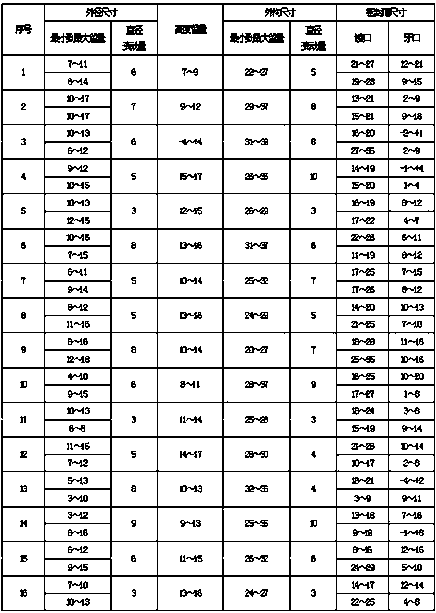

Patents

Literature

42results about How to "Good heat treatment performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

P110 steel level high frequency straight welded pipe manufacturing method

InactiveCN102430901AImprove toughnessImprove resistance to delayed crackingFurnace typesHeat treatment furnacesMedium frequencyEngineering

A P110 steel level high frequency straight welded pipe manufacturing method comprises (1) taking hot-rolled coil as raw material; (2) shaping the coil into a straight seam pipe by continuous shaping techniques, welding the straight seam on the pipe by a high frequency inductive welding machine to produce a primary pipe, and after the welding, timely removing external and internal burrs of the primary pipe; (3) heating the primary pipe removed of burrs by a medium frequency induction furnace to 920-950 degrees centigrade and conveying it to a hot rolling and diameter reducing machine, rolling the primary pipe into pipe blanks with different apertures by hot mechanical rolling; (4) conducting whole-pipe quenching and tempering to the hot roller pipe blank to produce finished pipe; (5) conducting ultrasonic flaw detection and pipe end magnetic powder inspection to the finished pipe. The invention takes low steel level coil as raw material to produce primary pipe, produces pipe blanks with different diameter specifications by the primary pipe with the same specification, and produces oil casing product with high steel level and high performance by low steel level economical pipe blanks. The working efficiency is high. The production cost is low.

Owner:BAOJI PETROLEUM STEEL PIPE

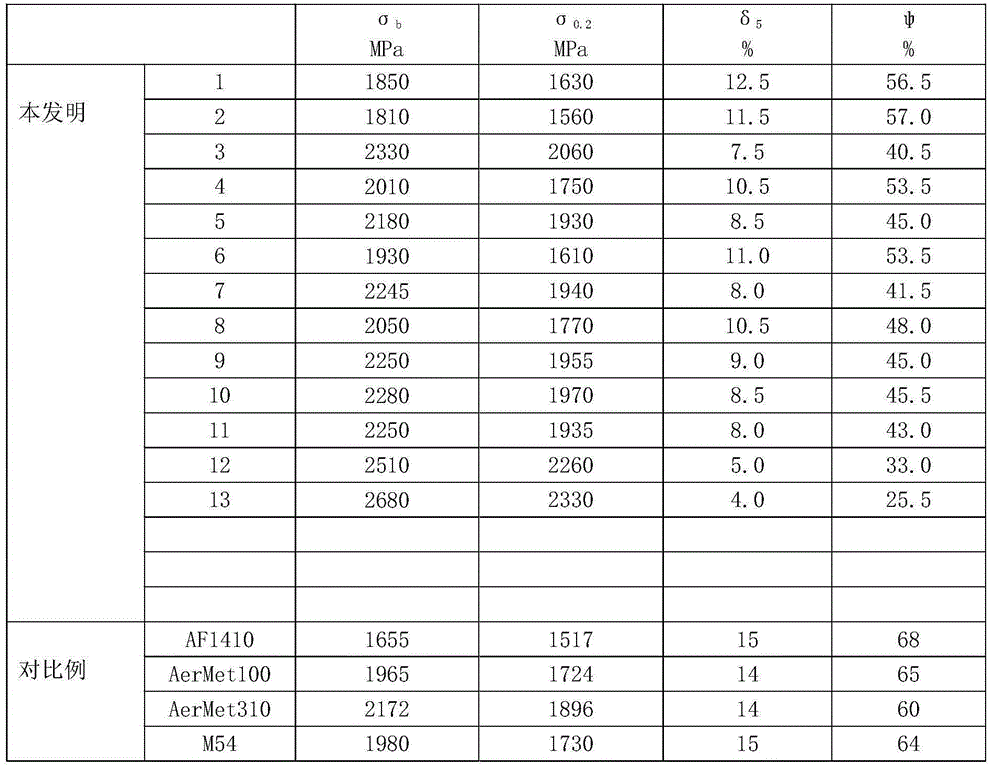

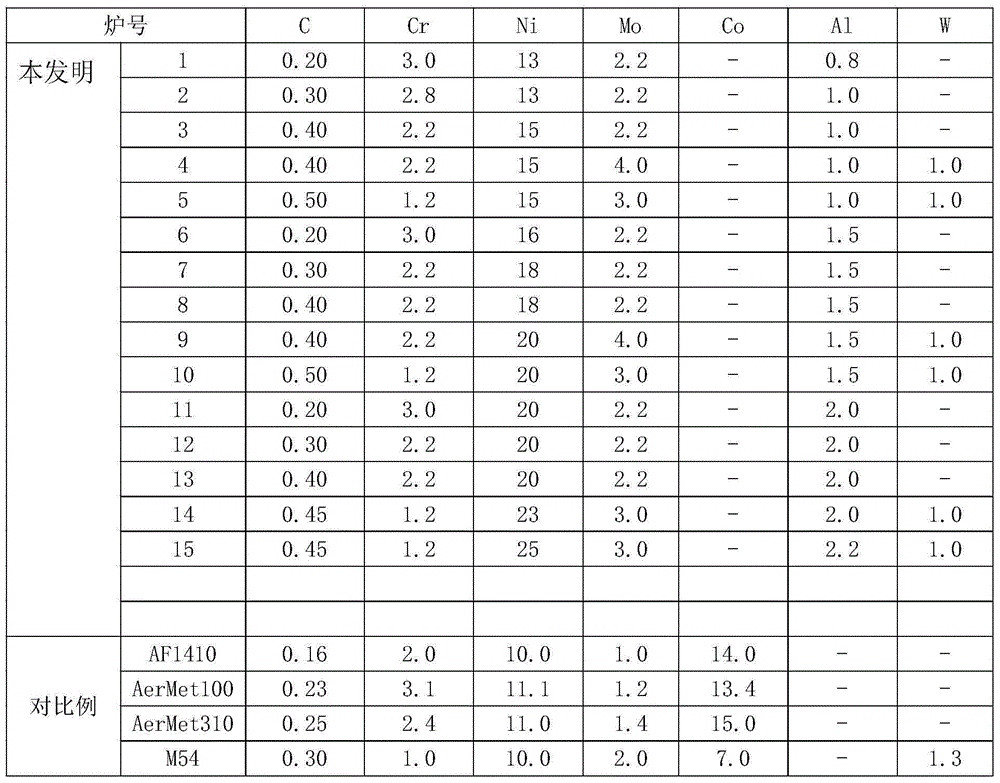

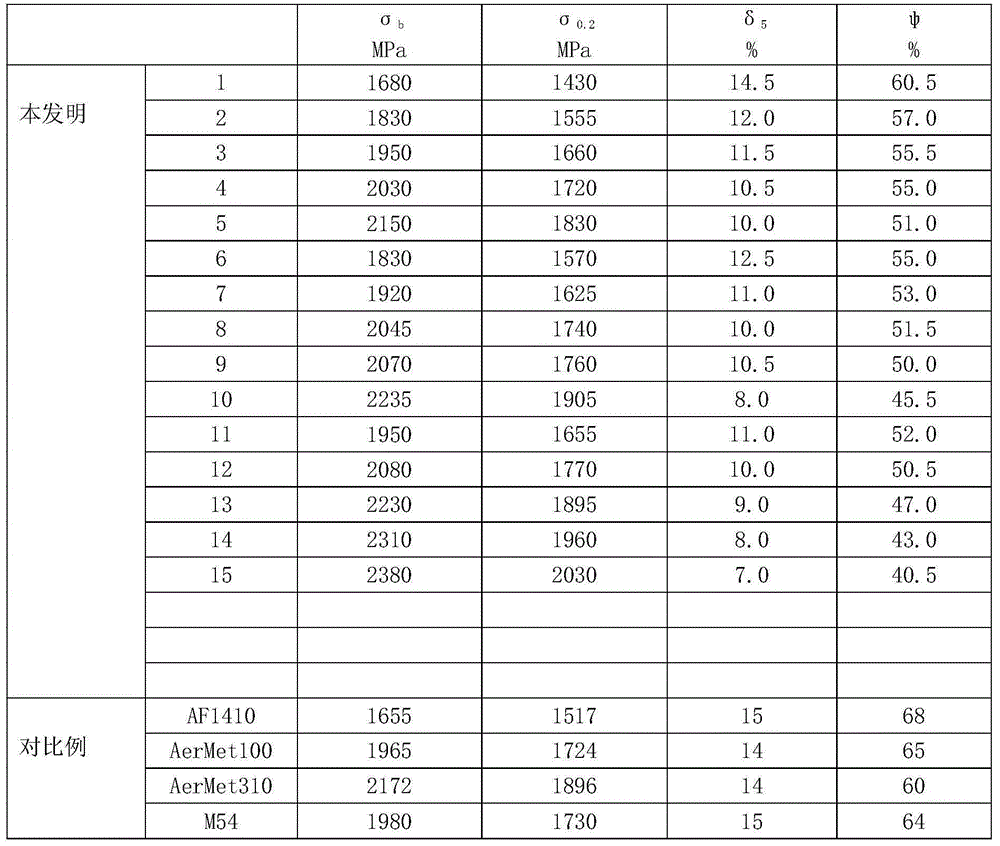

Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel and preparation method thereof

ActiveCN104911499ASave Co element contentImprove performanceChemical compositionUltimate tensile strength

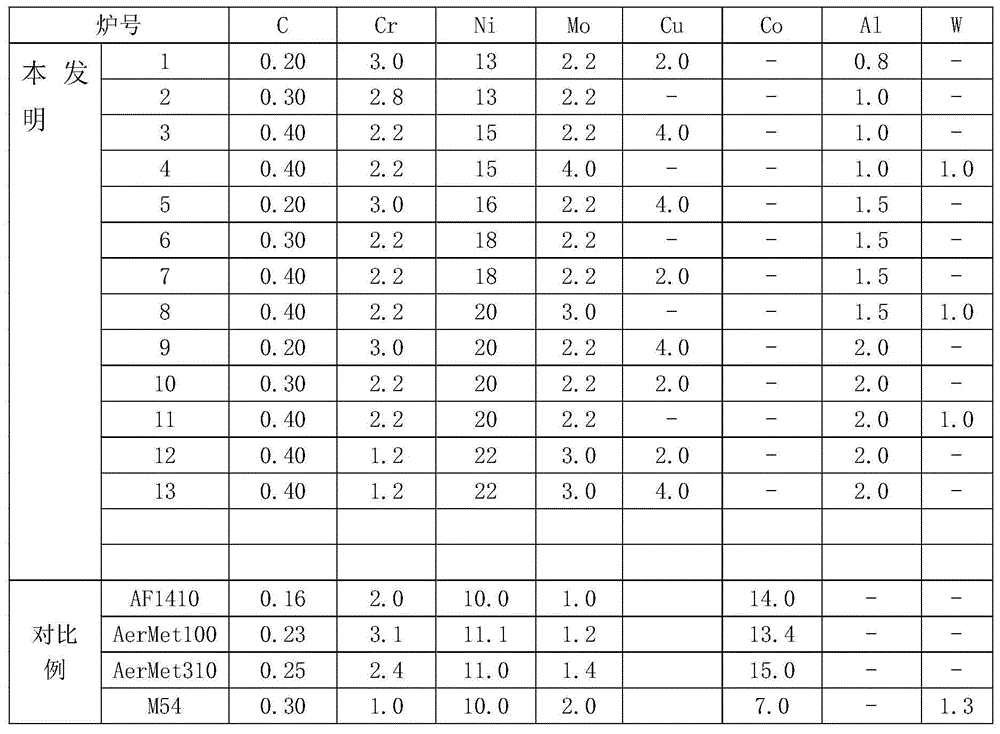

The invention discloses Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel and a preparation method, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.20-0.50% of C, 1.0-5.0% of Cr, 8.0-30.0% of Ni, 1.0-5.0% of Mo, 1.0-5.0% of Cu, 0-3.0% of Al, 0-2.0% of W, less than or equal to 0.30% of V, less than or equal to 0.20% of Nb and the balance of Fe and unavoidable impurities. According to the preparation method, the vacuum induction and vacuum consumable remelting technology or the vacuum induction and electroslag remelting technology can be adopted. Compared with the prior art, the Cu-reinforced Co-free secondary-hardening ultrahigh-strength steel has the advantages of good comprehensive performance, higher strength, good plasticity and toughness, good heat treatment process performance and higher tempering resistance and overaging resistance; the content of strategic resource Co element is saved and the economical efficiency is remarkably improved.

Owner:CENT IRON & STEEL RES INST

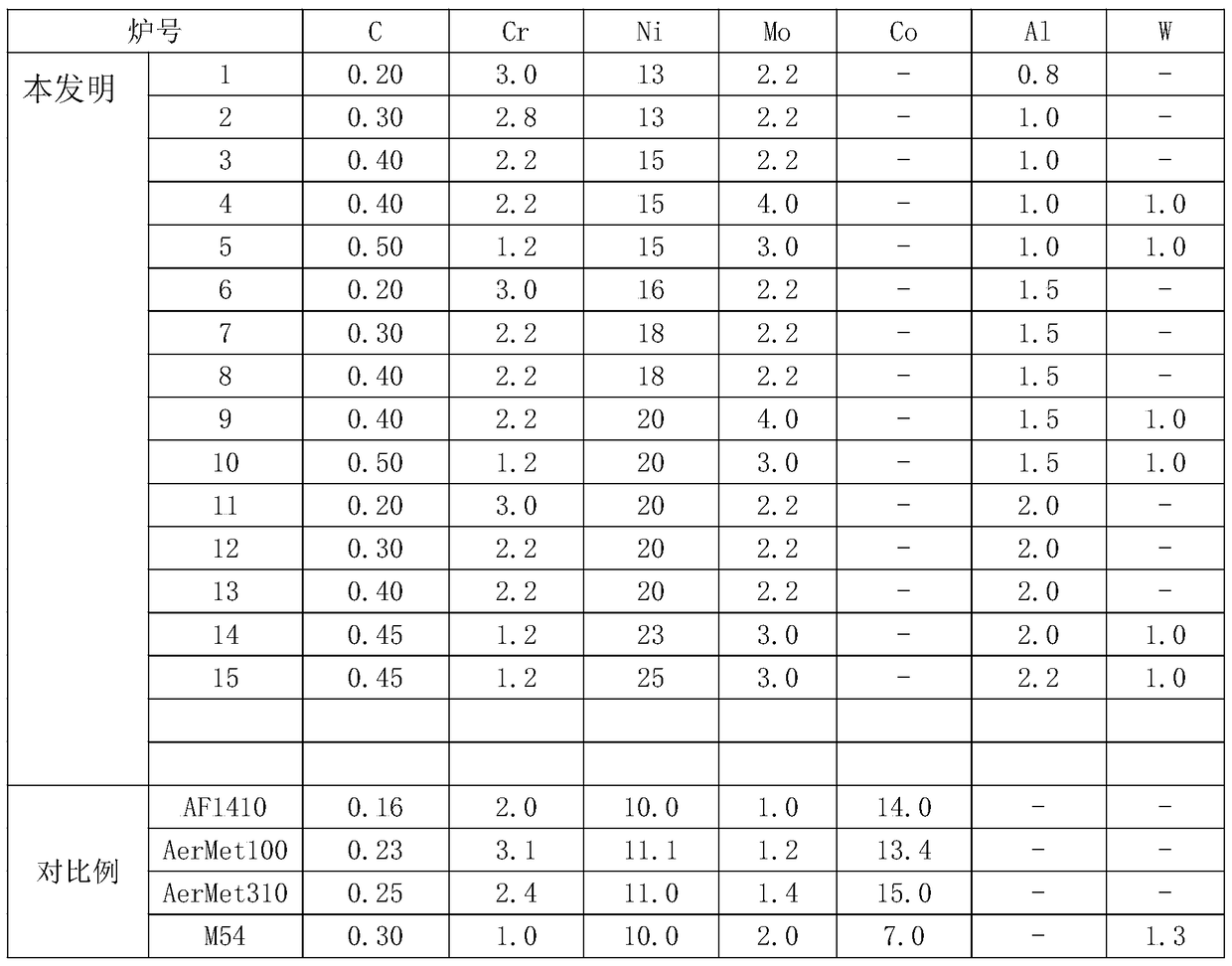

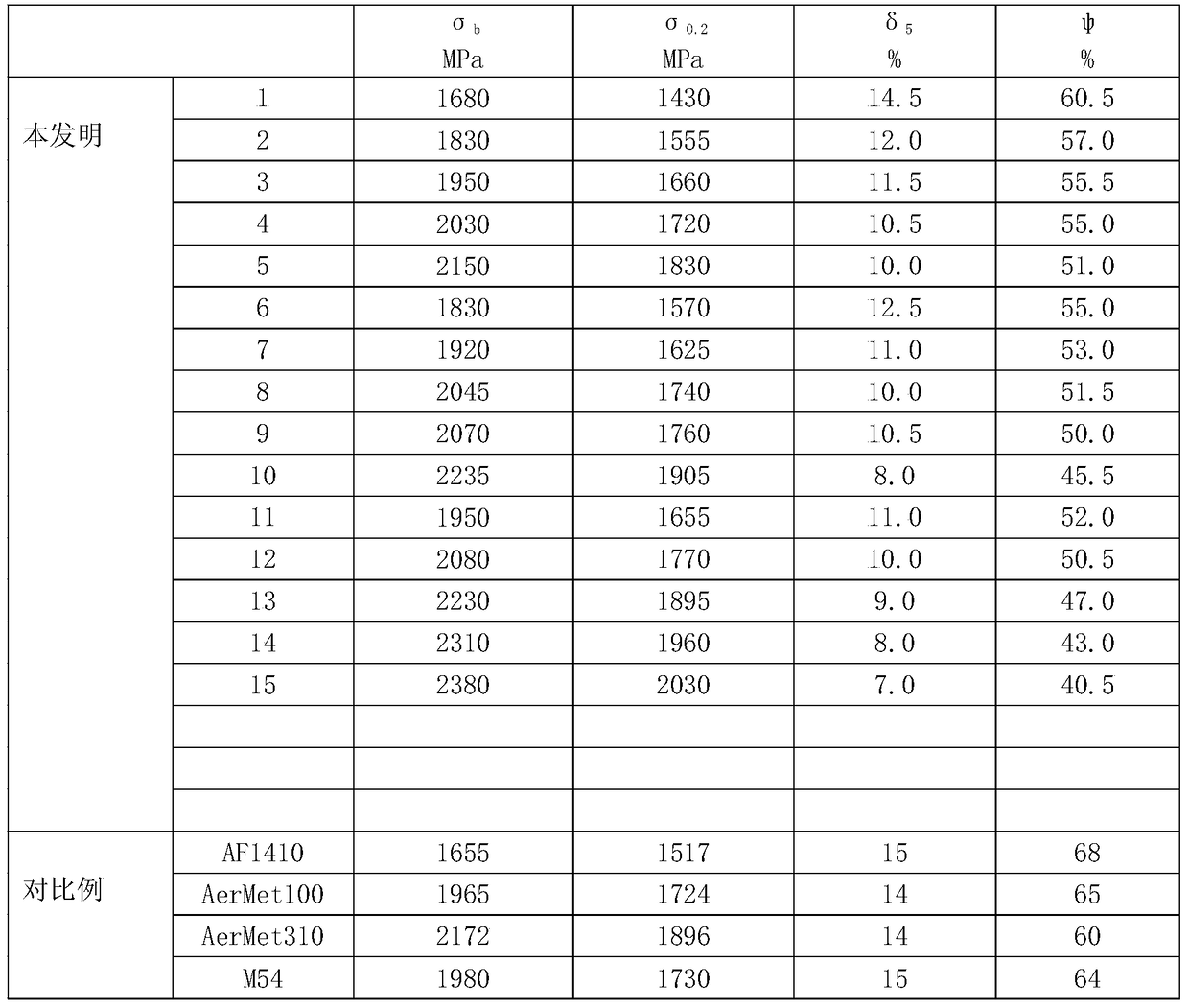

Co-free composite reinforced secondary hardening ultrahigh-strength steel and preparing method

