Rotary exchanging method and rotary exchanging device for double workpiece platforms based on synchronous steering of turntable gear

A technology of double workpiece table and workpiece table, which is applied in the direction of exposure device, electrical components, conveyor objects, etc. in the photolithography process, can solve the problems of shortening the balance time, loss of laser interferometer target, small moment of inertia, etc. The effect of engraving machine productivity, shortening balance time, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

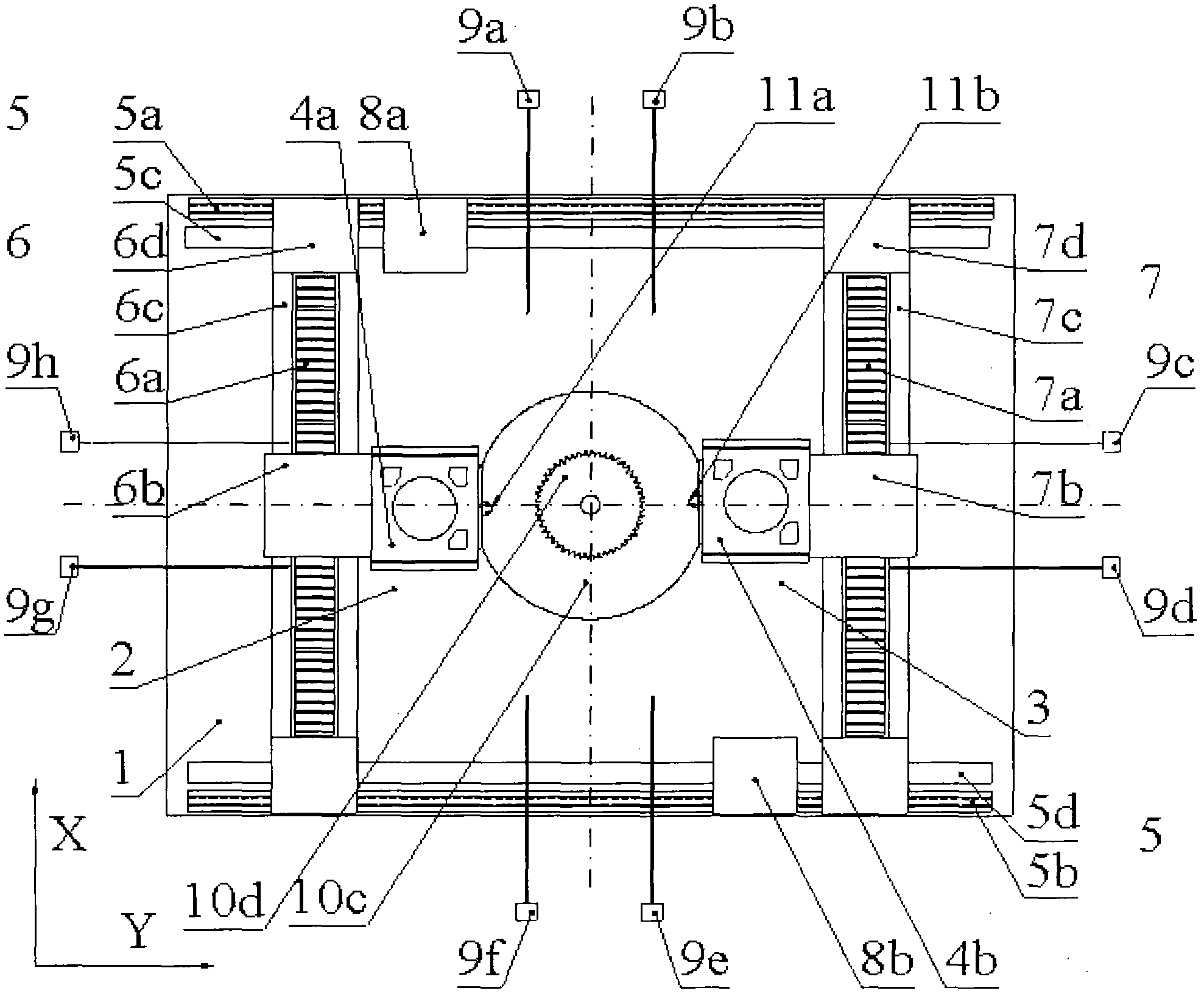

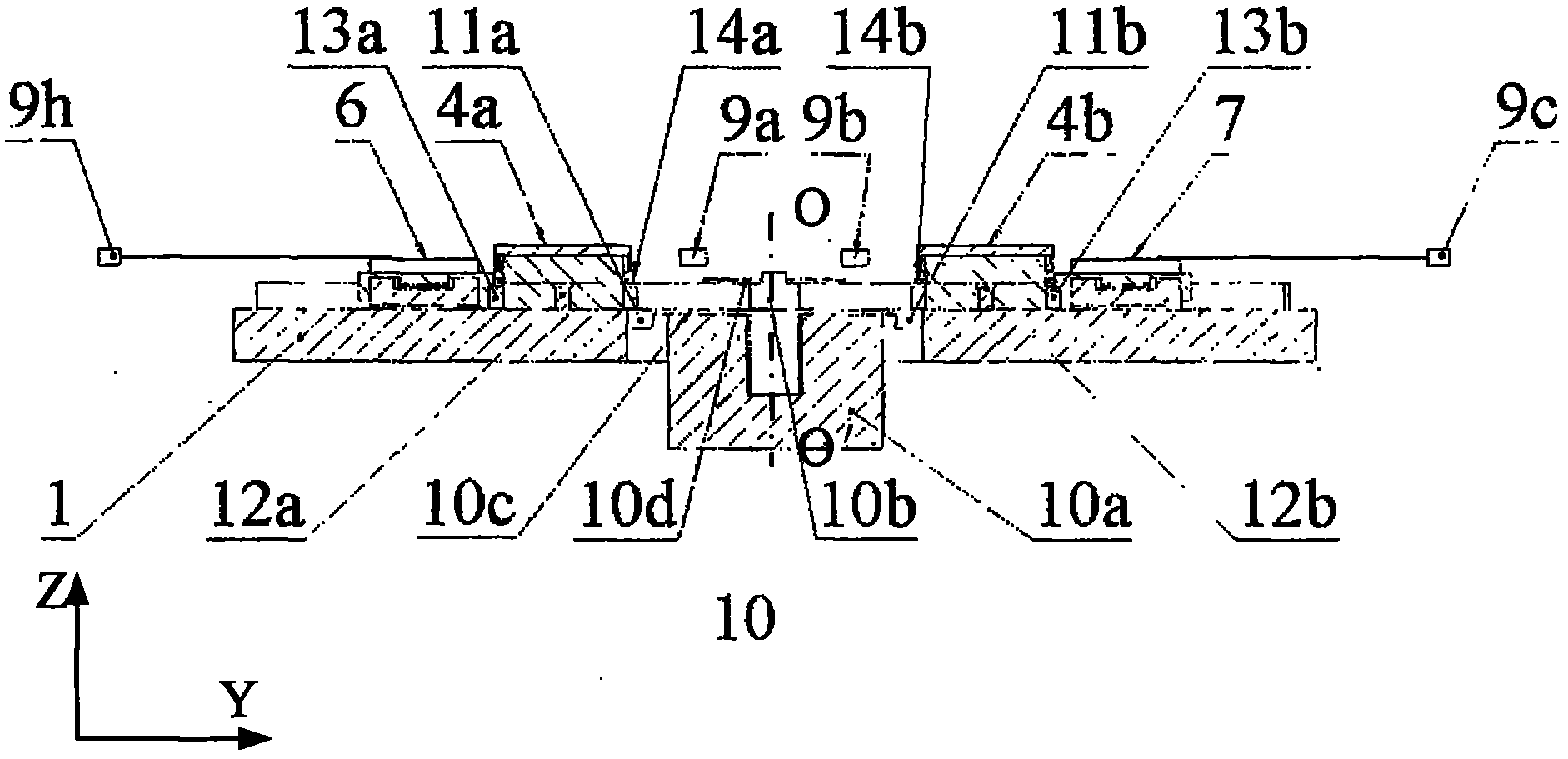

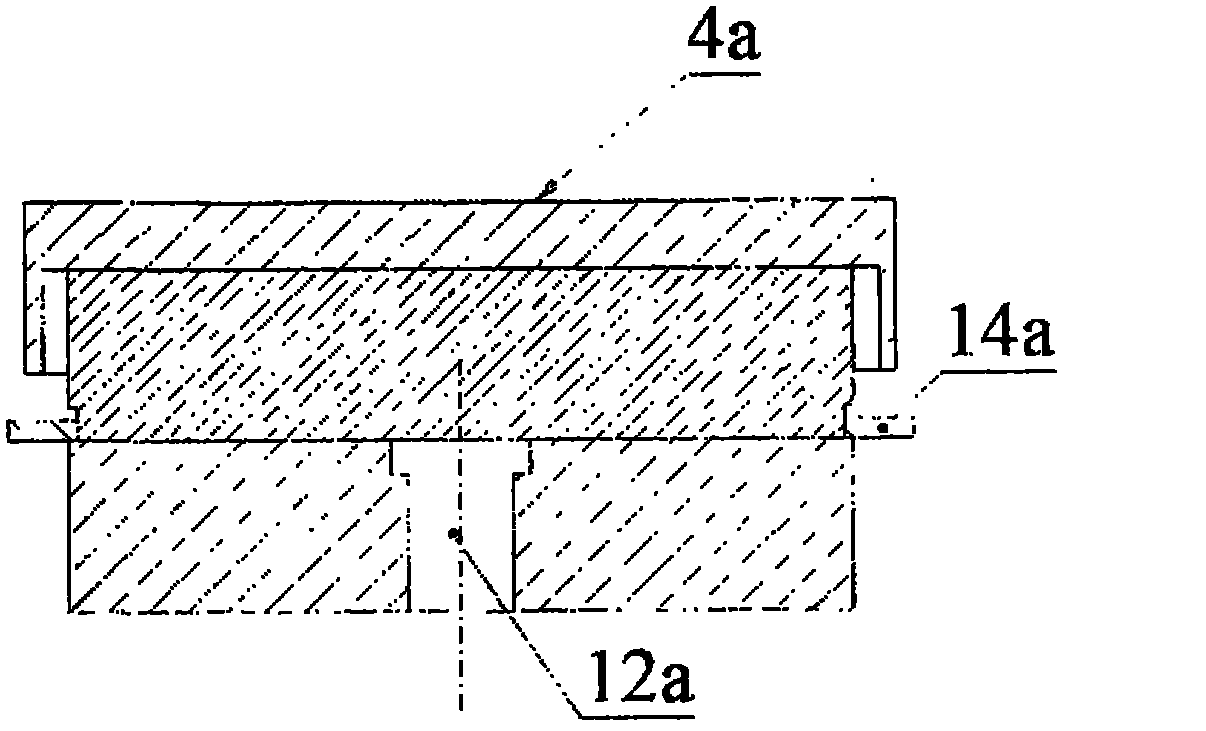

[0025] The present invention will be further described in detail below in conjunction with the drawings:

[0026] A double-workpiece table rotation exchange method based on the synchronous direction adjustment of the turntable gears, the method includes the following steps:

[0027] The initial working state of the system is that the pre-alignment of the second workpiece stage of the pretreatment station is completed, and the first workpiece stage of the exposure station completes the exposure work;

[0028] In the first step, the first workpiece stage after exposure is driven by the Y-direction long-stroke linear motion unit and the X-direction first long-stroke motion unit to the predetermined position for the stage change, and then the first shaft connection device installed on the return stage device is lifted. And connect with the rotation axis of the first work table at the bottom of the first work table. At the same time, the second shaft connection device is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com