Patents

Literature

56results about How to "Improve weld structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

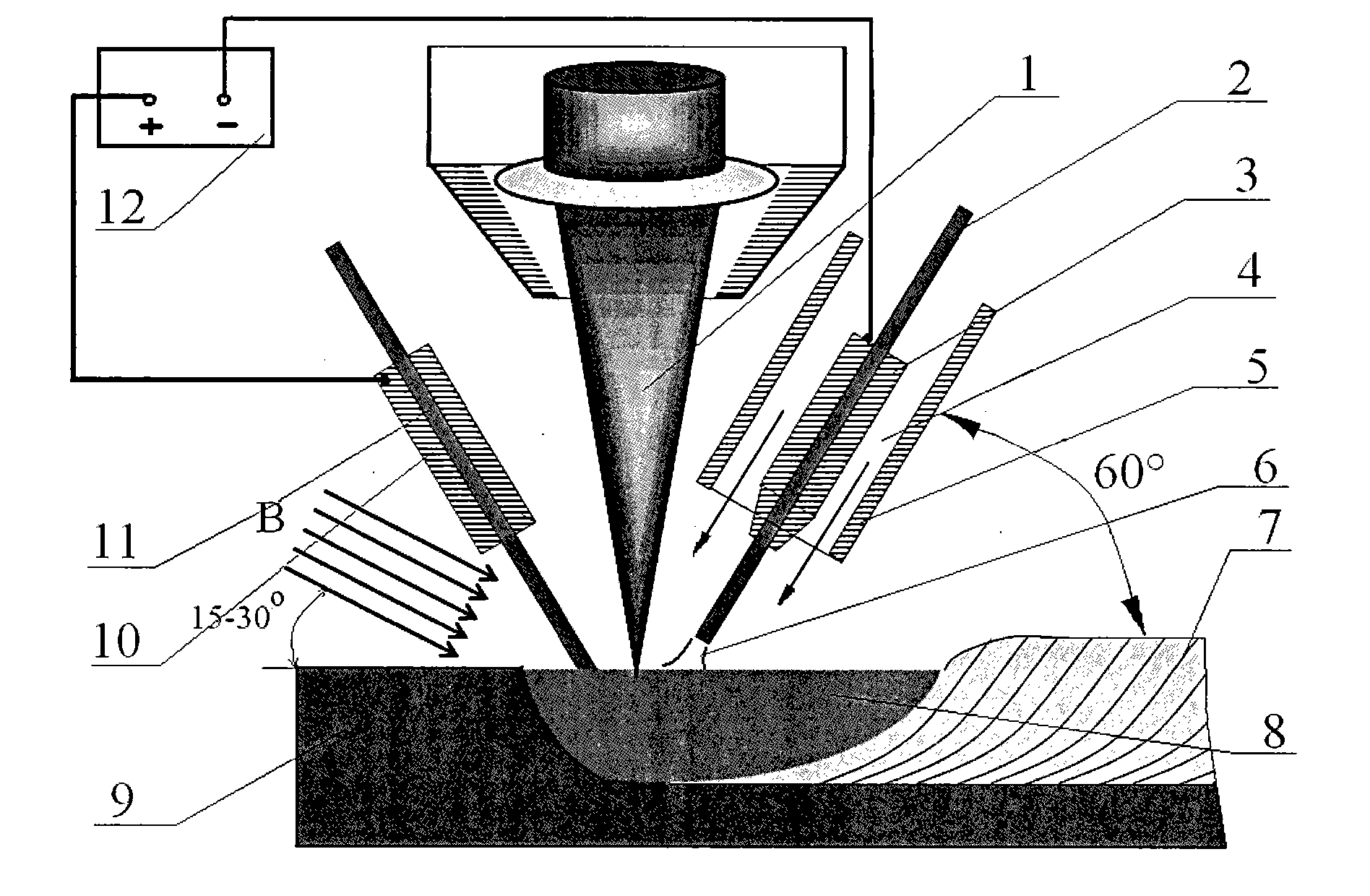

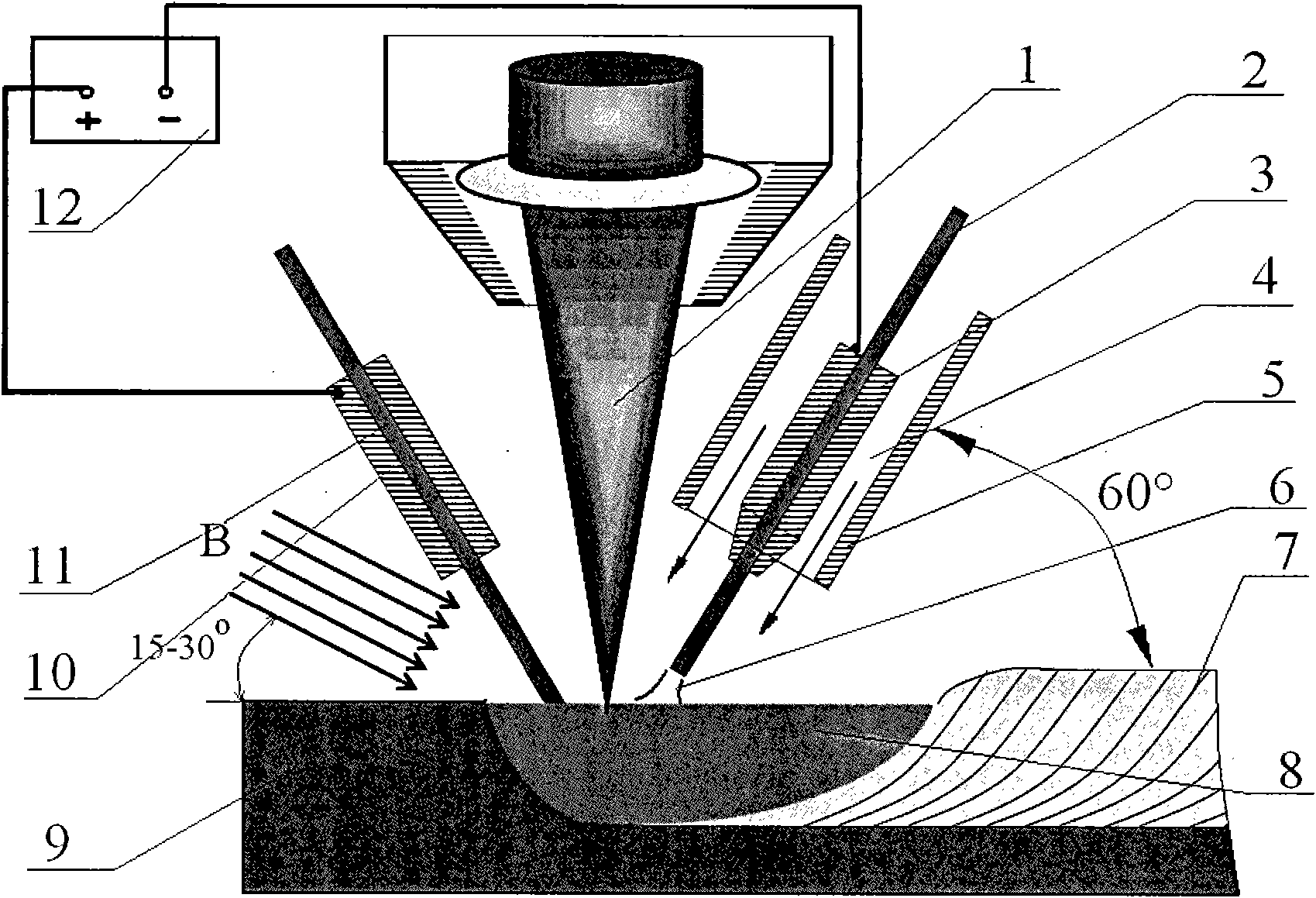

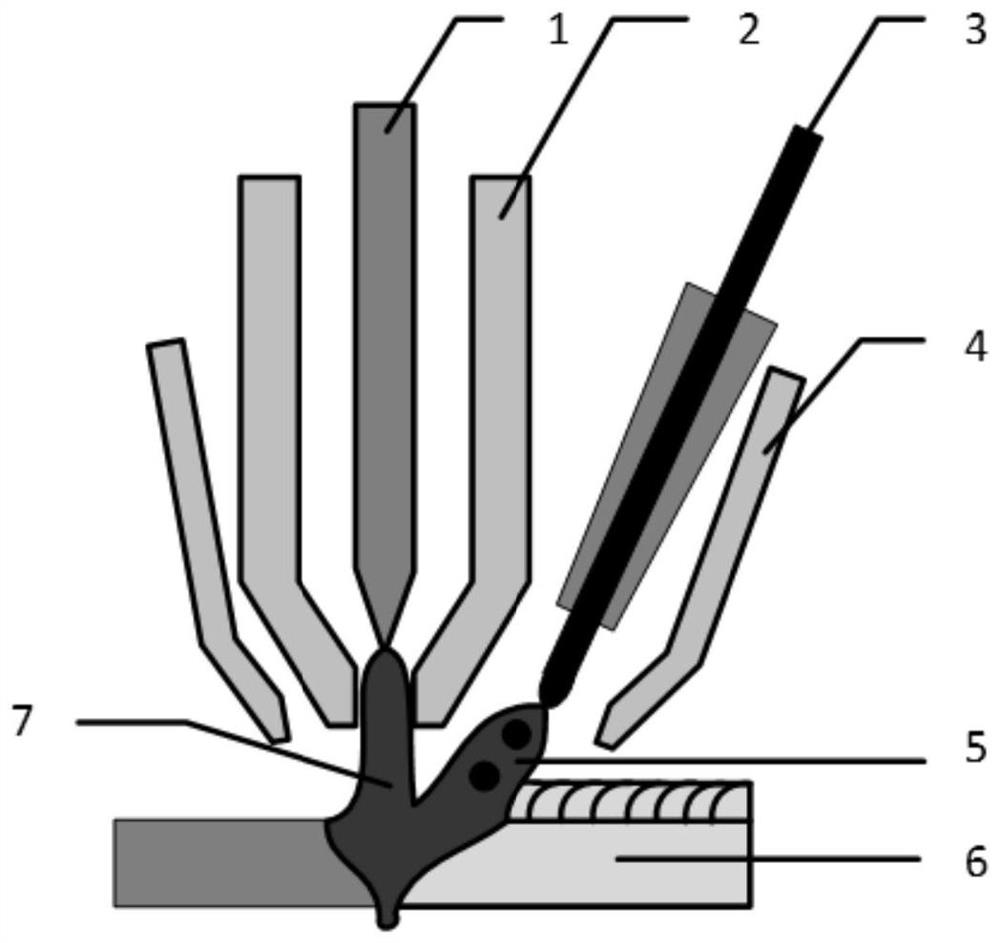

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

Hot rolling wire rod for 60 kg-stage high-strength welding wire and production method thereof

ActiveCN109706391AReduce manufacturing costGood performance and stabilityImpurityCooling temperature

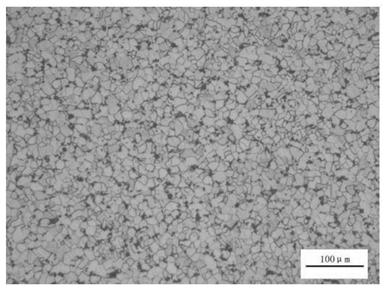

The invention discloses a hot rolling wire rod for a 60 kg-stage high-strength welding wire and a production method thereof. The hot rolling wire rod comprises the following chemical components including, by mass, 0.06% to 0.12% of C, 0.40% to 0.80% of Si, 1.50% to 2.00% of Mn, 0.020% or less of P, 0.020% or less of S, 0.040% to 0.060% of V, 0.050% to 0.090% of Ti, 0.20% to 0.45% of Cr and the balance Fe and unavoidable impurities. The production method comprises steel making, continuous casting, heating, rolling, spinning and cooling procedures. According to the hot rolling wire rod for the 60 kg-stage high-strength welding wire and the production method thereof, the hot rolling wire rod for high-strength welding is produced through vanadium and titanium alloying, microstructures of equiaxial ferrite and pearlite are obtainedin cooperation with control over the finish rolling temperature, spinning temperature, cooling temperature and winding temperature, the hot rolling wire rod is processed into a gas shielded welding rod, the deposited metal tensile strength is 600 MPa to 700 MPa, and the wire rod is low in cost and good in performance stability.

Owner:HEBEI IRON AND STEEL

Solid state heat sink device used for friction stir welding and welding method of solid state heat sink device

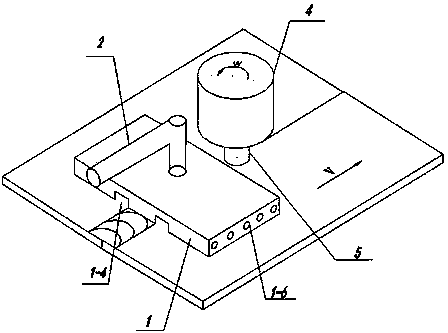

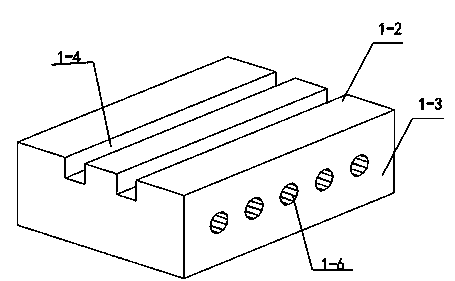

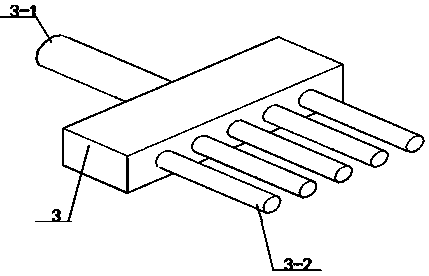

InactiveCN103639588AImprove performanceReduce unevennessWelding/cutting auxillary devicesAuxillary welding devicesWater channelEngineering

The invention discloses a solid state heat sink device used for friction stir welding and a welding method of the solid state heat sink device. The solid state heat sink device comprises a solid state heat sink, a push rod connected with the solid state heat sink and a cooling water pipe, wherein the solid state heat sink comprises an upper bottom face, a lower bottom face and a side face, heat dissipation through grooves are formed in the lower bottom face, cooling water channels are formed in the side face, the cooling water channels are connected with the cooling water pipe, and an installation hole used for installation of the push rod is formed in the upper bottom face of the solid state heat sink. The solid state heat sink device synchronously moves in the welding direction along with a friction stir welding device, and the lower bottom face makes full contact with the surface of a weldment so that heat conduction can be achieved, heat dissipation and cooling can be conducted on a weld joint which is still at a high temperature, and the peak temperature of the weld joint can be effectively lowered. Meanwhile, cooling water is injected into the water channels formed inside the heat sink to conduct forced heat dissipation and cooling. According to the solid state heat sink device and the welding method, the weld joint can be prevented from being overheated, weld joint crystalline grains are refined, the well-formed formation is improved, residual stress and strain of a welded joint can be eliminated or reduced, and the aims of improving the quality of the weld joint and improving the comprehensive performance of the joint are achieved.

