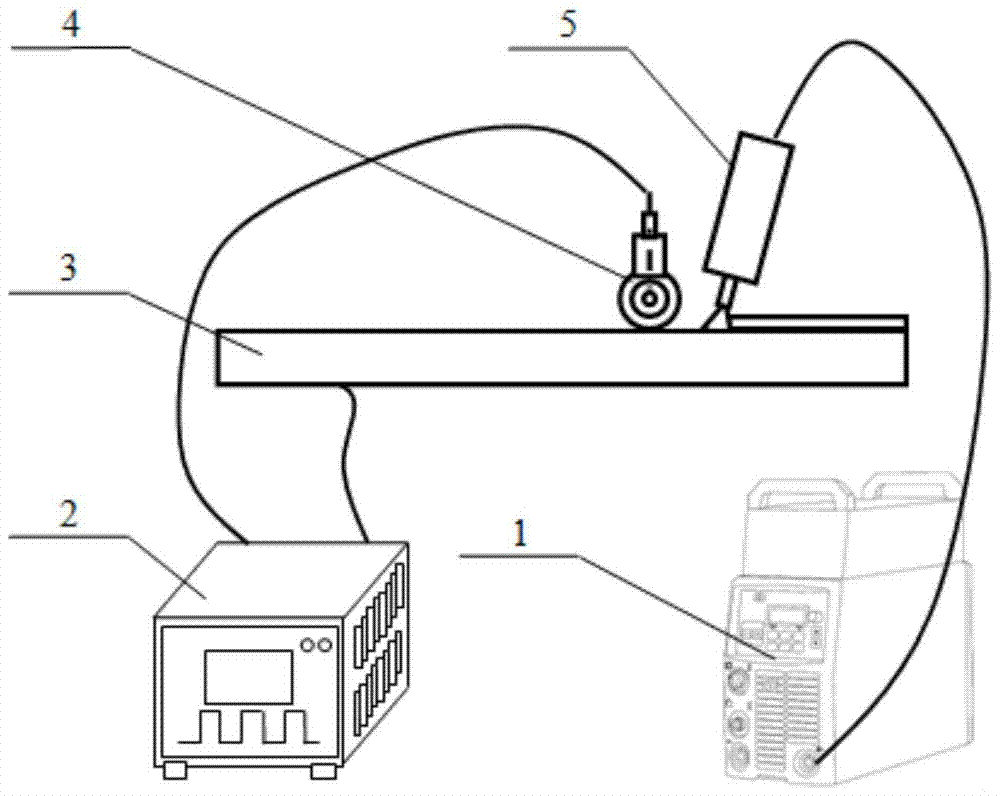

A pulse current assisted welding device and welding method

An auxiliary welding and pulse current technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems that the auxiliary pulse current cannot be applied, the power density should not be too large, and arc start, etc., to achieve grain refinement, Effect of improving weld structure and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

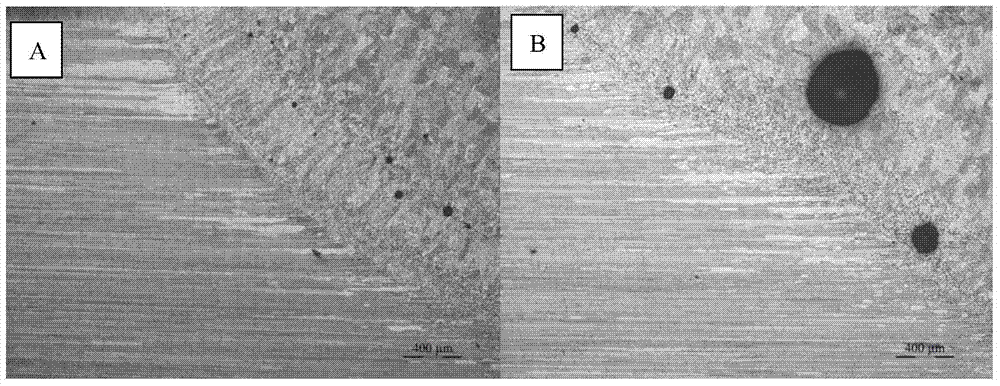

[0026] In order to illustrate the welding effect of the pulse current assisted welding device and welding method provided by this method, the aluminum alloy test plate is used as the workpiece 3 for welding as an example. The welding wire is connected, the output negative terminal is connected to the workpiece 3, and the arc heating is carried out between the welding torch 5 and the workpiece 3 at the joint position during welding, so that the base metal and the welding wire are melted to form a welding pool. At the same time, the output positive pole of the pulse power supply 2 is connected to the Connected with the welding compression wheel 4, the output negative electrode of the pulse power supply 2 is connected with the workpiece, the amplitude of the pulse current is 200A, the pulse width is 25us, and the frequency is 200Hz. The current flows out from the positive pole of the pulse power supply 2, flows through the welding press wheel 4, then passes through the workpiece 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com