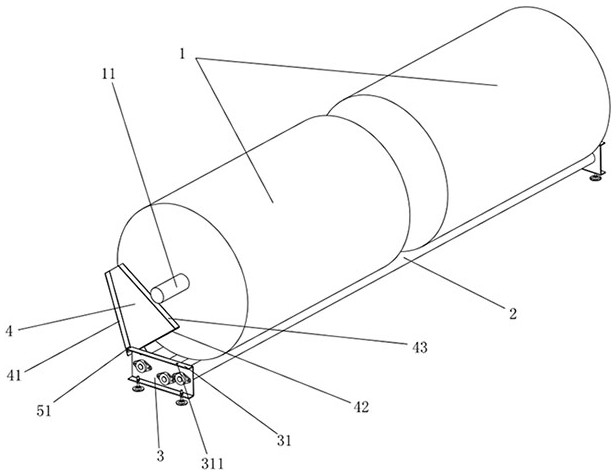

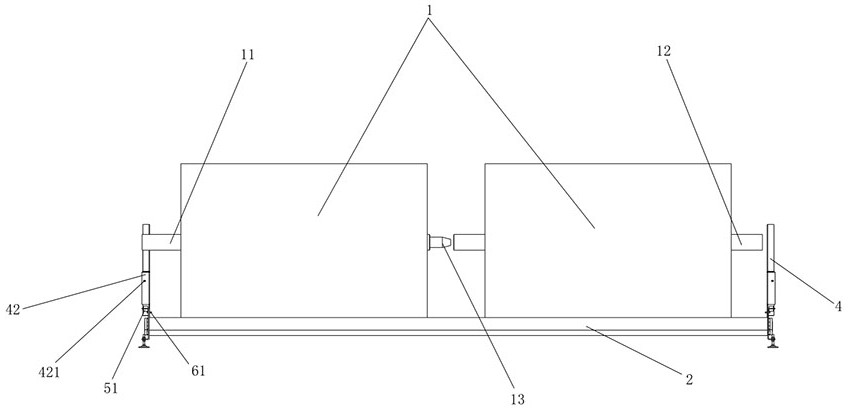

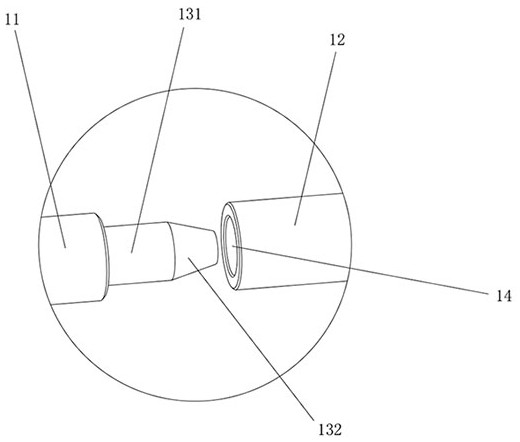

[0027] Such as figure 1 , 2, 3, 4, 5, 6, 7 and 8, a double-needle bed double-width warp knitting machine rolling mechanism unloading device, including the coiling machine 2, the first cloth reel 11 and the second cloth reel 12, the first One end of a cloth reel 11 is provided with a positioning rod 13, and one end of the second cloth reel 12 is provided with a positioning hole 14 matched with the positioning rod 13. After the positioning rod 13 is inserted into the positioning hole 14, the first cloth reel 11 and the second cloth reel 11 can be realized. The stable connection of the two cloth reels 12 facilitates the rolling operation. The side plate 3 of the coiling machine 2 is rotatably connected with a baffle plate 4, and the top of the side plate 3 is provided with a support plate 31. The baffle plate 4 includes a main board 44, the main board One side of 44 is provided with a limiting plate 41 corresponding to the side plate 3, the bottom of the main board 44 and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com