The invention discloses Co-free composite reinforced secondary hardening ultrahigh-strength steel and a preparing method and belongs to the technical field of alloy steel. The Co-free composite reinforced secondary hardening ultrahigh-strength steel comprises, by weight, 0.20-0.50% of C, 1.0-5.0% of Cr, 10.0-30.0% of Ni, 0.50-3.0% of Al, 1.0-5.0% of Mo, 2.0% of W or less, 0.30% of V or less, 0.20% of Nb or less, and the balance Fe and unavoidable impurities. The vacuum induction technology, the vacuum arc remelting or vacuum induction technology and the electroslag remelting technology can be adopted in the alloy. Compared with the prior art, the Co-free composite reinforced secondary hardening ultrahigh-strength steel has the beneficial effects that the comprehensive performance is good, ultrahigh strength and good ductility and toughness are achieved, the heat treatment technology is superior in performance, high temper resistance and overaging resisting capability are achieved, the content of the strategic resource of the Co element is saved, and the economical efficiency is improved.

Owner:CENT IRON & STEEL RES INST

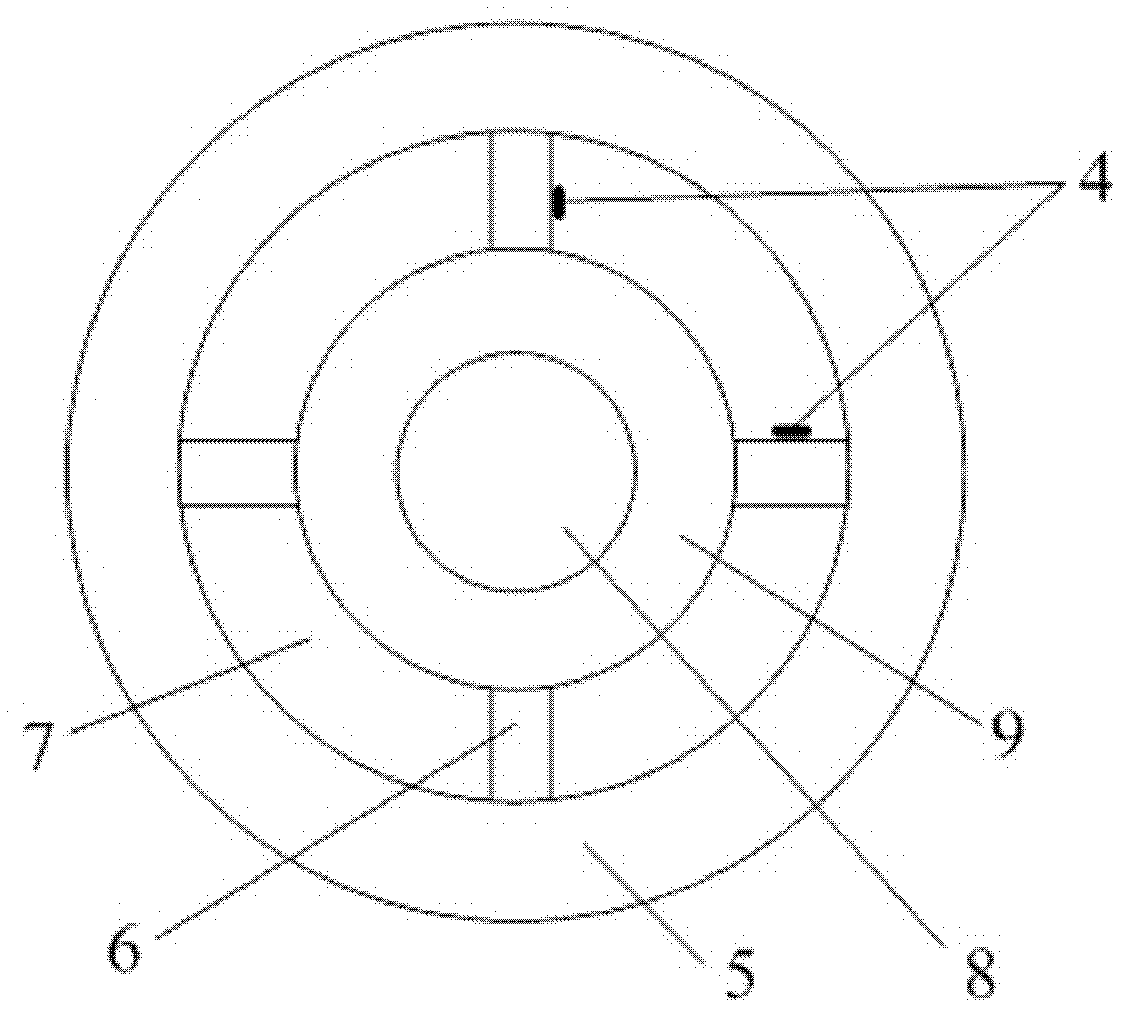

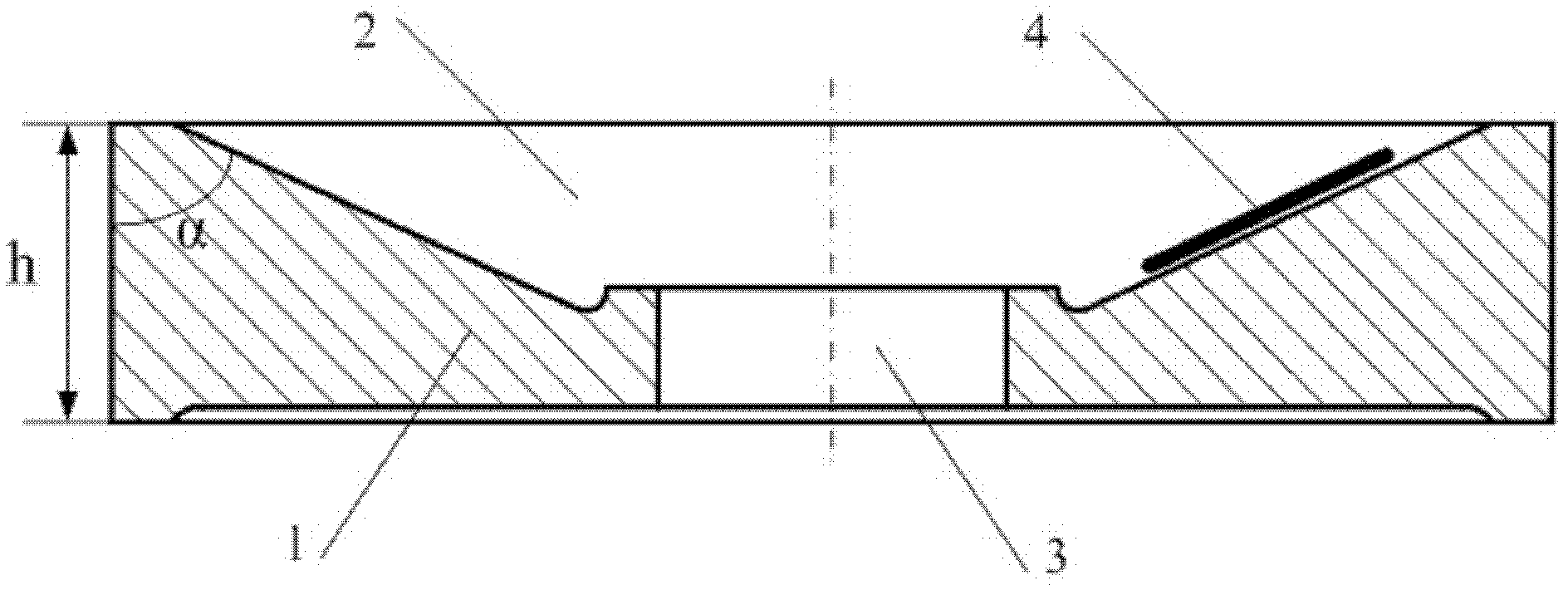

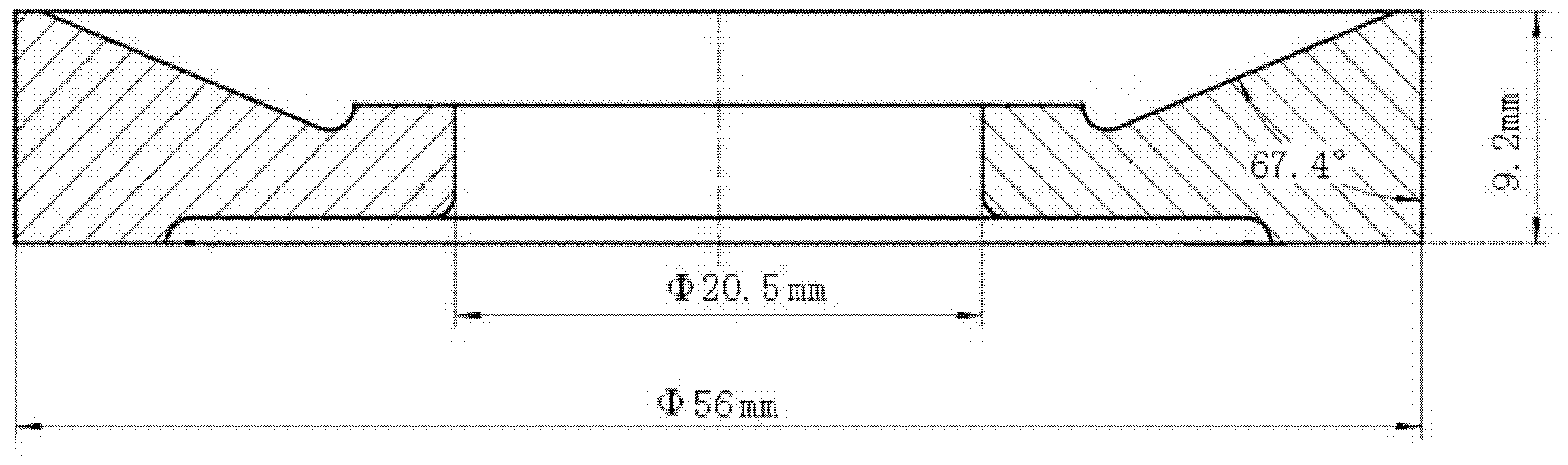

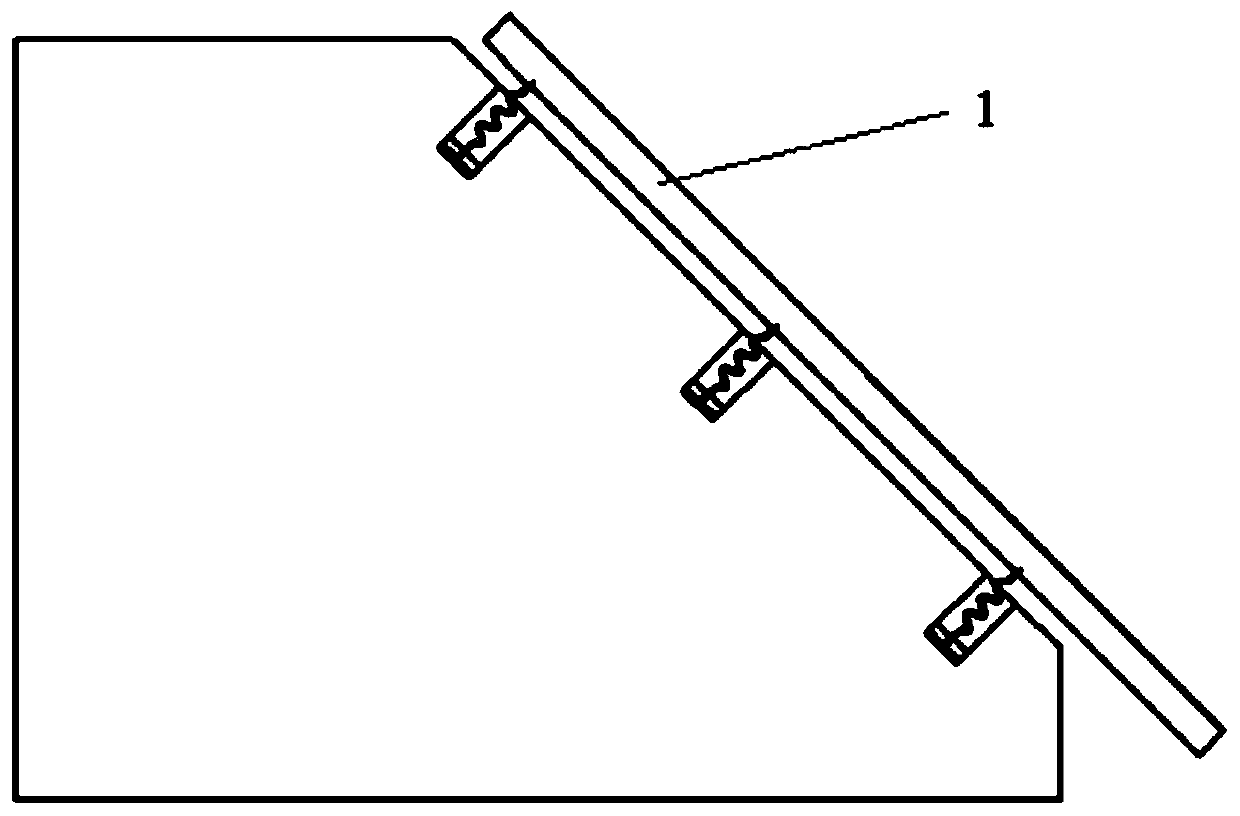

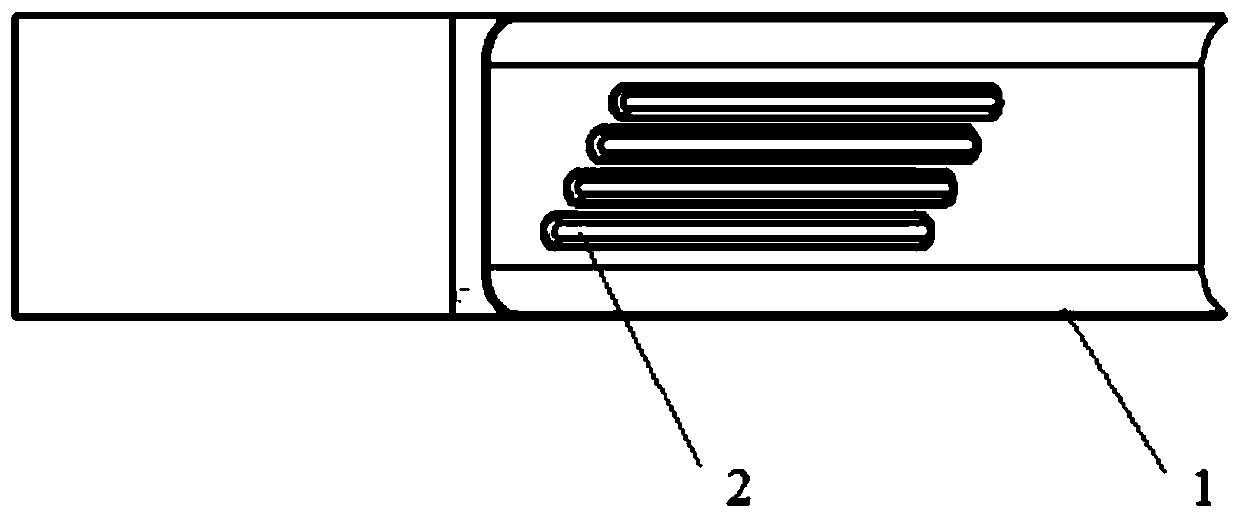

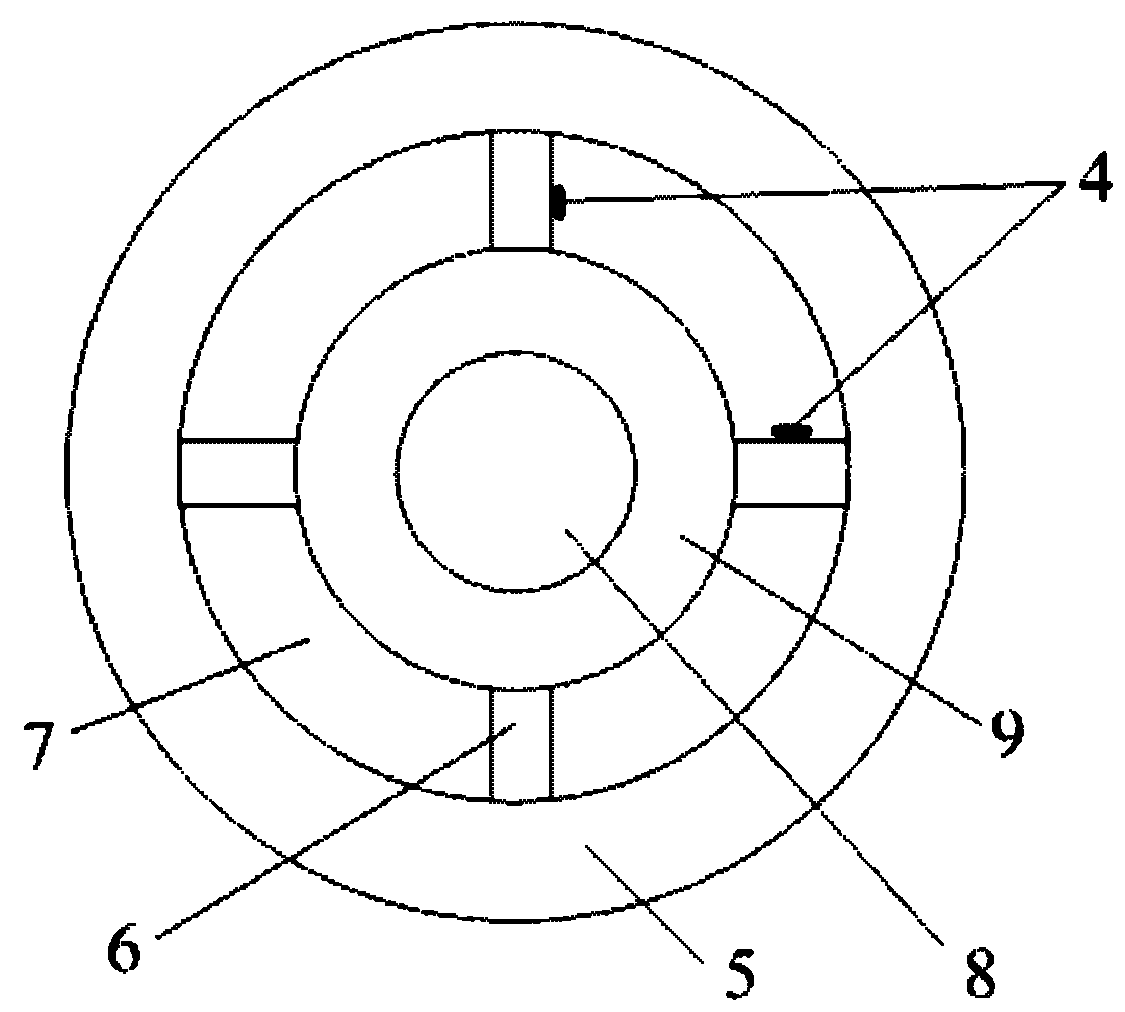

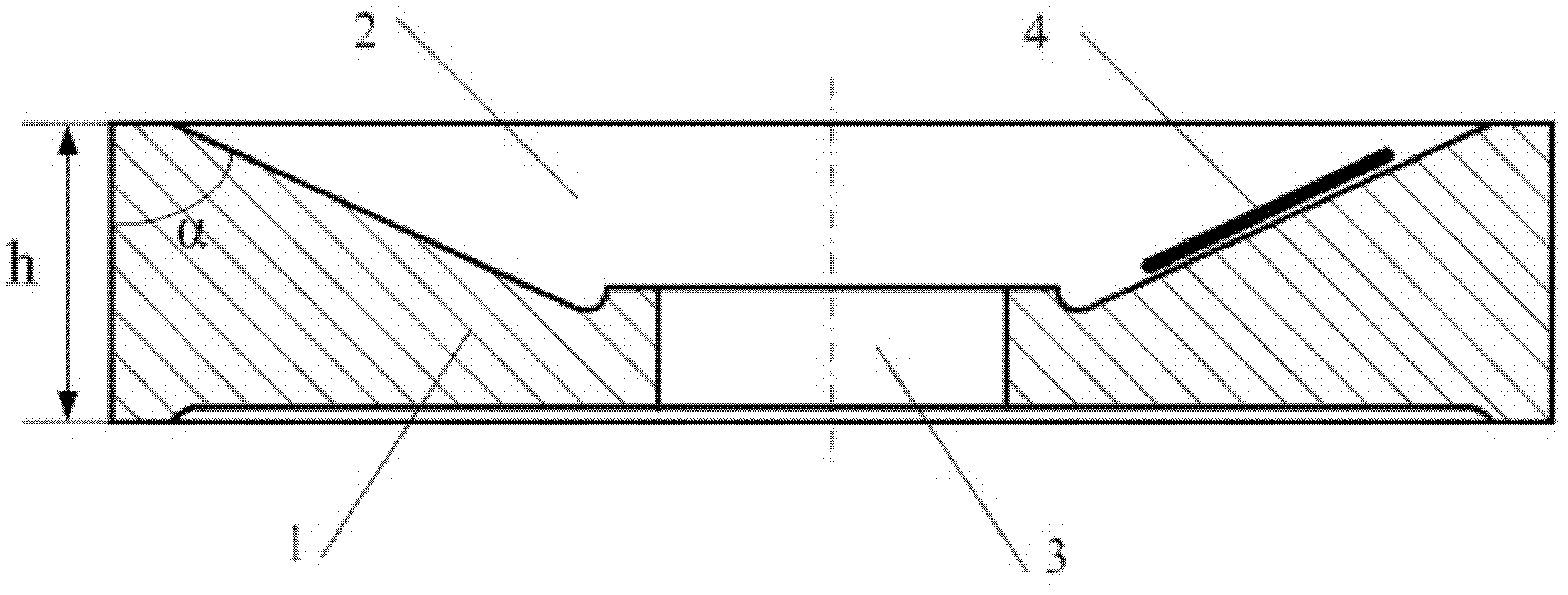

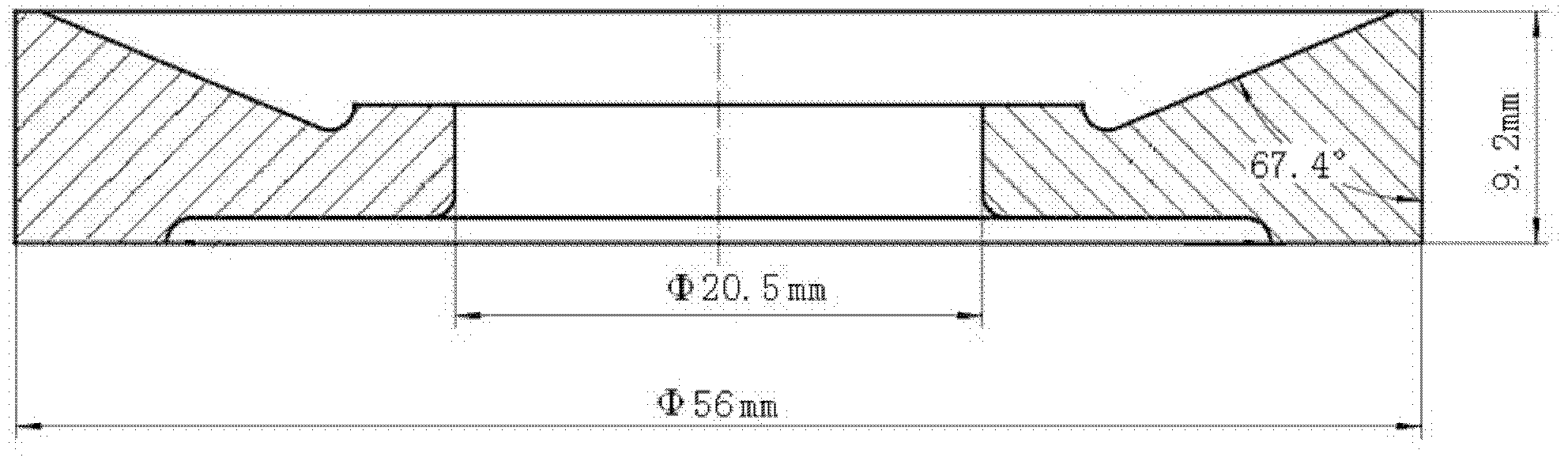

Inner conical elastomer for strain force transducer, and optimization method for inner conical elastomer

InactiveCN102539031AHigh sensitivitySimple shapeForce measurement using piezo-resistive materialsStress levelStrain gauge

The invention provides an inner conical elastomer for a strain force transducer. The inner conical elastomer comprises a cylindrical base body; the upper part of the base body is provided with a conical concave part; the bottom of the conical concave part is provided with a central hole; and the conical surface of the conical concave part is provided with a strain gauge. The optimization method for the elastomer comprises the following steps of: estimating an initial size; calculating stress of the elastomer under the action of the axial force of a bolt by a finite element method, and adjusting the cone angle of a model until stress on the inner conical surface is distributed uniformly; adjusting the thickness of the base body under the condition of not changing the cone angle to ensure that the stress level on the conical surface meets the requirement; and rounding the model size obtained through finite element calculation, wherein the rounded model size is used as the final size of the elastomer. The inner conical elastomer is a simple revolution solid, and is high in processing and heat treatment manufacturability; the stress of the adhesion part of the strain gauge is distributed uniformly; and the accuracy of the adhesion position of the strain gauge is not required. The axial size of the elastomer is smaller than that of a spoke elastomer, and the elastomer is more suitable for measuring the axial force of the bolt.

