Patents

Literature

124results about How to "Soften fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of whole wheat flour

The invention relates to a production method of whole wheat flour, solving the problems that wheat bran is difficult to crash, deficient in nutrient component utilization and shorter in shelf life. The production method of the whole wheat flour comprises the following steps: clearing wheat material, removing impurities in the wheat material, then rinsing to obtain wheat grains, carrying out heat treatment for sterilizing, killing enzyme and drying, and then crashing the wheat grains, wherein various known treating methods, such as a microwave heating method or a hot-air drying method can be adopted in the heat treatment method. As the optimal schemes, the water content of the rinsed wheat grains is 15-20 percent, and the water content of the wheat grains subject to heat treatment is below 14 percent. The invention has the advantages that: (1) the process flows are shortened; (2) the quality of the wheat bran is ensured by the rapid heat-moisture treatment, the shelf life is prolonged, and the problem that the wheat bran is difficult to crash is also solved; (3) the nutritional components in the whole wheat flour are stabilized, and the nutritional value of the product is improved.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

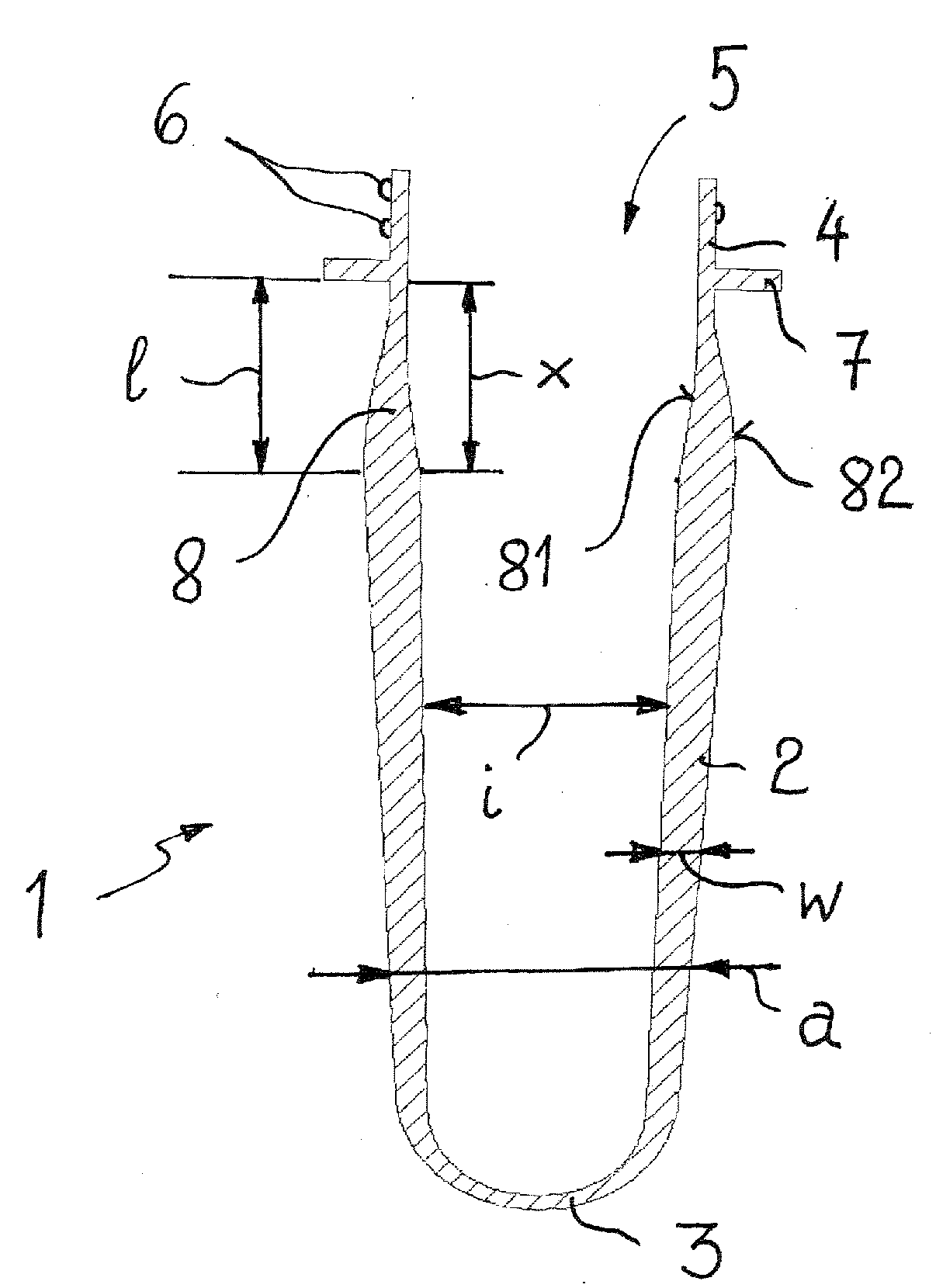

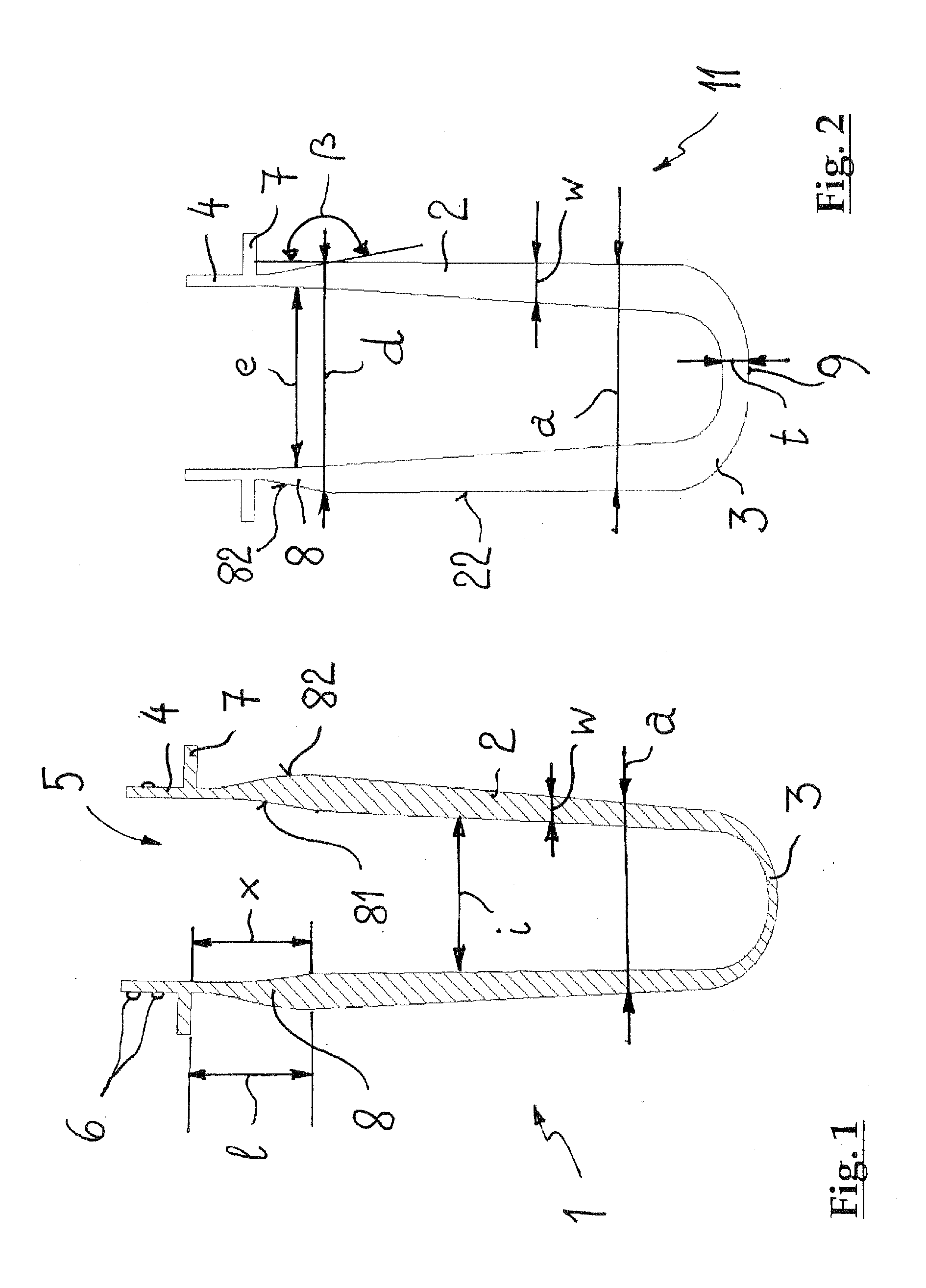

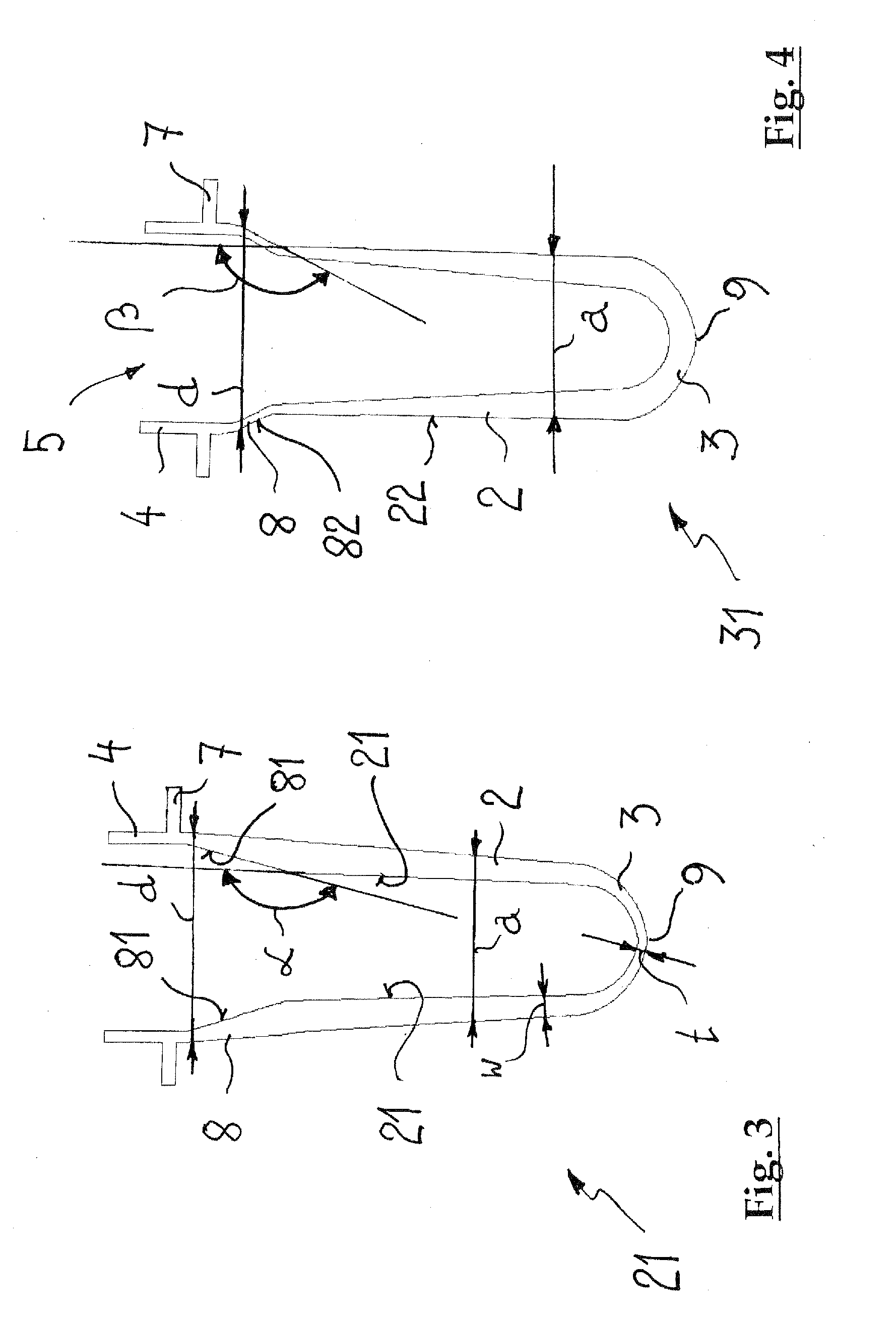

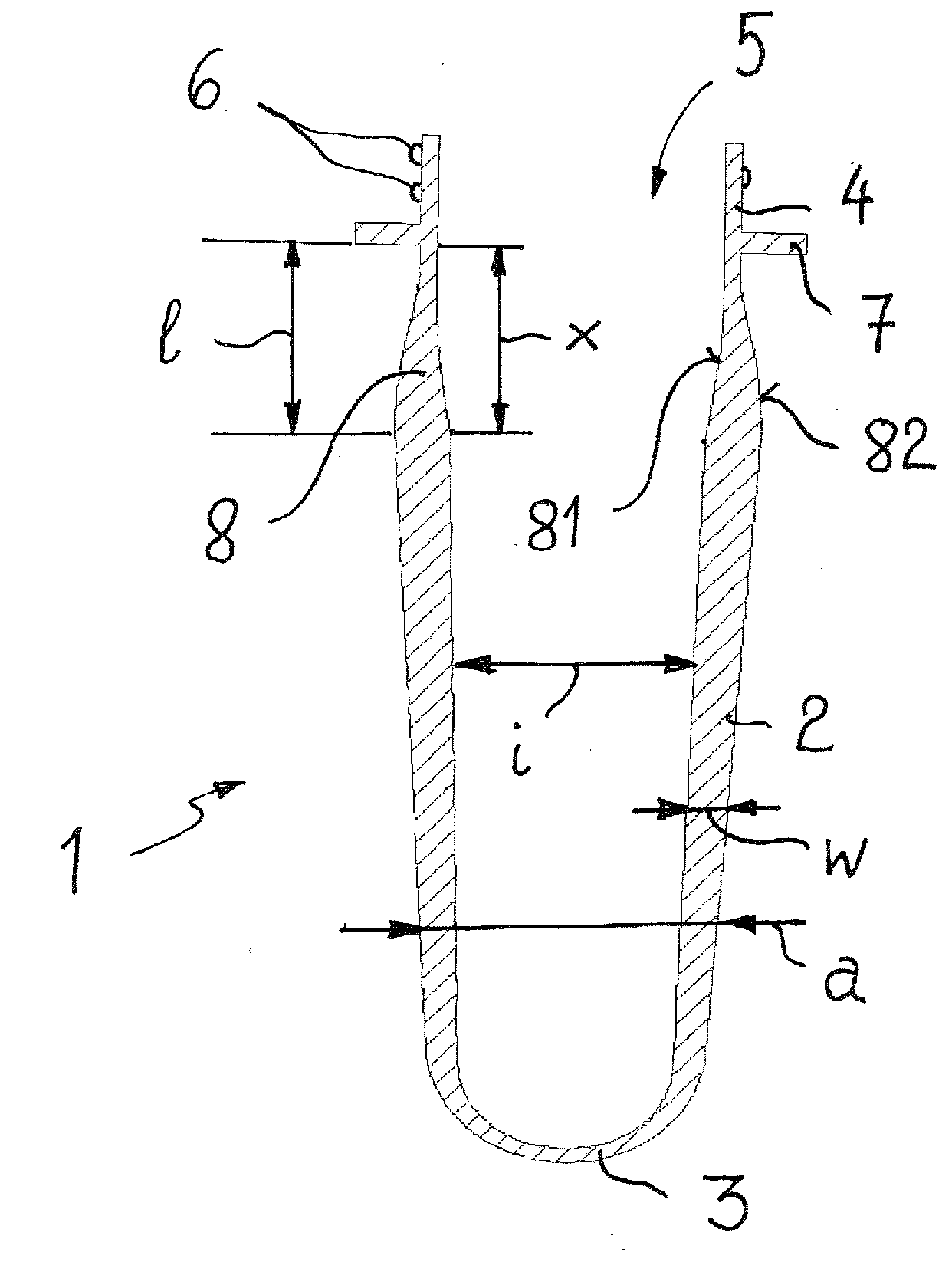

Preform for plastics material bottles or wide-necked vessels

InactiveUS20100304168A1High pressureHigh mechanical strengthBottlesContainer/bottle contructionEngineeringPlastic materials

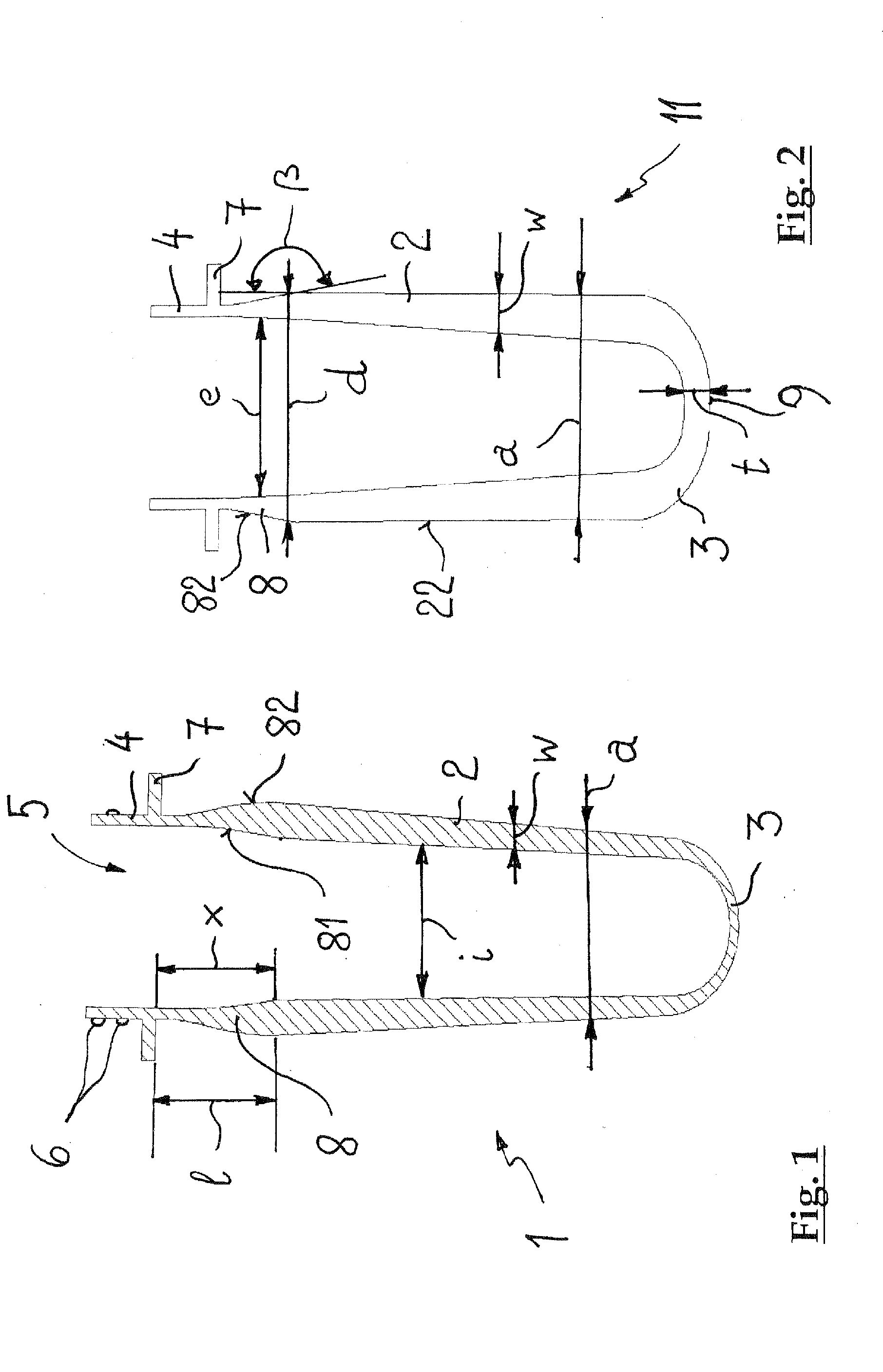

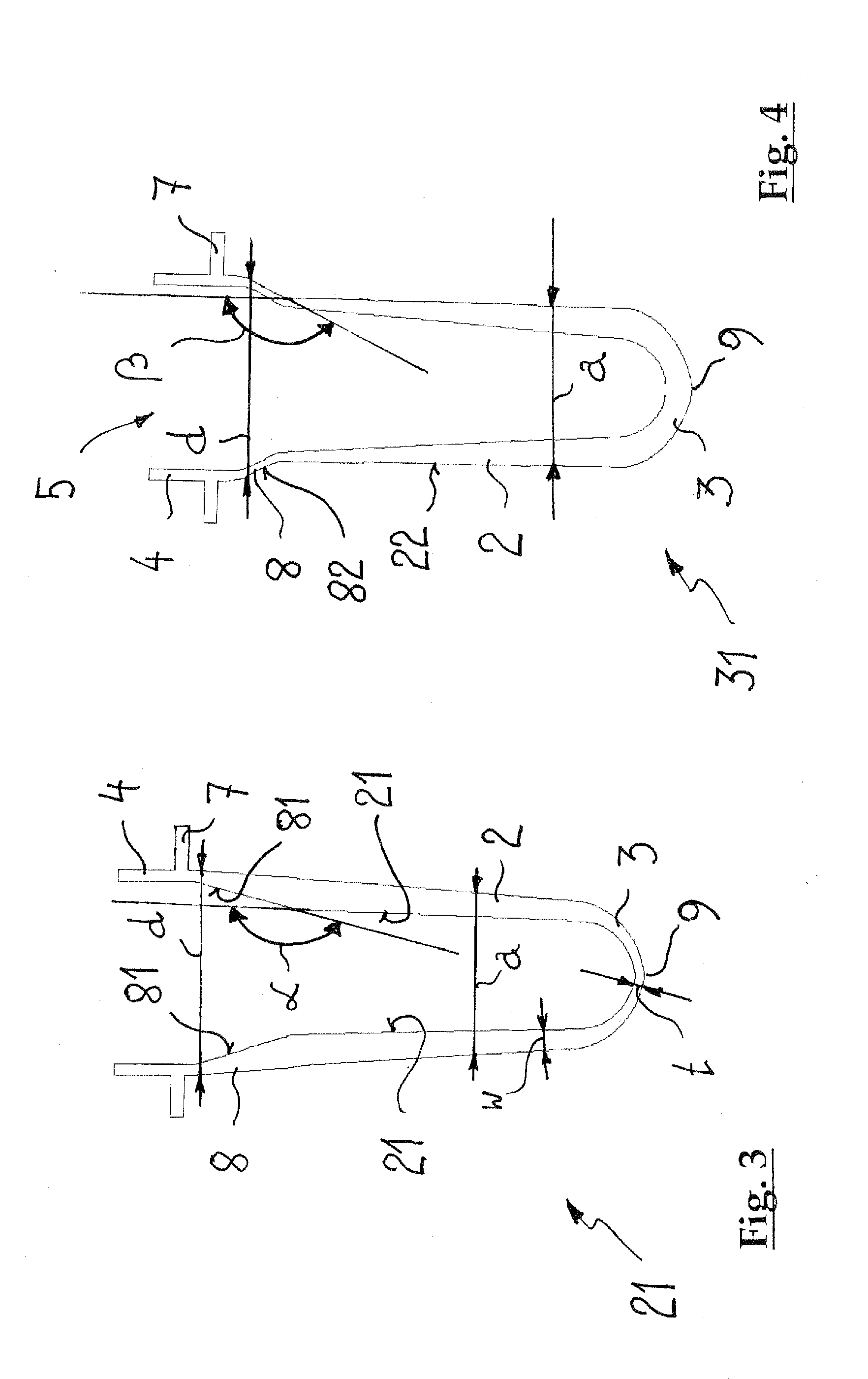

A preform for manufacturing plastics material bottles or wide-necked vessels is described, having a rigid, substantially elongate, frustoconical body portion that is closed at one of its longitudinal ends by a dome-shaped end portion and at its opposite longitudinal end adjoins via a preform collar a neck portion provided with a pouring opening. The preform possesses in the body portion an external diameter that is reduced from the preform collar to the end portion. The body portion has a wall thickness which changes over its longitudinal extension substantially constantly by up to +2 mm. For this purpose, it possesses an internal diameter which decreases substantially constantly from a transition to the preform collar up to a transition to the dome-shaped end portion.

