Patents

Literature

66results about How to "Impact size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

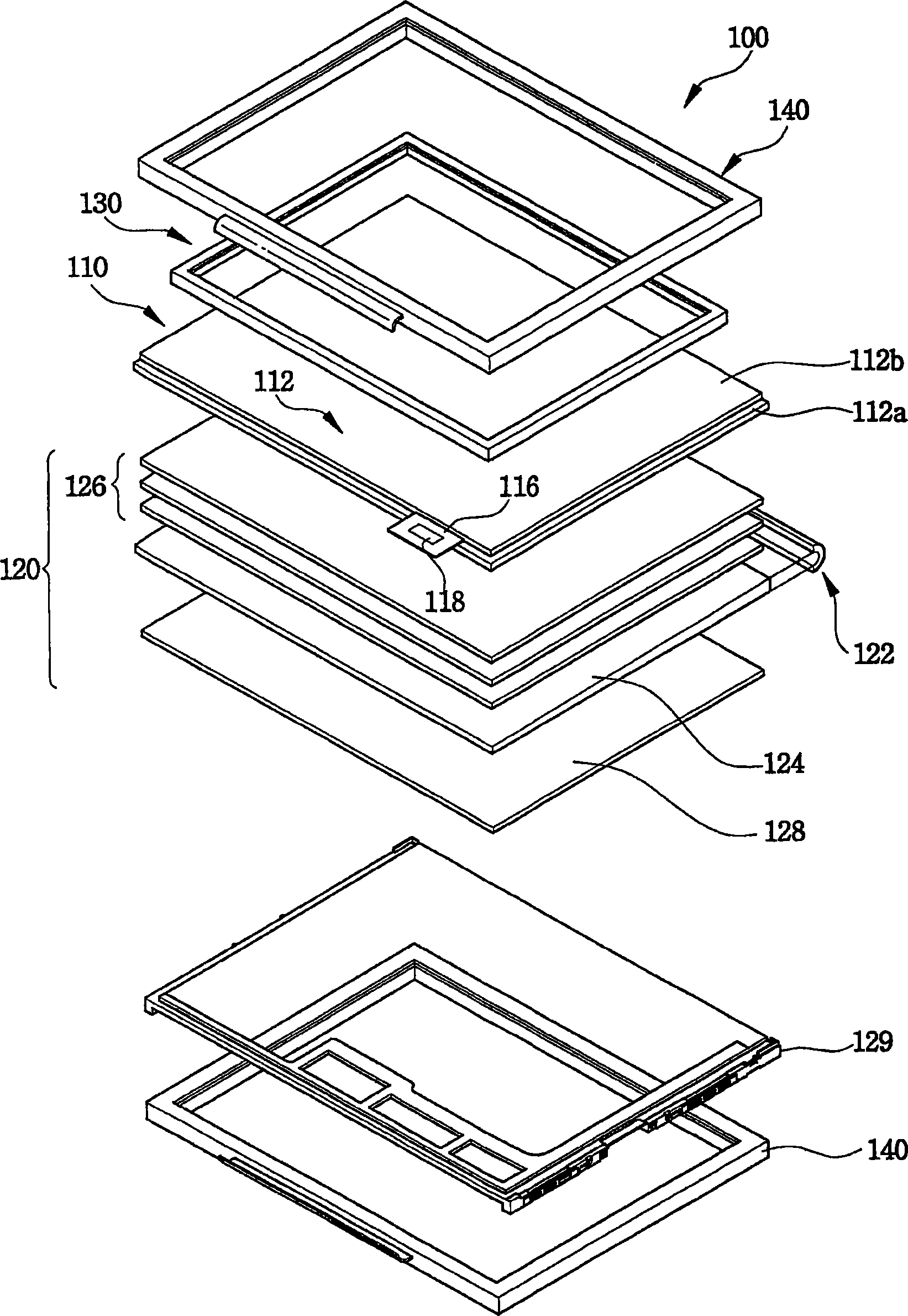

Display device and control method thereof and storage medium

ActiveCN108717244AImpact sizeInfluence shapeStatic indicating devicesSolid-state devicesDisplay deviceComputer science

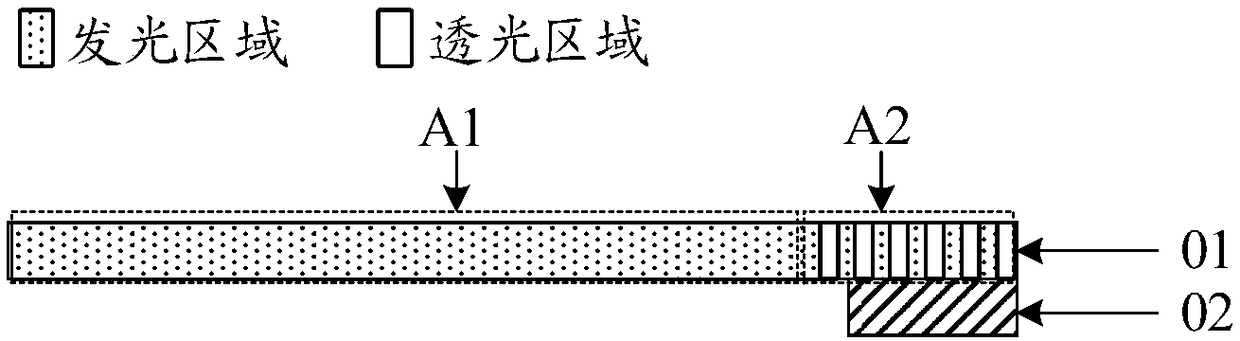

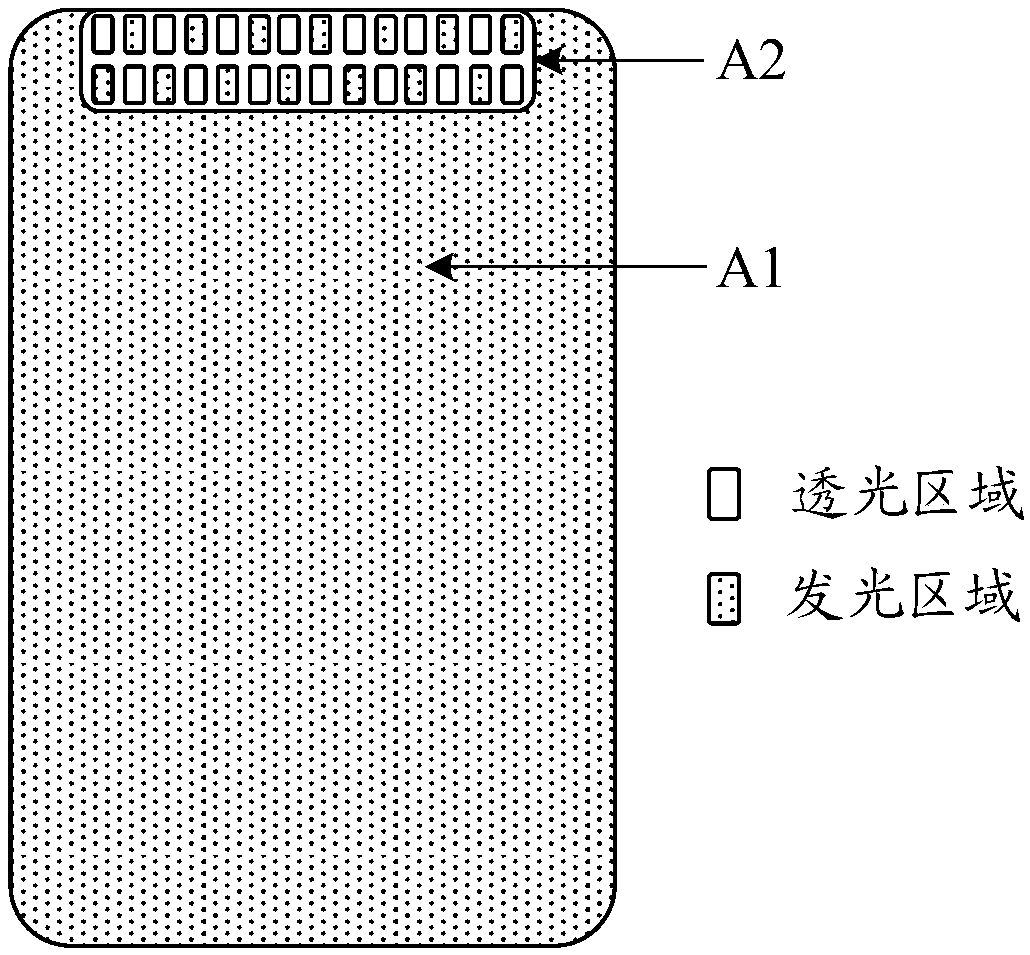

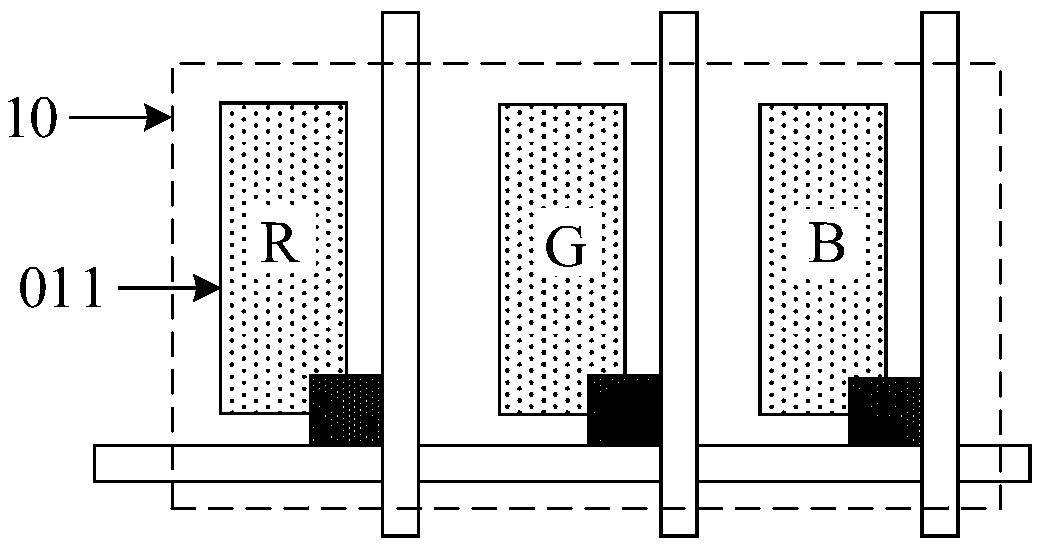

The invention discloses a display device and a control method thereof and a storage medium, and belongs to the technical field of display. The display device comprises a display panel and a sensor assembly; the display panel comprises a first display area and a second display area, and the sensor assembly is located in the second display area; and the second display area comprises a plurality of light emitting areas and light transmitting areas which are arranged staggeredly. The provided sensor assembly in the display device can sense light through the light transmitting areas in the second display area, thereby being capable of working normally. It is not needed that a grooving is formed in the display panel, therefore the size and shape of the display panel cannot be affected, thereby being conductive to achieving a full-screen display device and improving the display effect of the full-screen display device.

Owner:BOE TECH GRP CO LTD +1

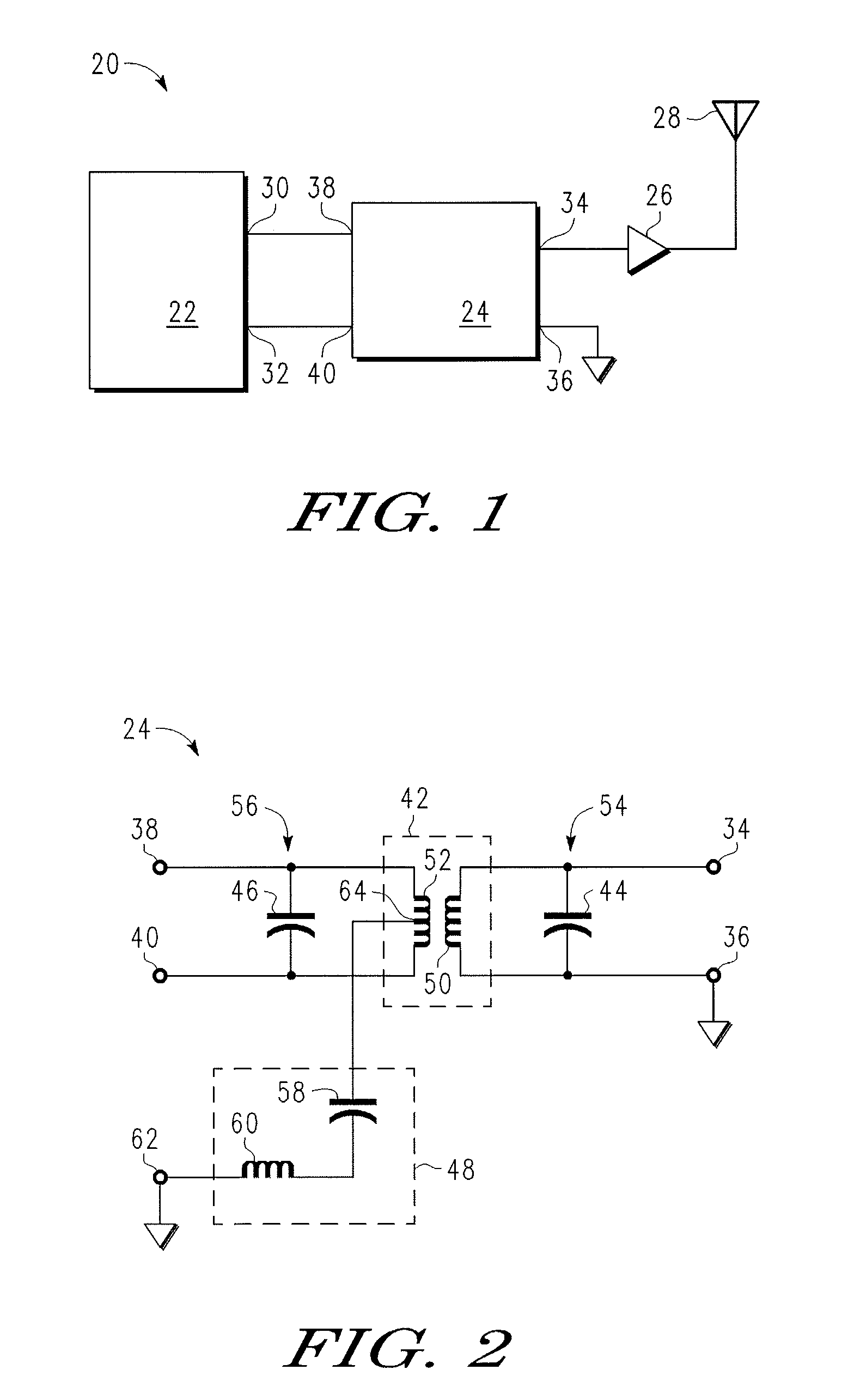

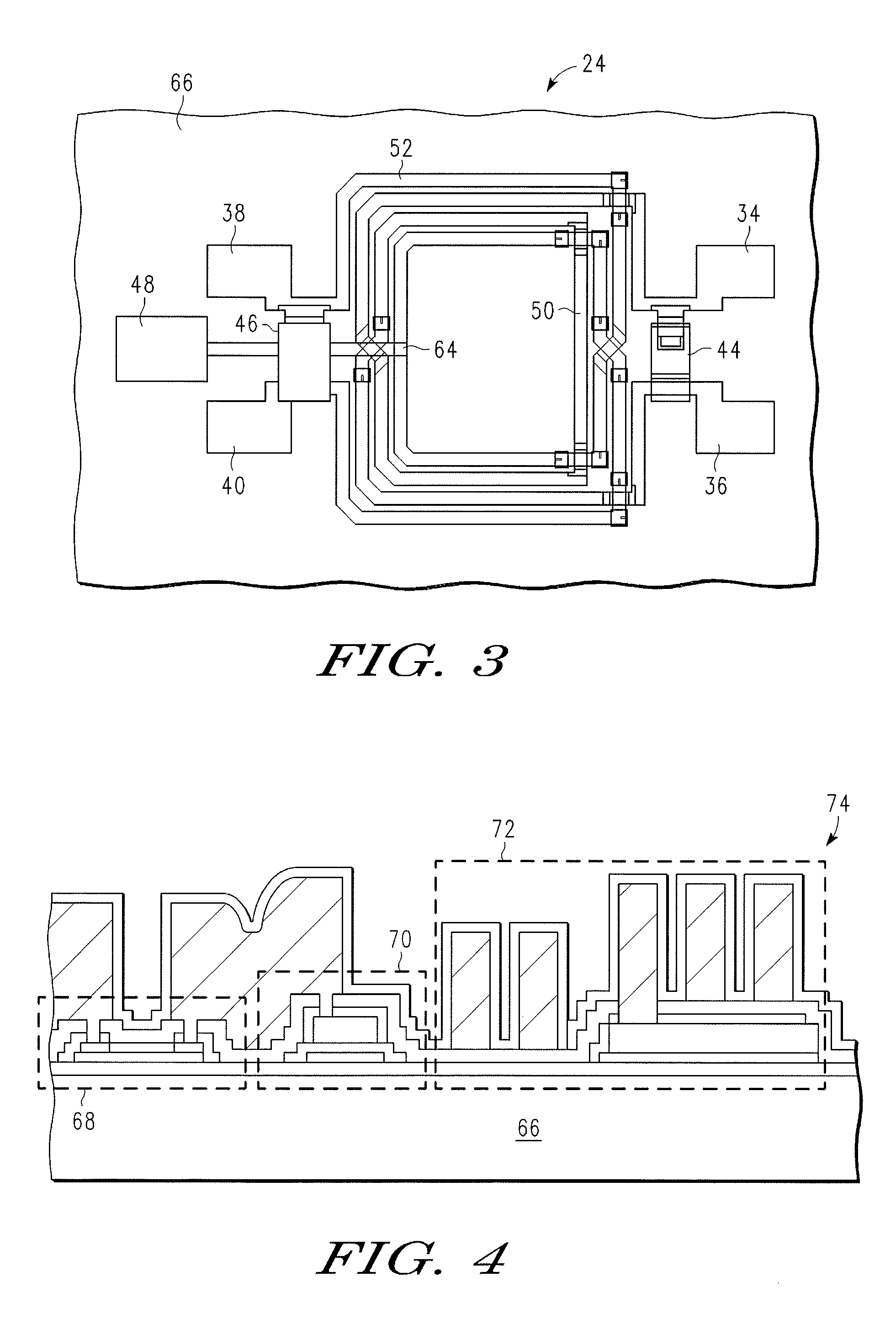

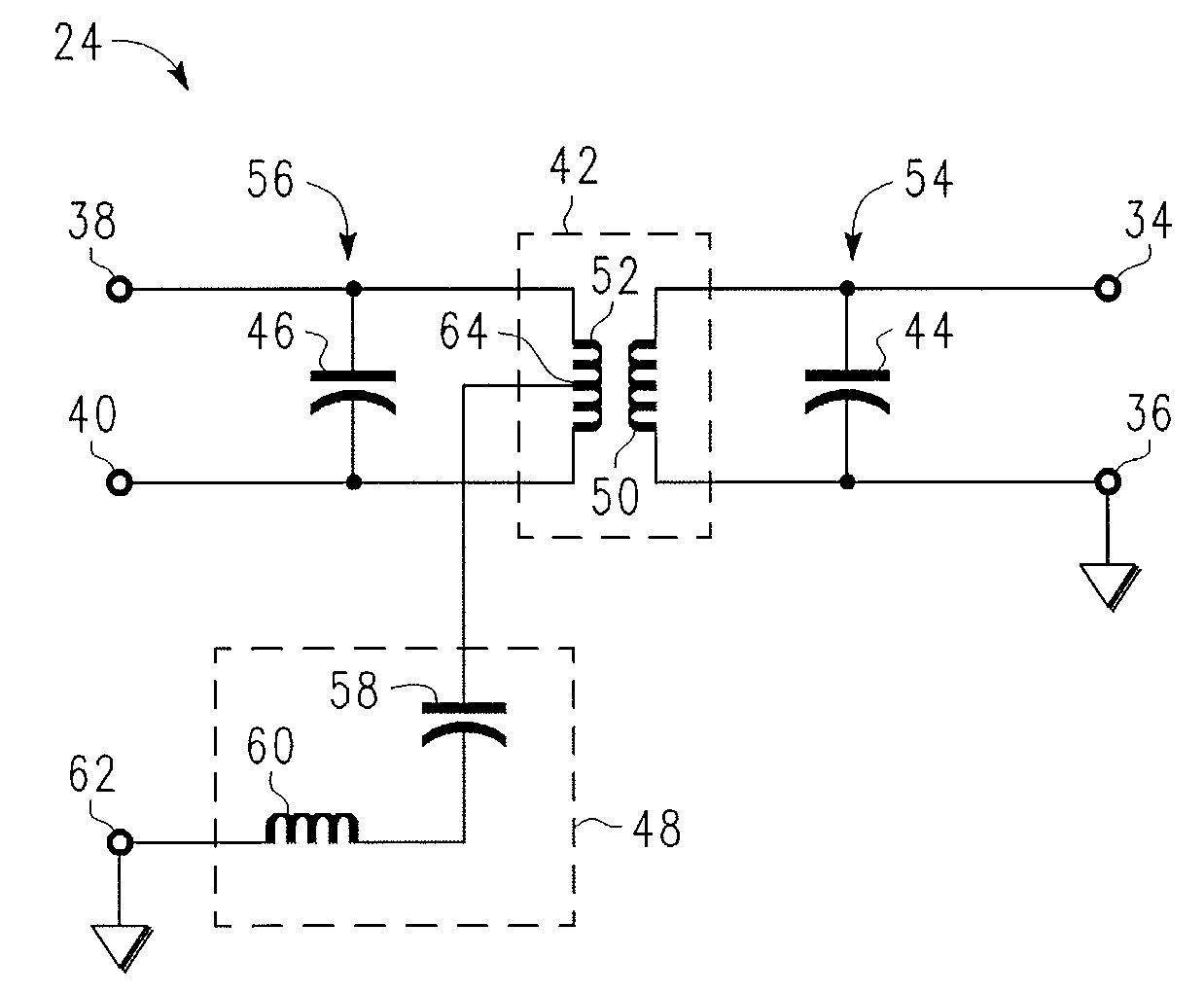

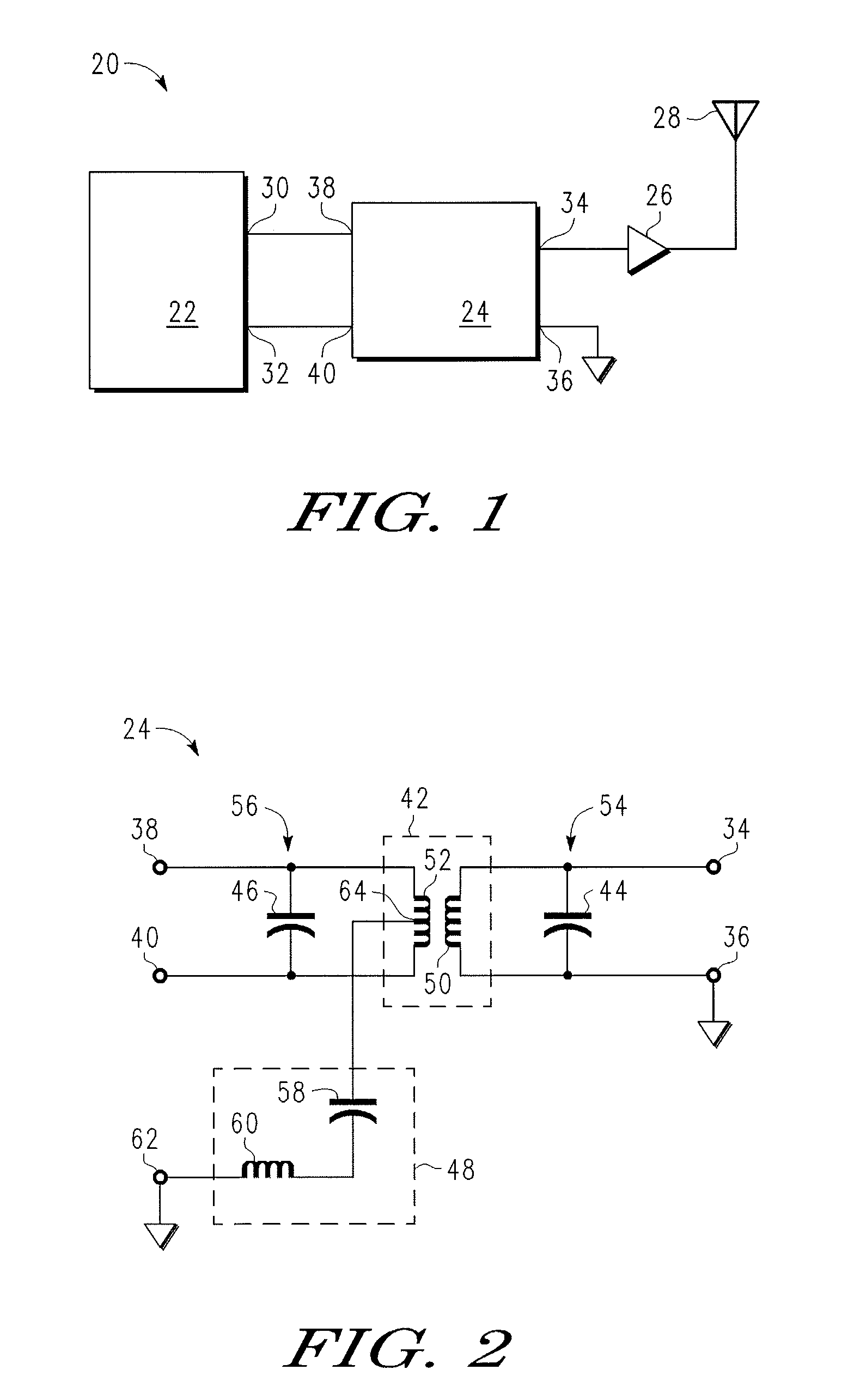

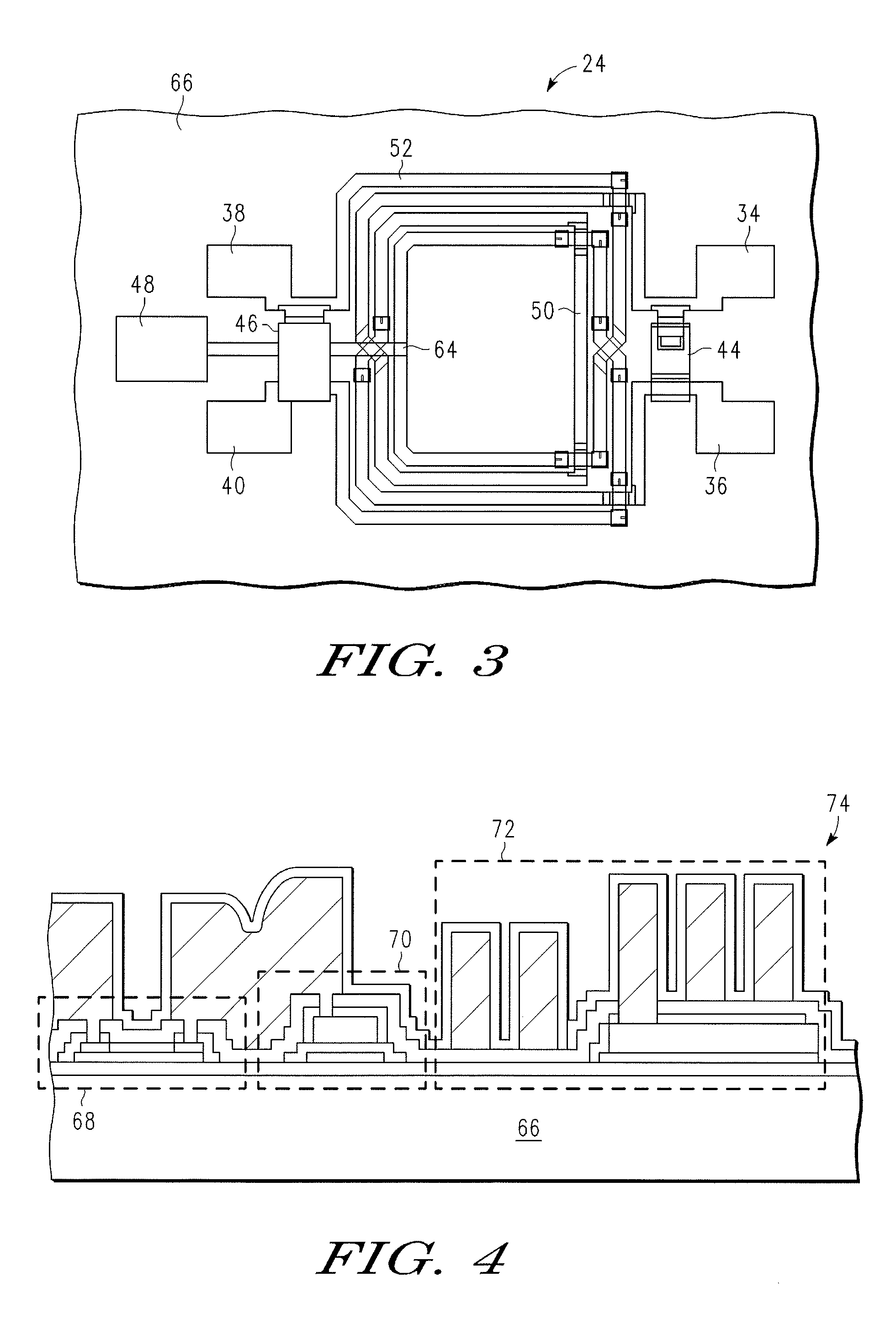

Balun transformer with improved harmonic suppression

ActiveUS20090195324A1Improve performanceImprove device performanceMultiple-port networksOne-port networksTransformerHarmonic

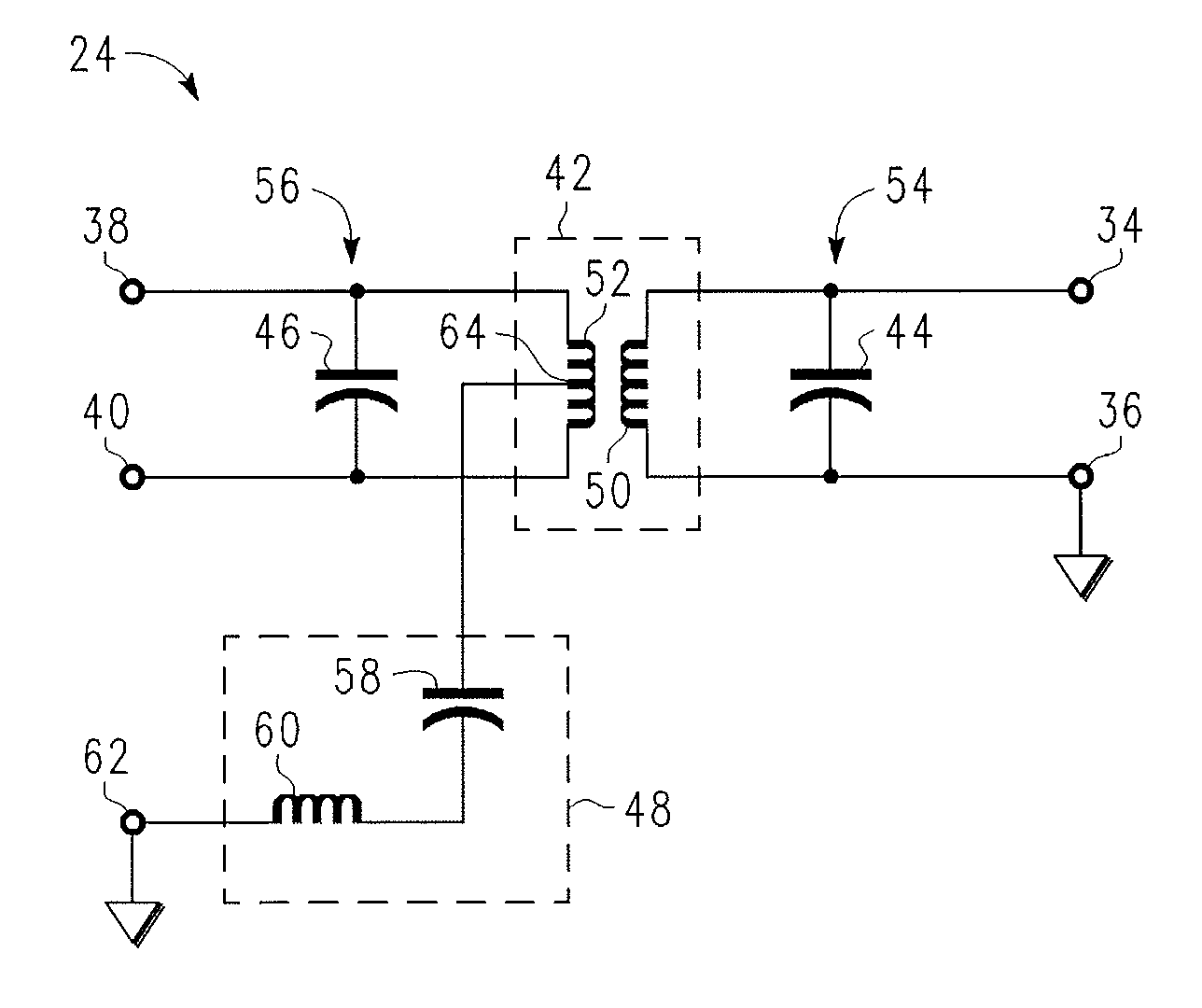

An electronic assembly includes a substrate (66), a balun transformer (42) formed on the substrate (66) and including a first winding (50) and a second winding (52), each having respective first and second ends, and a reaction circuit component (48) formed on the substrate (66) and electrically coupled to the second winding (52) between the first and second ends thereof. The balun transformer (42) and the reaction circuit component (48) jointly form a harmonically suppressed balun transformer having a fundamental frequency, and the reaction circuit component (48) is tuned such that the harmonically suppressed balun transformer resonates at a selected harmonic of the fundamental frequency.

