Patents

Literature

49results about How to "Easy to process and shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttrium aluminum garnet fluorescent glass, manufacturing method thereof and use thereof

InactiveCN101696085ASimple preparation processEasy to process and shapeSpectral modifiersYttriumGlass matrix

The invention discloses yttrium aluminum garnet fluorescent glass, a manufacturing method thereof and use thereof. The yttrium aluminum garnet fluorescent glass comprises a glass matrix of BaO-Na2O-B2O3-SiO2-Al2O3 and a yttrium aluminum garnet fluorescent powder component. The yttrium aluminum garnet fluorescent glass is manufactured by mixing initial components and yttrium aluminum garnet fluorescent powder, calcining the mixture and casting. The method has the advantages of simple preparation process, easy processing and forming, cheap raw material and large-scale industrial production. The YAG fluorescent powder is well matched with a blue InGaN chip, has the advantages of high luminescent efficiency, stable performance and the like and is the preferred yellow fluorescent material for packaging white LEDs. Indeed, the YAG fluorescent powder glass manufactured by sintering the YAG fluorescent powder in glass is a novel fluorescent material with high performance, low cost and wide application range.

Owner:NANTONG UNIVERSITY

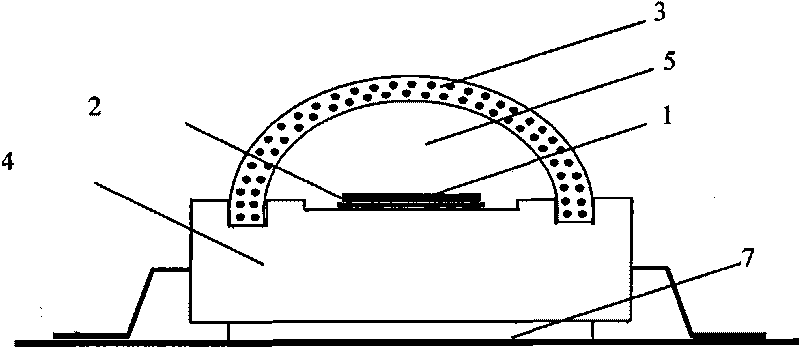

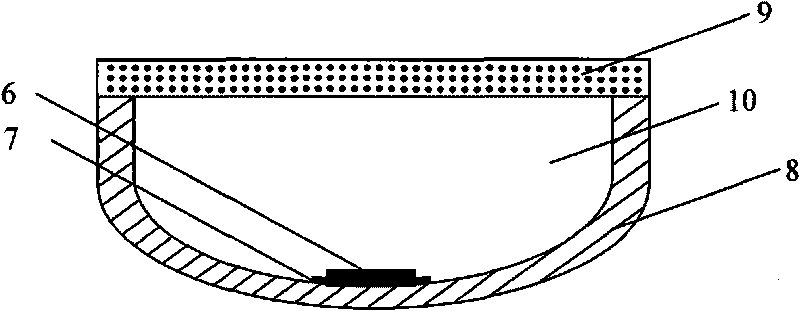

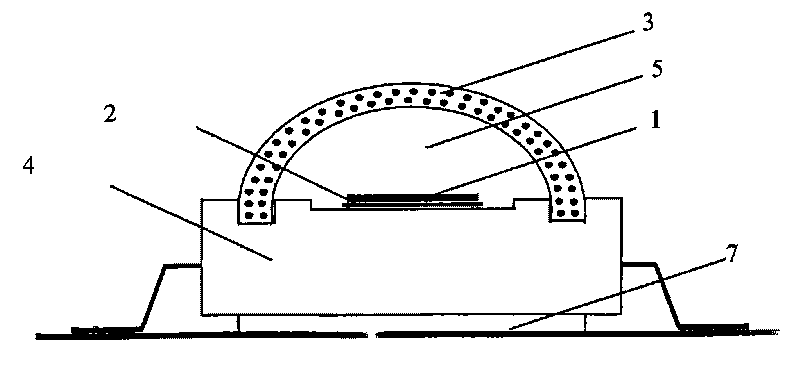

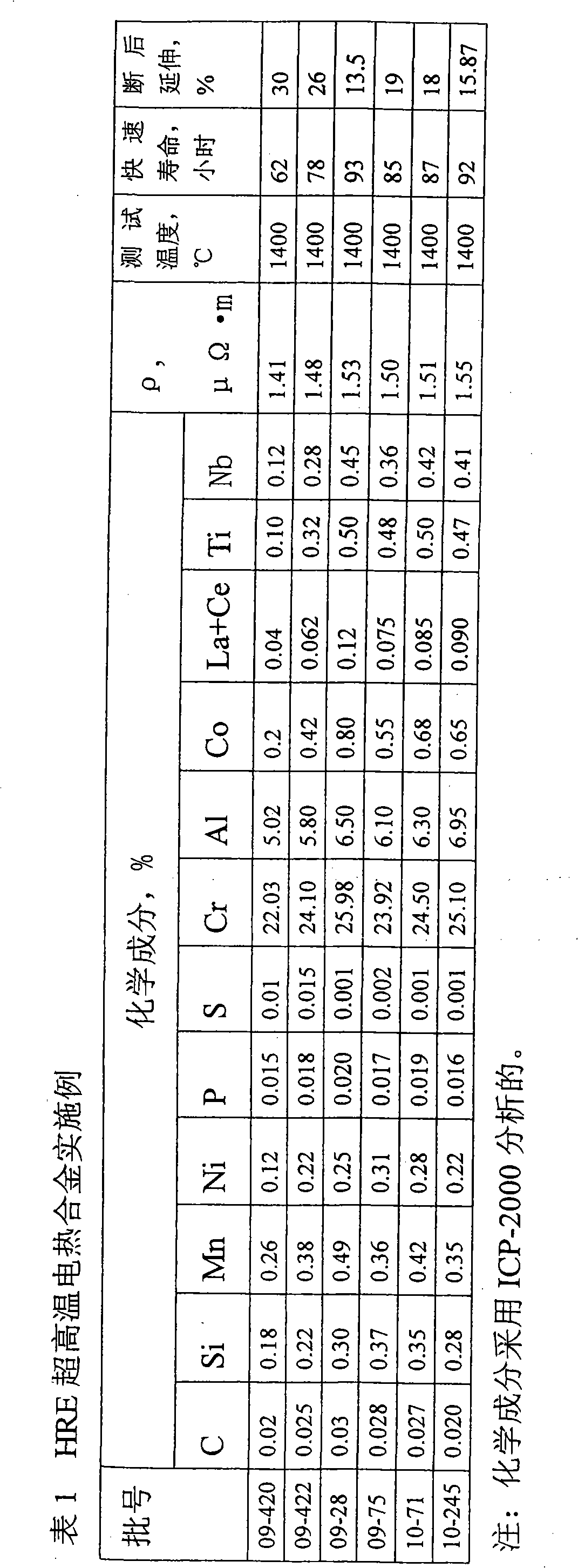

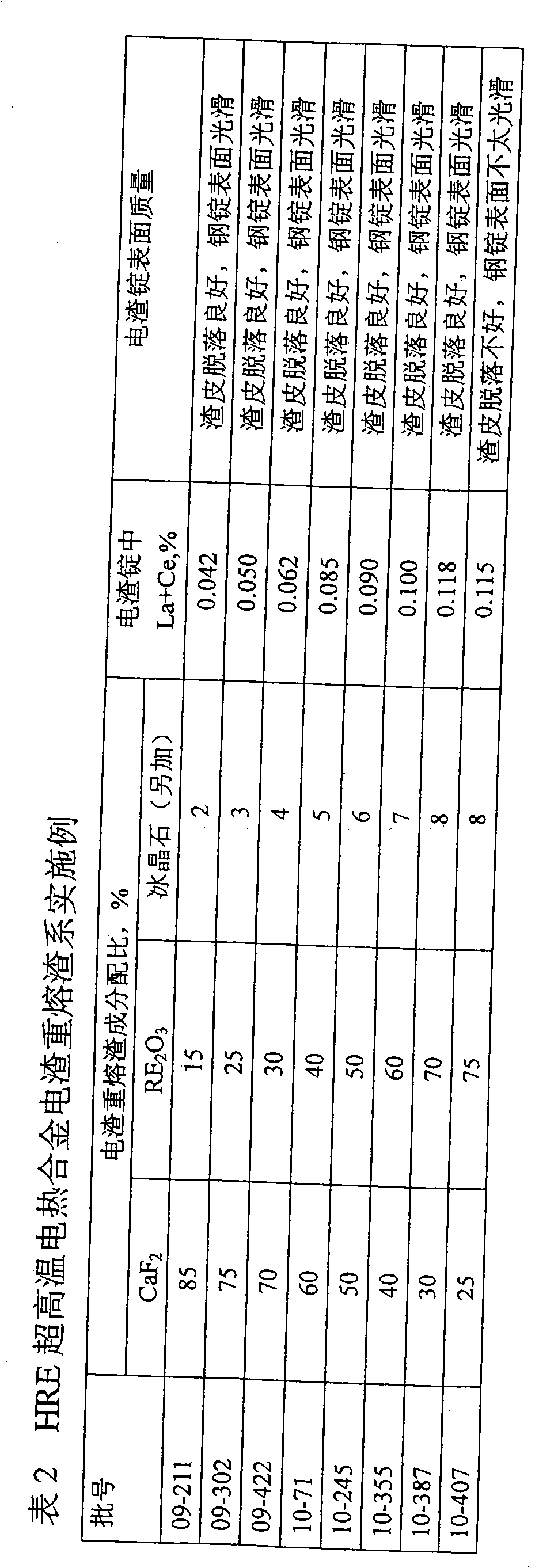

Ultra-high temperature electrothermal alloy and preparation method thereof

InactiveCN101892434AGood winding performanceEasy to process and shapeThermal treatmentChemical composition

The invention belongs to the metal material field and relates to an ultra-high temperature electrothermal alloy and a preparation method thereof. The electrothermal alloy comprises the following chemical components in percentage by mass: not more than 0.03% of C, not more than 0.25% of Si, not more than 0.5% of Mn, not more than 0.5% of Ni, not more than 0.01% of S; not more than 0.02% of P, 22-26% of Cr, 5.0-7.0% of Al, 0.04-1% of one or more of La+Ce, Y, Hf and Zr, 0.01-0.5% of Ti, 0.1-0.5% of Nb, 0.2-1.0% of Co and the balance Fe. The alloy has good winding performance, resistivity at 20 DEG C of 1.4-1.55, 650-800MPa of tensile strength and accelerated life at 1400 DEG C of 93h and better oxidation resistance and high-temperature creep resistance, is easy in machine-forming and is mainly used for the electrothermal elements of such furnaces with working temperature of 1200-1300 DEG C as single crystal diffusion furnaces, sintered metal product sintering furnaces, ceramic calcinating furnaces, high-temperature thermal treatment furnaces, etc.

Owner:BEIJING SHOUGANG GITANE NEW MATERIALS

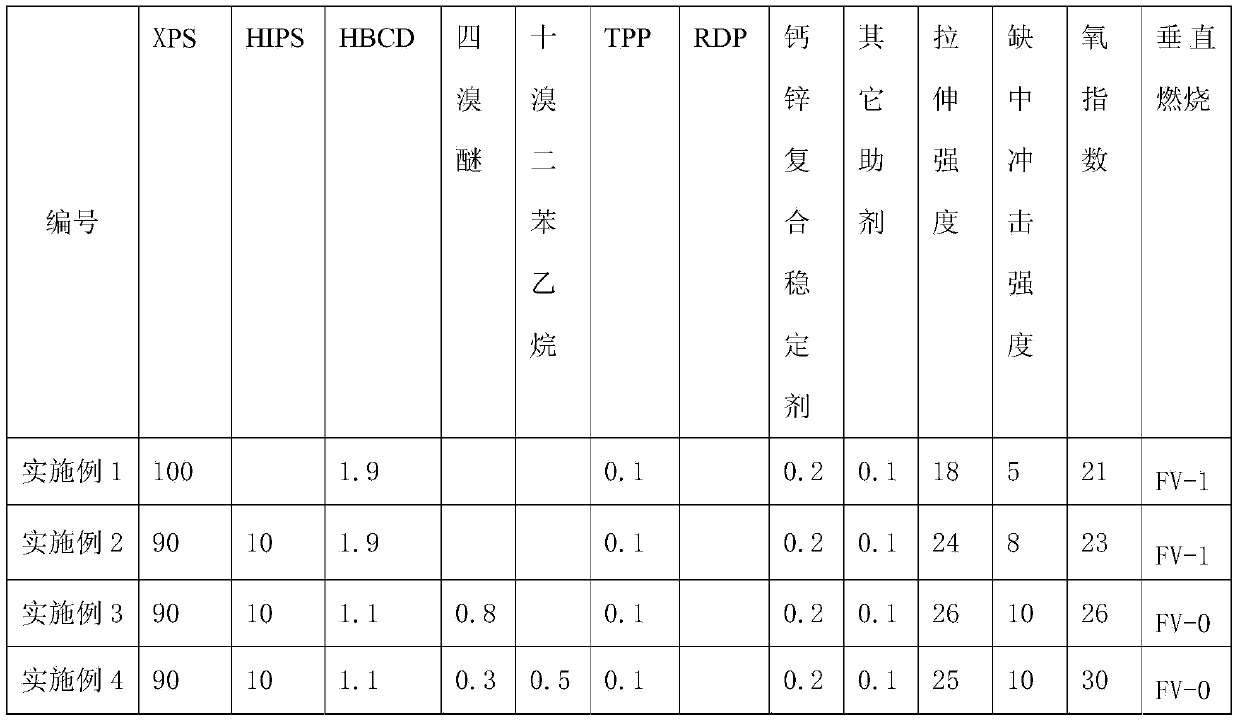

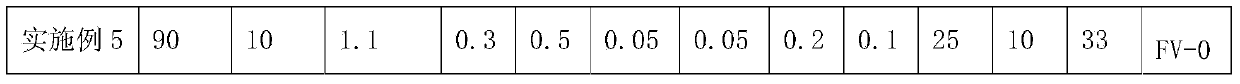

High fire-retardant and high impact-resistant regenerated polystyrene XPS particle and preparation method thereof

InactiveCN103739975AGood mechanical propertiesEasy to process and shapePolystyrene particleFire retardant

The invention discloses a high fire-retardant and high impact-resistant regenerated polystyrene XPS particle, which is composed of a composite carrier, a fire-retardant system, a thermal stable system, and a mixed auxiliary agent; wherein the mass ratio of the composite carrier: the fire-retardant system: the thermal stable system: the mixed auxiliary agent is 90-110:1-5:0.1-0.5:0.05-0.3; the composite carrier is composed of regenerated polystyrene XPS particles and high impact-resistant polystyrene particles, and the fire-retardant system is composed of a solid powder fire retardant and a liquid retardant. Recycled regenerated polystyrene resin is adopted as the main raw material to product the high fire-retardant and high impact-resistant regenerated polystyrene XPS particle, then a novel carrier is added, a novel fire retardant is selected, and the thermal stable system and other auxiliary agent system are optimized, so that the product has the advantages of high fire retardant property, high impact resistance, environment-friendliness, good thermal stability, good mechanical property, and easy processing and forming property.

