Patents

Literature

40results about How to "Reduce wasted man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic painting robot for shipbuilding coating

The invention discloses an automatic painting robot for shipbuilding coating. The automatic painting robot for shipbuilding coating comprises a painting movement mechanism, a PLC and a spray gun; the painting movement mechanism comprises a side-to-side movement mechanism, a front-to-back movement mechanism and a rotational movement mechanism; the side-to-side movement mechanism comprises a first shell, a sliding block and a first motor, the first motor drives the sliding block to move from side to side, the spray gun is fixedly arranged on the sliding block, and the first shell is provided with a distance measuring sensor; the front-to-back movement mechanism comprises a second shell, an inner shell and a second motor, and the inner shell moves back and forth in the second shell; the rotational movement mechanism comprises a support plate, a third motor and a fixed gear wheel, the side-to-side movement mechanism and the support plate are connected with the inner shell through a bearing, the third motor drives the side-to-side movement mechanism to rotate around the bearing, and the distance measuring sensor, the first motor, the second motor and the third motor are electrically connected with the PLC. According to the automatic painting robot for shipbuilding coating, the work efficiency is improved, the labor cost is reduced, the construction period is shortened, the evenness of a paint coating is good, and the quality of the paint coating is improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

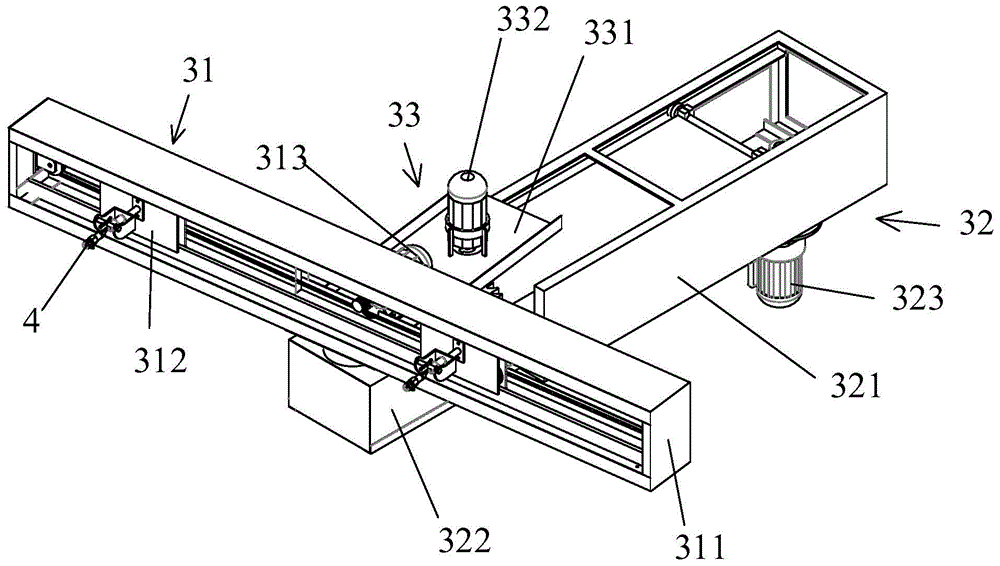

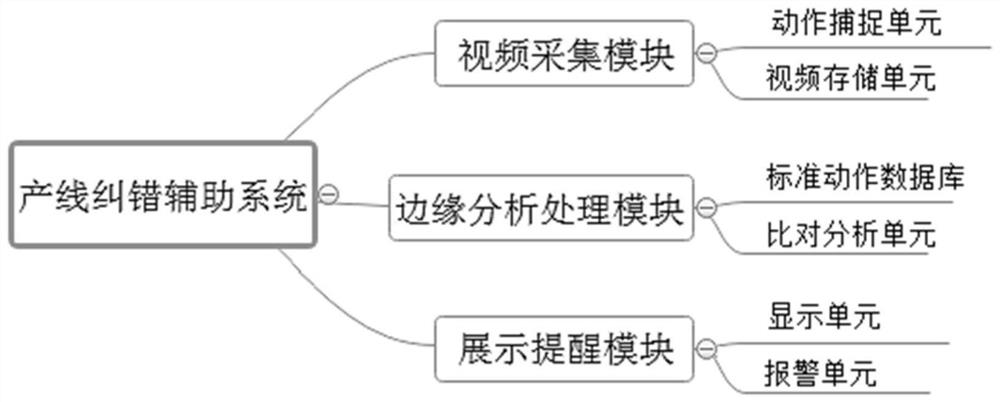

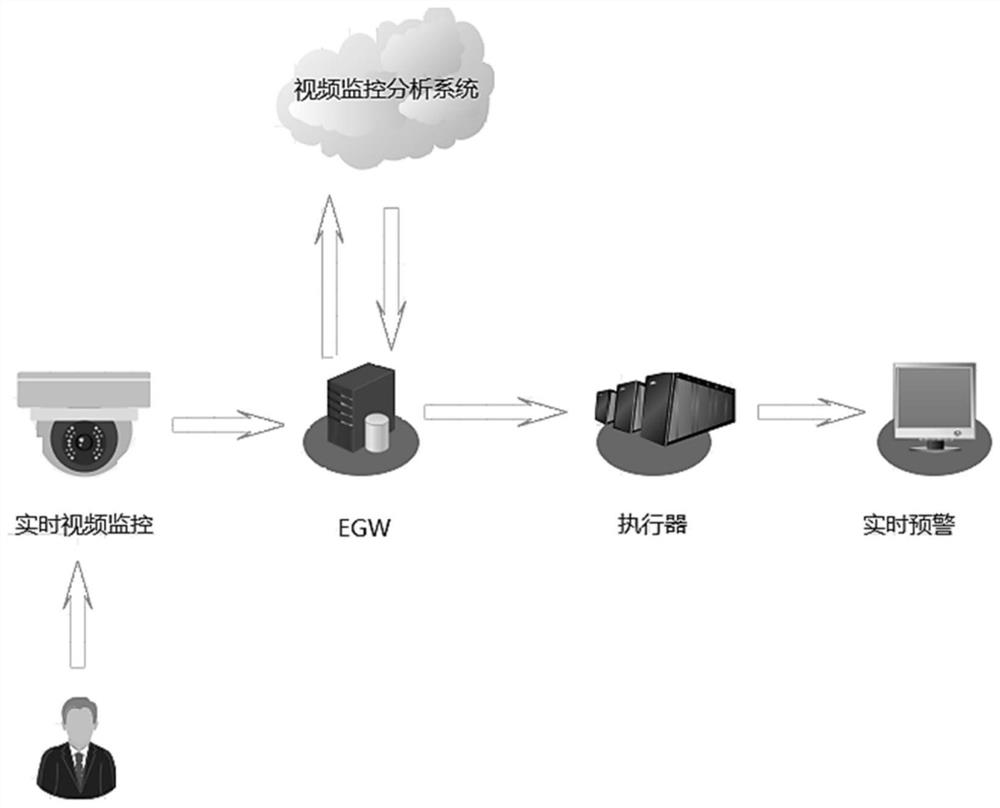

Production line error correction auxiliary system and method based on edge gateway

PendingCN112689069AAvoid transmissionAvoid processing powerTelevision system detailsImage analysisVideo monitoringProduction line

The invention relates to a production line error correction auxiliary system and method based on an edge gateway, and the method comprises the steps: collecting the movement of a production line operator and the time from the arrival of a product on a production line to the departure of the product from the production line operator in real time through a real-time video monitoring camera, and connecting the product with the edge gateway through the Ethernet; the edge gateway receiving the video data stream, firstly preprocessing the video data, converting the format of the video data into a predetermined video format, then performing image detection, performing feature point extraction in an image, and uploading an extraction result to the cloud video monitoring analysis server through wifi; after intelligent judgment is carried out at the cloud, the edge gateway sending an action instruction to the actuator according to a result, the display reminding module being activated, and achieving a series of display actions such as reminding and alarming. Compared with the prior art, the method has the advantages that the problem of action of an operator can be found in time, and labor hour waste caused by unnecessary action is reduced.