Owner:NXP USA INC

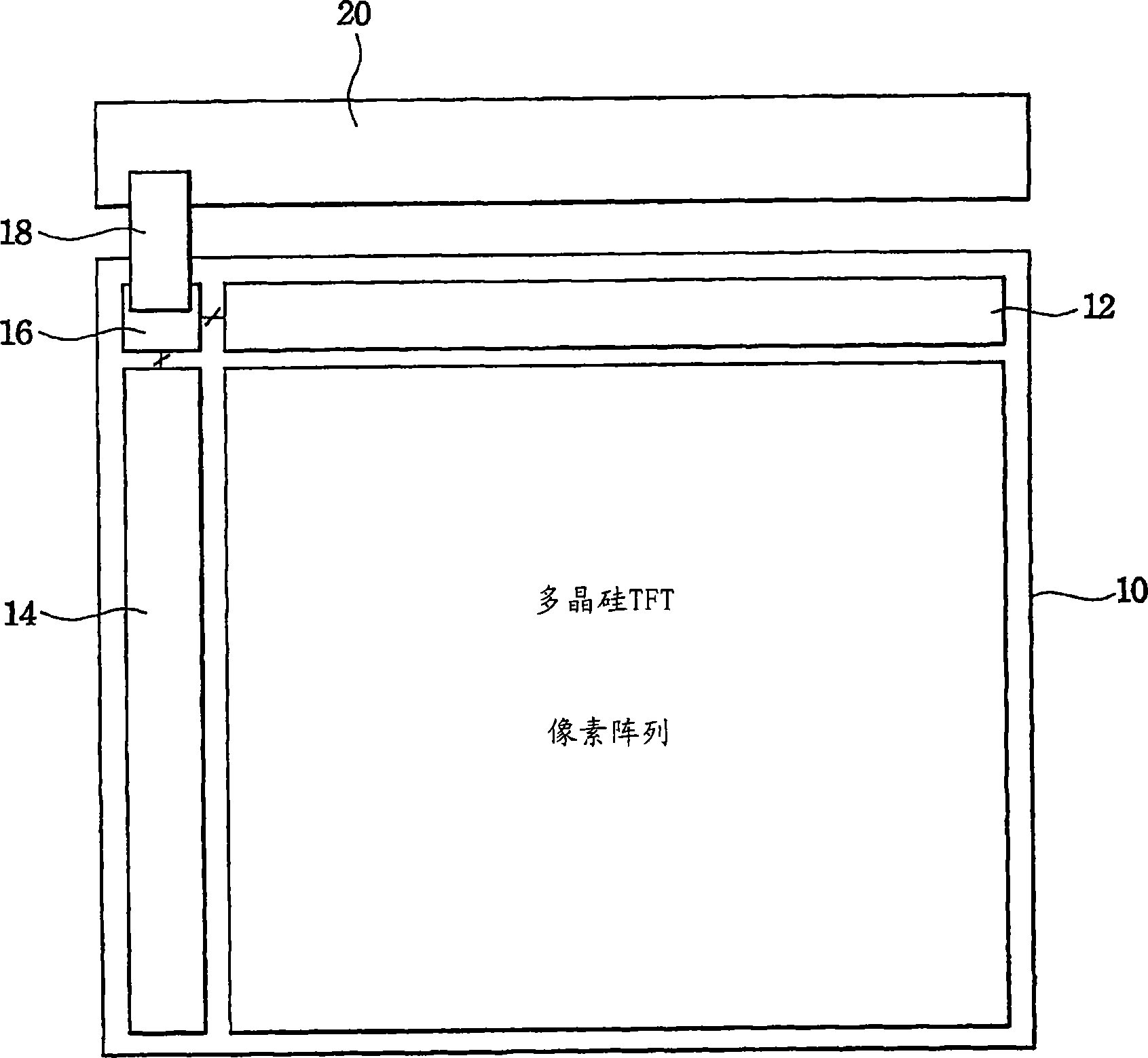

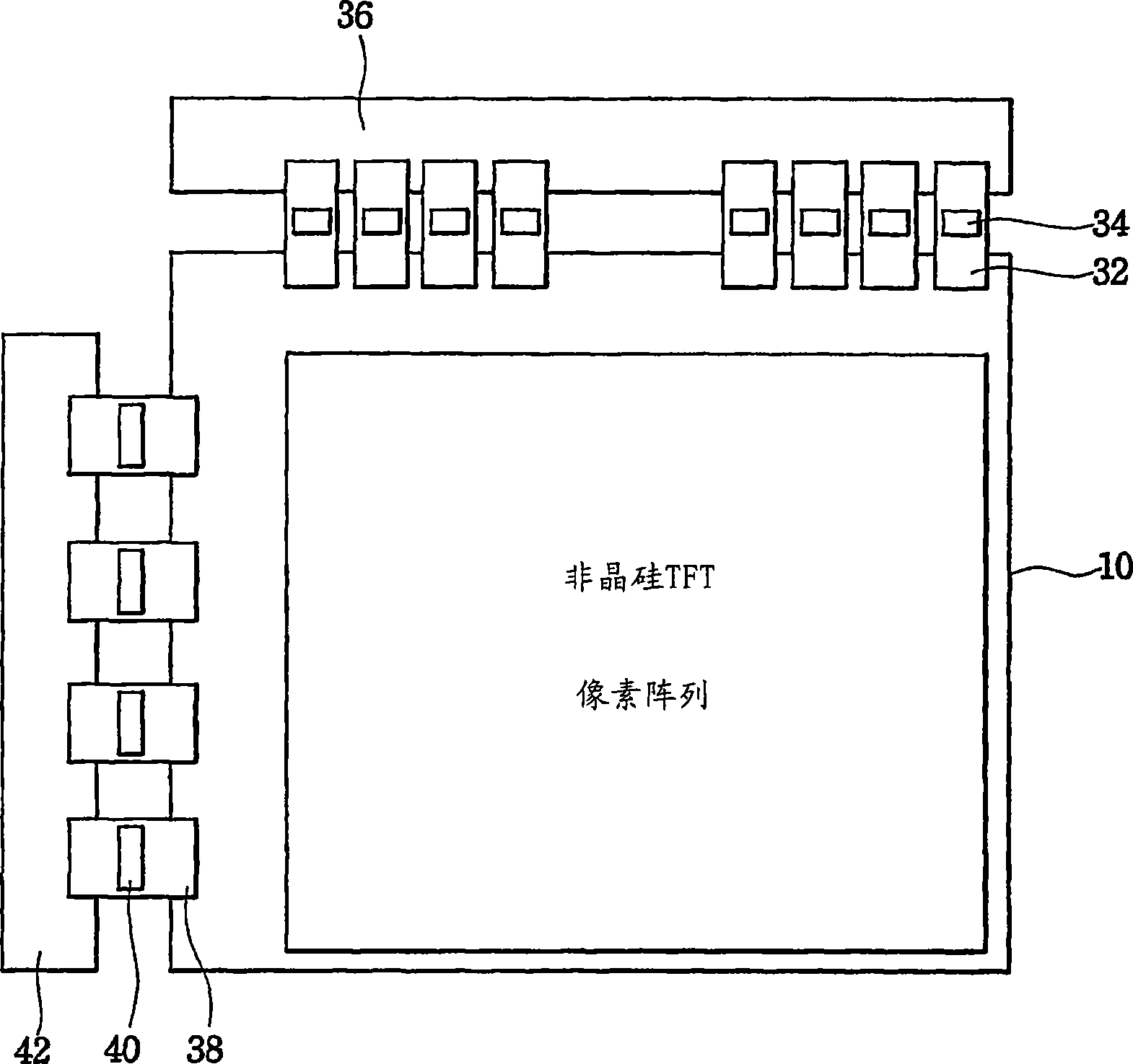

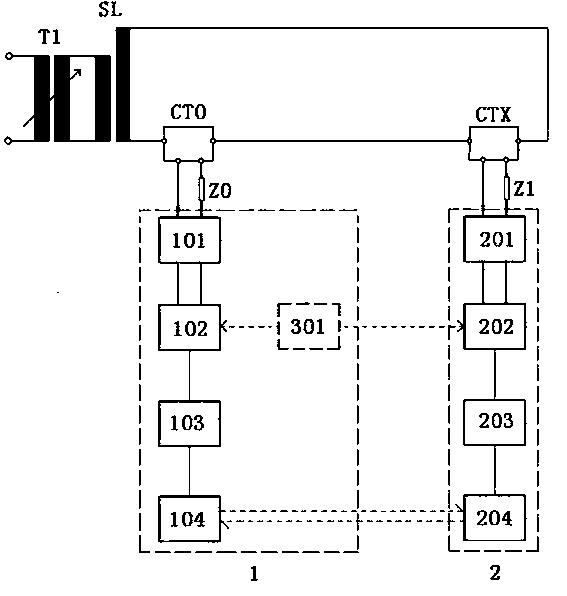

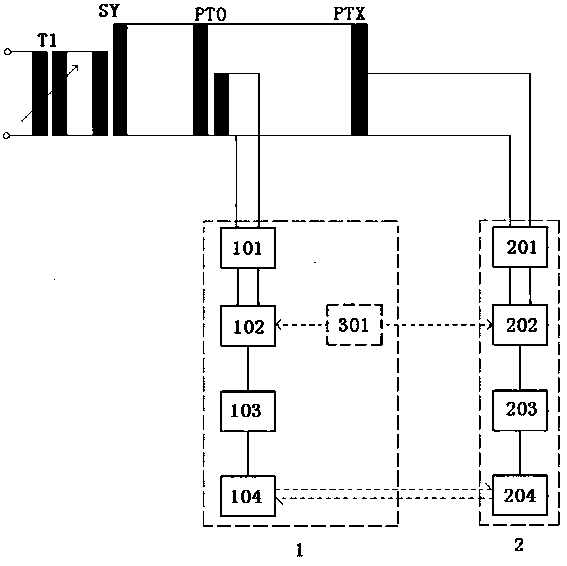

Method of driving a shift register, a shift register, a liquid crystal display device having the shift register

InactiveCN1860519ADelay minimizationAvoid loading effectStatic indicating devicesDigital storageShift registerLiquid-crystal display

In a shift register and LCD device having the shift register that may be employed in the liquid crystal display device having a large screen size and a large resolution, the shift register includes stages connected with each other and each of the stages have a carry buffer for generating a carry signal. The pull-down transistor of each of the stages of the shift register is divided into a first pull-down transistor and a second pull-down transistor. A power voltage Vona larger than the power voltage Von applied to a clock generator is applied to the shift register. A signal delay due to the RC delay of the gate lines may be minimized, the shift register is independent of the variation of the threshold voltage of the TFTs, and image display quality may not be deteriorated.