Owner:LIHAI CHEM IND CO LTD OF JIANGSU JINQIAO SALT & CHEM GRP

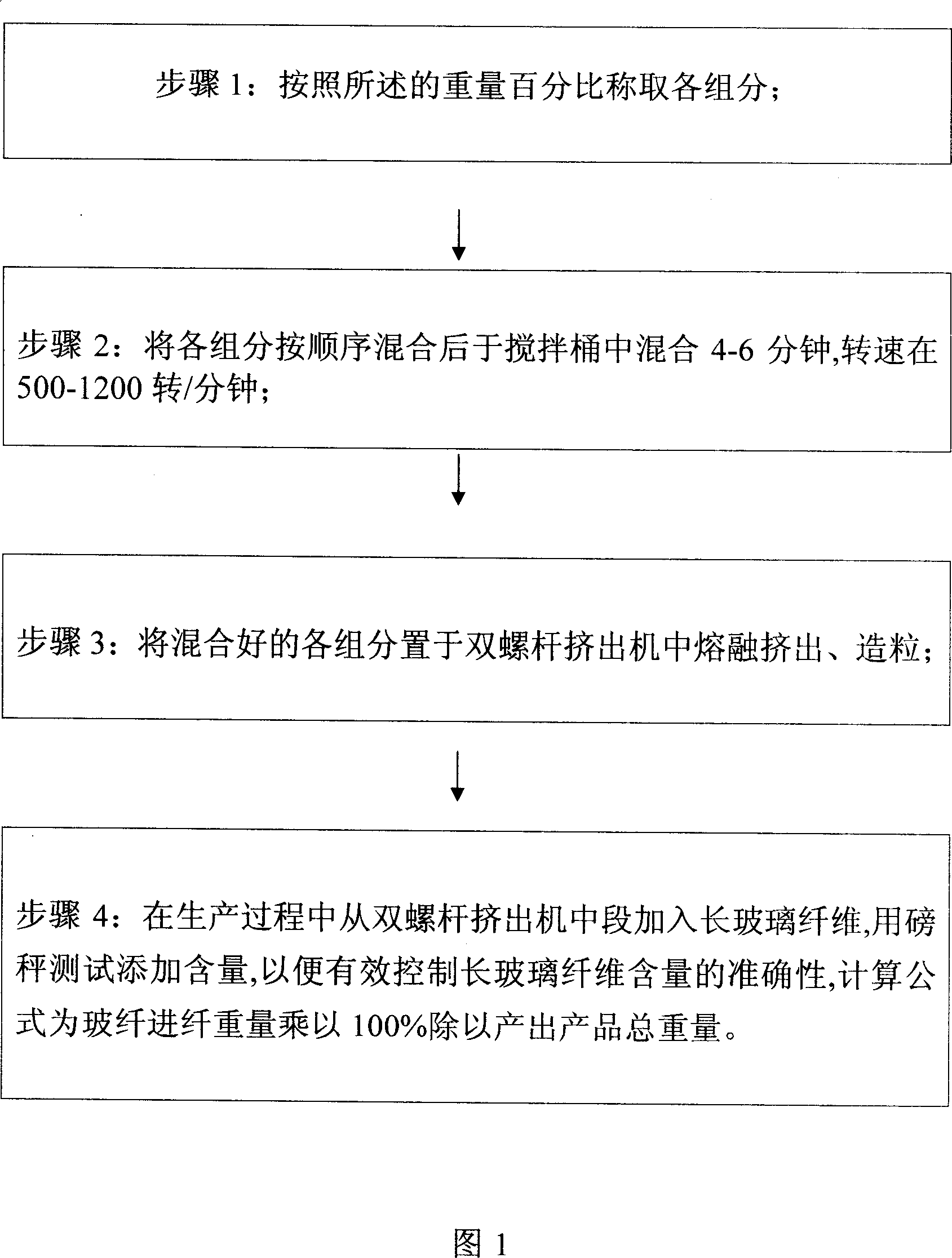

Polybutylene terephthalate and polyhexamethylene adipamide fibre-added fire-retardant alloy and preparation method thereof

A fiber fire-retardant alloy of polybutylene terephthalate and polydecamethylene diamine and its production are disclosed. It consists of polybutylene terephthalate 15-25 wt%, polydecamethylene diamine 22.55-32.55 wt%, bromine fire retardant 12-16 wt%, antimonous oxide 4.0-5.4 wt%, long glass fiber 28-32 wt%, lubricant 0.1-0.2 wt%, antioxidant 0.1-0.3 wt% and plasticizer 3-5 wt%. It costs low, has excellent rigidity, toughness and heat resistance. It can be used for heat-resisting electrical appliance piece, IC slot, connector and work-piece of vehicles.

Owner:SHENZHEN KEJU NEW MATERIAL

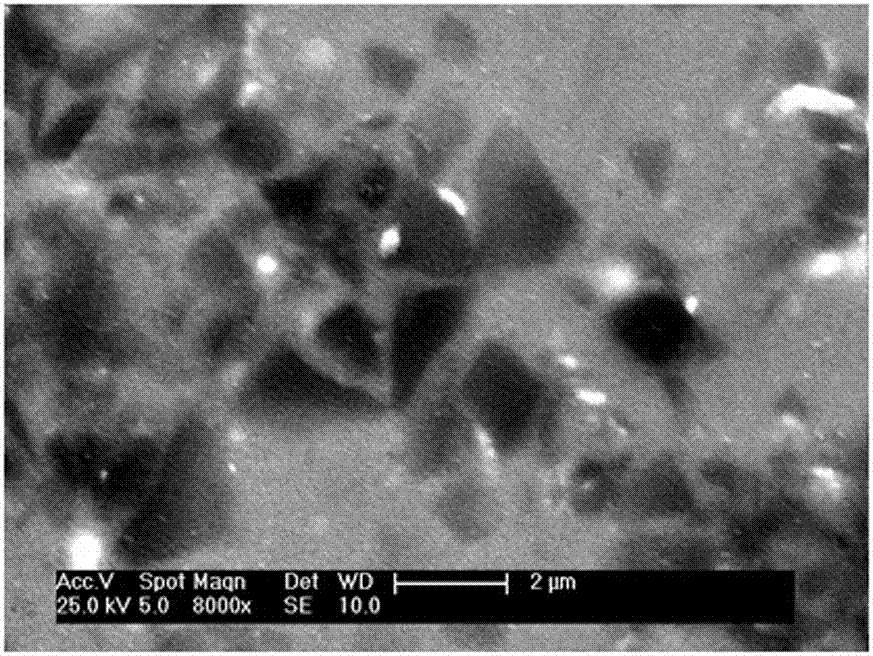

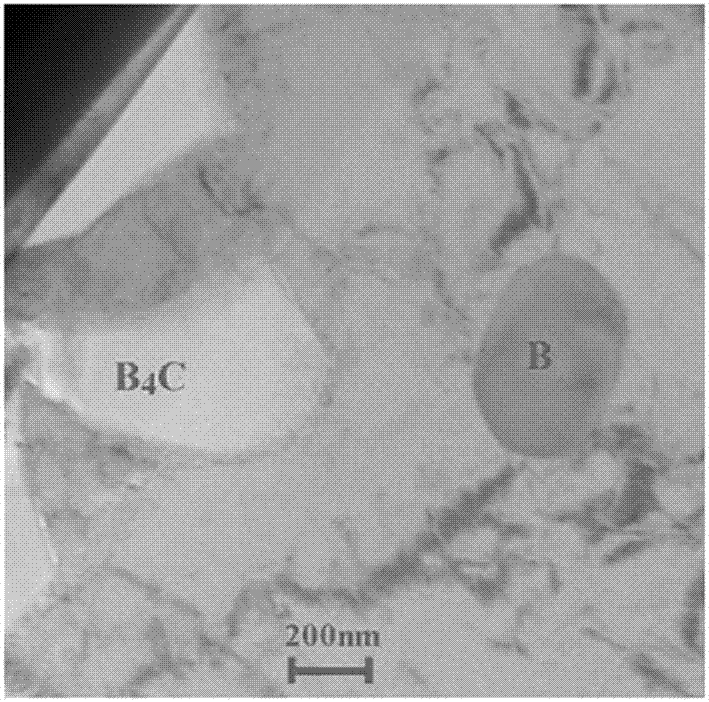

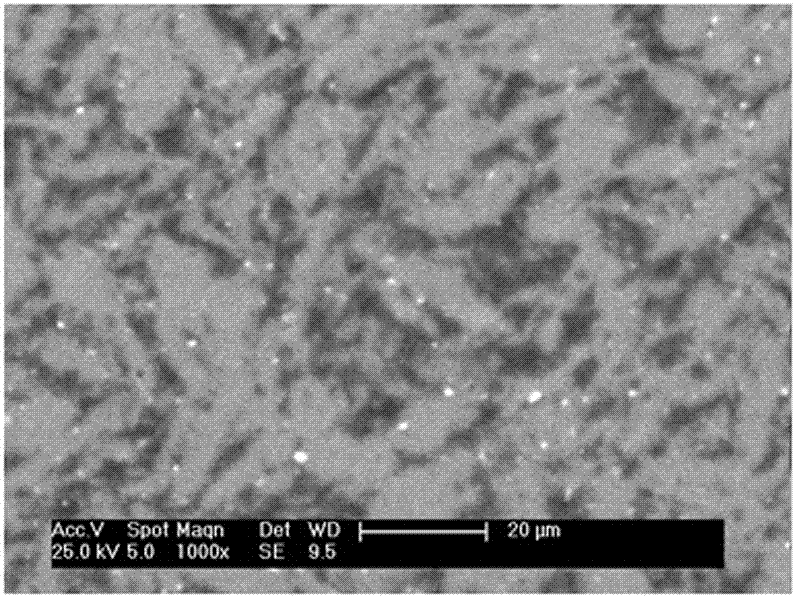

Novel AlB4CB neutron absorbing material and preparation method thereof

The invention discloses a novel AlB4CB neutron absorbing material and a preparation method thereof. The invention aims to solve the problems that along with the content increase of B4C particles in aluminum-base boron carbide, the preparation difficulty of a composite board with aluminum-base boron carbide is also increased, the processing performance and the plasticity become bad, and rolling is difficult; if the content of B4C in aluminum-base boron carbide is too low, the neutron shielding performance cannot be ensured, and the critical safety is difficultly ensured. The composite material of which the particles are uniformly dispersed obtained by the invention has a good comprehensive performance and good resistance to radiation, has high critical safety when being used as a spent fuel storage grid material, and meets the need of neutron absorption.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Completely-degradable composite material with high toughness

The invention discloses a completely-degradable composite material with high toughness, which comprises the following components in percentage by weight: 5 to 94% of PBS or / and PBAT, 5 to 70% of starch, and 0.5 to 60% of plasticize. The use of the starch as a component of the starch reduces production cost and speeds up the degradation of the composite material; and the system of the composite material can increase the melt flow index of the PBAT, so the composite material is easy to process and form. The high toughness of the composite material allows the composite material to be formed into films by casting and blowing or plastic products by blowing, extruding and injecting.

Owner:大河宝利材料科技(苏州)有限公司

Compound braiding material and its production method and matted carpet thereby

InactiveCN1670278AGood waterproof, anti-fouling and anti-corrosion performanceEasy to process and shapeYarnBraidFiberMetal

The invention discloses a compounding weaving material that is made up of heat waxiness material, additive and silkiness material used for industrial. The heat waxiness material includes polyvinyl chloride, polyethylene, rubber, plastic and the mixture of plastic and rubber. The industrial used silkiness material includes chemical fiber silk, natural chemical fiber silk and metal wire. The invention also discloses the manufacturing method to compound the weaving material and carpet weaved by the material. The material is waterproof, dirt-proof, and is easy to be manufactured.

Owner:许赞有

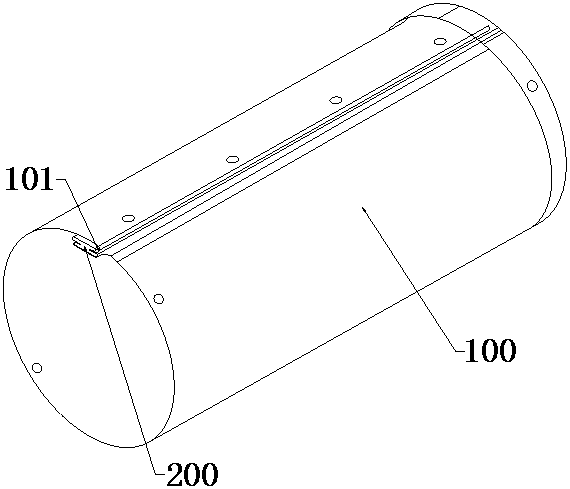

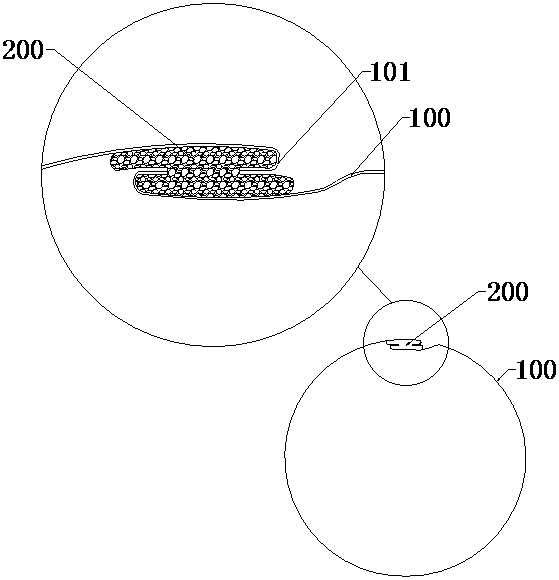

Square lithium ion power battery

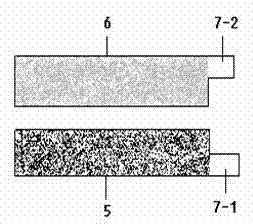

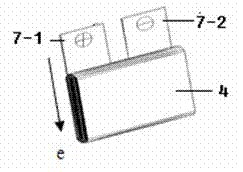

ActiveCN102244209AGood heat dissipationEasy to process and shapeCell component detailsCooling/ventilation/heating modificationsThin shellsCopper foil

The invention relates to a square lithium ion power battery, which is characterized in that a lug of a mandrel is placed at the outermost layer of the mandrel, the lug extends along the arc side surface of the mandrel and the extending direction of the lug is perpendicular to the arc side surface. An anode lug is threaded through a spacer and welded on a cover plate; a cathode lug is threaded through a spacer and welded on a connecting sheet. The anode / cathode lug and the connecting sheet are folded at the rear of a spacer groove, the spacer is fastened on an insulated rubber pad of the coverplate. The invention also provides a method for welding the cathode lug. The present invention has the advantages that a thin shell with wide and short shape is employed, the heat dissipation of the battery is good and the metal shell is easy to process for forming. The lug is arranged at the outermost layer of the mandrel, which avoids the problem of short circuit generated when the battery falls or the impacted lug and the connecting sheet enter in the mandrel. The method of welding cathode lug is capable of effectively inhibiting the disadvantage of easy rupture force of copper foil cathode lug when being smashed and being pulled by external force; an engagement structure of the spacer and the insulated rubber pad is employed for effectively preventing the poor positioning of the spacer.

Owner:JIAN UTILITY TECH CO LTD

Halogen-free flame-retardant enhanced PC/ABS alloy and preparation method thereof

InactiveCN103421294AGood mechanical properties and dimensional stabilityEasy to process and shapePentaerythritolAnoxomer

The invention relates to a halogen-free flame-retardant enhanced PC / ABS alloy and a preparation method thereof, and belongs to the technical field of high molecular materials. The alloy is composed of the following raw materials, by weight, 60-80 parts of PC, 35-50 parts of ABS, 7-13 parts of aramid fibers, 6-10 parts of magnesium hydroxide whiskers, 5-8 parts of dimethyl methylphosphonate, 4-7 parts of melamine, 3-5 parts of pentaerythritol, 5-10 parts of compatilizer and 0.5-3 parts of antioxidant. The aramid fibers and the magnesium hydroxide whiskers are adopted to enhance the PC / ABS alloy, so that a prepared product has good mechanical performance and dimensional stability and is easy to process and form. In addition, organic phosphorous-nitrogen compound flame retardant and inorganic flame retardant magnesium hydroxide whiskers are adopted for synergy in raw materials, so that the halogen-free flame-retardant enhanced PC / ABS alloy has good flame-retardant effect, and application range of the PC / ABS alloy is greatly widened.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

High-pressure spray gun of polyurethane foaming machine

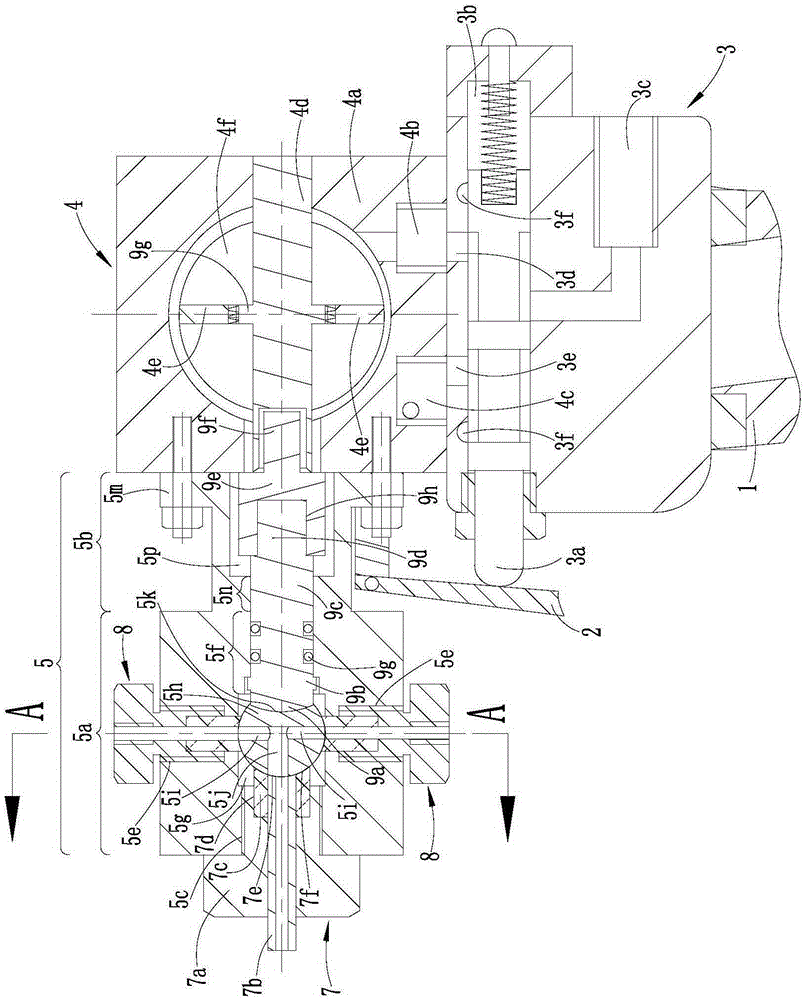

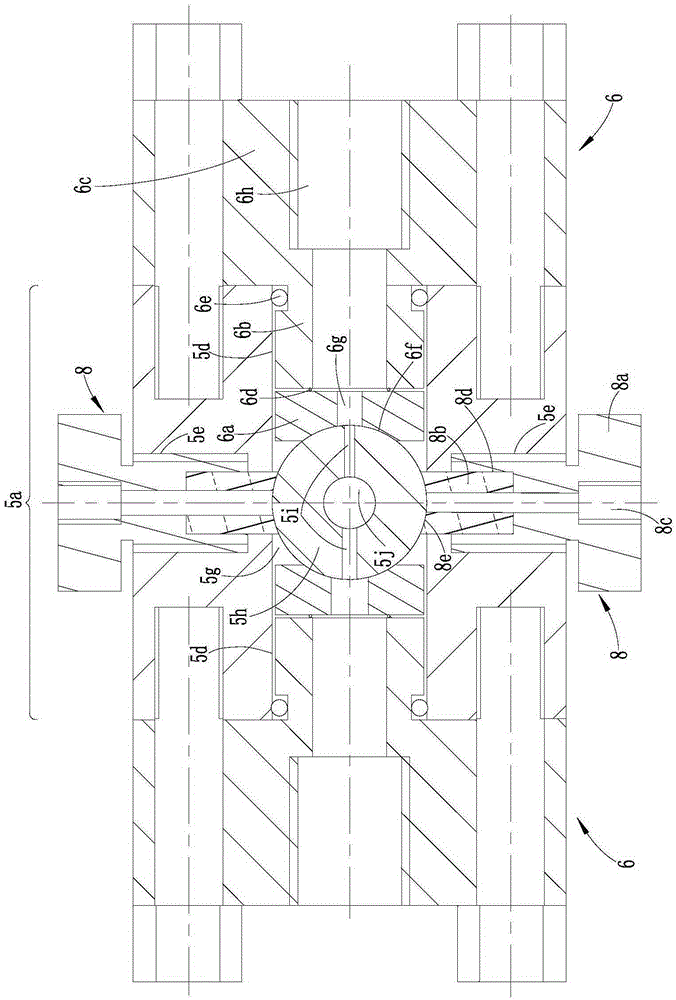

ActiveCN105327806ASimple and reasonable structureEasy to process and shapeSingle-unit apparatusCylinder blockHigh pressure