Owner:SHANGHAI SIIC LONGCHUANG SMARTER ENERGY TECH CO LTD

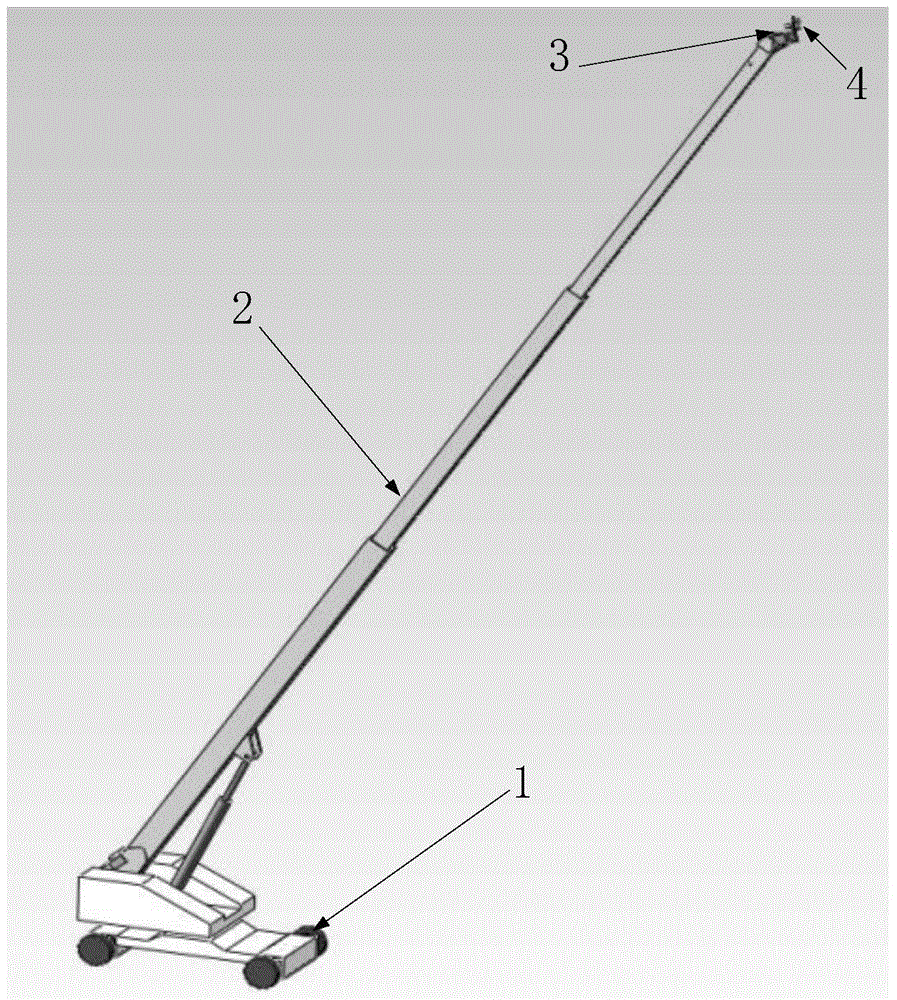

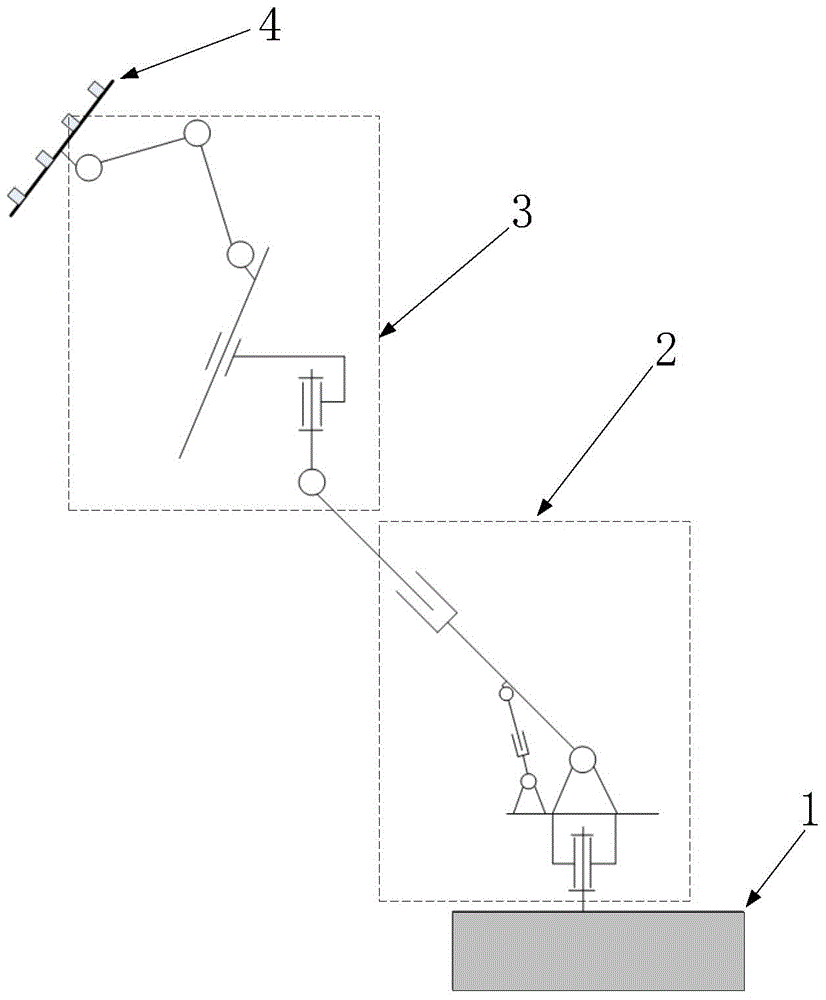

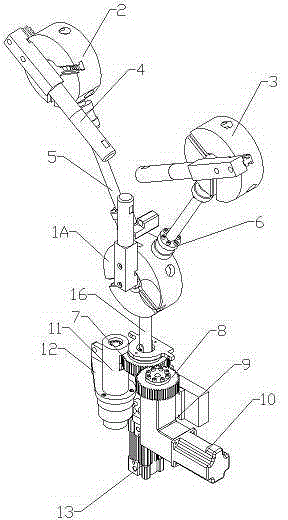

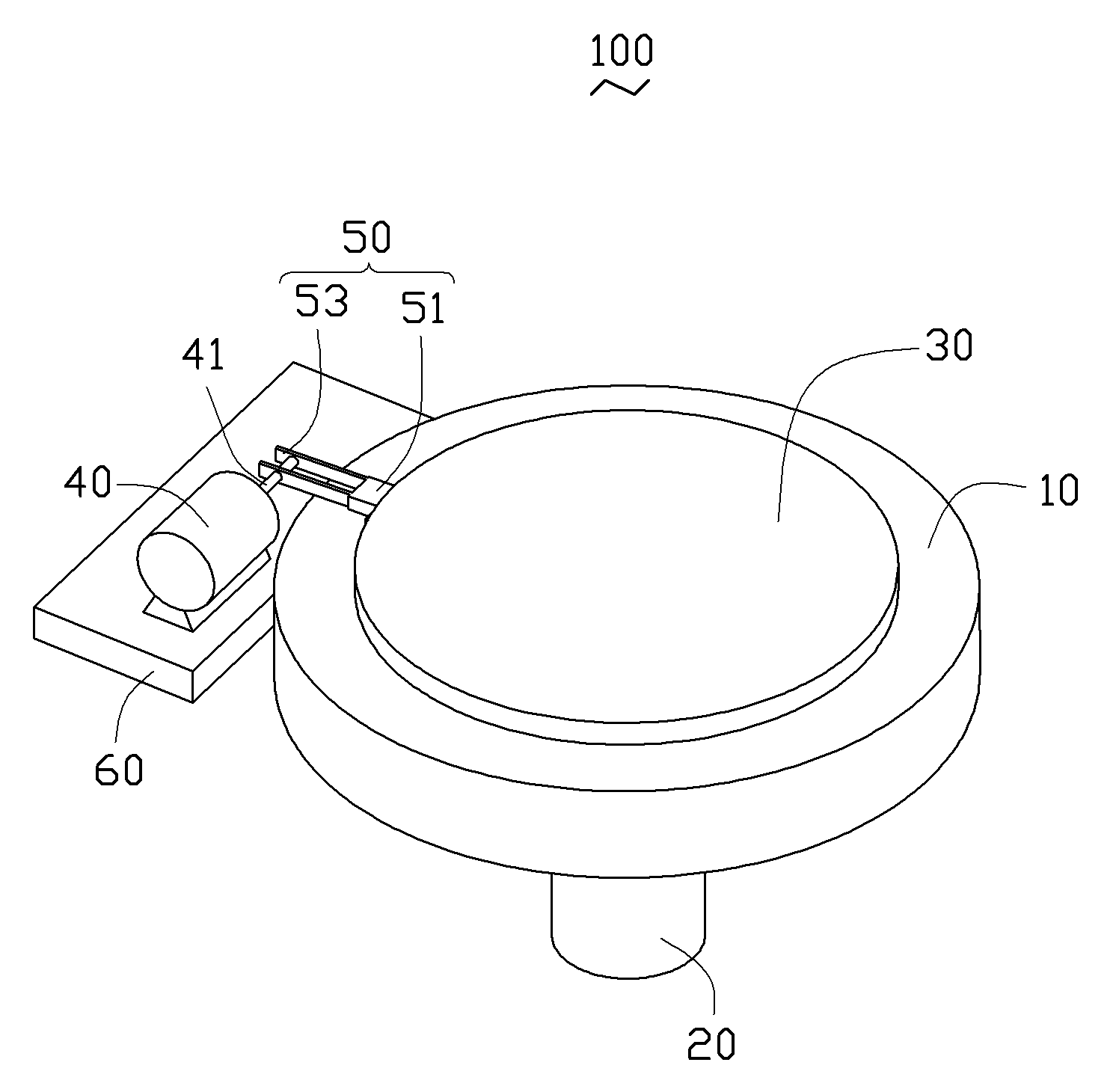

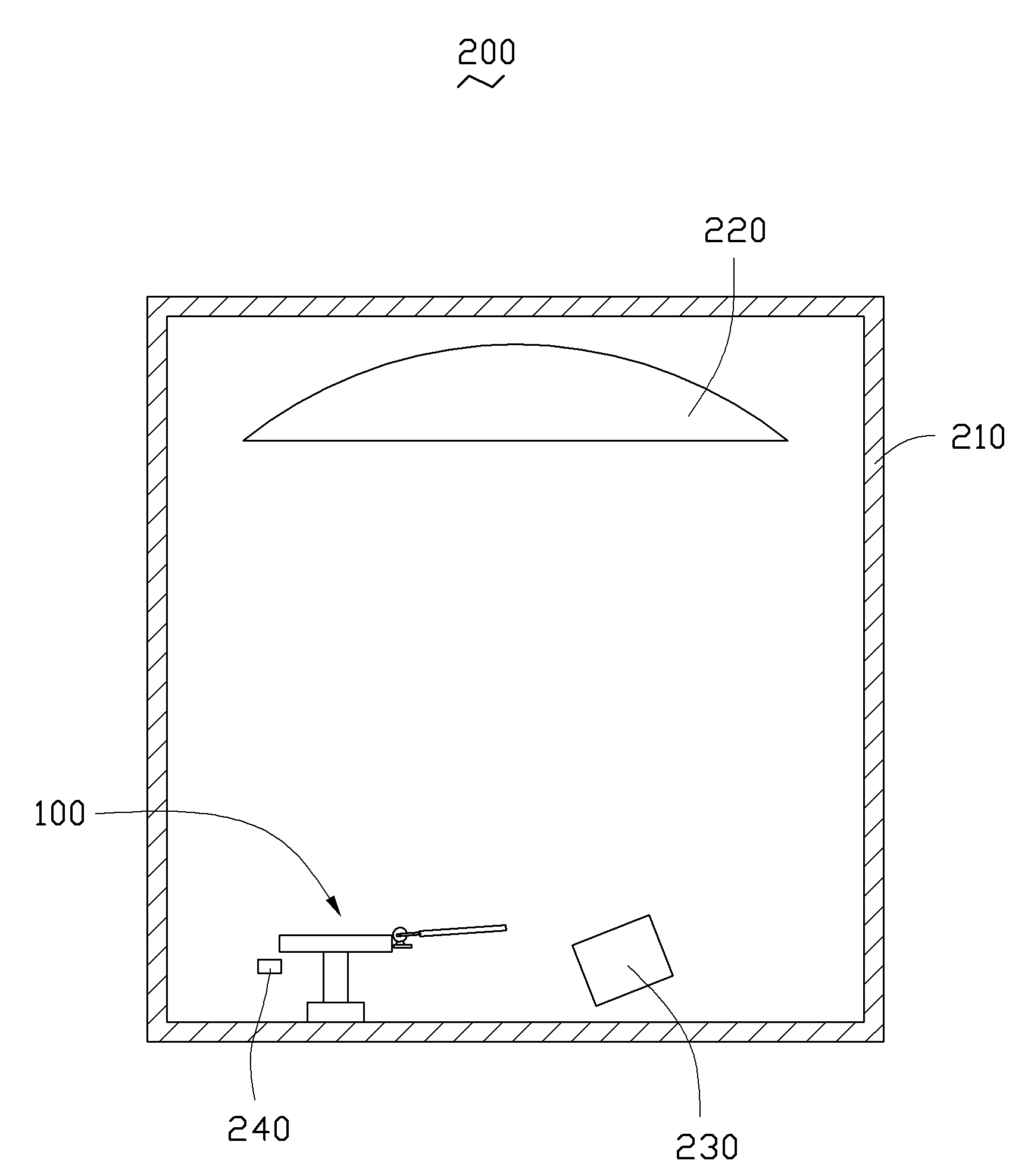

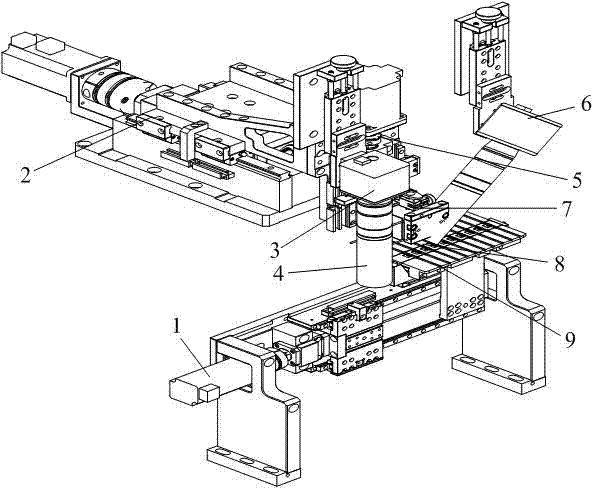

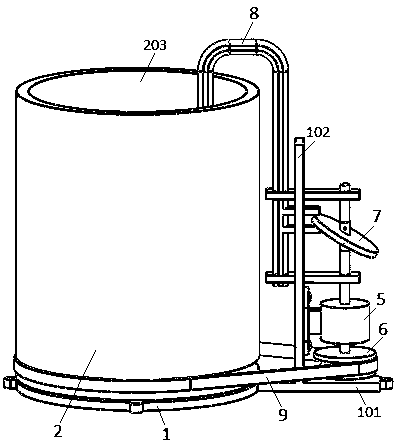

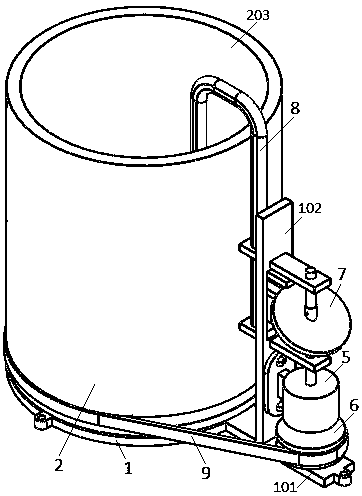

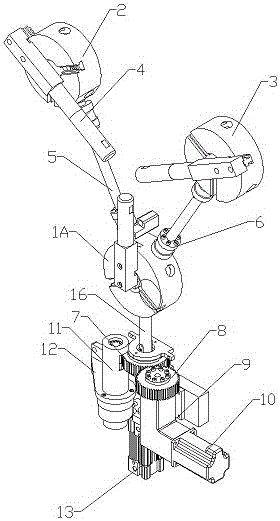

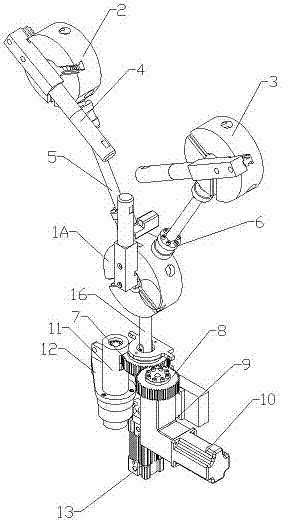

Spraying robot for surface of ship body

InactiveCN104624429AImprove spray uniformityHigh repeatabilitySpraying apparatusActuatorControl theory

The invention discloses a spraying robot for a surface of a ship body. The spraying robot comprises a chassis, a large arm, a small arm and a tail end actuator. The tail end actuator comprises a spraying gun installation base, at least one spraying gun and at least one laser displacement sensor for controlling the pose of the tail end actuator. The spraying robot for the surface of the ship body is used for avoiding influence of harmful gas in spraying and repeating the same operation action tirelessly, and is suitable for replacing manpower to carry out the operation in high pollution and intensity work like ship body spraying. The intelligent spraying robot for the ship body is adopted to complete the spraying work so that the pollution in the spraying process can be reduced, energy can be saved, and the working efficiency can be improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