Owner:JIANGSU UNIV OF SCI & TECH

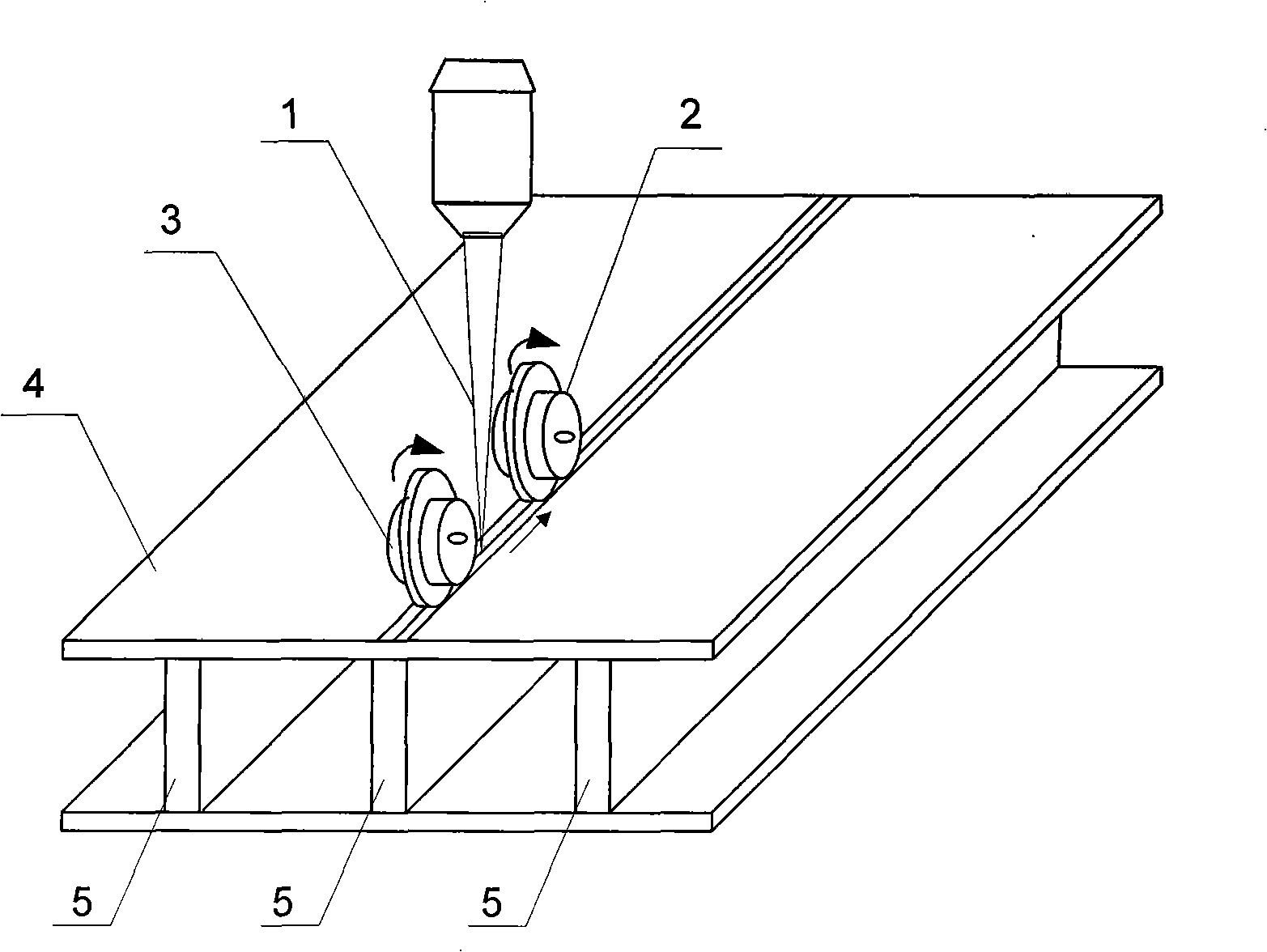

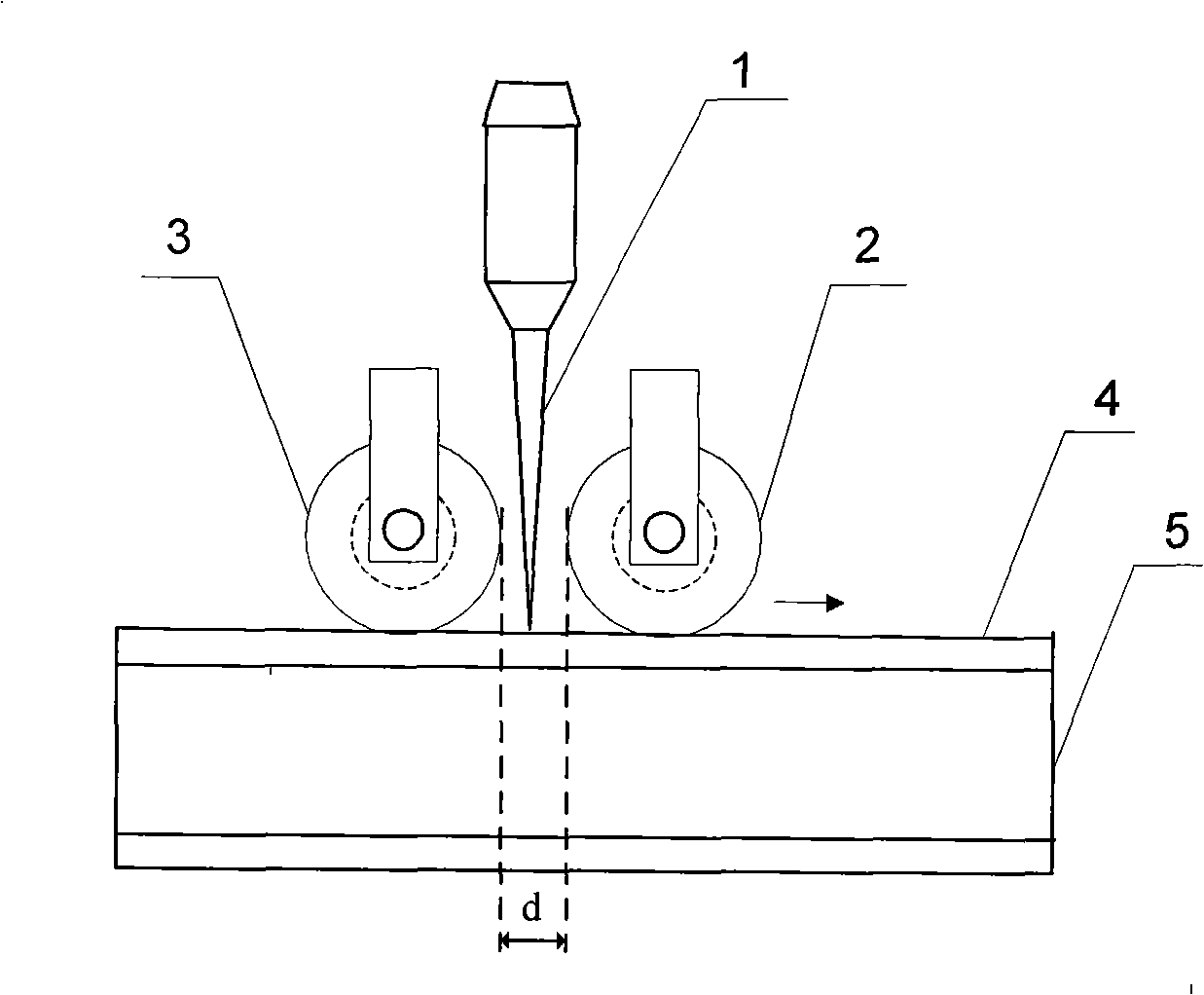

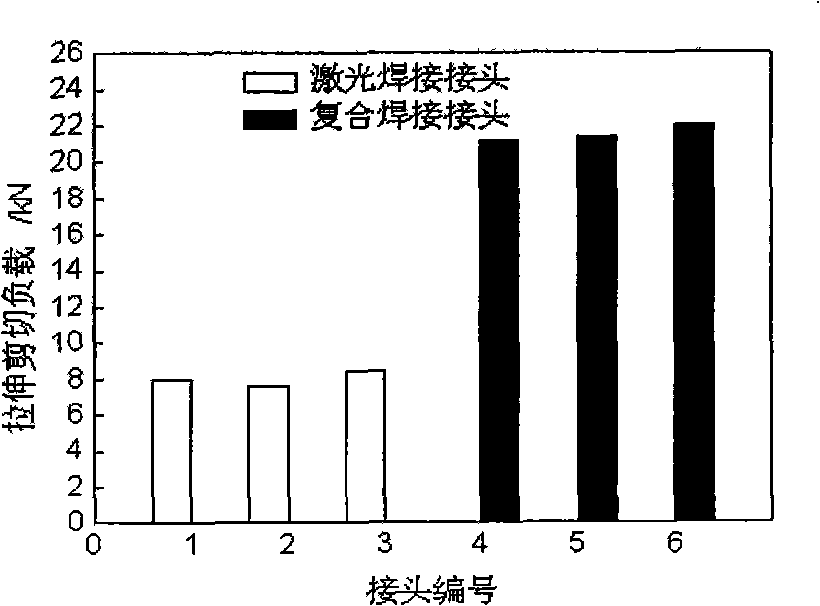

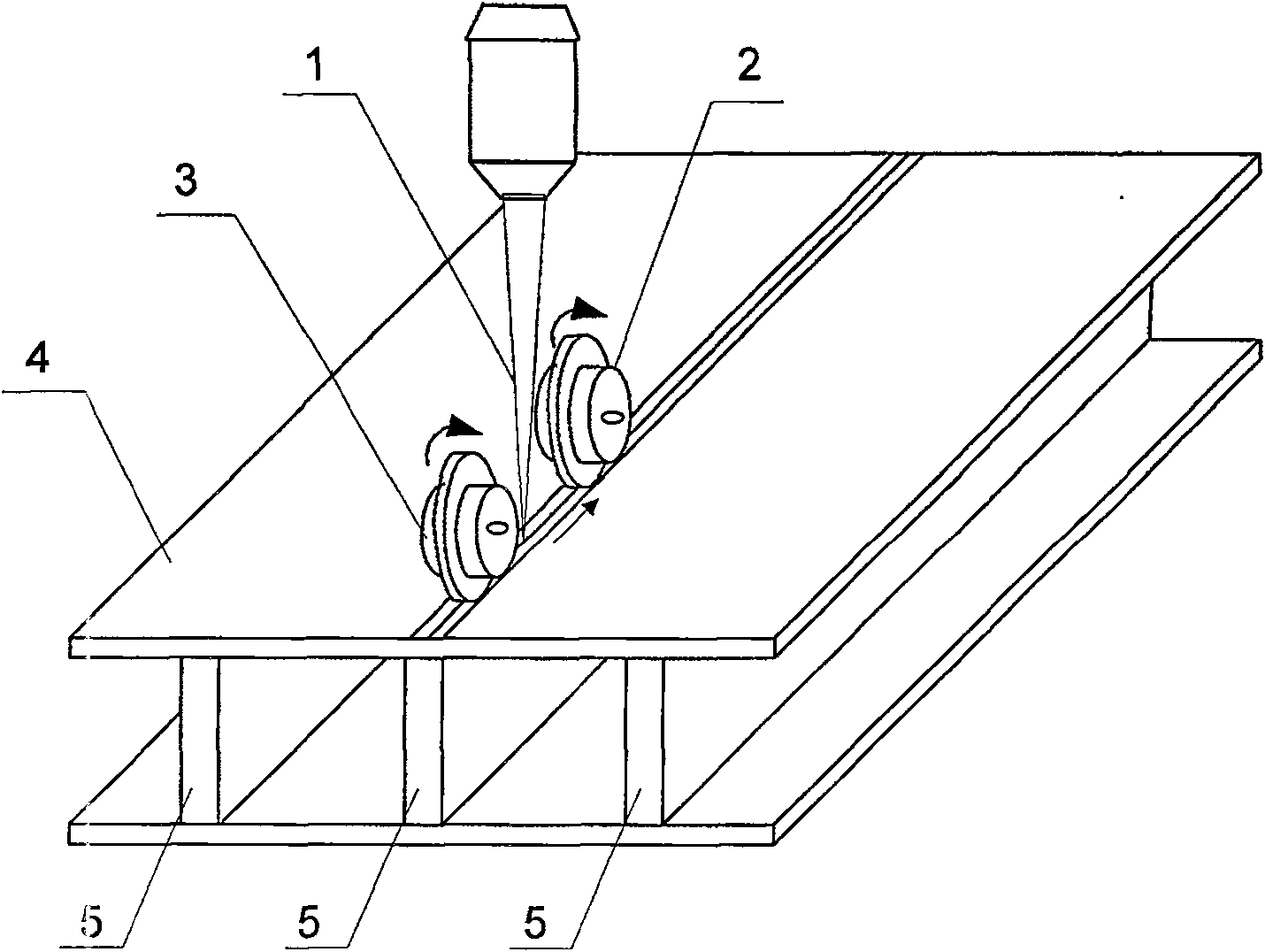

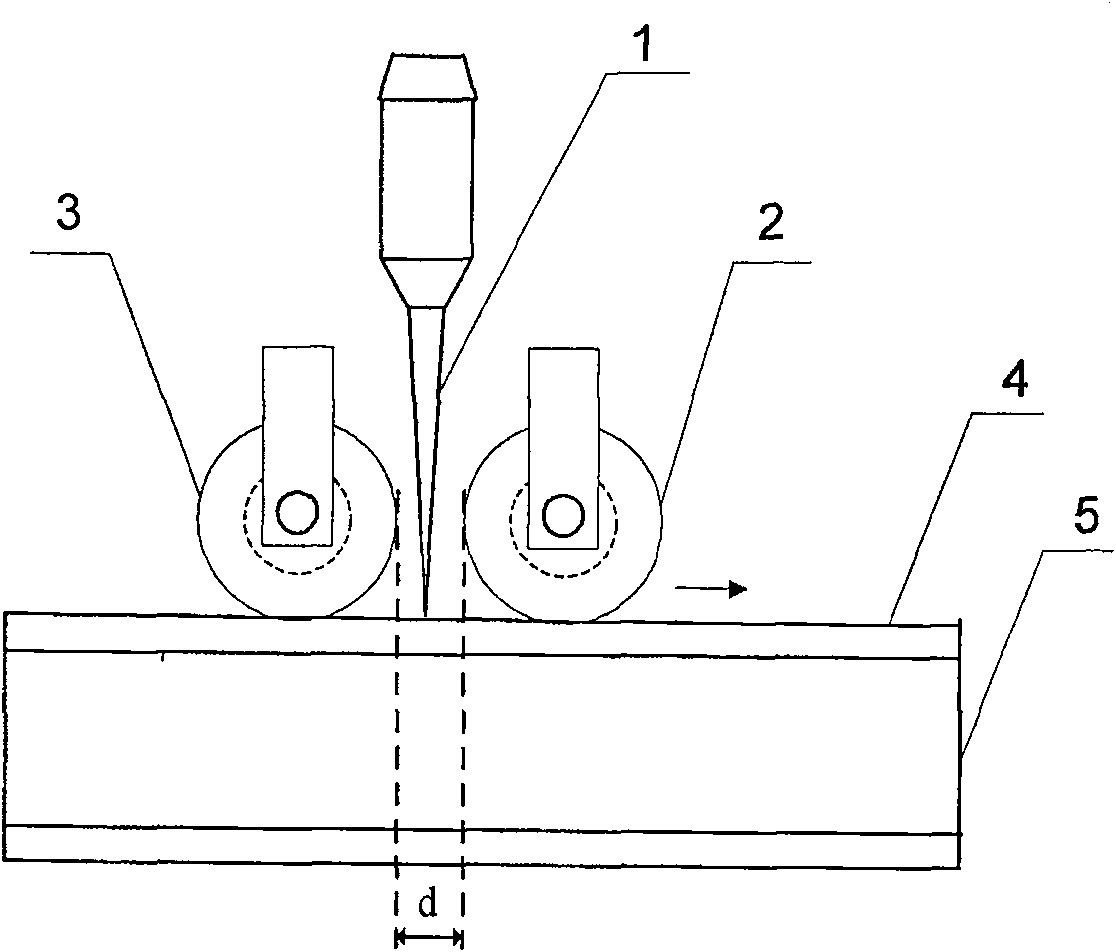

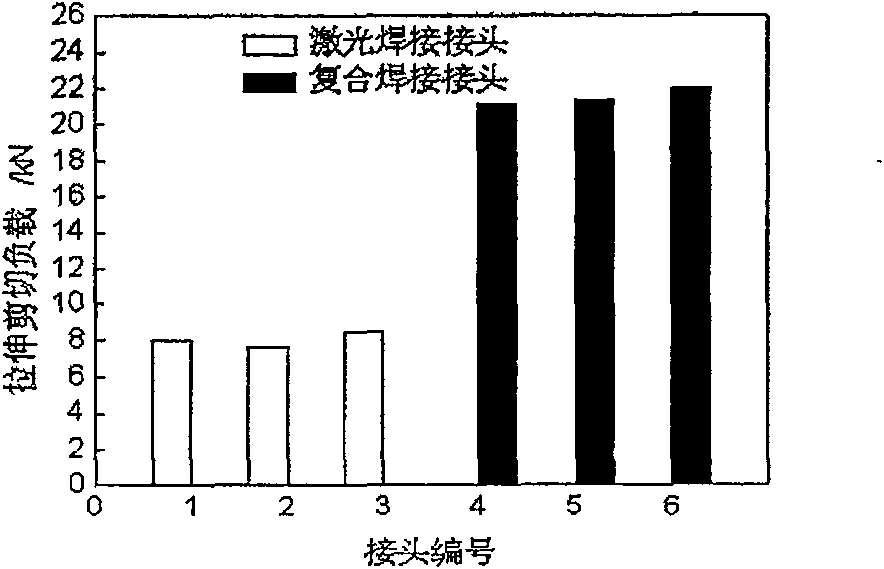

Laser-electric resistance seam welding in-phase compound welding method of frame-covering structure

InactiveCN101306491AFit tightlyImprove welding qualityWelding with roller electrodesLaser beam welding apparatusLight beamElectric resistance welding

A laser and electric-resistance seam-welding synchronous composite welding method for an envelope-framework structure relates to a novel laser and electric-resistance seam-welding synchronous composite welding method, belongs to the welding field, and aims to solve the problems in welding the envelope-framework structure by the single laser, such as narrow seam, low shear strength of the seam, a plurality of air vents on the faying surface of the envelope and the framework. The invention aims at the workpiece with the envelope-framework structure to be welded, and adopts the laser and the electric-resistance seam-welding synchronous composite welding; the electric-resistance seam-welding adopts double-roller single-side welding, two roller electrodes are disposed on the front and the back sides of the upper top surface of the envelope along the seam formed by the contact of the envelope and the framework, so that the envelope is pressed to the lower framework in the travel forward, and the laser beam is always positioned in the middle position of the two roller electrodes during the welding process. The seam formed by the welding method can improve the shear strength more than twice in comparison with the base material, and the air vent amount per area can be reduced from about 10% to about 2% of the laser welding.

Owner:HARBIN INST OF TECH

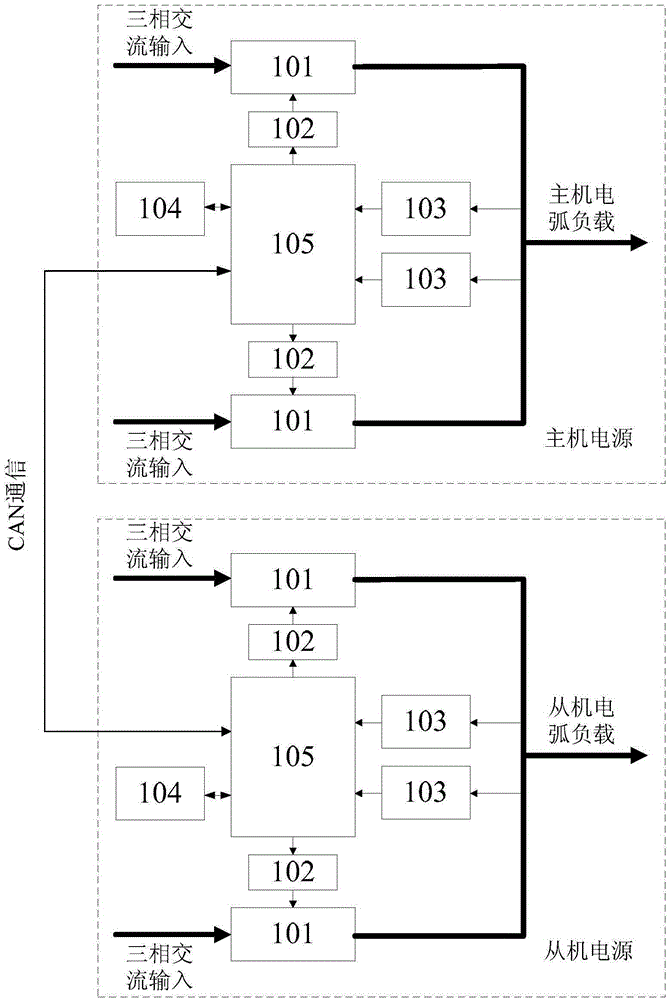

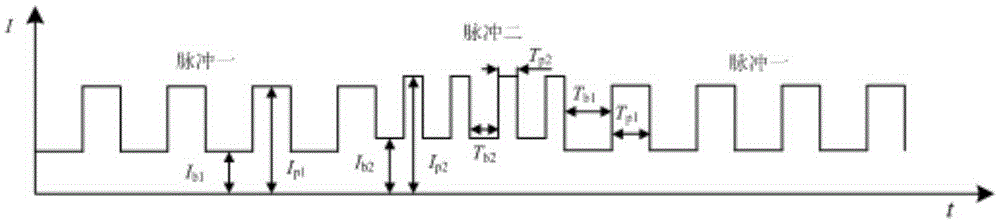

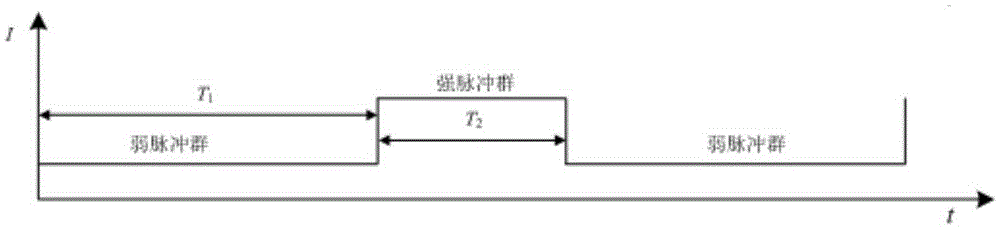

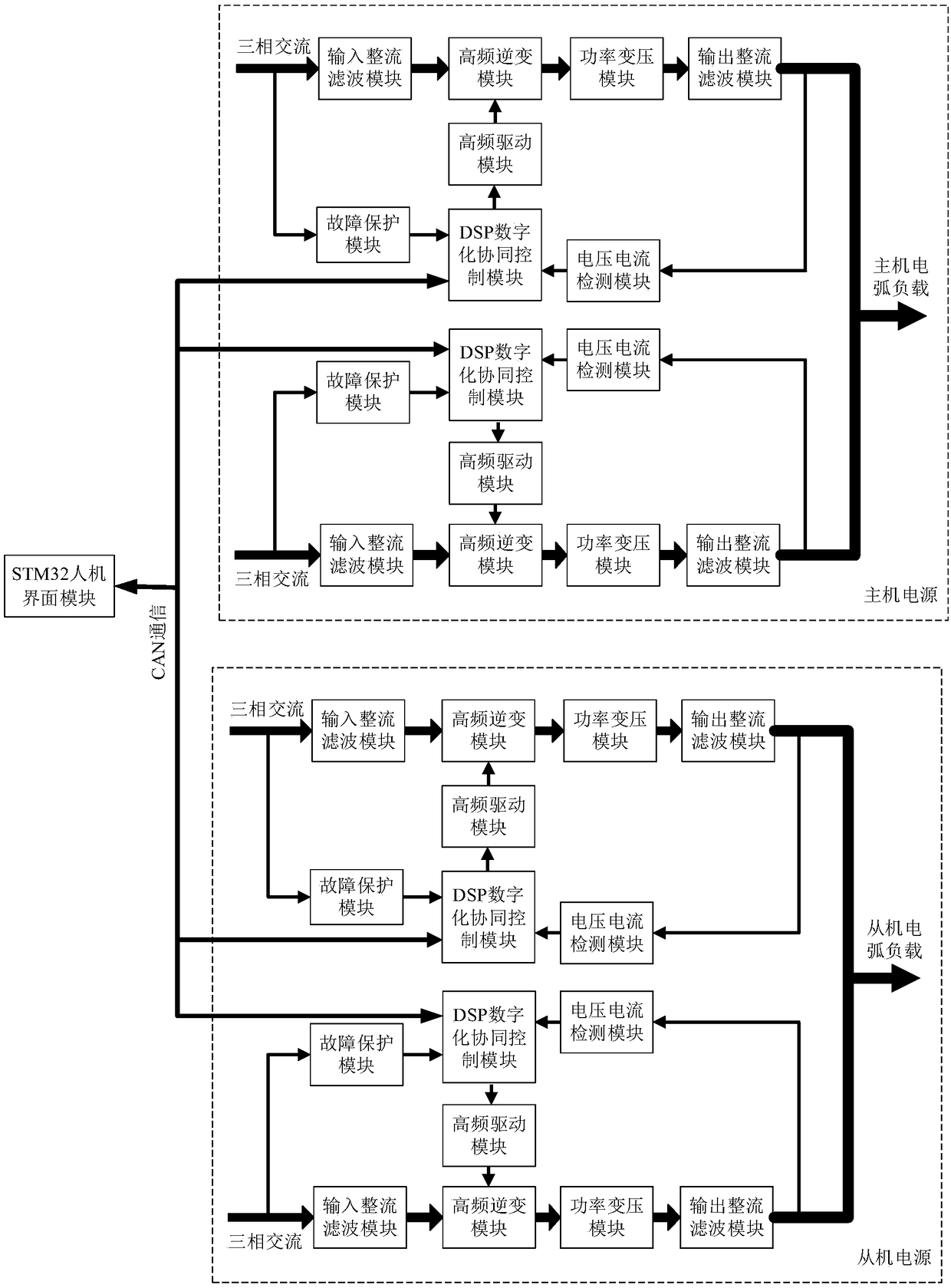

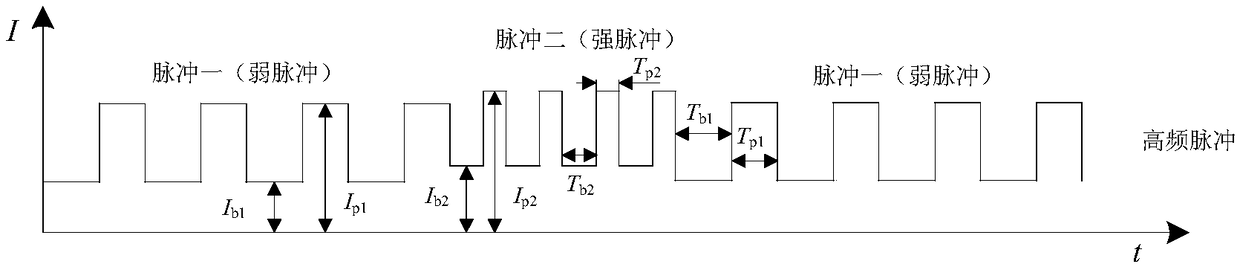

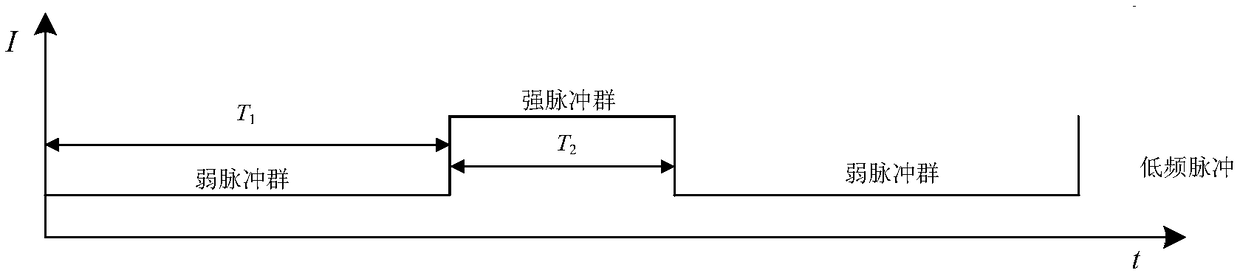

High-power double-wire pulse MIG welding low-frequency modulation type double-pulse control system

InactiveCN105269117AImprove welding efficiencyEasy to achieve one-time forming weldingWelding accessoriesHuman–machine interfaceAlternating current

The invention discloses a high-power double-wire pulse MIG welding low-frequency modulation type double-pulse control system. The system comprises a main engine power supply for supplying current to a front wire and cooperatively controlling the whole system, and a slave engine power supply for supplying current to a back wire, wherein a main engine and the slave engine power supply are connected through a CAN bus; the main engine power supply and the slave engine power supply respectively comprise two main circuits and control circuits; one ends of the two main circuits are connected with three-phase alternating current, and the other ends are connected with an electric arc load after parallel connection; the main circuits comprise power conversion modules; and the control circuits comprise human-computer interface modules, DSP digital cooperation control modules, high-frequency driving modules and voltage current detecting modules. The system can realize synchronous, alternating and random three types of low-frequency modulation type double pulses, and uses two ways of low-frequency modulation type double pulses of main and slave engines for acting on high-power double arcs and double-wire molten drops and causing the molten pool resonance to improve the welding process stability, to optimize the welding line structure and to improve the welding line forming quality.