The invention discloses a high-pressure spray gun of a polyurethane foaming machine. The high-pressure spray gun is characterized in that an air valve and a pneumatic actuator are arranged at the upper side of a handle; the upper end of a trigger is articulated with the front side of a cylinder body of the pneumatic actuator, and the middle part of the trigger is in contact with a valve core of the air valve; an output shaft connected to a gear shaft in the cylinder body is arranged at the front side of the cylinder body; the rear side of a combination chamber body is connected to the front side of the cylinder body, and a placement cavity is formed inside the front side of the combination chamber body; a nozzle assembly is arranged at the front end of the combination chamber body; two material injection assemblies and two blowing assemblies are arranged at the front side of the combination chamber body in another two directions being perpendicular to each other; a tee-junction hole comprising two material receiving holes and a material discharging hole is formed in a spherical core block in the placement cavity; the output shaft is placed in the combination chamber body and is connected to the spherical core block; the spherical core block is in close contact with the inner ends of the nozzle assembly, the two material injection assemblies and the two blowing assemblies; during material injection and material clearing, the material injection assemblies and the two blowing assemblies are communicated with the two material receiving holes, and yet the nozzle assembly is always communicated with the material discharging hole. The high-pressure spray gun has a good foaming effect; the frequency of blocking the spray gun is substantially reduced; and the effect of clearing the spray gun is relatively good.

Owner:蚌埠中正聚氨酯发泡设备有限公司

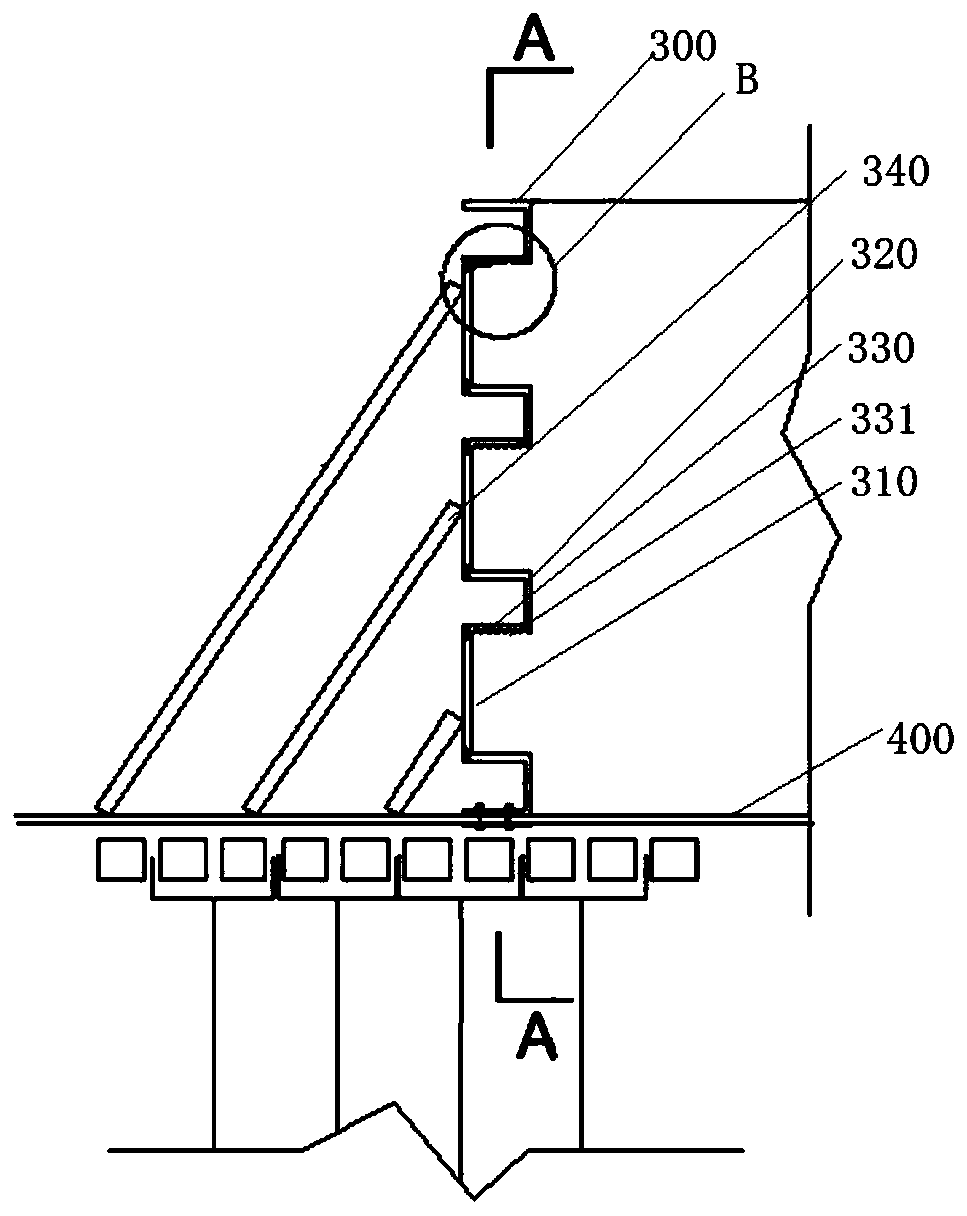

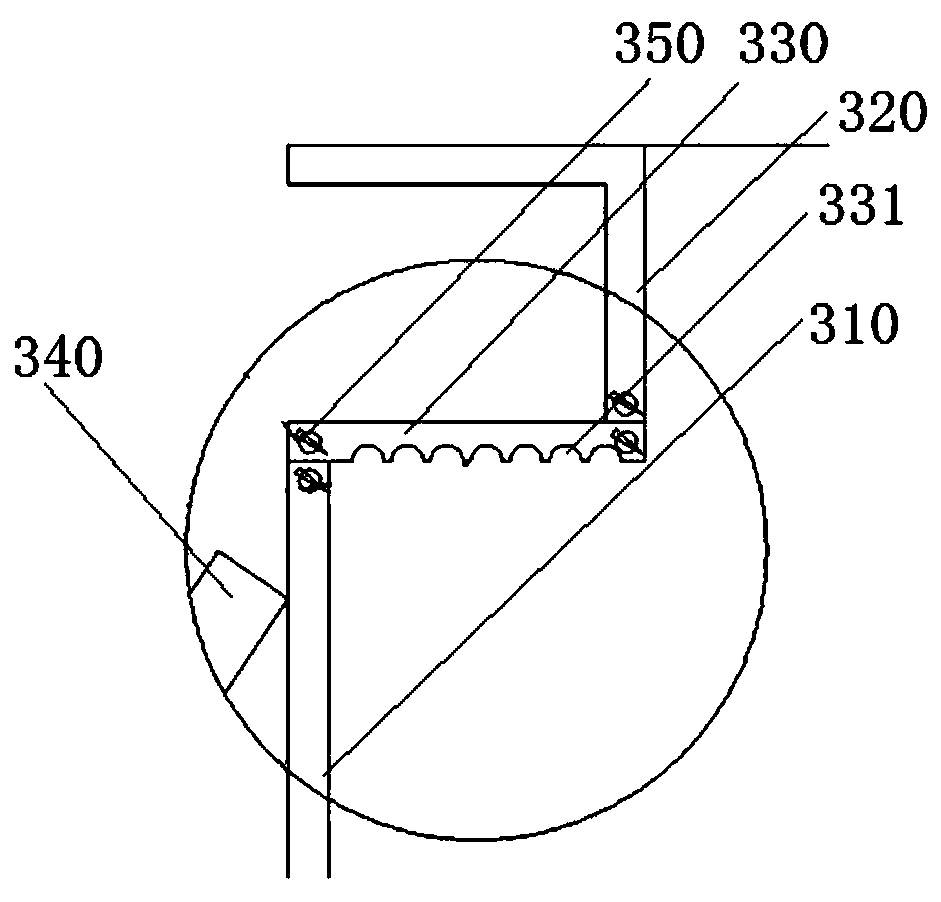

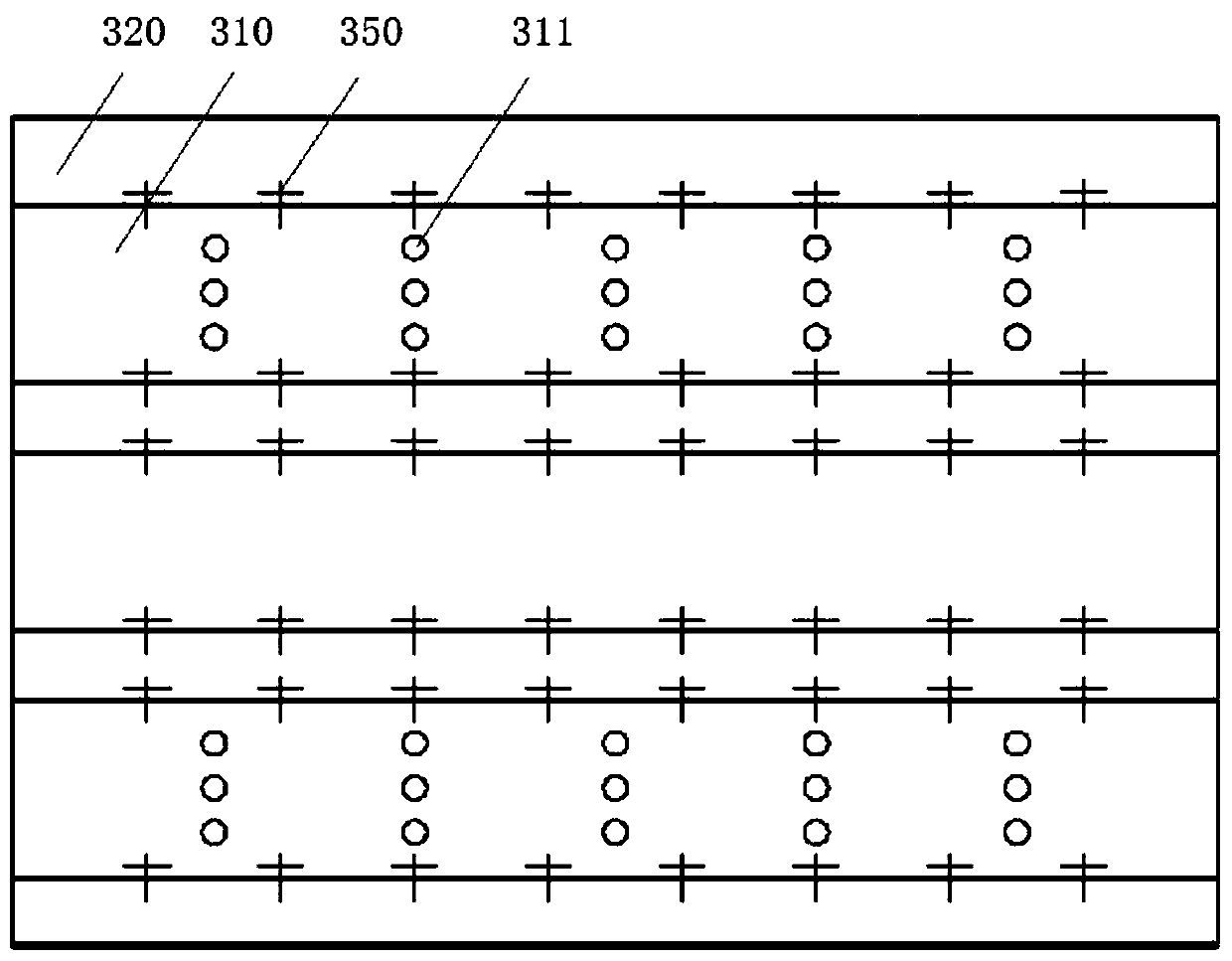

Construction method for vertical waterproof construction joint

ActiveCN110295739AEasy to process and shapeFormwork technology is matureForms/shuttering/falseworksBuilding insulationsAluminiumArchitectural engineering

The invention discloses a construction method for a vertical waterproof construction joint. The construction method comprises the following steps: S1, manufacturing a construction joint template; S2,mounting the construction joint template; S3, carrying out pouring for the first time; S4, preparing pouring for the second time; and S5, carrying out pouring for the first time. A water sealing and seepage resisting effect in a horizontal section and a vertical section is obtained by combining a tooth-shaped joint structural form between new and old concrete and a scabbing process, and a waterproof purpose of a large sized vertical construction joint is guaranteed. A process of combining a conventional aluminum template with construction joint construction is innovated by means of a sustainable utilizing theory of the aluminum template, and the aluminum template is easily processed, formed and manufactured. The template technology is sophisticated in operation and can be utilized sustainably. Use of conventional flexible waterproof and rigid waterproof materials is cancelled, the material cost is saved, and the construction period is shortened. New and old concrete is in contact by using the tooth-shaped joint structure, and the structural contact surface is increased, so that the anti-seizing ability is enhanced.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for preparing blend fibers of celluloses and high-fluidity elastomers

InactiveCN102978737AEasy to process and shapeImprove melt fluidityFilament forming substance formingConjugated cellulose/protein artificial filamentsIonMelt spinning

The invention relates to a method for preparing blend fibers of celluloses and high-fluidity elastomers. The method comprises the steps of: (1) drying the celluloses and the high-fluidity elastomers in vacuum; (2) evenly mixing 20-30% of the celluloses, 50-70% of ionic liquid and 5-20% of the high-fluidity elastomers; (3) extruding, defoaming and filtering the mixture by a co-rotating twin screw extruder, and then spraying from a spinning nozzle; and (4) solidifying the fibers into solid, stretching the solid after washing, and winding to form cellulosic fibers. The good processability and mechanical property are endowed to materials on the basis of preserving the property of the celluloses, so that the celluloses are smelted fully; and the melt fluidity of the celluloses is improved, and the method has significance on implementation on high-temperature melt spinning engineering and industrialized production of the celluloses.

Owner:DONGHUA UNIV

Formula and production process of PE film

The present invention discloses a formula of a PE film, wherein the base material is a polyethylene transparent film, and the matched material is formed by uniformly mixing and combining the following materials: 30-50 parts of metallocene linear low density polyethylene, 20-30 parts of smooth masterbatch, 10-15 parts of an antistatic masterbatch, 5-8 parts of a penetrating promoting agent, 2-5 parts of myrcene, 3-8 parts of a polypropylene resin, 4-8 parts of a styrene-butadiene rubber, 0.5-2 parts of silicone oil, 0.2-0.6 part of stearic acid, 2-5 parts of polyester fiber, 1-2 parts of cellulose acetate, 0.5-1 part of silica gel, 1-2 parts of aluminum oxide, 0.1-0.5 part of dimethylamide, and 1-2 parts of a light stabilizer. The production process comprises: 1, blending a primer; 2, unwinding; 3, coating the material; 4, drying; 5, cooling; 6, detecting; 7, winding; and 8, packaging. According to the present invention, with the formula and the production process of the PE film, the obtained product has characteristics of reasonable design, convenient processing and molding, high strength, high transparency, strong flame retardant performance and strong antibacterial performance, and can emit fragrance so as to make the packaged product have the additional value.