Owner:SAMSUNG DISPLAY CO LTD

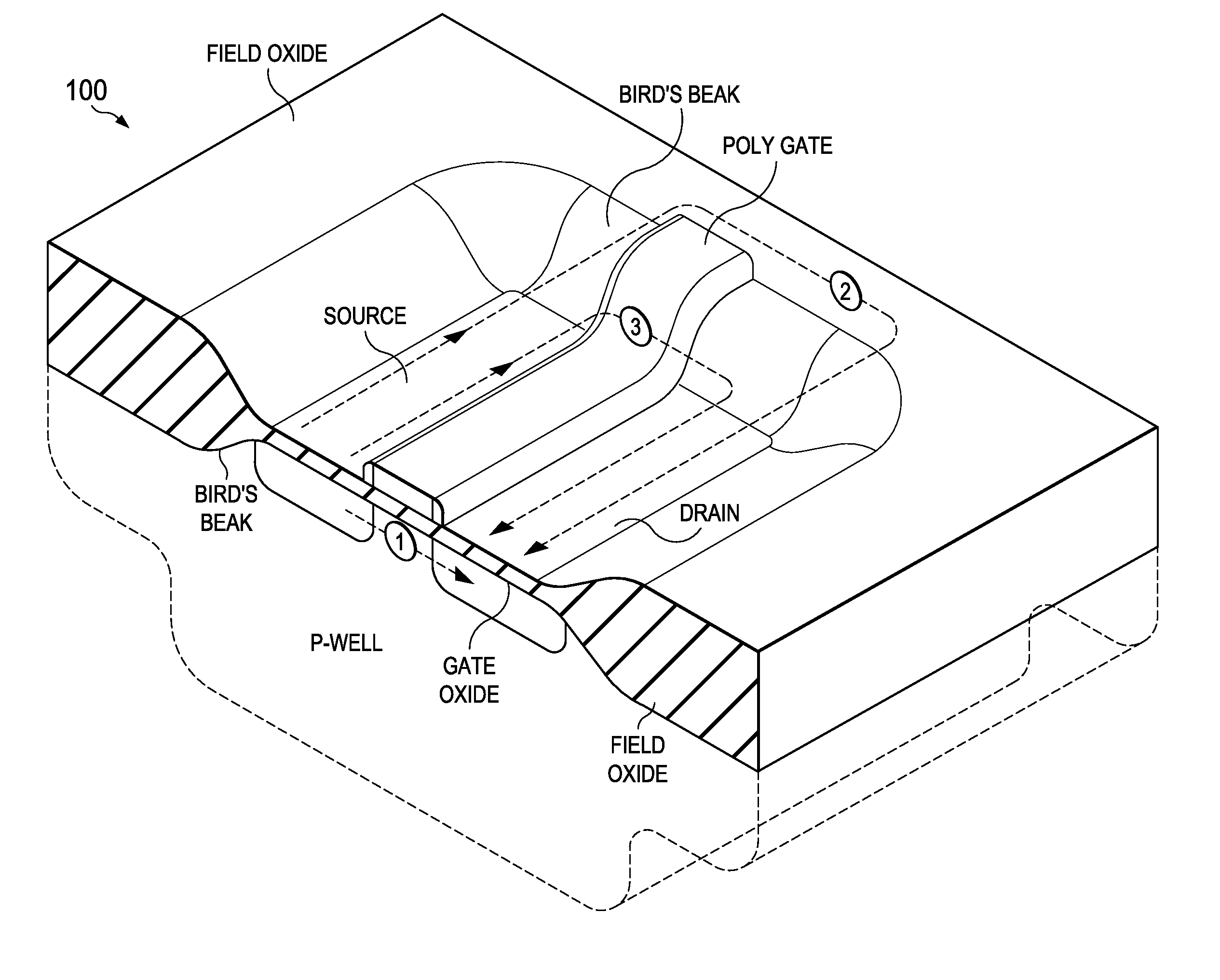

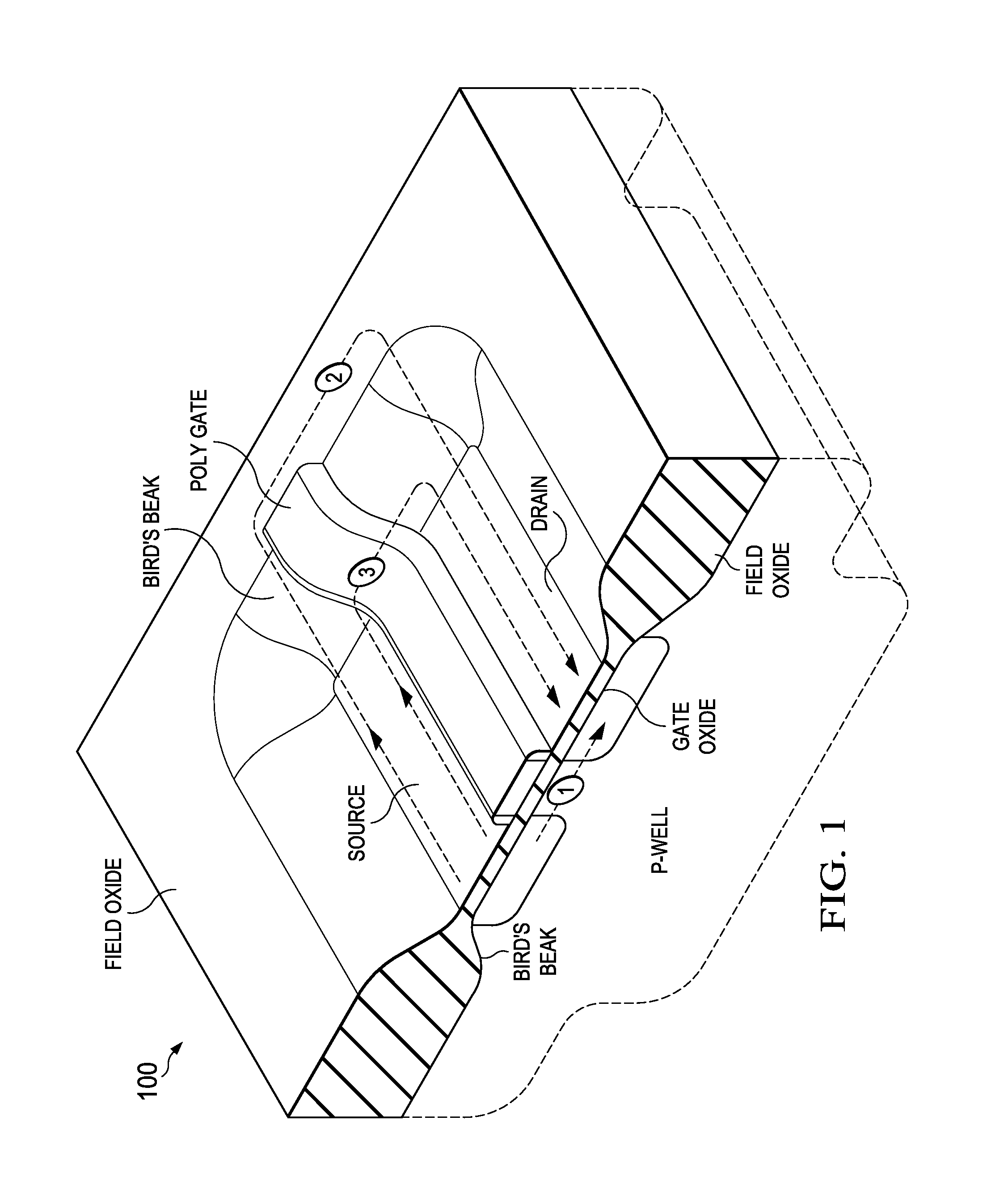

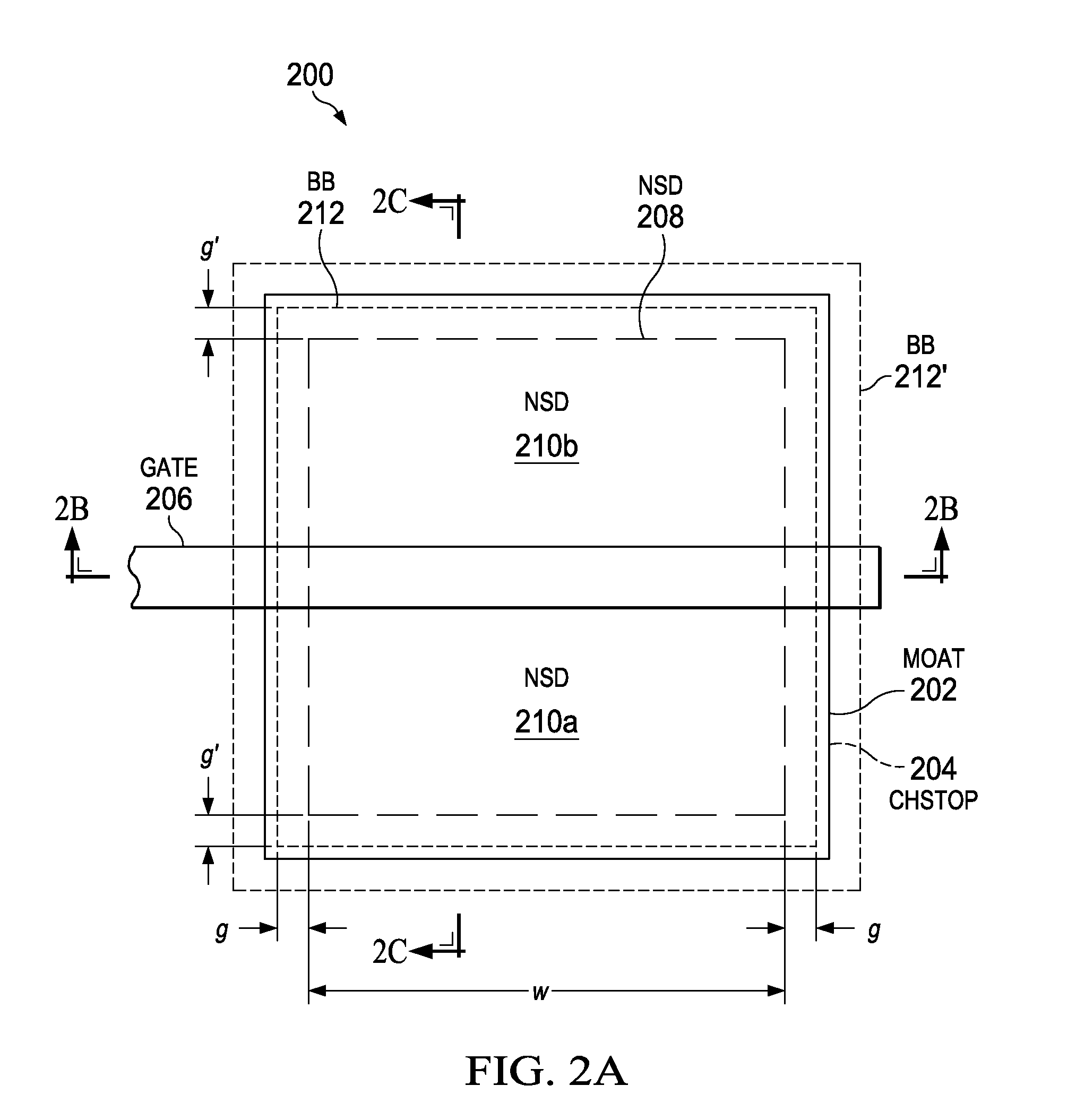

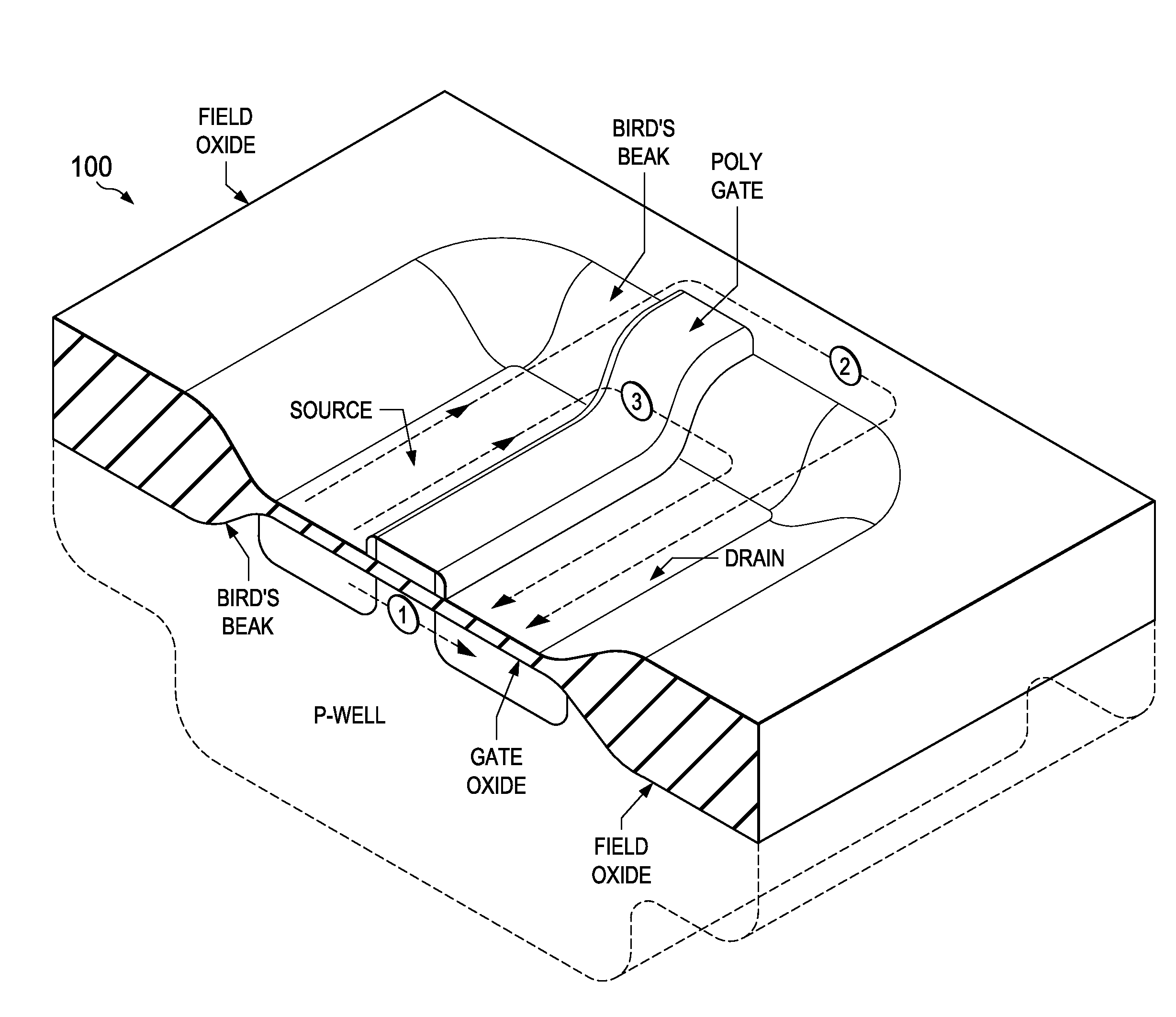

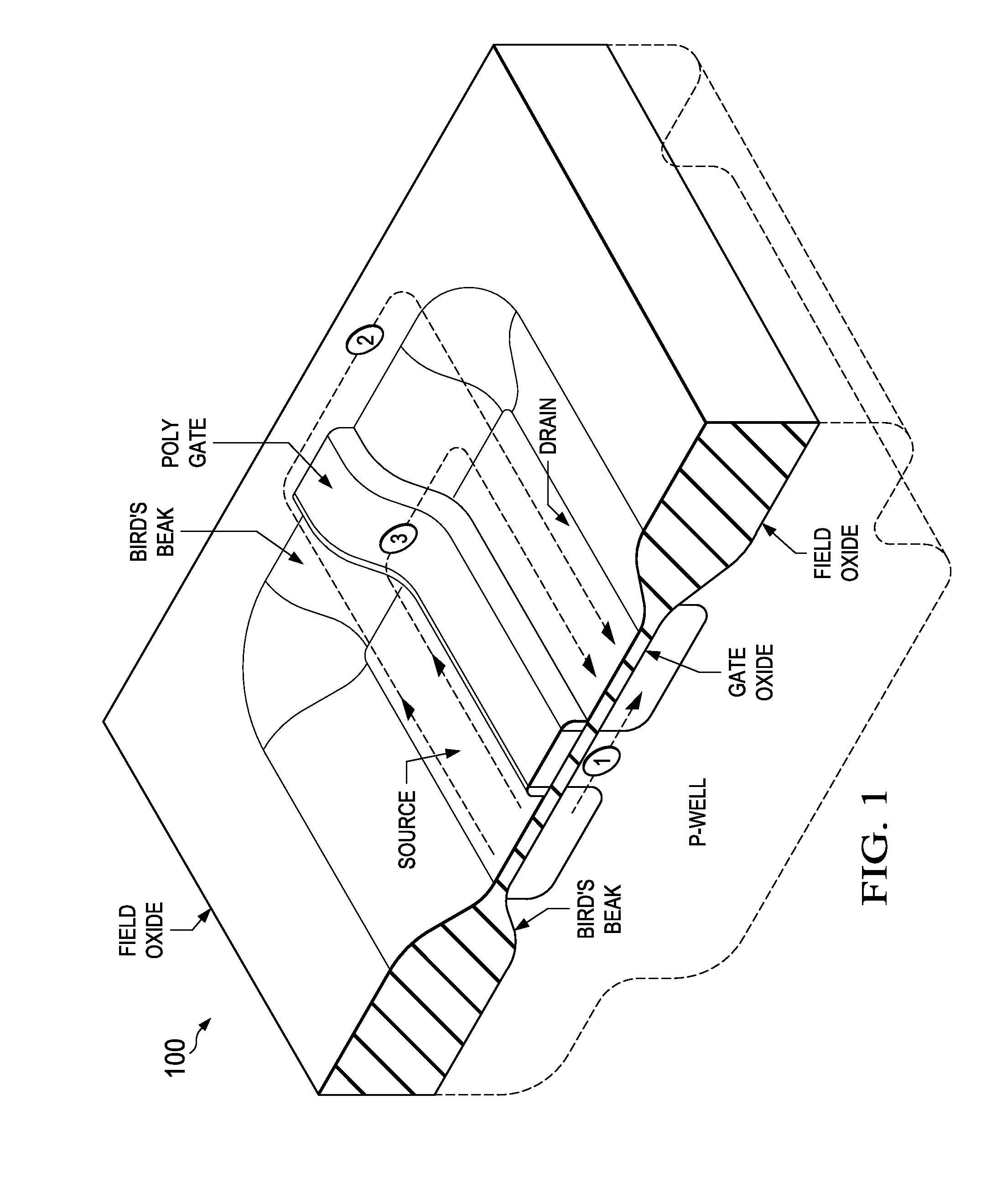

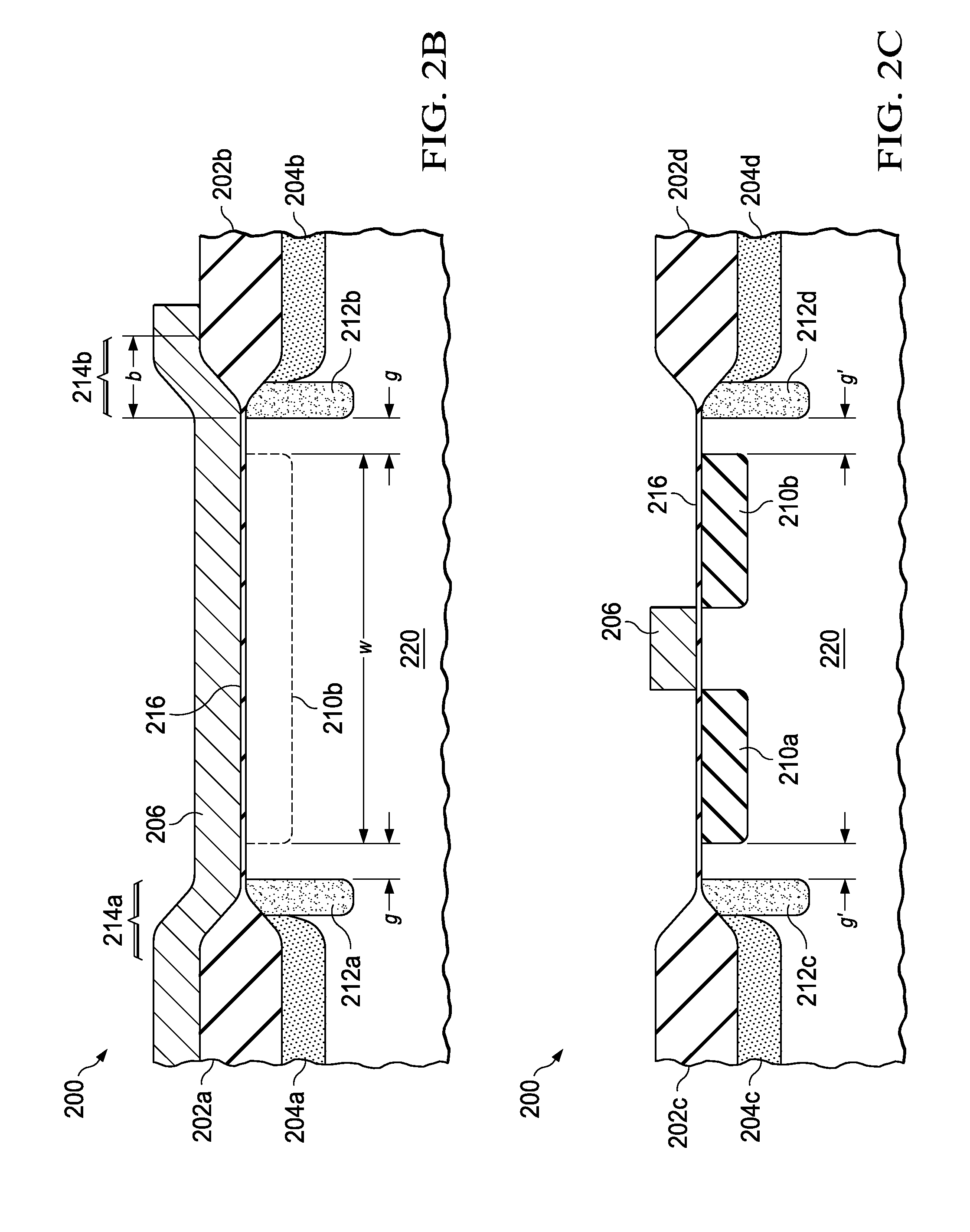

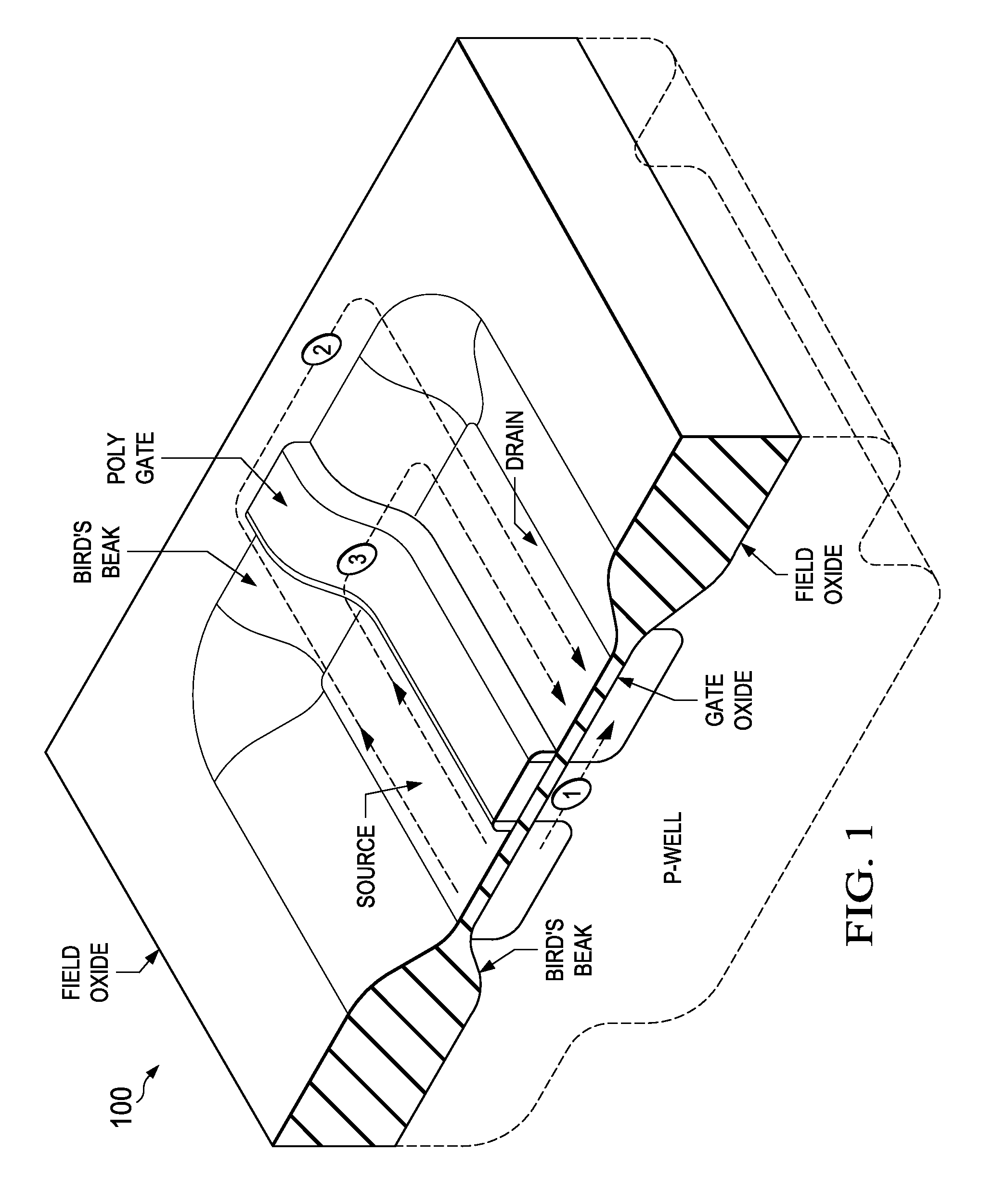

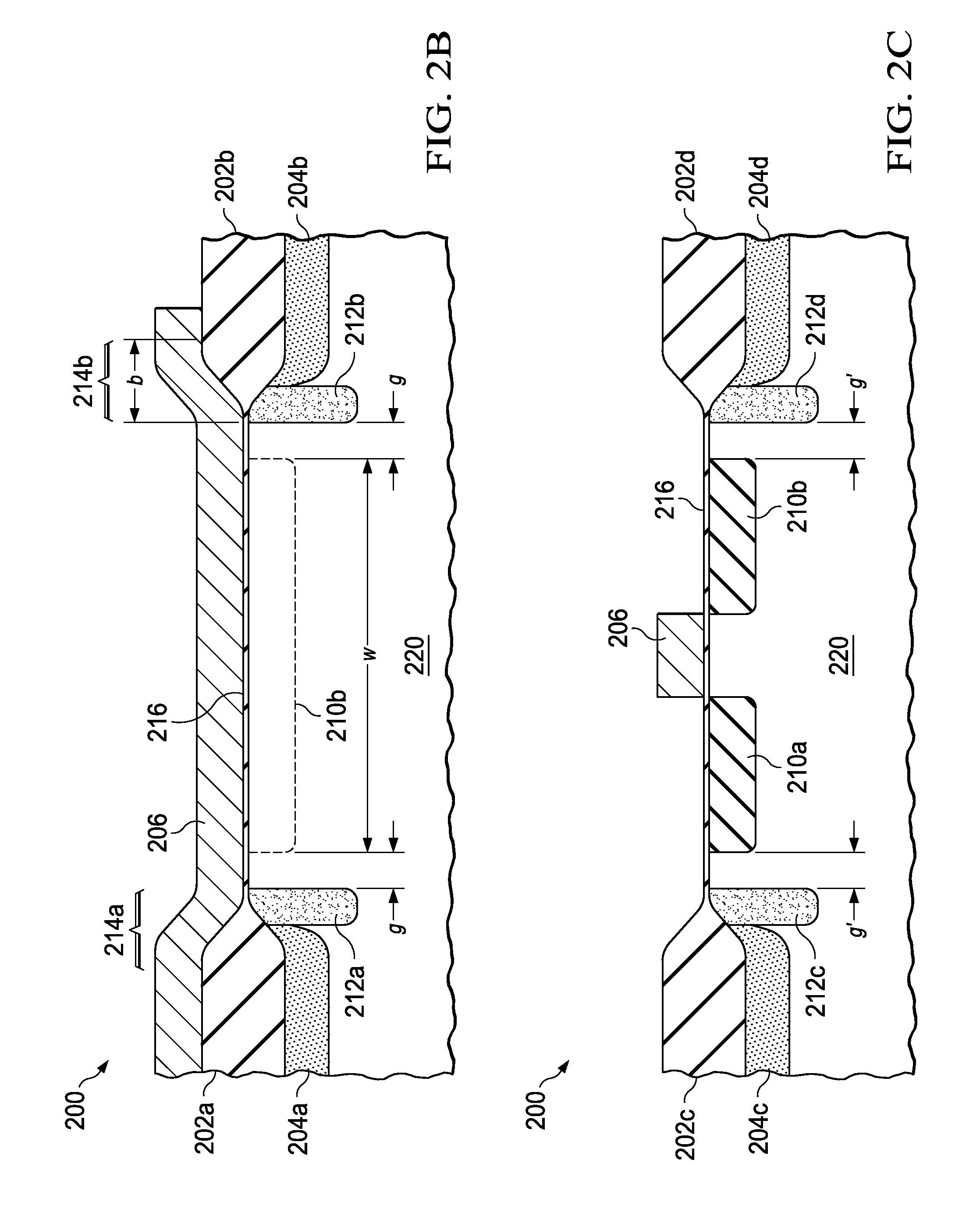

Radiation hardened mos devices and methods of fabrication

InactiveUS20110084324A1Improve radiation hardnessReducing radiation-induced leakageTransistorSolid-state devicesCMOSRadiation resistant

Radiation hardened NMOS devices suitable for application in NMOS, CMOS, or BiCMOS integrated circuits, and methods for fabricating them. A device includes a p-type silicon substrate, a field oxide surrounding a moat region on the substrate tapering through a bird's beak region to a gate oxide within the moat region, a heavily-doped p-type guard region underlying at least a portion of the bird's beak region and terminating at the inner edge of the bird's beak region, a gate crossing the moat region, and n-type source and drain regions spaced by a gap from the inner edge of the guard region. A variation of a local oxidation of silicon process is used with an additional bird's beak implantation mask as well as minor alterations to the conventional moat and n-type source / drain masks. The resulting devices have improved radiation tolerance while having a high breakdown voltage and minimal impact on circuit density.

Owner:TEXAS INSTR INC

Balun transformer with improved harmonic suppression

ActiveUS7683733B2Good harmonic suppressionImprove performanceMultiple-port networksOne-port networksTransformerHarmonic

An electronic assembly includes a substrate (66), a balun transformer (42) formed on the substrate (66) and including a first winding (50) and a second winding (52), each having respective first and second ends, and a reaction circuit component (48) formed on the substrate (66) and electrically coupled to the second winding (52) between the first and second ends thereof. The balun transformer (42) and the reaction circuit component (48) jointly form a harmonically suppressed balun transformer having a fundamental frequency, and the reaction circuit component (48) is tuned such that the harmonically suppressed balun transformer resonates at a selected harmonic of the fundamental frequency.