Owner:SOUTH CHINA UNIV OF TECH

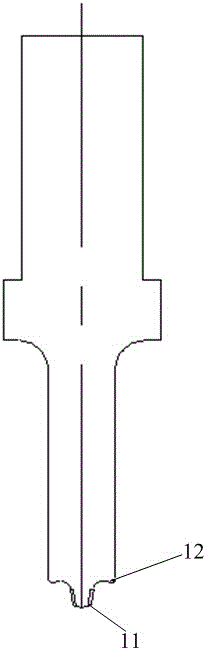

Friction-stir welding device and method thereof

InactiveCN106563878ASimple structurePrevent thinningNon-electric welding apparatusEngineeringHigh frequency vibration

The invention provides a friction-stir welding device. The friction-stir welding device comprises an ultrasonic generator, a variable-amplitude static shaft shoulder, a stirring needle and a mounting base, wherein the ultrasonic generator is in a hollow cylinder shape; the variable-amplitude static shaft shoulder is provided with a mounting opening in one end and coaxially and rigidly connected with the ultrasonic generator; the stirring needle, the ultrasonic generator and the variable-amplitude static shaft shoulder are coaxially mounted, and the non-operating end of the stirring needle is connected with a machine head spindle of the friction-stir welding device; and the mounting base is rigidly fixed to the ultrasonic generator. The invention further provides a method for conducting friction-stir welding on a workpiece through the friction-stir welding device. According to the method for conducting friction-stir welding on the workpiece through the friction-stir welding device, thinning of a weld joint can be effectively avoided through the non-rotational variable-amplitude static shaft shoulder; through high-frequency vibration of the variable-amplitude static shaft shoulder, welding flanges can be completely eliminated; and power ultrasounds are input into weld joint metal through the variable-amplitude static shaft shoulder, the structure of the weld joint can be optimized, and the mechanical performance of the weld joint is improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

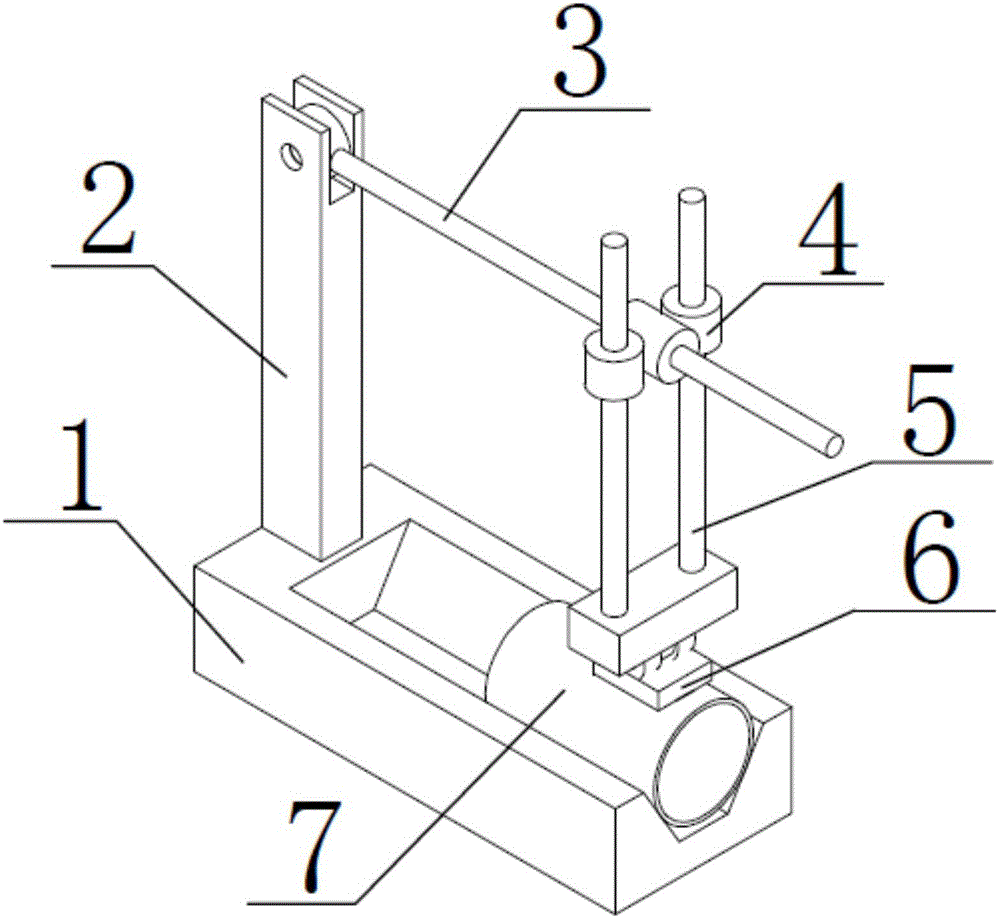

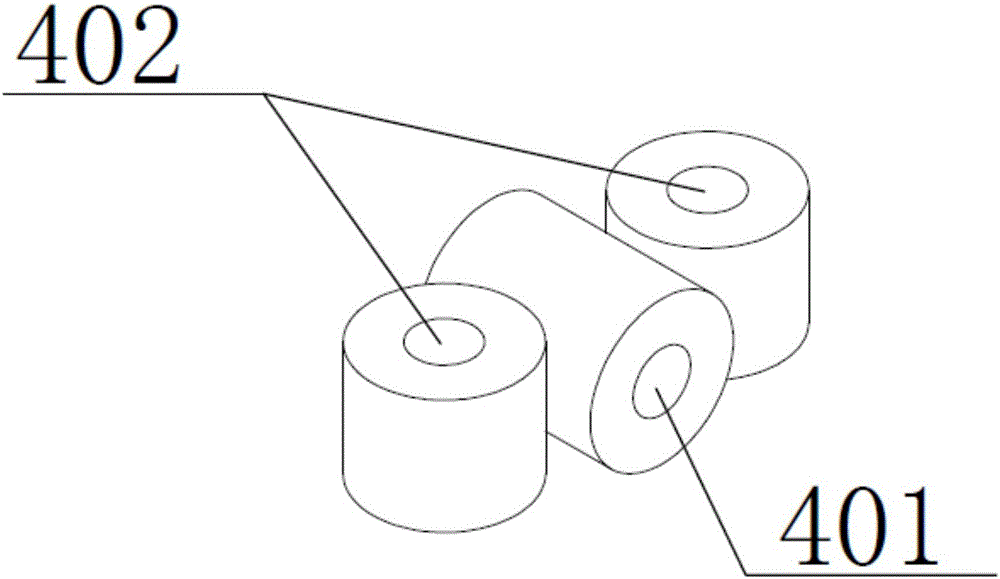

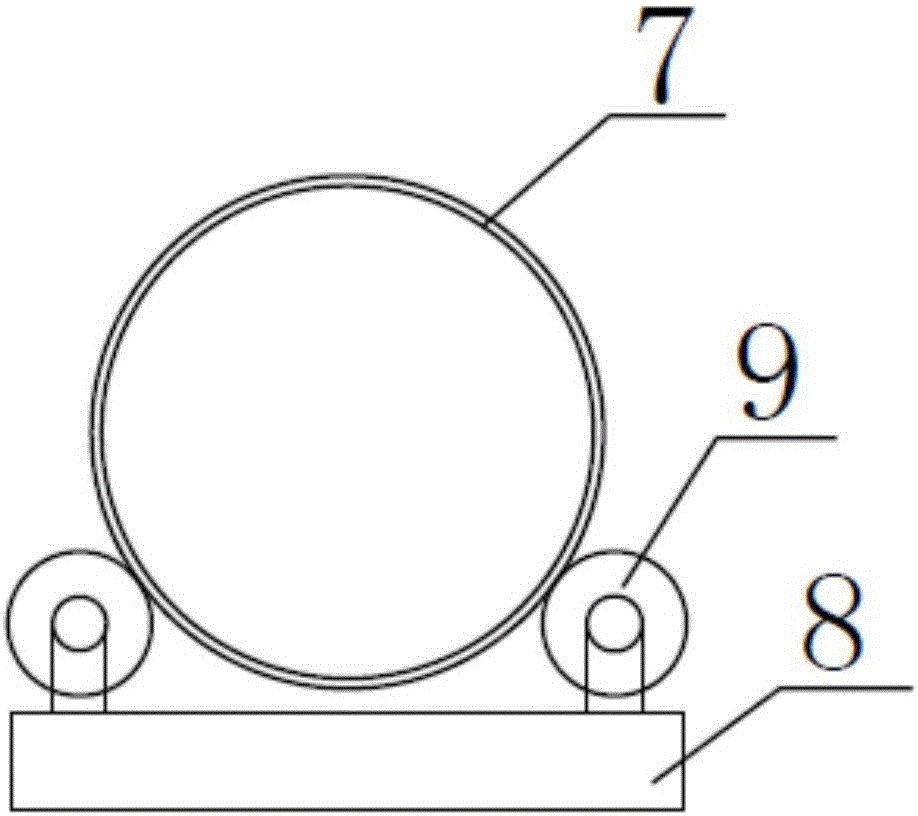

Longitudinal seam welded steel pipe manufacturing technology and spool pressing device for technology

InactiveCN106271432AQuality assuranceImprove weld structureWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyRoll forming

The invention provides a longitudinal seam welded steel pipe manufacturing technology which comprises the following steps of steel plate shearing, finishing, plate rolling forming, welding, welding seam polishing, roundness correction and dimension adjusting, wherein the step of welding comprises spot welding location and welding forming, and the step of roundness correction comprises automatic roundness correction and manual adjustment. The eccentricity of a longitudinal seam welded steel pipe manufactured by the longitudinal seam welded steel pipe manufacturing technology is less than 0.1mm, the circular runout of the longitudinal seam welded steel pipe is less than 0.4mm, the quality of the longitudinal seam welded steel pipe is ensured effectively, the longitudinal seam welded steel pipe has excellent welding seam structure and excellent overall performance, the welding quality is high, and an operation process is safe and controllable.

Owner:天津鑫凯建业科技有限公司

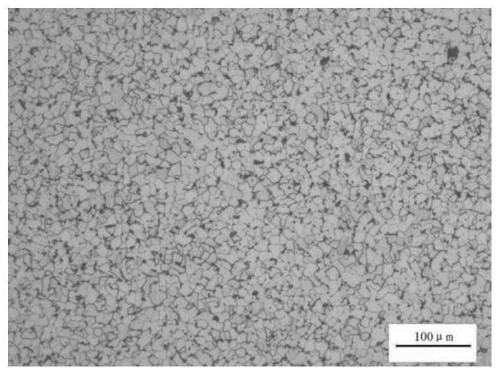

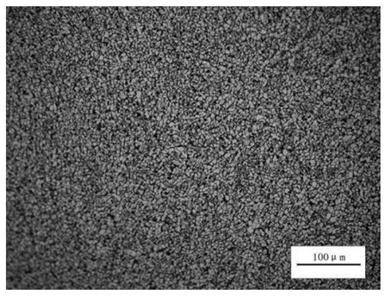

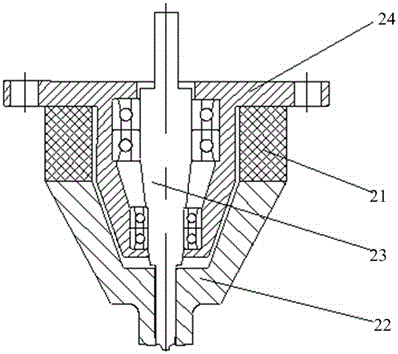

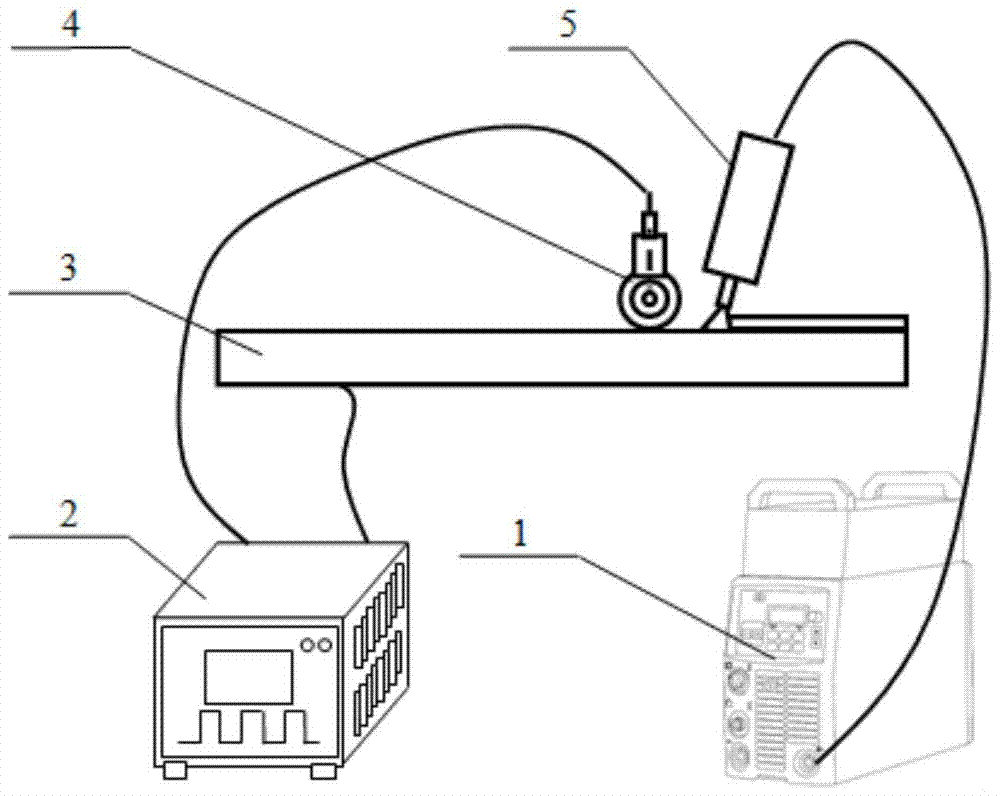

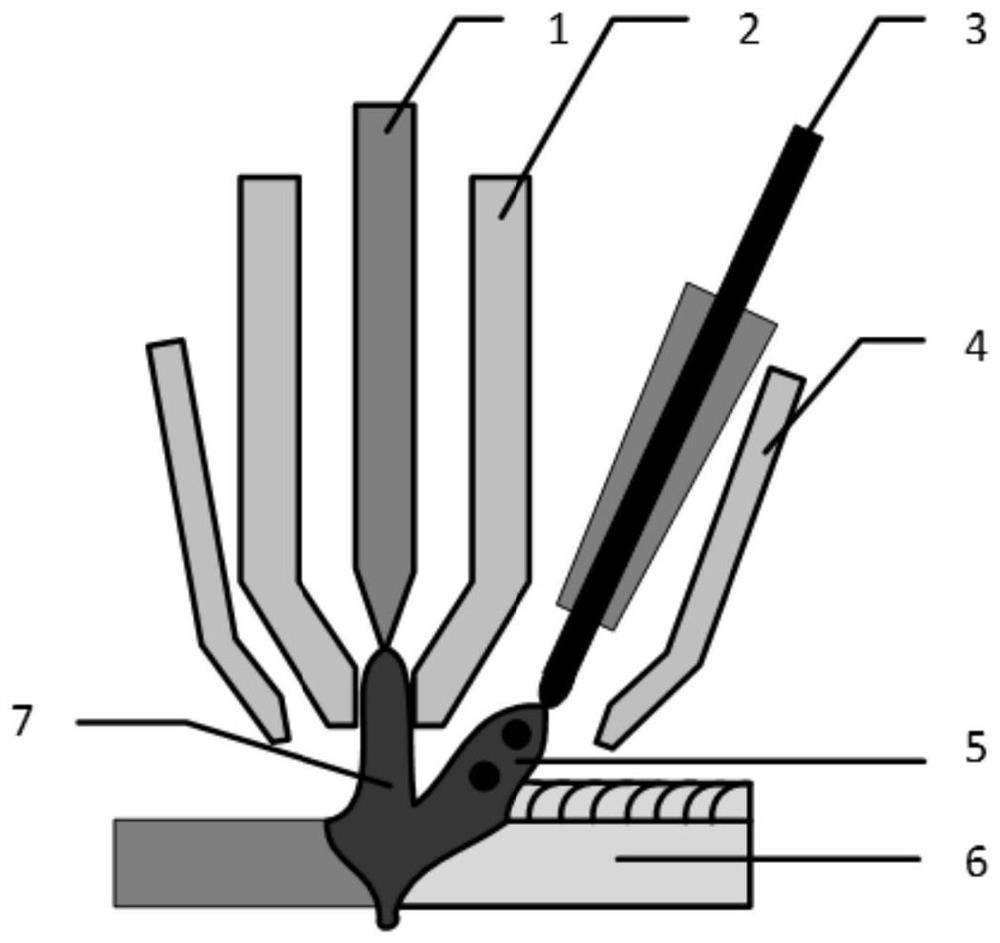

Method and device for refining weld joint structures by using pulsed magnet fields in welding process

ActiveCN102848058AStir wellImprove crystallizationWelding accessoriesWelding defectMaterials science

The invention relates to a processing technology for refining weld joint structures in a welding process, in particular to a method and a device for refining weld joint structures by using pulsed magnet fields in the welding process, and belongs to the technical field of welding. The method for refining weld joint structures by using pulsed magnet fields in the welding process includes that welding is performed by using an ordinary gas metal arc welding method, an applied magnetic field is added above a gas metal arc welding pool, mechanical movement and welding gun movement of the magnet fields are synchronous, electric arc and melt drip transition action is controlled by the magnet fields in a welding process, metal melt in the gas metal arc welding pool is forced to move, an electromagnetic stirring effect is produced, and weld joint structures are finally refined in the welding process. According to the method and the device, in the welding process, the weld joint structures are refined, welding defects are reduced, and further the cost is reduced, and the welding quality and the production efficiency are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

High-power twin-wire double-pulse MIG welding power supply system with adjustable high-and-low-frequency pulse phases and control method thereof

ActiveCN108746944AImprove welding efficiencyEasy to achieve one-time forming weldingArc welding apparatusDouble phaseWelding power supply

The invention discloses a high-power twin-wire double-pulse MIG welding power supply system with adjustable high-and-low-frequency pulse phases and a control method thereof. The power supply system comprises an STM32 human-computer interface module, a host power supply and a slave power supply, wherein the STM32 human-computer interface module is connected to DSP digital synchronic control modulesin the host power supply and the slave power supply; the host power supply provides current for a previous wire; the slave power supply provides current for a latter wire; and the host power supply,as well as the slave power supply, consists of two parallel main circuits and a control circuit. The power supply system can realize seven high-and-low-frequency pulse phase modes; two host and slavelow-frequency modulation double phases act on a high-power twin arc for double-wire melt dripping to arouse resonance of a molten pot; the temperature gradient of a temperature field of the molten potis optimized; double-arc interference is reduced; and the welding stability is improved, the weld microstructure is optimized, and the weld forming quality is improved.

Owner:SOUTH CHINA UNIV OF TECH

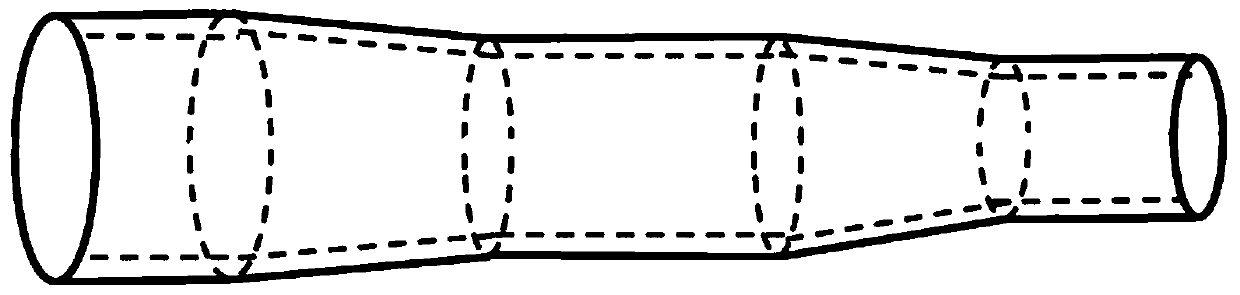

High-performance seamless continuous pipe and manufacturing method thereof

The invention discloses a high-performance seamless continuous pipe and a manufacturing method thereof. The method comprises the steps of preparing a continuous pipe dedicated board through processesof high-purity refining, continuous casting, thermal controlled rolling and controlled cooling, acid pickling and the like; preparing pipe blanks through rolled plate longitudinal shear, steel strip abut joint, cage-roll forming and high-frequency induction welding with protection gas; continuously producing equal-outer-diameter or variable-outer-diameter pipes through hot rolling reducing of thesame specification of pipe blanks; destressing the pipes to achieve the aims of reducing the pipe residual stress, improving the pipe toughness and reducing the pipe hardness, and obtaining the continuous pipe product with the good comprehensive property. The continuous pipe product meets the API standard need, through the hot rolling reducing technology, the pipe annular and longitudinal weldingjoint structure is obviously refined, and tends to be consistent with the base metal structure, physical seamlessness is achieved, the continuous pipe whole property can be effectively improved, the service life of the continuous pipe is prolonged, work safety of the continuous pipe is improved, the continuous pipe work technology advancing can be greatly pushed, and the market application prospect is wide.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

P110 steel level high frequency straight welded pipe manufacturing method

InactiveCN102430901AImprove toughnessImprove resistance to delayed crackingFurnace typesHeat treatment furnacesMedium frequencyEngineering

A P110 steel level high frequency straight welded pipe manufacturing method comprises (1) taking hot-rolled coil as raw material; (2) shaping the coil into a straight seam pipe by continuous shaping techniques, welding the straight seam on the pipe by a high frequency inductive welding machine to produce a primary pipe, and after the welding, timely removing external and internal burrs of the primary pipe; (3) heating the primary pipe removed of burrs by a medium frequency induction furnace to 920-950 degrees centigrade and conveying it to a hot rolling and diameter reducing machine, rolling the primary pipe into pipe blanks with different apertures by hot mechanical rolling; (4) conducting whole-pipe quenching and tempering to the hot roller pipe blank to produce finished pipe; (5) conducting ultrasonic flaw detection and pipe end magnetic powder inspection to the finished pipe. The invention takes low steel level coil as raw material to produce primary pipe, produces pipe blanks with different diameter specifications by the primary pipe with the same specification, and produces oil casing product with high steel level and high performance by low steel level economical pipe blanks. The working efficiency is high. The production cost is low.