Owner:东莞市伟达包装制品有限公司

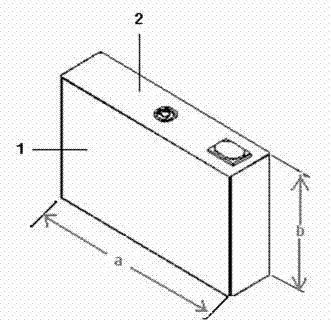

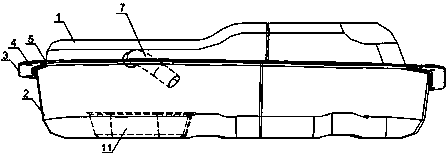

Fuel tank capable of reinforced integrally

InactiveCN103407366AEasy to process and shapeImprove corrosion resistanceUnderstructuresFuel tankPulp and paper industry

The invention discloses a fuel tank capable of reinforced integrally. The fuel tank capable of reinforced integrally comprises an upper tank body and a lower tank body, wherein a plurality of installing holes are correspondingly arranged at two ends of the upper tank body and two ends of the lower tank body, and the upper tank body is connected with the lower tank body through the installing holes and bolts. The fuel tank further comprises reinforcing boards arranged at the end portions of two ends of the lower tank body, a plurality of through holes are formed in the reinforcing boards, the through holes and the installing holes are arranged coaxially, the reinforcing boards and the end portions of the lower tank body are welded, an arranged fuel feeding mechanism can quickly enable fuel to enter the fuel tank, and meanwhile parts inside the fuel tank are prevented from being impacted by the fuel and damaged.

Owner:成都陵川车用油箱有限公司

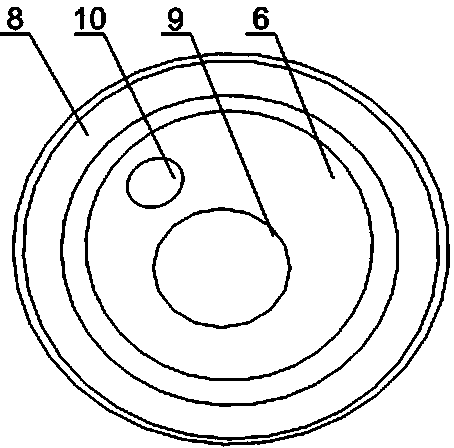

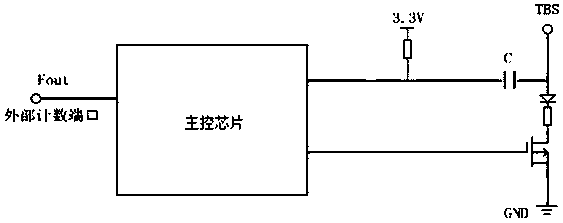

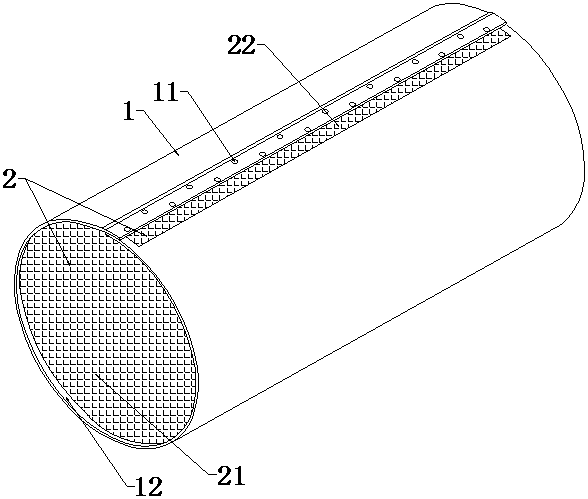

High-precision low-flow detection device based on constant power

ActiveCN109781199AEasy to install and removeEasy to process and shapeVolume variation compensation/correction apparatusPower sensorPetroleum

The invention discloses a high-precision low-flow detection device based on constant power and belongs to the technical field of petroleum logging instruments. The device comprises a constant-power sensor and a detection processing transmission circuit connected with the constant-power sensor, wherein the detection processing transmission circuit is installed in a circuit installation shell, the constant-power sensor is installed in a flow sensor installation shell, the circuit installation shell and the flow sensor installation shell are connected in a screw-thread fit mode, and the free endof the circuit installation shell and the free end of the flow sensor installation shell are both sealed to form a pressure-bearing sealed column structure; and the constant-power sensor is composed of a constant-power heater and a temperature sensor, wherein the constant-power heater and the temperature sensor are oppositely installed at the two ends inside the flow sensor installation shell, anda gap is reserved between the end of the constant-power heater and the end of the temperature sensor. The device overcomes the limitation on starting discharge capacity of a traditional flow logginginstrument, a mechanical rotation device does not need to be arranged, the defect of a logging instrument in a domestic low liquid-producing well is overcome, and the device has the advantages of highsensitivity, high precision, simple structure and high stability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

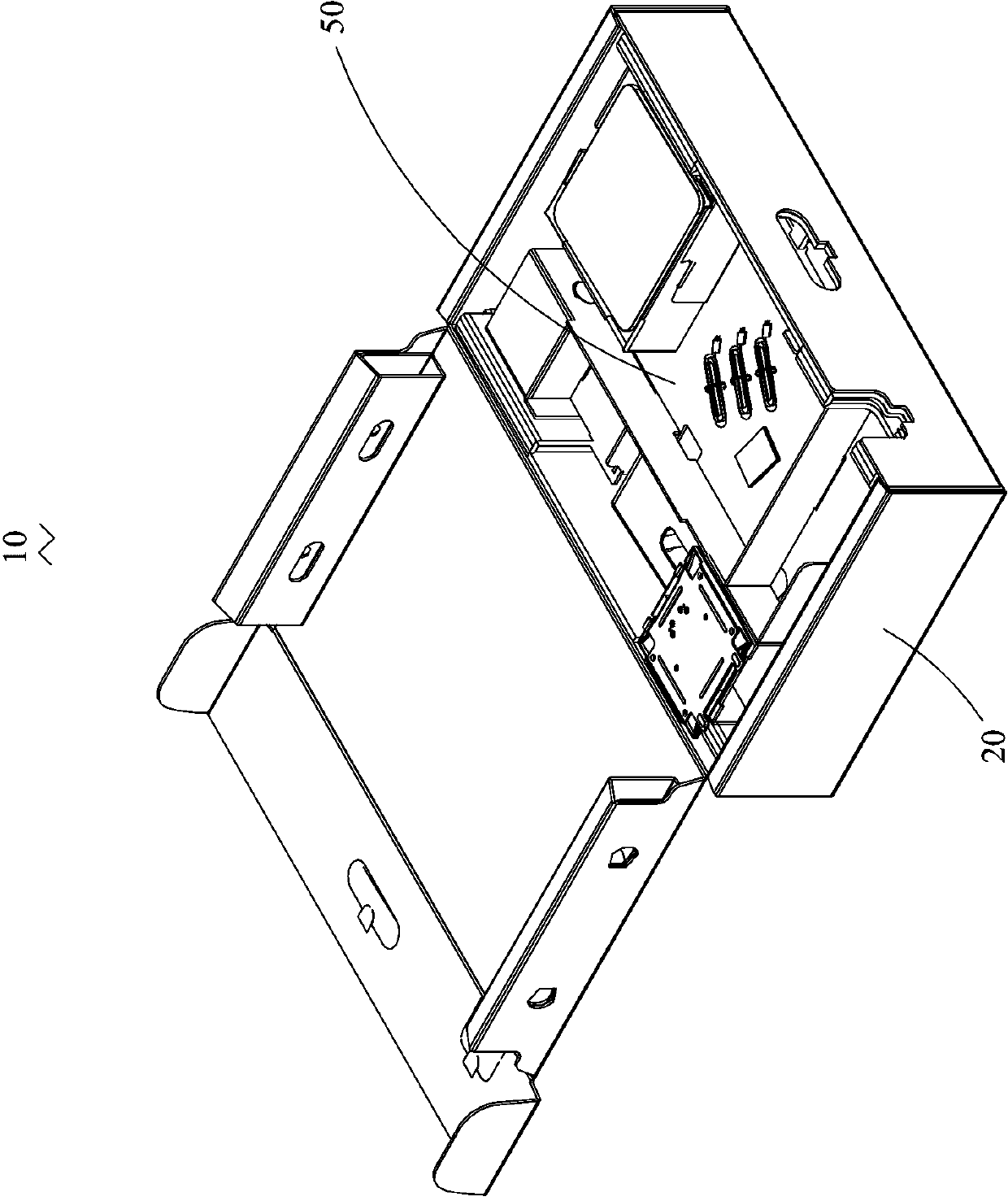

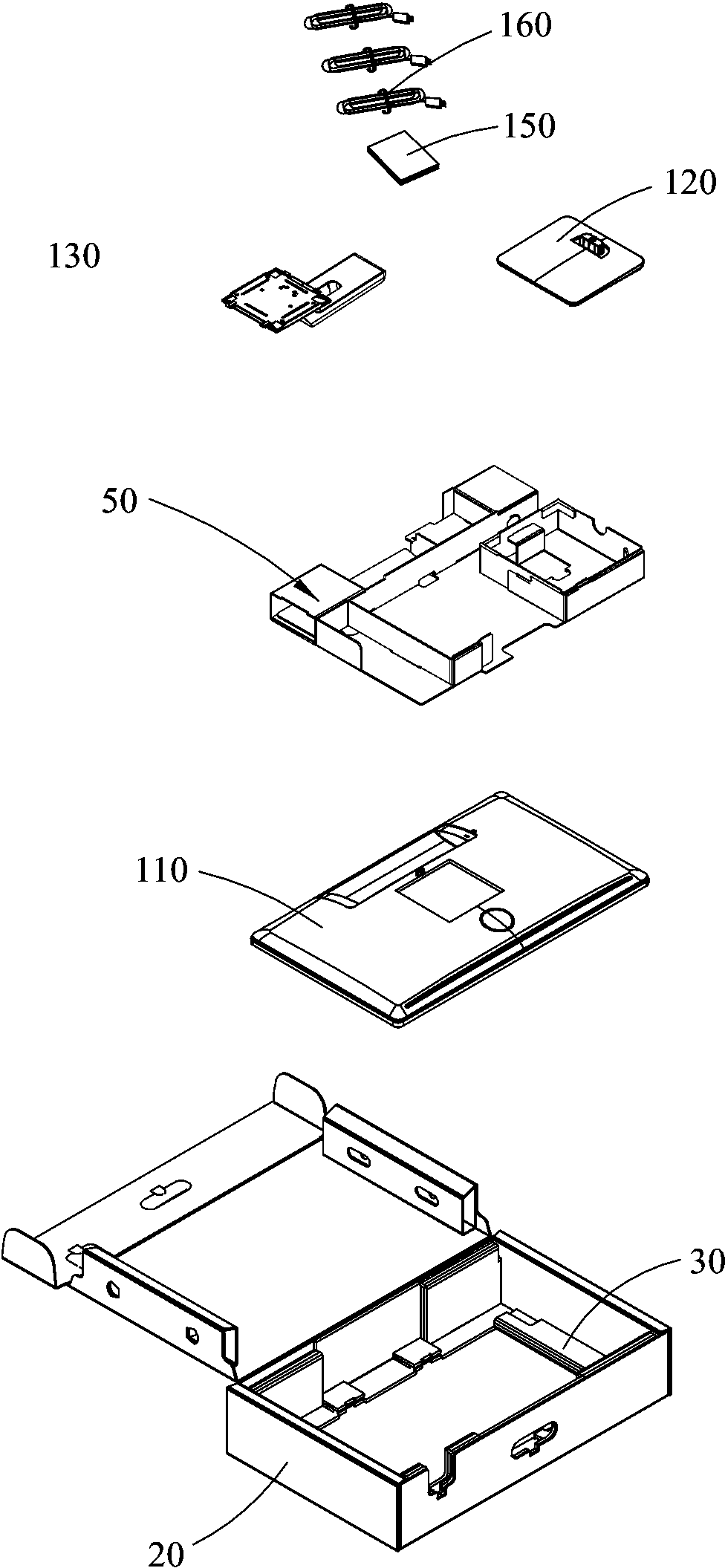

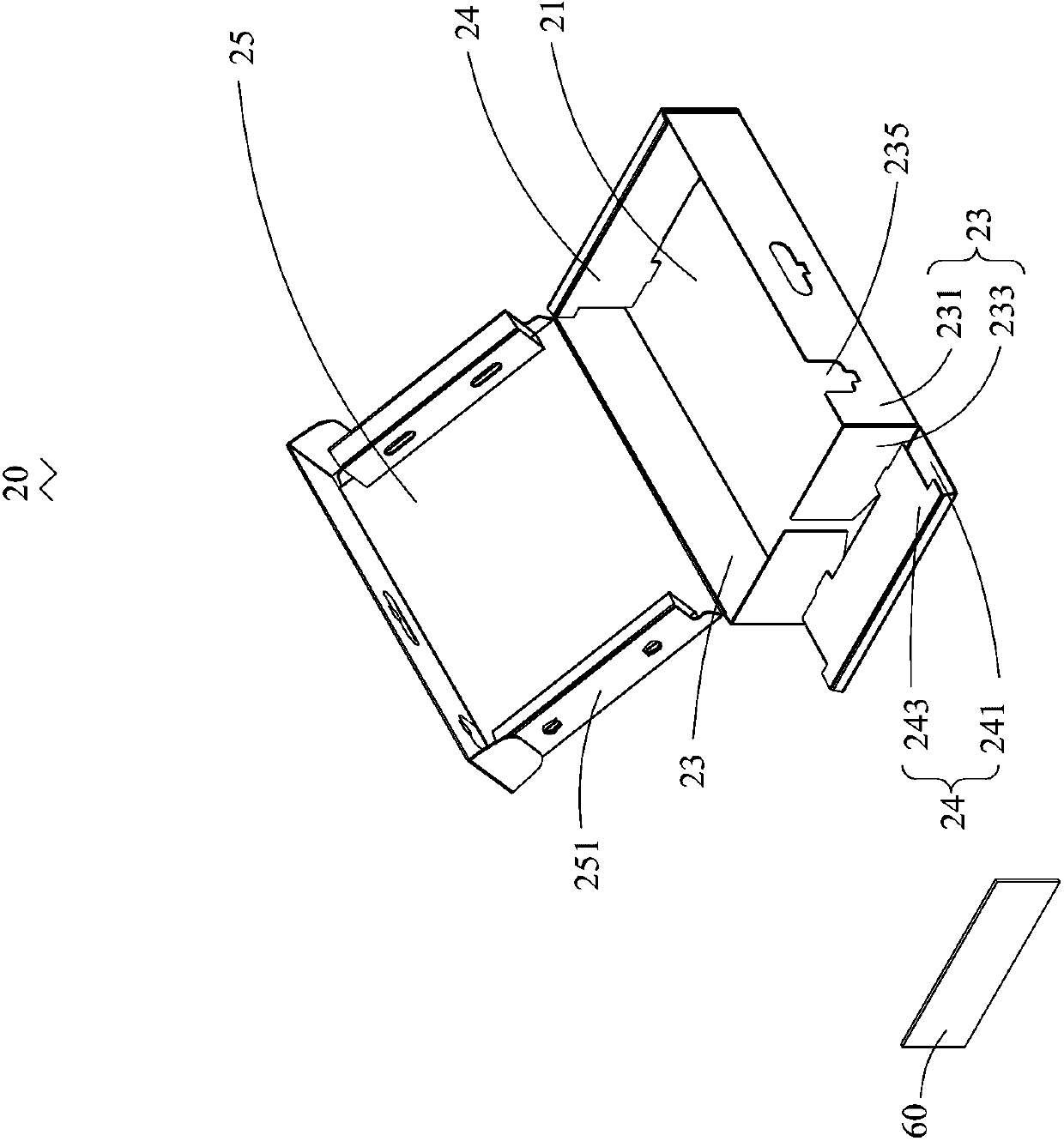

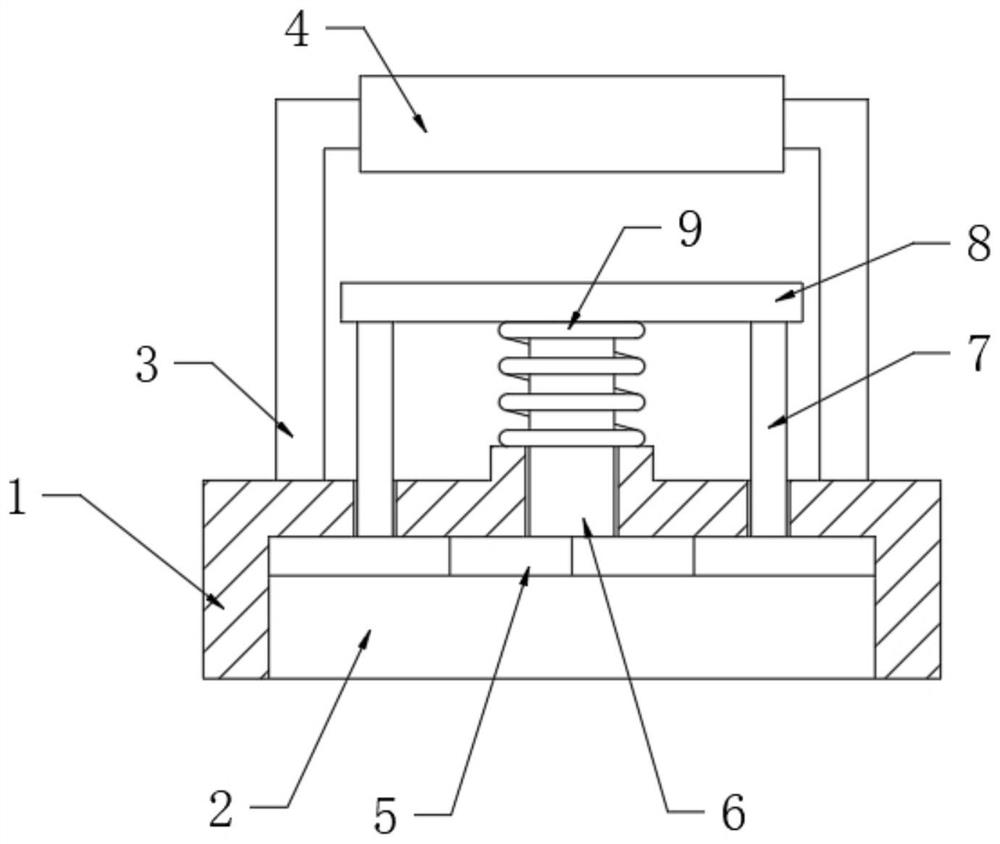

Cushioning packaging box for display

ActiveCN103738558AEasy to process and shapeLow comprehensive costRigid containersDamagable goods packagingCushioningDisplay device