Owner:ALPLA WERKE ALWIN LEHNER

Preform for plastics material bottles or wide-necked vessels

InactiveUS20100304169A1Improve thermal stabilityIncrease pressureBottlesContainer/bottle contructionPlastic materialsEngineering

Owner:ALPLA WERKE ALWIN LEHNER

Method of making soft ice cream on a commercial scale

Pouring soft state ice cream as a precursor of hard state ice cream into a cone, cup or other shape made either one of paper, plastic resins or edible material and the thus poured ice cream is frozen to a hard state ice cream of -30 DEG C. to -40 DEG C. as it stands or wrapped within a plastic film and is held at -15 DEG C. to -25 DEG C., and the thus held ice cream is heated rapidly upto 0 DEG C. to -8 DEG C. by an electronic range upon request of a customer to be given to the customer without being touched by a person other than the customer so that it is held under very sanitary conditions.

Owner:ITO SADAHARU

Electrostatic image forming toner and developer

InactiveUS20130196263A1Soften fastMaintain good propertiesDevelopersPolyester resinPolymer chemistry

An electrostatic image forming toner including: toner base particles each containing at least a colorant, a binder resin, and a releasing agent, wherein the binder resin contains a non-crystalline polyester resin A and a crystalline polyester resin B, wherein a ratio of B / (A+B)×100 is 10 or more but less than 50 where (A+B) is a total mass of the non-crystalline polyester resin A and the crystalline polyester resin B and “B” is a mass of the crystalline polyester resin B, and wherein the toner base particles have a TMA compression deformation amount (TMA %) of 10% or less which is measured at 50° C. and a relative humidity of 90%.

Owner:RICOH KK

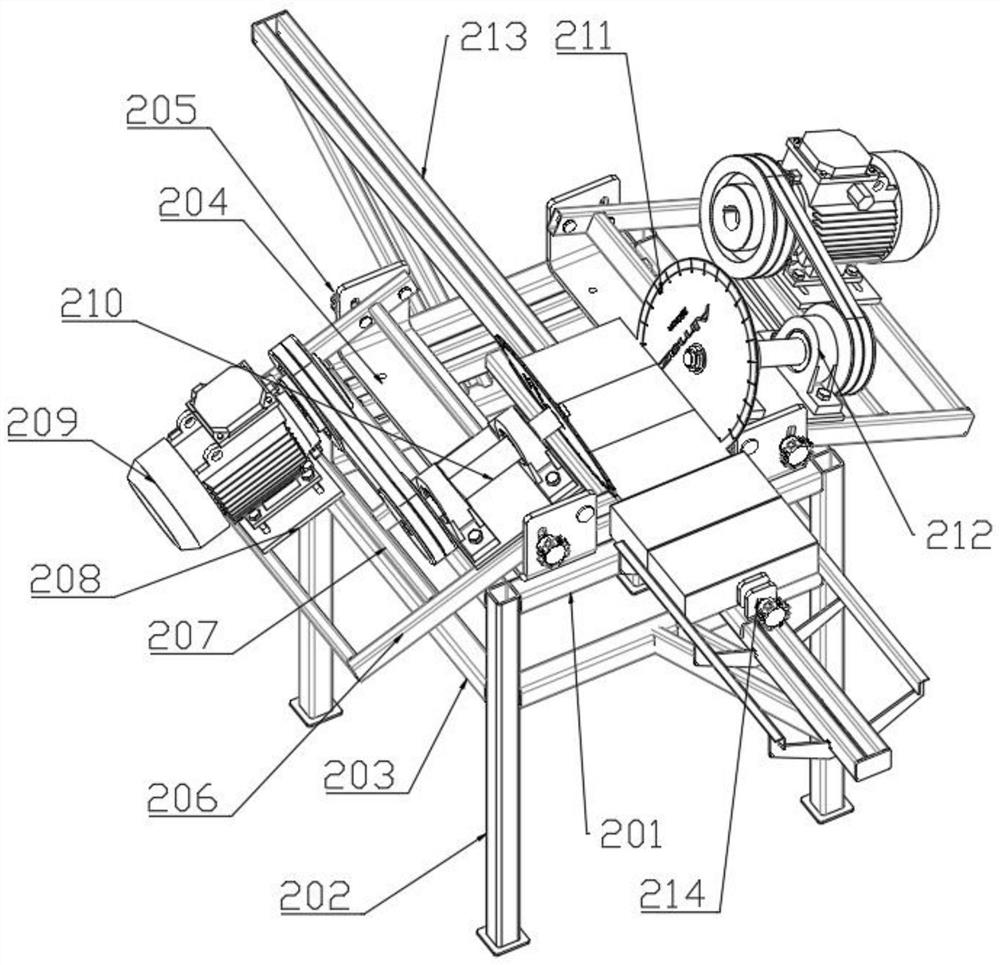

In-situ composting method and device of crop straws

InactiveCN102050646APromote degradationEasy to killBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringPulp and paper industry

The invention relates to an in-situ composting method and device of crop straws, belonging to the research field of agricultural environment protection. The method comprises the following steps: grinding harvested straws in an improved straw grinder or kneading in a straw kneader; adding calcium superphosphate, magnesium sulfate or urea based on the weight percent of the straws; composting and fermenting at high temperature; and turning until the temperature rises to above 65 DEG C. Feeding equipment is added at the front end of the grinding device of the grinder, so that the grinder can adapt to feed, crush and grind creeper or thick-stem vegetable residuals, thus reducing nitrogen losses, thoroughly eliminating pathogenic organisms carried by the straws in the process of composting the vegetable straws, and greatly quickening warming, softening and decomposing processes of the straws. The key technology and the device are provided for effectively treating and utilizing the straws in time, thus providing technological support for forbidding firing and discarding the straws and recycling the straws.

Owner:JIANGSU ACAD OF AGRI SCI

Straw rubbing process

The invention provides a straw rubbing process, which comprises the following operating steps: 1) carding raw material straws, removing sundries, such as broken pieces and the like, and cutting fringe pulling ends away; 2) rolling the straws with a continuous roll squeezer; 3) softening the straws with vapor; 4) drying the straws and controlling water content; 5) rubbing the straws with a straw rubbing machine to obtain straw threads and removing dust during the rubbing process; and 6) screening the straw threads to extract the straw threads with lengths not less than 5cm and diameters of 1 to 3mm. The process has the advantages of simple operation, easy implementation, low cost, high efficiency, no pollution to the environment, relatively longer silky fibers and high mechanical strength, and is mainly used for manufacturing products, such as a vegetation carpet, a green pad and the like.

Owner:SICHUAN UNIV

Zirconium corundum heavy load strong abrasive band

ActiveCN101134300AImprove toughnessImprove grinding effectAbrasion apparatusHeavy loadMaterials science

The present invention relates to abrasive belt, and is especially one kind of powerful zirconia corundum supported abrasive belt comprising cloth base, adhesive and grinding material zirconia corundum adhered onto the cloth base. It features the adhesive comprising thermosetting phonetic resin 28-36 wt%, diphenol propane type epoxy resin 4-8 wt%, melamine resin 1-4 wt%, boron 0.2-0.6 wt%, dispersant 0.1-0.3 wt%, coupling agent 0.1-0.3 wt%, diluent 3-6 wt%, fluoride salt 45-60 wt%, fluoride of inert gas 0.5-1 wt%. The abrasive belt has high heat resistance high adhesion strength at high temperature, capacity of softening metal surface and lowering surface hardness, no damage to metal surface and high grinding efficiency.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