Owner:XIAN UNIV OF TECH

Degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN110373588AEnhance biological antibacterial effectImprove antibacterial propertiesTissue regenerationProsthesisOsteoblastDie casting

The invention provides a degradable antibacterial magnesium alloy and a preparation method of the degradable antibacterial magnesium alloy, and relates to the field of metal biomedical materials. Thedegradable antibacterial magnesium alloy comprises main active elements of Ag, Cu, Zn and Sr, and by means of composition optimization design of the magnesium alloy, the components comprise, by mass,1.35-1.65% of Ag, 0.9-1.1% of Cu, 3.6-4.4% of Zn, 0.9-1.1% of Sr, 0.36-0.44% of Ca and the balance Mg and other inevitable impurities. After the magnesium alloy material implant finishes the action, the magnesium alloy material implant can be completely degraded to avoid secondary operation removal, the medical cost and the pain of patients are reduced, the antibacterial property of the implant isimproved, and the magnesium alloy material implant has the functions of promoting osteoblast formation and inhibiting osteoclast bone absorption; the degradable antibacterial magnesium alloy adopts asemi-solid rheological die casting process, the microstructure of the product is uniformly distributed, the internal structure is compact, the defects of pores, segregation and the like are few, andthe requirements for high quality and high precision of implant products can be met.

Owner:NORTHEASTERN UNIV

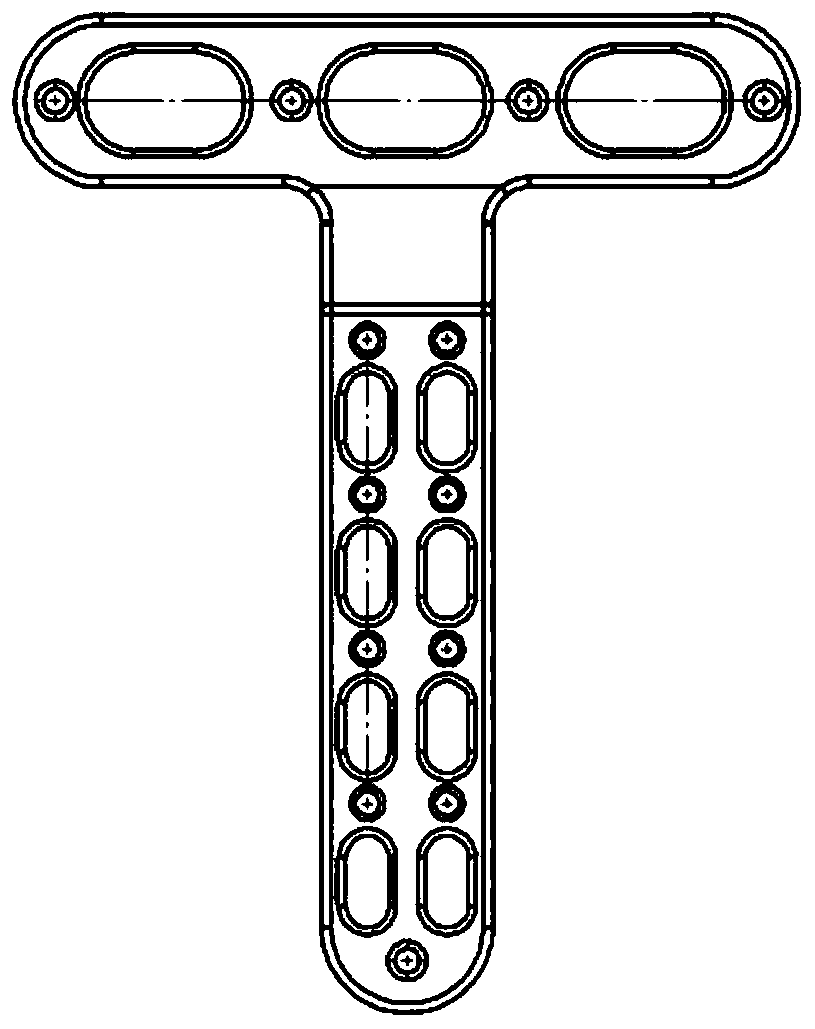

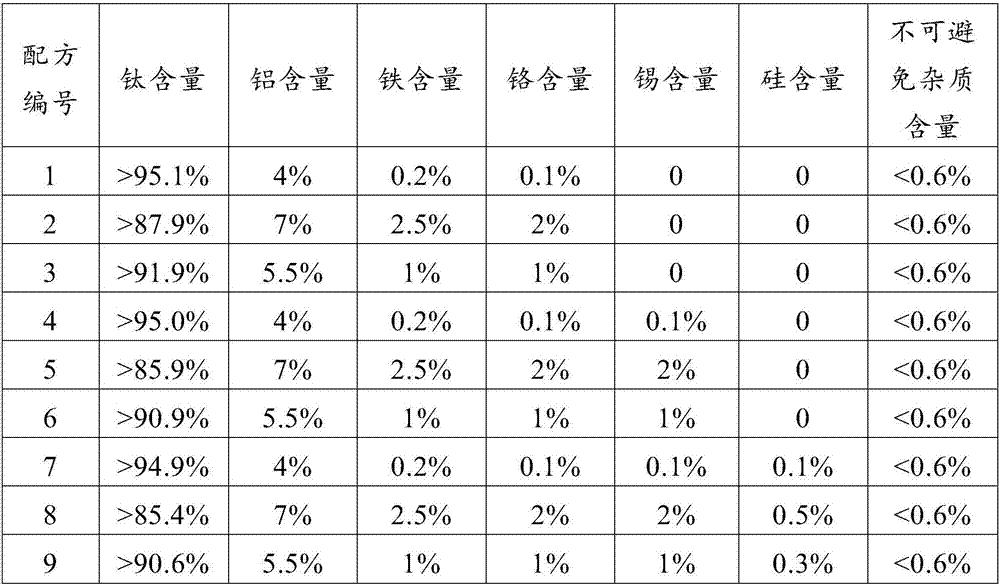

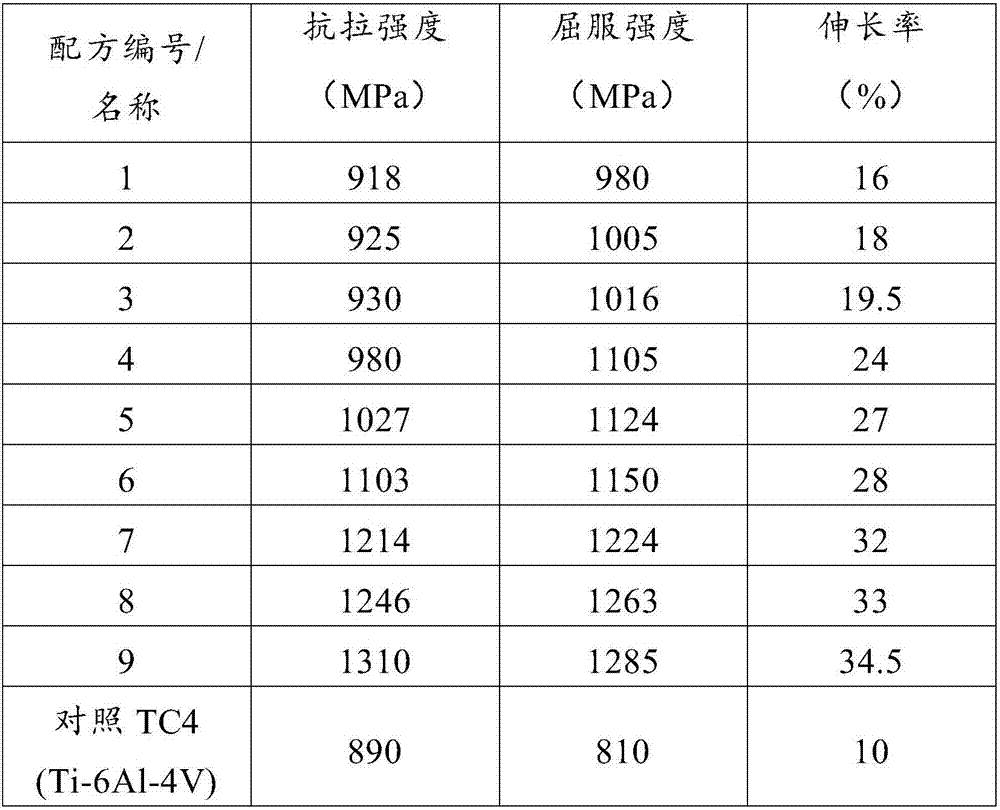

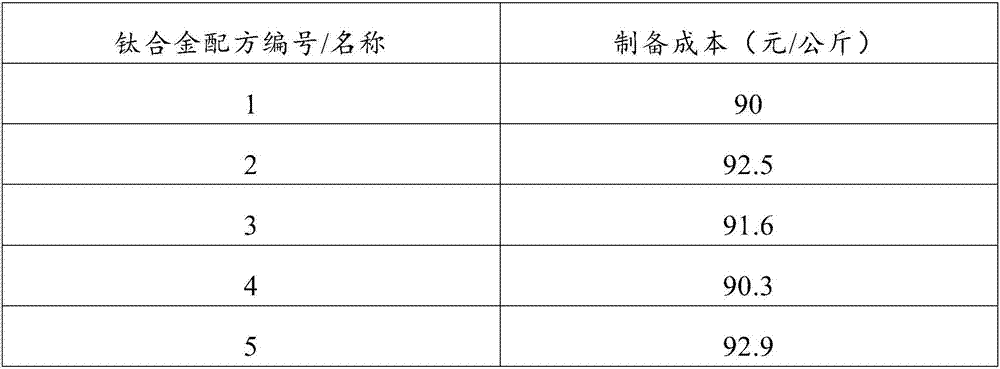

High cost performance titanium alloy and preparation method thereof

The invention belongs to the field of alloy materials and relates to a high cost performance titanium alloy and a preparation method thereof. Titanium is mainly contained, besides, the titanium alloy further contains, by weight, 4%-7% of aluminum, 0.2%-2.5% of iron, 0.1%-2% of chromium and little inevitable impurities, and the titanium alloy does not contain molybdenum and vanadium. Compared with a TC4 titanium alloy material widely used in the prior art, the high cost performance titanium alloy is easier to machine, heat treatment performance is good, machining forming is easier, performance is better, and the production cost and the final price of the alloy material can be reduced.

