Method for monitoring magnetic suspension concentration in flaw detection process

A technology of magnetic suspension and concentration, applied in the direction of magnetic performance measurement, etc., can solve problems such as waste of working time, delay in workpiece circulation, missing detection, etc., and achieve the effects of easy promotion and use, reducing waste of working hours and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

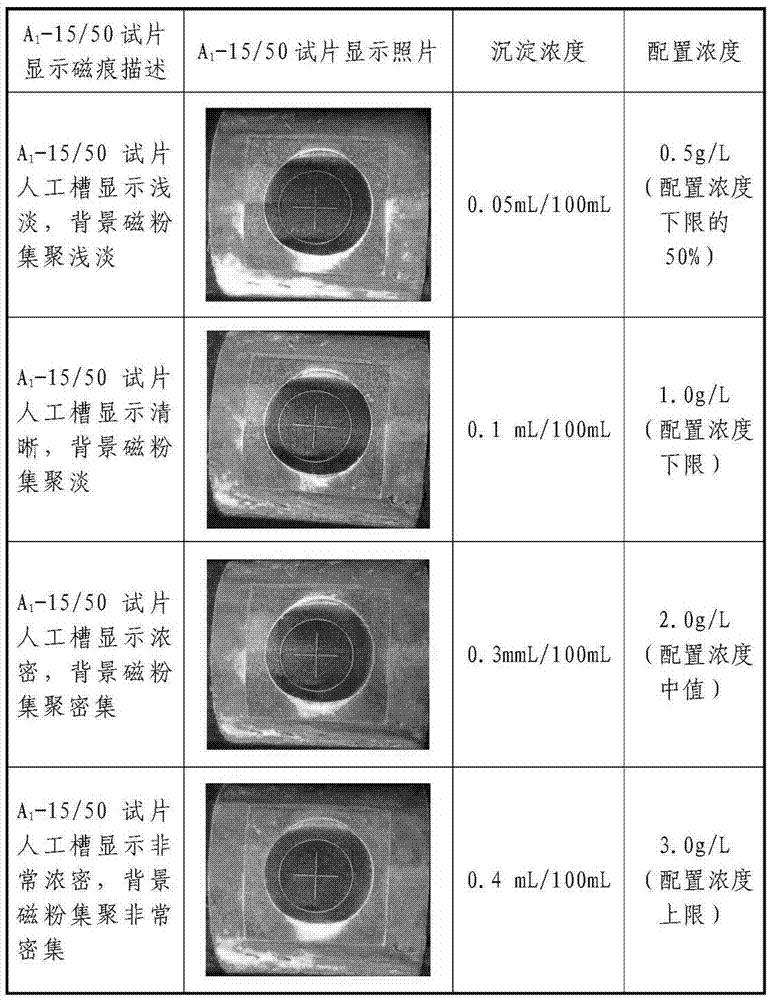

[0012] The method for monitoring the concentration of the magnetic suspension in the flaw detection process of the present invention includes selecting a workpiece and pasting A on the surface of the workpiece. 1 -15 / 50 test piece, clamp the workpiece to the clamping electrode of the magnetic particle flaw detection machine, determine the circumferential magnetization current and longitudinal magnetization ampere-turns according to the magnetic particle flaw detection standard of the workpiece, and perform the wet continuous method magnetic particle flaw detection on the workpiece Carry out magnetization and spraying in the process, observe the display of the test piece, and compare the density of the artificial groove display of the test piece and the concentration of the background magnetic powder around the artificial groove of the test piece with the pre-made "magnetic suspension concentration - test piece display". Table" to determine the concentration range of the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com