Owner:BAOJI PETROLEUM STEEL PIPE

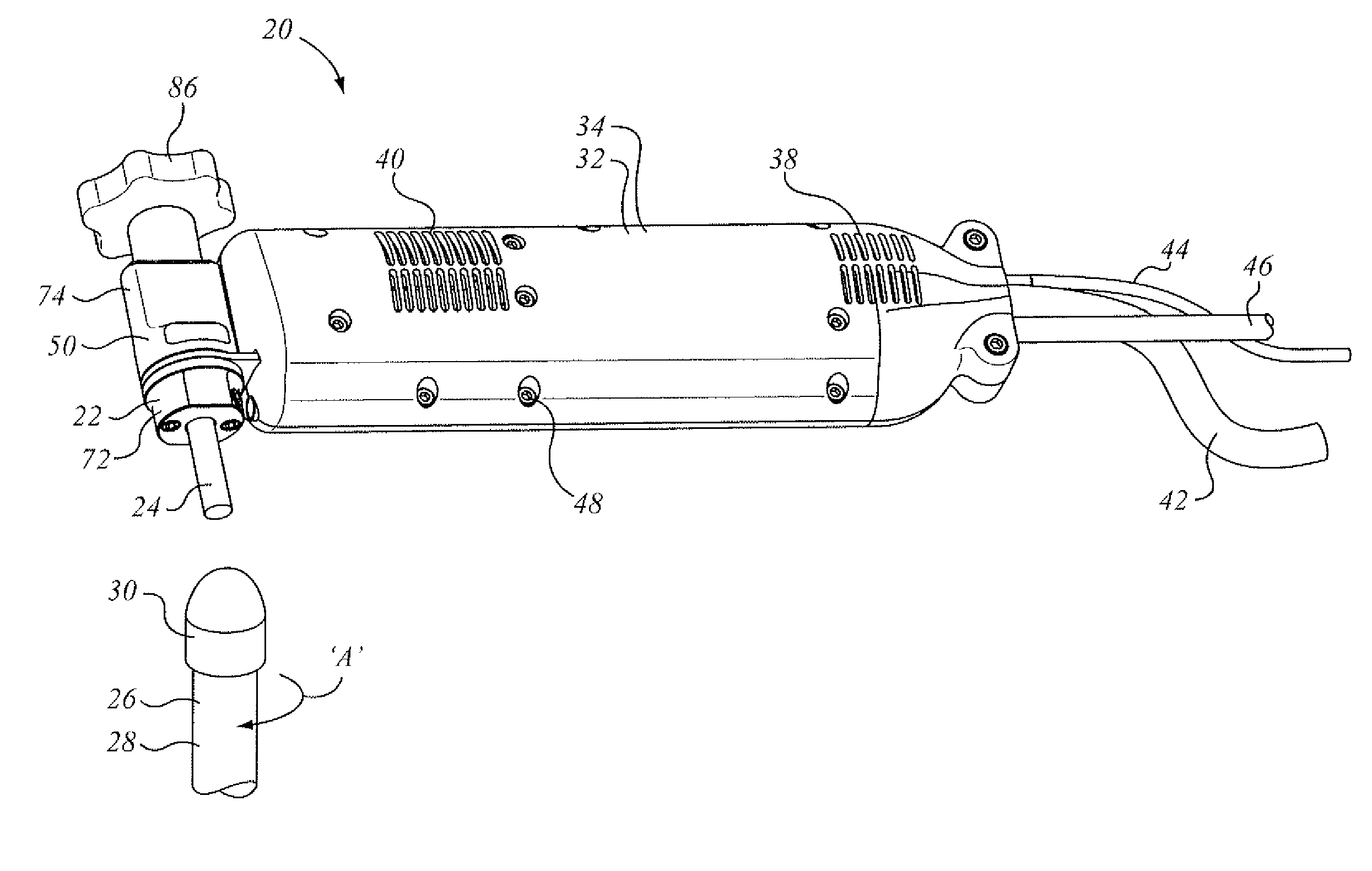

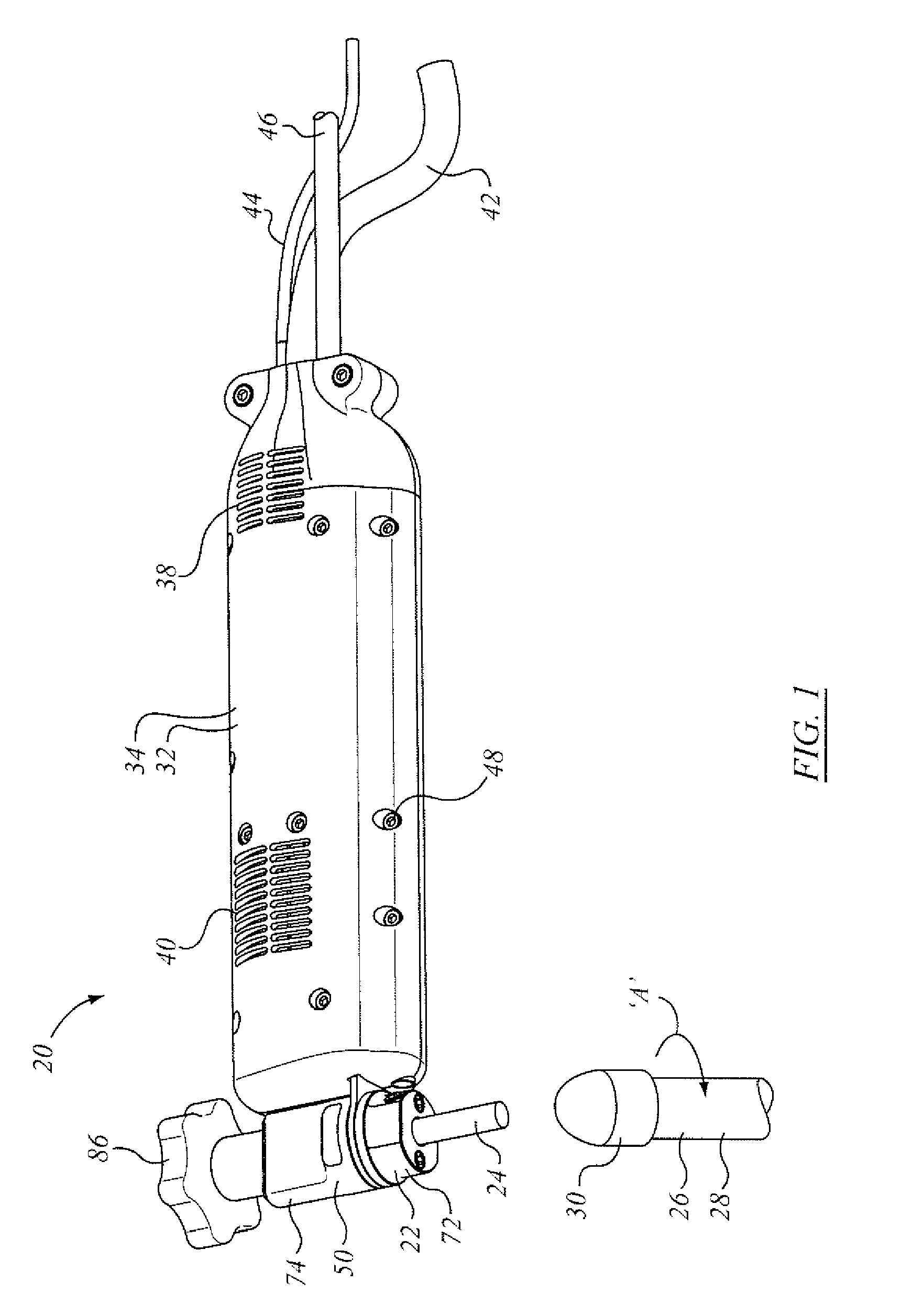

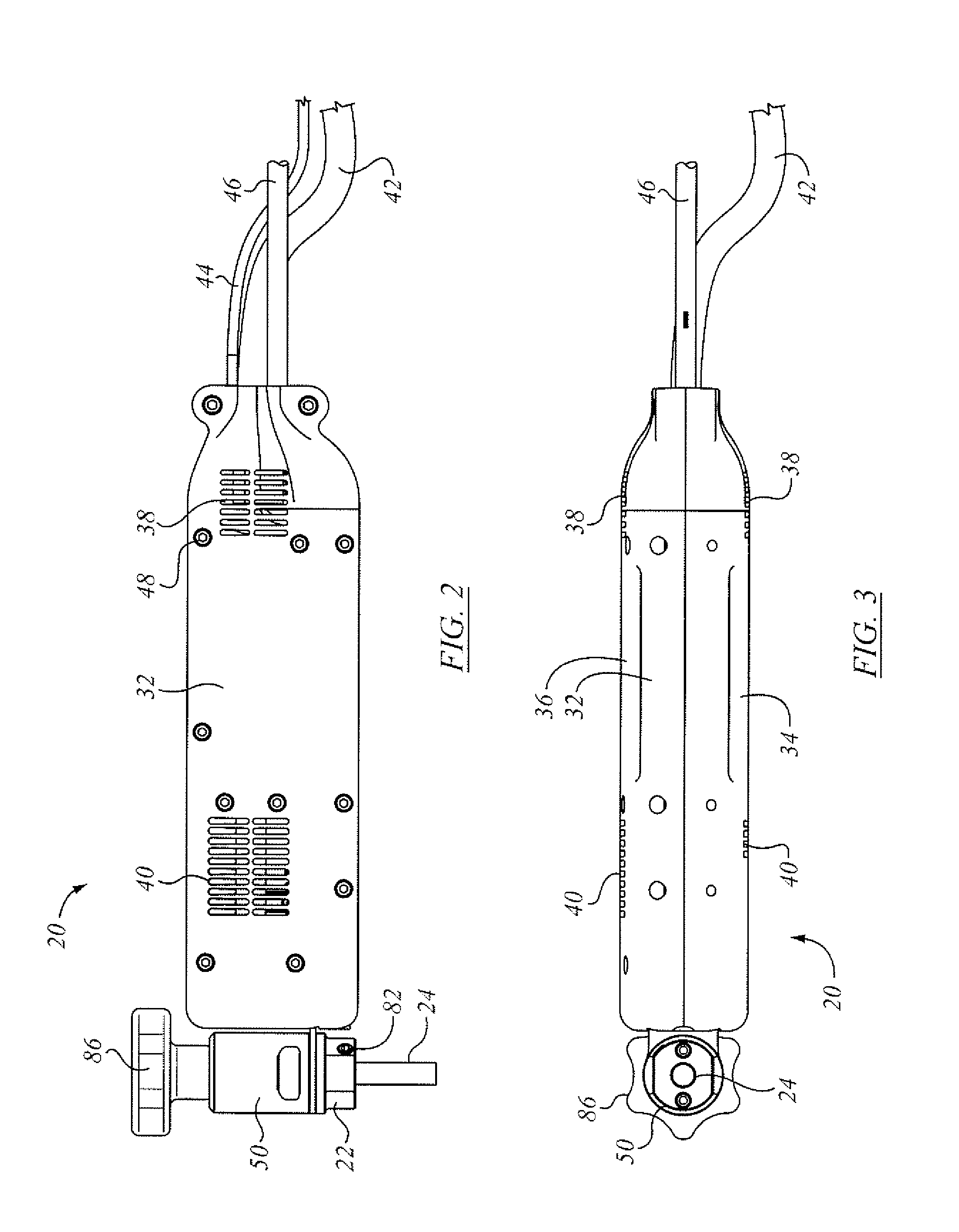

Welding method and apparatus therefor

ActiveUS20150183042A1Improve weld structureImprove performanceElectrode vibration holdersSpark gapsUltrasonic vibrationEngineering

A welding process involves a fixture for holding a workpiece and a welder, or welding electrode. The fixture imposes ultrasonic vibration on the workpiece. The welder vibrates during vibration, and is operable at a first voltage for welding and a second voltage for peening. The peening may occur while the weld metal is crystallizing. The welding process may be a process of welding two parts together, or of filling a groove or other feature, or of applying or restoring a surface, or of applying a hard facing or ceramic to a parent metal or object. The weld metal may be the same, or substantially the same, as the parent metal, or it may be different. The different material may be a ceramic material.

Owner:HUYS IND

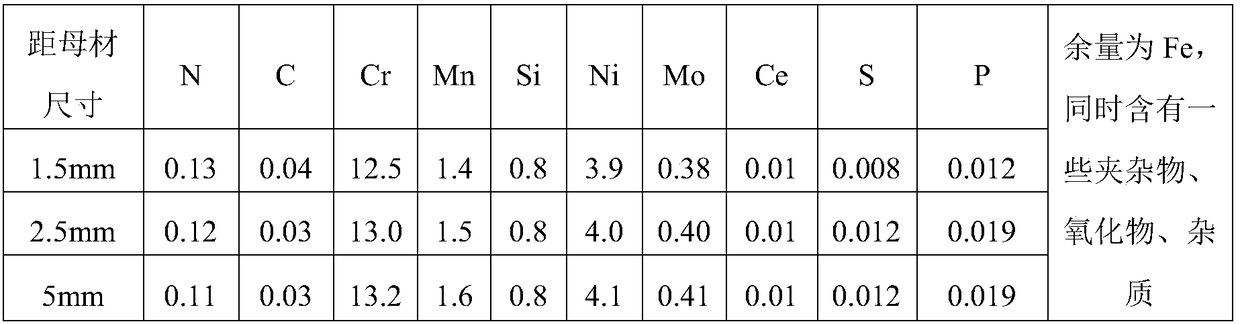

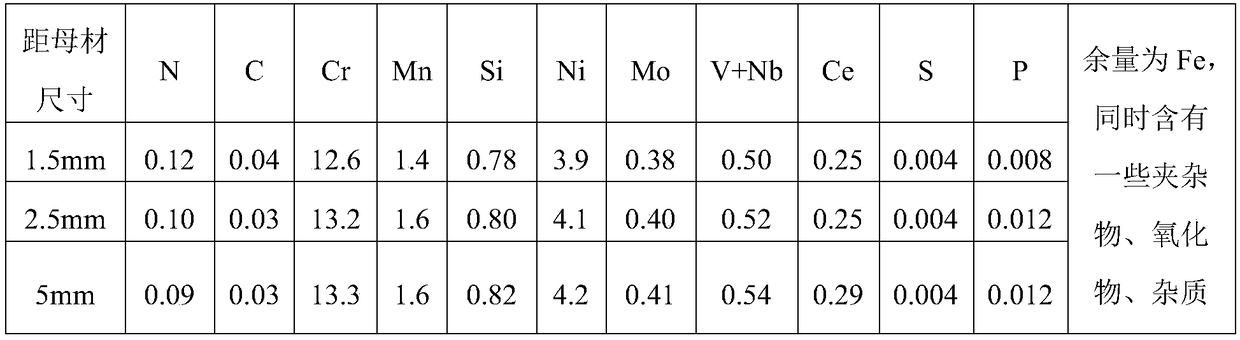

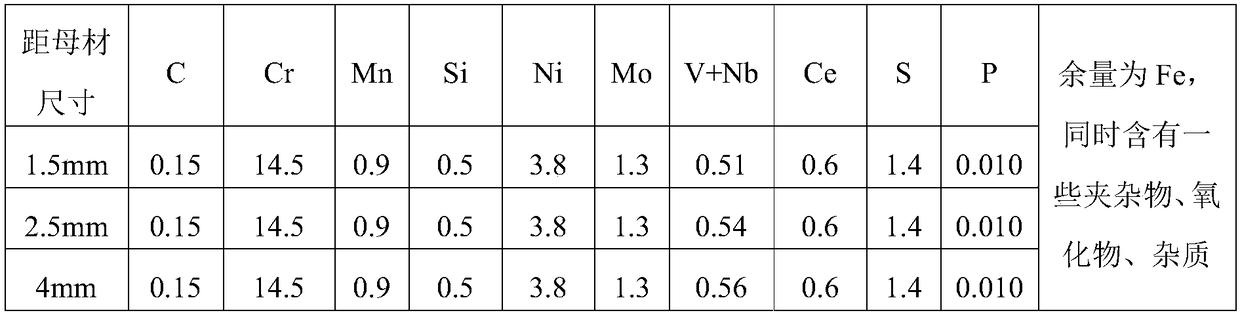

Submerged-arc surfacing flux-cored wire and technology for composite production and reproduction of continuous casting rollers

ActiveCN109014654ASolve the lack of hardnessAvoid the pitfalls of insufficient ingredientsArc welding apparatusWelding/cutting media/materialsRare-earth elementHardness

The invention discloses a submerged-arc surfacing flux-cored wire and a technology for composite production and reproduction of continuous casting rollers. The deposited metals of the flux-cored wirecomprises components in percentage by weight as follows: 0.02%-0.3% of C, 0.8%-2.8% of Mn, 0.1%-1.0% of Si, 12.0%-15.0% of Cr, 0.3%-2.0% of Mo, 1.5%-5.0% of Ni, 0.01%-1.5% of rare-earth elements, 0-1.2% of V and Nb, 0-0.16% of N, less than 0.03% of S, less than 0.03% of P and the balance of Fe. The technology comprises steps as follows: (1) rollers are turned into the size before surfacing; (2) the rollers are detected before surfacing; (3) the surfacing technology is determined, and technological parameters are determined according to the surfacing technology; (4) single-layer surfacing forming is performed; (5) components, hardness and structures of different positions after surfacing are detected. The technology is good in technological property and has the high cost performance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