Owner:NXP USA INC

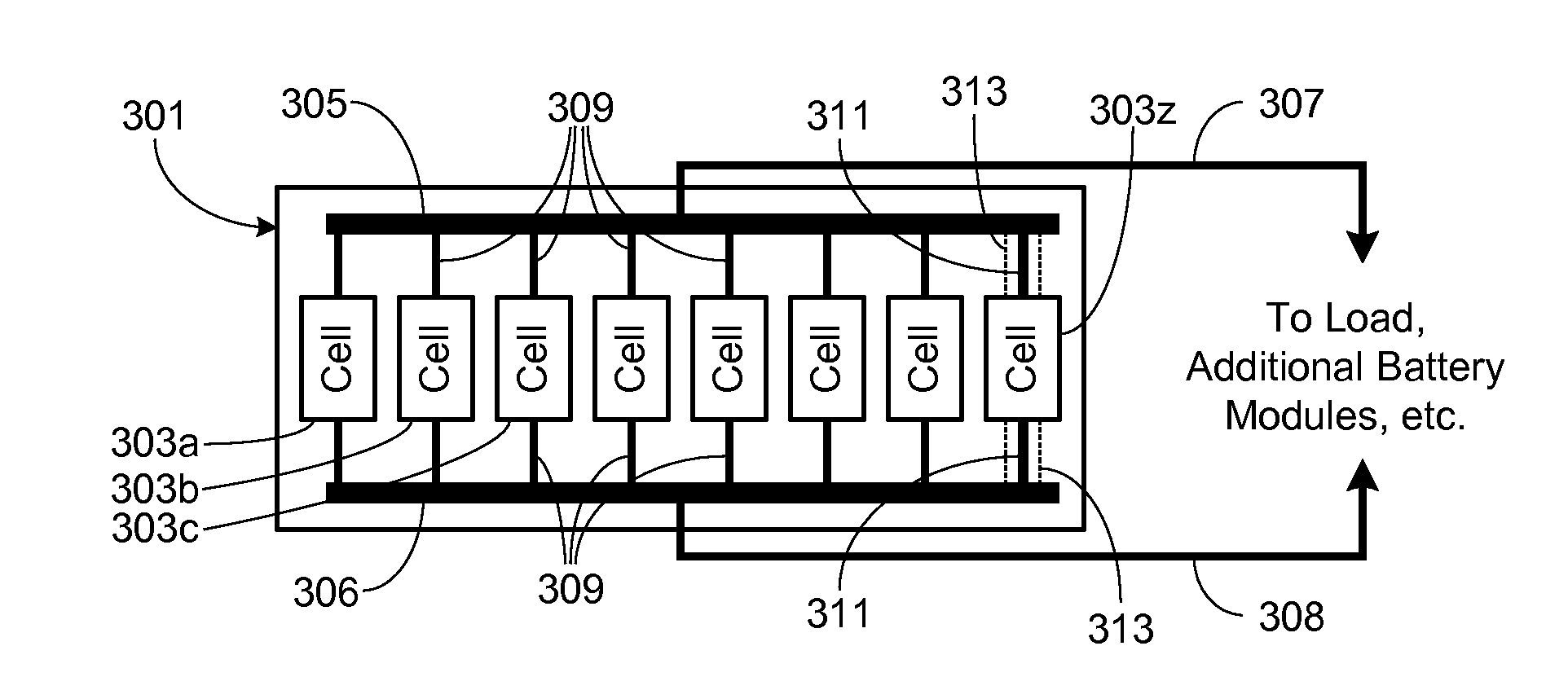

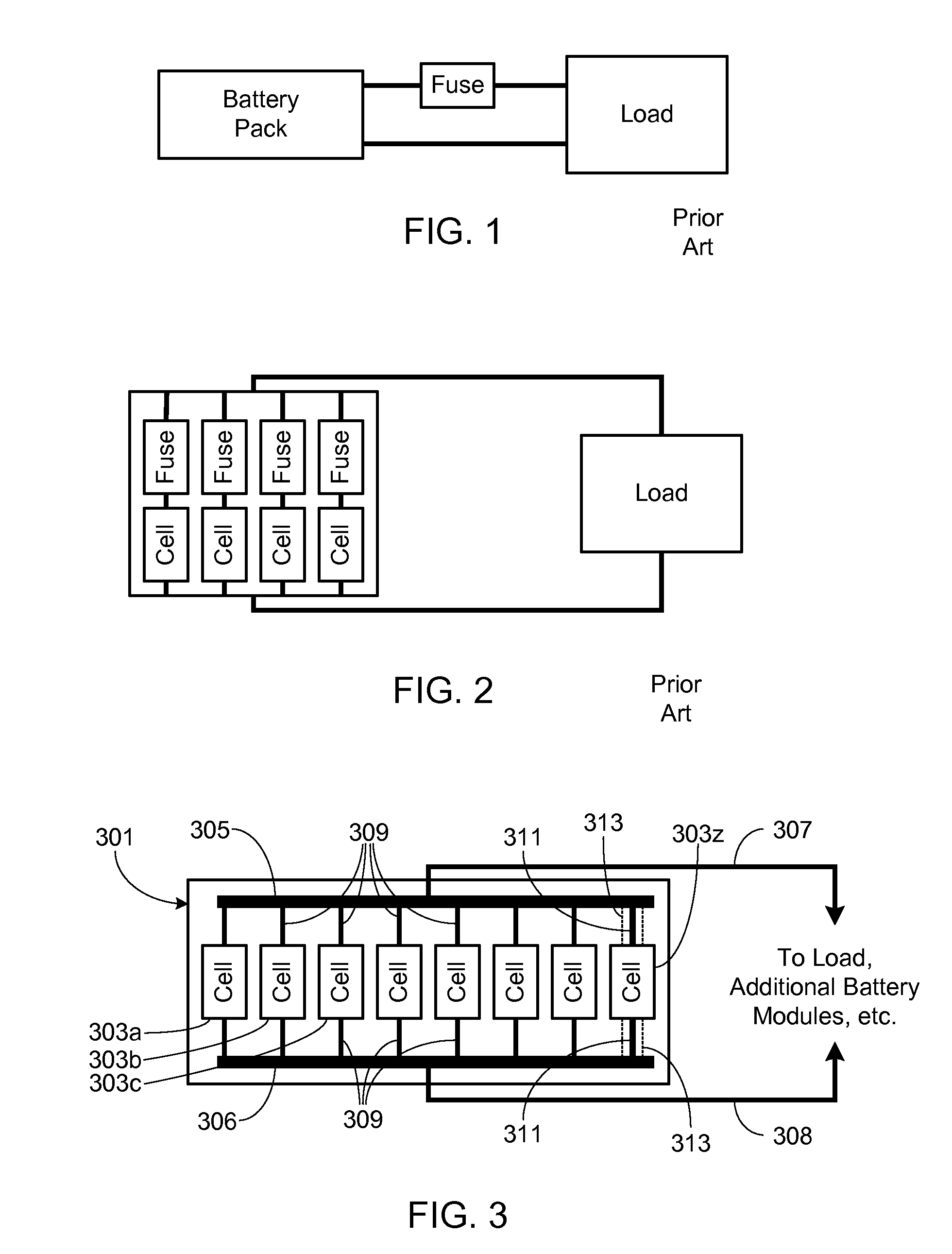

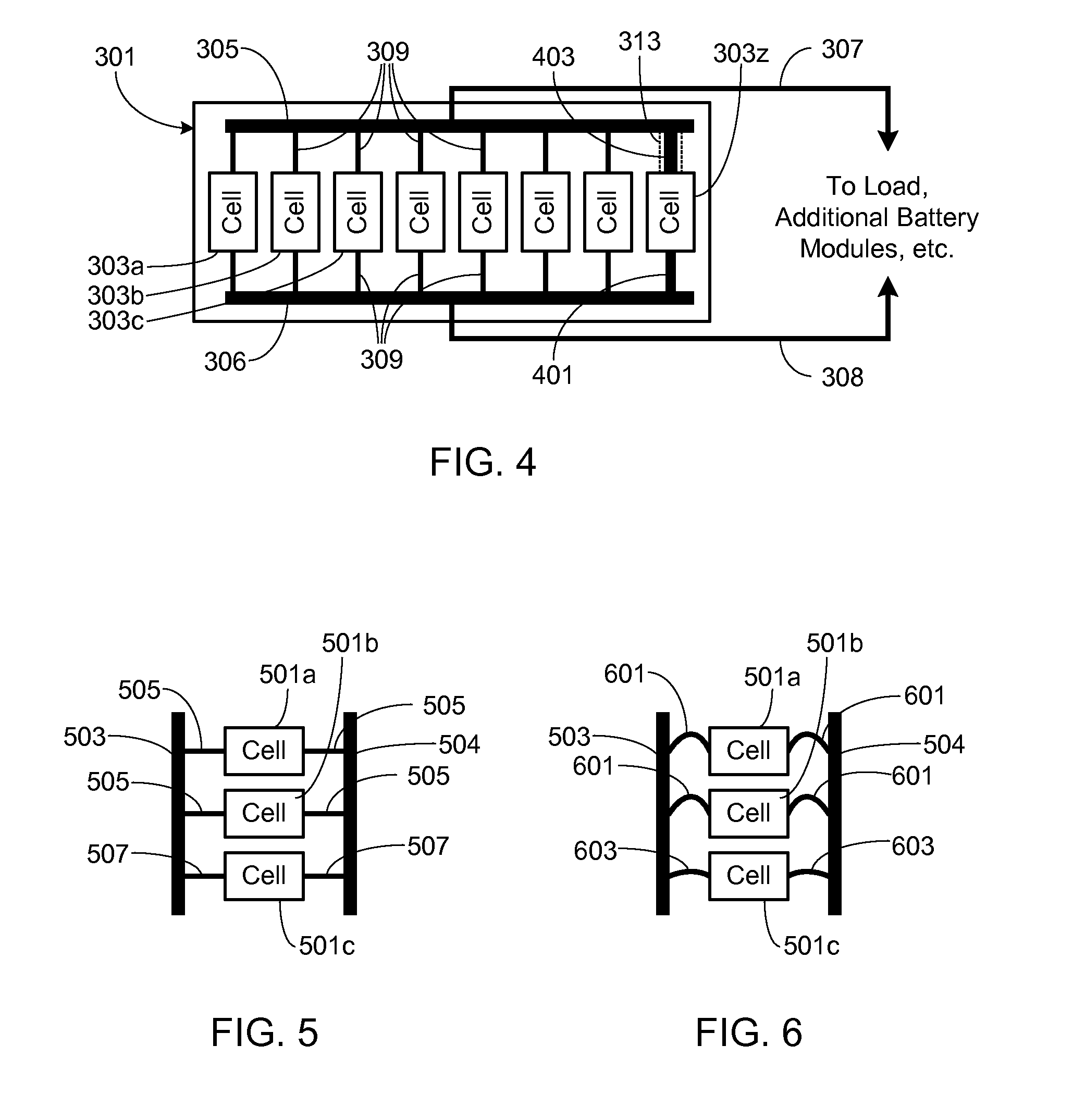

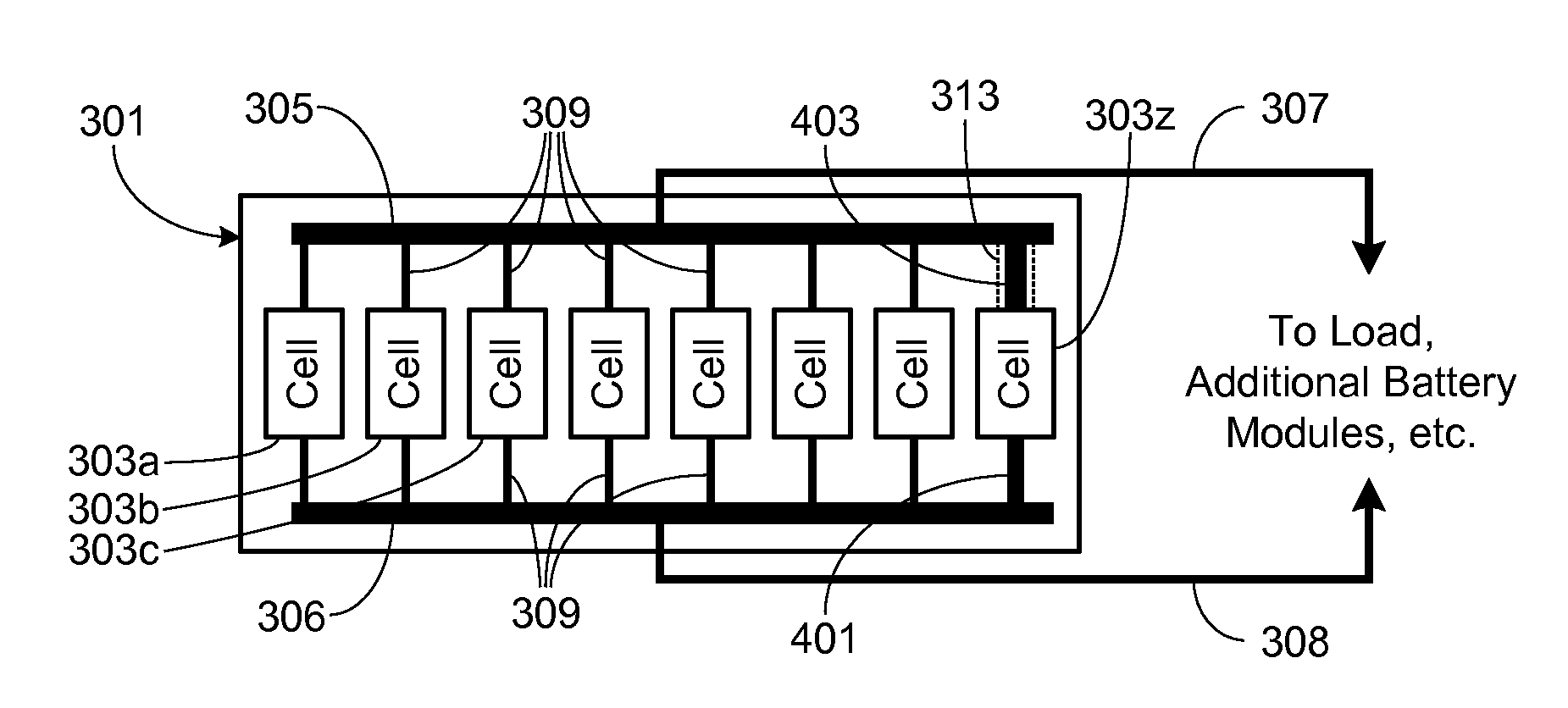

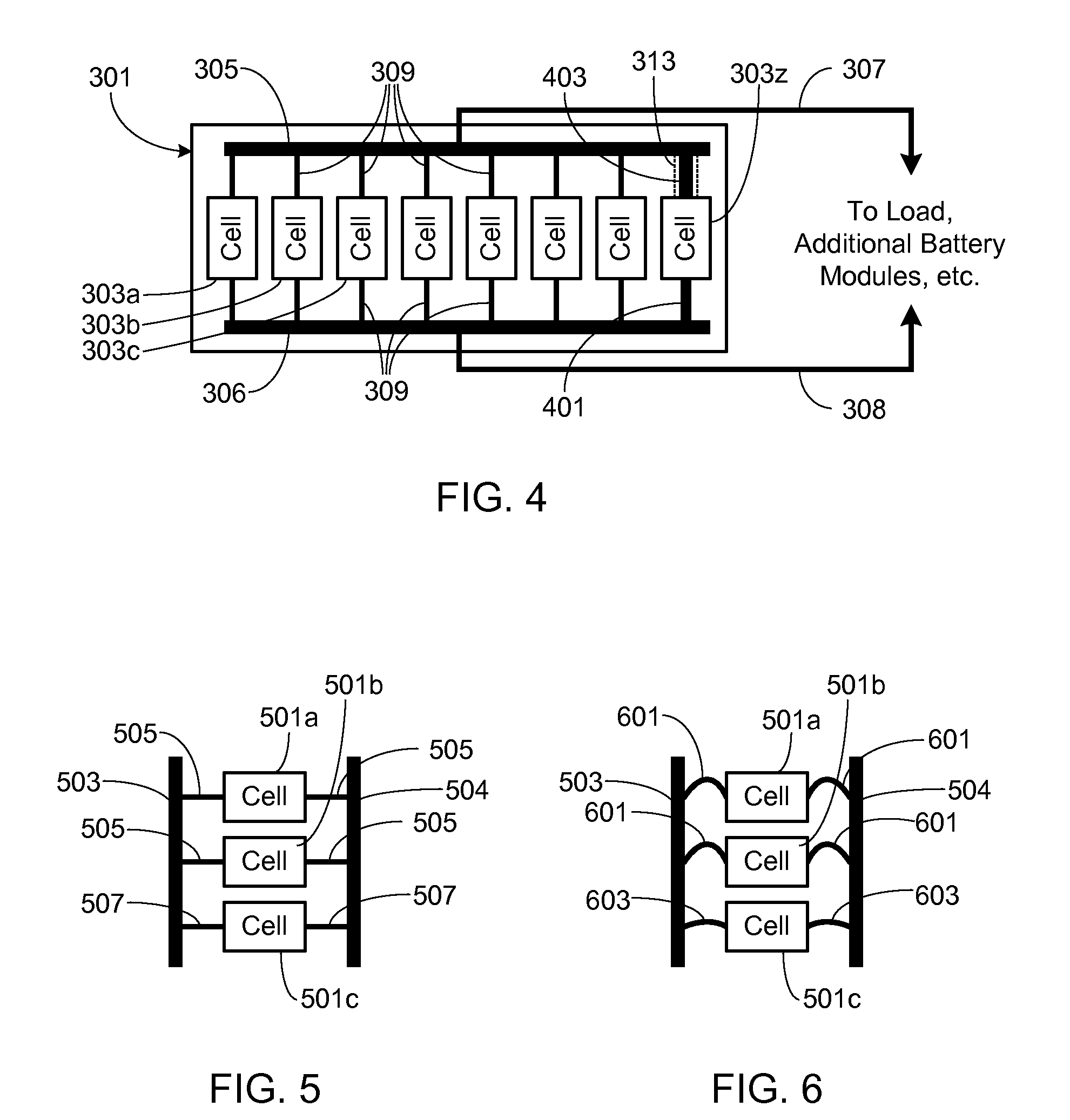

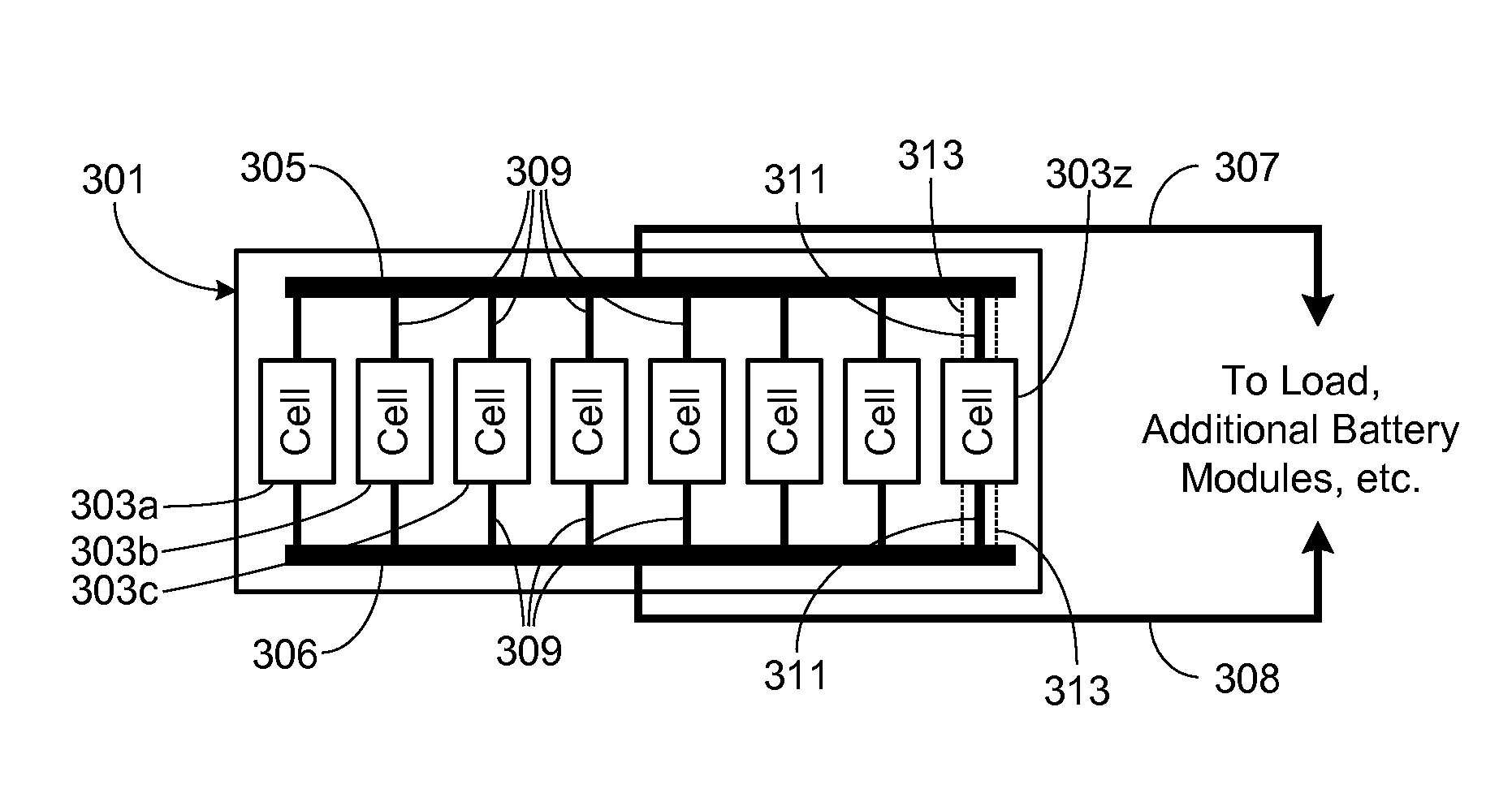

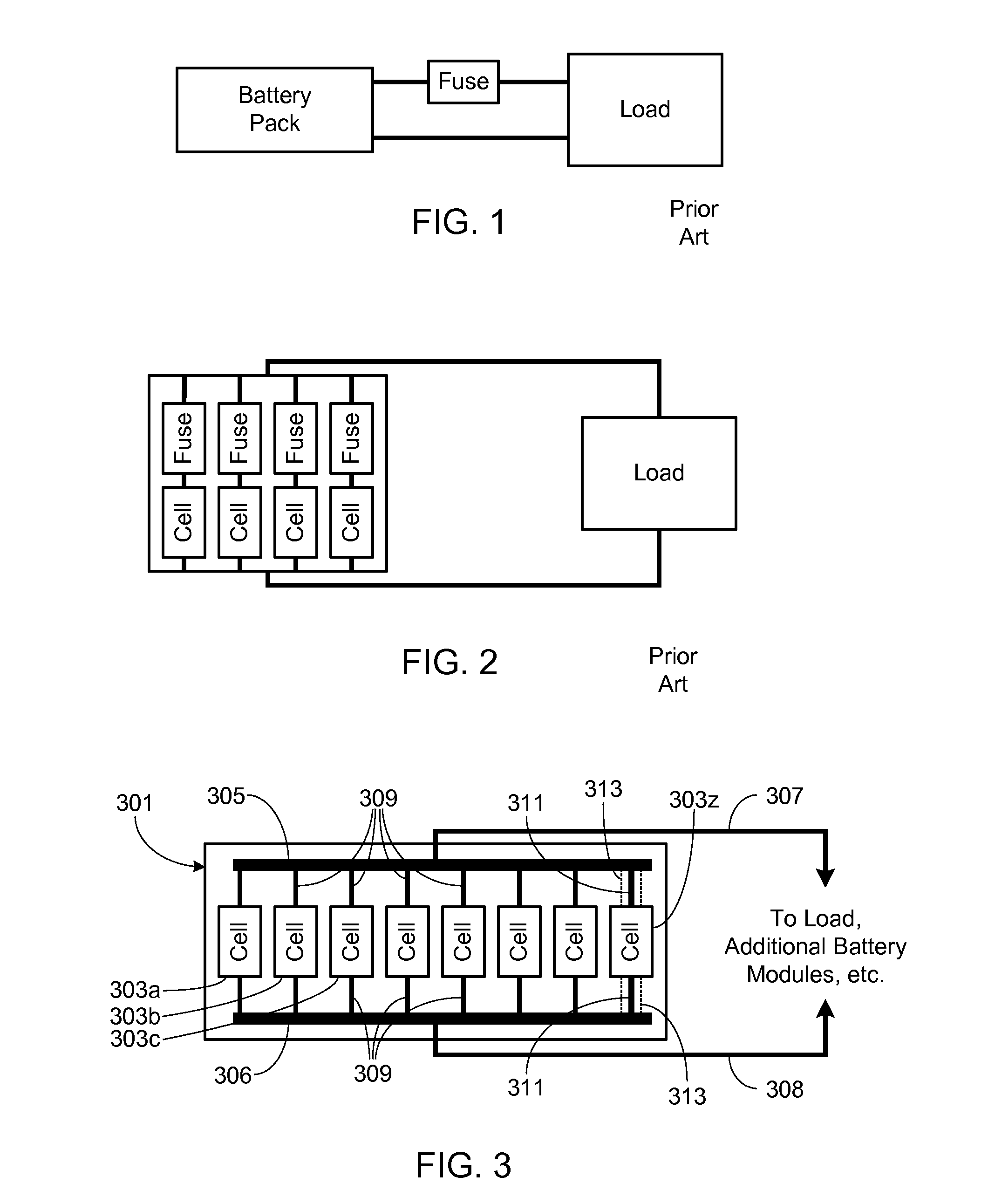

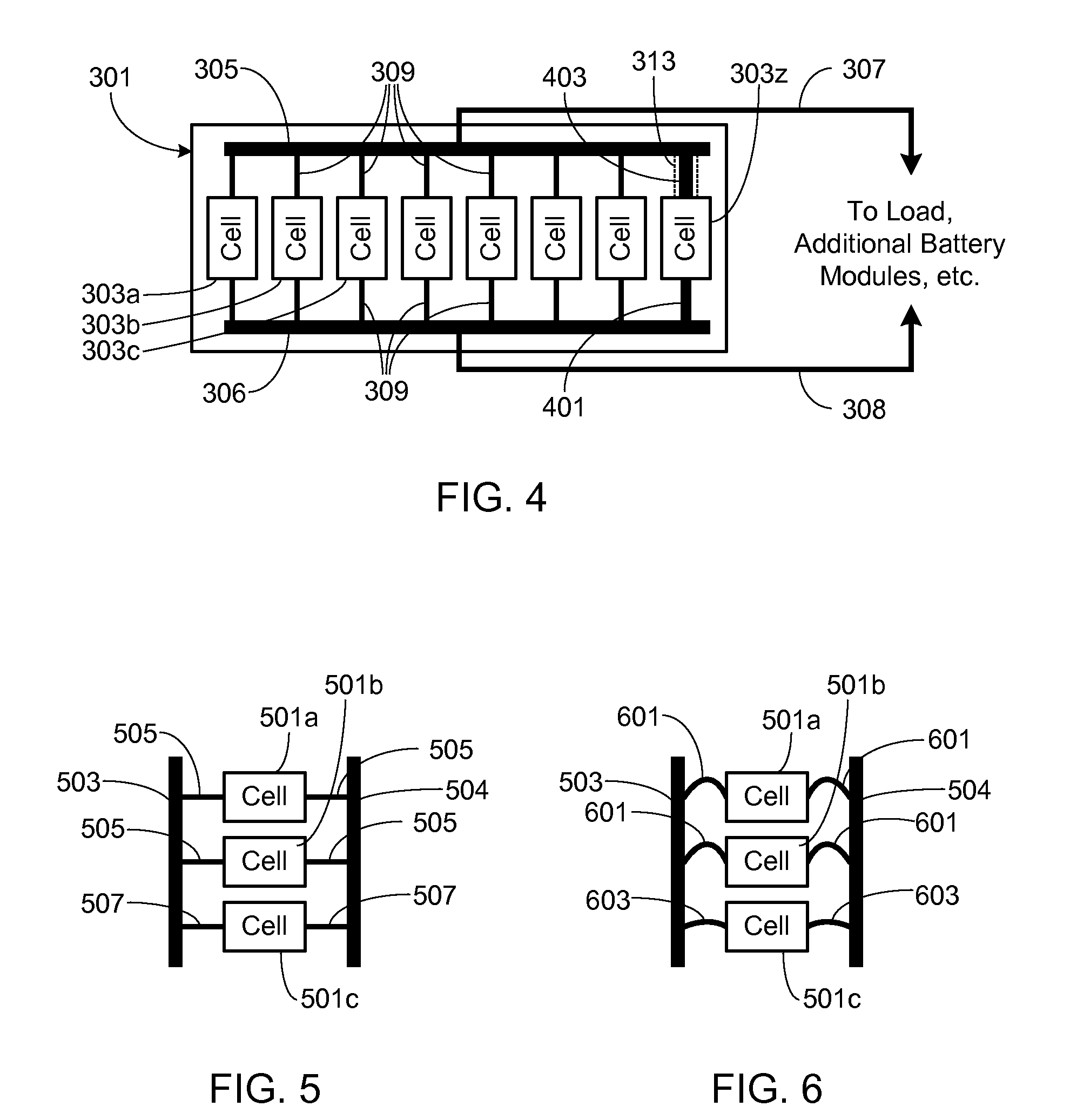

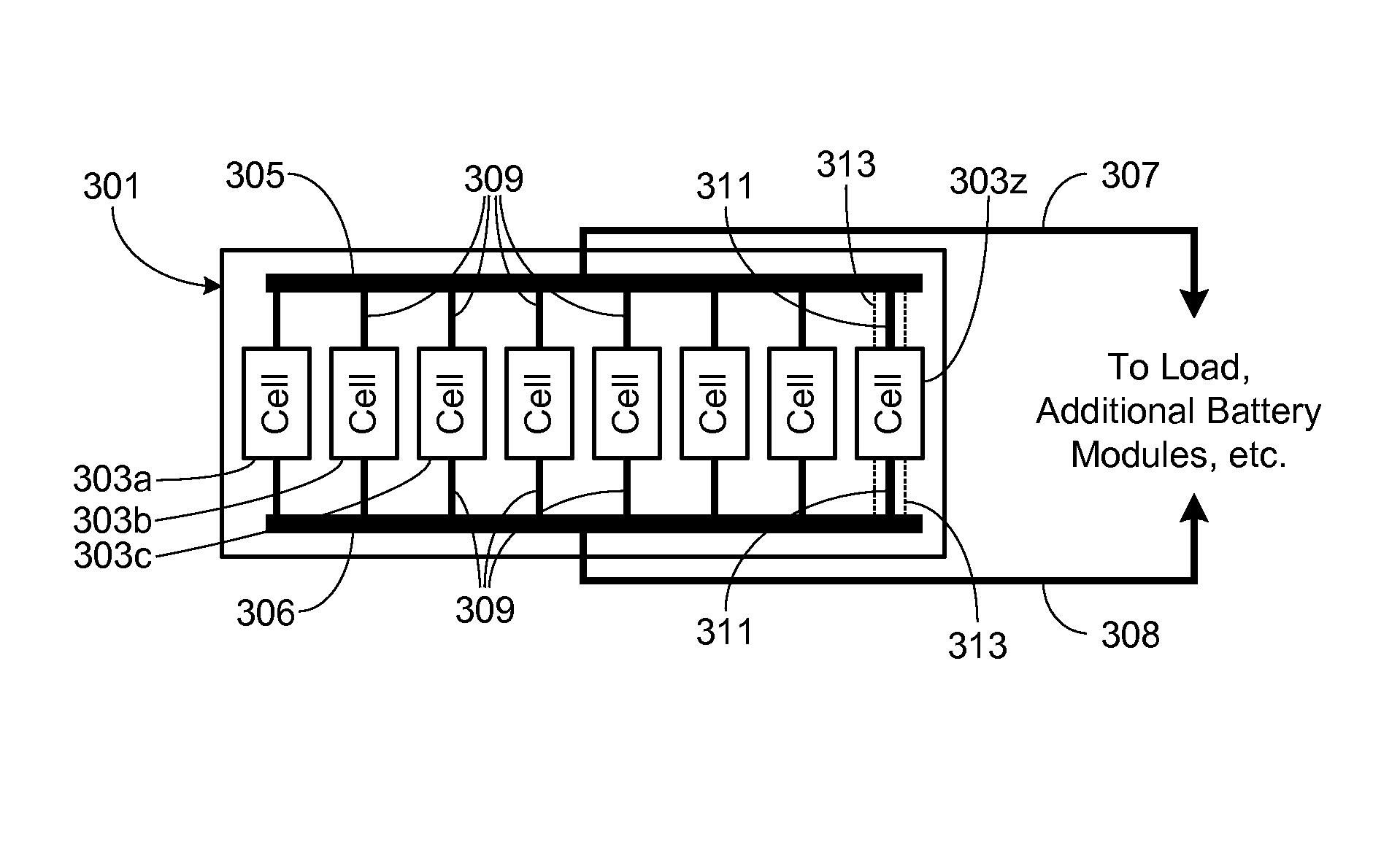

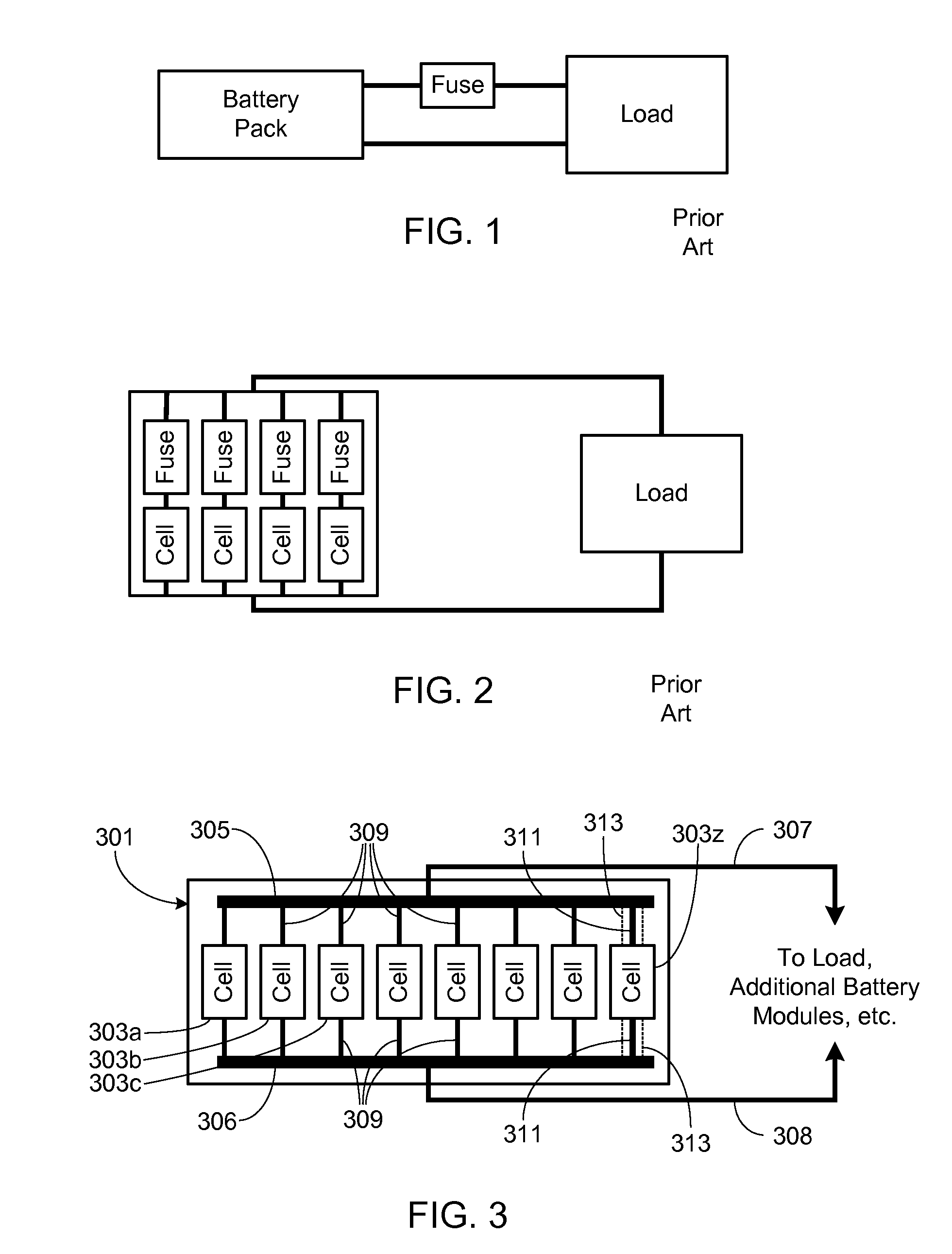

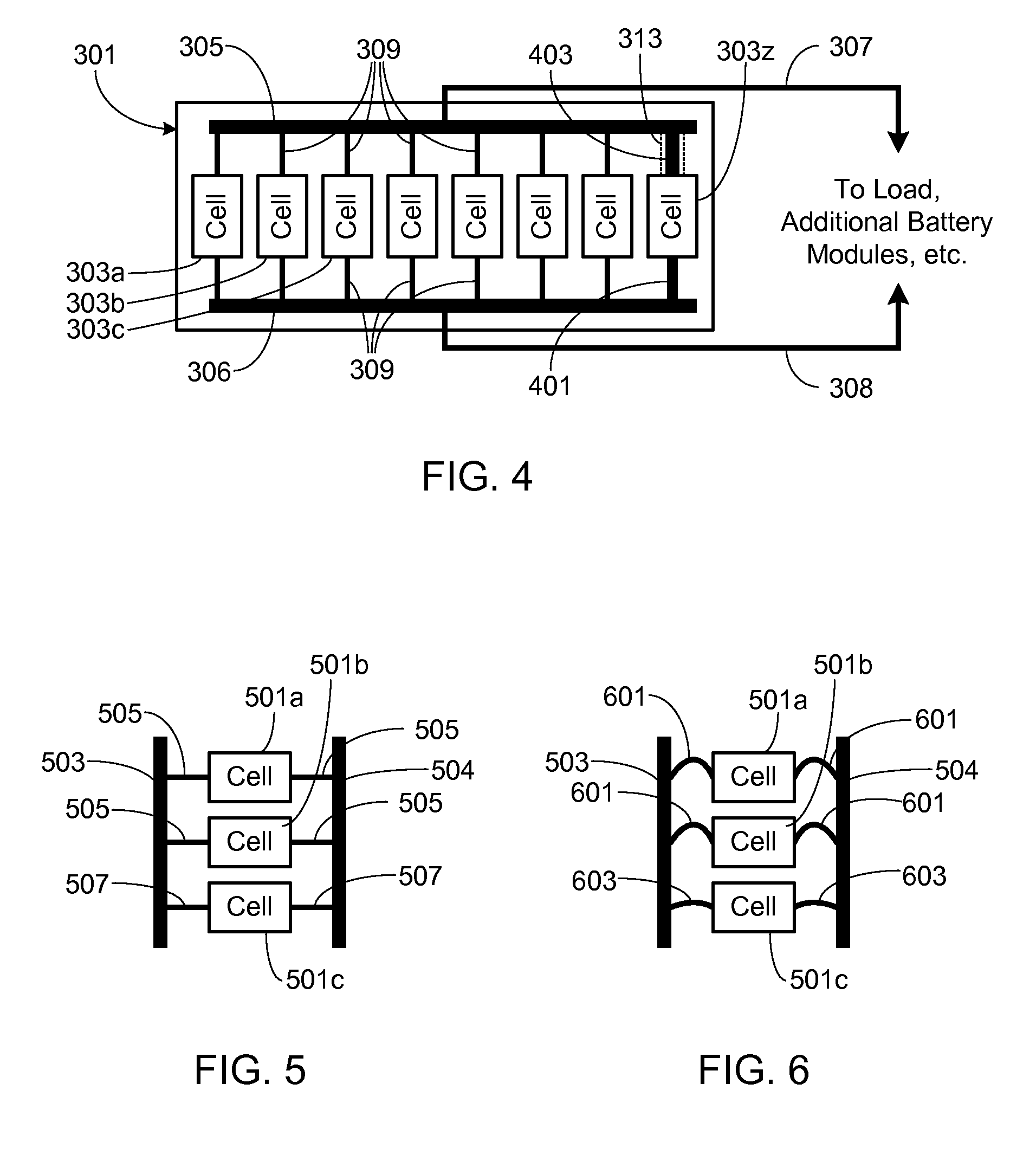

Battery Pack with Cell-Level Fusing

ActiveUS20120034497A1Risk minimizationImprove performancePrimary cell to battery groupingBatteries circuit arrangementsSystem safetyElectrical battery

A battery pack, or battery pack module, is provided that achieves improved battery pack performance, system reliability and system safety while impacting only a small region of the battery pack / battery module, and thus having only a minor impact on battery pack cost, complexity, weight and size. The battery pack / battery module is designed such that the fusible interconnects associated with a single battery, or a specific fusible interconnect associated with a single battery, will be the last interconnect(s) to fuse during a short circuit event. The risk of sustained arcing for the predetermined interconnect(s) is minimized through the use of rapid clearing interconnects. As a result, the risk of damage and excessive heating is also minimized.

Owner:TESLA INC

Method of Controlled Cell-Level Fusing Within a Battery Pack

ActiveUS20120030932A1Risk minimizationImprove performanceBatteries circuit arrangementsPrimary cellsElectrical batteryComputer module

A method is provided that achieves improved battery pack performance, system reliability and system safety while impacting only a small region of the battery pack / battery module, and thus having only a minor impact on battery pack cost, complexity, weight and size. The battery pack / battery module is designed such that the fusible interconnects associated with a single battery, or a specific fusible interconnect associated with a single battery, will be the last interconnect(s) to fuse during a short circuit event. The risk of sustained arcing for the predetermined interconnect(s) is minimized through the use of rapid clearing interconnects. As a result, the risk of damage and excessive heating is also minimized.

Owner:TESLA INC

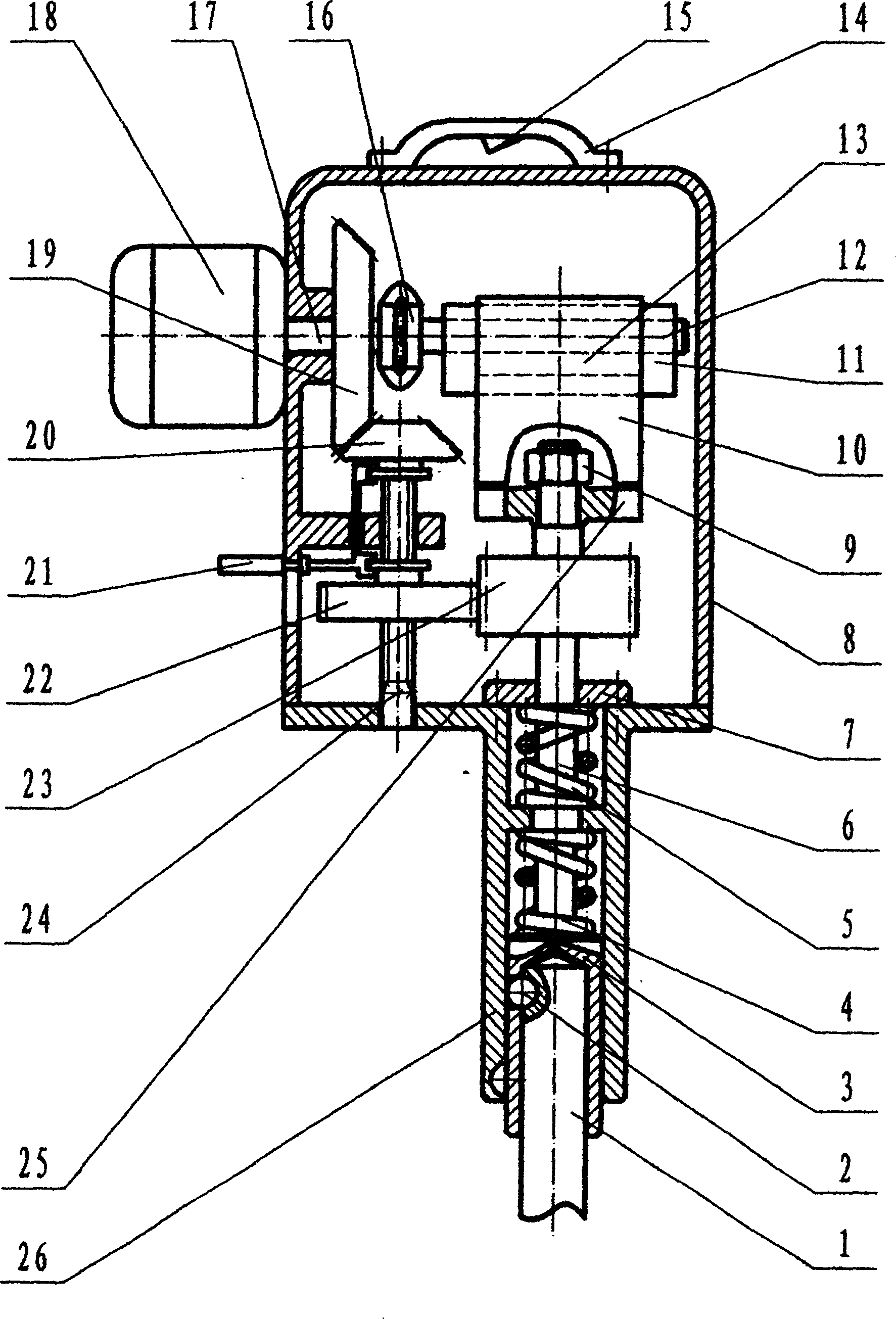

Low-noise strong-impact weak-recoil electric hammer drill

The invention is low-noise, strong-impulsion and weak-recoil electric hammer anvil, and belongs to the electric tools field. It is to solidify the kinematical bearing seat with eccentric block on the two plate springs. The plate springs, the base, the impulsion rod and the anvil rod are connected orderly. The impulsion can slide in the shaft sleeve and has the buffer and the spacing springs. When the electric machine driving the eccentric block to revolve, the circle vibration produced drives the anvil rod produce impulsion under the function of the plate spring, and meanwhile the electric machine shaft transmits the revolving movement to the anvil rod through the gear transmission and makes the anvil rod has hammer and anvil functions. The device does not have inner noise because it is without inner impulsion. The impulsion of the anvil rod is decided by the moment of the eccentric block and the revolving speed of the electric machine. The recoil is small as without the external power of the worker.