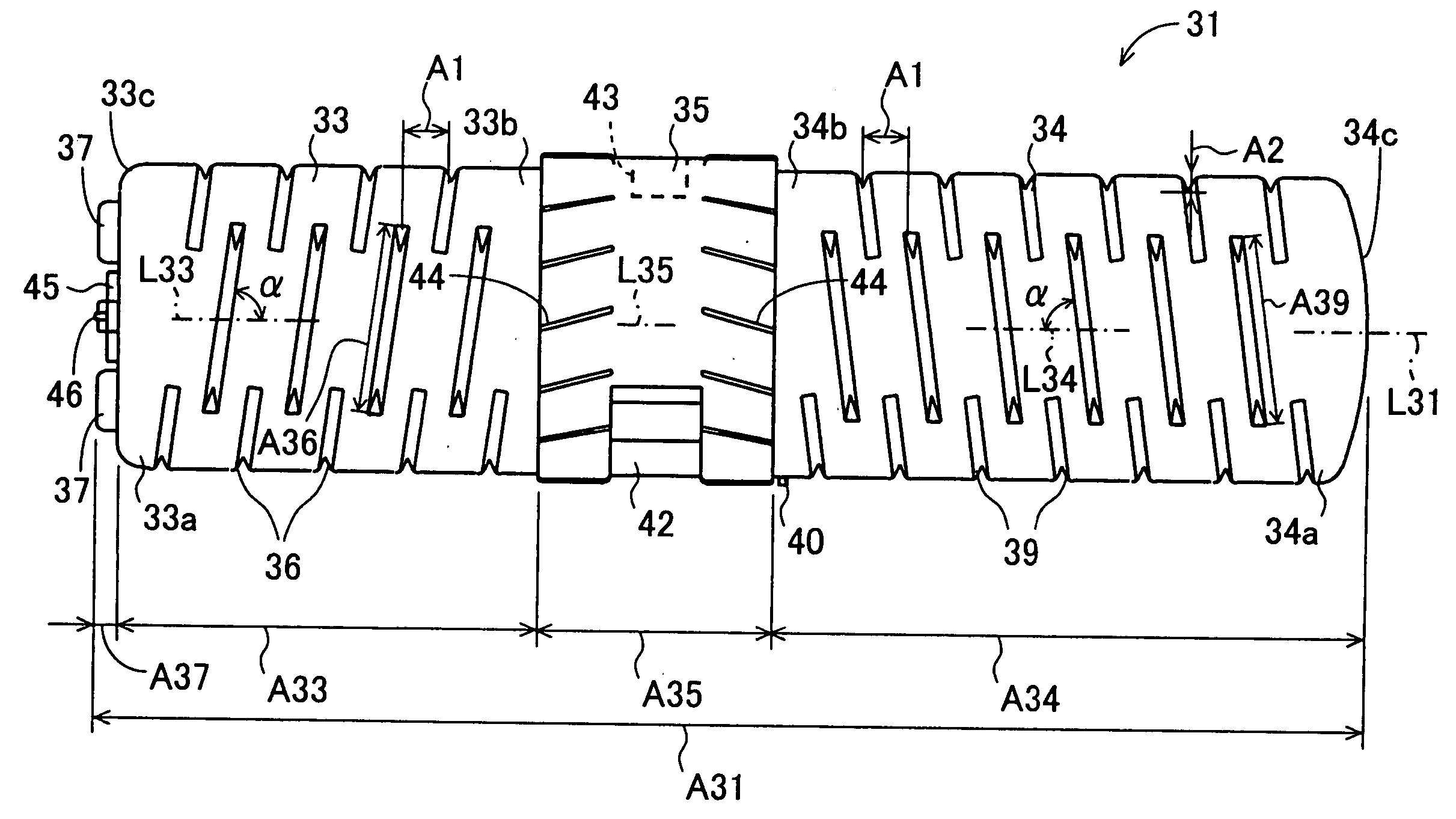

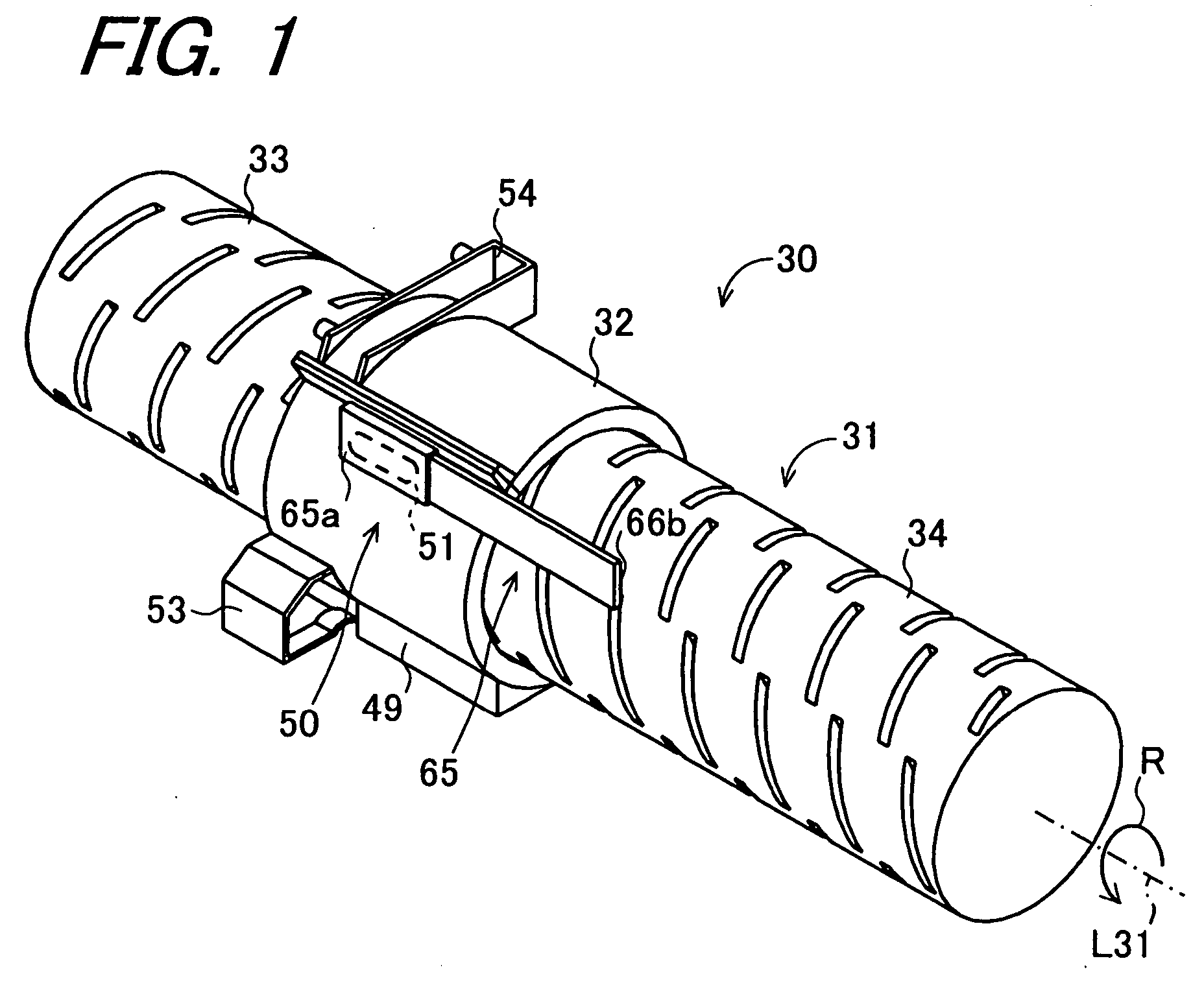

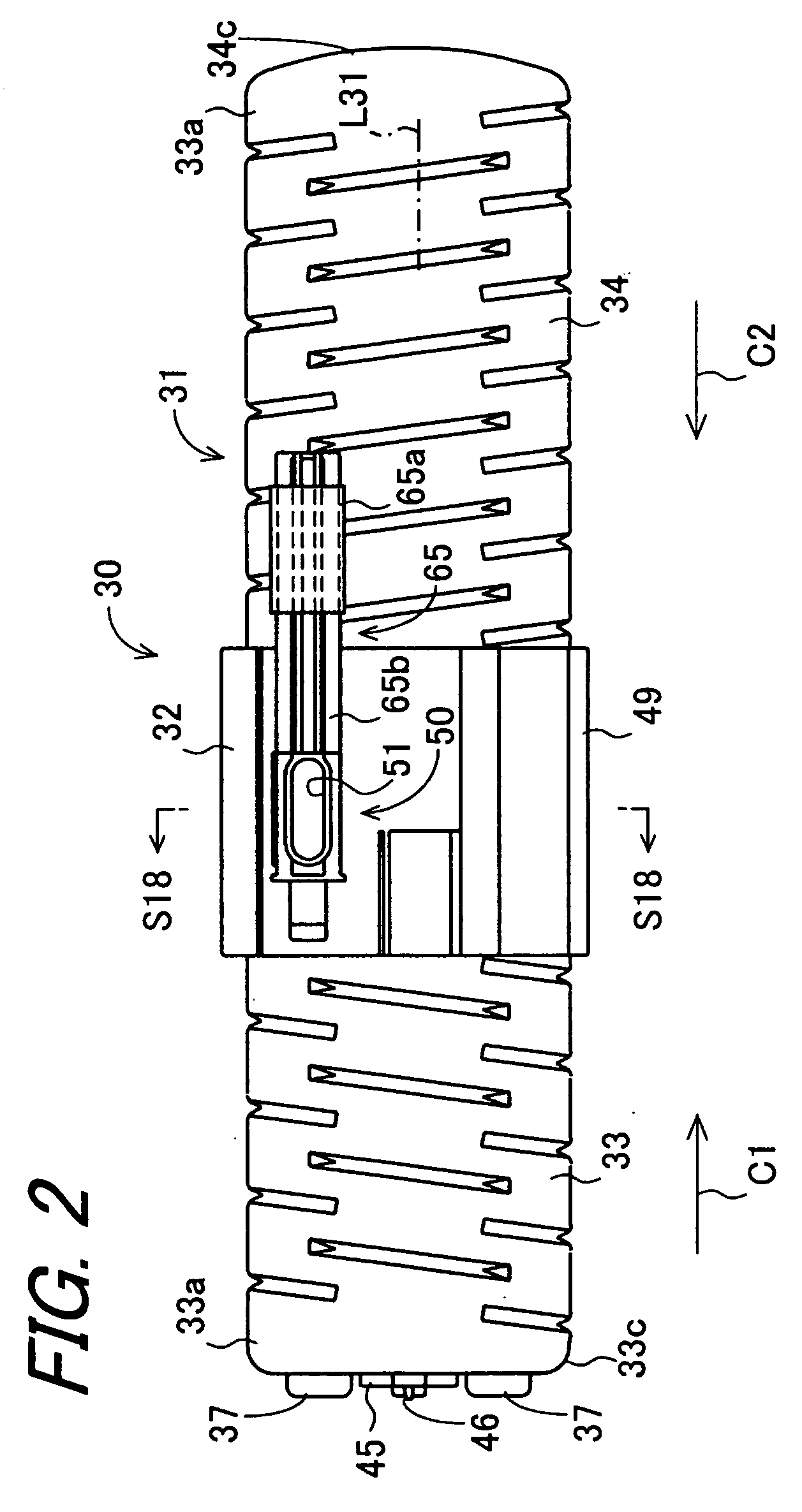

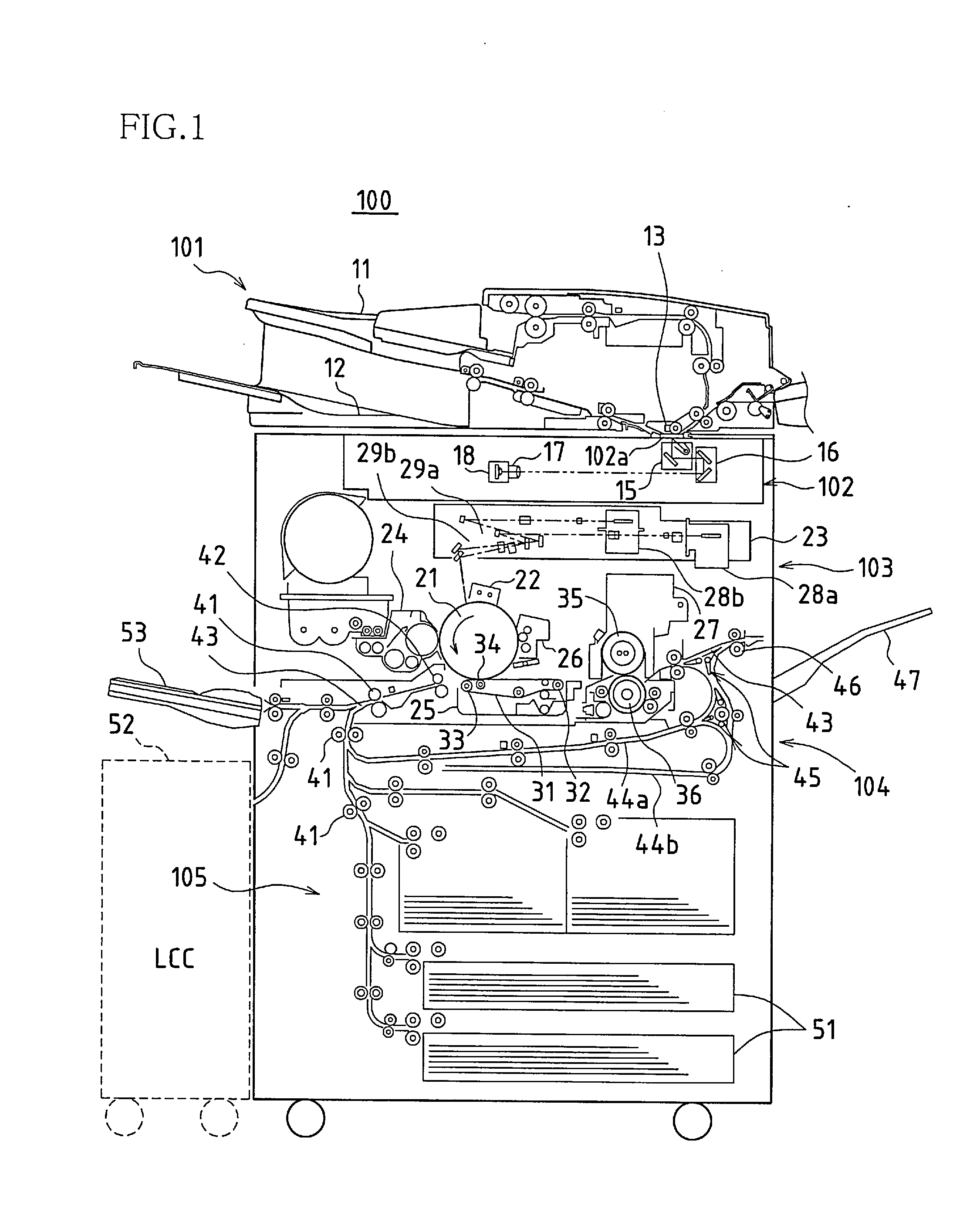

Developer container and image forming apparatus

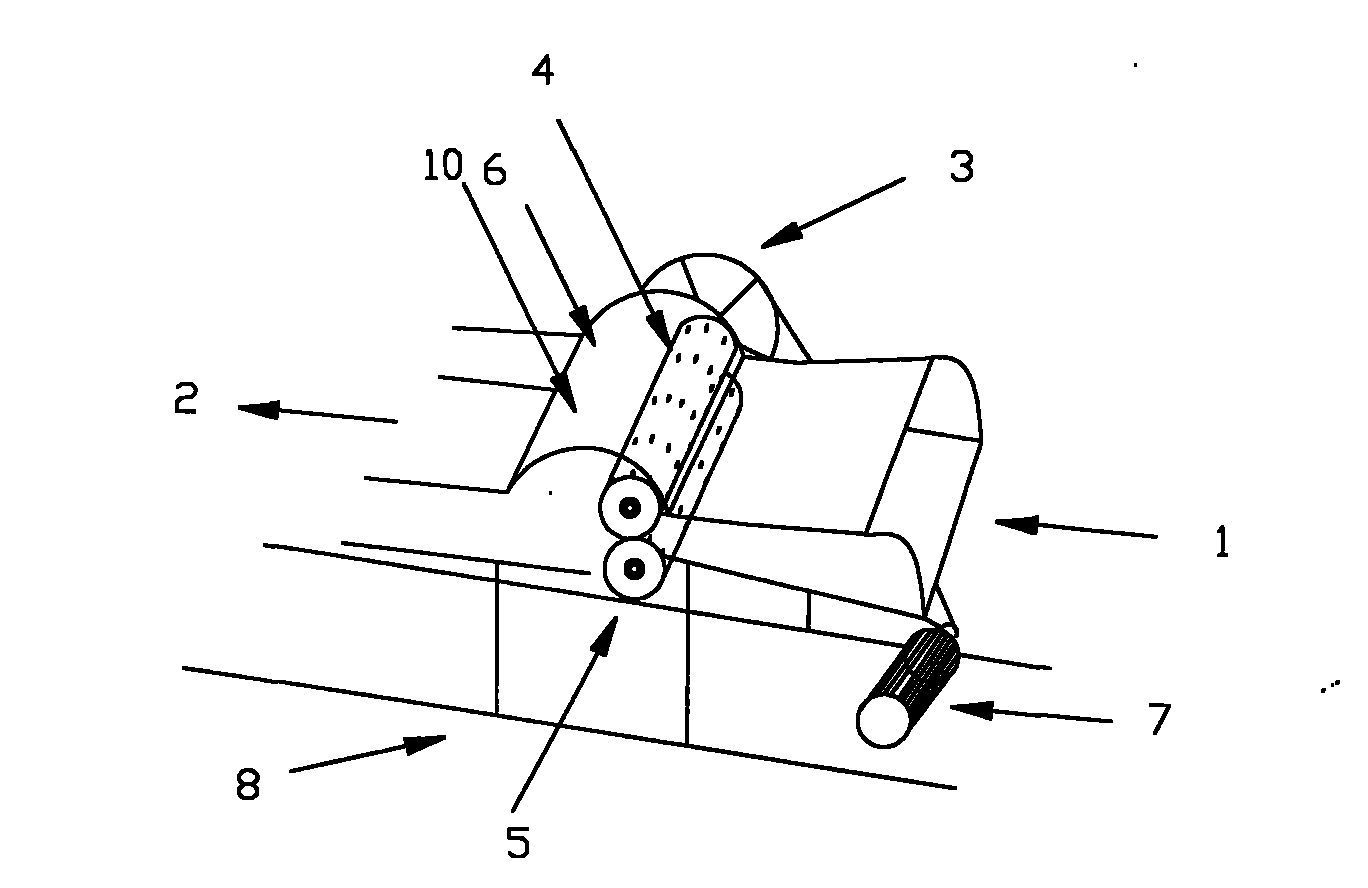

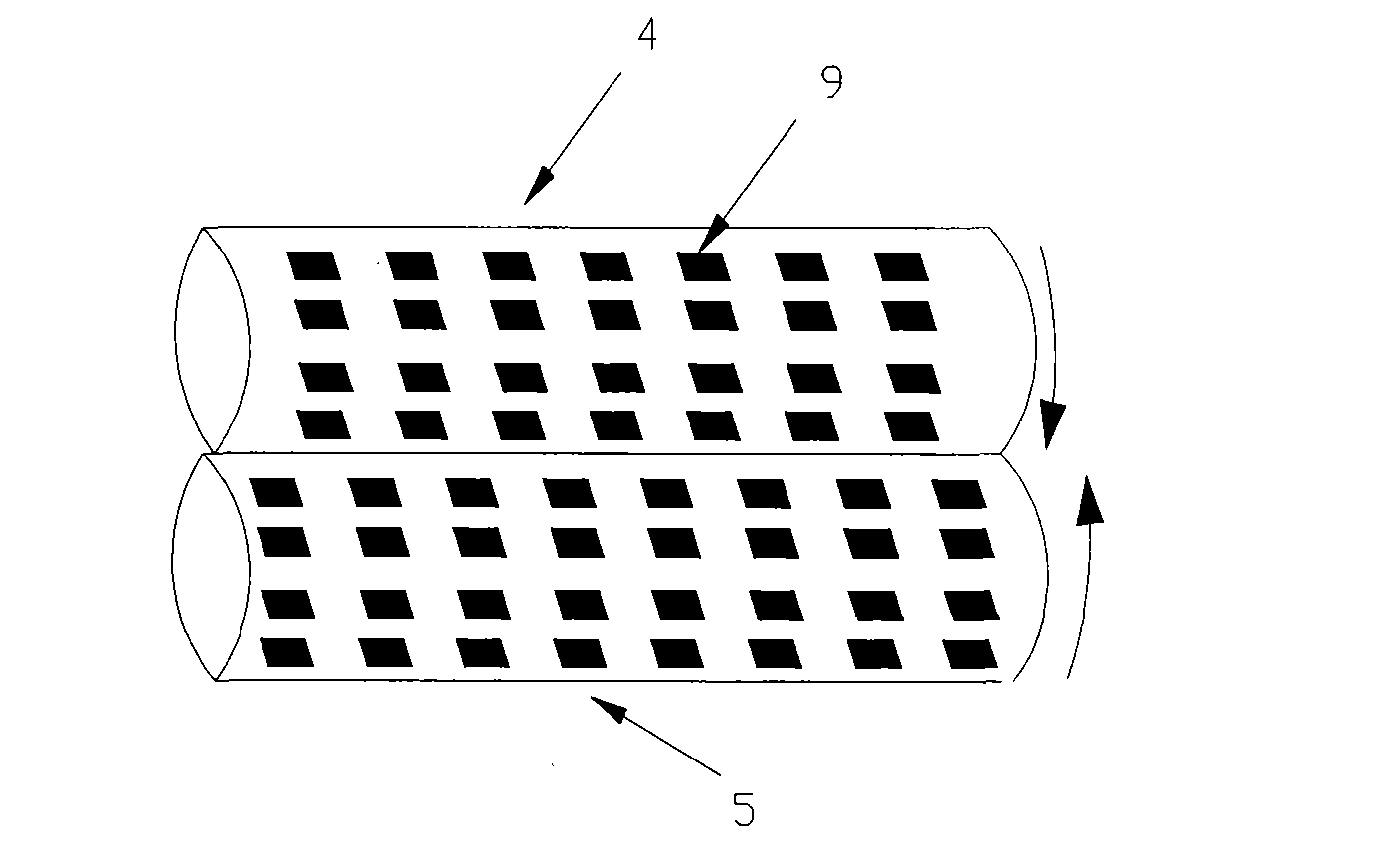

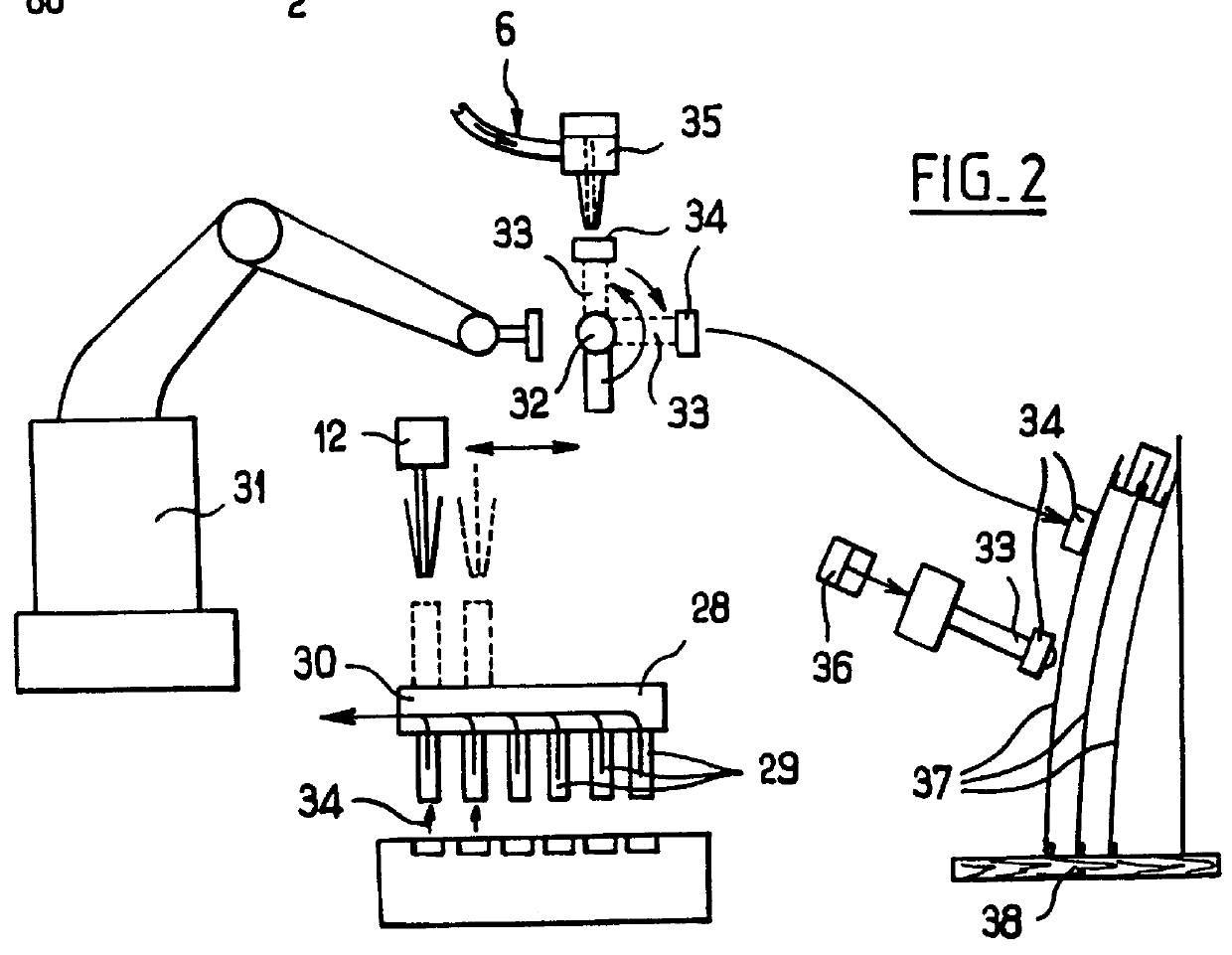

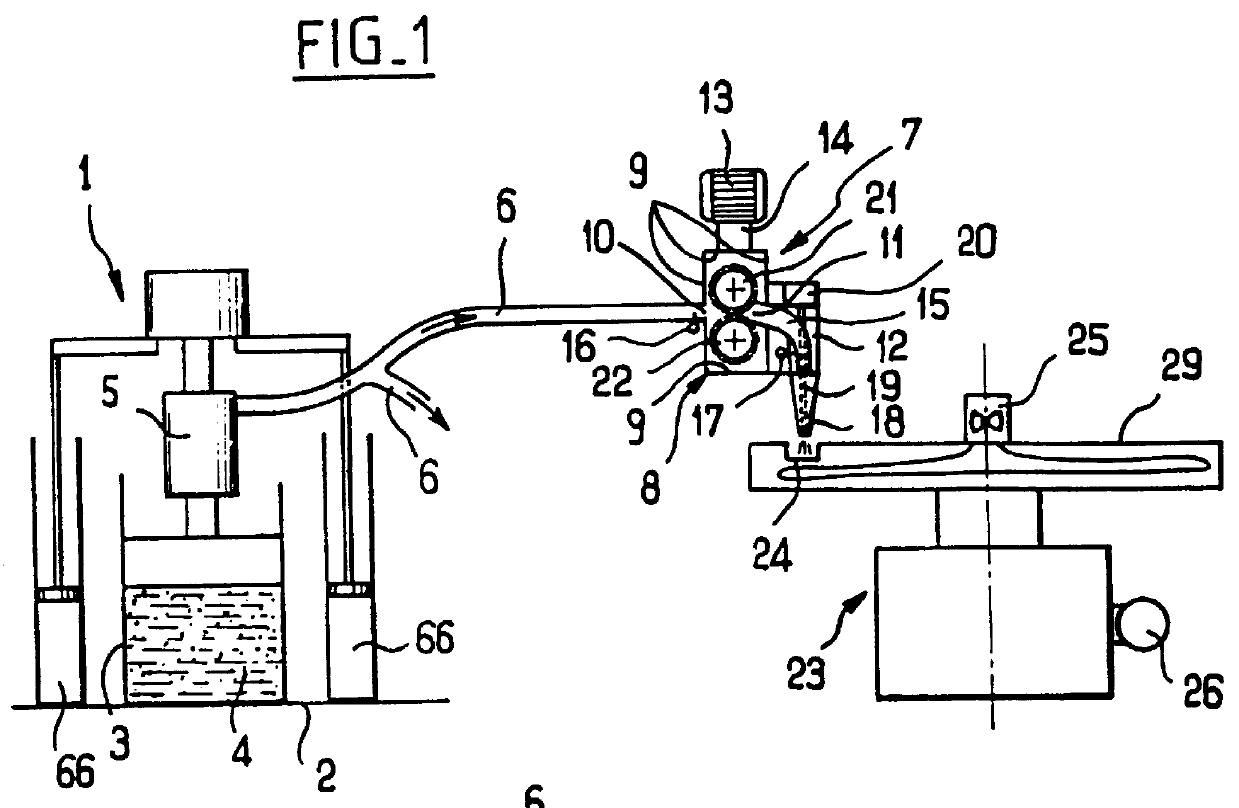

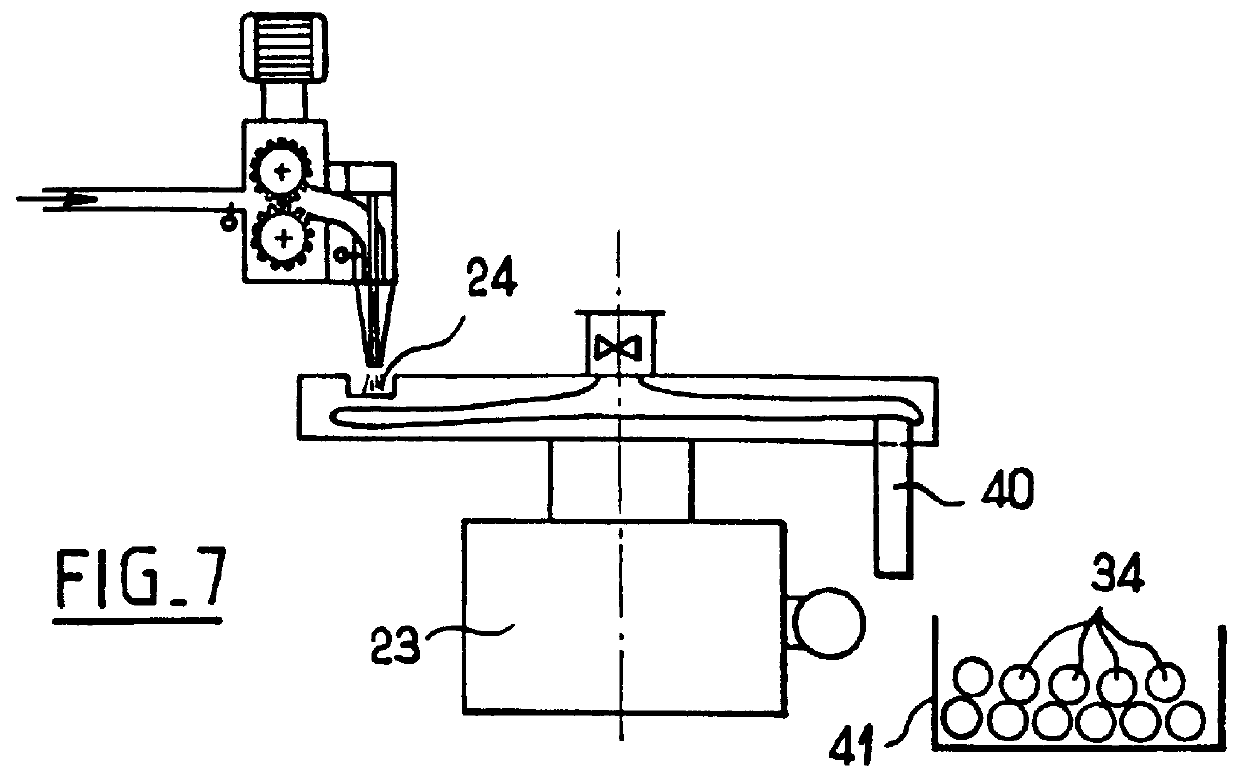

InactiveUS20060147228A1Prevent coagulationSoften fastPowdered material dispensingElectrographic process apparatusImage formationEngineering

An object of the invention is to provide a developer container in which a container main body is protected against damage by an external torsional and bending force and an impact as much as possible, developer in the vicinity of conveying means is prevented from aggregating as much as possible, and developer in the vicinity of a discharge hole is prevented from aggregating as much as possible. The developer container includes a cylindrical container main body (31) for containing developer for use in image formation, and is detachably mounted on an image forming apparatus, the container main body (31) being rotated about an axis thereof by drive means provided in the image forming apparatus to supply developer to the image forming apparatus, wherein conveying means for conveying the developer in an axial direction when the container main body is rotated about the axis is provided in an inner circumferential portion of the container main body (31), and the conveying means has a plurality of first and second protrusions (36, 39) extending in first and second extending directions and arranged at intervals in a circumferential direction and the axial direction.