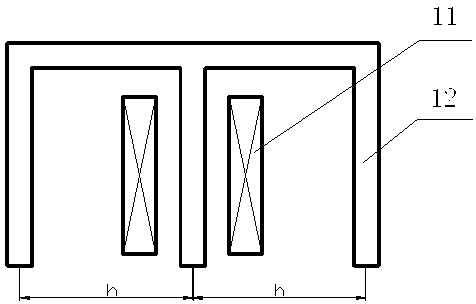

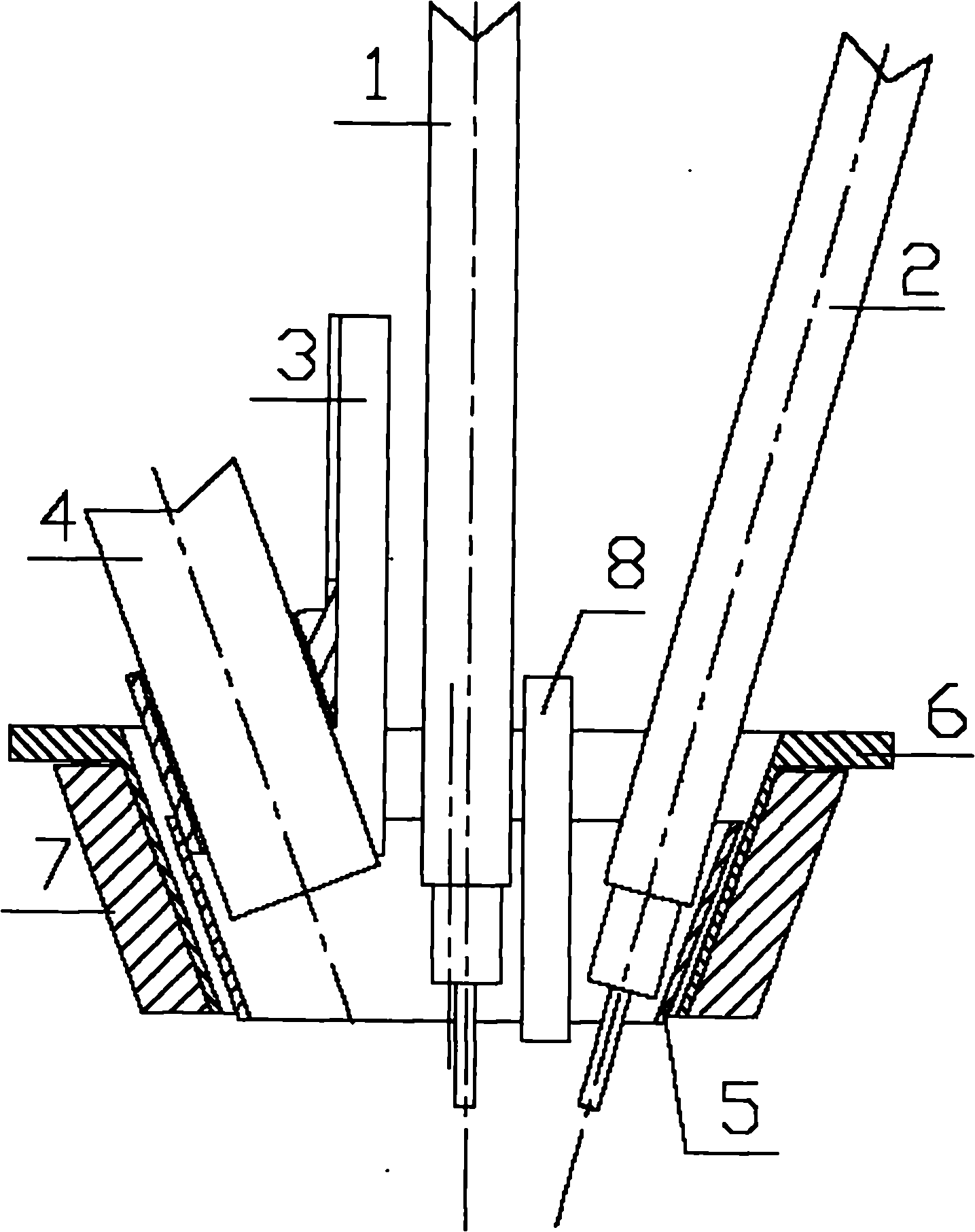

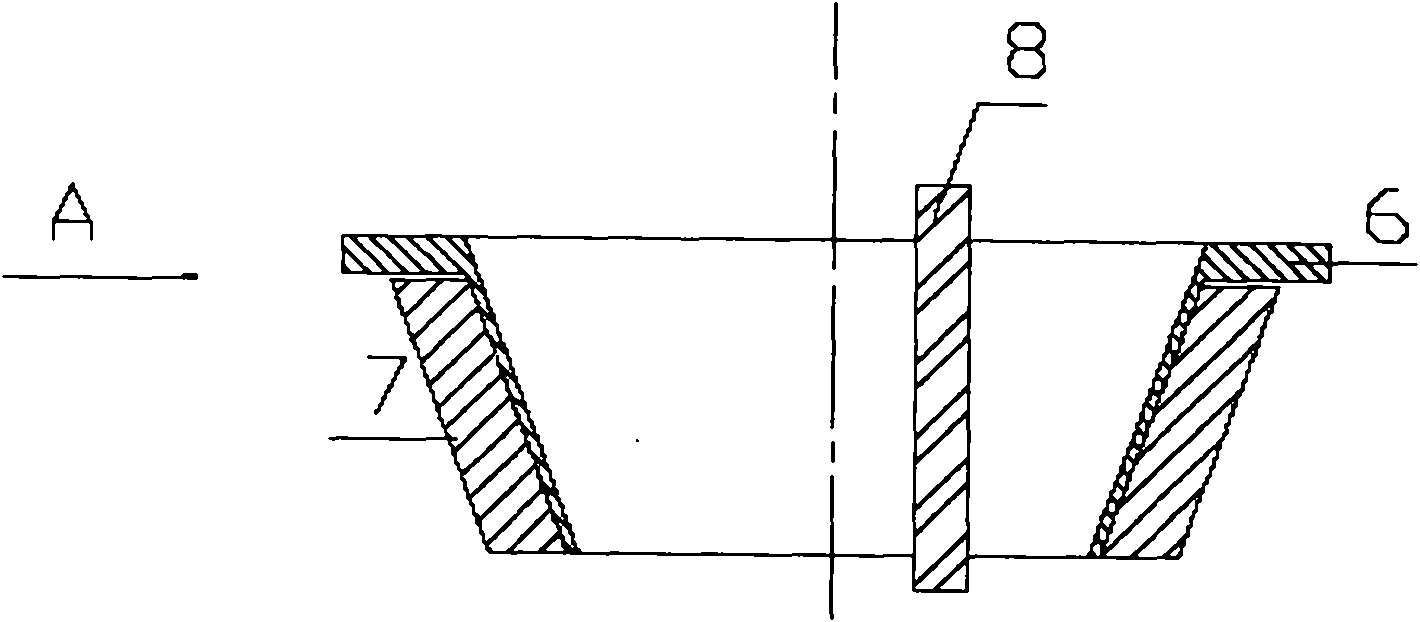

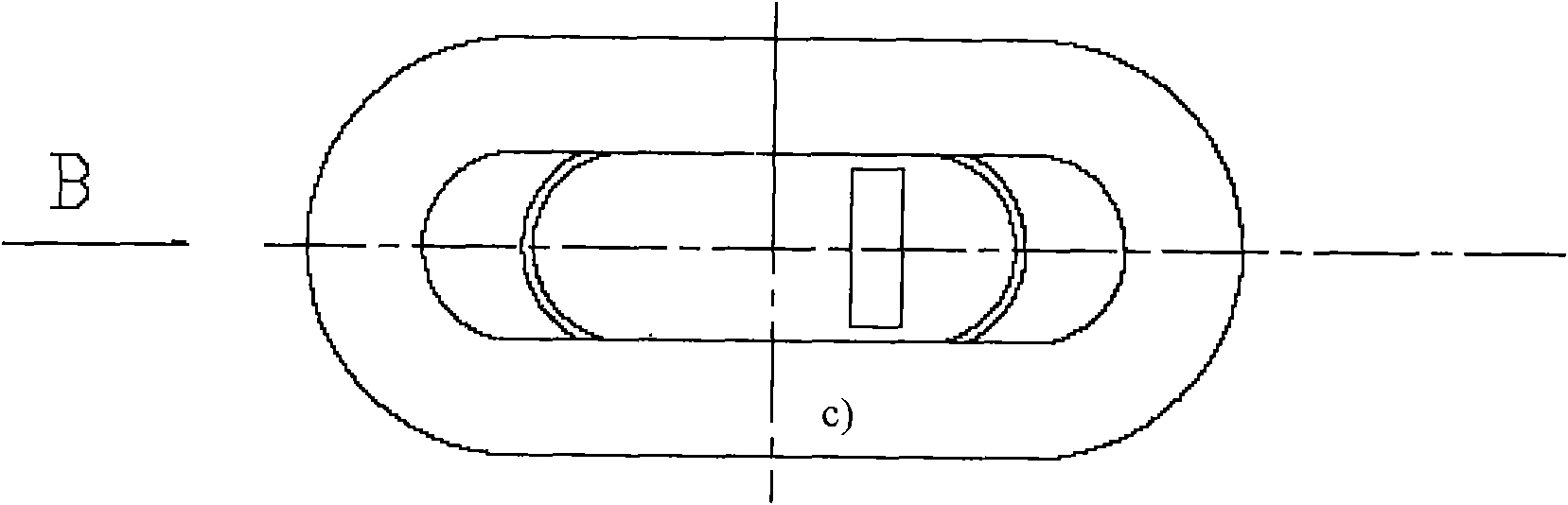

Electromagnetic stirring magnetic head of double-wire submerged arc welding machine

The invention relates to an electromagnetic stirring magnetic head of a double-wire submerged arc welding machine, which is provided with a framework and a field coil winding wrapped on the framework, wherein a magnetic core made of a soft magnetic material is arranged in the framework, the longitudinal displacement of the magnetic core can be regulated without dependence on the field coil winding; the longitudinal section of the coil winding, along the welding direction, is shaped as a cone, and the size of the cross section in the vertical welding direction is smaller than that in the welding direction; the framework is installed on the peripheries of a flux flattening cavity, a flux delivering channel, a chucking mechanism of a flux delivering device; and the magnetic core is arranged in the middle of two welding pistols of the double-wire submerged arc welding machine and above double-wire submerged arc welding co-welding pool. By virtue of the invention, the size of the stirring magnetic head can be reduced; the welding pool below the magnetic core can be evenly stirred because the magnetic core can be closer to the welding pool; the welding line structure and the welding line toughness can be improved through affecting the heat dissipation of a welding line and the flow in the pool; and the influence of magnetic field on a welding arc and a magnetic environment on magnetic field distribution can be reduced, and the stability of a welding process and an electromagnetic stirring process can be enhanced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

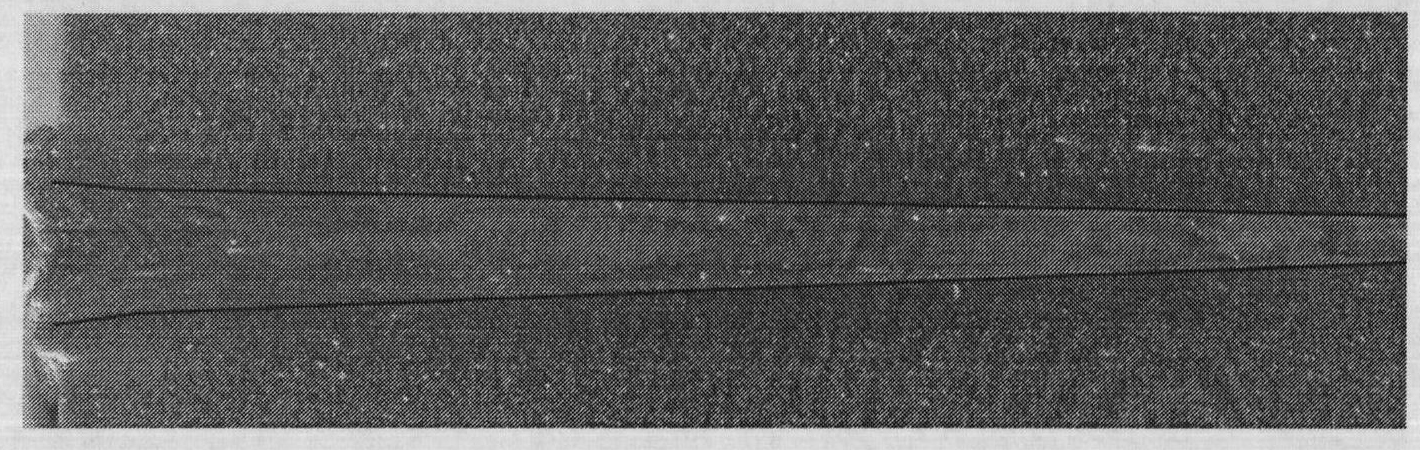

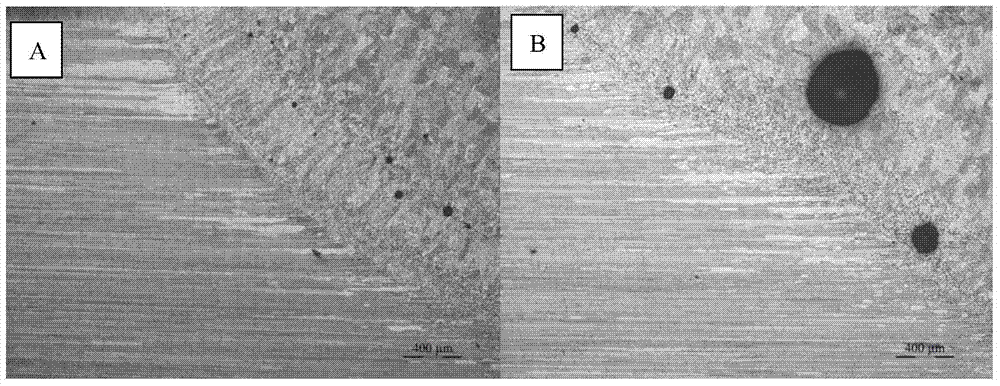

Laser welding method applicable to aluminum alloy

InactiveCN104028892AHigh strengthImprove weld structureWelding/soldering/cutting articlesLaser beam welding apparatusPorosityShielding gas

The invention discloses a laser welding method applicable to aluminum alloy. The method includes that technological parameters are used for the aluminum alloy, which include that the laser power is 2000-2400w, the welding speed is 0.8-1.2m / min, the off-focus value is (minus 0.5)-0.5 and the protective gas flow speed is 12-18L / min, and good weld joints are obtained. The aluminum alloy is 7000 series aluminum alloy, especially, 7000 series aluminum alloy for automobiles. The laser welding method applicable to the aluminum alloy has the advantages that the aluminum alloy, especially, the 7000 series aluminum alloy for the automobiles, which are processed by the method, can gain good weld joint structures, and weld porosity, structure boundaries and obvious coarse-grain zones are absent. The strength of a weld assembly is high.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Electric-arc ultrasonic seam-welding composite welding device

The invention discloses an electric-arc ultrasonic seam-welding composite welding device. The electric-arc ultrasonic seam-welding composite welding device comprises an ultrasonic device and an electric-arc welding device, wherein the ultrasonic device comprises an ultrasonic seam-welding machine and an arc welding rolling wheel, the arc welding rolling wheel is connected with an output shaft of the ultrasonic seam-welding machine, and the ultrasonic seam-welding machine converts an ultrasonic wave to vibration and transfers the vibration onto the arc welding rolling wheel; and the electric-arc welding device comprises an electric-arc welding gun, the electric-arc welding gun is fixed together with the ultrasonic seam-welding machine, and the arc welding rolling wheel generates vibration for a workpiece to be welded to refine grains in a welding area while the electric-arc welding gun welds the workpiece to be welded. In this way, the arc welding rolling wheel rotates on an arc welding guide rail to generate high-frequency vibration for the welding area and co-acts with the electric-arc welding gun clamped on the ultrasonic seam-welding machine to refine the grains in the welding area while the ultrasonic seam-welding machine and the arc welding rolling wheel move along a flexible guide rail, thus weld structure and mechanical properties are improved, and the welding effect is improved.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

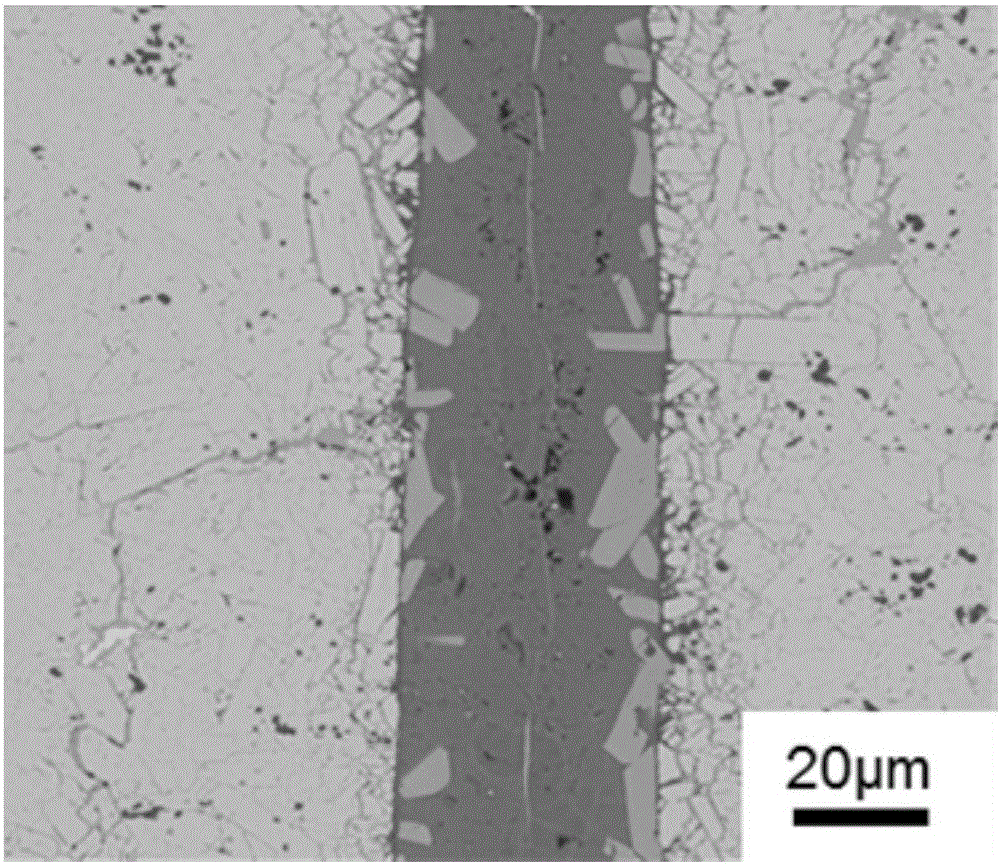

Method for brazing Ti2AlC ceramics by Al base brazing filler metal

InactiveCN107433401ALow melting pointLow costWelding/cutting media/materialsSoldering mediaVacuum pumpingUltimate tensile strength

The invention relates to a method for brazing Ti2AlC ceramics by Al base brazing filler metal, and aims to solve the technical problem of short service life of an existing electric contact component. The method includes the steps: first, preparing the brazing filler metal; second, assembling a Ti2AlC ceramic / brazing filler metal / Ti2AlC ceramic structural part, placing the structural part into a vacuum brazing furnace, performing vacuum pumping to reach 6.0*10<3>Pa, increasing temperature to 300 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 30min, increasing the temperature to 660-900 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 5-30min under the pressure of 0.2-1.0MPa, reducing the temperature to 300 DEG C at the cooling rate of 10 DEG C / min, performing furnace cooling and finishing brazing the Ti2AlC ceramics by the Al base brazing filler metal. By the method, a joint with an excellent mechanical property can be obtained, the shear strength of the joint is 70-120MPa, and electrical conductivity is 3.73-4.18*10<6>S / m and reaches 94% or more of the electrical conductivity of the Ti2AlC ceramics.