Owner:BEIJING JINYU SHUNDA TECH CO LTD

Quenching agent for die steel and preparation method of quenching agent

InactiveCN104593557AGood heat treatment performanceImprove hardenabilityQuenching agentsSodium silicateEther

The invention discloses a quenching agent for a die steel. The quenching agent is characterized by being prepared from the following raw materials in parts by weight: 2-4 parts of sodium molybdate, 3-5 parts of sodium chloride, 0.3-0.5 part of sodium silicate, 0.1-0.2 part of disodium hydrogen phosphate, 0.5-1 part of octyl phenol polyethylene ether, 0.3-0.5 part of sodium methylene dinaphthalene sulfonate, 1-2 parts of hydroxypropyl guar gum, 0.5-1 part of sodium carboxymethyl starch, 0.5-1 part of oxalic acid, 0.1-0.2 part of polymaleic anhydride, 3-5 parts of auxiliaries and 70-80 parts of water. The quenching agent disclosed by the invention is good in thermal treatment process performance, high in quenching degree, and small in thermal treatment deformation, the work-piece is high in hardness and abrasion resistance and suitable for the quenching treatment of the die steel.

Owner:安徽东星汽车部件有限公司

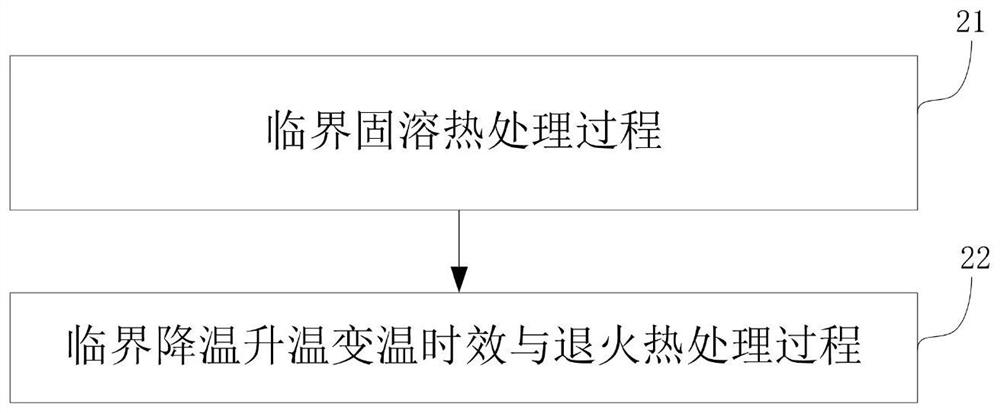

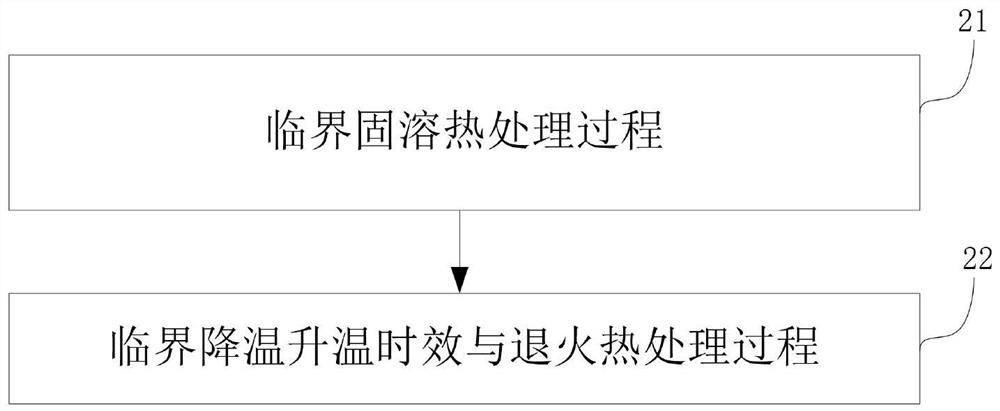

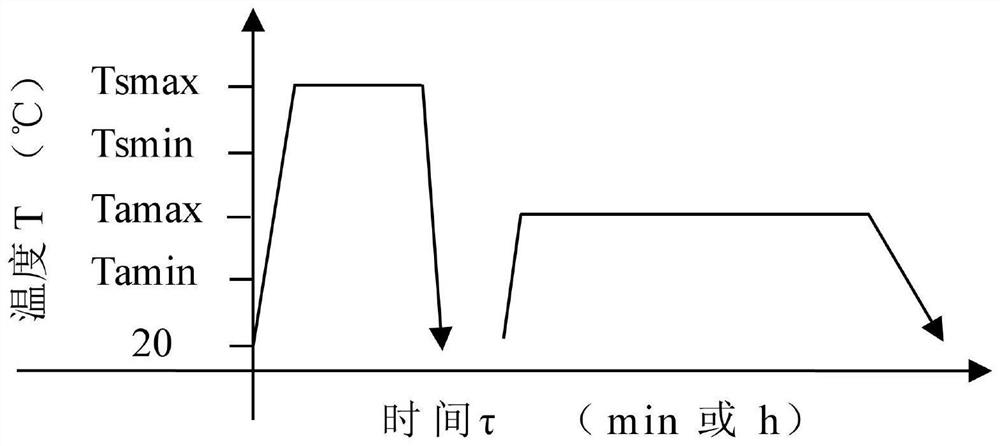

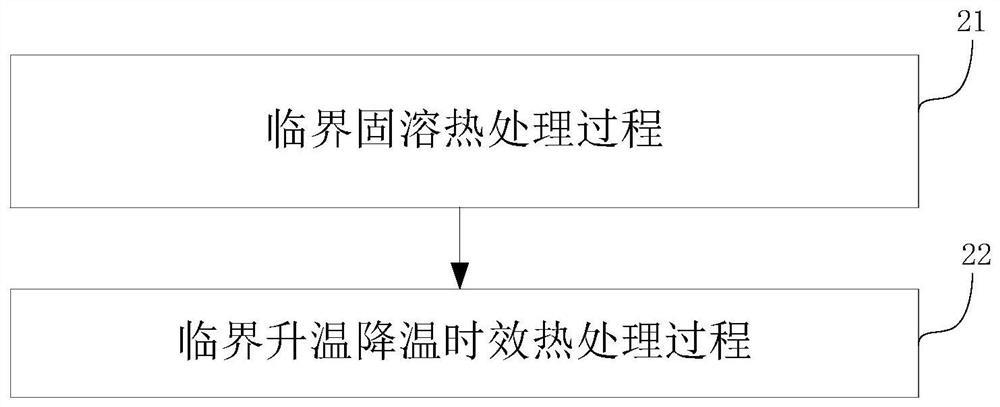

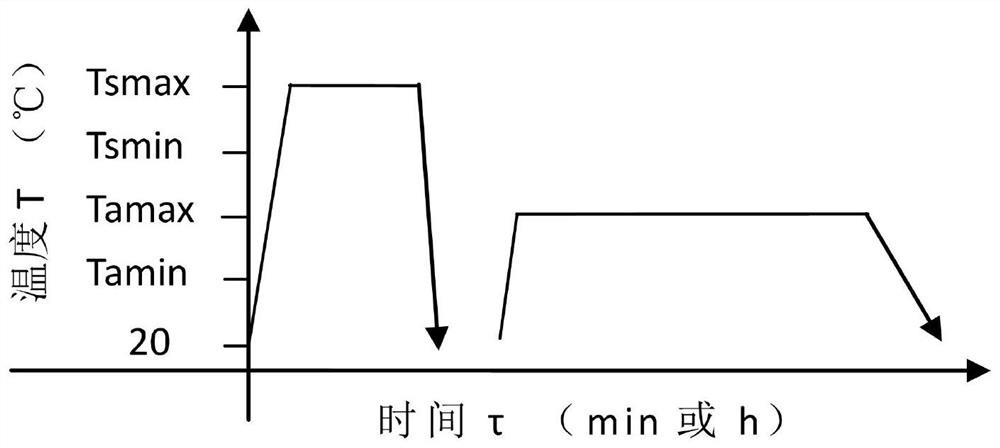

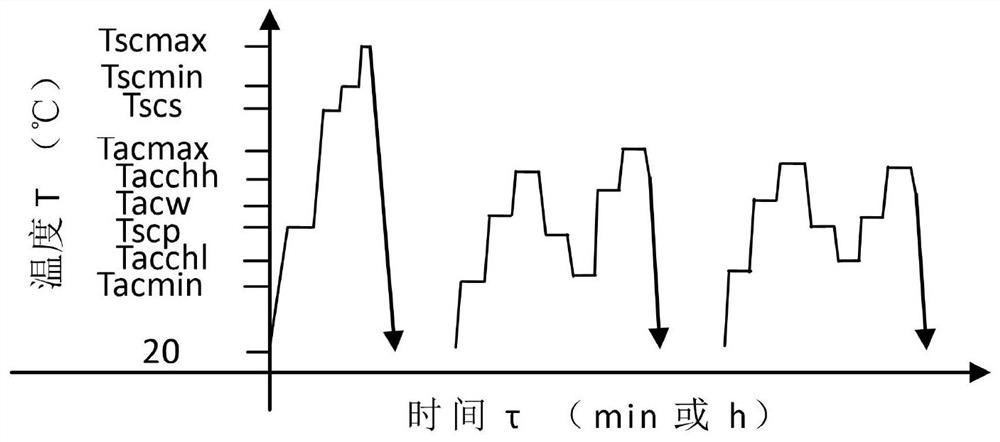

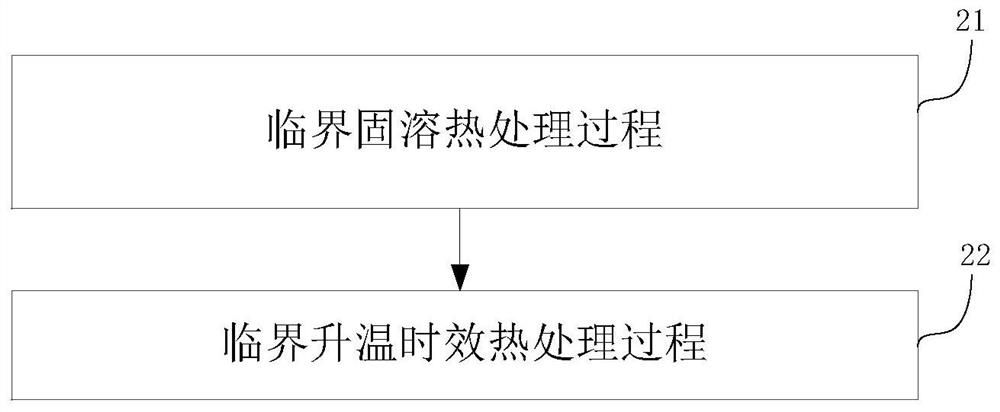

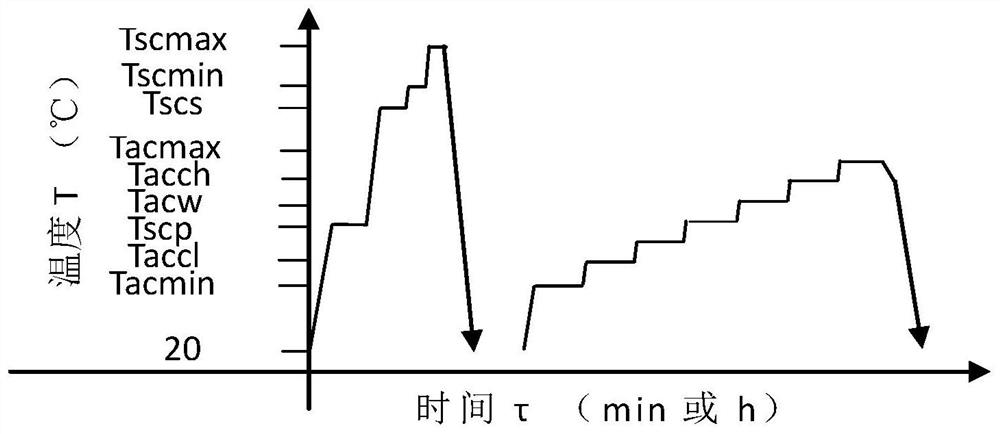

Critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method

The invention provides a critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method. The critical solid solution and critical cooling and heating variable-temperature aging and annealing heat treatment method comprises a critical solid solution heat treatment process and a critical cooling and heating variable-temperature aging and annealing heat treatment process. According to the scheme, the method has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, the advantages can be effectively adopted, disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel are avoided, the special heat treatment problems of poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, poor discoloration and corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature parts, high cost and the like of austenitic stainless steel heat treatment are solved, the method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel involved in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