Owner:SHARP KK

Manufacturing method of remaking light-colored bamboo for outdoors

ActiveCN110744671AReduce soak softening timeAvoid damageNon-macromolecular adhesive additivesWood treatment detailsCelluloseMaterials science

The invention discloses a manufacturing method of remaking light-colored bamboo for outdoors. By softening, rolling and combing the bamboo, the bamboo is prepared into bamboo fiber bundles , impregnation gluing is carried out in a modified phenolic resin adhesive, after the sizing bamboo fiber bundles are uniformly paved into slabs, the bamboo fiber bundles are fed into a hot press for hot press molding. A bamboo chip softening solution is set to a multi-step implementation softening solution, the soaking softening time of a conventional acid solution or a conventional alkali liquor is reduced, by occurring an acylation reaction of glacial acetic acid, dicyclohexylcarbodiimide and maleic anhydride in a cooperating mode, saccharides, starch and protein can be rapidly decomposed by the acylation reaction on one hand, the damage to a cellulose microstructure is reduced and the breakage of a molecular bond of lignin is reduced, the reaction process of the acylation reaction is mild, the color of the fiber bundles is not deepened, the rinsing process is reduced, the bonding performance of the bamboo fiber bundles and the phenolic resin is increased by modifying the phenolic resin adhesive, and the overall mechanical property of a composite plate is increased by adding filler.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Crease removing and flattening device for plastic film

The invention discloses a plastic film wrinkle-removing and flattening device, which comprises a bottom plate, a side plate and a top plate, a film rolling wheel with a plastic film is installed on a placing frame, a horizontal shaft is arranged on the mounting frame, and a horizontal shaft is arranged on the horizontal shaft. There is a roller, the side wall of the roller is provided with a plurality of heating pipes arranged in a ring, the lower end of the lifting hydraulic cylinder is provided with a hydraulic rod, the lower end of the hydraulic rod is fixedly connected with a horizontal plate, and the two sides of the lower end of the horizontal plate are provided with Vertical side plates, a shell is arranged between the two vertical side plates, a plurality of pressure rollers arranged in a ring are arranged inside the shell, the top of the shell is connected with the lower end surface of the horizontal plate through a compression spring, and both ends of the shell are provided with A fixed rod, one end of the fixed rod is connected to the side of the vertical side plate through a sliding mechanism. The invention has simple structure, high plastic film wrinkle removal efficiency, can remove wrinkles and flatten plastic films with different thicknesses, improves the smoothness of the plastic film, is easy to operate, and has strong practicability.

Owner:刘小华

Processing method of insect-resistant cotton seeds before sowing

InactiveCN105052295AImprove the bactericidal effectSoften fastBiocidePlant growth regulatorsGramSoftening

The invention discloses a processing method of insect-resistant cotton seeds before sowing. The method comprises the following steps: (1) collecting matured insect-resistant cotton seeds, drying the cotton seeds under the scorching sun in the sunny day for 2 to 3 days, then storing the cotton seeds in a warehouse, and controlling the temperature of the warehouse in a range of 9 to 12 DEG C and the relative humidity in a range of 65 to 70%; (2) taking out the insect-resistant cotton seeds one or two days before sowing, and filling 45 to 50 grams of cotton seeds into a gauze bag to produce seed bags; (3) soaking the seed bags into magnetized water for 6 to 8 hours, then taking out the seed bags to drain the water, then subjecting the seed bags to a softening and sterilization treatment, soaking the dried seed bags into a processing liquid for 12 to 18 hours, then washing the seed bags by clean water, drying in the sun, storing the seed bags in a warehouse for later use, and controlling the temperate of the warehouse in a range of 9 to 12 DEG C and the relative humidity in a range of 65 to 70%, wherein the storage time cannot exceed 48 hours. The provided method is simple, the actual operation is convenient, the provided processing liquid can kill the bacteria in a short time and can also soften the seeds, thus the seed germination will not influenced by the bacteria, and at the same time, the seed germination is promoted in a proper environment.

Owner:CHAOHU XINYU BREEDING FARMER PROFESSIONAL COOP

Bending forming process for V-shaped groove wood veneer

ActiveCN113103393AEasy to handleEasy to transportEdge grinding machinesWood treatment detailsWood veneerPulp and paper industry

The invention discloses a bending forming process for a V-shaped groove wood veneer, and relates to the technical field of basic processes. The method comprises the following steps that firstly, wood is processed, and processed wood is placed on a log cutting machine to be processed; secondly, wood slicing is conducted, specifically, the processed wood is placed on a slicing machine to be processed and sliced; thirdly, burr cleaning is conducted, specifically, the sliced wood is placed on a grinding machine to be processed and ground; fourthly, wood board cutting is conducted, specifically, the processed wood board is placed on a multi-functional wood planer, and the wood board is cut into sections and roughly planed through the multi-functional wood planer; and fifthly, polishing and grinding are conducted, specifically, the wood board obtained after section cutting is polished and ground, and the wood veneer is formed by the wood board. Through the arrangement of the log cutting machine, the unprocessed wood can be processed, and subsequent treatment of the device on the wood is facilitated.

Owner:DONGGUAN ZHONGJIN FURNITURE CO LTD

Seed treating agent capable of shortening germination time of insect-resistant cotton seeds

InactiveCN105076266AImprove the bactericidal effectSoften fastBiocidePlant growth regulatorsNeutral proteasePolydextrose

The invention provides a seed treating agent capable of shortening germination time of insect-resistant cotton seeds. The seed treating agent is prepared from, by weight, 90-110 parts of spring water, 1.5-2.5 parts of tea saponin, 1-2 parts of purple sweet potato anthocyanin, 1-2 parts of compound sodium nitrophenolate, 1.5-2.5 parts of table salt, 4-6 parts of alanine, 3-5 parts of monopotassium phosphate, 1.5-2.5 parts of highland barley wine, 1.5-2.5 parts of alga micro-powder, 1-2 parts of portulaca oleracea extract, 1.5-2.5 parts of armoise commune ash, 0.4-0.6 part of polydextrose, 0.4-0.6 part of glyceryl behenate, 1-2 parts of witch hazel extract, 0.4-0.6 part of neutral protease, 1.5-2.5 parts of amylodextrin, 1-2 parts of garlic extract, 1.5-2.5 parts of gibberellin, 0.4-0.6 part of potassium permanganate and 0.4-0.6 part of potassium sorbate. A method is simple, actual operation is convenient, the treating fluid capable of shortening germination time has the effects of quick sterilization and seed softening within short time, the influences of bacteria and the like on seed germination are avoided, and meanwhile the seeds can be stimulated to quickly germinate in proper environments.

Owner:CHAOHU XINYU BREEDING FARMER PROFESSIONAL COOP

Seed replication method of lespdeza virgata

InactiveCN101213913ASprout fastPreprocessing time saves labor and timeSeed and root treatmentFertilising methodsSowingLespedeza virgata

The prevent invention discloses a reproduction method for the seed of the Lespedeza virgata, the steps of which are that: firstly, the fruit spur, which does not reach full maturity, of the Lespedeza virgata is picked to be kept cool and to be adequately matured, and after the seed reaches full maturity and turns chocolate brown, the seed is collected; secondly, the seed coat is softened and bony-oriented in the hot water at the temperature of 80 DEG C, so that the seed can be inflated and activated rapidly; thirdly, the seed shall be mixed with the dry sand in a given ratio for sowing; fourthly, the seed is covered with mulch film for the culture of seedling, so that the emergence of seedlings can be rapid and orderly. The method of the present invention is not only convenient to operate, but also saves labor and time; through controlling the picking time of the seed, performing the later-maturity processing for the seed and pre-processing the seed with hot water, the sprouting rate reaches more than 86 percent and the seedling rate reaches more than 95 percent.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

Preparation method of acellular dermal matrix material

InactiveCN109364298AClean up thoroughlyLow toxicityTissue regenerationProsthesisAntigenSplit skin graft

The invention discloses a preparation method of an acellular dermal matrix material. The preparation method of the acellular dermal matrix material is characterized in that removing flesh and hair from an animal skin, then taking a split-skin graft, and carrying out defatting, unhairing, inactivation of virus, cell extraction, crosslinking modification, cleaning and moisturizing, packing and irradiation sterilization processes to obtain the acellular dermal matrix material. The preparation method of the acellular dermal matrix material has the characteristics that the process time is short, aneffect of removing antigen substances is good, and the material has quite good adhering property, moisture retention property, breathability and the like.

Owner:JIANGYIN BENXIANG BIOTECHOLOGY

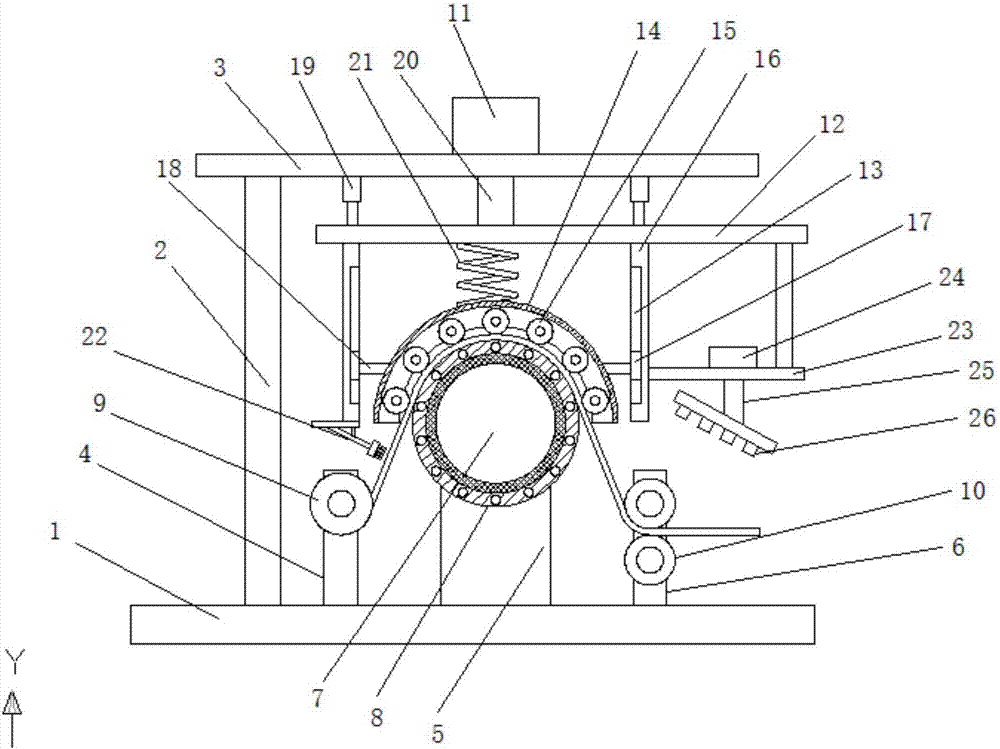

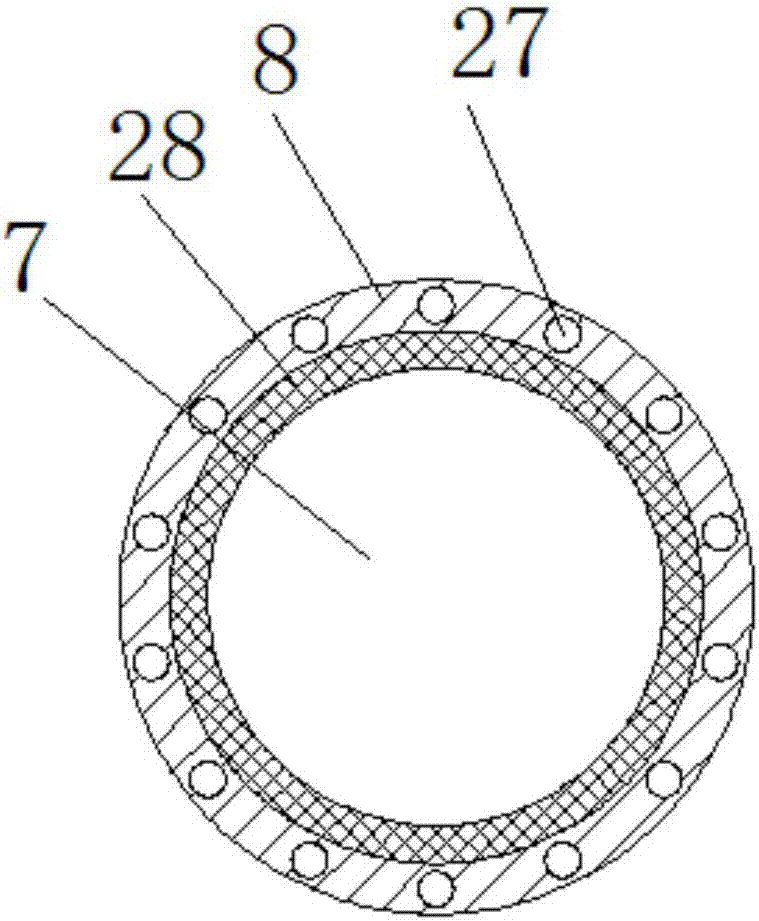

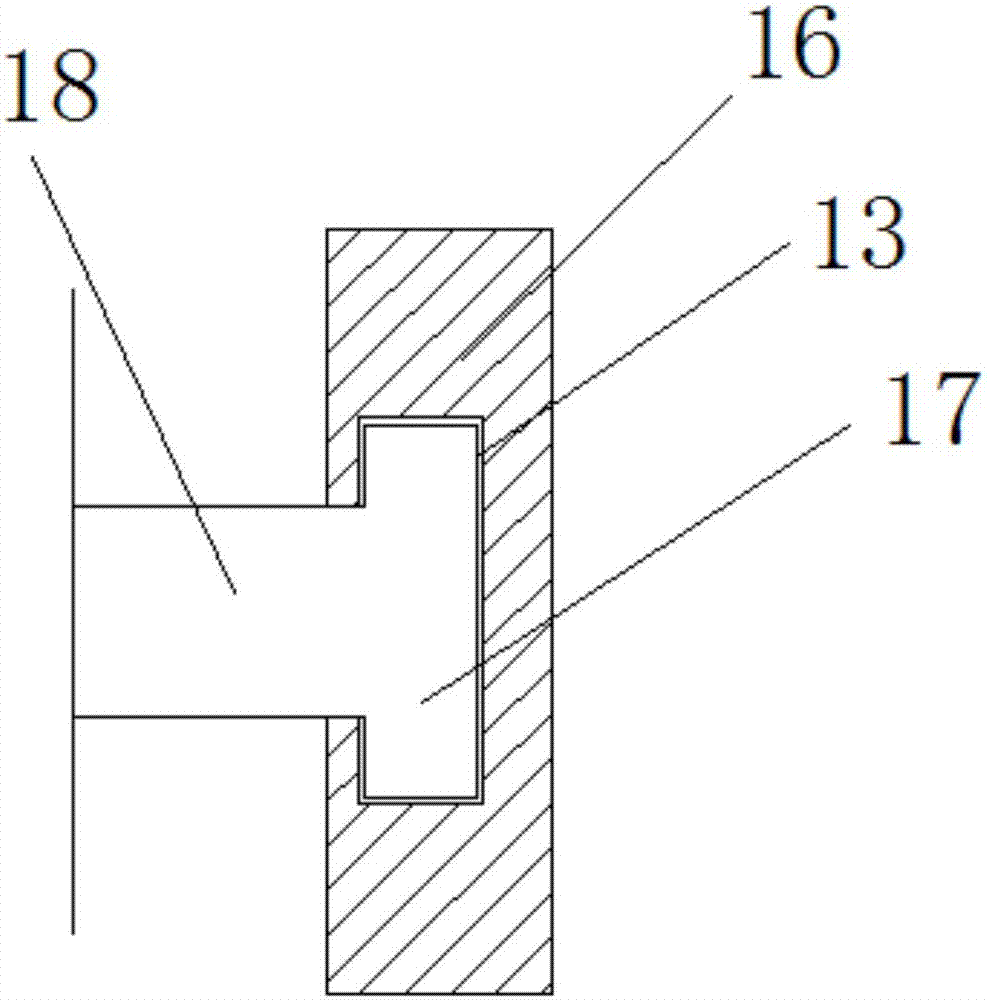

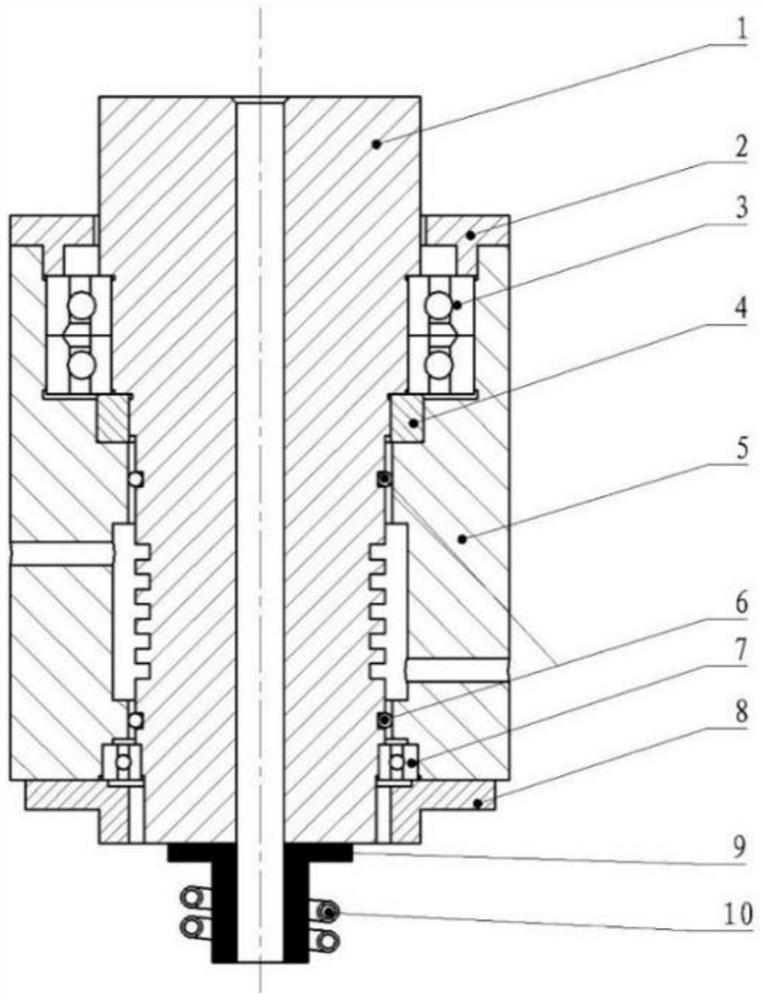

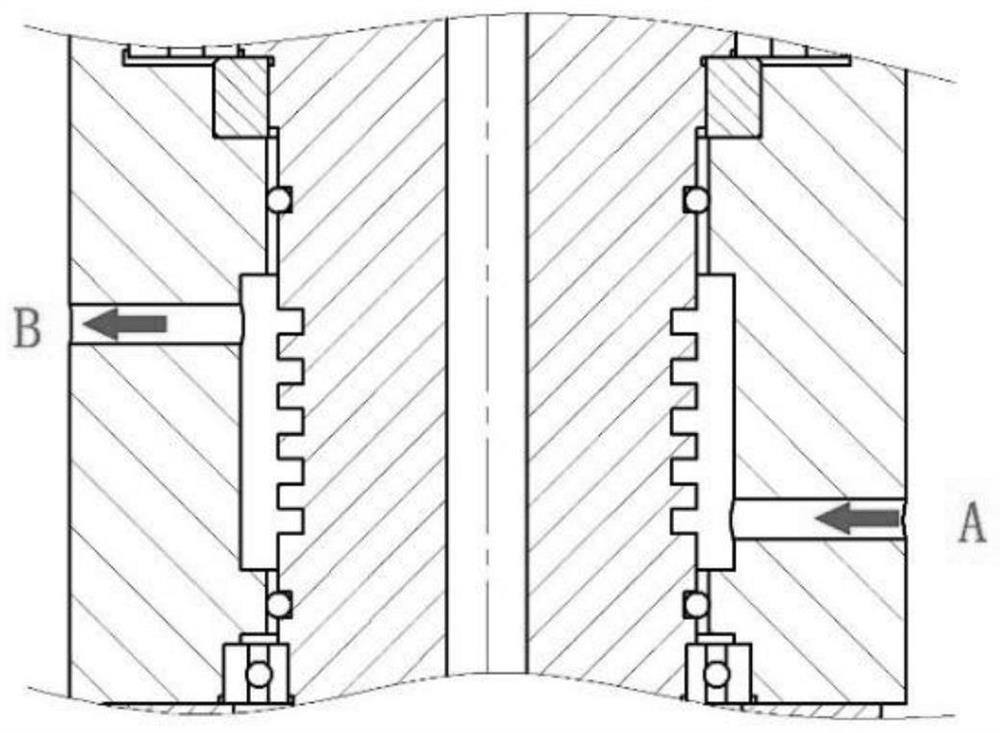

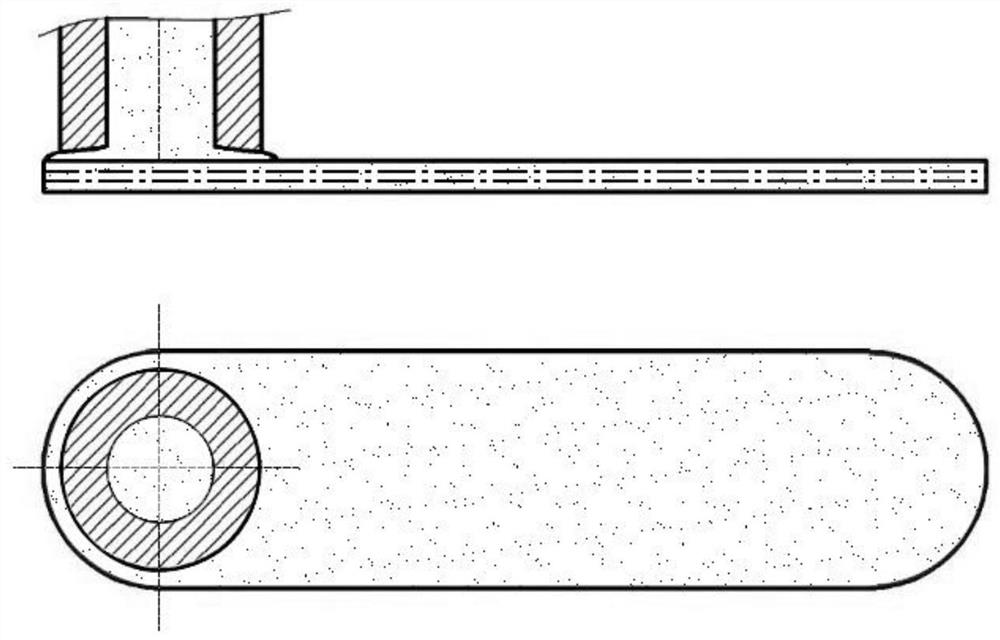

High-performance alloy steel solid-phase additive forming device and process based on induction heating compensation

