High-precision low-flow detection device based on constant power

A technology of constant power and detection device, applied in measurement device, liquid/fluid solid measurement, volume change compensation/correction device, etc., can solve the problems of large dispersion, formation water pollution, and inability to meet the production needs of low permeability wells, etc. To achieve the effect of convenient processing and molding, easy maintenance and replacement, excellent thermal conductivity and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in further detail below in conjunction with accompanying drawing:

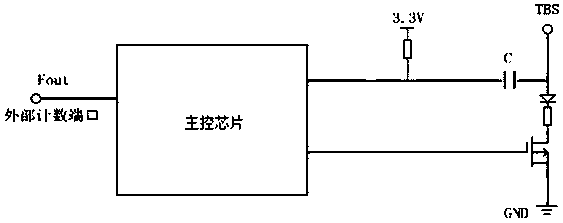

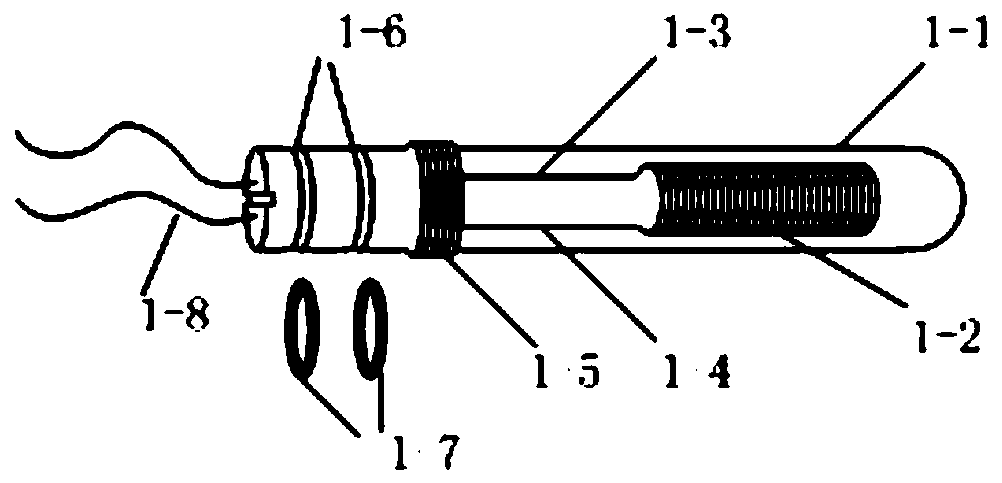

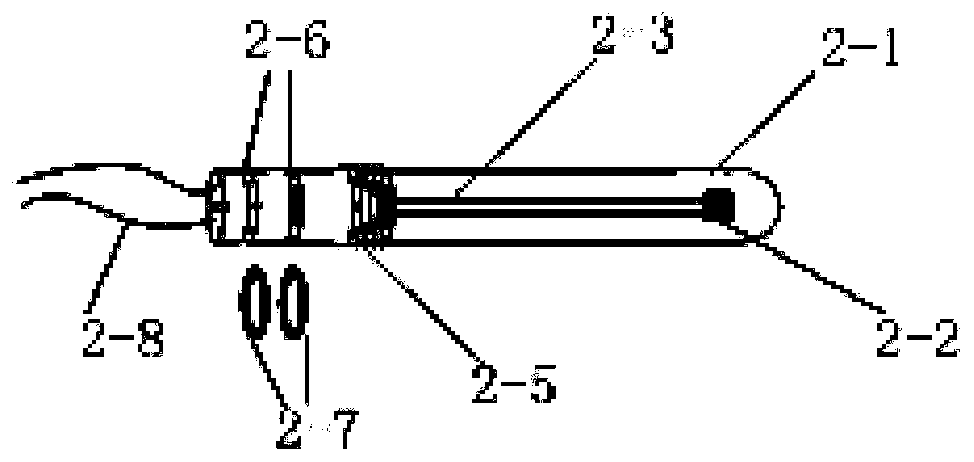

[0043] Such as Figure 1-8 , the high-precision low-flow detection device based on constant power disclosed by the present invention includes a constant power heating element 1, a temperature sensing element 2, an integrated functional module, a circuit mounting shell 5, and a flow sensor mounting shell 6; the constant power heating element 1 and the temperature sensing body 2 are installed on the flow sensor installation housing 6, one end of the flow sensor installation housing 6 is sealed, and the other end is connected to the integrated function module, and the integrated function module is installed inside the circuit installation housing 5 of one end of the hollow cylinder structure , the other end of the circuit installation shell 5 is sealed;

[0044]The flow sensor installation housing 6 is a cylindrical structure with a hollow section in the middle. The two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com