Owner:贺启宇

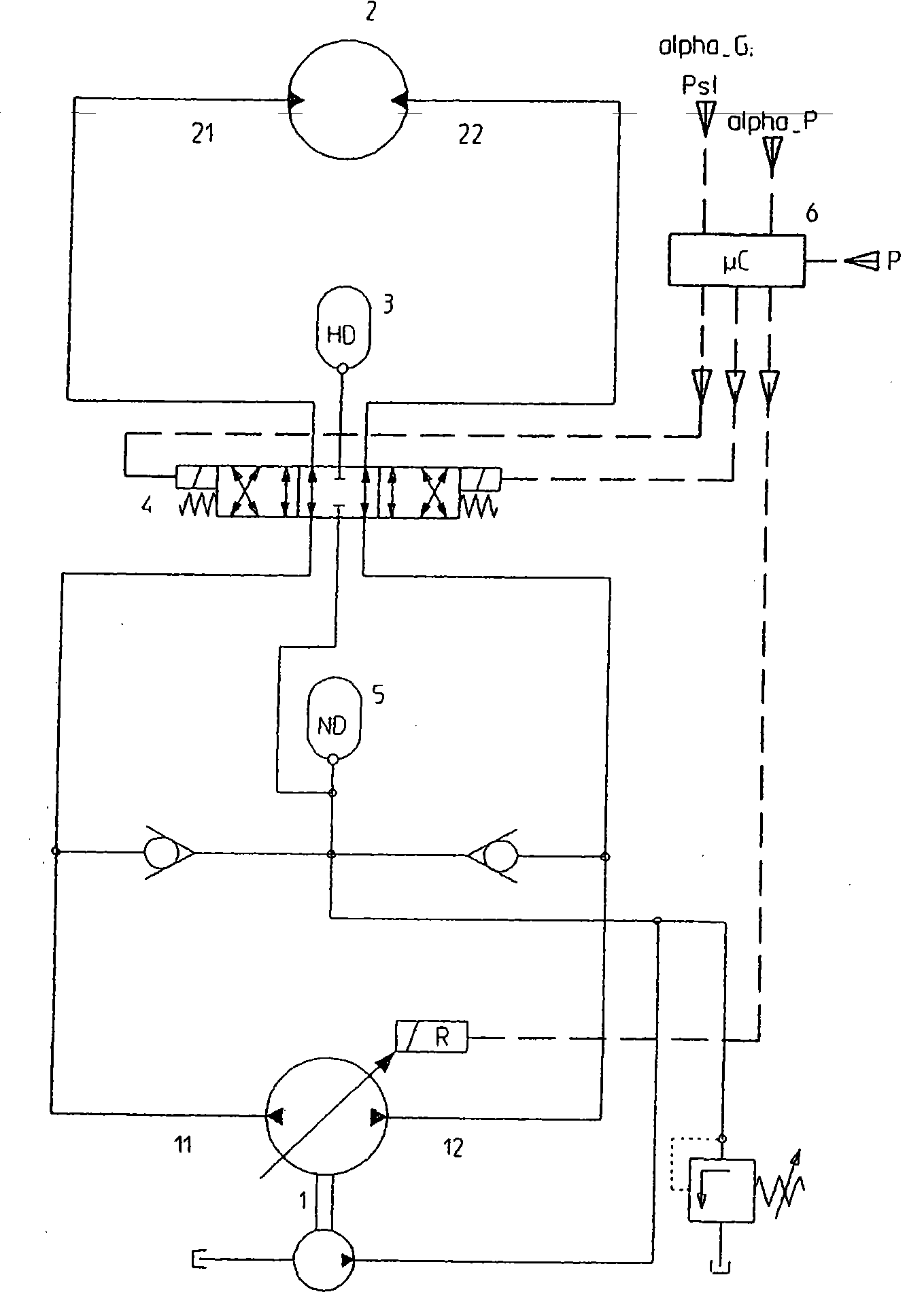

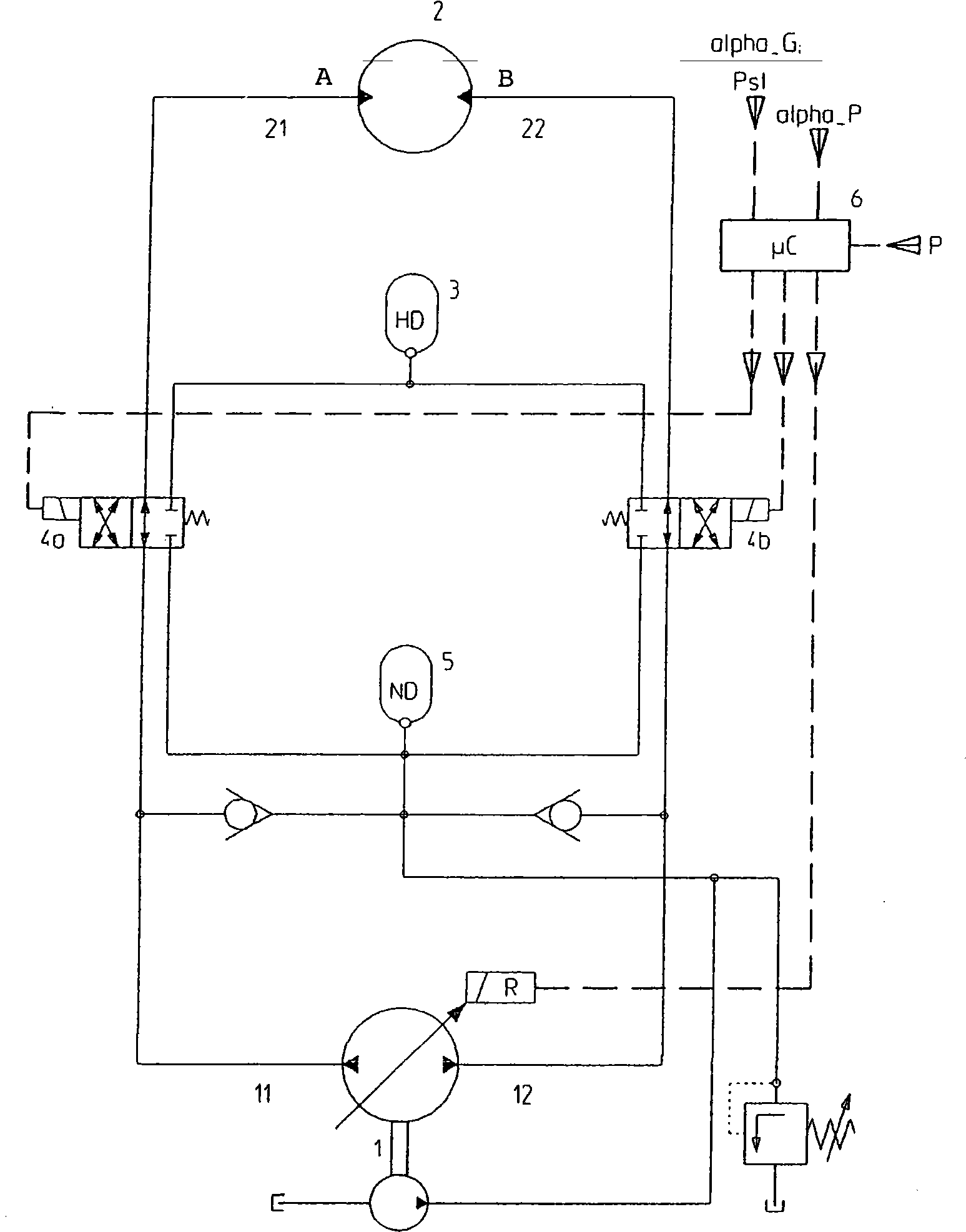

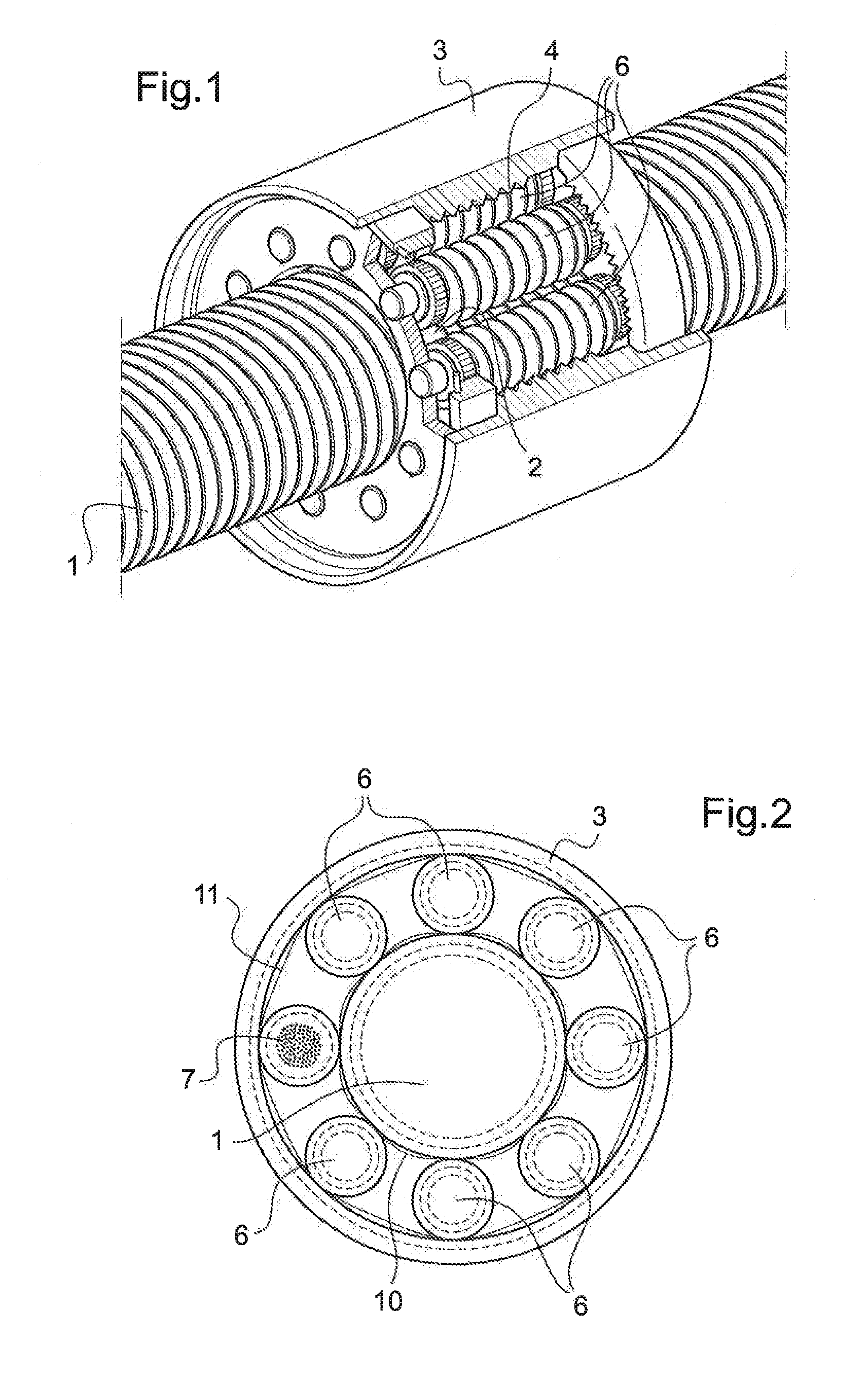

Hydraulic drive, particularly of a digger, particularly for a rotation system

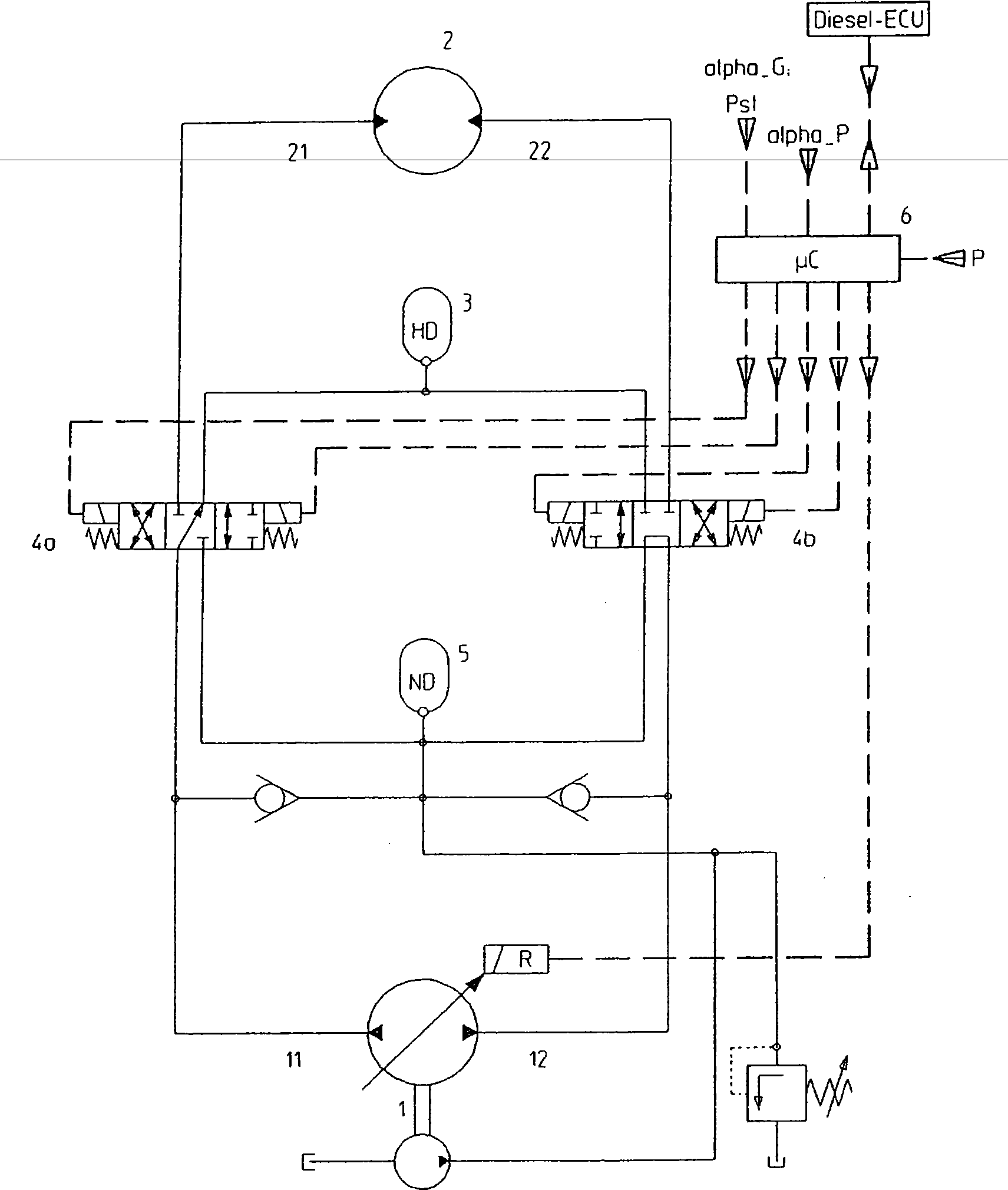

InactiveCN101861437AAchieve feedbackFavorable working pointGearing controlSoil-shifting machines/dredgersHydraulic circuitHigh pressure

The present invention relates to a hydraulic drive, particularly of a digger, particularly for a rotation system having a hydraulic circuit comprising a pump (1) and a motor (2), wherein a high-pressure reservoir (3) connectable to the pump and / or motor via at least one valve (4) and a control unit (6) controlling the at least one valve are provided.

Owner:LIEBHERR FRANCE

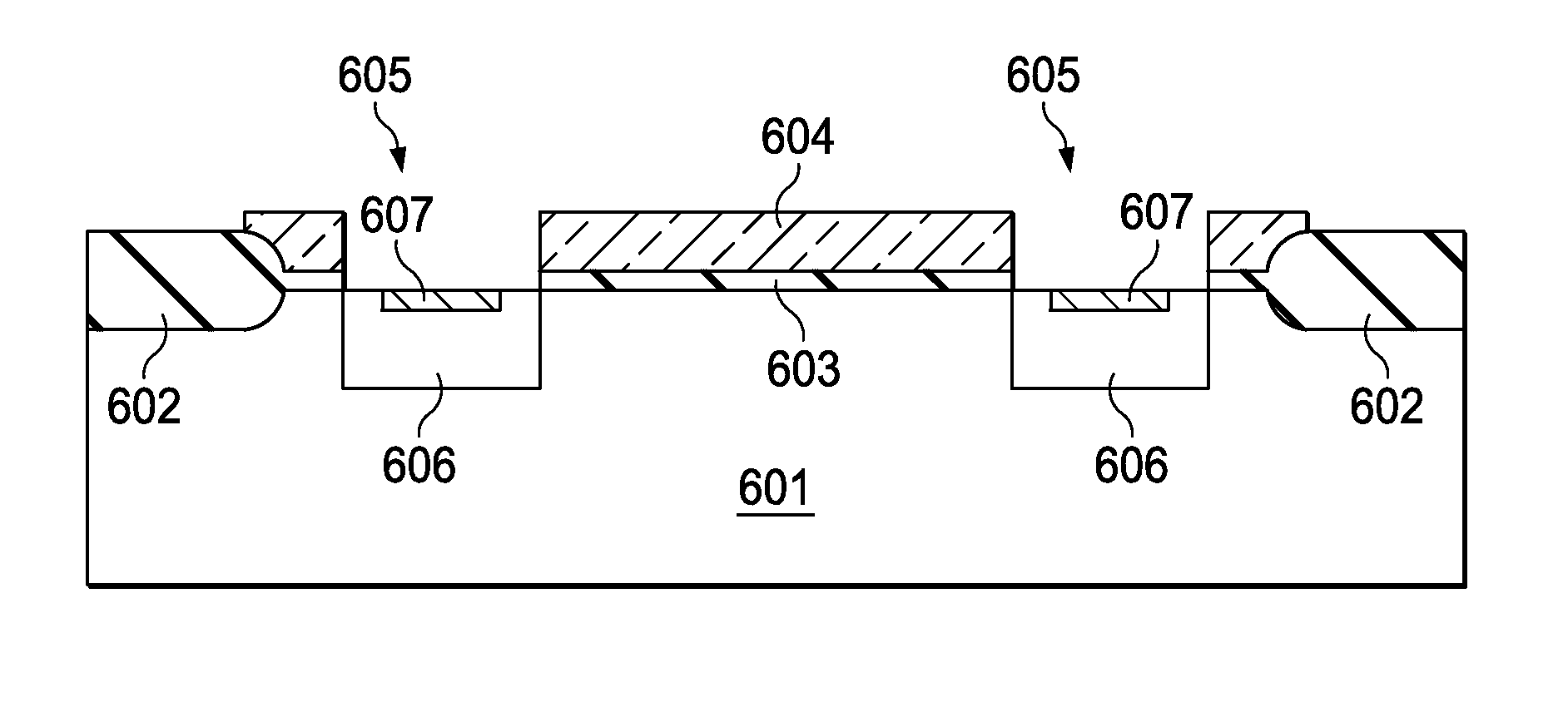

Pixel circuit and driving method thereof, electroluminescent display panel and display device

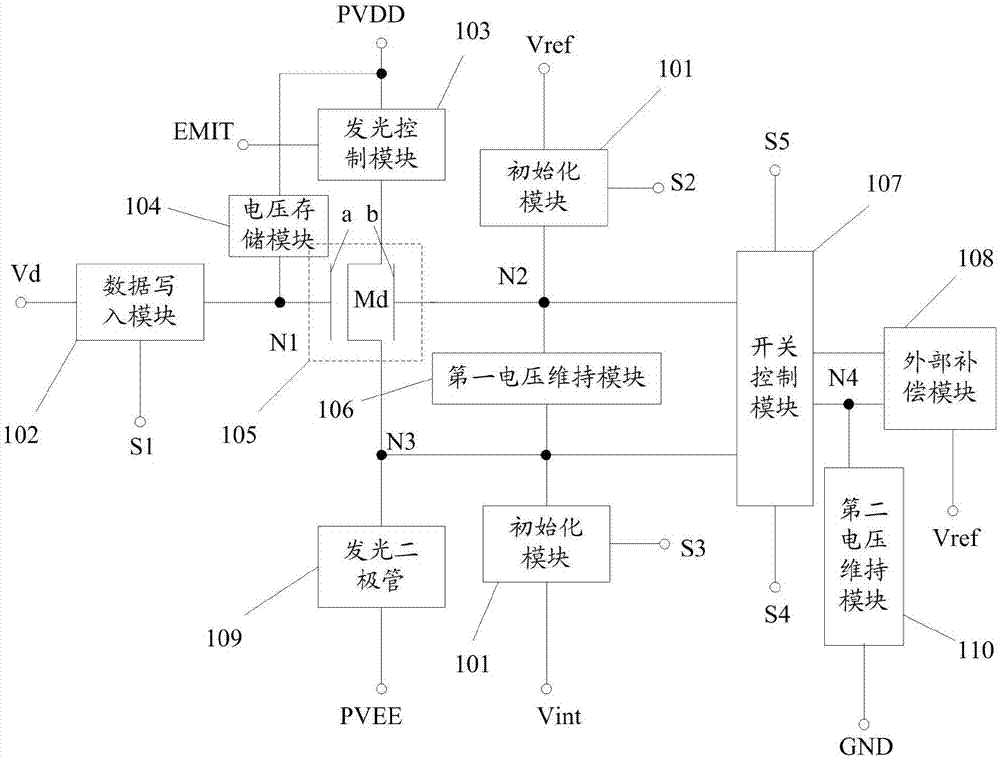

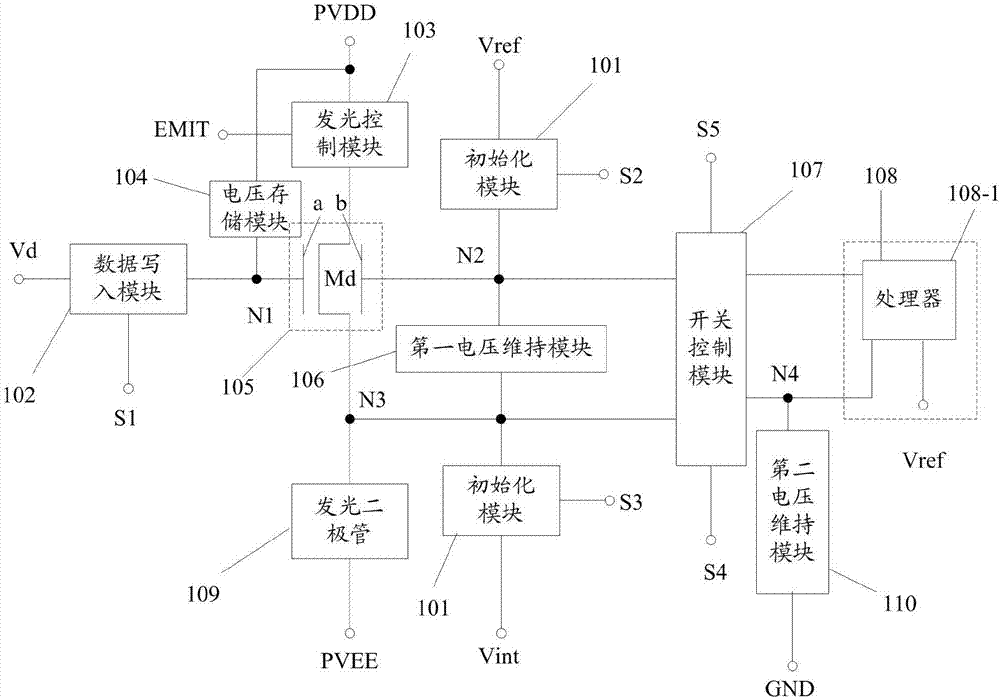

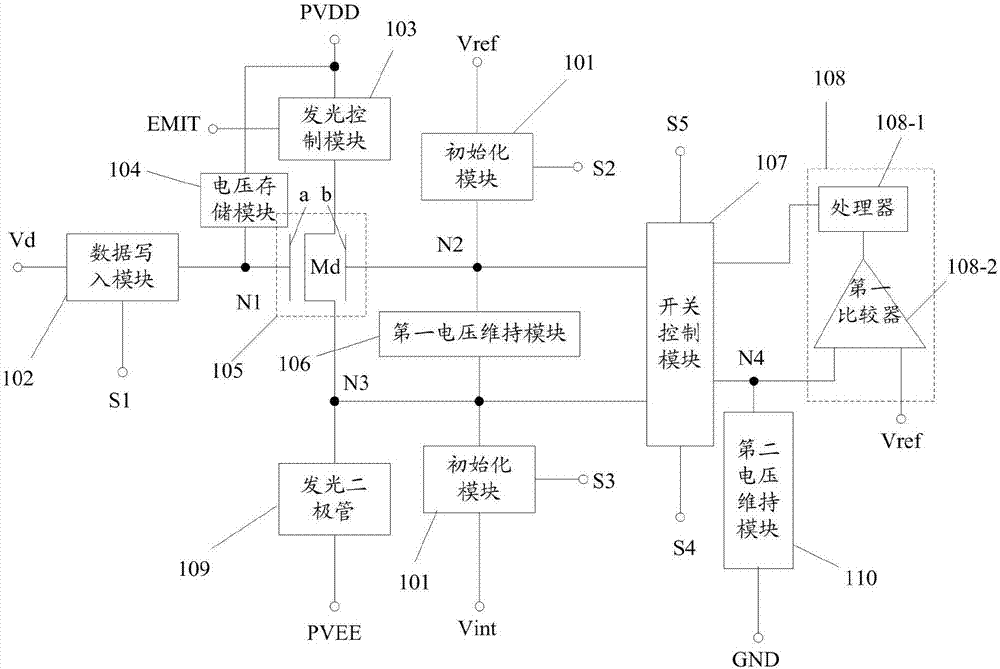

ActiveCN107358916AThreshold Voltage AdjustmentImpact sizeStatic indicating devicesSolid-state devicesDisplay deviceEngineering

The invention discloses a pixel circuit and a driving method thereof, an electroluminescent display panel and a display device. The pixel circuit comprises an initialization module, a data writing-in module, a light emitting control module, a voltage storage module, a driving transistor, a first voltage maintaining module, a switch control module, an external compensation module and a light-emitting diode. The driving transistor is a double-gate transistor; and a second gate of the double-gate transistor is electrically connected with the external compensation module through the switch control module. Under the control of the switch control module, the external compensation module collects the voltage of a third node and then provides a compensation voltage for a second node so as to realize adjustment of the threshold voltage of the dual-gate transistor, so that the threshold voltage of the dual-gate transistor is close to a standard threshold voltage and the current of the light-emitting diode during light emitting is be independent of the threshold voltage. Therefore, a phenomenon that the current is affected by the drift of the threshold voltage is avoided; and the residual image is eliminated to improve the quality of the displayed picture.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

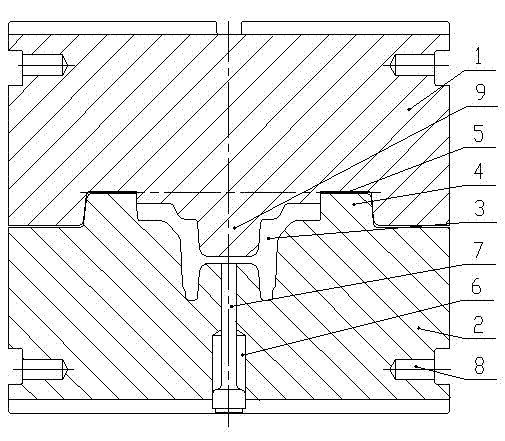

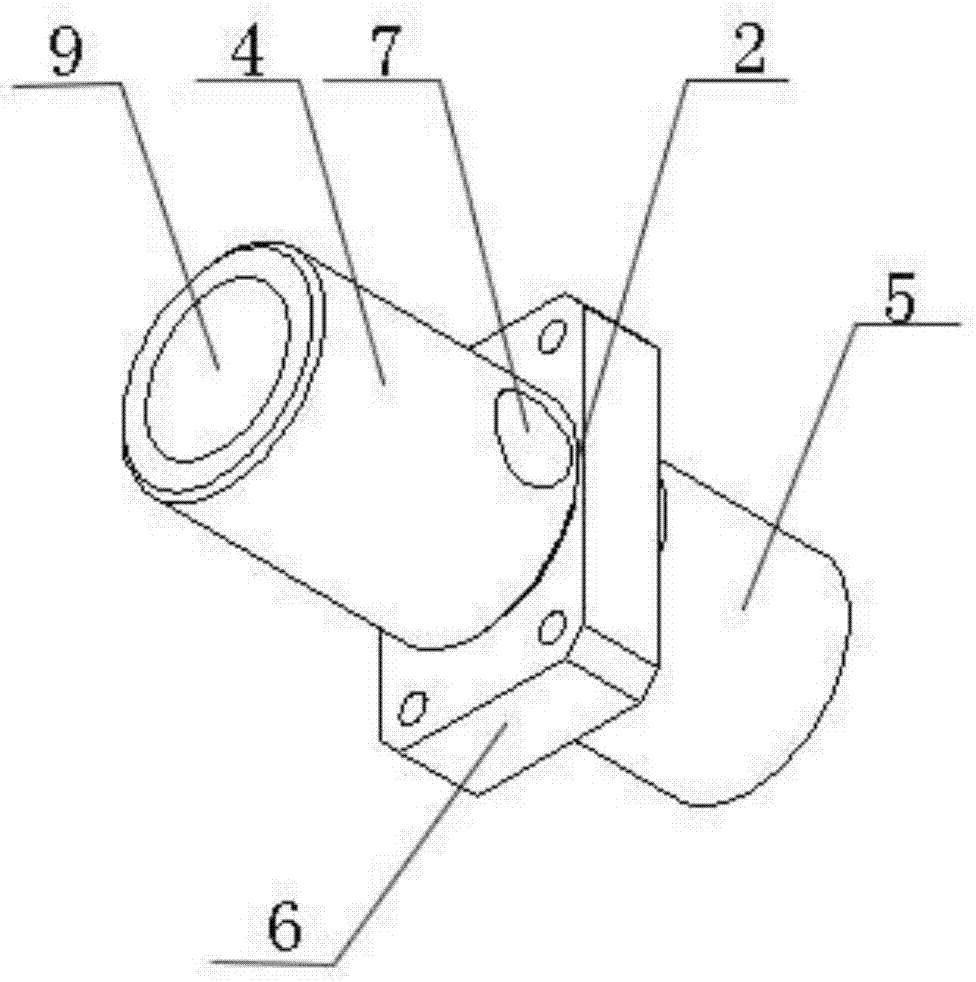

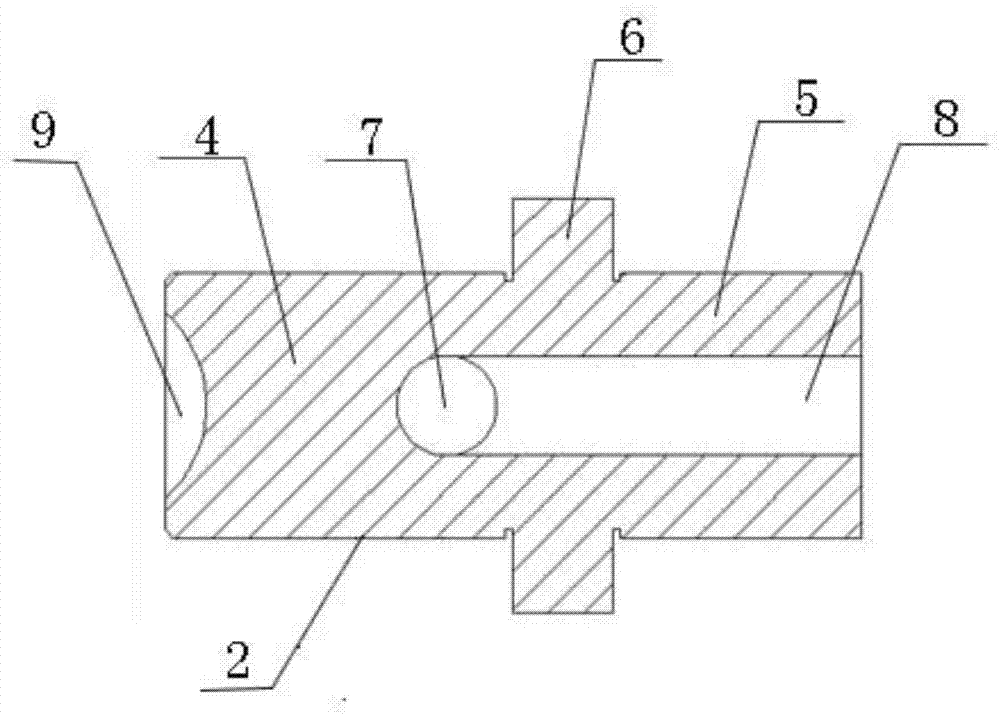

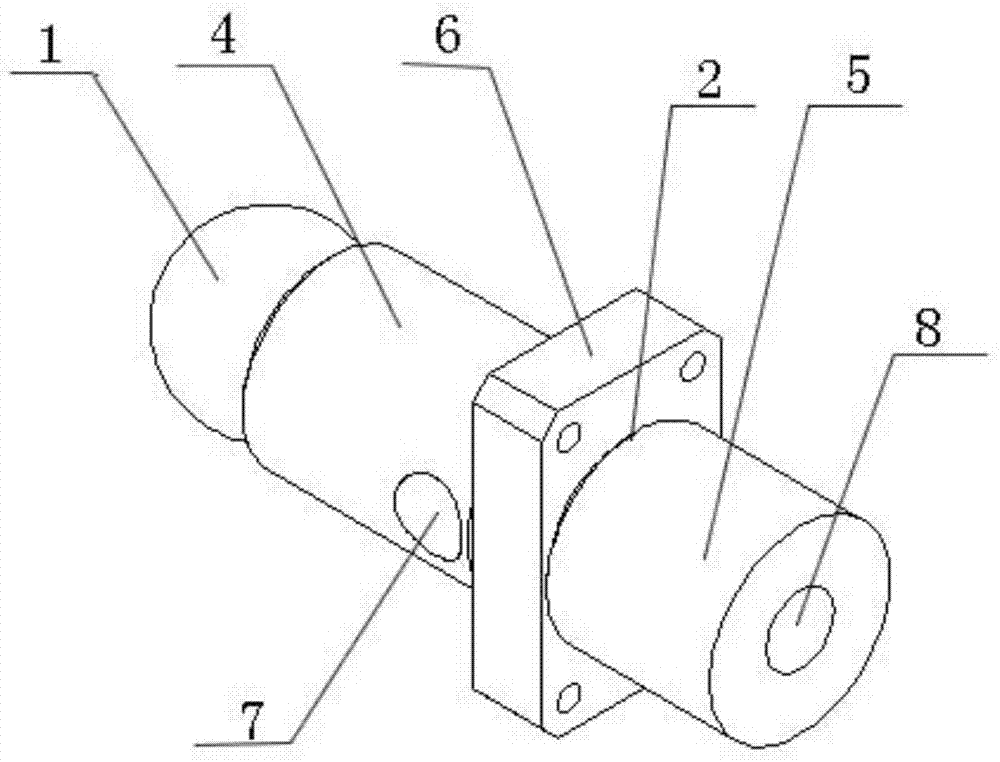

Non-flash forging process for middle flanges of transmission shafts

InactiveCN102873240APrevent stuffy traffic, etc.Reduce processing costsForging/hammering/pressing machinesEngine componentsPunchingDrive shaft

The invention discloses a non-flash forging process for middle flanges of transmission shafts. The non-flash forging process includes steps of (1) blanking: blanking 45# steel into blanks in given size by a full-automatic sawing machine or shearing machine; (2), medium-frequency induction heating: controlling heating temperature of the blanks within the range of 1100-1200 DEG C on the basis of an infrared temperature measurement instrument; (3), upsetting: removing scales on surfaces of the blanks; (4), finish forging: placing the blanks into a forging die after upsetting, striking the die with moderated striking force; and (5), punching: removing middle slugs of finished forged parts. Processes of primary forging die are reduced, production cost is reduced, energy is saved while consumption is lowered, forging difficulty is reduced, flash is eliminated in a forging process of the prior art, raw materials are saved, and a subsequent process of grinding burrs is omitted.

Owner:XUCHANG ZHONGXING FORGING +1

Method of controlled cell-level fusing within a battery pack

ActiveUS8133287B2Improve performanceImprove reliabilityBatteries circuit arrangementsPrimary cellsElectrical batteryComputer module

Owner:TESLA INC

Radiation hardened mos devices and methods of fabrication

ActiveUS20150108588A1Improve radiation hardnessMinimal impactTransistorSemiconductor/solid-state device detailsCMOSBeak

Radiation hardened NMOS devices suitable for application in NMOS, CMOS, or BiCMOS integrated circuits, and methods for fabricating them. A device includes a p-type silicon substrate, a field oxide surrounding a moat region on the substrate tapering through a Bird's Beak region to a gate oxide within the moat region, a heavily-doped p-type guard region underlying at least a portion of the Bird's Beak region and terminating at the inner edge of the Bird's Beak region, a gate included in the moat region, and n-type source and drain regions spaced by a gap from the inner edge of the Bird's Beak and guard regions. A variation of minor alterations to the conventional moat and n-type source / drain masks. The resulting devices have improved radiation tolerance while having a high breakdown voltage and minimal impact on circuit density.