ActiveCN113695597AHeating fastSoften fastAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsAlloy steel

The invention discloses a high-performance alloy steel solid-phase additive forming device and process based on induction heating compensation. The high-performance alloy steel solid-phase additive forming device and process are mainly used for solid-phase additive manufacturing of high-performance alloy steel and other metal material parts which are high in melting point and difficult to deform. The device comprises a rotating spindle, a fixed cooling shell, an additive forming tool head, an induction heating coil and other parts, wherein ultrahigh-strength solid-phase additive forming is achieved through the procedures of extrusion feeding, induction heating temperature rising, load applying and the like. According to the method, rapid heating and softening of the high-performance alloy steel are achieved through the induction heating principle, the severe large plastic deformation characteristic of stirring friction is combined, and the solid-phase additive manufacturing of the nearly-forged structure and performance of the high-performance alloy steel part is achieved. The device and the process can effectively break through the integral high-performance forming bottleneck of high-performance alloy steel complex components.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

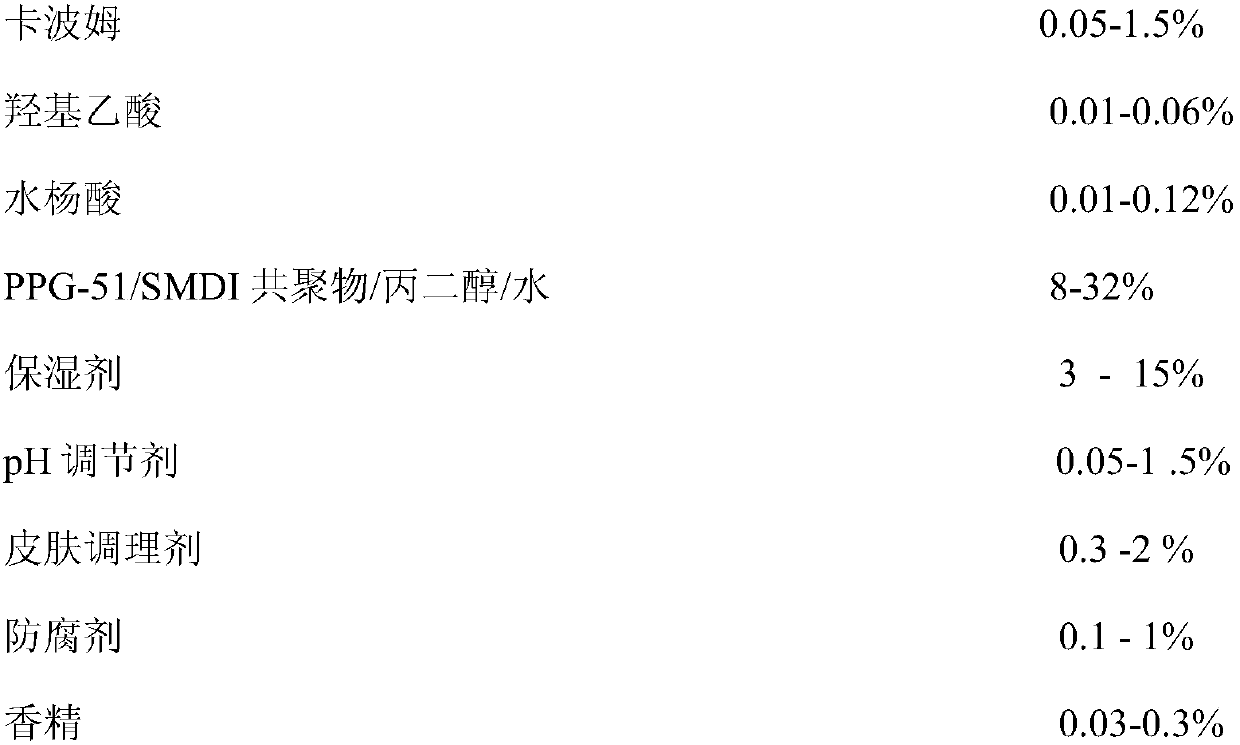

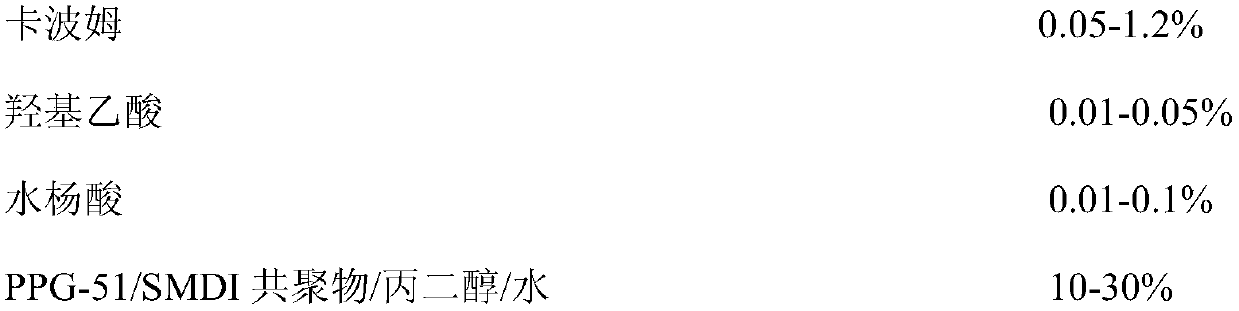

Cutin-removing cosmetic

InactiveCN107693387ASoften fastHigh exfoliation efficiencyCosmetic preparationsMake-upCutinSalicylic acid

The invention provides a cutin-removing cosmetic and a preparation method thereof. The cutin-removing cosmetic is characterized by comprising 0.05 to 1.5 percent of carbomer, 0.01 to 0.06 percent of hydroxyacetic acid, 0.01 to 0.12 percent of salicylic acid, and 8 to 32 percent of PPG-51 / SMDI copolymer / propylene glycol / water. The cutin-removing cosmetic also comprises 3 to 15 percent of a wettingagent, 0.05 to 1.5 percent of a pH regulator, 0.3 to 2 percent of a conditioner, 0.1 to 1 percent of a preservative, 0.03 to 0.3 percent of essence and the balance of water. The pH value of the cutin-removing cosmetic provided by the invention is close to 7, and the structure is a macromolecule with a charged group. The cutin-removing cosmetic can complex and adsorb aged amino acid groups on skin,achieves wrapping and emulsifying effects in the rubbing process to achieve a stripping effect and finally achieve an exfoliating scrub effect, is mild and non-irritant, and has a makeup removing effect.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +2

Pregermination method of honeysuckle seeds

InactiveCN107567750AImprove seedling efficiencyImprove planting efficiencySeed and root treatmentAdditive ingredientEmbryo

The invention mainly relates to the technical field of planting, and discloses a pregermination method of honeysuckle seeds. The pregermination method comprises the following steps: soaking, freezing,pregermination and sowing. The method is simple and convenient to operate, so that the pregermination time is shortened to be 1 to 2 days, the seeds are germinated to get out of soil 4 to 5 days later after sowing, and the germination rate reaches 87.2%, so that the seedling efficiency of honeysuckle is obviously improved; the honeysuckle seeds are put in a solution of sodium selenite and coppergluconate with relatively high temperature for soaking, so that seed coats can be quickly softened, the absorption of the seeds for nutritional ingredients is promoted, and the embryo activity is improved; the seeds are put at low temperature after being soaked, short-time freezing is carried out, the seeds are prevented from getting frozen, low-temperature stimulation is performed on the seeds, the embryo stress resistance and environmental suitability are improved, the fermentation rate of the seeds is improved, the seeds are put into a sodium selenite solution again after being taken out for carrying out normal temperature soaking, the absorption of the seeds for the nutritional ingredients is promoted, and the nutritional ingredients required for seed germination are accumulated.

