Yttrium aluminum garnet fluorescent glass, manufacturing method thereof and use thereof

A technology of yttrium aluminum garnet and fluorescent glass is applied in lighting and heating equipment, optical elements for changing the spectral characteristics of emitted light, lighting devices, etc. Consistency and product yield, stable performance, easy to process and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

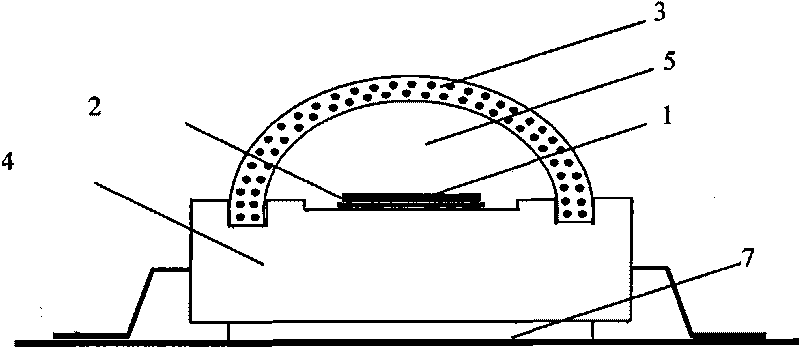

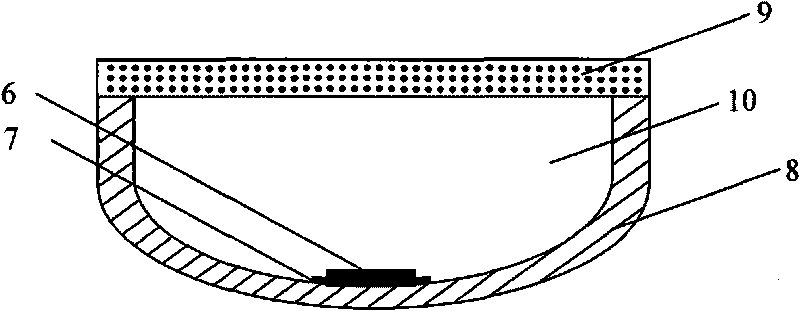

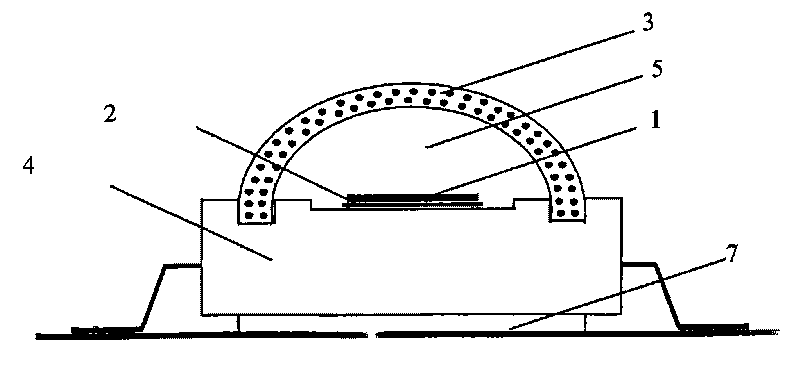

Image

Examples

Embodiment 1

[0025] According to the formula of the initial material of the glass matrix, weigh the required drug powder, namely BaCO 3 (1g), Na 2 CO 3 (0.4g), H 3 BO 3 (0.9g), SiO 2 (0.3g), Al 2 o 3 (0.56g), YAG (0.83g), the weighed glass matrix initial material was ground with a mortar to make it evenly mixed. Put the ground mixed material into the corundum crucible, add the crucible cover, and put it into the atmosphere protection resistance furnace. Calcined at 1300°C for 4 hours, annealed at 500°C after casting, cut, polished, and polished into YAG fluorescent glass flakes, the glass matrix is: BaO-Na 2 O-B 2 o 3 -SiO 2 -Al 2 o 3 , for white LED packaging.

Embodiment 2

[0027] According to the formula of the initial material of the glass matrix, weigh the required drug powder, namely BaCO 3 (1g), Na 2 CO 3 (0.4g), H 3 BO 3 (0.9g), SiO 2 (0.3g), Al 2 o 3 (0.56g), Y 3-X Ge X Al 5 o 12 : Ce (0.83g), the weighed glass matrix initial material is ground with a mortar to make it evenly mixed. Put the ground mixed material into the corundum crucible, add the crucible cover, and put it into the atmosphere protection resistance furnace. Calcined at 1300°C for 4 hours, annealed at 500°C after casting, cut, polished, and polished into YAG fluorescent glass flakes, the glass matrix is: BaO-Na 2 O-B 2 o 3 -SiO 2 -Al 2 o 3 , for low color temperature white LED packaging.

Embodiment 3

[0029] According to the formula of the initial material of the glass matrix, weigh the required drug powder, namely BaCO 3 (1g), Na 2 CO 3 (0.4g), H 3 BO 3 (0.8g), SiO 2 (0.3g), Al 2 o 3 (0.65g), YAG (0.83g), grind the weighed glass matrix initial material with a mortar and mix it evenly. Put the ground mixed material into the corundum crucible and put it into a high temperature resistance furnace. Calcined at 1400°C for 4 hours, annealed at 500°C after casting, cut, polished, and polished into YAG fluorescent glass flakes, the glass matrix is: BaO-Na 2 O-B 2 o 3 -SiO 2 -Al 2 o 3 , for white LED packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com