Owner:TEXAS INSTR INC

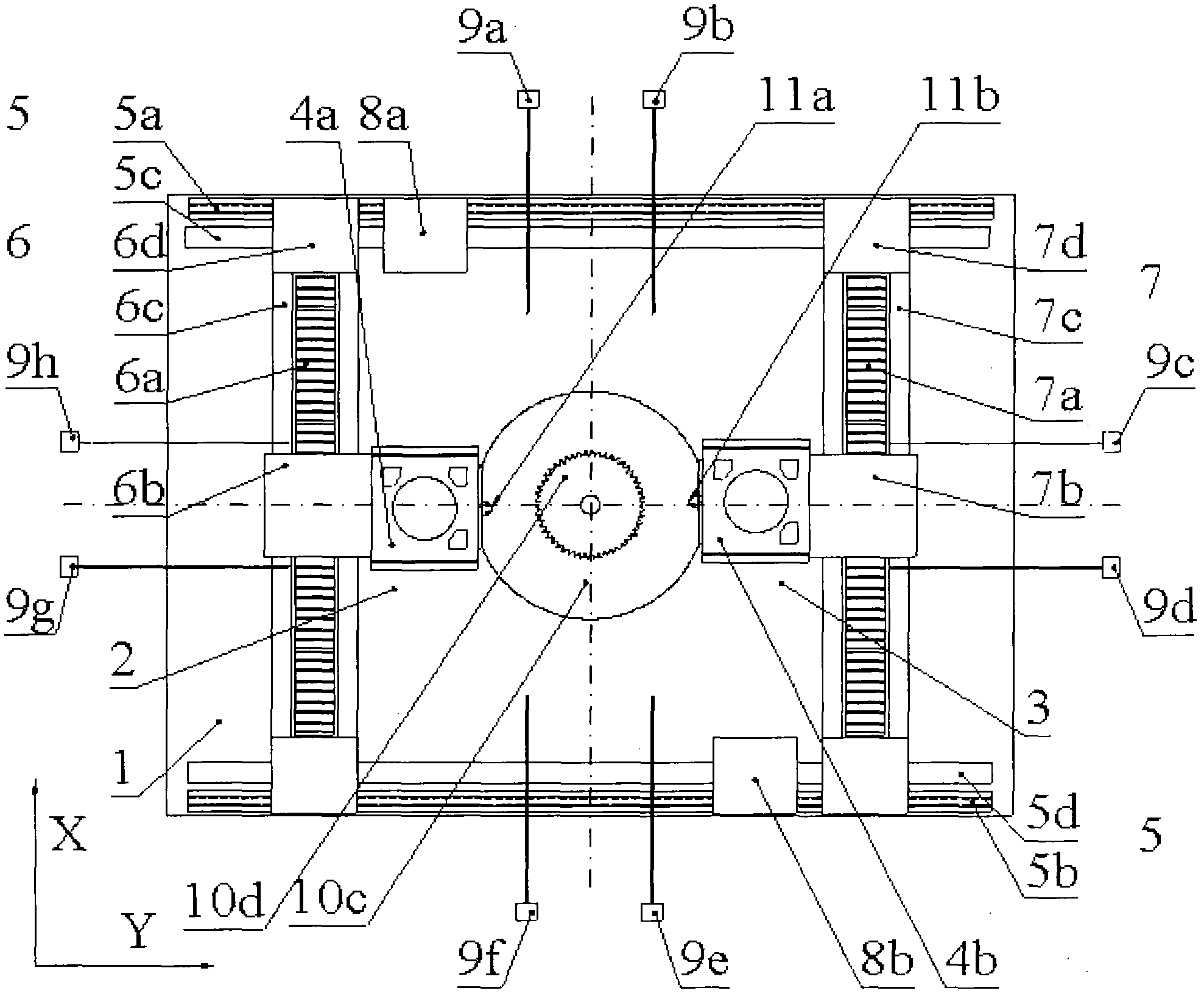

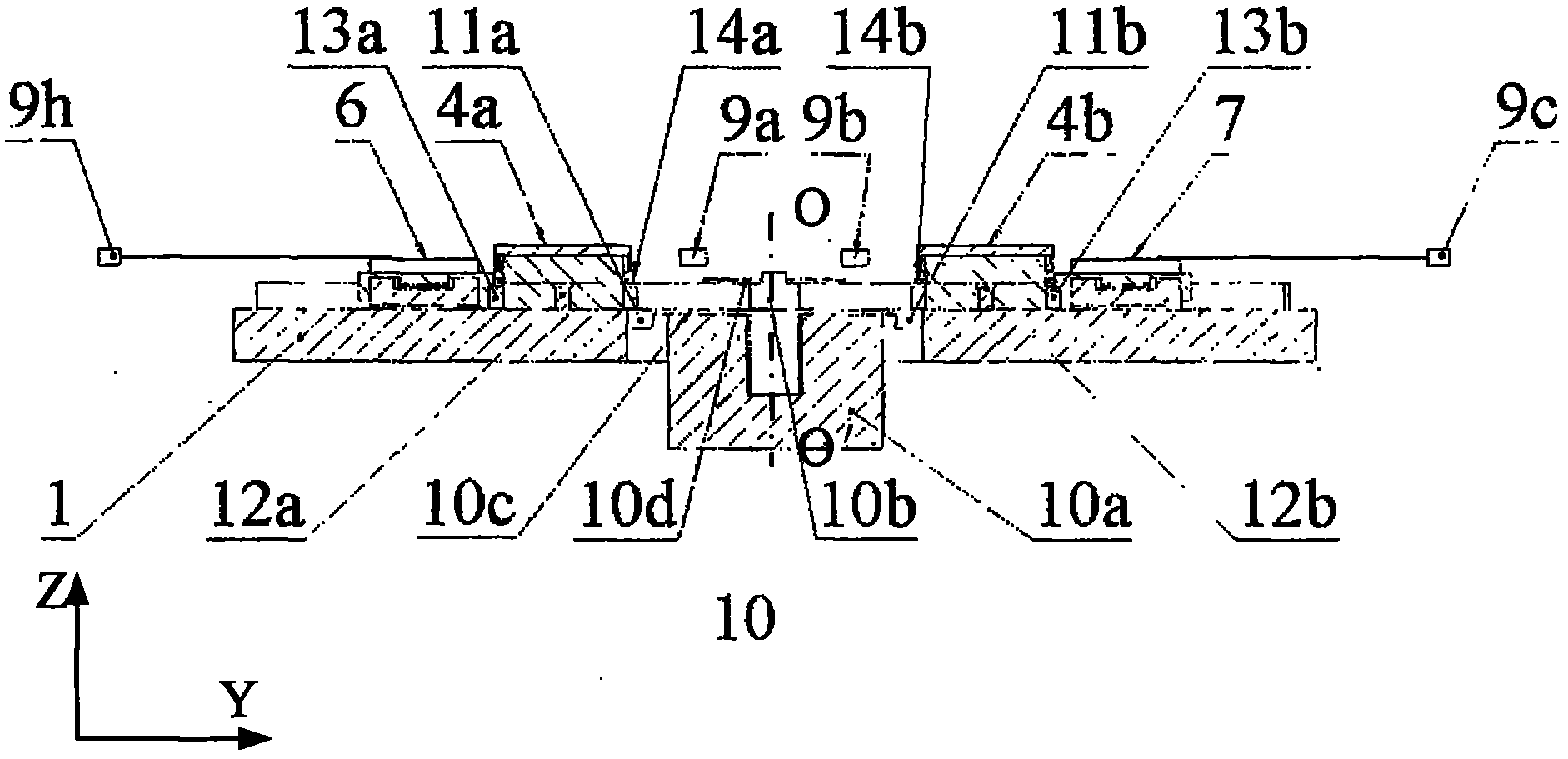

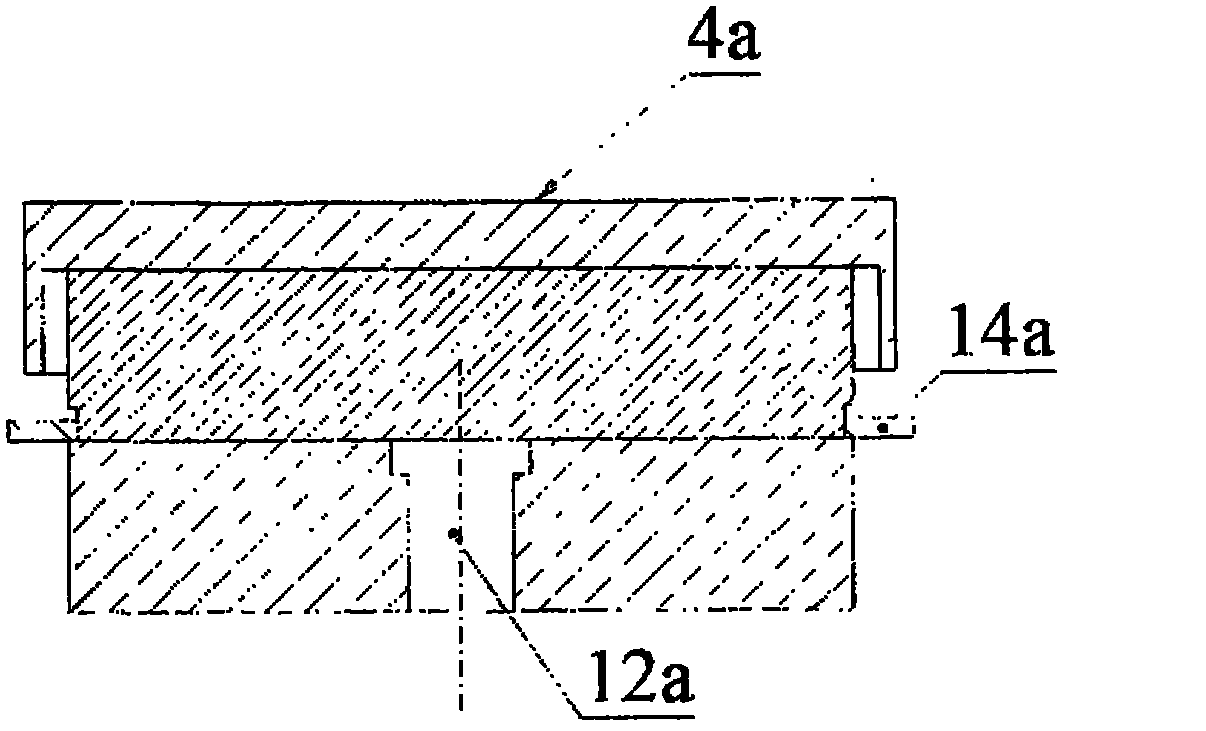

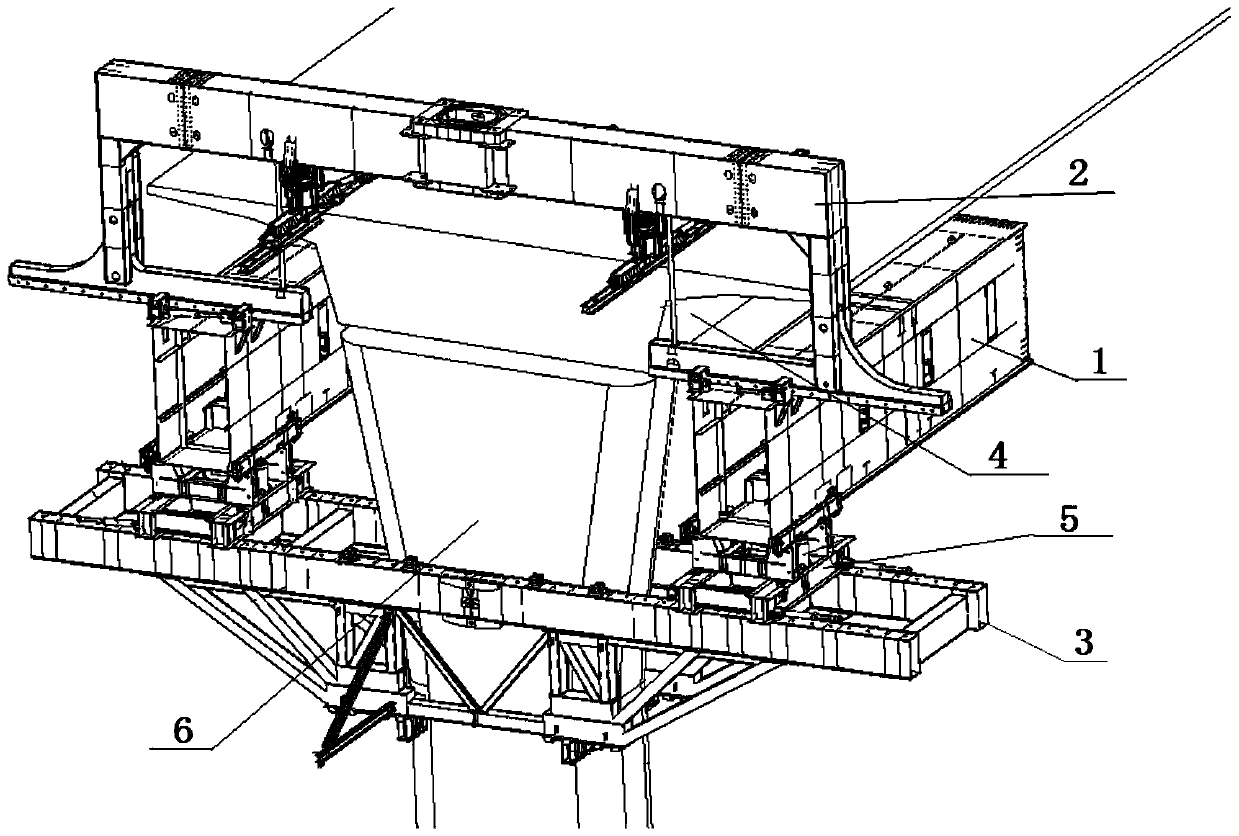

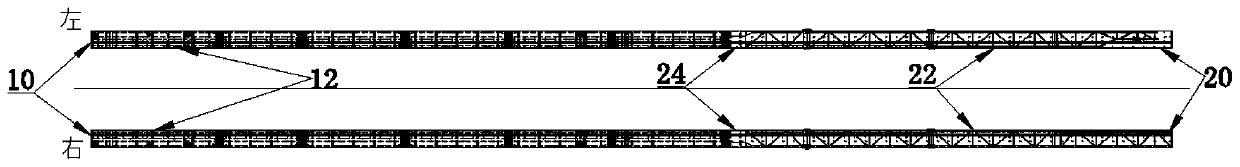

Rotary exchanging method and rotary exchanging device for double workpiece platforms based on synchronous steering of turntable gear

InactiveCN102508414ASolve the problem of too many beats (five beats)Improve production rateSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRotational axisElectric machine

The invention discloses a rotary exchanging method and a rotary exchanging device for double workpiece platforms based on synchronous steering of a turntable gear and belongs to semiconductor manufacturing equipment. The device comprises a rotary platform switching device consisting of a rotary motor stator, a rotary motor rotor, a rotating platform embedded in a base station and a rotary platform switching gear, wherein a liftable first shaft coupling device and a second shaft coupling device are arranged on the rotary platform; a first workpiece platform rotating shaft is arranged at the bottom of a first workpiece platform; a first workpiece platform switching device is arranged on the lateral surface of the first workpiece platform; a first workpiece platform gear is arranged at the waist part of the first workpiece platform; a second workpiece platform rotating shaft is arranged at the bottom of a second workpiece platform; a second workpiece platform switching device is arrangedon the lateral surface of the second workpiece platform; and a second workpiece platform gear is arranged at the waist part of the second workpiece platform. According to the rotary exchanging methodand the rotary exchanging device disclosed by the invention, in the switching process of double platforms, the orientations of the workpiece platforms are always kept unchanged and the problems that a cable in a traditional rotary platform switching scheme is not convenient to mount and an interferometer loses a target are solved; and meanwhile, the rotary exchanging method and the rotary exchanging device disclosed by the invention have the advantages that a rotational inertia in the specific implementation process is small, the required torque under the same platform switching time is smalland the like.

Owner:HARBIN INST OF TECH

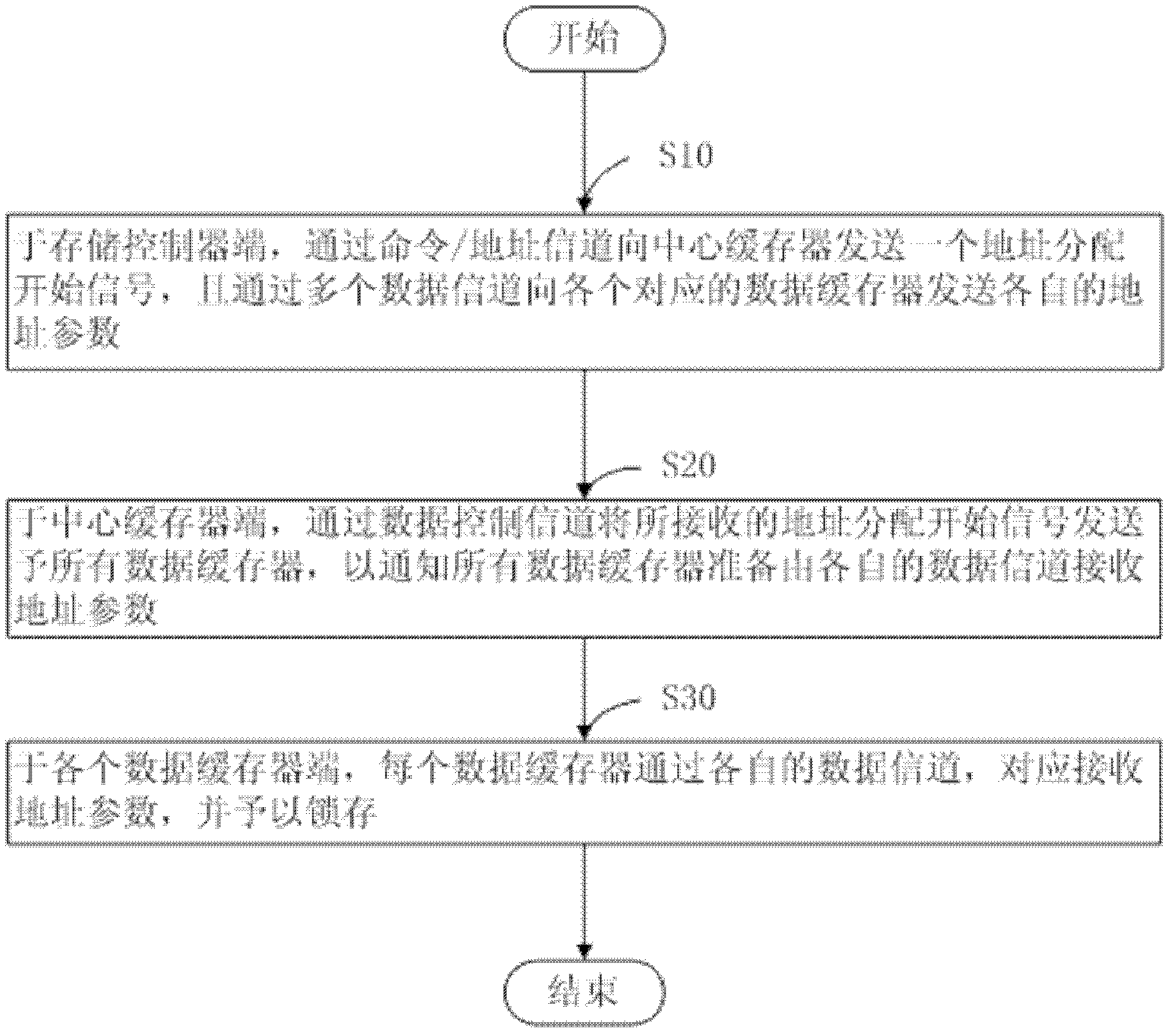

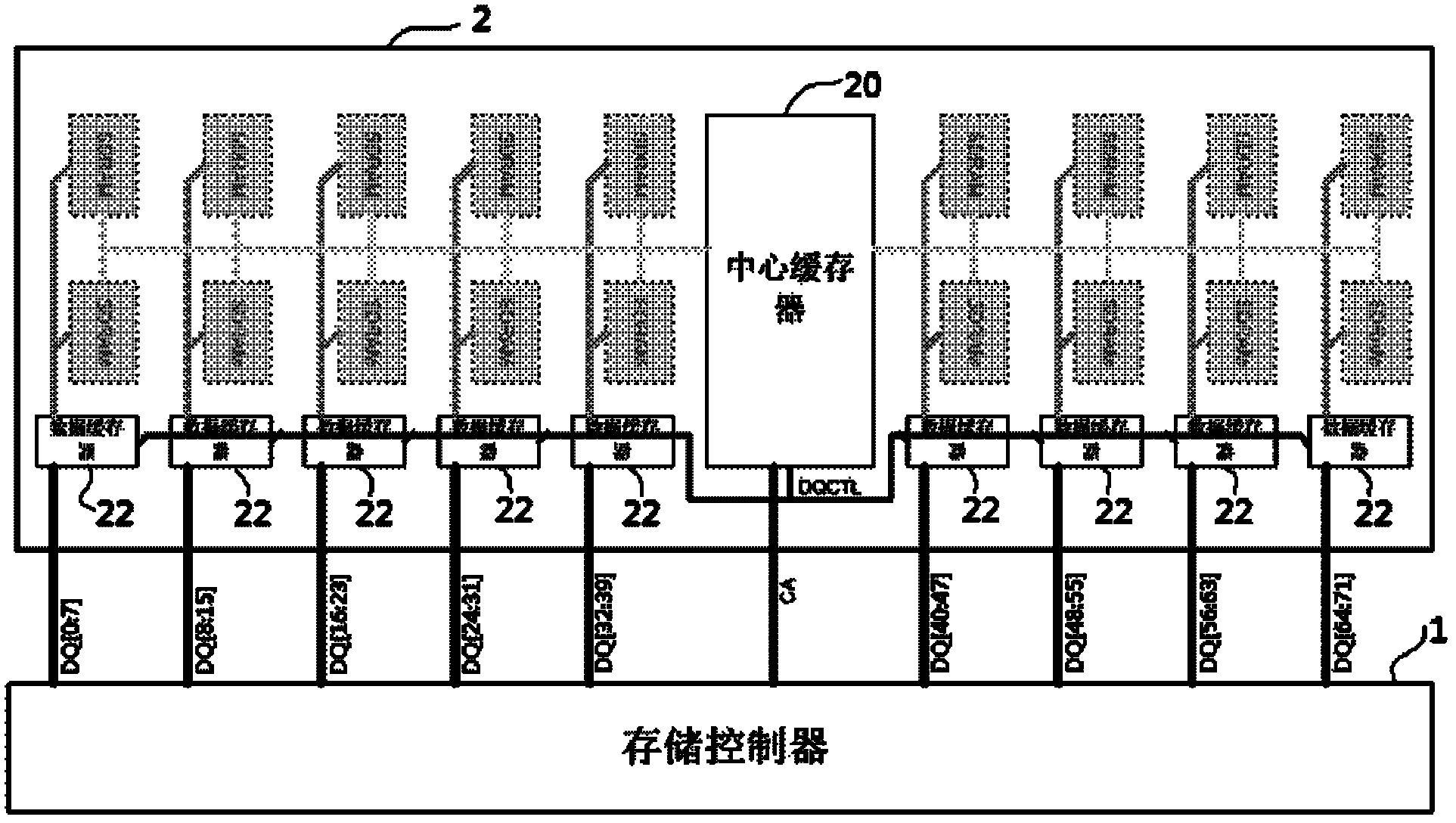

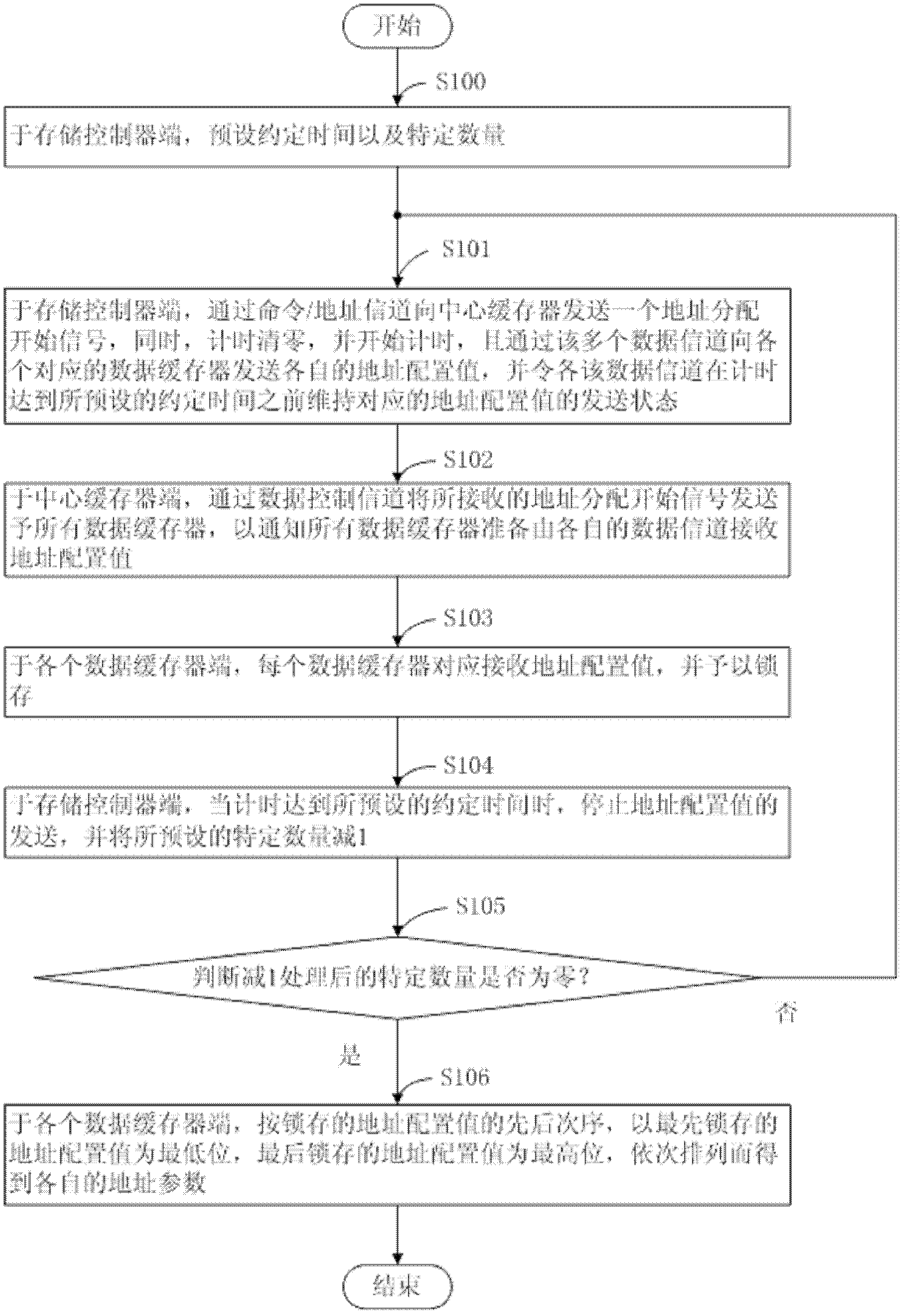

Address assignment method for data registers of distributed cache chipset

The invention relates to an address assignment method for data registers of a distributed cache chipset. The address assignment method includes: a memory controller informs a central register through a command / address channel to start address assignment, then the central register informs all the data registers through a data control channel to prepare to receive address parameters through respective data channels, and the data registers receive and latch respective address parameters from the memory controller through the data channels. The defect that the data registers need multiple extra address pins to assign respective address data in the prior art, and size simplification of the data registers and the overall distributed cache chipset is influenced accordingly can be overcome.

Owner:MONTAGE TECHNOLOGY CO LTD

Method of driving a shift register, a shift register, a liquid crystal display device having the shift register

InactiveCN100476941CDelay minimizationAvoid loading effectStatic indicating devicesDigital storageShift registerLiquid-crystal display

Owner:SAMSUNG DISPLAY CO LTD

Device having improved radiation hardness and high breakdown voltages

Radiation hardened NMOS devices suitable for application in NMOS, CMOS, or BiCMOS integrated circuits, and methods for fabricating them. A device includes a p-type silicon substrate, a field oxide surrounding a moat region on the substrate tapering through a Bird's Beak region to a gate oxide within the moat region, a heavily-doped p-type guard region underlying at least a portion of the Bird's Beak region and terminating at the inner edge of the Bird's Beak region, a gate included in the moat region, and n-type source and drain regions spaced by a gap from the inner edge of the Bird's Beak and guard regions. A variation of minor alterations to the conventional moat and n-type source / drain masks. The resulting devices have improved radiation tolerance while having a high breakdown voltage and minimal impact on circuit density.

Owner:TEXAS INSTR INC

Battery pack with cell-level fusing

ActiveUS8133608B2Improve performanceImprove reliabilityPrimary cell to battery groupingBatteries circuit arrangementsEngineeringBattery cell

Owner:TESLA INC

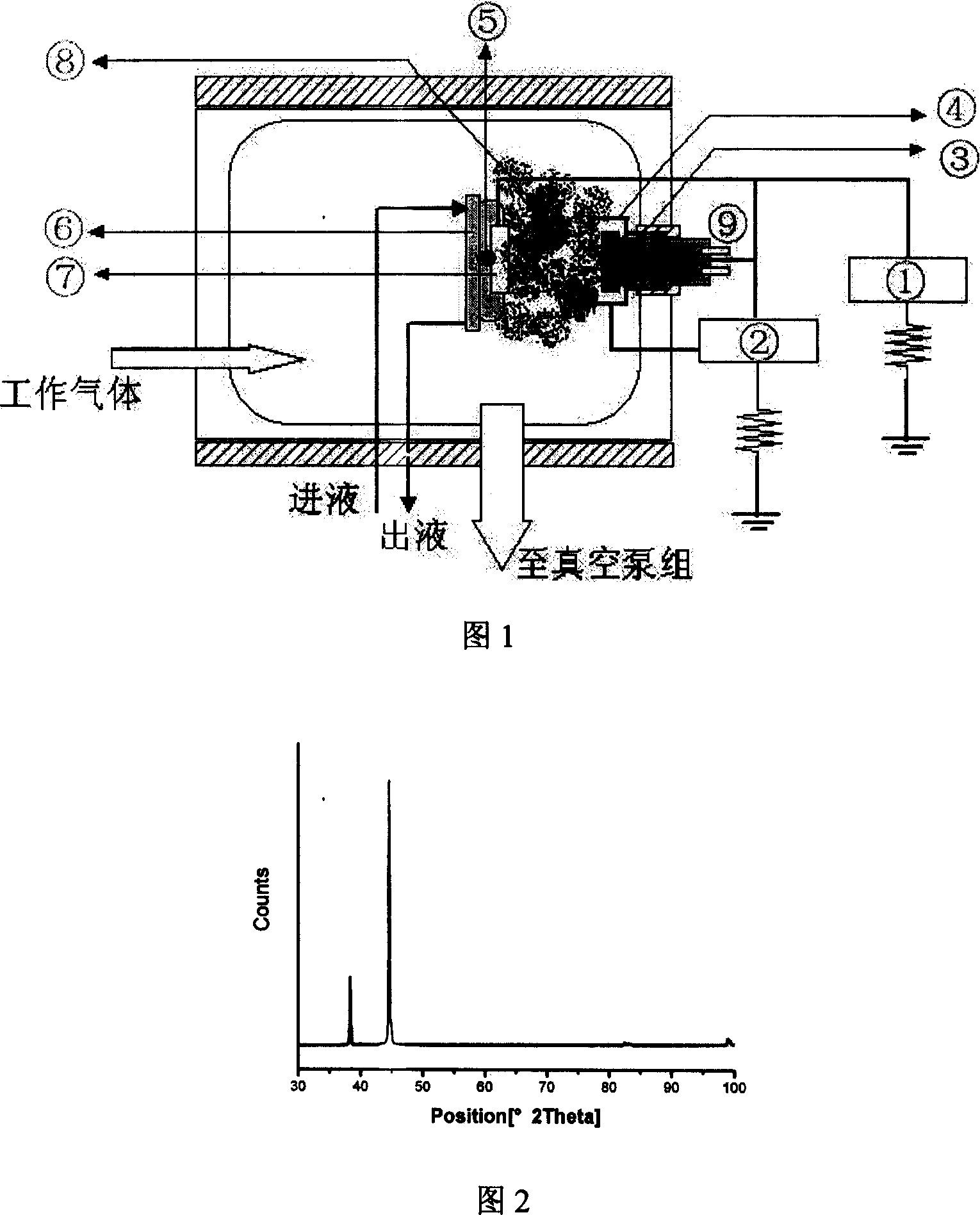

Method for preparing metal-base lubricating film by low temperature ion plating

InactiveCN101144151AImprove bindingImprove the lubrication effectVacuum evaporation coatingSputtering coatingPhysical chemistryLiquid nitrogen

The present invention discloses a method for preparing metal matrix lubrication film by low temperature ion plating. The method uses the ion plating technology and adopts a specimen holder cooled by liquid nitrogen to clamp the matrix of the film to be plated, the liquid nitrogen is added to the specimen holder during the film plating process, thereby the matrix gets low temperature, and the metal matrix lubrication film is deposited on the surface of the low temperature matrix. The film preparation method has the advantages that the matrix gets the low temperature condition during the film depositing process, simultaneously the selections of the main film plating parameters of the direct-current bias, the target current, the voltage and the depositing atmosphere partial pressure, etc. are not influenced. The metal matrix lubrication film prepared with the method has high binding force with the matrix and good lubrication performance, and thereby the method is a metal matrix lubrication film preparation method with application potential.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

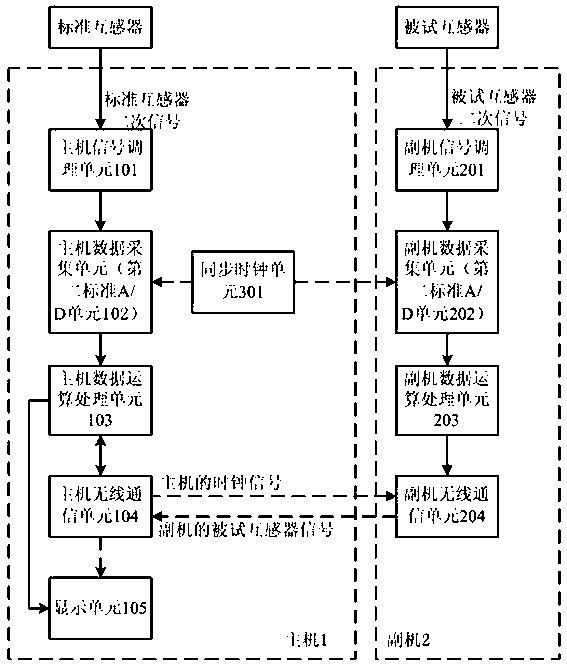

Mutual inductor field wireless calibration instrument for 750kV substation

InactiveCN103308879AReduce the impactImpact sizeTransmission systemsElectrical measurementsEnvironment effectData operations

The invention discloses a mutual inductor field wireless calibration instrument for a 750kV substation. The mutual inductor field wireless calibration instrument comprises a main machine and an auxiliary machine, which are connected in a wireless mode and generate synchronous signals; the main machine is used for conditioning, collecting and carrying out A / D (analog / digital) conversion on the secondary signal of a standard mutual inductor, and transmitting a synchronous signal to the auxiliary machine; the main machine is also used for performing data operation processing on a digital signal of the standard mutual inductor, obtained from the A / D conversion, and a digital signal of a tested mutual inductor, transmitted by the auxiliary machine in the wireless mode, obtaining the comparison value and phase difference of the digital signals compared with each other, and displaying the comparison value and the phase difference; and the auxiliary machine is used for conditioning, collecting and carrying out A / D conversion on the secondary signal of the tested mutual inductor, and transmitting the digital signal of the tested mutual inductor after being subjected to A / D conversion to the main machine in the wireless mode after receiving the synchronous signal transmitted by the main machine. The mutual inductor field wireless calibration instrument for the 750kV substation can overcome the defects of great environmental influence, high fault rate and high error and the like in the prior art and realize the advantages of small environmental influence, high reliability and low error.