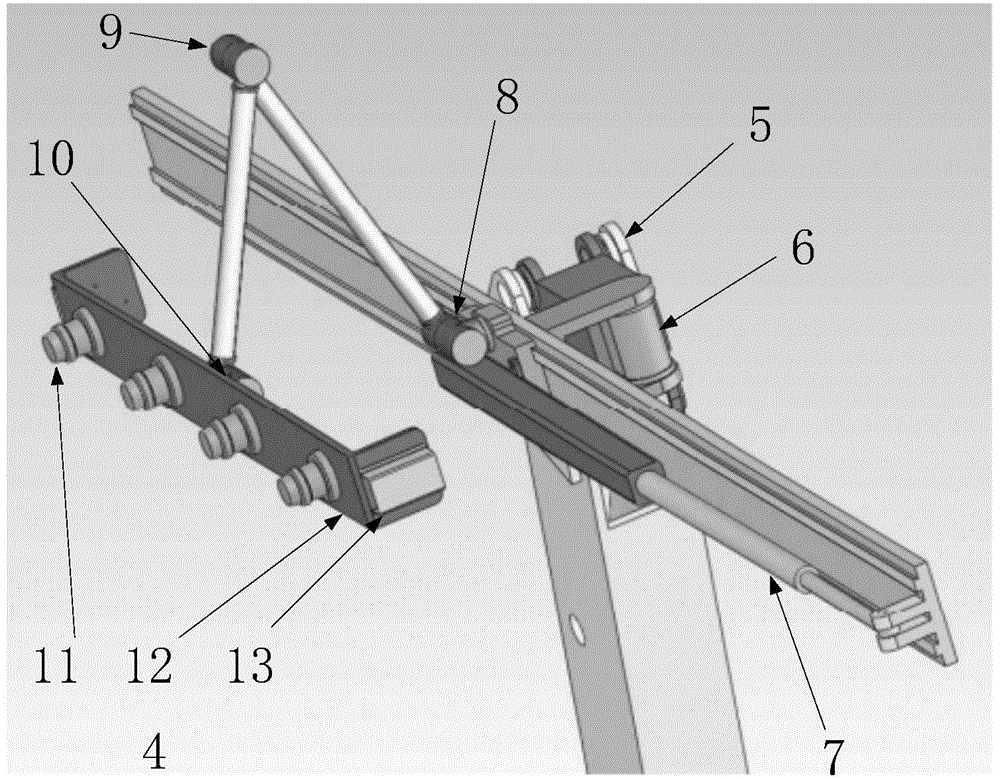

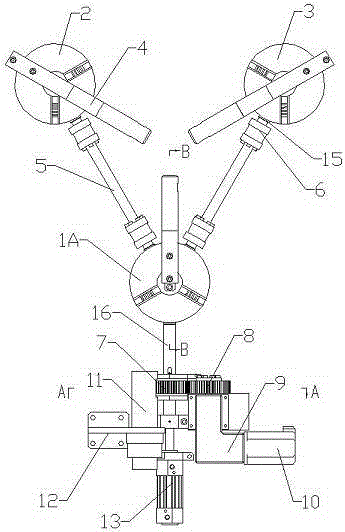

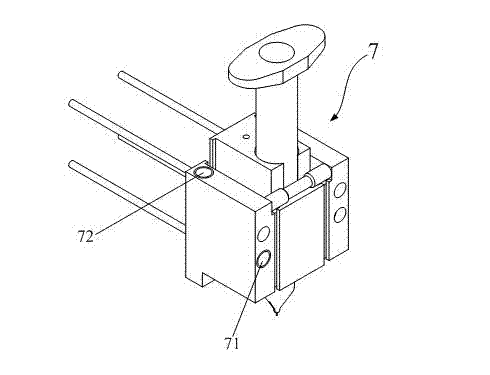

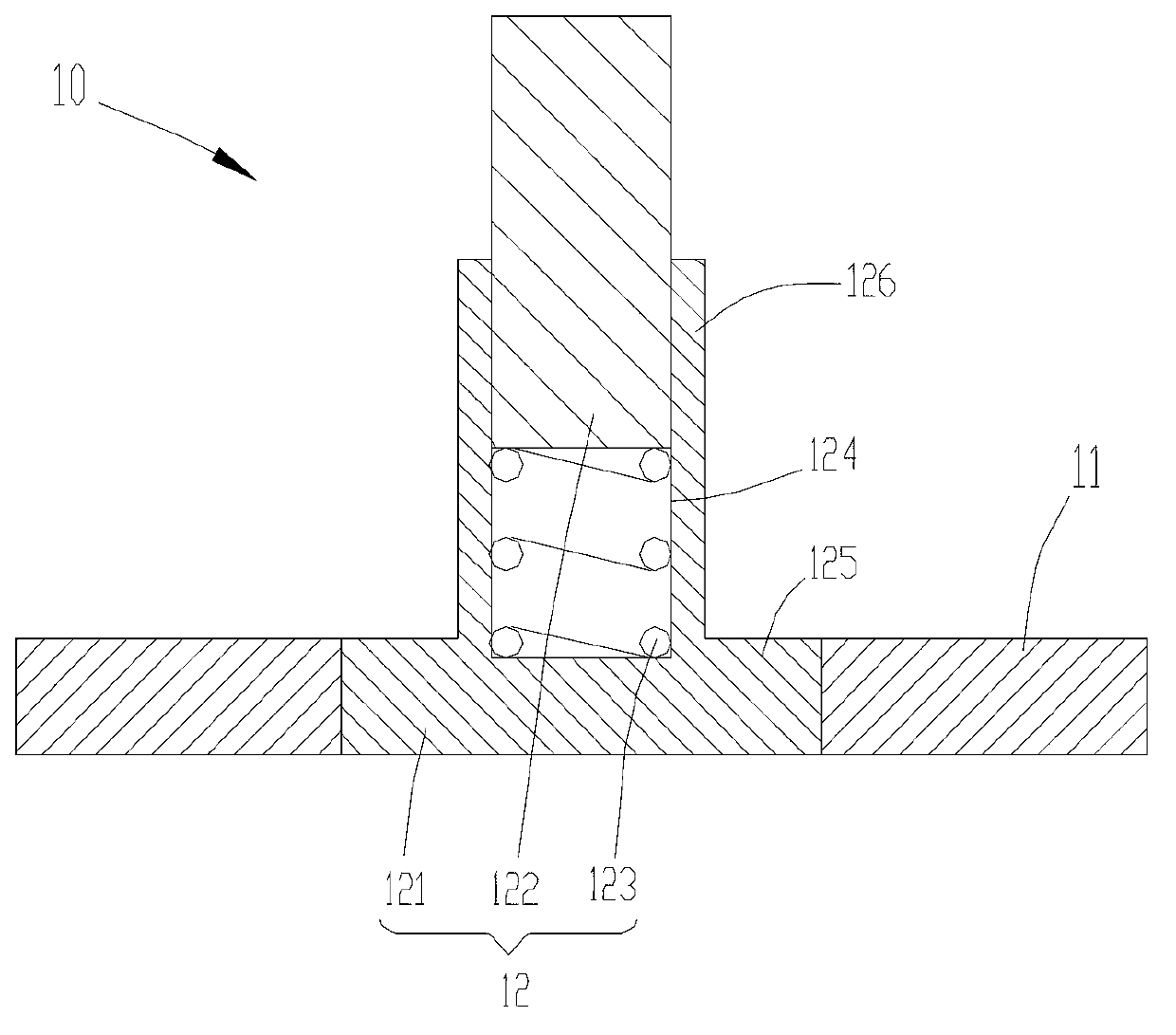

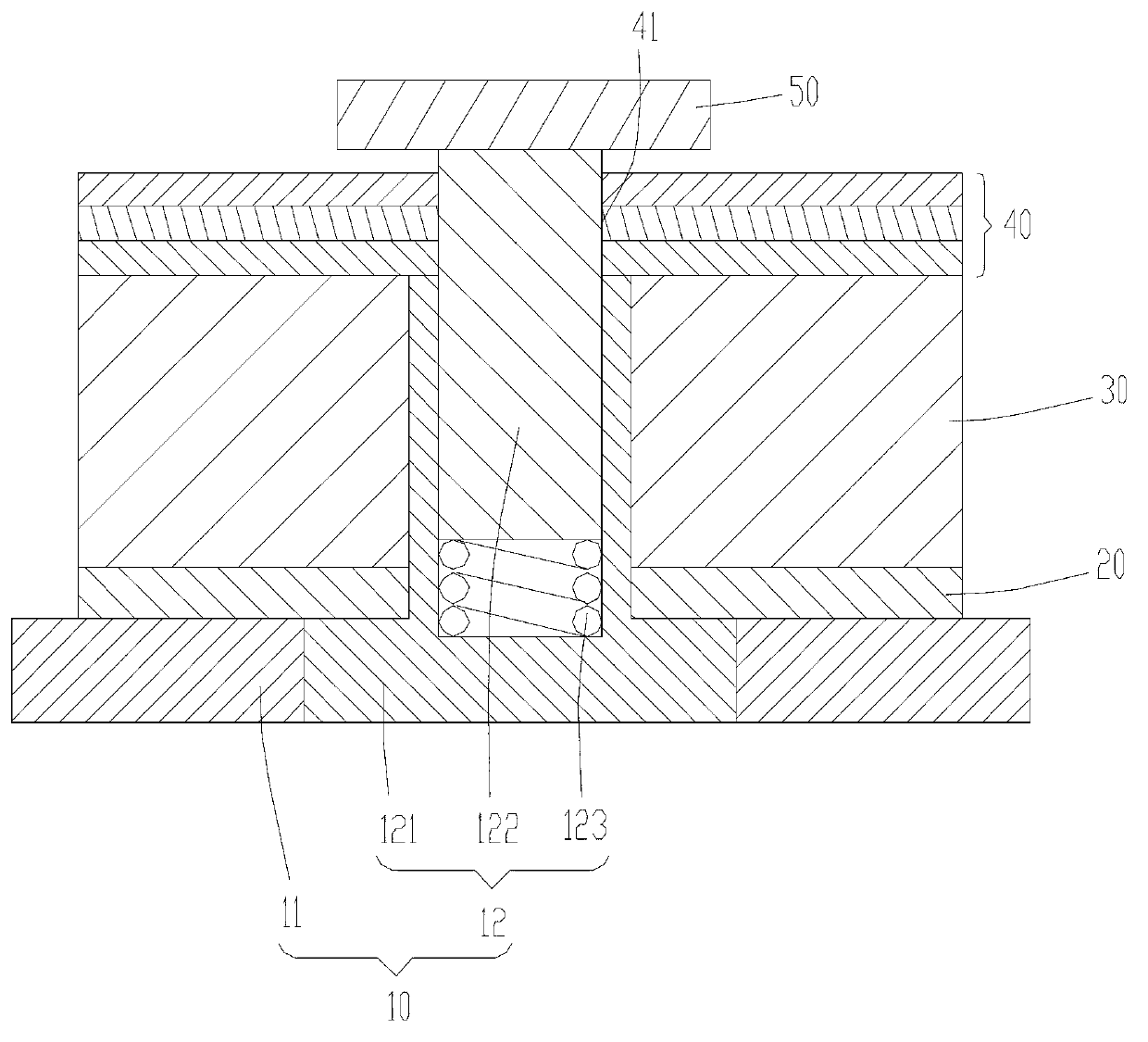

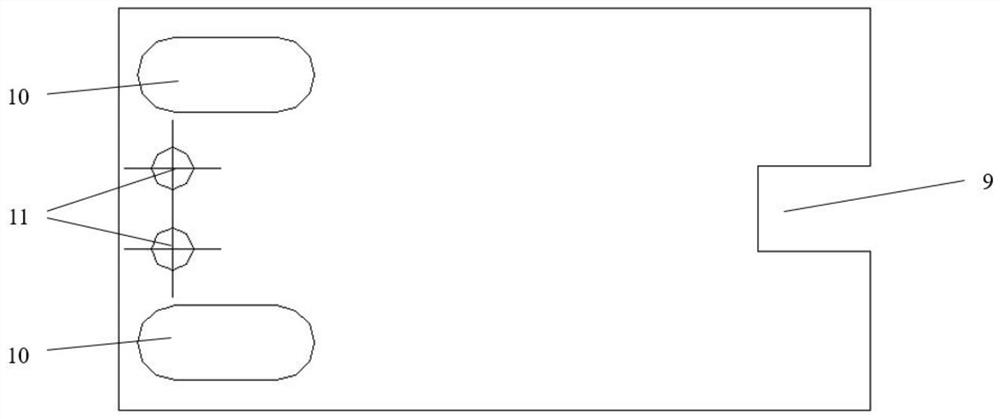

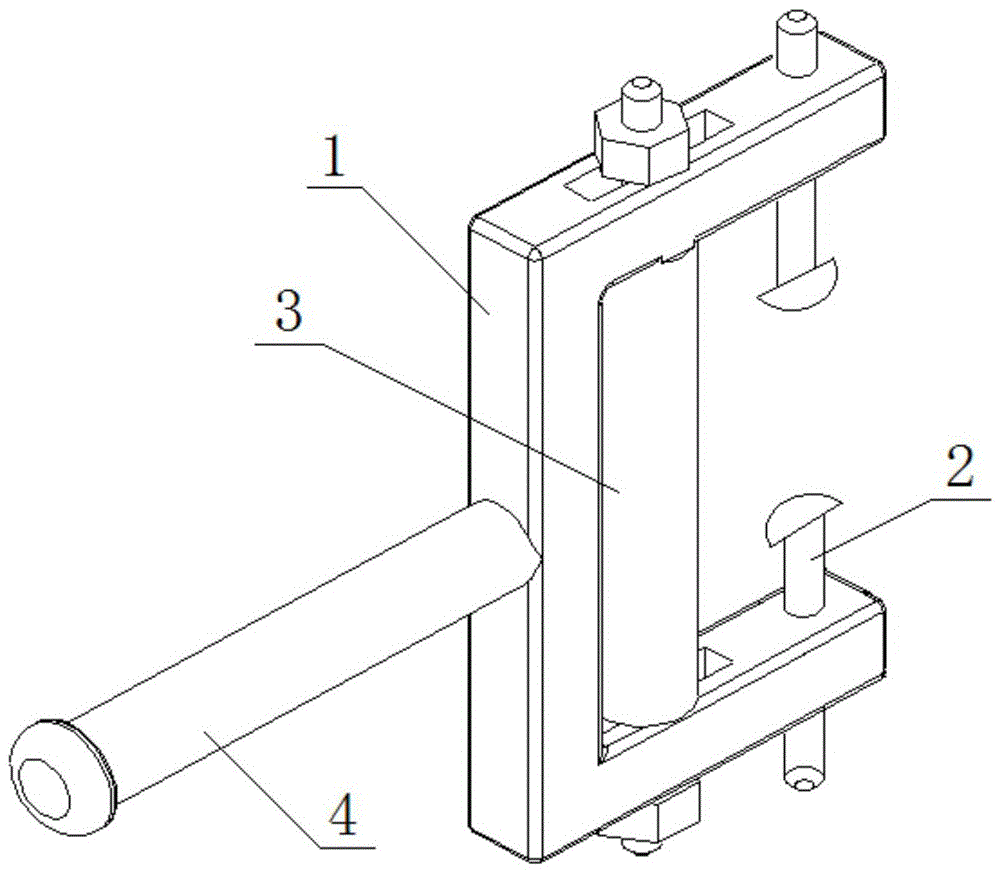

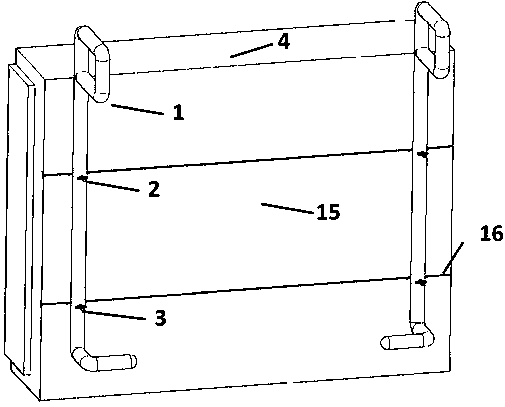

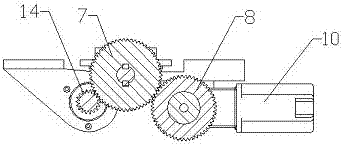

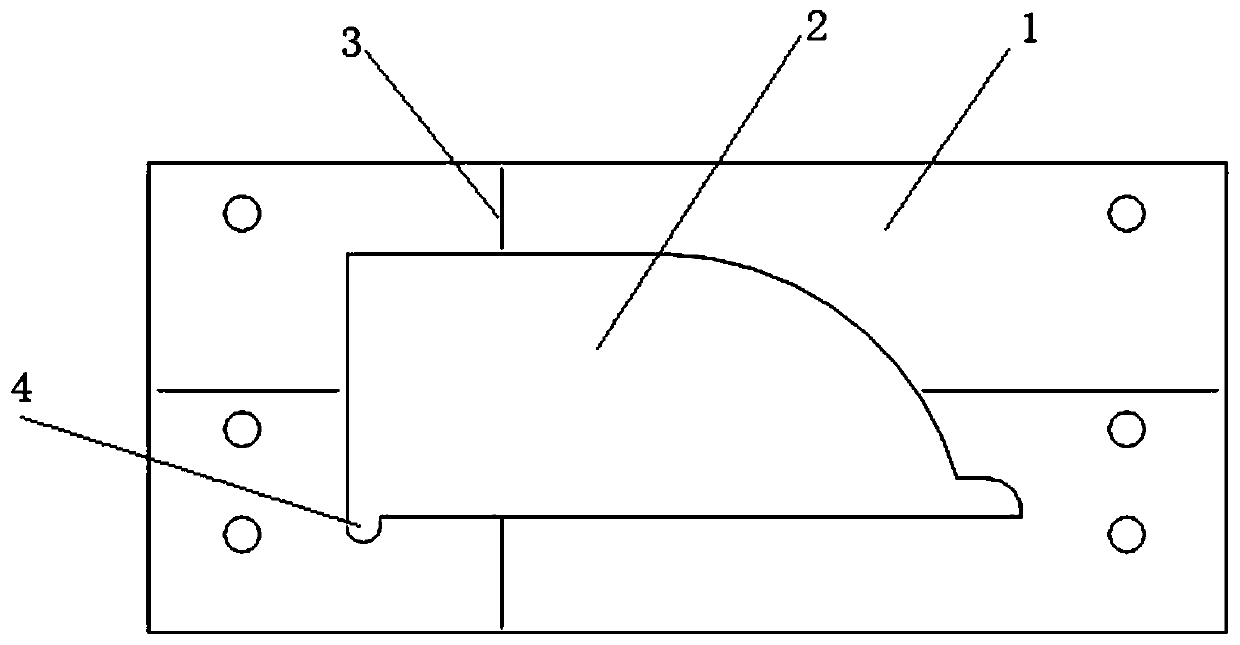

Three-jaw self-centering chuck clamping device

ActiveCN105171324AReliable clampingReduce wasted man-hoursWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a three-jaw self-centering chuck clamping device. The three-jaw self-centering chuck clamping device is composed of three centering chucks distributed in a triangular shape, and the three centering chucks are driven by the same power and linked synchronously, so that a self-centering function is achieved. According to the three-jaw self-centering chuck clamping device, the centering chucks are adopted, so that the device is especially suitable for automatic backing welding of a connecting pipe with flanges on the two sides and the flanges, and the workpiece can be directly lifted away along the chucks after being welded.