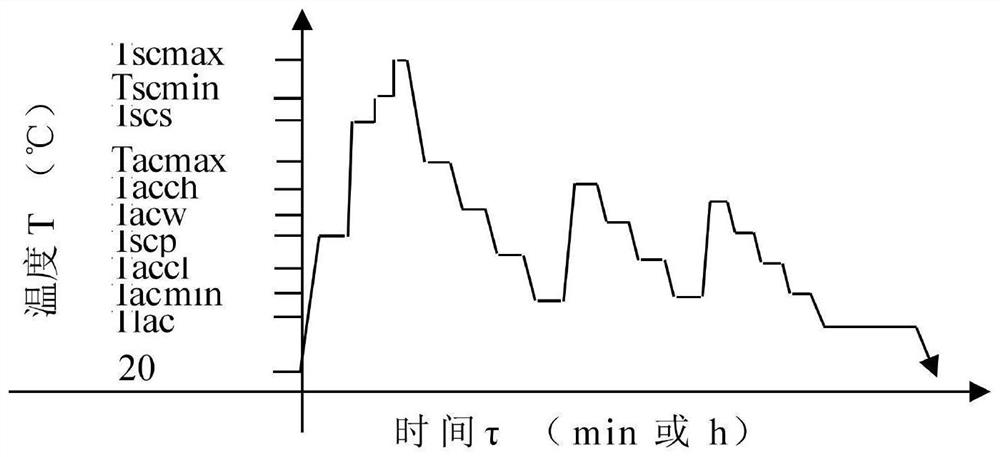

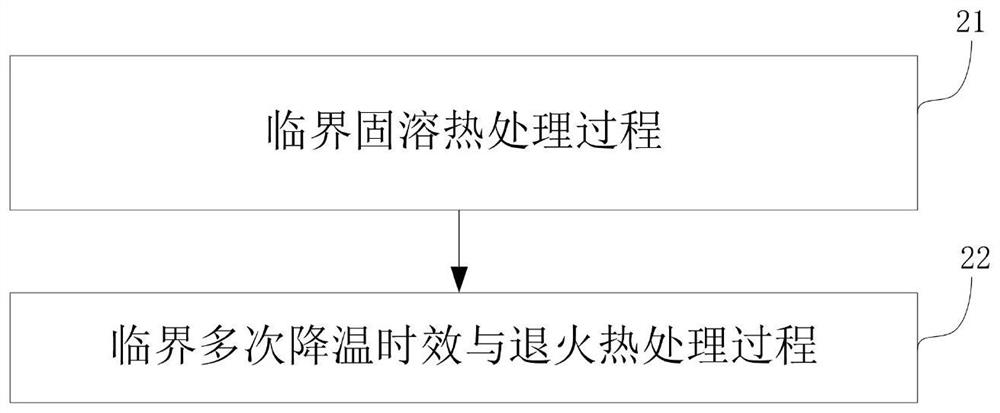

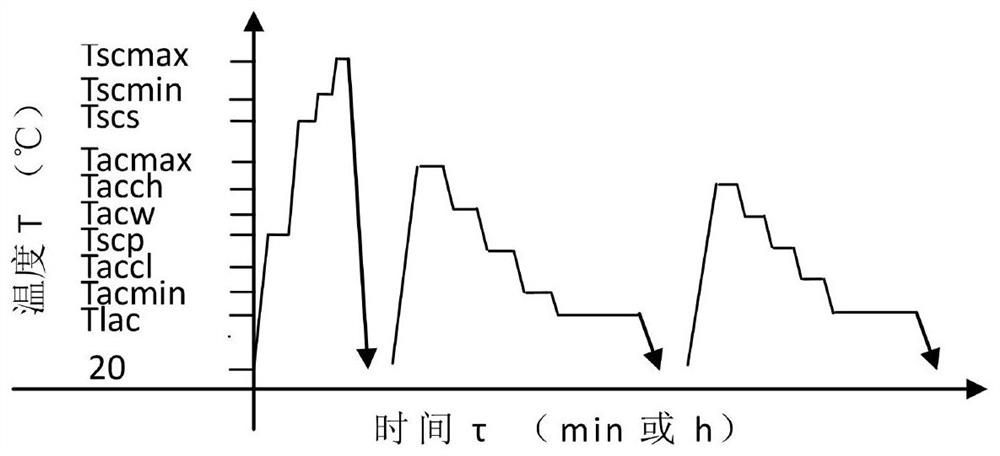

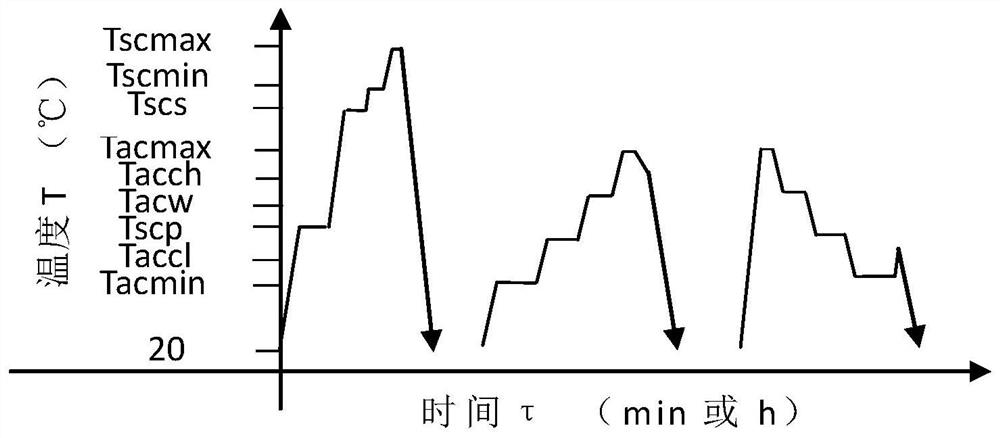

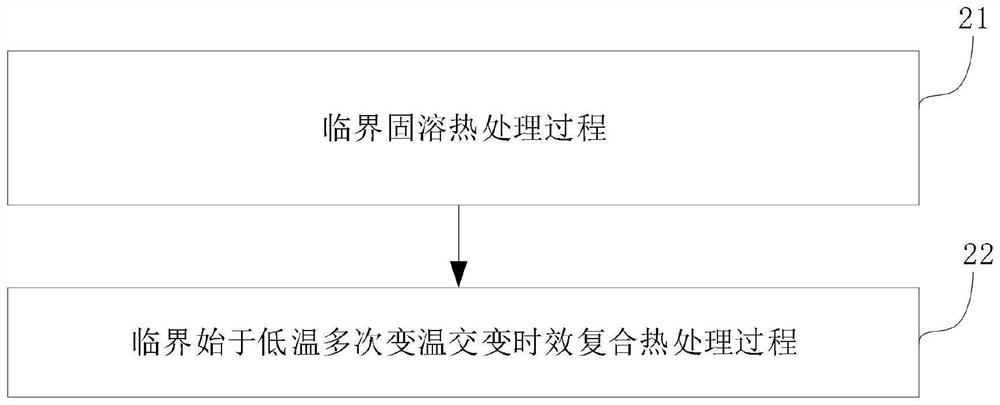

Critical solid solution and critical multiple cooling variable temperature aging and annealing composite heat treatment method

PendingCN114395668ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeAustenite

The invention provides a critical solid solution and critical multiple cooling variable temperature aging and annealing composite heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multiple-cooling variable-temperature aging and annealing composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

Inner conical elastomer for strain force transducer, and optimization method for inner conical elastomer

InactiveCN102539031BIncrease the output signal amplitudeReduce distortionForce measurement using piezo-resistive materialsStress distributionElastomer

The invention provides an inner conical elastomer for a strain force transducer. The inner conical elastomer comprises a cylindrical base body; the upper part of the base body is provided with a conical concave part; the bottom of the conical concave part is provided with a central hole; and the conical surface of the conical concave part is provided with a strain gauge. The optimization method for the elastomer comprises the following steps of: estimating an initial size; calculating stress of the elastomer under the action of the axial force of a bolt by a finite element method, and adjusting the cone angle of a model until stress on the inner conical surface is distributed uniformly; adjusting the thickness of the base body under the condition of not changing the cone angle to ensure that the stress level on the conical surface meets the requirement; and rounding the model size obtained through finite element calculation, wherein the rounded model size is used as the final size of the elastomer. The inner conical elastomer is a simple revolution solid, and is high in processing and heat treatment manufacturability; the stress of the adhesion part of the strain gauge is distributed uniformly; and the accuracy of the adhesion position of the strain gauge is not required. The axial size of the elastomer is smaller than that of a spoke elastomer, and the elastomer is more suitable for measuring the axial force of the bolt.

Owner:XIAN UNIV OF TECH

40Mn2B alloy structural steel material

The invention discloses a 40Mn2B alloy structural steel material, which is used for manufacturing alloy structural steel with high hardenability and low hardening break sensitivity. The 40Mn2B alloy structural steel material comprises the following chemical components in percentage by weight: 0.37-0.42 percent of C, 0.17-0.37 percent of Si, 1.40-1.70 percent of Mn, 0.20-0.60 percent of Cr, 0.0010-0.0035 percent of B, 0.015-0.045 percent of Ti, less than or equal to 0.035 percent of P, less than or equal to 0.035 percent of S, less than or equal to 0.06 percent of Mo, less than or equal to 0.15 percent of Ni and less than or equal to 0.25 percent of Cu. The hardness of the 40Mn2B alloy structural steel material can reach J13 / 50-60 HRC, the tempering hardness of 217-269 HB can be reached in a normalized condition, the effective hardened layer depth of 10-16mm can be achieved for shaft type parts, the cost is lower than that of the 42CrMo material, the hardening break sensitivity is low, and the thermal treatment processibility is good.

Owner:DONGFENG DANA AXLE

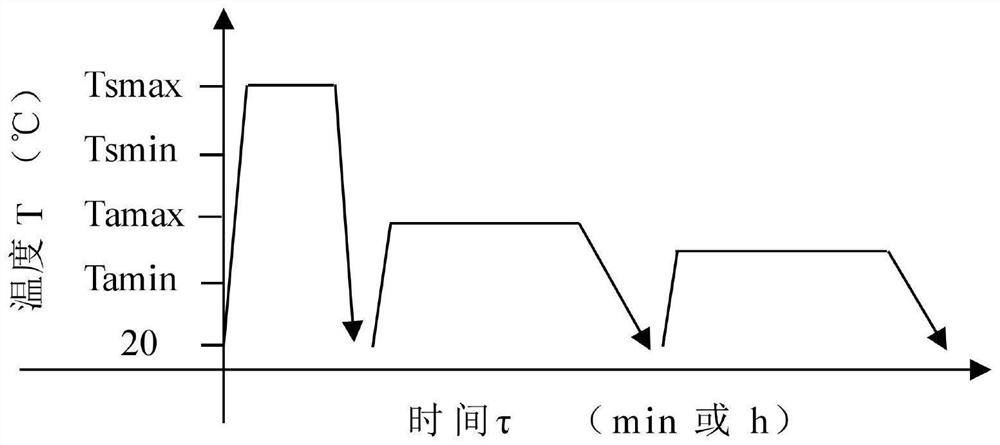

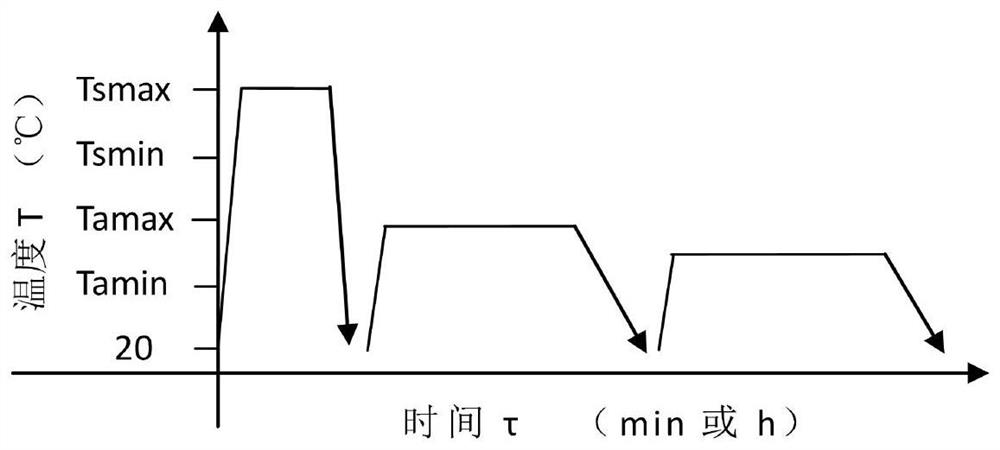

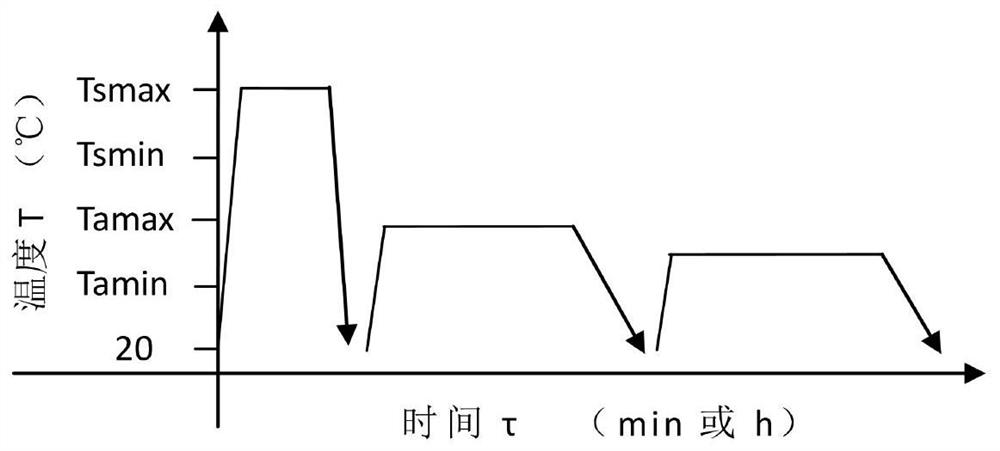

Critical solid solution and critical repeated cooling aging and annealing heat treatment method

The invention provides a critical solid solution and critical repeated cooling aging and annealing heat treatment method which comprises a critical solid solution heat treatment process and a critical repeated cooling aging and annealing heat treatment process. The scheme of the invention has technical feasibility, process adaptability, quality reliability, economic reasonability and use safety, can effectively enhance the advantages and avoid the disadvantages of a conventional mainstream heat treatment method of austenitic stainless steel, fundamentally solves the "one-long one-high four-poor five-low" special heat treatment technical difficult problems of "poor quality stability, low rate of qualified products, low hardness, low mechanical property, poor consistency, poor discoloration and rust corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment and low service life and high cost of a high-temperature component" of existing austenitic stainless steel heat treatment, and is particularly suitable for the technical field of heat working engineering such as smelting, steel rolling, forging, heat treatment and the like related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

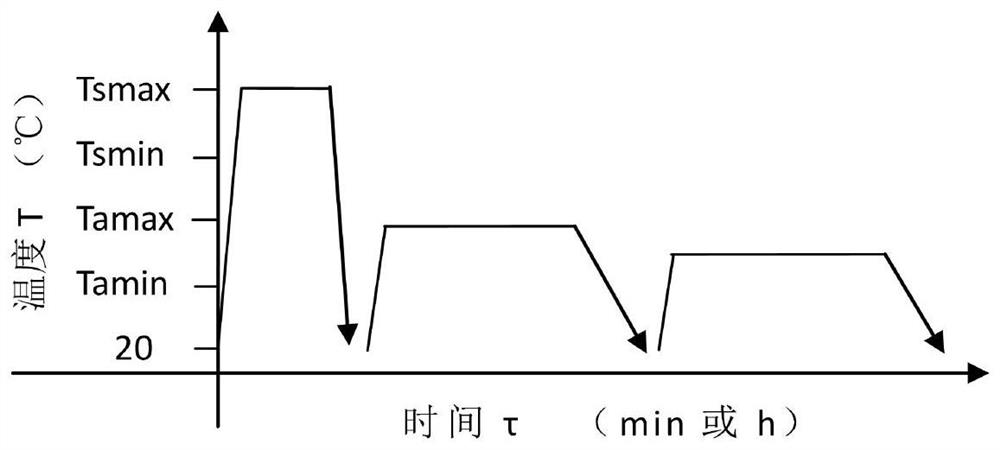

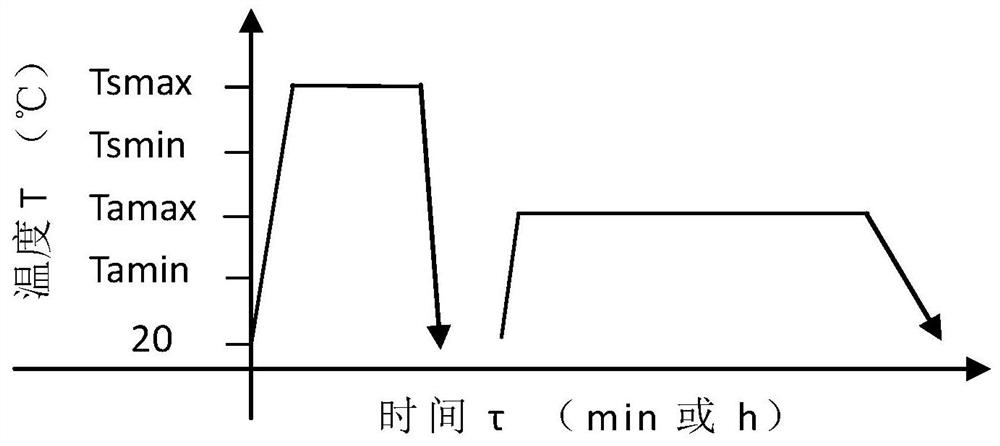

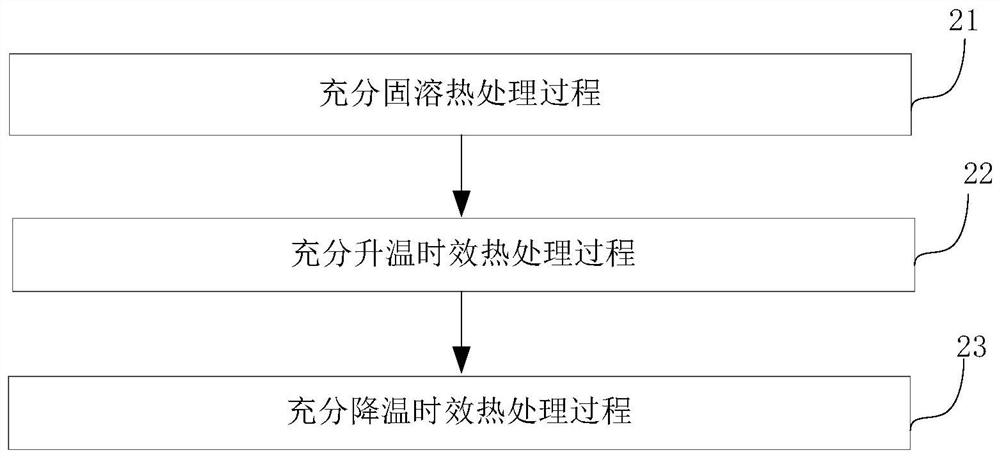

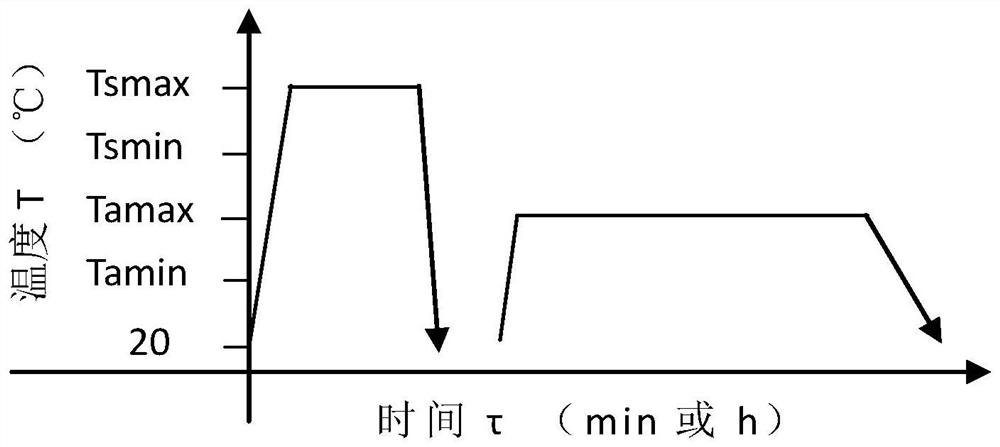

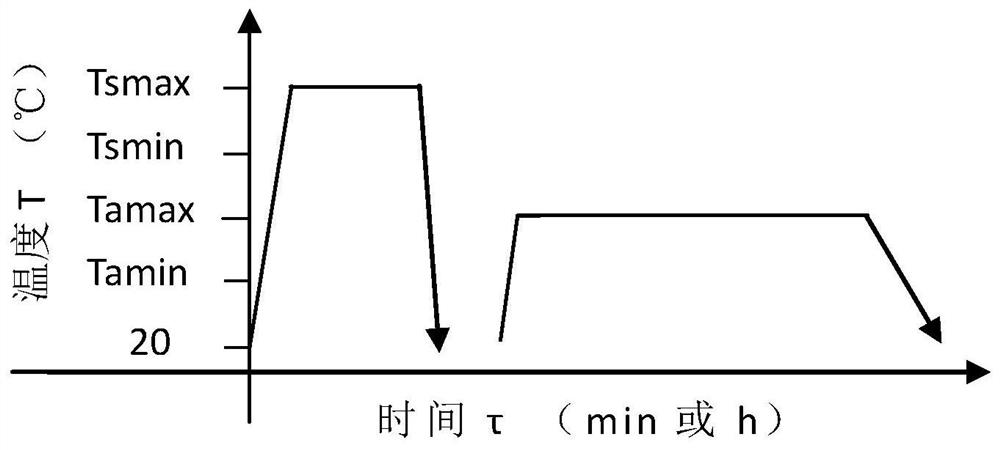

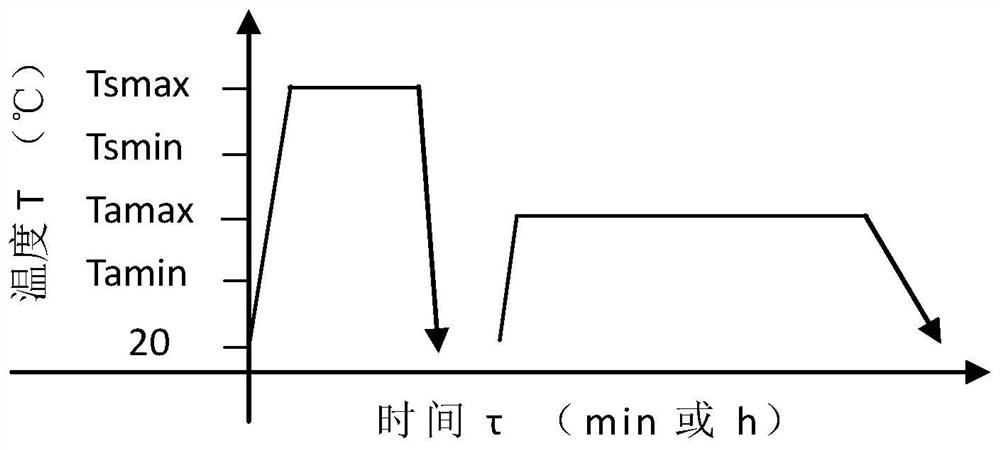

Aging heat treatment method with sufficient solid solution and sufficient heating and cooling