Owner:HARBIN INST OF TECH

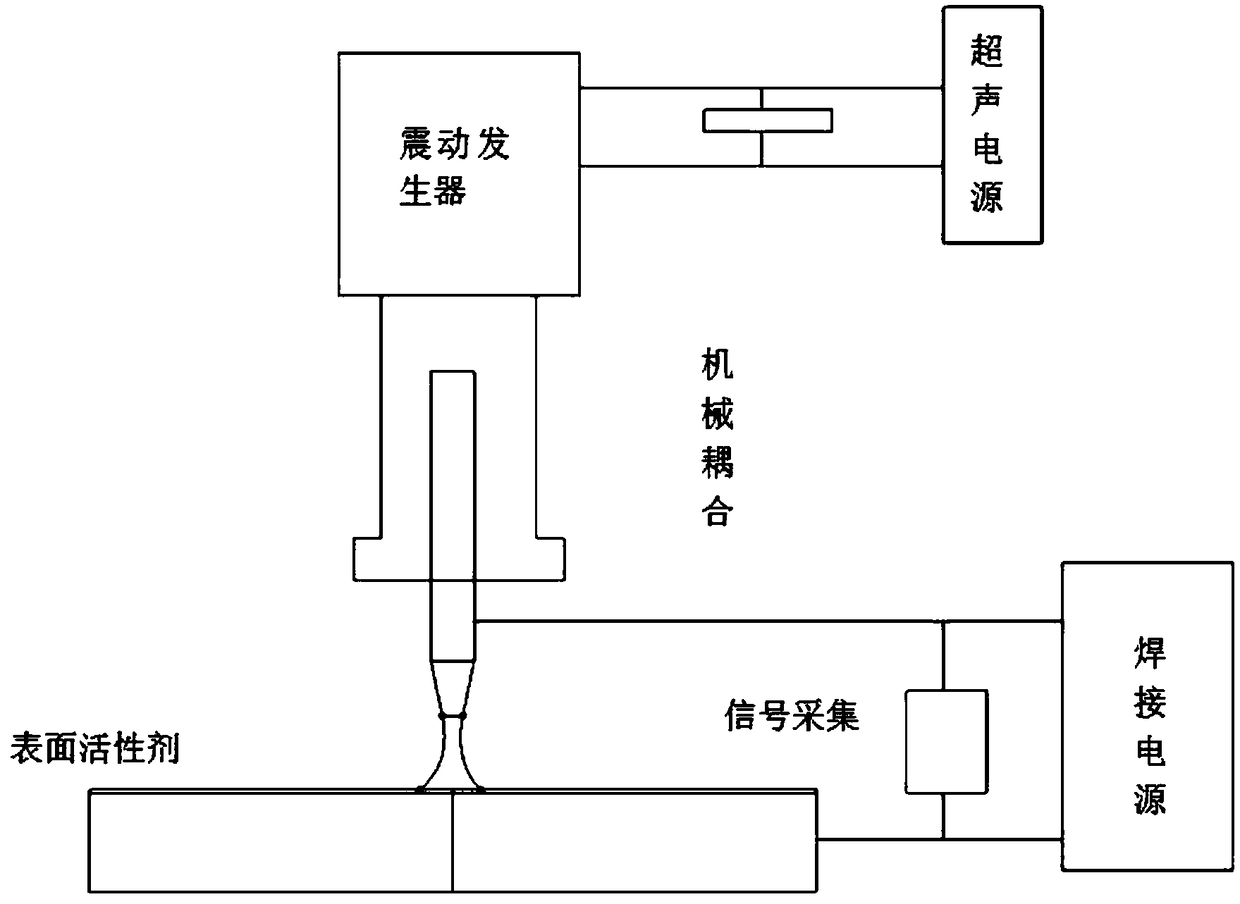

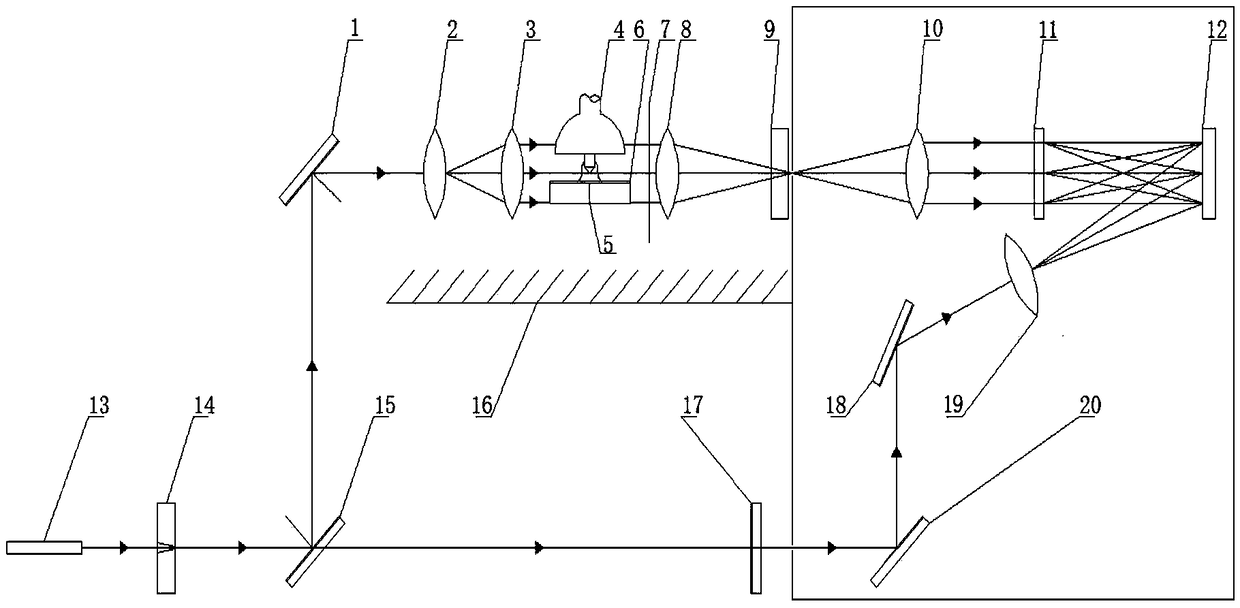

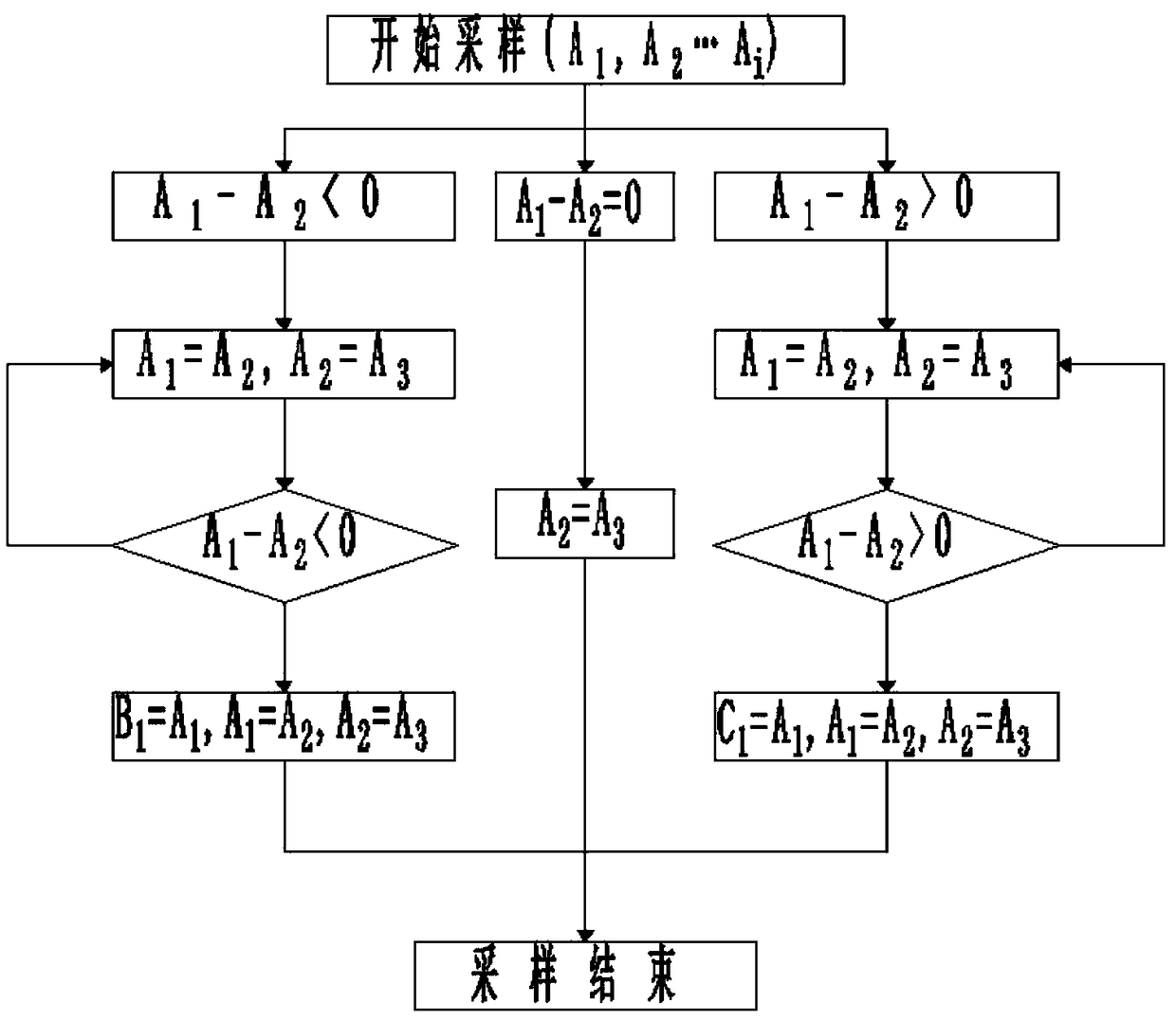

Aluminum alloy TIG tracking method based on ultrasonic electric arc

InactiveCN109128440AReal-time trackingImprove welding efficiencyWelding/soldering/cutting articlesWelding accessoriesWeld seamActive agent

The invention relates to an aluminum alloy TIG tracking method based on an ultrasonic electric arc. The aluminum alloy TIG tracking method is used for overcoming the defects that aluminum alloy TIG single-pass welding is small in weld penetration depth, low in welding efficiency and poor in manual welding weld seam quality. According to the method, a small-angle double-exposure holographic interference method is designed; by means of the method, influences of an oxide active agent, a chloride active agent, a fluoride active agent and a mixed active agent formed by the oxide active agent, the chloride active agent and the fluoride active agent on arc plasmas are confirmed, and the active agent with the best arc gathering effect is selected as an experiment material; the selected active agent is sprayed, and ultrasound is loaded in the coaxial direction of the TIG electric arc; after welding starts, the waveform of welding current is extracted, the envelope curve value of semiconservative filtering is designed, tracking is conducted, and feasibility of the method is verified through the small-angle double-exposure holographic interference method. The method has the beneficial effectthat ordinary ultrasound and electric arc compound welding is achieved, and the ultrasonic electric arc and the surface active agent are fused.

Owner:XIANGTAN UNIV

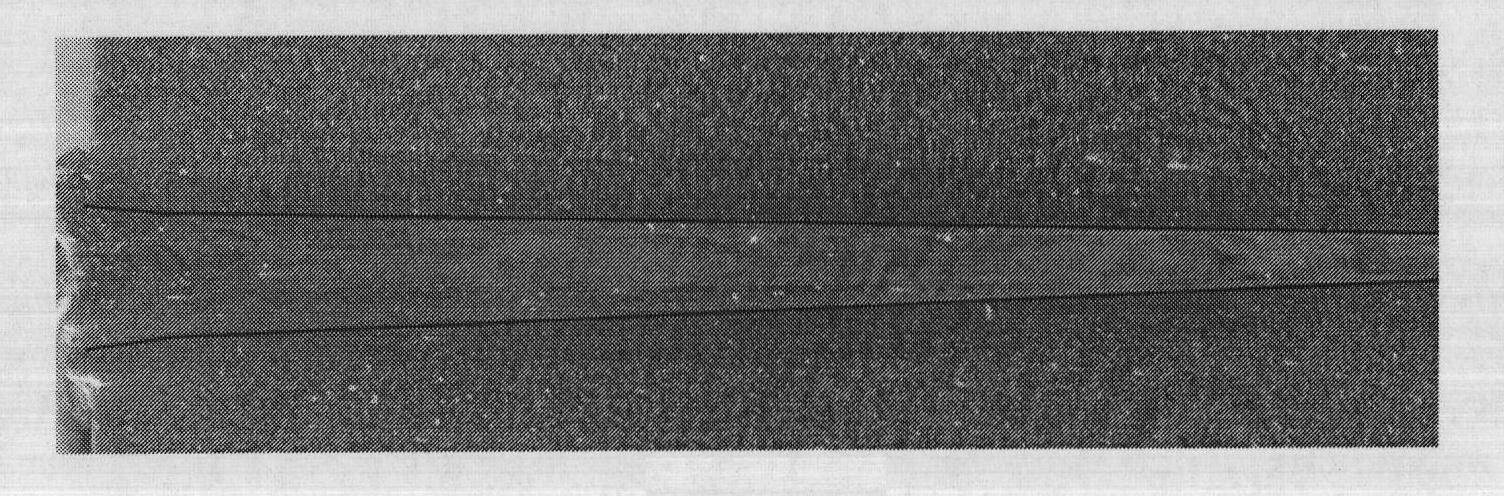

Electron beam welding method suitable for injection-molded 7000-series aluminum alloy

InactiveCN102371430AHigh strengthImprove weld structureElectron beam welding apparatusWelding/soldering/cutting articlesPower flowSolid solution

The invention discloses an electron beam welding method suitable for an injection-molded 7000-series aluminum alloy. In the method, electron beam welding is performed on the injection-molded 7000-series aluminum alloy by adopting the process parameters of welding current of 18-22mA, voltage of 70-75kV, welding speed of 280-320 mm / min and scanning frequency of 1.8-2.4Hz to obtain a good weld seam. The method has the advantages that: a good weld seam structure can be obtained for the injection-molded 7000-series aluminum alloy treated with the method, and no welding air hole, structural boundary line or remarkable coarse crystal strip exists. The intensity of a weld assembly can be enhanced by performing subsequent solid solution and aging treatment.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Laser-electric resistance seam welding in-phase compound welding method of frame-covering structure

InactiveCN100577342CFit tightlyImprove welding qualityWelding with roller electrodesLaser beam welding apparatusLight beamElectric resistance welding

A laser and electric-resistance seam-welding synchronous composite welding method for an envelope-framework structure relates to a novel laser and electric-resistance seam-welding synchronous composite welding method, belongs to the welding field, and aims to solve the problems in welding the envelope-framework structure by the single laser, such as narrow seam, low shear strength of the seam, a plurality of air vents on the faying surface of the envelope and the framework. The invention aims at the workpiece with the envelope-framework structure to be welded, and adopts the laser and the electric-resistance seam-welding synchronous composite welding; the electric-resistance seam-welding adopts double-roller single-side welding, two roller electrodes are disposed on the front and the back sides of the upper top surface of the envelope along the seam formed by the contact of the envelope and the framework, so that the envelope is pressed to the lower framework in the travel forward, and the laser beam is always positioned in the middle position of the two roller electrodes during the welding process. The seam formed by the welding method can improve the shear strength more than twice in comparison with the base material, and the air vent amount per area can be reduced from about 10% to about 2% of the laser welding.

Owner:HARBIN INST OF TECH

Rare earth solid welding wire with excellent low-temperature impact toughness

PendingCN113798729AHigh strengthExcellent low temperature impact toughnessWelding/cutting media/materialsSoldering mediaRare-earth elementWeld seam

The invention discloses a rare earth solid welding wire with excellent low-temperature impact toughness. The rare earth solid welding wire comprises the following chemical components including, by mass, 0.06 to 0.10 percent of C, 1.40 to 1.55 percent of Mn, 0.80 to 0.95 percent of Si, 0.10 to 0.20 percent of Cr, 0.05 to 0.12 percent of Ti, 5 to 30 ppm of a rare earth element Ce and the balance Fe and inevitable impurities, wherein P in the impurities is less than or equal to 0.025 percent, and S in the impurities is less than or equal to 0.025 percent. The invention is suitable for 600 Mpa-level solid welding wires, the rare earth element Ce is transited into welding seams, and the welding seams have more excellent low-temperature-resistant impact toughness on the basis of high strength through the effects of refining welding seam grains, improving welding seam structures and purifying welding seam metal microalloying treatment.

Owner:BAOTOU IRON & STEEL GRP

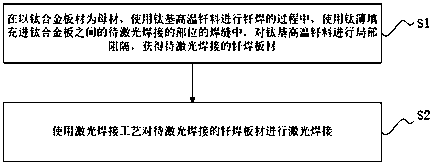

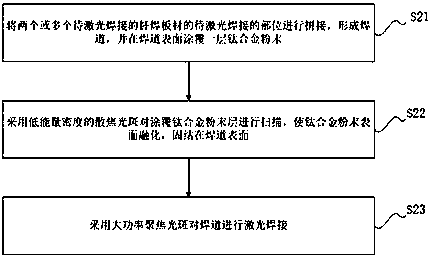

Laser welding method for titanium alloy sandwiched brazed plates

ActiveCN108393586ARealize the purpose of laser weldingLaser welding process optimizationLaser beam welding apparatusTitaniumTitanium alloy

The invention provides a laser welding method for titanium alloy sandwiched brazed plates. The laser welding method for the titanium alloy sandwiched brazed plates comprises the steps that while brazing is carried out through titanium-based high-temperature brazing filler metal with titanium alloy plates as base metal, a weld joint of the to-be-subjected to laser welding part between the titaniumalloy plates is filled with a titanium thin strip so that the titanium-based high-temperature brazing filler metal can be locally blocked, and accordingly brazed plates to be subjected to laser welding are obtained; and laser welding is carried out on the brazed plates to be subjected to laser welding through a laser-welding process. According to the method, the titanium thin strip fills the spacebetween the brazed titanium alloy plates to form a blocking strip, then laser welding is carried out on the multiple layers of brazed plates at the portions of the blocking strips through the laser welding process, the purpose of laser welding of the titanium alloy sandwiched brazed plates is achieved, the laser welding process is optimized, the welding quality is improved, and the weld joint hasgood texture.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