The invention provides a cushioning packaging box for a display. The cushioning packaging box comprises a box body, a bottom liner and a top liner. A first cushioning step, a second cushioning step and an accommodation frame are arranged on the top liner. The bottom liner is arranged in the box body. The display comprises a display screen, a display support and a display base which are arranged separately. The display screen is arranged on the bottom liner, the top liner is arranged on the display screen, one end of the display support is arranged on the first cushioning step, the other end of the display support abuts against the end surface of the second cushioning step, and the display base is arranged on the first cushioning step. According to the cushioning packaging box, the display comprises the display screen, the display support and the display base which are arranged separately, so that a user can put in or take out required parts of the display conveniently, the dismounting and mounting time is saved, and the utilization efficiency is improved.

Owner:MYS GRP CO LTD

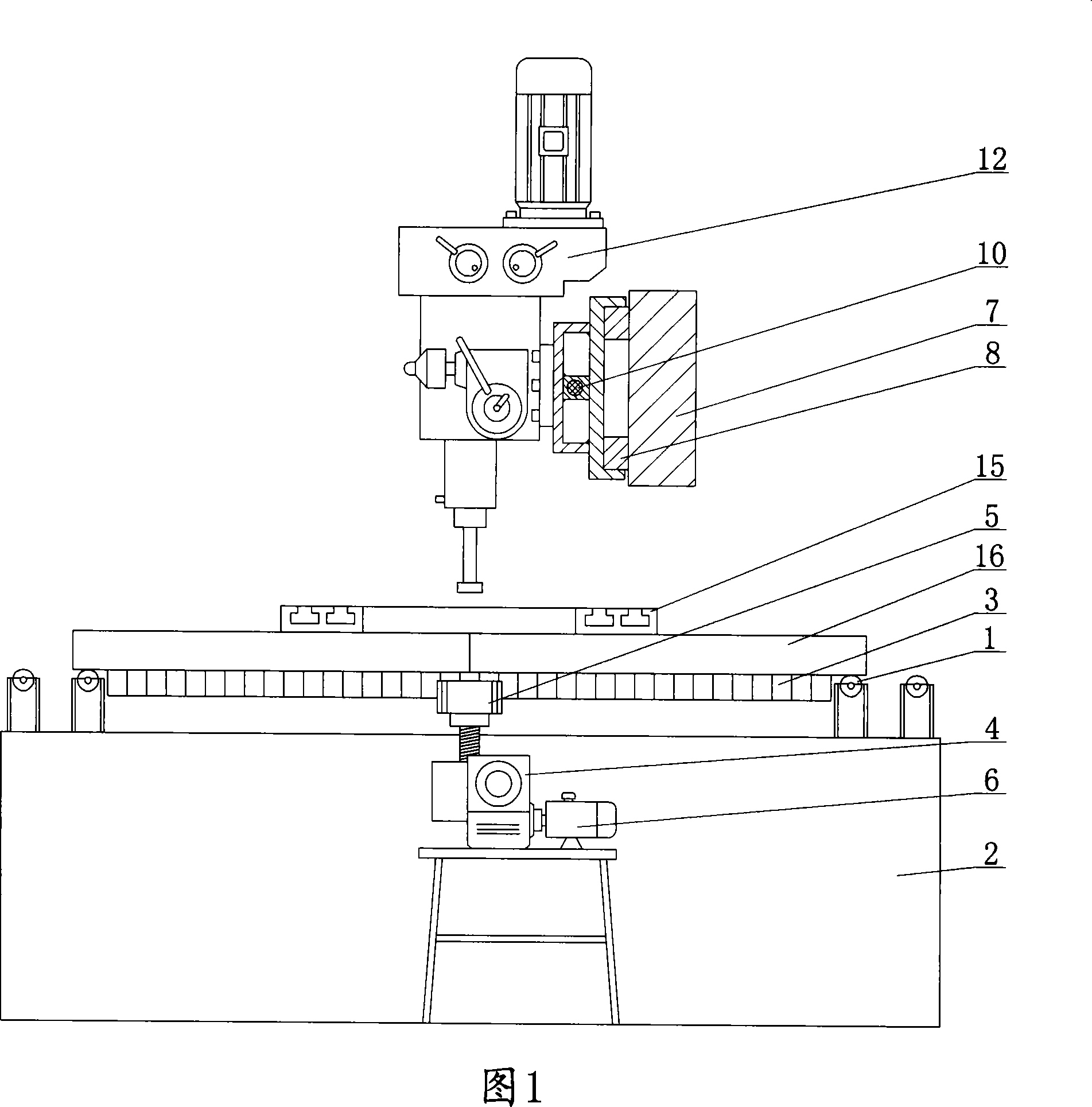

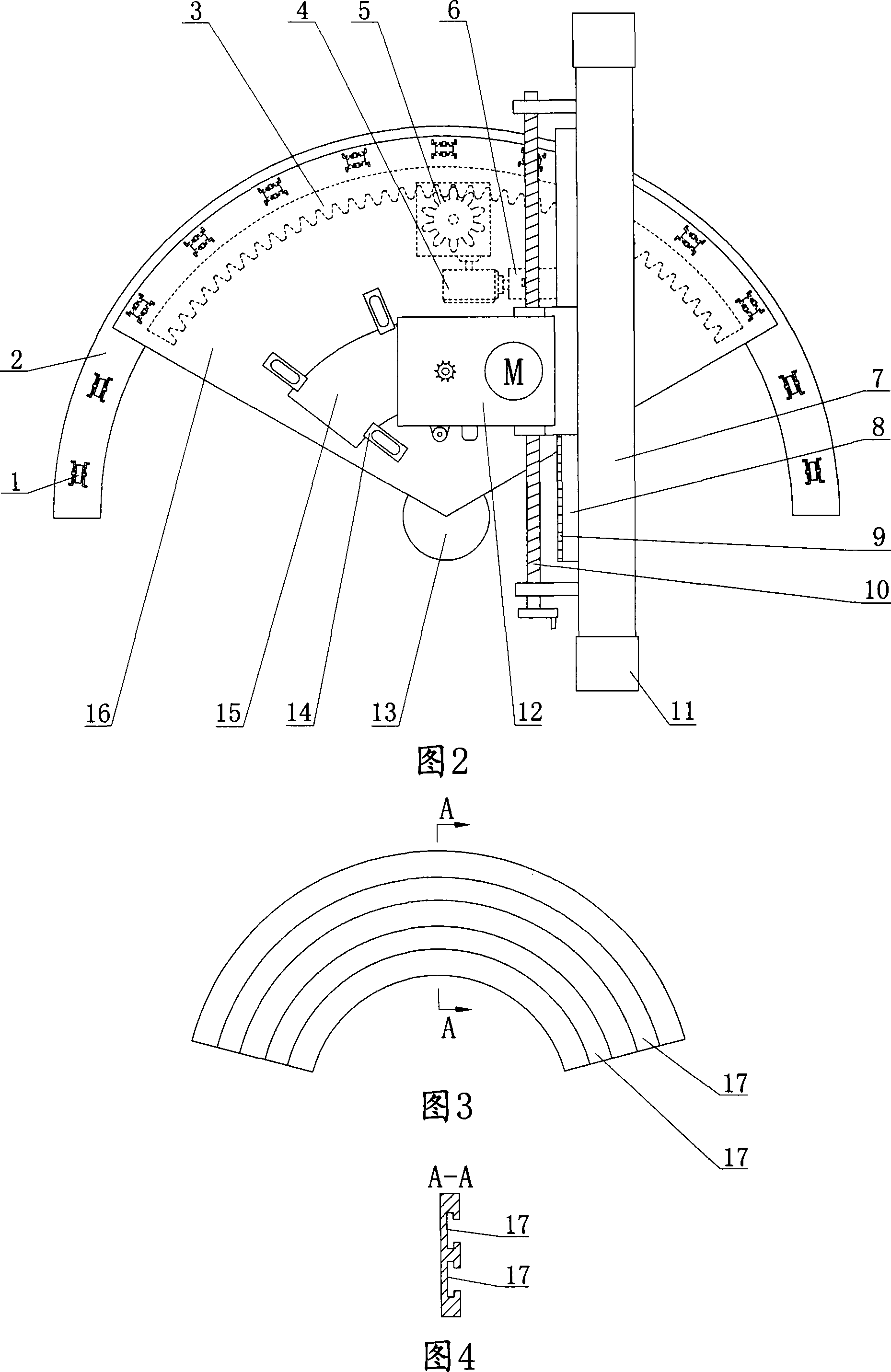

Milling machine special for magnetic turning guideway

InactiveCN101229596ARun smoothlyEasy to process and shapeLarge fixed membersMilling equipment detailsDrive motorProcessing accuracy

The invention provides a special milling machine of a magnetic turning guide track, which comprises a work platform, a support sliding guide, a bearing box, a vertical mill head mechanism and a work platform driving mechanism. The bullseye of the work platform is arranged on the bearing box and the bottom face with arc sides is supported on a sliding track at the top end of the support sliding guide; the work platform has stable operation, which is convenient for processing and forming and has labor-saving and convenient operation; the vertical mill head mechanism comprises a beam, a bracket, a vertical mill head, a guide track, a leading screw and a scale, wherein, the vertical mill head can move back and forth on the guide track to adjust processing sizes, thus having the advantages of stable operation and convenient control as well as automatic locking to guarantee processing accuracy of workpieces and promotion of working efficiency; the work platform driving mechanism comprises a drive motor, a reduction gear box, a drive gear and a gear rack; the gear rack is arranged at the bottom of the work platform and meshed with the drive gear. The invention has low production cost, simple structure, flexible and convenient operation, less waste material and high processing accuracy and saves materials, thus being the special equipment for processing the magnetic turning guide track.

Owner:吴长发

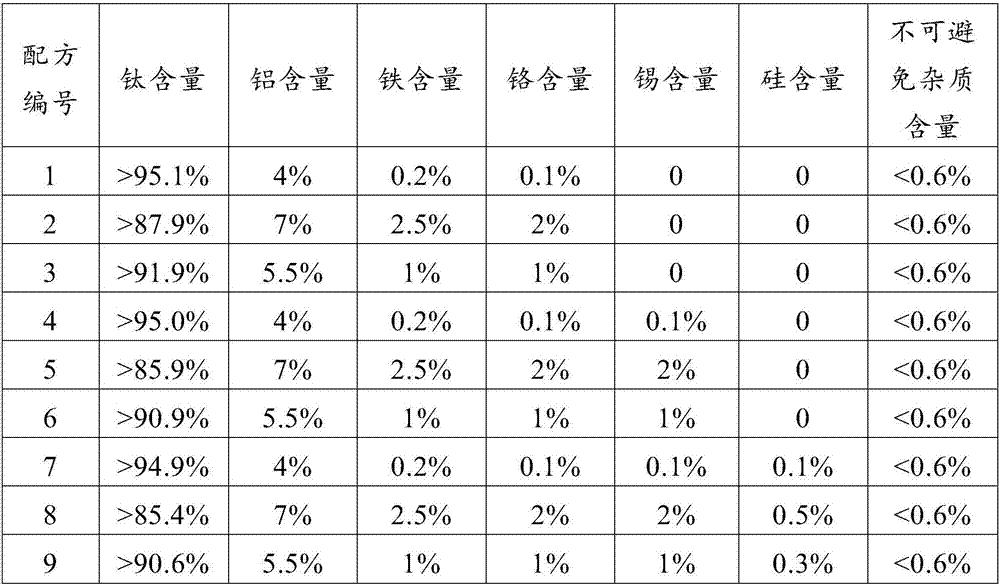

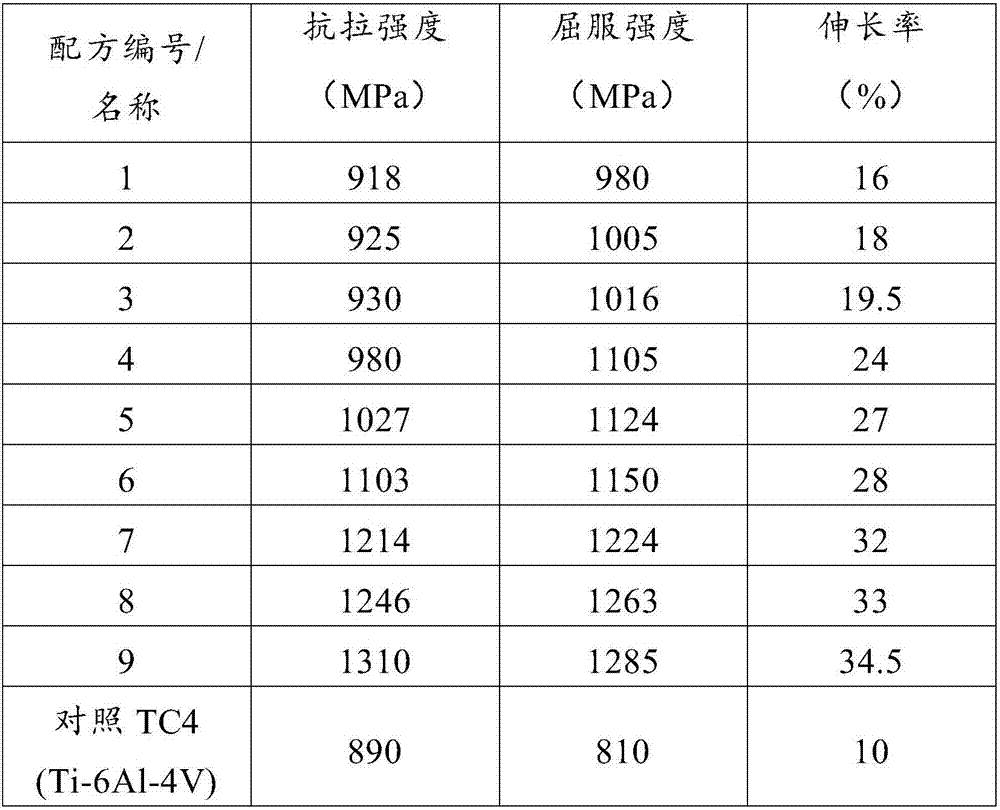

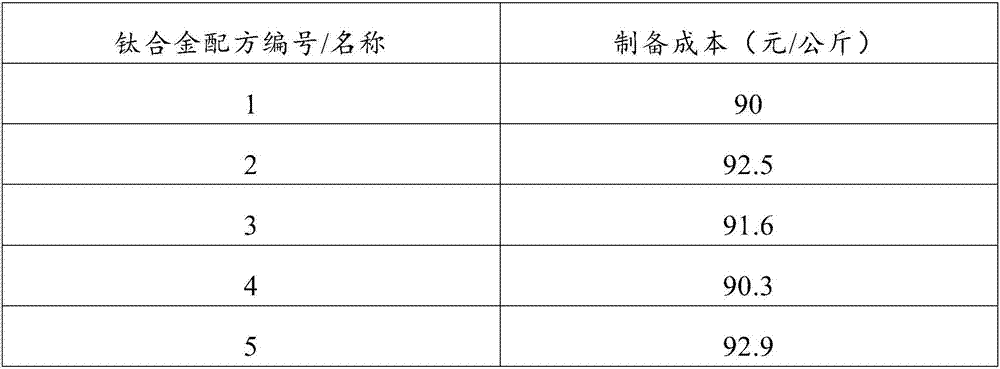

High cost performance titanium alloy and preparation method thereof

The invention belongs to the field of alloy materials and relates to a high cost performance titanium alloy and a preparation method thereof. Titanium is mainly contained, besides, the titanium alloy further contains, by weight, 4%-7% of aluminum, 0.2%-2.5% of iron, 0.1%-2% of chromium and little inevitable impurities, and the titanium alloy does not contain molybdenum and vanadium. Compared with a TC4 titanium alloy material widely used in the prior art, the high cost performance titanium alloy is easier to machine, heat treatment performance is good, machining forming is easier, performance is better, and the production cost and the final price of the alloy material can be reduced.