The invention provides an aging heat treatment method with sufficient solid solution and sufficient heating and cooling. The method comprises a sufficient solid solution heat treatment process, a sufficient heating aging heat treatment process and a sufficient cooling aging heat treatment process. According to the scheme, the special heat treatment technical problems of poor quality stability, low qualified product rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature parts, high cost and the like of existing austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

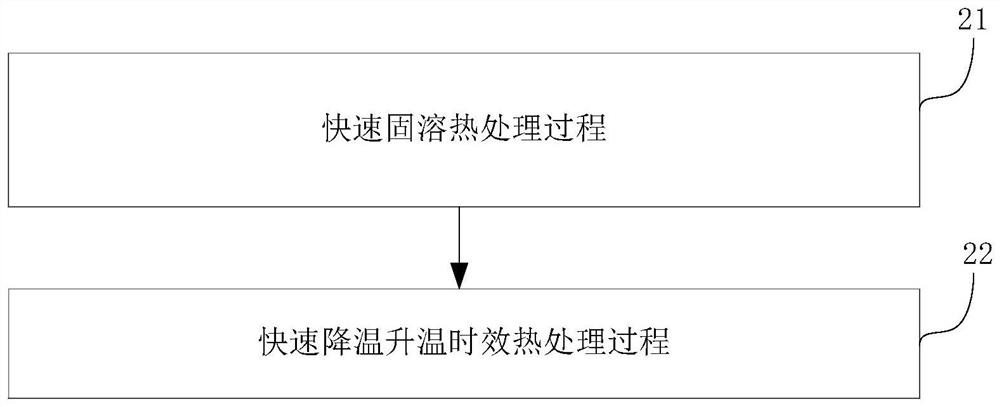

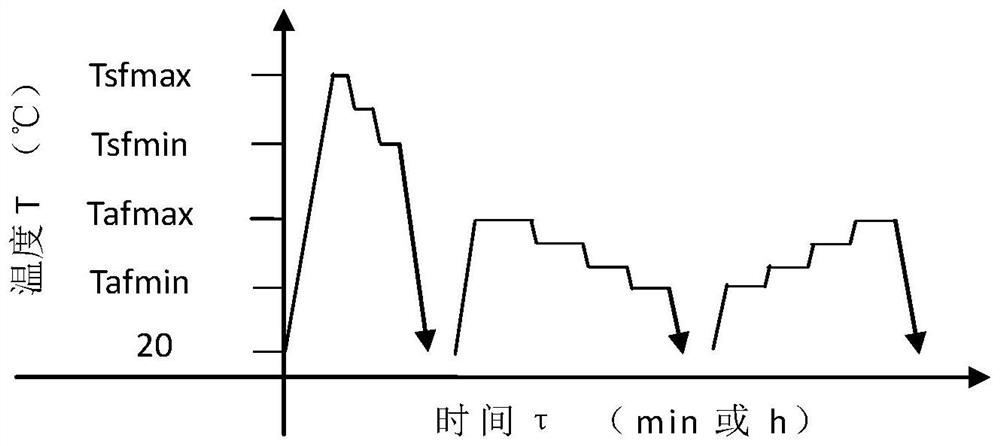

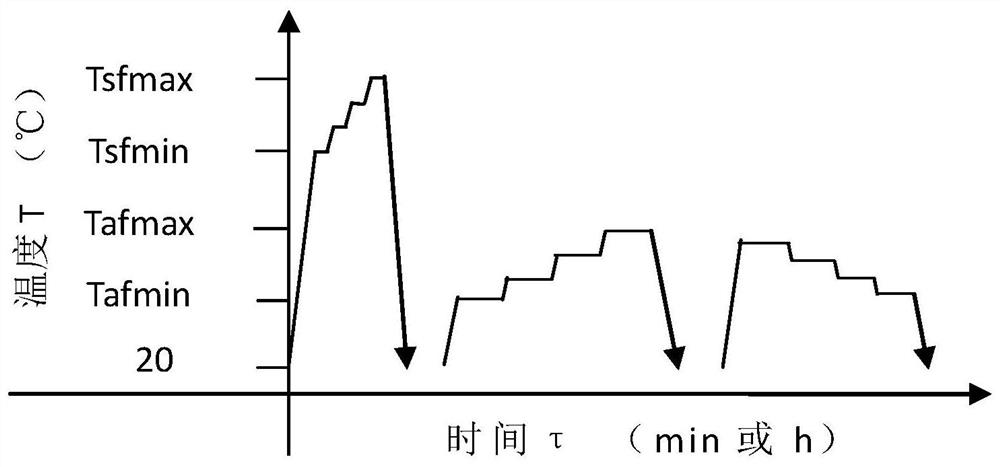

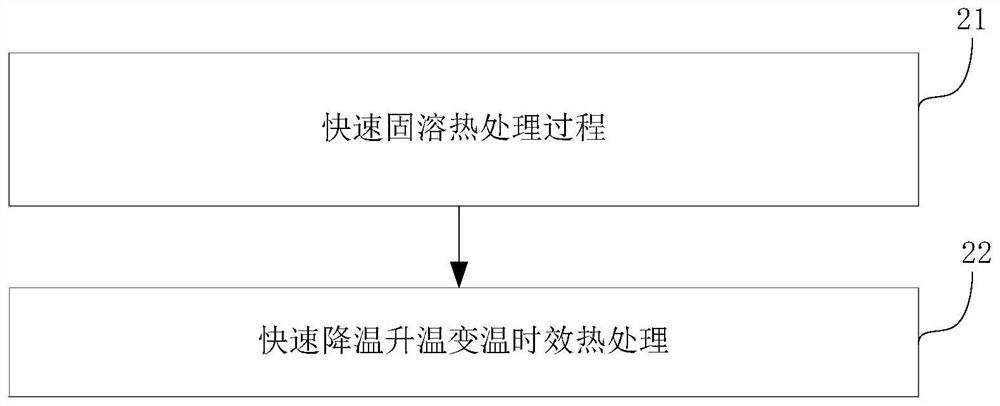

Rapid solid solution and rapid cooling and heating aging heat treatment method

The invention provides a rapid solid solution and rapid cooling and heating aging heat treatment method. The method comprises a rapid solid solution heat treatment process and a rapid cooling and heating aging heat treatment process. According to the scheme of the method, the specific heat treatment technical problems of poor quality stability, a low qualified rate, a low hardness, a low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, a short service life of high-temperature components, high cost and the like in heat treatment of austenitic stainless steel can be solved.

Owner:山西柴油机工业有限责任公司

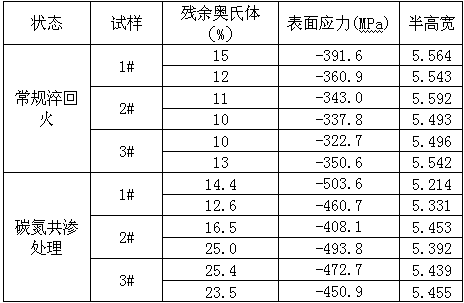

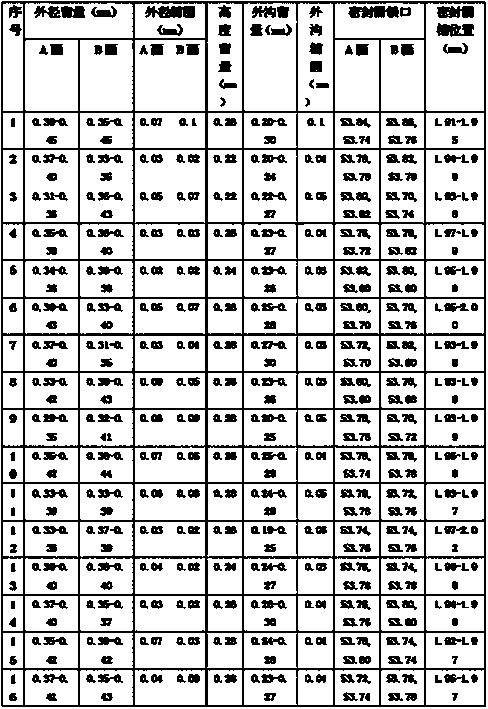

A kind of carbonitriding heat treatment process method

ActiveCN106637060BAdd depthAvoid defectsSolid state diffusion coatingFurnace typesCarbon potentialAlcohol

The invention discloses a carbonitriding heat treatment technique under a new atmosphere. The technique comprises the following steps that (a), a multi-purpose chamber furnace suitable for carburizing treatment is selected; (b), a nitrogen, methyl alcohol, ammonia gas and dimethylmethane carburizing medium is adopted, and an oxygen probe is adopted to control the carbon potential, so that control over the carbon potential of the atmosphere in the furnace is achieved; (c), according to a charging mode, charging layers are chosen according to the heights of workpieces, and gaps are kept between the workpieces of each layer to guarantee the uniformity of infiltration layers; (d), according to technological parameters, the carbonitriding temperature is 815 DEG C-825 DEG C, the carbon potential is 1.20%-1.30%, and strong infiltration is conducted for 3 h-3.5 h; in the diffusion period, the temperature is 815 DEG C-825 DEG C, the carbon potential is 1.10%-1.20%, and diffusion is conducted for 3 h-3.5 h; KR-218 fast bright quenching oil is used for quenching, and cooling is conducted for 8 min-15min; and air cooling is conducted after tempering; and (e), steel foil is used for carbon determination during strong infiltration of each furnace. According to the carbonitriding heat treatment technique under the new atmosphere, a carbonitriding layer with a certain depth can be obtained in a relatively short time, and higher hardness is achieved.

