Automatic painting robot for shipbuilding painting

A technology of automatic painting and robots, applied in the direction of spraying devices, etc., can solve the problems of low work efficiency and uneven spraying thickness, and achieve the effects of improving efficiency, reducing paint consumption coefficient, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment is given below to illustrate the present invention more clearly and completely in conjunction with the accompanying drawings.

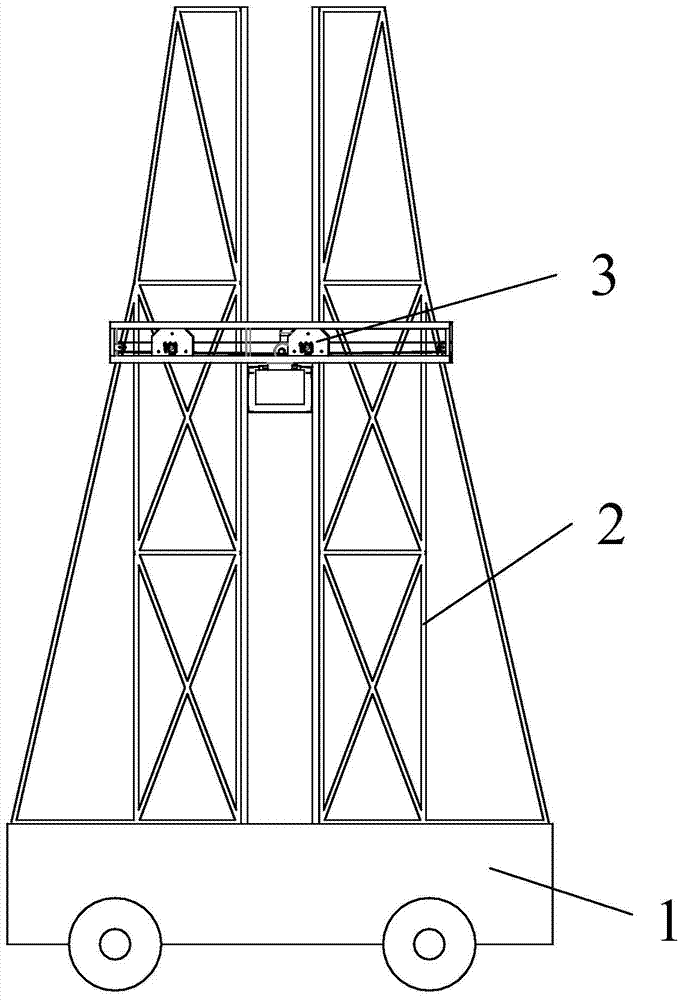

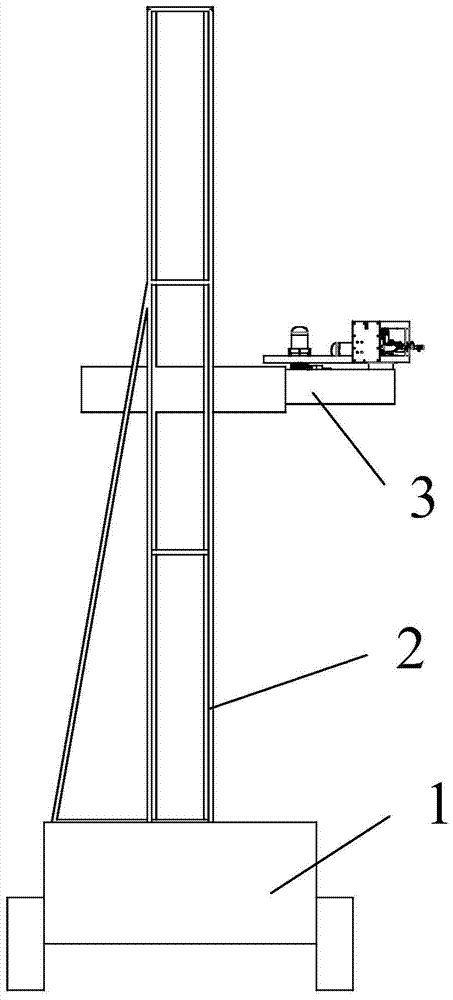

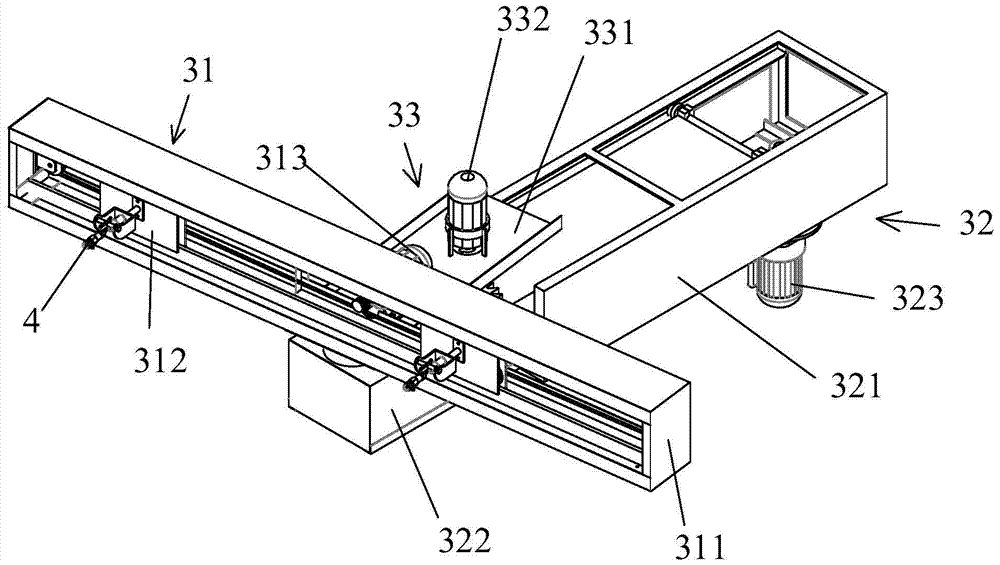

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, an automatic paint spraying robot for shipbuilding coating includes a moving base 1, a supporting member fixed on the moving base 1, a spraying movement mechanism 3, and a programmable logic controller (not shown in the figure) ) And a spray gun 4, the support member 2 is provided with a lifting mechanism, the spraying movement mechanism 3 is fixed on the lifting mechanism; the spraying movement mechanism 3 includes a left and right movement mechanism 31, a forward and backward movement mechanism 32 and a rotation movement mechanism 33; The mechanism 31 includes a first housing 311, a slider 312, and a first motor 313. The slider 312 is located in the first housing 311. The first motor 313 is fixed to the first housing 311. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com