Owner:BEIJING JINYU SHUNDA TECH CO LTD

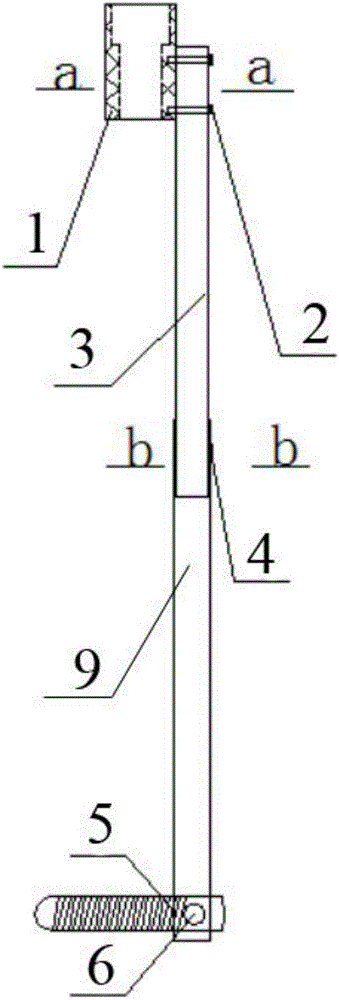

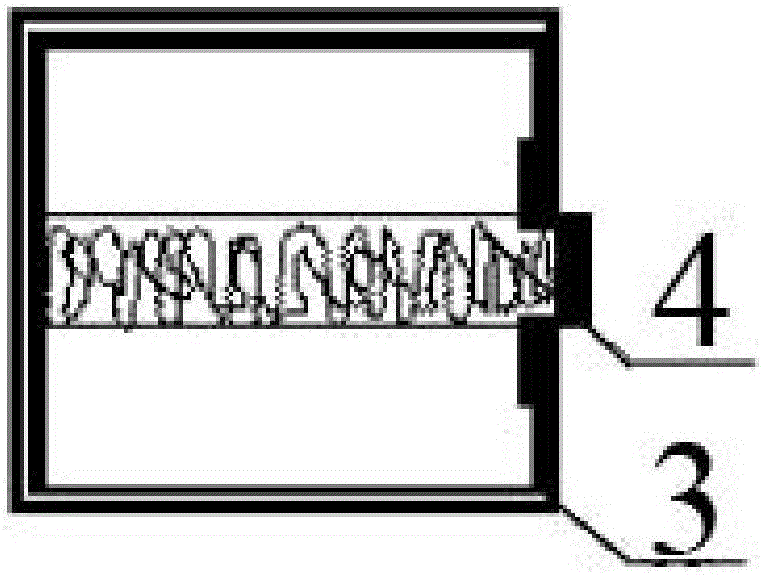

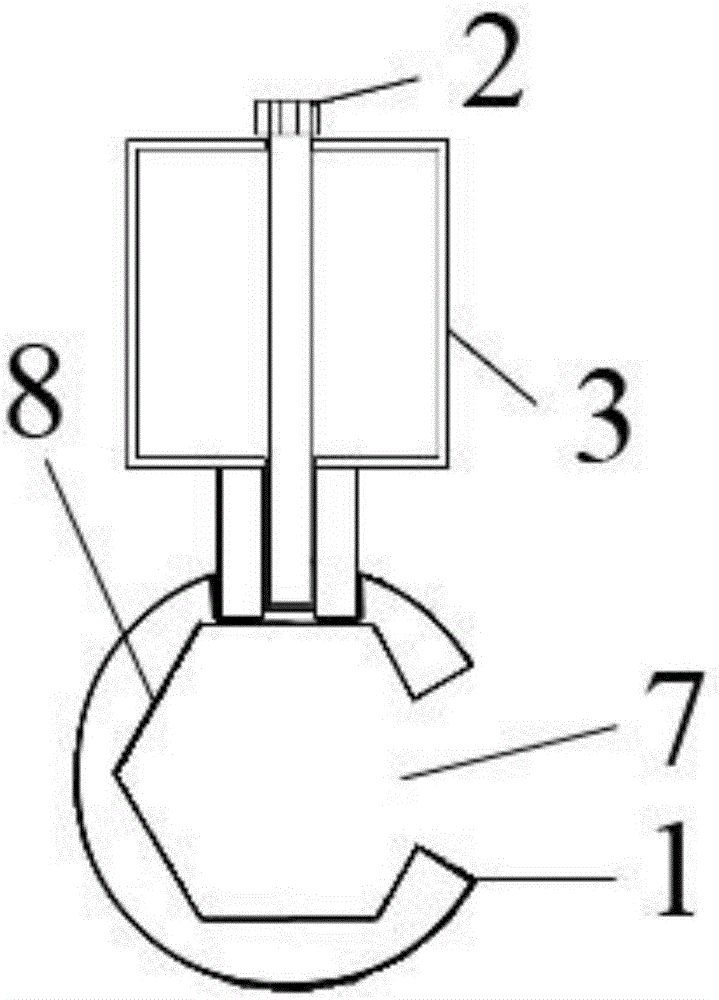

Lifting rod mounting device

The invention discloses a lifting rod mounting device. The lifting rod mounting device comprises a semicircular bolt fixing device, an extension rod and a rotating handle; a groove is formed in one side of the semicircular bolt fixing device; the extension rod includes extension sections; and the rotating handle is arranged at the bottom of the extension rod. The lifting rod mounting device is simple in structure, convenient for machining and molding and wide in application range, can be suitable for installation of ceilings with higher clear heights and lifting rods of water and electricity pipelines and installation of lifting rods under the condition of narrow ceiling operation surface, is simple in operation in the use process, convenient for disassembly, few in scattered parts, economical and practical, and is suitable for mounting the lifting rods with various heights through adjusting the length of the aluminum alloy extension rod.

Owner:CHINA RAILWAY CONSTR GROUP

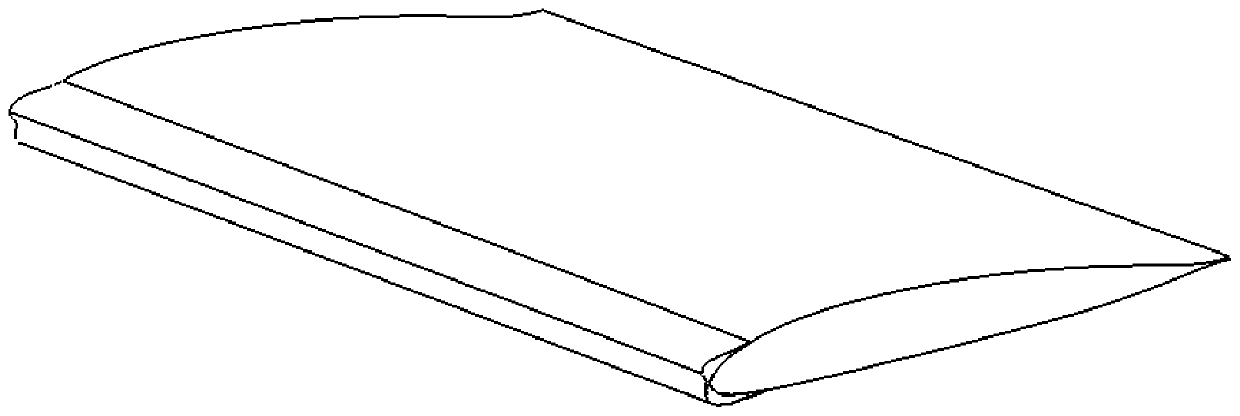

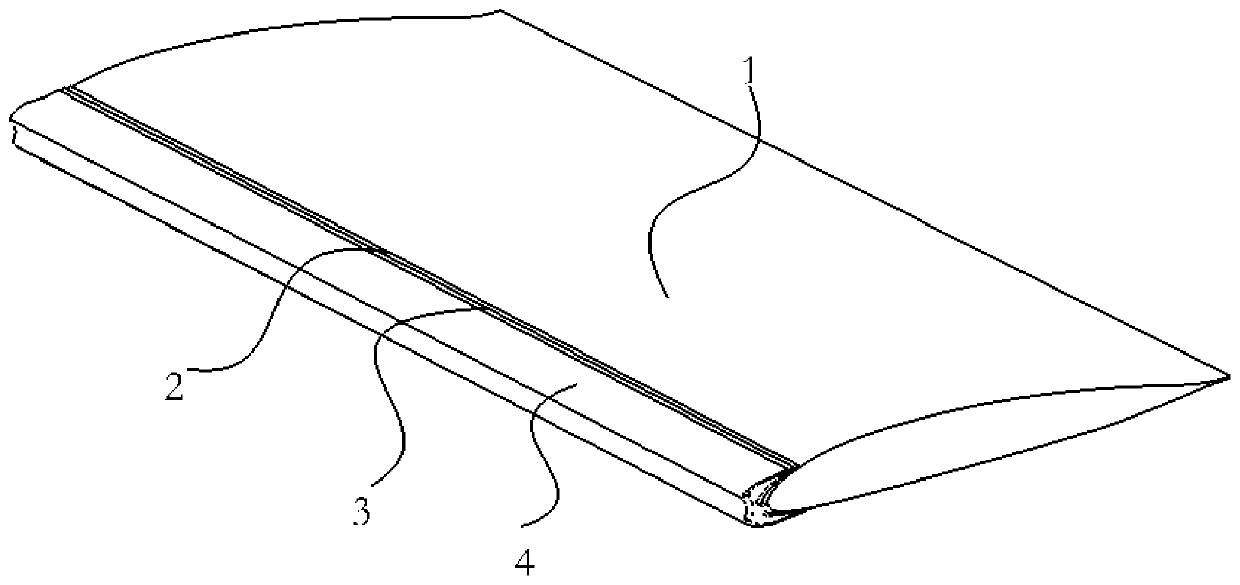

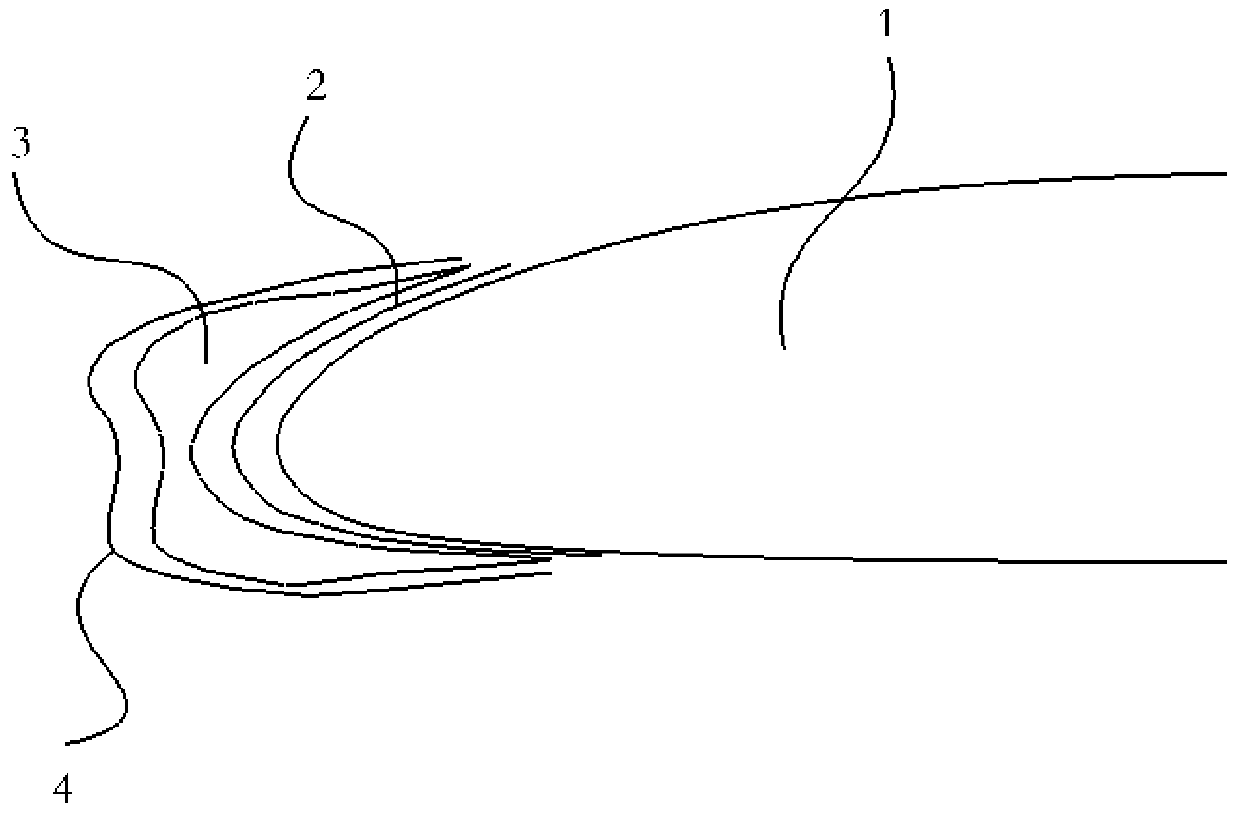

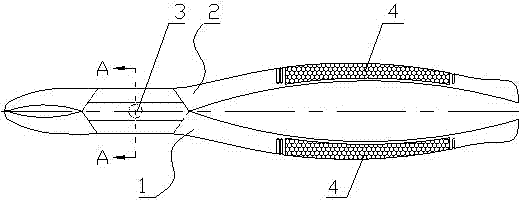

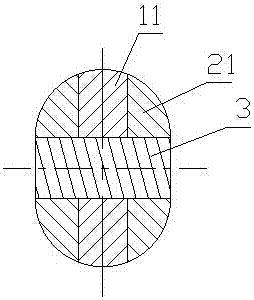

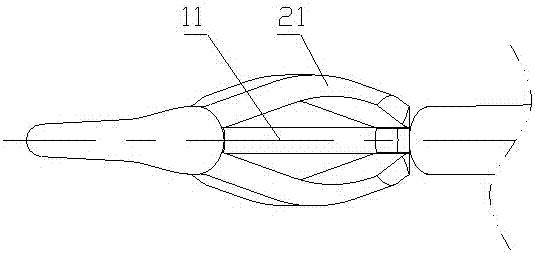

Helicopter rotor blade simulating transparent ice structure and integration method

PendingCN110758767AEasy to process and shapeIncrease marginAircraft components testingSustainable transportationEngineeringIce formation

The invention belongs to the technical field of helicopter rotor blade ice preventing and removing performance verification and relates to a helicopter rotor blade simulating transparent ice structureand an integration method. The helicopter rotor blade simulating transparent ice structure is made of a light high-strength foam material. The material compressing strength under the normal temperature is no smaller than 2.5 MPa, the shearing strength is no smaller than 1.5 MPa, and the foam density is between 70 kg / m3 and 200 kg / m3. The light high-strength foam material is formed into the bladesimulating transparent ice structure. The shape of the inner surface is consistent with that of a blade surface simulating transparent ice area. The shape of the outer surface is obtained by means offlow field analysis and calculation under the specific icing condition or from the ice wind tunnel test of the ice type. The blade simulating transparent ice structure is bonded to the blade surface simulating transparent ice area. By means of the technology, material selecting and manufacturing of the simulating ice type and transparent ice type structure can be achieved, and the structure is integrated with a helicopter rotor blade, and used for simulating icing flight test check of the helicopter rotor blade under the dry air condition.

