Double workpiece stage rotary exchange device based on synchronous gear direction adjustment

A technology of double workpiece table and synchronous gear, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of shortening the balance time, small moment of inertia, loss of laser interferometer target, etc., and achieves improved photolithography The effect of improving machine productivity, improving operating efficiency, and shortening the balance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

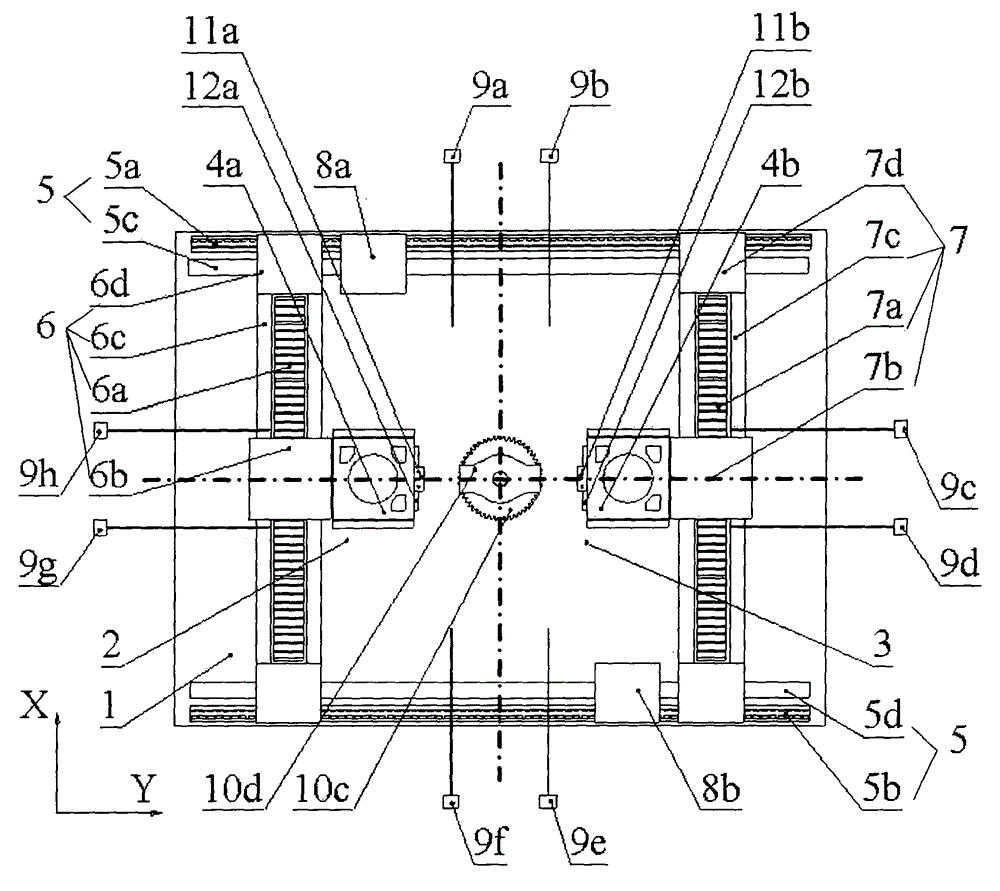

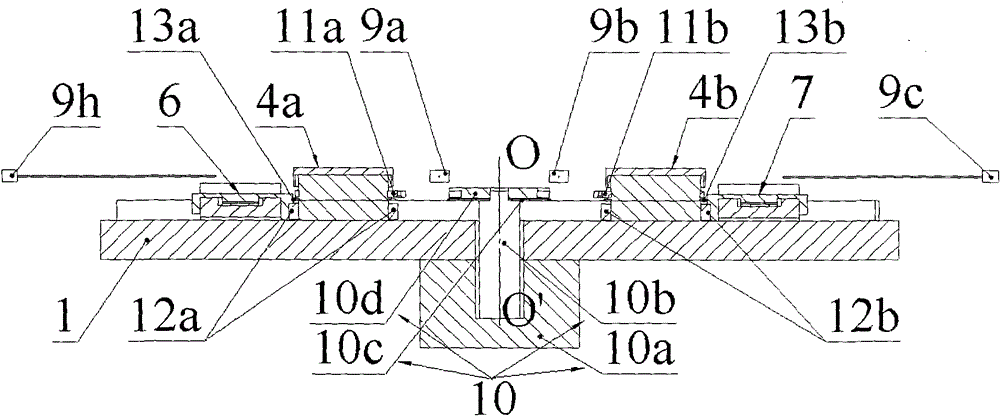

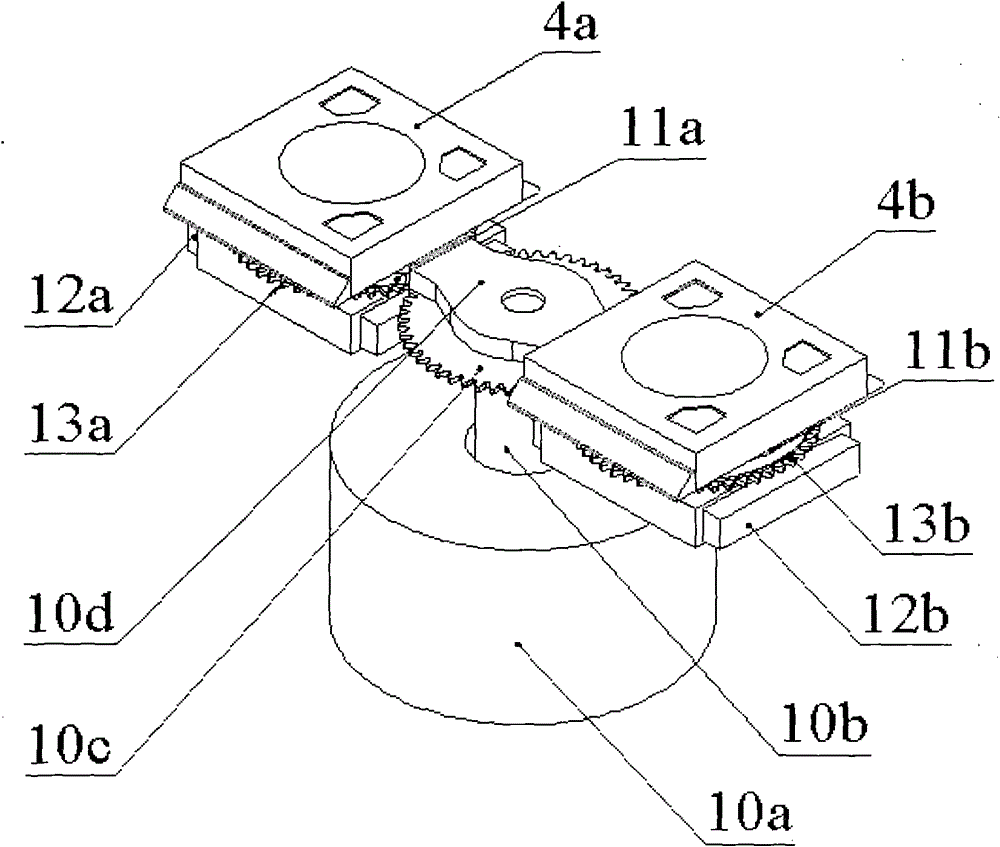

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] A dual-workpiece rotary exchange device based on synchronous gear direction adjustment. The exposure station 2 and the pretreatment station 3 are set at both ends of the base 1 in the Y direction, and the Y positions are respectively set along the long sides of the base 1. To the long-stroke linear motion unit 5, the X-direction first long-stroke linear motion unit 6 and the X-direction second long-stroke linear motion unit 7 are respectively arranged on the exposure station 2 and the pretreatment station 3, and the first workpiece table 4a and The second workpiece table 4b is detachably fitted on the X-direction first long-stroke linear motion unit 6 and the X-direction second long-stroke linear motion unit 7, and the X-direction first long-stroke linear motion unit 6 and the X-direction second long-stroke linear motion unit The long-stroke linear motion unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com