Owner:STATE GRID CORP OF CHINA +3

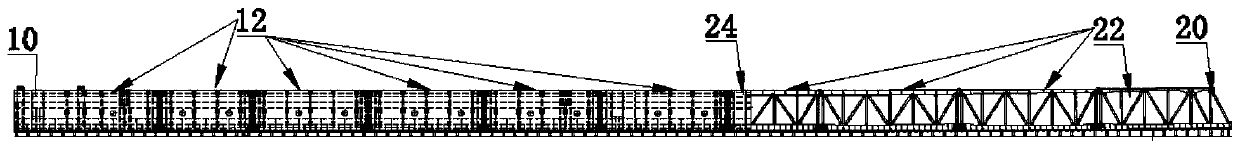

Manufacturing process of self-propelled movable formwork main beam structure and main beam structure

ActiveCN111576221AHigh precisionImprove straightnessBridge erection/assemblyManufacturing engineeringMechanical engineering

Owner:广州文冲船舶修造有限公司

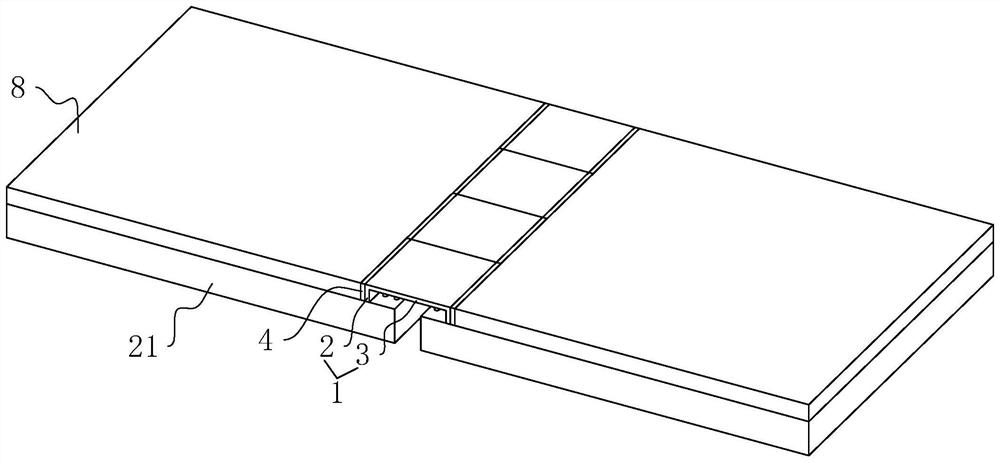

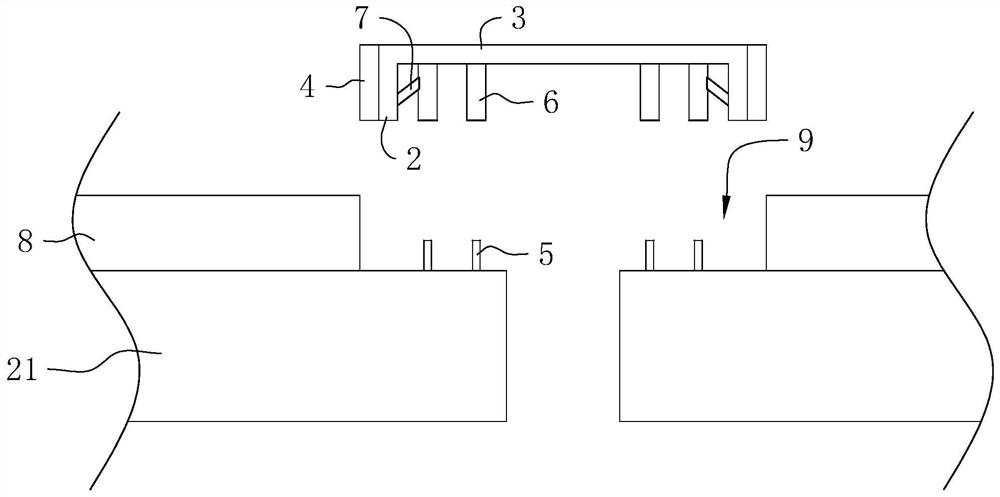

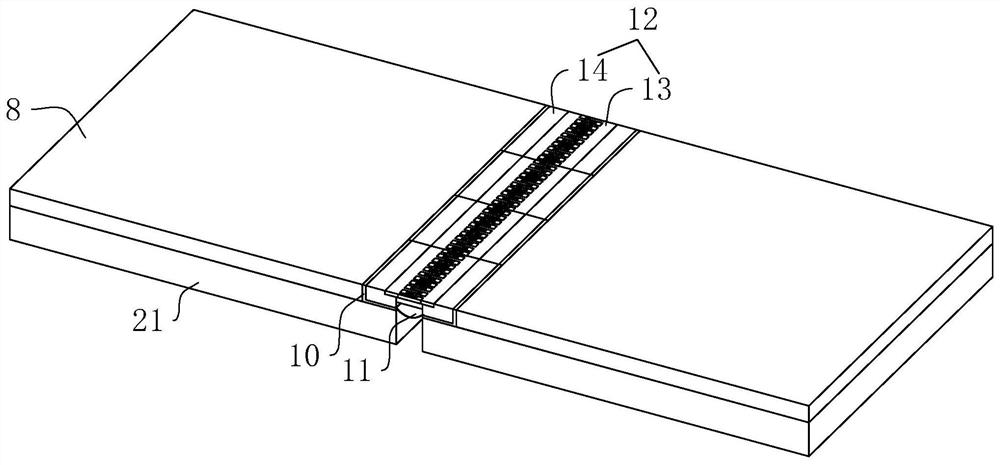

Bridge assembly type expansion joint device construction method

ActiveCN112900256AImpact sizeAvoid pollutionBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a bridge assembly type expansion joint device construction method which comprises the following steps that 1, a temporary supporting piece is built between the ends, close to each other, of two adjacent beam bodies used for building a bridge, wherein the temporary supporting piece comprises a supporting plate and two baffles arranged on the two opposite side walls of the supporting plate correspondingly; the two ends of the supporting plate extend to one ends of the two adjacent beam bodies correspondingly, the baffle is vertically arranged, the lower end of the baffle abuts against the upper surfaces of the beam bodies, and the supporting plate is provided with a positioning piece used for limiting the supporting plate from disengaging from the beam bodies; 2, concrete is poured on the upper surface of the beam body to form a concrete bridge floor, and a reserved groove used for installing an expansion joint device is formed in the beam body area corresponding to the supporting plate; and 3, after the concrete is solidified and cured, when the expansion joint device needs to be installed, positioning of the supporting plate by the positioning piece is canceled, the supporting plate is taken down, the reserved groove is cleaned, and then the expansion joint device is installed in the reserved groove. The method has the effect of improving the negative effect caused by grooving in the prior art.

Owner:湖南发通路桥集团有限公司

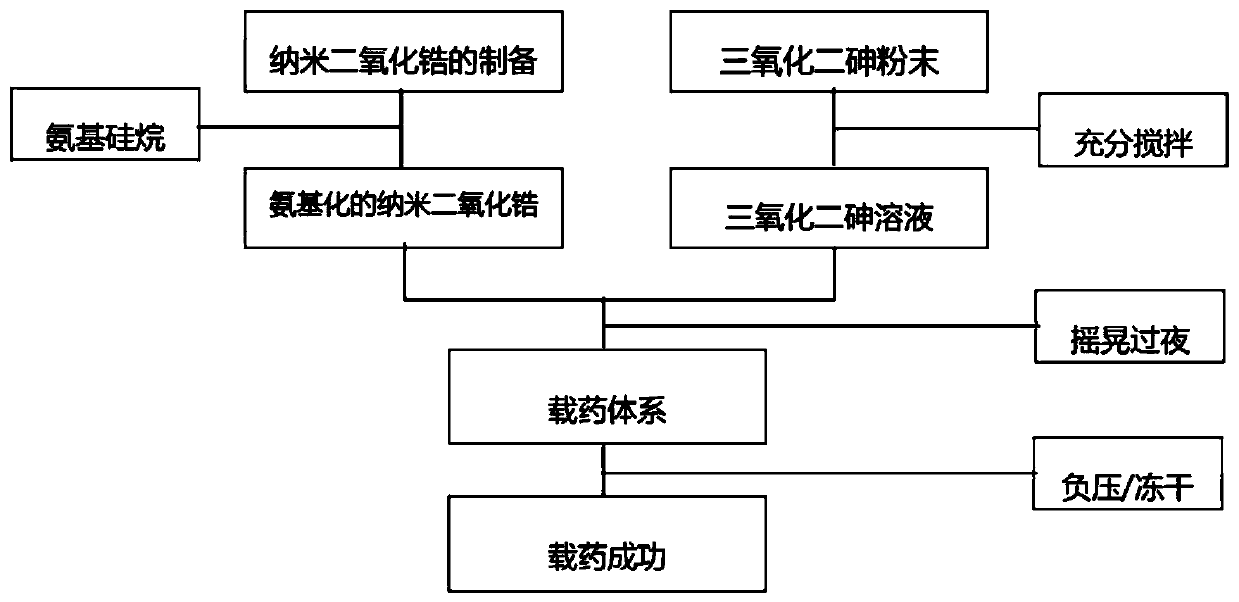

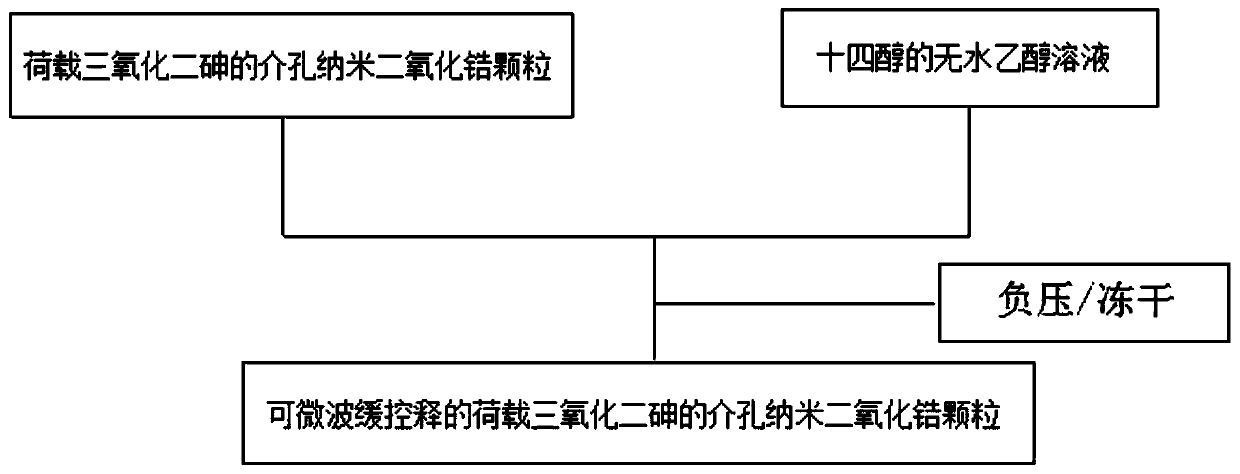

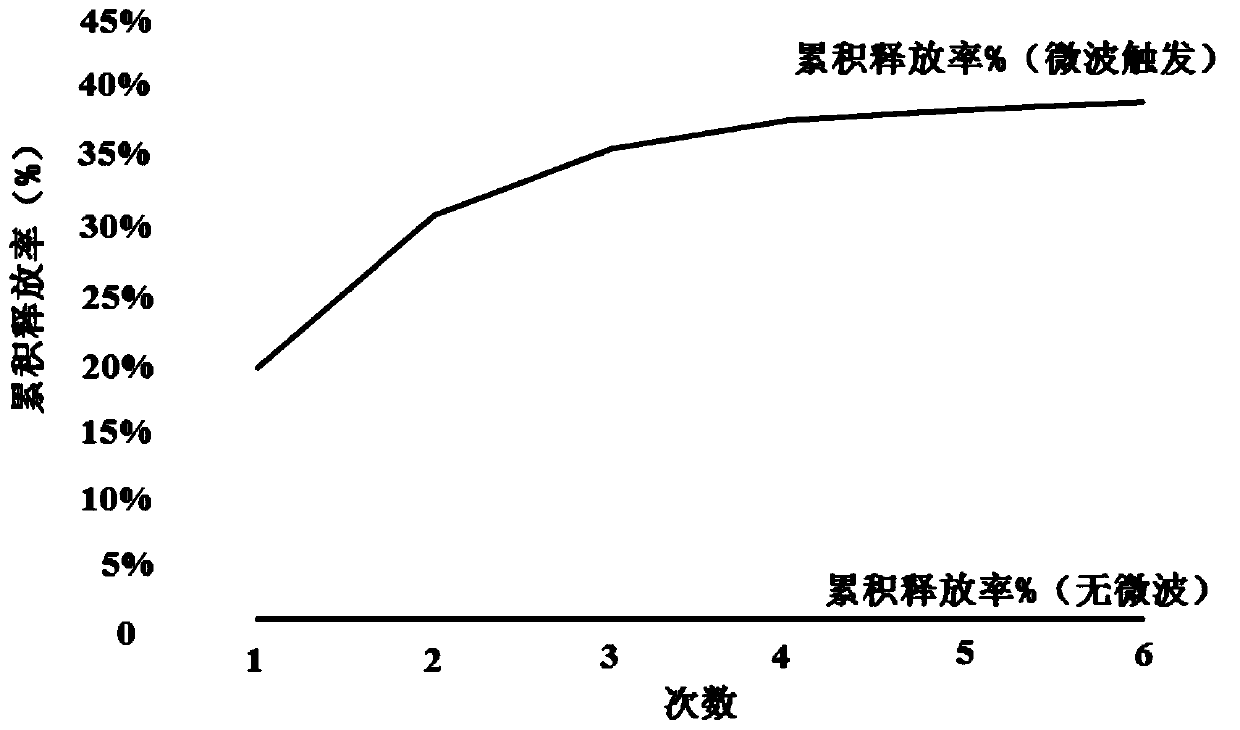

Mesoporous nano-zirconia drug-carrying material, preparation method thereof and controlled-release drug

ActiveCN109806400AAffects mesostructureImpact sizeNanomedicinePharmaceutical non-active ingredientsControl releaseMedicine

The invention relates to a mesoporous nano-zirconia drug-carrying material. The surface of mesoporous nano-zirconia is modified with an amino-containing group; the amino-containing group is selected from at least one of an aminosilane group, an amino-containing acrylic group and an amino-containing olefin group; the drug-carrying material has high drug carrying stability and biosecurity. The invention also relates to a preparation method of the mesoporous nano-zirconia drug-carrying material and application of the mesoporous nano-zirconia drug-carrying material in a controlled-release drug. The preparation method of the mesoporous nano-zirconia drug-carrying material is simple, efficient, and high in operability, and successively creates a mesoporous nano-zirconia drug-carrying system loading a negative charge drug active component, bringing a new method and a new idea for loading negative charge drugs which have different negative charges as the mesoporous nano-zirconia to the mesoporous nano-zirconia. The controlled release effect of the controlled-release drug is remarkable.

Owner:THE FIRST HOSPITAL OF CHINA MEDICIAL UNIV

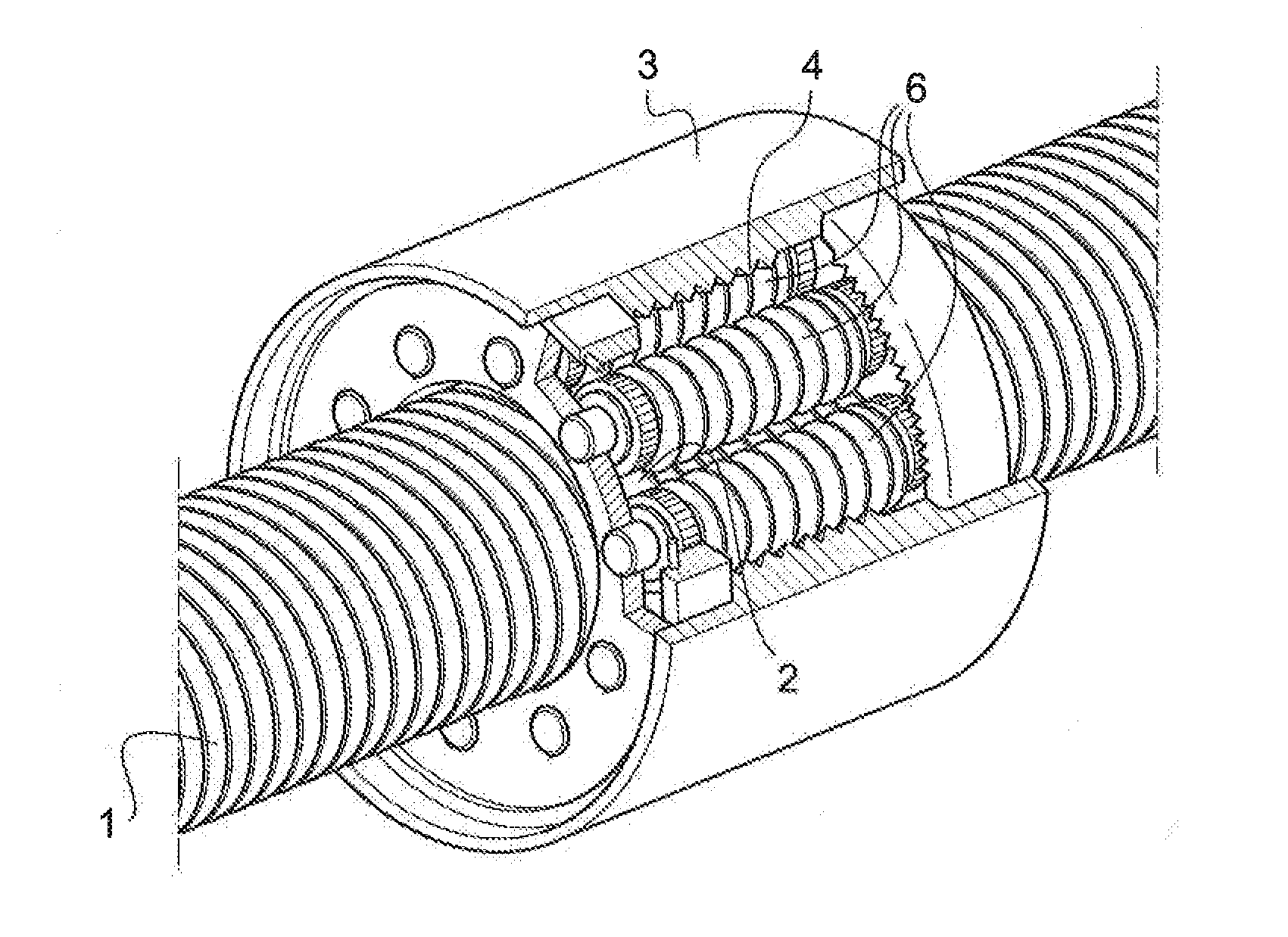

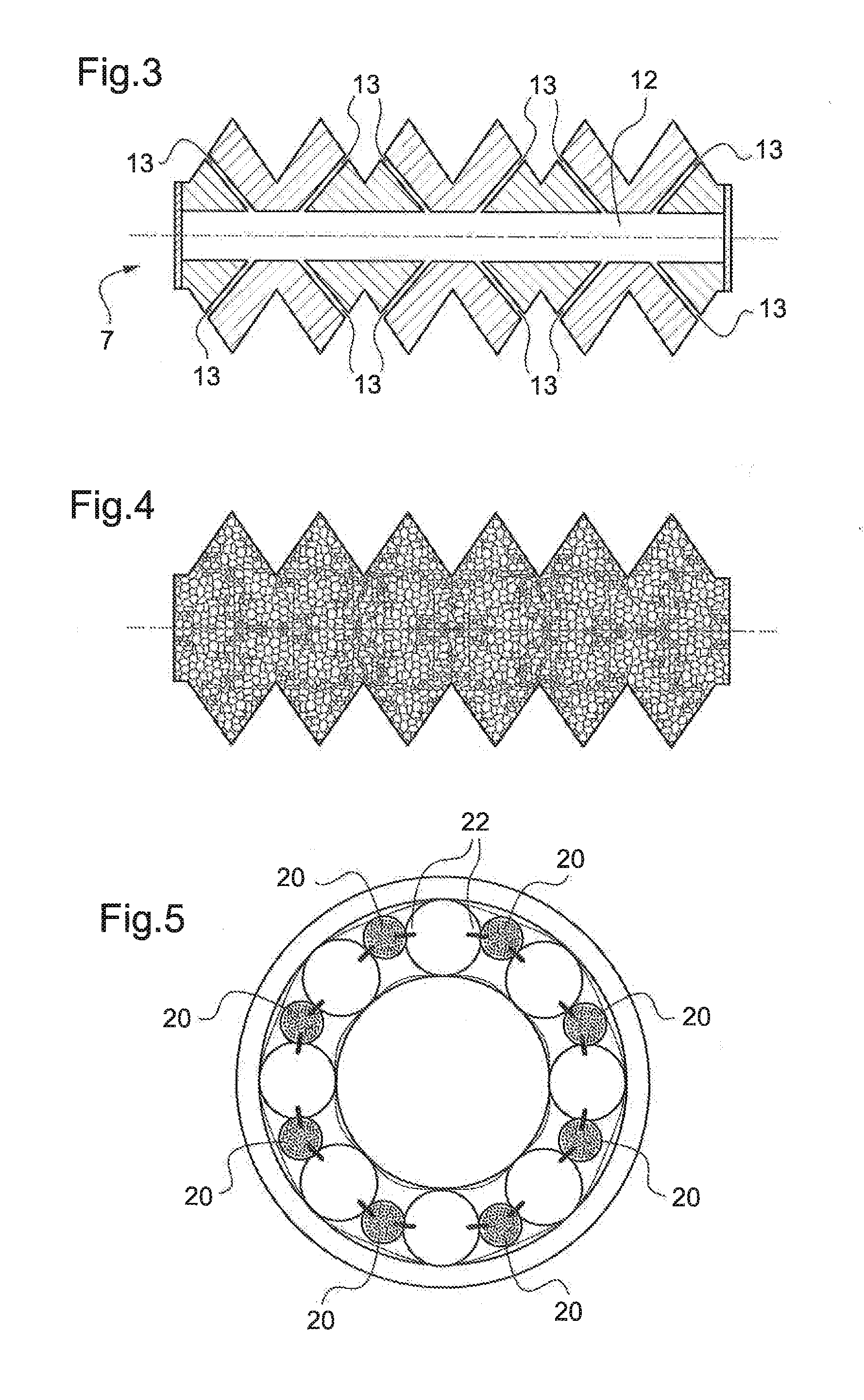

Mechanical member

ActiveUS20140331799A1Impact sizeImpact weightToothed gearingsGear lubrication/coolingEngineeringContact zone

The invention relates to a mechanical member wherein a first part in contact with a second part movable relative to the first part, at least one of the parts including a coating of solid lubricant at least at contact zones between the first part and the second part, the solid lubricant being suitable on its own for lubricating the mechanical member. According to the invention, the mechanical member includes retention and capillary distribution means for distributing a fluid between the parts in such a manner as to form a film between said parts, which film can be pierced temporarily at each contact zone.

Owner:SAFRAN ELECTRONICS & DEFENSE

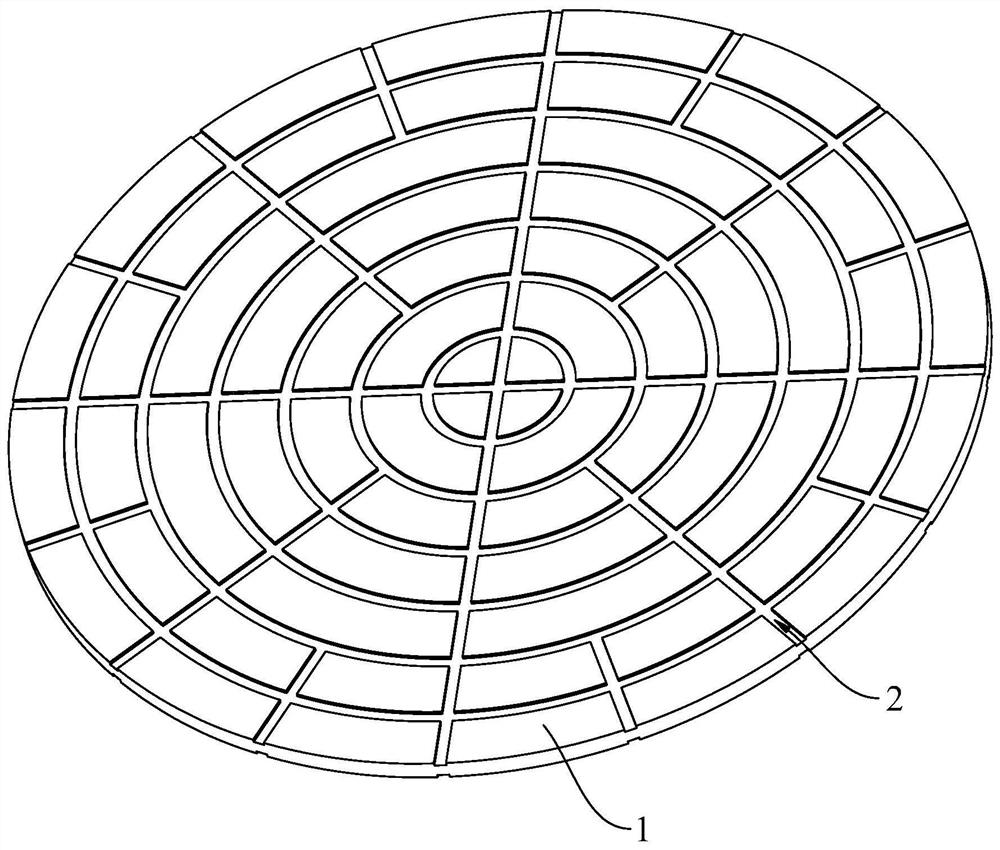

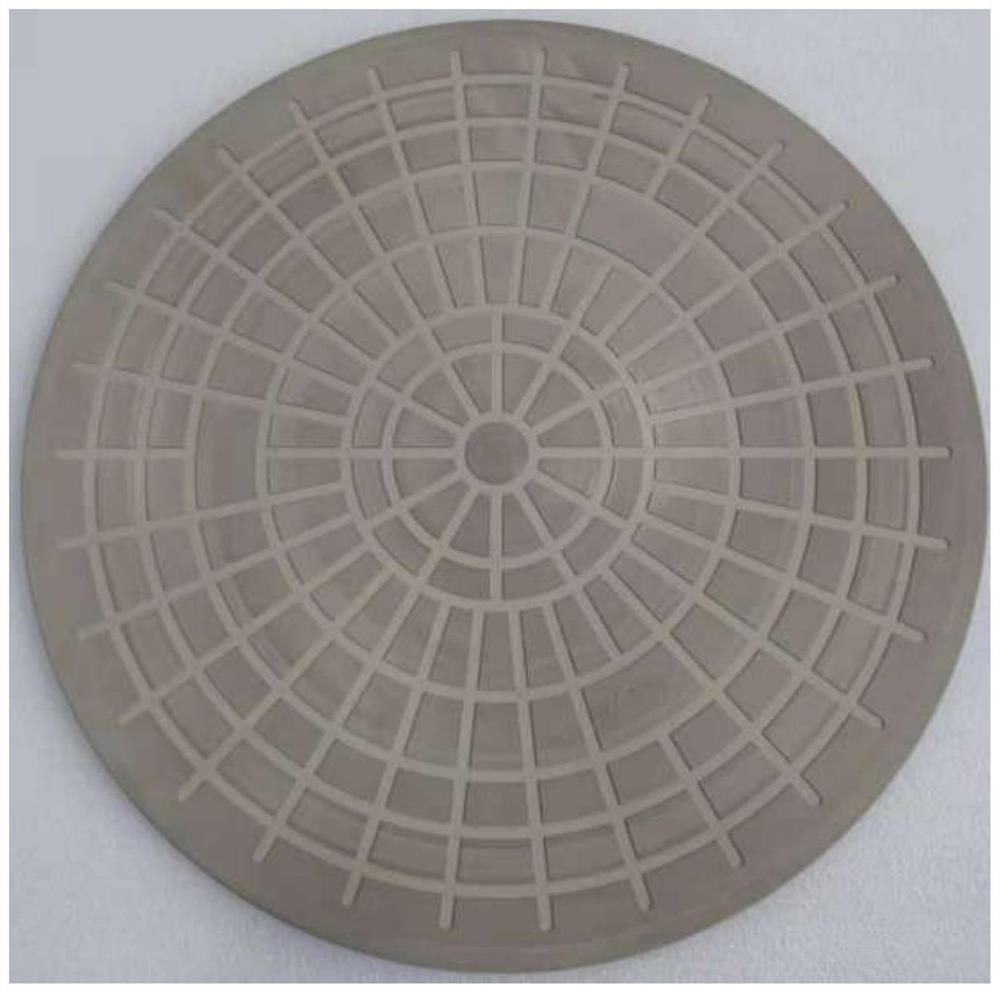

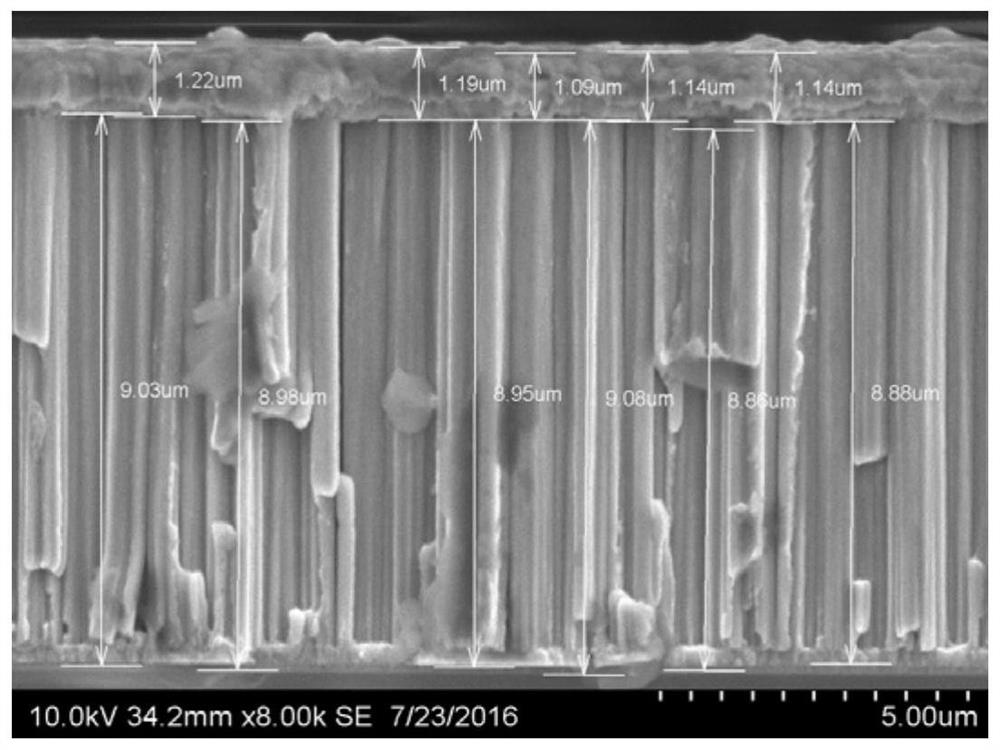

Manufacturing method of silicon carbide carrying disc for plasma etching and silicon carbide carrying disc

ActiveCN113698208AReduce processing timeReduce manufacturing costSemiconductor/solid-state device manufacturingCarbide siliconMetallurgy

The invention belongs to the technical field of carrying discs, and particularly relates to a manufacturing method of a silicon carbide carrying disc for plasma etching and the silicon carbide carrying disc. The manufacturing method of the silicon carbide carrying disc comprises the following steps of (1) forming a plain blank, namely forming the silicon carbide plain blank meeting the size requirement by adopting silicon carbide granulation powder of a solid-phase sintering system through a process of firstly performing dry pressing and then performing isostatic pressing or directly performing isostatic pressing, (2) plain blank processing: according to the finished product size and the high-temperature sintering shrinkage rate of the plasma etching carrier disc, reserving certain sintering allowance for the outer circle, the total thickness and the groove depth of the front and back surfaces, and processing the formed plain blank, (3) high-temperature sintering: carrying out high-temperature sintering on the processed silicon carbide carrier plate blank, (4) finish machining: performing precision grinding and plane grinding on the outer circle of the carrying disc, and then machining the reverse side of the carrying disc by taking the groove depth of the reverse side as a reference, processing the front surface of the carrying disc by taking the total thickness requirement of the carrying disc as a reference, and finally, precisely grinding the wafer groove until the groove depth requirement is met.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

