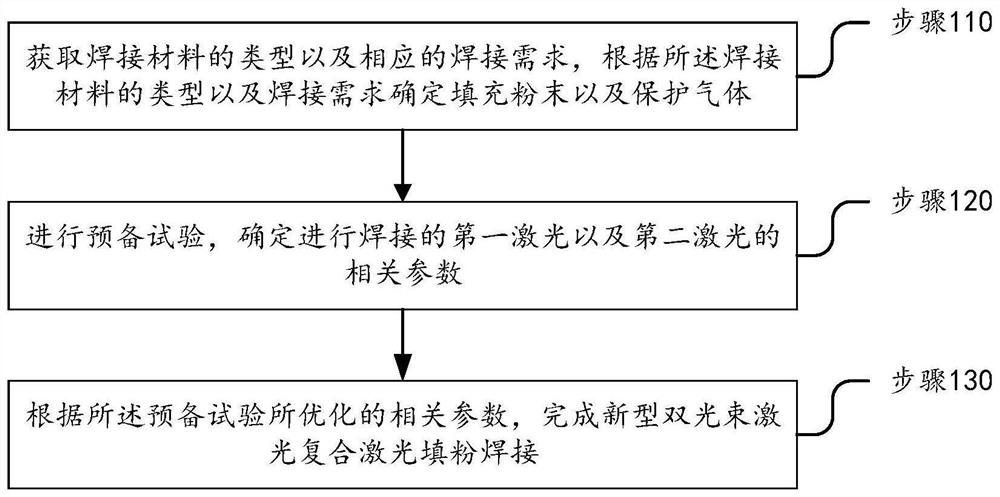

Novel double-beam laser composite laser powder filling welding method and device

A welding method and a technology of a welding device, which are applied in the field of laser repair, can solve problems such as tissue disorder, poor welding, and pores, and achieve improved weld structure and mechanical properties, reduced chemical composition inhomogeneity, and shortened dendrite arm spacing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

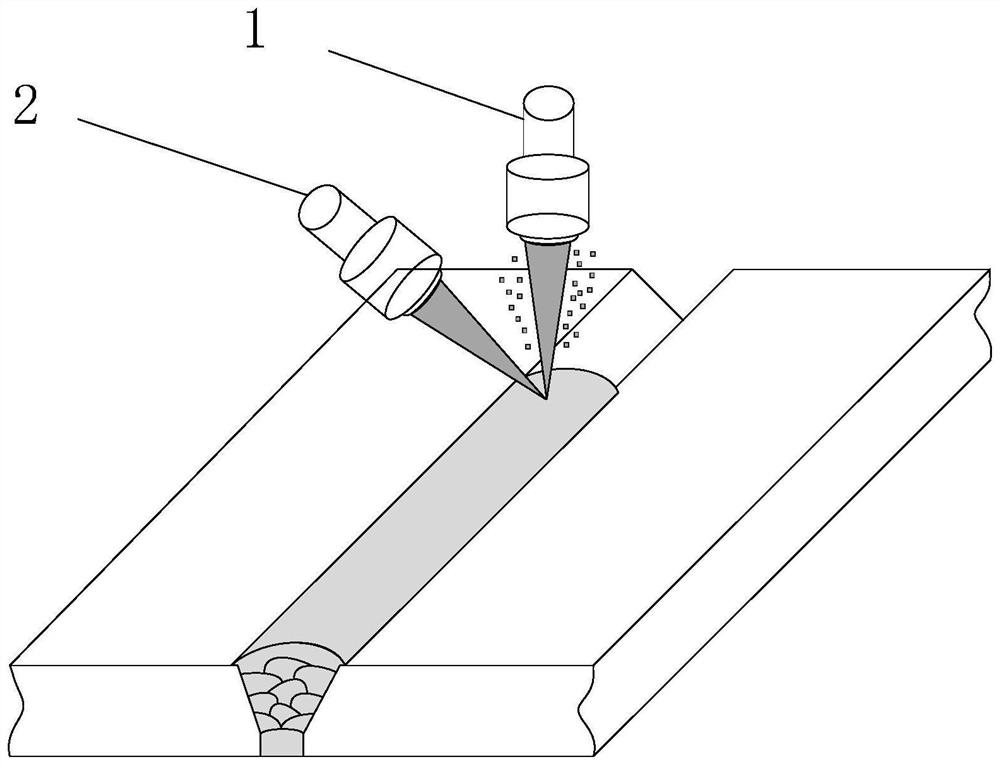

[0040] Embodiment 2, the present invention also proposes a novel dual-beam laser composite laser powder filling welding device, including,

[0041] The first laser is used to generate a first laser, and the first laser is used as a welding laser to provide a continuous laser, and the thermal effect thereof is used to melt the filling powder and the welding area to form a molten pool;

[0042] The second laser is used to generate a second laser, and the second laser is used as a micro-forging laser to provide a short-pulse laser to impact and stir the molten pool;

[0043] a visual tracking system, configured to acquire splash images in the molten pool area, and form a first graph, the first graph including a mapping relationship between the spatter rate and the parameters of the second laser, the spatter rate being splashed through the molten pool area The image is obtained, and the parameters of the second laser at the lowest spatter rate are obtained through the first graph,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com