Owner:HIMILE MECHANICAL MFG

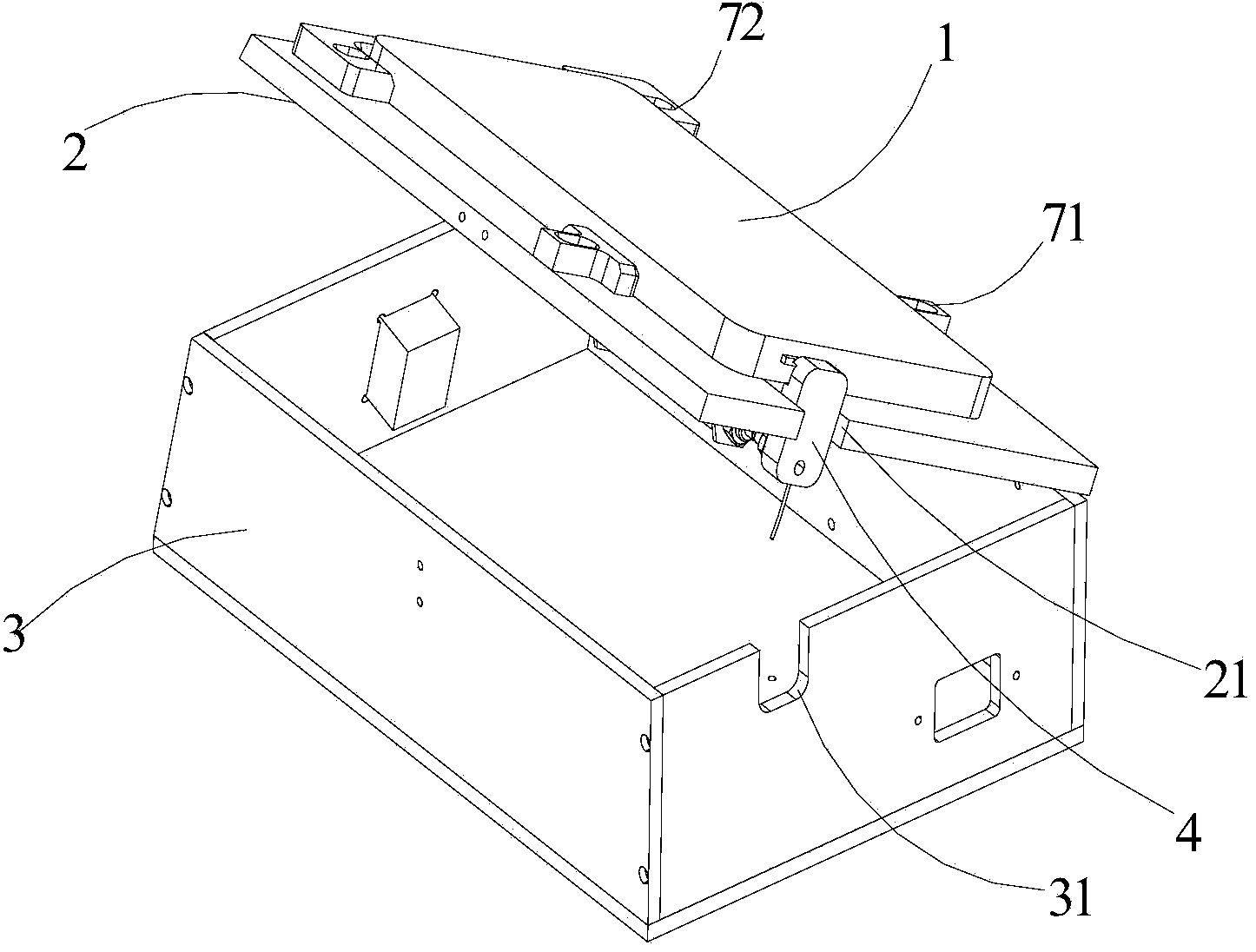

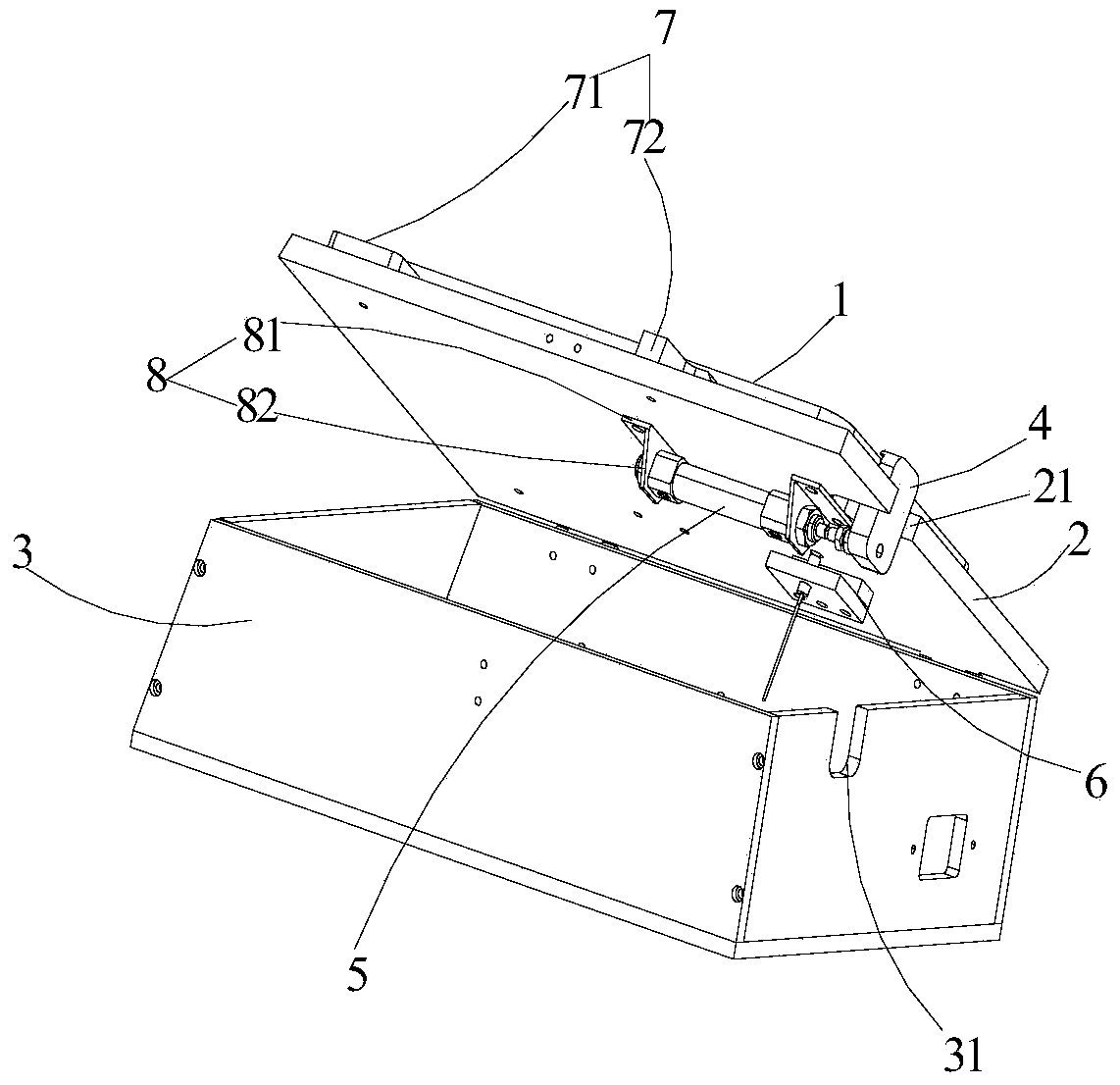

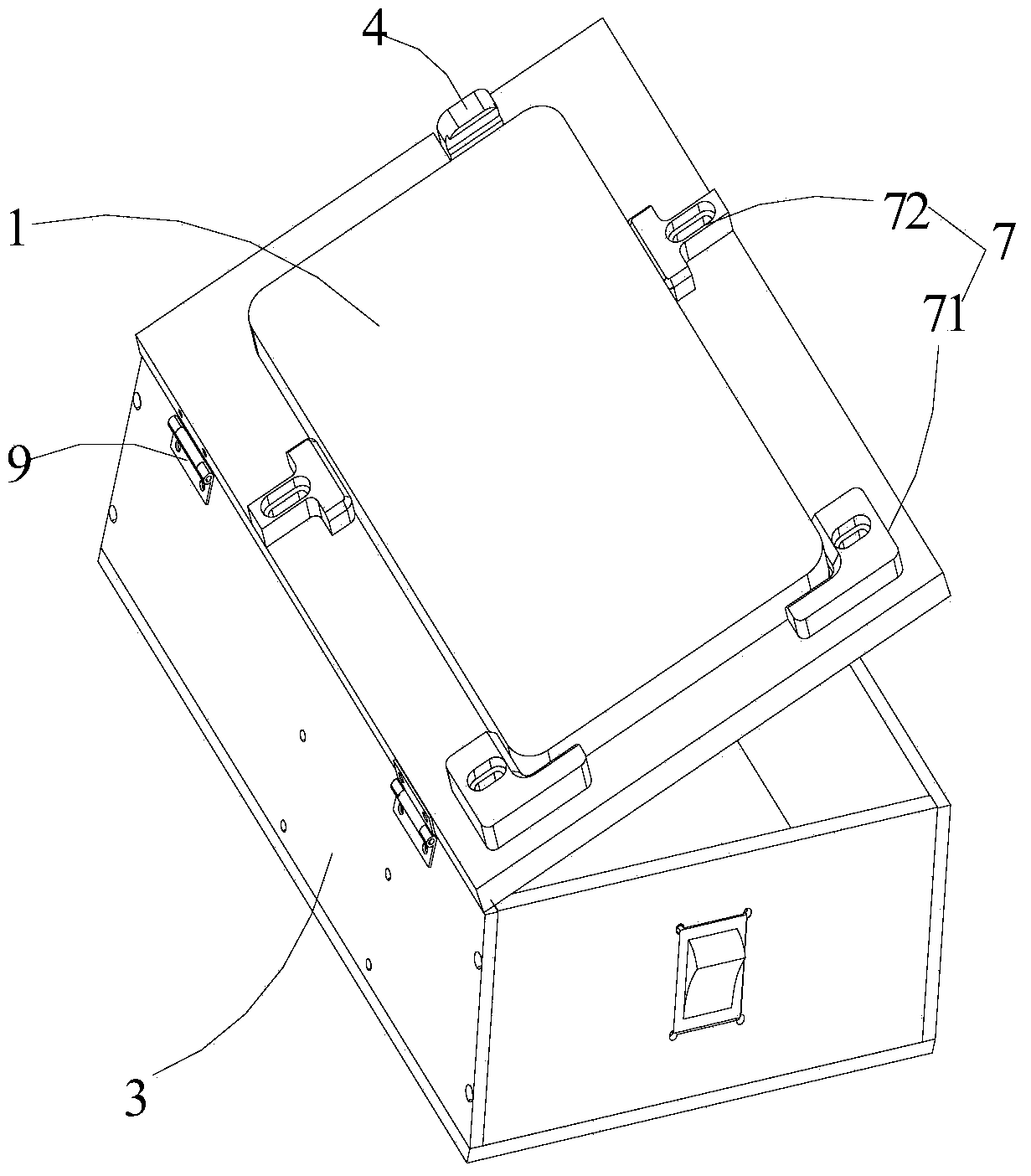

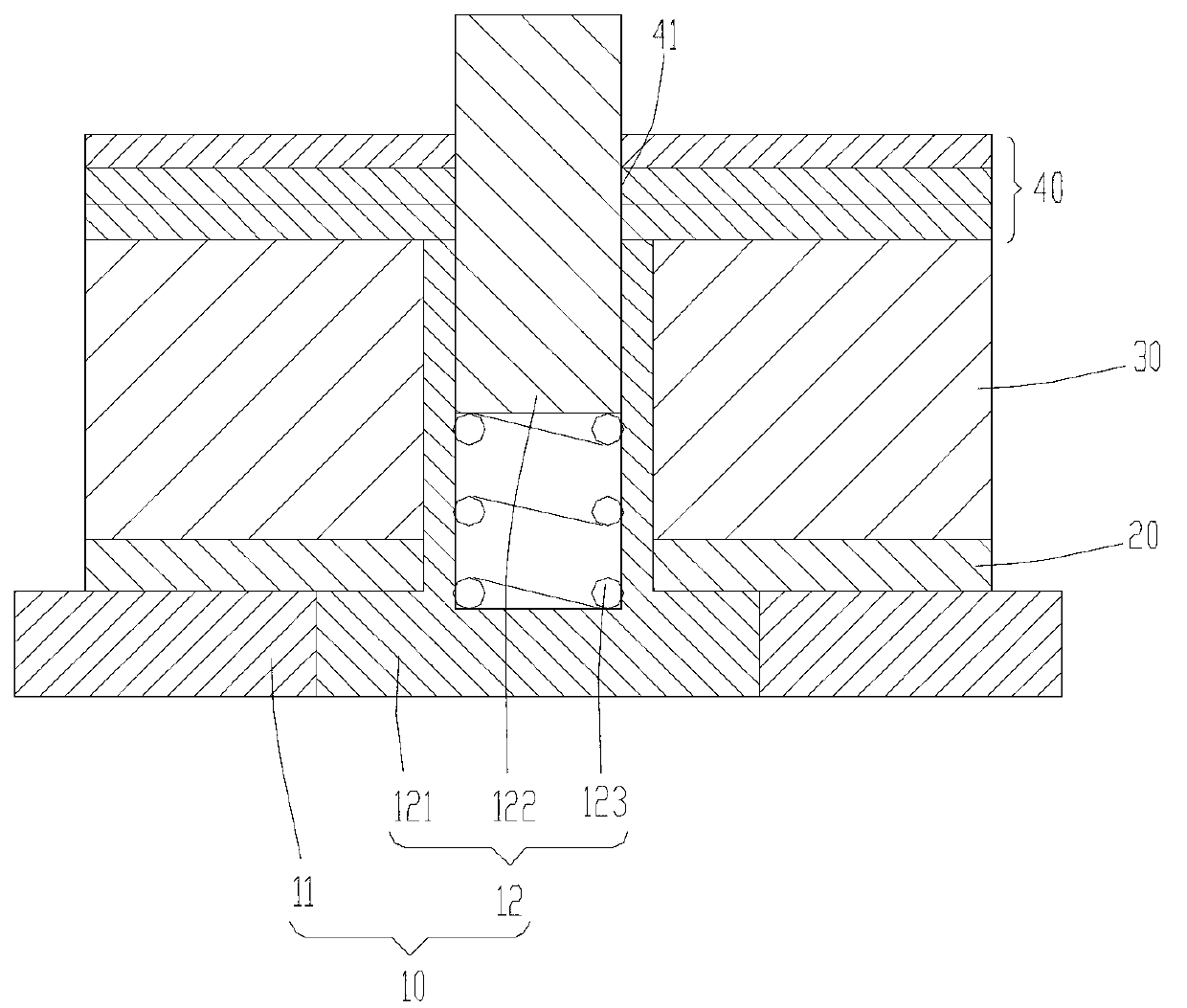

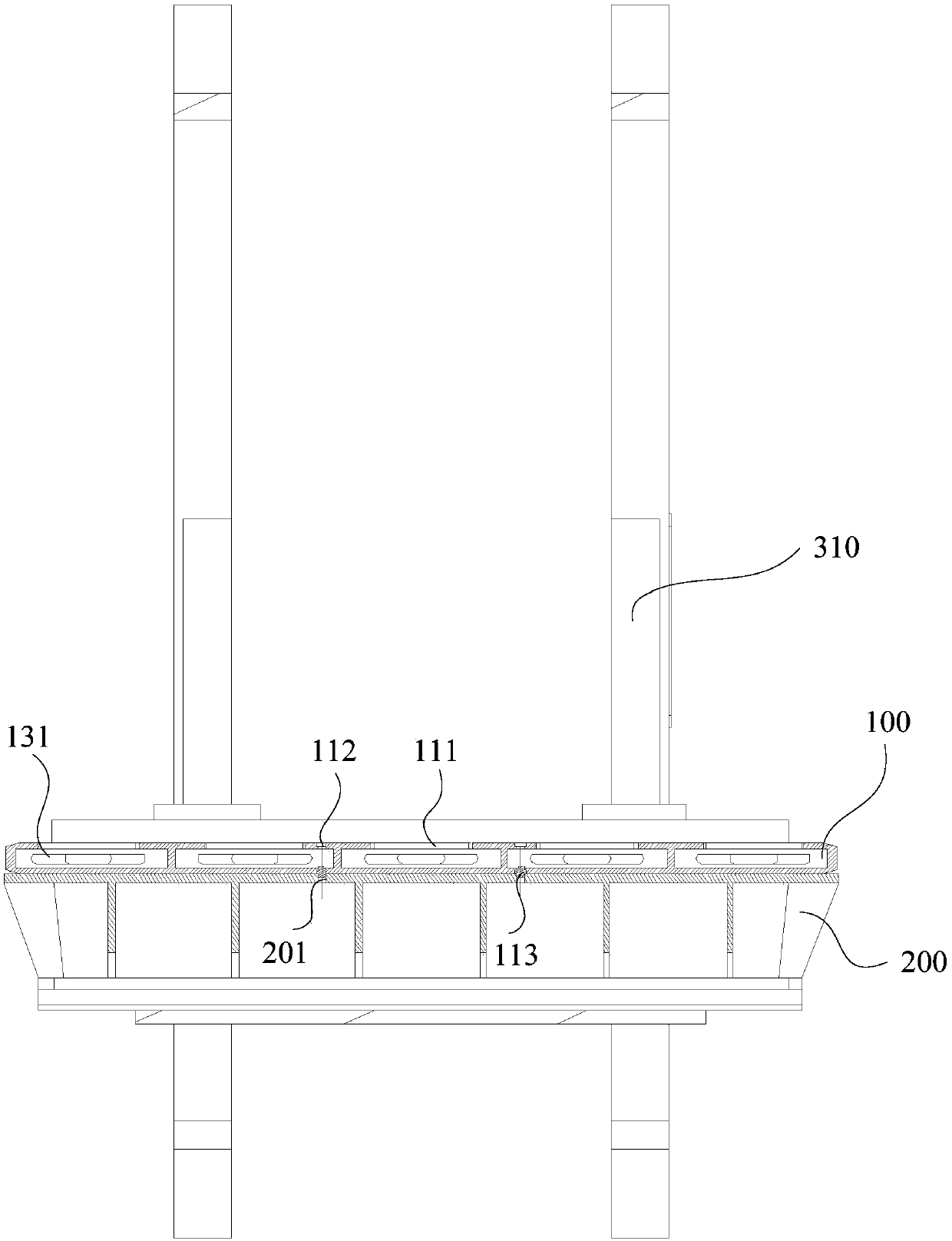

Film material processing device and vapor deposition equipment with same

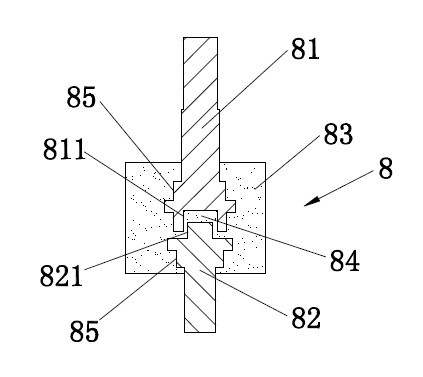

InactiveCN102337502AEvenly heatedCompact internal structureVacuum evaporation coatingSputtering coatingCrucibleDrive shaft

The invention discloses a film material processing device which is used for leveling vapor deposition film material and comprises a crucible and a rotating shaft, wherein the crucible is provided with an accommodating hole for accommodating the film material; and the rotating shaft is connected with the crucible which can rotate around the rotating shaft. The film material processing device further comprises a leveling cover and a driver; the leveling cover and the accommodating hole of the crucible are matched for leveling the film material in the accommodating hole; the leveling cover is provided with a leveling surface of which the shape corresponds to the shape of the accommodating hole; the driver is provided with a driving shaft; the driving shaft and the leveling cover are matched; the driver is used for driving the leveling cover to rotate around the driving shaft so as to close or open the accommodating hole of the crucible; and when the accommodating hole is closed by the leveling cover, the leveling surface faces the bottom of the accommodating hole. The invention also provides vapor deposition equipment which is provided with the film material processing device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

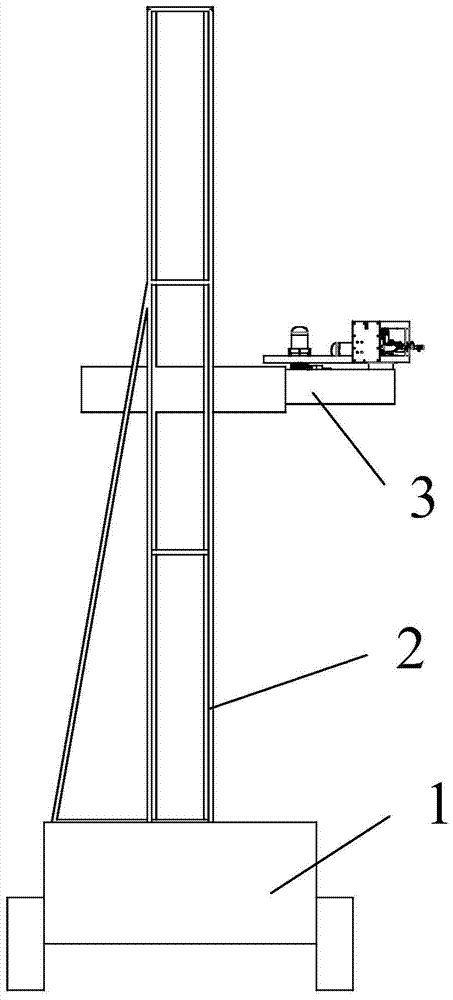

Shallow soft soil solidifying device and solidifying method thereof

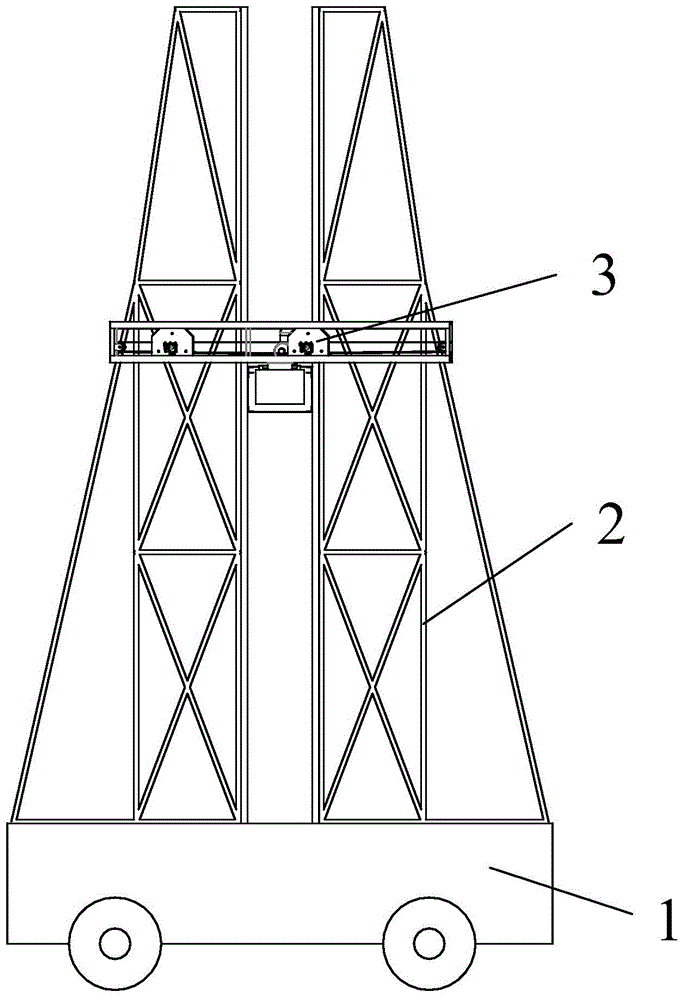

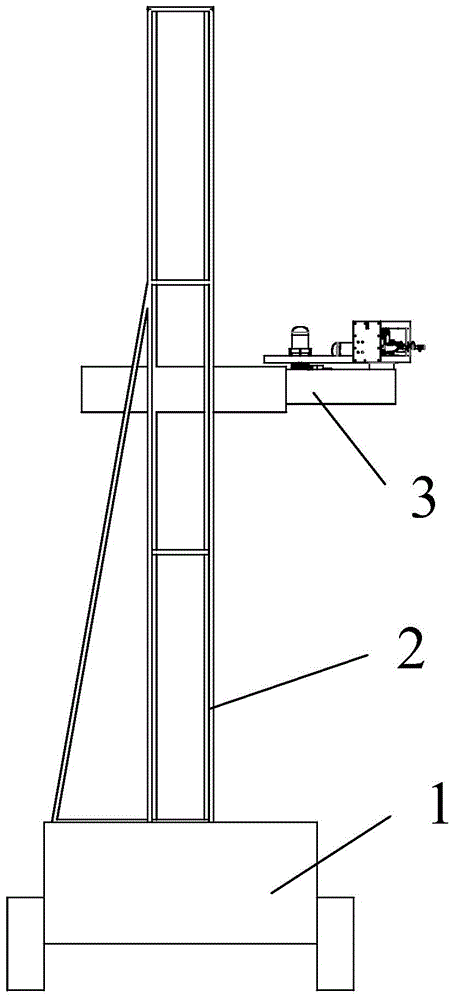

The invention discloses a shallow soft soil solidifying device and a solidifying method thereof. The shallow soft soil solidifying device comprises a chassis, a support and a top platform; the support is arranged between the chassis and the top platform in a supporting mode, the chassis is provided with two parallel press roll shafts, the longitudinal axes of the press roll shafts are perpendicular to the advancing direction, a hoe wheel and a press roll are sequentially installed on the press roll shafts in the advancing direction, the hoe wheel is shaped like a cylinder, hoe hooks are densely distributed on the surface of the hoe wheel, the hoe wheel is driven by a hoe wheel motor, and a flame jetting device used for evaporating ground water is arranged on the inner side of the chassis; a land compacting heavy block is arranged under the top platform and rises and falls through a jack mechanism. Compared with the prior art, the shallow soft soil solidifying device and the solidifying method thereof have the advantages that surface soft soil can be softened and subjected to heating pretreatment to enable the water in the surface soft soil to be volatilized and then subjected to hardening treatment through land compacting, therefore, the efficiency can be improved, the soft soil can be quickly softened, and unnecessary labor and time waste can be reduced.