Owner:界首市民兴家庭农场

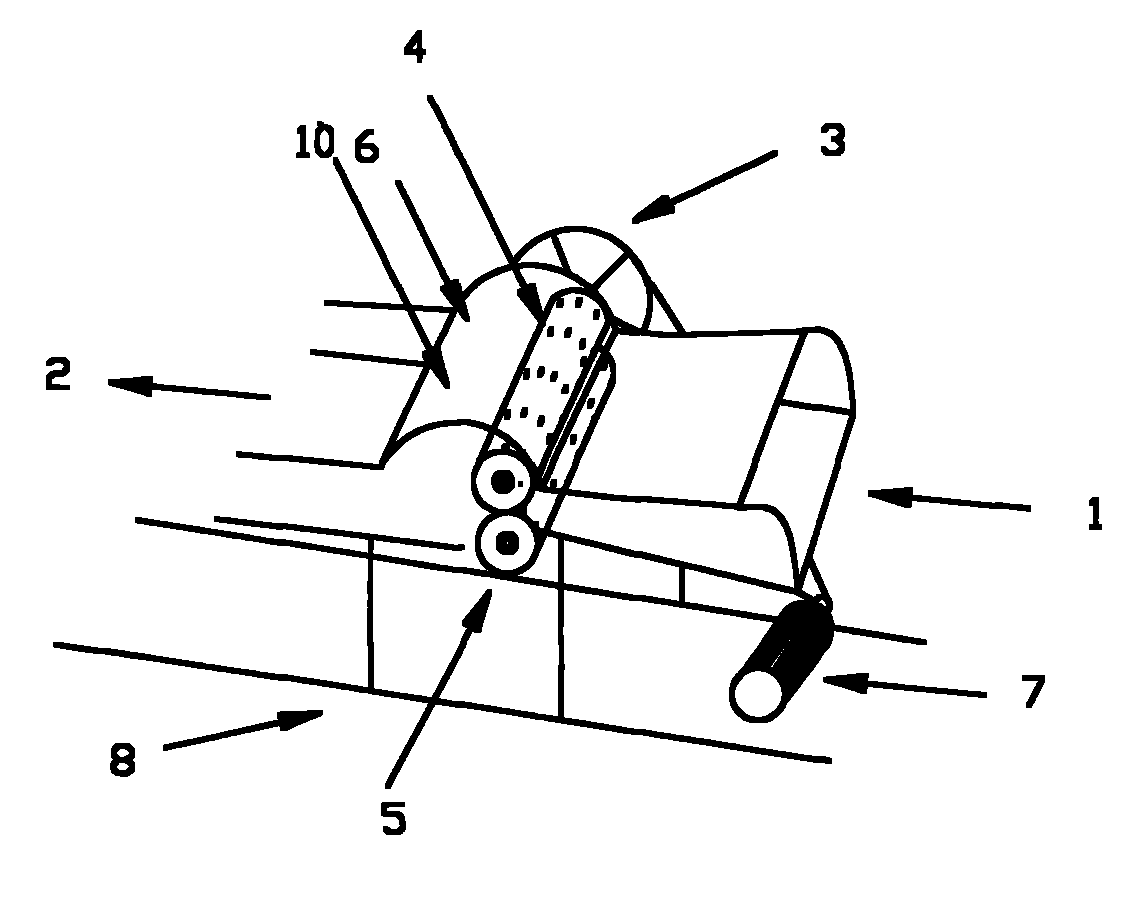

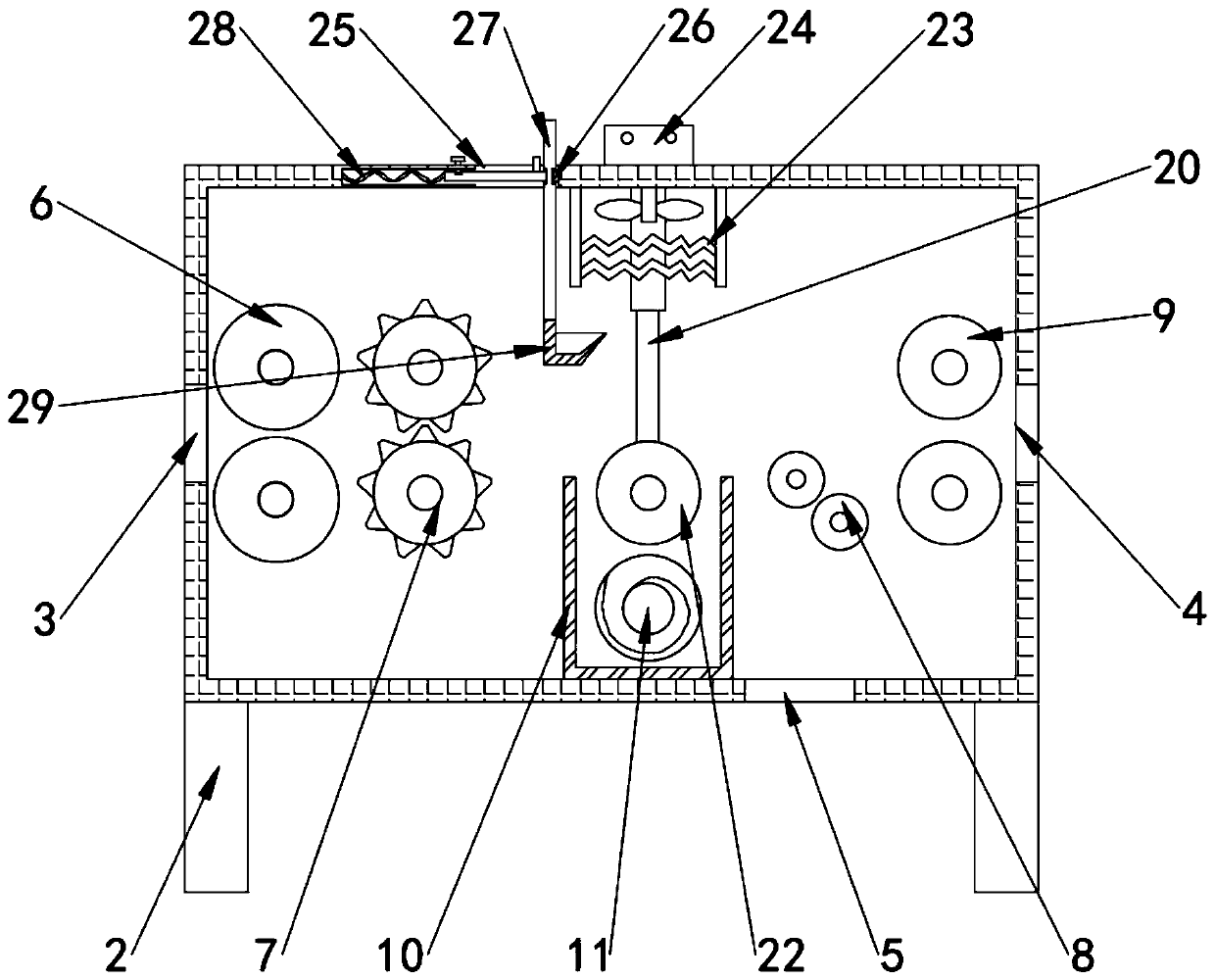

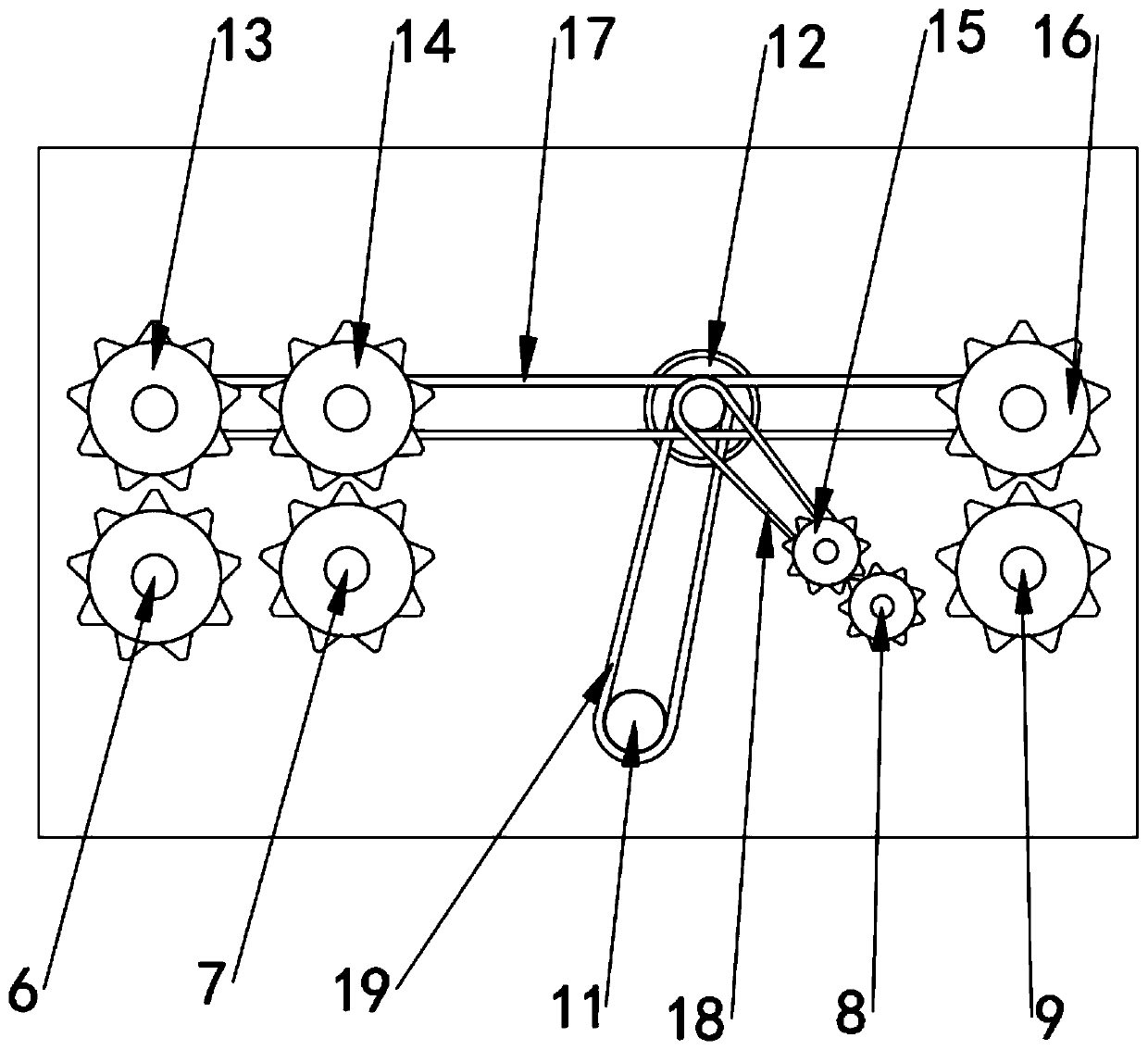

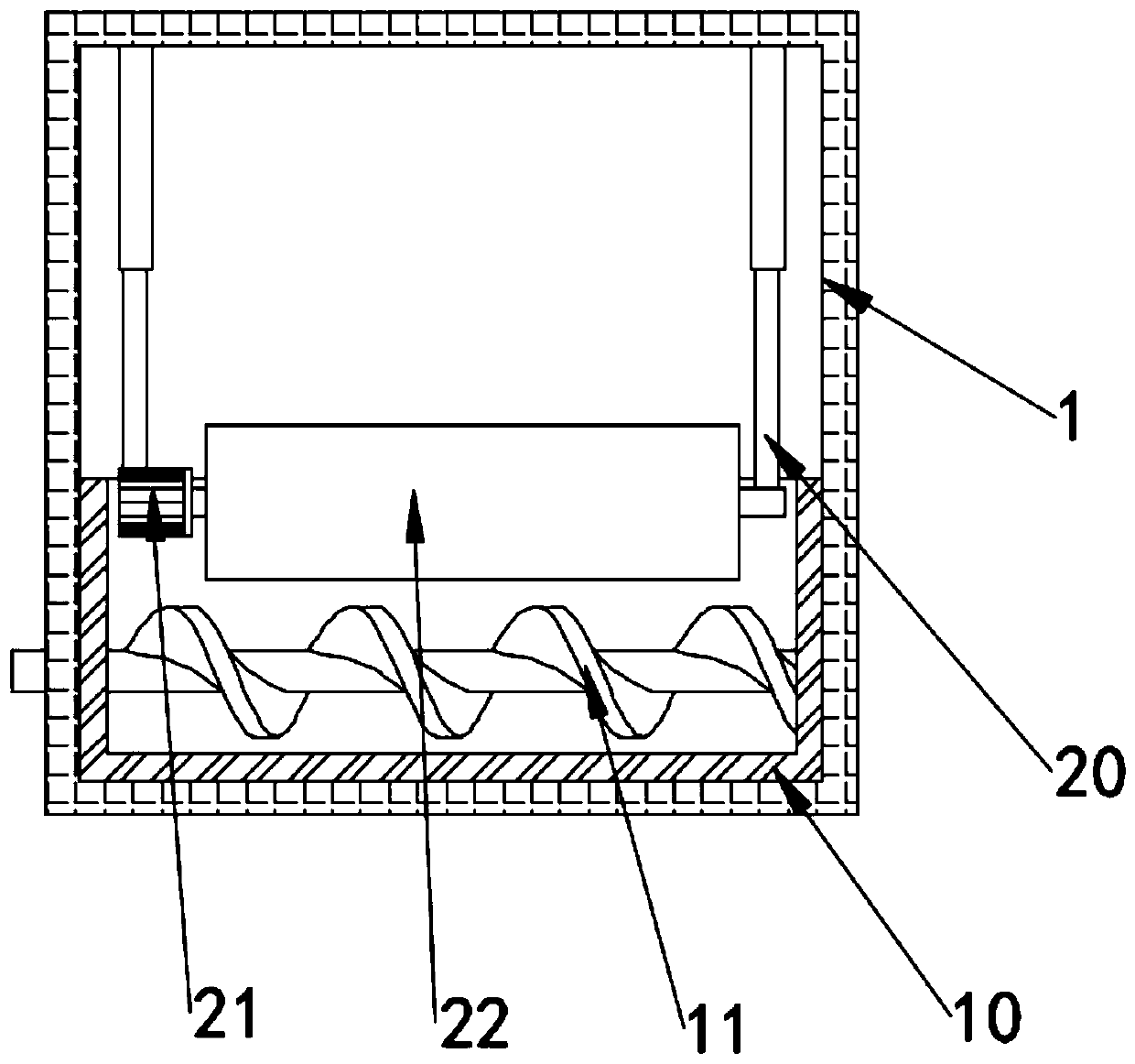

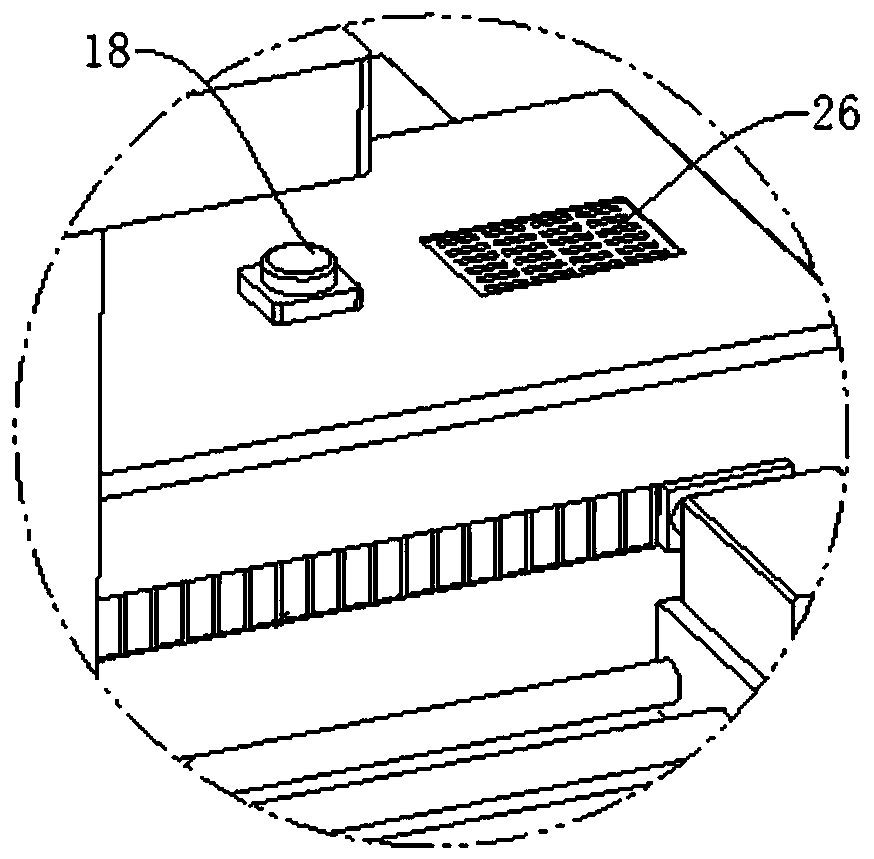

Single face corrugating machine

InactiveCN110722830AEasy to moveEasy to cleanLiquid surface applicatorsMechanical working/deformationElectric machineAdhesive glue

The invention relates to the technical field of corrugated paper production equipment and discloses a single face corrugating machine. The single face corrugating machine comprises a box body, whereinsupporting legs are fixedly mounted at four corners of the bottom of the box body respectively; and a first paper feeding opening, a paper discharge opening and a second paper feeding opening are formed in two sides and bottom of the box body respectively. According to the single face corrugating machine provided by the invention, a glue spreading roll and a secondary motor are provided with retractable rods respectively, so that the glue spreading roll is conveniently driven to move upward to a position in contact with a glue scraping plate when the glue spreading roll stops working; an electric heating net and a draught fan are arranged at the top of the glue spreading roll so that glue which is previously hardened and condensed on the glue spreading roll is convenient to soften rapidlyby the electric heating net and the draught fan during running; the glue spreading roll is driven to rotate through starting the secondary motor, and the softened glue on the glue spreading roll canbe conveniently cleaned by the glue scraping plate along with the rotation of the glue scraping plate, thereby achieving the effect of automatically cleaning the residual glue attached on the surfaceof the glue spreading roll in a working process of the equipment; and the equipment is good in glue removing effect and high in practicability.

Owner:江门市世昌纸业有限公司

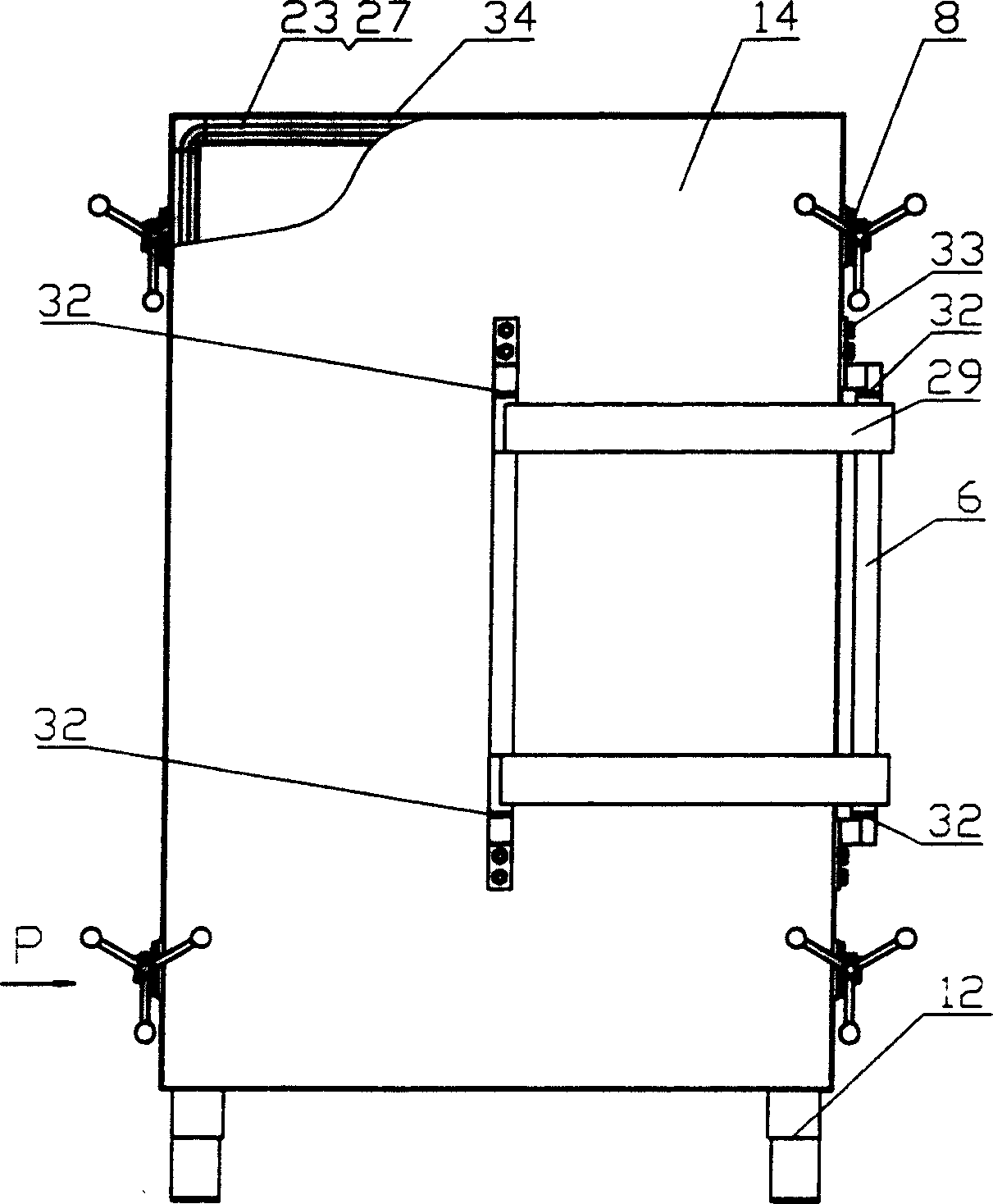

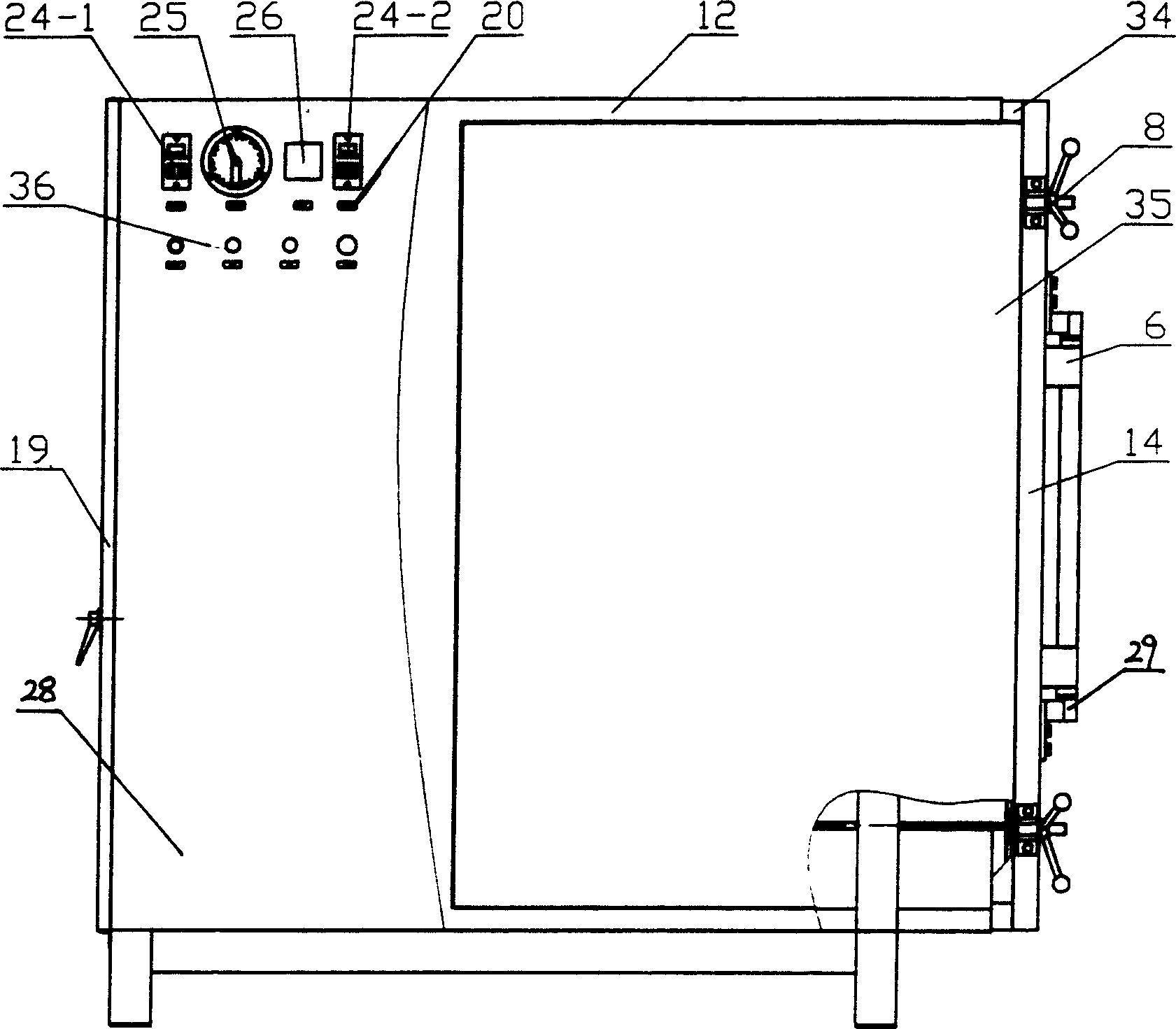

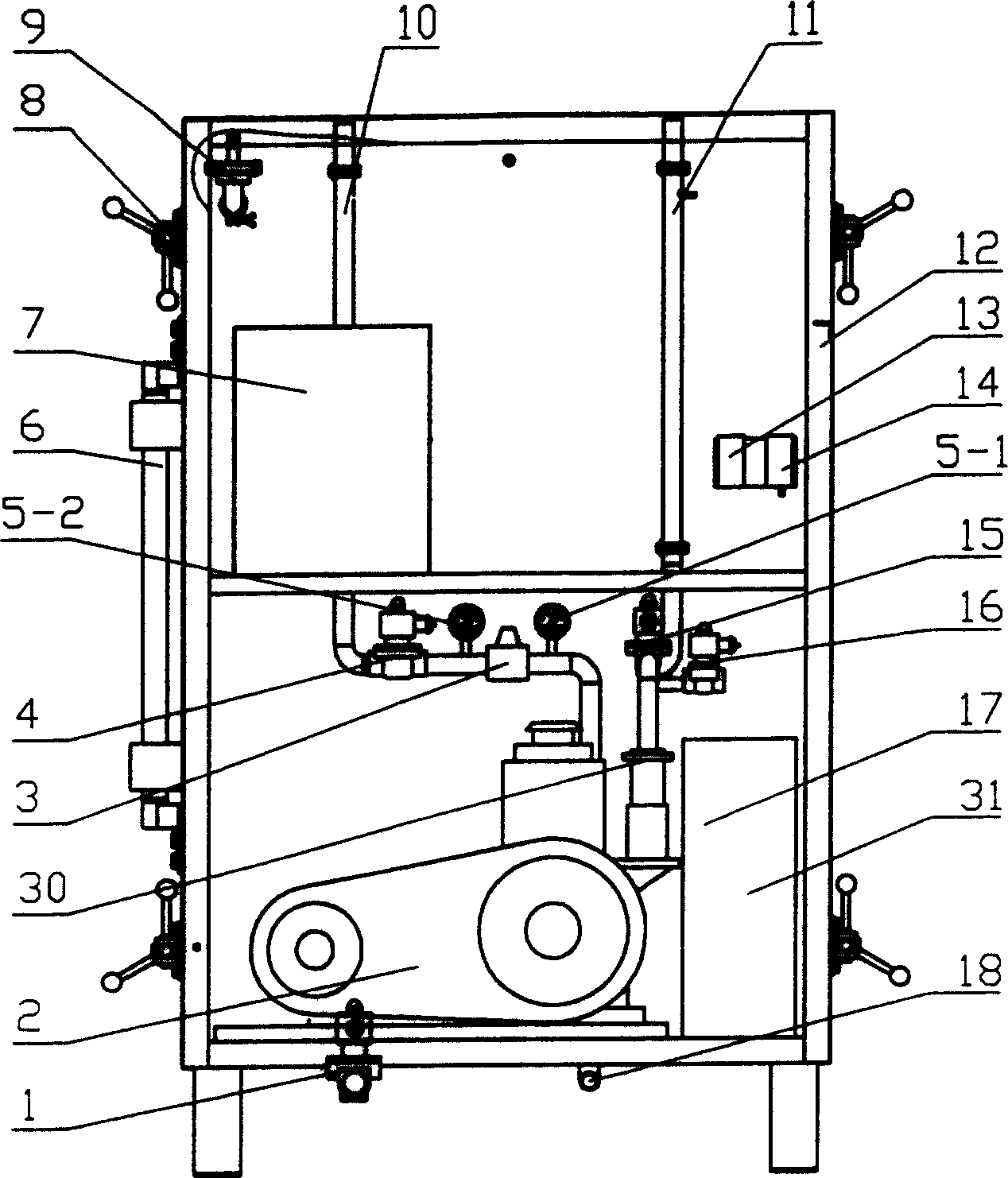

Gas phase replaceable demulcen machine

InactiveCN1561943AQuality improvementIncrease moisture contentPharmaceutical product form changeGas phaseElectrical control

A gas-phase displacement type wetting machine for softening the Chinese-medicinal materials and agricultural products in order to make post-treating easier is composed of case, gate mechanism, vacuumizing unit, electric controller, sealing unit including the sealing elastic ruber tube embedded in the slot on gate frame, and steam pipeline.