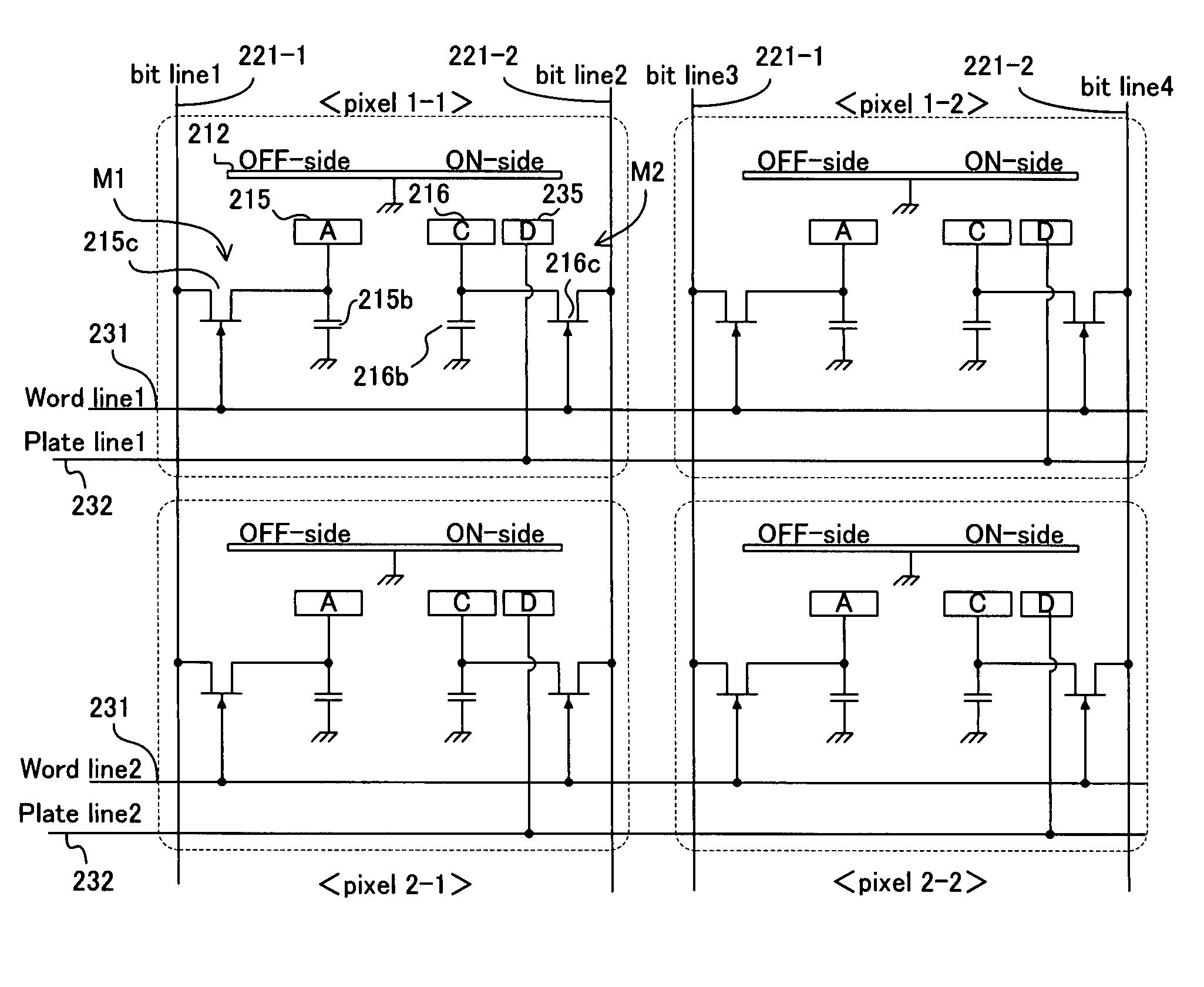

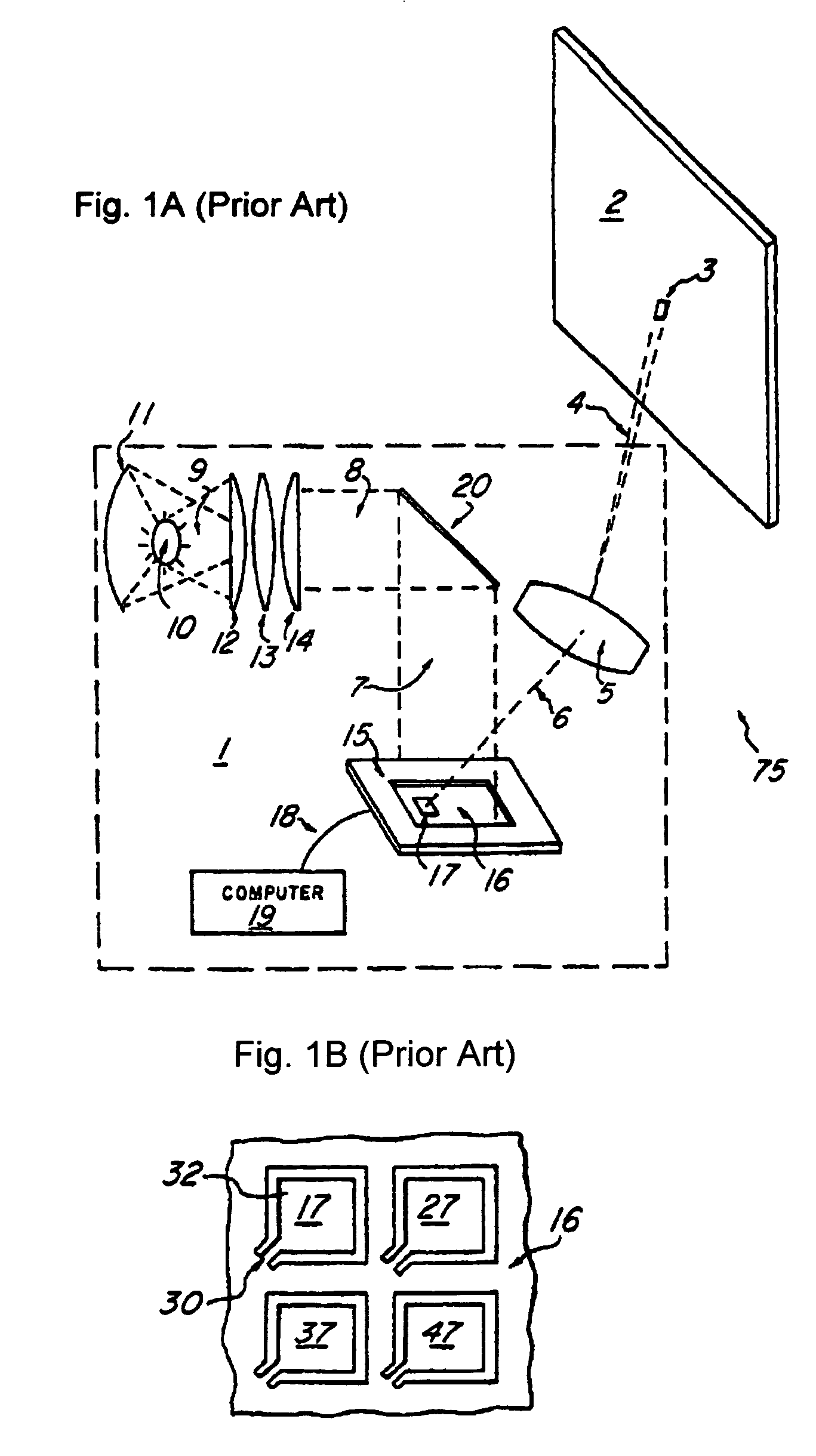

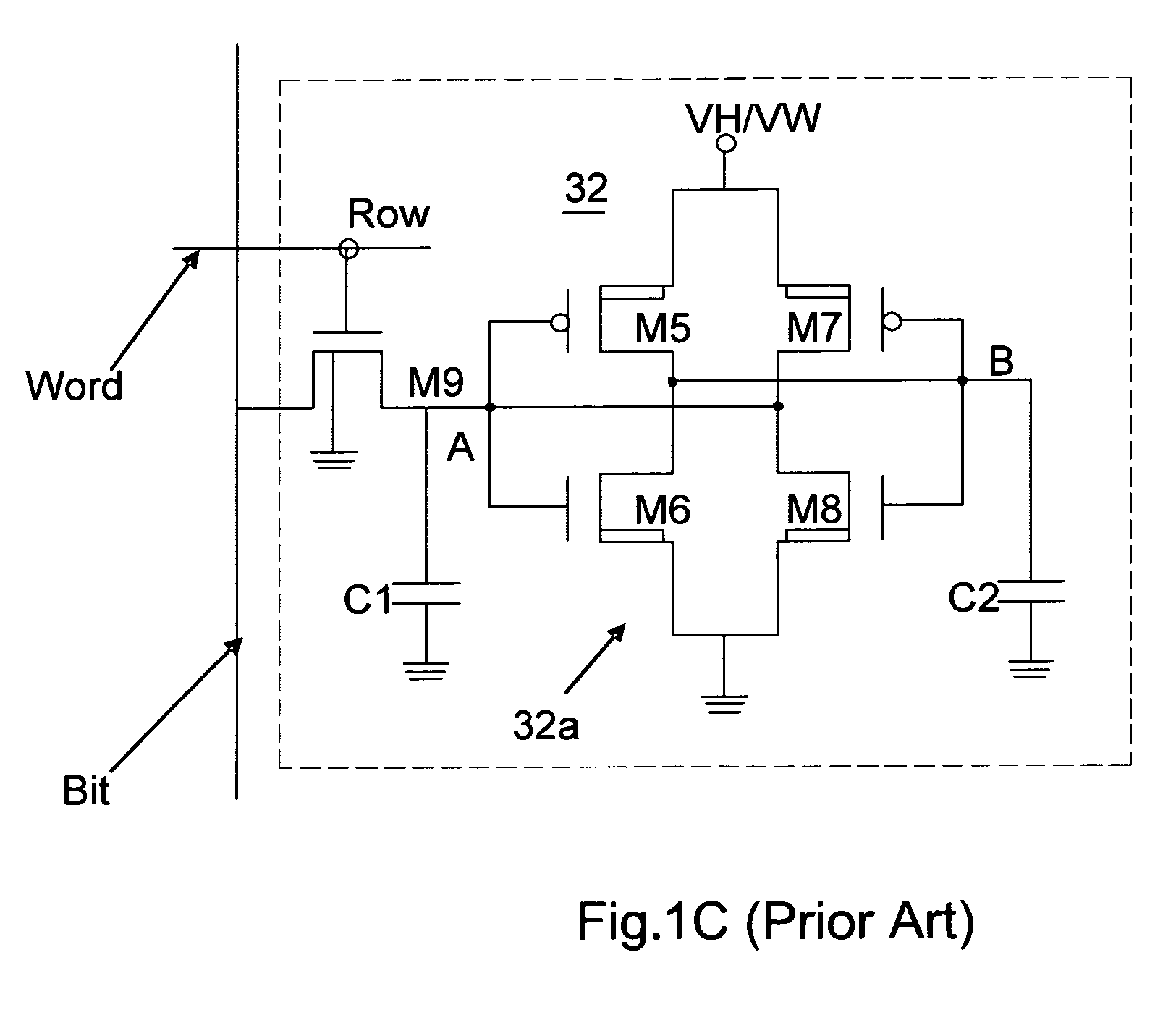

Spatial light modulator and mirror device

InactiveUS7969395B2Low costHigh performance featuresTelevision system detailsStatic indicating devicesSpatial light modulatorControl signal

The present invention discloses a spatial light modulator includes a plurality of pixel elements disposed on a substrate. Each of the pixel elements comprises a deflectable micromirror. Specifically, instead of SRAM, the spatial light modulator is implemented with a DRAM in each of the pixel elements. The DRAM in each of the pixel elements has a smaller number of transistors than SRAM. The spatial light modulator can be manufactured with smaller pixel size and circuit configuration with improved withstand voltage. Further improvements can also be achieved for manufactured the spatial light modulator with smaller capacitor with better layout configuration for wire connections and control signal transmissions.

Owner:SILICON QUEST KABUSHIKI KAISHA +1

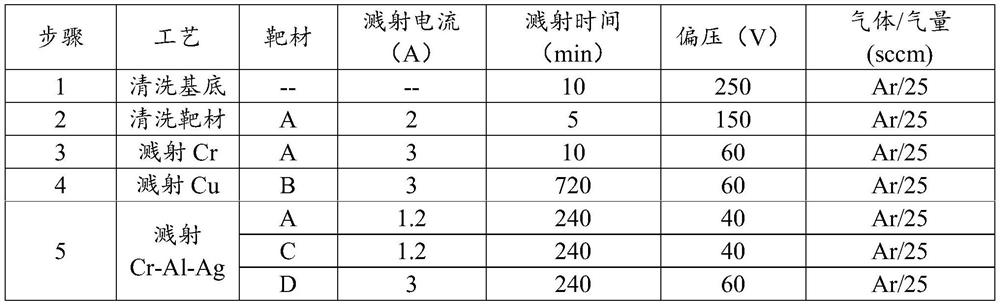

Cavity clad layer of magnetism-based or aluminum-based filter and preparation method thereof

PendingCN111962035AImprove machine performanceImprove anti-oxidative discoloration abilityVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceThin membrane

The invention discloses a cavity clad layer of a magnetism-based or aluminum-based filter and a preparation method thereof and belongs to the field of magnetron sputtering coating. The preparation method comprises the following steps of first, plating a 200-300 nm Cr layer as a priming coat by magnetron sputtering to replace a 200-700 nm Ni priming coat which is obtained by conventional electroplating or chemical plating; and then sputtering a Cu layer, and depositing a 1-2 [mu]m Cr-Al-Ag co-sputtering layer by a magnetron co-sputtering technology, wherein the use level of Ag is further reduced while the electrical property is ensured, and the cost is lowered; and by adding Cr into the co-sputtering layer, the binding force among films is improved, and Cr and Al can improve the antioxidantdiscoloration performance of the clad layer. The preparation method provided by the invention improves the compactness of the clad layer and reduces defects in the film, so that the surface contact resistance is reduced, and the integral performance of the filter is improved favorably.

Owner:西安匠心云涂科技有限公司

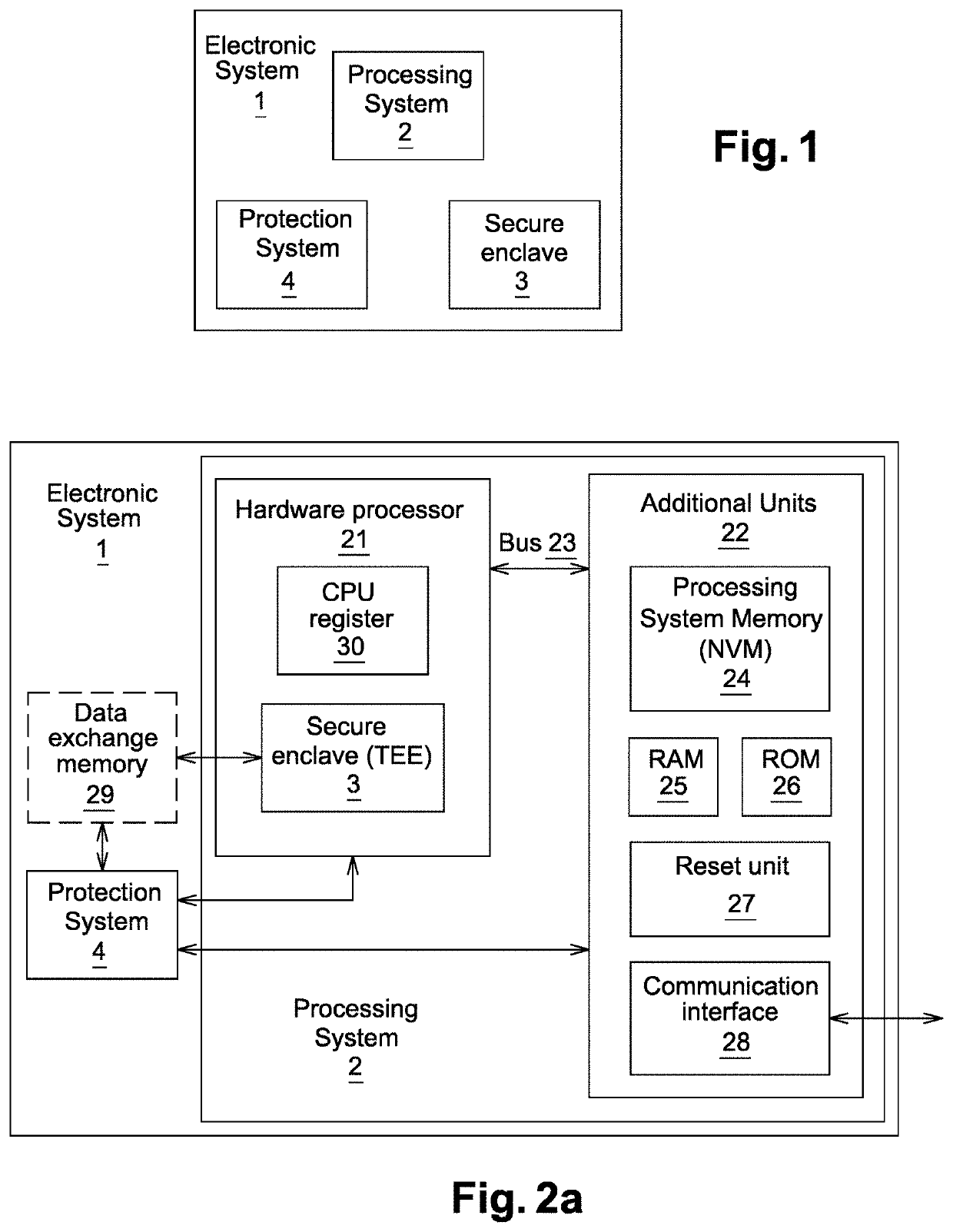

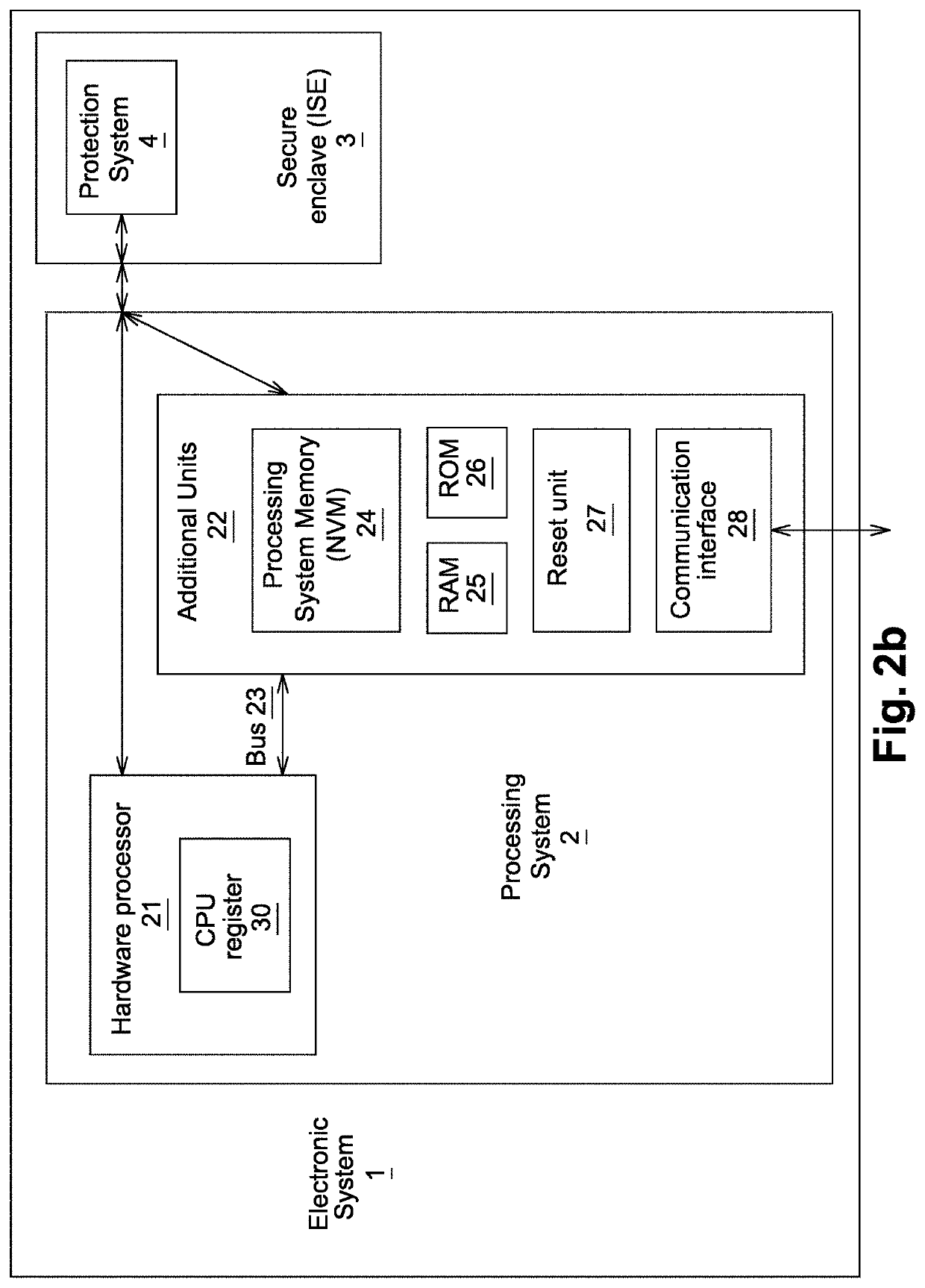

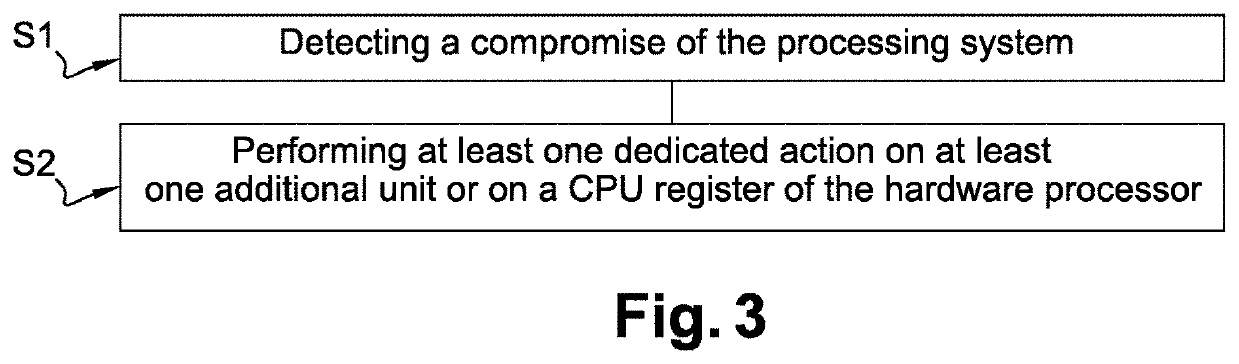

Electronic system and method for preventing malicious actions on a processing system of the electronic system

PendingUS20210224386A1Malicious action is preventedImpact sizeInternal/peripheral component protectionPlatform integrity maintainanceElectronic systemsHandling system

An electronic system having a processing system with a hardware processor and at least one additional unit the hardware processor having a CPU register and the additional unit having a processing system memory. A secure enclave of the system is configured to monitor the behavior of the processing system and detect a compromise of the processing system. A protection system of the electronic system is configured, upon detection of a compromise of the processing system by the secure enclave, to perform at least one dedicated action on at least one additional unit among the additional units for raising an alert or for applying countermeasures, or on the hardware processor modifying a CPU register of the hardware processor, the protection system and the secure enclave being connected to the additional units.

Owner:THALES DIS FRANCE SA

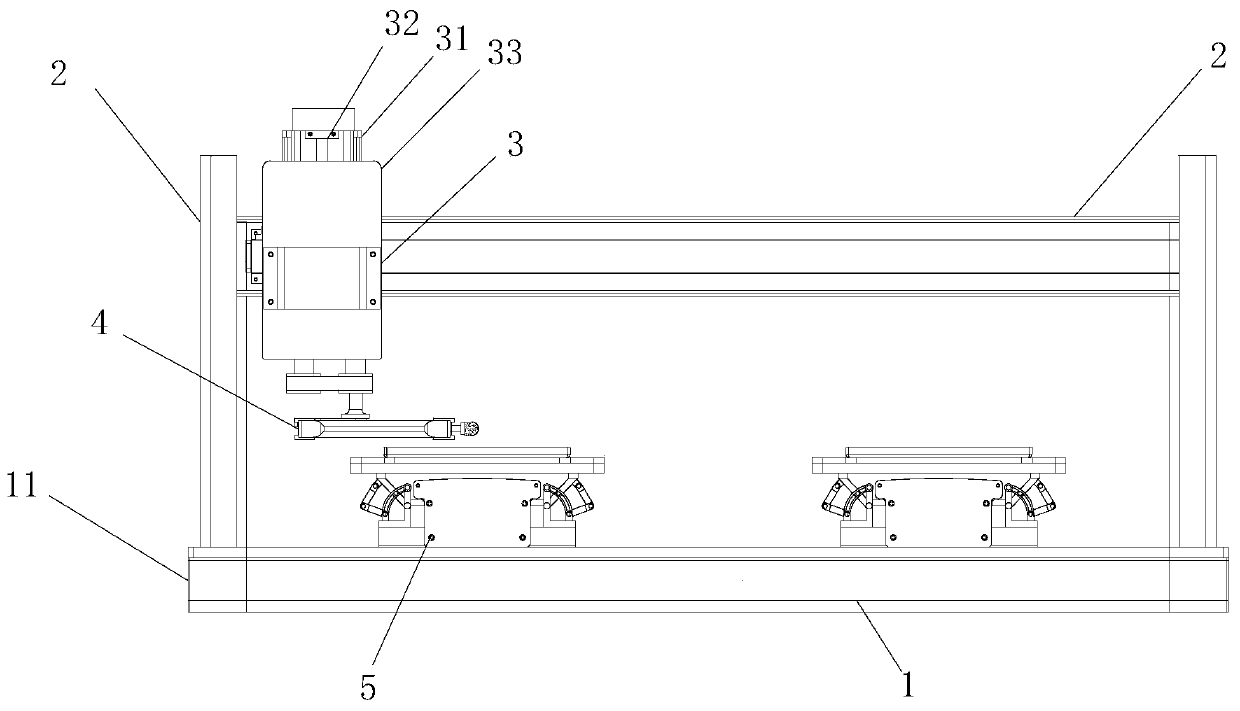

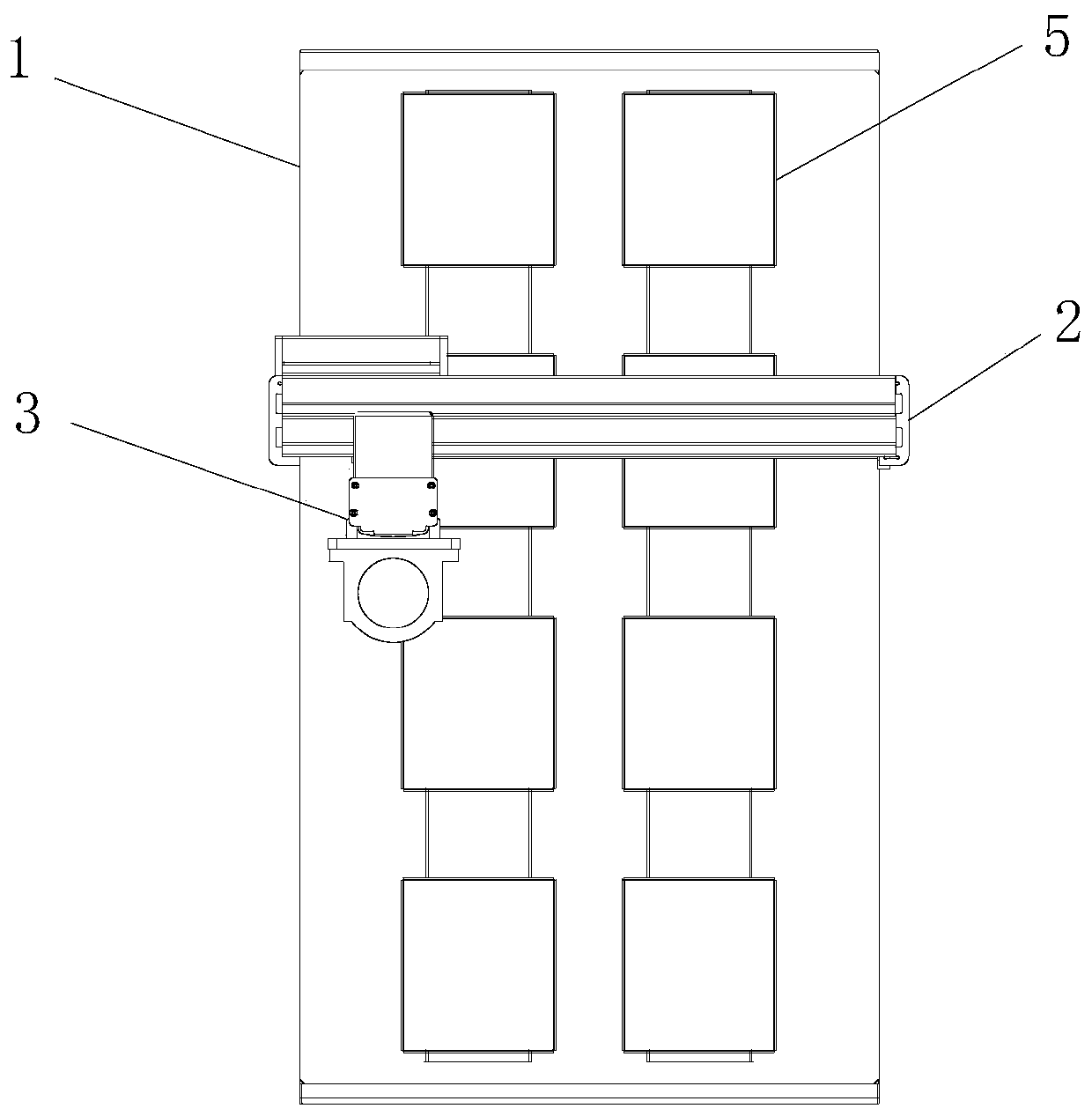

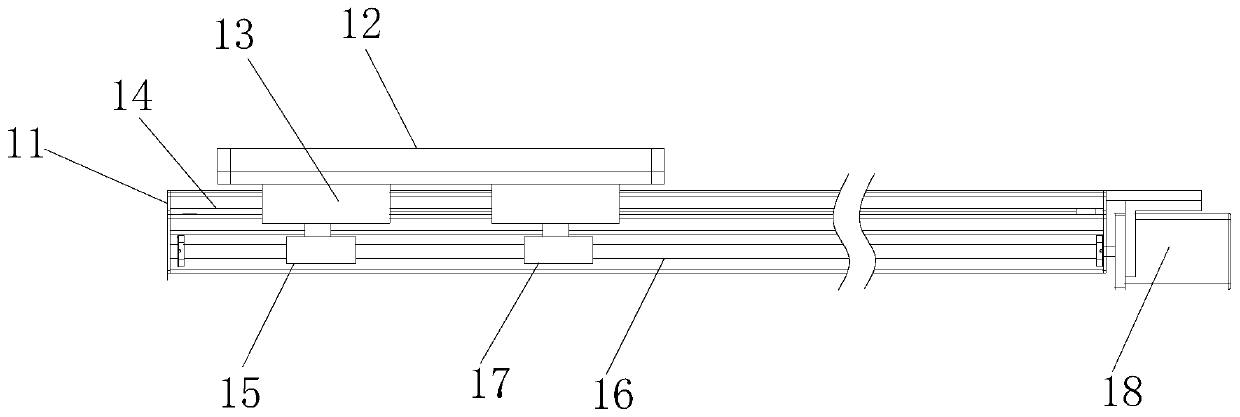

Three-dimensional multi-station machining device for electronic parts

ActiveCN110355665ASatisfy the process processing methodMeet the needs of modern process technology environmentGrinding carriagesGrinding drivesEngineeringMachine tool

The invention relates to the related technical field of electronic science and technology, in particular to a three-dimensional multi-station machining device for electronic parts. The device comprises a machine tool, a transmission machine frame and an operation machine frame, the transmission machine frame is mounted on the machine tool, the operation machine frame is mounted on the transmissionmachine frame, the transmission machine frame and the side edge of the machine tool are movably mounted through a longitudinal transmission mechanism, a transverse transmission guide rail is arrangedon the transmission machine frame, a transverse sliding block is installed on the transverse transmission guide rail, a transverse transmission lead screw is installed in the transverse transmissionguide rail, the transverse sliding block is installed on the transverse transmission lead screw through threaded connection, the operation machine frame is installed on the transverse sliding block, the operation machine frame comprises a fine adjustment track and an operation cabinet, and the operation cabinet is installed on the fine adjustment track. According to the design, multiple stages oftransmission mechanisms are arranged and adjust the operation direction in a three-dimensional mode in the X-Y-Z-axis direction, and therefore the requirements of multi-station and multi-point streamline machining are met.

Owner:聊城西科自动化设备有限公司

Device for accurate measurement of micro deformation of composite rod for space

The invention provides a device for accurate measurement of micro deformation of a composite rod for space, and relates to the field of aerospace. The device solves the problems that an existing measuring method is low in measurement accuracy and cannot be used for effectively measuring micro deformation of a composite rod for space. The device comprises a steel ball made of 16-level-accurcy stainless steel materials and a straight joint made of invar steel materials with the linear expansion coefficient being zero; the two ends of the straight joint are of a first cylindrical structure and a second cylindrical structure respectively, the middle of the straight joint is of a square structure, the end of the first cylindrical structure is provided with a spherical groove for fixing the steel ball, and the spherical groove is the same as the steel ball in diameter; the diameter of the second cylindrical structure is in clearance fit with the inner diameter of the composite material rod, and the composite material rod is installed on the second cylindrical structure in a sleeved mode and connected together with the second cylindrical structure in a cementing mode. When the device is used for measuring the micro deformation of the composite rod, the repeatability is within 0.5 micrometer, and the measuring accuracy is high.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com