Owner:LUOYANG LYC BEARING

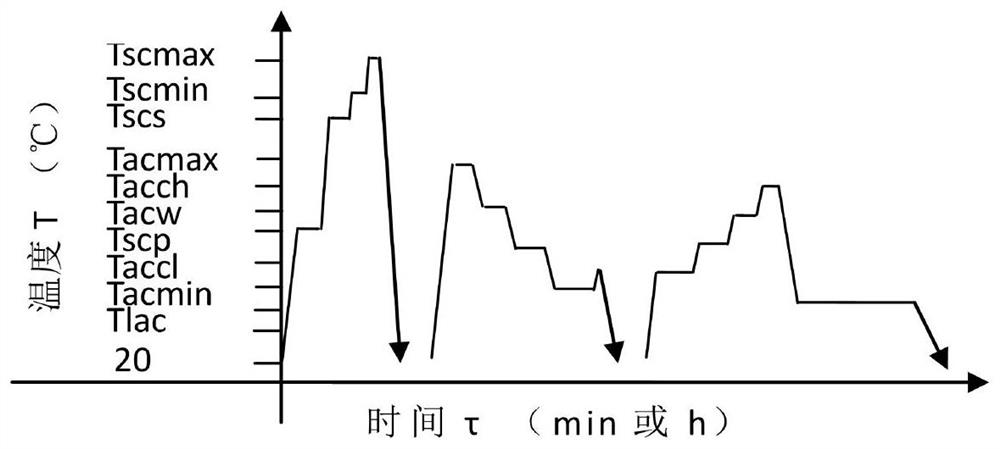

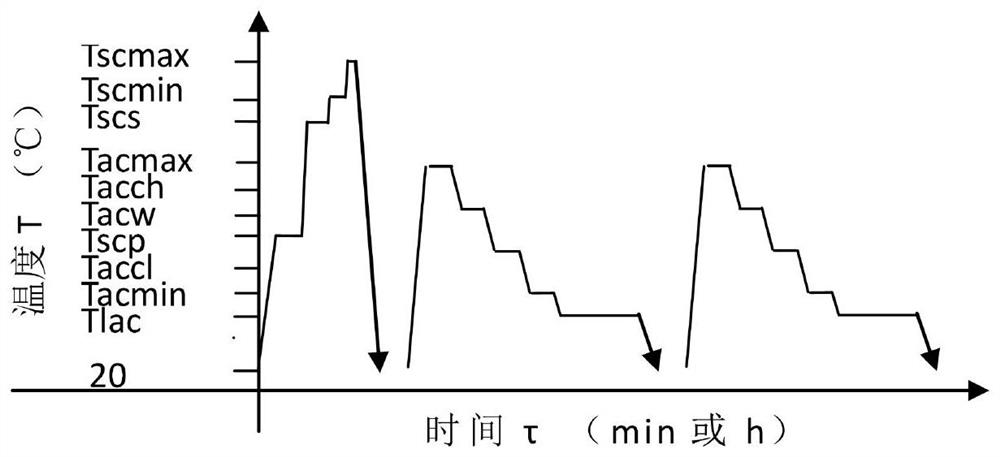

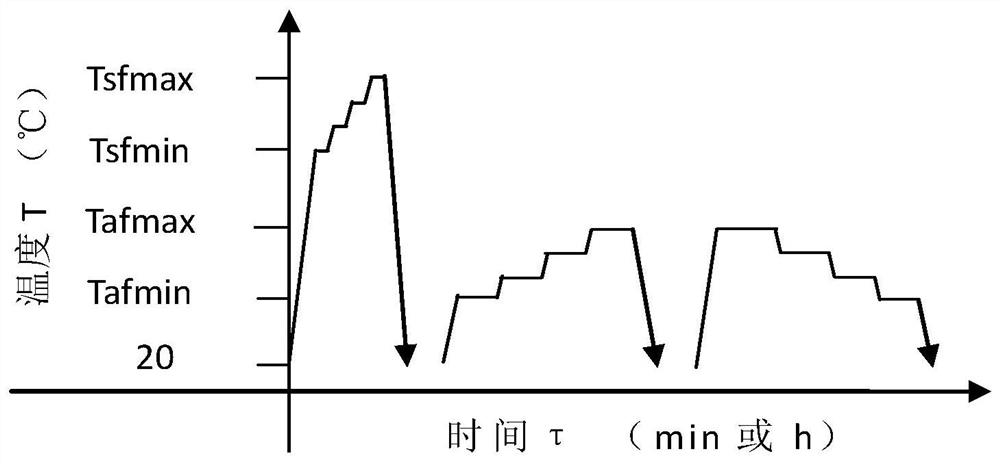

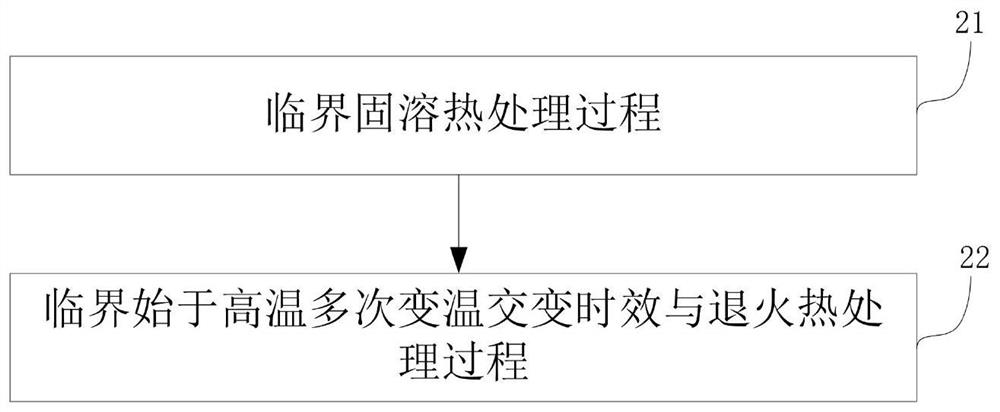

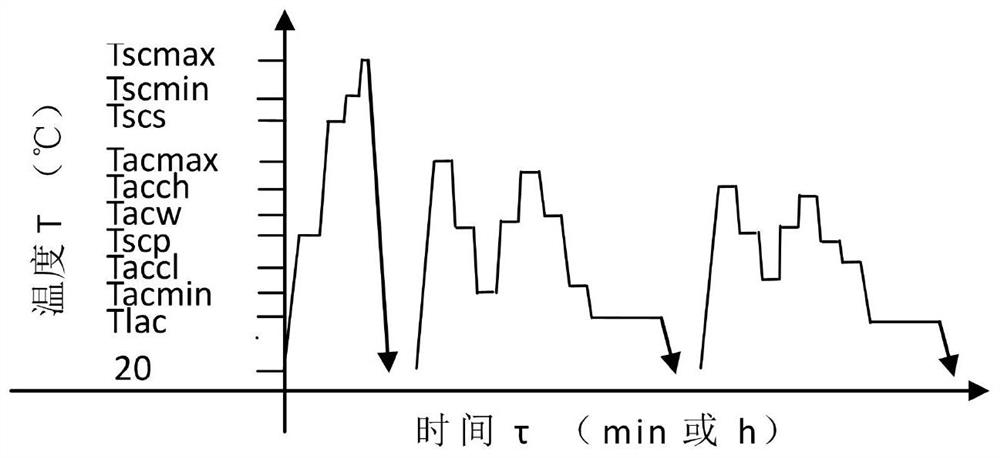

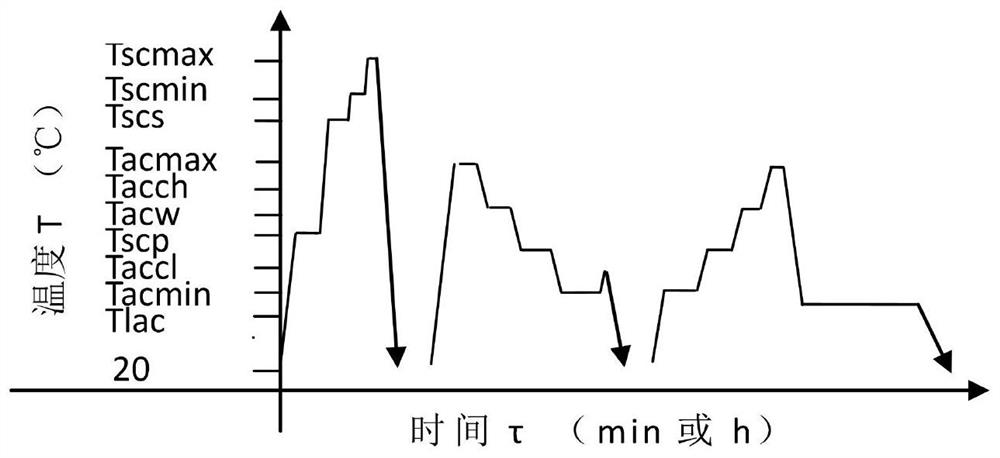

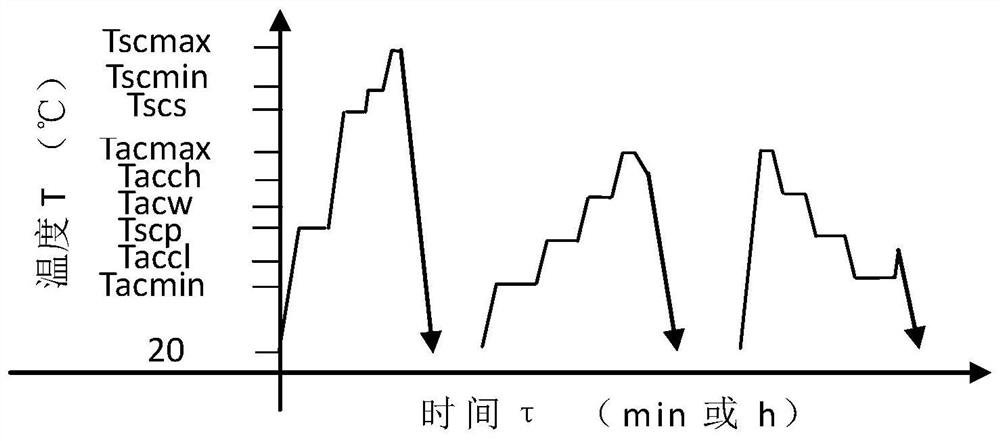

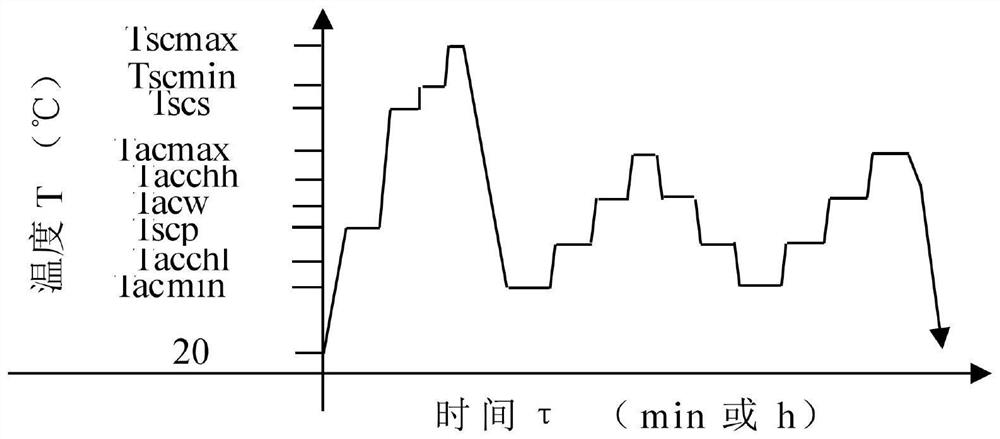

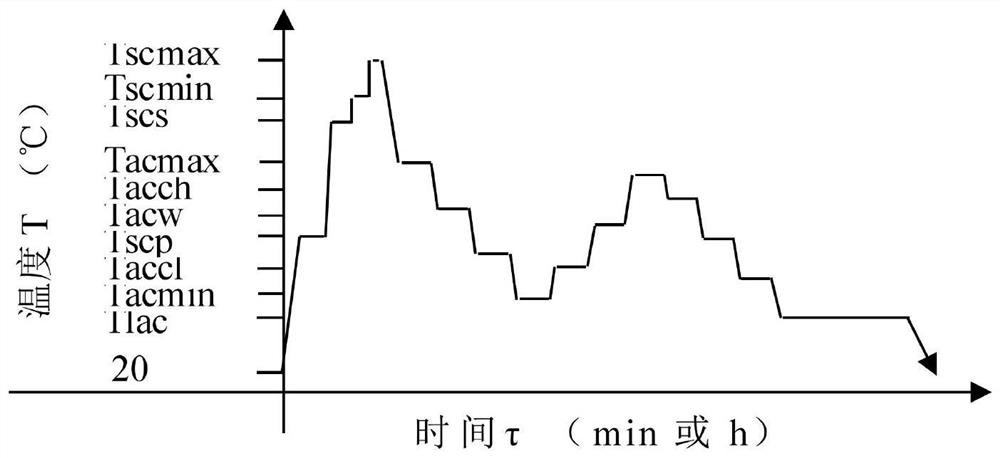

Critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method

The invention provides a critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method. The critical solid solution and high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment method comprises a critical solid solution heat treatment process and a critical high-temperature-starting multi-time variable-temperature alternating aging and annealing heat treatment process. The scheme provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, can effectively develop the advantages and avoid the disadvantages of traditional major heat treatment methods of austenitic stainless steel, and special heattreatment technical the problems, namely being long in one aspect, high in one aspect, poor in four aspects and low in five aspects, that existing austenitic stainless steel heat treatment is poor inquality stability, low in the rate of qualified products, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time and low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components and parts are short in service life, and the cost is high, are fundamentally solved. The method isparticularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel involved in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

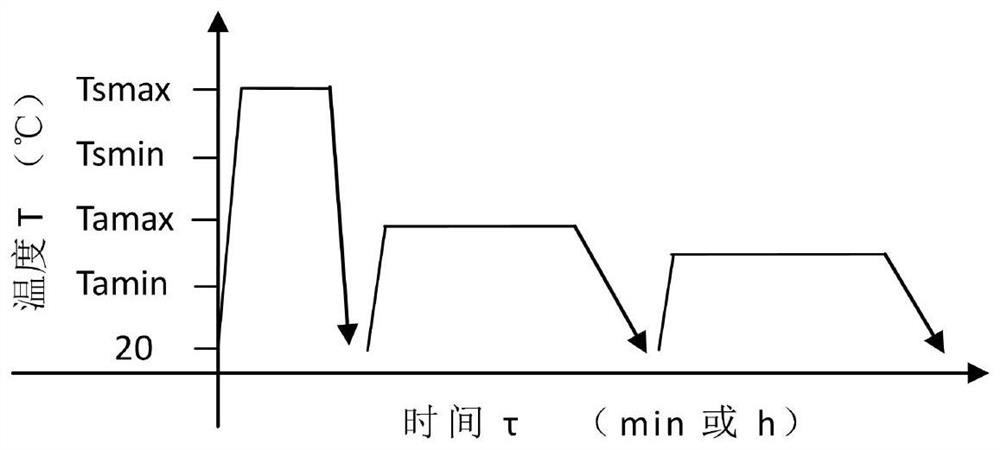

Critical solid solution and critical cooling and heating aging and annealing heat treatment method

The invention provides a critical solid solution and critical cooling and heating aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical cooling and heating aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel; the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology problems are fundamentally solved. The method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method

The invention provides a critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multi-cooling variable-temperature aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel, so that the problems that the existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like are fundamentally solved. The critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

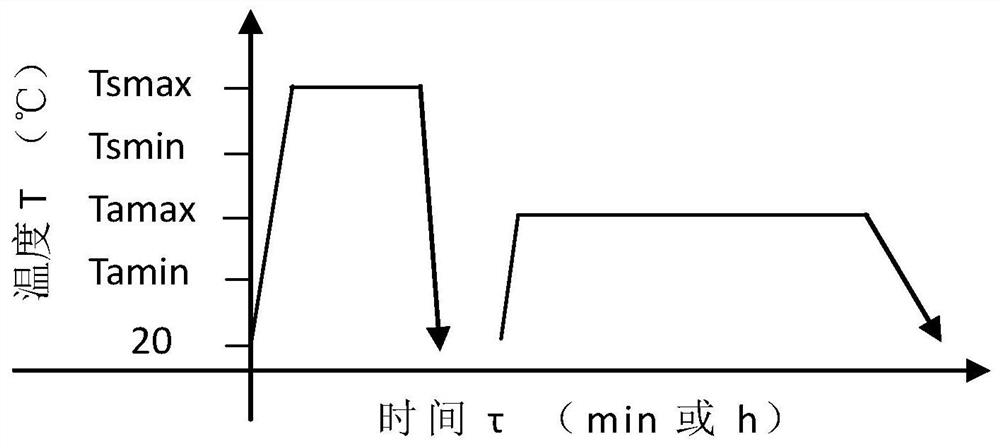

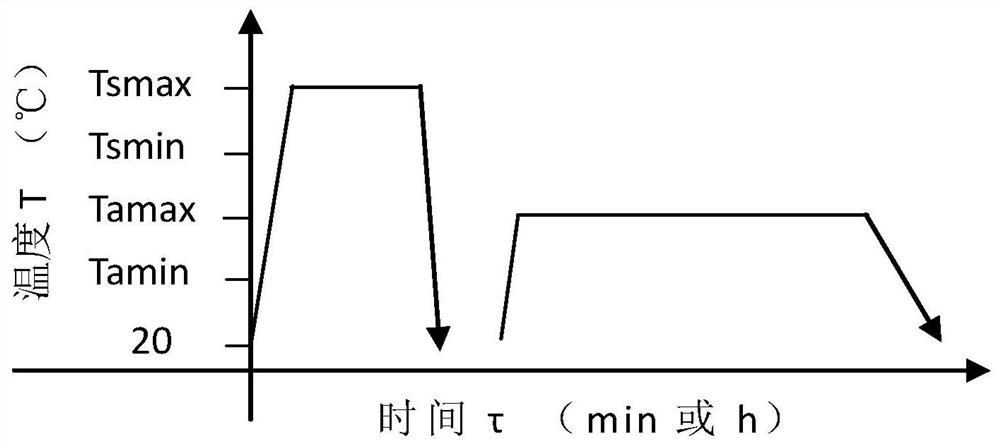

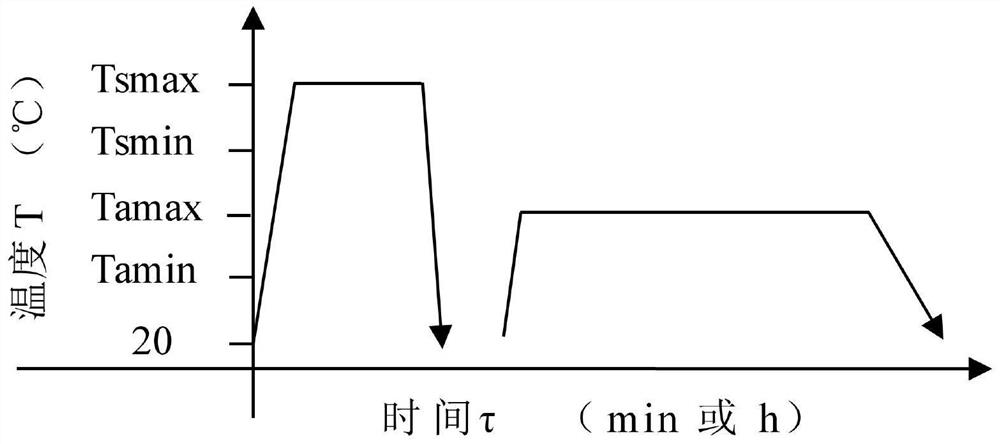

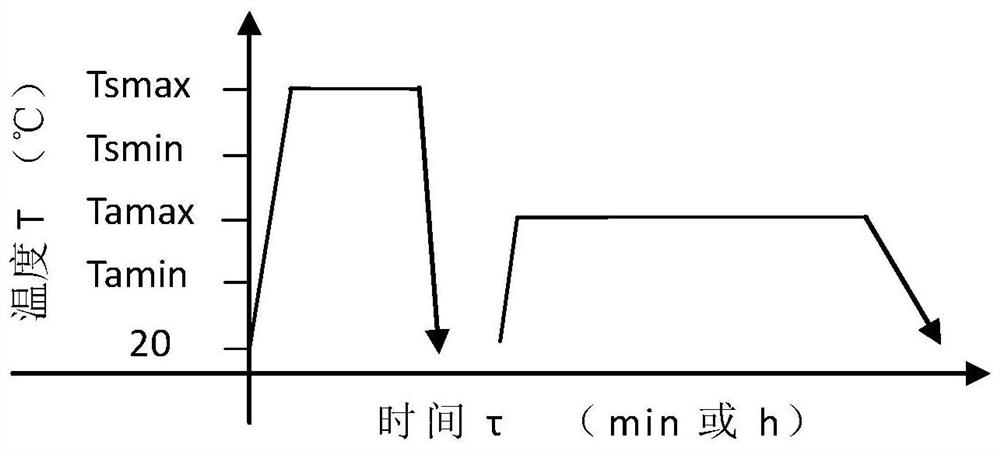

Aging heat treatment method for critical solid solution as well as critical temperature rise, temperature fall and temperature variation

The invention provides an aging heat treatment method for critical solid solution as well as critical temperature rise, temperature fall and temperature variation. The aging heat treatment method comprises a critical solid solution heat treatment process as well as a critical temperature rise, temperature fall and temperature variation aging heat treatment process. The aging heat treatment method provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety; the advantages and disadvantages of a traditional mainstream heat treatment method for austenitic stainless steel can be effectively enhanced and avoided; the specific heat treatment technology problems that in the existing austenitic stainless steel heat treatment process, the quality stability is low, the rate of qualified products is low, the hardness is relatively low, the mechanical performance is low, the consistency is poor, the discoloration and corrosion resisting capacity is poor, the heating time is long, the efficiency is low, the heating reliability of heat treatment equipment is poor, the service life of high-temperature components is short, and the cost is high can be fundamentally solved; and the aging heat treatment method is particularly applicable to the technical fields of hot-working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel in steel mills and manufacturing plants.

Owner:山西柴油机工业有限责任公司

Co-free composite strengthened secondary hardened ultra-high strength steel and preparation method

ActiveCN105039862BSave Co element contentImprove performanceElectro-slag remeltingVacuum arc remelting

The invention discloses Co-free composite reinforced secondary hardening ultrahigh-strength steel and a preparing method and belongs to the technical field of alloy steel. The Co-free composite reinforced secondary hardening ultrahigh-strength steel comprises, by weight, 0.20-0.50% of C, 1.0-5.0% of Cr, 10.0-30.0% of Ni, 0.50-3.0% of Al, 1.0-5.0% of Mo, 2.0% of W or less, 0.30% of V or less, 0.20% of Nb or less, and the balance Fe and unavoidable impurities. The vacuum induction technology, the vacuum arc remelting or vacuum induction technology and the electroslag remelting technology can be adopted in the alloy. Compared with the prior art, the Co-free composite reinforced secondary hardening ultrahigh-strength steel has the beneficial effects that the comprehensive performance is good, ultrahigh strength and good ductility and toughness are achieved, the heat treatment technology is superior in performance, high temper resistance and overaging resisting capability are achieved, the content of the strategic resource of the Co element is saved, and the economical efficiency is improved.

Owner:CENT IRON & STEEL RES INST

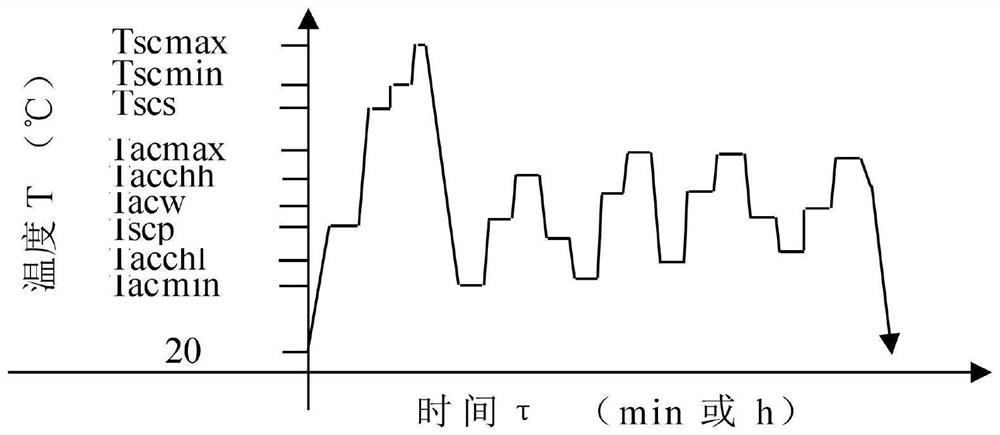

Critical solid solution and multi-time variable-temperature alternating aging composite heat treatment method starting from low temperature

PendingCN114410925ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeAustenite

The invention provides a critical solid solution and multi-time variable-temperature alternating aging composite heat treatment method starting from low temperature. The method comprises a critical solid solution heat treatment process and a critical-starting low-temperature multi-time variable-temperature alternating aging composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

Sufficient solid solution and sufficient heating and cooling variable-temperature aging heat treatment method

The invention provides a sufficient solid solution and sufficient heating and cooling variable-temperature aging heat treatment method. The method comprises a sufficient solid solution heat treatment process, a sufficient heating aging heat treatment process and a sufficient cooling variable-temperature aging heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology problems can be solved.