Owner:HANGZHOU HAISHAN PHARMA EQUIP

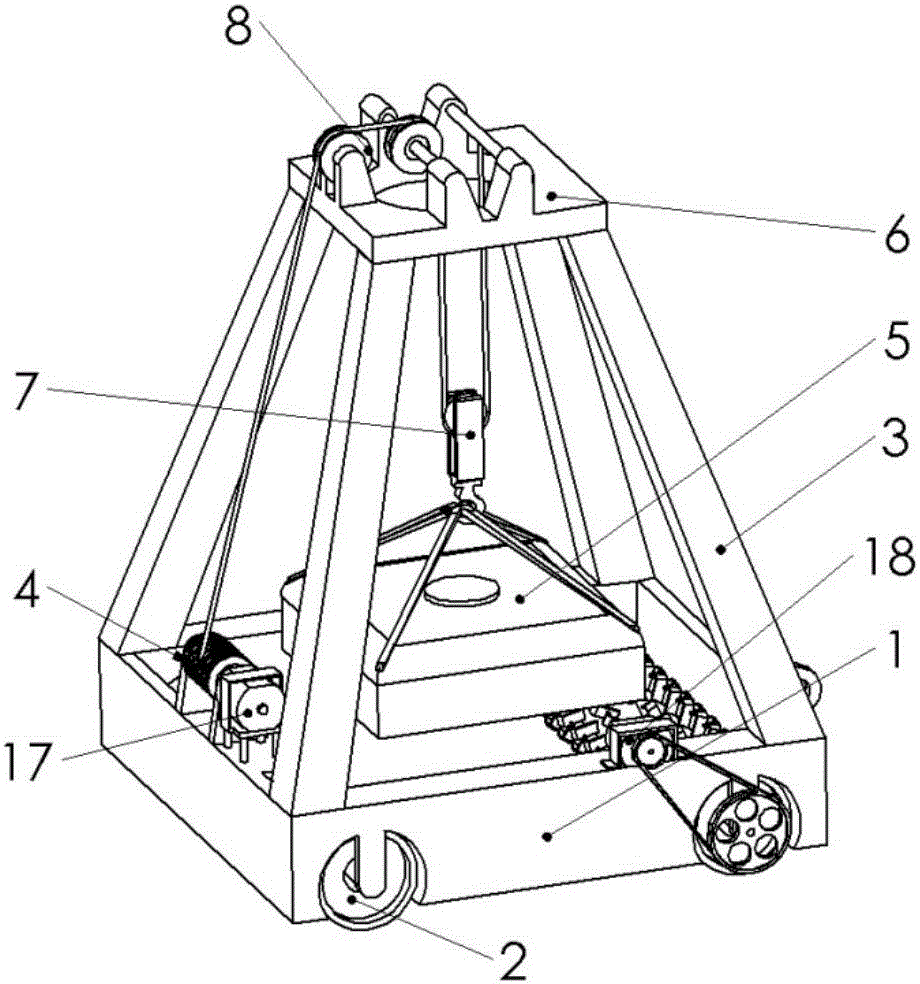

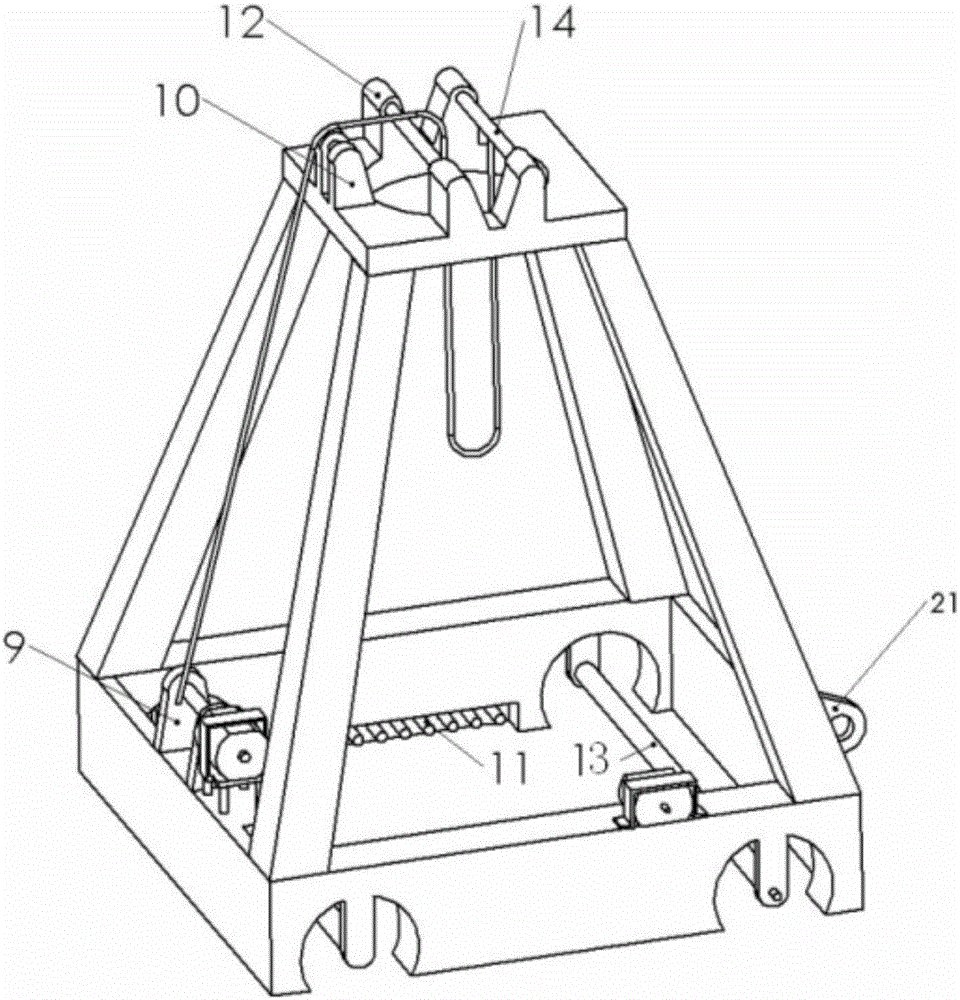

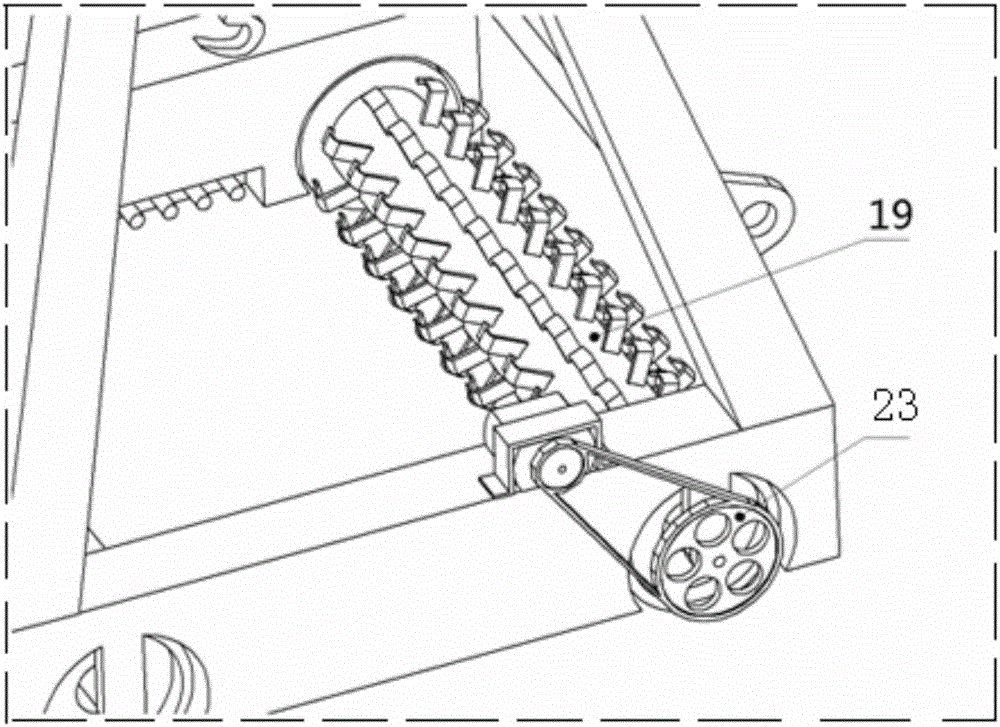

Shallow soft soil solidifying device and solidifying method thereof

The invention discloses a shallow soft soil solidifying device and a solidifying method thereof. The shallow soft soil solidifying device comprises a chassis, a support and a top platform; the support is arranged between the chassis and the top platform in a supporting mode, the chassis is provided with two parallel press roll shafts, the longitudinal axes of the press roll shafts are perpendicular to the advancing direction, a hoe wheel and a press roll are sequentially installed on the press roll shafts in the advancing direction, the hoe wheel is shaped like a cylinder, hoe hooks are densely distributed on the surface of the hoe wheel, the hoe wheel is driven by a hoe wheel motor, and a flame jetting device used for evaporating ground water is arranged on the inner side of the chassis; a land compacting heavy block is arranged under the top platform and rises and falls through a jack mechanism. Compared with the prior art, the shallow soft soil solidifying device and the solidifying method thereof have the advantages that surface soft soil can be softened and subjected to heating pretreatment to enable the water in the surface soft soil to be volatilized and then subjected to hardening treatment through land compacting, therefore, the efficiency can be improved, the soft soil can be quickly softened, and unnecessary labor and time waste can be reduced.

Owner:HOHAI UNIV

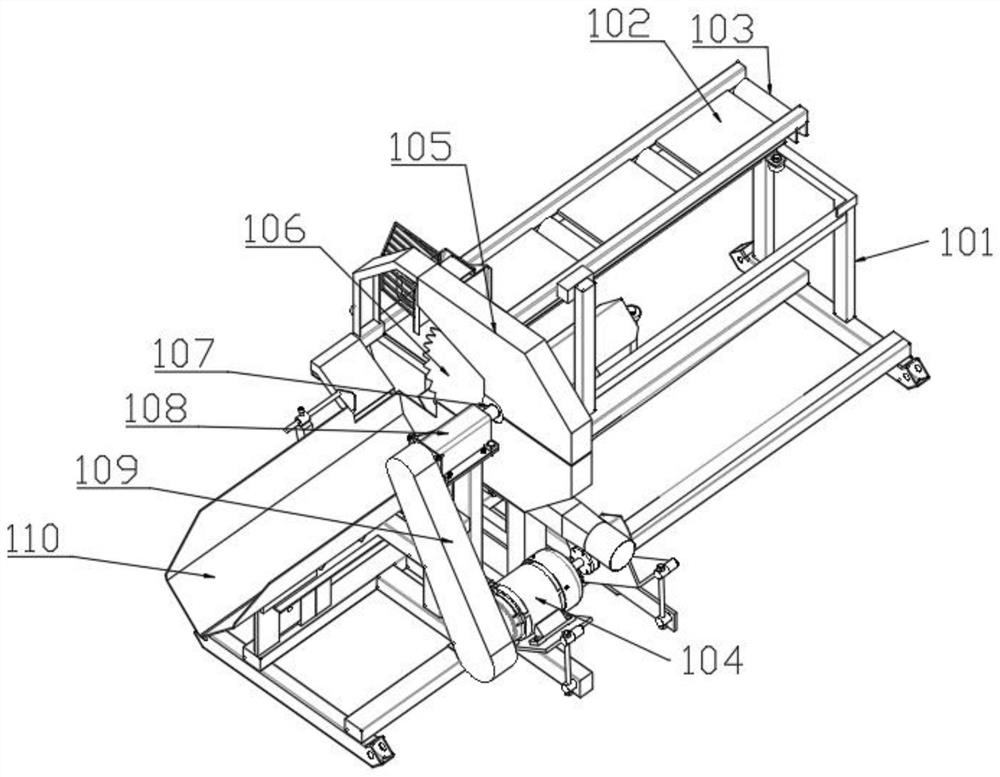

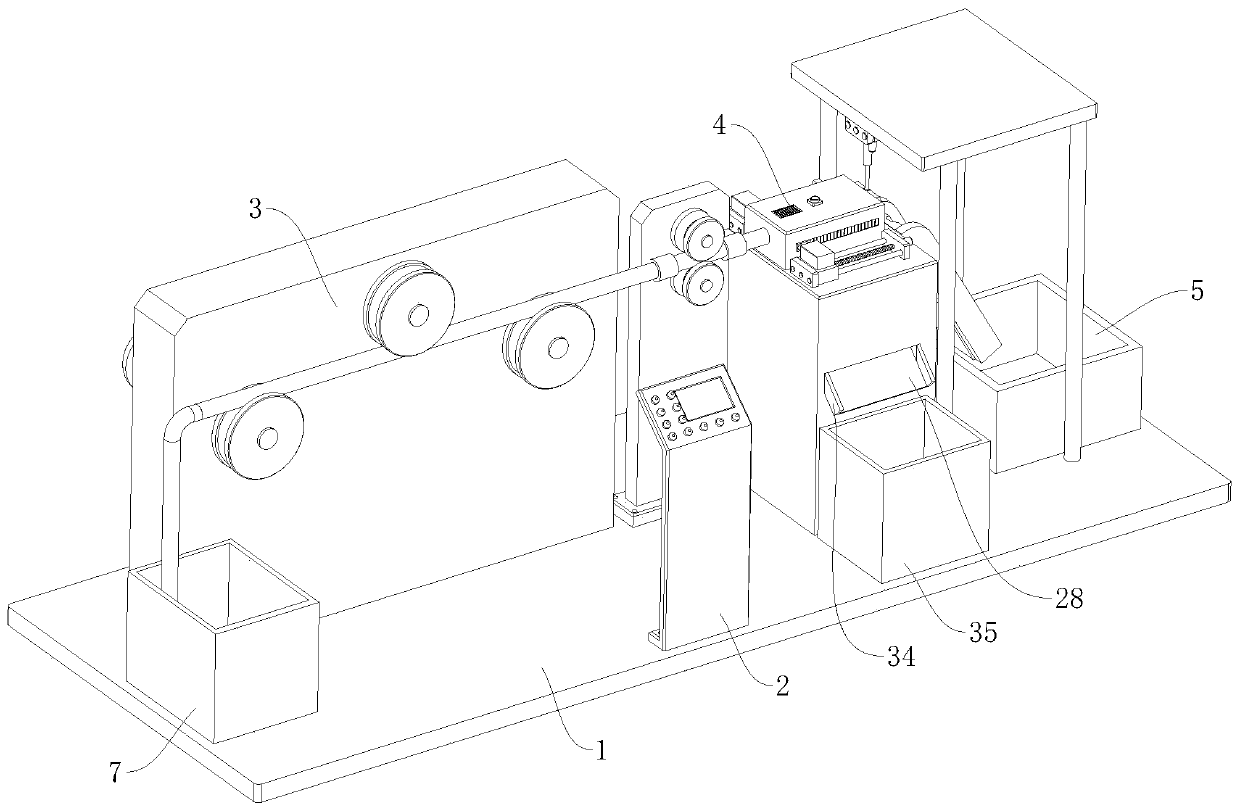

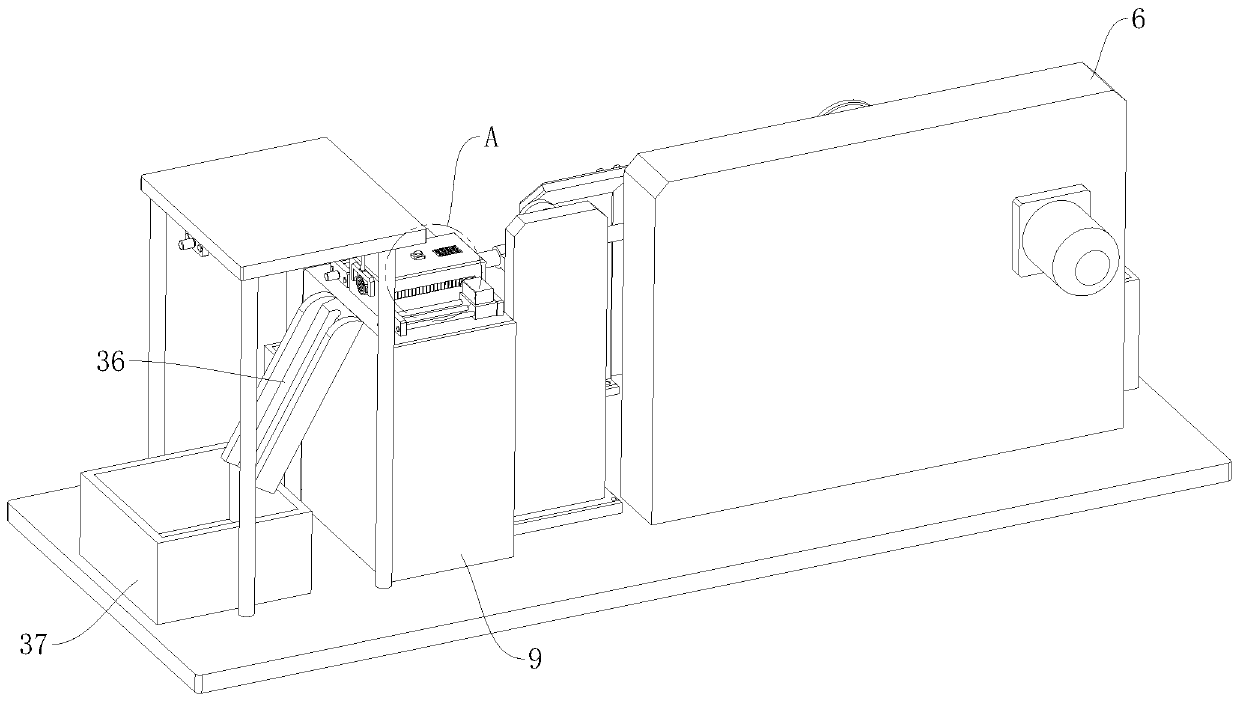

Automatic cable stripping and separating device and stripping and separating method

ActiveCN111384687AAvoid meltingFast peeling speedBasic electric elementsApparatus for removing/armouring cablesStructural engineeringElectric cables

The invention relates to the technical field of cables, and particularly relates to an automatic cable stripping and separating device and a stripping and separating method. The device comprises a base, and also comprises a controller, a continuous feeding mechanism, a peeling mechanism and a discharging mechanism. The continuous feeding mechanism comprises a straightening machine, a container anda positioning assembly. The peeling mechanism comprises a workbench, a heating assembly and two sets of scraping assemblies. The discharging mechanism comprises a hanging plate and a clamping assembly, wherein four supporting rods are symmetrically arranged at the top of the base; the hanging plate is fixedly arranged at the tops of the four supporting rods; the clamping assembly is arranged at the bottom of the hanging plate in a sliding mode. The automatic cable peeling and separating device is high in peeling speed and high in efficiency; meanwhile, peeled skin layers can be separated frominternal wires of cables and can be effectively collected, and recycling and secondary utilization are facilitated.

Owner:日照市睿翅电子商务产业有限公司

Method for softening woven bamboo

InactiveCN106142271ASimple methodShort processing cycleWood treatment detailsReed/straw treatmentFiber structureSaline water

The invention discloses a method for softening woven bamboo. The method is simple, the processing period is shortened to be 9-10 hours, working efficiency is improved by 11.7%, production cost is reduced by 13.4%, and the natural color and luster of the bamboo cannot be influenced. The method includes the steps that a bamboo billet is soaked in saline water, sterilization and high-temperature dehydration can be achieved at the same time, the cellular structure is changed, and treating fluid can better permeate in the later period; the bamboo billet is subjected to high-temperature sand bath, wet leaves are used for spacing, the bamboo billet is wetted at first and then dried, the fiber structure is softened primarily, and permeability is enhanced; permeability of a softener solution is good, bamboo fibers can be softened quickly, and the bamboo is made pliable, tough, soft, smooth and free of cracking; bamboo filaments can be processed conveniently, the softened bamboo cannot mildew, cannot breed insects and is resistant to high temperatures for a long time, and thus storage and use are facilitated; and at last, by means of medium-temperature drying, moisture is evaporated slowly, moisture again can be avoided, energy is saved, and the environment is protected.

Owner:阜南县东奥工艺品有限公司

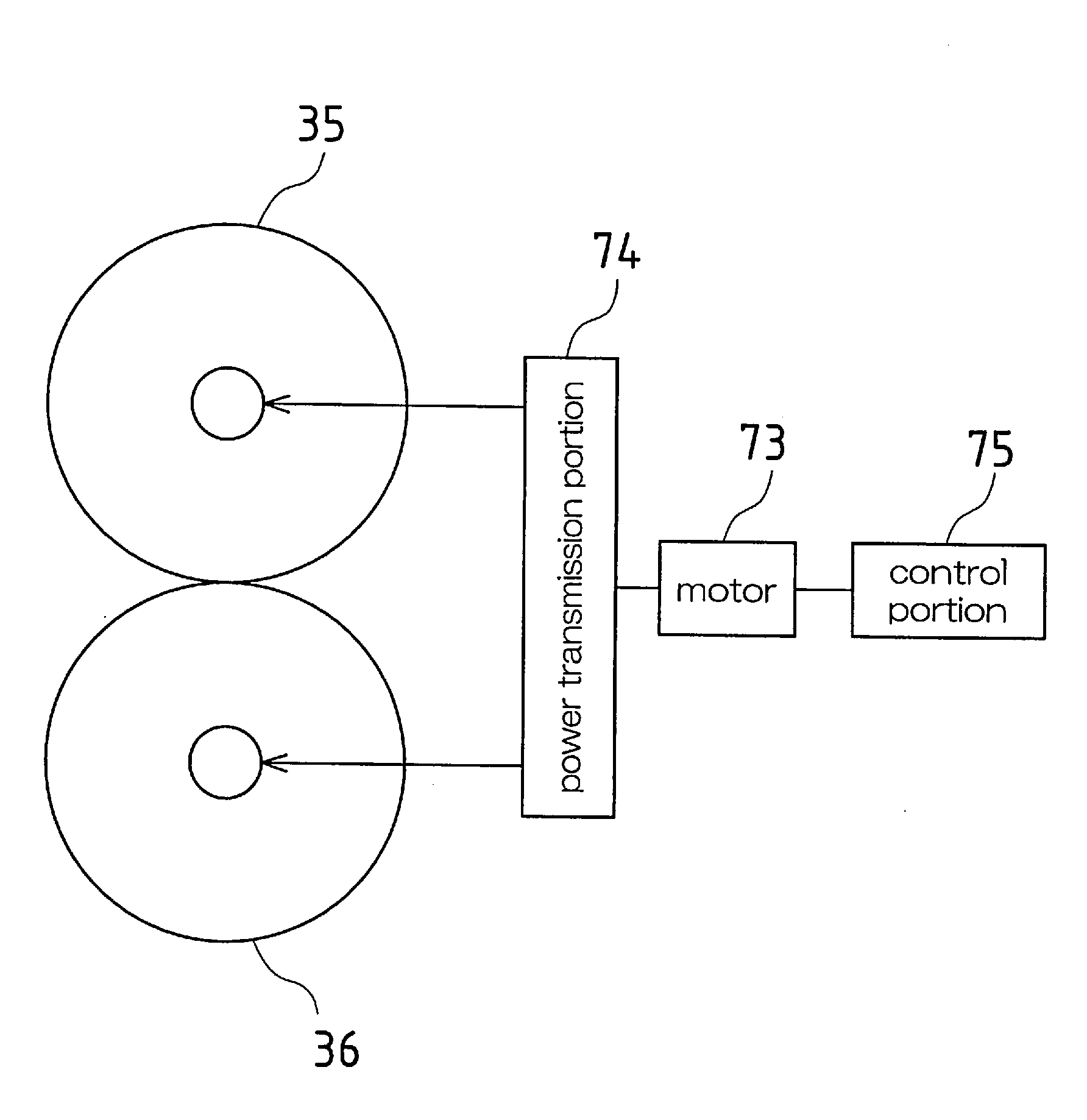

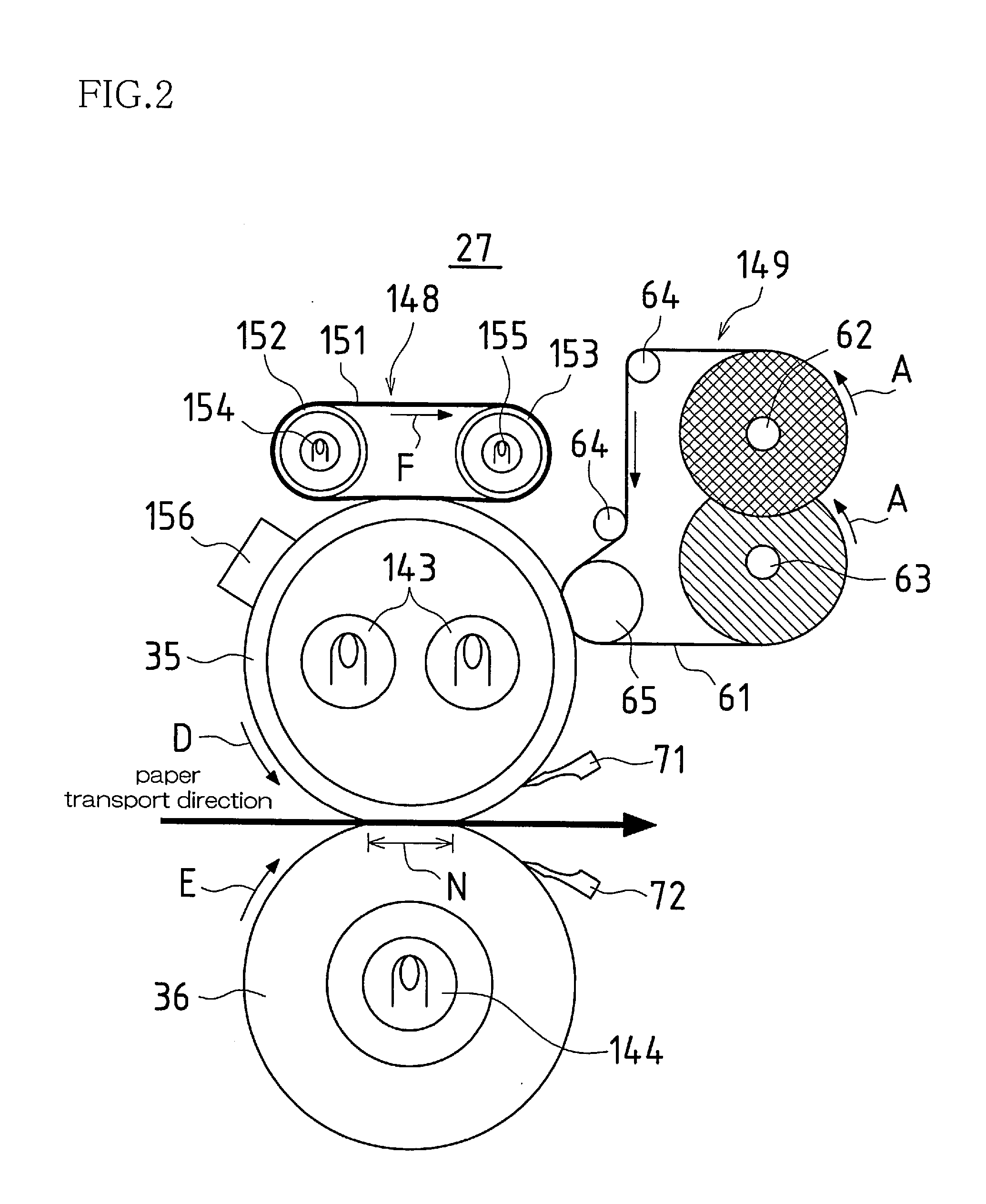

Roller drive control method of fixing apparatus and fixing apparatus

InactiveUS20080253790A1Improve vibrationNot easy to gapElectrographic process apparatusControl engineeringProcess engineering

