1553 bus interface circuit rapid screening system and method based on self testing

A bus interface, self-testing technology, applied in the detection of faulty computer hardware, etc., can solve the problems of waste of human and financial resources, huge workload, and difficult testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

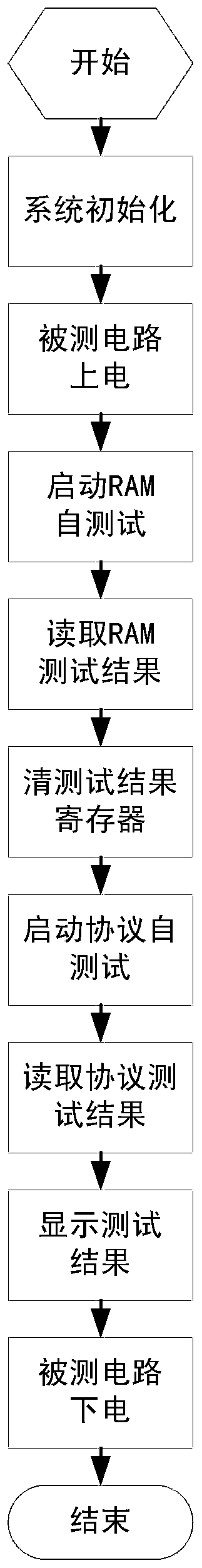

[0047] The present invention will be further introduced below in conjunction with the accompanying drawings.

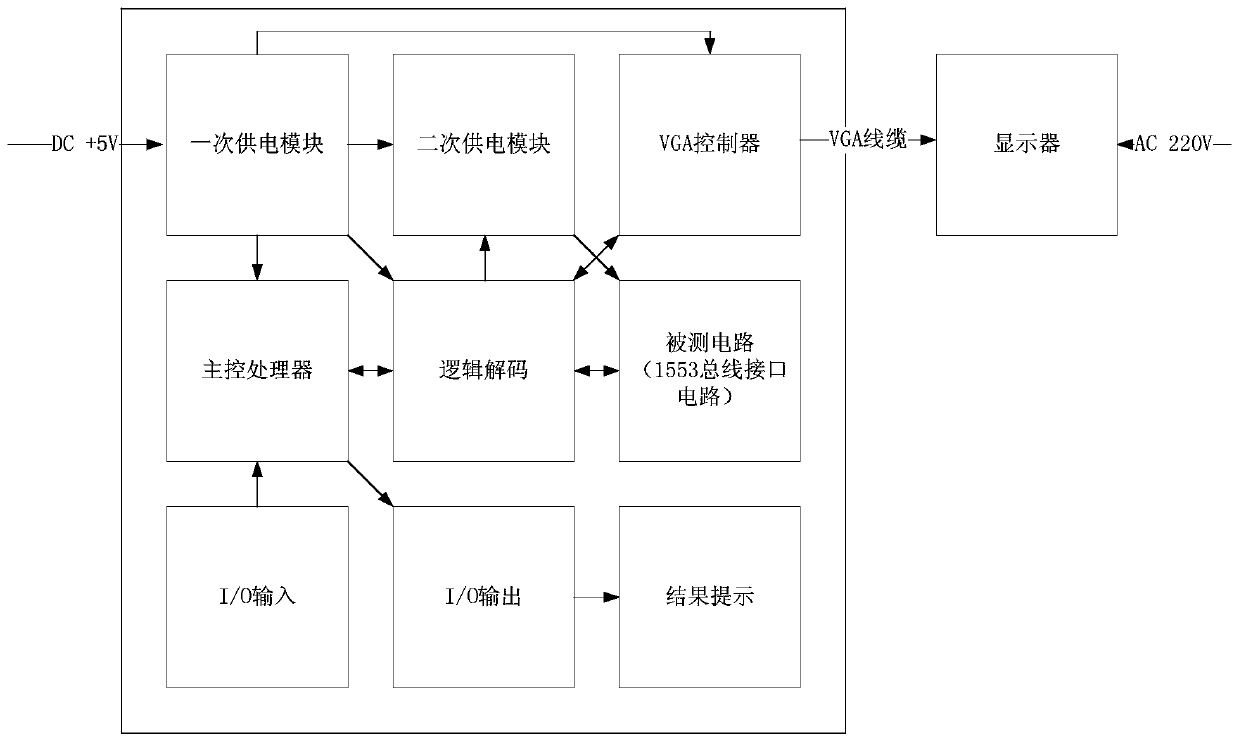

[0048] Such as figure 1 As shown, the present invention uses the MINI-ACE series 1553 bus interface circuit as the circuit to be tested, and proposes a self-test-based 1553 bus interface circuit rapid screening system, including: a primary power supply module, a secondary power supply module, a main control processor, I / O input module, I / O output module, logic decoding module, VGA controller and result display module;

[0049] The primary power supply module receives DC+5V input from the outside to supply power for other modules;

[0050] The input of the secondary power supply module is the output of the primary power supply module, which is isolated and output to the circuit under test to supply power for the circuit under test. The output of the secondary power supply module is controllable to realize power-on / off control of the circuit under test;

[0051] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com