Owner:HOHAI UNIV

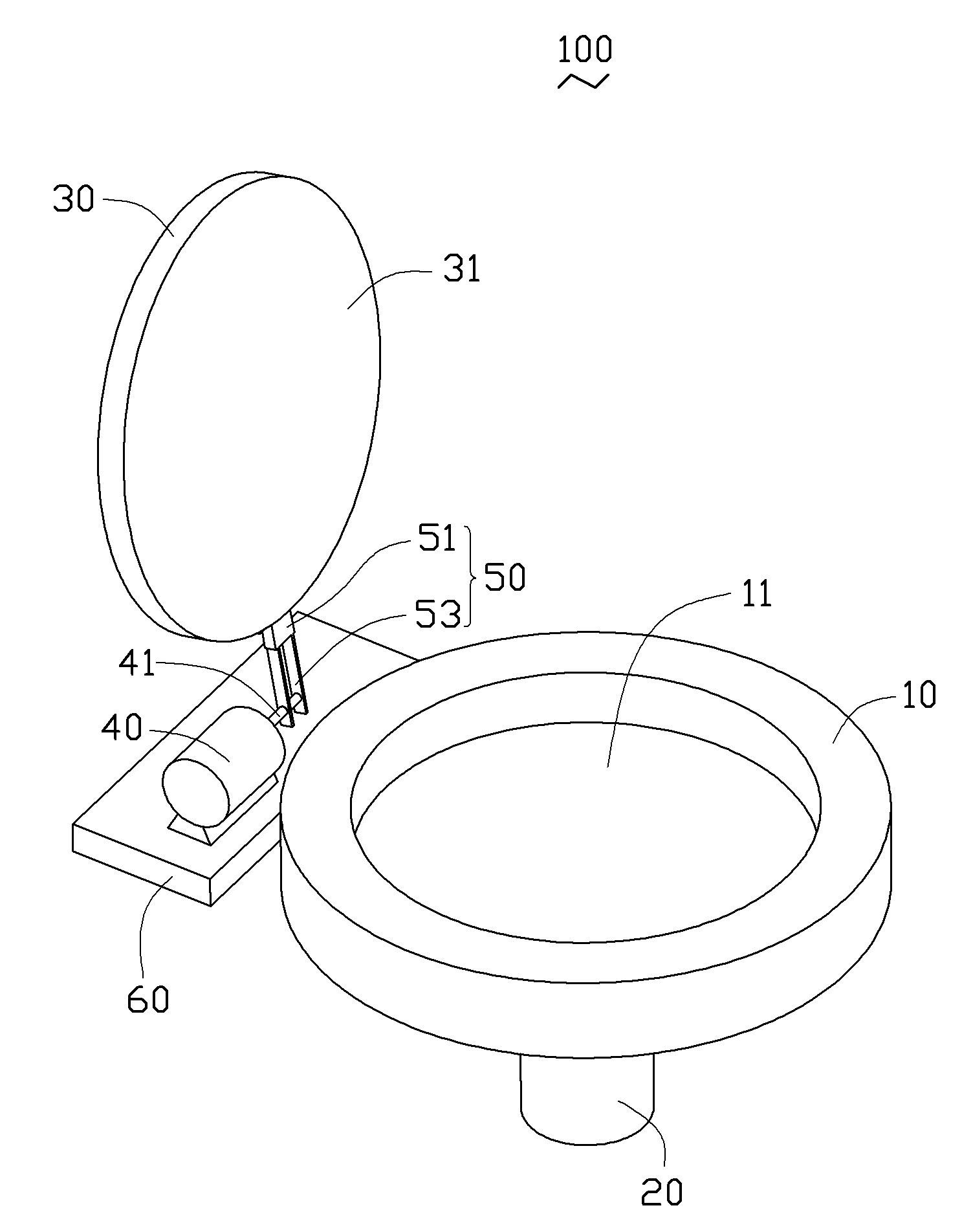

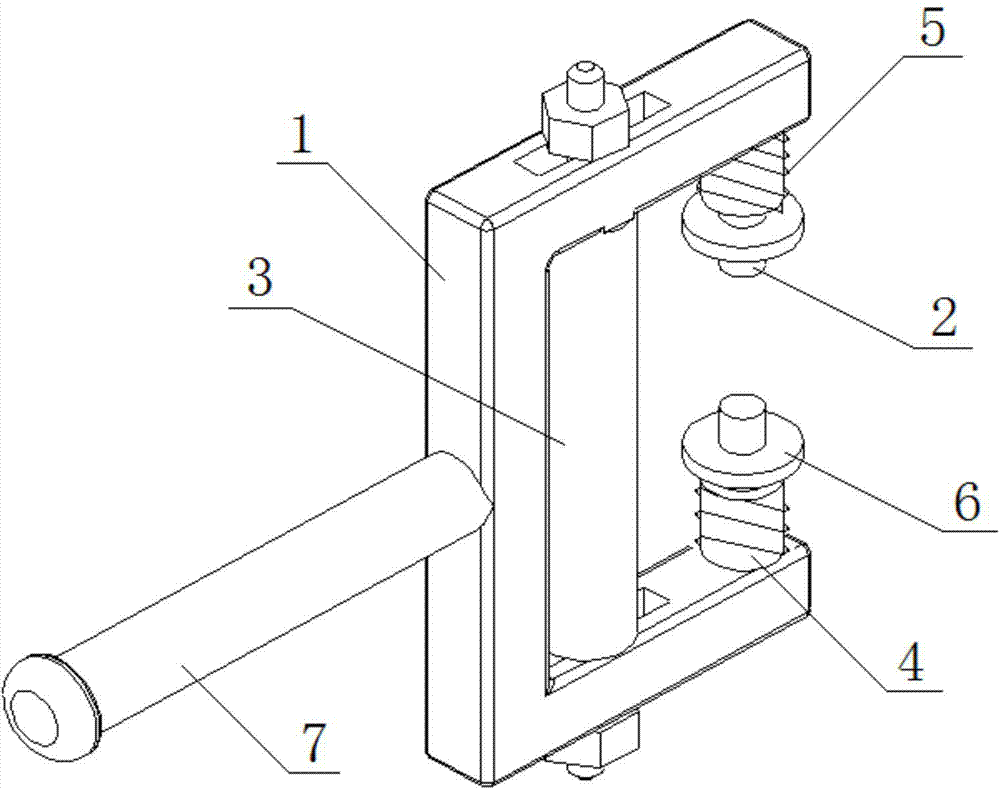

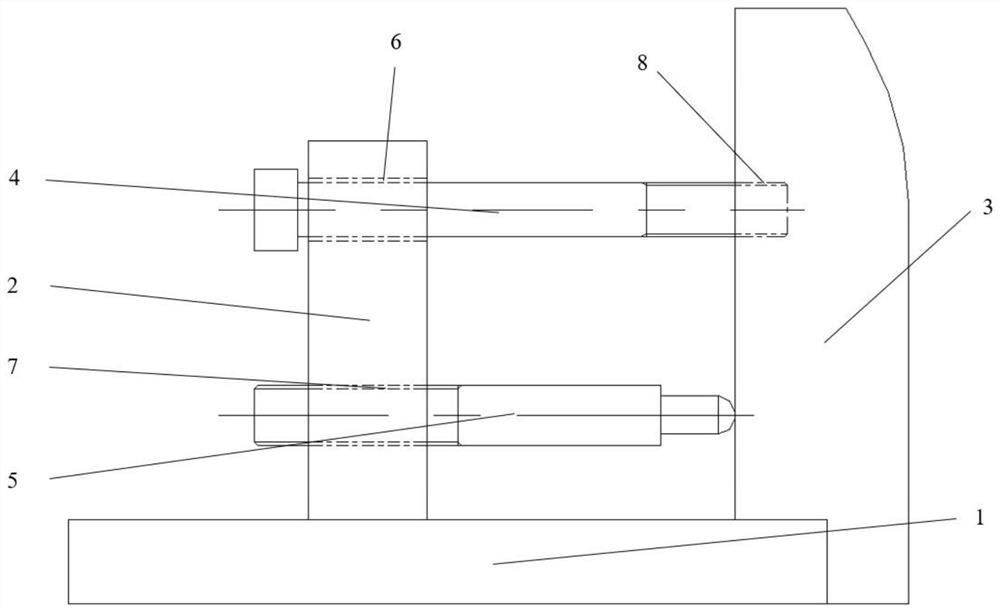

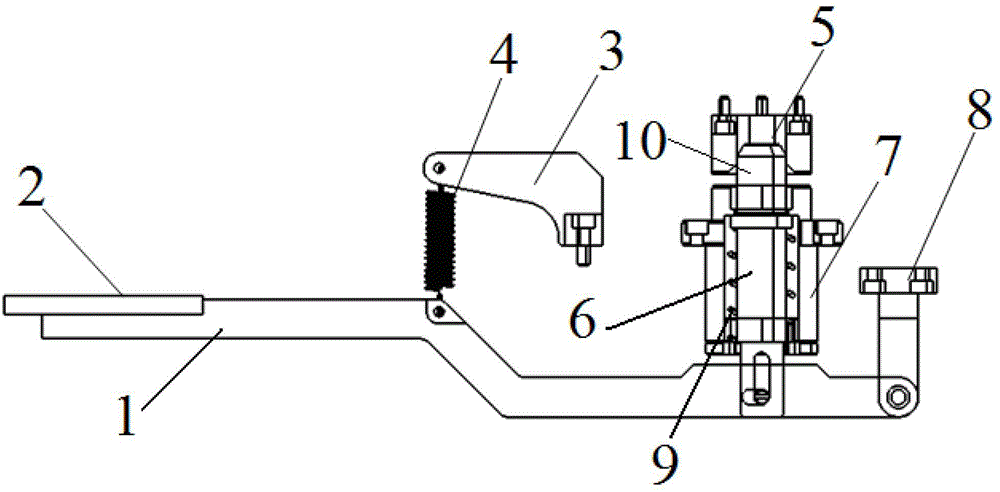

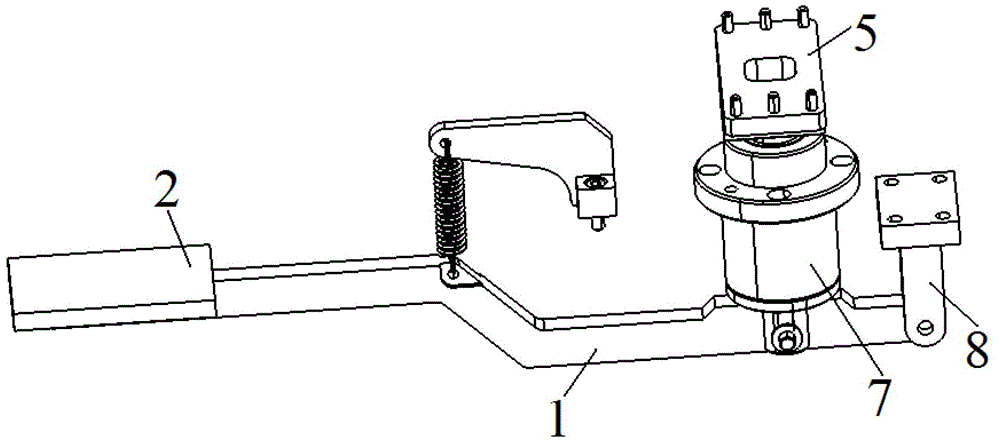

Automatic power-on device

ActiveCN104297527ASave boot timeReduce wasted man-hoursElectrical measurement instrument detailsElectrical testingMobile phoneControl system

The invention belongs to the technical field of clamps and particularly relates to an automatic power-on device. The automatic power-on device comprises an installation board, a support, a pressure head, a drive device, an induction device and a control system, wherein a product to be powered on is placed on the installation board, the support is used for supporting the installation board, the pressure head is used for pressing a power-on button of the product to be powered on, the drive device is used for controlling the pressure head to move, the induction device is used for inducing whether the product to be powered on is placed on the installation board or not, the drive device is connected with the pressure head, and the drive device and the induction device are arranged on the installation board and connected with the control system. Compared with the prior art, as the induction device, the drive device and the pressure head are installed on the installation board with the to-be-powered-on device such as a mobile phone and a Pad, automatic power-on operation can be achieved, the power-on time is shortened for operators, working hour waste in the power-on process is reduced, operators can carry out other test actions due to the saved power-on time, the working hour is utilized more reasonably, and working efficiency is improved.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

Radial magnetic bearing and sensor bracket split structure

InactiveCN106402158ASimplify control proceduresReduce control errorBearing assemblyShaft assemblySensor holderEngineering

Owner:NANJING CIGU TECH CORP LTD

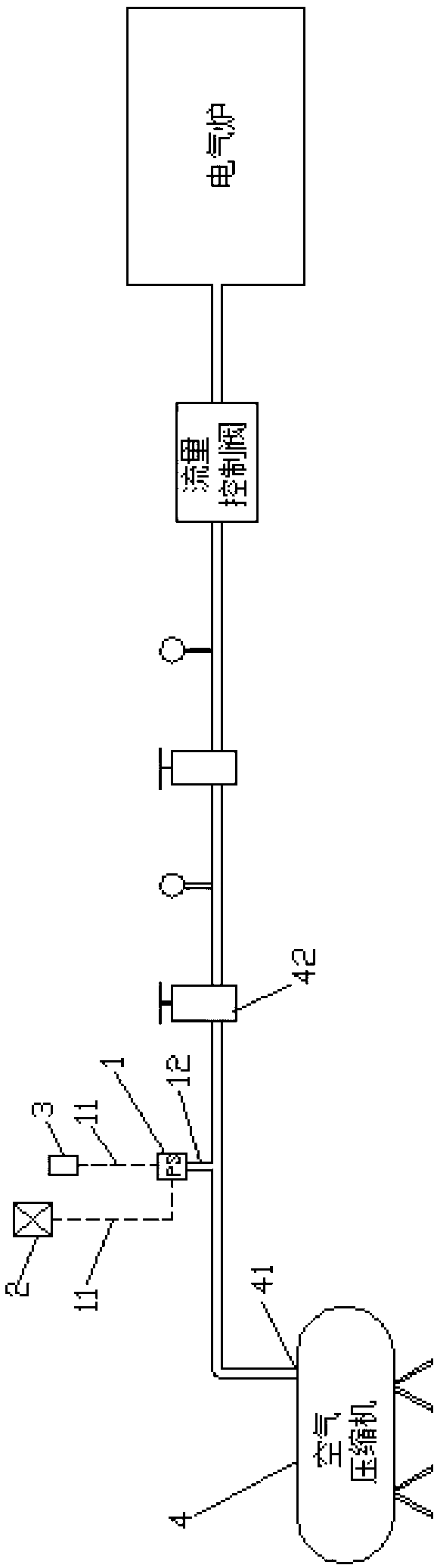

Low-pressure prevention alarm device for air compressor

InactiveCN103062032AReduce wasted man-hoursProduct quality is stablePump controlPositive-displacement liquid enginesEngineeringAlarm device

The invention discloses a low-pressure prevention alarm device for an air compressor. The low-pressure prevention alarm device comprises a pressure switch and an alarm. The pressure switch is electrically connected with the alarm and a power source through electric wires. A pressure detecting head of the pressure switch is mounted between an air outlet of the air compressor and a reducing valve through a connecting pipeline. By the aid of the low-pressure prevention alarm device for the air compressor, waste of working hours for spot check for multiple times can be effectively reduced, real-time monitoring can be realized, and the low-pressure prevention alarm device plays a significant role in stabilizing product quality and reducing product loss.

Owner:KUSN NICERA ELECTRICAL APPLIANCE

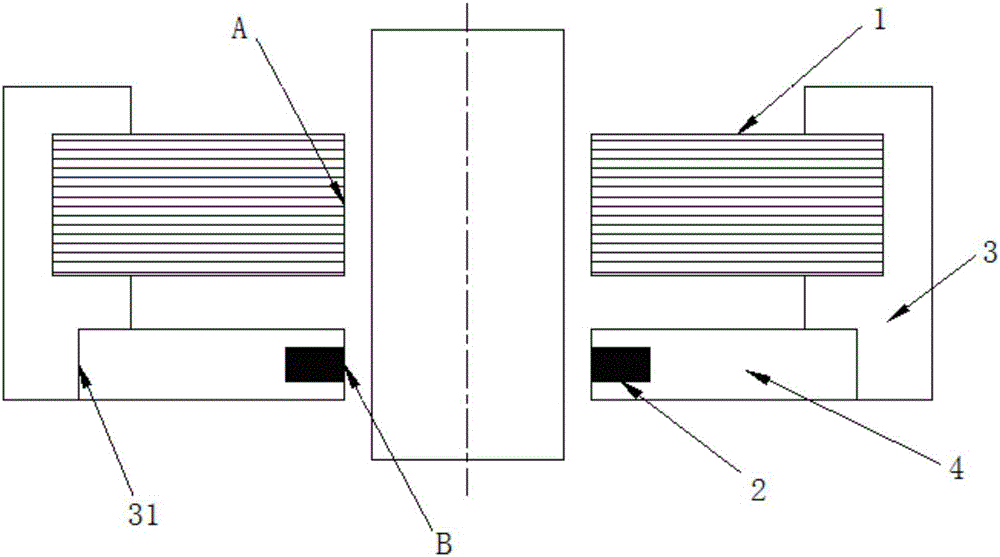

Laminating device for car-door protective film

InactiveCN103569400AFlanging pressure is evenly stressedEliminate non-fit phenomenonPackagingTectorial membraneEngineering

The invention discloses a laminating device for a car-door protective film. The laminating device comprises a U-shaped laminating device body, wherein fixing clips used for fixing a car door are respectively arranged on the inner sides and the tops of two edges of the laminating device body, and rollers are arranged on the inner sides and the bottoms of the two edges of the laminating device body. Two ends of each roller are respectively installed at the two edges of the U-shaped laminating device body through bolts, and the rollers do rotational motion relative to the laminating device body. With the above structure, the laminating device for the car-door protective film fixes the car door through the fixing clips and laminates the protective film through the rollers, so that the flange of the protective film is uniformly laminated and stressed, the frequency of the non-pasted phenomenon of the protective film is reduced or even stopped. Moreover, the positions of the fixing clips can be adjusted according to different car types, the fixing clips can be suitable for various car types, and the universality of the laminating device is increased.

Owner:WUHU SHUNCHANG AUTO PARTS

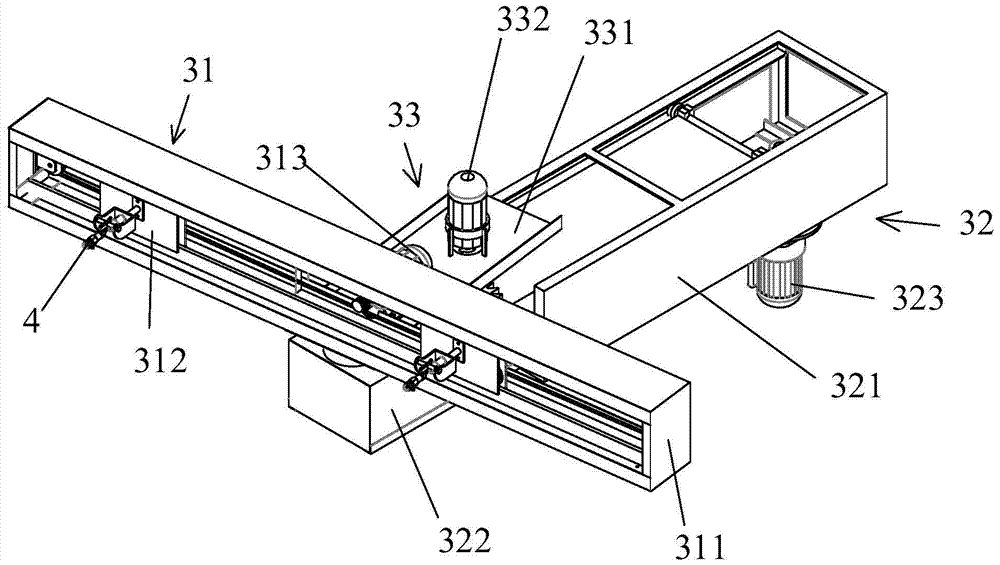

Device used for dispensing balanced armature earphone receiver

ActiveCN102861704AAvoid vision lossReduce the failure rateLiquid surface applicatorsCoatingsTemperature controlEngineering

The invention relates to a device used for dispensing a balanced armature earphone receiver. An X-axis transmission unit is installed on a rack; a platform passageway is arranged on a slide block of the X-axis transmission unit; a Y-axis transmission unit is arranged above the platform passageway; a Z-axis transmission unit is installed on a slide rail of the Y-axis transmission unit; a positioning and clamping mechanism is installed on a slide rail of the Z-axis transmission unit; a first camera is arranged on the positioning and clamping mechanism; a constant temperature mechanism is also installed on the slide rail of the Z-axis transmission unit; a dispensing head is connected with the lower part of the constant temperature mechanism; and a second camera is arranged above sides of the platform passageway. The device provided by the invention realizes high-precision position dispensing, constant temperature control and high-precision camera monitoring, and obviously reduces reject ratio and reprocessing rate of products.

