Elastic telescopic positioning device for automobile body sheet metal part stamping die

A technology for stamping dies and automobile bodies, applied in the field of automobile stamping production, can solve the problems of waste of personnel and efficiency, troubles in the production workshop, etc., and achieve the effect of reducing waste of working hours and ensuring production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

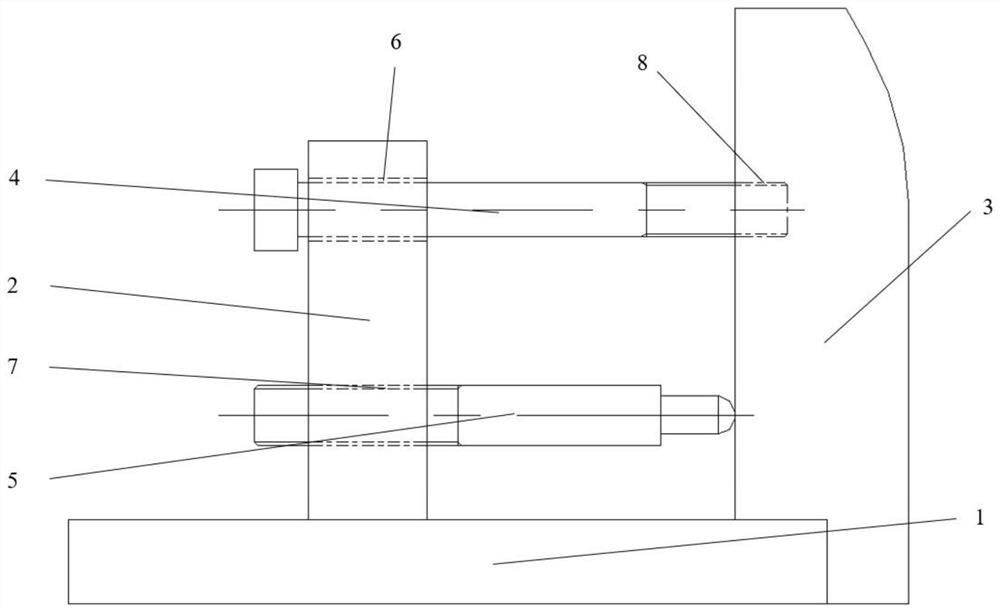

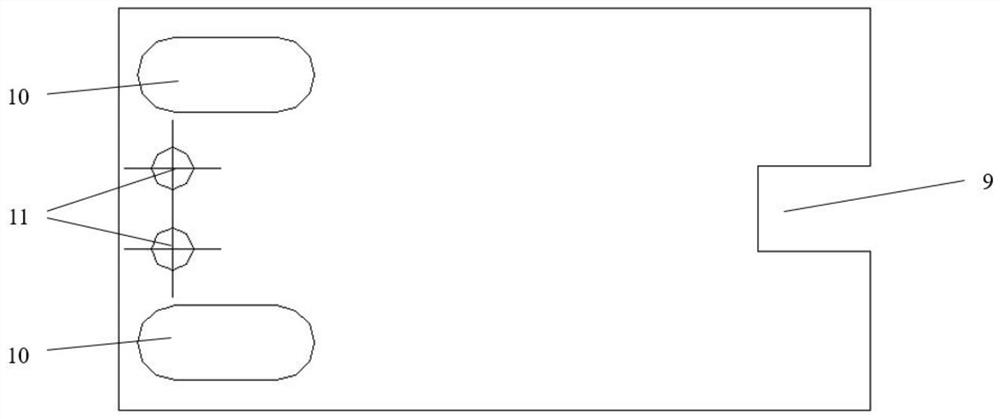

[0012] Attached below figure 1 , 2 The specific embodiment of the present invention will be further described.

[0013] The elastic telescopic positioning device for the stamping die of automobile body sheet metal parts includes a base 1, a base U-shaped groove 9 is opened on one edge of the base 1, and two base bolt through holes are opened in the other side of the base 1 at intervals and in parallel. 10. The positioning pin 3 is inserted into the U-shaped groove 9 of the base perpendicular to the base 1, and the inner side of the positioning pin 3 is provided with a positioning pin bolt hole 8; the support plate 2 is vertically welded on the base 1, and the support plate 2 is provided with a support plate bolt inside Through hole 6, support plate bolt hole 7; adjusting bolt 4 passes through the support plate bolt through hole 6 and is threadedly connected with the positioning pin bolt hole 8, one end of the ejector pin 5 is threaded with the support plate bolt hole 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com