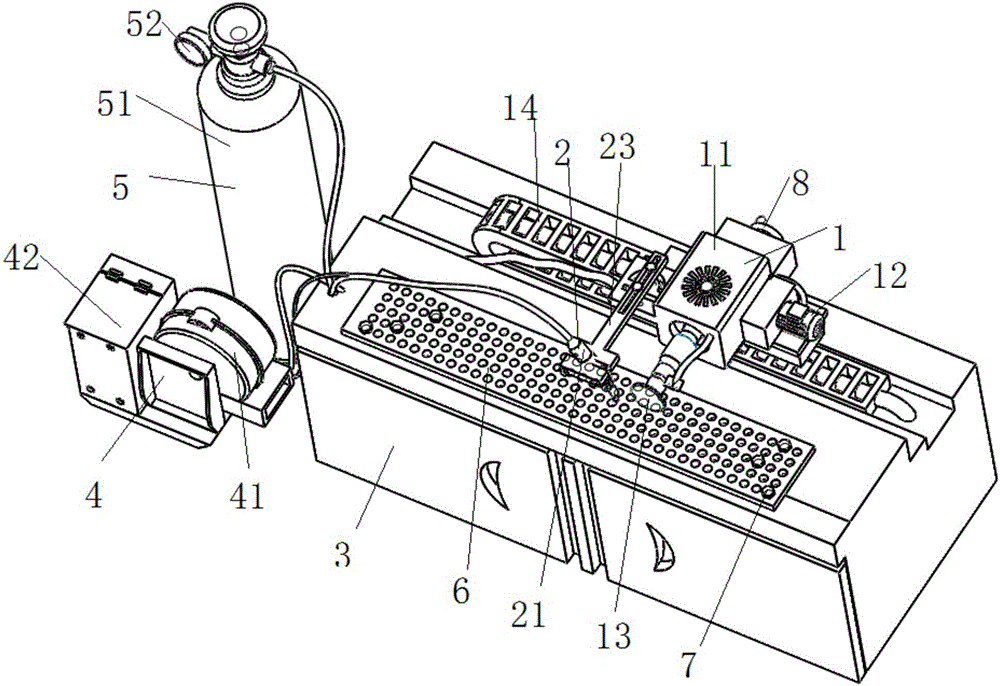

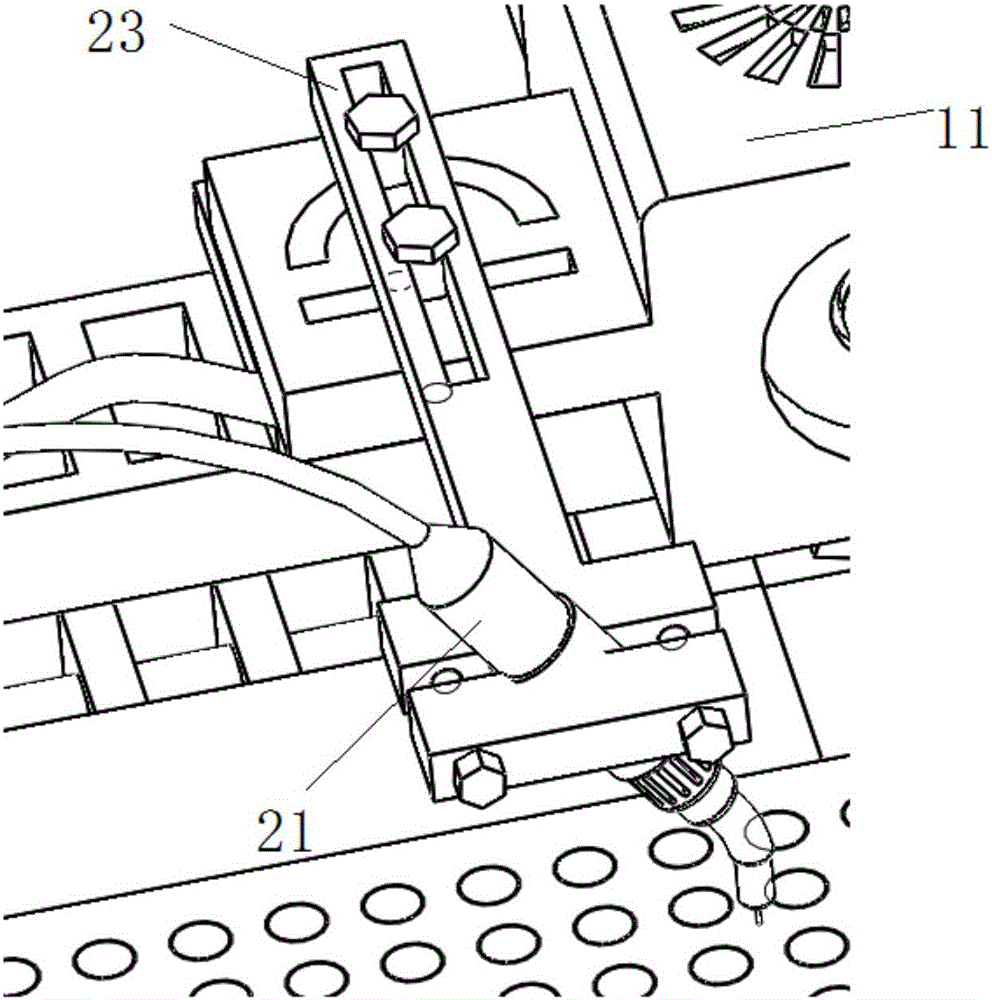

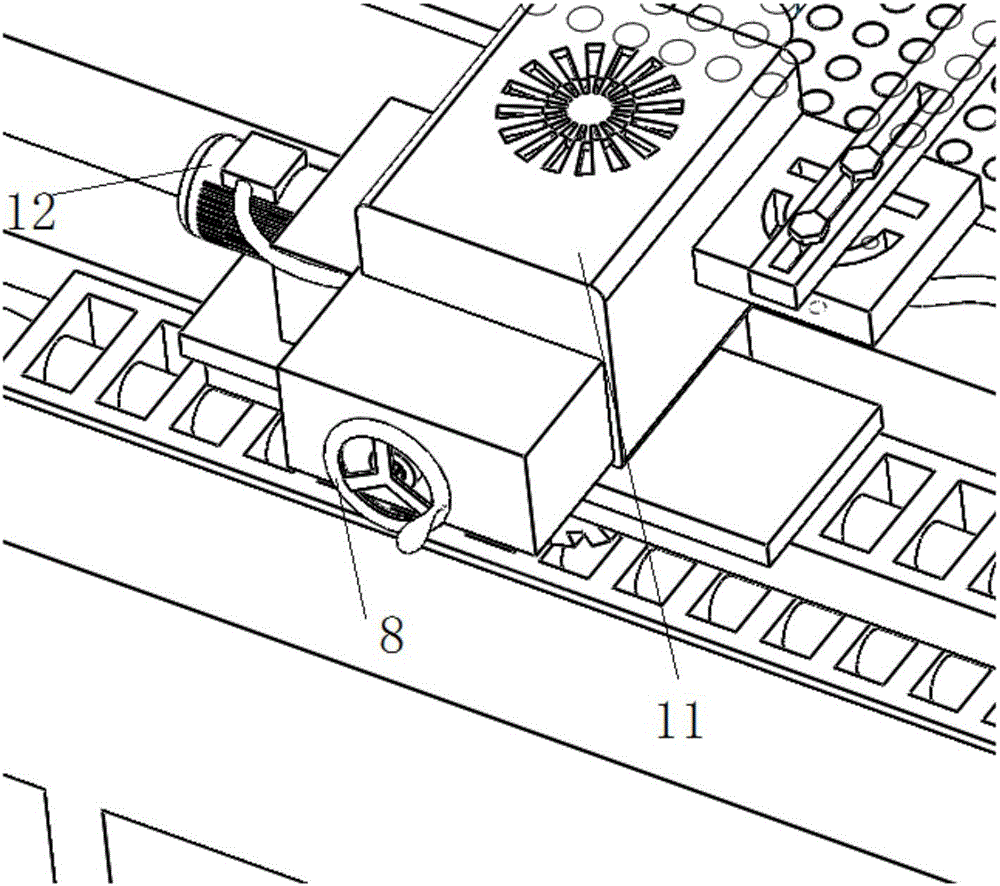

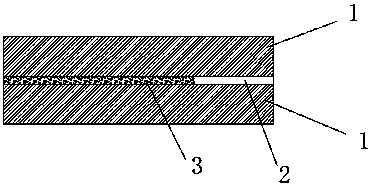

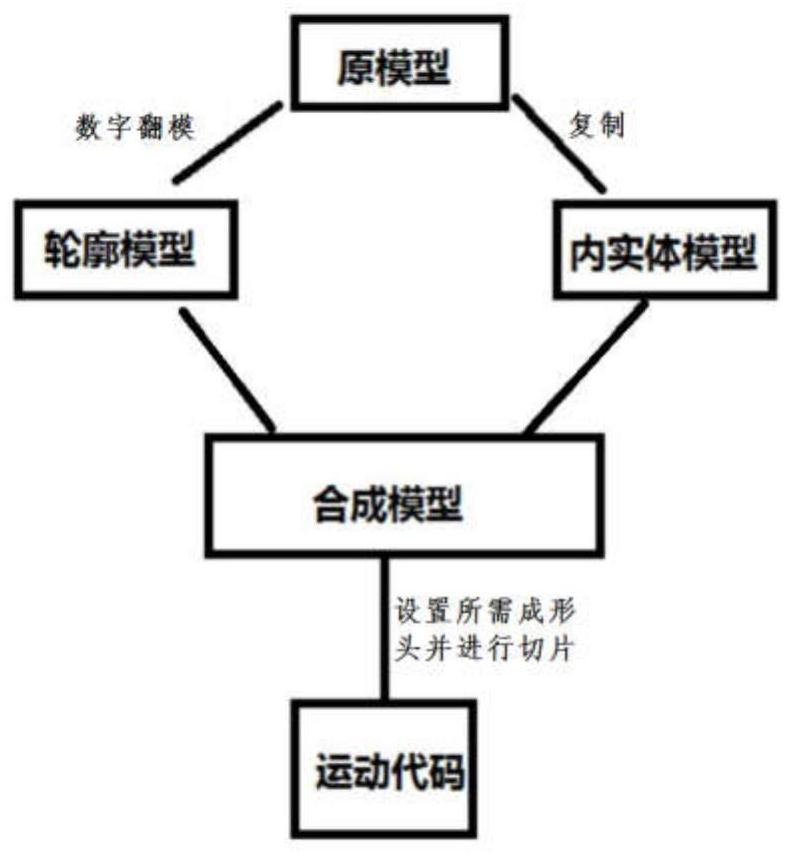

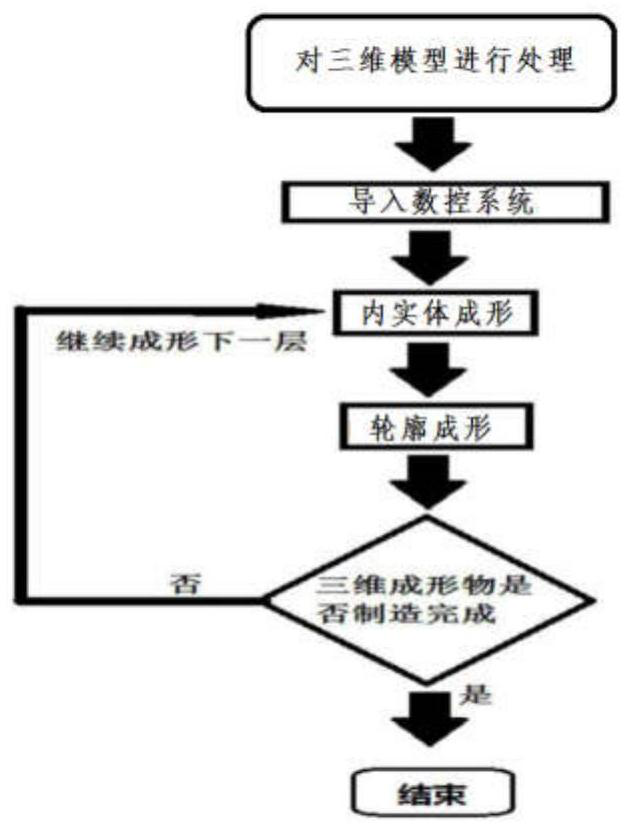

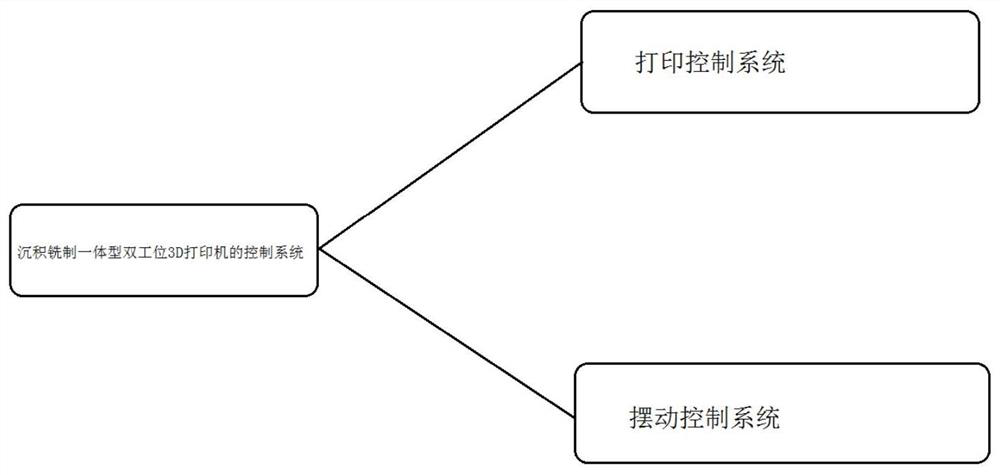

Deposition and milling integrated double-station 3D printer

ActiveCN113070472ASmall sizeFlat surfaceAdditive manufacturing apparatusMilling equipment detailsStructural engineeringManufacturing engineering

The invention discloses a deposition and milling integrated double-station 3D printer. According to the deposition and milling integrated double-station 3D printer, firstly, a three-dimensional formed object to be printed is subjected to model treatment; in the treatment process, the forming process of the three-dimensional formed object is divided into two parts which are related in shape and different in function to conduct forming according to different principles; and according to the operation of dividing forming of the three-dimensional formed object into two parts which are related in shape and different in function to conduct forming according to different principles, a three-dimensional model is divided into an inner solid model, an inner contour model and an outer contour model, the inner solid model is subjected to additive forming through a fused deposition nozzle, the inner contour model and the outer contour model are subjected to subtractive forming through a milling module, and the fused deposition nozzle and the milling module are mounted on a multi-station lifting type switching tackle.

Owner:赵晴堂

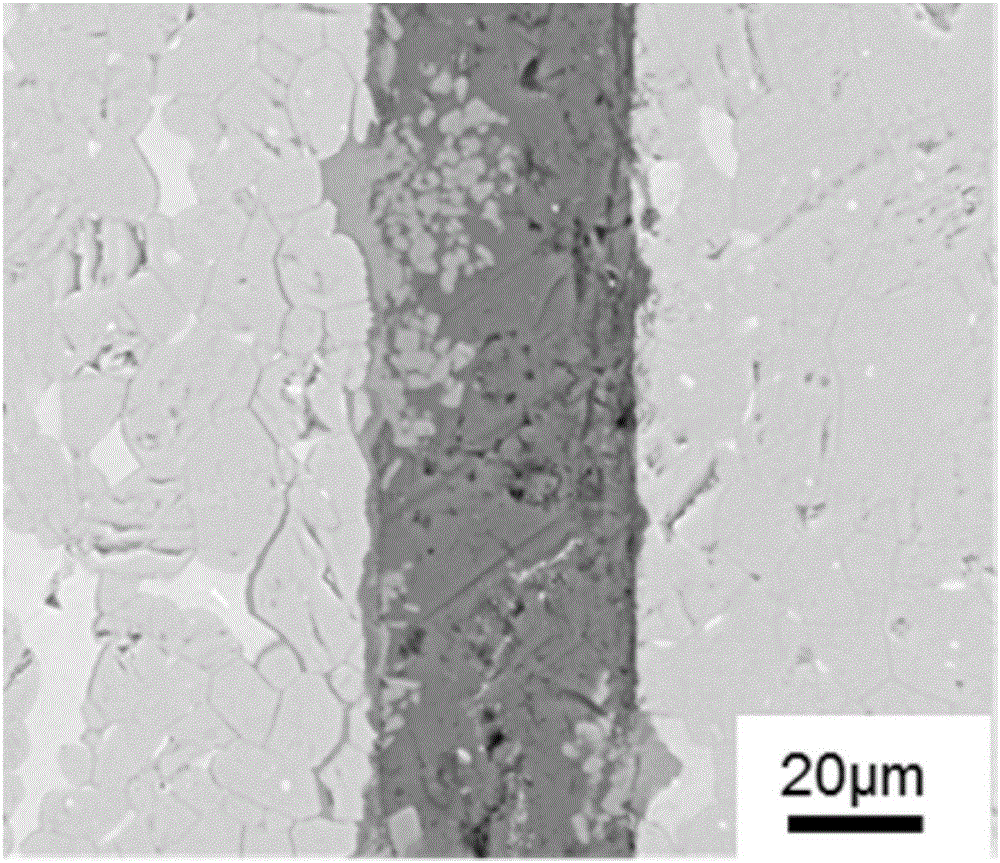

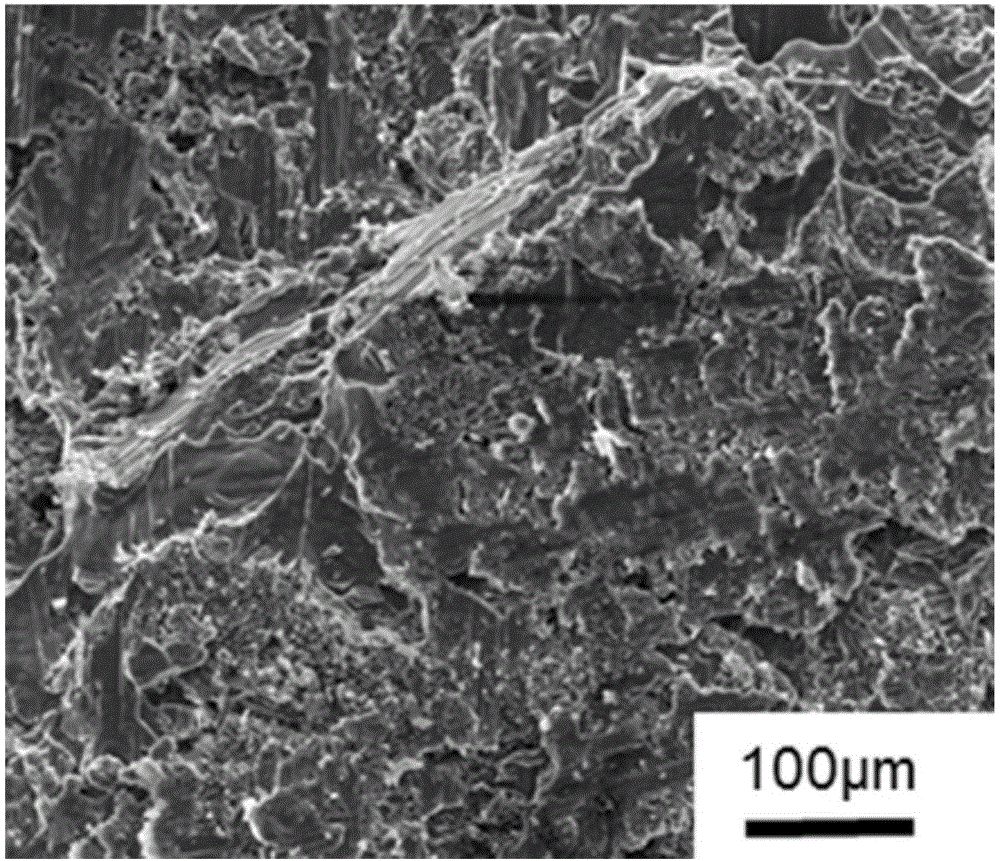

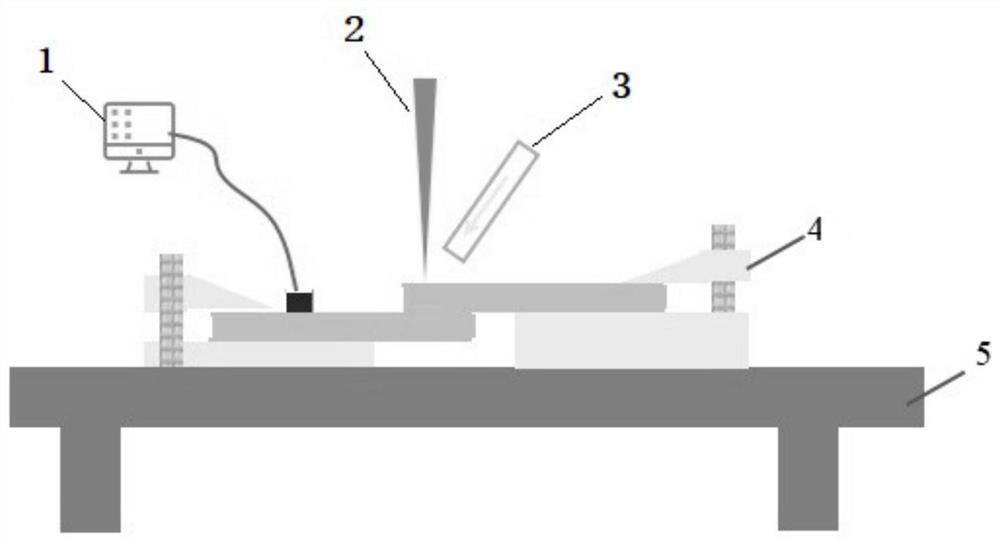

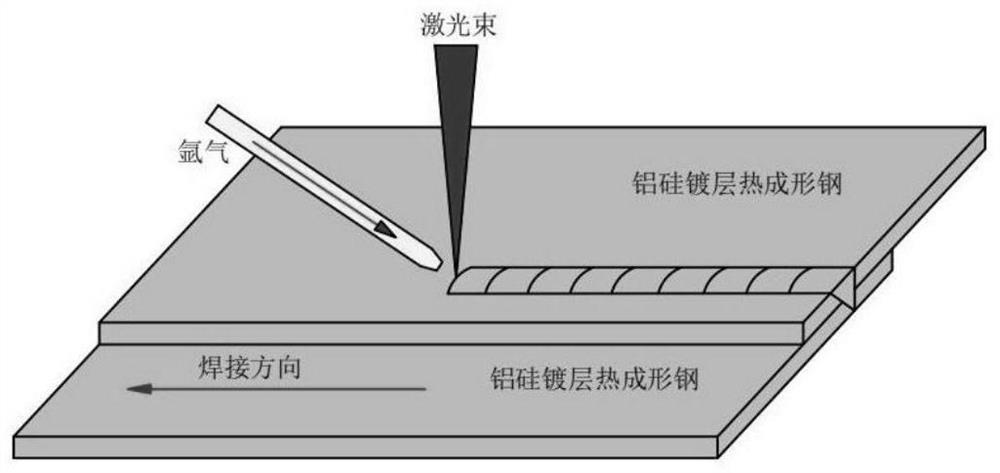

Micro-vibration auxiliary laser lap welding method for aluminum-silicon coating hot forming steel

PendingCN113263259AImprove weld structureReduce welding defectsLaser beam welding apparatusWeld seamLap joint

The invention provides a micro-vibration auxiliary laser lap welding method for aluminum-silicon coating hot forming steel. A laser welding process is adopted, auxiliary micro-vibration is used in the welding process, and a well-formed aluminum-silicon coating hot forming steel laser lap welding seam can be obtained. According to the method, laser process parameters are controlled, a mechanical vibration external field is applied on the basis, and vibration parameters are adjusted, so that the aggregation degree of an aluminum coating dissolved in the welding seam is effectively reduced, the structure of the welding seam is optimized, and welding defects are reduced, so that a high-quality lap welding joint is obtained, and the method is suitable for welding of the aluminum-silicon coating hot forming steel for automobiles; and compared with a traditional laser lap joint method, an aluminum-silicon coating on the surface of the hot forming steel does not need to be removed, the lap joint welding technological process is simplified, the production efficiency is improved, meanwhile, due to application of mechanical vibration, the aggregation degree of the aluminum coating in the welding seam is relieved, grains are refined, the residual stress of the joint is reduced, and the strength of the lap welding joint is improved.

Owner:SHANGHAI UNIV OF ENG SCI

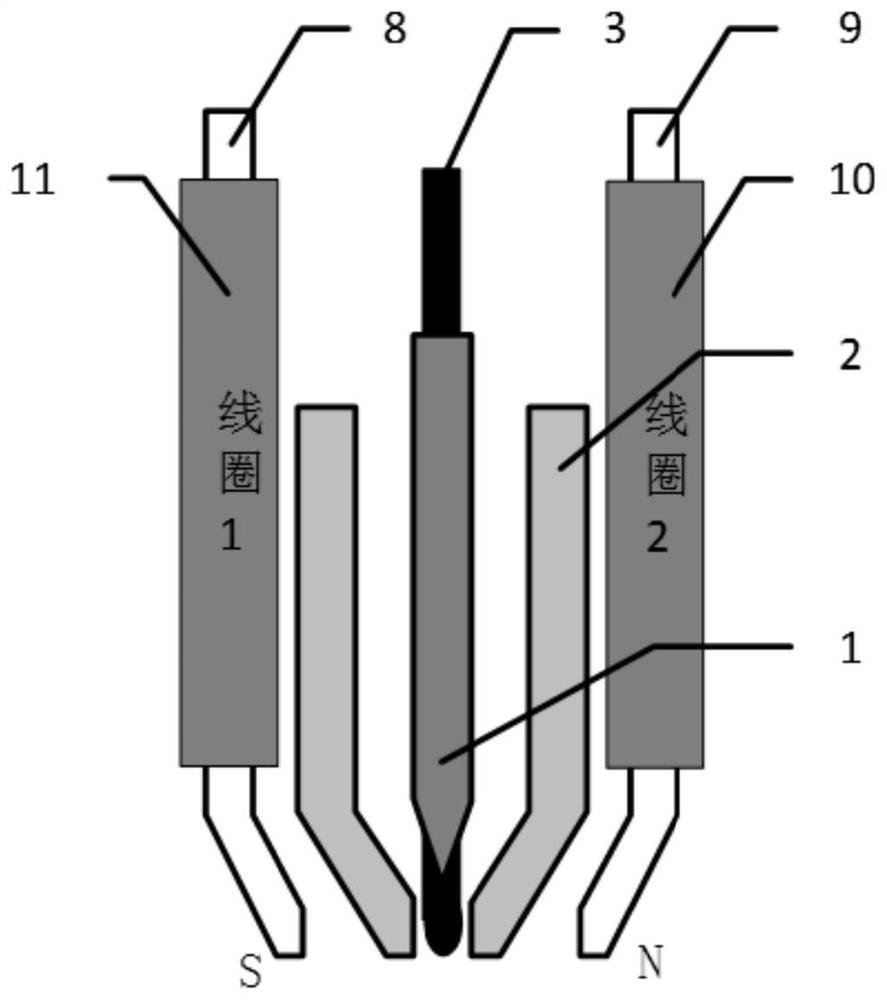

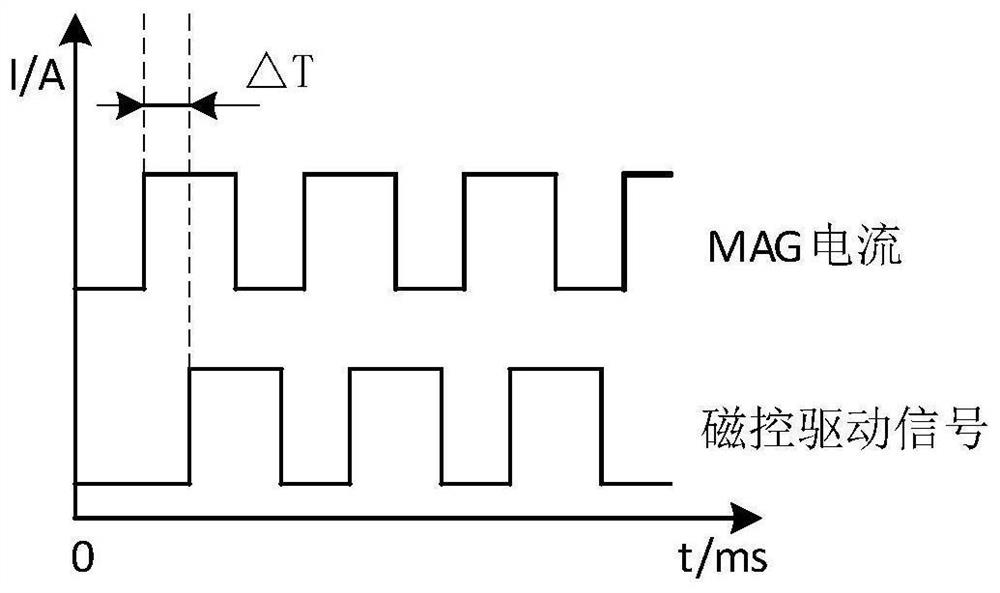

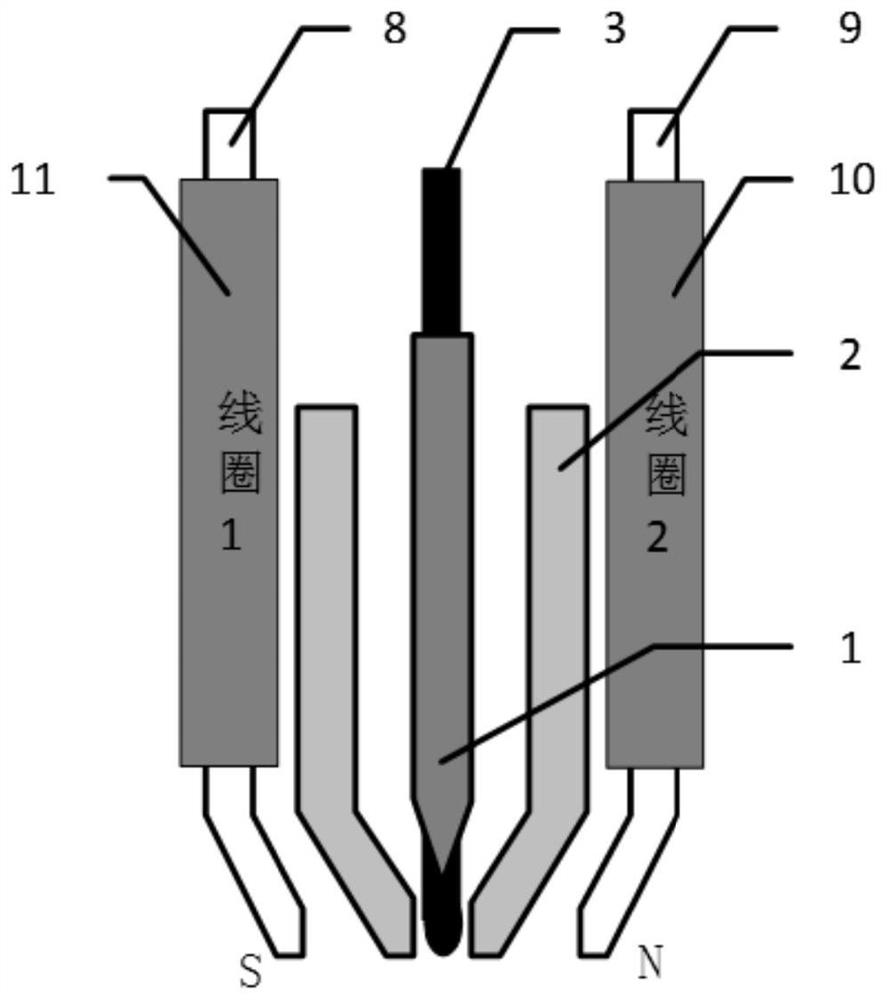

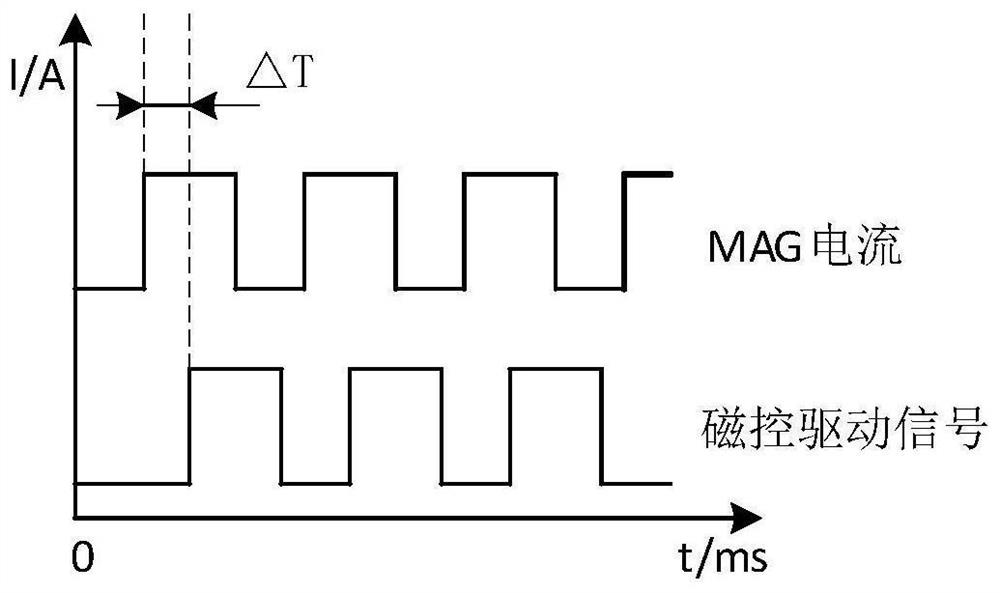

Magnetic field phase regulation type plasma MIG welding device and method

ActiveCN113560755AIncreased repellencyImprove welding stabilityPlasma welding apparatusWelding accessoriesMagnetic polesTransverse magnetic field

