Spherical flat steel mooring seat opening mold

A technology of spherical flat steel and mould, which is applied in the field of opening molds for mooring seats of spherical flat steel, which can solve problems such as poor cutting accuracy, reduced construction efficiency, and increased construction cost, so as to save man-hours, reduce waste of man-hours, and improve cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

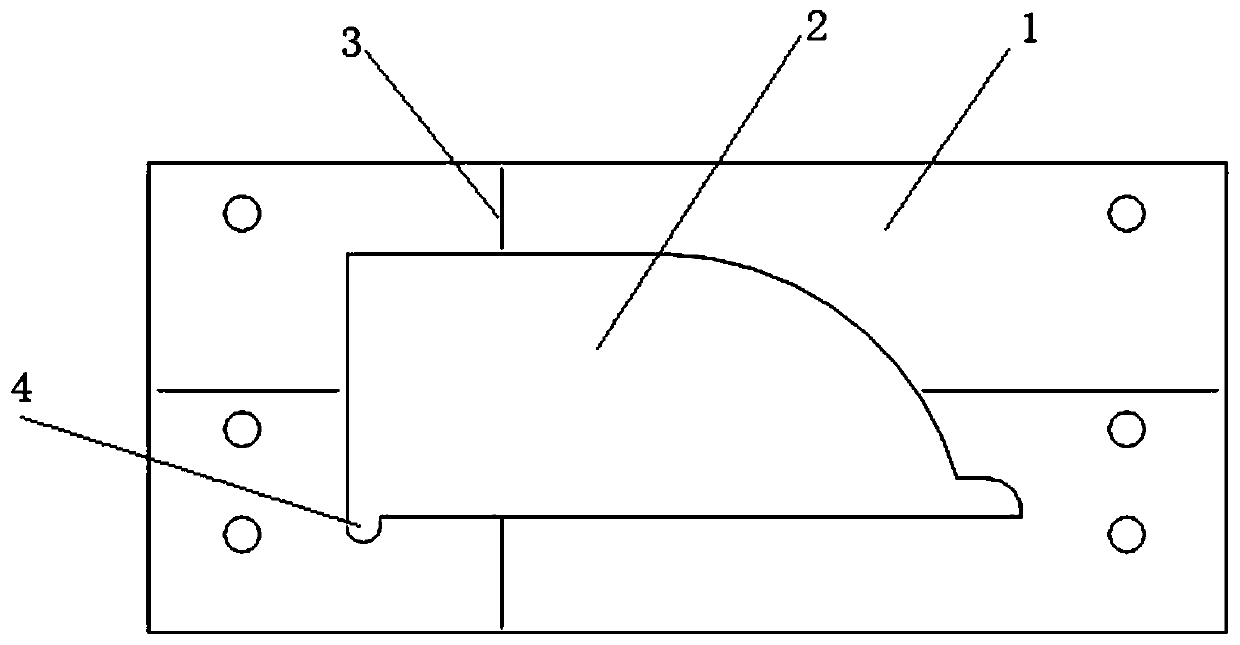

[0015] see figure 1 and figure 2 , the invention discloses a hole-opening mold for a spherical flat steel mooring seat, which is characterized in that: it includes a mold body 1, and the mold body 1 is provided with a hole contour 2, and the hole contour 2 is cut according to a design template , and a 5mm cutting compensation value is placed around; the opening profile 2 has a semicircular arc ignition and extinguishing opening 6, with fixing members 4 on the left and right sides, and positioning elements 3 on the front and rear sides.

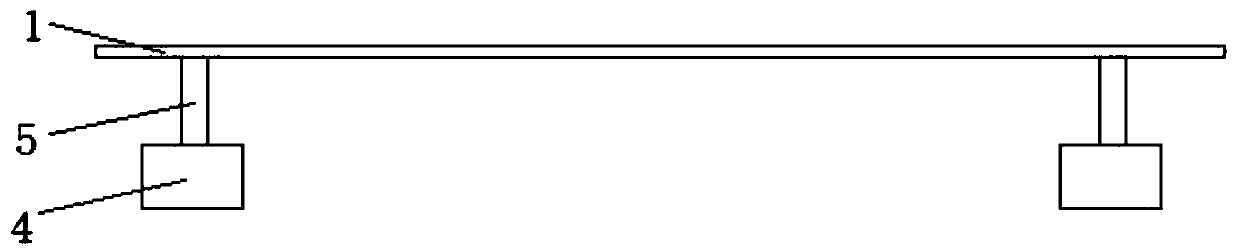

[0016] Further, the fixing member 4 is a fixing bolt or an electromagnet, and a lifting mechanism 5 is provided between the electromagnet and the mold body 1 for adjusting the height of the mold body; Position groove, the limit rod is slidingly embedded with a limit rod, and the upper end of the limit rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com