Owner:HARBIN

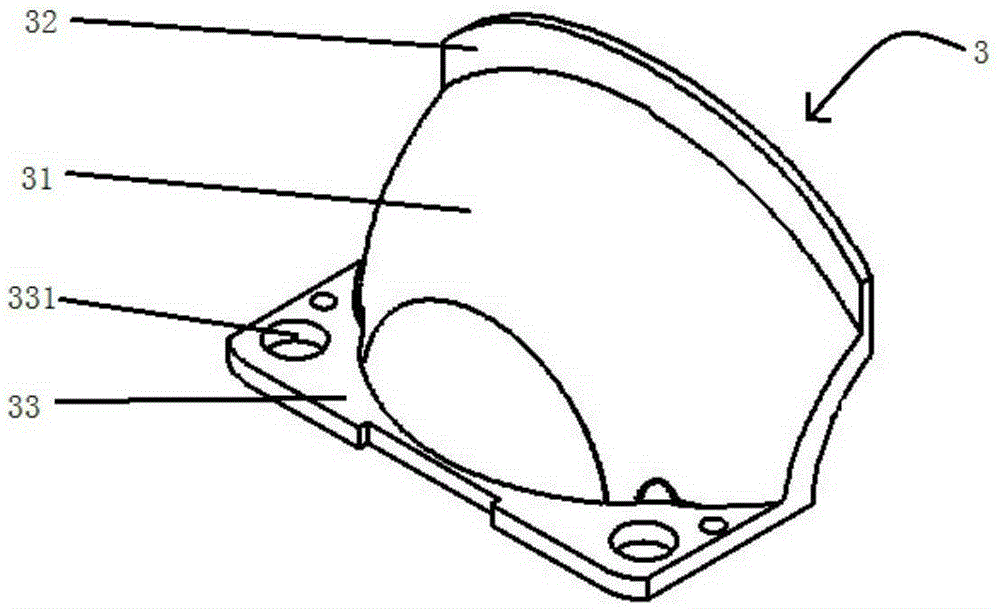

Reflector of electric bicycle lamp module

InactiveCN105258075AEasy to process and shapeUniform light patternVehicle headlampsOptical signallingOptical pathEllipsoid

The invention provides a reflector of an electric bicycle lamp module. The reflector comprises a reflection cup which is of an ellipsoid shape; the bottom part of the reflection cup is provided with an opening; an arc cup opening at the light path outlet end of the reflection cup is provided with an outward-turned skirt border; the end, opposite to the light path outlet end, of the reflection cup extends toward the direction away from a light emergent end to form a second fixing plate; and threaded holes are formed in the second fixing plate in the thickness direction. Compared with the prior art, the reflector is advantaged in that the ellipsoid shaped reflection cup, namely the reflection face of the reflector is formed by a single ellipsoid face; the reflection cup can be easily machined and shaped by adopting the single curved face; and meanwhile, the light pattern which is formed through reflection of the ellipsoid face is uniform, so that the light emergent effect of the bicycle lamp is improved.

Owner:ANHUI ZHANLAN OPTOELECTRONICS TECH

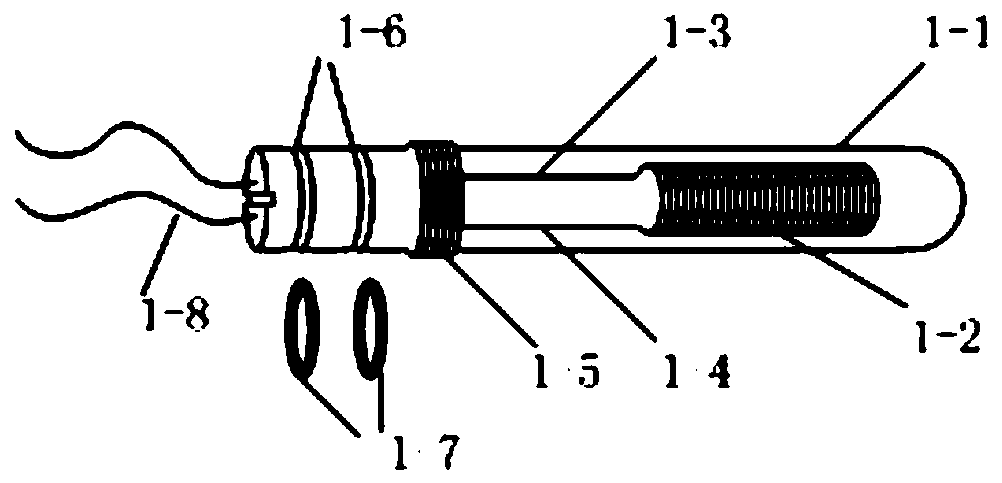

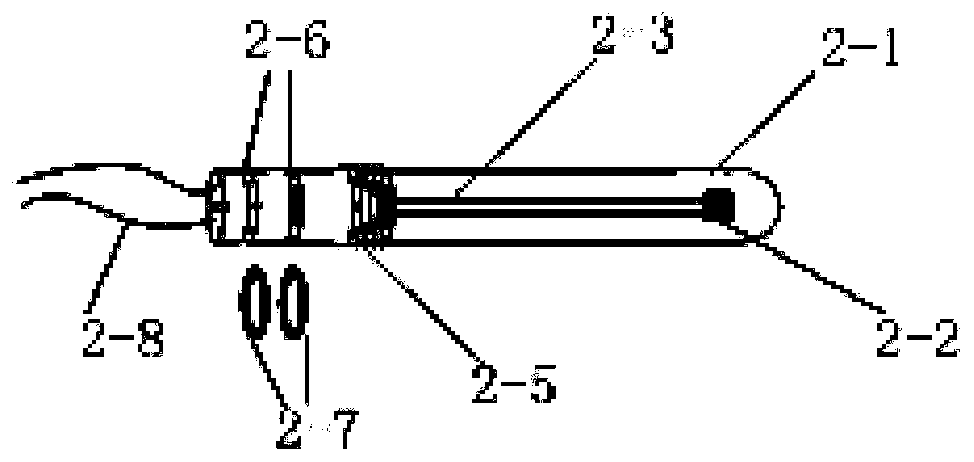

Manufacturing process of cheek-through type dental forceps

The invention discloses a manufacturing process of a pair of cheek-through type dental forceps. The manufacturing process includes the following steps: 1, acquiring a male sheet semi-finished product and a female sheet semi-finished product through casting; 2, using a sand skin to remove an oxide layer of a cheek portion of the male sheet semi-finished product; 3, high-frequency heating the female sheet semi-finished product to above 700 DEG C, opening two cheeks of the cheek portion of the female sheet semi-finished product to form an arc through hole, inserting the male sheet semi-finished product into the female sheet semi-finished product through the arc through hole, and aligning the cheek portions of the male sheet semi-finished product and the female sheet semi-finished product; 4, beating the female sheet semi-finished product, allowing the two cheeks of the female sheet semi-finished product to be closed and aligning heads of the two cheeks; 5, drilling a through hole in the center of the female sheet semi-finished product as a reference; 6, putting a circular bar in the through hole, beating two ends of the circular bar so as to fix two ends at the dental forceps, of the circular bar; 7, completely welding and fixing the two ends of the circular bar and the dental forceps together; 8, handle pattern rolling; and 9, polishing treatment. The beneficial effects of the invention are that the manufacturing process is simple and is low in cost; and the manufactured dental forceps are high in precision, are beautiful in appearance, are anti-corrosion, are high in strength, are easy to use, and are long in service life.

Owner:上海伟荣医疗器材有限公司

Transparent heat-insulating polystyrene composite material

InactiveCN106751081AImprove insulation effectImprove flame retardant performancePolyvinyl butyralCellulose

The invention discloses a transparent heat-insulating polystyrene composite material. The transparent heat-insulating polystyrene composite material comprises the following raw materials in parts by weight: 70 to 100 parts of polystyrene, 10 to 30 parts of polyterpene phenolic resin, 3 to 7 parts of K resin, 5 to 10 parts of polyvinyl butyral, 1 to 5 parts of tert-butyl peroxybenzoate, 1 to 3 parts of resorcinol bis(diphenyl phosphate), 5 to 10 parts of hydroxy propyl distarch phosphate, 1 to 3 parts of hydroxyl silicone oil, 0.5 to 2 parts of sodium polyacrylate, 100 to 200 parts of heat-insulating filler, 0.5 to 1.5 parts of an antioxidant and 0.5 to 1.5 parts of a light stabilizer; the heat-insulating filler comprises modified transparent powder, hollow nano-silicon dioxide microspheres and polyanionic cellulose which are in the mass ratio of 2-4:1-2:1. Through a plurality of experiments, the transparent heat-insulating polystyrene composite material has good heat insulating performance, simultaneously can maintain good fire resistance, transparency and corrosion resistance, and is convenient to process and plasticize; the application range of the heat-insulating material is further enlarged.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

Modification preparation method of bamboo aggregate and application thereof

ActiveCN113563000AEasy to prepareEasy to process and shapeSolid waste managementComposite materialCorrosion resistant

The invention discloses a modification preparation method of bamboo aggregate and an application thereof, moso bamboos are used as main raw materials, the moso bamboos are cut into bamboo particles, after vibration screening, the bamboo particles are prepared into the bamboo aggregate which can be applied to the field of buildings through treatment methods such as water boiling, water washing, soaking in a sodium alginate solution, soaking in a calcium chloride solution, drying and the like. The compressive strength of a concrete finished product prepared from the bamboo aggregate treated by the modification method is 10-20 times that of a bamboo particle concrete finished product prepared from untreated bamboo particles, and the concrete finished product has better anti-freezing and corrosion-resistant performance than the untreated bamboo particles; compared with common concrete, the bamboo aggregate has high porosity, can achieve good sound absorption and heat preservation effects, is 30-40% lighter than the common concrete due to the existence of the bamboo aggregate, is convenient to transport and assemble, and has high practical value.

Owner:绍兴华放新材料有限公司

Acrylonitrile-butadiene-styrene copolymer based heat-insulation composite material

InactiveCN106832737AGood heat insulationImprove flame retardant performancePlastic/resin/waxes insulatorsSilanesAntioxidant

The invention relates to an acrylonitrile-butadiene-styrene copolymer based heat-insulation composite material, which is prepared from the following raw materials in parts by weight: 50 to 70 parts of acrylonitrile-butadiene-styrene copolymer, 10 to 20 parts of diallyl phthalate, 10 to 20 parts of triallyl isocyanurate, 5 to 15 parts of vinyltrib (beta-methoxyethoxy) silane, 3 to 8 parts of styrene-maleic anhydride copolymer, 1 to 5 parts of diallyl phthalate, 1 to 3 parts of hydroxyl silicone oil, 2 to 4 parts of fluorine diol, 0.5 to 2 parts of sodium polyacrylate, 2 to 6 parts of tert-butyl peroxybenzoate, 2 to 5 parts of resorcinol (bis-diphenyl) phosphate, 40 to 60 parts of heat-insulation filler, and 0.5 to 1.5 parts of antioxidant. The invention relates to the acrylonitrile-butadiene-styrene copolymer based heat-insulation composite material with a favorable heat-insulation performance, and better fire resistance, insulativity and corrosion resistance obtained through multiple experiments, the material can be processed and shaped conveniently, a favorable machinable property of ABS is maintained, and the application range of an ABS material is further expanded.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

Shielding layer manufactured by copper-clad plate

PendingCN108335884AFlexible designEasy to process and shapeMagnetic/electric field screeningTransformers/inductances coils/windings/connectionsCopper coatingCopper plating

The invention discloses a shielding layer manufactured by a copper-clad plate. The shielding layer comprises an insulating layer and copper coatings, wherein the copper coatings include a first coppercoating and a second copper coating; the first copper coating is arranged on one side of the insulating layer, and the second copper coating is arranged on the other side of the insulating layer; thesecond copper coating is positioned at one end on the other side of the insulating layer; a plurality of soldering round holes used for soldering fixation are formed in the other end of the second copper coating on the insulating layer; an insulating position is arranged between the first copper coating and the edge of the insulating layer. The shielding layer disclosed by the invention has the beneficial effects that the copper coatings are arranged on the insulating layer, so that the insulating layer is flexible in design and can be simply processed and formed, and plated with copper on the surfaces to serve as the shielding layer; meanwhile, the two sides can be freely plated with copper, so that the two sides are not connected with each other, and after the shielding layer is rounded, the insulating layer is capable of effectively partitioning circuits at two ends; the shielding layer does not form a loop at the joint, the joint structure is simple, and the soldering round holescan be fixedly soldered by virtue of soldering, so that the joint process is simple.

Owner:KELAN TECHNICS ENVIRONMENTAL PROD CO LTD

PVC separation wall composite board and preparation method thereof

The invention discloses a formula of a PVC separation wall composite board which comprises at least following ingredients: PVC resin, nano-calcium, calcium carbonate, an impact modifier, a calcium-zinc stabilizer, paraffin and stearic acid, and the weight ratio of the ingredients according to the formula is (30-70):(0-70):(0-70):(3-9):(1-5):(1-2):(1-6). According to the PVC separation wall composite board, the PVC main raw material is used, the material is easy to process and shape, the manufacturing cost is low, at the same time, the nano-calcium and / or calcium carbonate are / is added in the PVC main raw material, not only is the product volume increased, but also the cost is reduced; meanwhile, the impact modifier, the calcium-zinc stabilizer, the paraffin and the stearic acid are added to regulate the performance of the composite board, and the mechanical performance, the stability and the demolding effect of the composite board are enhanced; the preparation method of the composite board and the formula are in mutual combination in the production process, the production processes are regulated, no environment pollution is produced while the production efficiency is improved, andthe product yield is controlled.

Owner:浙江雄冉装饰材料有限公司

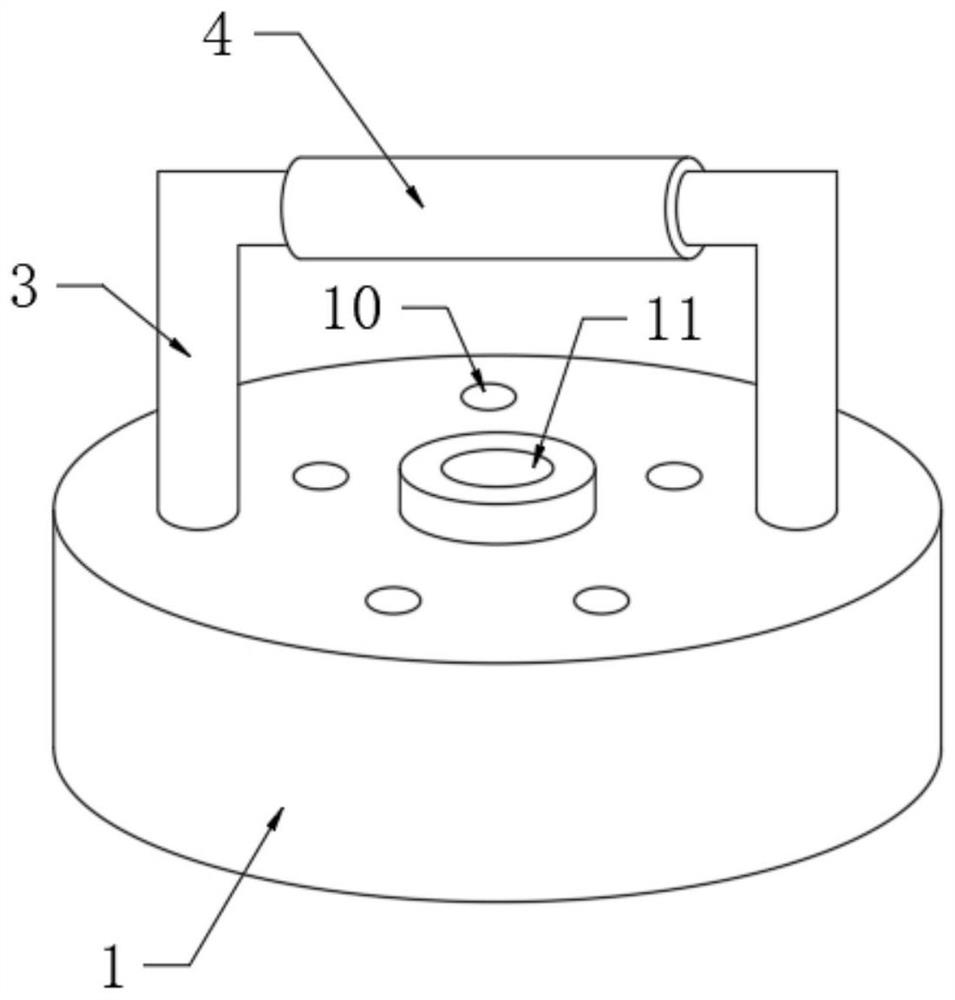

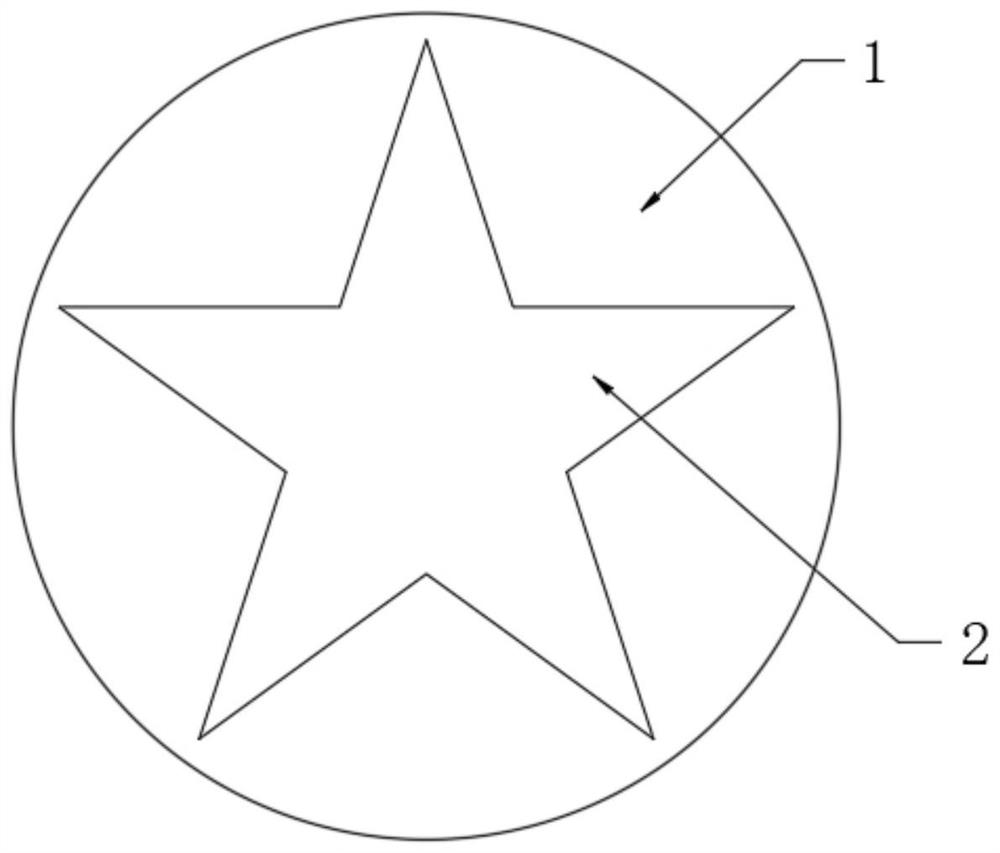

Food forming device and forming method

The invention provides a food forming device and a forming method. The food forming device comprises a forming base, a forming groove is formed in the forming base, the forming groove is arranged to be pentagonal, mold unloading plates are slidably installed in the forming groove, a first mold unloading rod and second mold unloading rods are installed on one sides of the mold unloading plates, the mold unloading plates are installed at one end of the first mold unloading rod and one end of each second mold unloading rod, a handle is installed on one side of the forming base, and a number of second mold unloading rods correspond to pentagons of the mold unloading plates in a one-to-one mode. According to the invention, the first mold unloading rod and second mold unloading rods are installed on one sides of the mold unloading plates, the second mold unloading rods correspond to the pentagons of the mold unloading plates in a one-to-one mode, one side of each mold unloading plate can bear uniform thrust, the mold unloading plates can be conveniently and stably pushed out relative to the forming groove for mold unloading, food forming incompleteness caused by uneven thrust borne by the mold unloading plates during mold unloading is prevented, the yield is increased, and mold unloading is convenient and fast.