The invention relates to a magnetic field phase regulation type plasma MIG welding device and method. The device is characterized in that a magnetic pole regulation mechanism is arranged, the magnetic pole regulation mechanism comprises a first coil and a second coil which are used for generating parallel magnetic fields, the magnetic induction line directions of the parallel magnetic fields generated by the first coil and the second coil are perpendicular to the connecting line direction of a plasma arc and an MAG arc, a pulsed magnetic field excitation power supply is arranged in the magnetic pole regulation mechanism, and the pulsed magnetic field excitation power supply is connected with the first coil and the second coil. According to the device and the method, a transverse magnetic field perpendicular to the connecting line direction of the two arcs is added, and phase regulation of the pulsed MAG and the intermittent magnetic field is achieved, so that the MAG arc is flexibly compounded with the plasma arc under the action of Lorentz force, the repulsive interaction between the two arcs is effectively improved, and welding spattering and welding stability are remarkably improved at the same time; meanwhile, a welding pool can be oscillated and stirred through the MAG arc under the pulsating action of the magnetic fields, and the welding seam structure is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

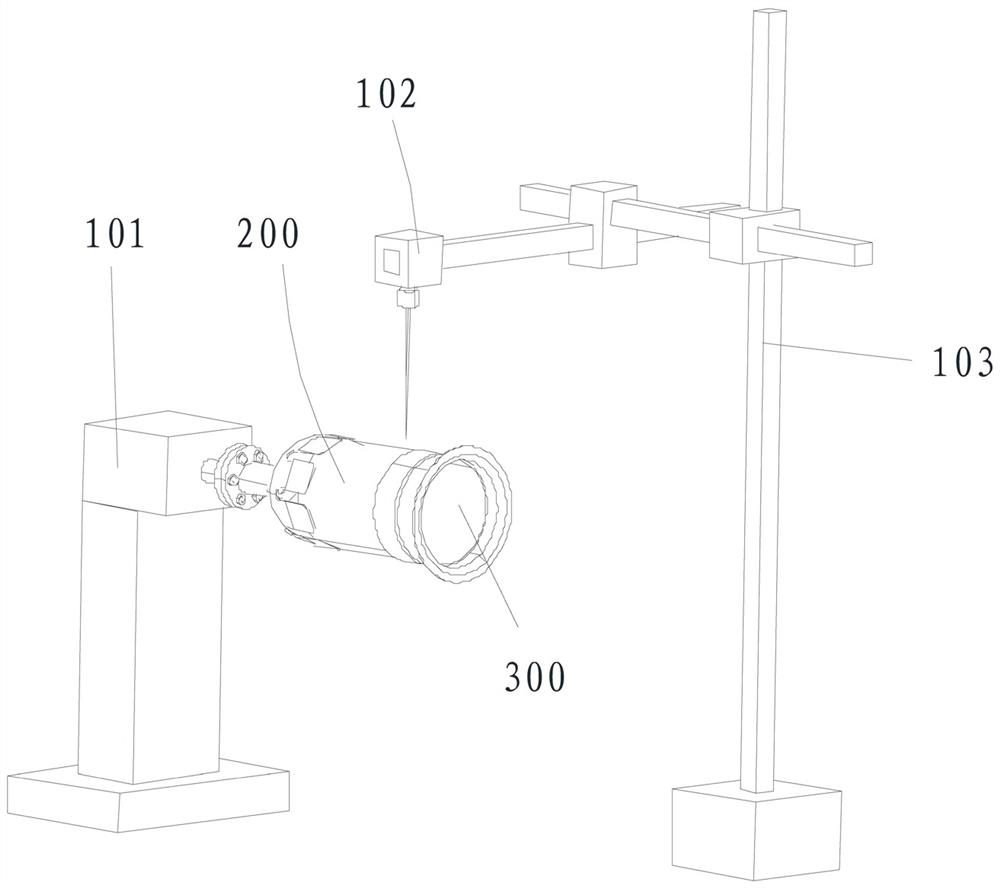

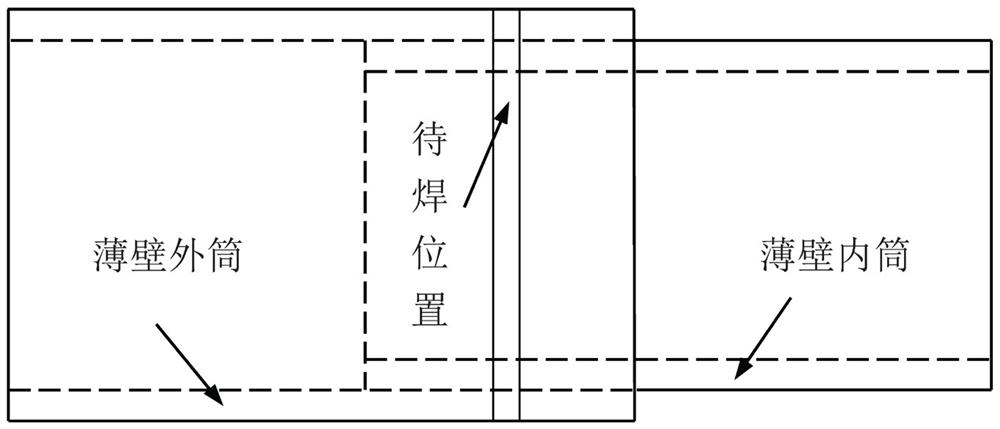

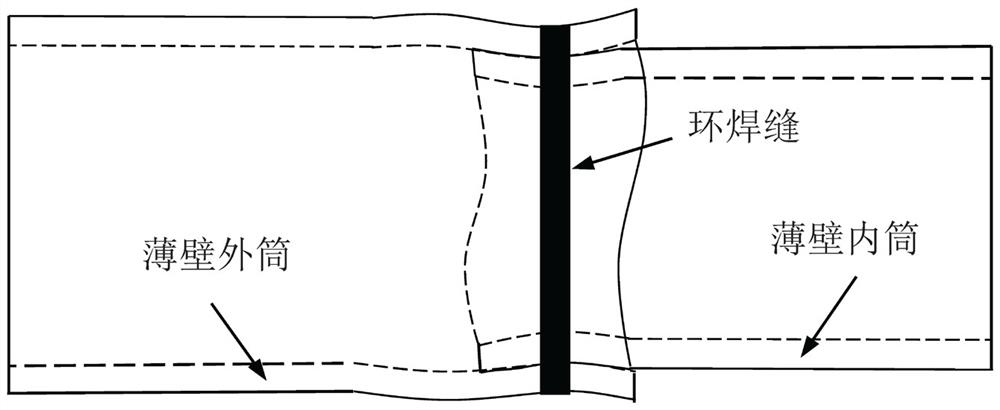

Device and method for controlling welding deformation of girth of thin-walled cylinder through thermal field regulation and control

ActiveCN114101912AEliminate instability deformationControl deformationLaser beam welding apparatusTension stressThin walled cylinder

The invention provides a device and method for controlling girth welding deformation of a thin-walled cylinder through thermal field regulation and control, the device is composed of a supporting part, a resistance wire, an annular lock sleeve and other components, and the method comprises the steps that before welding, the device is placed on the inner wall of a cylinder body of the thin-walled cylinder to be welded, and after the resistance wire embedded in the device is powered on, the annular lock sleeve is locked to the inner wall of the cylinder body of the thin-walled cylinder to be welded; the supporting part and the annular lock sleeve absorb heat transmitted by the resistance wire and simultaneously generate outward and inward expansion, the expanded device enables the thin-wall cylinder structure to deform in the circumferential direction, and then pre-circumferential tensile stress of a certain size is formed in the cylinder structure before welding to serve as welding auxiliary stress. And the pre-circumferential tensile stress and dynamic stress in welding are coupled and superposed, so that the welding residual compressive stress of the welded thin-walled cylinder is lower than the critical instability stress of the thin-walled cylinder, and the instability deformation is eliminated, thereby controlling the girth welding deformation of the thin-walled cylinder.

Owner:HUAQIAO UNIVERSITY

A pulse current assisted welding device and welding method

ActiveCN105127552BImprove performanceGrain refinementWelding accessoriesPulse power supplyPulse current

The invention provides a pulse current auxiliary welding device and method. The pulse current auxiliary welding device comprises a welding machine and a pulse power supply and a trailing welding tight wheel, wherein a positive output end of the welding machine is connected with a welding wire in a welding gun; a negative output end of the welding machine is connected with a workpiece; the positive pole of the pulse power supply is connected with the trailing welding tight wheel; the negative pole of the pulse power supply is connected with the workpiece; the trailing welding tight wheel is arranged in front of the welding gun; and the forward direction of welding is a front side. The device and method provided by the invention have functions of thinning welding line tissues and improving the performance of a connector.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

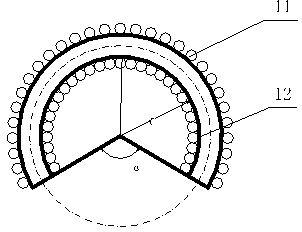

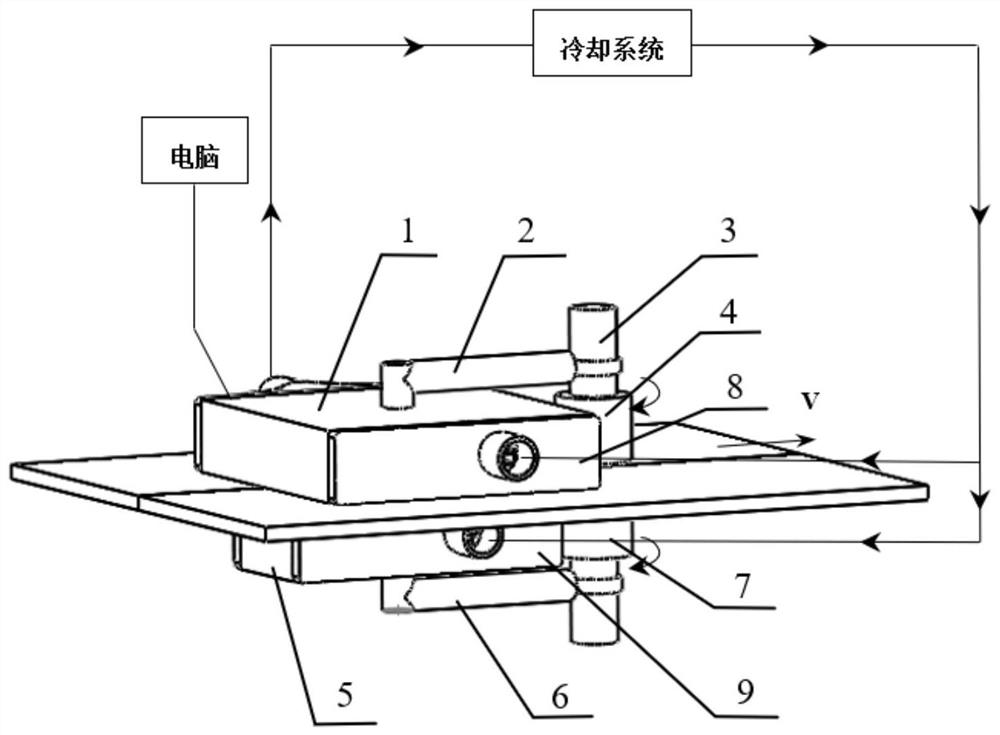

A double-sided micro-channel heat sink for suppressing fsw joint delta phase and its application method

ActiveCN111283318BImprove performanceReduce weld temperatureNon-electric welding apparatusFriction weldingEngineering

The invention discloses a double-sided microchannel radiator for suppressing the delta phase of a FSW joint and a use method thereof, comprising an upper microchannel radiator, a lower microchannel radiator, a push rod connected with the microchannel radiator, and a pipeline for transporting nanofluids , the side of the micro-channel heat sink is provided with a micro-channel, the micro-channel is connected to the pipeline for transporting nanofluid, the micro-channel heat sink device is connected to the friction stir welding spindle through a push rod, and moves synchronously along the welding direction, and the bottom surface is in full contact with the surface of the weldment to Realize heat conduction, dissipate heat and cool down the welds that are still at high temperature, effectively reduce the peak temperature of the welds, and in addition, pass nanofluids through the microchannels opened inside the radiator for forced heat dissipation and cooling. The invention suppresses the formation of delta ferrite, reduces weld overheating, refines weld grains, improves tissue uniformity, reduces or eliminates residual stress and deformation of welded joints, and achieves the purpose of improving the quality of welded joints and improving the comprehensive performance of joints.

Owner:NANJING TECH UNIV

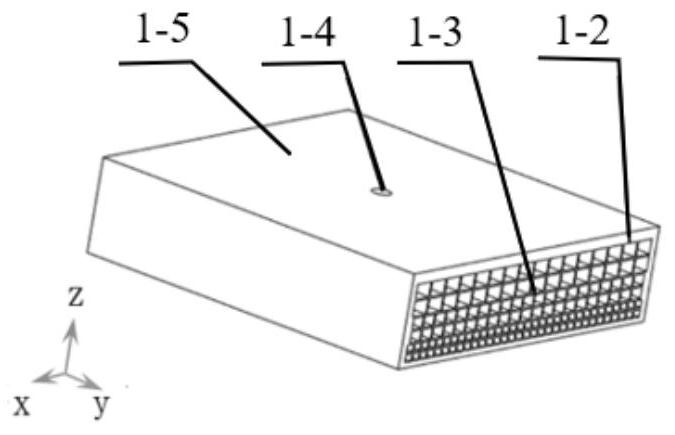

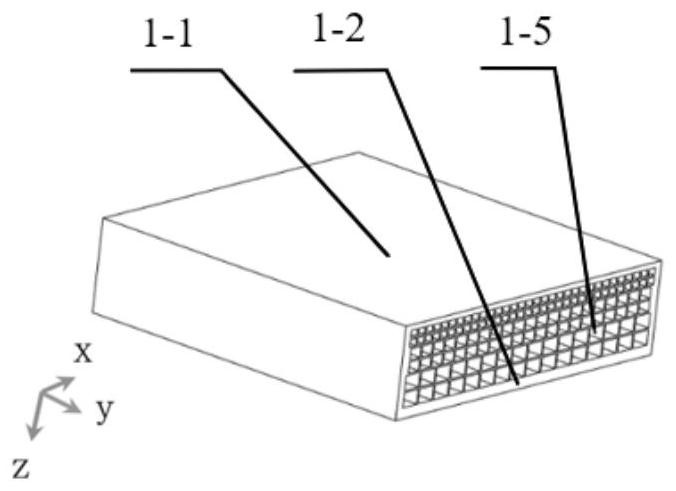

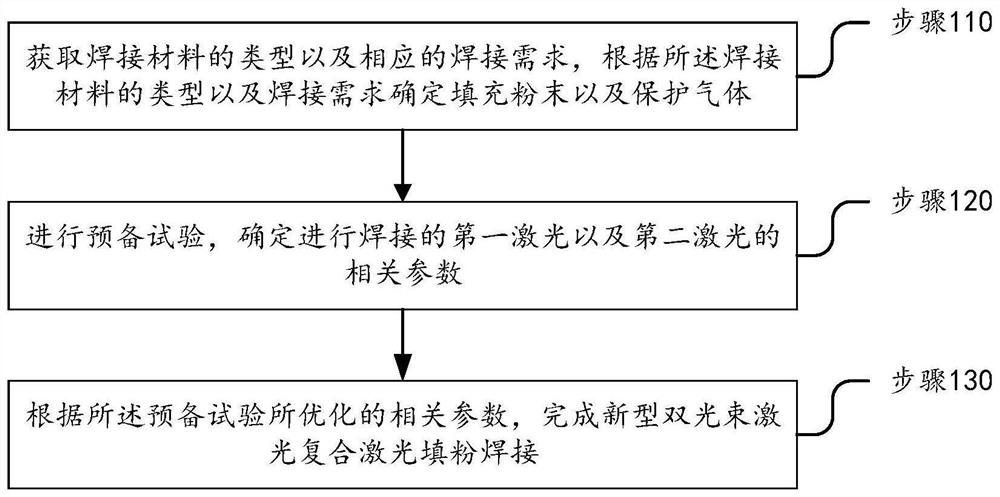

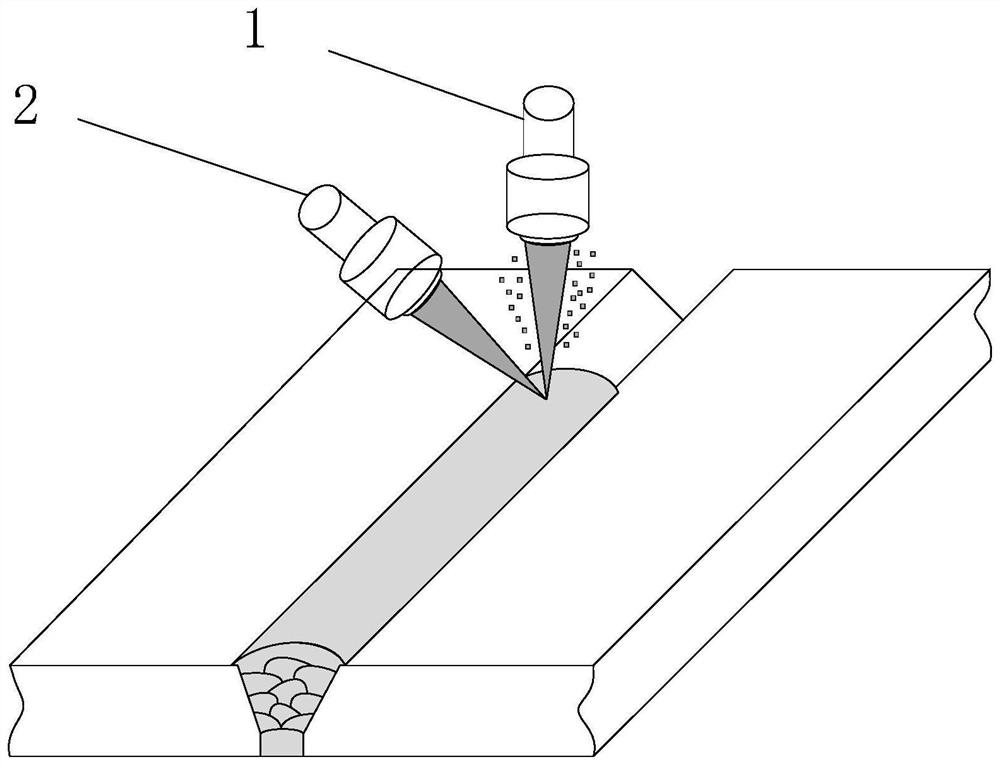

Novel double-beam laser composite laser powder filling welding method and device

ActiveCN112247359AInhibition amountSmall spacingIncreasing energy efficiencyLaser beam welding apparatusMolten stateDual beam

The invention provides a novel double-beam laser composite laser powder filling welding method which comprises the following steps that 110, the welding purpose is obtained, and filling powder and protective gas are determined according to the type of a welding material and the welding requirement; 120, a preliminary test is performed, process parameters of the two beams of laser are preliminarilyset, an optimal liquid micro-forging area is determined by using a visual tracking system and a temperature sensing system, and the process parameters of the two beams of laser are optimized to update the process parameters; and 130, the novel double-beam laser composite laser powder filling welding is completed according to the related parameters optimized by the preliminary test. Under the action of micro-forging laser on a welding area in a molten state, the number of air holes in a weld joint is restrained, columnar crystals are converted into isometric crystals, the structure is finer, the morphology and the size of a primary phase and an eutectic structure are affected, the dendritic crystal arm distance is shortened, the chemical component nonuniformity of a molten pool area is reduced, and the weld joint structure and the mechanical property are improved.

Owner:GUANGDONG LASER PEENING TECH CO LTD

Magnetic field phase control type plasma mag welding device and method

ActiveCN113560755BIncreased repellencyImprove welding stabilityPlasma welding apparatusWelding accessoriesMagnetic polesPhase control

Owner:HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com