Owner:KERUI AUTOMATION TECH SUZHOU

Backlight module and membrane positioning structure thereof

InactiveCN103277747APrevent jumpingImprove production capacity and product yieldLight fasteningsNon-linear opticsBackplaneEngineering

The invention provides a membrane positioning structure which comprises a backplane and a positioning piece, wherein the positioning piece comprises a base and a positioning column, the base is fixedly connected with the backplane, and the positioning column is arranged on the base in a telescopic mode and protrudes out of one side, facing towards a membrane, of the backplane. According to the membrane positioning structure, the membrane is positioned through the telescopic positioning column arranged on the base; when the membrane is assembled, the positioning column stretches outwards to provide a larger length for positioning of the membrane, and tripping and displacement of the membrane can be prevented; labor-hour waste and quality abnormal damage brought by the tripping and the displacement of the membrane are effectively reduced, productivity and the yield of products are improved, and the optical quality of a backlight module is guaranteed. The invention further provides the backlight module with the membrane positioning structure.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

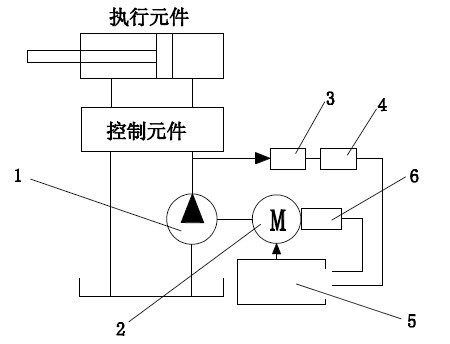

Energy-saving control system of injection machine

The invention provides an energy-saving control system of an injection machine, comprising a servo motor, a pressure sensor, a D / A (Digital / Analog) converter and a controller. The pressure sensor is electrically connected with the D / A converter which is electrically connected with the controller; and the controller is electrically connected with the servo motor and controls the servo motor to actuate. The control system also comprises an internal engaged gear pump, and the pressure sensor is arranged at the oil outlet of the internal engaged gear pump and used for detecting the pressure of liquid output by the internal engaged gear pump and conveying a detected signal to the D / A converter which converts the detected analog signal into a digital signal and transmits the digital signal to the controller. The internal engaged gear pump has the advantages of simple and compact structure, low working abrasion and smaller ripple and noise, and especially has low requirement on the cleanness of oil liquid without regularly checking or filtering the oil liquid, thereby greatly reducing unnecessary working hour waste of workers.

Owner:WENZHOU ANXIN TECH +1

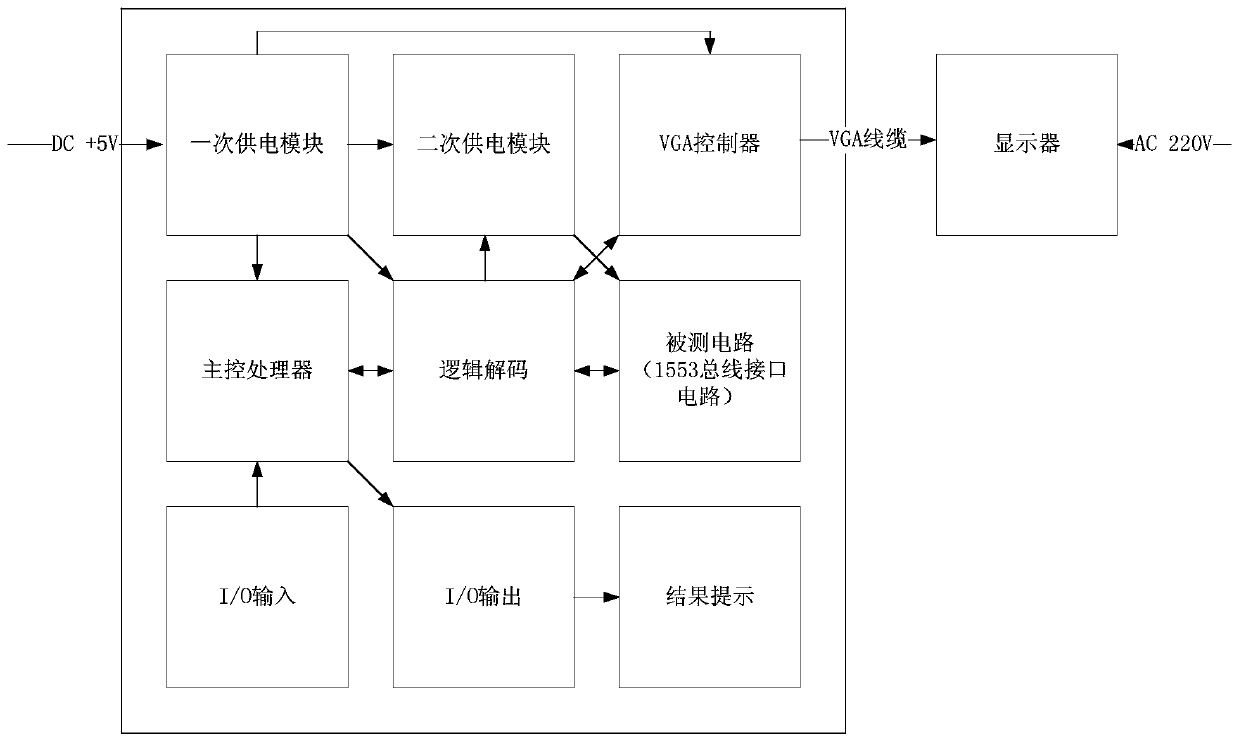

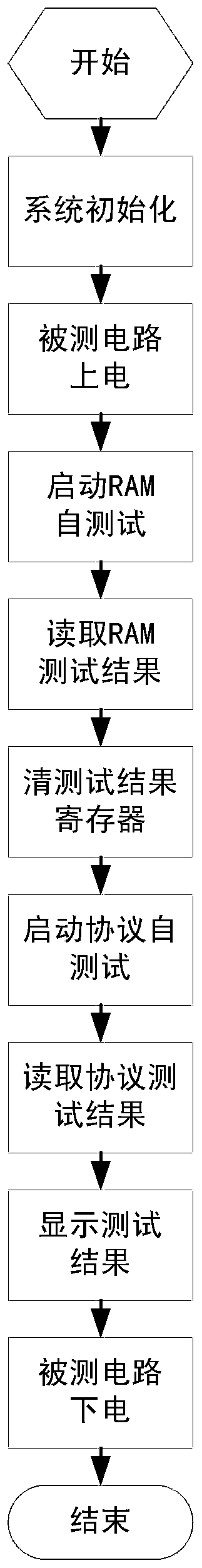

1553 bus interface circuit rapid screening system and method based on self testing

PendingCN109753393APerfect production flowReduce wasted man-hoursDetecting faulty computer hardwareDisplay deviceBus interface

A 1553 bus interface circuit rapid screening system and method based on self testing are used for function abnormity screening on a Mini-ACE series after completing MCM packaging, to eliminate a protocol failure circuit and a memory failure circuit. The system comprises primary power supply, secondary power supply, a main control processor, I / O input and output, logic decoding, a VGA controller, aresult prompt and a display. The main control processor inputs screening excitation to the to-be-tested circuit through the HOST interface of the to-be-tested circuit according to a corresponding screening mode, and starts RAM test, stops RAM test, starts a protocol test, and stops a protocol test, and outputs a result to screening personnel through a prompt module and a display according to thescreening condition. The method is used for the production process of the 1553 series interface circuit with the self-test function, the failure circuit can be removed in the early stage, the work ofconventional anti-fuse structure melting and burning, three-temperature test, effectiveness test and the like on the failure circuit in the production process is avoided, the labor hour waste is greatly reduced, and the production efficiency and the productivity are improved.

Owner:BEIJING MXTRONICS CORP +1

Laminating method for sticking automobile door protective film

ActiveCN103568467AFlanging pressure is evenly stressedEliminate non-fit phenomenonLamination ancillary operationsLaminationTectorial membraneEngineering

The invention discloses a laminating method for sticking an automobile door protective film. The laminating method comprises the steps: 1, after flanging and sticking a protective film, regulating the position of a corresponding part of a laminating device; 2, regulating the position of a roller wheel on a laminating device body through regulating bolts at two ends of the roller wheel according to the thickness of an automobile door, and fixing to ensure that the roller wheel is in contact with the protective film on the surface of the upper part of the automobile door in the use process; 3, after the laminating device is fixed, operating the laminating device to enable the roller wheel to roll so as to ensure that the protective film can be completely jointed on the surface of the automobile door. According to the laminating method for sticking the automobile door protective film with the structure, the automobile door is fixed by using an arranged fixing clamp, and the protective film is laminated through the roller wheel so that the protective film is flanged, laminated and stressed uniformly, and the frequency of generating a non-jointing phenomenon of the protective film is reduced, and even avoided, and meanwhile, the position of the fixing clamp can be regulated according to different automobile types, the protective film can be suitable for the multiple automobile types, and thus the universality of the laminating device is improved.

Owner:响水县永恒传动件制造有限公司

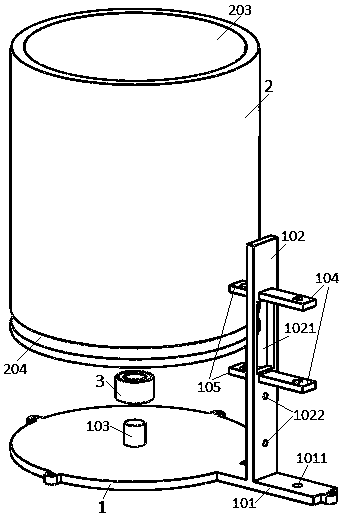

Konjac glucomannan gel preparation device and method

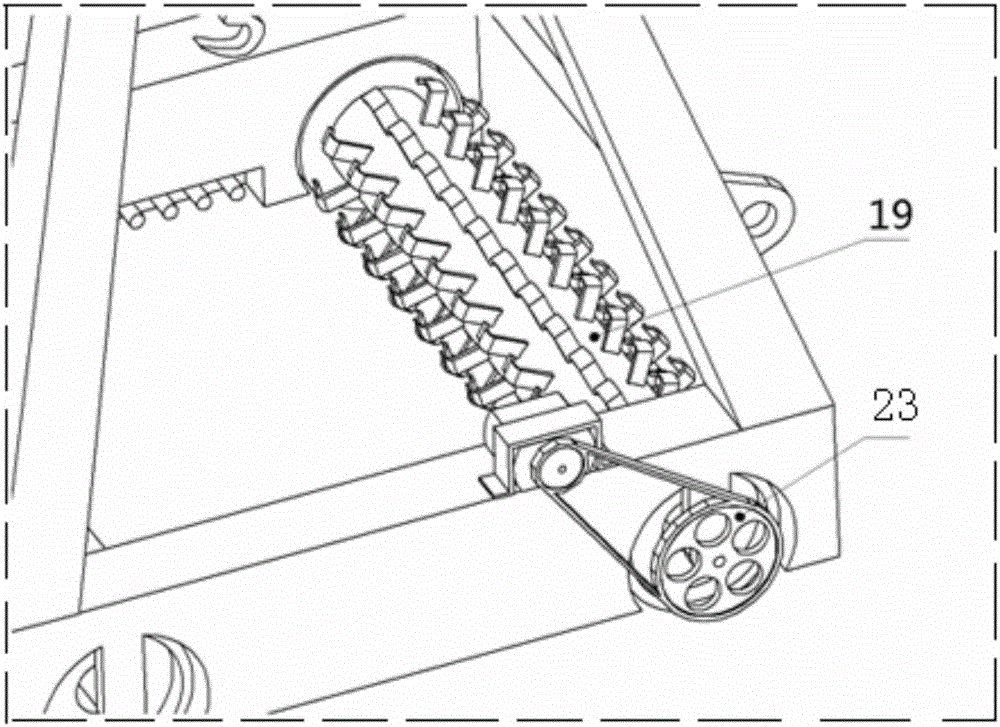

PendingCN108393045AOvercoming the problem of difficult turningRelease fullyGel preparationColloidal chemistry detailsGel preparationDrive wheel

The invention provides a konjac glucomannan gel preparation device. The konjac glucomannan gel preparation device comprises a base plate, a tank body, a bearing, conical rollers, a motor, a belt wheel, a drive wheel, a stirrer and a belt, wherein a central column is arranged on the top surface of the base plate; a bearing inner ring is embedded into the center of the bottom surface of the tank body; the conical rollers are arranged on the bottom surface of the tank body; a vertical plate is arranged at one side of the base plate; a motor bracket is in threaded connection on the right side surface of the vertical plate; the output shaft of the upper side of the motor is in pin connection with an inclined drive wheel; the belt wheel is in pin connection on the output shaft of the lower sideof the motor; the belt wheel is connected onto the belt ring-shaped slot in the cylindrical surface of the tank body through the belt; the stirrer is n-shaped; a vertical rod at the right side is inserted into a stirrer limiting plate at the left side of the vertical plate; two horizontal drive vanes extend on the vertical rod at the right side, and are clamped on the left side edge of the drive wheel; a horizontal stirring plate is arranged on the vertical rod at the left side of the stirrer; and the vertical rod at the left side is arranged in an inner cavity of the tank body. The motor drives the belt wheel and the drive wheel to rotate, the tank body rotates, and the stirrer moves up and down repeatedly.

Owner:NINGDE VOCATIONAL & TECHN COLLEGE

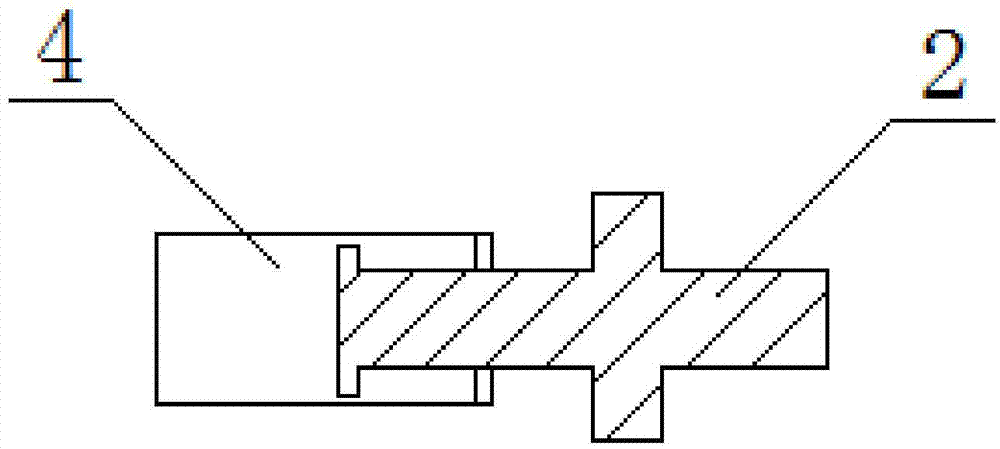

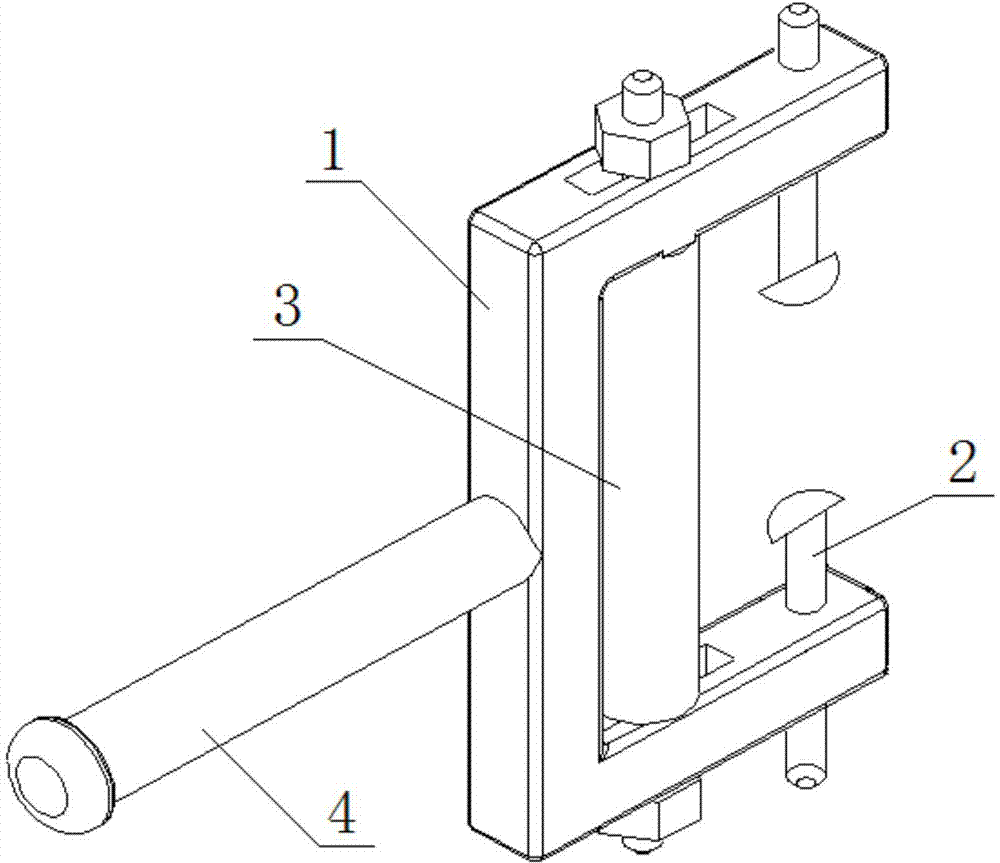

Elastic telescopic positioning device for automobile body sheet metal part stamping die

PendingCN112605294AReduce wasted man-hoursGuaranteed production efficiencyShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

The invention discloses an elastic telescopic positioning device for an automobile body sheet metal part stamping die. The elastic telescopic positioning device comprises a base, a base U-shaped groove is formed in the edge of one side of the base, and two base bolt through holes are formed in the other side of the base at intervals in parallel; a positioning pin is perpendicular to the base and is inserted into the base U-shaped groove, and a positioning pin bolt hole is formed in the inner side of the positioning pin; a supporting plate is vertically welded to the base, and a supporting plate bolt through hole and a supporting plate bolt hole are formed in the supporting plate; and an adjusting bolt penetrates through the supporting plate bolt through hole to be in threaded connection with the positioning pin bolt hole, one end of an elastic lifting pin is in threaded connection with the supporting plate bolt hole, and the other end of the elastic lifting pin is in contact with the inner side of the positioning pin. The adjusting amount of the positioning pin can be changed by applying pressure to the positioning pin and the elastic lifting pin through the weight of a raw material steel plate, the positioning pin can be adjusted without shutdown when the sizes of the raw material steel plate are greatly different, then the production efficiency is guaranteed, and labor-hour waste of personnel is reduced.