Owner:苏州得一鲜食品科技有限公司

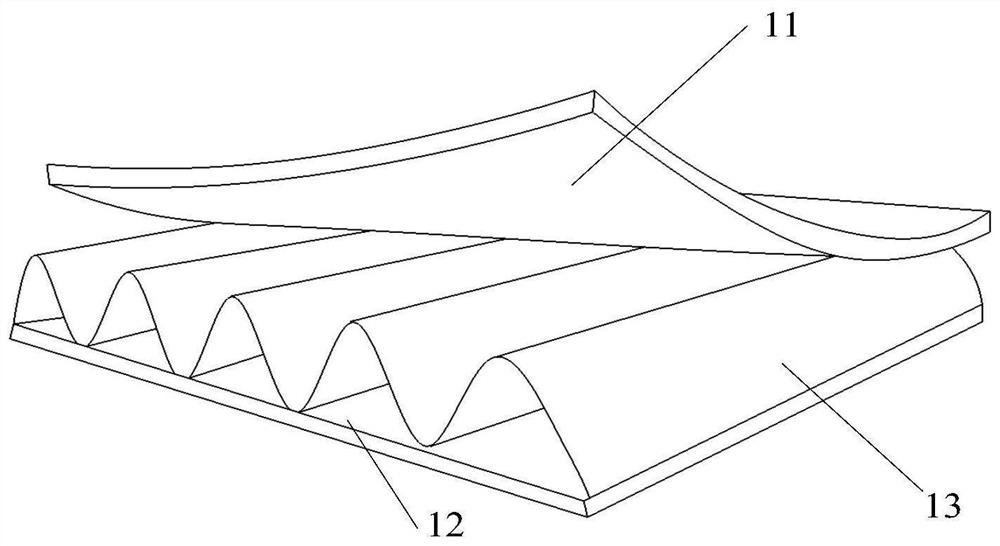

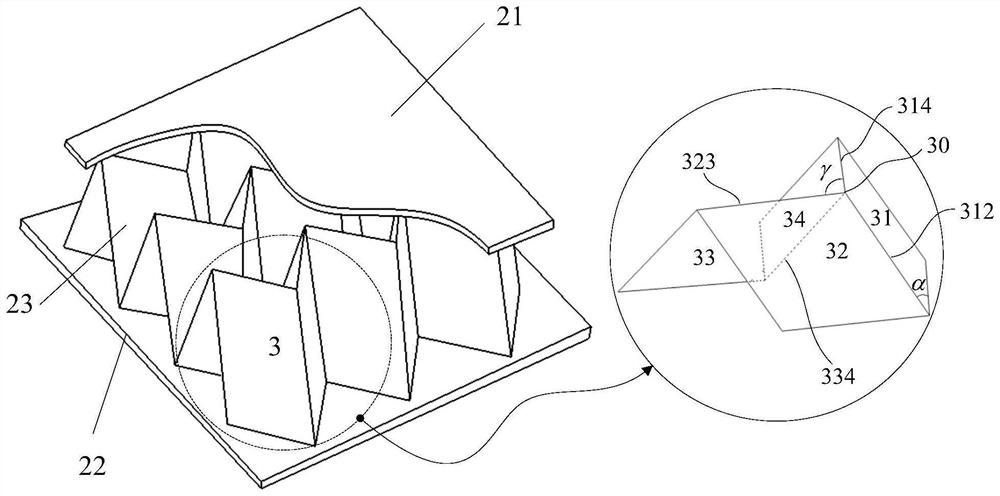

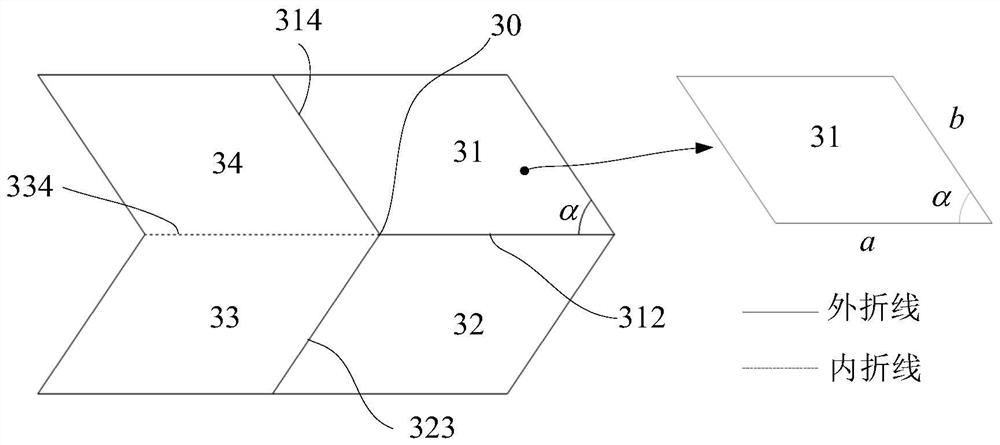

Manufacturing method for paper buffer type board with bidirectional corrugated structure sandwich layer

PendingCN113910688AEasy to process and shapeWide range of altitudeMechanical working/deformationTotal thicknessCorrugated fiberboard

The invention discloses a manufacturing method for a paper buffer type board with a bidirectional corrugated sandwich layer. The manufacturing method comprises the steps that a flat-plate-shaped upper panel and a flat-plate-shape lower panel are manufactured; a cell paperboard composed of a plurality of cell plane structures is manufactured, and the multiple cell plane structures are connected and arranged on the same paperboard in a close array mode; each cell plane structure is mainly formed by connecting four identical parallelogram boards which are arranged in a shape like a Chinese character 'tian' through folding lines, and the cell paperboard is folded through folding lines of the cell paperboard to form the sandwich layer formed by a plurality of cell three-dimensional structures; and the sandwich layer is bonded with the upper panel and the lower panel correspondingly to form the paper buffer type board. The manufactured board is easy to process and form, the structural height change range is wide, and the problem that the thickness of a single corrugated board is limited is solved; and the unit mass bearing capacity and the buffering energy absorption characteristic are excellent, and the mechanical property is synchronously improved on the premise that the total thickness of the sandwich board is increased.

Owner:ZHEJIANG SCI-TECH UNIV +1

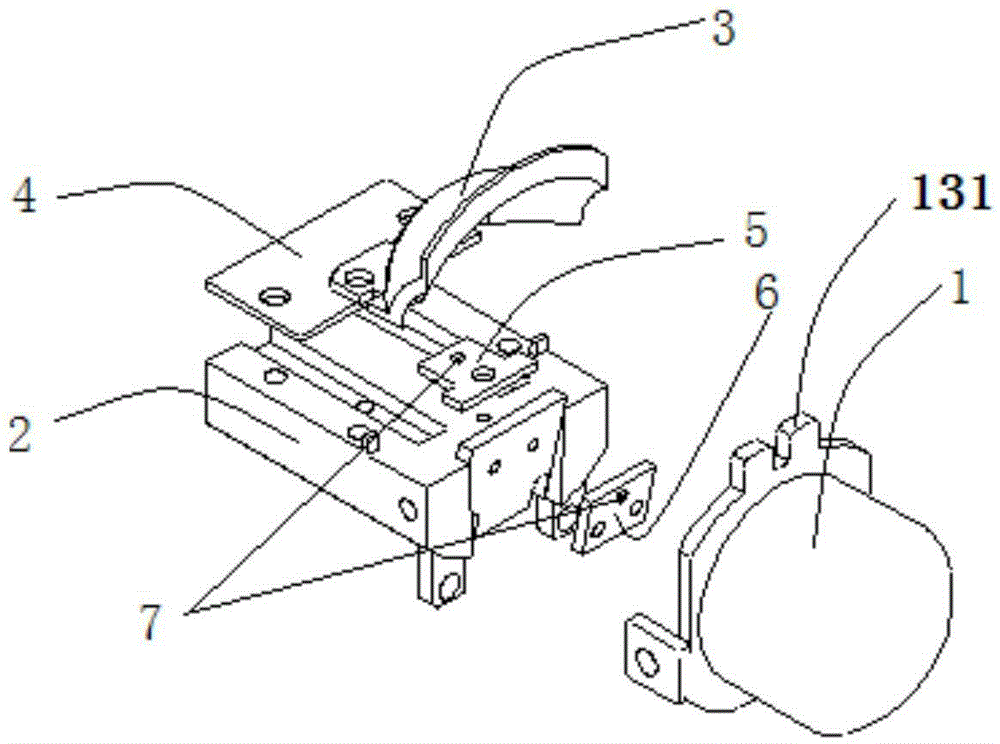

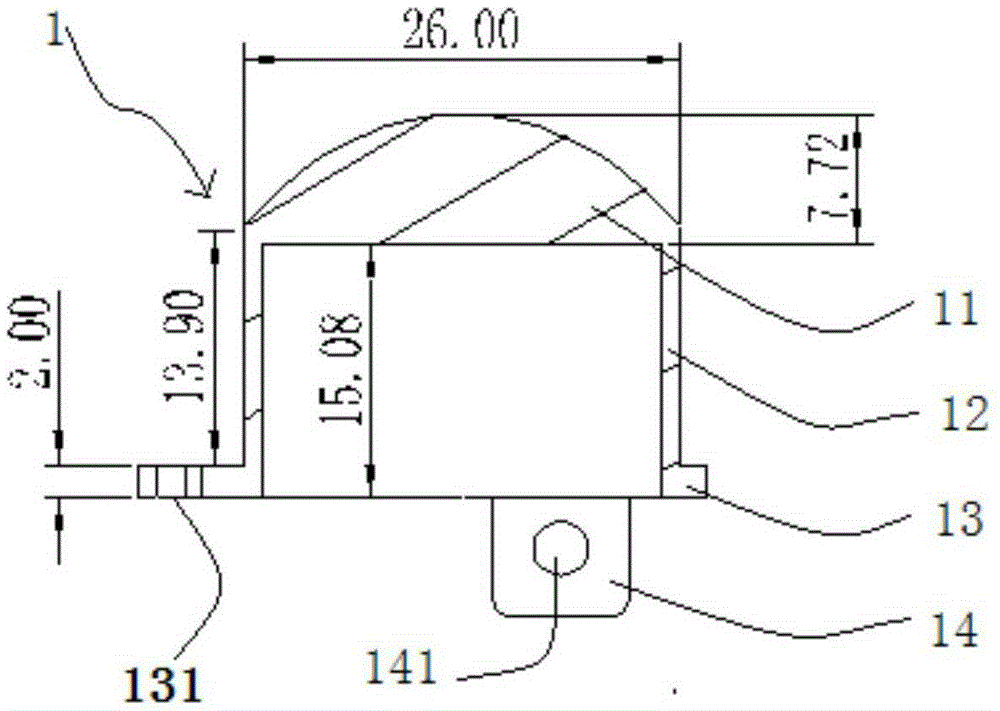

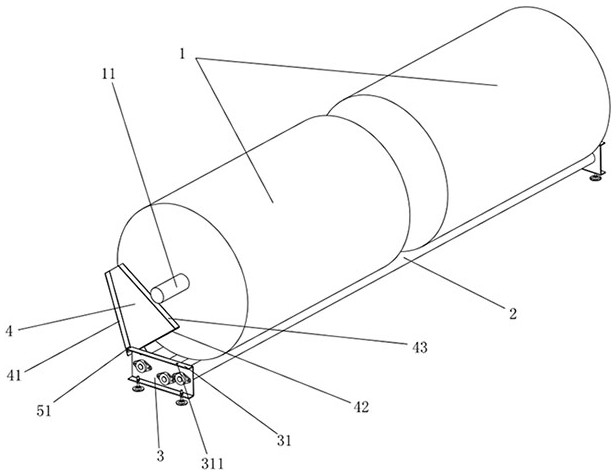

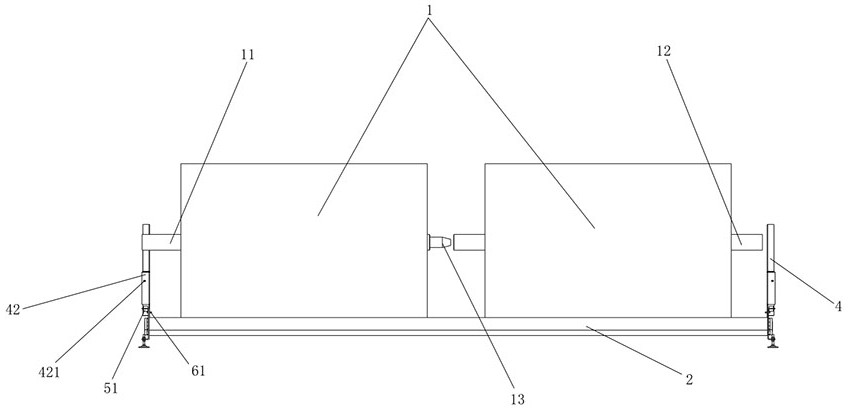

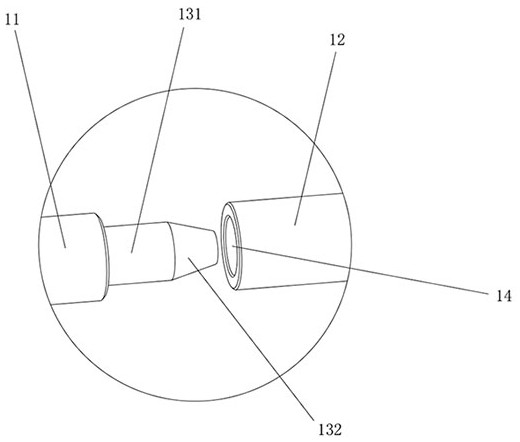

Shaft unloading device for coiling mechanism of double-needle-bar double-width warp knitting machine

ActiveCN114108176AEasy to process and shapeConvenient shaft unloadingWarp knittingStructural engineeringMechanical engineering

The invention relates to the technical field of shaft unloading devices, in particular to a shaft unloading device for a coiling mechanism of a double-needle-bar double-width warp knitting machine. A shaft unloading device for a coiling mechanism of a double-needle-bar double-width warp knitting machine comprises a coiling machine, a first cloth rolling shaft and a second cloth rolling shaft, a positioning rod is arranged at one end of the first cloth rolling shaft, a positioning hole matched with the positioning rod is formed in one end of the second cloth rolling shaft, a baffle is rotationally connected to a side plate of the coiling machine, a supporting plate is arranged above the side plate, and a clamping groove is formed in the side plate. The baffle comprises a main plate, a limiting plate corresponding to the side plate is arranged on one side of the main plate, a positioning rotating plate is arranged on the side, close to the limiting plate, of the bottom of the main plate, and a movable bottom plate corresponding to the supporting plate is arranged on the side, away from the limiting plate, of the bottom of the main plate. According to the shaft unloading device, shaft unloading operation can be conveniently carried out, the shaft unloading efficiency is high, the burden of workers can be relieved, and therefore the benefits of enterprises are guaranteed.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com