Owner:SHARP KK

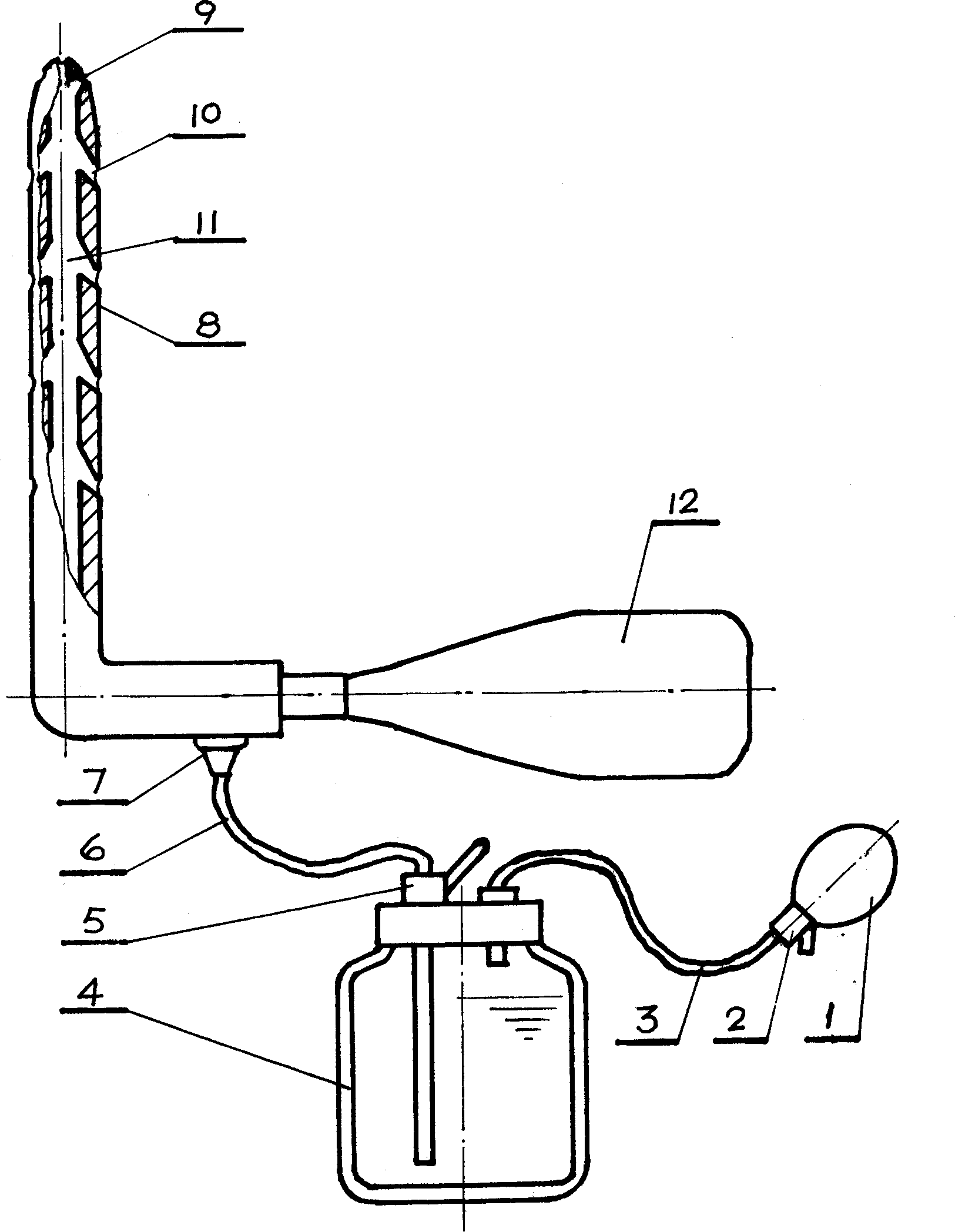

Cathartic equipment for constipation

InactiveCN1907509AInjection pressure can be adjusted freelyEasy to useEnemata/irrigatorsEngineeringControl valves

The invention relates to a cathartic device used in rectum part, which comprises: a pressurize device, an one-way valve, a gas inlet tube, a liquid storage pot, a control valve, a liquid outlet tube and a liquid inlet interface; and it has a rod ejector with at least two liquid ejectors. The invention can be used in hospital or common family, to quickly soften fecal blocks; and it gives a downward rotational pushing force; and it has washing function, to clean the rectum, to recover activity of rectum. And it can be used as cleaner at other parts.

Owner:宣伯民

Cultivation method for interplanting apple with radix hedysari

InactiveCN103181281AIncrease water permeability and breathabilitySoften fastCultivating equipmentsHorticultureFresh waterGibberellin

The invention discloses a cultivation method for interplanting apple with radix hedysari, relates to an interplanting method, and belongs to the field of agricultural planting. The method ensures that the yield of sweetvetch root is increased by interplanting apple trees with radix hedysari, can improve the yield and the quality of the radix hedysari, improves the land utilization rate, and reduces the planting cost. The method is characterized in that radix hedysari seeds are soaked in fresh water for 18 to 32h before being planted; the radix hedysari seeds in the fresh water are stirred every 2 to 3h; the fresh water is changed every 4h; after the fresh water is drained, allocated nutrient soil containing phoxim granules, cellulose, gibberellin, turfy soil and pyrethrin is used for seed dressing and then seeding is performed. The method has the benefits that yield and mass per unit area are improved, the germination time is effectively shortened, the germination rate is improved, the cost is reasonable, the method is simple to operate, and the application mode is flexible.

Owner:梁惠英

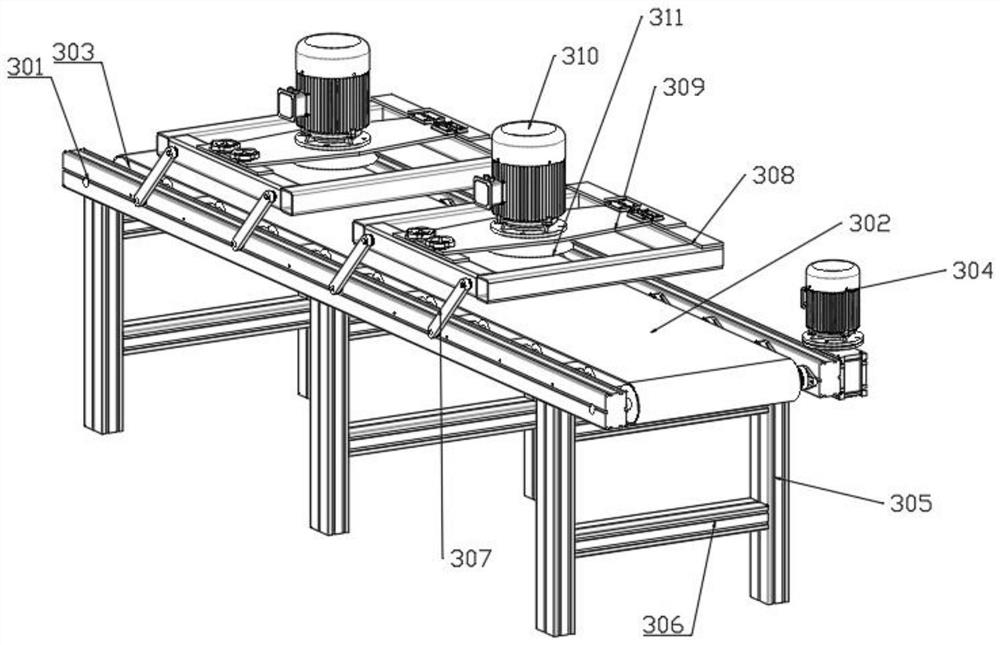

Wheat and rice straw filament rubbing process

InactiveCN103789841ASoften fastKeep moistureVegetable materialMechanical fibre separationRice strawWater content

The invention relates to a wheat and rice straw filament rubbing process which includes the steps of firstly, combing raw straws, removing impurities such as disintegrated slag, and cutting off spike end; secondly, rolling with a continuous rolling machine; thirdly, using steam for softening; fourthly, drying the straws and controlling water content; fifthly, performing filament rubbing with a straw filament rubbing machine to obtain straw filaments, and performing dust collecting during filament rubbing; sixthly, screening the straw filaments, and extracting the straw filaments not shorter than 5cm and 1-3mm in diameter. The process is simple to operate, easy to implement, low in cost, high in efficiency, and free of environment pollution. In addition, the produced filaments are long in fiber, high in mechanical strength and mainly applicable to manufacturing of products such as a vegetation carpet and a greening pad.

Owner:CHANGSHA CHUANGYUAN ENVIRONMENTAL PROTECTION TECH

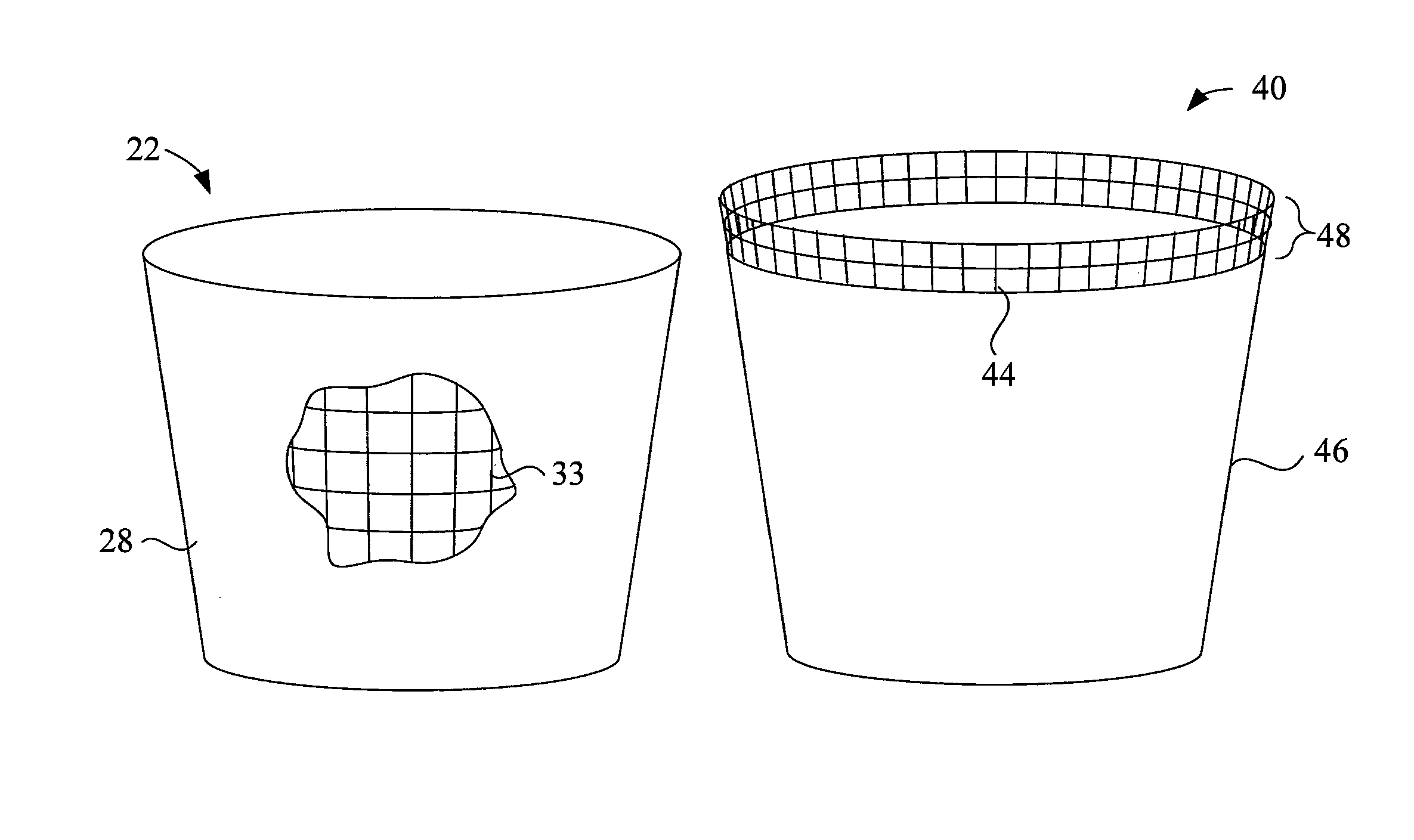

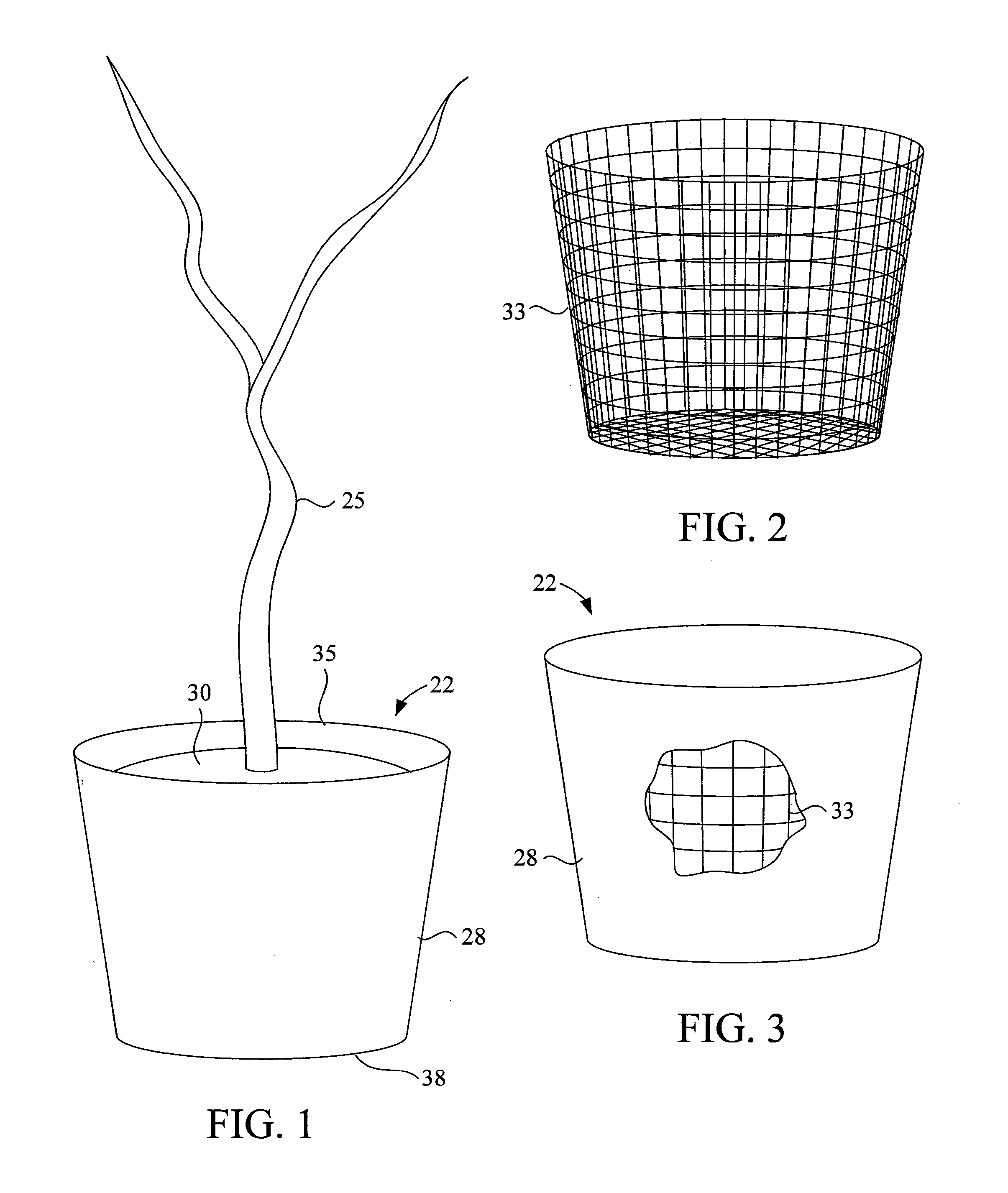

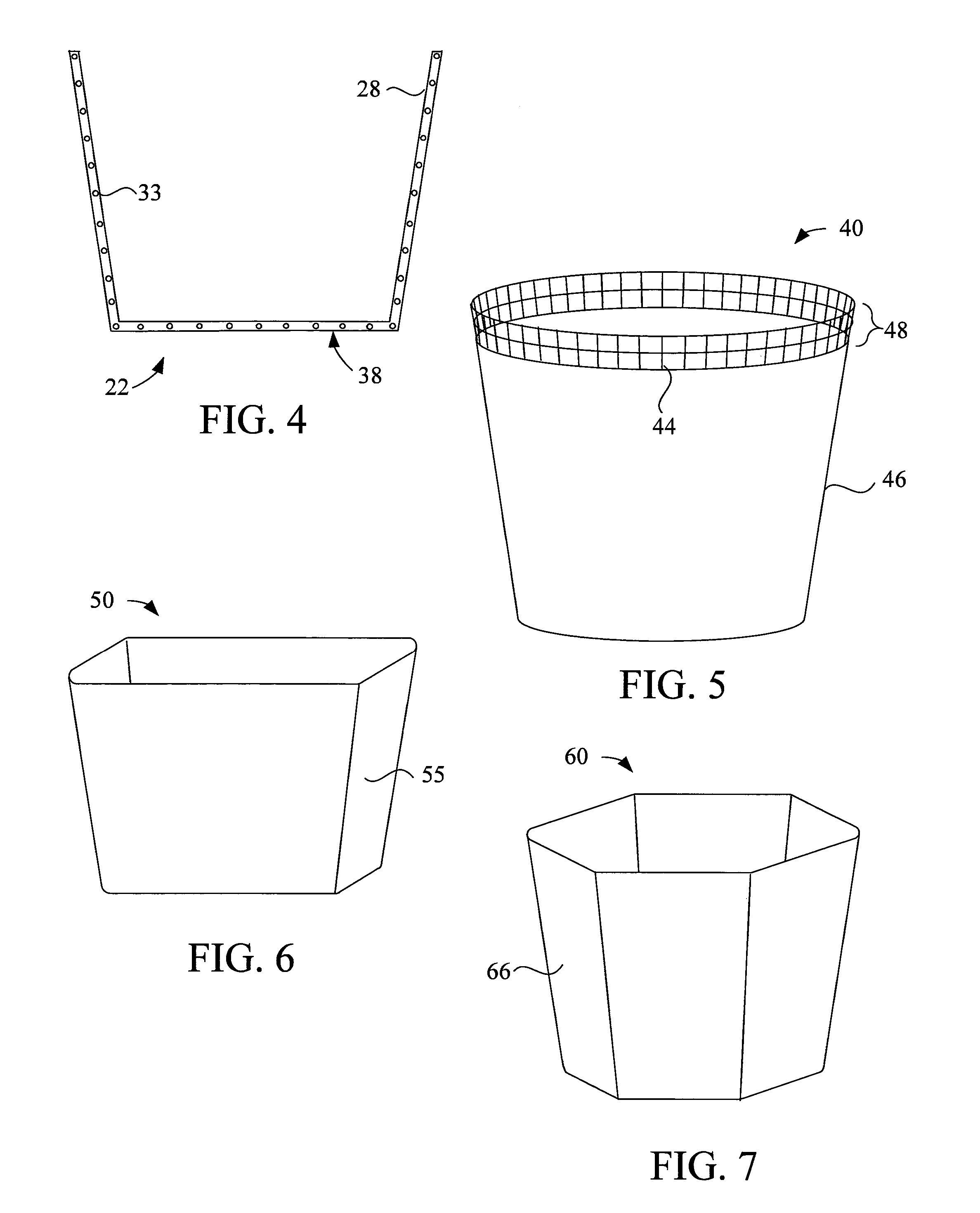

Planting pots with wire mesh and biodegradable material

InactiveUS9307702B1Easy passRoot damageCultivating equipmentsReceptacle cultivationPlant rootsEngineering

A container for a plant includes a wire mesh that is formed in the shape of a plant pot, and a layer of biodegradable material that is attached to the wire mesh in the shape of the pot. The container provides protection to plant roots from gophers and protection from root damage during transplanting, and can reduce air gaps between a pot and a hole in the ground, saving plants from drying out. The wire mesh provides a supportive frame so that the biodegradable material layer can be thinner, with the biodegradable material quickly softening and / or decomposing to let the plant roots grow through the pot into the soil. The wire mesh can extend beyond the biodegradable material layer at a top of the pot to provide protection against surface foraging rodents.

Owner:LAUER MARK

Separation device for sheet products and its fabrication process

InactiveUS6074746AEasily withdrawnSolve the lack of adhesionConveyorsCharge manipulationEngineeringElectrical and Electronics engineering

Owner:SAINT-GOBAIN GLASS FRANCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com