Owner:DALIAN JIAXIANG SCI & TECH

Locking device for welding rotary jig of automobile body

ActiveCN103358075BAchieve unlockAchieve lockingWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

Owner:CHERY AUTOMOBILE CO LTD

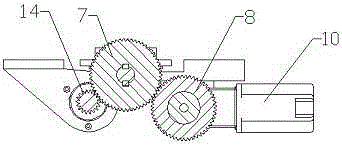

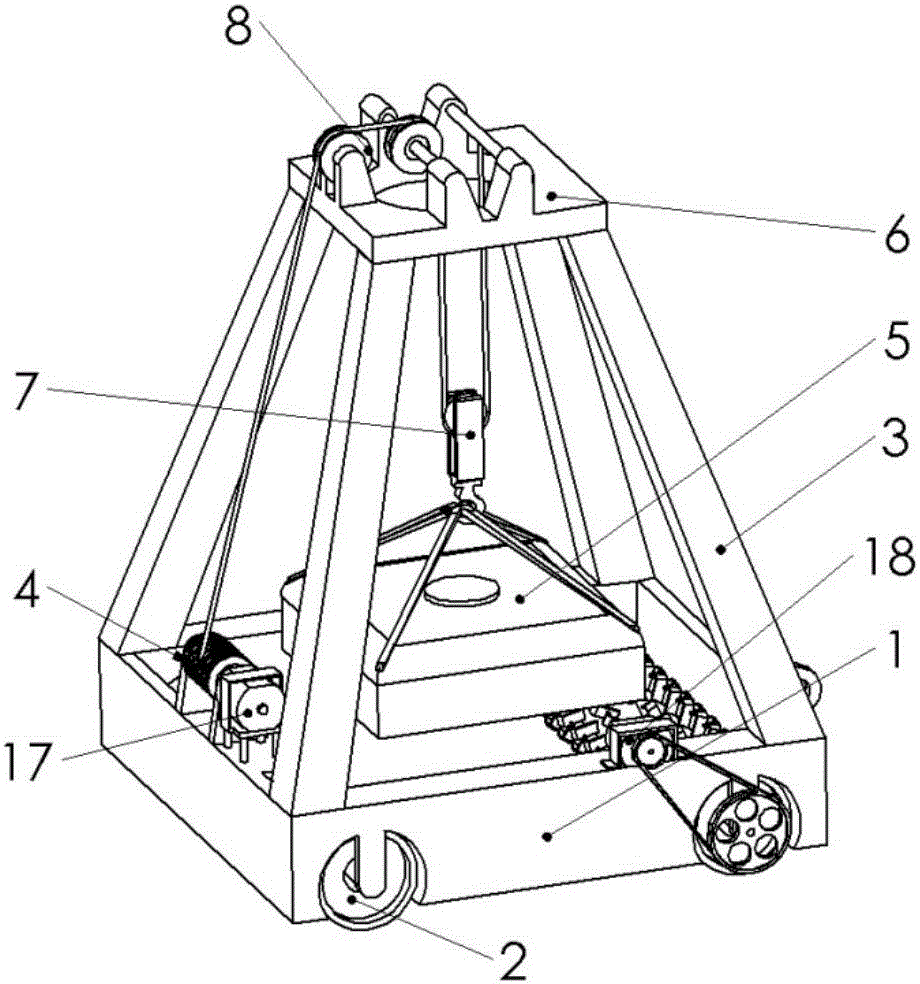

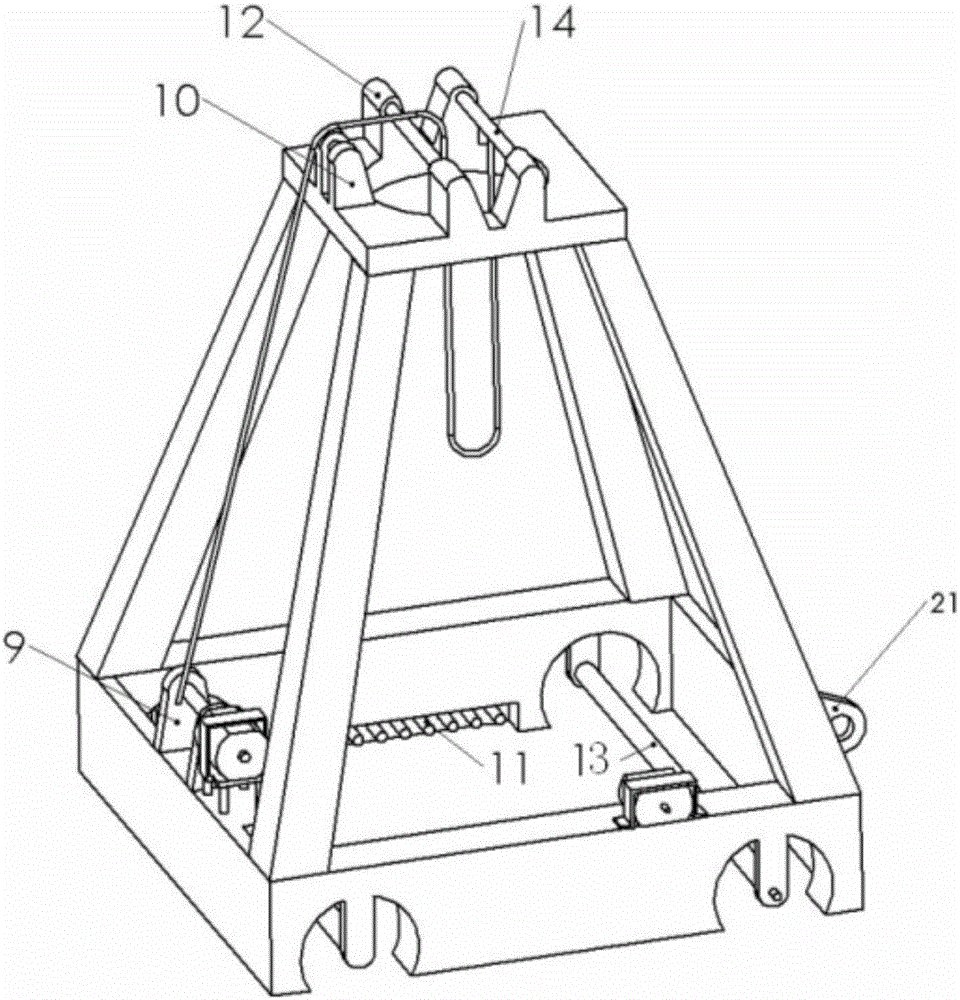

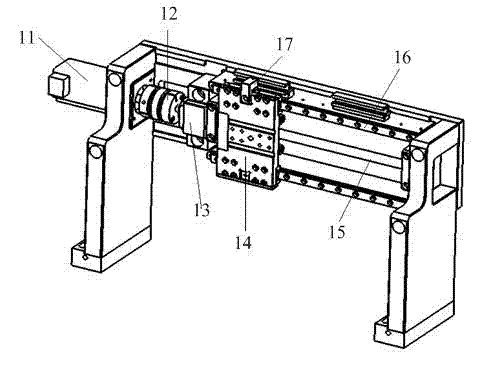

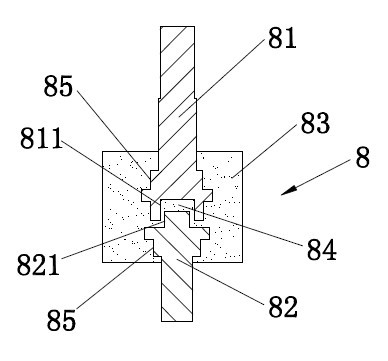

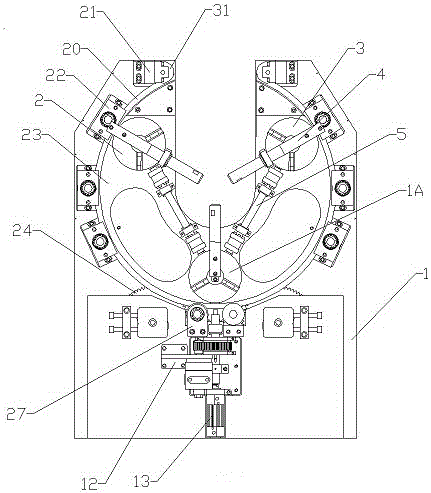

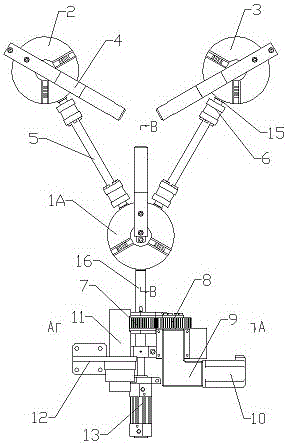

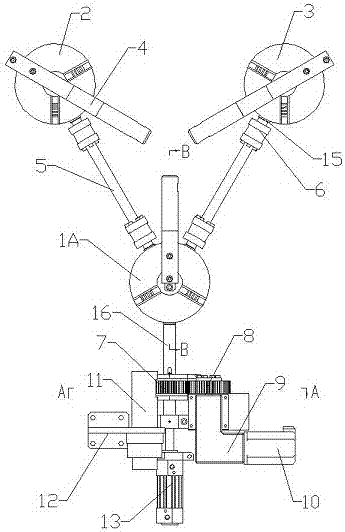

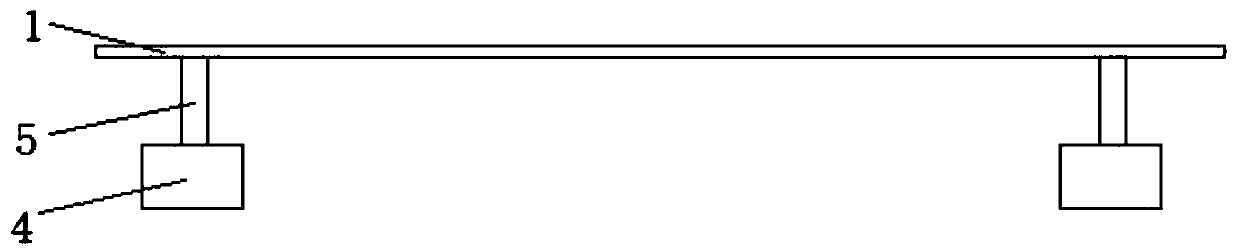

Open three-jaw self-centering rotary device

ActiveCN105171323BWith self-locking functionPrevent accidental fall offWelding/cutting auxillary devicesAuxillary welding devicesMan-hourEngineering

The invention discloses an open-type three-jaw self-centering rotation device. The device comprises a self-centering clamping disc portion and a self-centering rotation portion which are assembled together. The self-centering clamping disc portion is used for clamping workpieces. The self-centering rotation portion drives the workpieces to conduct rotation machining. The open-type self-centering clamping disc is adopted, so that the open-type three-jaw self-centering rotation device is particularly suitable for automatic bottoming welding of flanges and connecting pipes with the flanges on the two edges, and the workpieces can be directly lifted away along an opening of the clamping disc after welding is completed. The open-type three-jaw self-centering rotation device is quite suitable for automatic welding, hole forming, cutting and the like of some long circular workpieces, the working mode that long workpieces must be inserted into one end of rotation clamping disc equipment with a central through hole during operation is avoided, the long workpieces can be directly placed on the open-type three-jaw self-centering rotation device from bottom to top by the adoption of the open-type three-jaw self-centering rotation device, unnecessary man-hour waste can be reduced, the working efficiency of the open-type three-jaw self-centering rotation device is improved, and the overall length of the open-type three-jaw self-centering rotation device is decreased.

Owner:HIMILE MECHANICAL MFG

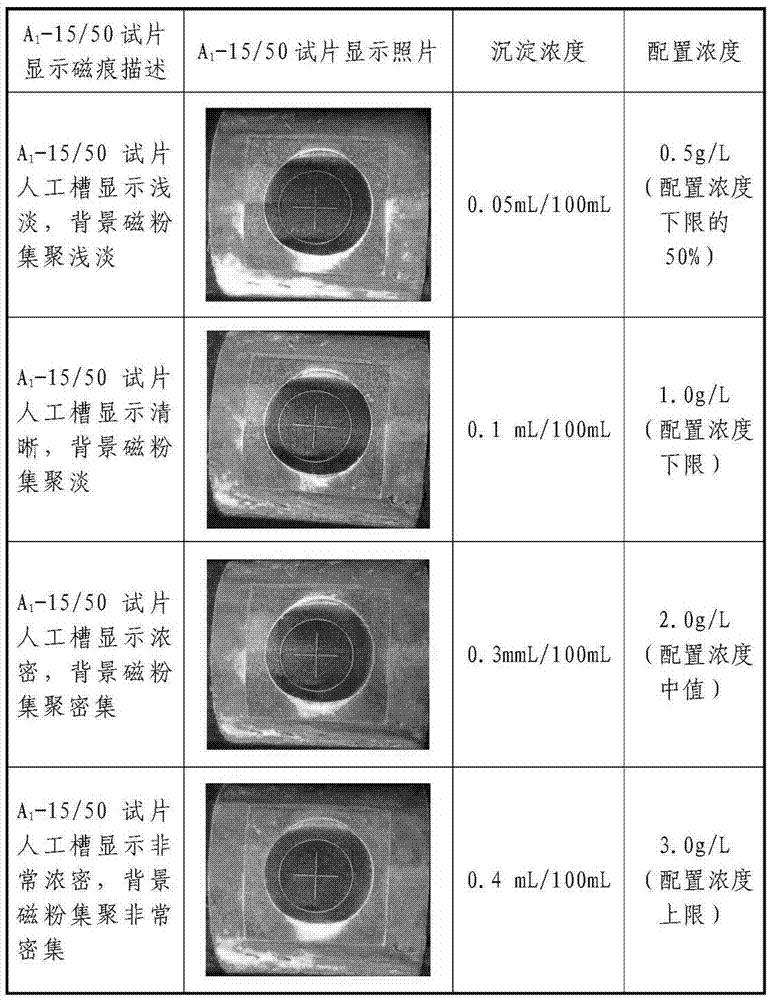

Method for monitoring magnetic suspension concentration in flaw detection process

ActiveCN106872915ASaving Concentration ValueTrue reflection concentration valueMagnetic property measurementsEngineeringWorking hours

The invention discloses a method for monitoring the magnetic suspension concentration in a flaw detection process, and the method comprises the steps: selecting a workpiece; pasting an Al-15 / 50 test piece on the surface of the workpiece; clamping the workpiece on a clamping electrode of a magnetic particle flaw detector; determining a circumferential magnetization current value and longitudinal magnetization ampere turns according to the magnetic particle flaw detection standard of the workpiece; carrying out the magnetization and spraying of the workpiece according to a wet process continuous method magnetic particle flaw detection technology, and observing the display condition of the test piece; observing the display concentration degree of an artificial notch groove of the test piece and the surrounding background magnetic particle concentration degree of the artificial notch groove of the test piece, and carrying out the comparison with a preset magnetic suspension concentration-test piece display comparison table, thereby determining the section of the of the magnetic suspension concentration used in the flaw detection process. The method can check the magnetic suspension concentration in a working section, and reduces the waste of the work hour.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

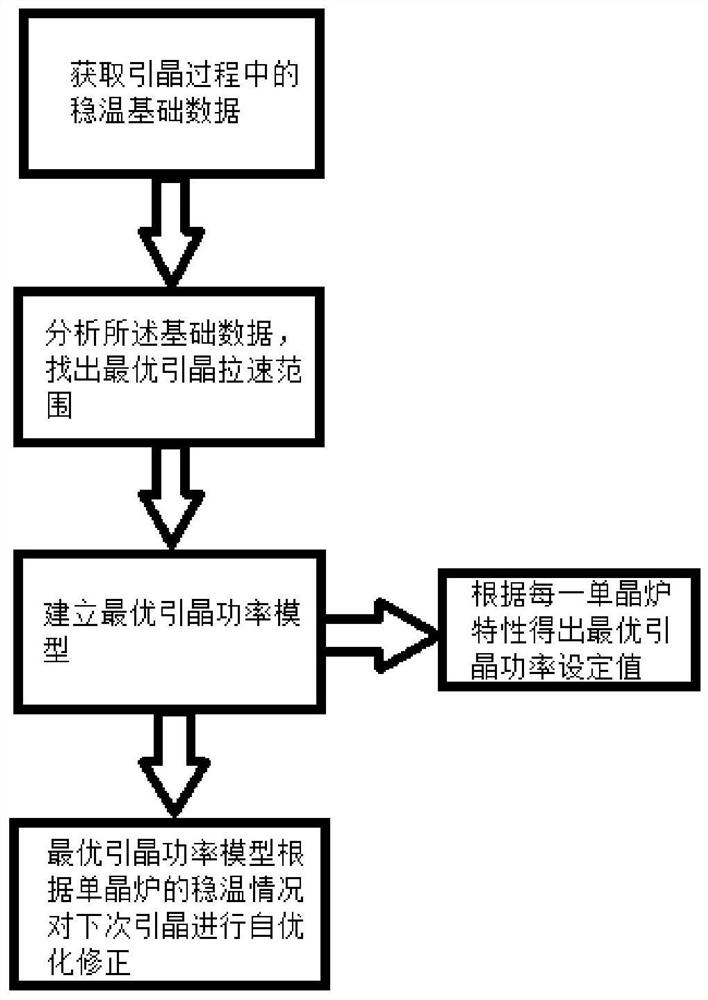

Stable-temperature power self-optimization method and system, computer equipment and storage medium

PendingCN114840966AReduce human interventionReduce wasted man-hoursPolycrystalline material growthBy pulling from meltProcess engineeringSingle crystal

The invention provides a stable-temperature power self-optimization method and system, computer equipment and a storage medium. The stable-temperature power self-optimization method comprises the steps that S1, stable-temperature basic data in the seeding process is acquired; s2, analyzing the basic data, and finding out an optimal seeding pulling speed range; s3, establishing an optimal seeding power model according to the basic data through a logical algorithm, wherein the optimal seeding power model obtains an optimal seeding power set value according to the characteristics of each single crystal furnace; and S4, carrying out self-optimization correction on next seeding by the optimal seeding power model according to the stable temperature condition of the single crystal furnace. The method has the beneficial effects that the problems of low setting accuracy, unstable production, low crystal pulling production efficiency, too many human factors and relatively high crystal pulling production cost due to the fact that more field personnel carry out setting based on crystal pulling experience are effectively solved.