Owner:山西柴油机工业有限责任公司

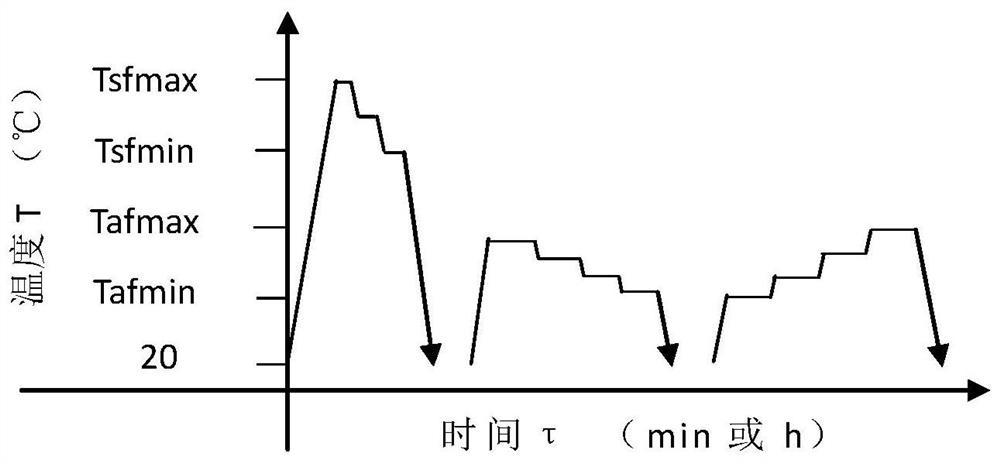

Rapid solid solution and rapid cooling, heating and variable-temperature aging heat treatment method

The invention provides a rapid solid solution and rapid cooling, heating and variable-temperature aging heat treatment method. The heat treatment method comprises a rapid solid solution heat treatment process and a rapid cooling, heating and variable-temperature aging heat treatment process. According to the scheme, the specific heat treatment technical problems of low quality stability, qualified rate, hardness, mechanical property and consistency, long heating time, low efficiency, low heating reliability of heat treatment equipment, short service life and high cost of high-temperature components and the like during austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

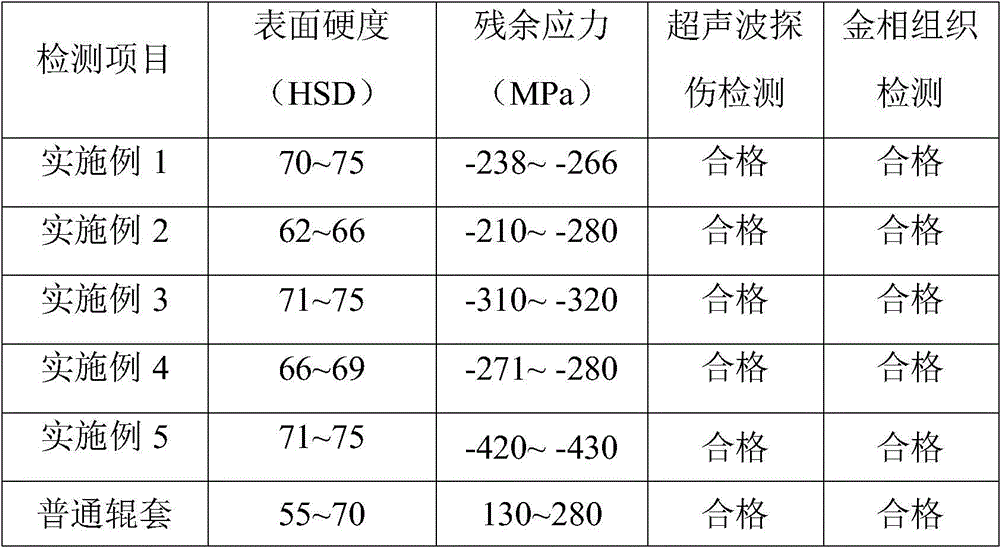

Large forged alloy steel backup roll sleeve and manufacturing method thereof

ActiveCN104593691BImproved resistance to contact fatigueExcellent resistance to contact fatigueThermal impactIngot

The invention discloses a roller sleeve for large forged alloy steel carrying roller and a manufacturing method thereof. The roller sleeve for large forged alloy steel carrying roller comprises following chemical constituents in percentage by mass: 0.40-0.80% of C, 0.20-1.20% of Si, 0.20-1.00% of Mn, 3.00-8.00% of Cr, 0.15-1.50% of Mo, 0.05-0.40% of V, Ni<=0.80%, P<=0.02%, S<=0.02% and the balance of Fe and ineluctable impurities. The manufacturing method for the roller sleeve for large forged alloy steel carrying roller comprises four steps, including refining steel ingot, forging roller sleeve base, pre-heating and machining and final heat treatment. The product of the invention is excellent in anti-contact fatigue performance, abrasion performance and roller shape retention, so that a complex carrying roller can satisfy rolling requirements of high-accuracy plates. According to the invention, the complex carrying roller obviously precedes conventional carrying rollers in contact-fatigue performance, roller shape retention and anti-mechanical and anti-thermal impact performances, and has especially excellent performance when being used as a sleeve for a convexity-changeable complex carrying roller.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

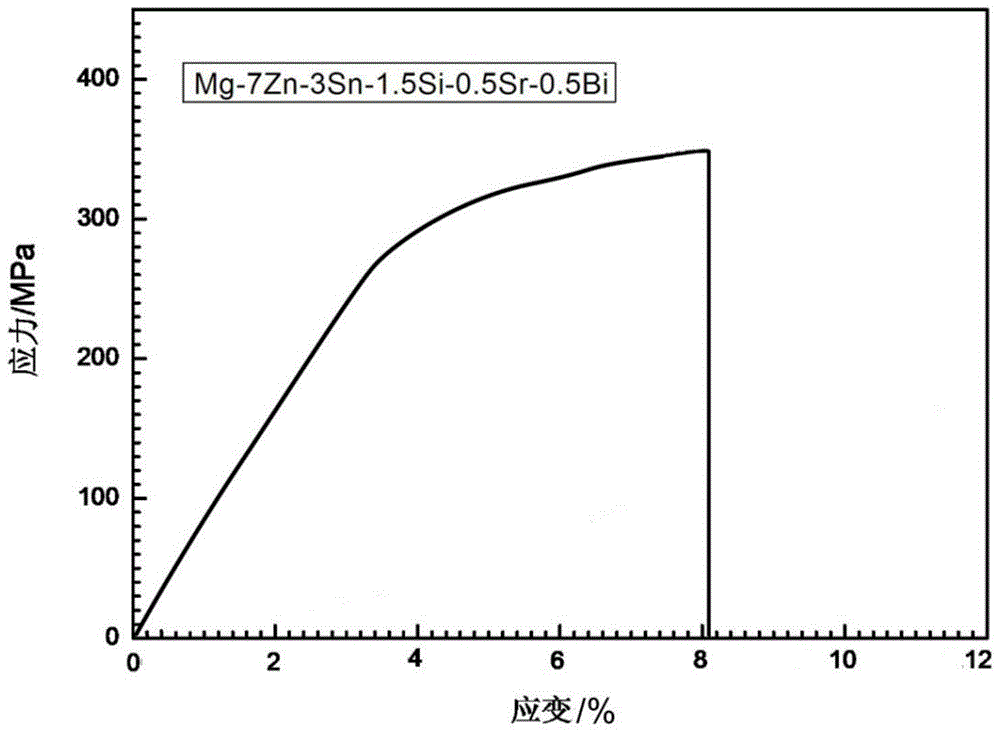

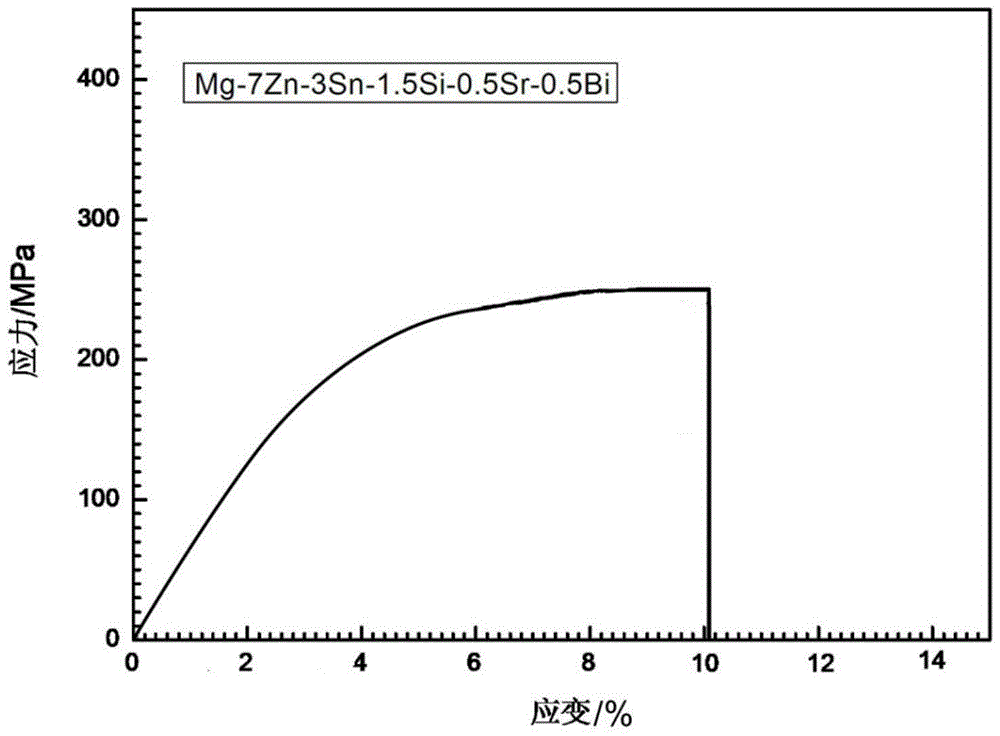

High-performance heat-resistant cast magnesium alloy and preparation method thereof

ActiveCN104561717BImprove the effect of solid solution aging strengtheningImprove plasticityAviationCrucible

Owner:HANDAN LIANCHENG MACHINERY MFG CO LTD

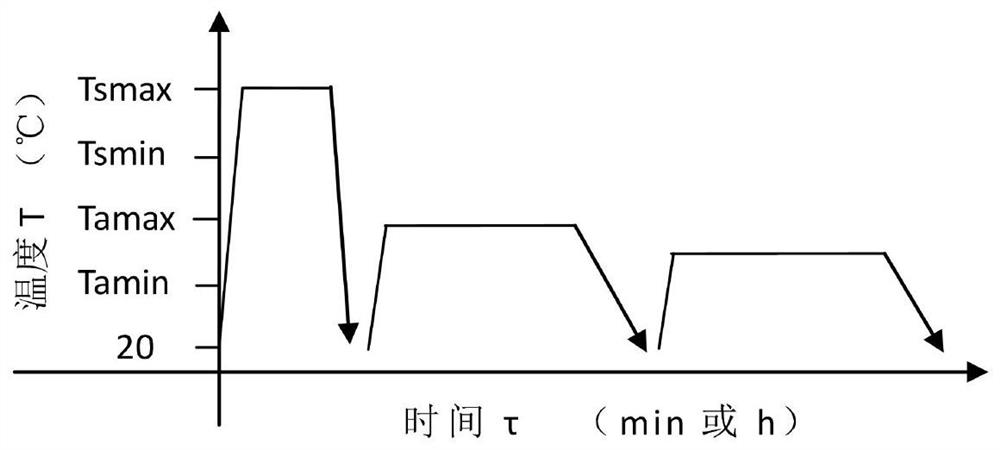

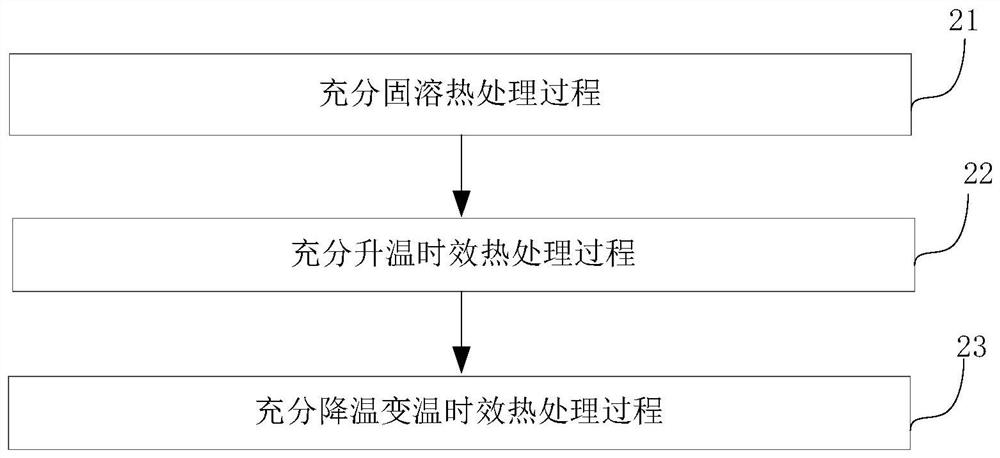

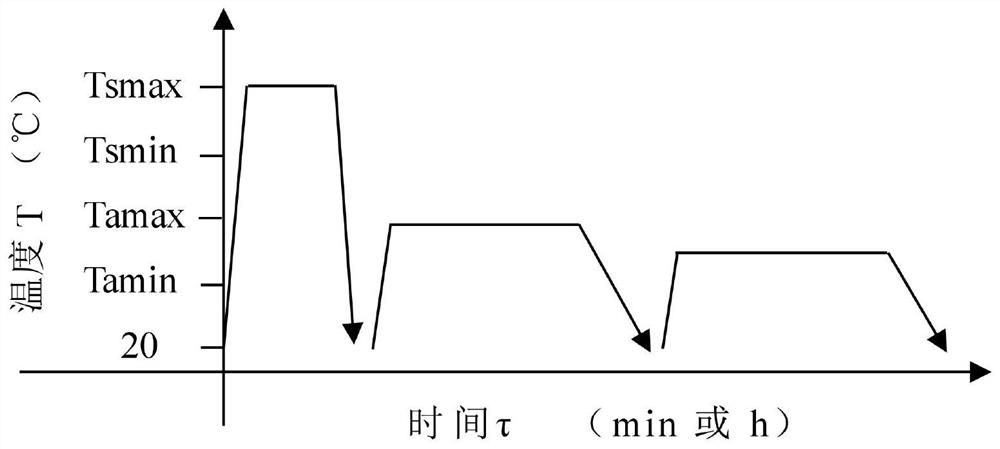

Aging heat treatment method for critical solid solution as well as critical temperature rise and temperature fall

The invention provides an aging heat treatment method for critical solid solution as well as critical temperature rise and temperature fall. The aging heat treatment method comprises a critical solid solution heat treatment process, a critical temperature rise aging heat treatment process and a critical temperature fall aging heat treatment process. The aging heat treatment method provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety; the advantages and disadvantages of a traditional mainstream heat treatment method for austenitic stainless steel can be effectively enhanced and avoided; the specific heat treatment technology problems that in the existing austenitic stainless steel heat treatment process, the quality stability is low, the rate of qualified products is low, the hardness is relatively low, the mechanical performance is low, the consistency is poor, the discoloration and corrosion resisting capacity is poor, the heating time is long, the efficiency is low, the heating reliability of heat treatment equipment is poor, the service life of high-temperature components is short, and the cost is high can be fundamentally solved; and the aging heat treatment method is particularly applicable to the technical fields of hot-working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel in steel mills and manufacturing plants.

Owner:山西柴油机工业有限责任公司

Critical solid solution and critical starting low-temperature alternating aging composite heat treatment method

PendingCN114410915AGood workmanshipIncrease solid solution and aging strengthening phaseHeat treatment process controlAustenitic stainless steelHeating time

The invention provides a critical solid solution and critical-beginning low-temperature alternating aging composite heat treatment method. The method comprises a critical solid solution heat treatment process and a critical low-temperature alternating aging composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

Critical solid solution and critical starting low-temperature multiple variable-temperature alternating aging heat treatment method

The invention provides a critical solid solution and critical starting low-temperature multiple variable-temperature alternating aging heat treatment method. The method involves a critical solid solution heat treatment process and a critical starting low-temperature multiple variable-temperature alternating aging heat treatment process. The scheme provided by the method has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively improve the advantages and avoid the disadvantages of the traditional mainstream heat treatment method of austenitic stainless steel; the special heat treatment technical problems of "one long, one high, four poor and five low", namely, poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, poor discoloration and corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components and high cost and the like of the existing austenitic stainless steel heat treatment can be fundamentally solved; and method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment of the austenitic stainless steel involved in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Critical solid solution and critical heating aging heat treatment method

The invention provides a critical solid solution and critical heating aging heat treatment method. The critical solid solution and critical heating aging heat treatment method comprises a critical solid solution heat treatment process and a critical heating aging heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel; the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology problems are fundamentally solved. The method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Critical solid solution and variable-temperature alternating aging and annealing composite heat treatment method starting from high temperature

The invention provides a critical solid solution and high-temperature-varying alternating aging and annealing composite heat treatment method. The method comprises a critical solid solution heat treatment process and a heat treatment process which is critically started from high-temperature variable-temperature alternating aging and annealing composite heat treatment process. According to the scheme, the problems that existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like can be solved. The heating reliability of heat treatment equipment is poor; the service life of a high-temperature component is short; the cost is high; and the like.

Owner:山西柴油机工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com