Shallow soft soil solidifying device and solidifying method thereof

A curing device and soft soil technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as low bearing capacity, plant construction, fracture, etc., and achieve the effect of improving efficiency and reducing waste of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail through the following embodiments in conjunction with the accompanying drawings. Apparently, the described embodiments are only sub-embodiments of the present invention.

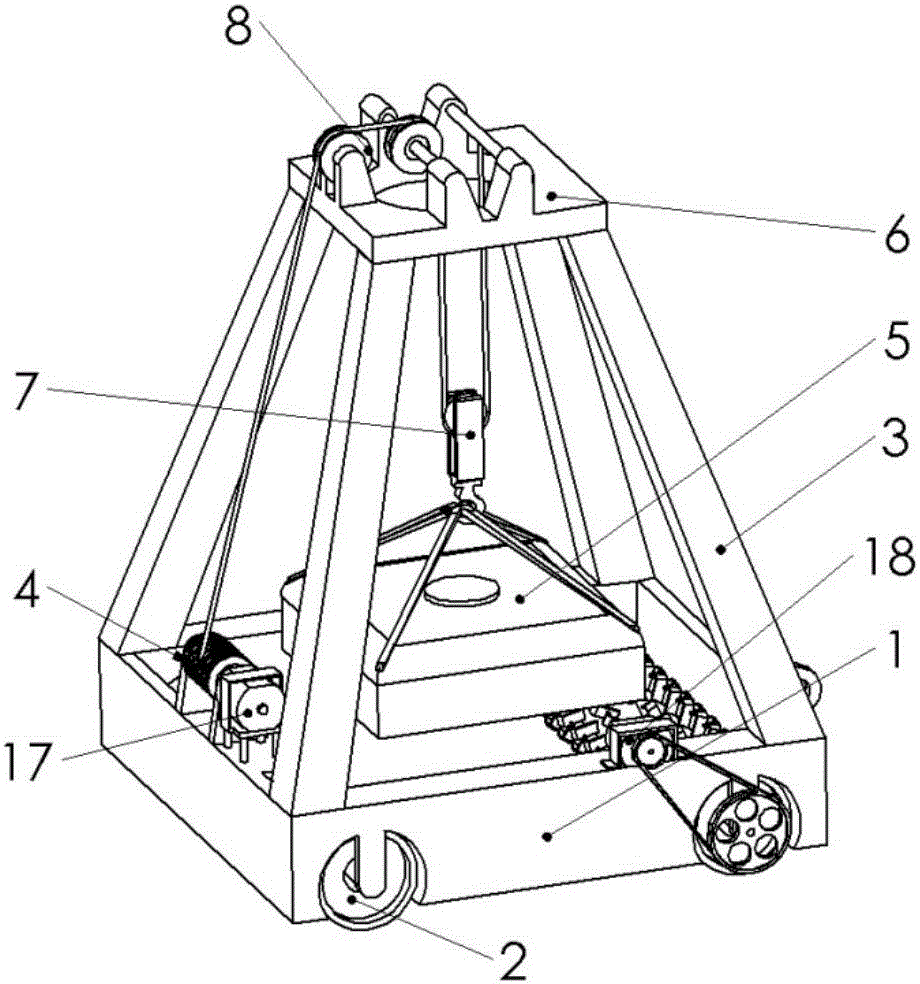

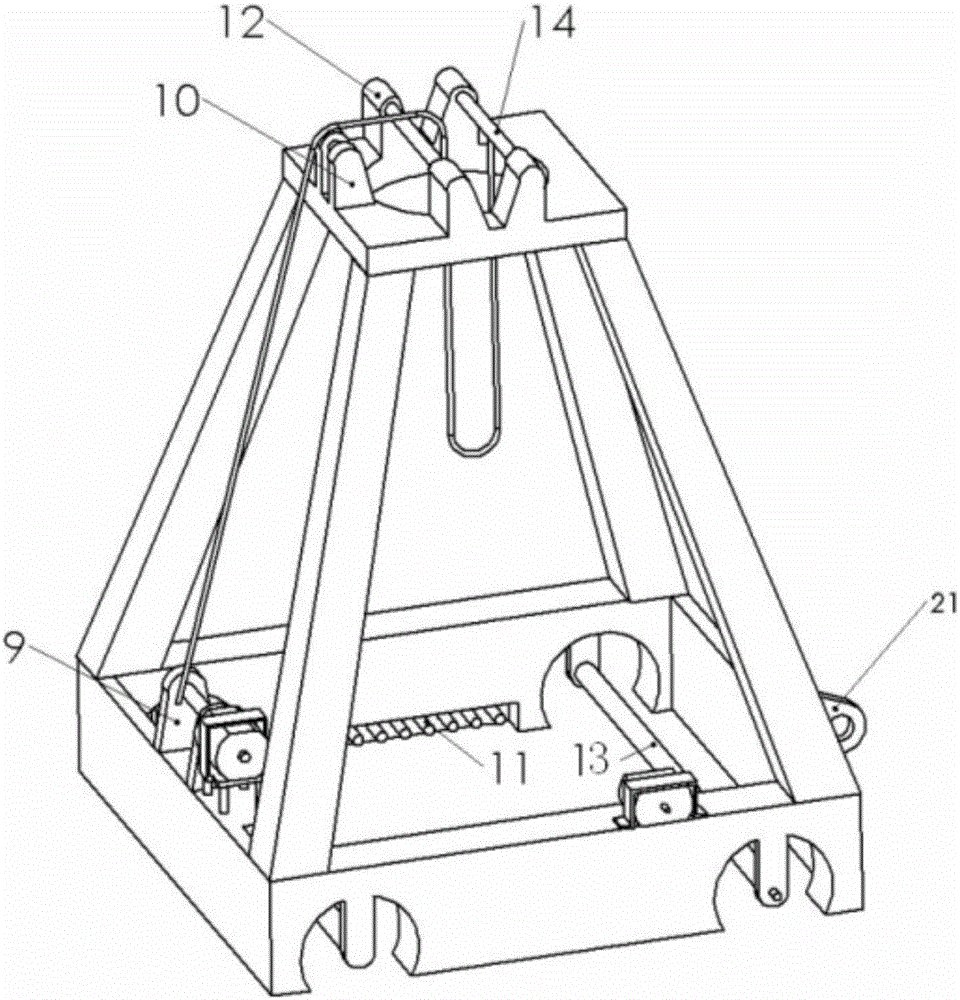

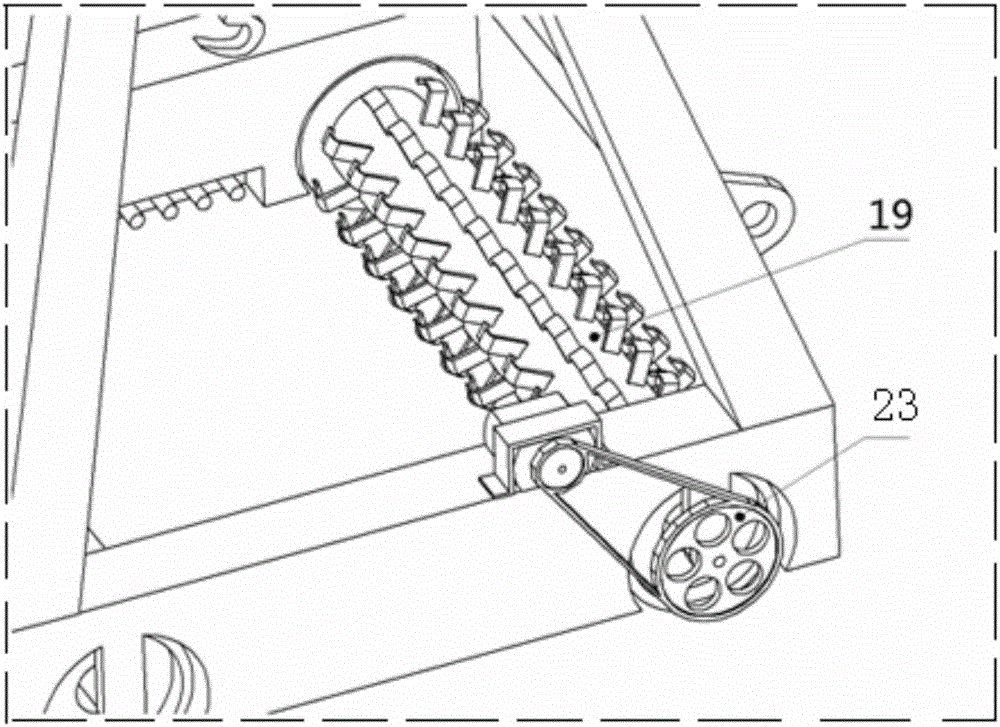

[0029] See attached figure 1 , 2 , a shallow soft soil curing device, including a chassis, a pressure roller, a bracket, a steel cable rotating winding wheel, a winding wheel driving motor, a tamping weight, a flame injection device, a top platform, a pulley hook, a fixed pulley assembly, a hoe Wheel and Hoe Motors. The chassis is in the shape of a mouth, and two pressure roller shafts are arranged inside, on which a hoe wheel and a pressure roller are sequentially installed along the traveling direction, that is to say, the hoe wheel first contacts the soft soil surface during the advancing process. Here the hoe wheel is driven by the hoe wheel motor, see attached image 3 , The transmission method adopts the reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com