Owner:内蒙古中环晶体材料有限公司

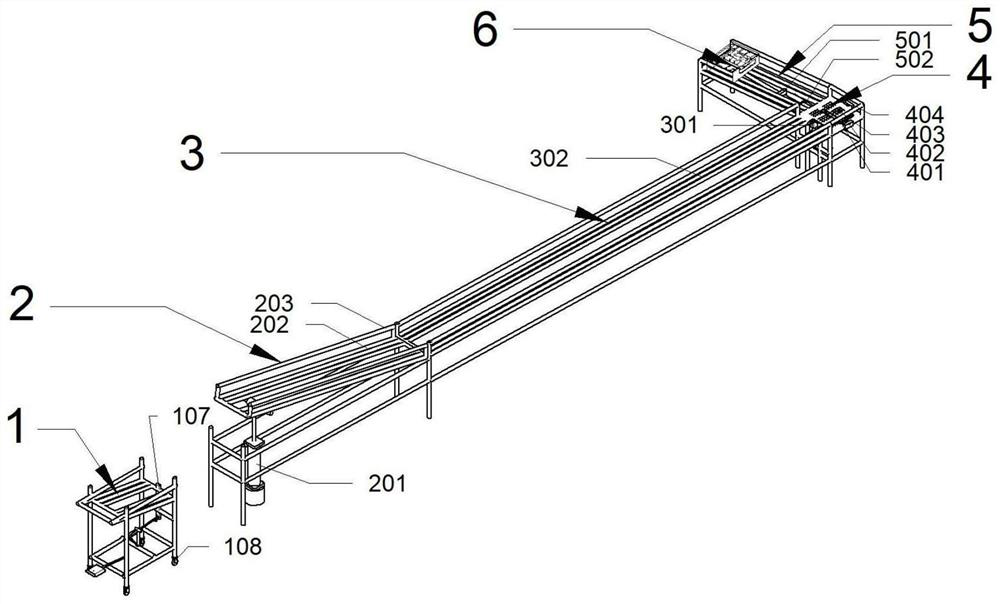

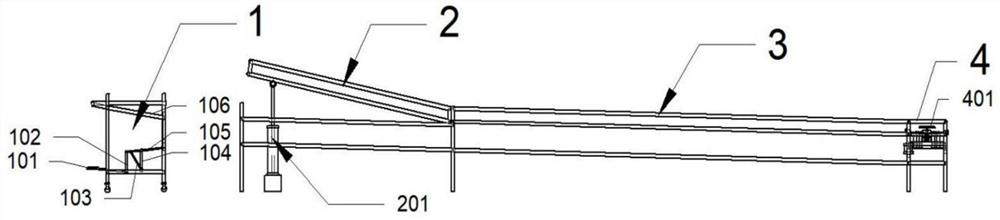

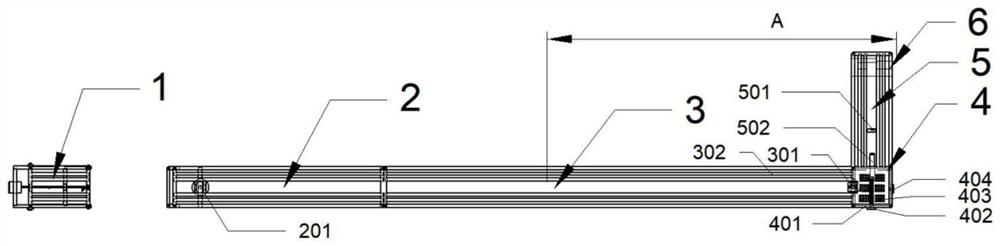

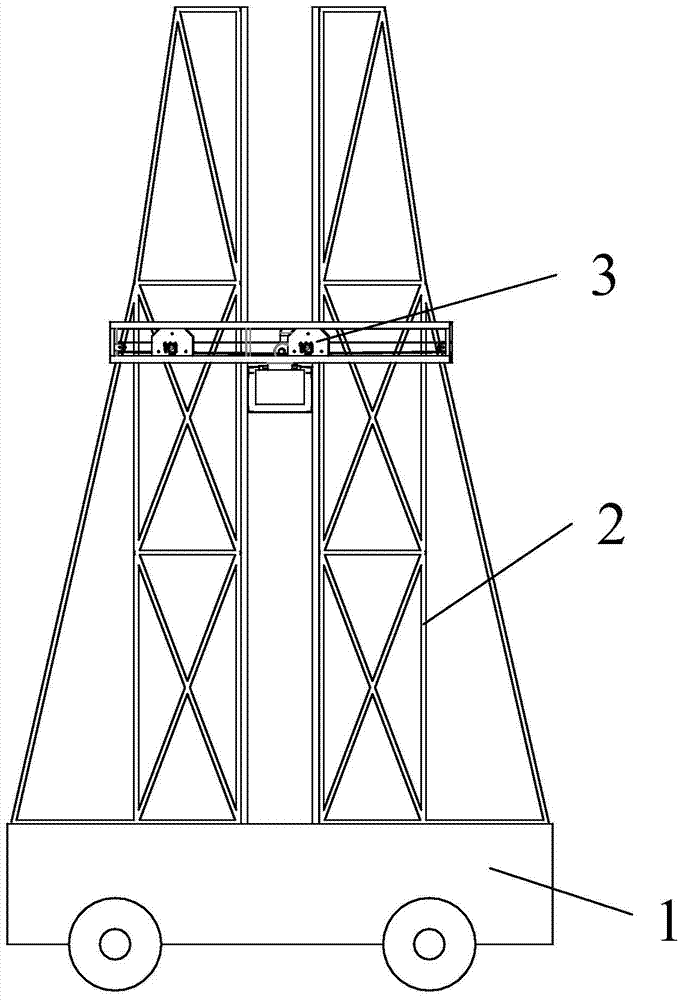

A kind of material automatic on-line device and its operation method

ActiveCN111332765BReduce wasted man-hoursEasy to assemble ingredientsConveyor partsHand carts with multiple axesControl engineeringProcess engineering

The invention provides a material automatic loading device, which includes a material turnover vehicle, a lifting guide mechanism, a conveying guide mechanism, a right-angle reversing mechanism, a material retrieving platform, and a material box; the material turnover vehicle includes a material discharging pedal mechanism and a loading platform, the discharging pedal mechanism is used to discharge the materials on the line; the lifting and guiding mechanism includes a lifting device, a lifting roller table and a guardrail, which are used to raise the position of the material and make the material slide; the conveying and guiding mechanism includes The blocking device and the conveying roller table, the blocking device is used to block and separate the materials; the right-angle reversing mechanism includes an inductor and a pulling rod, and the sensor is used to detect the position of the material box and the pulling rod, and the The material pulling rod is used to drive the material to change direction; the reclaiming platform includes a buffer space sensor, which is used to sense whether there is a buffer space on the reclaiming platform. The device of the invention has simple structure and convenient operation, can reduce defective rate of assembly and production, and effectively improve production efficiency.

Owner:GAC FIAT CHRYSLER AUTOMOTIVE CO LTD

Automatic painting robot for shipbuilding painting

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Supporting method of stopping mining in fully mechanized mining face

ActiveCN108316956BTake full advantage of the bearingRelieve pressureUnderground chambersTunnel liningWork periodSpelunking

The invention relates to a roof support process under a coal mine, in particular to fully mechanized mining face mining stopping support method. The problems that an existing fully mechanized mining face is high in mining stopping I-shaped steel support cost, large in labor intensity of workers and long in mining stopping support construction period, and top plate local breaking is prone to occurring are solved. According to the fully mechanized mining face mining stopping support method, anchor cables, anchor rods, metal nets, steel belts and combined anchor cable groups are adopted for combining support, the self-bearing capability of a bracket is matched, and mining stopping support is conducted; and the working face is divided into a frame dismantling channel, a bracket and mining stopping support combined support area and a natural caving area according to purposes after mining stopping to conduct top plate management during mining stopping, local support strengthening is conducted in a targeted mode, and I-shaped steel is replaced by the combined anchor cable groups, so that support is more timely, and the top plate separate layer phenomenon is avoided. Compared with existingmining stopping support, the material cost and manual consumption are greatly reduced, and the safety risk in construction is also reduced. The mining stopping support working period is shortened from 25 working days to 13 working days.

Owner:DATONG COAL MINE GRP

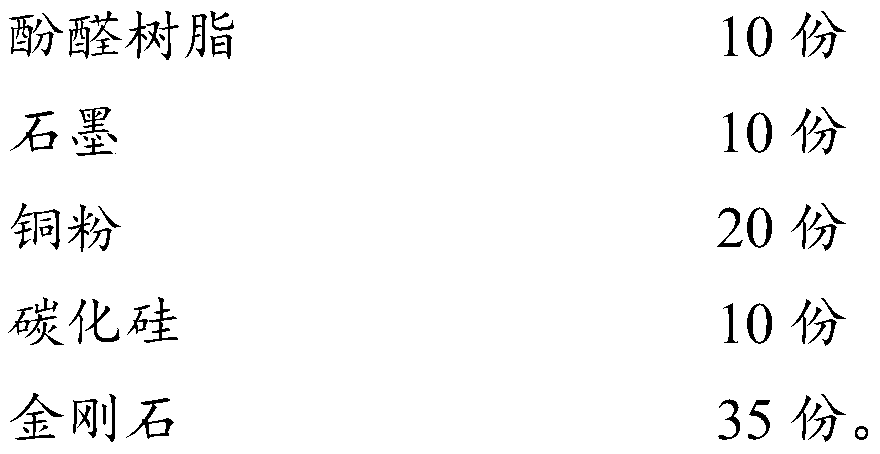

Composition and grinding wheel made of composition

The invention relates to the field of materials, in particular to a composition and a grinding wheel made of the composition. Through targeted design, the diameter of the grinding wheel is reduced to125 mm, dynamic balance is carried out well, the load of a main shaft is remarkably reduced, and the service life of the main shaft is greatly prolonged. According to the composition and the grindingwheel, by means of the design of a grinding material layer formula and by selecting an appropriate grinding material to carry out testing, the service life of the single grinding wheel is prolonged to28 days at present from the original 6 days under the situation of guaranteeing the qualified workpiece quality. Continuous operation of an assembly line is guaranteed, the usage rate of the assemblyline is increased, the labor hour waste of shutdown caused by changing the grinding wheel is greatly reduced, and the cost performance of the grinding wheel is increased.

Owner:上海橄榄精密工具有限公司

Pressing device for car door protection film

InactiveCN103569399BFlanging pressure is evenly stressedEliminate non-fit phenomenonPackagingTectorial membraneEngineering

The invention discloses a laminating device for a protective film of an automobile door. The laminating device comprises a U-shaped laminating device body, wherein fixing clips for fixing the automobile door are arranged on the inner sides and at the tops of the two edges of the laminating device body respectively; each fixing clip comprises a bolt and a flexible pad positioned at the head of the bolt; the tails of the bolts penetrate out from the inner side of the laminating device body to the outer side; rollers are arranged on the inner sides and at the bottoms of the two edges of the laminating device body; the two ends of the rollers are mounted on the two edges of the U-shaped laminating device body by the bolts respectively; and the rollers make rotary motion relative to the laminating device body. According to the laminating device with the structure, the automobile door is fixed by the arranged fixing clips, and the protective film is laminated by the rollers, so that a flange of the protective film is laminated and stressed uniformly, and the frequency of no binding of the protective film is reduced or even precluded; and positions of the fixing clips can be adjusted according to different automobile types, so that the laminating device can be suitable for multiple automobile types.

Owner:常熟市董浜科技创业投资发展有限公司

Auxiliary device for installing LNG ship insulating box and using method of auxiliary device

ActiveCN110722516AImprove installation efficiencyImprove installation accuracyMetal-working hand toolsMarine engineeringStructural engineering

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

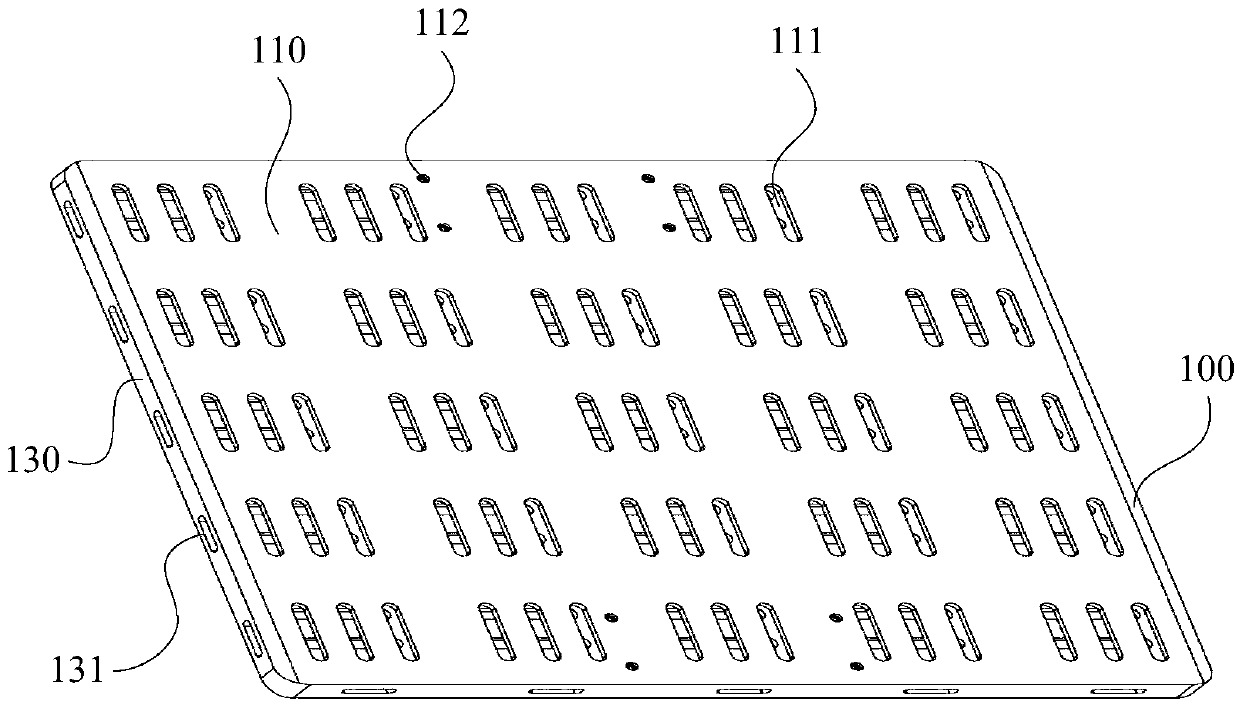

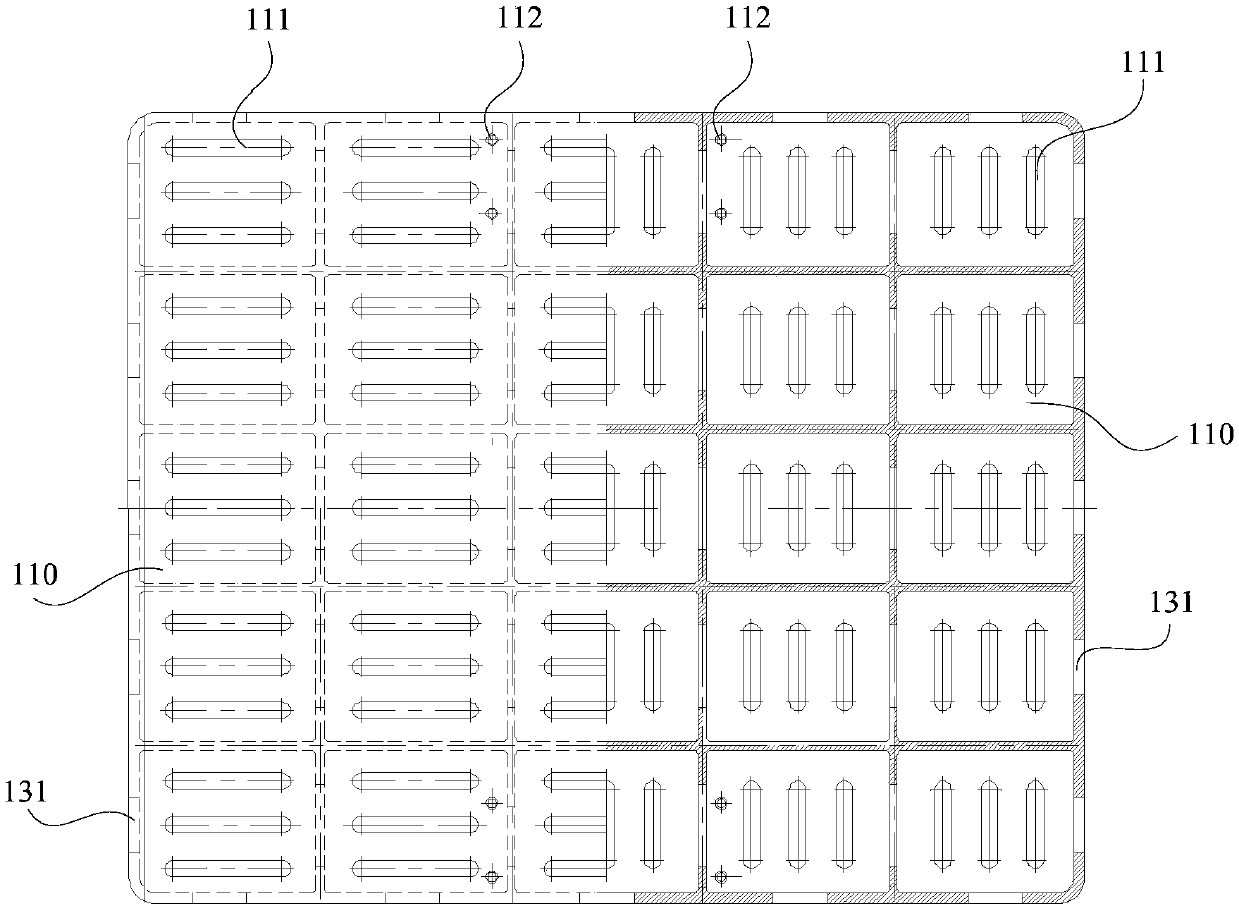

Double-surface core supporting plate

ActiveCN109604527AReduce wasted man-hoursIncrease productivityFoundry mouldsFoundry coresEngineeringSupport surface

Owner:CRRC DALIAN CO LTD

Three-jaw self-centering chuck clamping device

ActiveCN105171324BReliable clampingReduce wasted man-hoursWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a three-jaw self-centering chuck clamping device. The three-jaw self-centering chuck clamping device is composed of three centering chucks distributed in a triangular shape, and the three centering chucks are driven by the same power and linked synchronously, so that a self-centering function is achieved. According to the three-jaw self-centering chuck clamping device, the centering chucks are adopted, so that the device is especially suitable for automatic backing welding of a connecting pipe with flanges on the two sides and the flanges, and the workpiece can be directly lifted away along the chucks after being welded.

Owner:HIMILE MECHANICAL MFG

Spherical flat steel mooring seat opening mold

ActiveCN106493612BImprove cutting efficiencySave man hoursCopying process control systemsWorking hoursTrepanning

The invention discloses a flat-bulb steel mooring seat trepanning die. The flat-bulb steel mooring seat trepanning die comprises a die body. A trepanning outline is formed in the die body and formed through cutting according to a design template, and the cutting compensation value of 5 mm is additionally added on the periphery. The trepanning outline is provided with a semicircular arc striking and extinguishing hole, fixing components are arranged on the left side and the right side of the trepanning outline, and positioning elements are arranged on the front side and the rear side of the trepanning outline. By means of the flat-bulb steel mooring seat trepanning die, the cutting efficiency can be improved, and work hours are saved; mooring seat cutting trepanning can be finished in a high-precision and high-quality manner at a time, field assembling trimming is avoided, work hour waste is reduced, and therefore the segmented construction efficiency and quality are improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com